Siemens SED2-0.75/22B, SED2-0.55/22B, SED2-2.2/22B, SED2-3/22B, SED2-4/22B Operating Instructions Manual

...

SED2 variable speed drives

Operating instructions

CM1U5192en

01.2002

Siemens Building Technologies

HVAC Products

2/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products 01.2002

3/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

Table of contents

1 Introduction ...................................................................................................7

1.1 Purpose of this document .............................................................................7

1.2 Validity...........................................................................................................7

1.3 Target audience............................................................................................7

1.4 Document structure.......................................................................................7

1.5 Referenced documents.................................................................................7

1.6 Document conventions..................................................................................8

1.7 Environmental compatibility and disposal.....................................................9

2 Safety instructions.......................................................................................11

2.1 General........................................................................................................11

2.2 Commissioning............................................................................................11

2.3 Operation.....................................................................................................12

2.4 Repairs........................................................................................................12

3 Mechanical installation................................................................................13

3.1 Installing the SED2 after extended storage.................................................13

3.2 Ambient conditions......................................................................................13

3.3 Mounting......................................................................................................14

3.3.1 Dimensions of SED2 drives with IP20/NEMA 0 rating ................................14

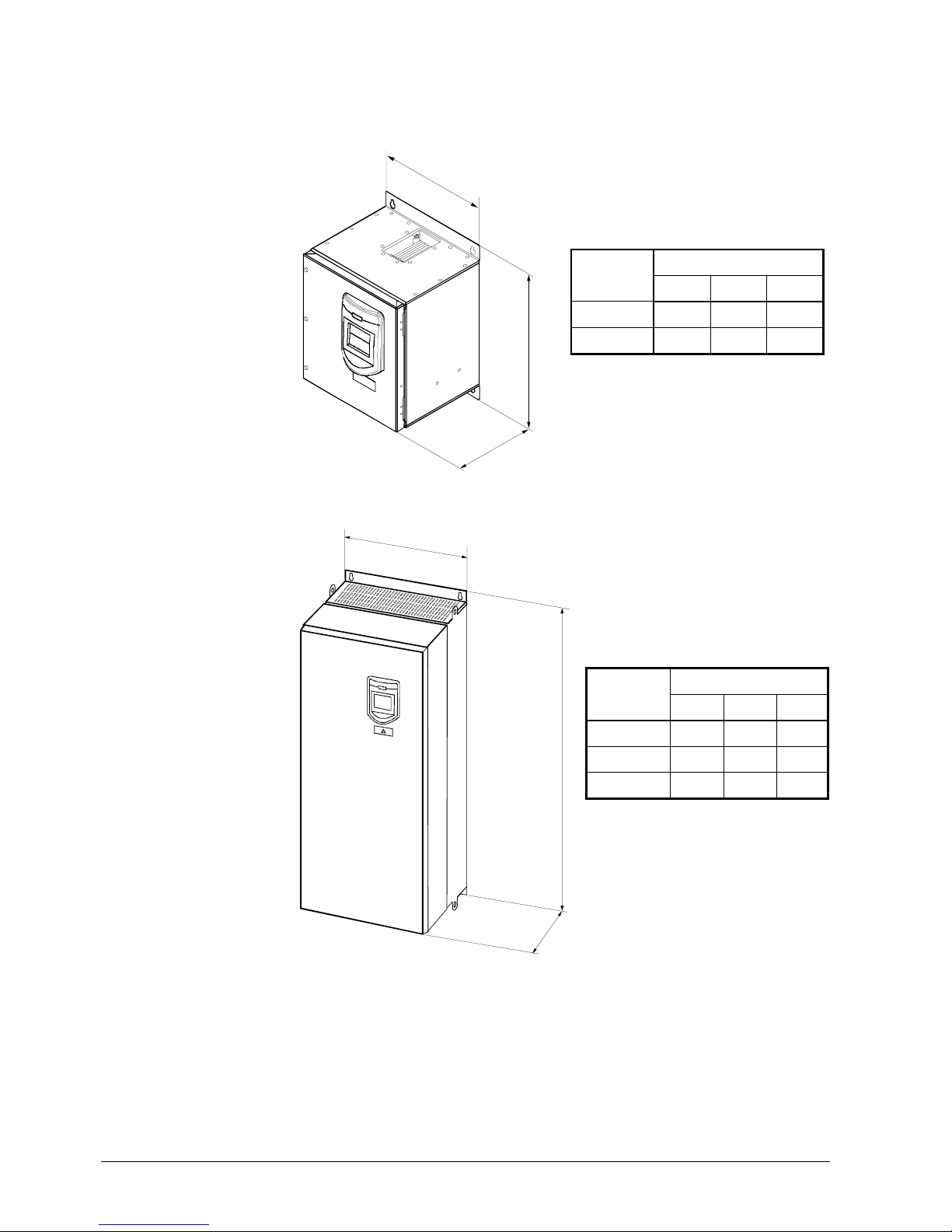

3.3.1.1 Dimensions of SED2 frame sizes A to C.....................................................14

3.3.1.2 Dimensions of SED2 footprint filters for frame sizes A to C........................15

3.3.1.3 Dimensions of SED2 frame sizes D to F.....................................................15

3.3.2 Dimensions of SED2 drives with IP54/NEMA 12 rating ..............................16

3.3.2.1 Dimensions of SED2 frame sizes B and C..................................................16

3.3.2.2 Dimensions of SED2 frame sizes D to F.....................................................16

3.3.3 Mounting SED2 drives with IP20/NEMA 0 rating ........................................17

3.3.4 Mounting SED2 drives with IP54 / NEMA 12 rating ....................................18

4 Electrical installation....................................................................................19

4.1 General........................................................................................................19

4.1.1 Maximum length of motor cables ................................................................19

4.1.2 Operation with ungrounded systems...........................................................19

4.1.2.1 Precautions for ungrounded systems (IT protective systems) .................... 19

4.1.3 Operation with a residual current device (RCD)..........................................22

4.2 EMC-compatible installation........................................................................23

4.2.1 EMC-compatible wiring ...............................................................................23

4.3 Mains and motor connections .....................................................................25

4.3.1 Access to connection terminals: Frame size A............................................26

4.3.2 Access to connection terminals: Frame sizes B and C...............................27

4.3.3 Access to connection terminals: Frame sizes D to F IP20..........................28

4.3.4 Power and motor terminals: Frame sizes A to F.........................................30

4/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

4.3.5 Power connection for drives with a built-in EMC filter ................................31

4.3.6 Tightening torque for connection terminals ................................................ 34

4.3.7 Cross-sections for power and motor cables ............................................... 34

4.3.8 Block diagram showing typical installation ................................................. 36

4.3.9 Direction of rotation .................................................................................... 36

4.3.10 Star or delta connection..............................................................................37

4.3.11 Connecting several motors......................................................................... 37

4.3.12 External motor overload protection.............................................................37

4.4 Control terminals ........................................................................................ 38

4.5 SED2 block diagram...................................................................................39

5 Commissioning........................................................................................... 41

5.1.1 DIP switch settings.....................................................................................42

5.1.1.1 Setting the DIP switches on the I/O module...............................................42

5.1.1.2 DIP switch settings on the control board .................................................... 42

5.2 Checklist prior to start.................................................................................43

5.3 Operator panels for the SED2 .................................................................... 43

5.3.1 Description of the basic operator panel (BOP)...........................................43

5.3.2 Description of the advanced operator panel (AOP).................................... 44

5.3.3 Exchanging the operator panels................................................................. 44

5.3.4 Buttons and their functions on the operator panel (BOP and AOP) .......... 45

5.4 Commissioning modes...............................................................................46

5.4.1 Overview of commissioning with the BOP or AOP.....................................46

5.4.2 Quick commissioning.................................................................................. 46

5.4.3 Motor data for parameterization ................................................................. 48

5.4.4 Commissioning with the BOP or AOP ........................................................ 48

5.4.4.1 Country-specific default settings for operation with the BOP .....................48

5.4.4.2 Setting parameters with the BOP or AOP ..................................................49

5.4.5 Resetting SED2 parameters to the factory settings....................................50

5.4.6 Basic operation with the BOP..................................................................... 50

5.4.7 10 Hz test ................................................................................................... 50

5.4.8 General operation.......................................................................................51

6 Programming..............................................................................................53

6.1 Introduction to the SED2 system parameters............................................. 53

6.1.1 General notes ............................................................................................. 53

6.2 Access to parameters.................................................................................53

6.2.1 Parameter access levels (P0003)............................................................... 53

6.2.2 Parameter filter (P004)...............................................................................53

6.2.3 Diagram for a parameter overview ............................................................. 54

6.3 Basic functions of the SED2.......................................................................55

6.3.1 Digital inputs............................................................................................... 55

6.3.2 Analog inputs..............................................................................................57

5/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

6.3.3 Analog outputs............................................................................................60

6.3.4 Frequency setpoint (P1000)........................................................................62

6.3.5 Selecting the command source (P0700) .....................................................62

6.3.6 OFF functions..............................................................................................63

6.3.7 Control types...............................................................................................63

6.3.8 Communication ...........................................................................................63

6.4 HVAC functions of the SED2 ......................................................................64

6.4.1 PID controller ..............................................................................................64

6.4.2 Belt failure detection without sensor (P2181)..............................................65

6.4.3 Belt failure detection with sensor (P0400)...................................................67

6.4.4 Staging pumps or fans ................................................................................68

6.4.5 Temperature control with LG-Ni 1000 sensor .............................................72

6.4.6 Bypassing the VSD.....................................................................................73

6.4.7 Hibernation mode........................................................................................75

6.5 System parameter list for levels 1 to 3........................................................77

6.6 Overview of factory and user parameter settings......................................105

7 Troubleshooting ........................................................................................107

7.1 Troubleshooting using the operator panel.................................................107

7.2 Error messages.........................................................................................108

7.2.1 Error code list............................................................................................108

7.2.2 Warning code lists.....................................................................................111

8 Technical data for the SED2 .....................................................................113

8.1 General technical data..............................................................................113

8.2 Type-specific data.....................................................................................115

9 Appendix ...................................................................................................119

9.1 Options......................................................................................................119

9.1.1 Retrofitting EMC filters for VSD frame sizes A to C ..................................120

9.2 Applicable standards.................................................................................120

9.3 List of abbreviations..................................................................................121

9.4 Index .........................................................................................................123

6/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

7/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

1 Introduction

1.1 Purpose of this document

These operating instructions contain all the information necessary to correctly mount,

install, c ommission, and parameterize (programming) SED2 variable speed drives

(VSD) as well as for effective and troublefree operation.

1.2 Validity

The operating instructions apply to all SED2 variable speed drives, frame sizes A to F.

They are supplied with the product, and are part of the full range of SED2 VSD

literature.

1.3 Target audience

This document is primarily intended for installers, electrical installers, service

technicians, and operators or end users of HVAC plants (Heating, Ventilating, and Air

Conditioning).

1.4 Document structure

The document is divided into the following sections:

Chapter 1 Introduction

Chapter 2 Safety instructions

Chapter 3 Mechanical installation

Chapter 4 Electrical installation and wiring of the motor and VSD

Chapter 5 Commissioning

Description of basic and advanced operator panels

Quick commissioning

Chapter 6 Programming (parameterization)

Description of functions

System parameter list

Chapter 7 Troubleshooting, warning and error code lists

Chapter 8 Technical data

Chapter 9 Appendix:

Applicable standards and declarations of conformity

List of abbreviations, index

1.5 Referenced documents

Getting Started Guide:

The Getting started guide is a brief multilingual guide to provide users fast access to

all the basic information necessary to install, set up, and operate the VSD.

Target audience: Ins tallers, ins talling engineers, and commissioning engineers.

Engineering manual: Documentation on bas ics.

This manual contains in-depth information on all technical matters relating to the SED2

VSD.

Target audience: Project design engineers , planners, users of the product, technical

staff, and service.

CM1G5192X

CM1J5192en

8/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

Data sheet

The data sheet contains a brief description of functions, notes on use, type codes,

accessories, ordering information, technical data, and a range overview.

Target audience: Project design engineers, planners, purchasing and sales staff, and

service.

1.6 Document conventions

Information pointing at immediate danger is printed under the heading “Danger” with

the symbol shown in the left margin. Failure to observe this information may result in

severe physical injury or death or severe property damage.

Information under the heading “Warning” is shown with the symbol in the left margin.

Failure to observe this category of information may result in physical injury

and/or property damage.

Information under the heading “Caution” is shown with the symbol in the left margin.

Failure to observe this type of information may result in property damage and/or

loss of data.

Other important information (headed “Important” or “Note”) is shown on a gray

background. Failure to observe this information will not result in any damage.

This relates to additional information important for the safety of personnel and

equipment, or provides details of additional options or technical requirements.

Helpful information to simplify the use of the product for the user.

"Authorized personnel" are persons familiar with installing, mounting, commissioning,

and operating the equipment, and aware of the associated hazards.

Authorized personnel must satisfy the following requirements:

• They must be trained and authorized to switch on, switch off, disconnect, and

ground electric circuits, and to attach warning labels in accordance with the

established safety instructions.

• They must have training in the proper care and use of protective devices in

accordance with all prevailing safety regulations.

• They must be trained in and capable of administering first aid.

CM1N5192en

Danger

Warning

Caution

Important

Note

.

..

.

Tips

Authorized personnel

9/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

1.7 Environmental compatibility and disposal

This product was developed and manufactured using materials and processes which

take full account of environmental issues and which comply with our environmental

standards.

Please not the following for disposal at the end of the product life, or in the event of its

replacement:

• For disposal, this product is defined as waste from electrical and electronic

equipment (“electronic waste”); do not dispose of it as household waste. This

applies particularly to the PCB assembly.

• Always use the most environmentally compatible method of disposal, in line with

the state-of-the-art technology in environmental protection, recycling, and waste

management.

Observe all local and applicable laws.

• Always aim for maximum re-use of the basic materials at minimum environmental

stress. Observe any notes on materials and disposal that may be attached to

individual components.

• Use local depots and waste management companies, or refer to your supplier or

manufacturer to return used products or to obtain further information on

environmental compatibility and waste disposal.

The law may mandate special handling of components such as electrolytic

capacitors and LCD panels, or it may be environmentally desirable.

The variable speed drive is delivered in re-usable packaging. Please retain the

packaging for later use or in case you need to return the product to the manufacturer.

General notes

Special electronic

components

Packaging

10/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Introduction 01.2002

11/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Safety instructions 01.2002

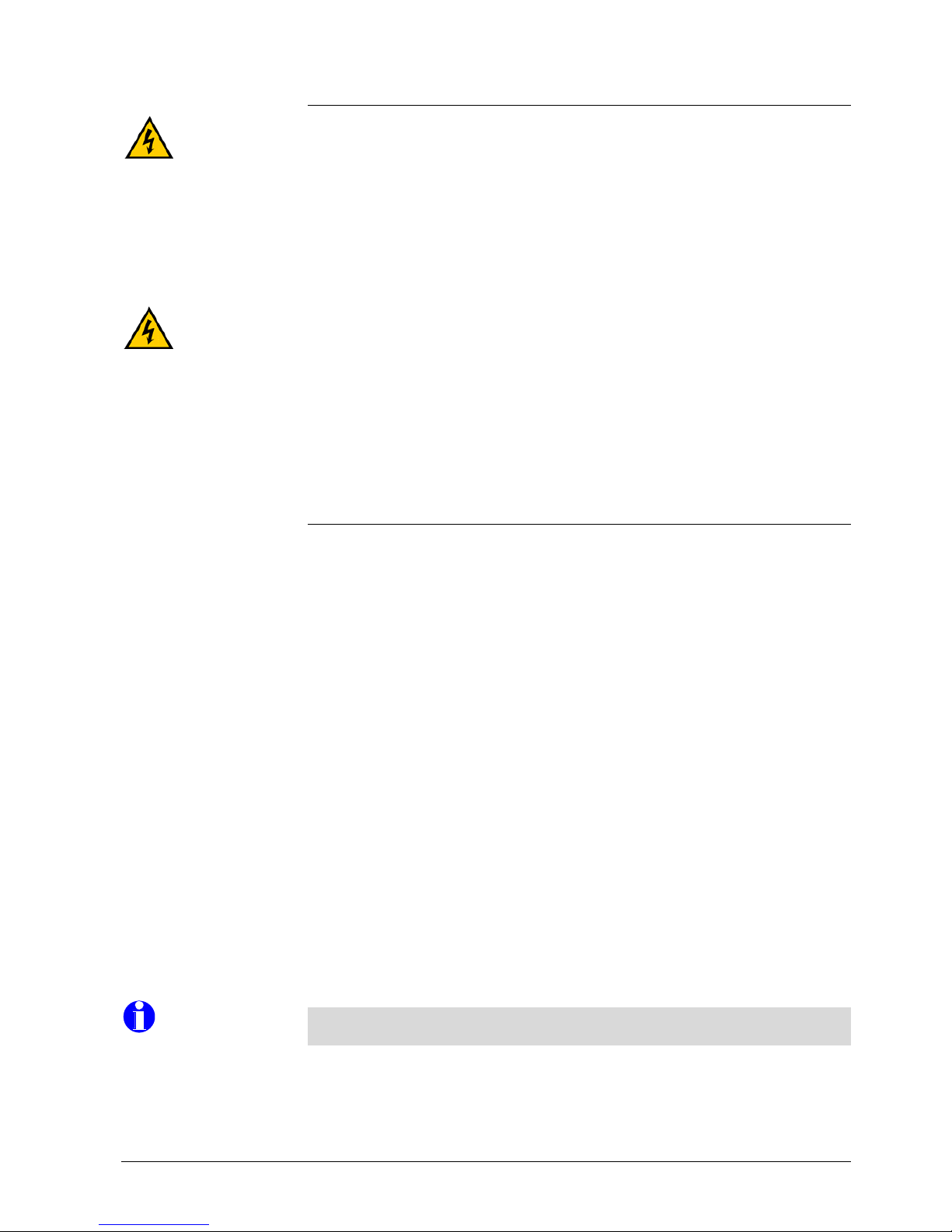

2 Safety instructions

The following warnings and notes on danger are provided for your safety and as a

means of preventing damage to the product or to any components of the connected

machinery. This section contains general warnings, preventive measures, and danger

warnings, which apply to all work on the SED2 variable speed drives. Specific warnings

applicable to particular tasks are summarized at the beginning of each chapter and

repeated throughout the chapter as necessary at the relevant points.

Please read this information carefully, as it is provided for your personal safety,

and to help extend the life of the SED2 variable speed drive and any equipment

connected to it.

Refer to section 1.6 Document conventions for information on the format of warning

notes and as sociated symbols.

2.1 General

♦ This equipment uses hazardous voltages and drives potentially dangerous rotating

mechanical parts. Non-c ompliance with warnings or failure to follow the

instructions in this manual may put lives at risk , or result in severe physical injury,

or serious damage to property/equipment.

♦ Only authorized personnel may work on this equipment. They must first acquaint

themselves with all the safety instructions, and installation and operating

instructions in this manual. Successful and safe operation of this device depends

on its proper handling, installation, commissioning, and operation.

♦ Prevent children and other unauthorized persons from accessing the equipment.

The DC link capacitors remain charged with dangerous voltages for five minutes after

power has been switched off.

Do not open the device for five minutes after switching off the supply voltage.

Use the equipment only for purposes as specified by the manufacturer. Unauthorized

modifications and use of spare parts or accessories not supplied or recommended by

the manuf acturer of this equipment may cause fires, electric shock, and physical injury.

Keep these operating instructions within easy reach of the equipment and make them

available to all users.

2.2 Commissioning

♦ Only authorized personnel trained in the setup, installation, commissioning, and

operation of the product may work on the product and plant.

♦ Only hard-wired mains connections are permissible. Ground the VSD (IEC 536,

Class 1, NEC and other relevant industry standards).

♦ If a residual current device (RCD) is to be used, it must be a type B device.

♦ Do not connect machines with a 3-phase power supply fitted with EMC filters to the

mains via an earth leakage current circuit breaker (ELCB) (see DIN VDE 0160,

section 6.5).

Format of warnings

Warning

Risk of electric shock

Danger

Purpose

Availability of the

operating instructions

12/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Safety instructions 01.2002

The following terminals may carry dangerous voltages even when the variable speed

drive is not running:

– Power supply terminals L1, L2, L3.

– Motor terminals U, V, W.

– Link terminals DC-, DC+/B+, DC/R+, B-.

To prevent inductive and capacitive interference, connect the power, motor, and control

cables to the variable speed drive as illustrated and described in section 4.2.1 “EMCcompatible wiring“.

2.3 Operation

♦ SED2 variable speed drives operate at high voltages.

♦ Emergency stop facilities in accordance with EN 60204 IEC 204 (VDE 0113) must

remain operative in all operating modes of the control equipment. Resetting the

emergency stop facility may not cause an uncontrolled or undefined restart.

♦ In cases where faults in the control equipment could cause significant equipment

damage or severe physical injury (e.g., potentially dangerous short circuits), take

additional external precautions or provide facilities to ensure or enforce safe

operation even in the event of a short circuit (e.g., independent limit switches,

mechanical interlocks, etc.).

♦ Certain parameter settings can cause an automatic restart of the variable speed

drive following an fault or supply voltage failure, provided the fault has been

eliminated/acknowledged or the supply voltage has been restored.

♦ The variable speed drive is capable of protecting the motor from overload. (Motor

overload protection in accordance with UL 508C, section 42). See P0610 and

P0335.

♦ Protection against motor overload can be instituted via an external PTC thermistors

(temperature variable conductor) via a special input (Class 14/15, see also section

4.3.12, page 37).

♦ Do not use the variable speed drive as an “Emergency Stop” mechanism

(see EN60204, 9.2.5.4).

2.4 Repairs

♦ Only the Siemens service, repair centers authorized by Siemens, or authorized

personnel fully acquainted with all the warnings and operating procedures as

specified in this manual may repair this equipment.

♦ Replace defective parts or components using parts from the relevant spare parts

list.

Disconnect the power supply before opening the device.

Danger

Caution

Danger

Danger

13/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Mechanical installation 01.2002

3 Mechanical installation

3.1 Installing the SED2 after extended storage

Recharge the capacitors in the variable speed drive following an ex tended period of

storage. Remember to calculate the storage time from the date of manufacture,

and not from the date of delivery. The required procedure varies according to the

storage period and is described below.

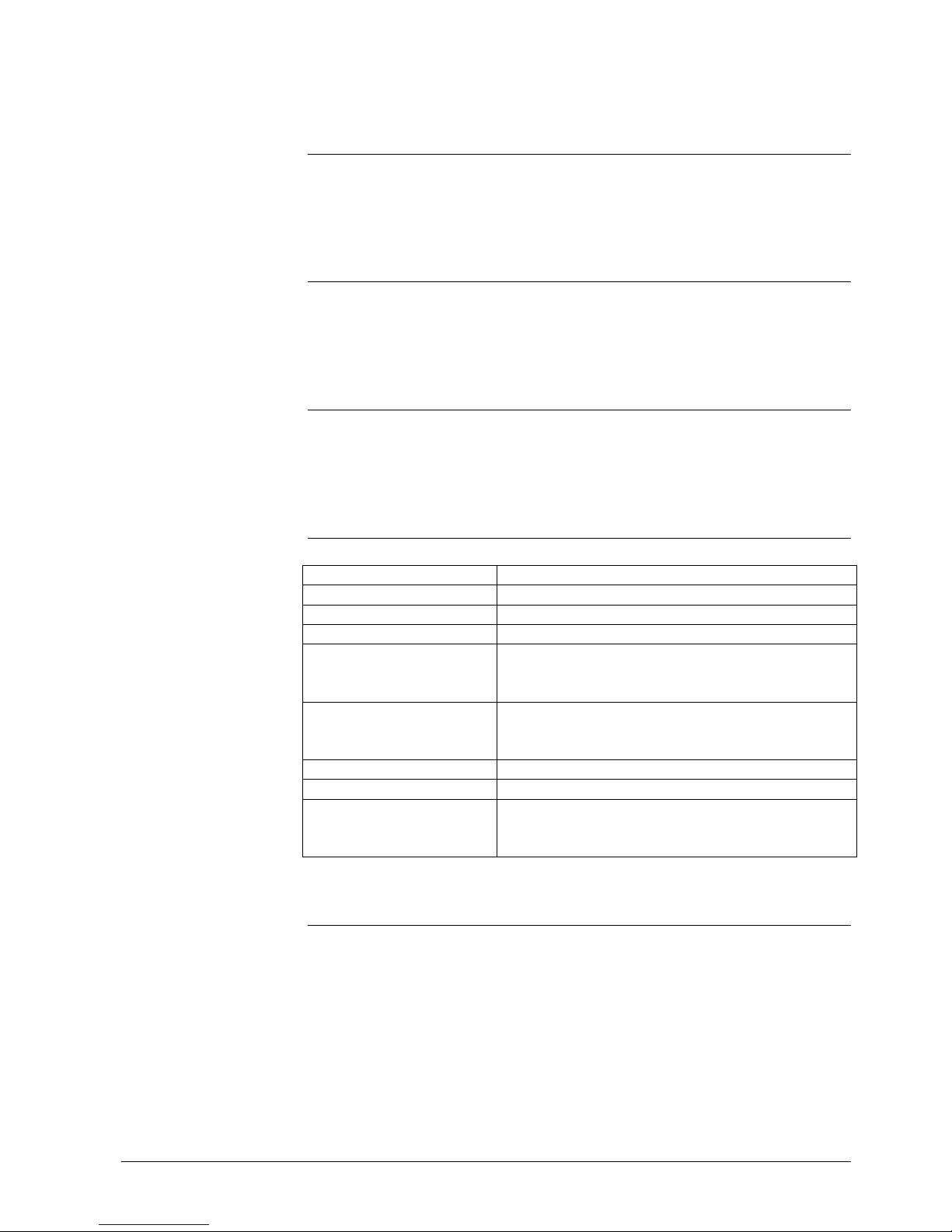

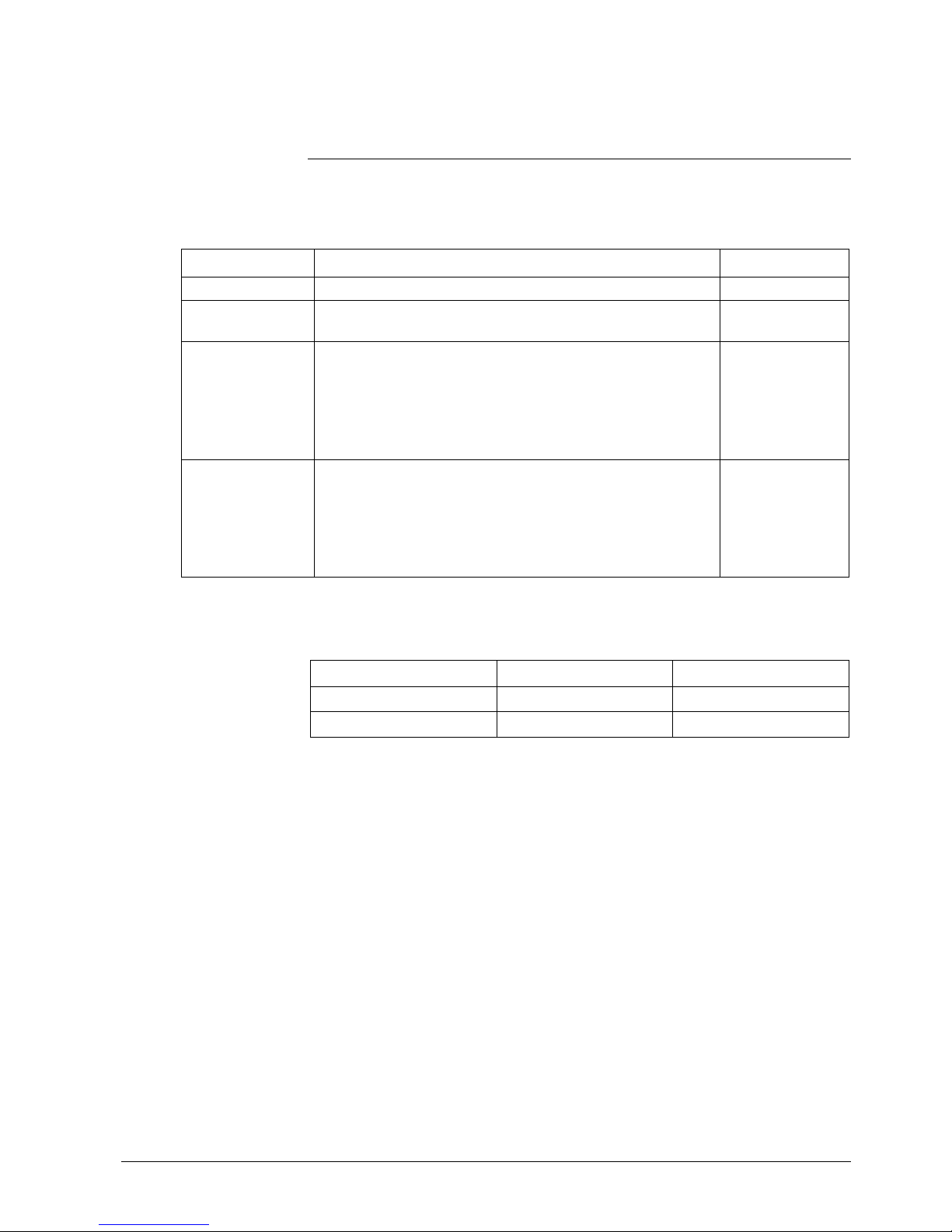

Period of storage Required action Preparation time

1 year or less Recharging not required. No preparation

1 to 2 years Before issuing the “Run” command, connect the variable speed

drive to the supply voltage for one hour.

1 hour

2 to 3 years Use a variable AC power source.

1. Apply 25% of the input voltage for 30 minutes.

2. Increase the voltage to 50% for a further 30 minutes.

3. Increase the voltage to 75% for a further 30 minutes.

4. Increase the voltage to 100% for a further 30 minutes.

The variable speed drive is then ready for operation.

2 hours

3 or more years Use a variable AC power source.

1. Apply 25% of the input voltage for 2 hours.

2. Increase the voltage to 50% for a further 2 hours.

3. Increase the voltage to 75% for a further 2 hours.

4. Increase the voltage to 100% for a further 2 hours.

The variable speed drive is then ready for operation.

8 hours

3.2 Ambient conditions

IP20 IP54

Min. operating temperature –10 °C –10 °C

Max. operating temperature +40 °C* +40 °C

* Be aware of the potential increase in temperature inside the control cabinet (derating

necessary; refer to the engineering manual).

Max. 95%, non-condensing.

If you want to install the VSD at an altitude of more than 1000 m, derating is required.

(Refer to the engineering manual).

Install the VSD vertically for optimum cooling. Do not obstruct the vents on the VSD.

Additional ventilation may be required if the drive is mounted horizontally. If mounted

vertically, VSDs with a protection standard of IP20 may be installed side by side. A

minimum clearance of 100 mm is necessary above and below the VSD. VSD of class

IP54 require greater clearances. See section 3.3.4 "Mounting SED2 drives with IP54 /

NEMA 12 rating".

Do not install the VSD in the vicinity of powerful sources for electromagnetic radiation.

Temperature

Humidity

Height above sea level

Overheating

Electromagnetic

radiation

14/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Mechanical installation 01.2002

Do not install the VSD in an environment containing atmospheric pollutants such as

dust, corrosive gases, etc. Devices subject to protection standard IP20 need additional

protection from dust, atmospheric pollutants, and water.

Do not install the VSD in a location where it might be exposed to repeated shock or

vibration.

3.3 Mounting

The device must be grounded.

♦ Extremely dangerous conditions can arise if you do not correctly ground the

variable speed drive.

♦ To ensure safe operation of the equipment, authorized persons must install and

commission it in full compliance with the notes and warnings set out in these

operating instructions.

♦ Take particular note of general and regional installation and safety regulations

regarding work on sites with dangerous voltages (e.g. EN 50178), and of the

relevant regulations f or the correct use of tools and personal protective equipment.

Dangerous voltages may occur at the following terminals even when the variable speed

drive is not running:

- Power supply terminals L1, L2, L3.

- Motor connection terminals U, V, W, DC-, DC+/B+, DC/R+, B-.

- Link terminals DC-, DC+/B+, DC/R+, B-.

Do not open the device for five minutes after switching off the supply voltage.

3.3.1 Dimensions of SED2 drives with IP20/NEMA 0 rating

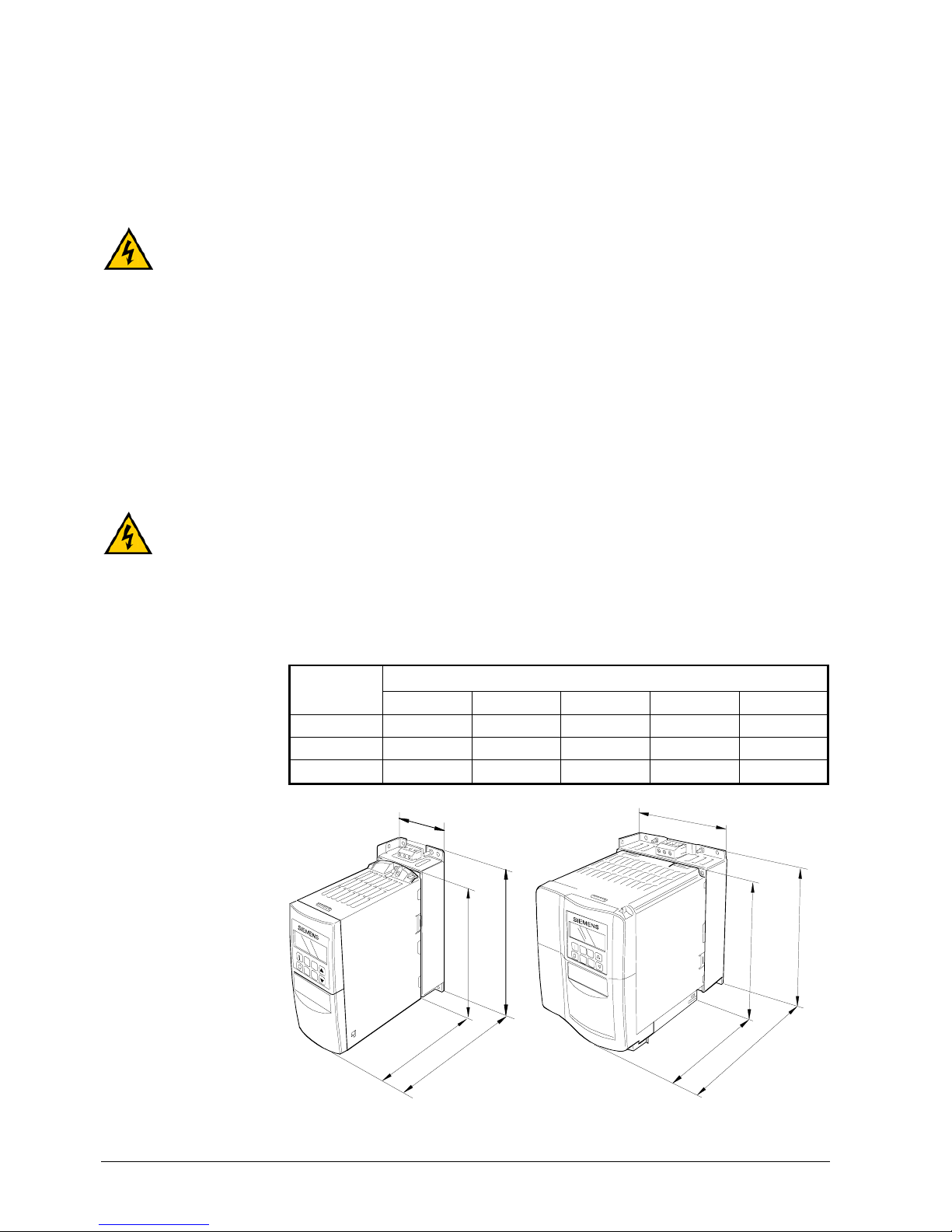

3.3.1.1 Dimensions of SED2 frame sizes A to C

Dimensions

Frame size

AA

1

BCC

1

A

173 200 73 149 192.5

B

202 213 149 172 222.5

C

245 261 185 195 250

A

1

B

C

C

1

5

1

5

2

J

0

1

A

Frame size A

A1

C1

5

1

9

2

J

0

2

B

C

A

Frame sizes B and C

Atmospheric pollution

Shock

Danger

Danger

15/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Mechanical installation 01.2002

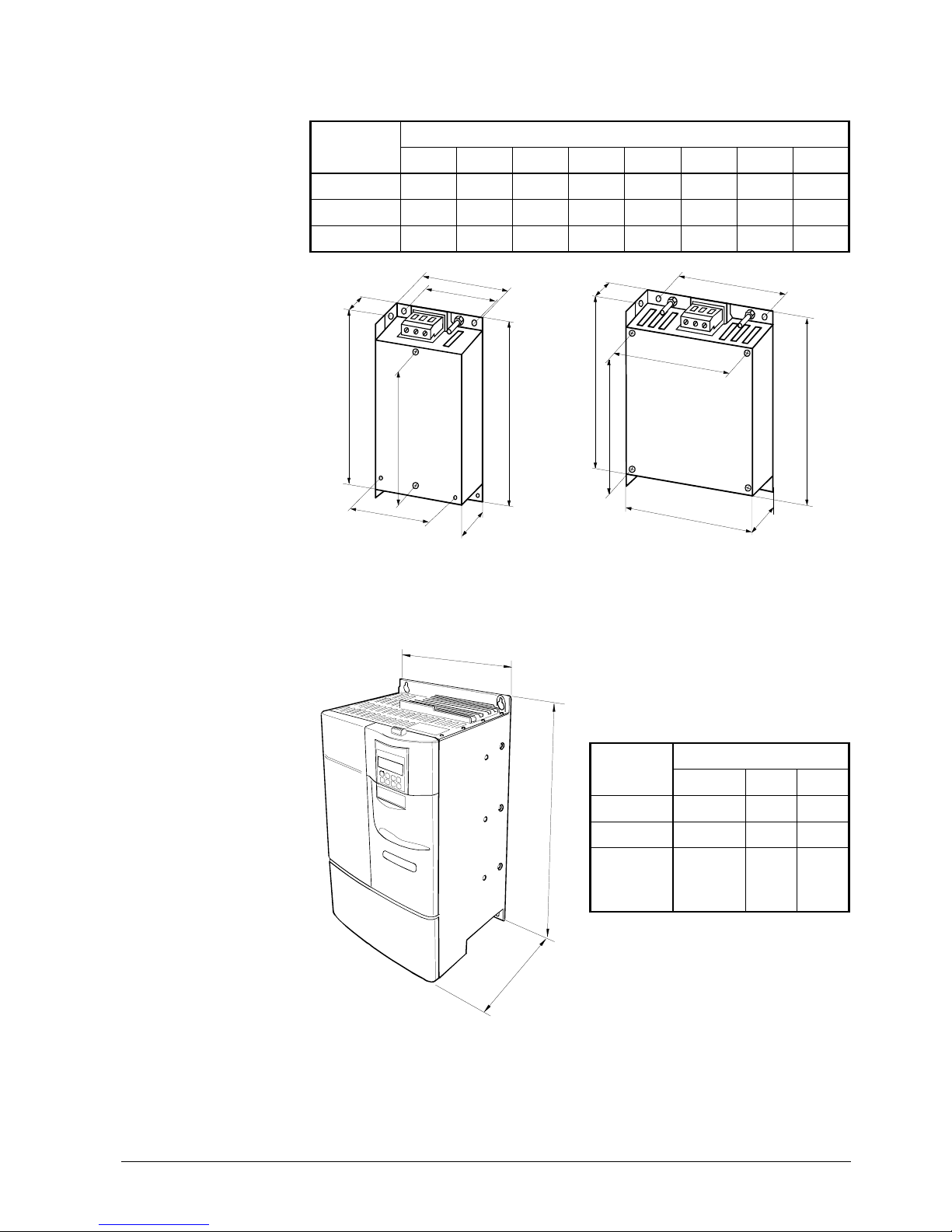

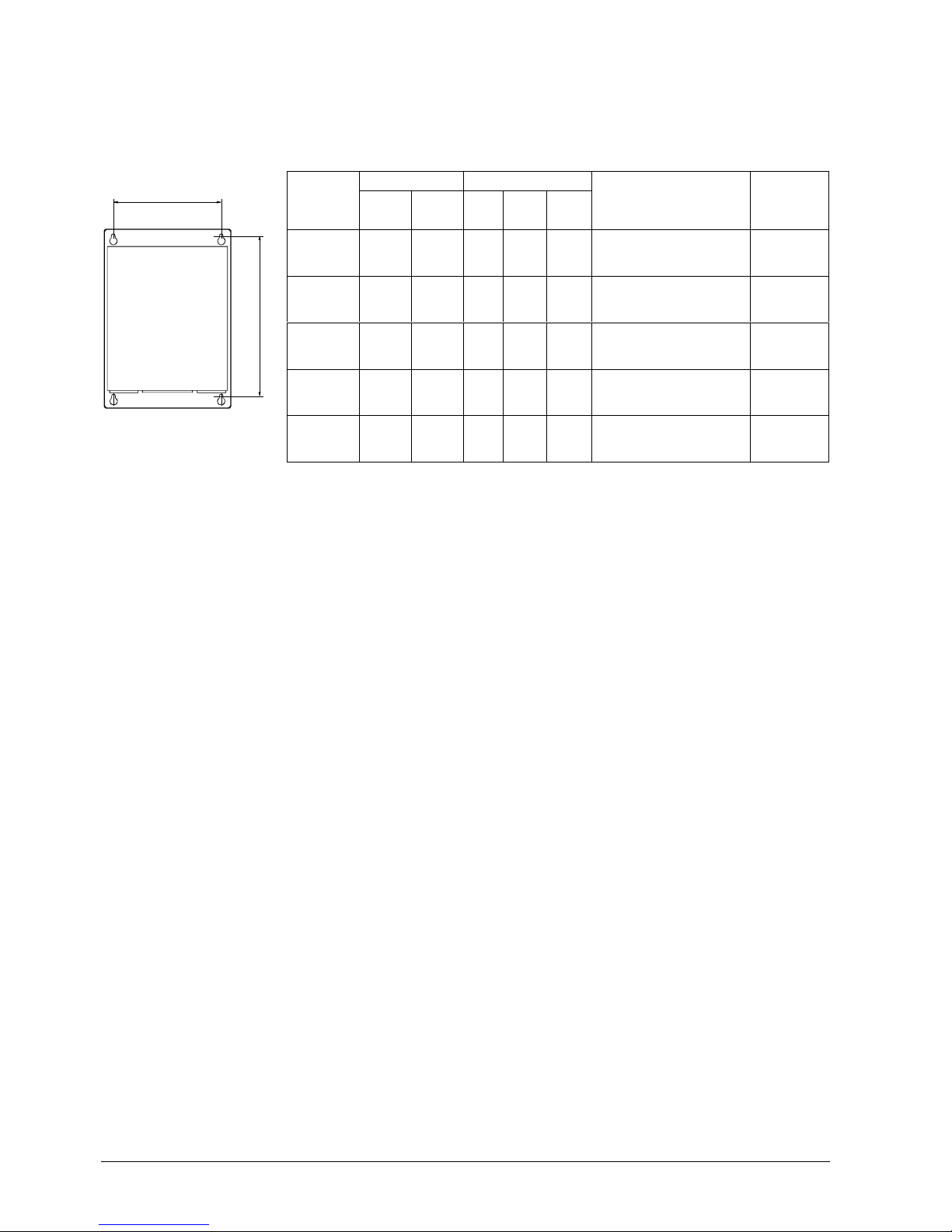

3.3.1.2 Dimensions of SED2 footprint filters for frame sizes A to C

Dimensions in mm

Frame size

ABCGHI JK

A

200 73 43.5 60 160 56 187 22

B

213 149 50.5 138 174 120 200 24

C

245 185 55 174 204 156 232 35

B

I

K

A

J

H

G

C

5192J03

I

K

A

J

H

C

5192J04

B

G

Filter for frame size A Filter for frame sizes B and C

3.3.1.3 Dimensions of SED2 frame sizes D to F

Dimensions in mm

Frame size

ABC

D

520 275 245

E

650 275 245

F

850

(with filter

1150)

350 320

5

1

9

2

J

0

5

A

B

C

16/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Mechanical installation 01.2002

3.3.2 Dimensions of SED2 drives with IP54/NEMA 12 rating

3.3.2.1 Dimensions of SED2 frame sizes B and C

Dimensions in mm

Frame size

ABC

B

385 270 268

C

606

350

284

B

C

A

5

1

9

2

J

0

6

3.3.2.2 Dimensions of SED2 frame sizes D to F

Dimensions in mm

Frame size

ABC

D

685 360 353

E

885 360 453

F

1150 450 473

A

B

C

5

1

9

2

J

0

7

17/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Mechanical installation 01.2002

3.3.3 Mounting SED2 drives with IP20/NEMA 0 rating

H

H

H

W

W

Frame size A

Frame size B

Frame sizes D, E and F

5192M01en

Hole spacing

Frame size

H in mm W in mm

Mounting materials

Tightening

torque

A

160

* 187

-

*56

2 x M4 bolts

2 x M4 nuts

2

x M4 spring lock washers

2 x M4 washers

or mounting on DIN rail

2.5 Nm

B

174

* 200

138

* 120

4

x M4 bolts

4 x M4 nuts

4

x M4 spring lock washers

4

x M4 washers

2.5 Nm

C

204

* 232

174

* 156

4

x M5 bolts

4 x M5 nuts

4

x M5 spring lock washers

4

x M5 washers

3.0 Nm

D 486 235

4

x M8 bolts

4 x M8 nuts

4

x M8 spring lock washers

4

x M8 washers

13 Nm

E

616.4 235

4

x M8 bolts

4 x M8 nuts

4

x M8 spring lock washers

4

x M8 washers

13 Nm

F

810

1110withfilter

300

4

x M8 bolts

4 x M8 nuts

4

x M8 spring lock washers

4

x M8 washers

25 Nm

* with footprint filter

A minimum clearance of 100 mm is required above and below each variable speed

drive.

Drilling plan for SED2

IP20

Note

.

..

.

18/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Mechanical installation 01.2002

3.3.4 Mounting SED2 drives with IP54 / NEMA 12 rating

Hole spacing Clearance (mm)

Frame size

H (mm) W(mm) Top BottomSide

Mounting materials

Tightening

torque

B 342.8 230 150 150 100

4xM6 bolts

4xM6 washers

4xM6 spring lock washers

5Nm

C 564 312.7 150 150 100

4xM6 bolts

4xM6 washers

4xM6 spring lock washers

5Nm

D 647 310 200 200 150

4xM8 bolts

4xM8 washers

4xM8 spring lock washers

13 Nm

E 847 310 200 200 150

4xM8 bolts

4xM8 washers

4xM8 spring lock washers

13 Nm

F 1112 400 300 250 150

4xM8 bolts

4xM8 washers

4xM8 spring lock washers

20 Nm

Drilling plan for SED2

IP54

W

H

5192M02

19/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

4 Electrical installation

The VSD must be grounded.

♦ To ensure safe operation of the equipment, authorized persons must install and

commission it in full compliance with the notes and warnings set out in these

operating instructions.

♦ Take particular note of general and regional installation and safety regulations

regarding work on sites with dangerous voltages (e.g. EN 50178), and of the

relevant regulations f or the correct use of tools and personal protective equipment.

♦ The cross-section of the ground bonding conductor must be at least equal to that of

the mains connection cables.

Dangerous voltages may occur at the following terminals even when the

variable speed drive is not running:

- Power supply terminals L1, L2, L3.

- Motor terminals U, V, W, DC+, DC-.

- Link terminals DC-, DC+/B+, DC/R+, B-.

After switching off the supply voltage, wait at least 5 minutes before starting any

installation or service work.

4.1 General

4.1.1 Maximum length of motor cables

The performance data given in the specifications cannot be guaranteed if the motor

cables exceed the following lengths: 50 m for shielded cables

100 m for unshielded cables

For devices featuring EMC filters, the maximum cable length is 25 m. For cables

shorter than > 25 m, the EMC guideline for filtered devices does not apply.

If you connect several motors to one VSD, the individual motor lines must be added to

the total line length.

4.1.2 Operation with ungrounded systems

SED2 variable speed drives with a protection standard of IP20 operate in ungrounded

systems, and remain in operation when an input phase connects to ground. In the

event of an output phase with a ground fault, the SED2 switches off and displays

message F0001.

SED2 drives with a protection standard of IP54/NEMA 12 cannot be operated in

ungrounded systems.

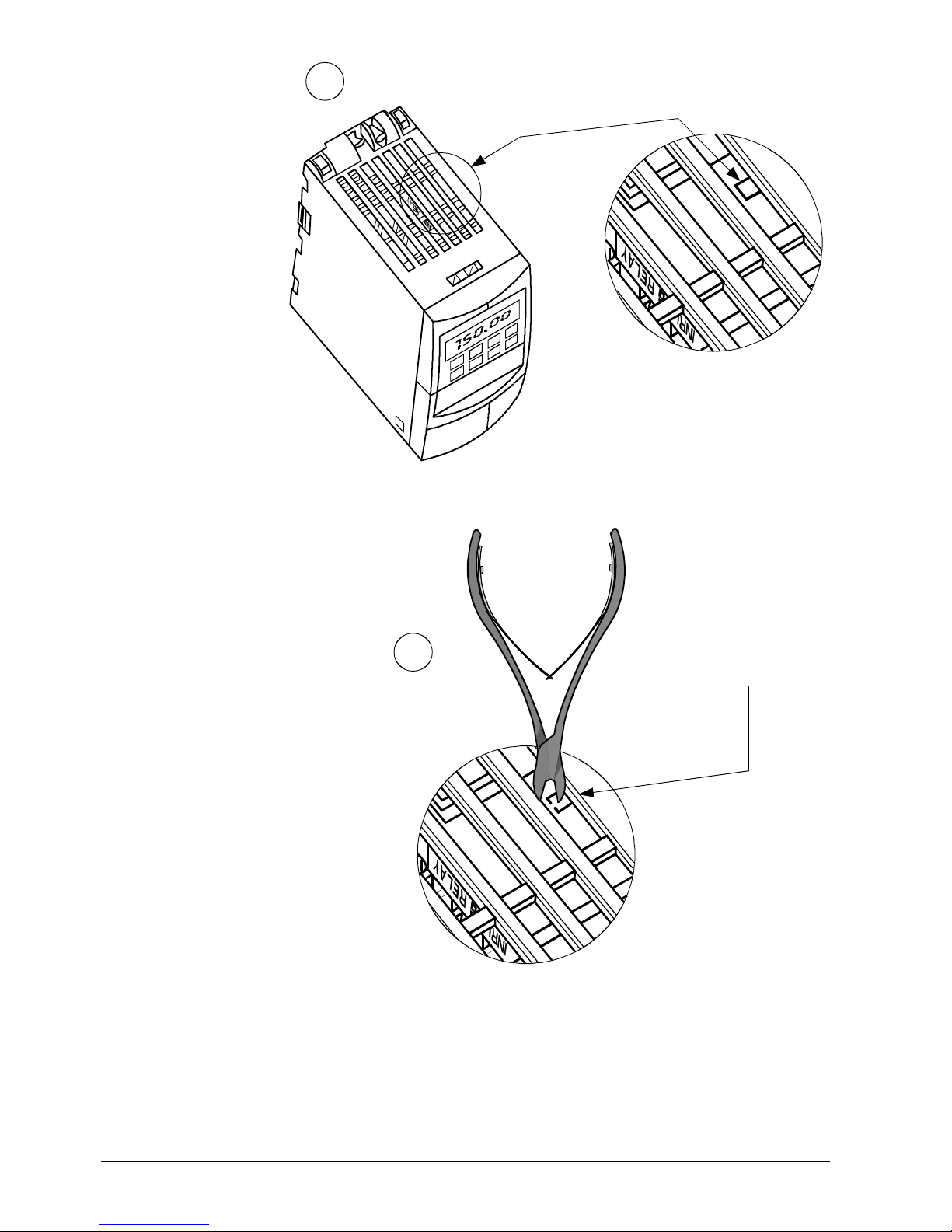

4.1.2.1 Precautions for ungrounded systems (IT protective systems)

In ungrounded systems, remove the Y capacitor, or break the connections to this

capacitor and integrate an output choke. The following procedure shows how to remove

or disconnect the capacitor.

Operation in ungrounded systems is possible only using the SED2, IP20, without

filter.

Danger

Danger

Note

.

..

.

IP20/NEMA 0

IP54/NEMA 12

Important

20/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

LK 700

1

2

5192Z01

Disconnecting the Y

capacitor in SED2

drives, frame size A

21/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

1

2

3

5192Z02

2021 22 2324 25

29 3017 26 27 2812 13 14 15 16

10 11678912345

ON

12

PE

5192Z03en

Torx driver T20

M4

Screw

Disconnecting the Y

capacitor in SED2

drives, frame sizes

BandC

Disconnecting the Y

capacitor in SED2

drives, frame sizes

DandE

22/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

4.1.3 Operation with a residual current device (RCD)

M6

T30

Torx screwdriver

5192J17en

If a residual current device (also referred to as a GLCI or RCCB) is connected, the VSD

operates without unwanted interruptions under the following conditions:

þ An RCD type B must be used.

þ The RCD must have a threshold current of 300 mA.

þ The neutral conductor in the system must be grounded.

þ Each RCD supplies only one VSD and no other consumers.

þ The output cables must not exceed 50 m in length (shielded) or 100 m

(unshielded).

Disconnecting the Y

capacitor in SED2 drives,

framesizeF

23/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

4.2 EMC-compatible installation

The SED2 VSDs operate in environments where they may be exposed to high levels of

electromagnetic interference (EMI). Normally, good installation practices ensure safe

and interference-free operation. However, should problems associated with EMI occur,

follow the guidelines below:

Ø

Ensure good electrical contact between the mounting plate and the metal housing

of the VSD via the mounting screws.

Ø

Use serrated lock washers and electrically conductive mounting plates.

Ø

If a footprint EMC filter is used, fit it under the VSD and ground it via the metal

backplate. When connecting the EMC filter to the inputs of the VSD, use shielded

cables and make sure that they are correctly grounded using cable clamps.

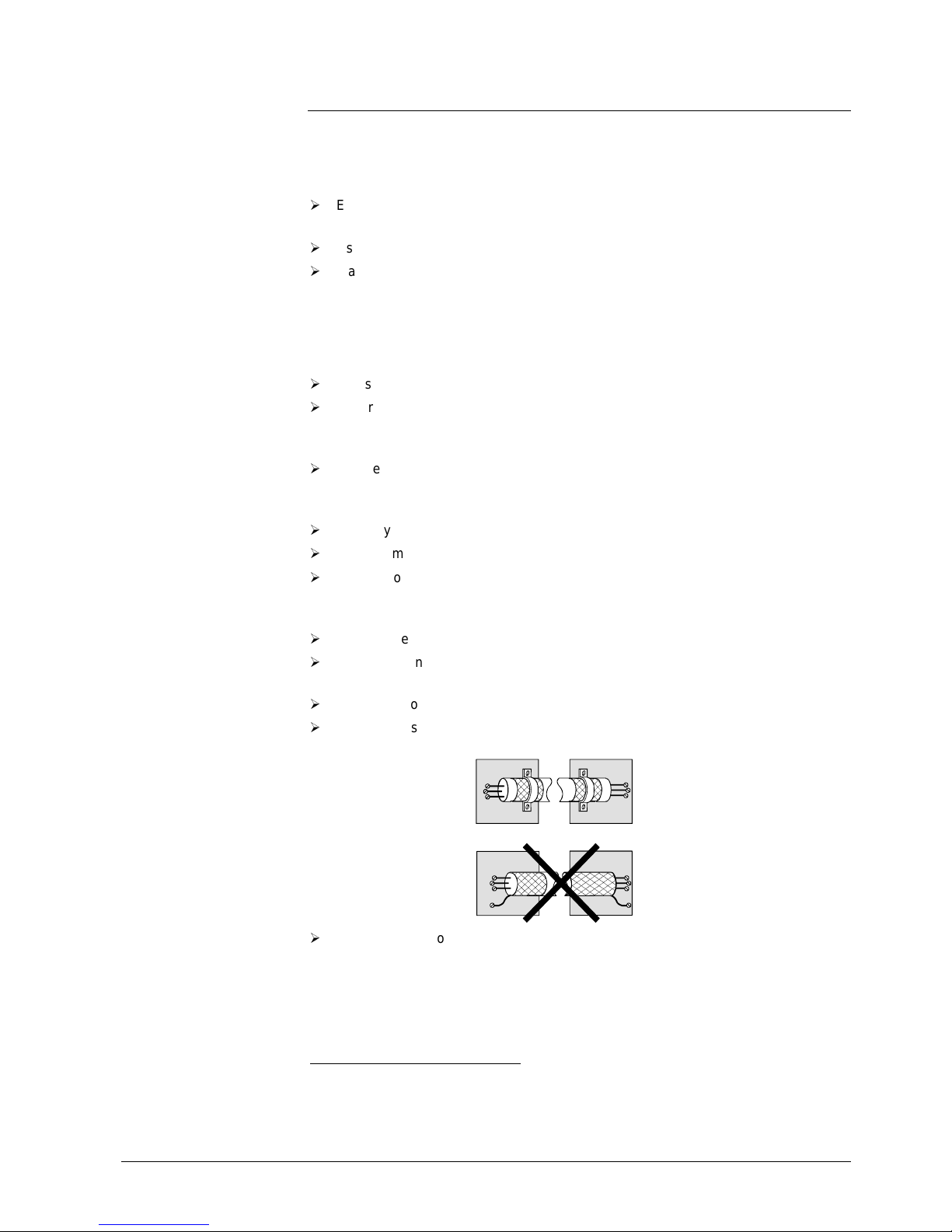

4.2.1 EMC-compatible wiring

Ø

Use shielded cables also inside control cabinets.

Ø

Ensure that all equipment in the control cabinet is properly grounded. Thus, make

sure that all equipment is connected by short, thick grounding conductors to a

common grounding point (flat ribbon lines are best) or bus bar.

Ø

Ensure that any control equipment (e.g. PLC or BACS1) connec ted to a VSD is

connected with a short, thick cable to the same ground or grounding point as the

variable speed drive itself.

Ø

Use only shielded motor and control cables. The shielding must be continuous.

Ø

Connect motor and control cables to ground at both ends.

Ø

Lay control, mains, and motor cables separately by routing them in separate cable

ducts and maintaining a minimum clearance of at least 200 mm (see diagram

below). If you must cross cables, run them at an angle of 90° if possible.

Ø

Motor cables should be as short as possible and should not exceed 25 m.

Ø

Connect the neutral conductor for the motors controlled by the variable speed

drives directly to the ground connection (PE) of the associated VSD.

Ø

Use flat ribbon cables, as they have a lower impedance at high frequencies.

Ø

Avoid pigtails. Use only grounding clamps to bond the screen (see diagram below).

5191Z01

Ø

Check that the contactors in the control cabinet are suppressed—either with RC

circuits for AC contactors, or flywheel diodes for DC contactors—and fit the

suppressors to the coils. Varistor surge voltage protectors are also effective. This is

important if the contactors are controlled by the variable speed drive relay.

1

SPS: Programmable controllers

BACS: Building automation and control system; sometimes incorrectly referred to as BMS (building

management system)

24/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

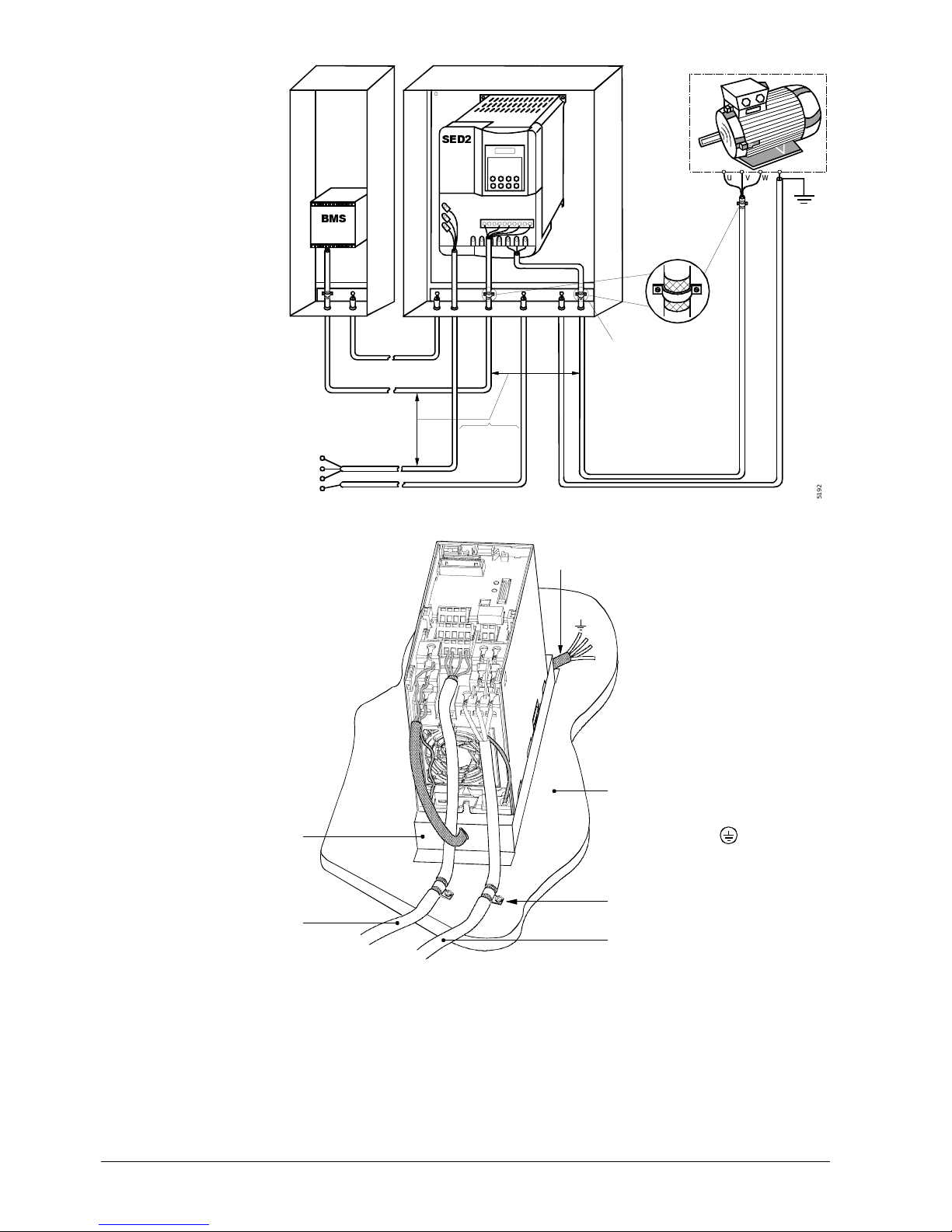

L1

L2

L3

PE

BMS

SED2

wvu

5192Z04en

Min. 16 mm²

(4 AWG)...

compensatingcable

Install all cables on the

same side of the plate

Min.200 mm

(7.8 inches)....

between

control cables,

motor cables and

mains cables

Motor cable

Mains power supply

Min.10 mm² (6 AWG)...

PE: min.10 mm² (6 AWG)...

Remove cable

insulation

Controlcables

Grounding rail

Motor

5192J10

1

L1

L2

L3

2

6

3

4

5

1 Incoming mains cable

2 Control cable

3 Motor cable

4 Footprint filter

5 Metal backplate

6 Use suitable cable clamps to

ensure good conductive

contact between the shield of

the motor and control cables

and the metal backplate

7 Connect the motor cable

shield to

.

Cable routing for frame

sizes A to C, with

footprint filter

25/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

Shield connected

with tube clips

Motor cable

Incoming mains voltage

5192J21us

4.3 Mains and motor connections

Warning and safety instructions

♦ Check that the VSD and motor are correctly sized for the supply voltage. Check

that the VSD corresponds to at least the motor output.

♦ Check that the mains cables are correctly sized for the anticipated use.

♦ Check that appropriate circuit breakers or fuses exist between the mains and the

variable speed drive.

Never use high voltage insulation test equipment on any cables connected to the

variable speed drive.

♦ Always isolate the power cables before connecting them to the VSD.

♦ Check that the terminal cover was replaced properly after connecting the power

and motor cables.

♦ Never switch on the VSD with the cover open.

♦ Always use ins ulated tools when working on the incoming power supply and the

motor terminals.

Cable routing for frame

sizes D to F, IP20 with

EMC filter

Caution

Warning

Danger

26/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

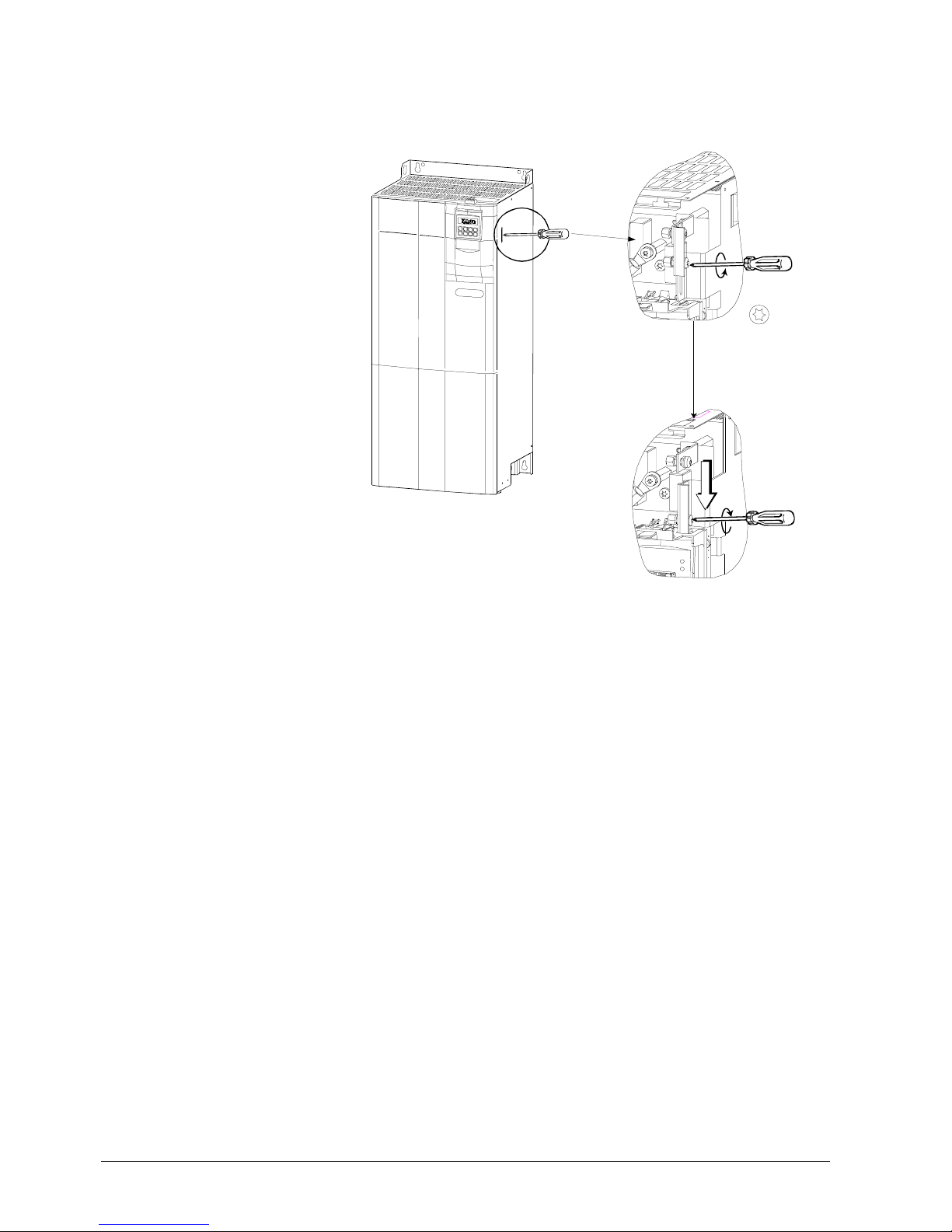

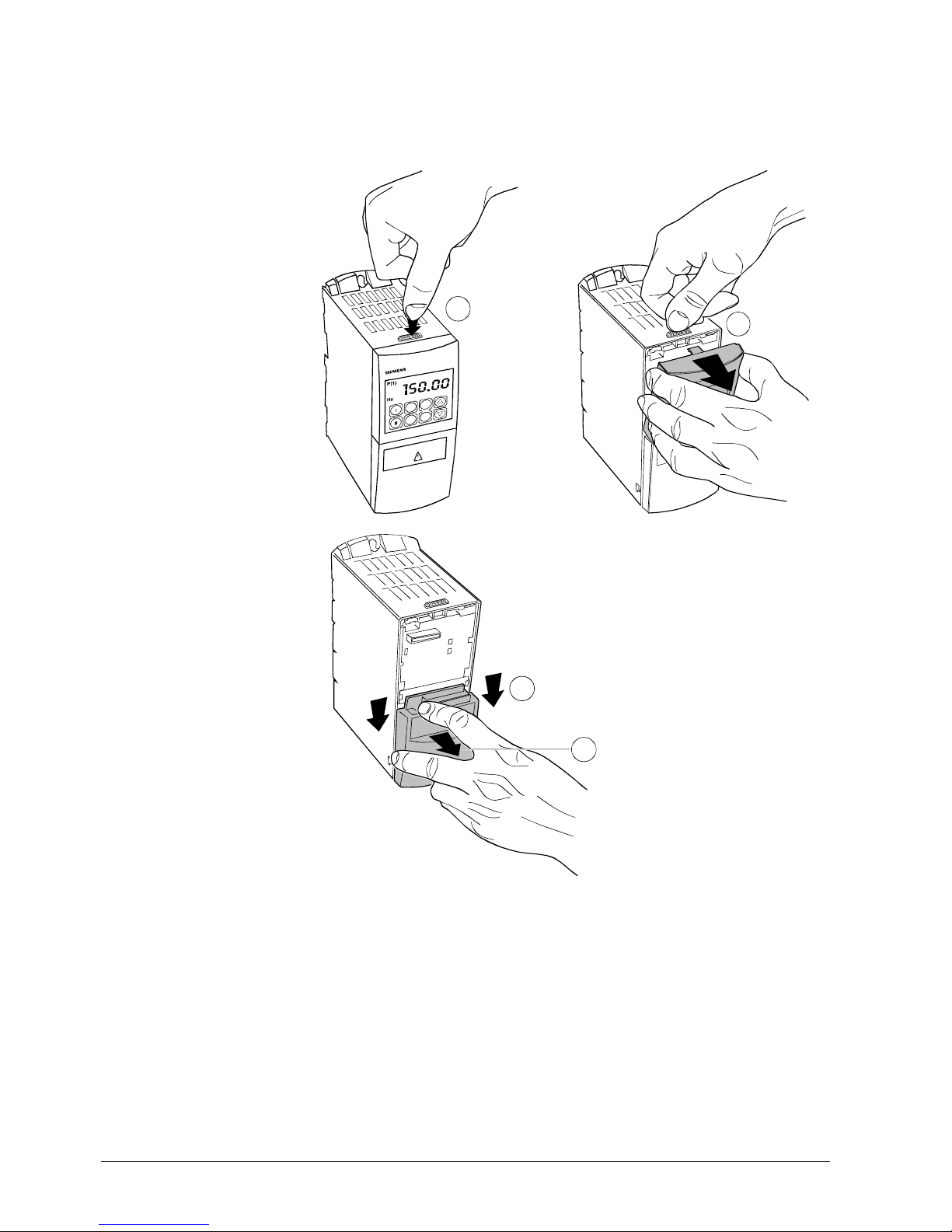

4.3.1 Access to connection terminals: Frame size A

To access the mains and motor terminals, first remove the operator panel, cover, and

I/O module as illustrated below.

5192J08

1

5192J09

1

5192J16

2

1

Removing the operator

panel (BOP or AOP)

Removing the terminal

cover of the I/O module

27/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

1

5192J20

2

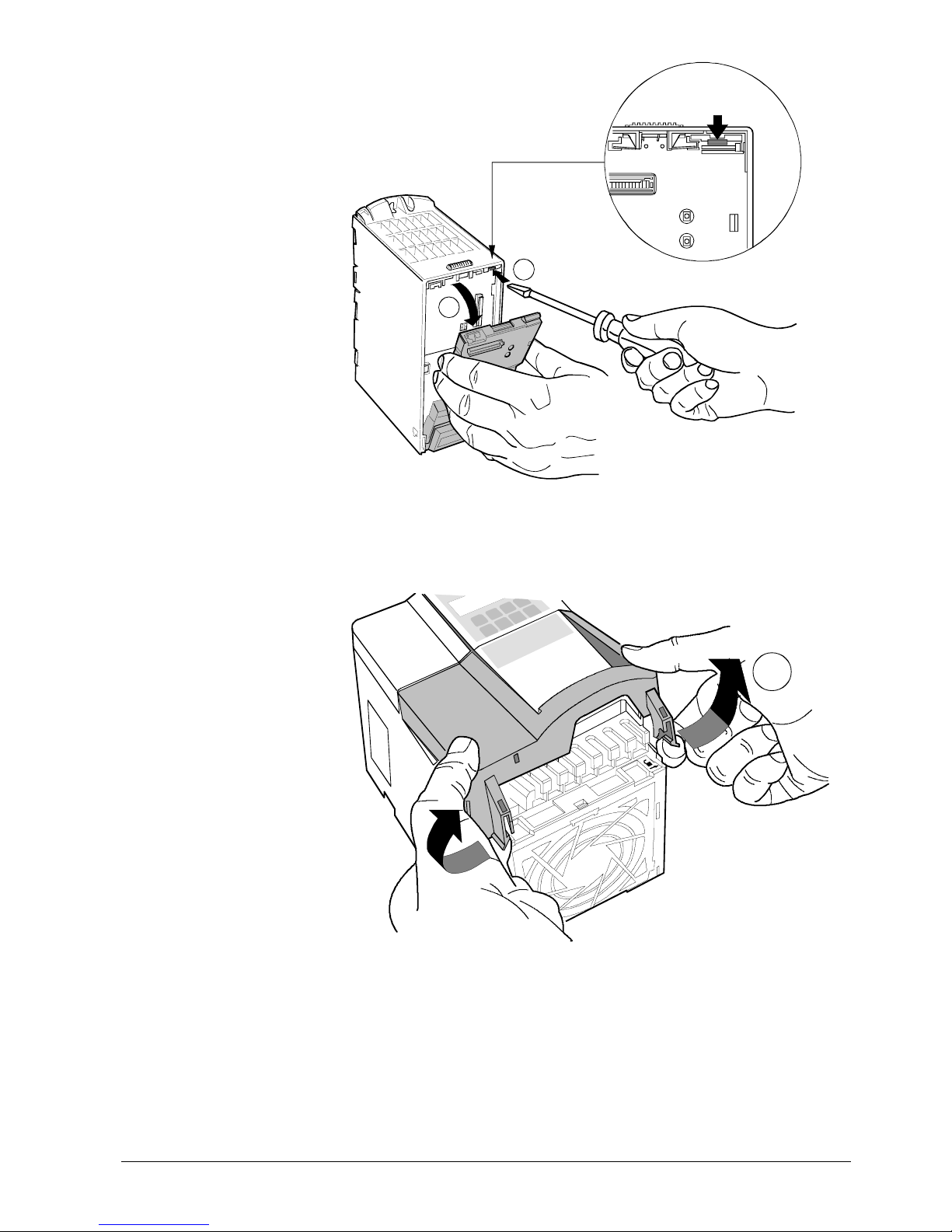

4.3.2 Access to connection terminals: Frame sizes B and C

1

5192J12

Removing the

I/O module

Removing the cover of the

mains and motor

terminals

28/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

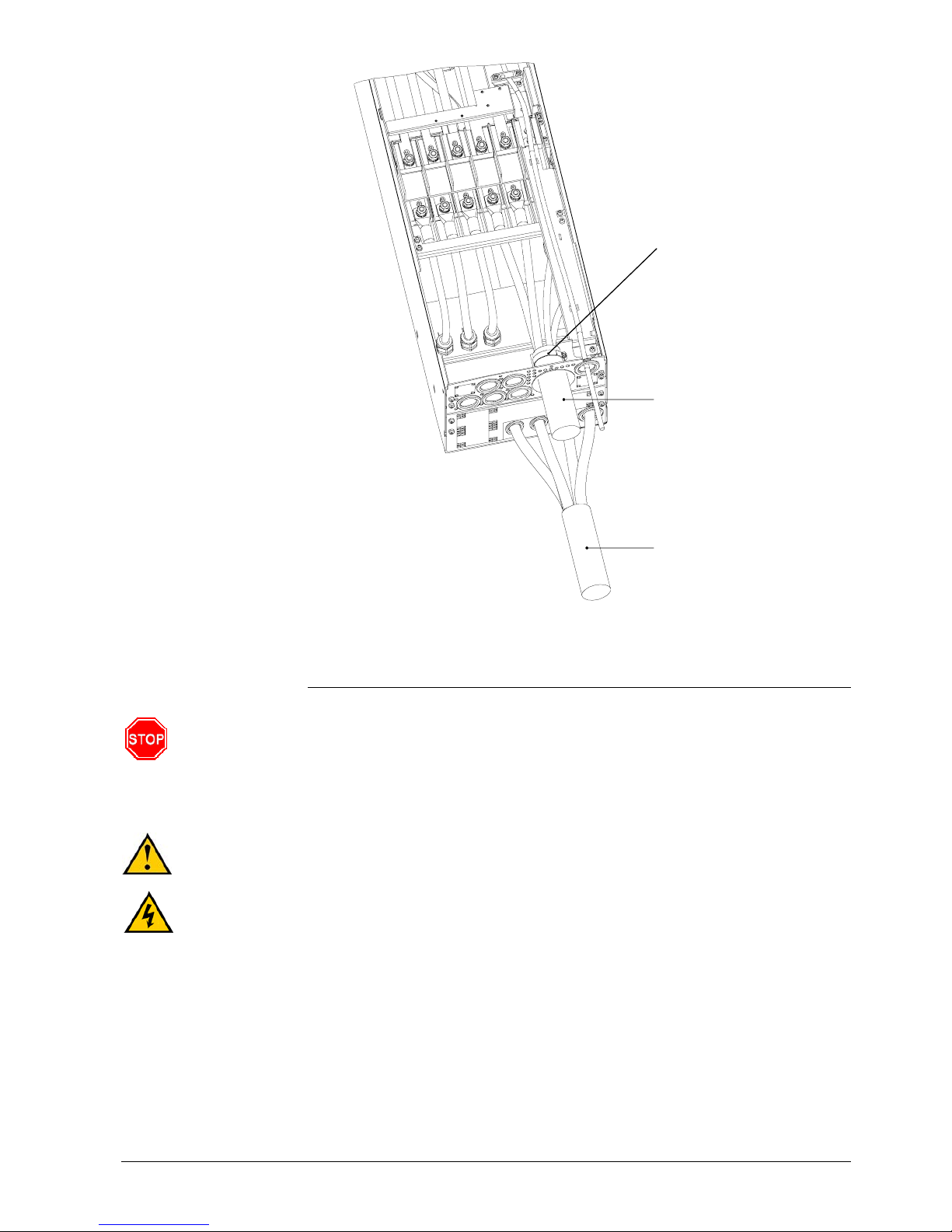

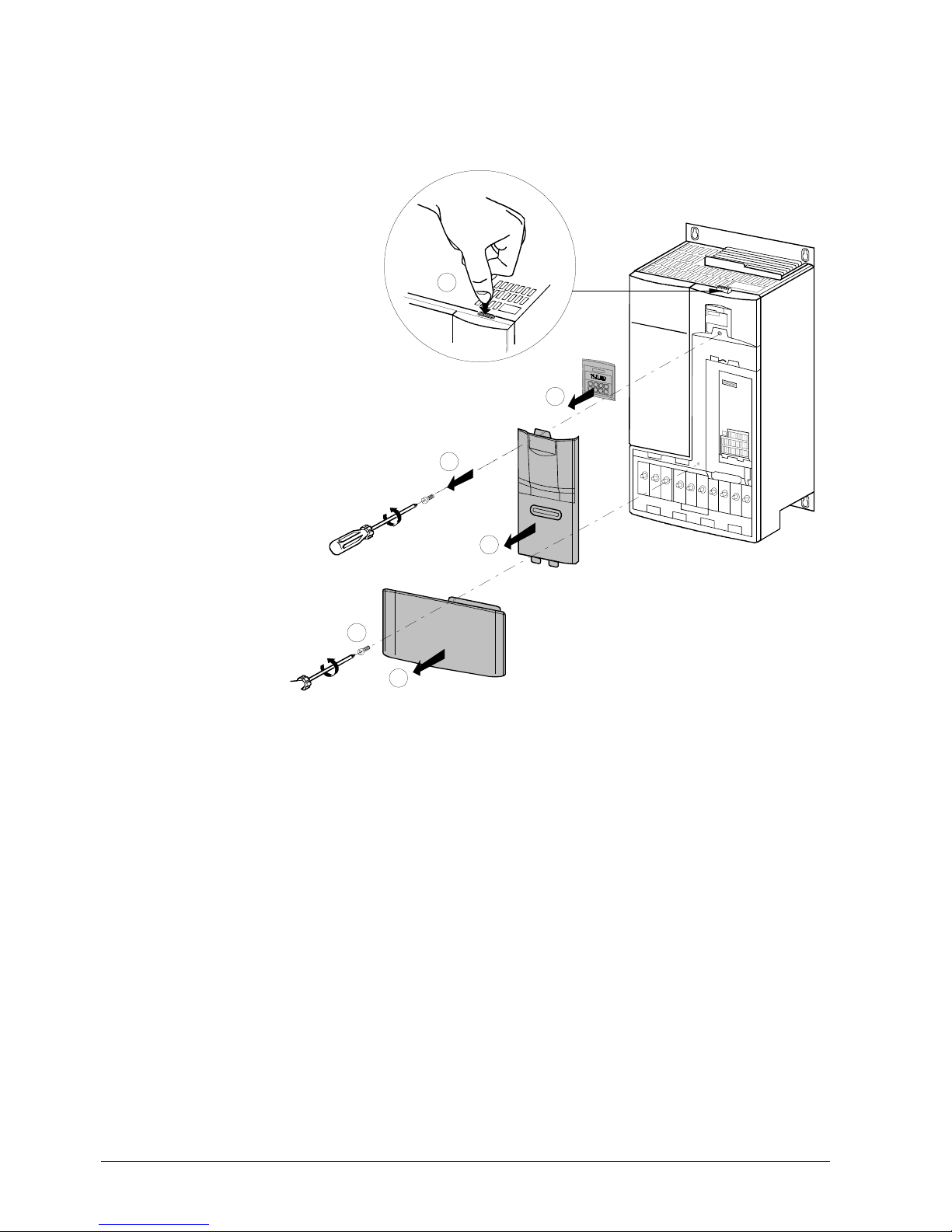

4.3.3 Access to connection terminals: Frame sizes D to F IP20

Refer to the relevant paragraph in Access to connection terminals: Frame size A.

3

1

2

5

6

4

5

1

9

2

J

1

3

Removing the operator

panel (BOP or AOP)

Opening the housing:

Frame sizes D and E

29/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

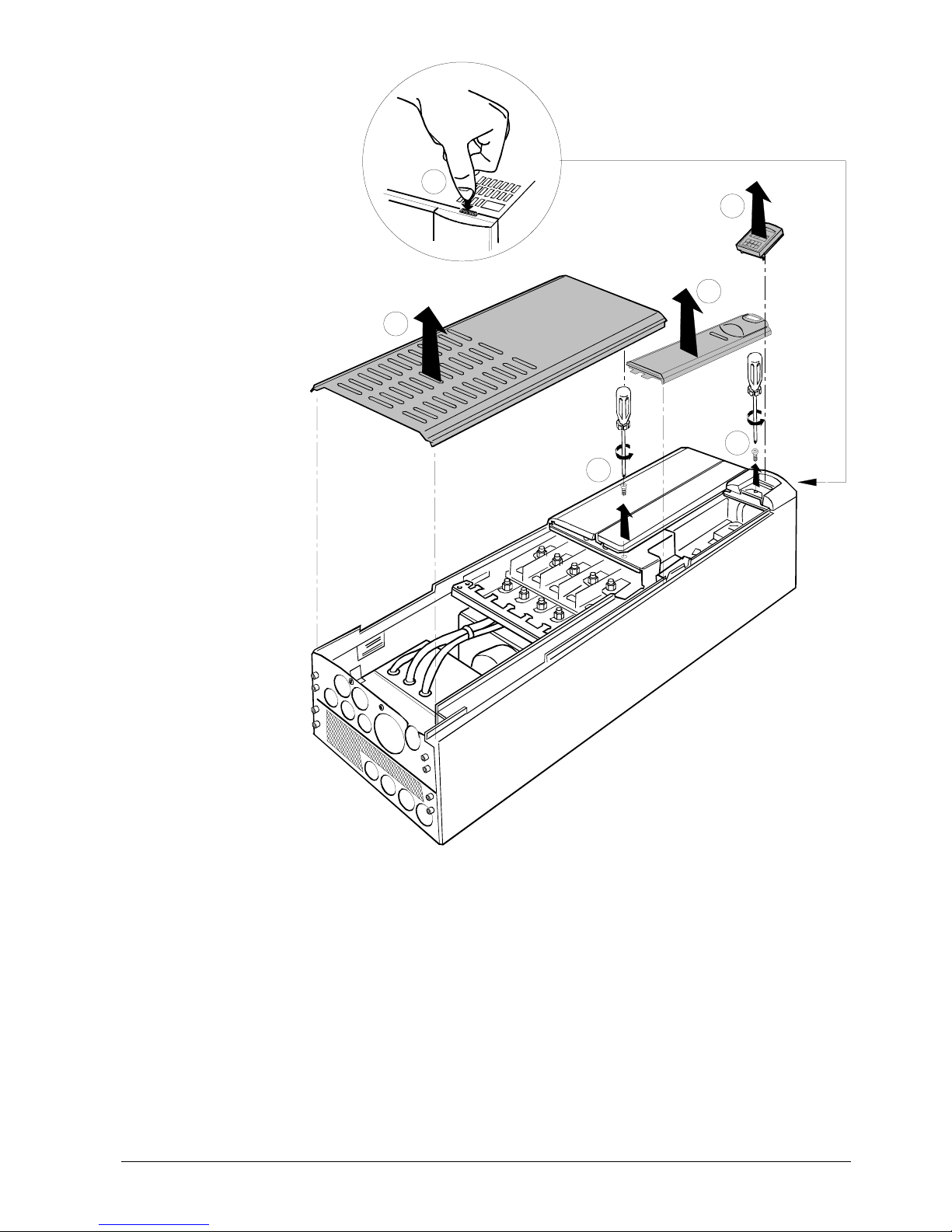

2

3

4

1

5

1

9

2

J

1

4

5

6

Opening the housing:

FramesizeF

30/126

Siemens Building Technologies SED2 variable speed drives CM1U5192en

HVAC Products Electrical installation 01.2002

4.3.4 Power and motor terminals: Frame sizes A to F

(Ground)

PE

(Ground)

L1

L2

L3

DC+ DC-

UVW

5192Z05

DC

R+

B-

UVWDC- DC+B+DCR+B-

L3

L2

L1

PE

5192Z06

L1 L2 L3 DC- DC+B+DC

R+

B- U V W

PE

5192Z07

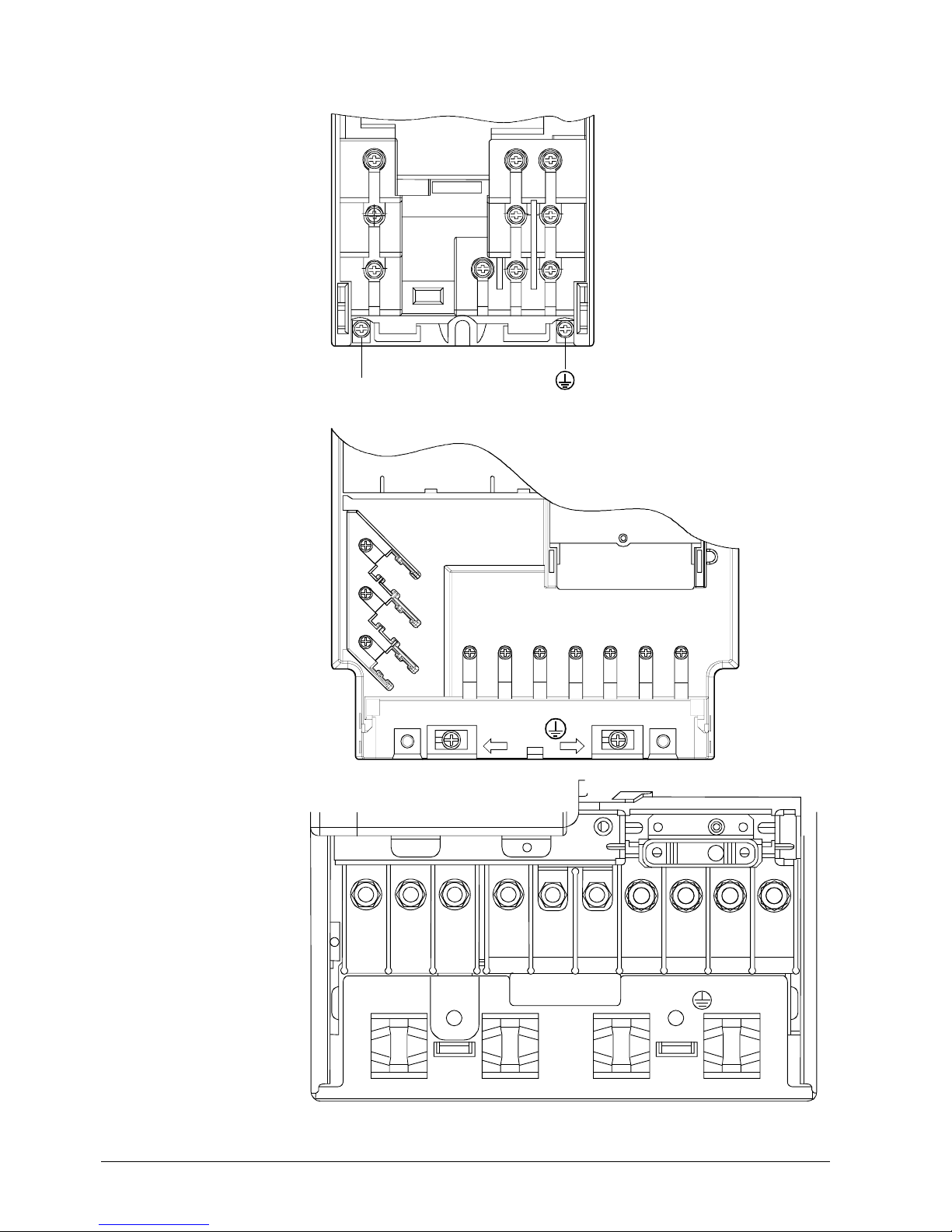

Terminal layout: Frame

size A

Terminal layout:

Frame sizes B and C

Terminal layout:

Frame sizes D and E

Loading...

Loading...