Siemens SIMATIC 500,SIMATIC 505 User Manual

)

%$"'

"' %%! ('!$

#"&#"

DANGER

!

DANGER indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury .

DANGER is limited to the most extreme situations.

WARNING

!

WARNING indicates a potentially hazardous situation that, if not avoided, could

result in death or serious injury , and/or property damage.

CAUTION

!

CAUTION indicates a potentially hazardous situation that, if not avoided, could

result in minor or moderate injury , and/or damage to property.

CAUTION is also used for property-damage-only accidents.

Copyright 1999 by Siemens Energy & Automation, Inc.

Reproduction, transmission, or use of this document or contents is not permitted without express consent of

Siemens Energy & Automation, Inc. All rights, including rights created by patent grant or registration of a utility model or design, are

reserved.

Since Siemens Energy & Automation, Inc., does not possess full access to data concerning all of the uses and applications of

customer’s products, we do not assume responsibility either for customer product design or for any infringements of patents or rights

of others which may result from our assistance.

All Rights Reserved — Printed in USA

MANUAL PUBLICATION HISTORY

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

Order Manual Number: Not applicable; manual ships with RBC.

Refer to this history in all correspondence and/or discussion about this manual.

Event Date Description

Original Issue 03/96 Original Issue (2806091–0001)

Second Edition 06/99 Second Edition (2806091–0002)

LIST OF EFFECTIVE PAGES

Pages Description Pages Description

Cover/Copyright Second Edition

History/Effective Pages Second Edition

1 — 28 Second Edition

Registration Second Edition

Contents

1 Overview 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features and Functions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RBC Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Setup and Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RBC Placement in Base 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing and Removing the RBC 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 RBC Ports 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 Port 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROFIBUS-DP Port 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Output State Selection on the RBC 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Output State (Off/Freeze) on the 505 RBC 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Output State (Off/Freeze) on the 500 RBC 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Discrete Output State 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Analog Output State 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Dipswitch Options: Baud Rate, Station Address, Status Display Mode 11. . . . . . . . . . . . . . .

Dipswitch Options 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baud Rate for the RS-232 Port 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assigning the RBC Station Address 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Pushbutton 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the RBC 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Display Mode 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Parameters Set by Software 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting User Parameters for the PROFIBUS-DP RBC 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete I/O Interval 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Word I/O Update Factor 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50X Ignore Mismatch Mode 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50X RS-232 Comm Port 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Diagnostic Data Reported by the RBC 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROFIBUS-DP Diagnostic Bytes 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Upgrading the Operating System 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download Instructions 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Assistance 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

1

1 Overview

Features and

Functions

The SIMATICr 505 PROFIBUS-DP Remote Base Controller (RBC),

PPX:505–6870, allows a Series 505t I/O base to function as a slave node on

a DP I/O channel that complies with the PROFIBUS standard (DIN 19245,

Part 3). The SIMATIC 500 PROFIBUS-DP Remote Base Controller (RBC),

PPX:500–6870, allows a Series 500t I/O base to function as a slave node on

a DP I/O channel that complies with the PROFIBUS standard.

The 505 and 500 PROFIBUS-DP RBCs offer the following features:

• The RBC is compatible with Siemens S5t and S7t, as well as Series

505, masters.

• The 505 RBC can be used in all currently-available Series 505 bases

(4-, 8-, 11-, and 16-slot models).

• The 500 RBC can be used in all Series 500 bases (6-, 12-, and 14-slot

models, or original 8- and 16-slot models with PPX:500–5840 adapter).

• The RBC supports communication speeds from 9.6 Kbaud (maximum

cable distance per segment: 1200 m) up to 12 Mbaud (maximum cable

distance per segment: 100 m).

• The LED display shows error codes or current station address.

• A serial port is available for remote programming of the CPU when the

RBC is used on a Series 505/500 system.

RBC Specifications

• The RBC has a field-upgradeable operating system that is stored in

flash memory.

• The base where the RBC resides can contain only modules that look

like discrete or analog I/O; Special Function modules like Peerlink or

NIMs are not supported.

• CPU commands received from the serial port are restricted to those

that cannot alter the PROFIBUS-DP I/O configuration.

• A “GSD” file is provided with the RBC to allow configuration by the

COM PROFIBUS configuration utility.

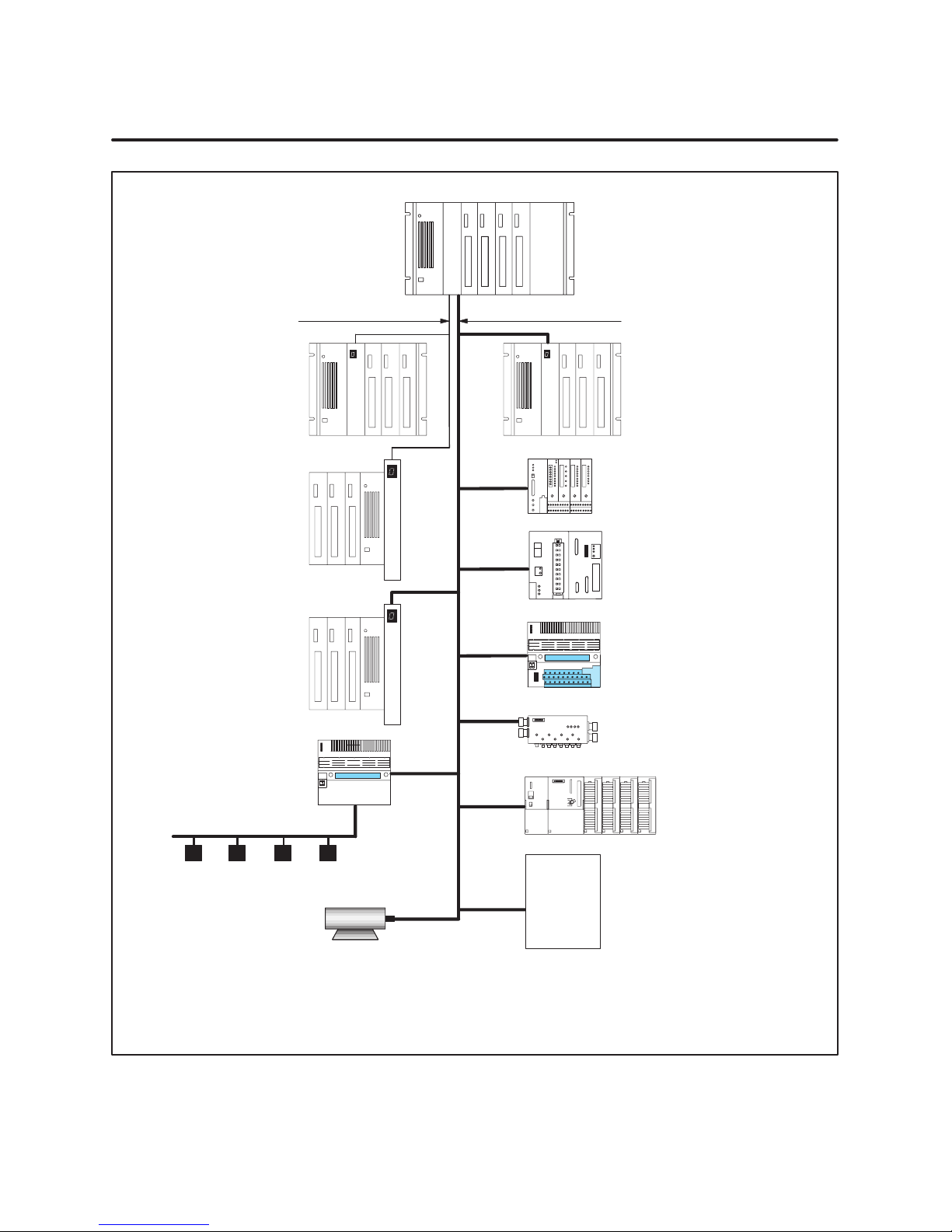

Figure 1 illustrates how the 505 and 500 PROFIBUS-DP RBCs fit into the

I/O architecture of a Series 505 system.

The physical and environmental specifications for the 505 PROFIBUS-DP

RBC are listed in the SIMATIC 545/555/575 System Manual.

2

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

545/555/575

C

C

P

U

Series 505 Remote

I/O Channel

(1 Mbaud)

Series 505 Base with RBC

(PPX:505–6851–A/B RBC)

Series 500 Base with RBC

(PPX:500–51 14–A RBC)

Series 500 Base with 500

PROFIBUS-DP RBC

(PPX:500–6870 RBC)

PROFIBUS-DP

I/O Channel

(12 Mbaud)

R

B

C

R

B

C

R

Series 505 Base with

505 PROFIBUS-DP RBC

(PPX:505–6870 RBC)

ET200U

B

C

95U/PROFIBUS-DP

R

B

C

ET200B

Block I/O

ET200C

AS-Interface Master

S7 I/O

AS-Interface Bus

Allen-Bradley

Limit SW P/B Solenoid PE Cell

Siemens AC/DC

Motors and Drives

Festo

Metlore-Toledo

Data Logic

ABB

AEG-Modicon

Bosch

Turk

etc.

Third Party

Products

Notes:

The Series 505 remote I/O channel supports up to 15 Series 505/Series 500 remote bases.

The PROFIBUS-DP I/O channel supports up to 112 SIMATIC and third-party DP I/O slaves.

A 575–2104 CPU can support either the 505 I/O channel or the PROFIBUS-DP channel, but not both simultaneously.

The 545–1 103/–1105 CPUs support only the PROFIBUS-DP channel, up to 32 SIMATIC and third-party DP I/O slaves, with the

optional PROFIBUS-DP I/O annex card.

Figure 1 I/O Architecture for Series 505 System

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

3

2 Setup and Installation

RBC Placement in

Base

The 505 PROFIBUS-DP RBC resides in a Series 505 base. Install it in the

second slot from the left, adjacent to the power supply module. See Figure 2.

P/S

I

I

I

I

I

I

I

505

RBC

I

/

/

/

/

O

O

O

O

O

/

/

/

/

O

O

O

Figure 2 Location of RBC in a Series 505 Base

The 500 PROFIBUS-DP RBC resides in a Series 500 base. Install it in the

rightmost slot, adjacent to the power supply module. See Figure 3.

Series 500

Remote Base Controller

Power Supply

Figure 3 Location of RBC in a Series 500 Base

4

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

Installing and

Removing the RBC

Use the following steps to install the 505–6870 RBC in a Series 505 base or

to install the 500–6870 RBC in a Series 500 base.

WARNING

!

Installing or removing an RBC from a powered-up base disrupts your process

and can damage the RBC. Disruption of your process can cause death or

serious injury to personnel, and/or damage to equipment.

Ensure that all power is disabled before installing or removing the RBC.

CAUTION

!

The RBC is sensitive to, and can be damaged by , electrostatic discharge.

Ensure that personnel make contact with a static-dissipative pad and/or wear a

grounded wrist strap when handling the RBC.

1. Verify that all jumper settings on the 505 RBC or the Off/Freeze toggle

switch on the 500 RBC are correct. See Section 4. It is advisable to set

the dipswitch options before installing the module. See Section 5.

2. Disconnect power to the base.

3. Position the RBC so that the bezel is facing you.

4. Grasp the top and bottom of the RBC.

5. Carefully push the RBC into the slot until it mates with the backplane

connector.

6. Tighten the top and bottom bezel screws.

CAUTION

!

Series 505 RBCs are not designed to be installed in VME bases. Doing so

results in damage to equipment.

Never attempt to install any Series 505 RBC in a VME base.

To remove the RBC, complete the following steps.

1. If attached, remove cables from the RBC.

2. Disconnect power to the base.

3. Loosen the top and bottom bezel screws.

4. Carefully pull the RBC from the base.

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

5

3 RBC Ports

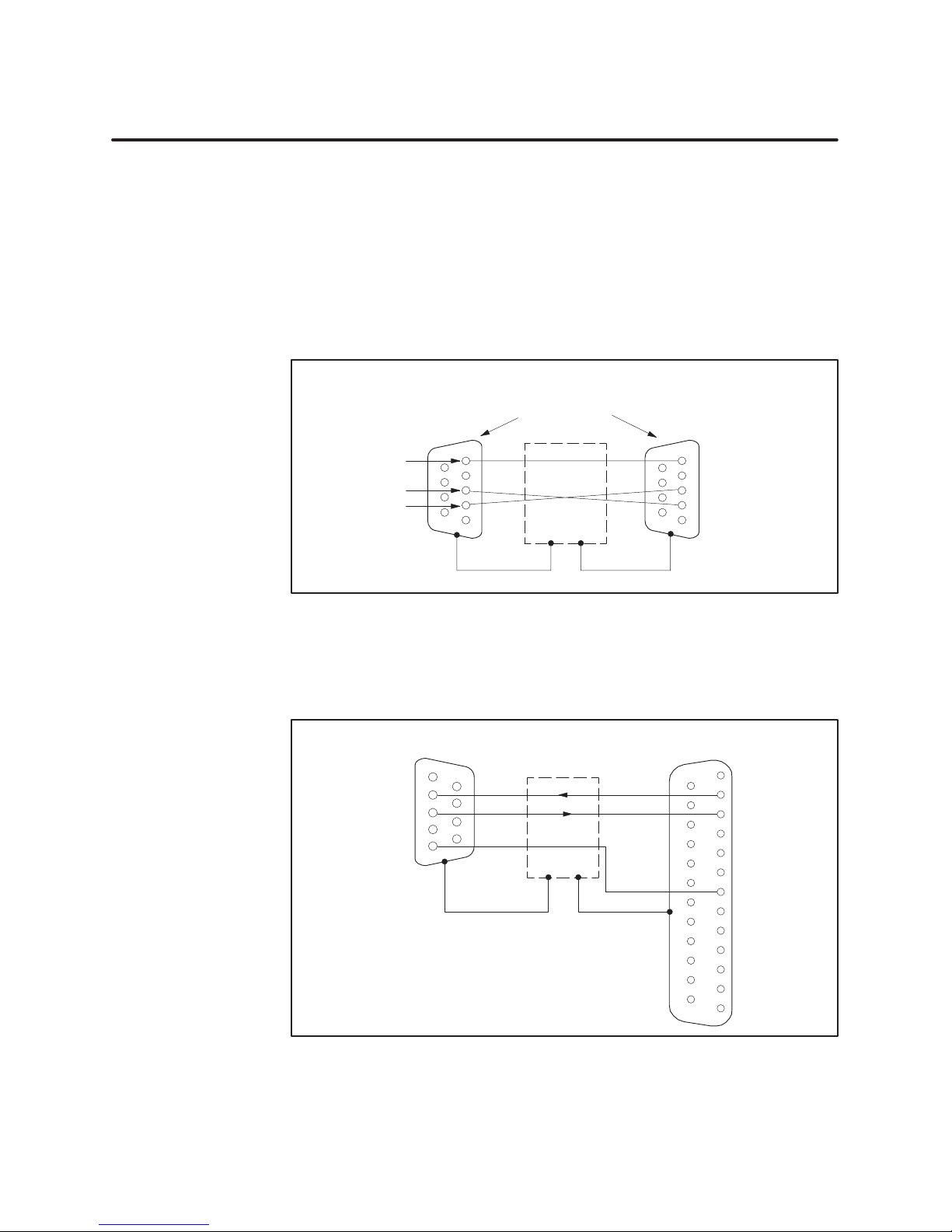

The 505 and 500 PROFIBUS-DP RBCs have two communication ports, an

RS-232 port and a PROFIBUS-DP I/O channel port.

RS-232 Port

When used with a Series 505 CPU, the RS-232 port is an interface to

programming devices that use software like TISOFT or other configuration

tools. To connect your RBC to a programming device/modem, use a standard

9-pin RS-232 serial cable that conforms at a minimum to the pinouts shown

in Figure 4. A standard cable that conforms to the minimum requirements

is available through Siemens; specify part number 2601094–8001.

Programming Device/Modem

Signal Ground (5)

Transmit Data (3)

Receive Data (2)

Pinouts

9

6

9-Pin, Female

D-Connector

5

3

2

1

Shield

RBC RS-232/423

Pinouts

5

9

6

Signal Ground

Transmit Data

3

Receive Data

2

1

Figure 4 RS-232 Serial Port, Minimum Cable Pinouts

Figure 5 shows the 25-pin cable connector pinouts required for the 25-pin

female communications port on the 500 RBC.

Programming Device/Modem

Pinouts

1

Receive Data

Transmit Data

Signal Ground

6

2

7

3

8

4

9

5

9-Pin, Female

D-Connector

Shield

Note: You can use the standard Siemens programming

cable (#2601094–8001) with a 9-to-25-pin male adapter.

RBC RS-232/423

Pinouts

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

Transmit Data

Receive Data

Signal Ground

25-Pin, Male

D-Connector

Figure 5 500 RBC RS-232 Serial Communications Cable Pinouts

6

SIMATIC 505/500 PROFIBUS-DP RBC User Manual

Loading...

Loading...