Siemens RVP550,RVP540 Installation Instructions Manual

Siemens Building Technologies / HVAC Products 74 319 0312 0 a 19.08.2002 1/28

74 319 0312 0

G2488

en

Installation Instructions

Energy Manager / Heating Controller

RVP540

RVP550

Installation

Place of installation

• In a dry room, e.g. the boiler room

• Installation choices:

- Control panel (in the panel front, on the inner wall, or

on a DIN rail)

- Control cabinet

- Sloping front of a control desk

• Permissible ambient temperature: 0...50 °C

Electrical installation

• The local regulations for electrical installations must

be complied with

• Cable strain relief must be ensured

• Cables from the controller to the actuators and

pumps carry mains voltage

• Sensor cables should not be run parallel to mains car-

rying cables

• To protect the solar collector sensor from voltage

surges (caused by lightning for example), the separately

available conduit box for overvoltage protection

(AGS2S.200/109) should be installed

Permissible cable lengths

• For all sensors, thermostats and external contacts:

Copper cable 0.6 mm dia. max. 20 m

Copper cable 1.0 mm

2

max. 80 m

Copper cable 1.5 mm

2

max. 120 m

• For room units:

Copper cable 0.25 mm

2

max. 25 m

Copper cable 0.5 mm

2

max. 50 m

• For the data bus:

0.75...2.5 mm

2

according to Data Sheets

N2030E and N2032E

Mounting and wiring the base

Wall mounting

1. Separate base from the controller.

2. Hold base against the wall. Marking TOP must be at

the top!

3. Mark fixing holes on the wall.

4. Drill holes.

5. If required, knock out holes on the base for the cable

entry glands.

6. Screw base to the wall.

7. Wire up the base.

DIN rail mounting

1. Fit rail.

2. Separate base from the controller.

3. If required, knock out holes on the base for the cable

entry glands.

4. Fit base to the rail. Marking TOP must be at the top!

5. If required, secure the base (depending on the type of

rail).

6. Wire up the base.

Flush panel mounting

• Panel cutout required: 92 x 138 mm

• Maximum thickness: 3 mm

1. Separate base from the controller.

2. If required, knock out holes on the base for the cable

entry glands.

3. Insert base in the panel cutout from behind until stop

is reached. Marking TOP must be at the top!

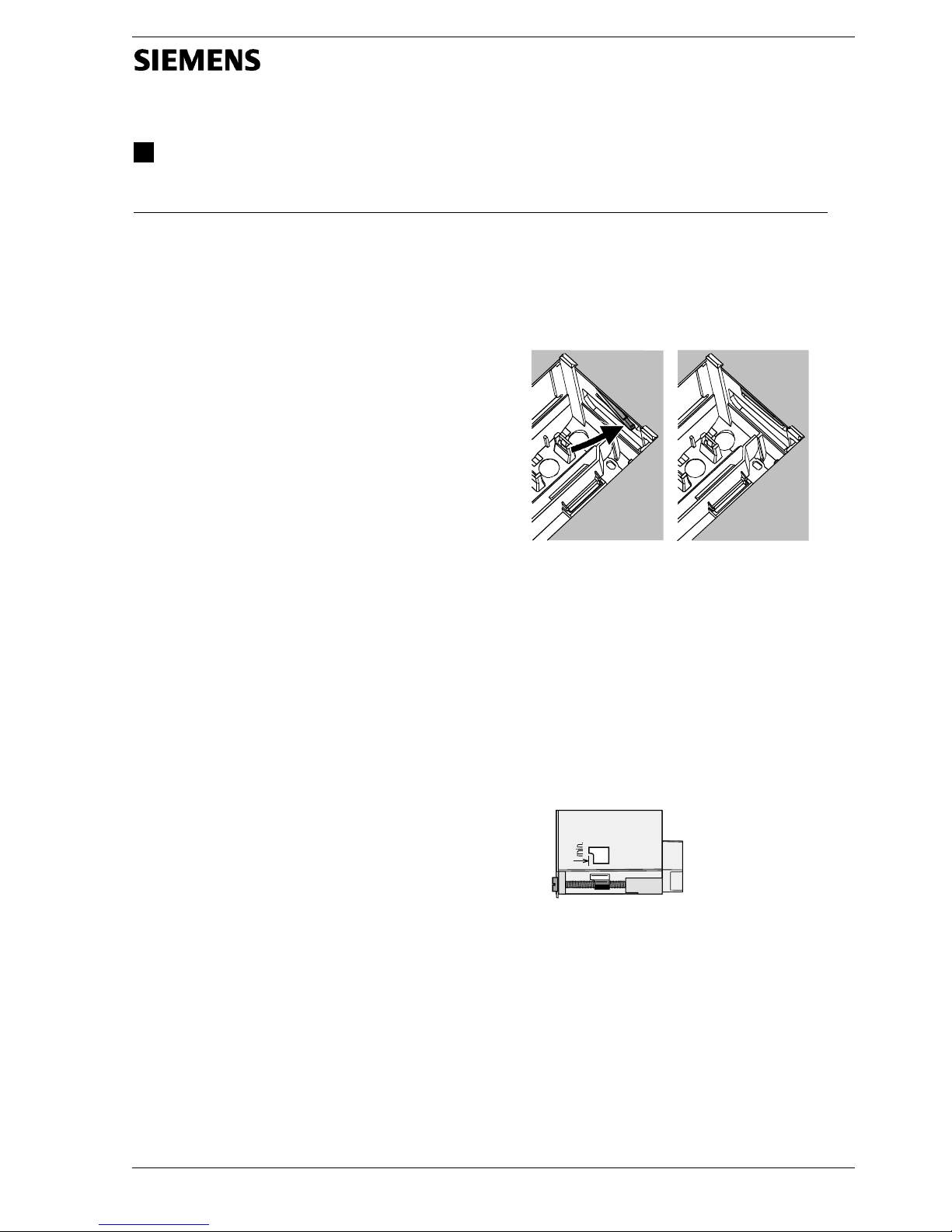

4. Push lateral tongues behind the front panel (refer to

illustration below).

2462Z06

Wrong Correct

Place tongues on both sides correctly – they may not be

located inside the cutout!

5. Wire up the base. Make sure the cable lengths are

such that there is sufficient space to open the control

panel door.

Commissioning

Preparatory checks

1. DO NOT switch on power yet.

2. Check wiring according to the plant connection diagram.

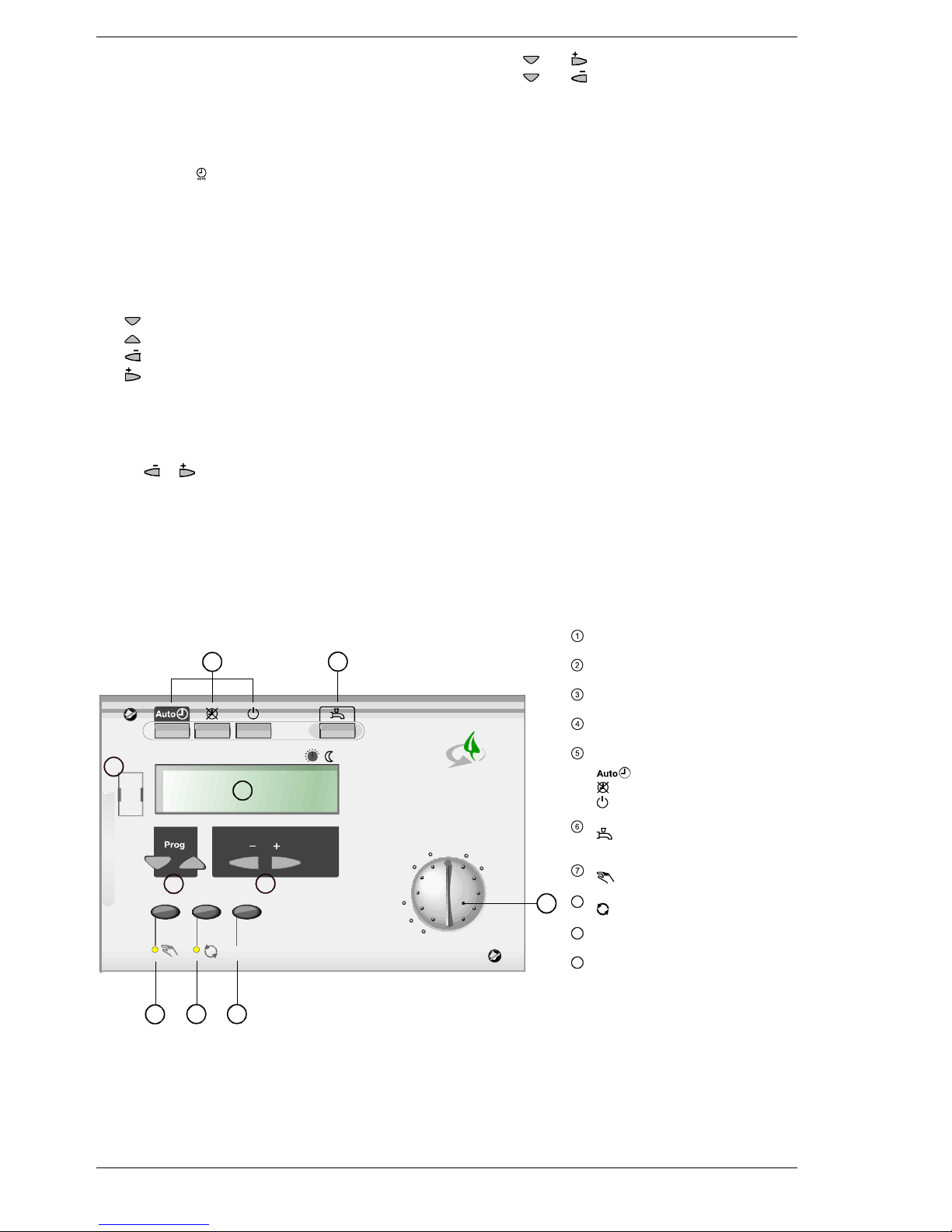

3. Ensure correct position and location of the levers by

turning the fixing screws (refer to illustration on the lateral wall of the unit).

2522Z13

4. Insert controller in the base until stop is reached.

Marking TOP must be at the top!

5. Tighten fixing screws alternately.

6. Check the motorized valves: See if

− they are correctly installed (observe direction of flow

as indicated on the valve body)

− the manual lever is disengaged.

7. Note with underfloor and ceiling heating systems:

The limit thermostat must be correctly adjusted. During

the functional test, the flow temperature may not exceed the maximum permissible level (usually 55 °C). If

it does, proceed immediately as follows:

- Either close the valve manually, or

- Switch off the pump, or

- Close the pump isolating valve

2/28 19.08.2002 74 319 0312 0 a Siemens Building Technologies / HVAC Products

8. Switch on power. The display must show something

(e.g. time of day). If not, the reason may be one of the

following:

- No mains voltage

- Main fuse blown

- Mains isolator or main switch not set to ON

9. If one of the operating mode buttons flashes, a room

unit or contact H1 overrides the controller. Select operating mode

on the room unit; switch off contact

H1.

General information about operation

• Setting elements:

− Setting knob

− Display; an operating line is assigned to each setting

− Buttons for selecting and adjusting setting values:

Next operating line below

Next operating line above

Decrease the displayed value

Increase the displayed value

• Adopting a setting value:

The setting value is adopted by selecting the next operating line (or by pressing one of the operating mode

buttons)

• Entering --.- / --:-- / --- (deactivating a function):

Keep

or depressed until the required display

appears

• Block jump function:

To select a single operating line quickly, 2 button

combinations can be used:

Press and to select the next line block above.

Press

and to select the next line block below.

Setting procedure

1. Make settings on the operating lines according to the

instructions provided by your local Siemens HVAC

Products sales office.

2. Select plant type on operating line 100.

3. Make the required settings on the controller. All functions and operating lines required for the selected type

of plant will be activated and can be set. Operating

lines that are not used will be hidden.

4. Enter the adjusted values in the table!

5. Set the general functions (independent of the type of

plant).

Commissioning and functional check

• Specific operating lines for the functional check:

200 = output test

201 = input test

296 = functional test oil- / gas-fired boiler

345 = functional test solar

395 = functional test wood-fired boiler

545 = functional test d.h.w. storage tank

745 = functional test heating circuit

888 = output test P1

894 = output test Ux

• If Er (ERROR) appears on the display: Refer to operating

line 50 to find the fault

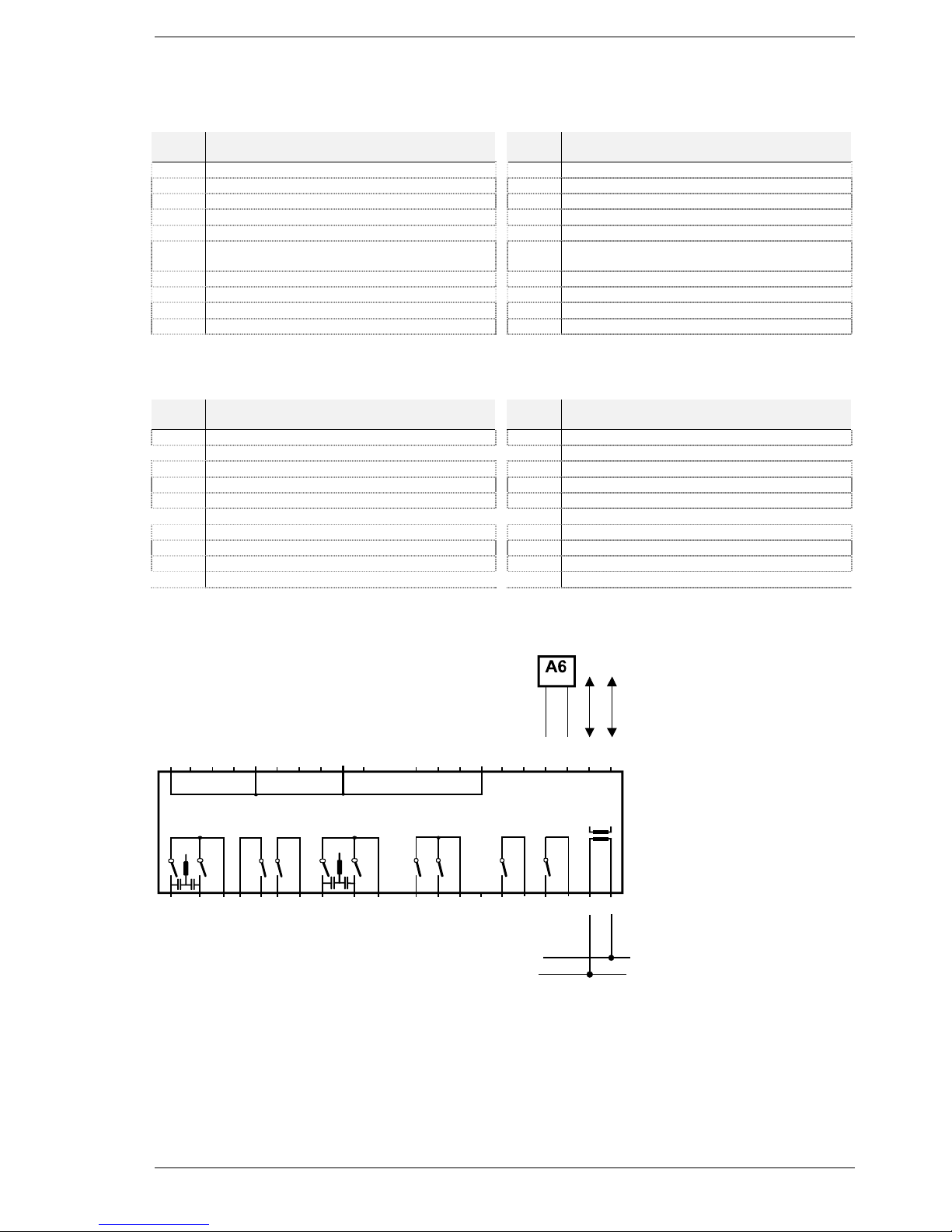

Operating elements

Room temperature setpoint knob

Adjustment of nominal room temperature setpoint

Setting buttons

Parameter settings (+ / -)

Operating line selection buttons (Prog)

Selection of parameters / switching operating lines

Display

Showing actual values and settings

Operating mode buttons heating circuit

Operating mode changes to:

Automatic operation

Continuous operation

Standby

Operating mode button d.h.w.

D.h.w. heating ON / OFF

Manual d.h.w. push

Function button with LED for manual operation

Manual operation ON / OFF

8

Green button with signal lamp

Green operation ON / OFF

9

Info button

Display of plant values

10

Connection facility for PC tool

Diagnostics and service with OCI69 / ACS69

An illuminated button or signal lamp indicates that the

relevant function is activated.

C

0 4 8 12 16 20 24

1 2 3 4 5 6 7 8 9 10

°C

20

26

14

Info

RVP540

6

5

4

1

7

8 9

2392 Z54a

10

3

2

Front of RVP540 and RVP550

Siemens Building Technologies / HVAC Products 74 319 0312 0 a 19.08.2002 3/28

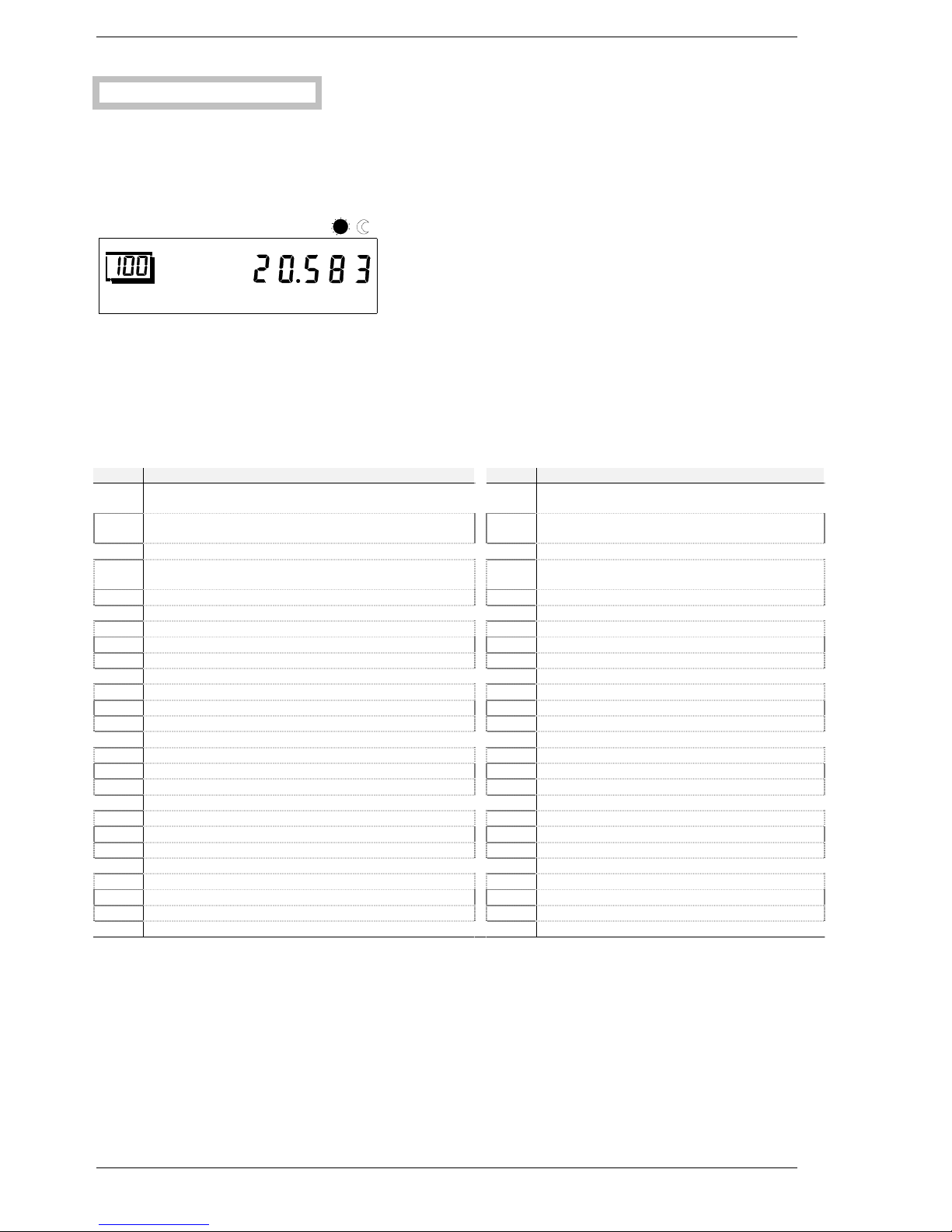

Connection diagrams

Markings of connection terminal on the low-voltage side

Terminal

Terminals Termi-

nal

Terminals

M Ground H1 Input H1 (contact or DC 0…10 V)

Ux Output DC 0…10 V B104 Temperature sensor

P1 PWM output B103 Temperature sensor

B109 Temperature sensor M Ground sensors

M Ground sensors B102 Temperature sensor

B108 Temperature sensor B101 Temperature sensor NTC / LG-Ni 1000

with automatic identification

B107 Temperature sensor MD Ground PPS (room unit, BMU)

B106 Temperature sensor A6 Data PPS (room unit, BMU)

M Ground sensors MB Ground bus (LPB)

B105 Temperature sensor DB Data bus (LPB)

Markings of connection terminal on the mains voltage side

Terminal

Terminals Termi-

nal

Terminals

Q110 Multifunctional output Q104 Multifunctional output

Q109 Multifunctional output Q103 Multifunctional output

F3 Phase Q109 / Q110 F1 Phase Q103 / Q104

F7 Phase Q108 E1 AC 230 V input

Q108 Multifunctional output Q102 Multifunctional output

Q107 Multifunctional output F5 Phase Q102

F6 Phase Q107 Q101 Multifunctional output

Q106 Multifunctional output F4 Phase Q101

Q105 Multifunctional output L Live conductor AC 230 V

F2 Phase Q105 / Q106 N Neutral conductor

Electrical connections

2392A03

M

B108

M

B105

H1

B104

B103

M

B106

B101

MD

A6

MB

DB

F2

N

Q105

Q106

F6

Q107

L

F4

Q101

F5

Q102

E1

F1

Q103

B107

Q104

B102

B109

Ux

M

Q108

F7

F3

Q109

Q110

P1

N

N

LPB

D1 D2

4/28 19.08.2002 74 319 0312 0 a Siemens Building Technologies / HVAC Products

Selection

Selecting the plant type:

Select the required type of plant (basic diagram number) on operating line 100 (refer to page 8). The selection activates all

functions that are required for the specific plant and shows the operating lines needed.

In addition, operating parameters 120 through 173 will be set to their default values required for the basic plant.

During the setting procedure, the basic diagram number on the display flashes. The required number must be confirmed by

pressing the + / - buttons twice for 3 seconds. Then, the basic diagram number will stop flashing.

Example:

2392a04

04

8 12162024

123

4567

89

10

Plant type

The basic plant diagram for the required type of plant and additional setting information will be provided by your local

Siemens Building Technologies / HVAC Products sales office.

Designations of relays and sensors

The relay designations used in the supplied basic diagram have the following meaning:

Relays Function (use) Relays Function (use)

K1 Heat pump stage 1 Y7 Maintained boiler return temperature, oil / gas

OPEN

K2 Heat pump stage 2 Y8 Maintained boiler return temperature, oil / gas

CLOSED

K3 Release of external wood-fired boiler Y9 Maintained boiler return temperature, wood OPEN

K4 Oil- / gas-fired boiler, stage 1 Y10 Maintained boiler return temperature, wood

CLOSED

K5 Oil- / gas-fired boiler, stage 2 Y14 Diverting valve partial storage tank charging

K6 Electric immersion heater for d.h.w. Y¯14 Inverted Y14 signal

K8 Solar collector pump or diverting valve heat exchanger 2 Y15 Diverting valve for return

K¯8 Inverted K8 signal Y¯15 Inverted Y15 signal

K9 Solar bypass valve or heat exchanger pump Q1 Boiler pump of oil- / gas-fired boiler

K¯9 Inverted K9 signal Q2 Heating circuit pump

K10 Alarm output Q3 D.h.w. charging pump

K11 Overtemperature protection Q¯3 Inverted Q3 signal

K¯11 Inverted K11 signal Q4 D.h.w. circulating pump

K12 Solar collector pump or diverting valve heat exchanger 1 Q5 Solar collector pump 1

K13 Output K13 for free time switch program Q9 Heat pump circulator

K14 Release of external oil- / gas-fired boiler Q10 Pump of wood-fired boiler

K15 Release of external heat pump Q11 Storage tank heat transfer pump

K16 Electric immersion heater for buffer storage tank Q12 Oil / gas bypass pump

K17 Flue gas temperature sensor function Q13 D.h.w. storage tank heat transfer pump

K18 Output for solar swimming pool heating Q14 System pump

K¯18 Inverted K18 signal Q15 Pump H1

Y1 Heating circuit mixing valve OPEN Q16 Solar collector pump 2

Y2 Heating circuit mixing valve CLOSED Q17 Additional pump Q17 for heat pump stage 2

Y3 Diverting valve d.h.w. E1 Mains input

Y4 Heat generation lock L Live conductor (mains connection)

Y¯4 Inverted Y4 signal N Neutral conductor (mains connection)

Siemens Building Technologies / HVAC Products 74 319 0312 0 a 19.08.2002 5/28

Sensor designations

The sensor designations used in the supplied basic diagram have the following meaning:

Sensor Function (use) Types of

sensors

Sensor Function (use) Types of sen-

sors

B1 Heating circuit flow sensor LG-Ni 1000 B7 Return sensor oil / gas LG-Ni 1000

B2 Sensor of oil- / gas-fired boiler LG-Ni 1000 B71 Return sensor heat pump LG-Ni 1000

B21 Heat pump flow sensor LG-Ni 1000 B72 Return sensor wood LG-Ni 1000

B22 Sensor of wood-fired boiler LG-Ni 1000 B73 Return sensor heating circuit LG-Ni 1000

B3 D.h.w. sensor 1 LG-Ni 1000 B8 Flue gas sensor Pt 1000

B31 D.h.w. sensor 2 LG-Ni 1000 B9 Outside sensor LG-Ni 1000

NTC 600

B32 D.h.w. sensor 3 LG-Ni 1000 B10 Common flow sensor LG-Ni 1000

B33 D.h.w. sensor 4 LG-Ni 1000 B13 Sensor for solar swimming pool

heating

LG-Ni 1000

B4 Buffer storage tank sensor 1 LG-Ni 1000 M Ground sensors H1, U1, P1 –

B41 Buffer storage tank sensor 2 LG-Ni 1000 H1 Contact or DC 0…10 V input –

B42 Buffer storage tank sensor 3 LG-Ni 1000 U1 DC 0…10 V output –

B43 Buffer storage tank sensor 4 LG-Ni 1000 P1 PWM output –

B6 Solar collector sensor 1 LG-Ni 1000 /

Pt 1000

A6 PPS data –

B61 Solar collector sensor 2 LG-Ni 1000 /

Pt 1000

MD PPS ground –

B62 Solar collector flow sensor DB LPB data

B63 Solar flow sensor for yield measurement LG-Ni 1000 MB LPB ground

B64 Solar return sensor for yield measure-

ment

LG-Ni 1000 –

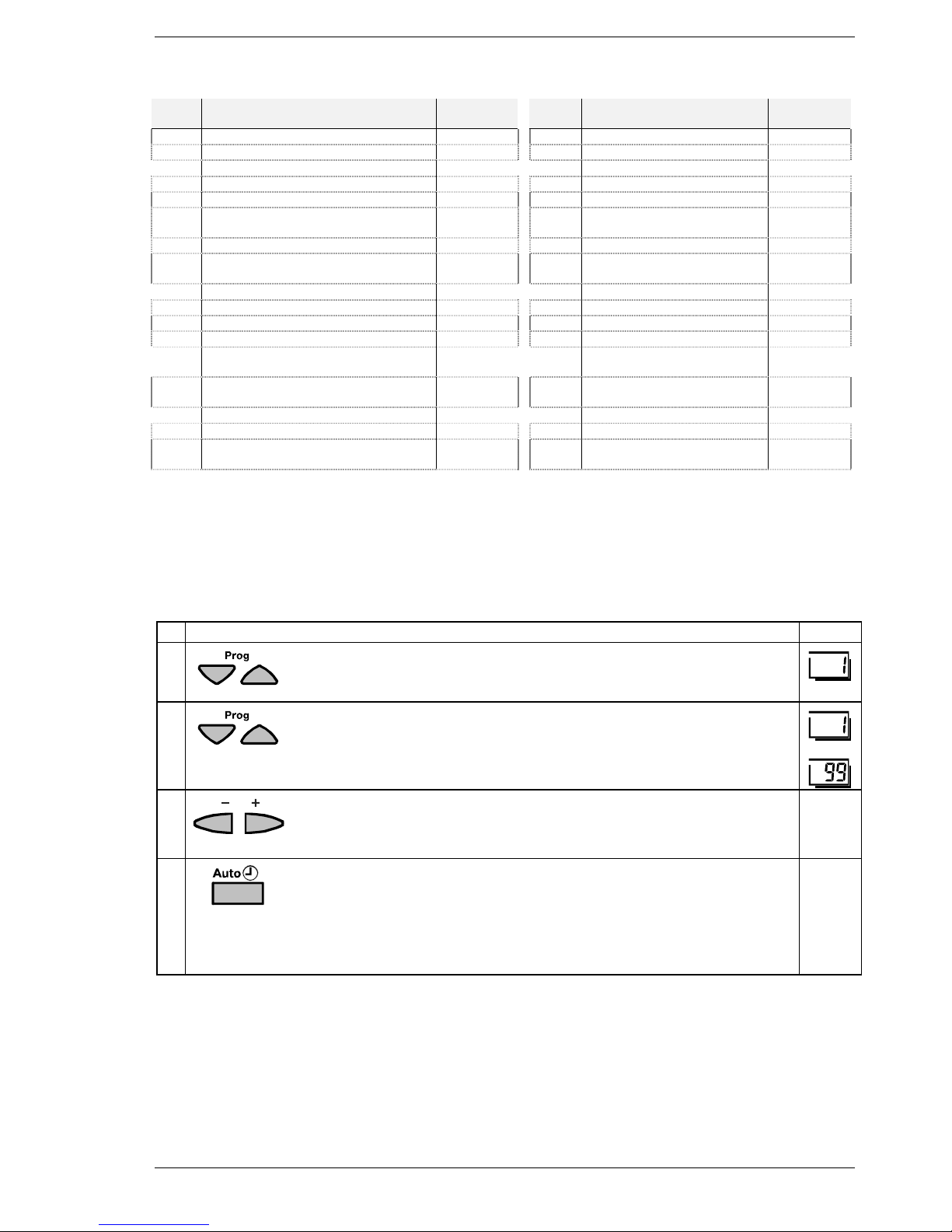

Parameter list

Settings to be made on the «Enduser» level

Settings that meet individual enduser needs.

Buttons Explanation Line

1

Press one of the operating line selection buttons.

This will take you directly to programming mode “Enduser“.

2

Press the operating line selection buttons to select the required operating line.

The following parameter list contains all settings that can be made.

• • •

3

Press the + or – button to set the required value.

The setting will be stored as soon as you leave the programming mode or

change to another line.

4

To leave programming mode “Enduser“, press any of the operating mode buttons.

è Note:

If no button is pressed for about 8 minutes, the controller will automatically return to the operating mode selected last.

Continuous

display

6/28 19.08.2002 74 319 0312 0 a Siemens Building Technologies / HVAC Products

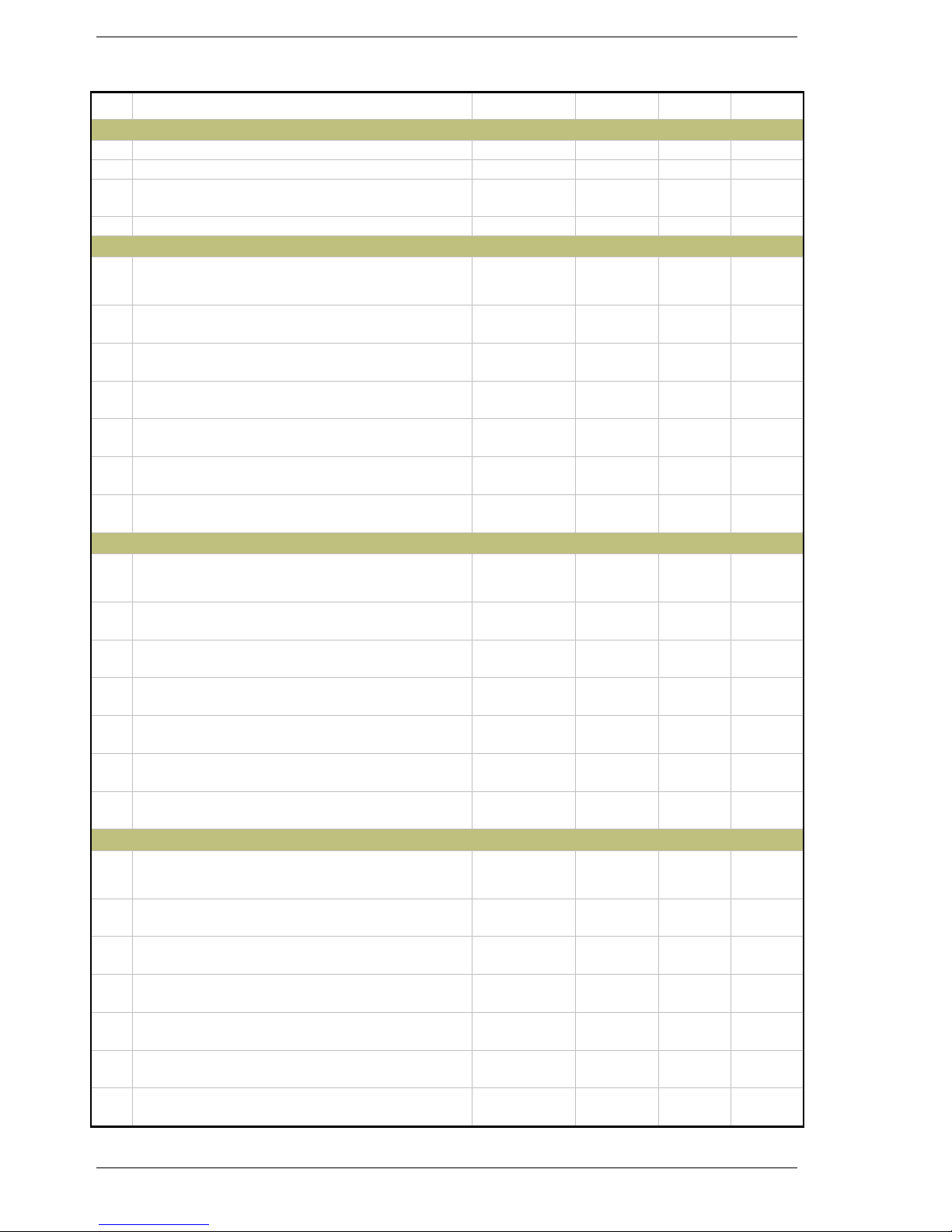

Overview of the enduser parameters

Line Function Range Unit Resolution Factory

setting

Setting the clock

1 Time of day 00:00...23:59 h / min .... : .... –

2 Weekday 1...7 Day ...... day –

3 Date 01.01...31.12 Day /

month

.... : .... –

4 Year 2001...2094 Year ...... year –

Time switch program for the heating circuit

5 Weekday – preselection heating circuit

1-7 7-day block

1...7 Individual days

1-7 / 1...7 Day ...... day –

6 Switch-on time 1st period heating circuit 00:00...24:00 h / min .... : ....

h / min

06:00

7 Switch-off time 1st period heating circuit 00:00...24:00 h / min .... : ....

h / min

22:00

8 Switch-on time 2nd period heating circuit 00:00...24:00 h / min .... : ....

h / min

- -:- -

9 Switch-off time 2nd period heating circuit 00:00...24:00 h / min .... : ....

h / min

- -:- -

10 Switch-on time 3rd period heating circuit 00:00...24:00 h / min .... : ....

h / min

- -:- -

11 Switch-off time 3rd period heating circuit 00:00...24:00 h / min .... : ....

h / min

- -:- -

Free time switch program

12 Weekday – preselection free time switch program

1-7 7-day lock

1...7 Individual days

1-7 / 1...7 Day ...... day –

13 Switch-on time 1st period free time switch pr. 00:00...24:00 h / min .... : ....

h / min

06:00

14 Switch-off time 1st period free time switch pr. 00:00...24:00 h / min .... : ....

h / min

22:00

15 Switch-on time 2nd period free time switch pr. 00:00...24:00 h / min .... : ....

h / min

- -:- -

16 Switch-off time 2nd period free time switch pr. 00:00...24:00 h / min .... : ....

h / min

- -:- -

17 Switch-on time 3rd period free time switch pr. 00:00...24:00 h / min .... : ....

h / min

- -:- -

18 Switch-off time 3rd period free time switch pr. 00:00...24:00 h / min .... : ....

h / min

- -:- -

Time switch program for d.h.w. heating

19 Weekday – preselection d.h.w.

1-7 7-day block

1...7 Individual days

1-7 / 1...7 Day ...... day –

20 Switch-on time 1st period d.h.w. 00:00...24:00 h / min .... : ....

h / min

06:00

21 Switch-off time 1st period d.h.w. 00:00...24:00 h / min .... : ....

h / min

22:00

22 Switch-on time 2nd period d.h.w. 00:00...24:00 h / min .... : ....

h / min

- -:- -

23 Switch-off time 2nd period d.h.w. 00:00...24:00 h / min .... : ....

h / min

- -:- -

24 Switch-on time 3rd period d.h.w. 00:00...24:00 h / min .... : ....

h / min

- -:- -

25 Switch-off time 3rd period d.h.w. 00:00...24:00 h / min .... : ....

h / min

- -:- -

Siemens Building Technologies / HVAC Products 74 319 0312 0 a 19.08.2002 7/28

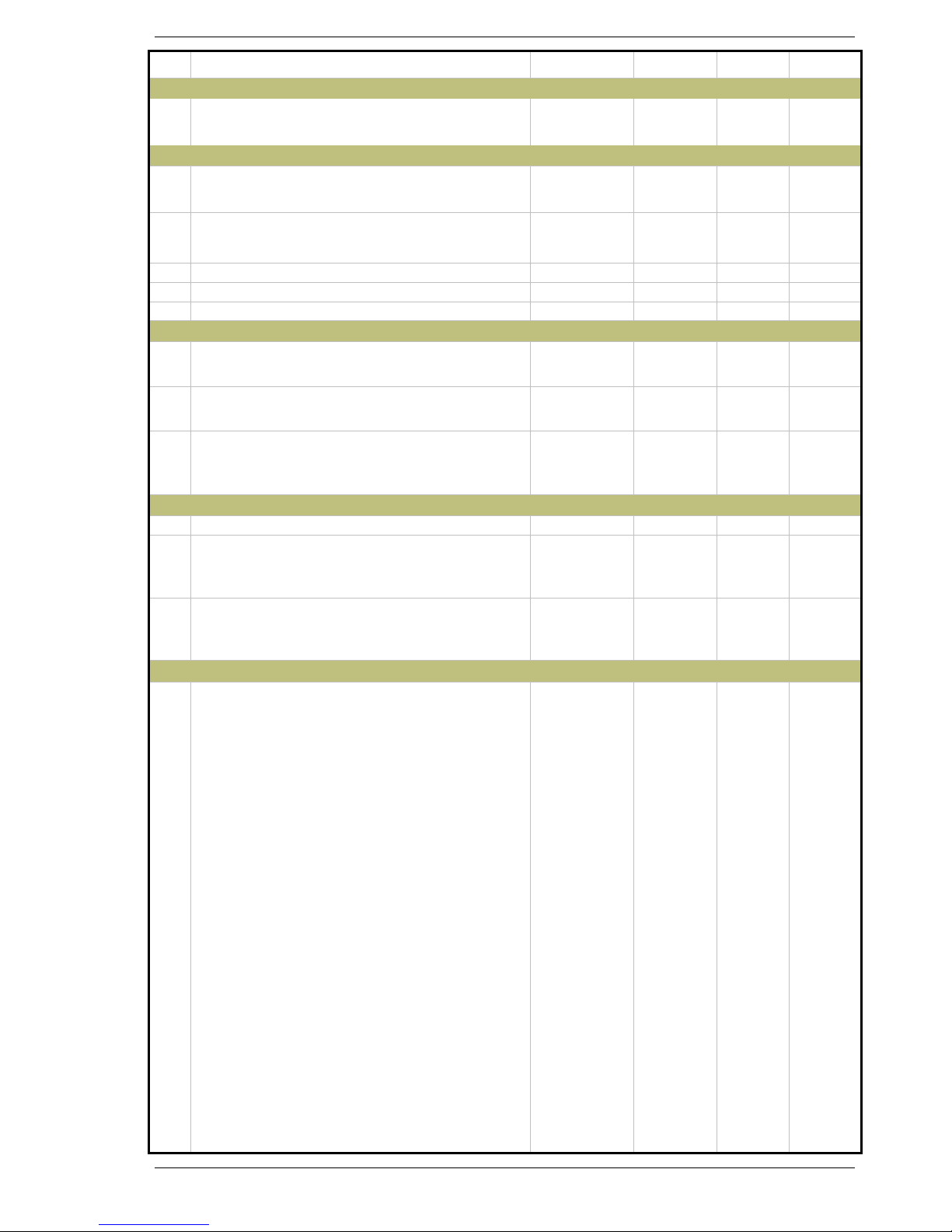

Line Function Range Unit Resolution Factory

setting

D.h.w. values

26 Nominal setpoint of the d.h.w. temperature (TBWw)

TBWR Line 770

TBWmax Line 750

EXP

TBWR...TBW

max

°C ...... °C 55

Heating circuit values

27 Reduced setpoint of the room temperature (TRRw)

TRF Line 28

TRN Setpoint knob

TRF...TRN °C ...... °C 16

28 Frost protection setpoint of the room temperature

(TRFw)

TRR Line 27

4...TRR °C ...... °C 10

29 Summer / winter changeover temperature 8...30 °C ...... °C 17

30 Slope of the heating curve 1.0...40 – ...... 15

33 Actual value of the room temperature (TRx) 0...50 °C – –

General

34 Actual value of the outside temperature (TAx)

To set the attenuated outside temperature to Tax, press the + / buttons simultaneously for 3 s

-50...+50 °C – –

38 Resetting the enduser parameters

To reset the parameters of the enduser level to their standard

values, press the + / - buttons simultaneously for 3 s

0 / 1 – – 0

39 Resetting the heating circuit and d.h.w. time switch

programs

To reset the time switch programs of the enduser level to their

standard values, press the + / - buttons simultaneously for 3 s

0 / 1 – – 0

Holiday program

40 Preselection of the holiday period 1...8 – ...... 1

41 Beginning of the holiday period

--.-- Inactive

To deactivate the set holiday period, press the + / - buttons simultaneously for 3 s

--.-- /

01.01...31.12

Day /

month

.... . ....

day /

month

--.--

42 End of the holiday period

--.-- Inactive

To deactivate the set holiday period, press the + / - buttons simultaneously for 3 s

--.-- /

01.01...31.12

Day /

month

.... . ....

day /

month

--.--

General / service

50 Indication of error signals

No display = no fault

10 = fault outside sensor

20 = fault boiler sensor oil / gas B2

25 = fault boiler sensor wood B22

26 = fault common flow sensor B10

28 = fault flue gas sensor B8

30 = fault flow sensor heating circuit B1

33 = fault flow sensor heat pump B21

40 = fault return sensor oil / gas B7

43 = fault return sensor wood B72

44 = fault return sensor heat pump B71

47 = fault common return sensor B73

50 = fault storage tank sensor / thermostat B3

52 = fault storage tank sensor / thermostat B31

55 = fault storage tank sensor / thermostat B32

56 = fault storage tank sensor / thermostat B33

61 = fault room unit

70 = fault storage tank sensor B4

71 = fault storage tank sensor B41

72 = fault storage tank sensor B42

73 = fault collector sensor B6

74 = fault collector sensor B61

75 = fault solar flow sensor B62

76 = fault storage tank sensor B43

79 = fault water / brine sensor B11

81 = short-circuit data bus (LPB)

82 = same bus address exists several times

86 = short-circuit PPS

100 = 2 clock time masters on the data bus (LPB)

127 = legionella temperature not reached

130 = maximum flue gas temperature exceeded

8/28 19.08.2002 74 319 0312 0 a Siemens Building Technologies / HVAC Products

Line Function Range Unit Resolution Factory

setting

134 = fault heat pump at input H1

135 = water / brine temperature too low

137 = fault heat pump at input E1

138 = fault control sensor heat pump (operating line 420)

145 = wrong PPS unit (BMU / room unit)

146 = configuration error (operating line 202)

147 = external heat source missing (PPS / LPB)

150 = fault BMU

171 = alarm signal at input H1

172 = alarm signal at input E1

211 = fault wood-fired boiler

231-239 = fault sensor input B101 - B109

241 = fault flow sensor yield measurement B63

242 = fault return sensor measurement B64

243 = fault swimming pool sensor B13

Oil- or gas-fired boiler

60 Chimney sweep

0 = OFF

1 = ON

Outside the programming level, the + / - buttons can be used to

activate / deactivate the second burner stage

0 / 1 – – 0

Solar collectors

65 24-hour yield solar energy 0...999.9 kWh – 0

66 Total yield solar energy

To reset the total yield to 0, press the + / - buttons simultaneously

for 3 s

0...9999999.9 kWh – 0

Heat pump

75 Acknowledgement of heat pump error messages

135 and 137

To reset the error messages to 0, press the + / - buttons simultaneously for 3 s

0 / 1 – – 0

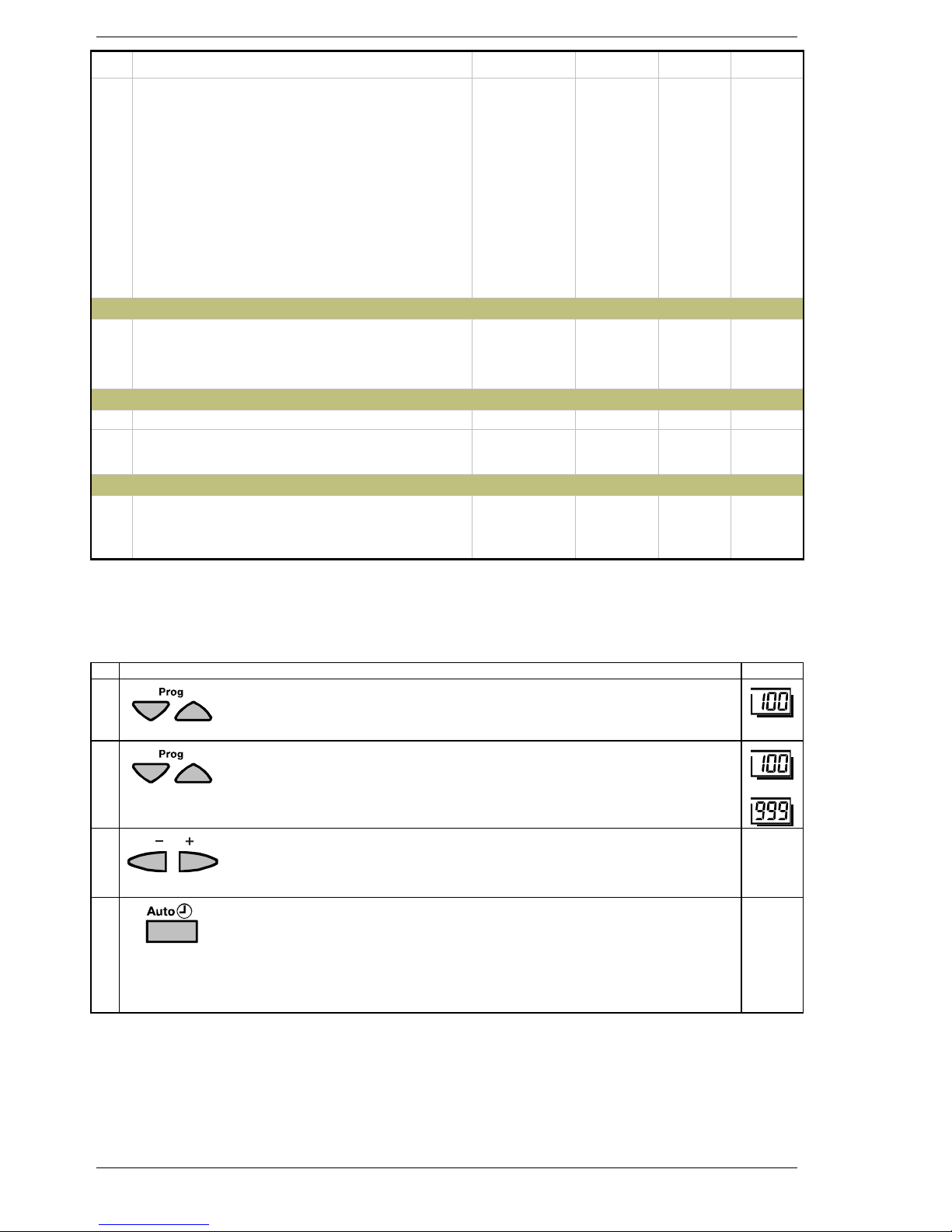

Settings to be made on the «Heating engineer» level

Settings required for the configuration and parameterization by the heating engineer.

Buttons Explanation Line

1

Press both operating line selection buttons for at least 3 seconds.

This will take you to programming level “Enduser”.

2

Press the operating line selection buttons to select the required operating line.

The parameter list on the next pages contains all operating lines on which settings can be made.

• • •

3

Press the + or – button to set the required value.

The setting will be stored as soon as you leave the programming mode or

change to another operating line.

4

To leave programming level “Heating engineer“, press one of the operating

mode buttons.

è Note:

If no button is pressed for about 8 minutes, the controller will automatically return

to the operating mode selected last.

Continuous

display

Siemens Building Technologies / HVAC Products 74 319 0312 0 a 19.08.2002 9/28

Overview of the heating engineer parameters

Line Function Range Unit Resolution Factory

setting

General / service

Basic diagrams

100 Selection of the basic diagram

0

No basic diagram selected

1...99.998 Basic diagrams

To adopt the selected diagram number, press the + / - buttons simultaneously for 3 s

0...99.998 – ...... 0

Configuration

Partial diagrams

120 Selection of partial diagram oil- / gas-fired boiler

0

Partial diagram inactive (OeG0)

1...9 Partial diagrams OeG1 through OeG9

0...9 – ...... 0

121 Selection of partial diagram solar collectors

0

Partial diagram inactive (OeG0)

1...16 Partial diagrams Sol1 through Sol16

0...16 – ...... 0

122 Selection of partial diagram wood-fired boiler

0 Partial diagram inactive (Ho0)

1...5 Partial diagrams Ho1 through Ho5

0...5 – ...... 0

123 Selection of partial diagram heat pump

0 Partial diagram inactive (Wp0)

1...5

Partial diagrams Wp1 through Wp5

0...5 – ...... 0

124 Display of partial diagram buffer storage tank

0 Partial diagram inactive (Sp0)

1...3 Partial diagrams Sp1 through Sp3

0...3 – ...... 0

125 Display of partial diagram d.h.w. storage tank

0 Partial diagram inactive (BwSp0)

1...10 Partial diagrams BwSp1 through BwSp10

0...10 – ...... 0

126 Selection of partical diagram combi storage tank

0 Partial diagram inactive (KoSp0)

1...6 Partial diagrams KoSp1 through KoSp6

0...6 – ...... 0

127 Selection of partial diagram heating circuit

0 Partial diagram inactive (Rh0)

1...3 Partial diagrams Rh1 through Rh3

0...3 – ...... 0

Hiding sensors that are not required

130 Source outside sensor

0 Signal via bus (PPS or LPB)

1 Signal via terminal

0 / 1 – ...... 0

131 Reduction 1st d.h.w. sensor B3

0 Without sensor B3

1 With sensor B3

0 / 1 – ...... 0

132 Reduction 2nd d.h.w. sensor B31

0 Without sensor B31

1 With sensor B31

0 / 1 – ...... 0

133 Reduction 2nd buffer storage tank sensor B41

0 Without sensor B41

1 With sensor B41

0 / 1 – ...... 0

135 Reduction wood-fired boiler return sensor B72

0 Without sensor B72

1 With sensor B72

0 / 1 – ...... 0

136 Reduction heat pump flow sensor B21

0 Without sensor B21

1 With sensor B21

0 / 1 – ...... 0

137 Reduction heat pump return sensor B71

0 Without sensor B71

1 With sensor B71

0 / 1 – ...... 0

138 Reduction water / brine sensor B11

0 Without sensor B11

1 With sensor B11

0 / 1 – ...... 0

Loading...

Loading...