Siemens SIJECT15, SIJECT16 Operation Manual

SIJECT15/16

Operation Manual

Software Version 1

User Manual 06.2003 Edition

User Documentation

SIJECT 15/16 Document Structure

General Documentation:

SINUMERIK

Short

Guide for

Start-up

User Manual: Operator Manual

SINUMERIK

Operation

Manual

Technical Manual: Start-Up

SINUMERIK

Start-up

SIJECT 15/16

Operation Manual

Software Version 1

User Manual

Introduction

Operator panel keys

SIJECT OP15B Screen

1

2

3

Valid for

Control System Software Version

SIJECT 15/16 1.08

06.2003 Edition

SIJECT® Documentation

Key to editions

The editions listed below have been published prior to the current edition.

The column headed "Note" lists the amended sections, with reference to the previous edition.

Marking of edition in the "Note" column:

A .... New documentation.

Unchanged reprint with new order number

B ....

C .... Revised edition of new issue.

If any technical details presented on one of these pages have been changed with reference to

the previous edition, it is indicated by another edition number in the header of the respective

page.

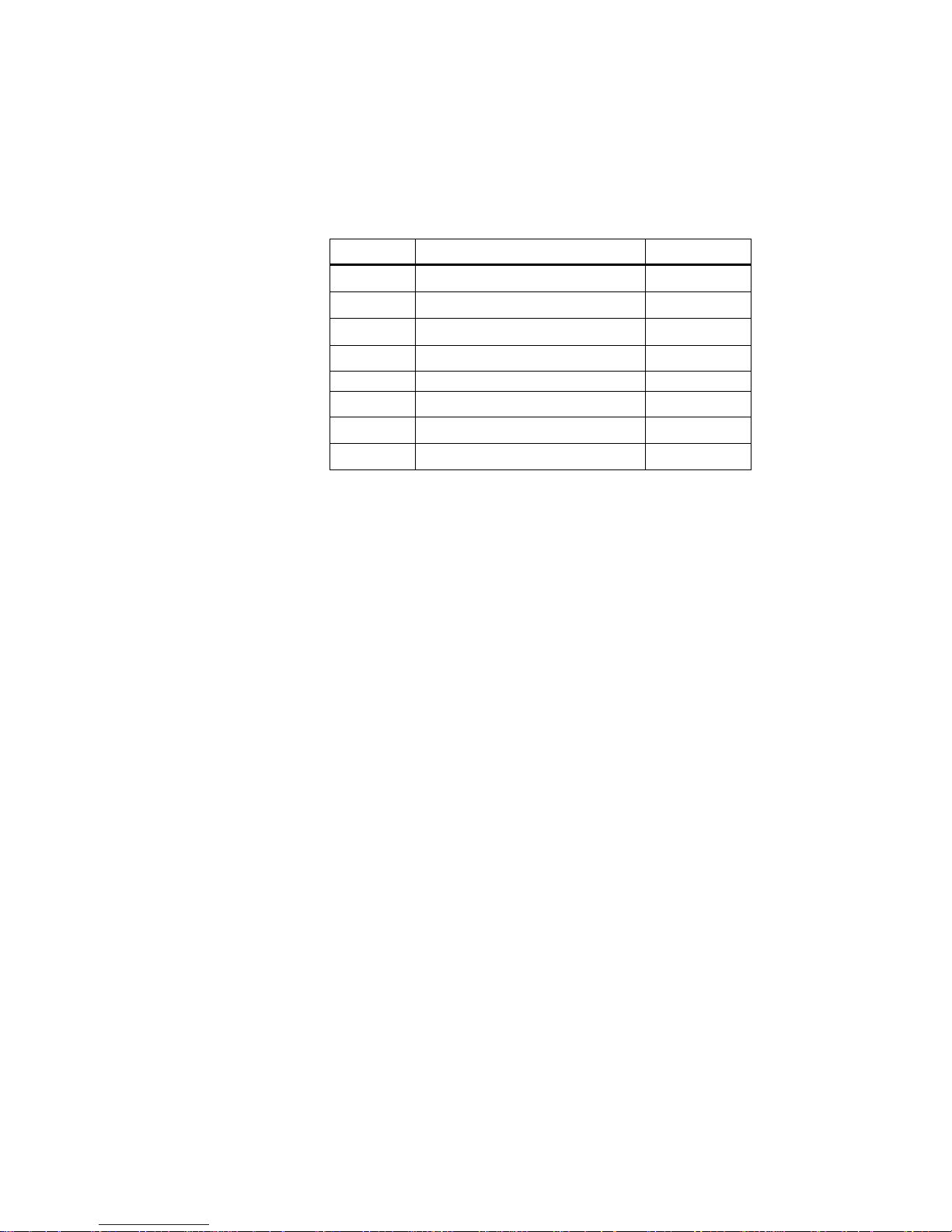

Edition

12.2000

06.2001

07.2002

Order No.

6AT1931-5AB41-0KA0

6AT1931-5AB41-0KA0

6AT1931-5AB41-0KA1

Remark

A

C

A

06.2003

Tested Siemens quality for software and training t o

DIN ISO 9001, Reg. No. 2160-01

This publication was made with WinWord V 7

and Designer V 6.0

Passing on and reproduction of this document, and utili zation and disclosure of its

contents is not allowed unless specifically authorized.

Violations shall be cause for damage liability. All rights reserved, par ticularly in the

event a patent is issued or a utility model patent is registered.

© Siemens AG 2003. All Rights Reserved.

Order No.

Printed in People’s Republic of China

Other functions which are not described in this Documentation can possibly also

be performed on the control system. However, the customer is n ot entitled to

demand these functions when new equipment is supplied or servici ng is carried

out.

Although we have checked the contents of this publication f or agreement with the

hardware and software described, we do not accept liability for total agreement

since differences cannot be totally ruled out. The inf ormation in this publication is

checked at regular intervals and necessary correction includ ed in the next release.

Suggestions are welcome.

Subject to change without prior notice.

Siemens-Aktiengesellschaft.

Table of Content

1 Introduction .................................................................................................. 1-1

1.1 Operating panel layout ......................................................................... 1-2

1.2 Overview of screens............................................................................. 1-4

1.3 Working process of injection molding machine.................................... 1-6

2 Operator panel keys .................................................................................... 2-1

2.1 Liquid crystal display (LCD) ................................................................. 2-2

2.2 Soft keys............................................................................................... 2-3

2.3 Screen hot keys.................................................................................... 2-6

2.4 Manual Operating Keys........................................................................ 2-8

2.5 Number Keys...................................................................................... 2-11

2.6 Cursor Keys........................................................................................ 2-11

2.7 Operating mode keys ......................................................................... 2-12

2.8 Motor keys and Heater keys .............................................................. 2-15

3 SIJECT OP15B Screens ............................................................................. 3-1

3.1 Hot key Screens ................................................................................... 3-2

3.1.1 Information Screen 3-9

3.1.2 Monitoring screen 3-12

3.1.3 Alarm screen 3-14

3.1.4 Temperature screen 3-16

3.1.5 Timer screen 3-17

3.1.6 Counter screen 3-19

3.1.7 Function screen 3-20

3.1.8 Save/load screen 3-22

3.1.9 Data screen 3-24

3.1.10 Service screen 3-26

3.2 Manual operation screen.................................................................... 3-38

3.2.1 Mold open/close screen 3-38

3.2.2 Ejector screen 3-40

3.2.3 Carriage Screen 3-42

3.2.4 Injection screen 3-43

3.2.5 Charging screen 3-45

3.2.6 Core 1 screen 3-47

3.2.7 Core 2 screen 3-50

3.2.8 Air blow screen 3-52

3.2.9 Mold adjustment screen 3-53

1 Introduction

Contents

Section Heading Page

1.1 Operator panel layout 1-2

1.2 Overview of screens 1-4

1.3

Working process of injection

molding machine

1-6

SIJECT 15/16 Operation Manual June, 2003

1-1

Introduction

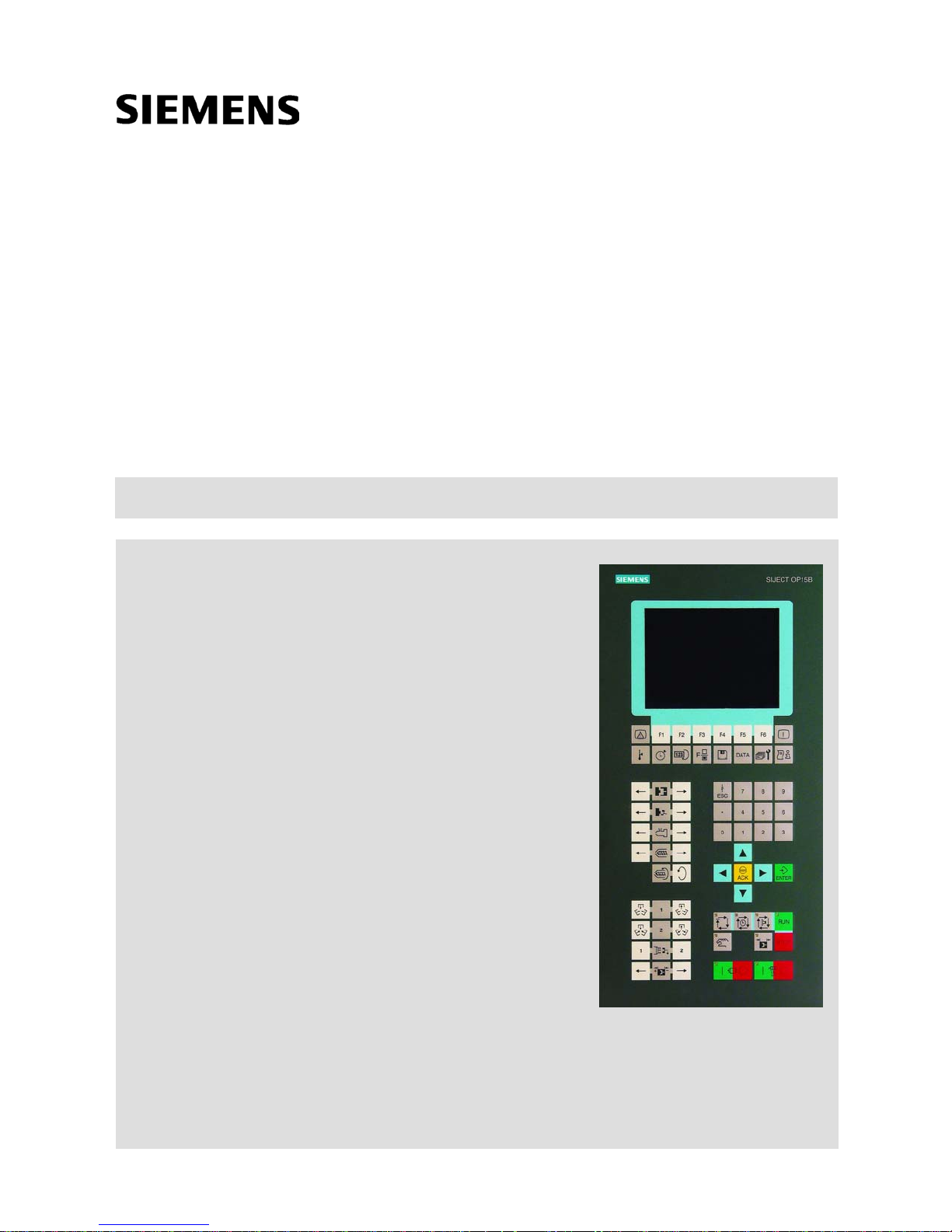

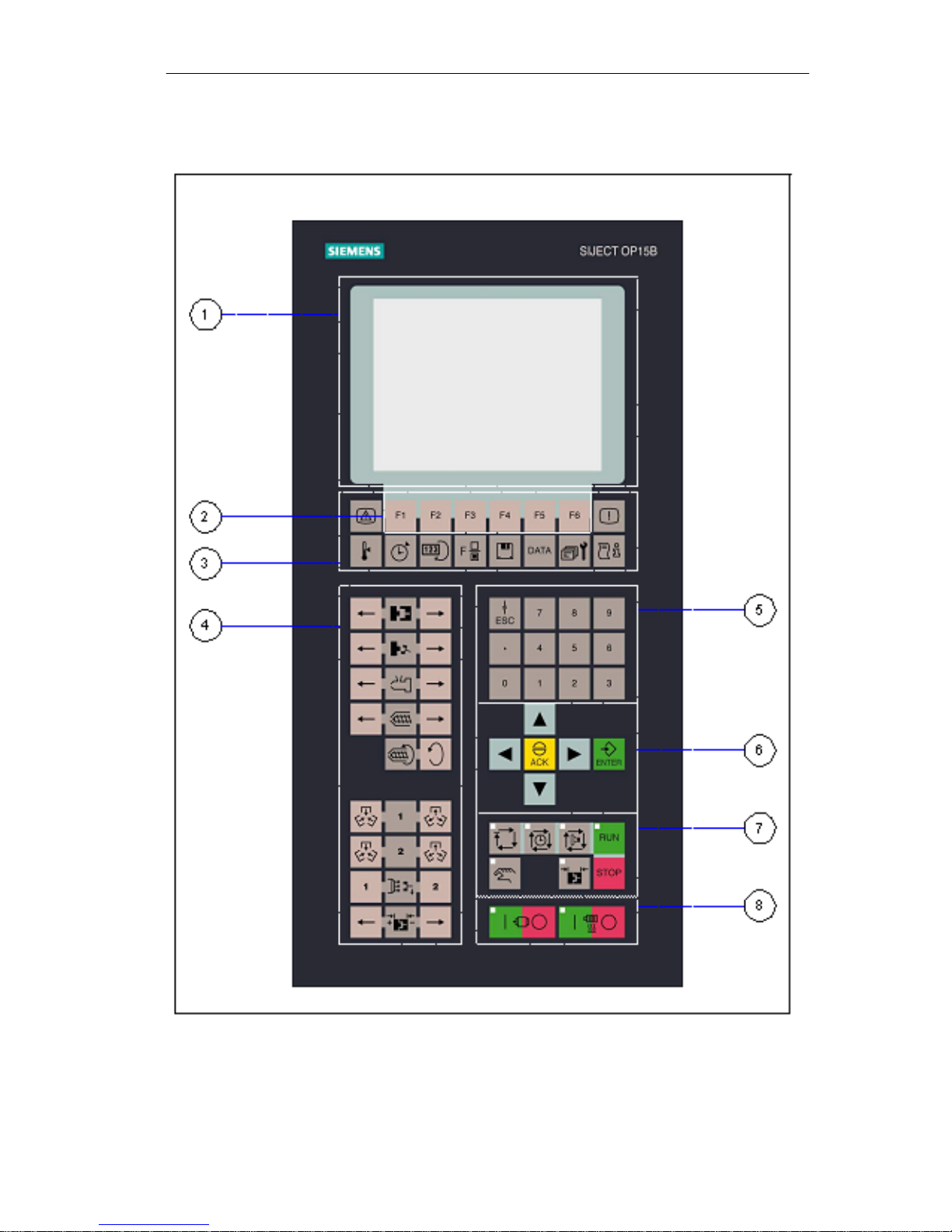

1.1 Operating panel layout

1-2

Fig. 1-1 Operator panel layout

SIJECT 15/16 Operation Manual June, 2003

Introduction

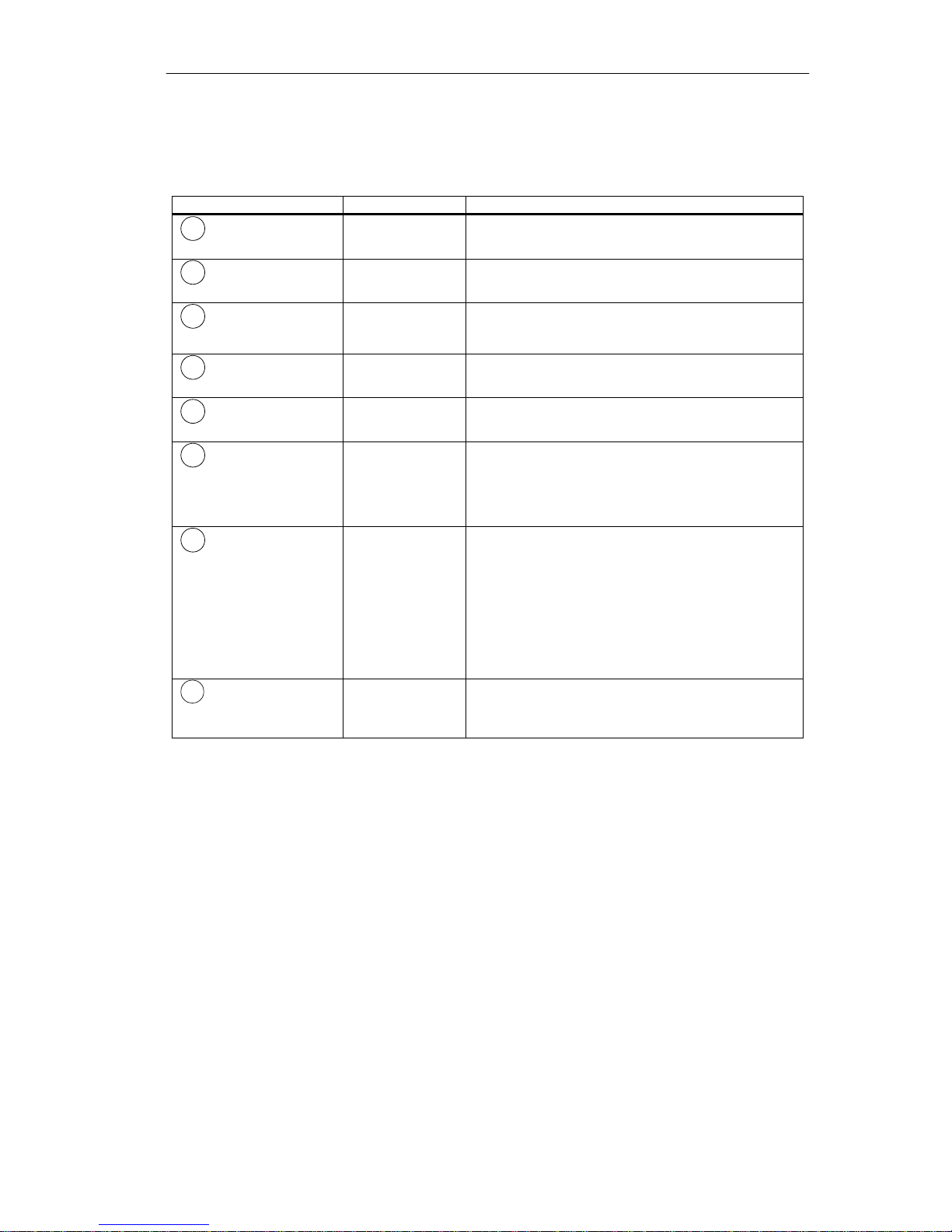

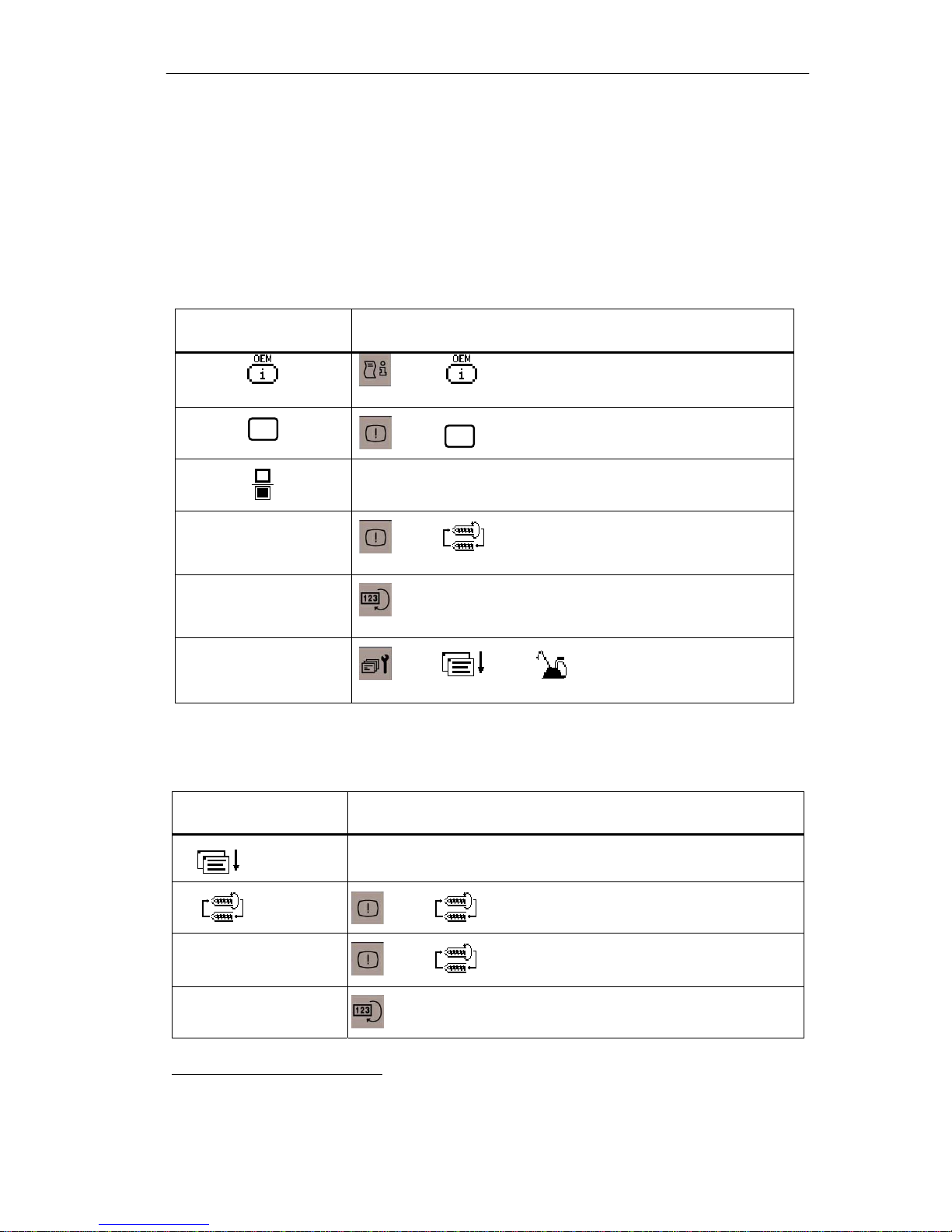

Description of softkey area

Explanation of the function of each softkey area is in Table 1-1.

Table 1-1 Description of softkey area

Operating area Key numbers Meaning

1

Liquid crystal display

2

Soft keys

3

Screen hot keys

4

Manual operating keys

5

Number keys

5

Cursor keys

7

Operating mode keys

8

Motor keys and heater

keys

-

5 keys

10 keys

26 keys

12 keys

6 keys

7 keys

4 keys

Display different control screens.

Call selected pictures from different screens.

Press each key and corresponding screen will be

displayed. Parameters setting, production

monitoring and data saving can be executed.

Call the parameter-setting screen with the key,

then control the machine movement manually.

Input number parameter. Create recipe data.

Move the cursor to the required position with

“Cursor key”, then press ”Enter” key to confirm

the setting.

Or, when screen displays the message “press

ACK key”, press “ACK” key to confirm.

Select machine mode with “Mode key”. When in

Semi Auto/Auto mode, press Run/Stop key to

start/stop the Semi Auto/Auto mode cycle.

Or, use “Manual Mode” key to select manual

mode, then you can press manual control key for

manual movement.

Or, press “Mode adjustment key” to select mold

adjustment mode, then you can do manual or

auto mold adjustment.

Control the motor start/stop, and heater on/off.

SIJECT 15/16 Operation Manual

1-3

Introduction

o

)

A

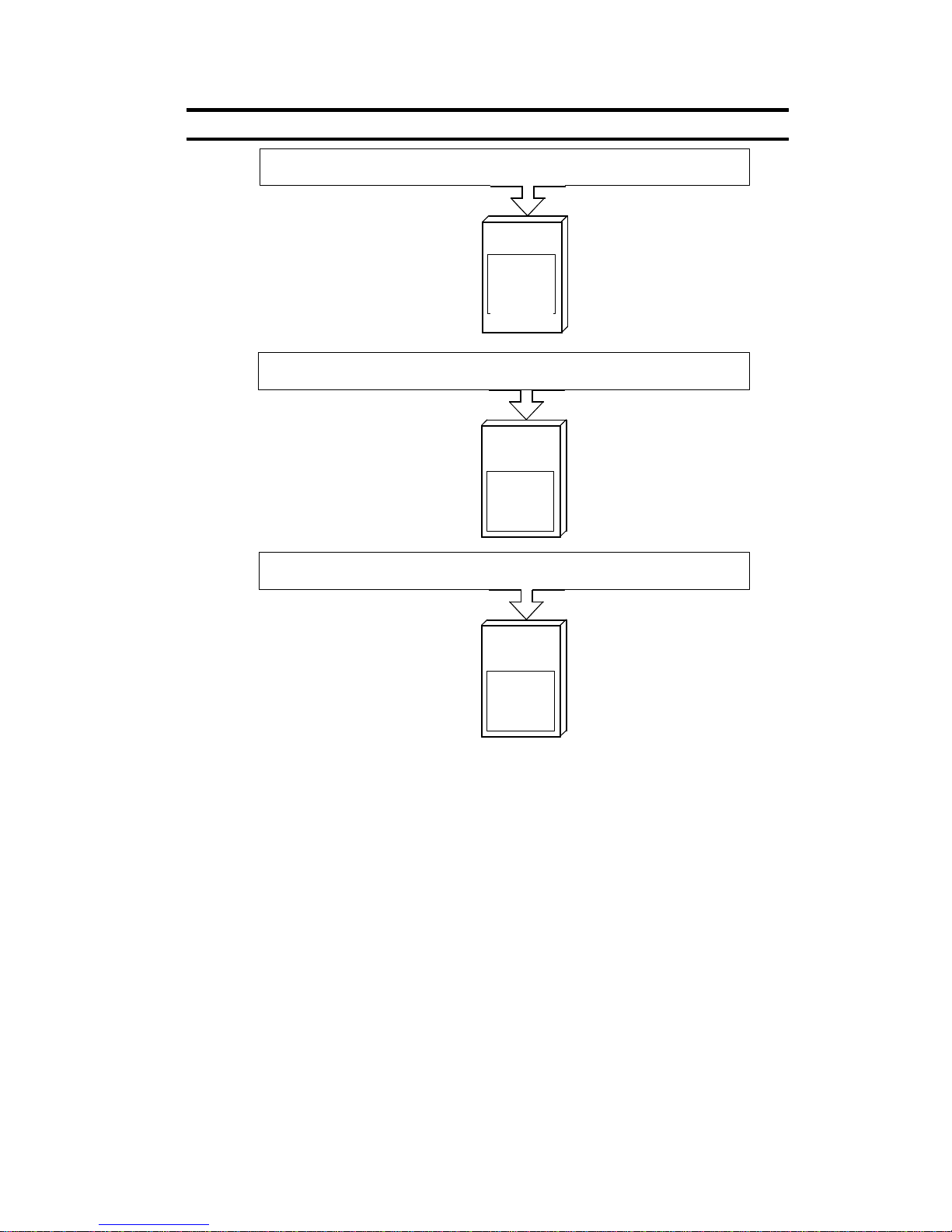

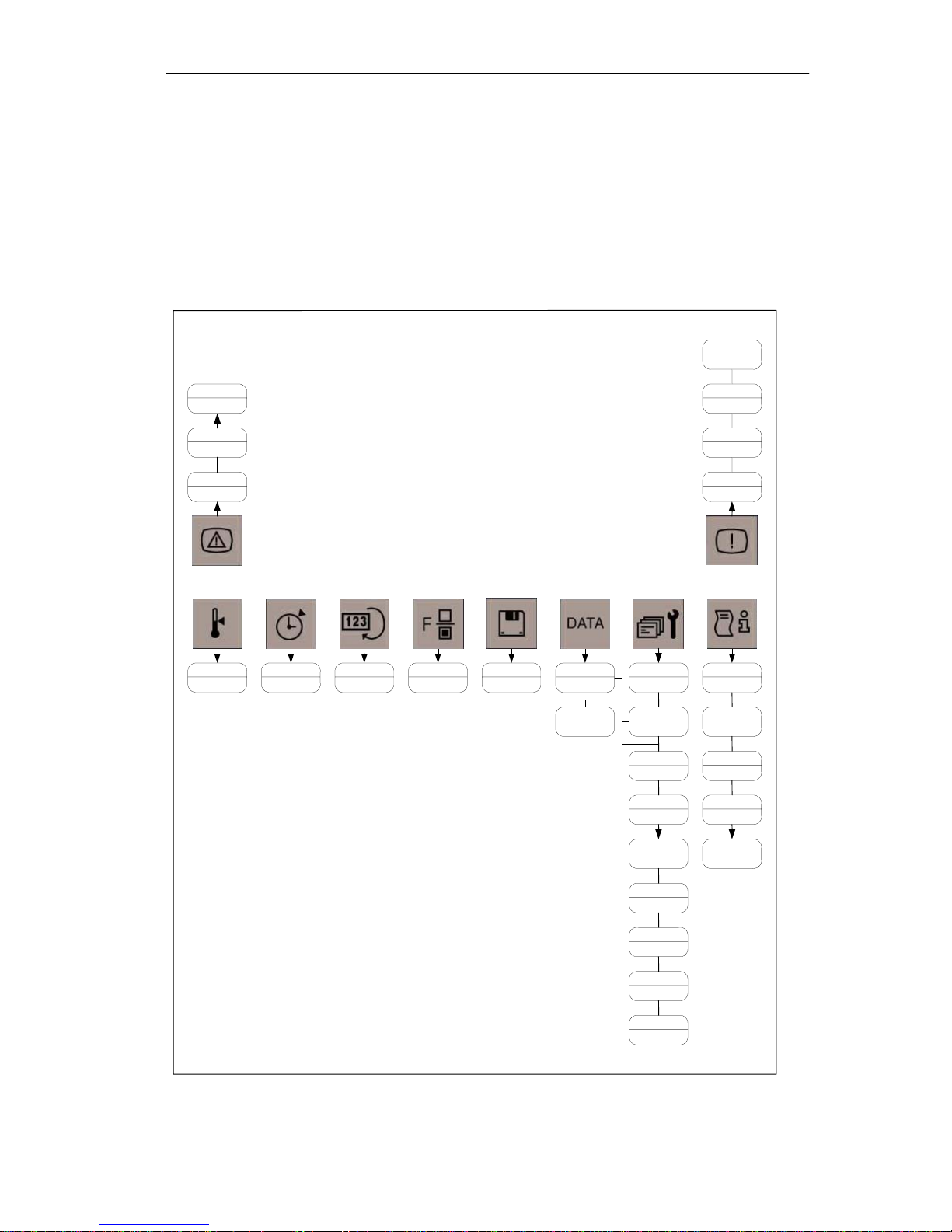

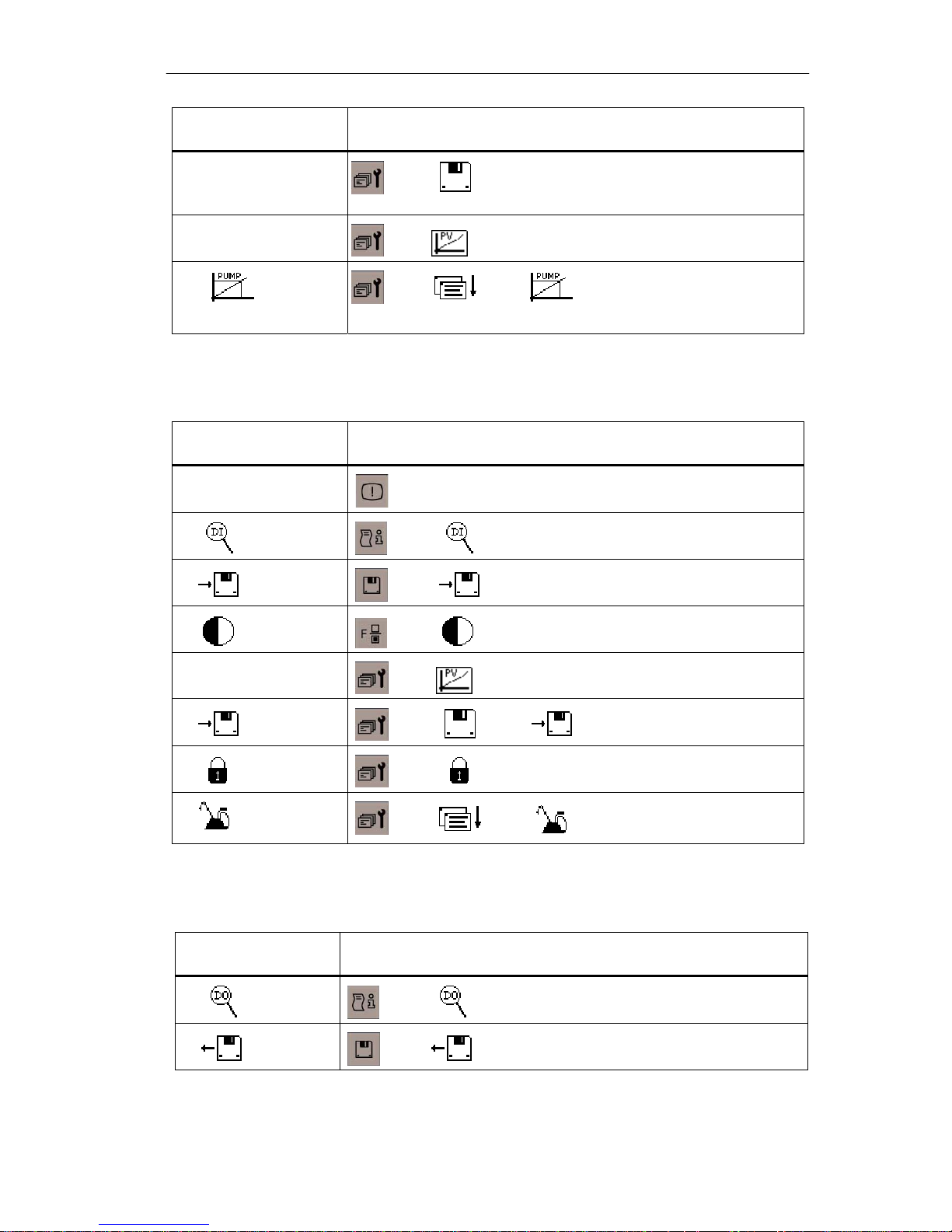

1.2 Overview of screens

Hot key screen

structure Service screen is designed in multistage structure, It is oriented to the

All hot key screens are listed in Table 1-2 for reference.

Table 1-2 Hot key screen structure

These screens are configured in different nested level. For instance, the

OEM-customer. Therefor it comprises the most important function

parameters for OEMs. Altogether nine different screens can be

displayed.

Screen 1.3

Manual lube

Screen 2

larm(con'd)

Screen 1.1

Event

Screen 1

Alarm

Screen 1

Temperature

Screen 1

Timer

Screen 1

Counter

Screen 1

Function

Screen 1

Load/save

Screen 1

Data

Screen 2

Data (con'd

Screen 1

Service

Screen 1.1

Password

Screen 1.2

Load/save

Screen 1.3

Set prop.valve

Screen 1.2

Purge

Screen 1.1

Event

Screen 1

Monitori ng

Screen 1

Version inf

Screen 1.1

OEM

Screen 1.2

DI

Screen 1.3

DO

1-4

Screen 2

Linear scale

Screen 2.1

Pump

Screen 2.2

Lubrication

Screen 2.3

Set function

Screen 2.4

Set ramp

Screen 2

PLC/CI Info

SIJECT 15/16 Operation Manual June, 2003

Introduction

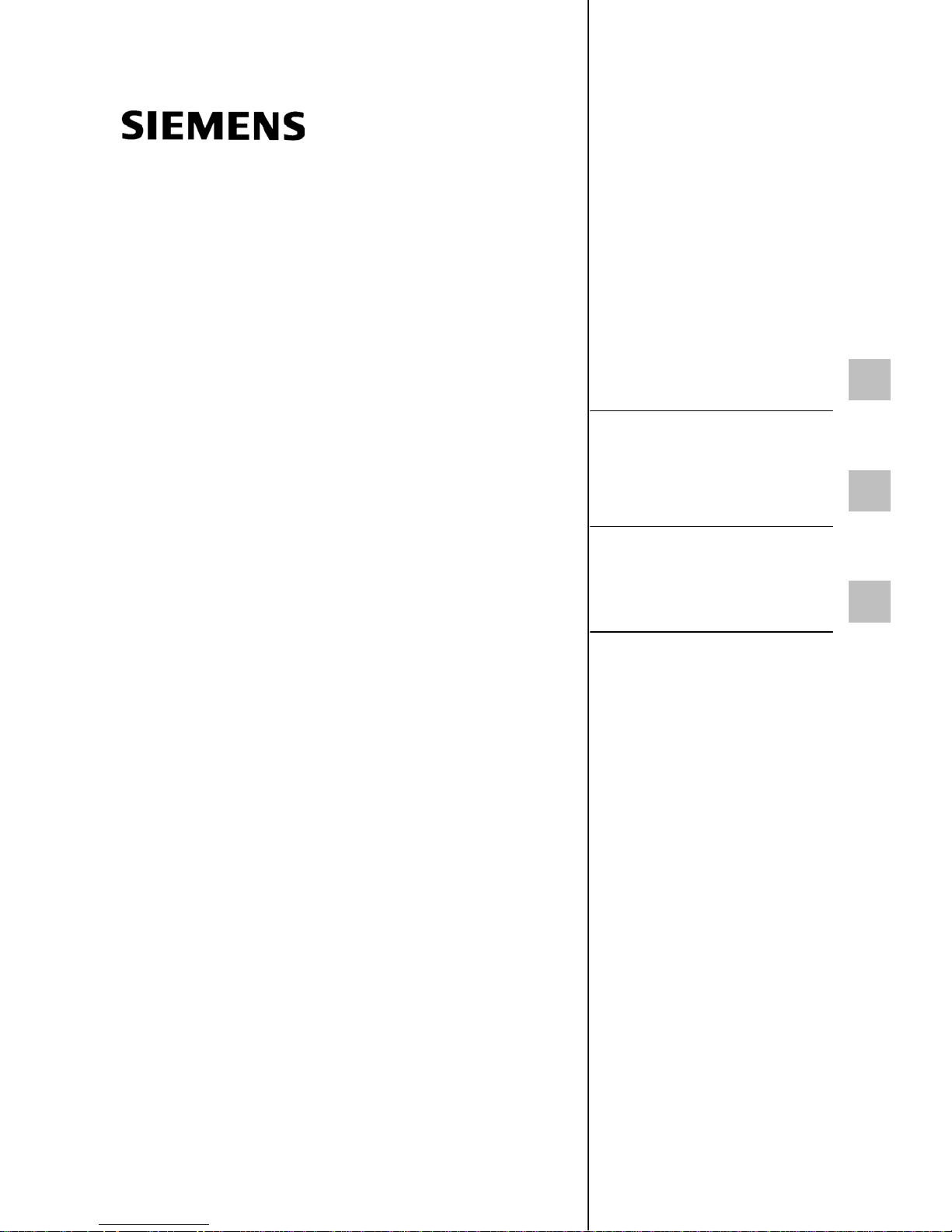

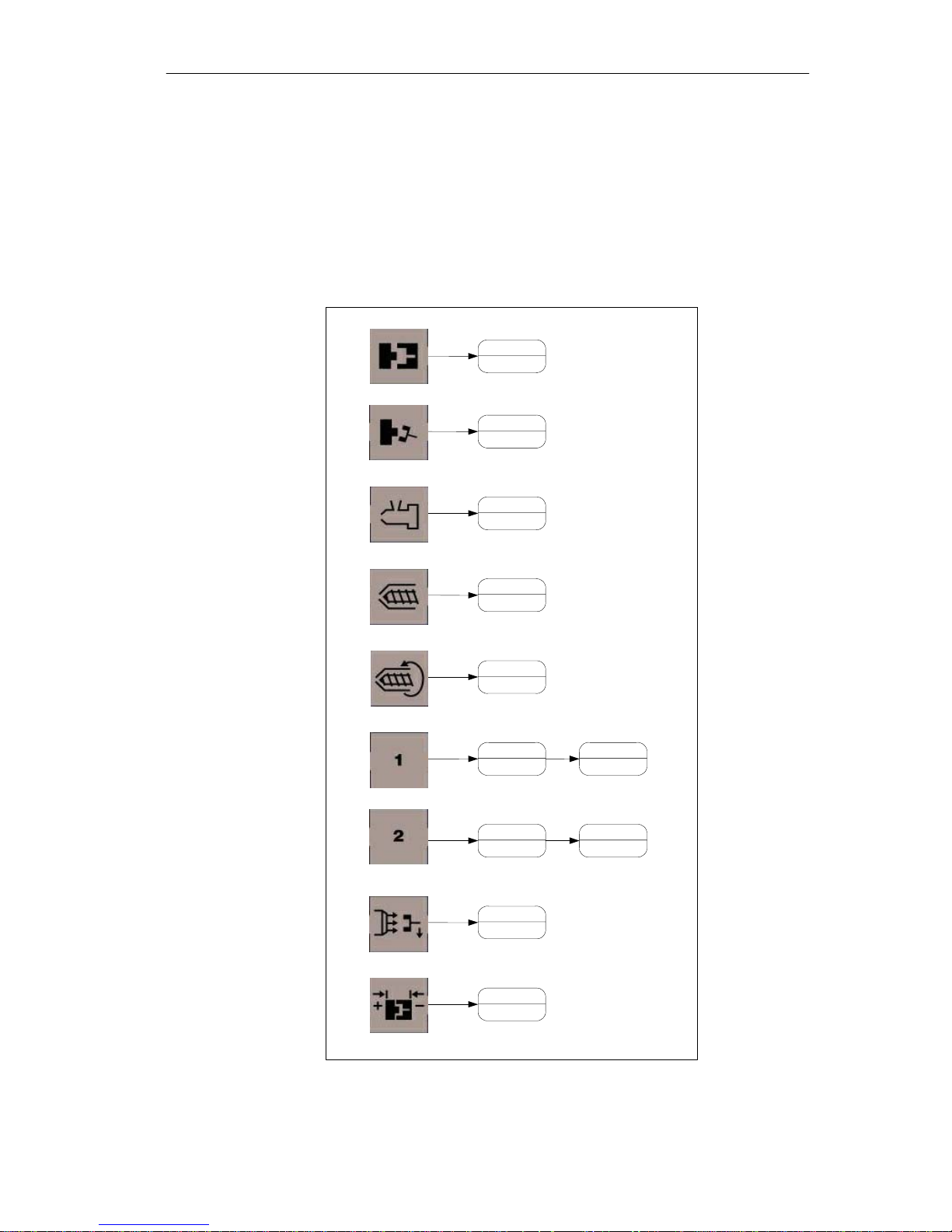

A

Screen structure of

manual operating keys

The screen structure here is relative simple in comparison with hot key

screen structure. It has only one level, and only the screens of core 1

in/out and core2 in/out have the 2

function.

The parameters like position, press, flow, delay, time, counter and mode

selection can be set in these screens.

Table 1-3 Screen structure of manual operating keys

Screen 1

Mld Clo/Opn

Screen 1

Eject

Screen 1

Carriage

nd

level, that is, they are used for core 3

Screen 1

Injection

Screen 1

Charging

Screen 1

Core 1

Screen 1

Core 2

Screen 1

ir blow

Screen 1

Mold adjust

Screen 2

Core 3

Screen 2

Core 3

SIJECT 15/16 Operation Manual

1-5

Introduction

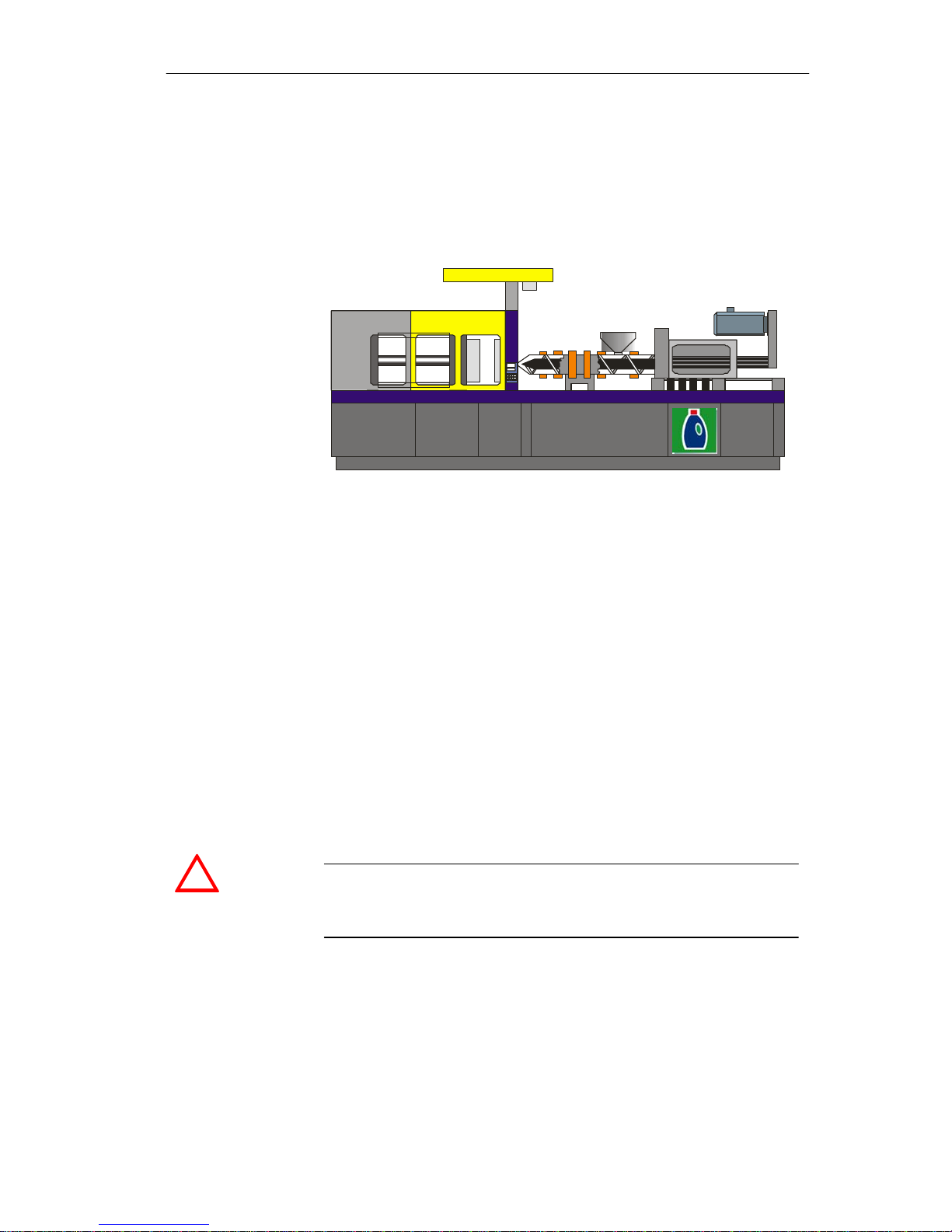

Working process of injection molding machine

General The most important components in the injection molding machine are:

— Injection unit

Mold close unit

—

— Electrical and hydraulic control

Fig. 1-2 Injection molding machine

SIJECT 15/16 Siject 15/16 is a compact control system. It can be widely used to control

injection molding machine from low end to middle and high end

customer. It is a series product and consists of different versions, i.e.

SIJECT 15

international version.

+

, SIJECT 16, SIJECT 16 international and SIJECT 16DP

Please see the manufacturer documentation “SIJECT 15/16 Start-up”

for detailed information.

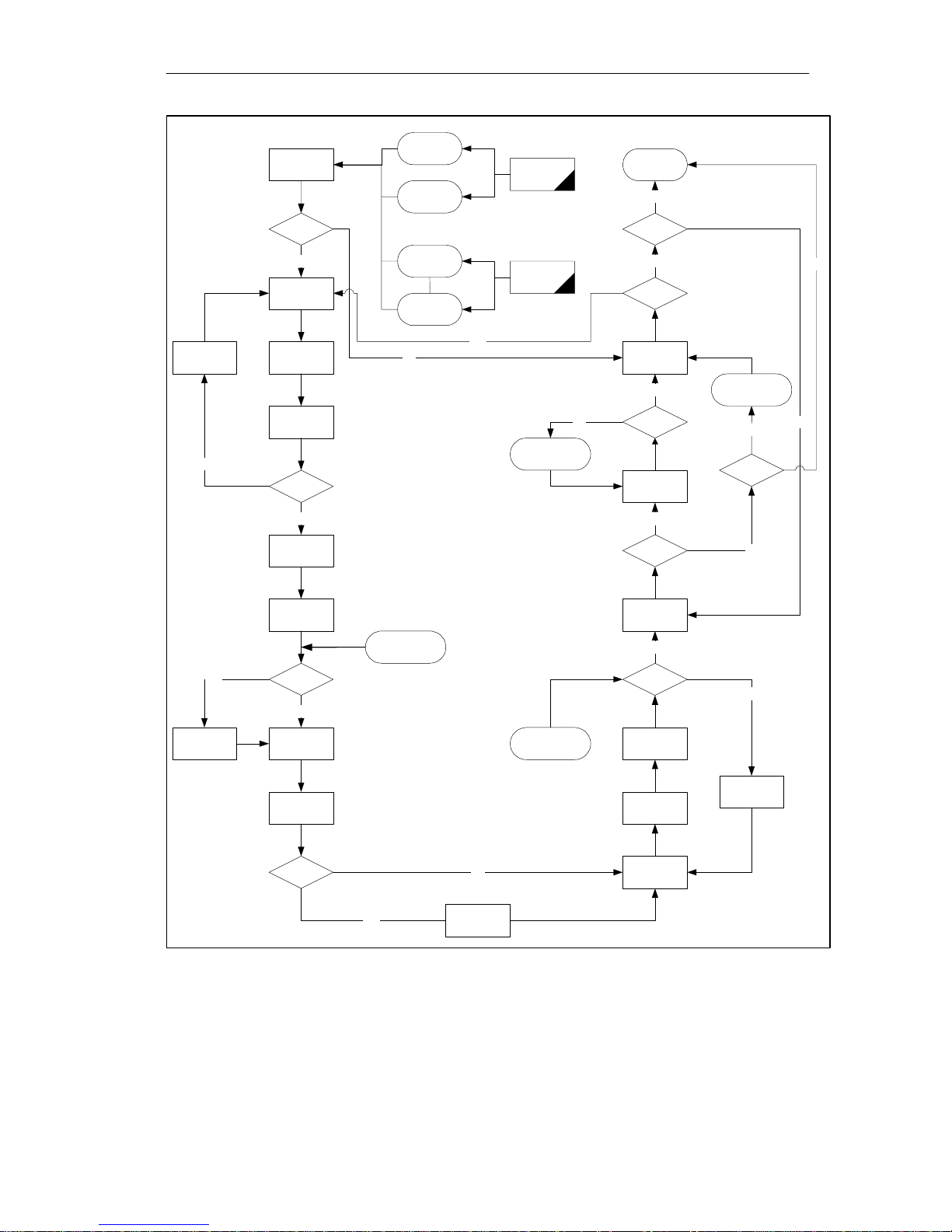

Control process The configuration of individual injection molding machine can be

different, but the working process should be implemented in a similar

way. Thus we describe it roughly in the following diagram.

It is provided in the diagram that the Core-in acts before Mold Close Start

or during Mold Close Process, the Core-out acts before Mold Open Start

or during Mold Open Process.

!

Caution

Other functions not described in the following diagram might be executed

in the control system. It is only available for reference.

1-6

SIJECT 15/16 Operation Manual June, 2003

Introduction

A

Time-full auto

Close mold

Cycle start

Ejector

retract end?

Yes

Core 1 in

Core 2 in

Sensor-full

auto

Safety door

close

Cycle key

start

No

Full auto

Semi auto

Yes

Cycle end

Yes

Counter

arrive

No

Ejector

auto-

retract?

Ejector retract

Yes

No

Yes

Carriage

retract

Core3 in

Mold clo se

end?

Yes

Carriage

advance

Injection/

holding

Back

feeding?

No

Charging

Suck back

Start cooling time

Ejector shake time

ir blow

Yes

No

Shake

times

arrive?

Ejector shake

Yes

Ejector

shake?

Ejector

advance

Yes

Mold open

end?

Core 1 out

Core 2 out

Stay time

No

Ejector

stay?

No

No

Open mold

No

Front

feeding?

Fig. 1-3 Flow chart for one cycle in injection molding machine

SIJECT 15/16 Operation Manual

Yes

No

Carriage

retract

Core 3 out

1-7

2 Operator panel keys

Contents

Section Heading Page

2.1 Liquid crystal display 2-2

2.2 Soft keys 2-3

2.3 Screen hot keys 2-6

2.4 Manual operating keys 2-8

2.5 Number keys 2-11

2.6 Cursor keys 2-11

2.7 Operating mode keys 2-12

2.8 Motor keys and heater keys 2-14

SIJECT 15/16 Operator manual June, 2003

2-1

Operator panel keys

2.1 Liquid crystal display (LCD)

General The LCD display with CCFL back-light has a good performance to

display:

Alarms

—

— Recipe data

— Customer specific picture

— Operation status

Performance The LCD has the following characteristics:

— 320x240 pixel

5.7” Chinese/English languages

—

— the brightness can be adjusted manually

2-2

SIJECT 15/16 Operation Manual June, 2003

Operator panel keys

2.2 Soft keys

General Users can press softkey to complete different operation as well as to

enter other screens.

Softkey F1:

1

Softkey F1

“ ” ——》 :OEM( Original Equipment Manufacturer )

Operation path and function

specific picture

i

“

“ ”

“Purge start”

“Injection reset”

Manual

“

Lubrication”

Softkey F2:

Softkey F2 Operation path and function

“ ”

”

——》

i

:Event information

Selection key

——》

”Purge start”: start up the purge

——》

function.

——》”Injection reset”: execute reset fuction of injection

counting.

——》 ——》 ——》”Manual lubrication”:

lubricate manually.

Page down

“

”

“Purge stop”

“Product reset”

1

Functions can be executed, which is also applicable for soft keys in following tables.

SIJECT 15/16 Operation Manual

——》

——》

purge key

:

”Purge stop”: stop purge function.

——》

——》”Product reset”: execute product reset function.

2-3

Operator panel keys

Softkey F2

“PLC version”

“Force output”

“ ”

Softkey F3:

Softkey F3 Operation path and function

“Manual lubrication”

“ ”

——》

——》

——》

——》

——》

Operation path and function

”PLC version”: display PLC version of

——》

MMC card.

”Manual lubrication”: lubricate manually

”Force output”: force output.

——》

——》

Digit input。

:

Pump combination

:

“ ”

“ ”

“ + ”

“ ”

“ ”

“ ”

Softkey F4:

“ ”

Softkey F4 Operation path and function

——》

——》

——》

——》

——》

——》

——》

save mold parameters into MMC card or CI

:

increase screen brightness

:

——》+ :

——》 :

set the password

:

——》

digit output

:

increase limit value

save program into MMC card

set manual lubrication

:

“ ”

2-4

SIJECT 15/16 Operation Manual June, 2003

——》

load mold parameters from MMC card or CI

:

Operator panel keys

Softkey F4

“ ”

“ - ”

“ ” ——》 ——》 :load program from MMC card。

“ ”

Softkey F5:

“

“ ”

Softkey F5 Operation path and function

”

——》

——》

——》

——》

——》

Operation path and function

decrease screen brightness

:

——》- :

——》

proportional valve start-up

:

——》

reduce limit value

temperature setting

:

ramp data setting

:

Softkey F6:

Softkey F6

Page up

Operation path and function

SIJECT 15/16 Operation Manual

2-5

Operator panel keys

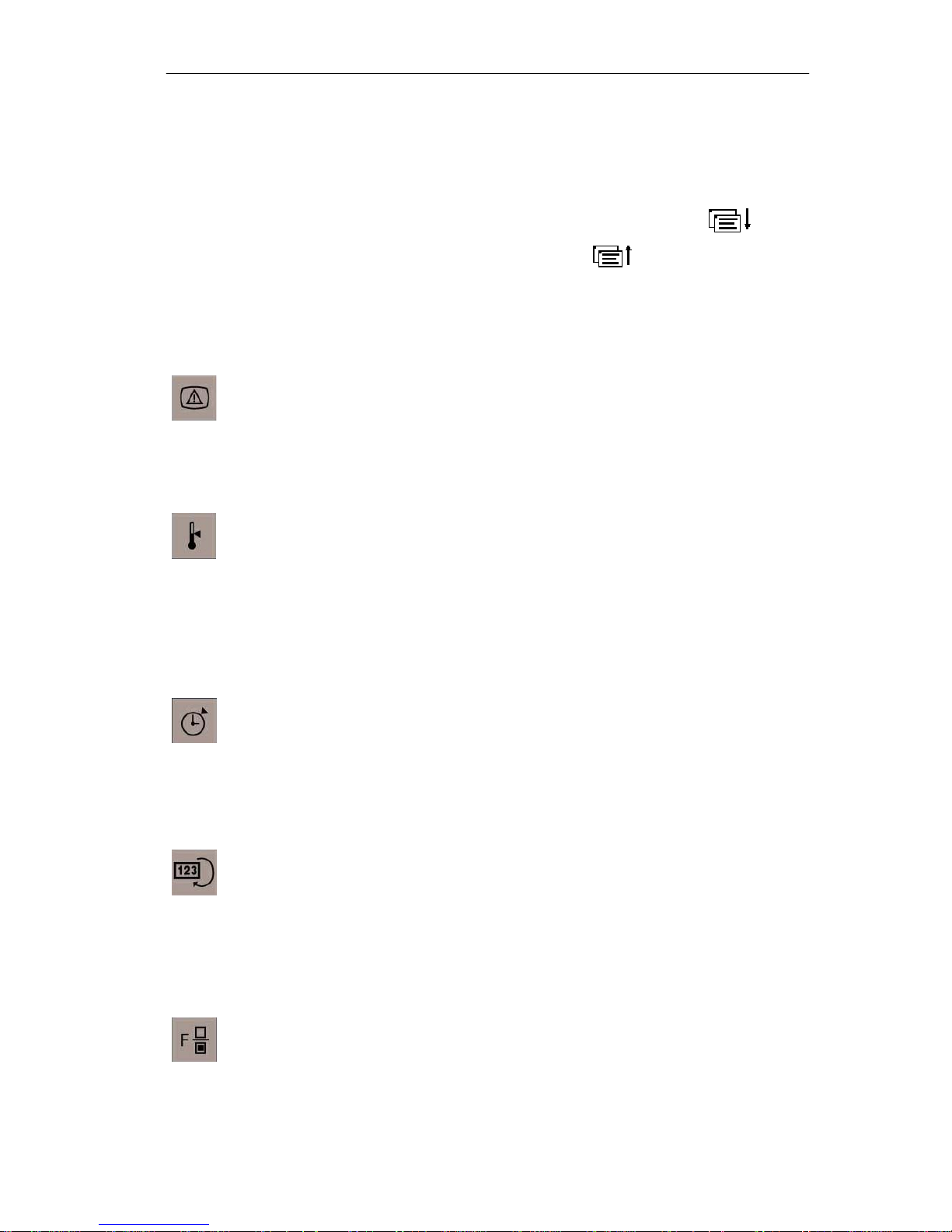

2.3 Screen hot keys

General Press each key and corresponding screen will be displayed. If the screen

has more than one layer, use the soft keys of page down

the next layer. Press the page up key

previous screen.

Alarm key

Press Alarm key to enter Alarm screen, and the current alarm will be

displayed on this screen. Press F1 key to enter the event record screen,

and you can check the record of all events.

Temperature key

at right to go back to the

to go to

You can also choose the control mode of nozzle (open loop/close loop).

Timer key

Counter key

Press this key to enter Counter screen. You can set the quantity of

Function key

Press Function key to enter

Press this key to enter Temperature screen where the set value of each

temperature channel can be input, and the actual value of temperature

channel can be displayed as well. In addition, you can choose the “heat

holding” function, and you can set the tolerance of temperature control.

Press this key to enter Timer screen. Every time duration can be set,

such as cycle time, cooling time, mold open/close time, as well as every

delay time and monitoring time.

products and the products of each mold. Also the current product

quantity, number of injection and products quantity after machine power

on can be displayed.

Function screen

language (Chinese/English), selection of robot and back light functions

can be set.

. The screen brightness,

2-6

SIJECT 15/16 Operation Manual June, 2003

Operator panel keys

Load/save key

Press this key to enter

saved into CI/MMC, and saved mold recipe data can be loaded from

CI/MMC.

Load/save screen

. Mold recipe data can be

Data key

Press this key to enter Data screen. You can review the production data

of last 10 injection cycles, including the position and time of each activity,

such as injection number, the position of mold open end point, injection

start point, injection end point, pressure hold end point, charging end

point and ejector end point, and the time for mold hold, mold lock,

injection, cycle and charging.

Service key

Information key

Press this key to enter

and functions here. Nine service screens are provided, including function

selection, linear scale setting, password setting, load/save setting,

proportional valve setting, pump setting, lubrication setting, temperature

setting and ramp setting.

When OEM has finished the start-up of injection molding machine, these

parameters will normally be protected by Password 2 by OEM.

Service screen

. OEM can set the factory data

Users can also check the operating status of each digit input/output.

Press Information key to enter Information screen where the version

message of OP, CI and PLC program can be read. Then press the

softkey F2, and continue to display the PLC status and OP

communication status.

Monitoring key

Press Monitoring key to enter Monitoring screen, which is the main

screen of system. The current machine running status are displayed,

including the positions of mold, screw, ejector; rotation speed of screw;

production quantity; power on time; cycle time and current mold number.

Additionally, the purge and lubrication can also be operated.

SIJECT 15/16 Operation Manual

2-7

Operator panel keys

2.4 Manual Operating Keys

General All the manual keys

the Manual mode and Mold adjustment is running.

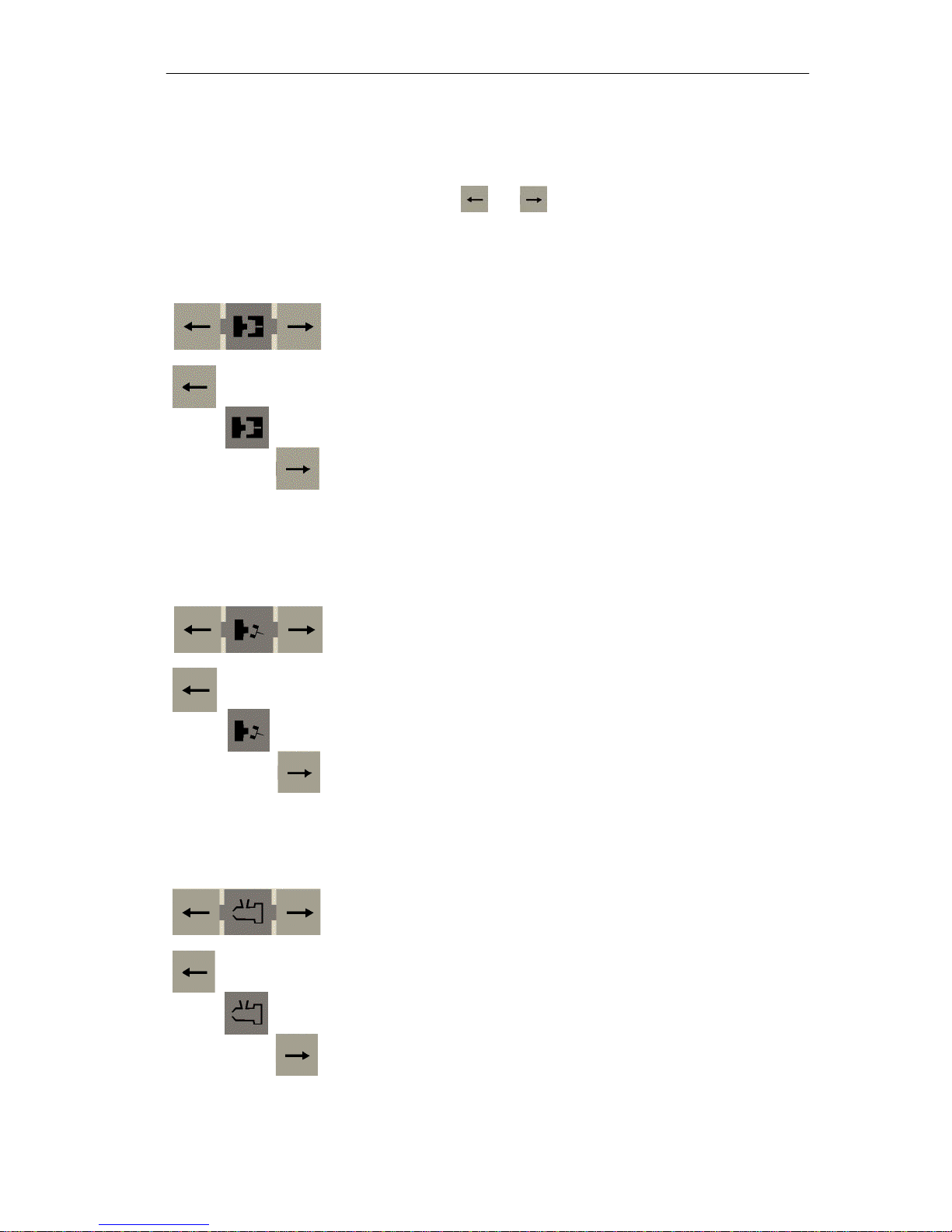

Mold key

Press the middle Mold key to enter Mold screen.

Input corresponding parameter (Position, pressure, flow and protecting

time) for each step.

Mold will open continuously if you keep pressing the left key.

Mold will close continuously if you keep pressing the right key.

Mold close/open keys can be operated in combination with core in/out

keys, for example, “Core in” can be done during, before or after mold

close, or “Core out” during, before or after mold open.

Ejector key

Press the middle Ejector key to enter

Now you can input corresponding parameter (Position, pressure, flow

and counter) for ejector advance and retract, and set counter and

ejector mode.

Ejector will retract continuously if you keep pressing the left key.

Ejector will advance continuously if you keep pressing the right key.

Repeat above-mentioned two steps to carry out multiple ejection.

Carriage key

Press the middle Carriage key to enter Carriage screen.

Now you can input corresponding parameter (pressure, flow and

injection time) for carriage advance and retract.

Carriage will advance continuously if you keep pressing the left key.

Carriage will retract continuously if you keep pressing the right key.

and described below can function only after

Ejector screen

.

2-8

SIJECT 15/16 Operation Manual June, 2003

Operator panel keys

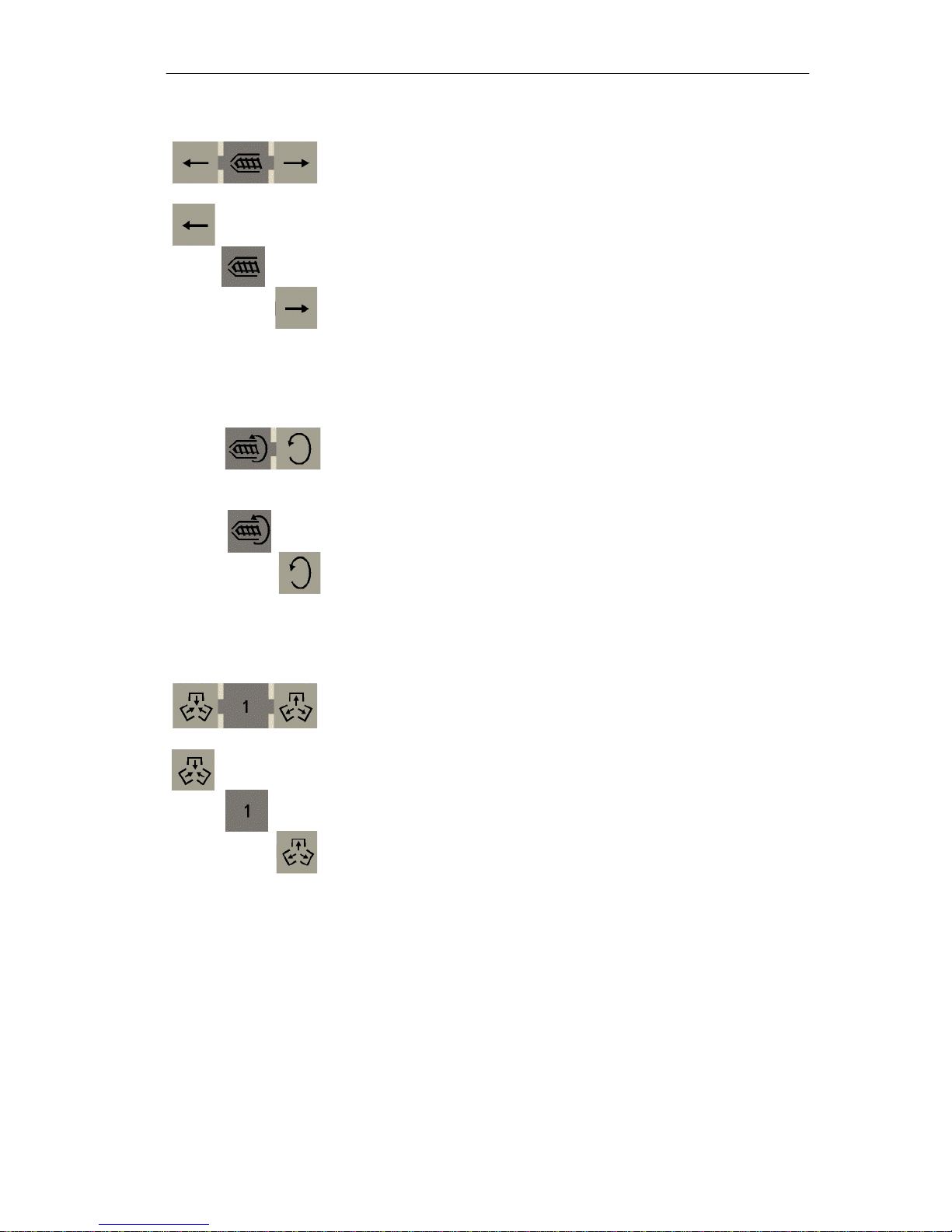

Injection key

Press the middle Injection key to enter Injection screen.

Input corresponding parameter (pressure, position, flow and total

injection time) for injection.

Machine will inject once if you press the left key. Keep pressing the left

key, the machine will come into pressure holding status automatically

after injection is finished.

Machine will suck back, i.e., screw retract, if you keep pressing the right

key.

Charge key

Press the middle Charge key to enter Charge screen.

Input corresponding parameter (Position, pressure and flow) for

charging.

Screw will be charging if you keep pressing the right key.

Core 1 key

Press the middle Core 1 key to enter

Input corresponding parameter for core 1, such as position, pressure,

flow, time and counting.

Keep pressing the left key to let core 1 in.

Keep pressing the right key to let core 1 out.

Core 1 screen

.

SIJECT 15/16 Operation Manual

2-9

Operator panel keys

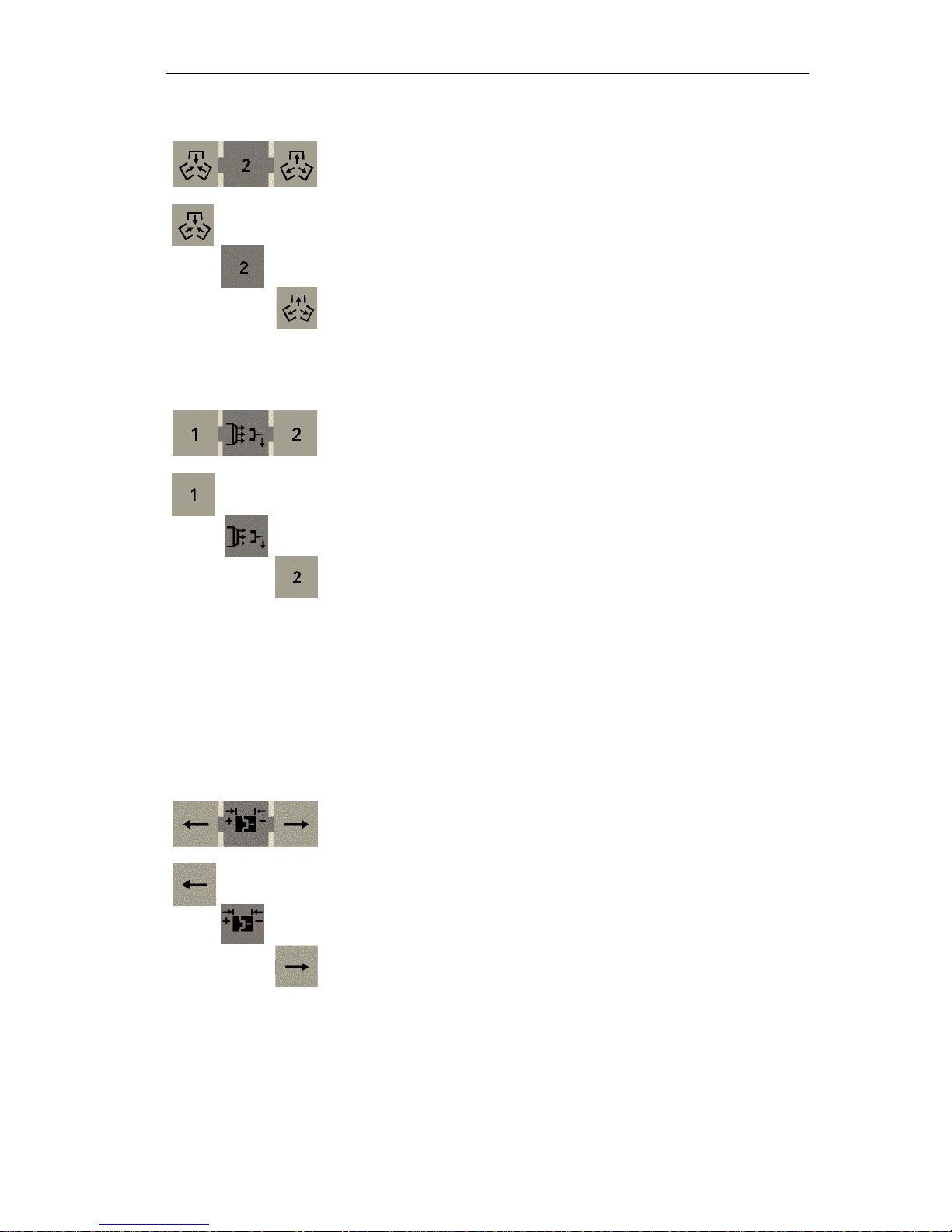

Core 2 key

Air-blow key

Press the middle Core 2 key to enter Core 2 screen.

Input corresponding parameter for core 2, such as position, pressure,

flow, time and counting.

Keep pressing the left key to let core 2 in.

Keep pressing the right key to let core 2 out.

Press the middle Air-blow key to enter

Input corresponding parameter (position and time) for Air-blow 1 and Airblow 2.

Air-blow 1 will work if you press the left key.

Air-blow screen

.

Air-blow 2 will work if you press the right key.

Press the Air-blow key again to enter Core 3 screen.

Input corresponding parameter (pressure, position, flow and time) for

core 3 in/out.

Keep pressing the left key to let core 3 in.

Keep pressing the right key to let core 3 out.

Mold adjustment key

Press the middle Mold adjustment key to enter Mold adjustment

screen.

Input pressure and flow for mold adjustment. There are two ways to

adjust mold. When manual mold adjustment is selected, you can set

pulse here. If auto mode is selected, you can set the time of adjusting.

Mold adjustment retracts if you keep pressing the left key.

Mold adjustment advances if you keep pressing the right key.

2-10

SIJECT 15/16 Operation Manual June, 2003

Loading...

Loading...