Siemens RWF 50.2,RWF55.5,RWF55.6,RWF55.50A9,RWF55.61A9,RWF55.51A9,RWF55.60A9 Installation, Use And Maintenance Instructions

20089337 (2) - 05/2015

Installation, use and maintenance instructions

Compact universal controllers

MODEL

Kit RWF 50.2

GB

20089337

Translation of the original instructions

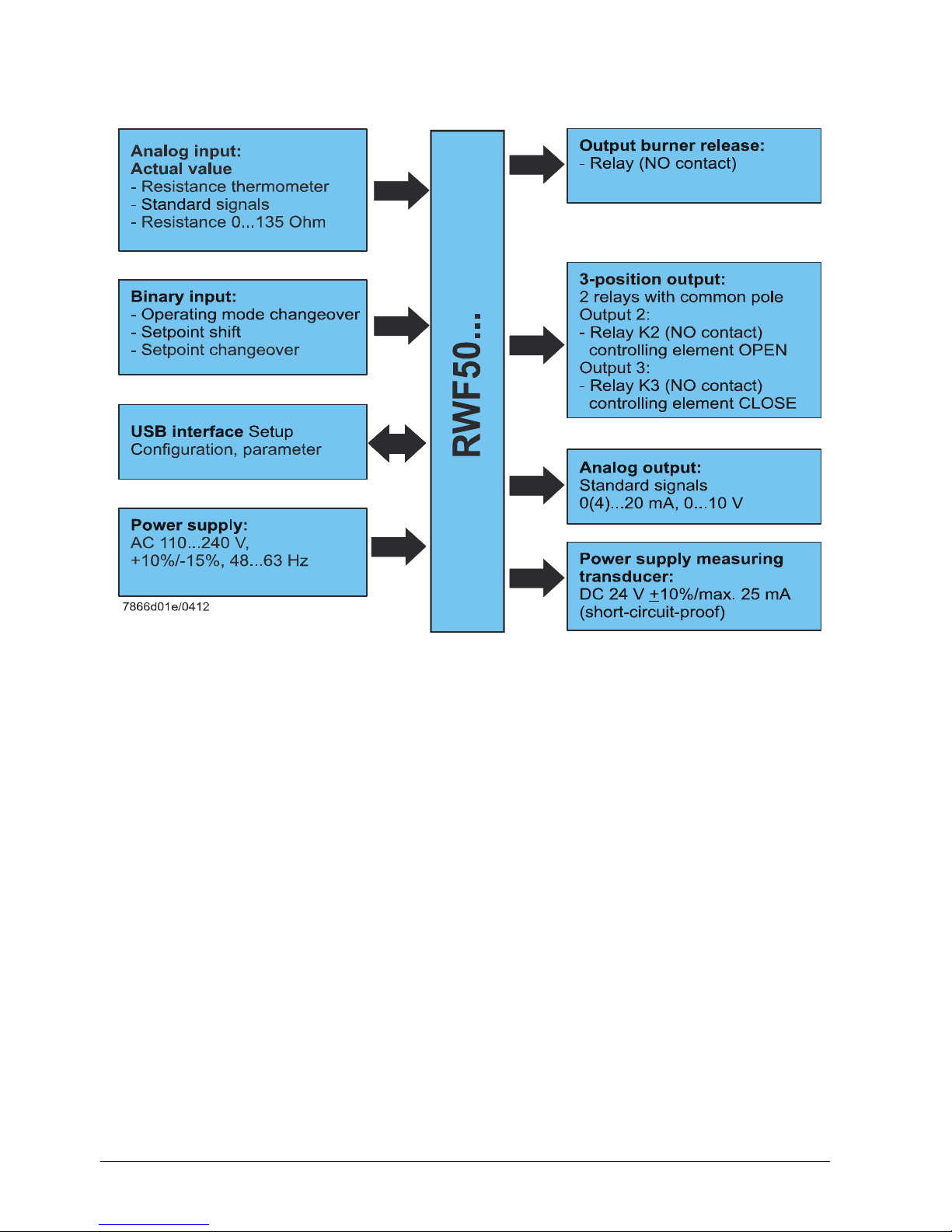

RWF50.2 and RWF50.3

Compact universal controllers

Optimized for temperature and pressure control in connection with

modulating or multistage burners and air conditioning systems

User Manual

The RWF50.2/RWF50.3 and th i s U s er M a n u a l a r e i n t e nd e d f o r use by OEMs which integrate the controllers in their

products!

Caution!

All safety, warning and technical notes contained in the Data Sheet on the

RWF50… (N7866) also apply to this document!

2/68

20089337

Supplementary documentation

Data Sheet RWF50... ............................................................................................. N7866

Environmental Declaration RWF50... ......................................................................E7866

3/68

20089337

4/68

20089337

Contents

1 Introduction...................................................................................................... 8

1.1 General notes .................................................................................................. 8

1.2 Typographical conventions.............................................................................. 9

1.2.1 Safety notes..................................................................................................... 9

1.2.2 Warning symbols ............................................................................................. 9

1.2.3 Notification symbols....................................................................................... 10

1.2.4 Presentation ..................................................................................................10

1.3 Description..................................................................................................... 11

1.4 Block structure............................................................................................... 12

2 Identification of product no. ...........................................................................13

2.1 Type field ....................................................................................................... 13

2.2 Scope of delivery ........................................................................................... 13

3 Installation .....................................................................................................14

3.1 Installation site and climatic conditions.......................................................... 14

3.2 Dimensions.................................................................................................... 14

3.3 Side-by-side mounting................................................................................... 15

3.4 Mounting the controller in a panel cutout....................................................... 15

3.5 Removing the controller from the panel cutout.............................................. 16

3.6 Cleaning the front .......................................................................................... 16

4 Electrical connections.................................................................................... 17

4.1 Installation notes............................................................................................ 17

4.2 Galvanic separation....................................................................................... 18

4.3 Assignment of terminals ................................................................................ 19

5 Operating modes ........................................................................................... 21

5.1 Low-fire operation.......................................................................................... 21

5.2 High-fire operation ......................................................................................... 22

5.2.1 Modulating burner, 3-position output ............................................................. 22

5.2.2 Modulating burner, analog output.................................................................. 23

5.2.3 2-stage burner, 3-position output................................................................... 24

5.2.4 2-stage burner, analog output .......................................................................25

5.3 Burner shutdown ...........................................................................................26

5.4 Predefined setpoint........................................................................................ 27

5.5 Response threshold (q) ................................................................................. 28

5.6 Cold start of plant ..........................................................................................29

5.7 Thermal shock protection (TSS).................................................................... 31

6 Operation....................................................................................................... 32

5/68

20089337

6.1 Meaning of display and buttons .....................................................................32

6.2 Basic display ..................................................................................................33

6.3 User level .......................................................................................................34

6.4 Manual control, modulating burner ................................................................35

6.5 Manual control, 2-stage burner ......................................................................36

6.6 Starting the self-setting function.....................................................................37

6.7 Display of software version ............................................................................38

7 Parameterization PArA....................................................................................39

8 Configuration ConF..........................................................................................41

8.1 Analog input InP1...........................................................................................42

8.2 Controller Cntr................................................................................................43

8.3 Thermal shock protection (TSS) rAFC ............................................................44

8.4 Control outputs OutP.......................................................................................45

8.5 Binary input binF............................................................................................46

8.6 Display diSP...................................................................................................47

9 Self-setting function .......................................................................................48

9.1 Self-setting function in high-fire operation......................................................48

9.2 Checking the controller parameters ...............................................................50

10 PC software ACS411 .....................................................................................51

10.1 Safety notes ...................................................................................................51

10.2 Setting the correct system parameters ..........................................................51

10.3 Changing the parameters ..............................................................................51

10.4 Place of installation ........................................................................................52

10.5 License and liability regulations .....................................................................52

10.6 Procurement of PC software ACS411 ...........................................................52

10.7 Languages .....................................................................................................52

10.8 Operating systems : Operating ......................................................................52

10.9 Prerequisites for hardware.............................................................................52

10.10 Installation......................................................................................................53

10.11 Others ............................................................................................................54

10.11.1 Use of USB port : Use of................................................................................54

10.11.2 Powering the controller via the USB port : Powering the controller via the

port.................................................................................................................54

11 What to do if ..................................................................................................55

11.1 Alarm messages: ...........................................................................................55

11.2 Others ............................................................................................................55

12 Technical data................................................................................................56

12.1 Inputs .............................................................................................................56

6/68

20089337

12.1.1 Resistance thermometers.............................................................................. 56

12.1.2 Input signals ..................................................................................................56

12.1.3 Binary input D1 .............................................................................................. 56

12.2 Monitoring the measuring circuit.................................................................... 57

12.3 Controller outputs OutP Controller o.............................................................. 57

12.4 Controller ....................................................................................................... 57

12.5 Electrical data ................................................................................................ 58

12.6 Housing .........................................................................................................58

12.7 Environmental conditions ..............................................................................59

12.8 Segment display ............................................................................................ 59

12.9 Standards and certificates ............................................................................. 59

13 Key ................................................................................................................61

14 List of figures ................................................................................................. 63

7/68

20089337

1 Introduction

1.1 General notes

Please read this User Manual before switching on the controller. Keep the

User Manual in a safe place which can be accessed by all users at all times.

Version!

This User Manual describes all necessary settings (applicable to controller

software version XXX.01.01).

Reference!

See chapter 6.7 Display of software version.

Should any problems arise during commissioning, do not make any

unauthorized manipulations on the unit. You could endanger your rights

under the warranty terms! Please contact us in such a case.

8/68

20089337

1.2 Typographical conventions

1.2.1 Safety notes

This User Manual contains information which must be observed to ensure your own

personal safety and to prevent damage to equipment and property. The instructions

and notes are highlighted by warning triangles, a hand or arrow symbol and are

presented as follows, depending on the hazard level:

Only qualified personnel are allowed to install and operate the equipment.

Qualified personnel in the context of the safety-related notes contained in this

document are persons who are authorized to commission, ground and tag devices,

systems and electrical circuits in compliance with established safety practices and

standards.

Note the following:

The controller may only be used on the applications described in the technical

documentation and only in connection with devices or components from other suppliers

that have been approved or recommended by Siemens.

The product can only function correctly and safely if shipped, stored, set up and

installed correctly, and operated and maintained as specified.

1.2.2 Warning symbols

The symbols for Caution and Attention are used in this User Manual under the

following conditions:

Caution This symbol is used where there may be a danger to

personnel if the instructions are disregarded or not

strictly observed!

Attention This symbol is used where damage to equipment or

data can occur if the instructions are disregarded or not

strictly observed!

Attention This symbol is used if precautionary measures must

be taken when handling electrostatically sensitive

components.

Qualified personnel

Correct use

9/68

20089337

1.2.3 Notification symbols

Note This symbol is used to draw your special attention to a

remark.

Reference This symbol refers to additional information in other

documents, chapters or sections.

abc¹

Footnote

Footnotes are comments, referring to specific parts of

the text. They consist of 2 parts:

1) Markings in the text are arranged as continuous

superscript numbers

2) Footnote text is placed at the bottom of the page

and starts with a number and a period

*

Action

An asterisk indicates that a required action is

described.

The individual steps are indicated by asterisks, for

example:

*

Press

1.2.4 Presentation

Buttons

Buttons are shown in a circle. Either symbols or text are

possible. If a button has multiple assignments, the text

shown is always the text corresponding to the function

currently used.

+

Button

combinations

Two buttons shown in combination with a plus sign

means that they must be pressed simultaneously.

ConF InP

InP1

Command

chain

Arrows between words serve for finding parameters at

the configuration level more easily or for navigating in the

ACS411 setup program.

10/68

20089337

1.3 Description

The RWF50... is used primarily for the control of temperature or pressure in oil- or gasfired heating plants. Depending on the model, it is employed as a compact 3-position

controller without feedback of angular positioning or as a modulating controller with an

analog output. An external switch is provided to convert it to a 2-position controller for

controlling 2-stage burners. The built-in thermostat function switches the burner on and

off.

The controller’s operating mode can be changed from heating to cooling, or vice versa.

Reference!

See chapter 8.2 Controller Cntr.

The controllers feature two 4-digit 7-segment displays for the actual value (red) and the

setpoint (green).

The RWF50.2 has a 3-position output consisting of 2 relays to open or close a

controlling element.

The RWF50.3 has an analog output.

In modulating mode, the RWF50... operates as a PID controller. In 2-stage mode, the

RWF50... provides control based on the set switching threshold. Using the binary input,

a change to a second setpoint can be made or the setpoint can be shifted. Standard

feature is a self-setting function used to determine the PID control parameters.

The controller insert measures 48 x 48 x 104 mm and is especially suited for installation

in control panels. All electrical connections are made via screw terminals at the rear of

the unit.

Use in heating plants

Cooling controller

RWF50...

Control

Mounting

11/68

20089337

1.4 Block structure

Only RWF50.3:

Only RWF50.2:

Air damper control

Figure 1: Block structure

12/68

20089337

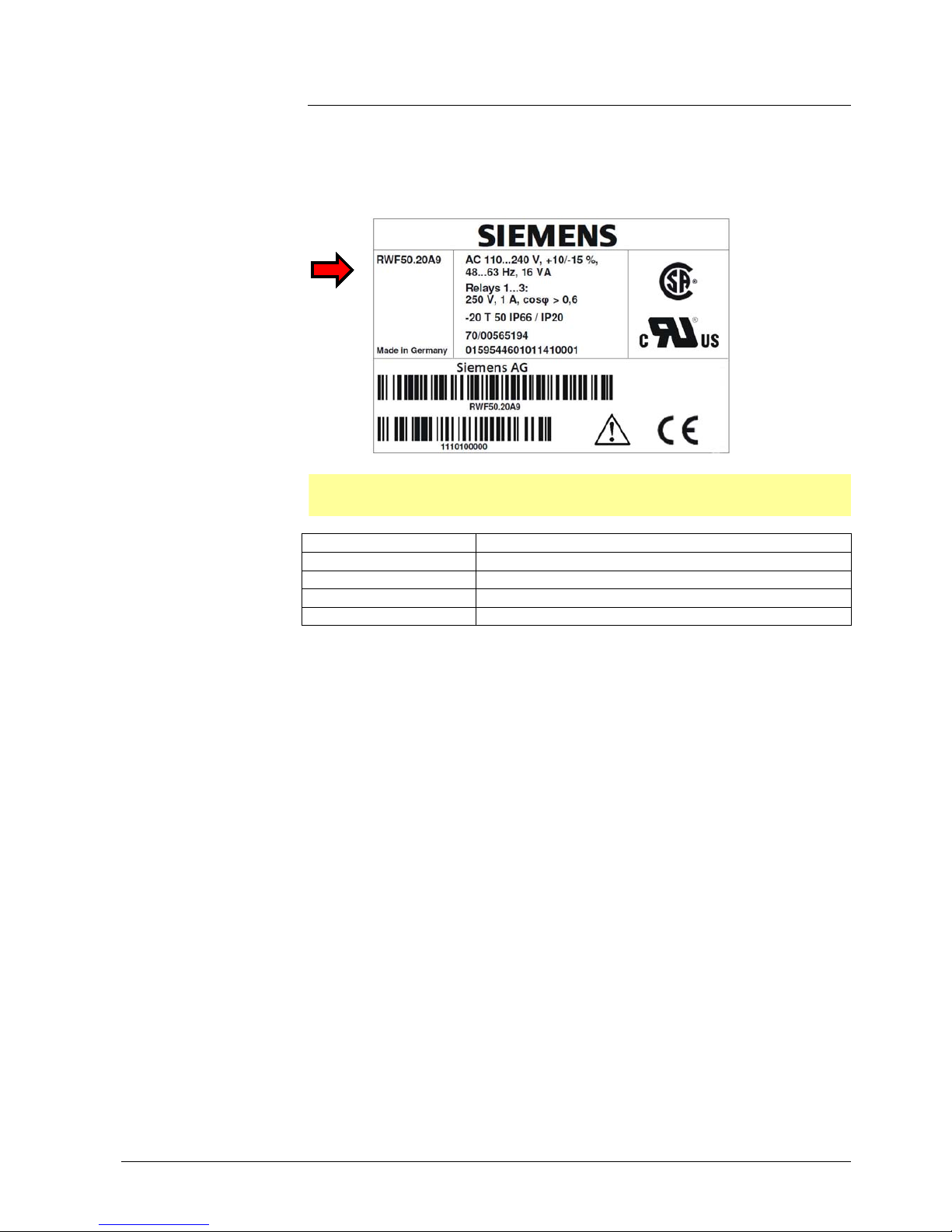

2 Identification of product no.

2.1 Type field

The type field is glued onto the housing. The arrow below indicates the product no.

7866z10/0612

Attention!

Mains supply must correspond to the operating voltage given on the type field.

Product no. Description

RWF50.20A9 Basic version with 3-position output – single pack

RWF50.21A9 Basic version with 3-position output – multipack

RWF50.30A9 Basic version with analog output – single pack

RWF50.31A9 Basic version with analog output – multipack

2.2 Scope of delivery

- Type of controller as ordered

- User Manual

Location

:

Example

Product nos.

:

13/68

20089337

3 Installation

3.1 Installation site and climatic conditions

- The installation site should be free from vibrations, dust and corrosive media

- The controller should be installed away from sources of electromagnetic fields, such

as variable speed drives or high-voltage ignition transformers

Relative humidity: 95% (noncondensing)

Ambient temperature: -20...50 °C

Storage temperature: -40...70 °C

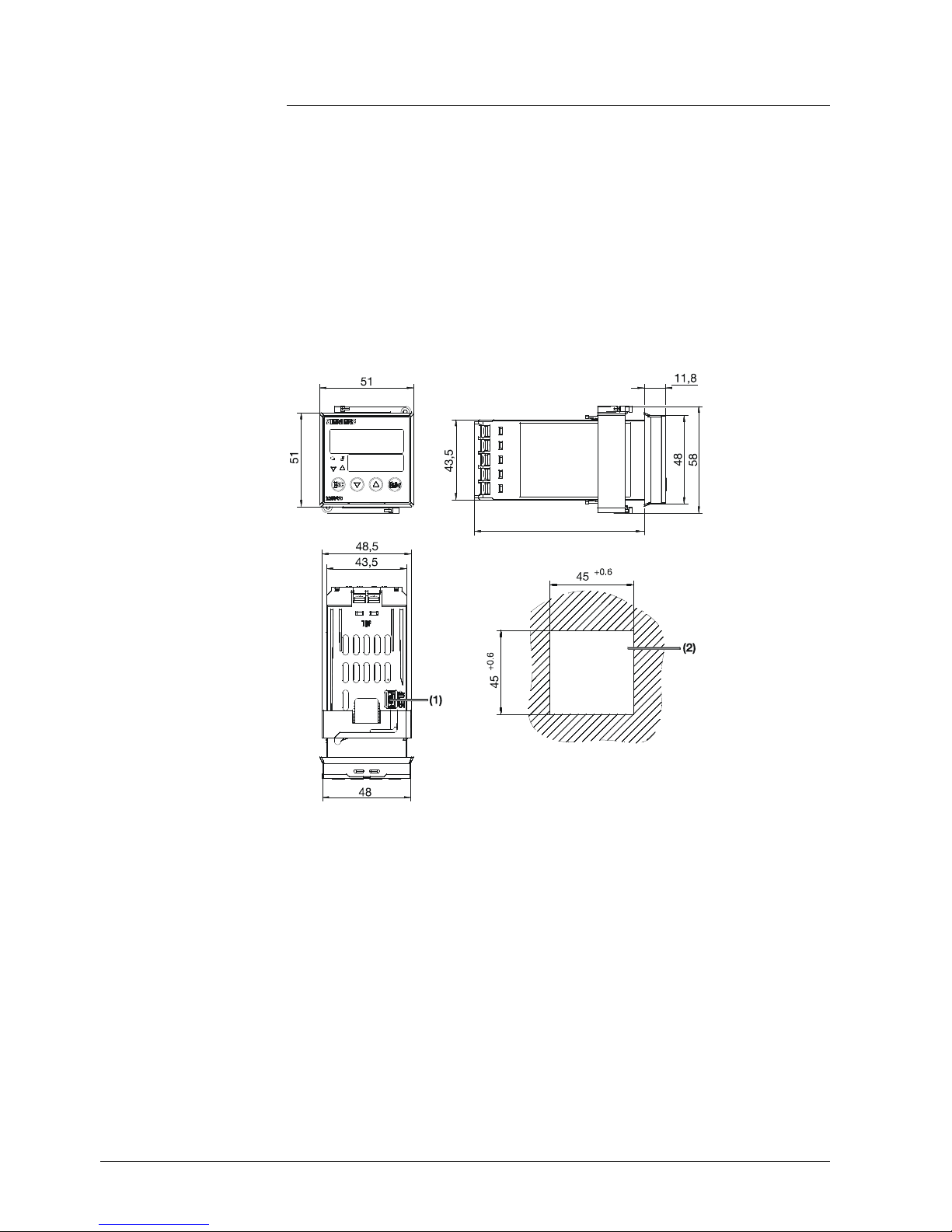

3.2 Dimensions

7866m01/0112

92

Figure 2: Dimensions of RWF50...

Key

(1) USB interface setup

(2) Panel cutout

14/68

20089337

3.3 Side-by-side mounting

If several controllers are mounted side-by-side or above one another in a control panel,

the horizontal distance between panel cutouts must be a minimum of 11 mm and the

vertical distance a minimum of 50 mm.

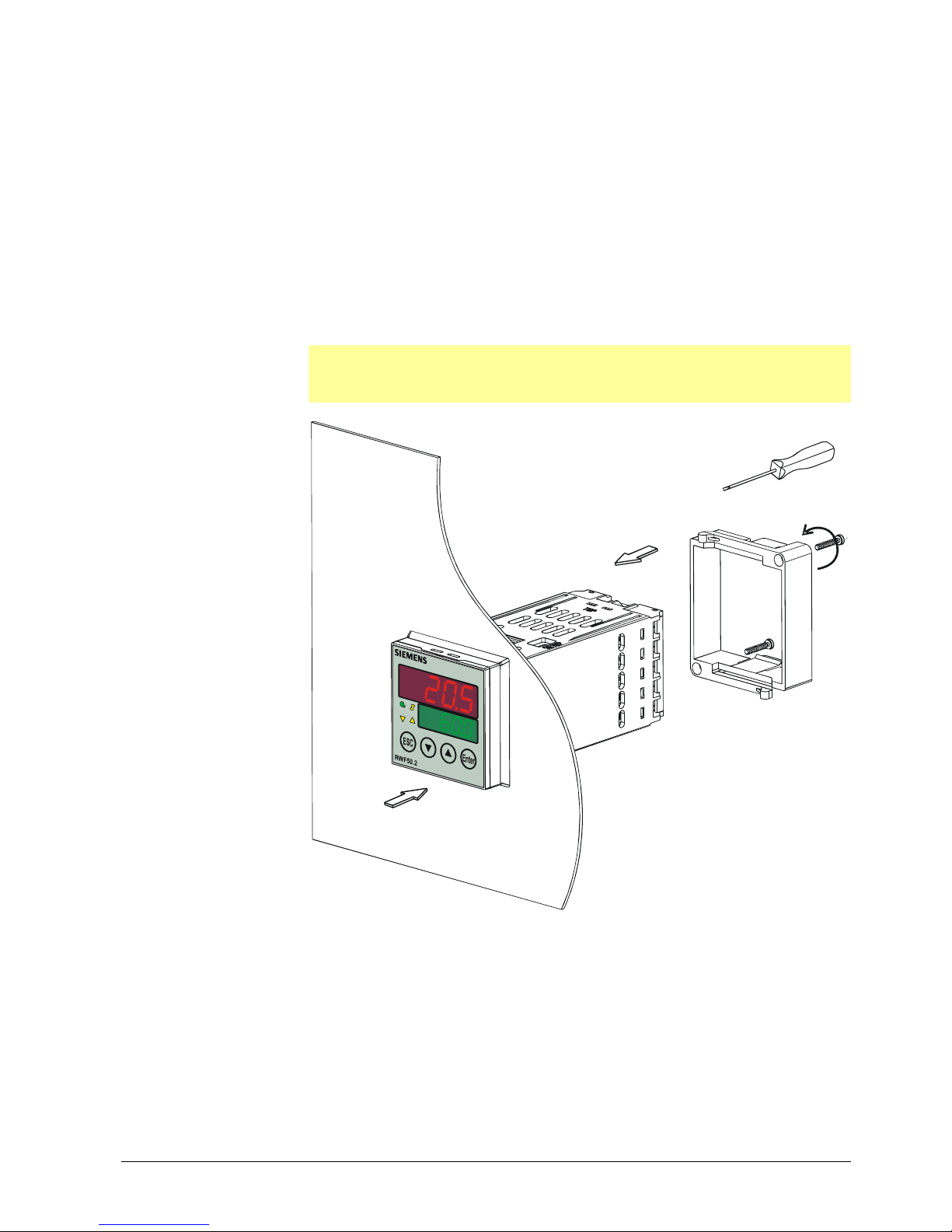

3.4 Mounting the controller in a panel cutout

*

Remove the frame

*

Fit the seal supplied with the controller

Attention!

The controller must be installed with the seal, preventing water or dirt from

entering the housing!

7866z02/0112

(1)

(2)

(3)

(3)

Figure 3: Mounting in a panel cutout

*

Insert the controller from the front into the panel cutout (1) and make certain the seal

is correctly fitted

*

Fit the frame from the rear (2) and let it engage in the grooves

*

Tighten the screws evenly with a screwdriver (3) until the controller is correctly

secured in the panel cutout

15/68

20089337

3.5 Removing the controller from the panel cutout

Attention!

When removing the controller, make certain that all cables are disconnected and that

they do not get squeezed between control panel and housing.

3.6 Cleaning the front

The front of the controller can be cleaned with normal washing/rinsing agents or

detergents.

Attention!

The front of the controller is not resistant to corrosive acids, caustic solutions and

abrasive cleaners. Do not clean with high-pressure cleaners!

16/68

20089337

4 Electrical connections

4.1 Installation notes

- The choice of cable, installation and electrical connections of the controller must

conform to VDE 0100 Regulations for the installation of power circuits with nominal

voltages below AC 1000 V, or the relevant local regulations

- The electrical connections must be made by qualified personnel

- If contact with live parts is possible while working on the unit, the controller must be

disconnected from power supply (all-polar disconnection)

Caution!

When connecting external components to the safety extra low-voltage inputs or

outputs of the RWF50... (terminals 11, 12, 13, D1, DG, G+, G-, A+, A-, and USB

port), it must be made certain that no dangerous active voltage are introduced to

the RWF50...

This can be achieved by using capsulated components with double/reinforced

insulation or SELV components, for example. If not observed, there is a risk of

electric shock.

Caution!

All screw terminals at the rear of the unit must always be properly tightened. This

applies to unused terminals as well.

Caution!

- Fusing on site must not exceed 20 A

- The fuse on the controller side (AC 250 V/1.6 A slow) conforms to IEC 60127-4

- To prevent the relay contacts from welding in the event of short-circuit in the load

circuit, fusing of the output relays must give consideration to the maximum

permissible relay current

Reference!

See chapter 12.3 Controller outputs OutP.

- No other loads may be connected to the controller’s main power supply terminals

- The electromagnetic compatibility and interference suppression levels conform to the

standards and regulations listed under Technical data

Reference!

See chapter 12.5 Electrical data.

- Input, output and supply cables should be routed separately, not parallel to one

another

- All input and output lines without connection to the power supply network must be

shielded and twisted. They must not be run close to live components or live cables.

On the controller side.

- The controller is not suited for installation in areas with explosion hazard

- Incorrect settings on the controller (setpoint, data of parameter and configuration

levels) can affect proper functioning of the process or lead to damage.

Safety devices independent of the controller, such as overpressure relief valves or

temperature limiters/monitors should therefore always be provided, and only be

capable of adjustment by qualified personnel. Please observe the relevant safety

regulations. Since self-setting cannot be expected to handle all possible control loops,

the stability of the resulting actual value should be checked

Safety regulations

Connection of

external components

Screw terminals

Fusing

Suppression of

interference

Incorrect use

17/68

20089337

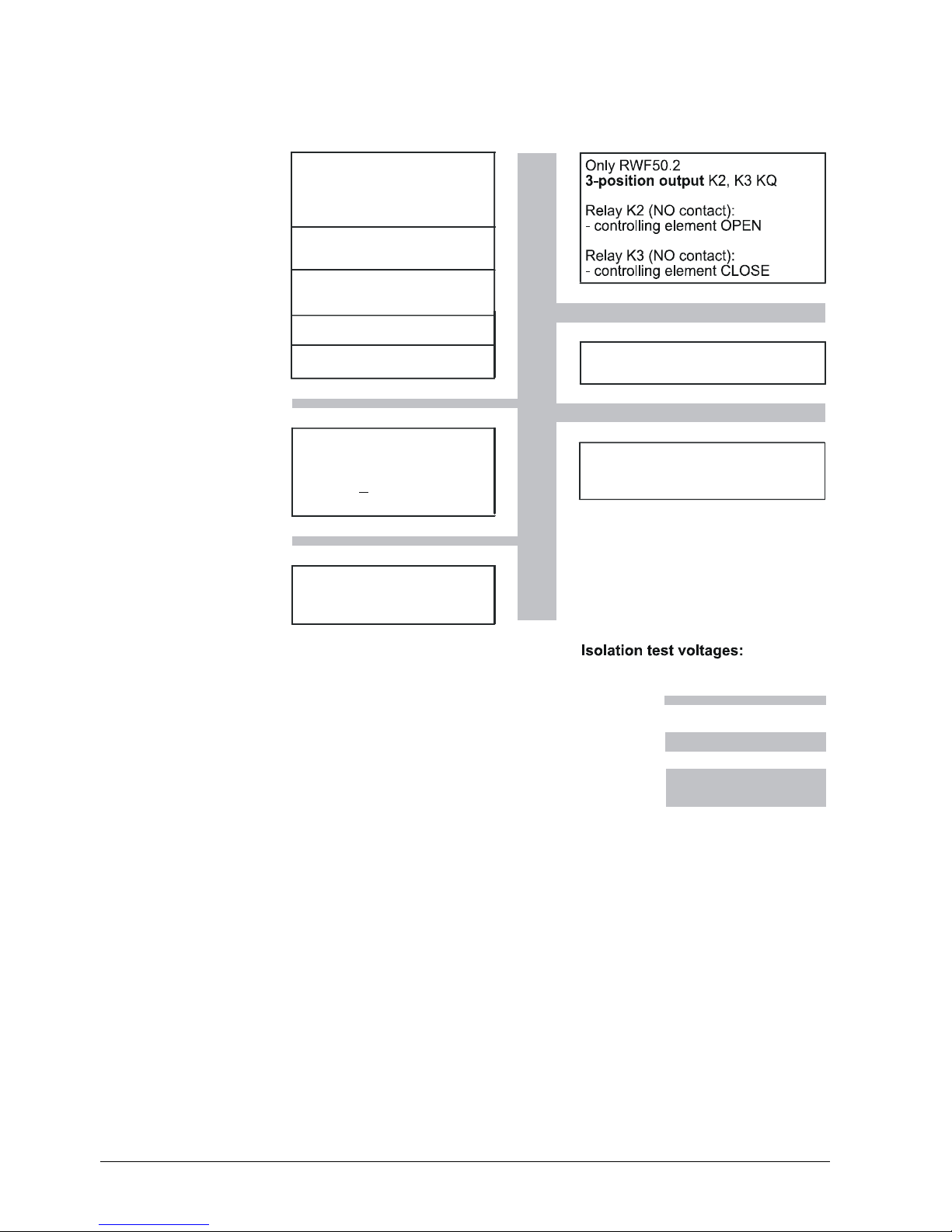

4.2 Galvanic separation

The illustration shows the maximum test voltages between the electrical circuits.

DC 50 V

AC 1500 V

AC 3300 V

Analog input

Binary input

USB interface

LED

Buttons

For resistor thermometer

or

standard signals

D1

For potential-free contacts

Setup

For PC software ACS411

InP

Power supply measuring

transducer

G+, GDC 24 V 10%/max. 25 mA

(short-circuit-proof)

+

Only RWF50.3

Analog output

A+, A-

Burner release

1P, 1N

Relay (NO contact)

Power consumption

at AC 110...240 V,

+10%/-15%, 48...63 Hz

Max. 16 VA

7866d02e/1212

Figure 4: Test voltages

18/68

20089337

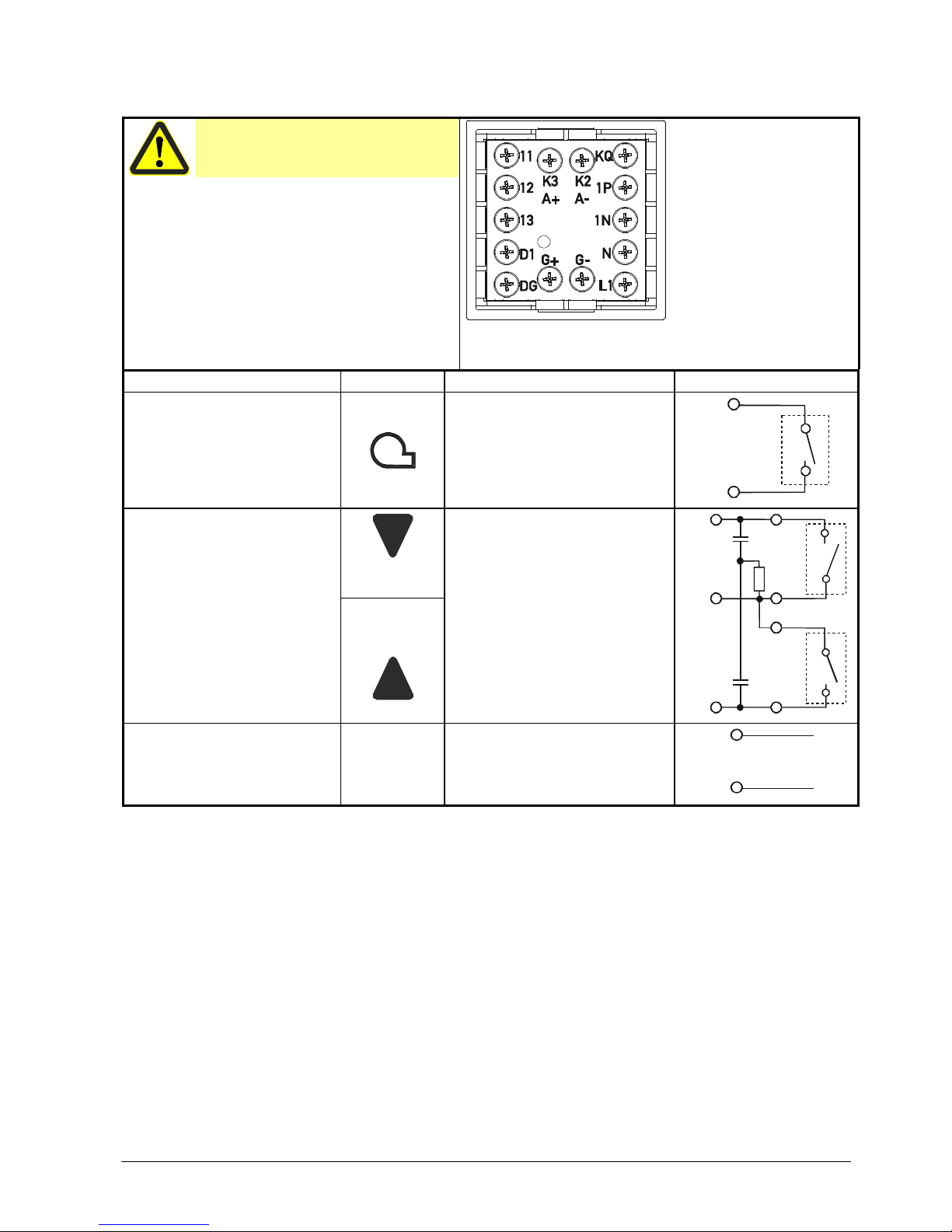

4.3 Assignment of terminals

Caution!

Electrical connections must always be

made by qualified personnel!

7866z09/0911

Figure 5: Assignment of terminals

Outputs Display LED Terminal no.

Connection diagram

Relay Burner release:

Relay K1: P, 1N

1P pole

1N NO contact

1P

P

S

1N

7866a01/0911

Only RWF50.2

3-position output:

Relay K3: Controlling element

CLOSE

Relay K2: Controlling element

OPEN

K3 NO contact

KQ common pole

K2 NO contact

P

S

K3

KQ

K2

S

P

7866a02/0911

Only RWF50.3

Analog output A+, ADC 0(4)...20 mA, DC 0...10 V

A+

A-

A+

A-

+

-

7866a03/0911

19/68

20089337

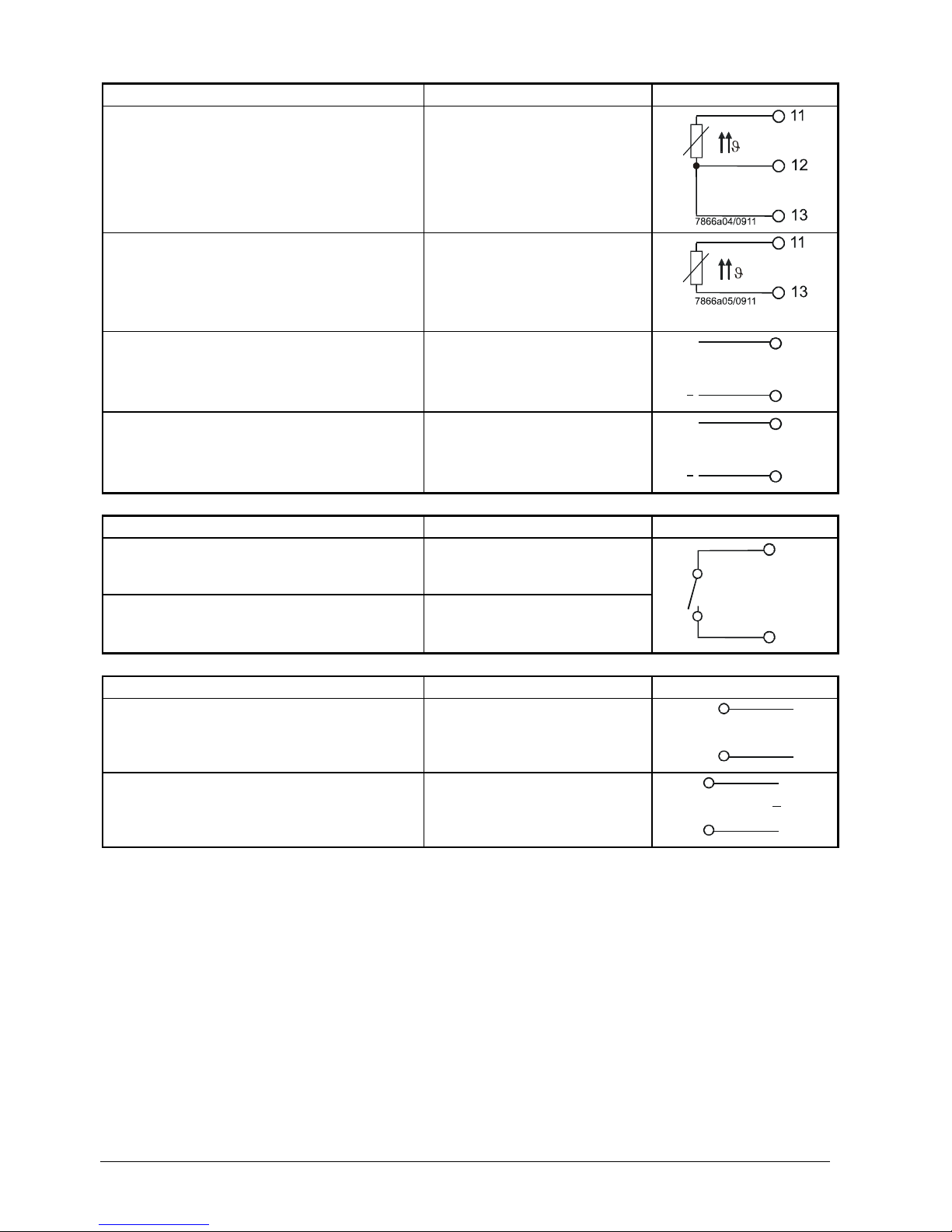

Analog input

InP1

Terminal no.

Connection diagram

Resistance thermometer in 3-wire circuit

11

12

13

Resistance thermometer in 2-wire circuit

11

13

Current input

DC 0...20 mA, 4...20 mA

12

13

13

12

+

7866a06/0911

Ix

Voltage input

DC 0...5 V, 1...5 V, 0...10 V

11

13

13

11

+

7866a06/0911

Ux

Binary inputs binF Terminal no.

Connection diagram

Binary input D1

D1

Common ground DG

DG

D1

DG

7866a08/0911

Power supply Terminal no.

Connection diagram

Power supply

AC 110...240 V +10%/-15%, 48...63 Hz

L1 Live conductor

N Neutral conductor

L1

N

7866a09/0911

Power supply measuring transducer

(short-circuit-proof)

G+

G-

G+

G-

+

-

7866a10/0412

DC 24 V 10%

max. 25 mA

+

20/68

20089337

Loading...

Loading...