Siemens SENTRON ATC6500 User Manual

3KC ATC6500 transfer control device

SENTRON

Transfer switching equipment and

load transfer switches

3KC ATC6500 transfer control

device

Manual

05/2019

L1V30538268002A

Introduction

1

General information

2

Applications

3

Product description

4

Functions

5

Installation

6

Connection

7

Operation

8

Parameterization

9

MODBUS communication

10

Accessories

11

Transfer

12

Technical specifications

13

Dimension drawings

14

ESD Guidelines

A

List of abbreviations

B

-01

Siemens AG

Smart Infrastructure

Low Voltage Products

Postfach 10 09 53

93009 REGENSBURG

GERMANY

Document order number: 3ZW1012-0KC00-5AC1

Ⓟ

Copyright © Siemens AG 2019.

All rights reser

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

05/2019 Subject to change

ved

Table of contents

1 Introduction ............................................................................................................................................. 9

1.1 About this documentation ......................................................................................................... 9

1.2 Product-specific information ................................................................................................... 10

1.2.1 Certification ............................................................................................................................. 10

1.2.2 Reference documents ............................................................................................................. 11

1.2.3 Advanced training courses ..................................................................................................... 12

1.2.4 Technical Support ................................................................................................................... 12

1.3 Safety instructions ................................................................................................................... 13

1.3.1 Security information ................................................................................................................ 13

1.3.2 Open Source Software............................................................................................................ 14

2 General information .............................................................................................................................. 15

2.1 Features of the ATC6500 transfer control device ................................................................... 15

2.2 Compatible Siemens SENTRON switching devices ............................................................... 17

3 Applications .......................................................................................................................................... 19

3.1 Transfer control ....................................................................................................................... 19

3.1.1 Network/network application ................................................................................................... 19

3.1.2 Network/generator application ................................................................................................ 20

3.1.3 Generator/generator application ............................................................................................. 20

3.1.4 Load management with the ATC6500 .................................................................................... 20

3.1.4.1 Application A: 2S – 0T............................................................................................................. 21

3.1.4.2 Application B: 2S - 1T - PL ..................................................................................................... 22

3.1.4.3 Application C: 2S – 1T – SI ..................................................................................................... 23

3.1.4.4 Application D: 2S - 1T - AI ...................................................................................................... 24

3.1.4.5 Application O: 2S - NPL .......................................................................................................... 25

3.2 Controlling the switching devices ............................................................................................ 26

3.2.1 Controlling motor-driven circuit breakers ................................................................................ 27

3.2.2 Controlling remotely operated transfer switching equipment.................................................. 27

3.2.3 Controlling contactors ............................................................................................................. 28

3.3 Voltage measurement ............................................................................................................. 28

3.3.1 P02 General ............................................................................................................................ 29

3.3.2 P06 Source Lines .................................................................................................................... 29

3.3.3 P08 Switch .............................................................................................................................. 29

3.3.4 P09 Source Line CHK ............................................................................................................. 30

4 Product description ............................................................................................................................... 33

4.1 Status LEDs ............................................................................................................................ 34

4.2 Keys ........................................................................................................................................ 35

4.3 Interface .................................................................................................................................. 35

4.4 Menu navigation ...................................................................................................................... 36

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

3

Table of contents

4.5 Description of the main menu ................................................................................................ 36

4.5.1 Description of the symbols ..................................................................................................... 37

4.6 Navigation through the main menu ........................................................................................ 38

4.7 Display pages of the ATC6500 .............................................................................................. 38

4.7.1 Description of the display pages ............................................................................................ 38

4.7.1.1 Voltage L-L ............................................................................................................................. 39

4.7.1.2 L-N Voltage ............................................................................................................................ 39

4.7.1.3 Threshold limits ...................................................................................................................... 40

4.7.1.4 Alarms status ......................................................................................................................... 41

4.7.1.5 Statistics ................................................................................................................................. 41

4.7.1.6 Battery Status ......................................................................................................................... 42

4.7.1.7 Expansion modules ................................................................................................................ 42

4.7.1.8 Inputs/outputs......................................................................................................................... 43

4.7.1.9 Inputs ..................................................................................................................................... 43

4.7.1.10 Outputs ................................................................................................................................... 43

4.7.1.11 Date/Time ............................................................................................................................... 44

4.7.1.12 Information page 1 ................................................................................................................. 44

4.7.1.13 Event log ................................................................................................................................ 45

4.7.1.14 Counter CNTx ........................................................................................................................ 46

4.7.1.15 User limits LIMx...................................................................................................................... 46

4.7.1.16 Automatic test ........................................................................................................................ 47

4.7.1.17 Setup menu ............................................................................................................................ 47

4.7.1.18 Password ...............................................................................................................................

48

4.7.1.19 Commands menu ................................................................................................................... 48

4.7.1.20 Synchronoscope .................................................................................................................... 49

4.7.1.21 Synchronization...................................................................................................................... 49

4.7.1.22 Delta voltages ........................................................................................................................ 50

4.7.2 Scrolling through the display pages ....................................................................................... 50

5 Functions .............................................................................................................................................. 51

5.1 Basic functions ....................................................................................................................... 51

5.1.1 Setting the real-time clock ...................................................................................................... 51

5.1.2 Password protection .............................................................................................................. 52

5.1.2.1 Password protection against physical access ....................................................................... 52

5.1.2.2 Password protection against remote access (remote password) .......................................... 53

5.1.2.3 Entering the password via user interface ............................................................................... 53

5.1.3 Keypad lock ............................................................................................................................ 55

5.1.3.1 Activation of the keypad lock by means of a programmable input ........................................ 55

5.1.3.2 Activation of the keypad lock by means of a key combination on the operator panel ........... 55

5.1.4 Expandability by modules ...................................................................................................... 56

5.1.4.1 Enabling additional resources ................................................................................................ 57

5.1.4.2 Inserting an expansion module .............................................................................................. 58

5.1.4.3 Behavior of the ATC6500 after inserting a module ................................................................ 59

5.1.5 Communication COMx ........................................................................................................... 60

5.1.6 Alarms .................................................................................................................................... 61

5.1.6.1 Features of the alarms ........................................................................................................... 62

5.1.6.2 Alarm description ................................................................................................................... 63

5.1.6.3 Alarm table ............................................................................................................................. 65

5.1.6.4 User alarms UAx .................................................................................................................... 67

5.1.7 Automatic test ........................................................................................................................ 67

5.1.7.1 Enabling the automatic test .................................................................................................... 68

3KC ATC6500 transfer control device

4 Manual, 05/2019, L1V30538268002A-01

Table of contents

5.1.8 Simulation of priority source failure (test mode) ..................................................................... 69

5.1.9 Commands menu .................................................................................................................... 70

5.1.9.1 Executing a command ............................................................................................................ 70

5.1.9.2 Table of commands ................................................................................................................ 72

5.1.9.3 Event log ................................................................................................................................. 73

5.2 Advanced functions ................................................................................................................. 74

5.2.1 Remote variables REMx ......................................................................................................... 74

5.2.2 User limit LIMx ........................................................................................................................ 75

5.2.3 Timer TIMx .............................................................................................................................. 77

5.2.4 Counter CNTx ......................................................................................................................... 78

6 Installation ............................................................................................................................................ 79

6.1 Dimensions for the door cutout ............................................................................................... 79

6.2 Installation of the ATC6500 .................................................................................................... 80

7 Connection ........................................................................................................................................... 83

7.1 Connection of the power supply for the ATC6500 .................................................................. 83

7.1.1 Use of a DC source / battery .................................................................................................. 85

7.1.2 Power supply using a dual power supply................................................................................ 87

7.1.3 Power supply by means of UPS ............................................................................................. 88

7.1.4 Power supply by means of contactors .................................................................................... 89

7.2 General connection drawings ................................................................................................. 90

7.2.1 Transfer between 2 sources, with 2 breakers ......................................................................... 90

7.2.2 Transfer with 2 circuit breakers ............................................................................................... 91

7.2.3 Transfer with remotely operated transfer switching equipment .............................................. 92

7.2.4 Transfer with contactors.......................................................................................................... 94

7.2.5 Transfer between 2 sources, with 3 switching devices ........................................................... 95

7.2.6 Transfer with 3 circuit breakers ............................................................................................... 97

7.3 Connection of Siemens SENTRON switching devices ......................................................... 101

7.3.1 Accessories for switching devices ........................................................................................ 101

7.3.2 Accessories for mechanical interlock .................................................................................... 102

7.3.3 Technical specifications of the Siemens SENTRON switching devices (IEC only) .............. 105

7.3.4 Typical operating times of the Siemens SENTRON switching devices (IEC only) ............... 107

7.4 Connection of 3VA molded case circuit breakers ................................................................. 109

7.4.1 Connection of 3VA molded case circuit breakers with MO (IEC, UL), 3VA with SEO

(IEC only) .............................................................................................................................. 109

7.4.1.1 Transfer between two 3VA molded case circuit breakers, with electrical interlock .............. 109

7.4.1.2 Transfer between three 3VA molded case circuit breakers, with electrical interlock ........... 111

7.4.1.3 Transfer between three 3VA molded case circuit breakers, without electrical interlock ...... 113

7.4.2 Connection of 3VA27 motor-driven molded case circuit breakers (IEC only) ...................... 115

7.4.2.1 Transfer between two 3VA27 molded case circuit breakers, with electrical interlock .......... 115

7.4.2.2 Transfer between three 3VA27 molded case circuit breakers, with electrical interlock ....... 117

7.4.2.3 Transfer between three 3VA27 molded case circuit breakers, without electrical

interlock .................................................................................................................................

119

7.5 Connection of the 3WL air circuit breaker............................................................................. 121

7.5.1 Transfer between two 3WL10 air circuit breakers, with electrical interlock .......................... 121

7.5.2 Transfer between three 3WL10 air circuit breakers, with electrical interlock ....................... 123

7.5.3 Transfer between three 3WL10 air circuit breakers, without electrical interlock .................. 125

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

5

Table of contents

7.6 Connection of 3WL air circuit breakers, FS I - III ................................................................. 127

7.6.1 Transfer between two 3WL FS I-III air circuit breakers, with electrical interlock ................. 127

7.6.2 Transfer between three 3WL air circuit breakers FS I-III, with electrical interlock ............... 129

7.6.3 Transfer between three 3WL air circuit breakers FSI-III, without electrical interlock ........... 131

7.7 Connection of 3WT8 air circuit breakers .............................................................................. 133

7.7.1 Transfer between two 3WT8 air circuit breakers, with electrical interlock ........................... 133

7.7.2 Transfer between three 3WT8 air circuit breakers, with electrical interlock ........................ 135

7.7.3 Transfer between three 3WT8 air circuit breakers, without electrical interlock ................... 137

8 Operation ............................................................................................................................................. 139

8.1 Operating modes of the ATC6500 ....................................................................................... 139

8.1.1 Setting the operating mode .................................................................................................. 139

8.1.2 OFF mode (OFF) ................................................................................................................. 140

8.1.3 TEST mode .......................................................................................................................... 140

8.1.4 Manual mode (MAN) ............................................................................................................ 140

8.1.5 Automatic mode (AUT) ........................................................................................................ 143

8.2 Inputs and outputs of the ATC6500 ..................................................................................... 144

8.2.1 Voltage measuring inputs .................................................................................................... 144

8.2.2 Digital inputs INPx ................................................................................................................ 145

8.2.3 Table of functions of the digital inputs ................................................................................. 145

8.2.4 Digital outputs OUTx ............................................................................................................ 148

8.2.5 Table of functions of the digital outputs ............................................................................... 150

8.2.6 Addressing the expansion modules with digital inputs/outputs ........................................... 152

8.2.7 Integrated RS485 interface COM1....................................................................................... 152

9 Parameterization .................................................................................................................................. 155

9.1 Parameterization via the user interface ............................................................................... 155

9.2 Changing the parameters .................................................................................................... 158

9.3 Parameterization via the powerconfig software ................................................................... 158

9.3.1 Procedure for parameterization via powerconfig ................................................................. 158

9.3.2 Parameterization via the front interface ............................................................................... 159

9.3.3 Parameterization via the RS485 interface or the expansion modules for

communication ..................................................................................................................... 160

9.4 Parameters ........................................................................................................................... 160

9.4.1 P01 - Settings ....................................................................................................................... 161

9.4.2 P02 - General ....................................................................................................................... 162

9.4.3 P03 - Password .................................................................................................................... 165

9.4.4 P04 - Battery ........................................................................................................................ 166

9.4.5 P05 - Acoustic alarms .......................................................................................................... 167

9.4.6 P06 - Source Lines .............................................................................................................. 168

9.4.7 P07 - Breakers ..................................................................................................................... 169

9.4.8 P08 - Switch ......................................................................................................................... 171

9.4.9 P09 - Control thresholds of the source lines ........................................................................ 174

3KC ATC6500 transfer control device

6 Manual, 05/2019, L1V30538268002A-01

Table of contents

9.4.10 P10 - Communications.......................................................................................................... 177

9.4.11 P11 - Automatic Test ............................................................................................................ 178

9.4.12 P12 - Digital Inputs ................................................................................................................ 179

9.4.13 P13 - Digital Outputs ............................................................................................................. 180

9.4.14 P14 - Miscellaneous .............................................................................................................. 180

9.4.15 P15 - User limit thresholds LIMx ........................................................................................... 181

9.4.16 P16 - Counter CNTx ............................................................................................................. 182

9.4.17 P17 - Timer TIMx .................................................................................................................. 183

9.4.18 P21 - User Alarms ................................................................................................................. 184

10 MODBUS communication ................................................................................................................... 185

10.1 General information on MODBUS ........................................................................................ 185

10.2 MODBUS RTU protocol ........................................................................................................ 185

10.3 MODBUS functions ............................................................................................................... 186

10.3.1 Function 04: Read input register ........................................................................................... 187

10.3.2 Function 06: Preset single register ....................................................................................... 188

10.3.3 Function 07: Read exception status ..................................................................................... 188

10.3.4 Function 16: Preset multiple register .................................................................................... 189

10.3.5 Function 17: Report Slave ID ................................................................................................ 190

10.3.6 Password entry by means of MODBUS ................................................................................ 191

10.4 Data library ............................................................................................................................ 192

10.4.1 Measured values (use with MODBUS function 03 and 04) .................................................. 192

10.4.2 Status bits (use with MODBUS function 03 and 04) ............................................................. 194

10.4.3 Commands (use with MODBUS function 06) ....................................................................... 199

10.4.4 Status of the ATC (use with MODBUS function 03 and 04) ................................................. 201

10.4.5 Real-time clock (use with MODBUS function 04 and 06) ..................................................... 201

10.5 Reading the event log ........................................................................................................... 202

10.6 Reading parameters by means of MODBUS ........................................................................ 204

10.7 Changing parameters by means of MODBUS ...................................................................... 205

11 Accessories ........................................................................................................................................ 209

11.1 Expansion modules ............................................................................................................... 209

11.1.1 Expansion module 4DI - 3KC9000-8TL60 ............................................................................ 210

11.1.2 Technical specifications 4DI ................................................................................................. 212

11.1.3 Expansion module 4DO - 3KC9000-8TL61 .......................................................................... 213

11.1.4 Technical Specifications 4DO ............................................................................................... 214

11.1.5 Expansion module 2DI 2DO - 3KC9000-8TL62 ................................................................... 215

11.1.6 Technical Specifications 2DI 2DO ........................................................................................ 216

11.1.7 Expansion module 2DO - 3KC9000-8TL63 .......................................................................... 218

11.1.8 Technical Specifications 2DO ............................................................................................... 219

11.1.9 Expansion module 2DI 2DO - 3KC9000-8TL64 ................................................................... 220

11.1.10 Technical Specifications 2DI 2DO ........................................................................................ 221

11.1.11 Expansion module Ethernet - 3KC9000-8TL75 .................................................................... 223

11.1.12 Technical Specifications Ethernet ......................................................................................... 224

11.2 IP protective seal - 3KC9000-8TL68 ..................................................................................... 225

11.3 USB front interface - 3KC9000-8TL73 .................................................................................. 225

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

7

Table of contents

12 Transfer ............................................................................................................................................... 227

12.1 Transfer types ...................................................................................................................... 227

12.1.1 Open transition ..................................................................................................................... 227

12.1.2 IN-PHASE transition ............................................................................................................ 228

12.2 Transfer sequence ............................................................................................................... 229

12.2.1 Transfer sequence for application A: 2S - 0T ...................................................................... 229

12.2.2 Transfer sequence for application B: 2S - 1T - PL............................................................... 230

12.2.3 Transfer sequence for application C: 2S - 1T - SI ............................................................... 231

12.2.4 Transfer sequence for application D: 2S - 1T - AI ............................................................... 232

12.2.5 Transfer sequence for application O: 2S - NPL ................................................................... 234

13 Technical specifications ....................................................................................................................... 237

14 Dimension drawings ............................................................................................................................. 241

A ESD Guidelines ................................................................................................................................... 243

A.1 Electrostatic sensitive devices (ESD) .................................................................................. 243

B List of abbreviations ............................................................................................................................. 245

Index ................................................................................................................................................... 247

3KC ATC6500 transfer control device

8 Manual, 05/2019, L1V30538268002A-01

1

1.1 About this documentation

Purpose of this manual

The information contained in this manual enables you to install, operate and use the

3KC ATC6500 transfer control device.

The manual contains information on:

● Product specifications

● Installation

● Operation

● Configuration

● Commissioning

● Application

Scope of validity of this document

This manual is a reference manual for technical information that users will need for

configuration and operation.

Knowledge required

To understand this manual, you will need to have a general knowledge of low-voltage

controls and power distribution.

Target readers

The information contained in this manual is provided for the benefit of:

● Users

● Electrically skilled persons

● Switchboard manufacturers

● Maintenance personnel

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

9

Introduction

1.2 Product-specific information

1.2 Product-specific information

1.2.1 Certification

Certification

3KC ATC6500 transfer control device

10 Manual, 05/2019, L1V30538268002A-01

Introduction

Title

Article number

Link

(http://www.siemens.com/switching-devices)

09751946)

09756861)

09754954)

09738725)

09758018)

09751947)

09751948)

9751949)

_V1_02.pdf) (EN)

1.2 Product-specific information

1.2.2 Reference documents

Further documents and information

You can find additional information in the following documents:

Siemens switching devices homepage - Siemens switching devices homepage

Operating instructions 3KC ATC6300

transfer control device

Manual 3KC ATC6300 transfer control

device

Manual 3KC3 and 3KC6 transfer

switching equipment

Manual 3KC4 and 3KC8 transfer

switching equipment

Operating instructions 3KC ATC6500

transfer control device

Operating instructions

ATC6 DI/DO expansion modules

Operating instructions

ATC6 Ethernet expansion modules

Operating instructions

ATC6 RS485 expansion modules

3ZW1012-0KC00-1AA0 3KC ATC6300 transfer control device

(

https://support.industry.siemens.com/cs/ww/en/view/1

3ZW1012-0KC00-4AB1 Manual 3KC ATC6300 transfer control device

https://support.industry.siemens.com/cs/ww/en/view/1

(

3ZW1012-3KC34-0AB1 Manual 3KC3 and 3KC6 transfer switching equipment

https://support.industry.siemens.com/cs/ww/en/view/1

(

3ZW1012-3KC83-0AB1 Manual 3KC4 and 3KC8 transfer switching equipment

(

https://support.industry.siemens.com/cs/ww/en/view/1

3ZW1012-0KC00-5AA0 3KC ATC6500 transfer control device

https://support.industry.siemens.com/cs/ww/en/view/1

(

3ZW1012-0KC00-2AA0 ATC6 DI/DO expansion modules

(

https://support.industry.siemens.com/cs/ww/en/view/1

3ZW1012-0KC00-3AA0 ATC6 Ethernet expansion modules

https://support.industry.siemens.com/cs/ww/en/view/1

(

3ZW1012-0KC00-4AA0 ATC6 RS485 expansion modules

(

https://support.industry.siemens.com/cs/de/en/view/10

MODBUS over Serial Line Specification

and Implementation Guide

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

- MODBUS over Serial Line Specification and Implementation Guide

(http://www.modbus.org/docs/Modbus_over_serial_line

11

Introduction

1.2 Product-specific information

1.2.3 Advanced training courses

Find out about training courses on offer on the following link.

Training for Industry (https://www.siemens.com/sitrain-lowvoltage

This is where you can choose from

● Web-based training courses (online, informative, free)

● Classroom training courses (course attendance, comprehensive, subject to fee)

.

You also have the possibility of compiling your own training portfolio via Learning paths.

1.2.4 Technical Support

You can find further support on the Internet at:

Technical Support (http://www.siemens.com/lowvoltage/technical-support

)

)

3KC ATC6500 transfer control device

12 Manual, 05/2019, L1V30538268002A-01

Introduction

1.3 Safety instructions

1.3 Safety instructions

1.3.1 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the Internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit Internet (https://www.siemens.com/industrialsecurity

).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer's exposure

to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed (http://www.siemens.com/industrialsecurity

).

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

13

Introduction

1.3 Safety instructions

1.3.2 Open Source Software

This product, solution or service ("Product") contains third-party software components listed

in this document. These components are Open Source Software licensed under a license

approved by the Open Source Initiative (www.opensource.org (http://www.opensource.org

or similar licenses as determined by SIEMENS ("OSS") and/or commercial or freeware

software components. With respect to the OSS components, the applicable OSS license

conditions prevail over any other terms and conditions covering the Product. The OSS

portions of this Product are provided royalty-free and can be used at no charge.

If SIEMENS has combined or linked certain components of the Product with/to OSS

components licensed under the GNU LGPL version 2 or later as per the definition of the

applicable license, and if use of the corresponding object file is not unrestricted ("LGPL

Licensed Module", whereas the LGPL Licensed Module and the components that the LGPL

Licensed Module is combined with or linked to is the "Combined Product"), the following

additional rights apply, if the relevant LGPL license criteria are met: (i) you are entitled to

modify the Combined Product for your own use, including but not limited to the right to

modify the Combined Product to relink modified versions of the LGPL Licensed Module, and

(ii) you may reverse-engineer the Combined Product, but only to debug your modifications.

The modification right does not include the right to distribute such modifications and you

shall maintain in confidence any information resulting from such reverse-engineering of a

Combined Product.

))

Certain OSS licenses require SIEMENS to make source code available, for example, the

GNU General Public License, the GNU Lesser General Public License and the Mozilla Public

License. If such licenses are applicable and this Product is not shipped with the required

source code, a copy of this source code can be obtained by anyone in receipt of this

information during the period required by the applicable OSS licenses by contacting the

following address:

Siemens AG

Smart Infrastructure

Low Voltage Products

Technical Support

Postfach 10 09 53

93009 Regensburg

Germany

www.siemens.com/lowvoltage/support-request

(https://support.industry.siemens.com/cs/us/en/ps

Keyword: Open Source Request (please specify Product name and version, if applicable)

SIEMENS may charge a handling fee to fulfil the request.

Warranty regarding further use of the Open Source Software

SIEMENS' warranty obligations are set forth in your agreement with SIEMENS. SIEMENS

does not provide any warranty or technical support for this Product or any OSS components

contained in it if they are modified or used in any manner not specified by SIEMENS. The

license conditions listed below may contain disclaimers that apply between you and the

respective licensor. For the avoidance of doubt, SIEMENS does not make any warranty

commitment on behalf of or binding upon any third-party licensor.

)

3KC ATC6500 transfer control device

14 Manual, 05/2019, L1V30538268002A-01

2

2.1 Features of the ATC6500 transfer control device

The 3KC ATC6500 transfer control device, in combination with Siemens motor-driven circuit

breakers (ACB, MCCB), enables a transfer between a main and an alternative power source.

The stability of the power supply is analyzed by means of voltage taps upstream of the

switching devices. User limit thresholds (voltage, frequency, phase sequence) function as

boundary conditions for analyzing the quality of the power supply.

If a threshold is undershot or exceeded for a specific defined time, the ATC6500 transfer

control device initiates a transfer to an alternative power source.

Apart from its use with two switching devices, the ATC6500 can control one additional motordriven circuit breaker. This enables a large number of applications with critical loads to be

implemented (for more detailed information, see chapter Load management with the

ATC6500 (Page 20)). It is also possible to implement an IN-PHASE Transition with the

ATC6500. In this application, the differences in frequency, voltage and phase angle of the

two sources are measured. The ATC waits for these parameters to be within a defined range

and then initiates a transfer when synchronism is present. The transfer takes place with open

transition, i.e. parallel network operation is not present. This creates a more stable load

transfer.

Features

The interaction of the ATC6500 with the switching devices has been exhaustively tested, but

does not absolve plant operators from their own responsibility.

The key features of the ATC6500 transfer control device are:

● Backlit LCD (128 x 80 pixels) for displaying measurements, events and alarms in eight

languages (German, English, French, Spanish, Italian, Portuguese, Polish, Russian)

● Integrated RS485 interface, expandable with a maximum of three additional expansion

modules with digital inputs and outputs, and by means of communication interfaces

(Ethernet)

● 3KC9000-8TL73 USB front interface for setting parameters on the front panel. The

parameterization by means of software therefore does not require the control cabinet to

be opened.

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

15

General information

2.1 Features of the ATC6500 transfer control device

Metering functions

The ATC6500 permits voltage measurement between L-L, between L-N, and between L-L

and L-N simultaneously. The following measurements can be made:

● Phase sequence and phase failure

● Minimum and maximum voltage

● Voltage unbalance

● Minimum and maximum frequency

● Phase displacement angle cos phi

● Voltage and frequency deviation of the two sources

● Deviation of the phase displacement angle cos phi of the two sources

Area of application

The ATC6500 transfer control device can be used in conjunction with Siemens switching

devices in areas in which a continuous power supply needs to be ensured.

The device is used in the following areas:

● Service sector

– Data centers (data and server rooms)

● Shopping malls

● Infrastructure

– Highways (e.g. tunnels)

– Hotels

● Industry

– Production lines in continuous operation

– Engine rooms

– Pumps

3KC ATC6500 transfer control device

16 Manual, 05/2019, L1V30538268002A-01

General information

Note

Transfer between circuit breakers

A motor operato

Precise connection diagrams can be obtained from chapter

further in

(P

2.2 Compatible Siemens SENTRON switching devices

2.2 Compatible Siemens SENTRON switching devices

The ATC6500 permits the transfer between two supply sources using the following Siemens

products.

r must be implemented to switch between circuit breakers.

Connection (Page 83). For

formation about testing, please refer to chapter Accessories for switching devices

age 101).

Compatible Siemens products

● Air circuit breakers (ACB)

● Molded case circuit breakers (MCCB)

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

17

General information

2.2 Compatible Siemens SENTRON switching devices

3KC ATC6500 transfer control device

18 Manual, 05/2019, L1V30538268002A-01

3

The following chapter contains information on:

● Transfer control

● Controlling the switching devices

● Voltage measurement

3.1 Transfer control

Fundamental information on the topic of transfer control is provided below.

Transfer with switch disconnectors / transfer switching equipment with motor operator

Switching devices with motor operator are required for this application. These can make

short-circuit currents and conduct them to a limited extent (1 sec. current), but cannot break

them.

Transfer with circuit breakers with motor operator

The transfer in this case is performed by means of motor-driven circuit breakers. These can

make and conduct short-circuit currents, and also break them in the event of an overload.

The ATC6500 functions as transfer switching equipment in connection with two Siemens

3VA molded case circuit breakers with motor operators, and in connection with two 3WL or

3WT air circuit breakers.

3.1.1 Network/network application

In the network/network application the load is normally connected to the main supply source

and is switched to the secondary supply source if an anomaly occurs in the main supply or if

an external signal is issued. By means of various setting options (interlock time, etc.) the

transfer behavior can be defined on a customer-specific basis.

You can find more information on this in the chapter Parameterization (Page 155).

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

19

Applications

3.1 Transfer control

3.1.2 Network/generator application

For the network/generator application the load is normally connected to the main source

(Source 1). Following a deviation in the voltage or frequency, and after the defined delay

time, a start signal is sent to the generator (Source 2). If the generator supplies the desired

voltage, the load is transferred to the secondary source (generator) until the main source

supplies the desired supply quality.

The load is then transferred back to the main source and the generator is kept in operation

without load to allow it to cool (duration can be set by user). The ATC6500 sends a start /

stop command to the generator through a relay output and can receive digital signals from

the generator indicating its status (generator ready, OK to accept load, etc.) through

programmable inputs.

An automatic generator test can be programmed, i.e. the generator can be started at set

times to check its correct operation, even if the network is within the thresholds.

This is done by setting the execution interval, starting time, days of the week on which the

test is to be carried out, duration, etc. More information on the various setting options can be

found in chapter Parameterization (Page 155).

3.1.3 Generator/generator application

In this case two generators are controlled, each with a start-stop relay and feedback signals,

if available. In this application a rotation between generators can be programmed, i.e. the

load can be switched from one to the other at regular intervals, with the purpose of sharing

out the generator work equally.

It is also possible to set the time of day when rotation is to occur, so that the load supply is

cut off at a specified time. In case of a problem in either generator, the load is always

transferred to the one in standby mode.

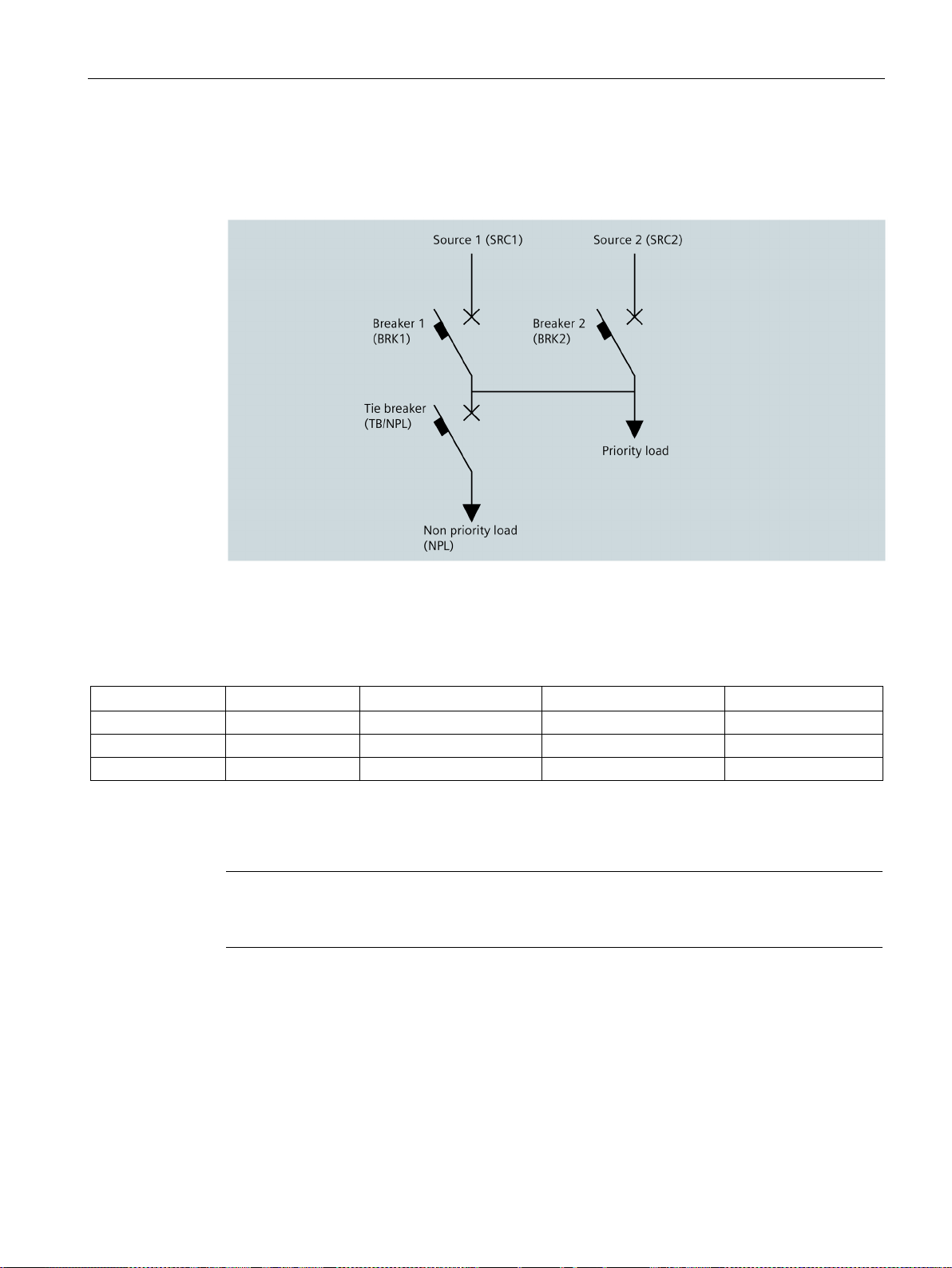

3.1.4 Load management with the ATC6500

Apart from applications with two switching devices, the ATC6500 can additionally control one

tie breaker. The ATC6500 has five predefined application settings.

The application must be selected in accordance with with the requirement in menu P02

under the parameter P02.01 (see chapter P02 – General (Page 162)).

The following applications can be implemented:

3KC ATC6500 transfer control device

20 Manual, 05/2019, L1V30538268002A-01

Applications

Source 1 (SRC1)

Source 2 (SRC2)

Breaker 1 (BRK 1)

Breaker 2 (BRK 2)

0 0 Open

Open

0 1 Open

Closed

1 1 Closed

Open

0 = Infeed source not available

1 = Infeed source available

Note

In this case Source 1 is regarded

modifying the source priority.

3.1 Transfer control

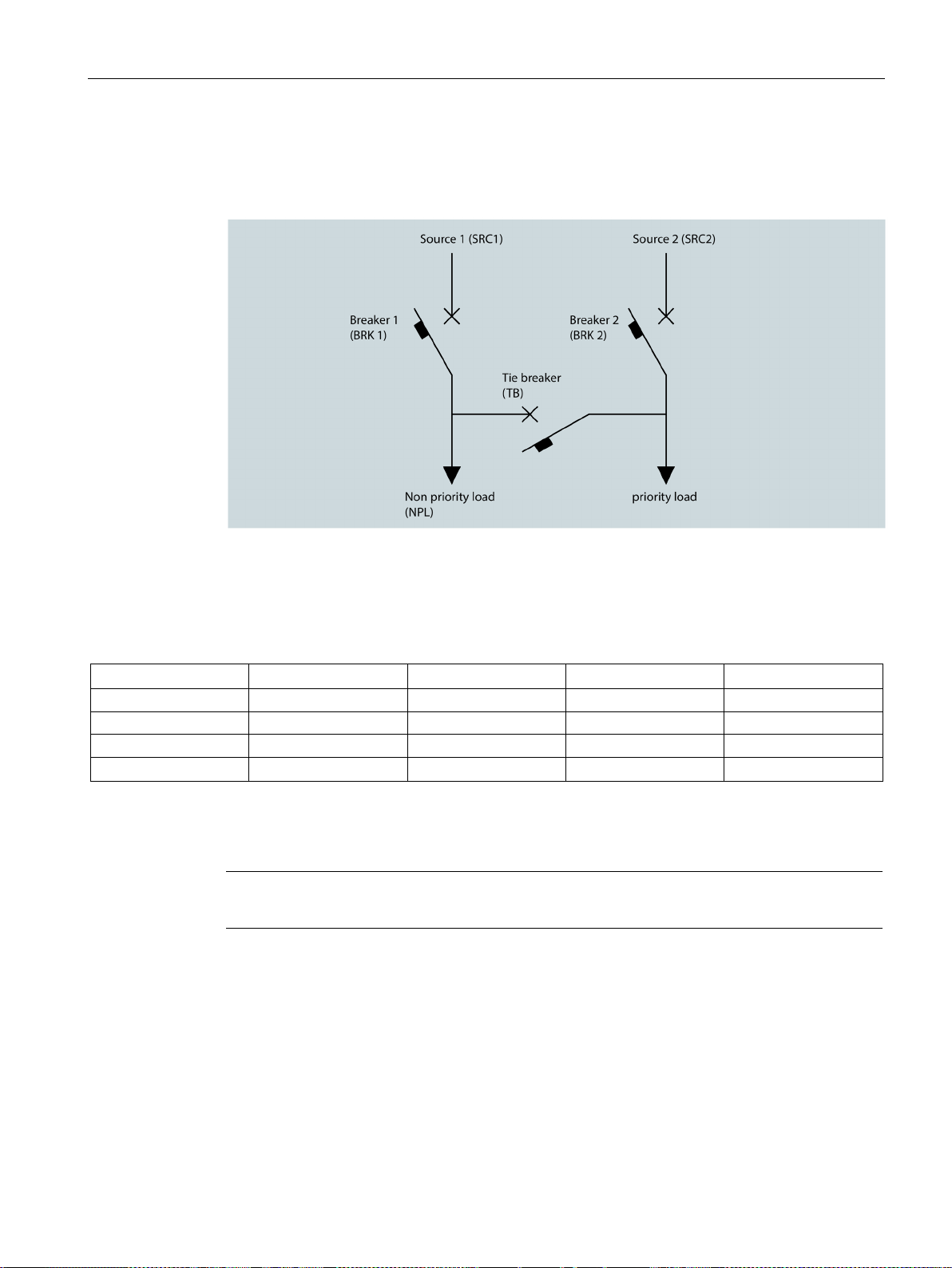

3.1.4.1 Application A: 2S – 0T

SRC1 (kVA) = SRC2 (kVA)

In this application two motor-driven circuit breakers with one outgoing load are used.

See also

The ATC6500 switches to one of the two sources, depending on the setting.

The states can be obtained from the table:

as the main source. The transfer can be influenced by

Parameterization (Page 155)

Transfer (Page 227)

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

21

Applications

Source 1 (SRC1)

Source 2 (SRC2)

Breaker 1 (BRK 1)

Breaker 2 (BRK 2)

Tie breaker (TB)

0 0 Open

Open

Open

0 1 Open

Closed

Open

1 1 Closed

Open

Closed

0 = Infeed source not available

1 = Infeed source available

Note

In this case Source 1 is regarded as the main source. The transfer can be influenced by

modifying the source priori

3.1 Transfer control

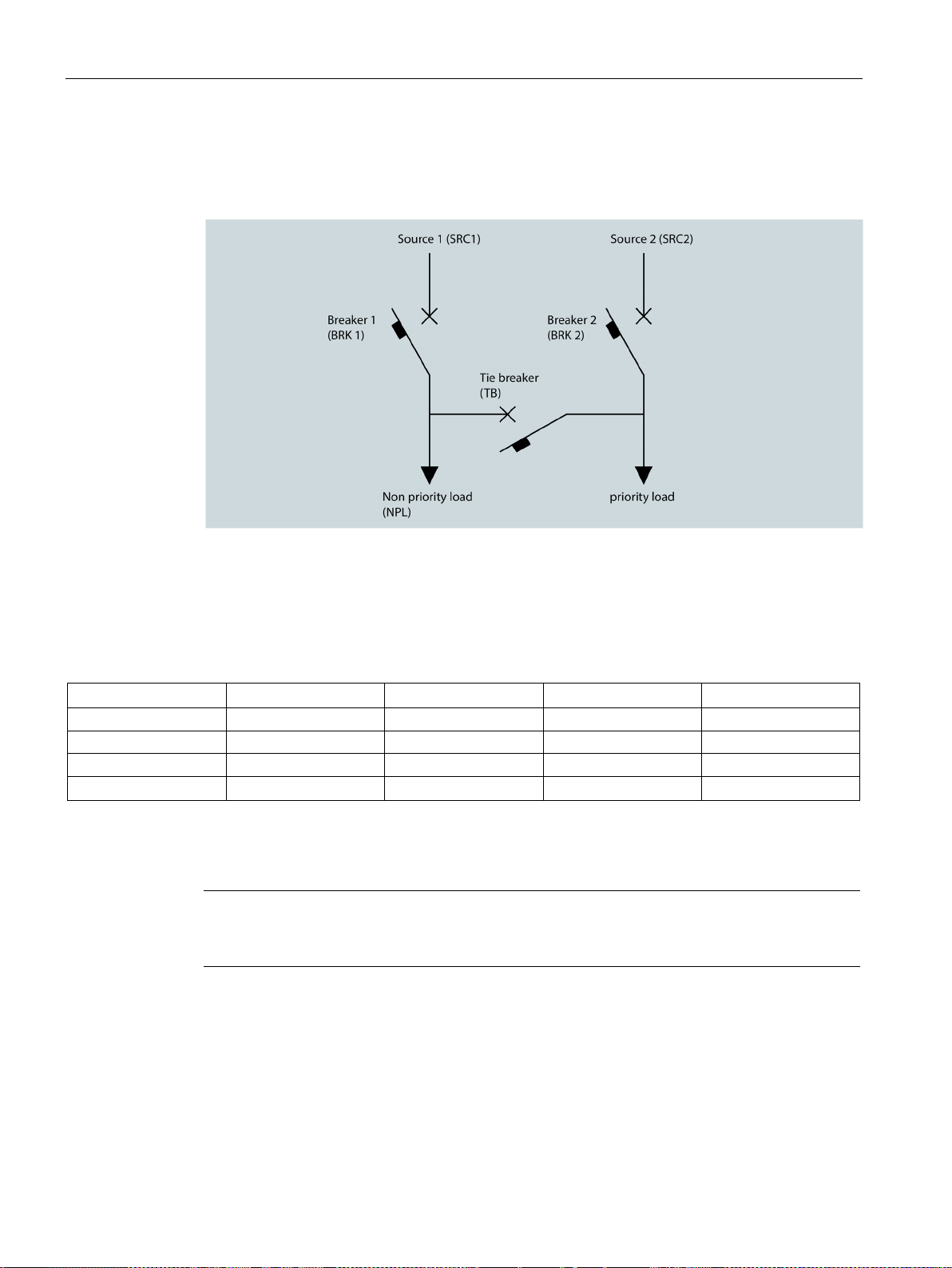

3.1.4.2 Application B: 2S - 1T - PL

SRC1 (kVA) > SRC2 (kVA)

In this application three motor-driven circuit breakers are used. A distinction is made

between prioritized load and non-prioritized load (NPL).

See also

On failure of the prioritized sources (in this case, Source 1), only the prioritized load is

supplied by the secondary source (in this case, Source 2). In normal circumstances (Source

1 available) both sources are supplied by the main network.

The states can be obtained from the table:

ty.

Parameterization (Page 155)

Transfer (Page 227)

3KC ATC6500 transfer control device

22 Manual, 05/2019, L1V30538268002A-01

Applications

Source 1 (SRC1)

Source 2 (SRC2)

Breaker 1 (BRK 1)

Breaker 2 (BRK 2)

Tie breaker (TB)

0 0 Open

Open

Open

0 1 Open

Closed

Closed

1 0 Closed

Open

Closed

Closed

Closed

0 = Infeed source not available

1 = Infeed source available

Note

In this case the priority of the sources is unimport

3.1 Transfer control

3.1.4.3 Application C: 2S – 1T – SI

SRC1 (kVA) = SRC2 (kVA)

In this application three motor-driven circuit breakers are used. A distinction is made

between prioritized load and non-prioritized load (NPL). In this case, both loads are supplied

by one source each in normal circumstances (both sources available). If one source fails, the

prioritized and non-prioritized loads are supplied by the source that remains available.

The states can be obtained from the table:

1 1

See also

Parameterization (Page 155)

Transfer (Page 227)

Open

ant.

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

23

Applications

Source 1 (SRC1)

Source 2 (SRC2)

Breaker 1 (BRK 1)

Breaker 2 (BRK 2)

Tie breaker (TB)

0 0 Open

Open

Open

0 1 Open

Closed

Open

1 0 Closed

Open

Closed

Closed

Closed

0 = Infeed source not available

1 = Infeed source available

Note

In this case Source 1 is regarded as t

modifying the source priority.

3.1 Transfer control

3.1.4.4 Application D: 2S - 1T - AI

SRC1 (kVA) > SRC2 (kVA)

In this application three motor-driven circuit breakers are used. A distinction is made

between prioritized load and non-prioritized load (NPL).

In this application, both loads are supplied by one source each in normal circumstances

(both sources available). If Source 2 fails, both the prioritized load and the non-prioritized

load are supplied by Source 1. Source 2, on the other hand, only supplies the prioritized

load.

1 1

See also

Open

he main source. The transfer can be influenced by

Parameterization (Page 155)

Transfer (Page 227)

3KC ATC6500 transfer control device

24 Manual, 05/2019, L1V30538268002A-01

Applications

Source 1 (SRC1)

Source 2 (SRC2)

Breaker 1 (BRK 1)

Breaker 2 (BRK 2)

Tie breaker (TB/NPL)

0 0 Open

Open

Open

0 1 Open

Closed

Open

1 1 Closed

Open

Closed

0 = Infeed source not available

1 = Infeed source available

Note

In th

modifying the source priority.

3.1 Transfer control

3.1.4.5 Application O: 2S - NPL

SRC1 (kVA) > SRC2 (kVA)

See also

In this application three motor-driven circuit breakers are used. A distinction is made

between prioritized load and non-prioritized load (NPL). In this application, on failure of the

prioritized sources (in this case, Source 1), only the prioritized load is supplied by the

secondary source (in this case, Source 2). In normal circumstances (Source 1 available)

both sources are supplied by the main network.

is case Source 1 is regarded as the main source. The transfer can be influenced by

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

Parameterization (Page 155)

Transfer (Page 227)

25

Applications

3.2 Controlling the switching devices

3.2 Controlling the switching devices

The ATC6500 can control various devices for automatic transfer switching. How the control

of the switching devices can be implemented is shown below.

● Depending on the type of transfer device used, the appropriate circuit diagram shall be

used (see chapter Connection (Page 83)), as well as the programmable inputs/outputs on

the ATC6500 (see chapter Inputs and outputs of the ATC6500 (Page 144)).

● Programmable outputs are set by default for the use of circuit breakers (see chapter P13

- Digital outputs (Page 180))

● The application is to be selected in accordance with the requirement (see chapter Load

management with the ATC6500 (Page 20) and chapter Parameterization (Page 155))

● The device status inputs (e.g. status of circuit breakers) shall be wired according to the

circuit diagram, so as to ensure reliable system operation.

● Nonetheless, it is possible to manage without wiring the status inputs. This enables the

programmable inputs to be used for other functions. In this case the device behaves as if

the status feedback messages were received immediately.

● If the device status inputs are not used, then after power-on the ATC6500 sends an

"open" command, in order to put the switching devices in a defined status.

● If the device status inputs are used, then after power-on the ATC6500 does not send any

commands to the breaker. The corresponding switching devices are not controlled until

anomalies occur in the network.

● Internal control relays are neither electrically nor mechanically interlocked.

3KC ATC6500 transfer control device

26 Manual, 05/2019, L1V30538268002A-01

Applications

3.2 Controlling the switching devices

3.2.1 Controlling motor-driven circuit breakers

The control of motor-driven circuit breakers requires four outputs (open and close commands

for Source 1 and Source 2) and two inputs for circuit breaker status feedback for the

application with two circuit breakers. If a further circuit breaker is used (see chapter Load

management (Page 20)) an additional 2 outputs (the commands Open / Close for the tie

breaker) and one input for the status of the tie breaker must be wired. For the control of the

tie breaker additional outputs can be attached by means of expansion modules.

Additional optional inputs may be required for alarm signals and TRIP.

● Open and close commands can be output as a continuous signal or a pulse. For the

continuous signal, the pulse is applied continuously until the circuit breaker has reached

the required position.

● The signal type (continuous signal or pulse) for the two circuit breakers can be selected

by setting the appropriate parameter under P08.01 in menu P08 to "Brk. Pul." or "Brk.

Con.". The control of the tie breaker is defined by parameter P02.22 in menu P02. For

this too, the signal setting can be adapted accordingly.

● The status for TRIP is ignored for a 15-second window every time an open command is

sent to the circuit breakers. This prevents a false alarm from being triggered if the circuit

breakers temporarily signal the TRIP status through their alarm switches while opening.

This has no effect on the function of the circuit breaker.

● If feedback inputs (circuit breaker status) are used and the circuit breaker does not close,

a second attempt is made before triggering an alarm.

See also

Connection (Page 83)

Parameters (Page 160)

3.2.2 Controlling remotely operated transfer switching equipment

The control of remotely operated transfer switching equipment (single motor operator) is

similar to the control of motor-driven circuit breakers, however it requires only three outputs

(close Source 1, open both sources, close Source 2) and two inputs for the status of the

transfer switching equipment.

● The command mode (continuous signal or pulse) can be selected by setting the

appropriate parameter under P08.01 in menu P08 to "Chg. Pul." or "Chg. Con.".

See also

Connection (Page 83)

Parameters (Page 160)

3KC ATC6500 transfer control device

Manual, 05/2019, L1V30538268002A-01

27

Applications

Note

Procedure for voltage measurement

The fundamentals of the procedure for adjusting the voltage measur

below. The exact parameters can be found in chapter

3.3 Voltage measurement

3.2.3 Controlling contactors

If contactors are used, two outputs (Close 1 and Close 2) and two status inputs are required.

If an additional contactor is used as a tie breaker, an additional output (close tie breaker) and

a status input are required.

● In this case the appropriate parameter under P08.01 in menu P08 must be set to

"Contactors" in the command mode. In addition, the parameter P02.22 in menu P02 must

be set to "Contactors".

See also

Connection (Page 83)

Parameters (Page 160)

3.3 Voltage measurement

This section illustrates how a voltage measurement is achieved for the ATC6500.

ement are explained

Parameters (Page 160).

All parameters and settings can be adjusted by the user in the menus P02 General

(Page 162), P06 Source Lines (Page 168

), P08 Switch (Page 171)and P09 Source Line

CHK (Page 174).

3KC ATC6500 transfer control device

28 Manual, 05/2019, L1V30538268002A-01

Loading...

Loading...