Siemens SENTRON PAC2200 Product Manual

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SENTRON

7KM measuring device

PAC2200

Manual

05/2018

L1V30415167B

Introduction

1

Description

2

Mounting

3

Connection

4

Operation

5

Commissioning

6

Service and maintenance

7

Technical data

8

Dimension drawings

9

Appendix

A

-02

Siemens AG

Division Energy Management

Postfach 32 20

91050 ERLANGEN

GERMANY

Document order number: 3ZW1012-7KM22-0AC1

Ⓟ

Copyright © Siemens AG 2017.

All rights reserved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

for the specific

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

05/2018 Subject to change

Table of contents

1 Introduction ................................................................................................................................................ 7

2 Description ............................................................................................................................................... 11

3 Mounting .................................................................................................................................................. 37

4 Connection .............................................................................................................................................. 39

1.1 Components of the product ...................................................................................................... 7

1.2 Latest information ..................................................................................................................... 7

2.1 Features .................................................................................................................................. 11

2.2 Measuring inputs ..................................................................................................................... 15

2.3 Averaging measured values ................................................................................................... 19

2.3.1 Acquisition of power demand .................................................................................................. 20

2.3.2 Energy counters ...................................................................................................................... 21

2.4 Digital inputs and outputs ....................................................................................................... 22

2.4.1 Digital input ............................................................................................................................. 22

2.4.2 Digital output ........................................................................................................................... 23

2.5 Communication ....................................................................................................................... 24

2.5.1 Ethernet .................................................................................................................................. 25

2.5.2 RS 485 .................................................................................................................................... 26

2.5.3 M-BUS .................................................................................................................................... 26

2.5.3.1 Three-phase connection (3P4W) ............................................................................................ 28

2.5.3.2 Single-phase connection (1P2W) ........................................................................................... 34

3.1 Introduction ............................................................................................................................. 37

3.2 Installation steps ..................................................................................................................... 38

3.3 Deinstallation .......................................................................................................................... 38

4.1 Safety notes ............................................................................................................................ 39

4.2 Connections ............................................................................................................................ 41

4.3 Connection examples ............................................................................................................. 43

4.4 Connecting the communication cable ..................................................................................... 45

4.4.1 Ethernet communication cable ............................................................................................... 45

4.4.2 RS 485 communication cable ................................................................................................. 46

4.4.3 M-Bus communication cable ................................................................................................... 46

4.4.4 Grounding of the Ethernet / RS 485 cable .............................................................................. 46

4.5 Gateway (slave) ...................................................................................................................... 48

PAC2200

Manual, 05/2018, L1V30415167B-02

3

Table of contents

5 Operation ................................................................................................................................................. 49

6 Commissioning ........................................................................................................................................ 57

7 Service and maintenance ........................................................................................................................ 71

8 Technical data ......................................................................................................................................... 75

9 Dimension drawings ................................................................................................................................ 85

A Appendix .................................................................................................................................................. 87

5.1 Device interface ..................................................................................................................... 49

5.1.1 Displays and operator controls .............................................................................................. 49

5.1.2 Control keys ........................................................................................................................... 50

5.2 Menu navigation ..................................................................................................................... 51

5.2.1 Measured value level ............................................................................................................. 51

5.2.2 Main menu level ..................................................................................................................... 52

5.2.3 Setting level ............................................................................................................................ 52

5.2.4 Editing level ............................................................................................................................ 52

5.3 Supporting software ............................................................................................................... 53

6.1 Overview ................................................................................................................................ 57

6.2 Applying the measuring voltage ............................................................................................. 58

6.3 Parameterizing the device ..................................................................................................... 58

6.3.1 Parameterizing with SENTRON powerconfig ........................................................................ 58

6.3.2 Setting parameters via the device menu ............................................................................... 62

7.1 Calibration .............................................................................................................................. 71

7.2 Firmware updates .................................................................................................................. 71

7.3 Troubleshooting guide ........................................................................................................... 72

7.4 Warranty ................................................................................................................................. 73

7.5 Disposal ................................................................................................................................. 73

8.1 Technical data ........................................................................................................................ 75

8.2 Labeling .................................................................................................................................. 83

9.1 Dimensional drawings ............................................................................................................ 85

A.1 Modbus TCP .......................................................................................................................... 87

A.1.1 Function codes ....................................................................................................................... 87

A.1.2 Modbus exception codes ....................................................................................................... 88

A.1.3 Modbus measured variables with the function codes 0x03 and 0x04 ................................... 89

A.1.4 Modbus-measured variables with function code "0x14" ........................................................ 92

A.1.5 Structure - Digital input status and digital output status with the function codes 0x03

and 0x04 ................................................................................................................................ 95

A.1.6 Structure - Device diagnostics and device status with the function codes 0x03 and

0x04 ....................................................................................................................................... 96

A.1.7 Modbus status parameters with the function code 0x02 ....................................................... 97

A.1.8 Modbus settings with the function codes 0x03, 0x04 and 0x10 ............................................ 98

A.1.9 Modbus communication parameters with the function codes 0x03, 0x04 and 0x10 ........... 101

A.1.10 Modbus device information with the function codes 0x03, 0x04 and 0x10.......................... 102

A.1.11 Modbus command parameters ............................................................................................ 104

PAC2200

4 Manual, 05/2018, L1V30415167B-02

Table of contents

Index ...................................................................................................................................................... 107

A.1.12 Modbus standard device identification with the function code 0x2B .................................... 105

PAC2200

Manual, 05/2018, L1V30415167B-02

5

Table of contents

PAC2200

6 Manual, 05/2018, L1V30415167B-02

1

1.1

Components of the product

Available accessories

1.2

Latest information

Up-to-the-minute information

on the Internet:

The package includes:

● 1 x PAC2200 measuring device

● PAC2200 operating instructions:

● SENTRON powerconfig software

(

powerconfig-v3-7?dti=0&lc=en-WW)

● SENTRON powermanager software

(

hf1?dti=0&lc=en-WW)

https://support.industry.siemens.com/cs/document/63452759/update-version-

https://support.industry.siemens.com/cs/document/64850998/powermanager-v3-3-incl-

You can find further assistance:

Website (https://support.industry.siemens.com/my/ww/en/requests)

PAC2200

Manual, 05/2018, L1V30415167B-02

7

Introduction

Third-party software information

1.2 Latest information

This product, solution or service ("Product") contains third-party software components listed

in this document. These components are Open Source Software licensed under a license

approved by the Open Source Initiative www.opensource.org (www.opensource.org

similar licenses as determined by SIEMENS ("OSS") and/or commercial or freeware

software components. With respect to the OSS components, the applicable OSS license

conditions prevail over any other terms and conditions covering the Product. The OSS

portions of this Product are provided royalty-free and can be used at no charge.

If SIEMENS has combined or linked certain components of the Product with/to OSS

components licensed under the GNU LGPL version 2 or later as per the definition of the

applicable license, and if use of the corresponding object file is not unrestricted ("LGPL

Licensed Module", whereas the LGPL Licensed Module and the components that the LGPL

Licensed Module is combined with or linked to is the "Combined Product"), the following

additional rights apply, if the relevant LGPL license criteria are met: (i) you are entitled to

modify the Combined Product for your own use, including but not limited to the right to

modify the Combined Product to relink modified versions of the LGPL Licensed Module, and

(ii) you may reverse-engineer the Combined Product, but only to debug your modifications.

The modification right does not include the right to distribute such modifications and you

shall maintain in confidence any information resulting from such reverse-engineering of a

Combined Product.

), or

Certain OSS licenses require SIEMENS to make source code available, for example, the

GNU General Public License, the GNU Lesser General Public License and the Mozilla Public

License. If such licenses are applicable and this Product is not shipped with the required

source code, a copy of this source code can be obtained by anyone in receipt of this

information during the period required by the applicable OSS licenses by contacting the

following address:

Siemens AG Energy Management, Low Voltage & Products

Siemensstrasse 10

93055 Regensburg

Germany

Internet: Technical Assistance (https://support.industry.siemens.com/My/ww/en/requests

Subject: Open Source Request (please specify Product name and version, if applicable)

SIEMENS may charge a handling fee of up to 5 EUR to fulfil the request.

)

PAC2200

8 Manual, 05/2018, L1V30415167B-02

Introduction

Warranty regarding further use of the Open Source Software

Security information

1.2 Latest information

SIEMENS' warranty obligations are set forth in your agreement with SIEMENS. SIEMENS

does not provide any warranty or technical support for this Product or any OSS components

contained in it if they are modified or used in any manner not specified by SIEMENS. The

license conditions listed below may contain disclaimers that apply between you and the

respective licensor. For the avoidance of doubt, SIEMENS does not make any warranty

commitment on behalf of or binding upon any third-party licensor.

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the Internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit

Industrial security (http://www.siemens.com/industrialsecurity

)

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer's exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Technical Support (https://support.industry.siemens.com/cs/start?lc=en-WW

)

PAC2200

Manual, 05/2018, L1V30415167B-02

9

Introduction

Note

Risk of manipulation

Several protective mechanisms can be activated in the device.

In order to reduce the

the protective mechanisms available in the device are activated.

•

•

See chapter

General safety instructions

DANGER

Hazardous Voltage

Will cause death or serious injury.

Safety-related symbols on the device

Symbol

Meaning

1.2 Latest information

risk of manipulation occurring on the device, it is recommended that

Password protection, to protect the device against unintentional adjustment of

parameters.

Hardware write protection, to effectively prevent changes to the device parameters

without physical access to the device.

Setting parameters via the device menu (Page 62)

Turn off and lock out all power supplying this device before working on it.

(1)

(2)

(3)

Risk of electric shock

General Warning Symbol

Electrical installation demands technical competence

PAC2200

10 Manual, 05/2018, L1V30415167B-02

2

2.1

Features

5 A device:

65 A device:

Measurement

Counters and power demand

The PAC2200 is a measuring device for measuring the basic electrical variables in lowvoltage power distribution. All measured variables are shown on the display of the PAC2200.

The device is capable of single-phase, two-phase, or three-phase measurement and can be

used in TN and TT networks.

The PAC2200 is mounted on a DIN rail.

The PAC2200 measuring device is available in several versions:

●

x / 1 A and x / 5 A current transformers can be used for current measuring.

●

No current transformers are required for current measuring. The device is connected directly

to the low-voltage network. Current of up to 65 A can be measured directly.

Depending on the device version, the PAC2200 measuring device has an integrated

Ethernet, RS485 or M-BUS interface.

Thanks to its large measuring voltage range, the PAC2200 measuring device can be

connected directly in any low-voltage system up to a voltage UL-L 480 V.

● Measurement of all relevant electrical variables in an AC system.

● Acquisition of minimum and maximum values of all measured variables.

● Averaging of all measured variables directly on the device in two steps, which are

independent of each other and freely configurable (aggregation).

● Recording of active, reactive and apparent energy by means of several energy counters

● Calculation and storage of the last measuring period demand for active power and

reactive power for simple generation of load profiles using software (programmable

measuring period of between 1 and 60 min.).

PAC2200

Manual, 05/2018, L1V30415167B-02

11

Description

Display and operator control

Interfaces

Memory

Response in the case of power failure and power restore

2.1 Features

● LC display

● Four control keys with variable function assignment

● LED for Ethernet communication, active energy pulse indicator

● SENTRON powerconfig from Version 3.7.

● SENTRON powermanager from Version 3.4.

● Web server (HTTP) (optional)

● Ethernet (optional)

● RS 485 interface (optional)

● M-BUS (optional)

● Digital input

● Digital output

● Adjusted device parameters are permanently stored in the device memory.

● Extreme values (maximum or minimum) are permanently stored in the internal device

memory. Values can be reset via SENTRON powerconfig, Modbus command or directly

on the device via the menu.

After a power failure, the device starts back at zero with the calculation of the power demand

of the

total active power and total reactive power.

Counter statuses and extreme values are written from the volatile to the

non-volatile memory at the following intervals:

Counter values Every 5 mins.

Extreme values Every 5 secs., if available

PAC2200

12 Manual, 05/2018, L1V30415167B-02

Description

Security

Note

Activate hardware write protection

When connecting the measuring device to a network, it is recommended that the hardware

write protection is activated.

2.1 Features

● Hardware write protection

● Password protection

● Access protection, IP filter

● Modbus TCP port, configurable

● HTTP port, configurable

● DHCP protocol included

● SNTP protocol included

● Attachment of lead seals possible

Using "Password protection" and "Hardware write protection", you can protect against write

access to the device settings of the PAC2200.

The protection takes effect in case of the following actions:

● Modify parameters in device

● Reset maximum

● Reset minimum

● Reset counter

● Reset device

● Reset device to factory defaults

● Reset password

● Update firmware on the device

The data can be read without any restrictions.

PAC2200

Manual, 05/2018, L1V30415167B-02

13

Description

Tariffs

MID-approved

See also

2.1 Features

SENTRON PAC2200 supports 2 tariffs for the integrated energy counter (on-peak and

off-peak).

Switching between tariffs

Tariff switching can be controlled via the digital input or the

communication interfaces.

Time-related switching is only possible using a higher-level system.

Tariff switching after synchronization

When synchronizing the power demand values via the communication interfaces

or the digital input, the tariff change will only become effective after expiry of the

period. Without synchronization, the tariff change takes effect immediately.

The synchronization frame contains the length of the demand period in minutes. The

synchronization command is ignored if the period length sent to the device with the

synchronization frame is different to the length parameterized in the device.

MID-approved devices are included in the portfolio. These devices are suitable for billing the

active energy.

The following actions cannot be carried out on MID-approved devices:

● FW update

● Resetting the secondary energy values

● Parameterization of the voltage input

● Inversion of the direction of current flow

The secondary value of the total active energy is suitable for billing purposes.

Energy counters (Page 21)

PAC2200

14 Manual, 05/2018, L1V30415167B-02

Description

2.2

Measuring inputs

Current measurement

NOTICE

AC current measurement only

Measuring current of 5 A for connecting standard current transformers.

Direct connection to the low-voltage network

Voltage measurement

NOTICE

AC voltage measurement only

Direct measurement on the network

Measurement voltage up to 277 V / 480 V

2.2 Measuring inputs

The device is not suitable for measuring DC current.

The 5 A device is designed for:

●

measuring input can take a continuous load of 10 A. A momentary overcurrent of up to

100 A and a duration of 1 s is possible.

The current direction can be changed for each phase individually. It is not necessary to

change the terminal connections of the current transformers in the event of connection

errors.

Each current

The 65 A device is designed for:

●

The device is not suitable for measuring DC voltage.

PAC2200 is designed for:

●

●

voltages up to 277 V to the neutral conductor and for measuring input voltages up to

480 V to the external conductor.

.

.

. The device is designed for measuring input

PAC2200

Manual, 05/2018, L1V30415167B-02

15

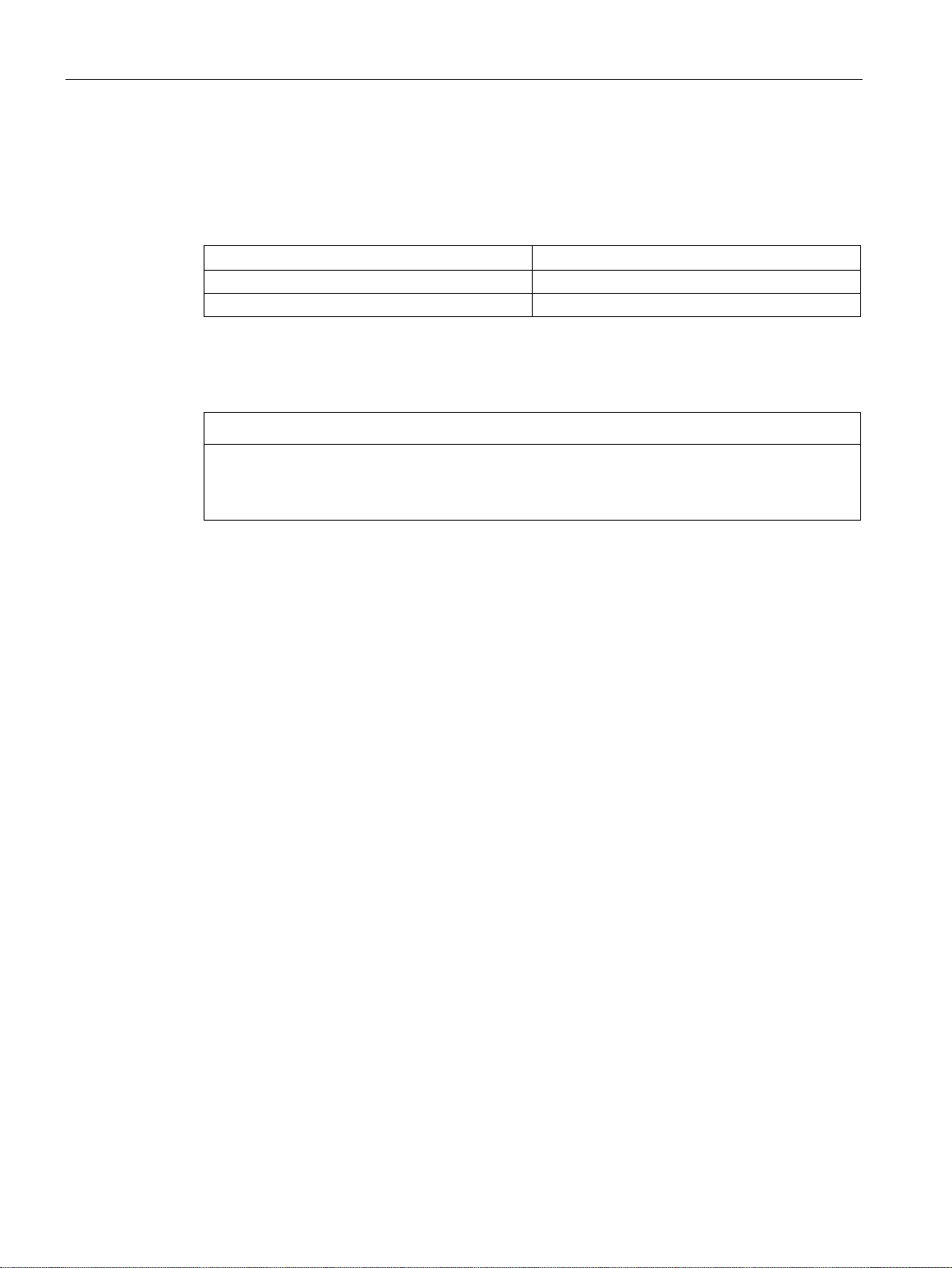

Description

Connection types

Short code

Connection type

3P4W (factory setting)

3 phases, 4 conductors, unbalanced load

NOTICE

The wrong system connection can destroy the device.

2.2 Measuring inputs

Two connection types have been provided. The device can be used in TN and IT networks.

Table 2- 1 Available connection types

1P2W (not MID devices) 1 phase, 2 conductors, unbalanced load

The input circuit of the device must correspond to one of the connection types listed. Select

the suitable connection type for the purpose.

Connection examples can be found in chapter Connection (Page 39)

Before connecting the PAC2200, you must ensure that the local power supply conditions

agree with the specifications on the rating plate.

The short code of the connection type must be entered in the device settings at startup. You

can find the instructions for parameterizing the connection type in chapter Commissioning

(Page 57).

PAC2200

16 Manual, 05/2018, L1V30415167B-02

Description

Display of the measured variables depending on the connection type

Connection type

Measured variable

3P4W

1P2W

Voltage L

1-N

✓

✓

Voltage L

✓

—

Voltage L

1-2

✓

—

Voltage L

✓

—

Voltage L

3-1

✓

—

Current L1

✓

✓

Current L2

✓

—

Current L3

✓

—

Apparent power L1

✓

✓

Apparent power L2

✓

—

Apparent power L3

✓

—

Active power L1

✓

✓

Active power L2

✓

—

Active power L3

✓

—

Reactive power L1

✓

✓

Reactive power L2

✓

—

Reactive power L3

✓

—

Total apparent power

✓

✓

Total active power

✓

✓

Total reactive power

✓

✓

Power factor L1

✓

✓

Power factor L3

✓

—

Frequency

✓

✓

Average voltage L - N

✓

—

2.2 Measuring inputs

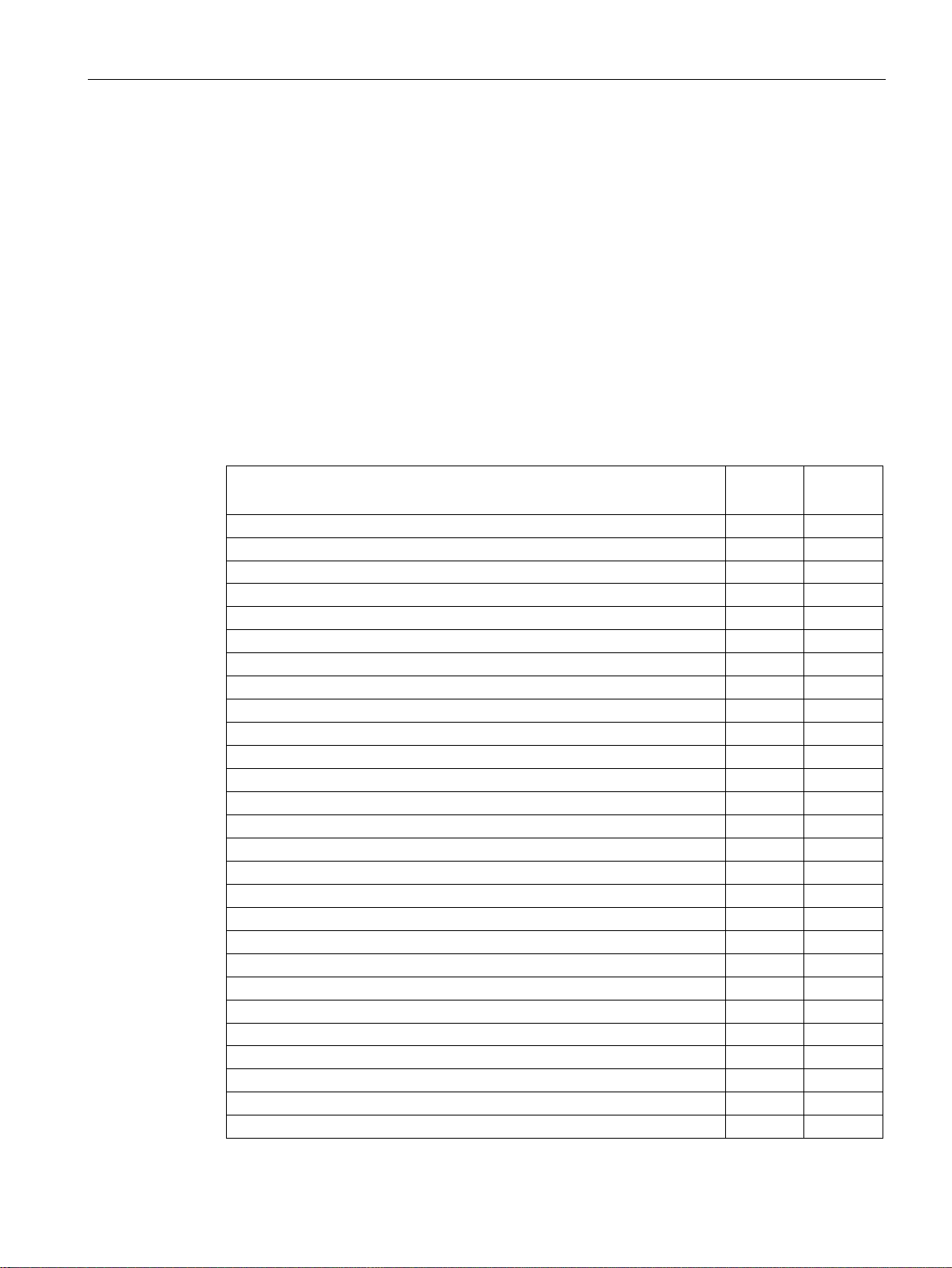

The table below shows which measured values can be represented depending on the

connection type.

The availability of the measured variables depends on the type of readout.

Depending on the device version, several different readout types are available:

● Device display

● ModbusTCP

● ModbusRTU

● M-Bus

● Web server

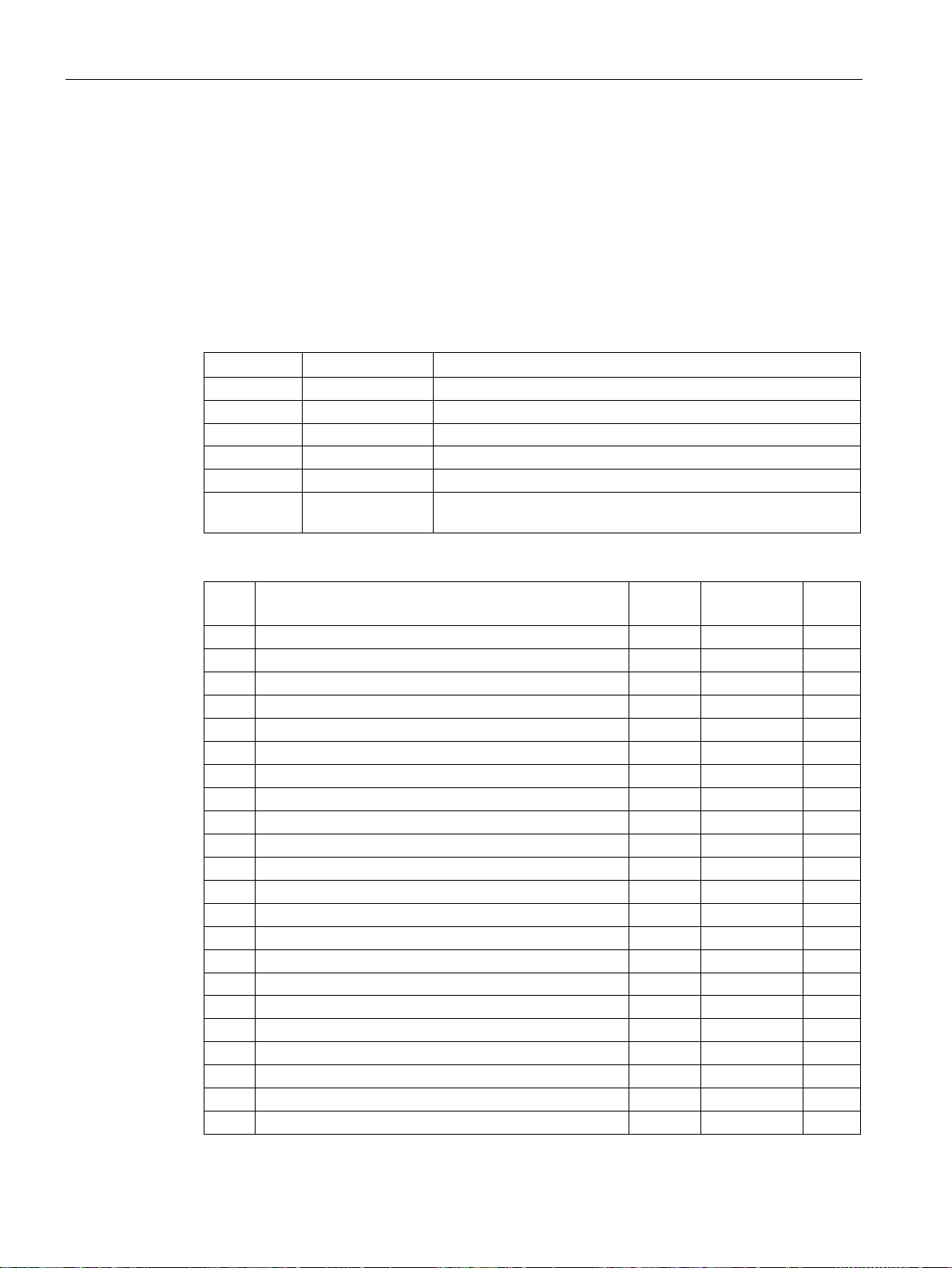

Table 2- 2 Display of the measured variables depending on the connection type

Voltage L

✓ —

2-N

3-N

2-3

PAC2200

Manual, 05/2018, L1V30415167B-02

Power factor L2 ✓ —

Total power factor ✓ ✓

17

Description

Connection type

Measured variable

3P4W

1P2W

Average voltage L - L

✓

—

Binary outputs

✓

✓

Binary inputs

✓

✓

Tariff ✓ ✓

Counter (configurable)

✓

✓

Active power import

✓

✓

Active power export (load profile)

✓

✓

Reactive power import (load profile)

✓

✓

Reactive power export (load profile)

✓

✓

Max. active power (load profile)

✓

✓

Min. active power (load profile)

✓

✓

Max. reactive power (load profile)

✓

✓

Min. reactive power (load profile)

✓

✓

Total active energy import tariff 1

✓

✓

Total active energy import tariff 2

✓

✓

Total active energy export tariff 1

✓

✓

Total active energy export tariff 2

✓

✓

Total reactive energy import tariff 1

✓

✓

Total reactive energy import tariff 2

✓

✓

Total reactive energy export tariff 1

✓

✓

Total reactive energy export tariff 2

✓

✓

Total apparent energy tariff 2

✓

✓

L1 active energy import tariff 2

✓

✓

L1 active energy export tariff 1

✓

✓

L1 active energy export tariff 2

✓

✓

L1 reactive energy import tariff 1

✓

✓

L1 reactive energy import tariff 2

✓

✓

L1 reactive energy export tariff 1

✓

✓

L1 reactive energy export tariff 2

✓

✓

L1 apparent energy tariff 1

✓

✓

L1 apparent energy tariff 2

✓

✓

L2 active energy import tariff 1

✓

—

L2 active energy import tariff 2

✓

—

L2 active energy export tariff 1

✓

—

L2 active energy export tariff 2

✓

—

L2 reactive energy import tariff 1

✓

—

L2 reactive energy import tariff 2

✓

—

L2 reactive energy export tariff 1

✓

—

2.2 Measuring inputs

Average current ✓ —

Total apparent energy tariff 1 ✓ ✓

L1 active energy import tariff 1 ✓ ✓

PAC2200

18 Manual, 05/2018, L1V30415167B-02

Description

Connection type

Measured variable

3P4W

1P2W

L2 reactive energy export tariff 2

✓

—

L2 apparent energy tariff 2

✓

—

L3 active energy import tariff 1

✓

—

L3 active energy import tariff 2

✓

—

L3 active energy export tariff 1

✓

—

L3 active energy export tariff 2

✓

—

L3 reactive energy import tariff 1

✓

—

L3 reactive energy import tariff 2

✓

—

L3 reactive energy export tariff 1

✓

—

L3 reactive energy export tariff 2

✓

—

L3 apparent energy tariff 1

✓

—

L3 apparent energy tariff 2

✓

—

Secondary total active energy (MID register)

✓

—

2.3

Averaging measured values

2.3 Averaging measured values

L2 apparent energy tariff 1 ✓ —

With appropriate load profiles, consumers can carry out a targeted optimization of their

energy consumption.

Instantaneous values are averaged over specific time periods to create load profiles. For this

purpose, measured values are read out via the communication and stored. This

increases the bus load considerably and occupies storage capacity.

The PAC2200 device has two average value generators, which can be parameterized

independently.

The aggregation of the measured values reduces the bus load without risk of loosing

information. Average values are calculated contiguously, based on the underlying values.

The values are updated each time after expiry of the set time period.

The default setting for average value 1 is a period length of 10 seconds.

The default setting for average value 2 is a period length of 15 minutes.

The period length can be set to anything between 3 seconds and 31536000 seconds (1

year).

This function is only available if communication interfaces via Modbus TCP/RTU are used.

The list of available measured values can be found in the appendix A.1.4 „Modbus variables

with function code 0x14“ on page 82 (Page 92).

PAC2200

Manual, 05/2018, L1V30415167B-02

19

Description

2.3.1

Acquisition of power demand

Values that can be read out

Example

Note

The power demand of the last measuring period can only be fetched during the current

measuring period.

Adjustable parameters

2.3 Averaging measured values

● The PAC2200 measuring device supplies the power demand of the last completed

measuring period:

● Mean values for active and reactive power, separately for import and export.

● Minimum and maximum active power and reactive power within the last measuring

period.

● Length of the measuring period in seconds. The period may be shorter for reasons of

external synchronization.

● Time in seconds since the last synchronization or since completion of the last period.

Period length: 15 minutes; time of day: 13:03; time in seconds: 180 s.

The following can be calculated from this: The last measuring period ended at 13:00. The

active measuring period will end at 13:15 or in 12 minutes.

Period length in minutes: 1 to 60 min adjustable, default 15 min

: Period length and length of the measuring period:

PAC2200

20 Manual, 05/2018, L1V30415167B-02

Description

2.3.2

Energy counters

Tariff 1

Tariff 2

Total

(T1 + T2)

Active energy kWh

Import

Total

X X X

L2 X X L3 X X Secondary value

X (MID)

Export

Total

X X X

L1 X X L2 X X L3 X X Secondary value

X

Reactive energy kvarh

Import

Total

X X X

L1 X X L2 X X L3 X X Secondary value

X

Export

Total

X X X

L1 X X L2 X X L3 X X

Secondary value

X

Apparent energy kVAh

L1 X X

L3 X X Secondary value

X

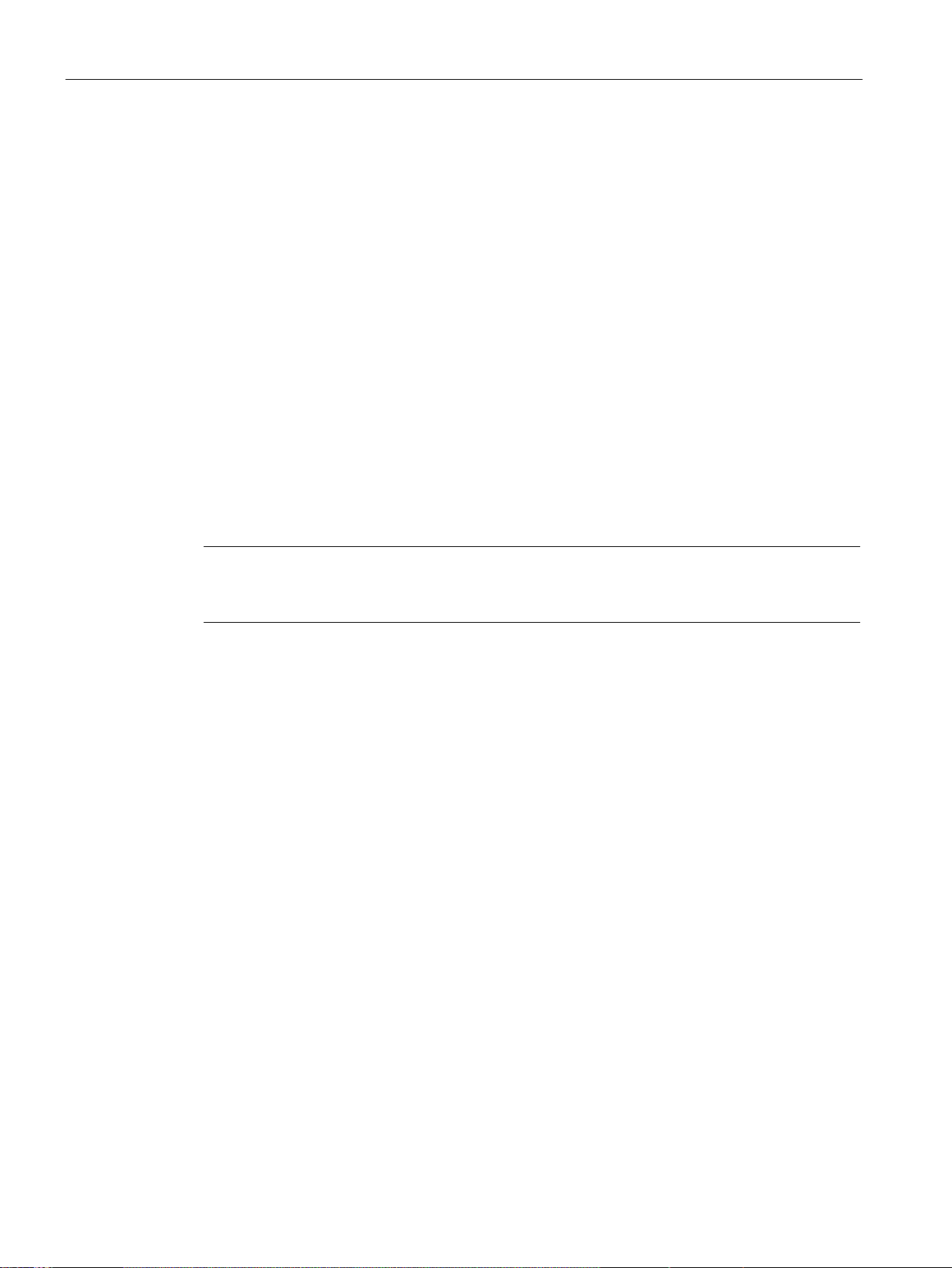

Secondary values

MID

YY

Indicates the year the MID marking was affixed

2.3 Averaging measured values

Available energy counters of the PAC2200 measuring device:

L1 X X

Total X X X

: Non-resettable energy counters. Transformer ratio is not taken into

L2 X X

account in the calculation.

: MID registers are marked in the menu with MID mark. Marked registers are suitable for

billing purposes.

PAC2200

Manual, 05/2018, L1V30415167B-02

21

Description

2.4

Digital inputs and outputs

1 digital input

1 digital output

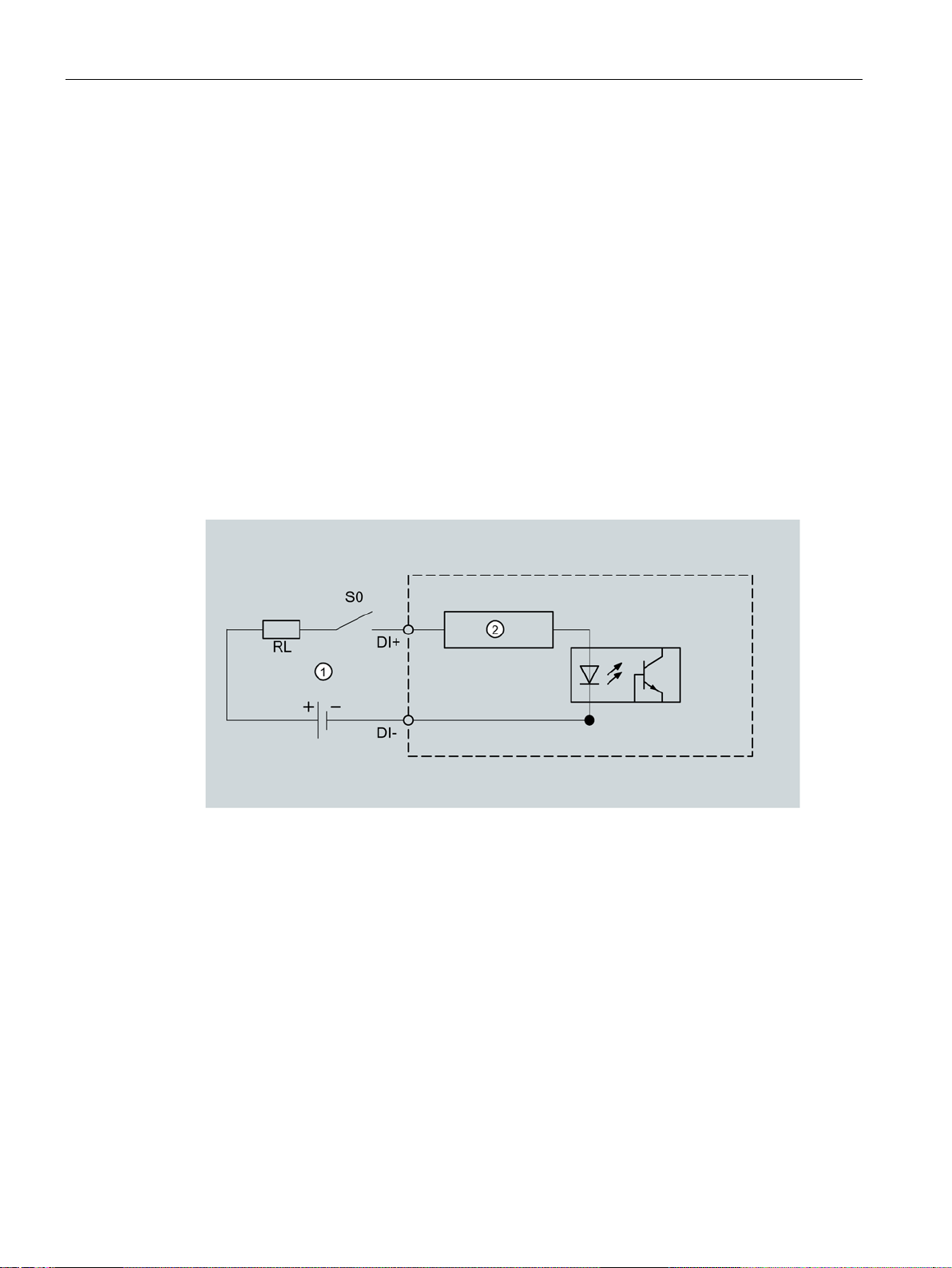

2.4.1

Digital input

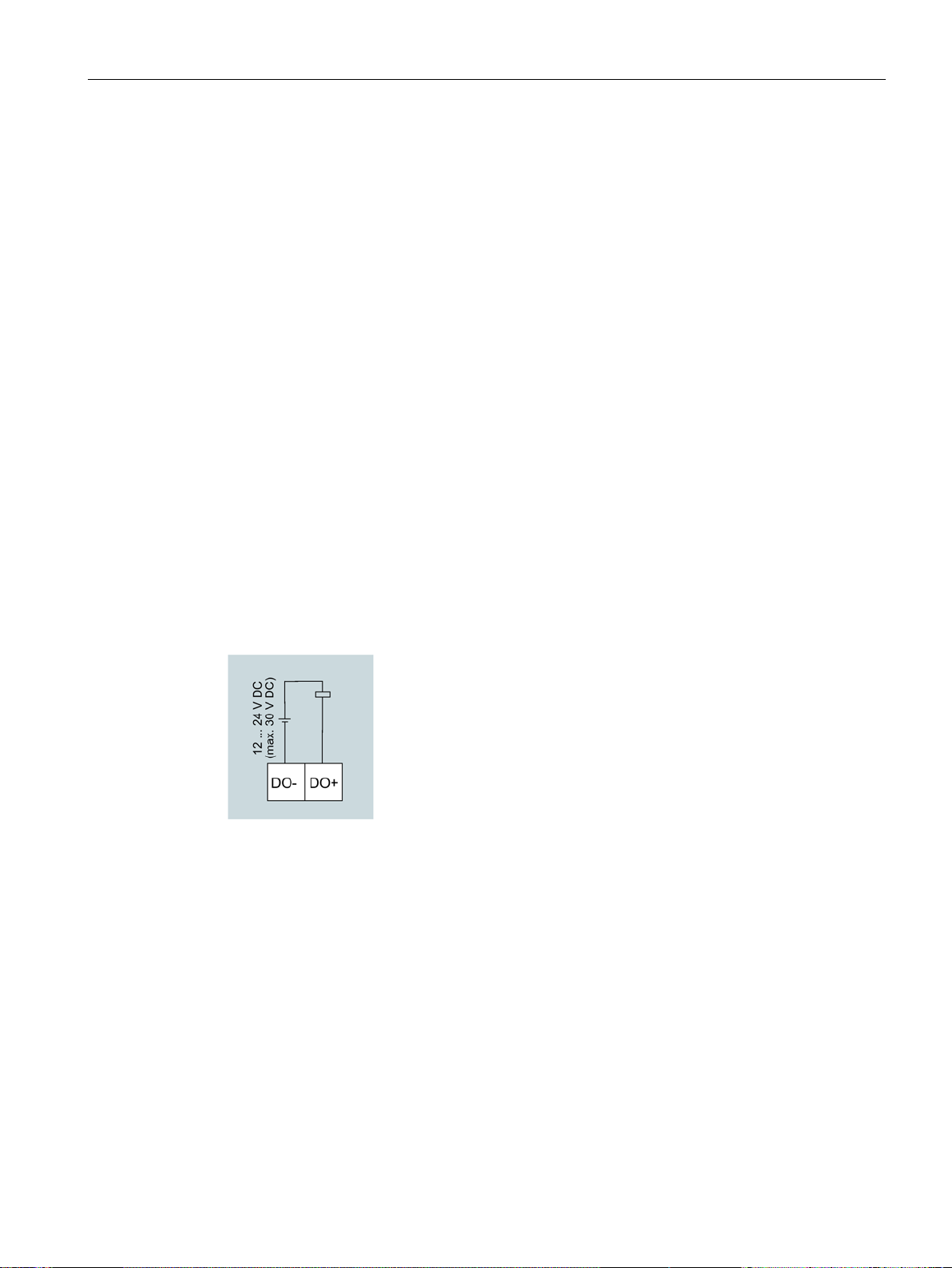

(1)

External power supply, max. 30 VDC, typically 24 VDC

(2)

Input electronics

2.4 Digital inputs and outputs

The PAC2200 has the following inputs/outputs:

●

●

The following functions can be assigned to the digital input:

● Status monitoring: Capturing statuses of connected signal encoders

● Tariff switch for two-tariff counters.

● Synchronization of the measuring period by means of the synchronization pulse of a

system control center or other device.

● Input for energy pulses (S0 interface)

Figure 2-1 Block diagram: Digital inputs

PAC2200

22 Manual, 05/2018, L1V30415167B-02

Description

2.4.2

Digital output

2.4 Digital inputs and outputs

The following functions can be assigned to the digital output:

● Not used

Digital output is deactivated.

● Device is ready for operation.

The digital output is ON.

● Remote control

The digital input is remotely controlled.

● Direction of rotation

The digital output is switched on by a counter-clockwise rotating electrical field and

remains active while the direction of rotation of the field remains unchanged.

● Energy pulse

The digital output outputs the parameterized number of pulses per energy unit (e.g. kWh).

The specified energy counter is evaluated here.

Figure 2-2 Block diagram: Digital outputs

PAC2200

Manual, 05/2018, L1V30415167B-02

23

Description

Wiring

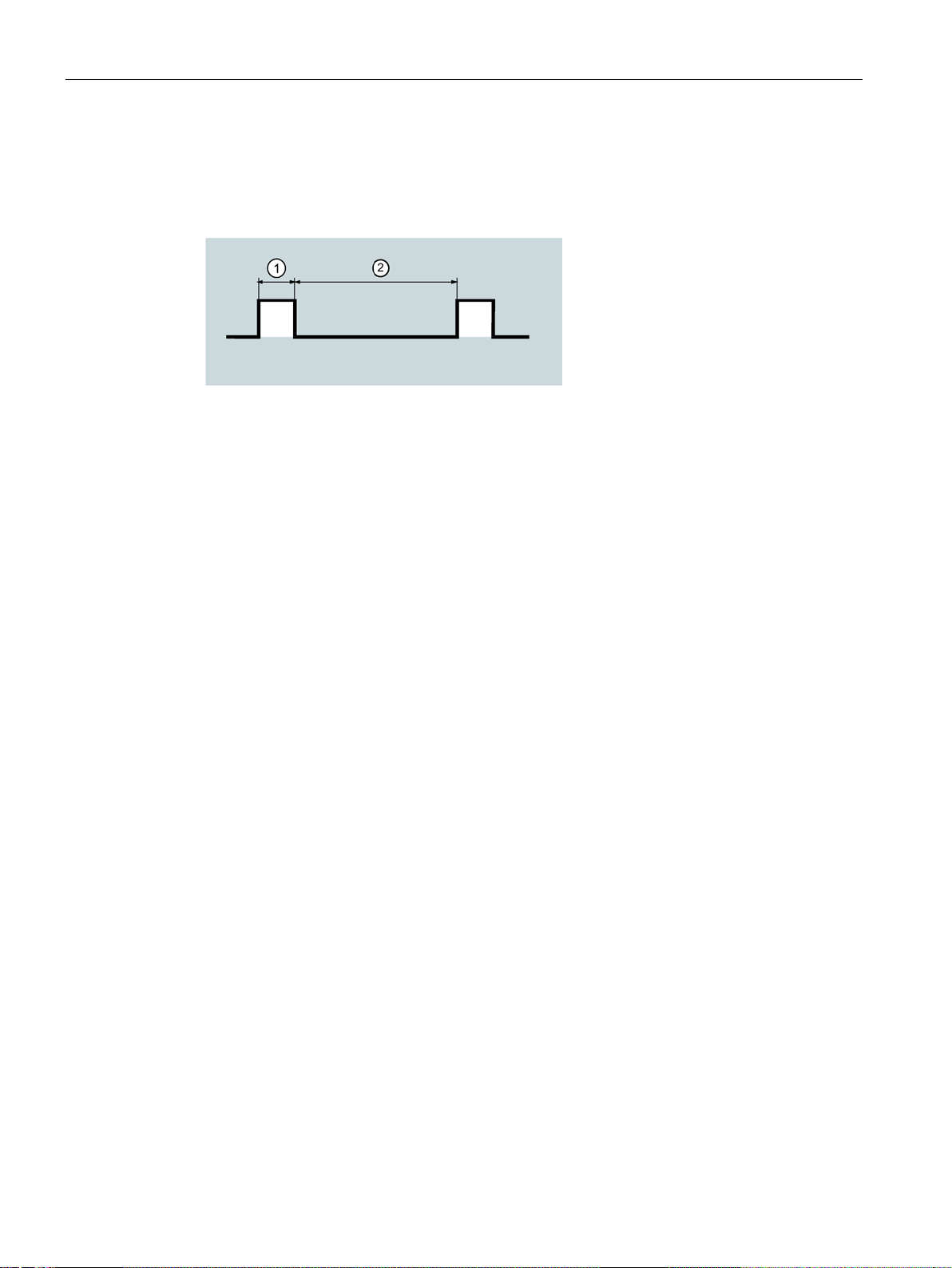

(1)

Pulse length

(2)

Turn-off time

2.5

Communication

Ethernet

RS 485

M-BUS

2.5 Communication

The digital output is passive and implemented exclusively as a switch.

Implementation of the pulse function corresponds to the IEC 62053-31 standard.

Figure 2-3 Pulse length and turn-off time

● Pulse length:

Time for which the signal at the digital output is "high". The minimum pulse length is

30 ms and the maximum 500 ms.

● Turn-off time:

Time for which the signal at the digital output is "low". The turn-off time depends on the

measured energy, for example, and can be days or months.

● Minimum turn-off time:

The minimum turn-off time corresponds to the programmed pulse length. 30 ms is the

absolute minimum.

Depending on the device version, the devices may be fitted with the following

communications interfaces:

●

●

●

The selection of the measured variables available for selection can vary according to the

communication mode selected.

PAC2200

24 Manual, 05/2018, L1V30415167B-02

Description

2.5.1

Ethernet

Modbus TCP

Web server (HTTP)

SNTP

DHCP

2.5 Communication

Permits communication via the following protocols:

●

The device can be configured via Modbus TCP

●

Protocol can be used to read out the measured values via web browser.

●

The SNTP (Simple Network Time Protocol) is used to automatically synchronize the internal

clock with a time server within the network.

Three function modes are available:

● No synchronization.

● Date/time synchronization via device request

The IP address of an NTP server must be configured. With this, the PAC2200

automatically requests the current time from the server and resets its internal clock, if

necessary.

● Date/time synchronization via SNTP server - Broadcast

The PAC2200 receives Broadcast time telegrams, which are sent from an NTP server.

This is practical, if the internal clocks in several devices in the same network

should be synchronous.

If the IP address of the NTP server has been configured, the PAC2200 only responds to

these telegrams. Furthermore, it can send a request to the server, if necessary.

●

Stands for "Dynamic Host Configuration Protocol". Protocol for obtaining network settings

from a DHCP server. Network settings are automatically assigned.

PAC2200

Manual, 05/2018, L1V30415167B-02

25

Description

2.5.2

RS 485

Note

RS 485 termination is recommended!

In order to avoid reflection on the bus cable, we recommend fitting a 120

resistor at the beginning and end of the bus cable.

2.5.3

M-BUS

2.5 Communication

Permits communication via the MODBUS RTU protocol. This interface features simple

topology and high immunity against EMC interference.

The data is transmitted differentially via two wires A and B. The third wire "COM" serves as

the common ground potential.

Grounding of the cable shield:

The serial Modbus data cable should be shielded. The shield should be connected to

protective ground at one end of the cable at least.

Grounding of the COM line:

Many masters do not have a common terminal. If this is the case, then RS 485 common

should reference the same functional ground as the master (at a single point). If the

master has a common terminal, then the common is connected to it, and it is not connected

to functional ground.

Ohm terminating

M-BUS is the abbreviation for Meter-Bus according to EN13757. The M-BUS is used as a

fieldbus for the acquisition of consumption data. The data is serially transmitted over a

reverse-polarity protected two-wire line.

PAC2200 data can be read out with an M-BUS master. The PAC2200 is then implemented

as an M-BUS slave.

To read out measurement data stored on the device, the slave address must be known.

The user can give a primary address to the device manually, or use the secondary address

of the device. The secondary address is automatically created from the serial number of the

device and must therefore not be set explicitly. Furthermore, the interface of the PAC2200

must be set to the baud rate used in your M-BUS system. Additionally the user can choose

between two different DIF / VIF codes ("mapping"). In "Mapping 1" the measured values are

coded in more detail with DIF / VIF with the result that all the data records have different

coding.

Different measurement data is available, depending on the connection type, 3P4W or 1P2W.

(With MID devices only connection type 3P4W is possible).

The connection type and the parameter setting in the M-BUS communications menu on the

device display define the data record structure or contents of the RSP_UD2 long datagram.

At the M-BUS interface the setting can be determined by means of the version number in the

header of the RSP_UD2 response datagram of an REQ_UD2 request (see M-BUS

specification)

PAC2200

26 Manual, 05/2018, L1V30415167B-02

Description

Header

Structure of RSP_UD2 datagram

es

es

Version 33

1-phase connection 1P2W

19 data records on 1 page

Mapping 1

2.5 Communication

Version 30 3-phase connection 3P4W 69 data records on 3 pag-

Version 31 1-phase connection 1P2W 19 data records on 1 page Mapping 0

Version 32 3-phase connection 3P4W 69 data records on 3 pag-

Mapping 0

Mapping 1

The factory setting when delivered is connection type "3P4W" with "Mapping 1".

If this setting is not changed the device addresses the M-BUS interface with version 32. The

device then supplies 69 data records on 4 pages (in 4 datagrams).

PAC2200

Manual, 05/2018, L1V30415167B-02

27

Description

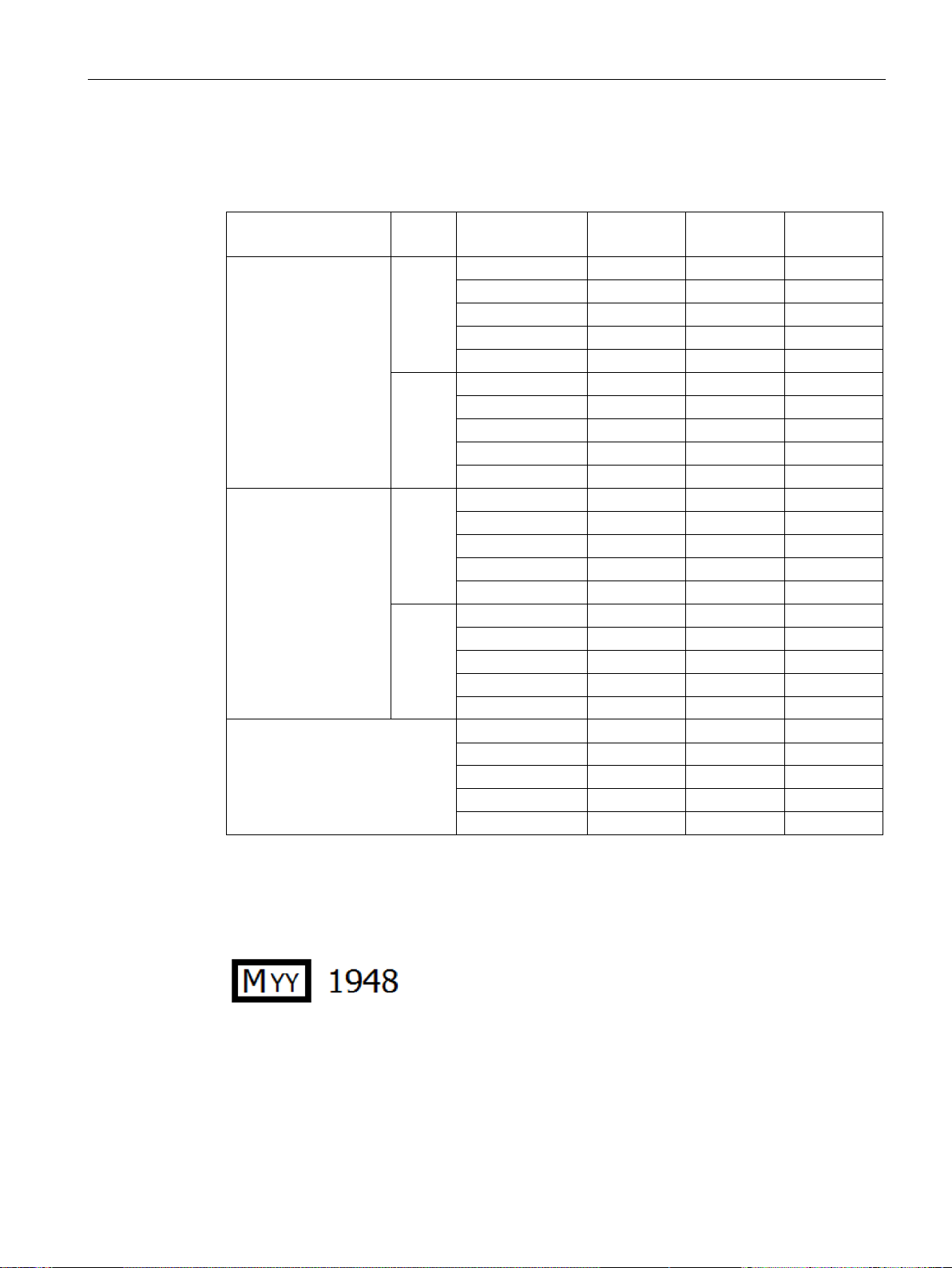

2.5.3.1

Three-phase connection (3P4W)

L2 active energy export tariff 2

BYTE No.

Coding

Description

Byte 1

0x86

DIF value format INT48 -> Integer 6 bytes length

Byte 2

0x20

DIFE tariff 2

Byte 3

0x83

VIF active energy / unit Wh

Bytes 5-6

0xFC 0x02

VIFE phase L2

XX

(bits)

1

Secondary total active energy (MID register)

48

INT48

Wh

2

Total active energy import tariff 1

48

INT48

Wh 3 Total active energy import tariff 2

48

INT48

Wh 4 Total active energy export tariff 1

48

INT48

Wh 5 Total active energy export tariff 2

48

INT48

Wh 6 L1 active energy import tariff 1

48

INT48

Wh 7 L1 active energy import tariff 2

48

INT48

Wh 8 L1 active energy export tariff 1

48

INT48

Wh 9 L1 active energy export tariff 2

48

INT48

Wh

10

L2 active energy import tariff 1

48

INT48

Wh

11

L2 active energy import tariff 2

48

INT48

Wh

12

L2 active energy export tariff 1

48

INT48

Wh

13

L2 active energy export tariff 2

48

INT48

Wh

14

L3 active energy import tariff 1

48

INT48

Wh

16

L3 active energy export tariff 1

48

INT48

Wh

18

Total active power

32

FLOAT32

W

19

Active power L1

32

FLOAT32

W

20

Active power L2

32

FLOAT32

W

21

Active power L3

32

FLOAT32

W

22

Voltage L1-N

32

FLOAT32

V

2.5 Communication

The measurement data is presented on three pages (Mapping 0) and on four pages

(Mapping 1). Multipage-capable masters can read out all three or four pages.

As an example, the coding of the data record with ID 13 (connection type 3P4W, Mapping 1,

i.e. version 32) is more accurately explained in the RSP_UD2 response datagram (see also

M-BUS specification):

Measured variable ID 13:

Byte 4 0xBC VIFE export

Bytes 7-12 XX XX XX XX XX

Integer value of measured variable

All measurement data that can be read out via the M-BUS are listed in the following table.

ID

Measured variable

Length

Format

Unit

15 L3 active energy import tariff 2 48 INT48 Wh

17 L3 active energy export tariff 2 48 INT48 Wh

PAC2200

28 Manual, 05/2018, L1V30415167B-02

Loading...

Loading...