Siemens SENTRON 3VL System Manual

Switching/protection devices

3VL molded-case circuit breakers

System Manual

•

03/2009

SENTRON

Answers for industry.

SENTRON

Switching/protection devices

3VL molded-case circuit breakers

System Manual

03/2009

110 0110 - 02 DS 01

About this document

Product-specific information

Product description

System overview

Functions

Application planning

Installing/mounting

Connecting

Displays and operator

controls

Parameter

assignment/addressing

Service and maintenance

Technical data

Dimensional drawings

Circuit diagrams

Spare parts/accessories

ESD guidelines

Appendix

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

A

B

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ordernumber: 3ZX1012-0VL10-0AC1

Ⓟ 03/2009

Copyright © Siemens AG 2009.

Technical data subject to change

Table of contents

1 About this document...........................................................................................................

1.1 Introduction ..................................................................................................................................11

2 Product-specific informatio

2.1 Important notes ...............................................................................................................

3 Product description...........................................................................................................

3.1 SENTRON VL overvi

3.2 Application overview ....................................................................................................................18

3.3 Configuration................................................................................................................................19

3.3.1 Functional principle ......................................................................................................................19

3.3.2 Subdivision according to power ranges

3.3.3 Thermomagnetic overcurrent trip units ........................................................................................20

3.3.4 Electronic

3.4 Mechanical operating mechanisms .............................................................................................23

3.4.1 Toggle handl

3.4.2 Rotary mechanism on front (optional)..........................................................................................24

3.4.3 Door-coupling rotary operating mechanism (optional).................................................................25

3.5 Motoriz

3.5.1 Stored-energy motori

3.5.2 Motorized operating mechanism without stored-energy mechanism ..........................................27

4 System overview...................................................................................................................................... 29

overcurrent trip unit (ETU) ........................................................................................

ed operating mechanisms (optional)................................................................................26

n..................................................................................................

ew...............................................................................................................15

.......................................................................................19

e operating mechanism

zed operating mechanism

...........................................................................................23

..........................................................................27

..................... 11

................... 13

.............13

....................... 15

..21

4.1 Possible applications ...................................................................................................................29

4.2 Key data.......................................................................................................................................30

4.2.1 General data - 3VL molded-case circuit breakers .......................................................................30

itches................................................................................34

4.2.2 General data - auxiliary and alarm

4.2.3 General data - Trip units ..............................................................................................................36

4.2.4 General data

5 Funct

6 Application planning

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

ions................................................................................................................................................. 41

5.1 Current protection ........................................................................................................................41

5.1.1 Overcurrent trip unit

5.1.2 Func

5.1.3 Setting options .............................................................................................................................46

5.1.4 Dimensioning short-circuit protection according to frame size ....................................................47

5.1.5 General technical specifications ..................................................................................................48

5.1.6 Differential current protection with RCD module..........................................................................51

5.1.7 Single-pole operation with

5.1.8 Ground-fault protection .......................................................................................................

5.2 Voltage protection ........................................................................................................................60

5.2.1 Underv

5.2.2 Shunt release...............................................................................................................................62

5.2.3 Auxiliary switches and alarm swit

tion overview ........................................................................................................................44

- motorized operating mechanisms........................................................................38

.....................................................................................................................41

RCD module

oltage release...................................................................................................................60

................................................................................................................................. 65

sw

......................................................................................56

ches.........................................................................................63

.........58

5

Table of contents

6.1 Use with frequency converters.................................................................................................... 65

6.2 Use of capacitor banks................................................................................................................ 67

6.3 Primary-side transformer protec

6.4 Use in DC sys

tems...................................................................................................................... 69

tion............................................................................................ 68

6.5 Use in IT networks ...................................................................................................................... 71

6.6 Use in the motor protec

6.7 Use in harsh environments:

tion area..............................................................................................

........................................................................................................ 78

6.8 Use in series connection ............................................................................................................. 81

7 Installing/mounting

...........................................................................................................

........................ 83

7.1 Installation methods .................................................................................................................... 83

7.2 Mounting and safety cl

earances

................................................................................................. 87

7.3 Locking devices........................................................................................................................... 91

8 Connecting

....................................................................................................................

.......................... 97

8.1 Cables and busbars .................................................................................................................... 97

8.2 Main connection types for fixed mounting................................................................................. 107

8.3 Main connection methods for plug-in and withdrawable version.............................................. 114

8.4 Terminal assignment

s..........................................................................................................

8.5 Auxiliary switch designations .................................................................................................... 118

8.6 Des

cription of the terminals....................................................................................................... 118

... 74

..... 116

9 Displa

ys and operator controls

.............................................................................................................. 121

9.1 Overcurrent trip unit without LCD display ................................................................................. 121

9.2 Overcurrent trip unit with LCD display ...................................................................................... 125

9.3 Stored-energy motori

10 Parameter assignment/add

zed operating mechanism

ressing ........................................................................................................ 135

....................................................................... 133

10.1 Setting the parameters.............................................................................................................. 135

Setting the protection parameters for motor protection (ETU10M, ETU30M and LCD-ETU

10.2

40M) ..........................................................................................................................

11 Service and maintenan

ce .......................................................................................................

................ 139

11.1 Preventive measures ................................................................................................................ 141

11.2 Troubleshooting ........................................................................................................................ 143

12 Technical

12.1

12.2 Configuration of main connections

data ....................................................................................................................................... 145

Technical overview

.................................................................................................................... 145

............................................................................................ 150

12.3 Switching capacity overview ..................................................................................................... 153

12.4 Switching capacity overview ..................................................................................................... 157

......................................................................................................................... 159

12.5 Derating fac

tors

12.6 Power loss................................................................................................................................. 167

............... 141

3VL molded-case circuit breakers

6 System Manual, 03/2009, 110 0110 - 02 DS 01

Table of contents

12.7 Mechanical operating mechanisms ...........................................................................................170

12.8 Motorized operating mechanisms ..............................................................................................171

12.9 Capacitor banks .........................................................................................................................173

12.10 Motor Protection.........................................................................................................................174

12.11 RCD modules.............................................................................................................................177

12.12 Undervoltage release.................................................................................................................178

12.13 Undervoltage release connection data ......................................................................................180

12.14 Shunt release .............................................................................................................................182

12.15 Shunt release connec

tion data

..................................................................................................184

12.16 Auxiliary switches and alarm switches.......................................................................................185

Position signaling switch ............................................................................................................187

12.17

12.18 Ground fault protection classes .................................................................................................188

12.19 IP degrees of protection

13 Dimen

sional drawi

ngs............................................................................................................................ 191

.............................................................................................................189

13.1 VL160X (3VL1), VL160 (3VL2), and VL250 (3VL3), 3- and 4-pole, to 250 A............................191

13.1.1 Circ

uit breakers..........................................................................................................................191

13.1.2 Operating mechanisms ..............................................................................................................193

13.1.3 Connections and phase barriers

13.1.4 Terminal c

overs .........................................................................................................................197

13.1.5 Locking device for the toggle handl

13.1.6

Rear locking module ..................................................................................................................198

Accessories................................................................................................................................200

13.1.7

................................................................................................195

e .........................................................................................198

13.1.8 Door cutouts...............................................................................................................................202

13.1.9 Plug-in socket and accessories

13.1.10 VL160X (3V

13.1.10.1 Plug-in

13.1.11 VL160 (3VL)

13.1.11.1

Withdrawable version and accessories .....................................................................................208

L1), 3- and 4-pole, up to 160 A...............................................................................206

socket and accessories .................................................................................................206

and VL250 (3VL3), 3- and 4-pole, up to 250 A.....................................................208

13.2 VL400 (3VL4), 3- and 4-pole, up to 400 A

13.2.1 Circ

uit breaker............................................................................................................................211

.................................................................................................204

.................................................................................211

13.2.2 Operating mechanisms ..............................................................................................................212

13.2.3 Connections and phase barriers

13.2.4 Terminal c

13.2.5 Rear interlocking module

13.2.6

Locking devices, locking device for toggle handle and

overs .........................................................................................................................215

...........................................................................................................216

................................................................................................213

accessories..........................................216

13.2.7 Door cutouts...............................................................................................................................219

13.2.8 Plug-in socket and accessories

.................................................................................................221

13.3 VL630 (3VL5), 3- and 4-pole, up to 630 A .................................................................................227

13.3.1 Circ

uit breaker............................................................................................................................227

13.3.2 Operating mechanisms ..............................................................................................................228

13.3.3 Connections and phase barriers

13.3.4 Terminal c

13.3.5 Rear interlocking module

13.3.6

Locking and locking device for toggle handle............................................................................232

13.3.7 Ac

cessories................................................................................................................................233

overs .........................................................................................................................230

...........................................................................................................231

................................................................................................229

13.3.8 Door cutouts...............................................................................................................................235

13.3.9 Plug-in socket and accessories

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

.................................................................................................237

7

Table of contents

13.3.10 Withdrawable version and accessories..................................................................................... 239

13.4 VL800 (3VL6), 3- and 4-pole, up to 800 A ................................................................................ 242

13.4.1 Circ

uit breaker........................................................................................................................... 242

13.4.2 Operating mechanisms ............................................................................................................. 243

13.4.3 Withdrawable version................................................................................................................ 244

13.4.4 Connections and phase barriers

13.4.5 Terminal c

overs......................................................................................................................... 249

13.4.6 Locking and locking device for toggle handle

............................................................................................... 248

........................................................................... 250

13.4.7 Rear interlocking module .......................................................................................................... 251

13.4.8

Accessories............................................................................................................................... 252

13.4.9 Door cutouts.............................................................................................................................. 254

13.5 VL1250 (3VL7) and VL 1600 (3VL8), 3-

and 4-pole, up to 1600 A

........................................... 256

13.5.1 Circuit breaker........................................................................................................................... 256

13.5.2 Operating mechanisms ............................................................................................................. 258

13.5.3 Withdrawable version................................................................................................................ 260

13.5.4 Connections and phase barriers

13.5.5 Terminal c

13.5.6 Rear interlocking module

13.5.7

Locking and locking device for toggle handle ........................................................................... 269

13.5.8 Ac

cessories............................................................................................................................... 269

overs......................................................................................................................... 265

.......................................................................................................... 268

............................................................................................... 264

13.5.9 Door cutouts.............................................................................................................................. 271

13.5.10 Current transformer................................................................................................................... 272

13.6 VL160X (3VL1) up to VL800 (3VL6), 3- and 4-pole, up to 800 A ............................................. 273

wi

......................................................................................................... 273

13.6.1 Locking with bowden

re

13.6.2 Busbar adapter system 8US1 ................................................................................................... 275

13.7 VL160X (3VL1) with RCD block, 3- and 4-pol

13.7.1

Circuit breakers ......................................................................................................................... 276

13.7.2 Connections and phase barriers

13.7.3 Terminal c

overs......................................................................................................................... 279

............................................................................................... 277

e, up to 160 A.................................................... 276

13.7.4 Door cutouts.............................................................................................................................. 281

13.7.5 Plug-in socket and accessories

13.8 VL160 (3VL2

) and VL250 (3VL3) with RCD module, 3- and 4

................................................................................................ 283

-pole, to 250 A.......................... 285

13.8.1 Circuit breakers ......................................................................................................................... 285

13.8.2 Connections and phase barriers

13.8.3 Terminal c

overs......................................................................................................................... 288

............................................................................................... 286

13.8.4 Door cutouts.............................................................................................................................. 290

13.8.5 Plug-in socket and accessories

................................................................................................ 292

13.9 VL400 (3VL4) with RCD m

odule, 3- and 4-pole, up to 400 A

................................................... 298

13.9.1 Circuit breakers ......................................................................................................................... 298

13.9.2 Connections and phase barriers

13.9.3 Terminal c

overs......................................................................................................................... 302

............................................................................................... 300

13.9.4 Door cutouts.............................................................................................................................. 304

13.9.5 Plug-in socket and accessories

13.10 Door-c

oupling rotary operating mechanisms 8UC

13.11 4NC current transformers for measuring purposes

13.12 COM20/COM21 (communications

13.13 COM10/COM 11 (communications module for SENTRON 3VL)

14 Circuit diagrams

3VL molded-case circuit breakers

..................................................................................................................................... 317

................................................................................................ 306

.................................................................... 312

.................................................................. 315

module for SENTRON 3VL)............................................... 316

.............................................. 316

8 System Manual, 03/2009, 110 0110 - 02 DS 01

Table of contents

15 Spare parts/accessories ........................................................................................................................ 329

15.1 Installation ..................................................................................................................................329

15.2 Electromechanical components .................................................................................................333

15.3 Mechanical components ............................................................................................................335

15.4 Electrical/electronic engineering ................................................................................................337

A ESD guidelin

es ................................................................................................................

...................... 339

A.1 ESD Directive.............................................................................................................................339

B Appendix................................................................................................................................................ 341

B.1 Selectivity...................................................................................................................................341

B.2 Conversion tables ......................................................................................................................344

B.3 Standards and specifications

B.4 Ordering data

Glossary ................................................................................................................................................ 351

.............................................................................................................................348

.....................................................................................................346

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

9

Table of contents

3VL molded-case circuit breakers

10 System Manual, 03/2009, 110 0110 - 02 DS 01

About this document

1.1 Introduction

Purpose of this manual

This manual is intended for reference purposes. The information in this manual enables you

to configure and operate the SENTRON VL system.

Audience

This manual is aimed at people with the required qualifications to commission and operate

the SENTRON VL system.

1

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

11

About this document

1.1 Introduction

3VL molded-case circuit breakers

12 System Manual, 03/2009, 110 0110 - 02 DS 01

Product-specific information

2.1 Important notes

Validity

This manual applies to SENTRON circuit breakers with the following designations:

● VL160X

● VL160

● VL250

● VL400

● VL630

● VL800

● VL1250

● VL1600

2

Standards and certifications

The SENTRON VL circuit breakers comply with the standards:

● IEC 60947-2 / DIN EN 60947-2 (VDE 0660-101)

● IEC 60947-1 / DIN EN 60947-1 (VDE 0660-100)

● Isolating features in accordance with IEC 60947-3 / EN 60947-3 (VDE 0660-107)

● Network disconnection features for stopping and shutting down in an emergency (main

switch and EMERGENCY-OFF switch) in accordance with IEC 60204-1 / DIN EN 602041 (VDE 0113-1)

Disclaimer of liability

The products described here were developed to perform safety-oriented functions as part of

an overall installation or machine. A complete safety-oriented system generally features

sensors, evaluation units, signaling units, and reliable shutdown concepts. It is the

responsibility of the manufacturer to ensure that a system or machine is functioning properly

as a whole. Siemens AG, its regional offices, and associated companies (hereinafter referred

to as "Siemens") cannot guarantee all the properties of a whole plant or machine that has

not been designed by Siemens.

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

13

Product-specific information

2.1 Important notes

Nor can Siemens assume liability for recommendations that appear or are implied in the

following description. No new guarantee, warranty, or liability claims beyond the scope of the

Siemens general terms of supply are to be derived or inferred from the following description.

Up-to-the-minute information

You can obtain further assistance by calling the following numbers:

Technical Assistance: Telephone: +49 (0) 911-895-5900 (8°° - 17°° CET)

Fax: +49 (0) 911-895-5907

or on the Internet at:

e-mail: technical-assistance@siemens.com

Internet: www.siemens.de/lowvoltage/technical-assistance

Technical Support:

Telephone: +49 (0) 180 50 50 222

Correction sheet

A correction sheet is included at the end of the manual. Please use it to record your

suggestions for improvements, additions and corrections, and return the sheet to us. This will

help us to improve the next edition of the manual.

3VL molded-case circuit breakers

14 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.1 SENTRON VL overview

SENTRON VL circuit breakers are resistant to extreme climates. They are designed for use

in closed rooms where no onerous operating conditions prevail (e.g. dust, caustic vapors,

hazardous gases).

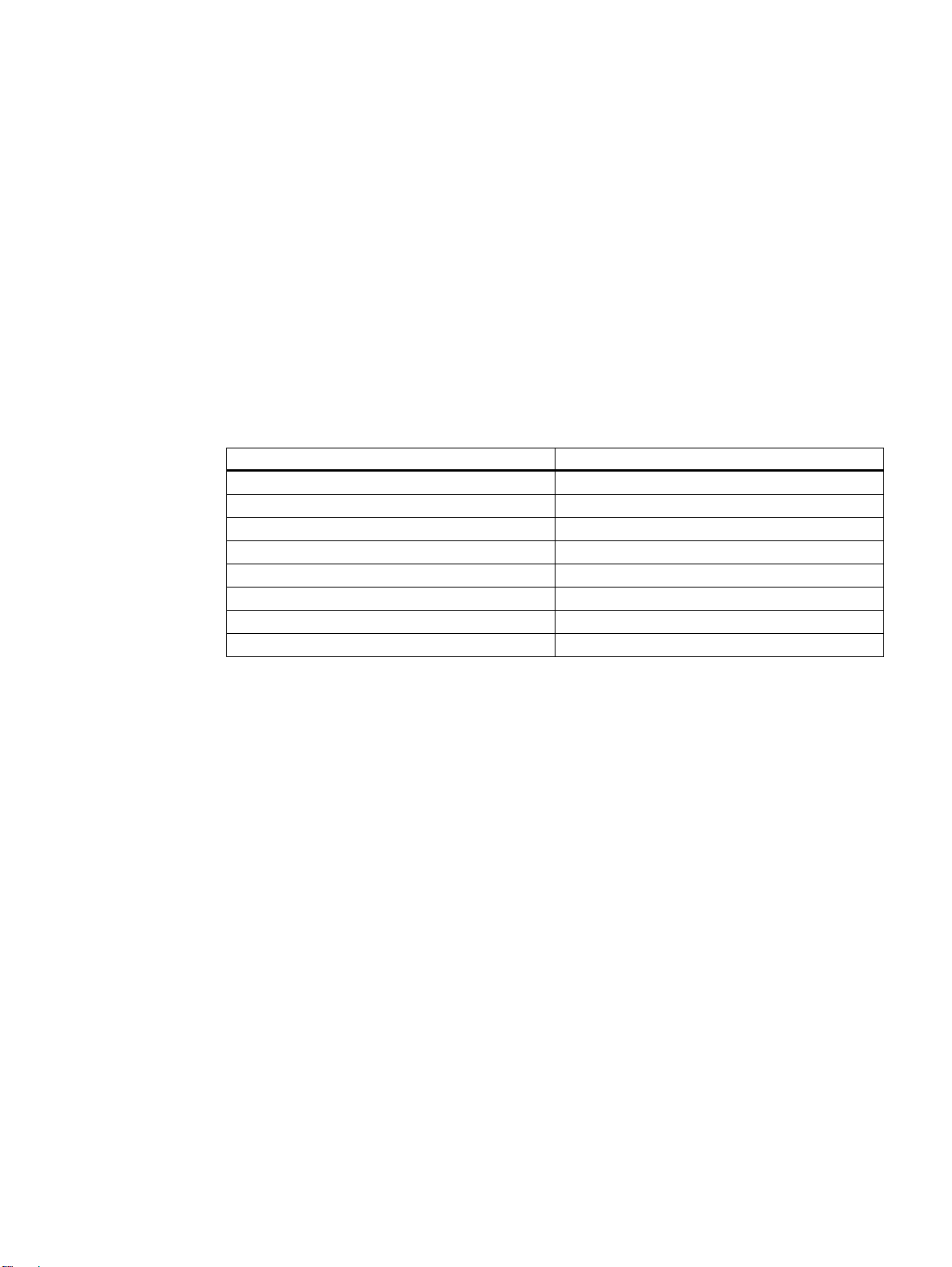

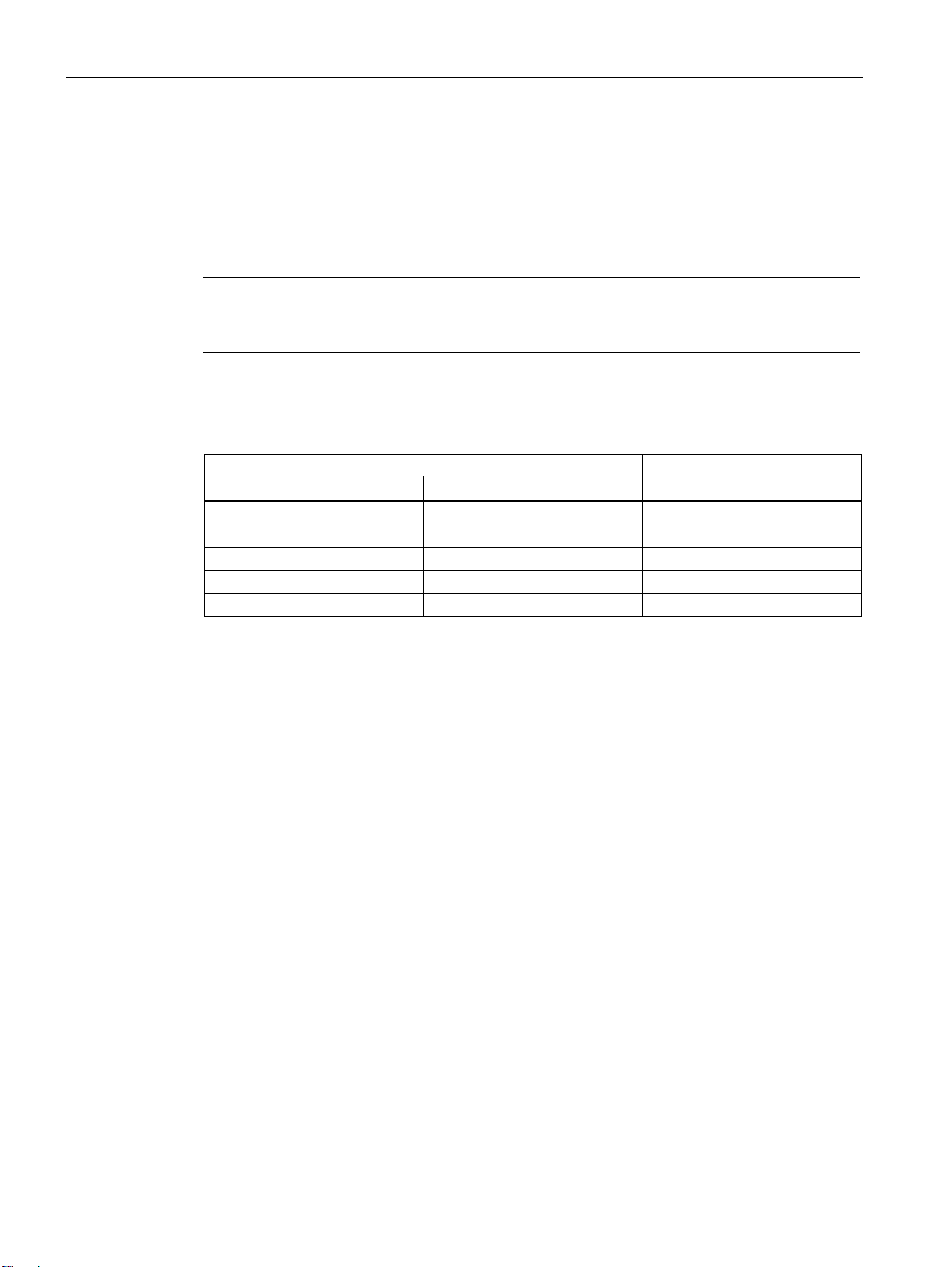

SENTRON VL types

The type designations of all available circuit breakers are oriented around the rated current

Type designation Maximum rated current (A)

VL160X 160

VL160 160

VL250 250

VL400 400

VL630 630

VL800 800

VL1250 1250

VL1600 1600

3

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

15

Product description

3.1 SENTRON VL overview

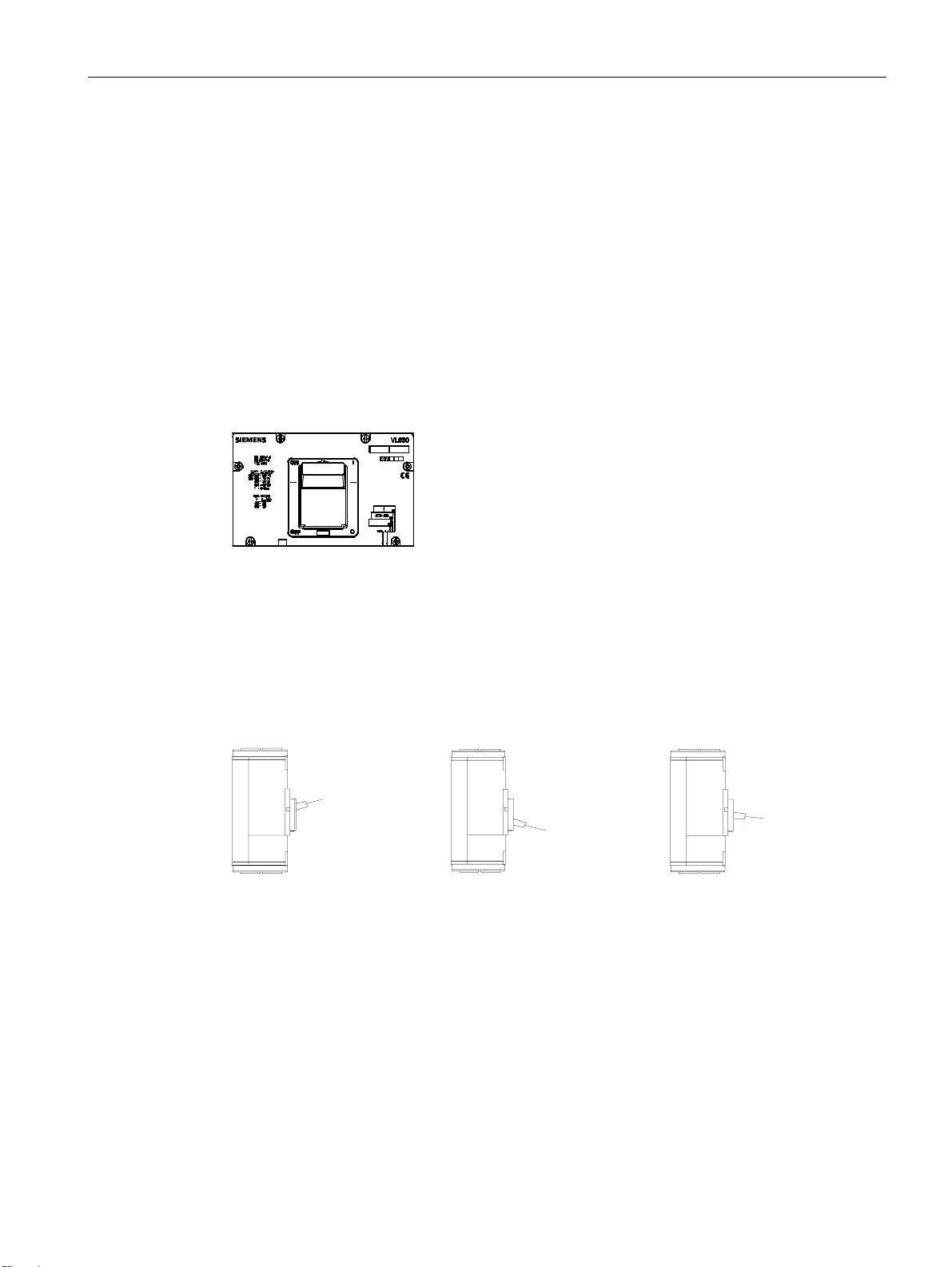

Type plate and ID number

The figure shows all the operator elements, setting options and names corresponding to the

precise specified use of the circuit breaker.

(1) Specified frame size

(2) Circuit breaker type

(3) Display of switching capacity

(4) Rating plate

(5) Accessories ID fields

(6) Catalog number (machine-readable product code)

(7) Overcurrent adjustment

(8) I

rated current of the circuit breaker

n

(9) Overcurrent tripping type TM (thermomagnetic)

(10) Reference temperature

(11) Short-circuit tripping/adjustment

(12) Test key

(13) Toggle handle with 3 positions

(14) Switching capacity

(15) Standards

(16) Accessories cover (removable)

Figure 3-1 SENTRON VL circuit breakers - labeling and operator elements

3VL molded-case circuit breakers

16 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.1 SENTRON VL overview

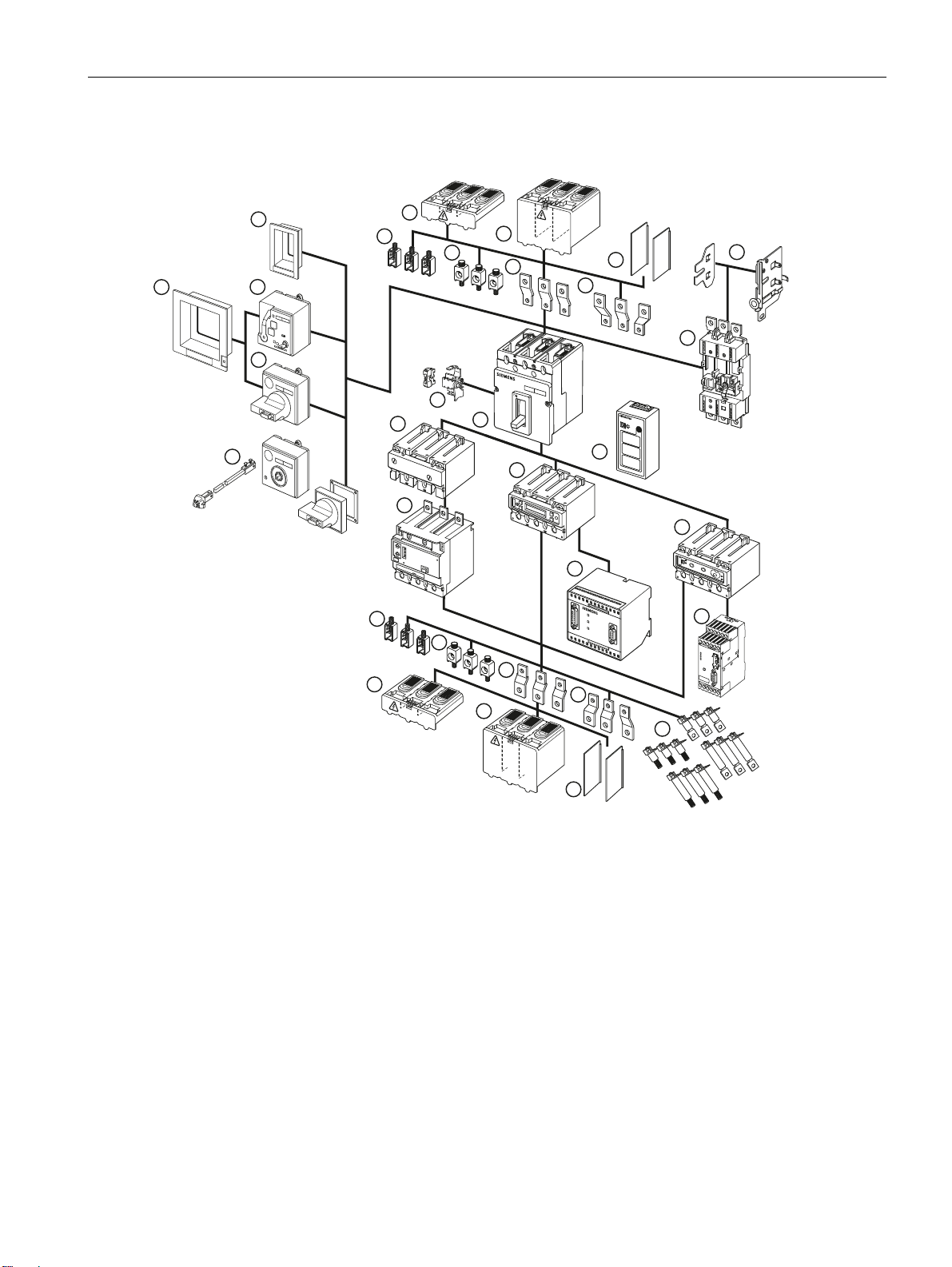

SENTRON VL accessories

(1) Withdrawable/plug-in socket (13) Door-coupling rotary operating mechanism

(2) Withdrawable side panels (14) SENTRON 3VL circuit breaker

(3) Phase barriers (15) Internal accessories

(4) Flared busbar extensions (16) Electronic overcurrent trip unit LCD ETU

(5) Straight connecting bars (17) Electronic overcurrent trip unit with communication function

(6) Multiple feed-in terminal for Al/Cu (18) Thermal/magnetic overcurrent trip unit

(7) Box terminal for Cu (19) RCD module

(8) Extended terminal cover (20) Rear terminals – flat and round

(9) Standard terminal cover (21) COM10 communication module for PROFIBUS-DP

(10) Masking/cover frame for door cutout (22) COM20 communication module for PROFIBUS-DP

(11) Stored-energy motorized operating

(23) Battery power supply with test function

mechanism

(12) Front rotary operating mechanism

Figure 3-2 SENTRON VL accessories

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

17

Product description

3.2 Application overview

3.2 Application overview

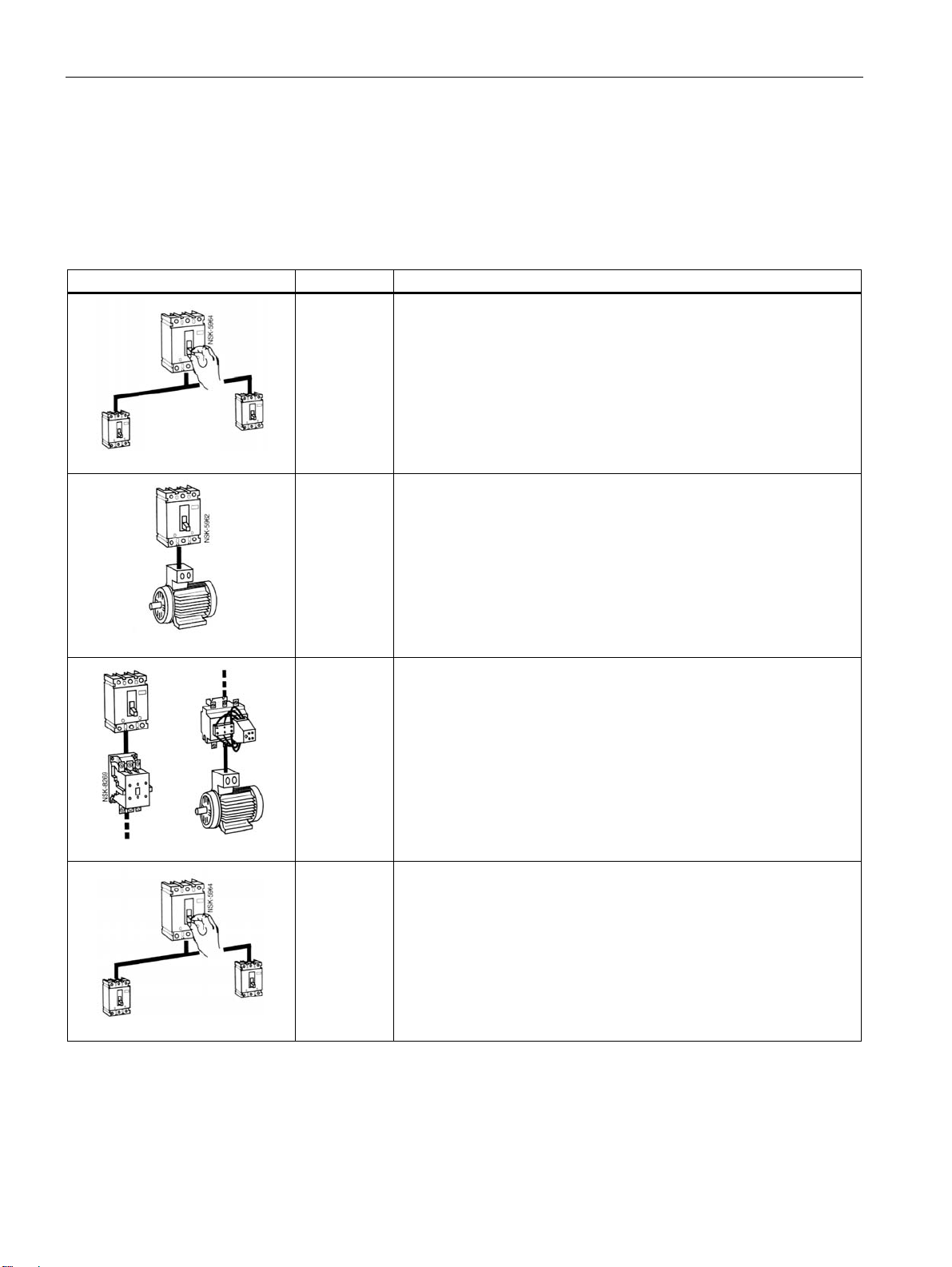

The following overview shows the most frequently occurring applications

Application overview

Application Type Description

Line protection

The trip units for line protection are designed to protect cables and nonmotorized loads against overload and short-circuit.

Motor/generator protection

The overload and short-circuit releases are designed for optimum

protection and direct-online starting of AC squirrel-cage motors. The

circuit breakers for motor protection have phase-failure sensitivity and a

thermal memory that protects the motor against overheating. The

adjustable time lag class enables users to adjust the overload release

to the startup conditions of the motor to be protected.

3- and 4-pole circuit breakers

VL160X

VL160

VL250

VL400

VL630

VL800

VL125

VL1600

VL160

VL250

VL400

VL630

3-pole circuit breaker

3-pole circuit breaker

3- and 4-pole circuit breakers

VL160

VL250

VL400

VL630

VL160X

VL160

VL250

VL400

VL630

VL800

VL1250

VL1600

Starter combination

Starter combinations consist of: Circuit breaker + contactor + overload

relay. The circuit breaker handles short-circuit protection and the

isolating function. The contactor has the task of switching the load

feeder normally. The overload relay handles overload protection that

can be specially matched to the motor. The circuit breaker for starter

combination is therefore equipped with an adjustable and non-delayed

short-circuit release.

Non-automatic air circuit breakers

These circuit breakers are used as incoming circuit breakers, main

switches or isolating switches without overload protection. They have

fixed short-circuit releases so that back-up fuses are not necessary.

3VL molded-case circuit breakers

18 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.3 Configuration

3.3 Configuration

3.3.1 Functional principle

Design - mechanical principle

All SENTRON VL circuit breakers have a trip-free mechanism that ensures the trip process

is not prevented even if the operating mechanism is blocked or manually held in the "ON"

position.

The contacts are opened and closed by a toggle handle positioned in the center. This is

attached to the front side on all circuit breakers.

All SENTRON VL circuit breakers are "joint trip units". This means all contacts open or close

simultaneously when the circuit breaker toggle handle is moved from "OFF" to "ON" or from

"ON" to "OFF", or when the tripping mechanism is activated by an overcurrent or with the

help of an auxiliary trip (shunt release or undervoltage release).

Current limiting

The SENTRON VL circuit breakers are designed on the principle of magnetic repulsion of

the contacts. The contacts open before the expected peak-value of the short-circuit current is

reached. Magnetic repulsion of the contacts very significantly reduces the thermal load I

well as the mechanical load resulting from the impulse short-circuit current I

components that occur during a short-circuit.

You can find more information in Chapter

3.3.2 Subdivision according to power ranges

VL160X circuit breakers

The most important components of the VL160X circuit breakers are the three current paths

with the incoming and outgoing terminals. The fixed and movable contacts are arranged in

such a way as to guarantee magnetic repulsion of the contacts. In conjunction with the arc

splitter chambers, a dynamic impedance is created that causes a current limitation through

the reduction in the harmful effects of I

The overcurrent trip unit is a thermomagnetic device installed at the factory. It is equipped

with fixed or adjustable overload releases and a fixed short-circuit release in each pole.

To the right and left of the centrally positioned toggle handle of every SENTRON VL circuit

breaker is a double-insulated accessories compartment for installing auxiliary switches or

alarm switches as well as voltage and undervoltage releases.

2

of the system

P

Use in the motor protection area (Page 74).

t and the Ip energy resulting from short-circuits.

2

t as

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

19

Product description

3.3 Configuration

VL160 to VL630 circuit breakers

The arrangement of current paths, contact configuration and switch mechanism of the VL160

to VL630 circuit breakers corresponds to that of the VL160X circuit breaker. The designs

diverge with regard to the overcurrent trip unit.

● The overcurrent trip units are available in a thermomagnetic version and in an electronic

version.

● The overcurrent trip units can be installed or replaced on-site without special tools.

● Thermomagnetic overcurrent trip units are available with adjustable overload releases

and short-circuit releases.

VL800 bis VL1600 circuit breakers

The arrangement of the current paths and switch mechanisms is identical to that of the

VL160X to VL630 circuit breakers.

However, the VL800 to VL1600 circuit breakers are only available in the version with

electronic overcurrent trip unit. As with all electronic overcurrent trip units for the SENTRON

VL circuit breakers from Siemens, the current transformers (one per phase) are

accommodated within the overcurrent trip unit housing. They transmit a signal proportional to

the load current to the electronic trip unit.

All SENTRON VL circuit breakers with electronic trip units measure the actual effective

current. This method is the most accurate way of measuring currents in electrical distribution

systems with extremely high harmonics.

3.3.3 Thermomagnetic overcurrent trip units

Thermomagnetic overcurrent trip units

A thermomagnetic overcurrent trip unit consists of two components - a thermal release for

protecting against overload, and a magnetic release for protecting against short-circuit. Both

trip unit components are switched in series.

The thermal trip unit

consists of a temperature-dependent bimetal that heats up as a result of the flow of current.

This means the release is current-dependent. The heating of the bimetal strip depends on

the ambient temperature of the circuit breaker. All current values specified for 3VL for

thermomagnetic trip units refer to an ambient temperature of 40°C. Where ambient

temperatures deviate from this, the values in the tables in Chapter

(Page 159) are to be used.

Derating factors

3VL molded-case circuit breakers

20 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.3 Configuration

The magnetic trip unit

comprises a yoke mounting through which a current path runs, and a flap armature that is

kept at a distance from the yoke mounting by a tension spring. If a short-circuit current now

flows along the current path, the magnetic field thus generated causes the flap armature to

be moved towards the yoke mounting against the opposite force of the tension spring. The

release time is almost current-independent and instantaneous. The flap armature releases

the switching lock and thus opens the switching contacts before the short-circuit current can

reach its maximum; a current limiting effect is thus achieved. Immediately after release, the

flap armature is moved back to its starting position by the opposite force of the tension

spring.

3.3.4 Electronic overcurrent trip unit (ETU)

Electronic trip units (ETU)

In contrast to thermomagnetic trip units (TMTUs) where the overcurrent trip is unit caused by

a bimetal strip or magnetic release, electronic overcurrent trip units (ETUs) use electronics

with current transformers. The ETU captures the actual currents and compares them with the

default specifications.

Configuration

All SENTRON 3VL circuit breakers with electronic overcurrent trips measure the actual

effective current (true RMS). This is the most accurate method of measuring.

ETUs are available from the VL160 circuit breaker up to and including the VL1600. The

SENTRON VL800, VL1250 und VL1600 circuit breakers are only available in the version

with electronic overcurrent trip unit.

The trip units can be replaced by the customer without special tools. Replacement is

described precisely in the operating instructions included with the ETUs. After installing the

electronic overcurrent trip unit in the relevant circuit breaker, the battery supply must be

tested with test function 3VL9000-8AP00.

The electronic overcurrent tripping system consists of:

● 3 to 4 (3-pole or 4-pole) current transformers that also provide their own power supply.

This means an external auxiliary voltage is not required.

● Evaluation electronics with microprocessor

● Tripping solenoid

In all versions with electronic trip units for the SENTRON 3VL circuit breakers, the current

transformers are located in the same housing as the trip unit. At the output of the electronic

overcurrent tripping module, there is a tripping solenoid that releases the circuit breaker in

the event of an overload or short-circuit.

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

21

Product description

3.3 Configuration

Power supply

The protection functions of the electronic overcurrent trip unit are guaranteed without

additional auxiliary voltage. The overcurrent trip units are supplied with energy via internal

current transformers. The protection function is parameterized via rotary encoding switches

on the ETU or via an LCD display. In the case of an LCD display, the electronic overcurrent

trip unit must be activated. This requires a 3-phase (3-pole) load current of at least 20% or,

in the case of a single-phase (single-pole) load, 30% of the relevant rated current of the

circuit breaker. If this load current is not available, the necessary auxiliary energy can be

supplied via a battery power supply (order no. 3VL9000-8AP00). With communicationcapable circuit breakers, the trip unit is supplied with energy via the COM10/COM20 module.

4-pole circuit breakers

The four-pole circuit breakers for system protection can be supplied in all 4 poles with or

without current transformers. The trip units in the 4th pole (N) can be set to 50% or 100% of

the current in the 3 main current paths dependent on the frame size, so that safe protection

of the neutral conductor can be guaranteed even with a reduced cross-section. In the case of

LCD-ETUs, the neutral conductor protection can be adjusted in steps from 50% to 100% or

switched off.

3VL molded-case circuit breakers

22 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.4 Mechanical operating mechanisms

3.4 Mechanical operating mechanisms

3.4.1 Toggle handle operating mechanism

In the basic version, the SENTRON VL circuit breakers have a toggle handle as an operating

mechanism. This also functions as an indicator of the switching position. The "Tripped"

position is also displayed in addition to the "ON" and "OFF" positions.

The toggle handle goes to the "tripped" position when the internal trip mechanism is

activated by an overcurrent situation, e.g. overload or short-circuit.

Activation by an undervoltage release or shunt release will also cause the toggle handle to

move to the "Tripped" position.

The toggle handle must be returned to the

"OFF/RESET" position before the circuit breaker can be

turned back on again. This enables the internal release

mechanism to be reset. SENTRON VL circuit breakers

with toggle handle operation comply with the "Network

Toggle handle in the "ON"

position

disconnecting device" condition (5.3.2 Section c) and

5.3.3) according to DIN EN 60204-1 (VDE 0113-1).

Toggle handle positions

ON OFF

Toggle handle positions

Tripped

RESET

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

23

Product description

3.4 Mechanical operating mechanisms

3.4.2 Rotary mechanism on front (optional)

The rotary mechanism on the front converts the vertical movement of the toggle handle into

rotary motion. The circuit breaker is switched on/off or tripped with the help of the rotary

mechanism on the front. The rotary motion on the switching knob is converted to vertical

motion on the toggle handle.

The rotary mechanism on the front is mounted direct on the circuit

breaker. SENTRON VL circuit breakers with rotary mechanism

comply with the "Network disconnecting device" condition of

DIN EN 60204-1 (VDE 0113-1).

Rotary mechanism

Degree of protection

The rotary mechanism on the front offers degree of protection IP30

Interlocking

Lockable in the "OFF" position with up to 3 padlocks.

A safety lock can also be used.

Application

Standard application:

● Black knob

● Gray indicator plate

Network disconnector facility with features for stopping and shutting down in an emergency:

● Red knob

● Yellow indicator plate

Accessories

Optionally, up to 4 changeover contacts can be used. Two contacts can be used as leading

NO contacts and two contacts as leading NC contacts. These are equipped with 1.5 m long

connection cables.

3VL molded-case circuit breakers

24 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.4 Mechanical operating mechanisms

3.4.3 Door-coupling rotary operating mechanism (optional)

The door-coupling rotary operating mechanism is available for installation in control cabinets

and distribution boards.

SENTRON VL circuit breakers with door-coupling rotary

mechanisms comply with the "Network disconnecting

device" condition of DIN EN 60204-1 (VDE 0113-1).

Door-coupling rotary operating

mechanism

The door-coupling rotary operating mechanism is designed as follows:

● Rotary mechanism on the front with shaft stub (without knob)

● Shaft coupling

● 300 mm extension shaft (600 mm optional, clip required)

● Actuator

Degree of protection

This mechanism offers degree of protection IP65

Interlocking

Lockable in the "OFF" position with up to 3 padlocks. A safety lock can also be used.

Application

Standard application:

● Black knob

● Gray indicator plate

Network disconnector facility with features for stopping and shutting down in an emergency:

● Red knob

● Yellow indicator plate

Accessories

Optionally, up to 4 changeover contacts can be used:

Two contacts can be used as leading NO contacts and two contacts as leading NC contacts.

These are equipped with 1.5 m long connection cables

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

25

Product description

3.5 Motorized operating mechanisms (optional)

3.5 Motorized operating mechanisms (optional)

Motorized operating mechanisms enable the circuit breaker to be switched on/off locally or

on-site or by remote control. For electrical and mechanical locking of the operating

mechanism, they are equipped with a locking device for padlocks (standard) and an

(optional) safety lock. Motorized operating mechanisms can also be actuated manually. Two

types of mechanisms are offered.

Note

SENTRON circuit breakers with motorized operating mechanisms cannot be used as

network disconnection devices in accordance with DIN EN 60204-1 (VDE 0113-1).

Designation of the connecting cables

Internal terminal strip

Internally wired Externally wired

PE X20.5 Green/yellow

L2- X20.1 N

S2A X20.2 S2A

S2B X20.3 S2B

L1+ X20.4 L1

Identifier

3VL molded-case circuit breakers

26 System Manual, 03/2009, 110 0110 - 02 DS 01

Product description

3.5 Motorized operating mechanisms (optional)

3.5.1 Stored-energy motorized operating mechanism

Motorized operating mechanism for VL160X-VL800

● The stored-energy motorized operating mechanism is suitable for synchronization tasks.

● The motor charges a stored-energy spring mechanism and moves the SENTRON VL

toggle handle to the "OFF/RESET" position.

● The stored-energy spring mechanism discharges when actuated, quickly switching the

SENTRON VL toggle handle to the "ON" position.

● A changeover switch allows local (Manual) or remote (Auto) operation to be selected.

● The manual actuator handle is located on the front of the operating mechanism cover.

Figure 3-3 Stored-energy motorized operating mechanism

3.5.2 Motorized operating mechanism without stored-energy mechanism

Motorized operating mechanism for VL1250-1600

● The motor drives a mechanism that switches the SENTRON VL toggle handle to the "ON"

and "OFF/RESET" positions.

● The manual actuator handle is located on the front of the operating mechanism cover.

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

27

Product description

3.5 Motorized operating mechanisms (optional)

3VL molded-case circuit breakers

28 System Manual, 03/2009, 110 0110 - 02 DS 01

System overview

4.1 Possible applications

Thanks to its universal connection and switching configuration, the SENTRON VL circuit

breaker offers a diverse range of possible applications:

Table 4- 1 Possible applications

Area of application Function

Plant

Motor/generator

4

Current limiting

Controller monitoring

Ground-fault protection

Undervoltage protection

Overload protection

Phase-failure protection

Thermodynamic winding protection

Harmonic protection Converter

Frequency-independent load protection

Remote trip units Switch disconnectors

Auxiliary contact/alarm trip unit

3VL molded-case circuit breakers

System Manual, 03/2009, 110 0110 - 02 DS 01

29

System overview

4.2 Key data

4.2 Key data

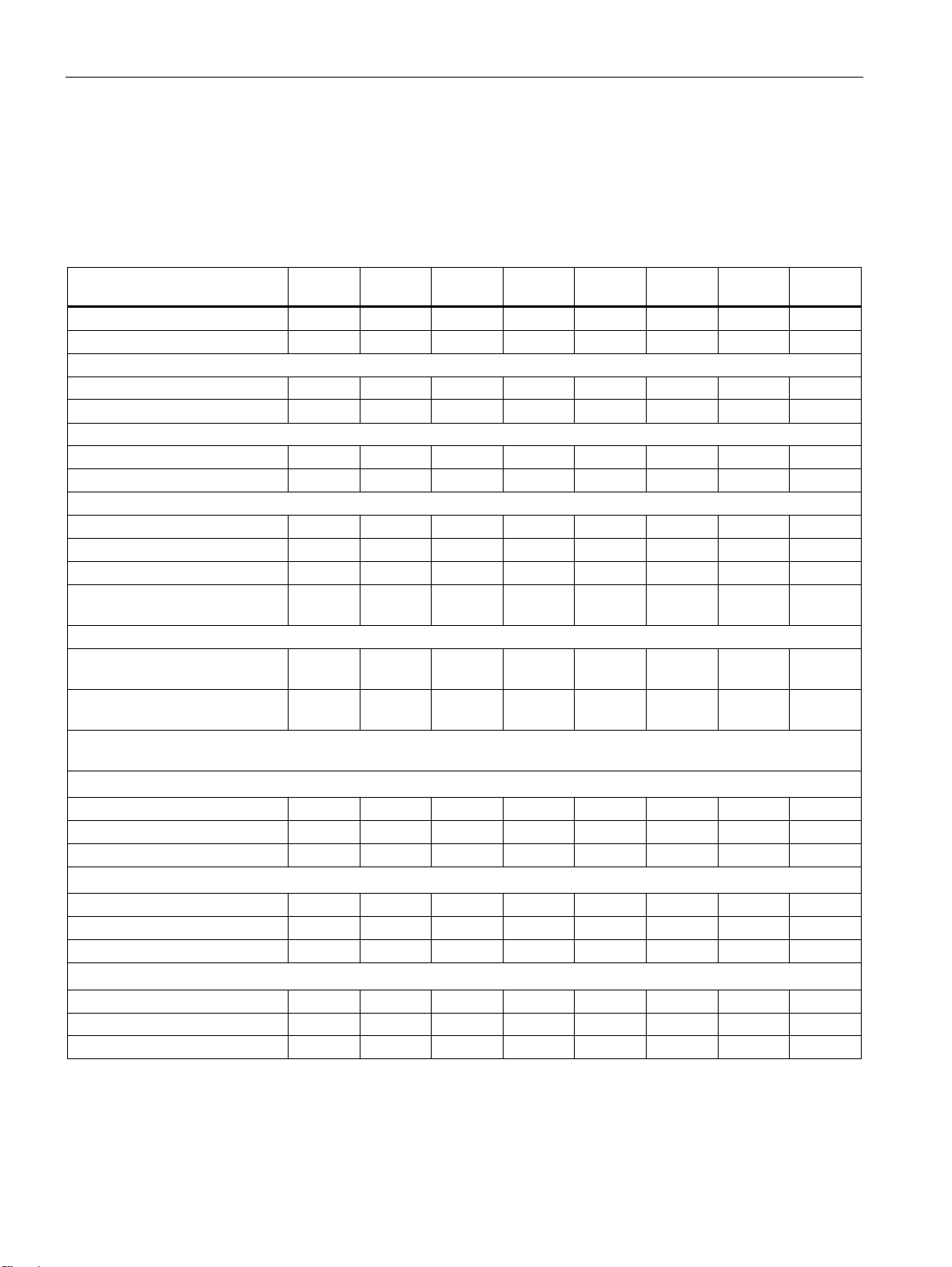

4.2.1 General data - 3VL molded-case circuit breakers

Type VL160X

3VL1

Max. rated current In [A] 160 160 250 400 630 800 1250 1600

N pole [A] 160 160 250 400 630 800 1250 1600

Rated insulation voltage Vi in accordance with IEC 60947-2

Main current paths [V AC] 800 800 800 800 800 800 800 800

Auxiliary circuits [V AC] 690 690 690 690 690 690 690 690

Rated impulse withstand voltage V

imp

Main current paths [kV] 8 8 8 8 8 8 8 8

Auxiliary circuits [kV] 4 4 4 4 4 4 4 4

Rated operating voltage Ue

IEC 50/60 Hz [V AC] 690 690 690 690 690 690 690 690

IEC 50/60 Hz (V DC2)) 500 600 600 600 600 -1) NEMA 60 Hz (V AC) 600 600 600 600 600 600 600 600

Utilization category

A A A A A

(IEC 60947-2)

Permissible ambient temperature 4)

Operation [°C] -25 to

+70

Storage [°C] -40 to

+80

Permissible load at different ambient temperatures

in the immediate vicinity of the circuit breaker, related to the rated current of the circuit breaker

• Circuit breaker for system protection

VL160

3VL2

-25 to

+70

-40 to

+80

VL250

3VL3

-25 to

+70

-40 to

+80

VL400

VL4

-25 to

+70

-40 to

+80

VL630

3VL5

3)

B

-25 to

+70

-40 to

+80

VL800

VL6

A

B3)

-25 to

+70

-40 to

+80

VL1250

3VL7

1)

-

A

B3)

-25 to

+70

-40 to

+80

VL1600

3VL8

1)

A

B3)

-25 to

+70

-40 to

+80

TM/ETU up to 50 °C [%] 100 /- 100 / 100 100 / 100 100 / 100 100 / 100 - / 100 - / 100 - / 100

TM/ETU up to 60 °C [%] 93 / - 93 / 95 93 / 95 93 / 95 93 / 95 - / 95 - / 95 - / 95

TM/ETU up to 70 °C [%] 86 / - 86 / 80 86 / 80 86 / 80 86 / 80 - / 80 - / 80 - / 80

• Circuit breakers for motor protection

Up to 50 °C [%] - 100 100 100 100 - - -

At 60 °C [%] - 95 95 95 95 - - At 70 °C [%] - 80 80 80 80 - - -

• Circuit breakers for starter combinations and non-automatic air circuit breakers

up to 50 °C [%] 100 100 100 100 100 100 100 100

At 60 °C [%] 93 93 93 93 93 93 93 93

At 70 °C [%] 86 86 86 86 86 86 86 86

3VL molded-case circuit breakers

30 System Manual, 03/2009, 110 0110 - 02 DS 01

Loading...

Loading...