Page 1

74 319 0817 0

G2546

Siemens Building Technologies 74 319 0817 0 a CE1G2546en 28.02.2011 1/12

en

Installation Instructions

Heating controller for

2 heating circuits and d.h.w.

RVP36..

Keep these instructions with the controller!

Installation

Place of installation

• In a dry room (e.g. in the boiler room)

• Installation choices:

– In a compact station

– In a control panel (panel front, inner wall,

or on a top hat rail)

– In a control cabinet

– In the sloping front of a control desk

• Permissible ambient temperature: 0...50 °C

Electrical installation

• Local regulations for electrical installations must be

complied with

• Only qualified personnel may carry out the electrical

installation

• Cable strain relief must be ensured

• Cable glands must be made of plastic

• Cables from the controller to the actuating devices

and pumps carry mains voltage

• Sensor cables must not be run parallel to mains

carrying cables

• A defective or apparently damaged unit must

immediately be disconnected from power

Permissible cable lengths

• For all sensors and thermostats:

Copper cable 0.6 mm dia. max. 20 m

Copper cable 1.0 mm

2

max. 80 m

Copper cable 1,5 mm

2

max. 120 m

• For room units:

Copper cable 0.25 mm

2

max. 25 m

Copper cable from 0.5 mm

2

max. 50 m

• For data buses: As per Siemens specification in

Basic System Data N2030 and

Basic Engineering Data N2032

Mounting and wiring the base

Wall mounting

1. Remove base from controller.

2. Hold base against the wall. Marking TOP must

be at the top!

3. Mark fixing holes on the wall.

4. Drill holes.

5. If required, knock out holes on the base to fit

the cable glands.

6. Screw base to the wall.

7. Wire up the base.

Rail mounting

1. Fit top hat rail.

2. Remove base from controller.

3. If required, knock out holes on the base to fit the

cable glands.

4. Fit base to the rail. Marking TOP must be at the top!

5. If required, secure the base (depending on type

of rail used).

6. Wire up the base.

Flush-panel mounting

• Maximum thickness of front panel: 3 mm.

• Required panel cutout: 138 × 92 mm.

1. Remove base from controller.

2. If required, knock out holes on the base to fit the

cable glands.

3. Insert base in the panel cutout from behind until

stop is reached. Marking TOP must be at the top!

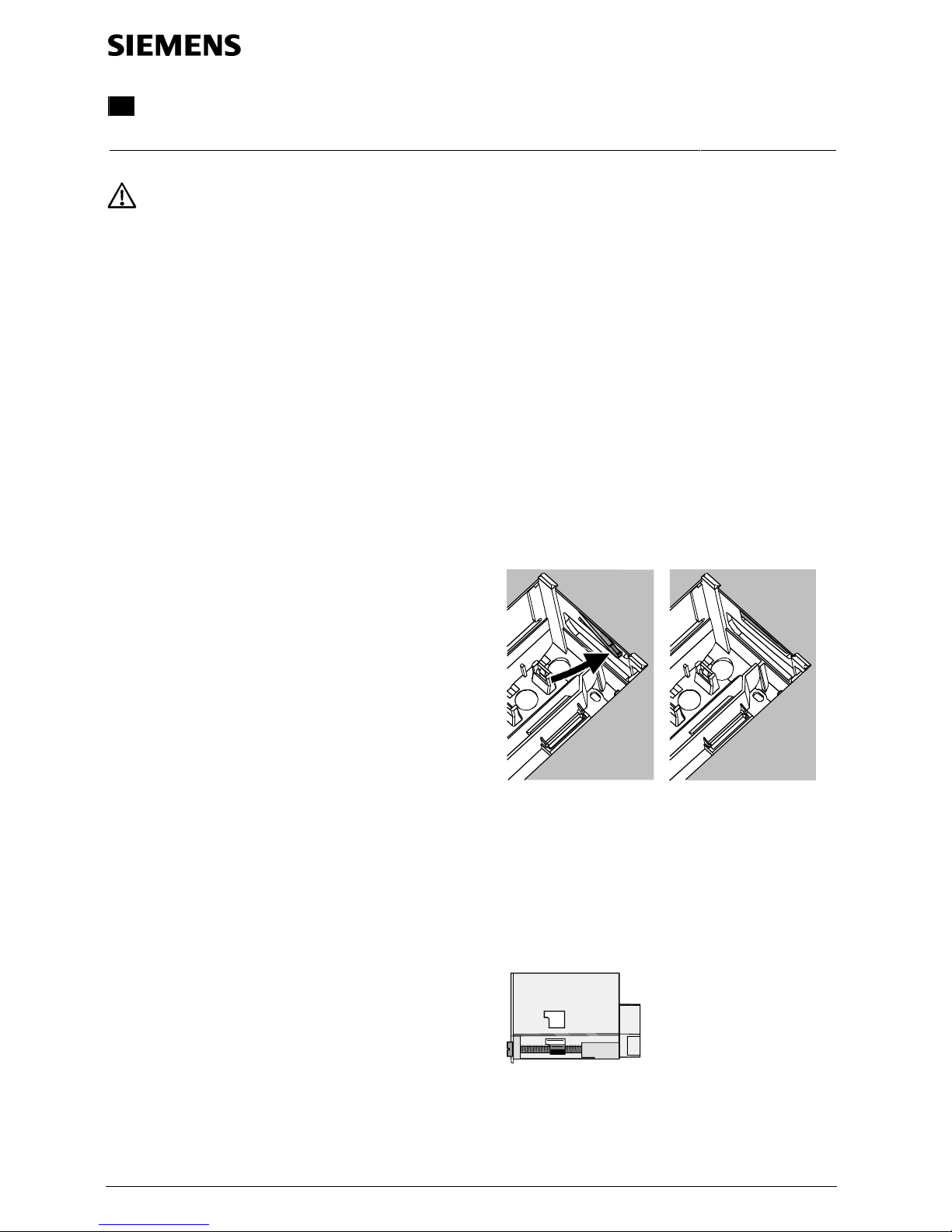

4. Push lateral tongues behind the front panel (see

illustration).

2462Z06

Wrong Correct

Place left and right tongue correctly – must not protrude

inside the cutout!

5. Wire up the base. Cable lengths should be chosen

such that sufficient space is left to open the control

panel door.

Securing the controller to the base

1. Ensure correct position and location of the levers

by turning the fixing screws. Symbol on lateral wall

of the controller:

2540Z04

2. Insert controller in the base until stop is reached.

Marking TOP must be at the top!

3. Tighten fixing screws alternately.

Page 2

Commissioning

Preparatory checks

1. Do NOT turn on power yet.

2. Check wiring to ensure it accords with the plant’s

connection diagram.

3. Check each actuating device to see if …

– it is correctly installed (observe direction of

flow indicated on valve body),

– manual control is disengaged.

4. Exercise caution in connection with floor and

ceiling heating systems!

The limit thermostat must be correctly set. During

the function check, the flow temperature must not

exceed the maximum permissible level (usually

55 °C); if it does, proceed immediately as follows:

– Either close the valve manually, or

– Switch off the pump, or

– Shut the pump isolating valve .

5. Turn on power. The display shows the time of day.

If not, the reason may be one of the following:

– No mains voltage

– Main fuse defective

– Main switch not set to ON

6. Addressing the room units:

– Room unit heating circuit 1 = address 1

(factory setting)

– Room unit heating circuit 2 = address 2

General information about operation

• Setting elements for commissioning:

– Readjustment of room temperature: Via setting knob,

separately for heating circuits 1 and 2!

– Other variables: On the display; each setting is

assigned an operating line. If required, make

separate settings for heating circuits 1 and 2!

• Buttons for selection and adjustment of values:

2/12 28.02.2011 CE1G2546en 74 319 0817 0 a Siemens Building Technologies

Press to select the next lower operating line

Press to select the next higher operating line

Press to decrease the display

ed value

Press to increase the displayed value

• Adopting a setting value:

Setting value is adopted by selecting a new operating

line or by pressing one of the operating mode buttons

• Enter --.- / --:-- / --- (deactivation of function):

Keep or

depressed until the desired display

appears

• Block jump function:

To select an individual operating line quickly,

2 button combinations can be used:

Keep depressed and press

to select the next

higher line block

Keep

depressed and press to select the next

lower line block

• When pressing one of the buttons, the display lighting

is switched on for a certain time

Setting procedure

1. Make the required settings on the "End-user" level

(operating lines 1…50).

2. Configure plant type on operating line 51.

3. Enter the relevant settings on the parameter list

below. All functions and operating lines required for

the configured plant type are activated and adjustable; all operating lines that are not required cannot

be accessed.

4. Make the required settings on the "Heating engineer"

level (operating lines 61…208).

Commissioning and function check

• Operating lines especially for the function check:

161 = simulation of outside temperature

162 = relay test

163 = sensor test

164 = display of setpoint

• If Er (error) appears on the display: Query operating

line 50 to pinpoint the fault

• If no operating line is selected for 30 minutes, or if

one of the operating mode buttons is pressed, the

controller switches to the "non-operated" state

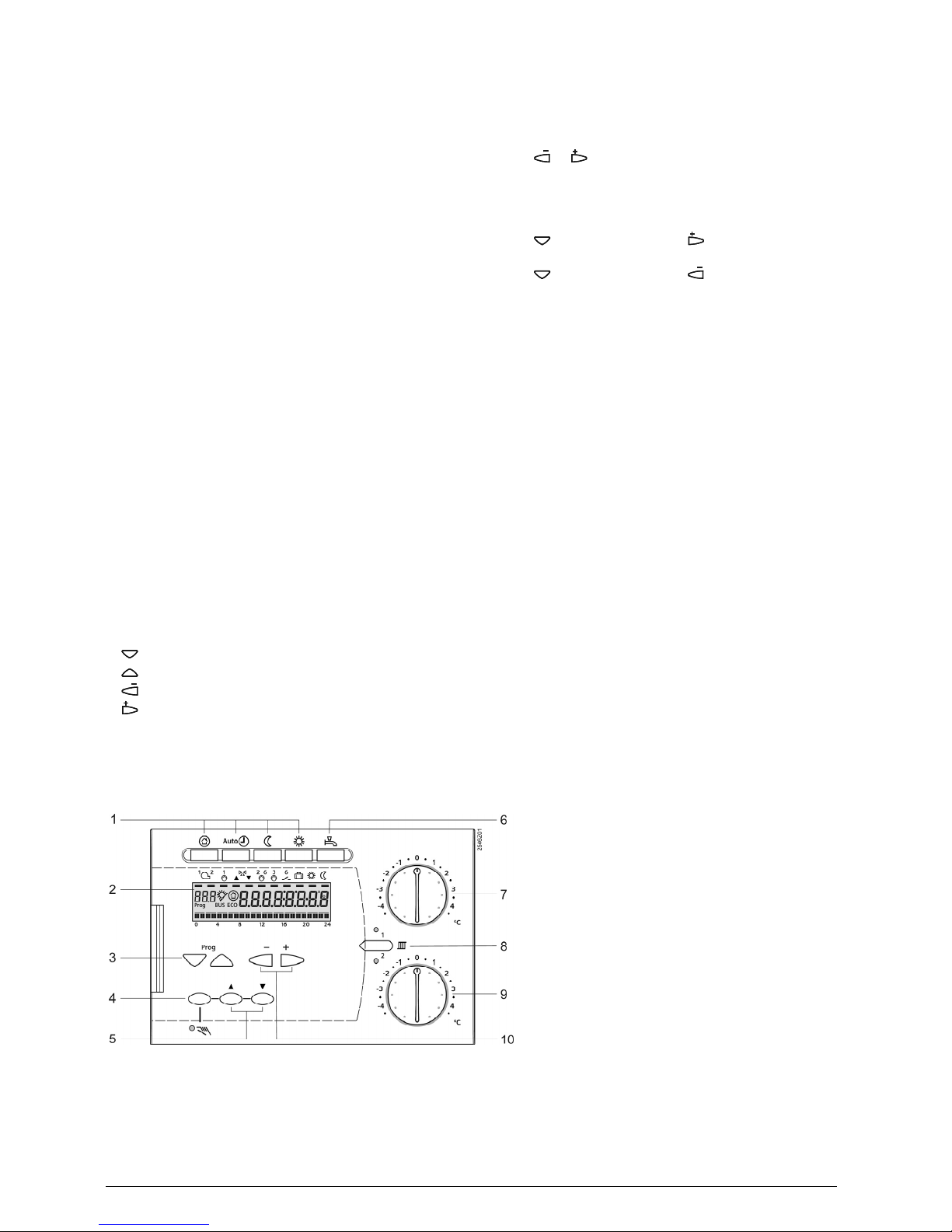

Setting elements

1 Buttons for selectiong the operating mode

2 Display (LCD)

3 Buttons for selecting the operating lines

4 Button for manual control ON / OFF

5 Buttons for valve OPEN / CLOSE when manual

control ON

6 Button for d.h.w. heating ON / OFF

7 Setting knob for readjusting the room temperature

of heating circuit 1

8 Button for switching between the heating circuits

9 Setting knob for readjusting the room temperature

of heating circuit 2

10 Buttons for adjusting values

Page 3

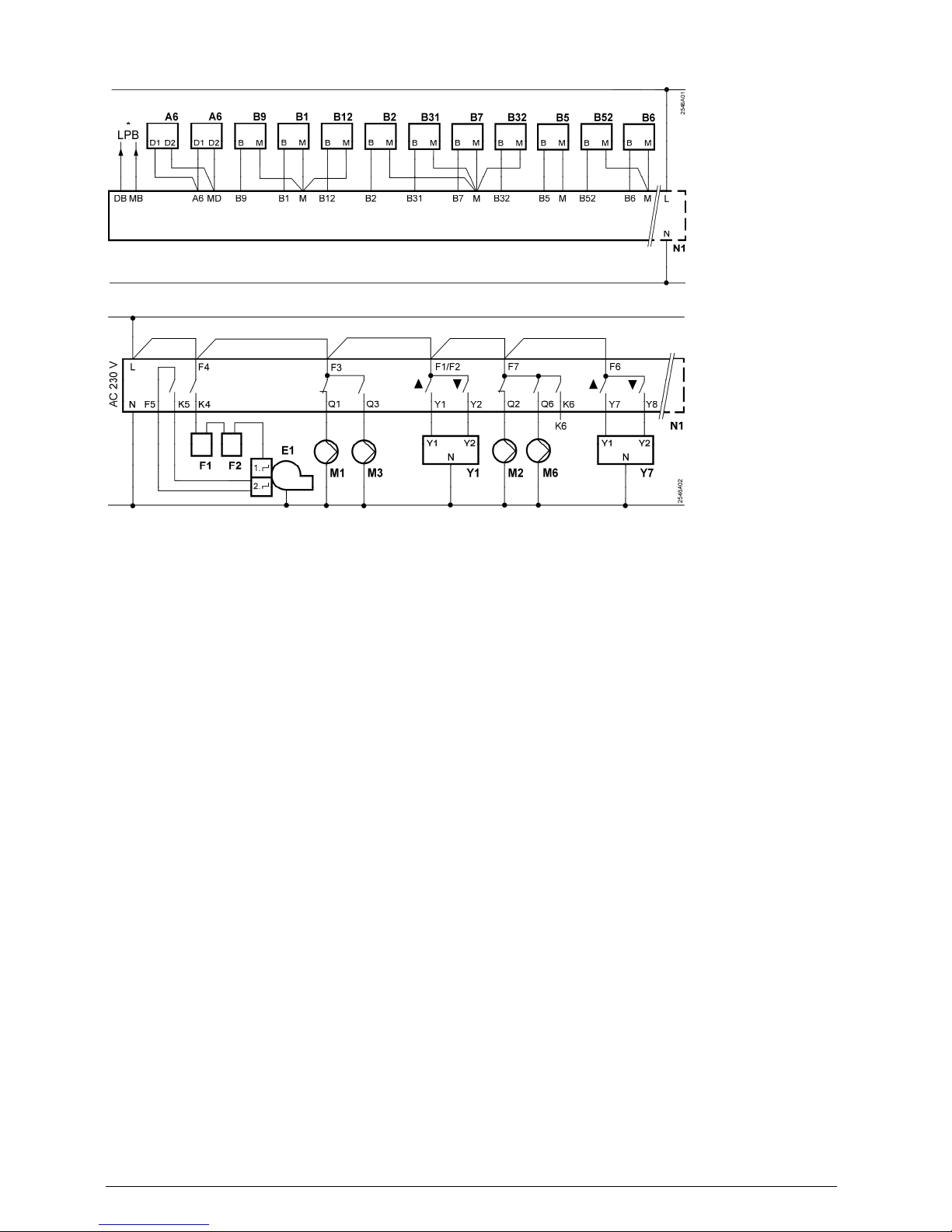

Connection diagrams

Low-voltage side

* LPB only RVP360

Mains voltage side

A6 Room unit F1 Thermal reset limit thermostat

B1 Flow sensor heating circuit 1 F2 Safety limit thermostat

B12 Flow sensor heating circuit 2 K6 Multifunctional output

B2 Boiler sensor LPB Data bus (only RVP360)

B31 D.h.w. storage tank sensor / thermostat M1 Circulating pump

B32 D.h.w. storage tank sensor / thermostat M2 Heating circuit pump heating circuit 1

B5 Room sensor heating circuit 1 M3 Storage tank charging pump

B52 Room sensor heating circuit 2 M6 Heating circuit pump heating circuit 2

B6 Collector sensor N1 Controller RVP36..

B7 Return sensor Y1 Actuator heating circuit 1

B9 Outside sensor Y7 Actuator heating circuit 2

E1 2-stage burner

Siemens Building Technologies 74 319 0817 0 a CE1G2546en 28.02.2011 3/12

Page 4

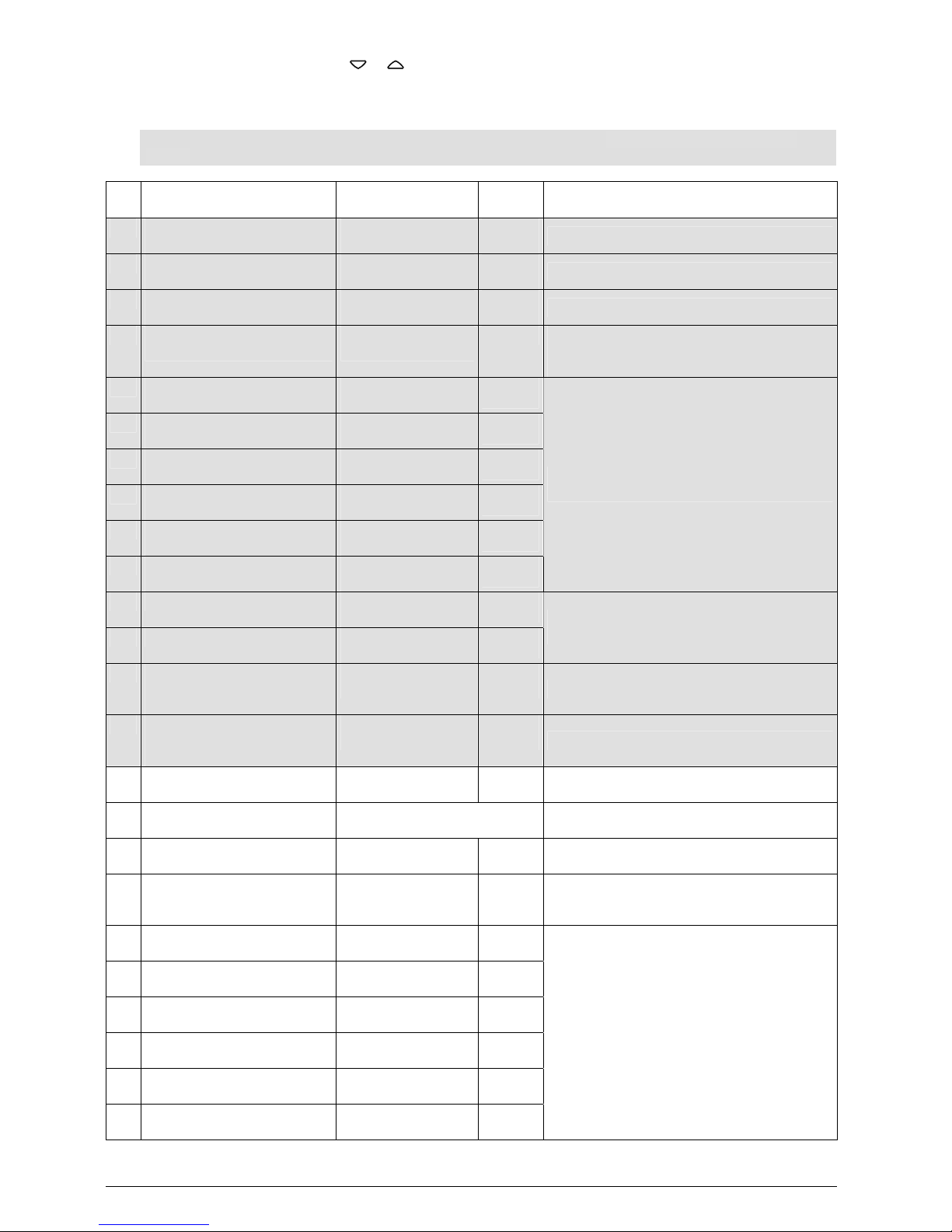

"End-user" level

To activate the "End-user" level, press or .

Note: The settings made on the controller should be entered on the following parameter list and the Installation

Instructions should be kept with the controller or in a suitable place.

Operating lines highlighted in grey require settings for heating circuit 1 (HC 1) and heating circuit 2

(HC 2)!

Line

Function, display Factory setting

(range)

HC 1

HC 2

Explanations, notes and tips

1 Room temp. setpoint for 20.0 °C .................°C

4/12 28.02.2011 CE1G2546en 74 319 0817 0 a Siemens Building Technologies

NORMAL heating (0.0…35.0) .................°C

2 Room temp. setpoint for 14.0 °C .................°C

REDUCED heating (0.0…35.0) .................°C

3 Room temp. setpoint for 10.0 °C .................°C

holiday / protection mode (0.0…35.0) .................°C

4 Weekday, for entering the Current weekday 1 = Monday

heating program (1…7 / 1-7) 2 = Tuesday, etc.

1-7 = entire week

5 1st heating phase,

start of NORMAL heating

6:00

(--:-- / 00:00…24:00)

........................

........................

6 1st heating phase,

end of NORMAL heating

22:00

(--:-- / 00:00…24:00)

........................

........................

7 2nd heating phase,

start of NORMAL heating

--:--

(--:-- / 00:00…24:00)

........................

........................

8 2nd heating phase,

end of NORMAL heating

--:--

(--:-- / 00:00…24:00)

........................

........................

9 3rd heating phase,

start of NORMAL heating

--:--

(--:-- / 00:00…24:00)

........................

........................

10 3rd heating phase,

end of NORMAL heating

--:--

(--:-- / 00:00…24:00)

Scheduler program for heating circuit

--:-- = phase deactivated

........................

........................

12 Date of first day of holiday --.--

(01.01…31.12)

........................

........................

13 Date of last day of holiday --.--

(01.01…31.12)

dd.mm

--.-- = holiday period deactivated

........................

........................

14 Heating curve, flow tempera- 30 °C .................°C

ture setpoint at an outside

temperature of 15 °C

(20…70) .................°C

15 Heating curve, flow tempera- 60 °C .................°C

ture setpoint at an outside

temperature of -5 °C

(20…120) .................°C

26 Setpoint for NORMAL

d.h.w. temperature

55 °C

(20…100)

.................°C

27 Display of current

d.h.w. temperature

Display function

28 Setpoint for REDUCED

d.h.w. temperature

40 °C

(8…80)

.................°C

31 Weekday, for entering

scheduler program 2

Current weekday

(1…7 / 1-7)

1 = Monday

2 = Tuesday, etc.

1-7 = entire week

32 Start of 1st ON phase 5:00

(--:-- / 00:00…24:00)

........................

33 End of 1st ON phase 22:00

(--:-- / 00:00…24:00)

........................

34 Start of 2nd ON phase --:--

(--:-- / 00:00…24:00)

........................

35 End of 2nd ON phase --:--

(--:-- / 00:00…24:00)

........................

36 Start of 3rd ON phase --:--

(--:-- / 00:00…24:00)

........................

37 End of 3rd ON phase --:--

(--:-- / 00:00…24:00)

........................

Scheduler program 2

--:-- = phase deactivated

Page 5

38 Time of day hh:mm

(00:00…23:59)

........................

39 Weekday Display function 1 = Monday

2 = Tuesday, etc.

40 Date dd.mm

(01.01…31.12)

........................

41 Year yyyy

(2009…2099)

........................

Display function

Example:

Interconnected system

Siemens Building Technologies 74 319 0817 0 a CE1G2546en 28.02.2011 5/12

20 = error code

06 = segment number (LPB)

02 = device number (LPB)

50 Faults

10 = fault outside sensor B9

20 = fault boiler sensor B2

30 = fault flow sensor B1, heating circuit 1

32 = fault flow sensor B12, heating circuit 2

40 = fault primary return sensor B7

50 = fault storage tank sensor B31

52 = fault storage tank sensor B32

60 = fault room sensor B5, heating circuit 1

61 = fault room unit A6, heating circuit 1

62 = device with wrong PPS identification

connected, heating circuit 1

65 = fault room sensor B52, heating circuit 2

66 = fault room unit A6, heating circuit 2

67 = device with wrong PPS identification

connected, heating circuit 2

73 = fault collector sensor B6

81 = short-circuit on data bus (LPB)

82 = 2 devices with the same bus

address (LPB)

86 = short-circuit PPS

100 = 2 clock time masters (LPB)

140 = inadmissible bus address (LPB)

Page 6

"Heating engineer" level

To activate the "Heating engineer" level, press and simultaneously for 3 seconds. This level is used to

configure the plant type and to set the plant-specific variables.

• The "End-user" level also remains activated when on the "Heating engineer" level.

Note: The heating engineer should enter the function of "Scheduler program 2" in the Operating Instructions.

Configuring the plant type:

Select the required plant type on operating line 51 (see the following plant diagrams). This activates all functions

needed for the particular type of plant and the required operating lines appear.

Example:

2477Z02

Display for plant type 5-1

51 Operating line

5 Heating circuit type

1 D.h.w. type

Plant types

For meaning of symbols, refer to "Connection diagrams".

Plant types 4-x

Plant types 5-x

6/12 28.02.2011 CE1G2546en 74 319 0817 0 a Siemens Building Technologies

Page 7

Plant types 6-x

Function block "Plant configuration"

51 Plant type 5-1

(4-0...6-1)

........................

See the plant diagrams above

Function block "Space heating"

61 Heating limit NORMAL 17.0 °C .................°C

--- = function deactivated

Siemens Building Technologies 74 319 0817 0 a CE1G2546en 28.02.2011 7/12

(ECO day) (--- / –5.0…25.0) .................°C

62 Heating limit REDUCED 5.0 °C .................°C

--- = function deactivated

(ECO night) (--- / –5.0…25.0) .................°C

63 Building time constant 20 h

(0…50)

....................h

10 h = light building construction

20 h = medium building construction

50 h = heavy building construction

64 Quick setback 1 0 = without quick setback

........................

(0 / 1) 1 = with quick setback

........................

65 Room temperature source A 0 = no room sensor available

........................

(0…3 / A) 1 = room unit connected to terminal A6

........................

2 = room sensor connected to terminal B5

3 = mean value of both devices connected to

terminals A6 and B5 (heating circuit 1)

and / or A6 and B52 (heating circuit 2)

A = automatic selection

66 Type of optimization 0 0 = optimization with room model

........................

(0 / 1) 1 = optimization with room unit / room sensor

........................

(setting 0 only provides optimum start control)

67 Maximum heating up period 0:00 h .....................h Maximum forward shift for switching on

(0:00...42:00) .....................h before occupancy starts

0:00 = no optimum start control

68 Maximum early shutdown 0:00 h .....................h Maximum forward shift for switching off

(0:00...6:00) .....................h before occupancy ends

0:00 = no optimum stop control

69 Maximum limitation of room --.- °C .................°C --- = limitation deactivated,

temperature (--.- / 0.0…35.0) .................°C function can only be provided with

room unit / room sensor

70 Influence of room 4 Function can only be provided with

........................

temperature (gain factor) (0…20) room unit / room sensor

........................

71 Boost of room temperature 5 °C .................°C

setpoint on boost heating (0…20) .................°C

Page 8

Function block "Pump heating circuit"

75 Overtemperature protection

for the pump heating circuit

1

(0 / 1)

.......................

0 = without overtemperature protection

1 = with overtemperature protection

Note: Can only be set for heating circuit 1

Function block "Actuator heating circuit"

81 Maximum limitation --- °C .................°C --- = function deactivated

8/12 28.02.2011 CE1G2546en 74 319 0817 0 a Siemens Building Technologies

flow temperature (--- / 0…140) .................°C

Caution: This is not a safety function!

82 Minimum limitation --- °C .................°C --- = function deactivated

flow temperature (--- / 0…140) .................°C

Caution: This is not a safety function!

83* Maximum rate of --- K/h ...............K/h

--- = function deactivated

flow temperature increase (--- / 1...600) ...............K/h

84* Setpoint boost mixing valve 10 K ....................K

(0…50) ....................K

85* Actuator running time 120 s

(30…873)

.....................s

.....................s

86* P-band of control 32.0 K

(1.0…100.0)

....................K

....................K

87* Integral action time of control 120 s

(10…873)

Settings only required for 3-postion control

.....................s

.....................s

88* Type of actuator 1 0 = 2-position control

.......................

.......................

(0 / 1) 1 = 3-position control

89* Switching differential 2 K ....................K

Setting only required for 2-postion control

(1…20) ....................K

* Note: Operating lines 83 through 89 with plant type 6-x can only be set for heating circuit 2!

Function block "Boiler"

91 Boiler operating mode 0

(0…2)

.......................

0 = with manual shutdown (button )

1 = with automatic shutdown (OFF when

there is no demand for heat)

2 = without shutdown

92 Maximum limitation boiler

temperature

95 °C

(25…140)

.................°C

Caution: This is not a safety function!

93 Minimum limitation boiler

temperature

10 °C

(5…140)

.................°C

94 Switching differential boiler 6 K

(1…20)

....................K

95 Minimum limitation burner

running time

4 min

(0…10)

..............min

96 Burner stage 2

release integral

50 °Cxmin

(0…500)

.......................

°Cxmin

97 Burner stage 2

reset integral

10 °Cxmin

(0…500)

.......................

°Cxmin

98 Burner stage 2

locking time

20 min

(0…40)

..............min

99 Operating mode pump M1 1

(0 / 1)

........................

0 = without shutdown on protective boiler

startup

1 = with shutdown on protective boiler startup

Function block "Limitation of return temperature"

101 Setpoint return temperature

limitation, constant value

--- °C

(--- / 0…140)

.................°C

--- = function deactivated

Page 9

Siemens Building Technologies 74 319 0817 0 a CE1G2546en 28.02.2011 9/12

Function block "D.h.w."

121 Assignment of d.h.w.

(only RVP360)

0

(0…2)

.......................

D.h.w. heating for

0 = locally

1 = all controllers in the interconnected

system having the same segment

number

2 = all controllers in the interconnected

system

123 Release of d.h.w. heating 2

(0…2)

........................

0 = always (24 h/day)

1 = according to heating program(s),

depending on setting made on

operating line 121

Start of release is shifted forward by

1 hour

2 = according to scheduler program 2

Note: This setting is to be entered in the

Operating Instructions.

Priority of d.h.w. Flow temperature

setpoint according to:

0 = absolute D.h.w.

1 = shifting D.h.w.

2 = shifting Maximum selection

3 = none (parallel) D.h.w.

124 D.h.w. priority 0

(0…4)

........................

4 = none (parallel) Maximum selection

126 D.h.w. storage tank

sensor / thermostat

0

(0…5)

........................

0 = one sensor

1 = two sensors

2 = one thermostat

3 = two thermostats

4 = one sensor with solar d.h.w. heating

5 = two sensors with solar d.h.w. heating

127 Boost d.h.w. charging

temperature

10 K

(0…50)

....................K

128 Switching differential d.h.w. 8 K

(1…20)

....................K

129 Maximum period d.h.w.

charging

60 min

(--- / 5…250)

..............min

--- = no limitation of charging time

130 Setpoint legionella function --- °C

(--- / 20…100)

.................°C

--- = function deactivated

131 Forced charging 0

(0 / 1)

........................

0 = without forced charging

1 = with daily forced charging on first

release

Function block "Multifunctional relay"

141 Function multifunctional

relay K6

RVP360

Plant types x-0

0

(0…2)

Plant types x-1

0

(0…9)

RVP361

Plant types x-0

0

(0…2)

Plant types x-1

0

(0…7)

........................

0 = no function

1 = relay energized in the event of fault

2 = relay energized when there is demand

for heat

3 = circulating pump ON 24 hours per day

4 = circulating pump ON according to the

heating program(s), depending on the

setting made on operating line 121

5 = circulating pump ON according to

scheduler program 2

6 = collector pump

7 = electric immersion heater, changeover

heating / electric according to own

controller

8 = electric immersion heater, changeover

heating / electric according to all

controllers in the interconnected system

having the same segment number

9 = electric immersion heater, changeover

heating / electric according to all

controllers in the interconnected system

Caution:

Wrong configurations will not be prevented!

Page 10

10/12 28.02.2011 CE1G2546en 74 319 0817 0 a Siemens Building Technologies

Function block "Legionella function"

147 Periodicity of

legionella function

1

(0…7)

........................

0 = daily

1 = Mondays

2 = Tuesdays, etc.

148 Starting point legionella func-

tion

05:00

(00:00…23:50)

.......................

hh:mm

149 Dwelling time at legionella

setpoint

30 min

(0…360)

..............min

150 Circulating pump runs during

legionella function

1

(0 / 1)

.......................

0 = no

1 = yes

Function block "Service functions and general settings"

161 Simulation of outside tempera-

ture

--.- °C

(--.- / –50.0...50.0)

.................°C

Simulation is automatically ended after

30 minutes

--.- = no simulation

162 Relay test 0

(0…12)

0 = normal operation (no test)

1 = all relays deenergized

2 = relay K4 energized

3 = relays K4 and K5 energized

4 = relay Q1 energized

5 = relay Q3 energized

6 = relay Y1 energized

7 = relay Y2 energized

8 = relay Q2 energized

9 = relay Q6 energized

10 = relay K6 energized

11 = Relay Y7 energized

12 = Relay Y8 energized

Ending the relay test:

• Select another operating line

• Press an operating mode button

• Automatically after 30 minutes

Caution: Before making the relay test,

always close the main valve!

163 Sensor test

Sensor:

– – –

= interruption /

no sensor

o o o

= short-circuit

Thermostat:

– – –

= contact open

o o o

= contact closed

0

(0…11)

0 = B9 outside sensor

1 = B1 Flow sensor

2 = B5 room sensor

3 = A6 room unit sensor

4 = B7 return sensor

5 = B31 d.h.w. storage tank sensor /

thermostat

6 = B32 d.h.w. storage tank sensor /

thermostat

7 = B6 collector sensor

8 = B2 Boiler sensor

9 = B12 Flow sensor heating circuit 2

10 = B52 Room sensor heating circuit 2

11 = A6 room unit sensor, heating circuit 2

164 Display of setpoint

– – –

= no setpoint

available

0

(0…11)

0 = no function

1 = B1 flow temperature setpoint

2 = B5 room temperature setpoint

3 = A6 room temperature setpoint

4 = B7 return temperature setpoint

5 = B31 d.h.w. temperature setpoint

6 = B32 d.h.w. temperature setpoint

7 = B6 collector setpoint

8 = B2 boiler temperature setpoint

(switch-off point)

9 = B12 flow temperature setpoint

heating circuit 2

10 = B52 room temperature setpoint

heating circuit 2

11 = A6 room temperature setpoint

heating circuit 2

Page 11

Siemens Building Technologies 74 319 0817 0 a CE1G2546en 28.02.2011 11/12

167 Outside temperature for

frost protection for the plant

2.0 °C

(--.- / 0.0...25.0)

................°C

--.- = no frost protection for the plant

168 Flow temperature setpoint for

frost protection for the plant

15 °C

(0...140)

................°C

169 Device number 0

(0...16)

......................

Data bus address (LPB)

0 = device without bus

170 Segment number 0

(0...14)

......................

Data bus address (LPB)

173 Locking signal gain 100%

(0...200)

..................%

..................%

Response to locking signals

174 Pump overrun time 6 min

(0…40)

..............min

175 Pump kick 0

(0 / 1)

.......................

0 = without periodic pump run

1 = with weekly pump run

176 Changeover

winter- / summertime

25.03

(01.01...31.12)

.......................

Setting:

Earliest possible changeover date

177 Changeover

summer- / wintertime

25.10

(01.01...31.12)

.......................

Setting:

Earliest possible changeover date

178 Clock mode 0

(0...3)

......................

0 = autonomous clock in the controller

1 = clock from bus (slave),

without remote readjustment

2 = clock from bus (slave),

with remote readjustment

3 = controller is the central clock (master)

179 Bus power supply, operating

mode and status indication

A

(0 / 1 / A)

......................

0 = OFF (no bus power supply)

1 = bus power supply ON

A = automatic bus power supply

180 Outside temperature source A

(A / 00.01…14.16)

......................

A = automatic or segment and device number

194 Hours run counter

Display function

195 Software version

Display function

Function block "Solar d.h.w."

201 Temperature differential

solar ON

8 K

(0…40)

...................K

Temperature differential of collector and

storage tank

202 Temperature differential

solar OFF

4 K

(0…40)

...................K

Temperature differential of collector and

storage tank

203 Fost protection temperature

for collector

--- °C

(--- / –20…5)

................°C

--- = no frost protection for the collector

204 Overtemperature protection

for collector

105 °C

(--- / 30…240)

................°C

--- = no overtemperature protection for

the collector

205 Evaporation temperature of

heat conducting medium

140 °C

(--- / 60…240)

...............°C

--- = no protection for the collector pump

206 Maximum limitation of

charging temperature

80 °C

(8…100)

...............°C

207 Maximum limitation of

storage tank temperature

90 °C

(8…100)

...............°C

Caution: This is not a safety function!

208 Collector start function

gradient

--- min/K

(--- / 1…20)

..........min/K

--- = function deactivated

Page 12

12/12 28.02.2011 CE1G2546en 74 319 0817 0 a Siemens Building Technologies

Dimensions

[mm]

2011 Siemens Switzerland Ltd Subject to change

Loading...

Loading...