Siemens Sentron 3VA User Manual

SENTRON

Protection devices

3VA molded case circuit breakers

with UL and IEC certification

Manual

01/2019

Introduction

1

Description

2

Applications

3

Accessories

4

Service and maintenance

5

Technical specifications

6

Appendix

A

ESD guidelines

B

List of abbreviations

C

Conversion tables

D

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

L1V30435333-01

Legal information

Warning notice system

DANGER

will

WARNING

may

CAUTION

NOTICE

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

indicates that death or severe personal injury

indicates that death or severe personal injury

indicates that minor personal injury can result if proper precautions are not taken.

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

result if proper precautions are not taken.

result if proper precautions are not taken.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

Siemens AG

Division Energy Management

Postfach 32 20

91050 ERLANGEN

GERMANY

Document order number: 3ZW1012-0VA51-0AC1

Ⓟ 01/2019 Subject to change

Copyright © Siemens AG 2019.

All rights reserved

Table of contents

1 Introduction ............................................................................................................................................. 9

2 Description ............................................................................................................................................ 13

1.1 About this documentation ......................................................................................................... 9

1.2 Product-specific information ................................................................................................... 10

1.2.1 Target readers ........................................................................................................................ 10

1.2.2 Technical Support ................................................................................................................... 10

1.2.3 Reference documents ............................................................................................................. 11

2.1 Overview - applications and portfolio ...................................................................................... 13

2.1.1 Applications and possible uses ............................................................................................... 13

2.1.2 Aspects of the UL market - Low-voltage systems in the USA ................................................ 14

2.1.3 Portfolio ................................................................................................................................... 16

2.1.4 Detailed information about applications and possible uses .................................................... 21

2.1.5 Technical specifications .......................................................................................................... 22

2.1.6 Molded case circuit breakers and accessories in the system ................................................ 26

2.2 Ergonomic design ................................................................................................................... 28

2.2.1 Installation variants for 3VA UL .............................................................................................. 28

2.2.2 Ergonomic design of circuit breakers, handles and control elements .................................... 31

2.2.3 Wide range of accessories ..................................................................................................... 34

2.2.4 Connection technology ........................................................................................................... 36

2.3 Technical details ..................................................................................................................... 38

2.3.1 Circuit breaker identification ................................................................................................... 38

2.3.2 Operation ................................................................................................................................ 47

2.3.3 Current limitation ..................................................................................................................... 48

2.4 Standards and guidelines ....................................................................................................... 50

2.4.1 Compliance with standards and electromagnetic compatibility .............................................. 50

2.4.2 Certificates .............................................................................................................................. 51

2.4.3 Ambient conditions .................................................................................................................. 51

2.4.4 Permissible mounting positions and mounting positions with accessories ............................ 53

2.4.5 Safety clearances (for IEC applications)................................................................................. 54

2.4.6 Breaker venting ....................................................................................................................... 59

2.4.7 Minimum enclosure dimensions ............................................................................................. 60

2.4.8 I

2.4.9 Environmental protection ........................................................................................................ 62

2.5 Protection functions ................................................................................................................ 63

2.5.1 Description of functions........................................................................................................... 64

2.5.2 Characteristic curves .............................................................................................................. 66

2.5.3 Guide to setting the tripping characteristic.............................................................................. 67

2.5.4 Overload protection (L) ........................................................................................................... 68

2.5.5 Short-time delayed short-circuit protection (S) ....................................................................... 69

2.5.6 Instantaneous short-circuit protection (I) ................................................................................ 69

P degrees of protection .......................................................................................................... 61

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

3

Table of contents

3 Applications .......................................................................................................................................... 99

4 Accessories ......................................................................................................................................... 151

2.5.7 Ground-fault protection .......................................................................................................... 70

2.5.7.1 Measurement method 1: Vectorial summation (residual) current .......................................... 70

2.5.7.2 Measurement method 2: Direct detection .............................................................................. 72

2.5.8 Neutral conductor protection (N) ............................................................................................ 73

2.5.9 Zone-selective interlocking ZSI .............................................................................................. 76

2.6 Thermal-magnetic trip unit ..................................................................................................... 79

2.6.1 Thermal-magnetic trip unit (TMTU) ........................................................................................ 79

2.6.2 Application cases and trip unit types...................................................................................... 79

2.7 Electronic trip unit................................................................................................................... 80

2.7.1 Electronic trip unit (ETU) ........................................................................................................ 80

2.7.2 Connections ........................................................................................................................... 81

2.7.3 Arc energy reduction .............................................................................................................. 81

2.7.4 Protection functions ............................................................................................................... 83

2.7.5 Operator controls ................................................................................................................... 84

2.7.6 Load acceptance and load shedding - load management ..................................................... 94

2.7.7 Measuring with a Rogowski coil ............................................................................................. 95

3.1 Use of the 3VA UL molded case circuit breakers in line protection ....................................... 99

3.1.1 Applications in line protection ................................................................................................ 99

3.1.2 Versions of the trip units ...................................................................................................... 102

3.1.2.1 Thermal-magnetic trip units ................................................................................................. 102

3.1.2.2 Electronic trip units ............................................................................................................... 105

3.1.3 Overview of 3VA UL molded case circuit breakers in line protection .................................. 132

3.2 Use as Motor Circuit Protector (MCP) for starter combinations .......................................... 134

3.3 Use of the 3VA UL molded case circuit breaker as a molded case switch (MCS) .............. 138

3.3.1 Compatibility of 3VA UL molded case switch and accessories ........................................... 140

3.4 Use of 3VA UL molded case circuit breaker in DC systems ................................................ 141

3.4.1 Introduction .......................................................................................................................... 141

3.4.2 Variants ................................................................................................................................ 142

3.4.3 Breaking capacity with direct current ................................................................................... 143

3.4.4 Recommended circuits for DC systems UL ......................................................................... 144

3.4.5 Recommended circuits for DC systems IEC ........................................................................ 146

3.5 Use of 3VA UL molded case circuit breakers in IT systems according to IEC 60947-2 ...... 148

3.5.1 Introduction .......................................................................................................................... 148

3.5.2 Selection criteria for 3VA UL molded case circuit breakers ................................................. 148

3.5.3 Fault situation ....................................................................................................................... 149

4.1 Overview - Accessories for 3VA UL molded case circuit breakers ...................................... 151

4.2 Internal accessories ............................................................................................................. 152

4.2.1 Mounting locations of 3VA UL molded case circuit breakers .............................................. 152

4.2.2 Auxiliary and alarm switches ................................................................................................ 156

4.2.3 Contact sequence diagrams ................................................................................................ 159

4.2.4 Technical specifications of auxiliary and alarm switches ..................................................... 160

4.2.5 Auxiliary releases ................................................................................................................. 162

4.2.6 Time-delay devices for undervoltage releases .................................................................... 166

4.2.7 COM060 communication module......................................................................................... 166

4.2.8 24 V module ......................................................................................................................... 167

3VA molded case circuit breakers with UL and IEC certification

4 Manual, 01/2019, L1V30435333-01

Table of contents

4.3 Connection system ............................................................................................................... 168

4.3.1 Introduction ........................................................................................................................... 168

4.3.2 General information about cables and busbars .................................................................... 168

4.3.3 Connection portfolio for 3VA UL molded case circuit breakers ............................................ 172

4.3.3.1 General overview .................................................................................................................. 172

4.3.3.2 Front cable connection.......................................................................................................... 176

4.3.3.3 Front busbar and compression lug connections ................................................................... 191

4.3.3.4 Rear busbar and compression lug connections ................................................................... 198

4.3.4 Further connection accessories ............................................................................................ 203

4.3.4.1 Insulating equipment ............................................................................................................. 203

4.3.4.2 Control wire tap ..................................................................................................................... 219

4.4 Plug-in and draw-out technology .......................................................................................... 221

4.4.1 Introduction ........................................................................................................................... 221

4.4.2 Overview of variants / products ............................................................................................ 224

4.4.3 General information .............................................................................................................. 225

4.4.4 Information about installation, built-on and built-in components .......................................... 226

4.4.5 Plug-in technology ................................................................................................................ 227

4.4.5.1 Product description ............................................................................................................... 227

4.4.5.2 Combination with other accessories ..................................................................................... 233

4.4.6 Draw-out technology ............................................................................................................. 234

4.4.6.1 Product description ............................................................................................................... 234

4.4.6.2 Combination with other accessories ..................................................................................... 243

4.4.7 Accessories for plug-in and draw-out units ...........................................................................

4

.4.7.1 Description of individual product variants ............................................................................. 244

244

4.4.7.2 Overview of technical specifications ..................................................................................... 256

4.4.7.3 Combination with other accessories ..................................................................................... 257

4.5 Manual operators .................................................................................................................. 258

4.5.1 Introduction ........................................................................................................................... 258

4.5.2 Operator control of the 3VA UL molded case circuit breakers with manual operators ......... 259

4.5.3 Front mounted rotary operator .............................................................................................. 264

4.5.3.1 Elements of the front mounted rotary operator ..................................................................... 264

4.5.3.2 Front mounted rotary operator with door interlock ................................................................ 265

4.5.3.3 Testing the tripping mechanism ............................................................................................ 267

4.5.3.4 Locking, blocking and interlocking ........................................................................................ 268

4.5.4 Door mounted rotary operator .............................................................................................. 271

4.5.4.1 Elements of the door mounted rotary operator ..................................................................... 271

4.5.4.2 Door interlock with door mounted rotary operator ................................................................ 272

4.5.4.3 Tolerance compensator ........................................................................................................ 274

4.5.4.4 Testing the tripping mechanism ............................................................................................ 275

4.5.4.5 Supplementary handle for door mounted rotary operator..................................................... 276

4.5.4.6 Variable depth adapter.......................................................................................................... 277

4.5.4.7 Locking, blocking and interlocking ........................................................................................ 278

4.5.5 Side wall mounted rotary operator ........................................................................................ 281

4.5.5.1 Elements of the side wall mounted rotary operator .............................................................. 281

4.5.5.2 Side wall mounted rotary operator with mounting plate ........................................................

4

.5.5.3 Locking, blocking and interlocking ........................................................................................ 283

282

4.5.6 Operator kit with Bowden cable (Max-Flex operator) ........................................................... 286

4.5.6.1 Elements of the operator kit with Bowden cable ...................................................................

.5.6.2 Door interlocking with the operator kit with Bowden cable ................................................... 287

4

286

4.5.6.3 Testing the tripping mechanism ............................................................................................ 289

4.5.6.4 Auxiliary switches for the operator kit with Bowden cable .................................................... 289

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

5

Table of contents

4.5.6.5 Locking, blocking and interlocking ....................................................................................... 290

4.5.7 Degree of protection ............................................................................................................ 291

4.5.7.1 IP degree of protection ......................................................................................................... 291

4.5.7.2 NEMA degree of protection .................................................................................................. 291

4.5.8 Accessories .......................................................................................................................... 292

4.5.8.1 Illumination kit ...................................................................................................................... 292

4.6 Motor operator...................................................................................................................... 293

4.6.1 Elements of the motor operator MO320 .............................................................................. 293

4.6.2 Description of front panel ..................................................................................................... 294

4.6.3 MANUAL, AUTO and LOCK modes .................................................................................... 295

4.6.4 Operating the molded case circuit breaker with motor operator .......................................... 296

4.6.5 Faults, causes of faults and rectification of faults ................................................................ 300

4.6.6 Technical specifications ....................................................................................................... 301

4.7 Locking and interlocking ...................................................................................................... 302

4.7.1 General information ............................................................................................................. 302

4.7.1.1 General information ............................................................................................................. 302

4.7.1.2 Locking ................................................................................................................................. 302

4.7.1.3 Interlocking ........................................................................................................................... 303

4.7.2 Blocking and locking ............................................................................................................ 305

4.7.2.1 Handle blocking device ........................................................................................................ 305

4.7.2.2 Cylinder locks for locking the 3VA molded case circuit breaker .......................................... 307

4.7.3 Front interlocking.................................................................................................................. 311

4.7.3.1 Cylinder locks for interlocking multiple 3VA UL molded case circuit breakers .................... 311

4.7.3.2 Cable interlock module using a Bowden cable ....................................................................

.7.3.3 Sliding bar ............................................................................................................................ 319

4

316

4.7.4 Rear interlock ....................................................................................................................... 321

4.8 Communication and system integration ............................................................................... 327

4.8.1 System description ............................................................................................................... 327

4.8.2 Communication system of the 3VA UL molded case circuit breaker ................................... 327

4.8.3 COM800 / COM100 breaker data server ............................................................................. 329

4.8.3.1 Area of application ............................................................................................................... 331

4.8.3.2 Features ............................................................................................................................... 331

4.8.4 Communication with ETUs ................................................................................................... 331

4.8.4.1 Area of application ............................................................................................................... 332

4.8.5 DSP800 display.................................................................................................................... 332

4.8.6 Commissioning and testing of electronic trip units using powerconfig ................................ 333

4.8.7 Power management with powermanager ............................................................................ 337

4.9 EFB300 external function box .............................................................................................. 338

4.9.1 General information ............................................................................................................. 338

4.9.2 Power supply ........................................................................................................................ 339

4.9.3 Functions of the digital input and digital outputs .................................................................. 339

4.9.4 Zone-selective interlocking ZSI ............................................................................................ 340

4.9.5 <SET> button ....................................................................................................................... 342

4.9.6 Technical specifications ....................................................................................................... 349

4.10 MMB300 maintenance mode box ........................................................................................

10.1 Operating principle of the MMB300 maintenance mode box ............................................... 351

4.

351

4.10.2 Configuration of MMB300 with a 3VA6 molded case circuit breaker ................................... 353

4.10.3 <SET> button ....................................................................................................................... 357

4.10.4 Power supply ........................................................................................................................

10.5 Technical specifications ....................................................................................................... 358

4.

358

3VA molded case circuit breakers with UL and IEC certification

6 Manual, 01/2019, L1V30435333-01

Table of contents

5 Service and maintenance .................................................................................................................... 381

6 Technical specifications ...................................................................................................................... 385

4.11 Test devices .......................................................................................................................... 360

4.11.1 Introduction ........................................................................................................................... 360

4.11.2 The TD300 activation and trip box ........................................................................................ 361

4.11.2.1 Operation and execution of the tripping function .................................................................. 362

4.11.2.2 Technical specifications of TD300 ........................................................................................ 364

4.11.3 The TD500 test device .......................................................................................................... 364

4.11.3.1 General information, preparations ........................................................................................ 364

4.11.3.2 Operation and execution of test functions ............................................................................ 369

4.11.3.3 Executing the test functions using a PC and powerconfig .................................................... 374

4.11.3.4 Parameterizing using the powerconfig software ................................................................... 374

4.11.3.5 Technical specifications ........................................................................................................ 375

4.12 External current transformer for N conductor ....................................................................... 376

4.13 Cover frame .......................................................................................................................... 378

4.13.1 Product description ............................................................................................................... 378

4.13.2 Labeling plate ........................................................................................................................ 380

5.1 Notes ..................................................................................................................................... 381

5.2 Regular maintenance ............................................................................................................ 382

5.3 Maintenance following tripping of a molded case circuit breaker ......................................... 383

5.4 Fault diagnostics ................................................................................................................... 384

6.1 Circuit diagrams .................................................................................................................... 385

6.1.1 3VA5 molded case circuit breakers ...................................................................................... 385

6.1.1.1 Basic units ............................................................................................................................. 385

6.1.1.2 Accessories ........................................................................................................................... 387

6.1.1.3 Example: 3VA5 molded case circuit breakers with accessories (external/internal) ............. 390

6.1.2 3VA6 molded case circuit breakers ...................................................................................... 391

6.1.2.1 Basic units ............................................................................................................................. 391

6.1.2.2 Accessories ........................................................................................................................... 392

6.1.2.3 Example: 3VA6 molded case circuit breakers with accessories (external/internal) ............. 402

6.1.3 Application example: Electrical interlocking of two 3VA UL molded case circuit

breakers with undervoltage releases .................................................................................... 403

6.2 Dimensional drawings ........................................................................................................... 404

6.2.1 Dimensions of basic units ..................................................................................................... 404

6.2.1.1 3VA51 ................................................................................................................................... 404

6.2.1.2 3VA52 ................................................................................................................................... 406

6.2.1.3 3VA61 / 3VA62 ..................................................................................................................... 407

6.2.1.4 3VA63 / 3VA64 ..................................................................................................................... 408

6.2.2 Dimensions of accessories ................................................................................................... 409

6.2.2.1 Connection technology ......................................................................................................... 409

6.2.2.2 Plug-in and draw-out units .................................................................................................... 416

6.2.2.3 Manual operators .................................................................................................................. 425

6.2.2.4 Motor operators ..................................................................................................................... 439

6.2.2.5 Locking and interlocking ....................................................................................................... 440

6.2.2.6 Communication and system integration................................................................................ 447

6.2.2.7 EFB300 external function box ...............................................................................................

6

.2.2.8 MMB300 maintenance mode box ......................................................................................... 448

448

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

7

Table of contents

A Appendix ............................................................................................................................................. 465

B ESD guidelines .................................................................................................................................... 467

C List of abbreviations ............................................................................................................................. 469

D Conversion tables ................................................................................................................................ 475

Glossary .............................................................................................................................................. 479

Index ................................................................................................................................................... 485

6.2.2.9 Test devices ......................................................................................................................... 449

6.2.2.10 Door cover frame ................................................................................................................. 449

6.3 Power losses ........................................................................................................................ 450

6.3.1 Power losses of 3VA5 molded case circuit breakers ........................................................... 450

6.3.2 Power losses of 3VA6 molded case circuit breakers ........................................................... 452

6.3.3 Power loses of 3VA UL molded case switches .................................................................... 453

6.4 Derating ................................................................................................................................ 454

6.4.1 Derating of 3VA5 molded case circuit breakers ................................................................... 454

6.4.2 Use of terminals with control wire tap .................................................................................. 456

6.4.3 Additional correction factors with frequencies other than 50/60 Hz for 3VA5 molded

case circuit breakers ............................................................................................................ 457

6.4.4 Derating for the electronic trip units of 3VA6 molded case circuit breakers ........................ 458

A.1 Standards and approvals ..................................................................................................... 465

B.1 Electrostatic sensitive devices (ESD) .................................................................................. 467

C.1 Table of abbreviations .......................................................................................................... 469

D.1 Conversion tables ................................................................................................................ 475

3VA molded case circuit breakers with UL and IEC certification

8 Manual, 01/2019, L1V30435333-01

1

1.1

About this documentation

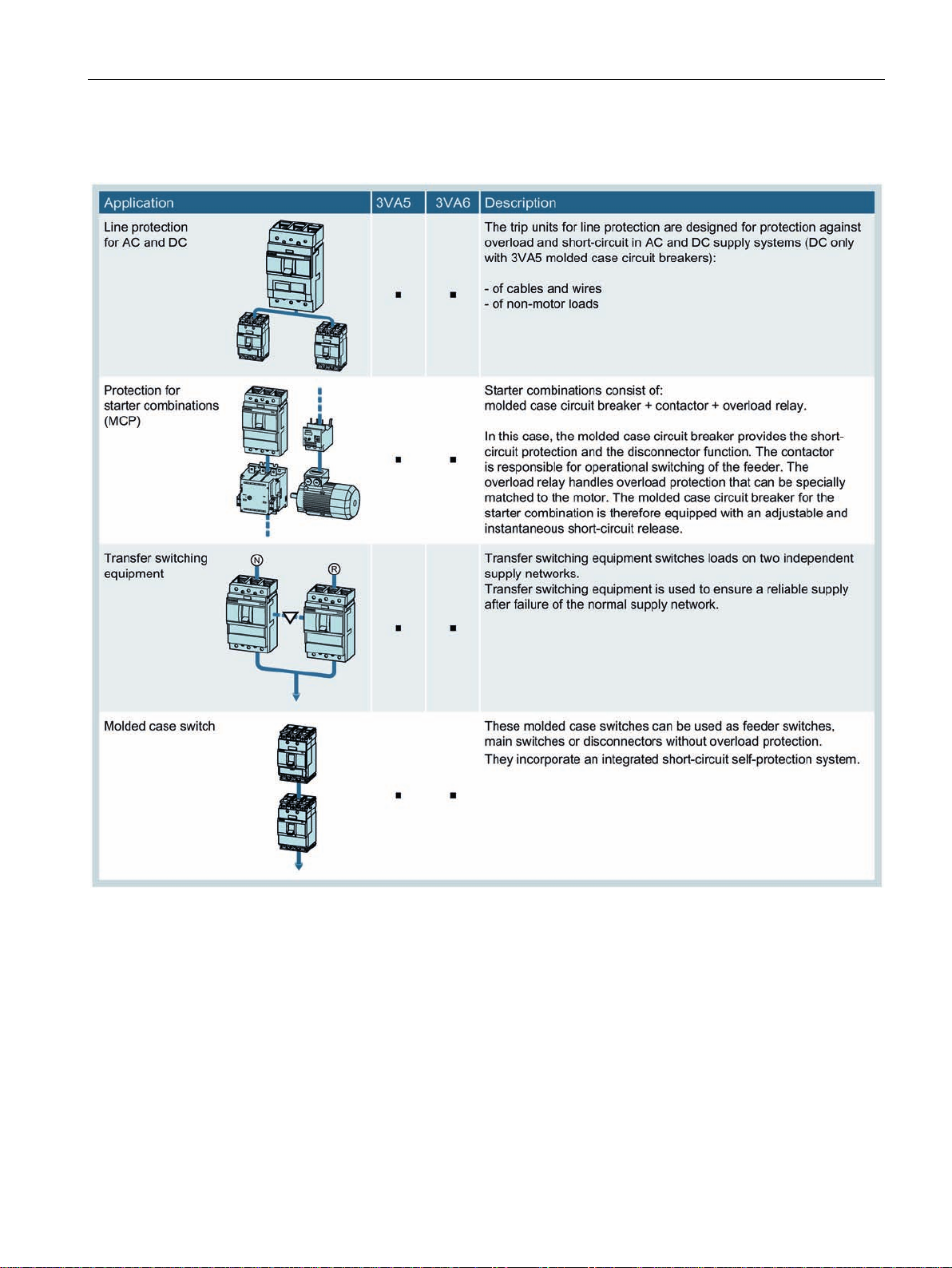

3VA molded case circuit breakers with UL 489 certification for the North American market

The 3VA molded case circuit breakers from the portfolio of SENTRON protection, switching,

measuring and monitoring devices ensure the reliable protection of people and property as

integral components of efficient power distribution systems.

For global applications, a special product portfolio has been developed that has the required

approvals according to standards UL 489 as well as IEC 60947. 3VA molded case circuit

breakers certified to UL 489 are suitable for the following applications:

● Incoming circuit breakers (feeders) and outgoing circuit breakers (branches) in

distribution systems

● Switching and protection devices for motors (motor protection in combination with a

contactor and motor protection relay), transformers and capacitors

● Disconnecting means with features for stopping and switching off in an emergency (main

disconnecting means and EMERGENCY-OFF switches) in conjunction with lockable

rotary operators.

The 3VA molded case circuit breakers certified to UL are available in the following versions:

1. For line protection:

The overload and short-circuit releases are designed for the protection of wiring and nonmotor loads.

2. For starter combinations:

These instantaneous trip circuit breakers are used for short-circuit protection as well as

for the disconnector function, which may be required in Combination Motor Controllers

consisting of instantaneous trip circuit breaker, overload relay and motor contactor.

These instantaneous trip circuit breakers are all equipped with adjustable, instantaneous

short-circuit releases.

3. As molded case switches:

These molded case switches can be used as feeder switches, main switches or nonautomatic circuit breakers without overload protection. They incorporate an integrated

short-circuit self-protection system.

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

9

Introduction

Scope of validity of this document

1.2

Product-specific information

1.2.1

Target readers

Target readers of this documentation

1.2.2

Technical Support

1.2 Product-specific information

This manual has been specially compiled for the 3VA molded case circuit breakers certified

to UL 489, or 3VA UL for short.

The accessories of the 3VA UL molded case circuit breakers are also described in this

manual.

This manual serves as a reference manual for technical information regarding the

configuration, commissioning and operation of 3VA UL molded case circuit breakers and

corresponding accessories.

This manual does not purport to cover all details or variations in equipment, or to provide for

every possible contingency in connection with installation, operation, or maintenance. Should

additional information be desired, please refer to the individual product instruction sheets or

contact the local Siemens sales office.

The contents of this manual shall not become part of or modify any prior or existing

agreement, commitment, or relationship. The sales contract contains the entire obligation of

Siemens. The warranty contained in the contract between the parties is the sole warranty of

Siemens. Any statements contained herein do not create new warranties or modify the

existing warranty.

The information contained in this manual is provided for the benefit of:

● Users

● Control panel manufacturers

● Switchboard manufacturers

● Maintenance personnel

You can find further support on the Internet at:

Technical Support (http://www.siemens.com/lowvoltage/technical-support

)

3VA molded case circuit breakers with UL and IEC certification

10 Manual, 01/2019, L1V30435333-01

Introduction

1.2.3

Reference documents

Further documents

Title

Article number

Link

1.2 Product-specific information

You will find further information in the following documents:

Table 1- 1 Reference documents

3VA IEC Molded Case Circuit Breakers

manual

3VA UL Molded Case Circuit Breakers

catalog (for the European-supported

markets)

3VA UL Molded Case Circuit Breakers

operating instructions

3VA Communication system manual DE 3ZW1012-0VA20-0BB0 3VA molded case circuit breakers

Automatic transfer control device

ATC5300 - Manual

ATSE - Remote Control Software Manual DE A5E02469028-01 ATSE - Remote Control Software Manual

ATSE - Modbus Communication Protocol DE A5E02469001-01 ATSE - Modbus Communication Protocol

Grundlagen der Niederspannungsschalttechnik (Fundamentals of Low-Voltage

Switchgear and Controlgear), Siemens

AG © 2008

Hartmut Kiank, Wolfgang Fruth:

Planungsleitfaden für Energieverteilungsanlagen (Planning Guide for Power

Distribution Plants),

Publicis Publishing

Schalten, Schützen, Verteilen in

Niederspannungsnetzen (Switching,

Protection and Distribution in LowVoltage Networks), substantially extended and revised edition 1997

DE 3ZW1012-0VA10-0AB1 3VA molded case circuit breakers

EN 3ZW1012-0VA10-0AC1

DE E86060-K8290-A101-A1 3VA UL Molded Case Circuit Breakers

EN E86060-K8290-A101-A1-7600

3VA UL Molded Case Circuit Breakers

EN 3ZW1012-0VA20-0BC0

DE A5E02469034-01 ATC5300 automatic transfer control

EN A5E02469035-01

EN

EN

— —

ISBN: A19100-L531-B115 —

ISBN 3-89578-041-3 —

documentation

(https://support.industry.siemens.com/cs/

ww/en/view/90318775)

catalog

(https://support.industry.siemens.com/cs/

ww/en/view/109744301)

operating instructions

(https://support.industry.siemens.com/cs/

ww/en/ps/man)

documentation

(https://support.industry.siemens.com/cs/

ww/en/view/98746267)

device

(http://support.automation.siemens.com/

WW/view/de/41909986/0/en)

http://support.automation.siemens.com/

(

WW/view/en/41909978)

(

http://support.automation.siemens.com/

WW/view/en/40761679)

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

11

Introduction

1.2 Product-specific information

3VA molded case circuit breakers with UL and IEC certification

12 Manual, 01/2019, L1V30435333-01

2

2.1

Overview - applications and portfolio

2.1.1

Applications and possible uses

This chapter provides an overview of all 3VA molded case circuit breakers with certification

according to the North American standard UL 489 (3VA UL) and shows the areas in which

the various molded case circuit breakers are used.

The topics discussed in this chapter are listed below:

● Applications and possible uses

● Aspects of the UL market - Low-voltage systems in the USA

● Portfolio

● Possible configurations

● Detailed information about applications and possible uses

● Technical specifications

● Molded case circuit breakers and accessories in the system

The 3VA UL molded case circuit breakers can be used in various areas in infrastructure,

industry or residential and commercial buildings where they perform different protection

tasks.

Portions of this manual are intended to familiarize customers and users residing outside the

North American market, who may build and export panels, with some of the unique aspects

of UL Certified applications. This range of applications is very diverse, and they are typically

solutions for industry.

Applications in infrastructure and buildings in the North American market are generally

directly supported from within the respective regions.

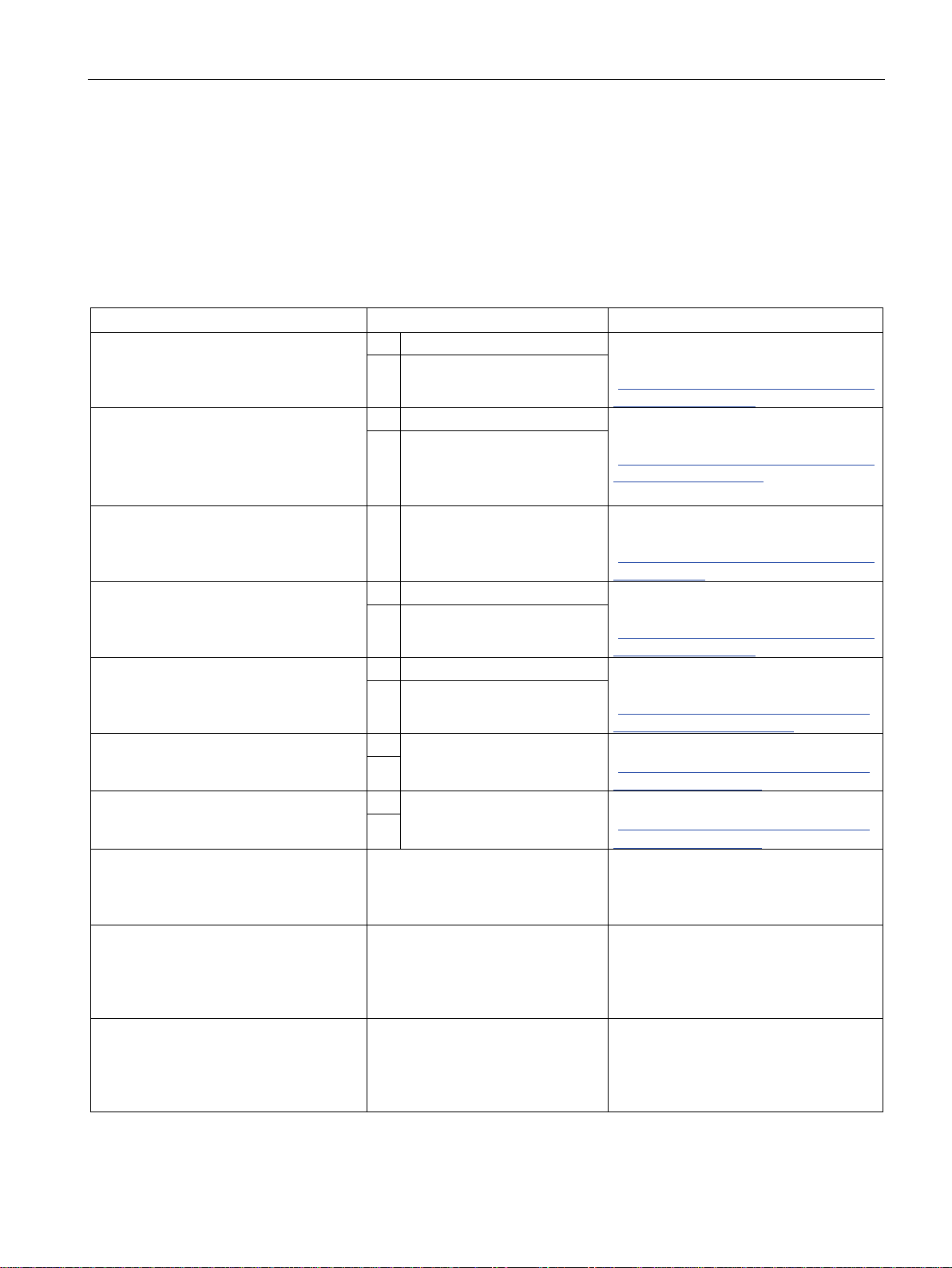

The 3VA UL molded case circuit breakers are used for various functions as shown in the

following table:

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

13

Description

2.1.2

Aspects of the UL market - Low-voltage systems in the USA

Low-voltage systems in the USA

2.1 Overview - applications and portfolio

This chapter is an excerpt from the document "The secrets of UL". You will find the complete

document under

http://w3app.siemens.com/mcms/infocenter/dokumentencenter/ce/Documentsu20Brochures

(

/e20001-a820-p305-v2-7600.pdf).

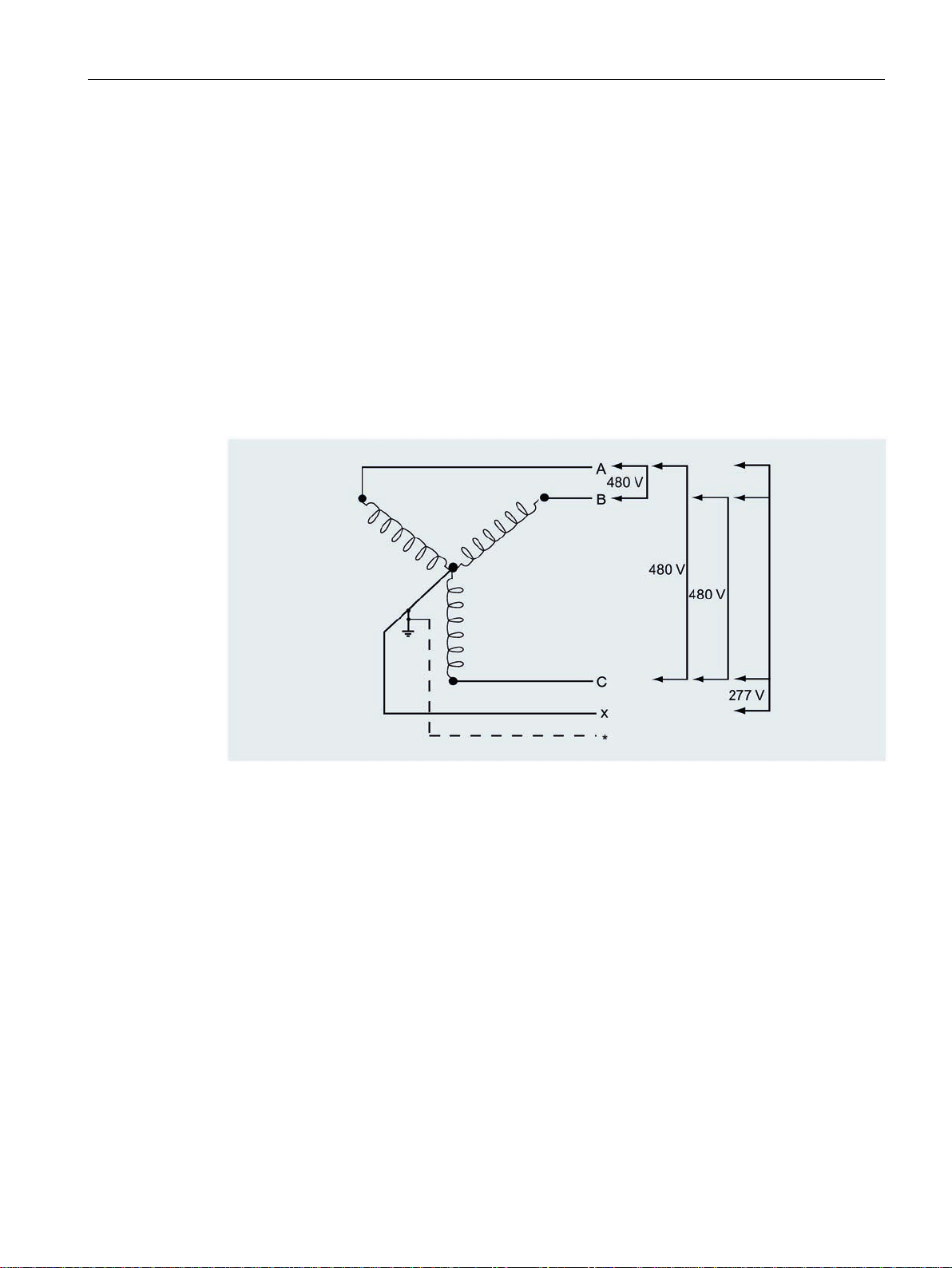

The usual system configurations in the USA are very different from those found in Europe.

Unlike in the IEC, there is a corner-grounded delta system in addition to the solidly grounded

wye system, which is very similar to the TN-S system. In the USA / UL / NEC, all voltages

that occur in the respective system configuration are always specified (see table below).

When devices are selected, very close attention must be paid to which system configuration

is present at the location of use and the system configuration for which the individual devices

are approved.

The main configurations in industry and in non-residential buildings are 3-phase networks

with 240 V and 480 V, as well as 3- and 4-conductor systems with 480Y/277 V. In residential

buildings and in office spaces of industrial and non-residential buildings, the single-phase

system with 120/240 V can also be commonly found.

1)

Y describes the "Solidly grounded circuit". The value "Y" indicates the voltage between the

phases (e.g. 480 V), and the value behind the slash indicates the voltage between the phase and

the grounding or the neutral conductor (e.g. 277 V with 480 V voltage between the phases).

3VA molded case circuit breakers with UL and IEC certification

14 Manual, 01/2019, L1V30435333-01

Description

Electric circuits with "straight" and "slash" voltages

Short circuit current rating of the control panel main (power) circuit

2.1 Overview - applications and portfolio

In the USA, voltages are considered from the power supply company side or the secondary

side of the power supply company transformers. The connection (wye or delta) of the electric

circuit and the method of grounding play a major role here.

In electric circuits with a Grounded Wye, the circuit breaker only switches the full voltage

between the phases (e.g. 480 V). The phase-to-ground voltage is only 277 V in this case,

which explains the "slash" voltage of 480Y/277 V. Industrial Control Panels in which these

devices are installed must be marked with the following inscription: "For use on a solidly

grounded wye source only" (UL 508A Art. 54.12).

In ungrounded or high-resistance grounded wye or delta circuits, and in corner-grounded

delta circuits, only devices (e.g. circuit breakers) that are labeled with a "straight" voltage,

such as 240 V, 480 V or 600 V, may be used. These devices must be able to switch the full

voltage between the phases and between one phase to ground.

Grounded wye, 480Y / 277 V, 3 phase, 4 wire

An industrial control panel must be marked with a short-circuit current rating (SCCR). In IEC

terms, this corresponds approximately to the I

describes the specifications of the short circuit current rating markings on industrial control

panels (with reference to UL 508A, SB4). For the short circuit current rating, not only is the

short-circuit breaking capacity (e.g. of the circuit breaker) relevant, but also the short-circuit

current rating of each individual device. The SCCR-relevant components in the main circuit

include circuit breakers, contactors, overload relays, and solid-state switching devices, as

well as terminals, busbars, the line side of control transformers and frequency converters,

but not the internal wiring of the control panel.

The lowest value applies to the entire control panel. A short-circuit current higher than this

must not be available at the input terminals of the control panel.

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

value of the panel. NEC 2017 Article 409

cw

15

Description

2.1.3

Portfolio

Sizes

2.1 Overview - applications and portfolio

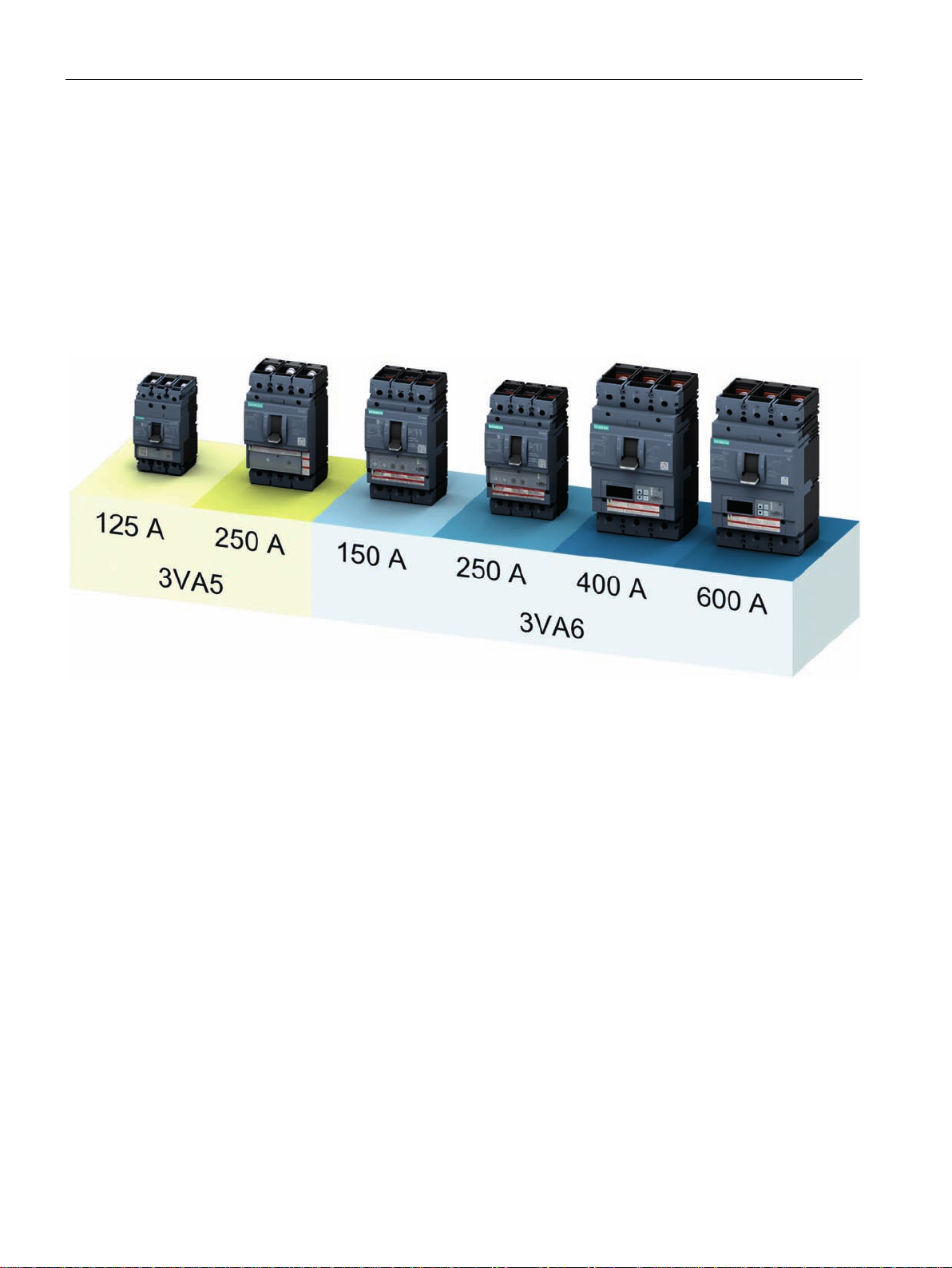

The integrated 3VA UL portfolio consists of two different ranges of molded case circuit

breakers in five different rated operational current versions (frame sizes).

The new 3VA UL molded case circuit breakers set new standards in flexibility and the variety

of modular accessories available. Standardized accessories suitable for use with several

sizes of circuit breaker from all the 3VA UL ranges help to cut costs and save time.

The new 3VA UL molded case circuit breakers are available in the following ranges:

● 3VA5 with thermal-magnetic trip units

● 3VA6 with electronic trip units

The 3VA5 molded case circuit breakers are available in the following versions:

● 1- and 3-pole version in size up to 125 A (3VA51)

● 2(3)-pole and 3-pole version in size up to 250 A (3VA52)

The 3VA6 molded case circuit breakers are available in the following versions:

● 3- and 4-pole version

The circuit breakers are suitable for rated operational currents ranging from 15 A to 600 A

and rated voltages up to 600 V AC, depending on the range and frame size.

3VA molded case circuit breakers with UL and IEC certification

16 Manual, 01/2019, L1V30435333-01

Description

3VA5 molded case circuit breakers

Features

Compact dimensions

Thermal-magnetic trip units

2.1 Overview - applications and portfolio

The new 3VA5 molded case circuit breakers reliably perform all the tasks required for line

protection.

The key features of the 3VA5 range are:

● Compact design

● Number of poles available (dependent on size):

– 1- and 3-pole versions in size 125 A

– (2)3-pole

1)

2-pole molded case circuit breaker in 3-pole frame

● Breaking capacity (dependent on size):

– 1-pole versions:

Breaking capacity of 25 kA to 50 kA at 277 V AC

– 3-pole versions:

Breaking capacity of 25 kA to 65 kA or 100 kA (3VA52) with 480 V AC

Breaking capacity of 50 kA to 100 kA with 500 V DC

1)

and 3-pole version in size 250 A

● Fixed mounting

● Thermal-magnetic trip units

● AC/DC applications

● Modular and easy-to-fit internal accessories with diverse functions

● Uniform accessories platform across all 3VA UL molded case circuit breakers

Due to its small dimensions, the 3VA UL molded case circuit breaker 125 A (3VA51) is

ideally suited to the protection of cables and systems wherever space is limited.

In addition, the 3VA51 molded case circuit breaker is suitable for mounting on 35 mm

DIN rails.

The 3VA5 molded case circuit breakers have a thermal-magnetic trip unit with overload and

short-circuit protection. This has been developed for implementing economical, cost-efficient

installations up to 250 A. It is suitable for use in three-phase networks, AC networks, and

400 Hz applications and with DC currents.

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

17

Description

3VA6 molded case circuit breakers

Features

Compact dimensions with expanded functionality

2.1 Overview - applications and portfolio

The new 3VA6 molded case circuit breakers reliably perform all the tasks required for line

protection.

This range is designed for applications with more exacting requirements:

● Increased breaking capacity

● Compact dimensions

● Integrated metering function

● Connection to a fieldbus communication system

The key features of the 3VA6 range are:

● Compact dimensions

● 3 and 4-pole versions

● Four breaking capacity classes with breaking capacities of

– 35 kA to 150 kA with 480 V AC

– 18 kA to 50 kA with 600 V AC

● Fixed-mounting, plug-in technology, draw-out technology

● Electronic trip units (ETU)

● Retrofittable communication for ETU 5-series and 8-series

● Depending on the ETU: Integrated metering function for voltages, currents, powers, etc.

● AC applications

● No derating up to +50 °C

● Modular and easy-to-fit internal accessories with diverse functions

● Uniform accessories platform across all 3VA UL molded case circuit breakers

● Electronic Trip Units (ETU) with different setting values

Besides the expanded functionality, the 3VA6 molded case circuit breaker is also

characterized by its compact dimensions for fixed mounting. In addition, plug-in and draw-out

sockets are available for 3VA6 molded case circuit breakers. Standard switches can be

retrofitted for these mounting methods with little effort.

Moreover, the different breaking capacity classes available and the many possibilities

afforded by the various electronic trip units also provide the flexibility needed for planning.

3VA molded case circuit breakers with UL and IEC certification

18 Manual, 01/2019, L1V30435333-01

Description

Electronic trip unit (ETU)

Energy management and communication

2.1 Overview - applications and portfolio

The current sensor of the 3VA6 molded case circuit breaker comprises an iron-cored

transformer for the internal power supply and a Rogowski coil for precise sensing and

measurement of the current values. Each of these transformers was specifically optimized

for its task. Thanks to the high accuracy of current measurement achieved by the Rogowski

coil, the 3VA6 molded case circuit breaker is suitable for power and energy measurement. In

addition, finer adjustment of ground fault current monitoring is possible.

The electronic trip units (ETUs) provide the following protection functions:

● Overload protection L ("L" = Long-time delay)

Adjustable in steps from 40% to 100% of the rated operational current of the molded case

circuit breaker.

● Short-time delayed short-circuit protection S ("S" = Short-time delay) for time-selective

response in case of a short circuit

● Instantaneous short-circuit protection I ("I" = instantaneous):

● Protection of the neutral conductor against overload and short-circuit ("N" = neutral)

● Protection against residual currents to ground ("G" = Ground fault).

Two possibilities are available for protection against residual currents to ground:

● Tripping of the breaker when a ground fault is present and thus disconnection of the

system

● Alarm-only indication, via LED, that a ground fault is present. The signal is also available

through communication and a digital output, when applied with the appropriate

accessories.

The breaker is not tripped here, the system remains connected although the ground fault

still exists.

3VA6 molded case circuit breakers with corresponding ETUs are available for both

applications.

The Electronic Trip Units (ETUs) provide the following energy management and

communication functions:

● Metering functions for current, voltage, power and energy consumption

● Transfer of measured values and status information of the circuit breaker

● Remote parameter assignment of tripping thresholds and miscellaneous parameters

● Flexible use of digital inputs and outputs of the optionally available EFB300 external

function box

● Commissioning/setting the plant topology and also individual breaker parameters with the

"powerconfig" software package

● Testing and archiving with the TD300 and TD500 test devices (with powerconfig)

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

19

Description

100% rated versions of the 3VA UL molded case circuit breaker

2.1 Overview - applications and portfolio

The US National Electrical Code, NEC recognizes two categories of overcurrent protective

devices (OCPD) and has different required load calculations for their application. The two

categories are standard OCPDs and OCPDs listed for operation at 100% of their rating

(commonly referred to as "100 % rated").

For standard OCPDs, the rating selected must be no less than the sum of 100% of the noncontinuous loads and 125% of the continuous loads (3 hours or more). For OCPDs listed for

operation at 100% of their rating, the calculation for the minimum rating is based on the sum

of 100% of the non-continuous loads and 100% of the continuous loads.

For 100% rated circuit breakers, there are additional UL489 requirements for the wire

connectors/lugs, conductor sizes and types, and minimum enclosure sizing.

3VA molded case circuit breakers with UL and IEC certification

20 Manual, 01/2019, L1V30435333-01

Description

2.1.4

Detailed information about applications and possible uses

2.1 Overview - applications and portfolio

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

21

Description

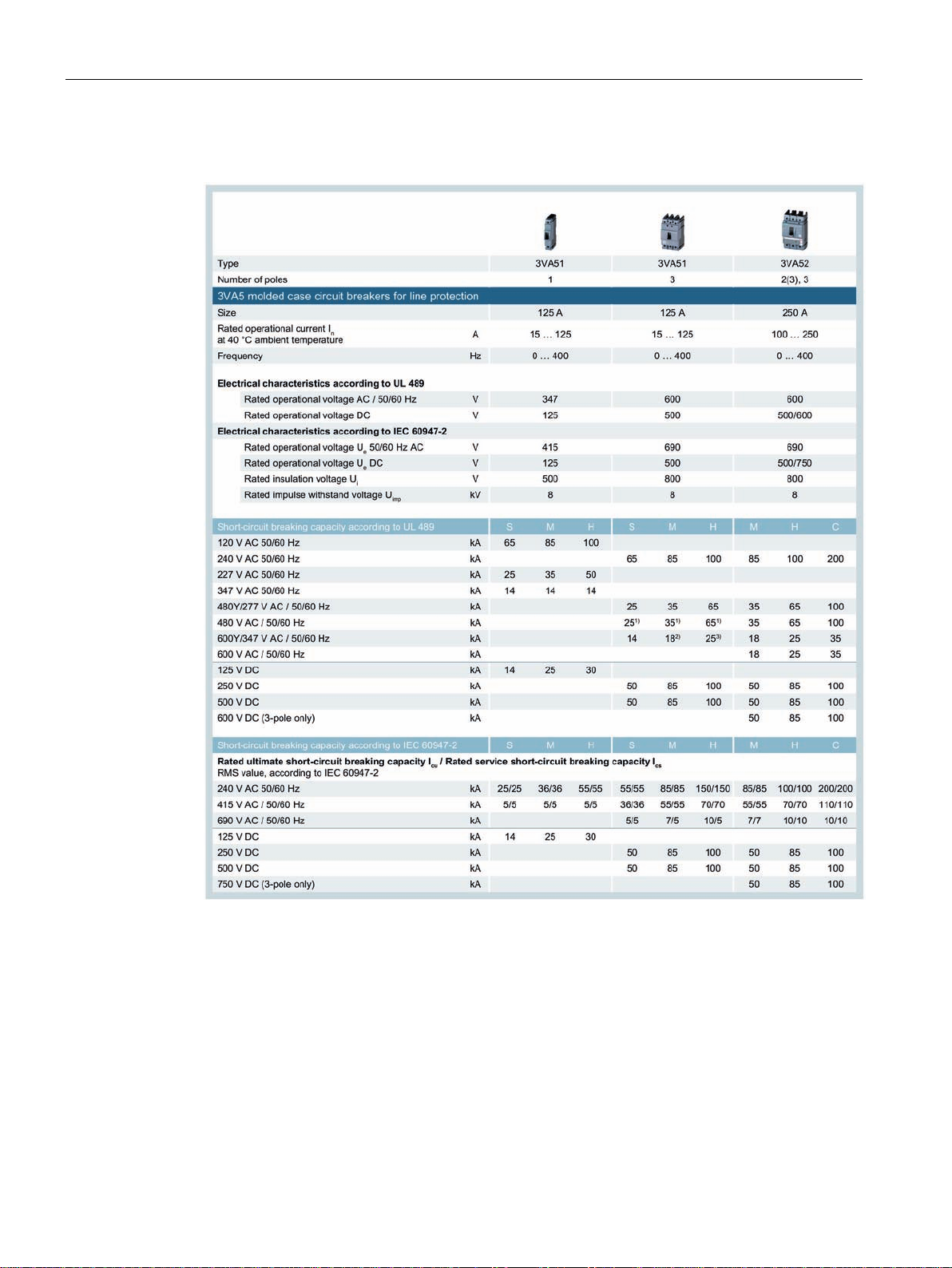

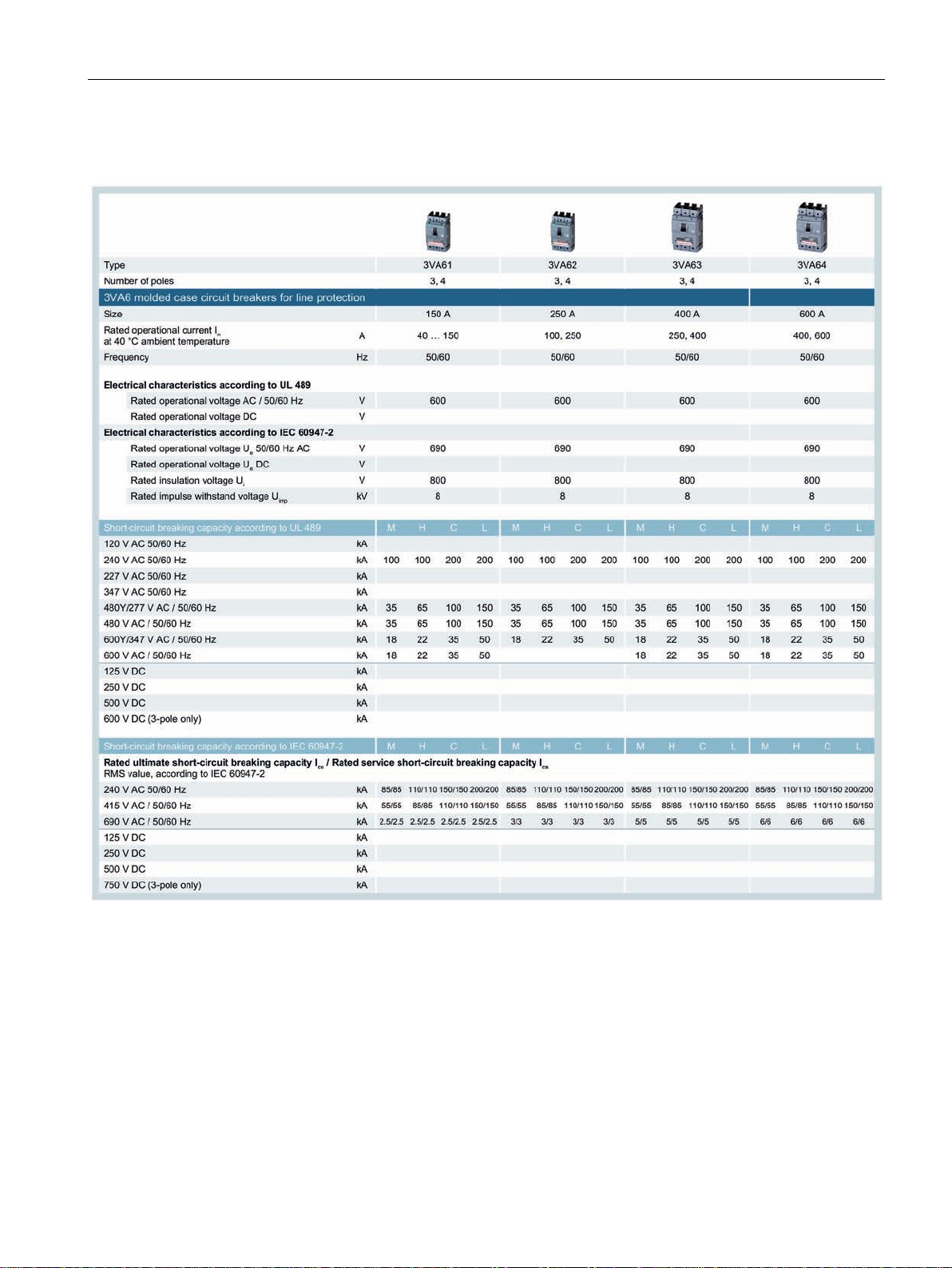

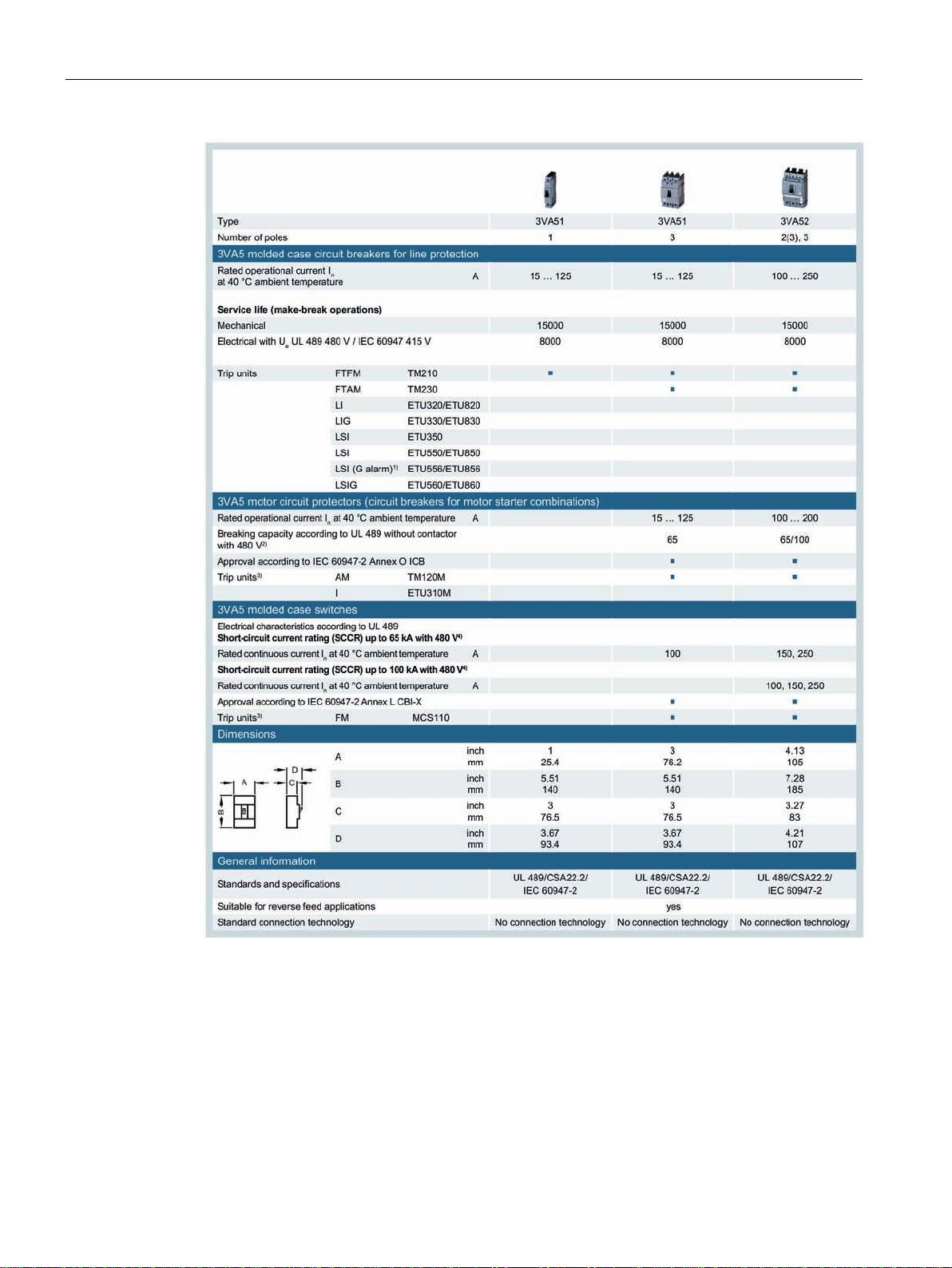

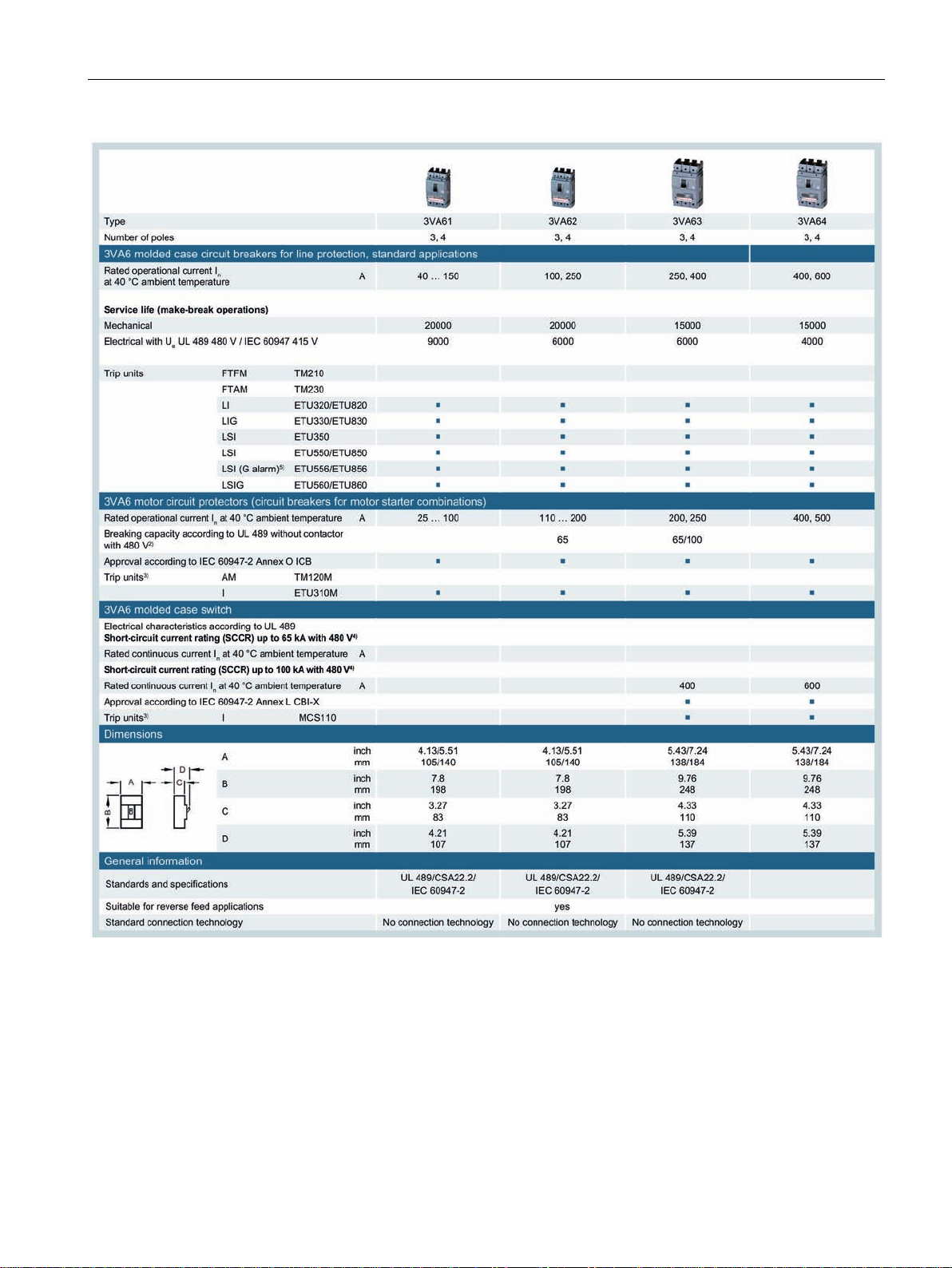

2.1.5

Technical specifications

2.1 Overview - applications and portfolio

1)

Applies to In 15 A to 90 A

2)

In 100 A to 125 A 14 kA

3)

In 40 A to 90 A 18 kA; 100 A to 125 A 14 kA

3VA molded case circuit breakers with UL and IEC certification

22 Manual, 01/2019, L1V30435333-01

Description

2.1 Overview - applications and portfolio

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

23

Description

2.1 Overview - applications and portfolio

1)

G alarm, no G protection (the G function sends an alarm message but does not trip the circuit

breaker)

2)

Breaking capacities in combination with contactors (SCCR ratings) may differ

3)

Integrated instantaneous short-circuit release for self-protection

4)

The short-circuit current rating (SCCR rating) is the maximum permissible short-circuit current

at the installation location of the MCS in combination with an appropriate additional overload

protection device.

3VA molded case circuit breakers with UL and IEC certification

24 Manual, 01/2019, L1V30435333-01

Description

2.1 Overview - applications and portfolio

1)

G alarm, no G protection (the G function sends an alarm message but does not trip the circuit breaker)

2)

Breaking capacities in combination with contactors (SCCR ratings) may differ

3)

Integrated instantaneous short-circuit release for self-protection

4)

The short-circuit current rating (SCCR rating) is the maximum permissible short-circuit current at the installation

location of the MCS in combination with an appropriate short-circuit protection device.

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

25

Description

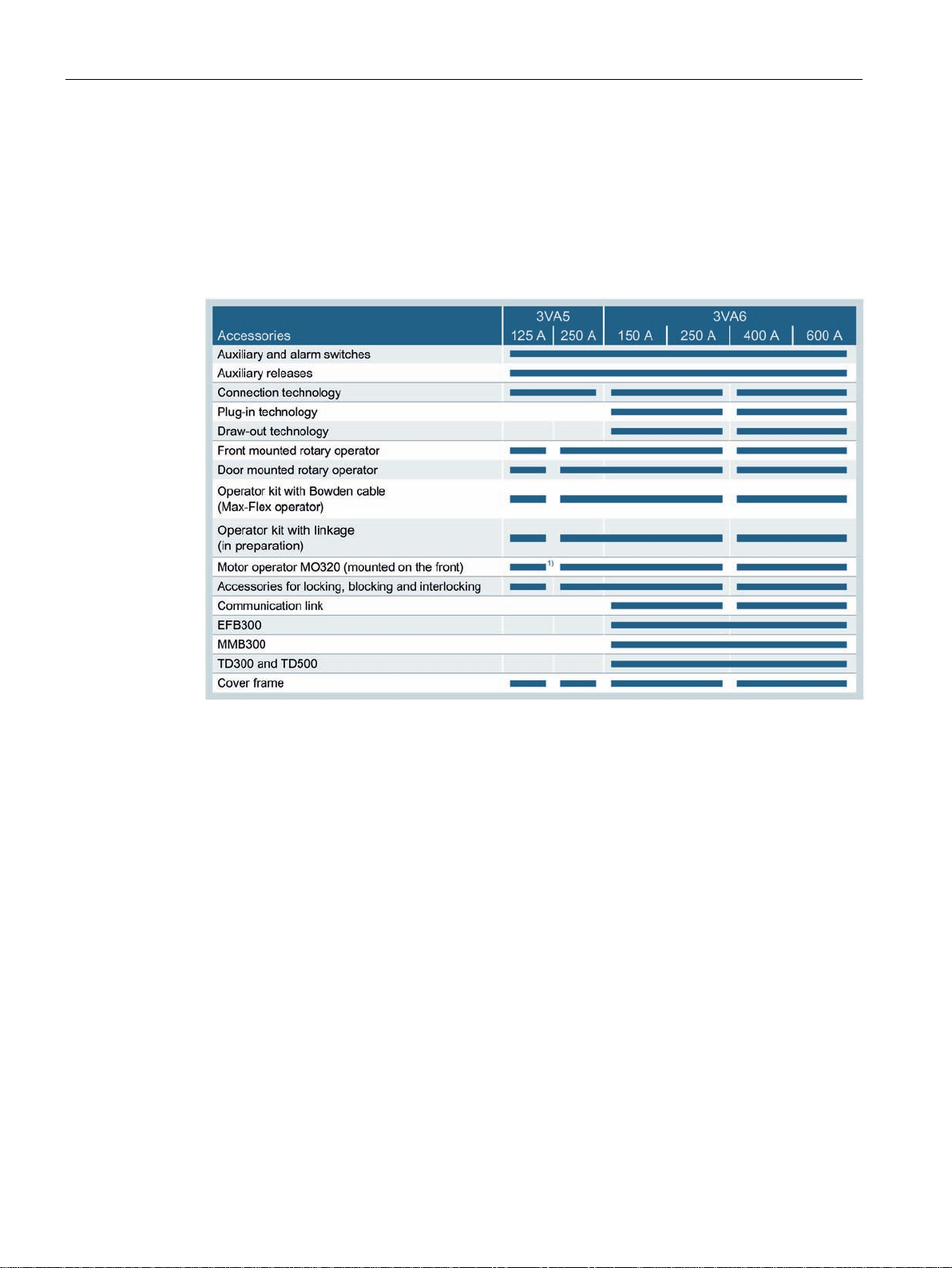

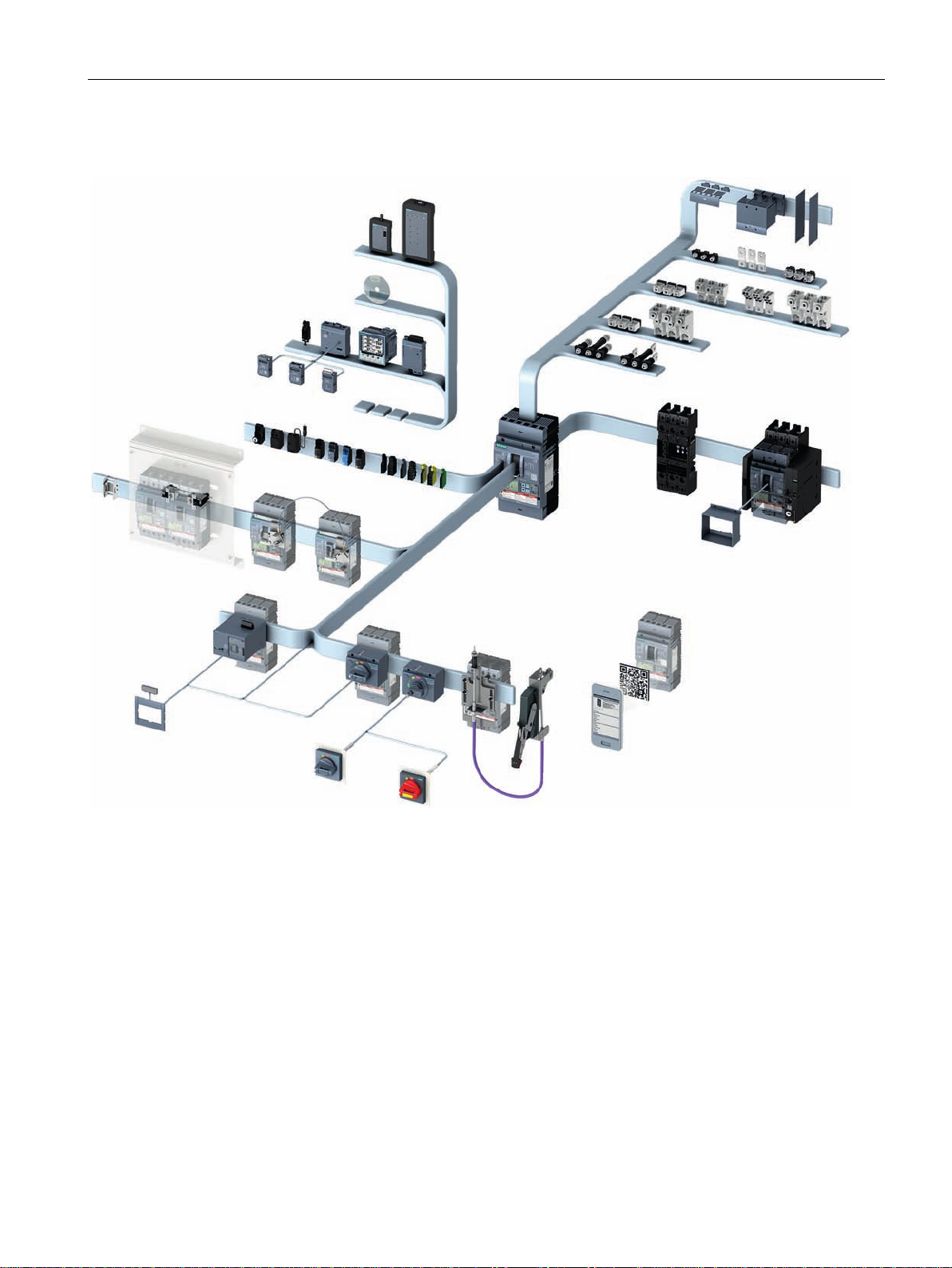

2.1.6

Molded case circuit breakers and accessories in the system

2.1 Overview - applications and portfolio

The new 3VA UL molded case circuit breakers come with a large portfolio of accessory

components that – depending on the type of accessory – can be flexibly installed internally or

externally regardless of the size of circuit breaker.

The table below indicates which accessories are compatible with particular molded case

circuit breakers, and which sizes of breakers are compatible with the same accessory:

1)

Only possible with fixed mounting and not when mounted on a DIN rail

3VA molded case circuit breakers with UL and IEC certification

26 Manual, 01/2019, L1V30435333-01

Description

Overview of accessories in the system

2.1 Overview - applications and portfolio

3VA molded case circuit breakers with UL and IEC certification

Manual, 01/2019, L1V30435333-01

27

Description

2.2

Ergonomic design

Integrated system

2.2.1

Installation variants for 3VA UL

2.2 Ergonomic design

This chapter provides an overview of the ergonomic design features of the new 3VA UL

molded case circuit breakers and explains what makes them so special.

The topics discussed in this chapter are listed below:

● Optional installation variants

● Color-coded indication of switching position in the draw-out unit

● Clear status indication

● Active illumination

● Ergonomic handle

● Color-coded control elements

● Broad range of accessories

● Connection options

The 3VA UL molded case circuit breakers set new standards, not only in terms of their

technical features and functional scope, but also in terms of their design.

The new 3VA UL range provides an integrated system with regard to operation, functionality

and installation. This principle is embodied in the basic units and in all internal and external

accessories.

The internal and external accessories of the 3VA UL molded case circuit breakers offer the

following benefits:

● Standardized methods of operation

● Standardized scope of functions

● Standardized installation procedures

● The same internal accessories for all circuit breaker sizes from 125 A to 600 A (auxiliary

switches, auxiliary releases)

To ensure full flexibility when planning a system, the molded case circuit breaker range can

be extended with additional components in such a way that operability is guaranteed in every

situation.

The following components can be installed to suit the installation location:

● Front mounted rotary operator

● Door mounted rotary operator

● Operator kit with Bowden cable (Max-Flex™ operator)

● Operator kit with rigid linkage (in preparation)

● Motor operator

3VA molded case circuit breakers with UL and IEC certification

28 Manual, 01/2019, L1V30435333-01

Loading...

Loading...