S7-200 Smart to

Stepper Drive

Communication

S7-200 SMART V2.4/ TIA V15.1

https://new.siemens.com/in/en/products/automation/systems/ind

ustrial/plc/simatic-s7-200-smart.html

Siemens

Industry

Online

Support

Legal information

Legal information

Use of application examples

Application examples illustrate the solution of automation tasks through an interaction of several

components in the form of text, graphics and/or software modules. The application examples are

a free service by Siemens AG and/or a subsidiary of Siemens AG ("Siemens"). They are

non-binding and make no claim to completeness or functionality regarding configuration and

equipment. The application examples merely offer help with typical tasks; they do not constitute

customer-specific solutions. You yourself are responsible for the proper and safe operation of the

products in accordance with applicable regulations and must also check the function of the

respective application example and customize it for your system.

Siemens grants you the non-exclusive, non-sub licensable and non-transferable right to have the

application examples used by technically trained personnel. Any change to the application

examples is your responsibility. Sharing the application examples with third parties or copying the

application examples or excerpts thereof is permitted only in combination with your own products.

The application examples are not required to undergo the customary tests and quality inspections

of a chargeable product; they may have functional and performance defects as well as errors. It is

your responsibility to use them in such a manner that any malfunctions that may occur do not

result in property damage or injury to persons.

ã Siemens AG 2020 All rights reserved

Disclaimer of liability

Siemens shall not assume any liability, for any legal reason whatsoever, including, without

limitation, liability for the usability, availability, completeness and freedom from defects of the

application examples as well as for related information, configuration and performance data and

any damage caused thereby. This shall not apply in cases of mandatory liability, for example

under the German Product Liability Act, or in cases of intent, gross negligence, or culpable loss of

life, bodily injury or damage to health, non-compliance with a guarantee, fraudulent

non-disclosure of a defect, or culpable breach of material contractual obligations. Claims for

damages arising from a breach of material contractual obligations shall however be limited to the

foreseeable damage typical of the type of agreement, unless liability arises from intent or gross

negligence or is based on loss of life, bodily injury or damage to health. The foregoing provisions

do not imply any change in the burden of proof to your detriment. You shall indemnify Siemens

against existing or future claims of third parties in this connection except where Siemens is

mandatorily liable.

By using the application examples, you acknowledge that Siemens cannot be held liable for any

damage beyond the liability provisions described.

Other information

Siemens reserves the right to make changes to the application examples at any time without

notice. In case of discrepancies between the suggestions in the application examples and other

Siemens publications such as catalogs, the content of the other documentation shall have

precedence.

The Siemens terms of use (https://support.industry.siemens.com) shall also apply.

Security information

Siemens provides products and solutions with Industrial Security functions that support the secure

operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is necessary

to implement – and continuously maintain – a holistic, state-of-the-art industrial security concept.

Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems, machines

and networks. Such systems, machines and components should only be connected to an

enterprise network or the Internet if and to the extent such a connection is necessary and only

when appropriate security measures (e.g. firewalls and/or network segmentation) are in place.

For additional information on industrial security measures that may be implemented, please visit

https://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends that product updates are applied as soon as they are available

and that the latest product versions are used. Use of product versions that are no longer

supported, and failure to apply the latest updates may increase customer’s exposure to cyber

threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS Feed

at: https://www.siemens.com/industrialsecurity.

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

2

Table of contents

Table of contents

Legal information ..................................................................................................... 2

1 Task ................................................................................................................. 4

1.1

Overview of the automation task ........................................................ 4

2 Automation solution ....................................................................................... 5

2.1 Hardware and software components used ......................................... 5

2.2 Setup................................................................................................. 6

3 Functional mechanisms ................................................................................. 7

3.1 Axis Control ....................................................................................... 7

3.2 Control program ................................................................................. 7

4 Commissioning ............................................................................................ 12

4.1

4.2

Setting Motion Control Wizard.......................................................... 12

Downloading the SIMATIC program ................................................. 18

5 Operation ...................................................................................................... 20

5.1 Positioning ....................................................................................... 20

5.2

Profiling ........................................................................................... 22

6 Appendix ....................................................................................................... 23

6.1 Service and support ......................................................................... 23

6.2 Application support .......................................................................... 24

6.3 Links and literature .......................................................................... 24

ã Siemens AG 2020 All rights reserved

6.4 Change documentation .................................................................... 24

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

3

1 Task

1 Task

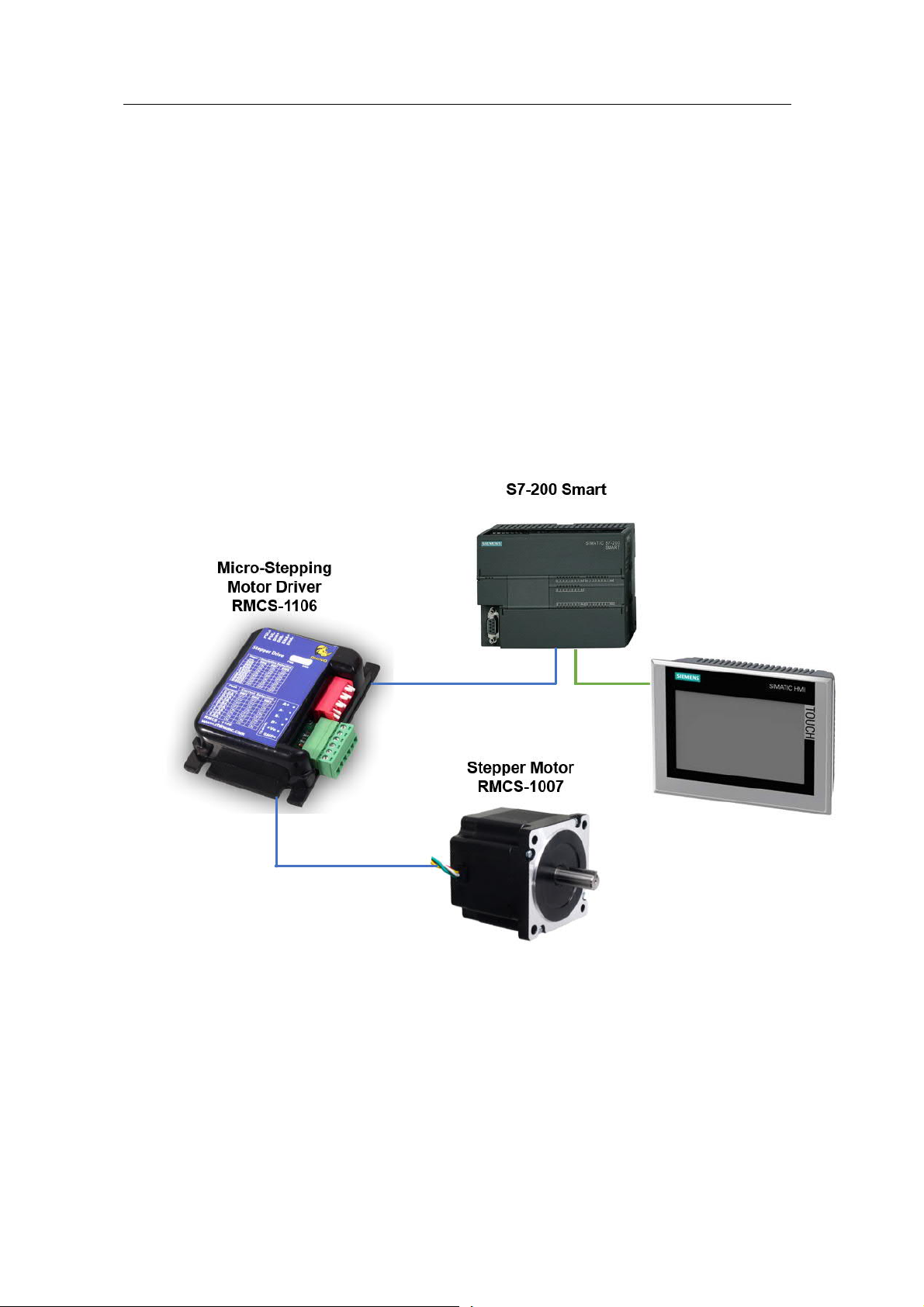

Communication between Stepper Drive and a PLC is often required in a diversity of general

“Cutting-to-Lenght“ applications. Taking reciprocating controlled positioning of an axis for

example, communication between a controller (S7-200 Smart)and a Stepper Drive RHINO

MOTION CONTROLS RMCS-1106.

ã Siemens AG 2020 All rights reserved

1.1

In the application, RMCS-1106 Stepper Drive controls a RMCS-1107 Stepper Motor using

motion control wizard.

The following figure provides an overview of the automation task:

Overview of the automation task

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

4

2 Automation solution

2 Automation solution

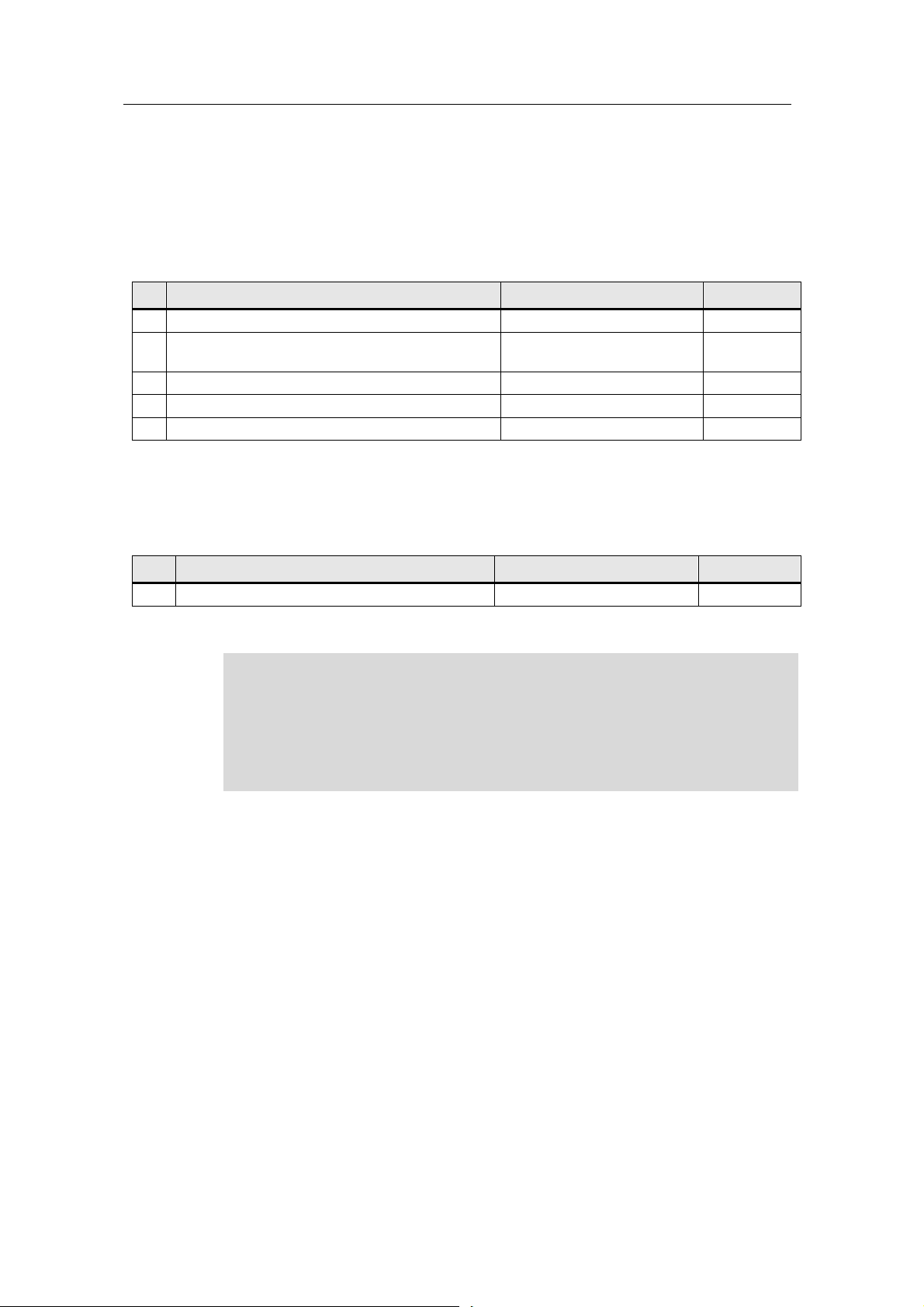

2.1 Hardware and software components used

2.1.1 Hardware components

No. Component Order number Quantity

1 SIMATIC S7-200 Smart ST30 6ES72881ST300AA0 1

2 Micro-Stepping Motor Driver

(Max. 40Vdc and 2A per phase)

3 Stepper Motor 3.75° Step Angle 0.65 Kgcm Torque

4 Comfort Panel TP 700

4 Ethernet Cable 1

2.1.2 Software components

User can order these CDs that contain the following software tools:

RMCS-1106 1

RMCS-1007

6AV2124-0GC01-0AX0

1

1

ã Siemens AG 2020 All rights reserved

No. Component Order number Quantity

1 STEP7 Micro/WIN SMART 2.4 6ES7288-SW01-0AA0 1

Most of the hardware components shown in the table are commercially

available in the global market. If unavailable in your country (or region), find an

Note

appropriate substitute at your own discretion.

The table lists key hardware components required for this

project. Other accessories such as cables and wires, supports, terminal strips,

and so on can be purchased separately.

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

5

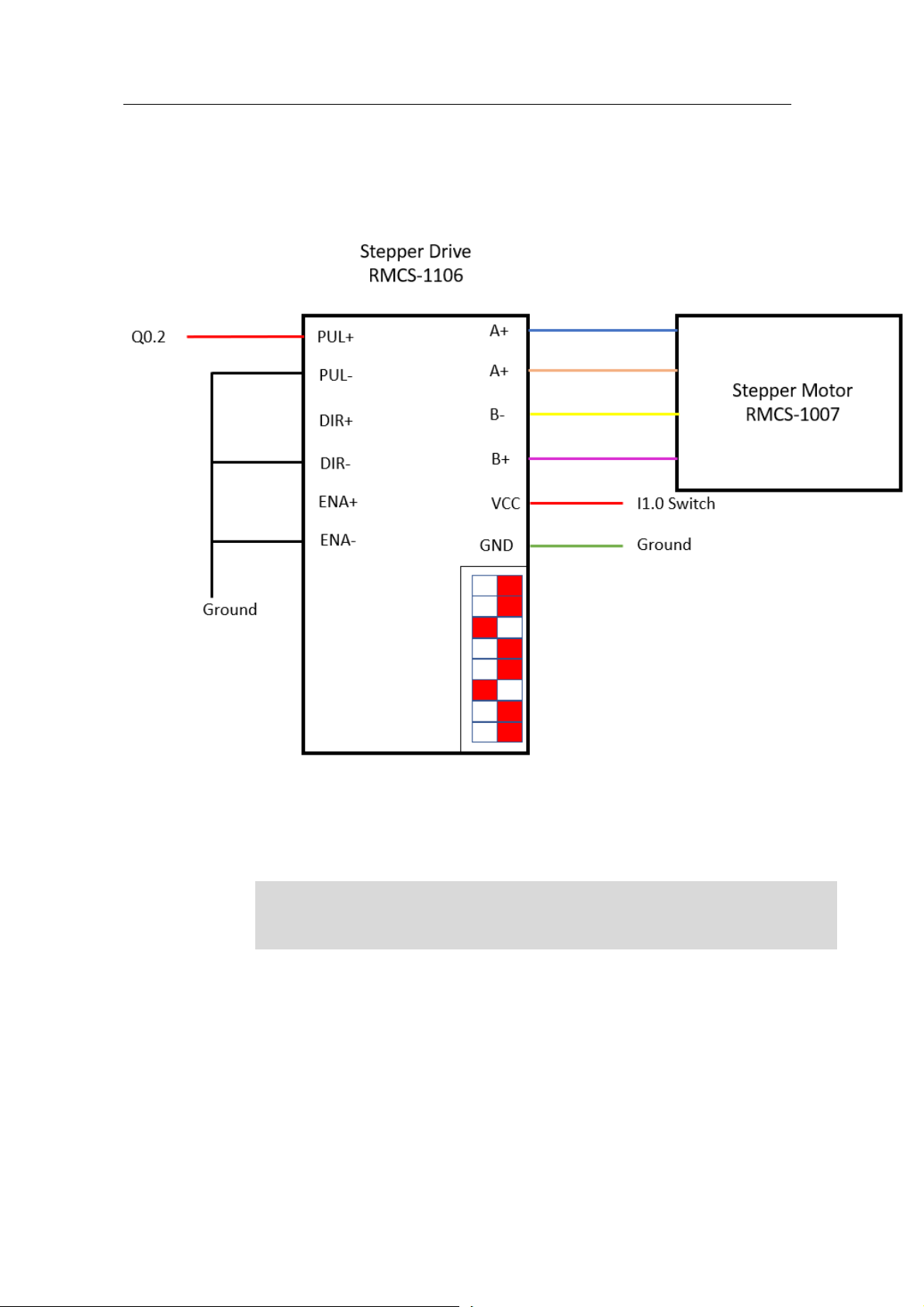

2.2 Setup

2 Automation solution

ã Siemens AG 2020 All rights reserved

Note

2.2.1 Figure 2-1 Stepper Motor connection

For more detail please refer operating manual of Stepper Drive RMCS-1106 and

Stepper Motor RMCS-1007

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

6

3 Functional mechanisms

LAD / FBD

STL

Description

3.1 Axis Control

The Axis of Motion provides a single pulse train output with integrated direction control

and disable outputs. It also includes programmable inputs which allow the CPU to be

configured for several modes of operation, including automatic reference point seek. The

Axis of Motion provides a unified solution for open loop control of the speed and position

for either stepper motors or servo motors.

To simplify the use of motion control in your application, STEP 7-Micro/WIN SMART

provides a Motion wizard to configure Axis of Motion and a PWM wizard to configure

PWM. The wizards generate motion instructions that you can use to provide dynamic

control of speed and motion in your application. For the Axis of Motion, STEP 7Micro/WIN SMART also provides a control panel that allows you to control, monitor, and

test your motion operations.

The motion control built into the CPU uses an Axis of Motion to control both the speed

and motion of a stepper motor or a servo motor. Using the Axis of Motion requires

expertise in the field of motion control. This chapter is not meant to educate the novice in

this subject. However, it provides fundamental information that will help as you use the

Motion wizard to configure the Axis of Motion for your application.

3 Functional mechanisms

ã Siemens AG 2020 All rights reserved

For more details refer operating manual section 12.2 Using Motion Control

3.2 Control program

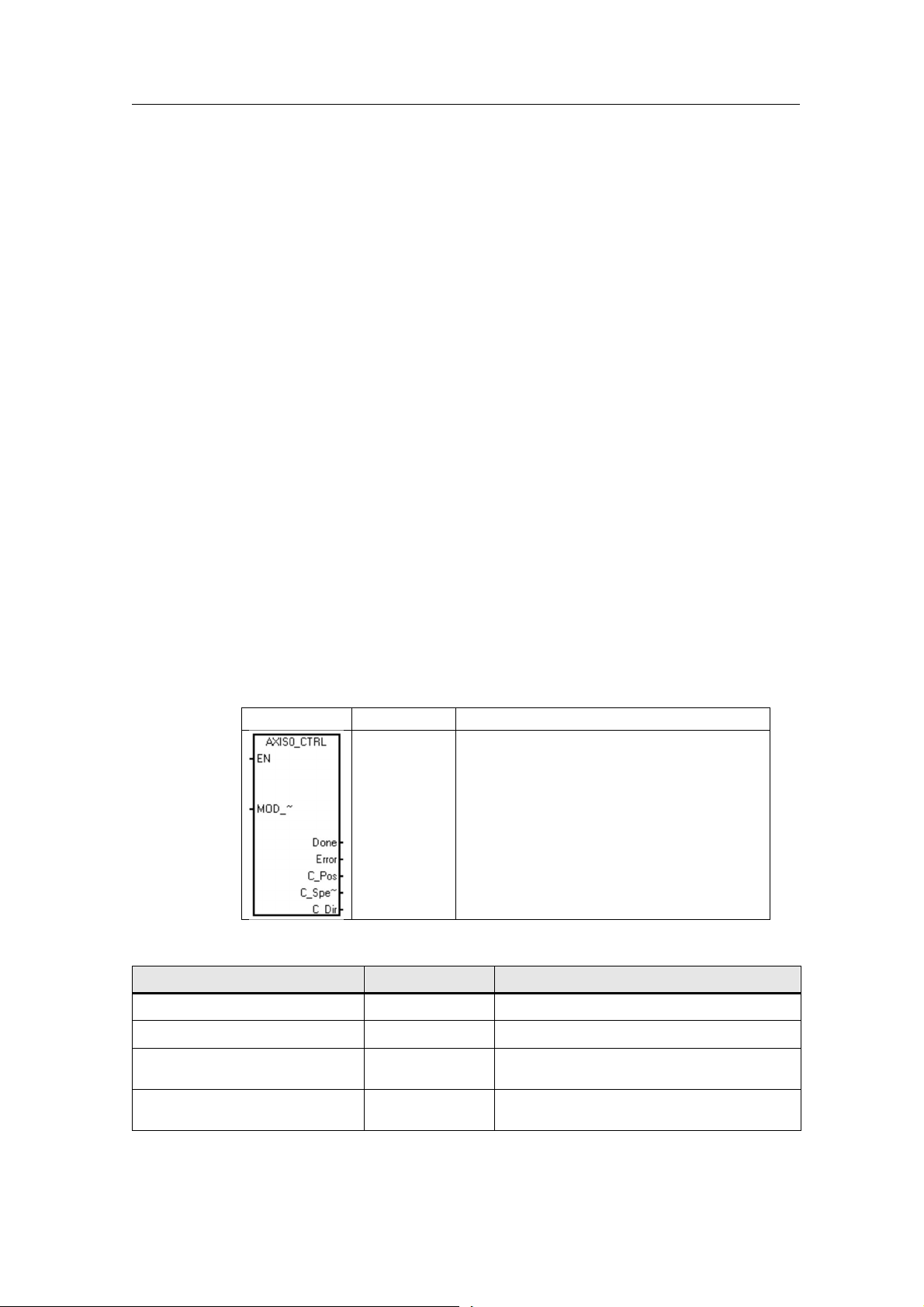

3.2.1 AXISx_CTRL subroutine

CALL

AXISx_CTRL,

MOD_EN,

Done, Error,

C_Pos,

C_Speed,

C_Dir

3.2.1.1 Figure 3-1

Input/output Date Type Value

MOD_EN BOOL I, Q, V, M, SM, S, T, C, L, Power Flow

Done, C_Dir BOOL I, Q, V, M, SM, S, T, C, L

The AXISx_CTRL subroutine (Control) enables

and initializes the Axis of Motion by

automatically commanding the Axis of Motion to

load the configuration/profile table each time the

CPU changes to RUN mode.

Use this subroutine only once in your project

per motion axis, and ensure

that your program calls this subroutine every

scan. Use SM0.0

(Always On) as the input for the EN parameter.

Error BYTE IB, QB, VB, MB, SMB, SB, LB, AC, *VD,

C_Pos, C_Speed DINT, REAL ID, QD, VD, MD, SMD, SD, LD, AC, *VD,

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

*AC, *LD

*AC, *LD

7

3 Functional mechanisms

LAD / FBD

STL

Description

The MOD_EN parameter must be on to enable the other motion subroutines to send

commands to the Axis of Motion. If the MOD_EN parameter turns off, then the Axis of

Motion aborts any command that is in progress and performs a decelerated stop.

The output parameters of the AXISx_CTRL subroutine provide the current status of the

Axis of Motion.

The Done parameter turns on when the Axis of Motion completes any subroutine.

The C_Pos parameter is the current position of the Axis of Motion. Based upon the units

of measurement, the value is either a number of pulses (DINT) or the number of

engineering units (REAL).

The C_Speed parameter provides the current speed of the Axis of Motion. If you

configured the measurement system for the Axis of Motion for pulses, C_Speed is a DINT

value containing the number of pulses/second. If you configured the measurement

system for engineering units, C_Speed is a REAL value containing the selected

engineering units/second (REAL).

· Signal state of 0 = positive

· Signal state of 1 = negative

ã Siemens AG 2020 All rights reserved

Note

The Axis of Motion reads the configuration/profile table only at power-up or when

commanded to load the configuration.

• If you use the Motion wizard to modify the configuration, then the AXISx_CTRL

subroutine automatically commands the Axis of Motion to load the

configuration/profile table every time the CPU changes to RUN mode.

• If you use the Motion control panel to modify the configuration, clicking the

Update Configuration button commands the Axis of Motion to load the new

configuration/profile table.

• If you use another method to modify the configuration, then you must also issue

an AXISx_CFG command to the Axis of Motion to load the configuration/profile

table. Otherwise, the Axis of Motion continues to use the old configuration/profile

table.

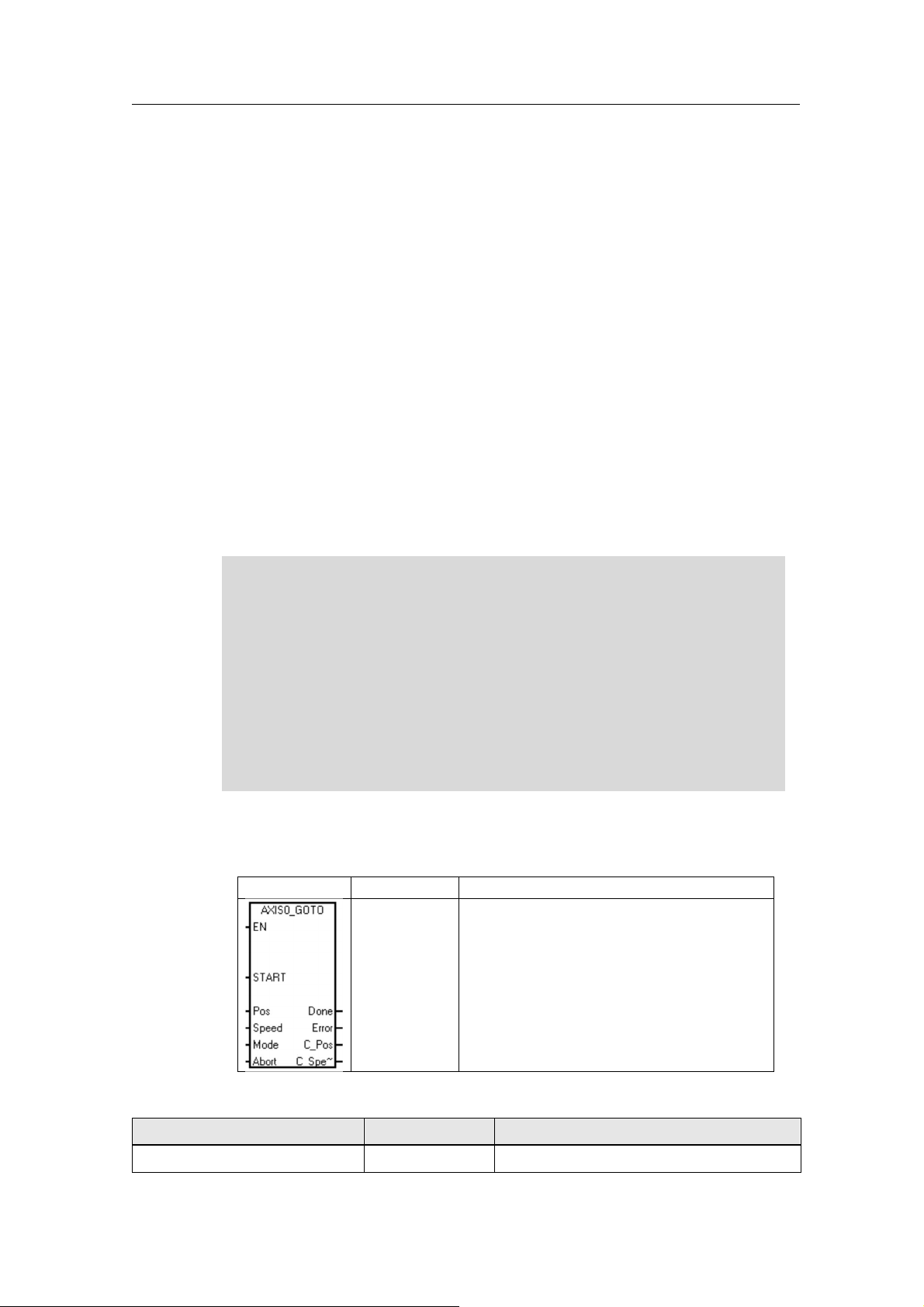

3.2.2 AXISx_GOTO subroutine

CALL

AXISx_GOTO,

START, Pos,

Speed,

Mode, Abort,

Done,

Error, C_Pos,

C_Speed

The AXISx_GOTO subroutine commands the

Axis of Motion to go to a

desired location.

Input/output Date Type Value

START BOOL

S7 –200 Smart to Stepper Drive Communication

Entry-ID: 6, V0.0, 01/2020

3.2.2.1 Figure 3-2

I, Q, V, M, SM, S, T, C, L, Power Flow

8

Loading...

Loading...