Siemens SENTRON PAC5200,SENTRON PAC5100 Device Manual

Preface

Open Source Software

Contents

Power Monitoring Device

and

Power Quality Recorder

SENTRON PAC5100/5200

7KM5212/5412

V1.00

Device Manual

User Information 1

Overview 2

Device Design 3

Measurands and Recording 4

Getting Started 5

Connection Principle 6

Operation at Use of a PC 7

Operation at Use of the Display 8

Time Synchronization 9

Maintenance, Storage, Transport 10

E50417-H1040-C568-A1

Failures and LED Indications 11

Technical Data 12

Operational Indications 13

Operating Parameters 14

Glossary

Index

NOTE

For your own safety, please observe the warnings and safety instructions contained in this document.

Disclaimer of Liability

This document has been subjected to rigorous technical review

before being published. It is revised at regular intervals, and any

modifications and amendments are included in the subsequent

issues. The content of this document has been compiled for

information purposes only. Although Siemens AG has made best

efforts to keep the document as precise and up-to-date as possible,

Siemens AG shall not assume any liability for defects and damage

which result through use of the information contained herein.

This content does not form part of a contract or of business

relations; nor does it change these. All obligations of Siemens AG

are stated in the relevant contractual agreements.

Siemens AG reserves the right to revise this document from time to

time.

Document version: E50417-H1040-C568-A1.00

Edition 03.2015

Version of the product described: V1.00

Copyright

Copyright Siemens AG 2015. All rights reserved.

The disclosure, duplication, distribution and editing of this

document, or utilization and communication of the content are not

permitted, unless authorized in writing. All rights, including rights

created by patent grant or registration of a utility model or a design,

are reserved.

Registered Trademarks

SENTRON

unauthorized use is illegal.

All other designations in this document can be trademarks whose

use by third parties for their own purposes can infringe the rights of

the owner.

®

is a registered trademark of SIEMENS AG. An

Preface

Purpose of this Manual

This manual describes the application, functions, installation, commissioning, and operation of the

Power Monitoring Device and Power Quality Recorder SENTRON PAC5100/5200 7KM5212/5412.

Targe t G r o u p

This manual is intended for project engineers, commissioning and operating personnel in electrical systems

and power plants.

Scope of Validity of this Manual

This manual is valid for the Power Monitoring Device and Power Quality Recorder SENTRON PAC5100/5200

7KM5212/5412.

Further Support

For any questions concerning your system, please contact your Siemens representative.

Siemens provides around-the-clock support.

Phone: +49 (911) 895-7222

Fax: +49 (911) 895-7223

Internet: http://www.siemens.com/automation/service&support

Training Courses

If you are interested in our current training program, please contact our training center:

Siemens AG

Siemens Power Academy TD

Humboldtstr. 59

D-90459 Nuremberg

Tel.: +49 (911) 433-7415

Fax: +49 (911) 433-7929

Internet: http://www.siemens.com/poweracademy

e-mail: poweracademy@siemens.com

E50417-H1040-C568-A1, Edition 03.2015

3SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

Notes On Safety

This manual is not a complete index of all safety measures required for operation of the equipment (module,

device). However, it comprises important information that must be noted for purposes of personal safety, as

well as in order to avoid material damage. Information is highlighted and illustrated as follows according to the

degree of danger.

DANGER

DANGER means that death or severe injury will occur if the appropriate safety measures are not taken.

✧ Follow all advice instructions to prevent death or severe injury.

WARNING

WARNING means that death or severe injury can occur if the appropriate safety measures are not taken.

✧ Follow all advice instructions to prevent death or severe injury.

CAUTION

CAUTION means that minor or moderate injury can occur if the appropriate safety measures are not taken.

✧ Follow all advice instructions to prevent minor injury.

NOTICE

NOTICE means that damage to property can occur if the appropriate safety measures are not taken.

✧ Follow all advice instructions to prevent damage to property.

NOTE

is important information about the product, the handling of the product, or the part of the documentation in

question to which special attention must be paid.

4 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

Personnel Qualified in Electrical Engineering

Only qualified electrical engineering personnel may commission and operate the equipment (module, device)

described in this document. Qualified electrical engineering personnel in the sense of this manual are people

who can demonstrate technical qualifications as electrical technicians. These persons may commission, isolate, ground, and label devices, systems and circuits according to the standards of safety engineering.

Use as Prescribed

The equipment (device, module) must not be used for any other purposes than those described in the Catalog

and the Technical Description. If it is used together with third-party devices and components, these must be

recommended or approved by Siemens.

If the device is not used in accordance with the operating instruction and this manual, the scheduled protection

is impaired.

Problem-free and safe operation of the product depends on the following:

• Proper transport

• Proper storage, setup, and installation

• Proper operation and maintenance

When electrical equipment is operated, hazardous voltages are inevitably present in certain parts. If proper action is not taken, death, severe injury, or property damage can result.

• The equipment must be grounded at the grounding terminal before any connections are made.

• All circuit components connected to the power supply may be subject to dangerous voltage.

• Hazardous voltages may be present in equipment even after the supply voltage has been disconnected

(capacitors can still be charged).

• Equipment with exposed current transformer circuits must not be operated. Prior to disconnecting the

equipment, ensure that the current transformer circuits are short-circuited.

• The limit values stated in the document may not be exceeded. This must also be considered during testing

and commissioning.

E50417-H1040-C568-A1, Edition 03.2015

5SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

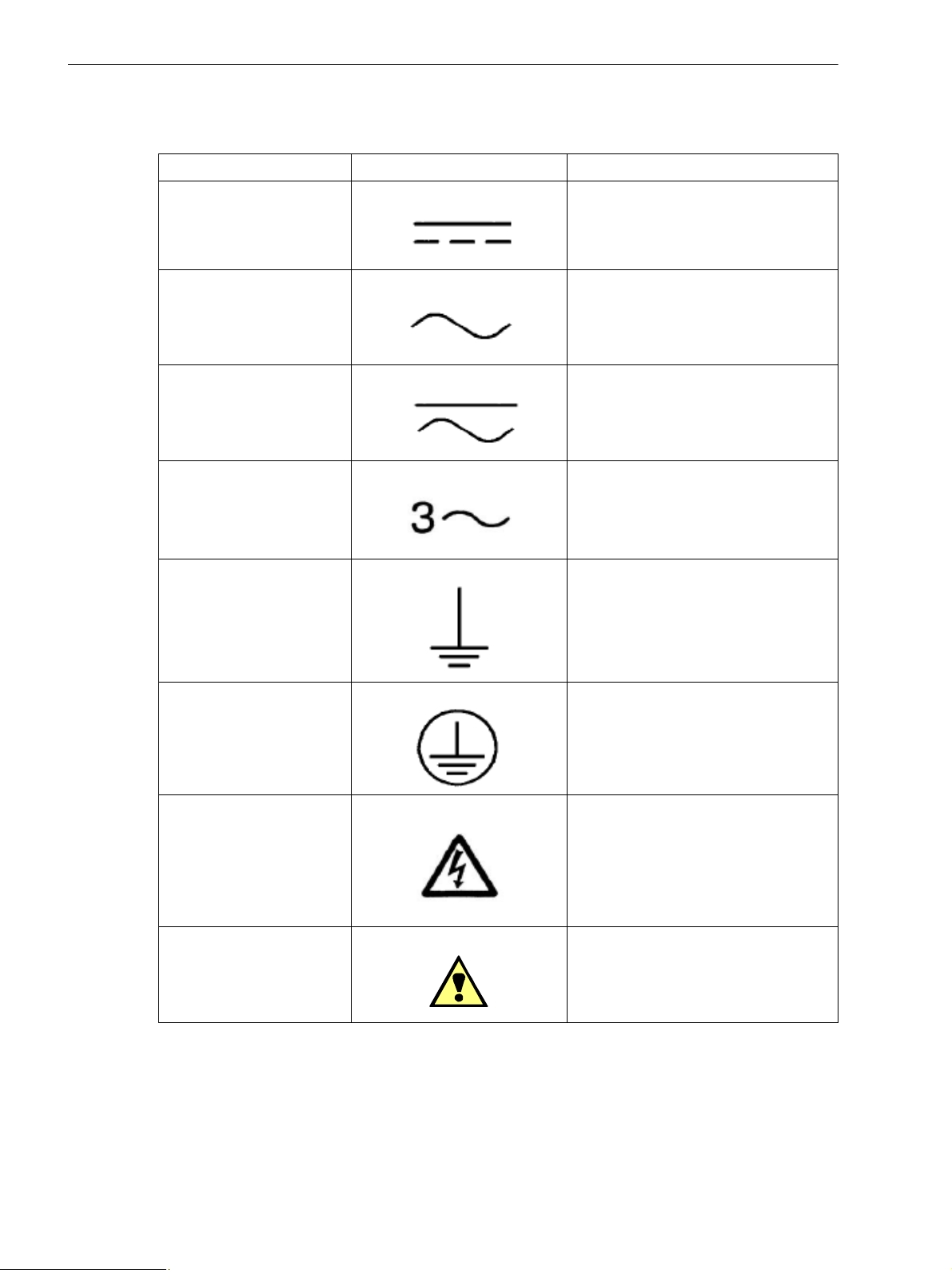

Used Symbols

No. Symbol Description

1 Direct current

IEC 60417-5031

2 Alternating current

IEC 60417-5032

3 Direct and alternating current

IEC 60417-5033

4 Three-phase alternating current

5 Earth (ground) terminal

IEC 60417-5017

6 Protective conductor terminal

IEC 60417-5019

7 Caution, risk of electric shock

8 Caution, risk of danger

ISO 7000-0434

6 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

Statement of Conformity

This product complies with the directive of the Council of the European Communities on the

approximation of the laws of the Member States relating to electromagnetic compatibility (EMC

Council Directive 2004/108/EC) and concerning electrical equipment for use within specified voltage

limits (Low-voltage Directive 2006/95/EC).

This conformity has been established by means of tests conducted by Siemens AG according to the

Council Directive in agreement with the generic standards EN 61000-6-2 and EN 61000-6-4 for the

EMC directives, and with the standard EN 61010-1 for the low-voltage directive.

The device has been designed and produced for industrial use.

The product conforms to the standard IEC 61557-12.

Further Standards

This product is UL-certified to Standard UL 61010-1, third edition, based on the specification stated in Chapter 12

(Technical Data).

UL File No.: E228586

Open-type Measuring Equipment

2UD1

For further information see UL database on the internet: http://ul.com.

Chose Online Certifications Directory and insert E228586 under UL File Number.

E50417-H1040-C568-A1, Edition 03.2015

7SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

8 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

Open Source Software

The product contains, among other things, Open Source Software developed by third parties. The Open

Source Software used in the product and the license agreements concerning this software can be found in the

Readme_OSS.

These Open Source Software files are protected by copyright. Your compliance with those license conditions

will entitle you to use the Open Source Software as foreseen in the relevant license. In the event of conflicts

between Siemens license conditions and the Open Source Software license conditions, the Open Source Software conditions shall prevail with respect to the Open Source Software portions of the software.

The Open Source Software is licensed royalty-free. Insofar as the applicable Open Source Software License

Conditions provide for it you can order the source code of the Open Source Software from your Siemens sales

contact - against payment of the shipping and handling charges - for a period of at least 3 years since purchase

of the Product. We are liable for the Product including the Open Source Software contained in it pursuant to

the license conditions applicable to the Product. Any liability for the Open Source Software beyond the program

flow intended for the Product is explicitly excluded. Furthermore any liability for defects resulting from modifications to the Open Source Software by you or third parties is excluded. We do not provide any technical support for the Product if it has been modified.

E50417-H1040-C568-A1, Edition 03.2015

9SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

10 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Open Source Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Device Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Ordering Information and Scope of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Device Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Mechanical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Display and Softkeys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Measurands and Recording . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Measuring and Recording System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1.1 Functioning of the Measuring System according to IEC 61000-4-30 . . . . . . . . . . . . . . . . . . . . . . . 26

4.1.2 Recording of Measurands and Events in SENTRON PAC5200 . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Measurands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.1 Measurands in 1-phase Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.2 Measurands in 3-wire and 4-wire Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.3 Measurands Depending on the Connection Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.2.4 Data Availability for SENTRON PAC5100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.2.5 Data Availability for SENTRON PAC5200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.3 Display of Measurands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4.3.1 Measurands and Operational Measurement Uncertainty acc. to IEC 62586-1 Product Standard,

Class S, and Standards IEC 61000-4-30, Ed. 2 and IEC 61000-4-7 and IEC 61000-4-15. . . . . . . 64

4.3.2 Measurands and Operational Measurement Accuracy acc. to IEC 61557-12 . . . . . . . . . . . . . . . . 65

4.3.3 Accuracy of the Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5 Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.1 Unpacking, Inspecting the Delivery, and Installing the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2.1 General Assembly Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.2.2 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.3 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.3.1 Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.3.2 Electrical Connection of SENTRON PAC5100/5200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.4 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.5 Access Rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

E50417-H1040-C568-A1, Edition 03.2015

11SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

5.6 Meaning of the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.7 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.7.1 Initial Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.7.2 Changes During Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.7.3 Starting the Device with the Default IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6 Connection Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.1 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.2 Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.3 Connection Types and Connection Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.3.1 Using SENTRON PAC5100/5200 in the Power Systems IT, TT, and TN . . . . . . . . . . . . . . . . . . . 87

6.3.2 Connection Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.3.3 Examples - Standard Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.3.4 Example - Special Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

7 Operation at Use of a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.1 General Usage Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.2 Start and Design of the User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7.2.1 Initial Start of the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7.2.2 Enabling JavaScript . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.2.3 Number of Connections via HTML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.2.4 Layout of the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

7.2.5 Starting the User Interface during Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.3 Configuration of the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.3.1 Device Configuration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.3.2 Access to the Passive Set of Parameters by Multiple Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

7.3.3 Setting the Operational Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.3.4 HMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

7.3.5 Recording and Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7.3.6 Setting Administrative Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7.4 Value View and Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

7.4.1 Process Connections and Automation Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

7.4.2 Evaluation and Data Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

7.5 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

7.5.1 Firmware Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

7.5.2 Formatting the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

7.5.3 Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

7.5.4 Message Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

7.5.5 Diagnosis Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

7.6 Example of a Parameterization and Measured Value Evaluation for SENTRON PAC5200 . . . . . . . 184

7.6.1 Task Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

7.6.2 Initial Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

7.6.3 Parameterization as Defined by the Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

7.6.4 Performing the Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

12 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

8 Operation at Use of the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

8.1 General Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

8.2 Starting Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

8.3 Display Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

8.4 Parameterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

8.4.1 Menu Tree of the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

8.4.2 Measurands Submenus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

8.4.3 Submenus for Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

8.4.4 Menu Tree of the Settings Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

8.4.5 User-defined Screens Submenus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

9 Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

9.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

9.2 Internal Time Keeping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

9.2.1 Time Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

9.2.2 Status Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

9.3 External Time Synchronization per NTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

9.4 External Time Synchronization via Fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

9.5 Internal Time Synchronization via RTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

10 Maintenance, Storage, Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

10.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

10.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

10.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

11 Failures and LED Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

11.1 General Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

11.2 Commissioning during Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.2.1 Automatic Start of the Boot Loader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.2.2 Manual Start of the Boot Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

11.3 Indications Signaled by LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

11.4 Troubleshooting and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

12 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

12.1 General Device Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

12.1.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

12.1.2 Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

12.1.3 Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

12.1.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

12.1.5 General Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

12.2 Test Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

12.2.1 Electrical Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

12.2.2 Mechanical Stress Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

12.2.3 Climatic Stress Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

12.2.4 Safety Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

12.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

E50417-H1040-C568-A1, Edition 03.2015

13SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

13 Operational Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

14 Operating Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

14.1 Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

14.1.1 AC Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

14.1.2 Binary Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

14.1.3 LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

14.2 Automation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

14.2.1 Limit Violation 1-8 and 9-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

14.2.2 Group Indications 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

14.3 HMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

14.3.1 Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

14.3.2 User Defined Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

14.4 Recording and Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

14.4.1 Event Recorders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

14.4.2 Trigger Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

14.4.3 Recorder Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

14.4.4 Memory Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

14.4.5 Report Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

14.4.6 Recording Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

14.5 Administrative. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

14.5.1 Time Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

14.5.2 Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

14 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

1 User Information

Application

The multifunctional SENTRON PAC5100/5200 devices record and process measurands and events according

to IEC 61000-4-30 Power Quality (PQ) standard. The devices are used on all voltage levels of power-supply

systems. SENTRON PAC5100/5200 devices are used in 1-phase systems, 3-phase systems, and 4-phase

systems (with neutral conductor).

In addition to the measuring function, SENTRON PAC5200 features various recorders (e.g. Measurement

recorder) to record the measurands in programmable time intervals. Long-term data and events are analyzed

and output as report according to power quality standards, for example, EN 50160. The device features a 2GB memory for data storage.

The input circuits for voltage measurement are galvanically isolated and can be used in IT, TT, and, TN

networks. To ensure galvanic separation for current measurements, the lines connected to the current

measuring inputs are galvanically separated from the current transformers.

The measurements are obtained from the alternating quantities of current and voltage supplied to the AC

inputs. When no external voltage and current transformers are used, the device can process rated input

alternating voltages of up to V

and rated input alternating currents up to 5 A.

The integrated web server can be used to set the parameters and display the measured values on HTML pages

from the connected PC or notebook. The softkeys located on the front of devices with an optional display

enable a limited parameterization and measured value output on the display.

= 400 V (347 V for UL condition) and V

P-N

= 690 V (600 V for UL condition)

P-P

Measurands

An Ethernet interface is available for communicating with the control center and other process automation systems.

The following measurands can be recorded or calculated from the measured quantities:

• Alternating voltage and alternating current

• Unbalanced of alternating voltage and alternating current

• Active, reactive, and apparent power

• Active, reactive, and apparent energy

• Power frequency

• Phase angle

• Power factor and active power factor

• THDS (Subgroup Total Harmonic Distortion) of alternating voltage and alternating current

• Harmonics of alternating voltage and alternating current

• Flicker acc. to IEC 61000-4-15 (only SENTRON PAC5200)

The uncertainty of operational measurements of the measurands is defined as per IEC 62586-1 product

standard, class S (leading standard), the IEC 61000-4-30 power quality standard, and the IEC 61557-12

standard.

For detailed information on measurands and measurements, see Chapter 4.2 and the technical data in

Chapter 13.

E50417-H1040-C568-A1, Edition 03.2015

15SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

1 User Information

Functionality of the Recorders in SENTRON PAC5200

The recorders are capable of recording both measurands and events in parameterizable time intervals. The

following recorder types are used in SENTRON PAC5200:

• Measurement recorder: recording of PQ measurands (acc. to IEC 61000-4-30) and non-PQ measurands

over parameterized periods, for example, 10-second frequency, aggregation of voltage, current, power

etc.

• Trend recorder: long-term recording and monitoring of the voltage change history over a parameterized

period of time in programmable tolerance ranges; 1/2 RMS values

• Fault recorder: Recording of sampled values of voltage and current using programmable triggers.

• Event recorder: recording of voltage events, frequency events, and voltage unbalance events

The device features a 2-GB memory for storing the recorder data.

Communication

To communicate with the systems control and other process automation equipment, the device features an

Ethernet interface.

Ethernet supports the device parameterization, the transmission of measured data, counter values and

indications/events, and the time synchronization via NTP. The communication protocols are HTTP and

Modbus TCP.

Time Synchronization

During operation SENTRON PAC5100/5200 needs the date and time for all time-relevant processes. This

ensures that a common time basis exists when communicating with peripheral devices and enables time

stamping of the process data. The following types of time synchronization can be executed:

• External time synchronization via Ethernet NTP (preferred)

• External time synchronization via fieldbus using the Modbus TCP communication protocol

• Internal time synchronization via RTC (if external time synchronization is not available)

Parameterization

Parameters are set using an internal Web browser with HTML pages from the connected PC or notebook.

Internet Explorer 6 (or higher) is required for this purpose. Devices featuring a display offer a limited

parameterization function using the front softkeys.

16 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

2 Overview

2.1 Device Versions 18

2.2 Ordering Information and Scope of Delivery 19

E50417-H1040-C568-A1, Edition 03.2015

17SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

2 Overview

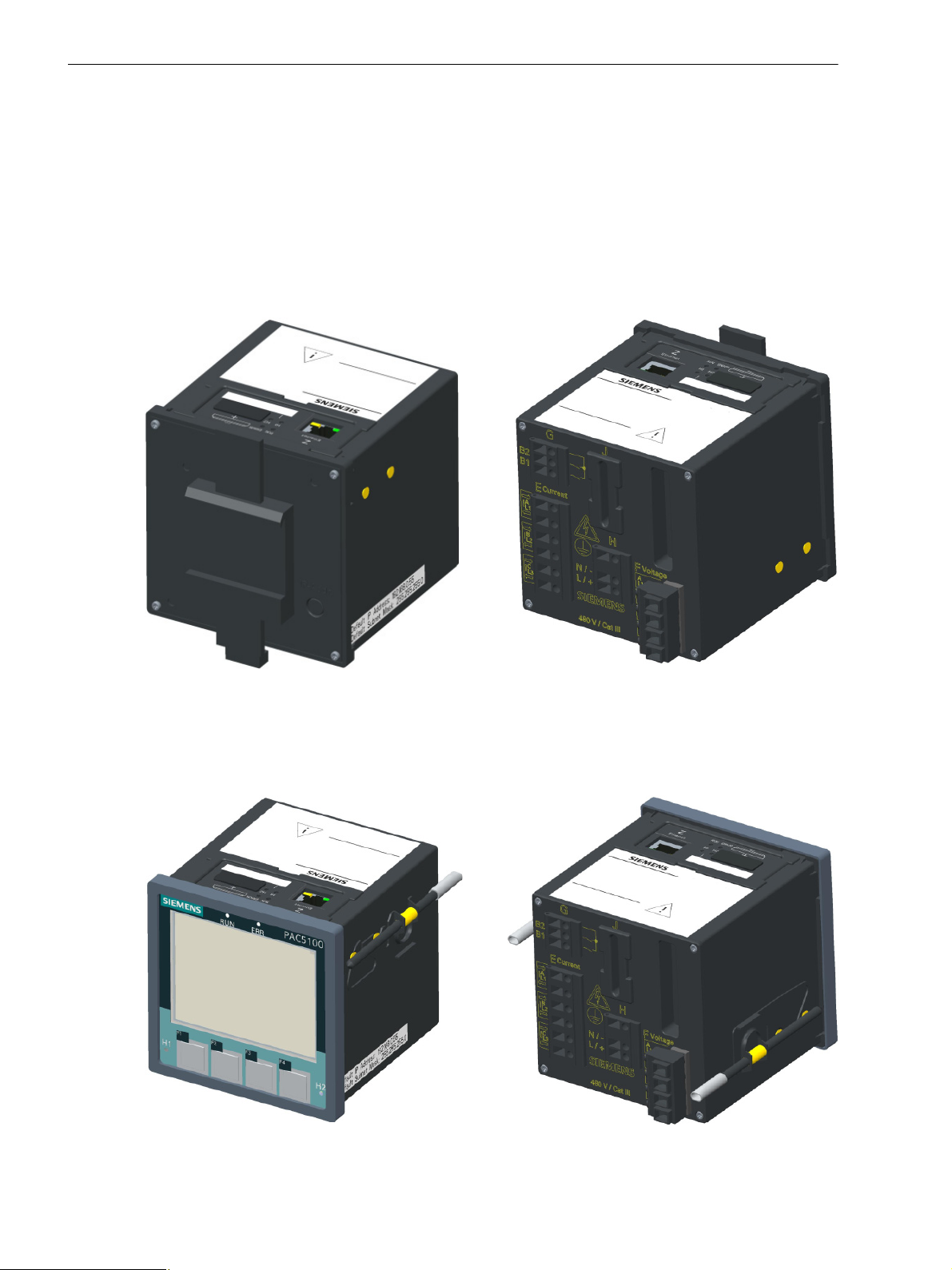

SENTRON PAC5x00 as DIN Rail Device,

SENTRON PAC5x00 as DIN Rail Device,

DIN Rail Side

Terminal Side

SENTRON PAC5x00 for Panel Flush Mounting,

SENTRON PAC5x00 for Panel Flush Mounting,

Display Side

Terminal Side

2.1 Device Versions

2.1 Device Versions

The multifunctional SENTRON PAC5100/5200 devices are used to detect, calculate, evaluate, display, and

transmit measured electrical quantities such as alternating current, alternating voltage, power values etc.

SENTRON PAC5200 devices additionally feature memory options for recorder functions such as mean values,

minimum and maximum values, and fault records.

The properties of the device versions can see you from the ordering information (see Table 2-1) .

SENTRON PAC5x00 Variant, DIN Rail Device

Figure 2-1 SENTRON PAC5x00 Variant, DIN Rail Device

SENTRON PAC5x00 Variant with Graphic Display, Panel Flush Mounting

Figure 2-2 SENTRON PAC5x00 Variant with Graphic Display

18 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

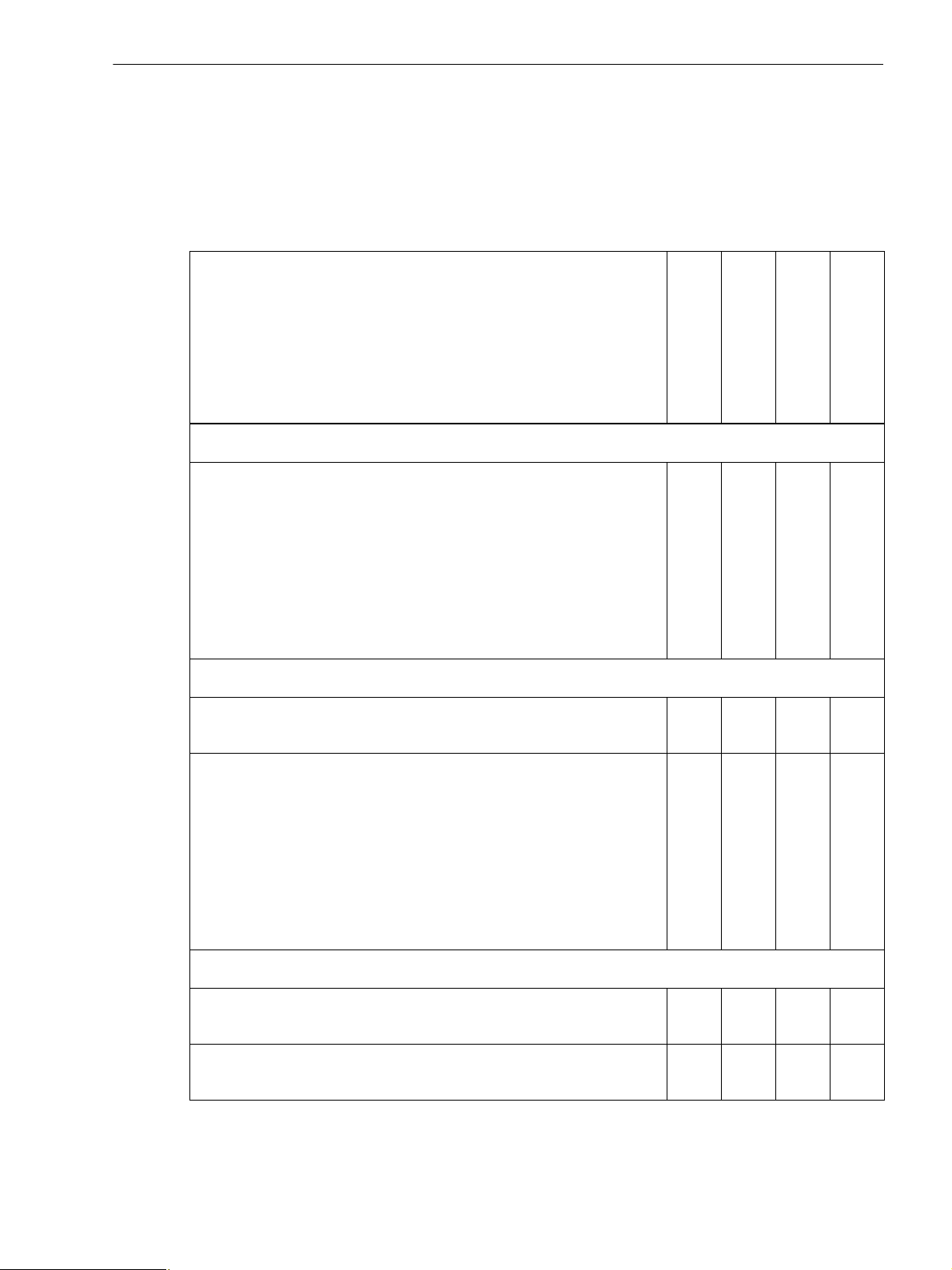

2.2 Ordering Information and Scope of Delivery

2.2 Ordering Information and Scope of Delivery

Ordering Information

Use the following ordering code to order SENTRON PAC5100/5200 devices:

Table 2-1 Ordering Information SENTRON PAC5100/5200

Properties

2 Overview

Device type

Dimensions 96 mm x 96 mm x 100 mm

4 Inputs for AC voltage measurements

3 Inputs for AC current measurements

2 Binary outputs

Galvanic isolated voltage measurement inputs

Web server for parameterization, visualization and data management

Online value visualization

Measurement acc. to standard IEC 61000-4-30, class S

Communication via Ethernet (RJ45) with Modbus TCP protocol

UL Certification

Monitoring, Recording and Power Quality (PQ) Functions

Basic measurements: V, I, f, P, Q, S, cos phi, limit violations, energy

measurements, measurements till 40th harmonics

Basic measurements and advanced measurements:

Power Quality instrument

Measurement min/max/mean values

Recorder for Power Quality measurements

Various recorders for other measurements

Event detection (e.g. Vdip), visualisation

Flicker acc. to IEC 61000-4-15

Online PQ reporting e.g. acc. to EN 50160

Data export acc. to IEEE Std. 1159-3 (PQDIF and COMTRADE data)

Internal memory 2 GB

(SENTRON PAC5100)

7KM5212-6CA00-1EA8

xxxx

xx

(SENTRON PAC5200)

7KM5412-6CA00-1EA8

xx

(SENTRON PAC5100)

7KM5212-6BA00-1EA2

(SENTRON PAC5200)

7KM5412-6BA00-1EA2

Housing and front degree of protection

Snap on mounting unit without graphical display

IP20

Panel mounted instrument with graphical display

IP40

E50417-H1040-C568-A1, Edition 03.2015

xx

xx

19SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

2 Overview

2.2 Ordering Information and Scope of Delivery

Scope of Delivery

The delivery comprises the following components depending on the ordering code:

• SENTRON PAC5100/5200 according to ordering code (see Table 2-1)

• Battery (insulated in the battery compartment of the device)

• Operating instruction

20 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

3 Device Design

3.1 Mechanical Design 22

3.2 Display and Softkeys 23

3.3 Electrical Design 24

E50417-H1040-C568-A1, Edition 03.2015

21SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

3 Device Design

RJ45 with

4LEDs

2LEDs

Cover of battery

compartment

Terminal block for

Default IP address

Default subnet mask

LED RUN

LED ERROR

LED H1

LED H2

Softkeys

F1 to F4

Terminal blocks for

measurements (voltage, current)

power supply

Terminal block for

binary outputs

Display

Terminal side

Display side

3.1 Mechanical Design

3.1 Mechanical Design

The electrical modules are installed in a plastic case with the dimensions 96 mm x 96 mm x 100 mm

(W x H x D).

In panel flush mounting devices, the display side accommodates the display, 4 softkeys located below and 4

LEDs of which the H1, H2, and ERROR LEDs can be parameterized. The ERROR LED can only be

parameterized for error messages.

The device top side holds the RJ45 Ethernet plug connector with 2 LEDs. 4 additional LEDs are identical to the

LEDs on the display side. At the cover of the battery compartment there is a labeling strip for the configurable

LEDs H1/H2 and a battery symbol that indicates the polarity. The label is also located on the top side and

provides among other information the most important rated data of the device. A lithium battery is located under

the removable cover of the battery compartment.

On the terminal side are available: terminals for all inputs and outputs, terminals for power supply and

protective grounding.

22 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

Figure 3-1 Layout of the Panel Flush Mounting Version of SENTRON PAC5x00 with Display

NOTE

DIN rail devices have a DIN rail support instead of the display. Therefore, this device side is referred to as the

DIN rail side.

E50417-H1040-C568-A1, Edition 03.2015

3.2 Display and Softkeys

MAX MENU

Voltage ph -n MAX 1.1

n 2.00 V Date/Time

c 229.00 V Date/Time

b 231.00 V Date/Time

a 230.00 V Date/Time

Title

Display area

Softkey functions

Softkeys F1 to F4

Display

The layout of the display is shown in the following figure.

3 Device Design

3.2 Display and Softkeys

Figure 3-2 Display and Softkeys

The top line (title) shows the name of the current display in the display area.

The display area below shows parameter settings, measured values, and graphic pictures.

The bottom line shows the 4 current functions of the softkeys below the display used to set the parameters.

Softkeys

The 4 softkeys on the display side are used to make the desired entries at the device.

To call and activate the IP address, press softkey F4 (for > 3 s, see Figure 3-2) on the right during system

startup if necessary. The IP address and the standard subnet mask are imprinted on the side panel of the device

(see Figure 3-1).

Chapter 8 gives a detailed description of the softkey functions.

E50417-H1040-C568-A1, Edition 03.2015

23SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

3 Device Design

4 x AC

voltage

measuring

inputs

Terminal

Power

supply

Terminal

3 x AC

current

measuring

inputs

Terminal

2 x Binary

outputs

Terminal

ADC

LED Ethernet

DSP

DisplaySoftkeys

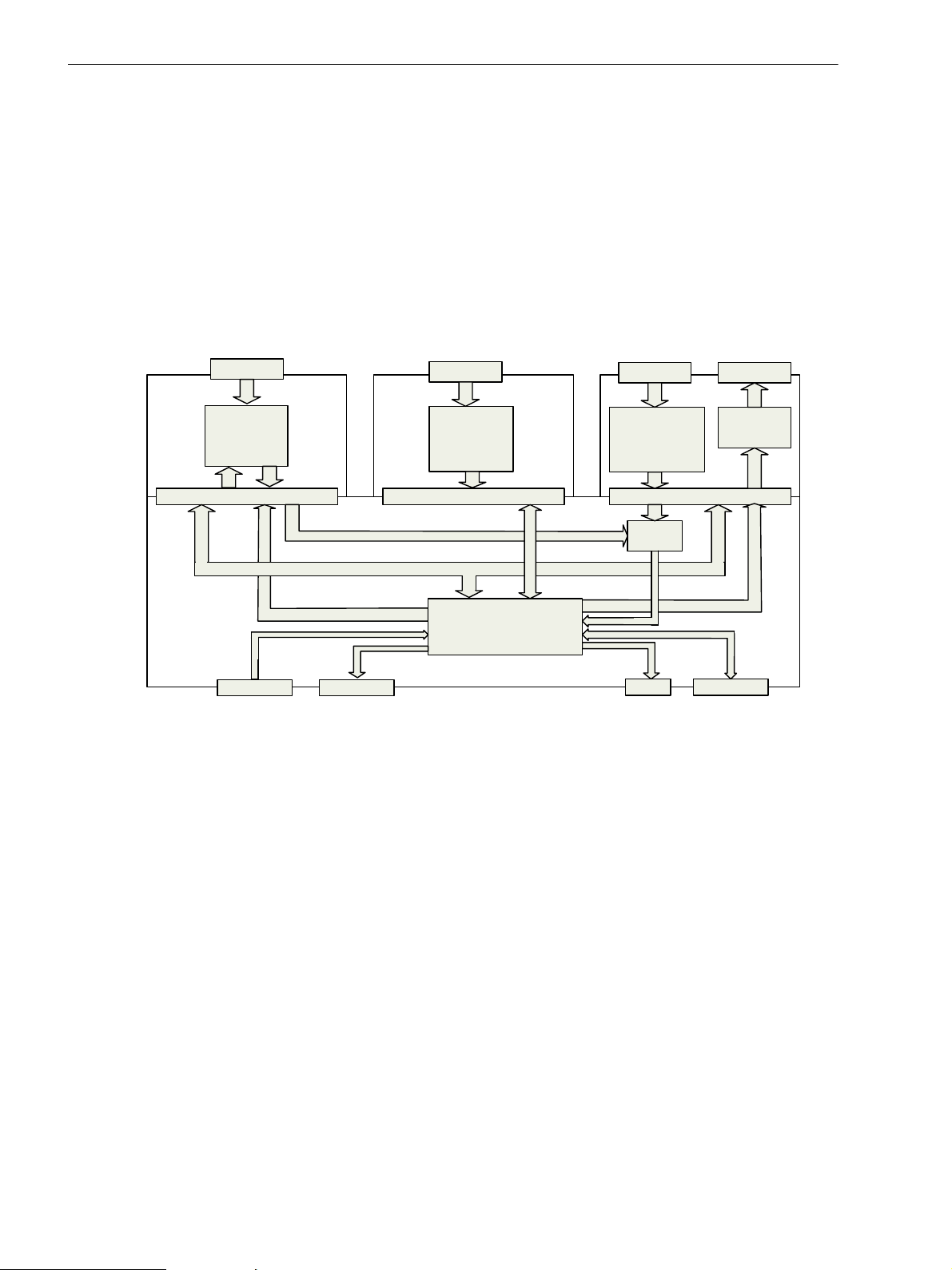

3.3 Electrical Design

3.3 Electrical Design

SENTRON PAC5100/5200 contains the following electrical modules:

• Digital signal processor (DSP)

• Display and Softkeys (optional)

• 4 inputs for alternating voltage measurements

• 3 inputs for alternating current measurements

• 2 binary outputs

• Supply voltage

• Ethernet interface

Figure 3-3 Block Diagram SENTRON PAC5x00 with Display (Optional)

24 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

4 Measurands and Recording

4.1 Measuring and Recording System 26

4.2 Measurands 39

4.3 Display of Measurands 64

E50417-H1040-C568-A1, Edition 03.2015

25SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

4 Measurands and Recording

RTC

10-minute

limit

k

10-minute interval (x+1)

j

10/12 periods

i

1

2 3

Overlapping area

10-minute interval (x)

10/12 periods

10/12 periods 10/12 periods

10/12 periods

10/12 periods

4.1 Measuring and Recording System

4.1 Measuring and Recording System

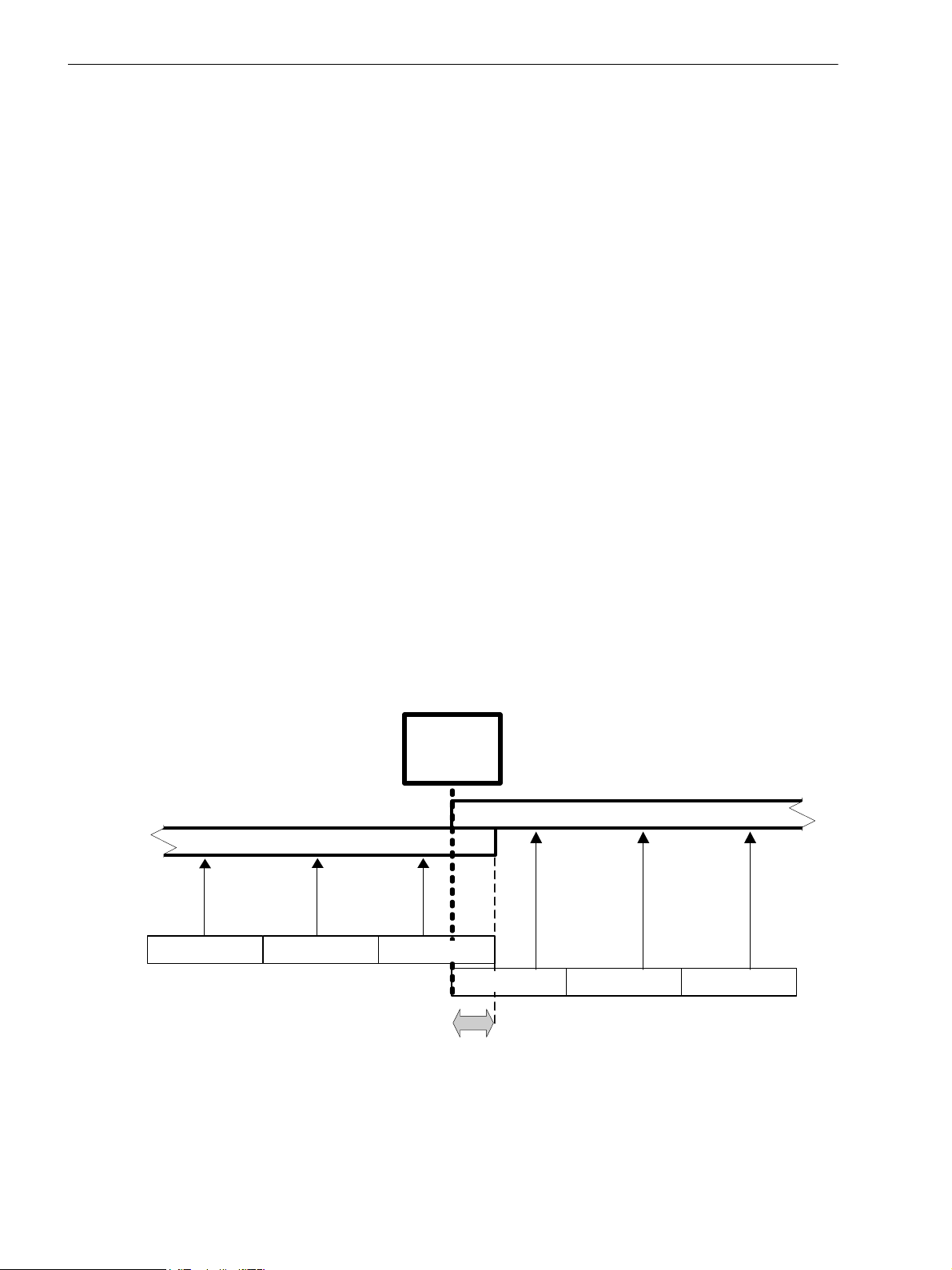

4.1.1 Functioning of the Measuring System according to IEC 61000-4-30

SENTRON PAC5100/5200 devices measure the power quality according to IEC 61000-4-30 in 1-phase or

multi-phase distribution systems. The measuring system is implemented according to class A. In terms of

functional scope, measuring ranges, and accuracy, the SENTRON PAC5100/5200 devices are class S.

The basic measuring interval for determining the values for mains voltage, harmonics of mains voltage, and

mains voltage unbalance is a 10-period time interval for 50-Hz distribution systems or a 12-period time interval

for 60-Hz distribution systems. The measurement of the 10-/12-period time intervals is resynchronized at each

RTC 10-minute limit.

Subsequently, the values for the 10-/12-period time intervals are aggregated over additional time intervals (for

example, 10-minute interval at SENTRON PAC5200).

10-Minute Interval (SENTRON PAC5200)

The value aggregated in a 10-minute interval is tagged with the absolute time (for example 01:10:00). The time

at the end of the aggregation interval is indicated as the time qualifier. The values for the 10-minute time interval

are calculated without interruption from the 10-/12-period time intervals.

• Each 10-minute interval begins at an RTC 10-minute limit. At this 10-minute limit, the 10-/12-period time

intervals are aggregated over a 10-minute interval. The last 10-/12-period time interval in a 10-minute

aggregation interval overlaps in time at an RTC 10-minute limit. Each overlapping 10-/12-period time

interval (for the overlapping area, see Figure 4-1) is included in the aggregation interval of the preceding

10-minute interval.

• The aggregation interval enables the power system quality to be evaluated according to EN 50160. The

aggregation interval can be adjusted to other applications using a parameter. A shorter aggregation

interval increases the storage capacity required for measured values and reduces the maximum possible

recording time in the memory.

26 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

Figure 4-1 Synchronization of the Aggregation Intervals for Class A

E50417-H1040-C568-A1, Edition 03.2015

Flagging Concept

During conditions of undervoltage, overvoltage, or voltage interruption, the measurement method can return

implausible values for other measurands (for example, frequency measurement, voltage harmonics). The

flagging concept therefore prevents an individual event from being accounted for multiple times in different

measurands (for example, a single undervoltage event both as undervoltage and simultaneously as a

frequency change).

Flaggings are only triggered by undervoltage, overvoltage, and voltage interruptions. Undervoltage and

overvoltage detection is based on a threshold value selected by the user. This value determines whether data

are flagged.

The flagging concept is used when measuring the power frequency, mains voltage, mains voltage unbalance,

and harmonics of the mains voltage.

If a value was flagged within a given time interval, the aggregated value containing that value will be flagged,

too. Flagged values are stored and optionally integrated in the calculation or hidden.

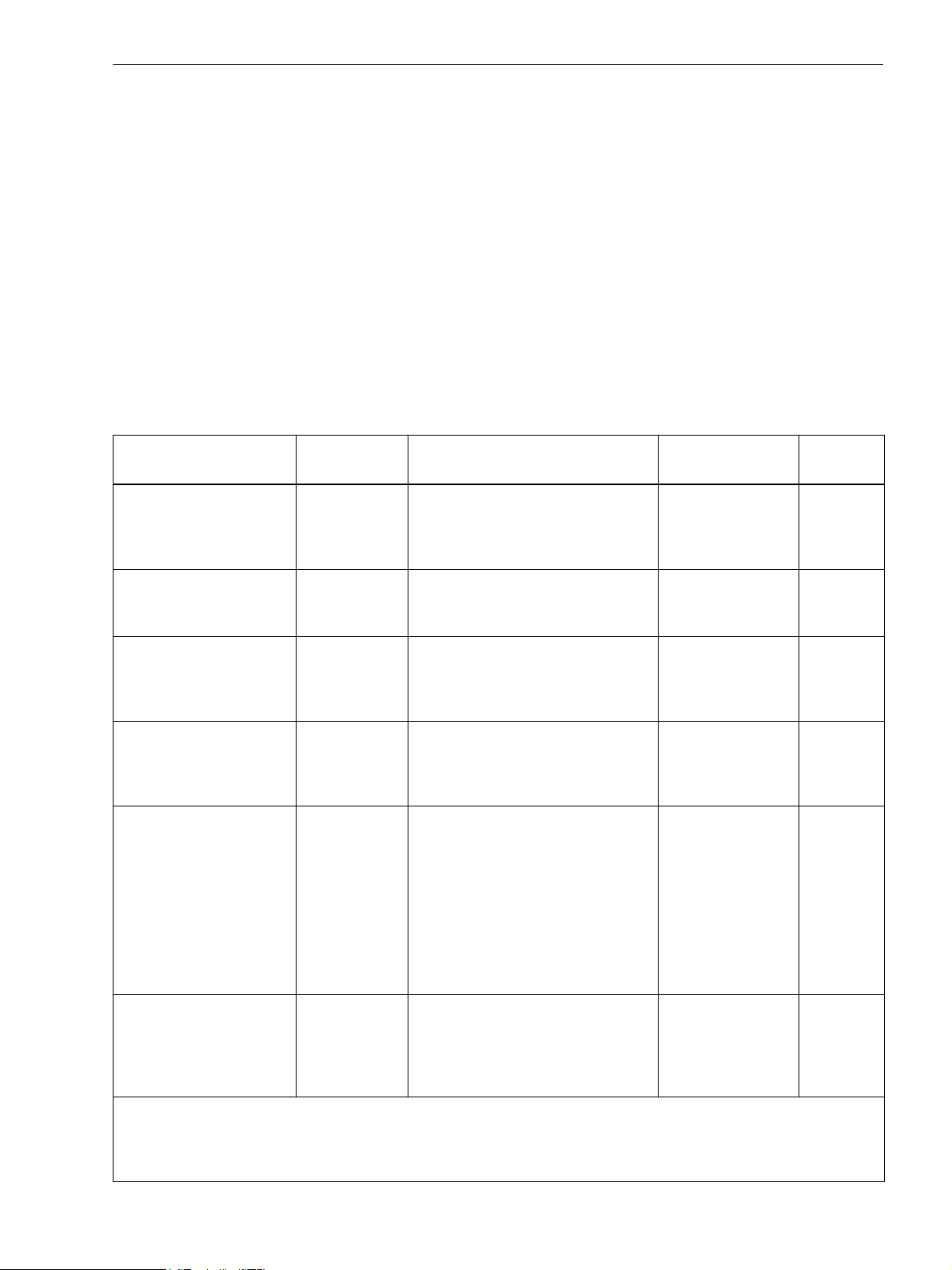

Table 4-1 Overview of the Measurands to Determine the Power Quality

4 Measurands and Recording

4.1 Measuring and Recording System

Measurand Method of

Measurement Uncertainty and

Measurement

Power frequency Class A Class S

±50 mHz in the measuring ranges:

50 Hz: 42.5 Hz to 57.5 Hz

60 Hz: 51.0 Hz to 69.0 Hz

Mains voltage level Class A Class S

smaller than ±0.5 % Udin in the

range from 20 % Udin to 120 % Udin

Undervoltages and

overvoltages of the mains

Class A Class S

±1.0 % of Udin, 1 period

voltage,

Voltage interruptions

Unbalance of the mains

voltage

Class A Class S

U

and U0 smaller than ±0.3 % in the

2

range

1 % to 5 % U

Harmonics of the mains

voltage

Class A Class S

Vm > 3 % Udin: ±5% V

Vm < 3 % Udin: ±0.15 % Udin

10 % to 100 % of the compatibility

levels of class 3 or IEC 61000-2-4

Measurement uncertainty:

Measuring range 200 %,

IEC 61000-4-7, Class 2

Measuring Range

, U

2

1

m

SENTRON

Flagging

PAC5100/5200

50 mHz

(see Table 4-17)

0.2 % x

0.2 % -

0.2 % x

Condition:

10 % V

V

m

rated

Maximum error:

±5 % V

m

----------------------Condition:

Vm < 10 % V

rated

Maximum error:

±0.5 % V

rated

x

x

Flicker Class A Class S

IEC 61000-4-30:

Pst: ±10 %

Pst: ±10 %

Plt: ±10 %

Pinst: ±16 %

-

Plt: ±10 %

Pinst: ±16 %

Udin: Declared input voltage (The primary nominal voltage is used for it in the SENTRON PAC5100/5200. At use of a

voltage converter the primary nominal voltage and the secondary nominal voltage of the transducer are used.)

: Measured value

V

m

V

: Rated voltage

rated

E50417-H1040-C568-A1, Edition 03.2015

27SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

4 Measurands and Recording

-70

-60

-50

-40

-30

-20

-10

0

10

20

30

40

50

60

70

V [V]

44,85 44,90 44,95

t [s]

V

rms

(1/2) :

RMS value over one period synchronized to the zero point of the fundamental

component, updated after each half period .

This value is only used to detect undervoltages , overvoltages and voltage

interruptions .

V

rms

n

n+1

n+2

n+3

n+4

n+5

n+6

n+7

n+8

n+ 9

n+10

V

rms

V

rms

V

rms

V

rms

V

rms

V

rms

V

rms

V

rms

V

rms

V

rms

4.1 Measuring and Recording System

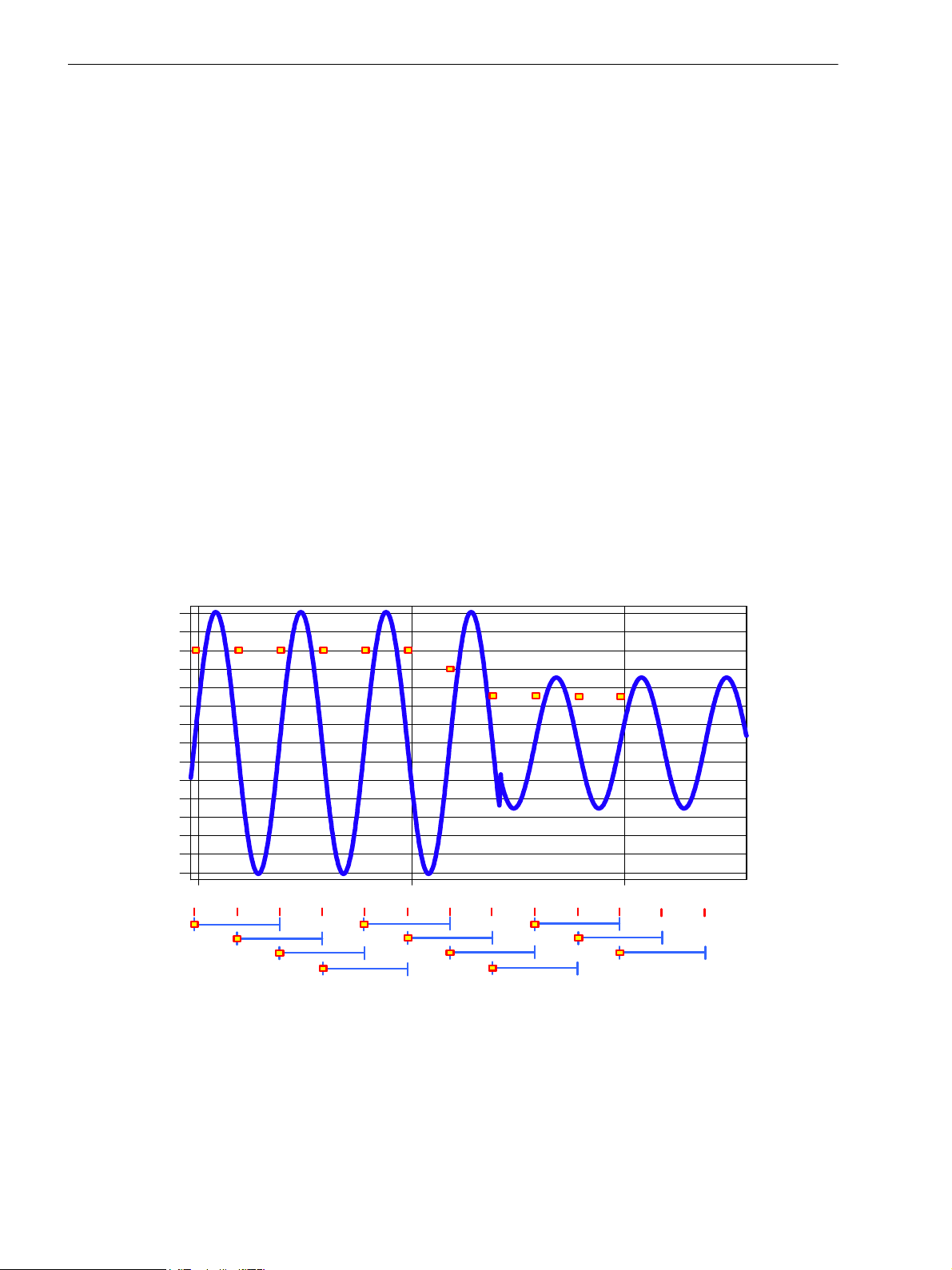

Definition of the Measurands

Mains Voltage Level

• The measurement determines the RMS value of the mains voltage over a 10-period time interval for 50Hz distribution systems and over a 12-period time interval for 60-Hz distribution systems. All 10-/12-period

time intervals are measured without interruption and overlapping (the overlapping area excluded, see

Figure 4-1).

Undervoltage of the Mains Voltage

• The basic measurement of the RMS value V

V

(1/2) for each single measuring channel (see Figure 4-2). The limiting value for undervoltages is a

rms

percentage value of Udin.

• The factory setting of the hysteresis is 2 % of Udin. It can be set from 1 % to 6 %.

• In multi-phase systems, all channels are independently synchronized in the zero point of the voltage.

• In 1-phase systems, undervoltage begins when the voltage V

undervoltage. Undervoltage ends when the voltage V

undervoltage plus the hysteresis.

• In multi-phase systems, undervoltage begins when the voltage V

undervoltage in one or more channels. Undervoltage ends when the voltage V

threshold value of the undervoltage plus the hysteresis in all measured channels.

• The undervoltage threshold value and the hysteresis are parameterized according to the measuring task.

• Undervoltage is characterized by the data pair residual voltage (V

The residual voltage is the smallest voltage value of V

undervoltage.

of an undervoltage is the determination of the RMS value

rms

falls below the threshold of the

rms

rises above the threshold value of the

rms

falls below the threshold of the

rms

) and duration (t):

res

which is measured in a channel during

rms

rises above the

rms

28 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

Figure 4-2 Undervoltage Representation

E50417-H1040-C568-A1, Edition 03.2015

4 Measurands and Recording

4.1 Measuring and Recording System

Overvoltage of the Mains Voltage

• The basic measurement of the RMS value V

V

(1/2) for each single measuring channel. The limiting value for overvoltages is a percentage value of

rms

of overvoltage is the determination of the RMS value

rms

Udin.

• The factory setting of the hysteresis is 2 % of Udin. It can be set from 1 % to 6 %.

• In multi-phase systems, all channels are independently synchronized in the zero point of the voltage.

• In 1-phase systems, overvoltage begins when the voltage V

overvoltage. Overvoltage ends when the voltage V

falls below the threshold value of the overvoltage

rms

rises above the threshold of the

rms

minus the hysteresis.

• In multi-phase systems, overvoltage begins when the voltage V

overvoltage in one or more channels. Overvoltage ends when the voltage V

rises above the threshold of the

rms

falls below the threshold

rms

value of the overvoltage minus the hysteresis in all measured channels.

• The overvoltage threshold value and the hysteresis were parameterized according to the measuring task.

• Overvoltage is characterized by the data pair Maximum value of overvoltage and duration (t):

The maximum value of an overvoltage is the highest voltage value of V

which is measured in a channel

rms

during overvoltage.

Voltage Interruption

• In 1-phase systems, a voltage interruption begins when the voltage V

voltage interruption. The voltage interruption ends when the voltage V

falls below the threshold of the

rms

rises above the threshold value

rms

of the voltage interruption plus the hysteresis.

• In multi-phase systems, the voltage interruption begins when the voltages V

the voltage interruption in all channels. The voltage interruption ends when the voltage V

fall below the threshold of

rms

rises above

rms

the threshold value of the voltage interruption plus the hysteresis in any of the measured channels.

• The voltage interruption threshold value and the hysteresis are parameterized according to the measuring

task.

• The factory setting of the hysteresis is 2 % of Udin. It can be set from 1 % to 6 %.

Unbalance of the Mains Voltage

• The mains voltage unbalance is determined using the method of the symmetrical components. In case of

unbalance, the negative-sequence component U2 is determined in addition to the positive-sequence

component U

. The fundamental component of the voltage is measured over a 10-period time interval for

1

50-Hz distribution systems and over a 12-period time interval for 60-Hz distribution systems.

Harmonics of the Mains Voltage

• interruption-free 10-/12-period measurement of a harmonics subgroup U

according to

sg,n

IEC 61000-4-7.

• The total distortion is calculated as the subgroup total harmonic distortion (THDS) according to IEC 610004-7.

• Measurements are performed up to the 40th harmonics order.

E50417-H1040-C568-A1, Edition 03.2015

29SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

4 Measurands and Recording

4.1 Measuring and Recording System

Flicker

• The short-term flicker value Pst and long-term flicker value Plt are determined for phase-to-ground voltages and delta voltages. The flicker measurement is performed according to EN 61000-4-15.

• The flicker measurement is performed on all 3 voltage channels.

• Flickers appear with a frequency from 0.005 to 35 Hz. The instantaneous flicker value is displayed in perceptibility units P.

• Short-term flicker value Pst

determined over 10 min (short-term flicker), fixed

• Long-term flicker value Plt

over 2 h (12 Pst values), fixed

• Perceptibility Pinst

30 SENTRON PAC5100/5200, 7KM5212/5412, Device Manual

E50417-H1040-C568-A1, Edition 03.2015

Loading...

Loading...