Page 1

RVL471

Heating and Domestic Hot Water Controller

Basic Documentation

Edition: 2.2

Controller series: C

CE1P2524E

23.10.2002

Siemens Building Technologies

HVAC Products

Page 2

2/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 23.10.2002

Page 3

Contents

1 Summary........................................................................................................11

1.1 Brief description and key features .................................................................11

1.2 Type summary...............................................................................................11

1.3 Equipment combinations................................................................................11

1.3.1 Suitable sensors ............................................................................................11

1.3.2 Suitable room units........................................................................................12

1.3.3 Suitable actuators..........................................................................................12

1.3.4 Communication..............................................................................................12

1.3.5 Passing on of heat demand signal.................................................................12

1.3.6 Documentation...............................................................................................12

2 Use.................................................................................................................13

2.1 Types of plant ................................................................................................13

2.2 Types of houses and buildings ......................................................................13

2.3 Types of heating systems..............................................................................13

2.4 Functions .......................................................................................................13

3 Fundamentals................................................................................................15

3.1 Key technical features ...................................................................................15

3.1.1 Plant types with regard to heating circuit.......................................................15

3.1.2 Plant types with regard to d.h.w. heating.......................................................15

3.1.3 Function blocks..............................................................................................15

3.2 Plant types.....................................................................................................16

3.2.1 Selectable combinations................................................................................16

3.2.2 Heating circuit type 1 – space heating with mixing valve...............................17

3.2.3 Heating circuit type 2 – space heating with boiler..........................................17

3.2.4 Heating circuit type 3 – space heating with district heat................................18

3.2.5 Heating circuit type 4 – precontrol with mixing valve.....................................18

3.2.6 Heating circuit type 5 – precontrol with boiler................................................18

3.2.7 Heating circuit type 6 – precontrol with district heat ......................................19

3.2.8 D.h.w. plant type 0 – no d.h.w........................................................................19

3.2.9 D.h.w. plant type 1 – d.h.w. storage tank with charging pump.......................19

3.2.10 D.h.w. plant type 2 – d.h.w. storage tank with mixing valve...........................19

3.2.11 D.h.w. plant type 3 – storage tank with diverting valve..................................20

3.2.12 D.h.w. plant type 4 – instantaneous d.h.w. heating via heat exchanger........20

3.2.13 D.h.w. plant type 5 – only electric immersion heater .....................................20

3.2.14 Summary of plant types and plant combinations...........................................21

3.3 Setting levels, function blocks and plant types..............................................22

3.4 Heating circuit operating modes ....................................................................23

3.4.1 Automatic operation.......................................................................................23

3/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 4

3.4.2 Continuously REDUCED heating.................................................................. 23

3.4.3 Continuously NORMAL heating .................................................................... 23

3.4.4 STANDBY ..................................................................................................... 23

3.5 D.h.w. operating modes ................................................................................ 23

3.6 Manual operation...........................................................................................24

3.7 Plant type and operating mode ..................................................................... 24

3.8 Operating state and operational level ...........................................................25

4 Acquisition of measured values ....................................................................26

4.1 Room temperature (A6, B5)...........................................................................26

4.1.1 Measurement ................................................................................................ 26

4.1.2 Handling faults ..............................................................................................26

4.1.3 Room model.................................................................................................. 26

4.2 Flow and boiler temperature (B1)..................................................................26

4.2.1 Measurement ................................................................................................ 26

4.2.2 Handling faults ..............................................................................................27

4.3 Outside temperature (B9).............................................................................. 27

4.3.1 Measurement ................................................................................................ 27

4.3.2 Handling faults ..............................................................................................27

4.4 Primary return temperature (B7) ...................................................................27

4.4.1 Measurement ................................................................................................ 27

4.4.2 Handling faults ..............................................................................................27

4.5 Secondary return temperature (B71)............................................................. 28

4.5.1 Measurement ................................................................................................ 28

4.5.2 Handling faults ..............................................................................................28

4.6 D.h.w. flow temperature (B3).........................................................................28

4.6.1 Measurement ................................................................................................ 28

4.6.2 Handling faults ..............................................................................................28

4.7 D.h.w. storage tank temperature (B31, B32)................................................. 28

4.7.1 Measurement ................................................................................................ 28

4.7.2 Handling faults ..............................................................................................28

5 Function block "Enduser space heating"....................................................... 30

5.1 Operating lines..............................................................................................30

5.2 Setpoints ....................................................................................................... 30

5.2.1 General..........................................................................................................30

5.2.2 Frost protection for the building..................................................................... 30

5.3 Heating program............................................................................................30

5.4 Holiday program............................................................................................ 31

6 Function block "Enduser d.h.w."....................................................................32

6.1 Operating lines..............................................................................................32

6.2 Setpoint.........................................................................................................32

4/118

Siemens Building Technologies Basic Documentation RV L471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 5

6.3 Actual value ...................................................................................................32

7 Function block "Enduser general"..................................................................33

7.1 Operating lines...............................................................................................33

7.2 Switching program 2......................................................................................33

7.3 Time of day and date.....................................................................................33

7.4 Indication of errors.........................................................................................34

8 Function block "Plant type"............................................................................35

8.1 Operating line.................................................................................................35

8.2 General..........................................................................................................35

9 Function block "Cascade slave".....................................................................36

9.1 Operating lines...............................................................................................36

9.2 Mode of operation..........................................................................................36

9.2.1 Boiler sequence release integral (KFI)...........................................................36

9.2.2 Boiler sequence reset integral (KRI)..............................................................36

10 Function block "Space heating".....................................................................37

10.1 Operating lines...............................................................................................37

10.2 ECO function .................................................................................................37

10.2.1 Compensating variables and auxiliary variables............................................37

10.2.2 Heating limits .................................................................................................38

10.2.3 Mode of operation..........................................................................................38

10.2.4 Operating modes and operating states..........................................................39

10.3 Room temperature source.............................................................................39

10.4 Optimization...................................................................................................39

10.4.1 Definition and purpose...................................................................................39

10.4.2 Fundamentals................................................................................................39

10.4.3 Process..........................................................................................................40

10.4.4 Room model temperature..............................................................................40

10.4.5 Optimum stop control.....................................................................................41

10.4.6 Quick setback ................................................................................................41

10.4.7 Optimum start control.....................................................................................42

10.4.8 Boost heating.................................................................................................42

10.5 Room functions..............................................................................................43

10.5.1 Maximum limitation of the room temperature.................................................43

10.5.2 Room influence..............................................................................................43

10.6 Heating curve.................................................................................................44

10.6.1 Purpose..........................................................................................................44

10.6.2 Basic setting ..................................................................................................44

10.6.3 Deflection.......................................................................................................45

10.6.4 Parallel displacement of heating curve..........................................................46

5/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 6

10.6.5 Display of setpoints.......................................................................................46

10.7 Generation of setpoint................................................................................... 47

10.7.1 Weather-compensated control......................................................................47

10.7.2 Demand-compensated control......................................................................47

11 Function block "3-position actuator heating circuit".......................................48

11.1 Operating lines..............................................................................................48

11.2 Limitations.....................................................................................................48

11.2.1 Flow temperature limitations ......................................................................... 48

11.2.2 Setpoint rise .................................................................................................. 49

11.3 3-position control........................................................................................... 49

11.4 Auxiliary variables in interconnected plants .................................................. 49

11.4.1 Excess mixing valve or heat exchanger temperature.................................... 49

11.5 Pulse lock...................................................................................................... 50

12 Function block "Boiler" .................................................................................. 51

12.1 Operating lines..............................................................................................51

12.2 Operating mode.............................................................................................51

12.3 Limitations.....................................................................................................51

12.3.1 Maximum limitation of the boiler temperature ...............................................51

12.3.2 Minimum limitation of the boiler temperature ................................................52

12.3.3 Actions during d.h.w. heating........................................................................52

12.4 2-position control........................................................................................... 52

12.4.1 Control with a single-stage burner ................................................................52

12.4.2 Control with a 2-stage burner........................................................................ 53

12.4.3 Frost protection for the boiler ........................................................................ 54

12.4.4 Protective boiler startup ................................................................................55

12.4.5 Protection against boiler overtemperatures................................................... 55

12.5 Operating mode of pump M1.........................................................................56

13 Function block "Setpoint of return temperature limitation" ............................57

13.1 Operating line................................................................................................ 57

13.2 Description .................................................................................................... 57

13.3 Minimum limitation of the return temperature................................................57

13.3.1 Acquisition of measured values ....................................................................57

13.3.2 Mode of operation ......................................................................................... 57

13.3.3 Mode of operation with a single device (with no bus) ...................................58

13.3.4 Mode of operation in interconnected plants .................................................. 58

14 Function block "District heat"......................................................................... 59

14.1 Operating lines..............................................................................................59

14.2 Limitations.....................................................................................................59

14.2.1 Maximum limitation of the primary return temperature..................................59

6/118

Siemens Building Technologies Basic Documentation RV L471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 7

14.2.2 Maximum limitation of return temperature differential (DRT limitation)..........60

14.2.3 Integral action time.........................................................................................61

14.2.4 Minimum stroke limitation (suppression of hydraulic creep) ..........................61

14.2.5 Limitation of the volumetric flow.....................................................................61

15 Function block "Maximum limitation of the return temperature, d.h.w.".........62

15.1 Operating line.................................................................................................62

15.2 Purpose..........................................................................................................62

15.3 Function.........................................................................................................62

16 Function block "Basic settings d.h.w." ...........................................................64

16.1 Operating lines...............................................................................................64

16.2 Assignment of d.h.w. heating.........................................................................64

16.3 Program for the circulating pump...................................................................64

16.3.1 General mode of operation............................................................................64

16.3.2 Operation of circulating pump during the holiday period...............................65

16.4 Frost protection for d.h.w...............................................................................66

16.4.1 Frost protection in the d.h.w. storage tank.....................................................66

16.4.2 Frost protection in the d.h.w. storage tank flow .............................................66

16.4.3 Frost protection for the secondary d.h.w. flow...............................................66

17 Function block "Release of d.h.w. heating"....................................................67

17.1 Operating line.................................................................................................67

17.2 Release..........................................................................................................67

17.2.1 Function.........................................................................................................67

17.2.2 Release programs..........................................................................................67

17.2.3 D.h.w heating during the holiday period.........................................................68

18 Function block "D.h.w. priority and flow temperature setpoint"......................69

18.1 Operating line.................................................................................................69

18.2 Settings..........................................................................................................69

18.3 D.h.w. priority.................................................................................................69

18.3.1 Absolute priority.............................................................................................69

18.3.2 Shifting priority...............................................................................................70

18.3.3 No priority.......................................................................................................70

18.4 Flow temperature setpoint .............................................................................70

18.4.1 Maximum selection........................................................................................70

18.4.2 D.h.w..............................................................................................................71

19 Function block "D.h.w. storage tank".............................................................72

19.1 Operating lines...............................................................................................72

19.2 D.h.w. charging..............................................................................................72

19.2.1 D.h.w. charging with hot water.......................................................................72

19.2.2 Alternate d.h.w. charging with hot water and electricity.................................72

7/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 8

19.3 D.h.w. temperature and d.h.w. switching differential.....................................73

19.4 Boost of the d.h.w. charging temperature ..................................................... 74

19.5 Maximum d.h.w. charging time......................................................................74

19.6 Setpoint of legionella function .......................................................................74

19.7 Forced charging ............................................................................................ 75

19.8 Protection against discharging......................................................................75

19.8.1 Purpose......................................................................................................... 75

19.8.2 Mode of operation ......................................................................................... 75

19.9 Manual d.h.w. charging.................................................................................76

20 Function block "3-position actuator for d.h.w.".............................................. 77

20.1 Operating lines..............................................................................................77

20.2 Function ........................................................................................................77

20.2.1 Flow temperature boost.................................................................................77

20.2.2 D.h.w temperature control............................................................................. 77

20.3 Pulse lock...................................................................................................... 77

21 Function block "Derivative action time d.h.w. heating via heat exchanger" .. 78

21.1 Operating line................................................................................................ 78

21.2 Description .................................................................................................... 78

22 Function block "Multi-functional relay"........................................................... 79

22.1 Operating lines..............................................................................................79

22.2 Functions....................................................................................................... 79

22.2.1 No function....................................................................................................79

22.2.2 Outside temperature switch ..........................................................................79

22.2.3 ON / OFF according to the time switch .........................................................80

22.2.4 Relay energized in the event of fault............................................................. 80

22.2.5 Relay energized during occupancy time ....................................................... 80

22.2.6 Relay energized during occupancy time (including optimizations)................80

22.2.7 Relay energized, if there is demand for heat ................................................80

22.2.8 Manually ON / OFF ....................................................................................... 80

23 Function block "Legionella function" .............................................................81

23.1 Operating lines..............................................................................................81

23.1.1 Periodicity of legionella function.................................................................... 81

23.1.2 Time of legionella function ............................................................................81

23.1.3 Dwelling time at the legionella setpoint.........................................................81

23.1.4 Circulating pump operation during the legionella function ............................81

23.2 Mode of operation ......................................................................................... 81

24 Function block "Switching program 3"...........................................................83

24.1 Operating lines..............................................................................................83

24.2 Function ........................................................................................................83

8/118

Siemens Building Technologies Basic Documentation RV L471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 9

25 Function block "Service functions and general settings" ...............................84

25.1 Operating lines...............................................................................................84

25.2 Display functions............................................................................................84

25.2.1 Flow temperature setpoint .............................................................................84

25.2.2 Heating curve.................................................................................................85

25.2.3 Hours run counter..........................................................................................85

25.2.4 Software version............................................................................................85

25.2.5 Identification number of room unit..................................................................86

25.2.6 Radio clock, elapsed time since last reception..............................................86

25.3 Commissioning aids.......................................................................................86

25.3.1 Simulation of the outside temperature...........................................................86

25.3.2 Relay test.......................................................................................................87

25.3.3 Sensor test.....................................................................................................87

25.3.4 Test of H-contacts..........................................................................................88

25.4 Auxiliary functions..........................................................................................88

25.4.1 Frost protection for the plant..........................................................................88

25.4.2 Flow alarm .....................................................................................................89

25.4.3 Manual overriding of operating mode (contact H1)........................................90

25.4.4 Pump overrun ................................................................................................90

25.4.5 Pump kick ......................................................................................................90

25.4.6 Winter- / summertime changeover.................................................................90

25.4.7 Gain of locking signal.....................................................................................91

25.5 Entries for LPB...............................................................................................92

25.5.1 Source of time of day.....................................................................................92

25.5.2 Outside temperature source ..........................................................................92

25.5.3 Addressing the devices..................................................................................93

25.5.4 Bus power supply...........................................................................................93

25.5.5 Bus loading number.......................................................................................94

25.6 Heat demand output DC 0...10 V...................................................................94

26 Function block "Locking functions" ................................................................95

26.1 Operating line.................................................................................................95

26.2 Locking the settings on the software side......................................................95

26.3 Locking the settings for district heat on the hardware side............................95

27 Communication..............................................................................................96

27.1 Combination with room units..........................................................................96

27.1.1 General..........................................................................................................96

27.1.2 Combination with room unit QAW50..............................................................96

27.1.3 Combination with room unit QAW70..............................................................96

27.1.4 Combination with SYNERGYR central unit OZW30......................................98

27.2 Communication with other devices................................................................98

27.2.1 Data bus.........................................................................................................98

9/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 10

27.2.2 Heat demand signal ...................................................................................... 99

28 Handling......................................................................................................100

28.1 Operation.....................................................................................................100

28.1.1 General........................................................................................................100

28.1.2 Analog operating elements .........................................................................101

28.1.3 Digital operating elements........................................................................... 102

28.1.4 Setting levels and access rights.................................................................. 103

28.2 Commissioning............................................................................................ 103

28.2.1 Installation instructions................................................................................ 103

28.2.2 Operating lines............................................................................................103

28.3 Installation...................................................................................................104

28.3.1 Mounting location........................................................................................104

28.3.2 Mounting choices ........................................................................................ 104

28.3.3 Electrical installation.................................................................................... 104

29 Engineering.................................................................................................105

29.1 Connection terminals ..................................................................................105

29.1.1 Low-voltage side ......................................................................................... 105

29.1.2 Mains voltage side ......................................................................................105

29.2 Connection diagrams .................................................................................. 106

29.2.1 Low-voltage side ......................................................................................... 106

29.2.2 Mains voltage side ......................................................................................106

30 Mechanical design ......................................................................................107

30.1 Basic design................................................................................................ 107

30.2 Dimensions .................................................................................................107

31 Technical data............................................................................................. 108

10/118

Siemens Building Technologies Basic Documentation RV L471 CE1P2524E

HVAC Products Contents 23.10.2002

Page 11

1 Summary

1.1 Brief description and key features

• The RVL471 is a multifunctional heating controller for use in residential and non-residential buildings that have their own d.h.w. heating facility

• Suited for:

− Heating zone control with or without room influence via weather-compensated flow

temperature control

− Precontrol via demand-compensated control of the main / secondary flow tem-

perature

− Precontrol via demand-compensated boiler temperature control. Suited for integra-

tion into heat source cascades or heat generation systems (heat pump, solar,

wood)

• For use in plants with own heat generation or with a district heat connection

• With regard to d.h.w. heating, the RVL471 is suited for plants with d.h.w. storage tanks,

electric immersion heaters and instantaneous systems with own heat exchangers

• The RVL471 has 29 plant types preprogrammed. When a certain type of plant is selected, all functions and settings required for that plant will be activated

• A scalable voltage output DC 0...10 V is used to pass the heat demand signal to other

systems

• A multifunctional relay provides additional control functions, if required

• For direct adjustment of the heating curve, the well known “bar" is used. Digital ad-

justment of the heating curve is possible also. A setting knob is used for making room

temperature readjustments

• All the other parameters are set digitally based on the operating line principle

• The RVL471 is capable of communicating with other units via LPB (Local Process Bus)

• Key design features: Operating voltage AC 230 V, CE conformity, overall dimensions

to DIN 43700 (144 x 144 mm)

1.2 Type summary

The RVL471 is a compact controller that requires no plug-in modules.

1.3 Equipment combinations

1.3.1 Suitable sensors

• For water temperatures:

Suitable are all types of temperature sensors that use a sensing element

LG-Ni 1000

− Strap-on temperature sensor QAD22

− Immersion temperature sensors QAE22...

− Immersion temperature sensor QAP21.3 complete with connecting cable

• For the room temperature:

Suitable are all types of temperature sensors that use a sensing element

LG-Ni

− Room temperature sensor QAA24

• For the outside temperature:

− 2XWVLGHVHQVRU4$&VHQVLQJHOHPHQW/*1L

− Outside sensor QAC32 (sensing element NTC 575)

7KHIROORZLQJW\SHVDUHSUHVHQWO\DYDLODEOH

7KHIROORZLQJW\SHVDUHSUHVHQWO\DYDLODEOH

11/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 1 Summary 23.10.2002

Page 12

1.3.2 Suitable room units

• Room unit QAW50

• Room unit QAW70

1.3.3 Suitable actuators

All types of actuators from HVAC Products with the following features can be used:

• Electromotoric or electrohydraulic actuators with a running time of 0.5...14.5 minutes

• 3-position control

• Operating voltage AC 24... 230 V

1.3.4 Communication

Communication is possible with the following units:

• All LPB-compatible controllers supplied by HVAC Products

• SYNERGYR central unit OZW30 (software version 3.0 or higher)

1.3.5 Passing on of heat demand signal

The scalable DC 0...10 V signal can be used to pass the heat demand signal to other

devices in the system.

1.3.6 Documentation

Type of documentation Ordering number (for English)

Data Sheet RVL471 CE1N2524E

Operating Instructions RVL471 4 319 2779 0

Installation Instructions RVL471 4 319 2770 0

Data Sheet QAW50 CE2N1635E

Data Sheet QAW70 CE2N1637E

Data Sheet "LPB Basic System Data" CE1N2030E

Data Sheet "LPB Basic Engineering

Data"

CE1N2032E

12/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 1 Summary 23.10.2002

Page 13

2 Use

2.1 Types of plant

The RVL471 is suitable for all types of heating plant that use weather-compensated

flow temperature control. In addition, it can be used for demand-compensated control of

the main flow.

With regard to d.h.w. heating, the RVL471 is suited for plants with storage tanks or

d.h.w. heating via heat exchangers (instantaneous d.h.w. heating).

Main applications:

• Heating zones and d.h.w. heating with own heat generation

• Heating zones and d.h.w. heating with a district heat connection

• Interconnected plants consisting of heat generation, several heating zones and central

or decentral d.h.w. heating

2.2 Types of houses and buildings

Basically, the RVL471 is suited for use in all types of houses and buildings It has been

designed especially for:

• Multi-family houses

• Single-family homes

• Small to medium-size nonresidential buildings

2.3 Types of heating systems

The RVL471 is suited for use with all standard heating systems, such as:

• Radiators

• Convectors

• Underfloor heating systems

• Ceiling heating systems

• Radiant panels

2.4 Functions

The RVL471 is used if one or several of the following functions is / are required:

• Weather-compensated flow temperature control

• Flow temperature control via a modulating seat or slipper valve, or boiler temper a t ur e

control through direct control of a single- or 2-stage burner

• D.h.w. storage tank charging through control of a mixing valve, charging pump or diverting valve, with or without circulating pump

• D.h.w. heating via heat exchanger (instantaneous d.h.w. heating), with or without circulating pump

• Optimum start / stop control according to the selected 7-day program

• Quick setback and boost heating according to the selected 7-day program

• ECO function: demand-dependent switching of the heating system based on the type

of building construction and the outside temperature

• Voltage output DC 0...10 V for passing on the heat demand signal

• Multifunctional relay

• 7-day program for building occupancy with a maximum of 3 setback periods per day

and daily varying occupancy schedules

• Own 7-day switching program for the release of d.h.w. heating

13/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 2 Use 23.10.2002

Page 14

• Third 7-day switching program

• Input of 8 holiday periods per year

• Automatic summer- / wintertime changeover

• Display of parameters, actual values, operating state and error messages

• Communication with other units via LPB

• Remote operation via room unit and external switches

• Service functions

• Frost protection for the plant, the boiler and the house or building

• Minimum or maximum limitation of the return temperature

• DRT limitation

• Minimum and maximum limitation of the flow temperature

• Maximum limitation of the room temperature

• Periodic pump run

• Pump overrun

• Maximum limitation of the rate of setpoint increase

• Flow alarm

• Legionella function

• Manual d.h.w. charging

For the preprogrammed heating and d.h.w. heating circuits and their possible combinations, refer to section 3.2 ”Plant types”.

14/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 2 Use 23.10.2002

Page 15

3 Fundamentals

3.1 Key technical features

The RVL471 offers 2 key technical features:

• The RVL471 has 6 heating circuit plant types and 5 d.h.w. plant types preprogrammed.

When making use of all possible or practical combinations, there is a total of 29 plant

types available

• All functions and their settings are combined in the form of function blocks

3.1.1 Plant types with regard to heating circuit

In terms of heating circuit, the following plant types are available:

• Heating circuit plant type 1 – space heating with mixing valve

• Heating circuit plant type 2 – space heating with boiler

• Heating circuit plant type 3 – space heating with district heat

• Heating circuit plant type 4 – precontrol with mixing valve

• Heating circuit plant type 5 – precontrol with boiler

• Heating circuit plant type 6 – precontrol with district heat

Heating circuit plant type 5 is suited for integration into heat source cascades or heat

generation systems.

3.1.2 Plant types with regard to d.h.w. heating

In terms of d.h.w., the following plant types are available:

• D.h.w. plant type 0 – no d.h.w.

• D.h.w. plant type 1 – storage tank with charging pump

• D.h.w. plant type 2 – storage tank with mixing valve

• D.h.w. plant type 3 – storage tank with diverting valve

• D.h.w. plant type 4 – instantaneous d.h.w. heating via heat exchanger

• D.h.w. plant type 5 – only electric immersion heater

3.1.3 Function blocks

The following function blocks are available:

• Function block “Enduser space heating”

• Function block “Enduser d.h.w.”

• Function block “Enduser general”

• Function block “Plant type”

• Function block “Cascade slave”

• Function block "Space heating"

• Function block “3-position actuator heating circuit”

• Function block “Boiler”

• Function block “Setpoint return temperature limitation”

• Function block “District heat”

• Function block "Maximum limitation of the return temperature d.h.w."

• Function block "Basic settings d.h.w."

• Function block "Release of d.h.w. heating"

• Function block "Priority and flow temperature setpoint d.h.w."

• Function block "D.h.w. storage tank"

• Function block "3-position actuator d.h.w."

• Function block “Derivative action time d.h.w. heating via heat exchanger”

15/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 16

• Function block “Multifunctional relay”

• Function block “Legionella function"

• Function block "Switching program 3"

• Function block “Service functions and general settings”

• Function block “Locking functions”

For each function block, the required settings are available in the form of operating

lines. On the following pages, a description of the individual functions per block and line

is given.

3.2 Plant types

The RVL471 has 29 plant types preprogrammed; the functions required for each type of

plant are ready assigned. When commissioning the installation, the relevant plant type

must be selected.

Each plant type consists of a heating circuit and a d.h.w. circuit. When making use of all

possible or practical combinations, there is a total of 29 plant types available.

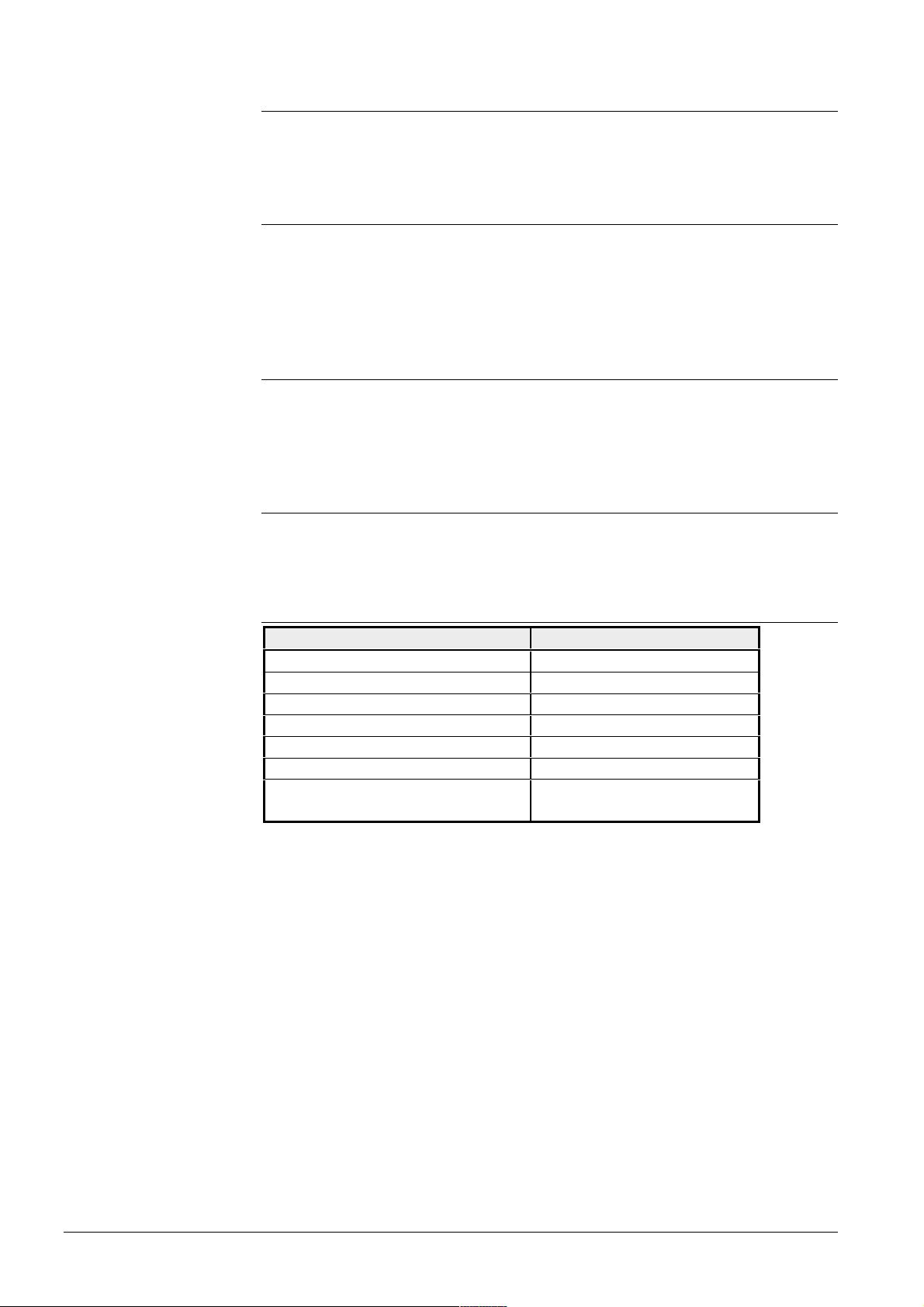

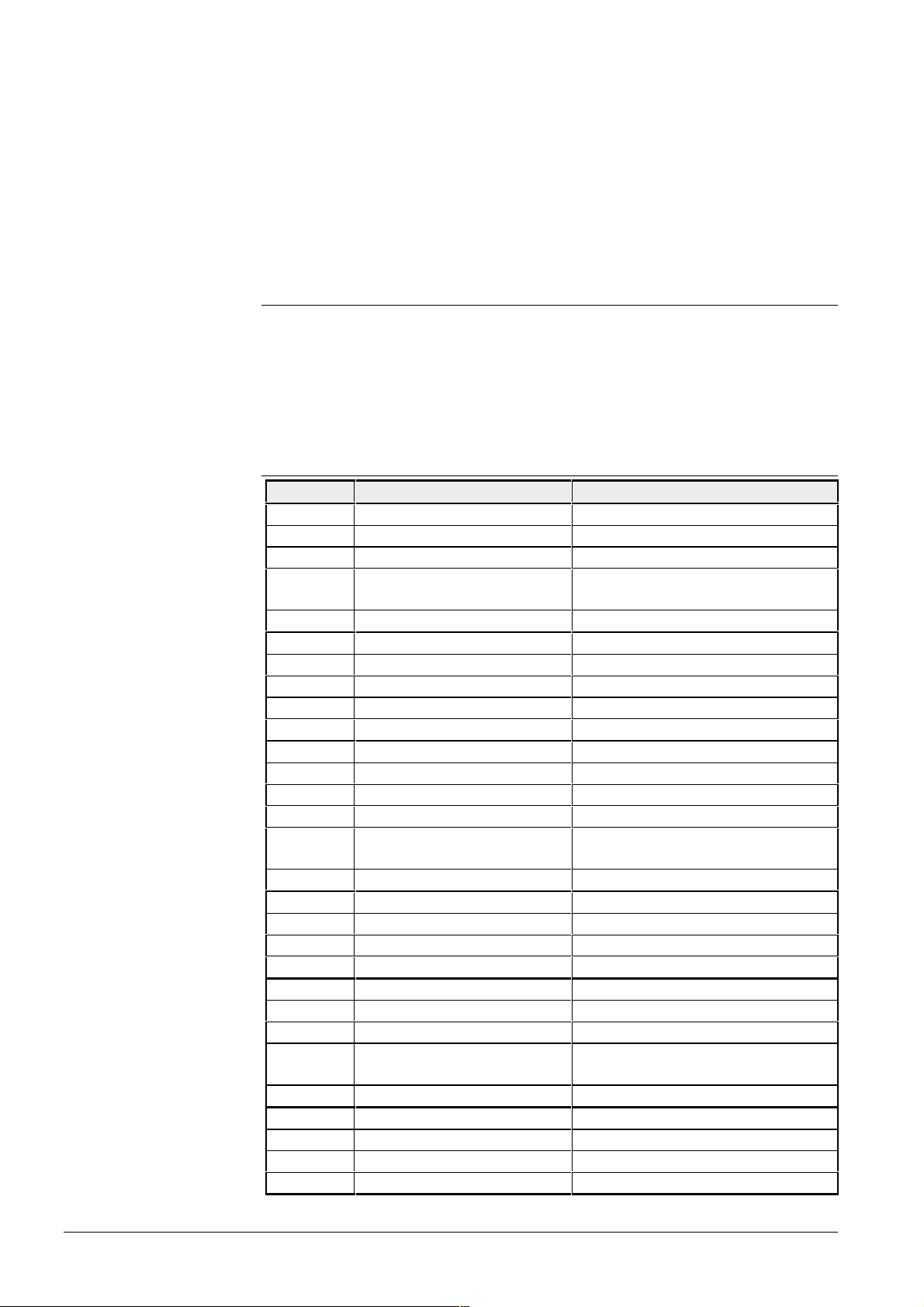

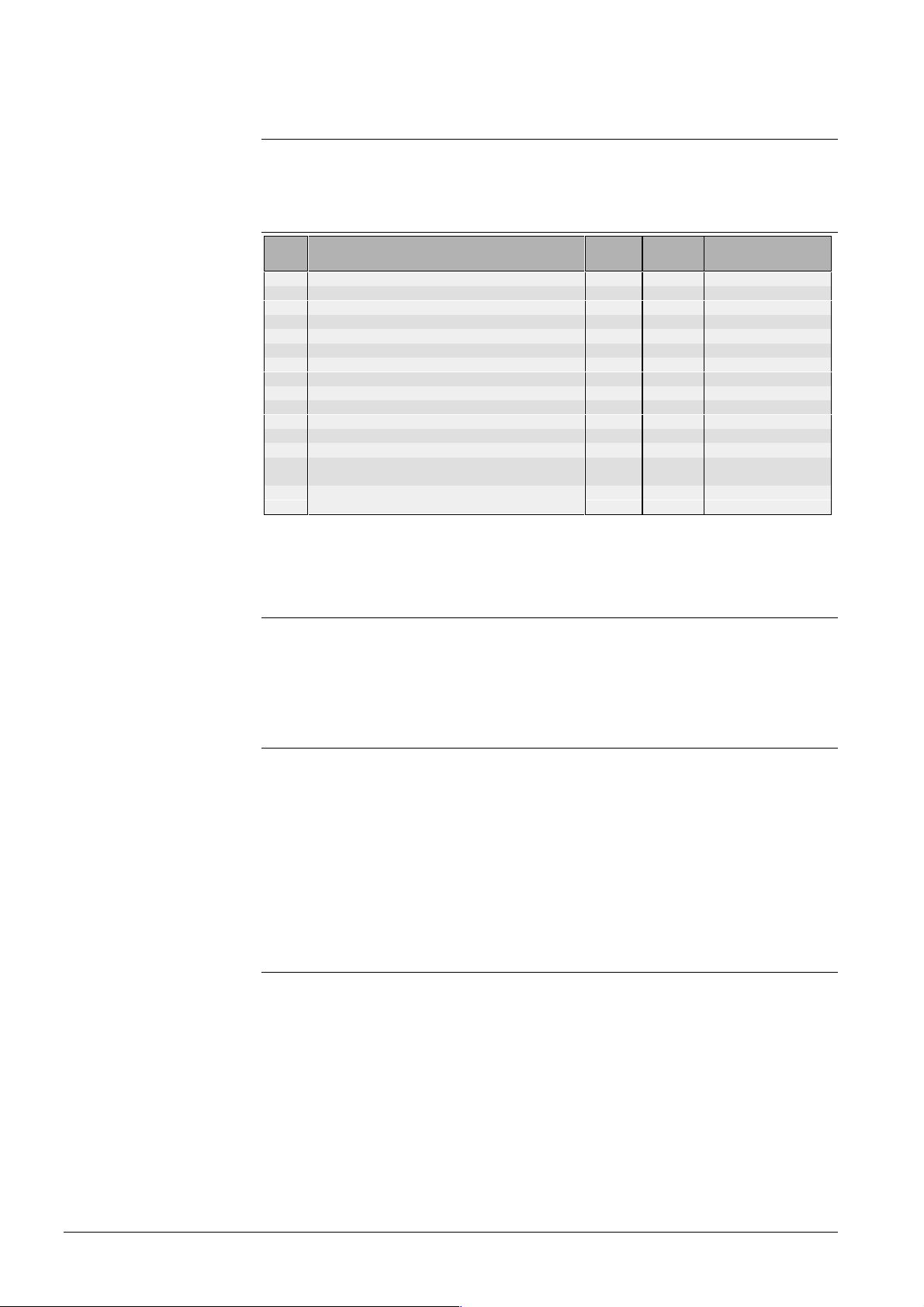

3.2.1 Selectable combinations

&RPELQDWLRQV Type of heating circuit Type of d.h.w. heating

1–0

1–1

1–2

1–4

1–5

2–0

2–1

2–2

2–3

2–5

3–0

3–1

3–2

3–3

3–4

3–5

4–0

4–1

4–2

4–5

5–0

5–1

5–2

5–4

5–5

6–0

6–1

6–2

6–5

Space heating with mixing valve No d.h.w.

Space heating with mixing valve Storage tank with charging pump

Space heating with mixing valve Storage tank with mixing valve

Space heating with mixing valve Instantaneous d.h.w. heating via heat

exchanger

Space heating with mixing valve Only electric immersion heater

Space heating with boiler No d.h.w.

Space heating with boiler Storage tank with charging pump

Space heating with boiler Storage tank with mixing valve

Space heating with boiler Storage tank with diverting valve

Space heating with boiler Only electric immersion heater

Space heating with district heat No d.h.w.

Space heating with district heat storage tank with charging pump

Space heating with district heat Storage tank with mixing valve

Space heating with district heat Storage tank with diverting valve

Space heating with district heat Instantaneous d.h.w. heating via heat

exchanger

Space heating with district heat Only electric immersion heater

Precontrol with mixing valve No d.h.w.

Precontrol with mixing valve Storage tank with charging pump

Precontrol with mixing valve Storage tank with mixing valve

Precontrol with mixing valve Only electric immersion heater

Precontrol with boiler No d.h.w.

Precontrol with boiler Storage tank with charging pump

Precontrol with boiler Storage tank with mixing valve

Precontrol with boiler Instantaneous d.h.w. heating via heat

exchanger

Precontrol with boiler Only electric immersion heater

Precontrol with district heat No d.h.w.

Precontrol with district heat Storage tank with charging pump

Precontrol with district heat Storage tank with mixing valve

Precontrol with district heat Only electric immersion heater

16/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 17

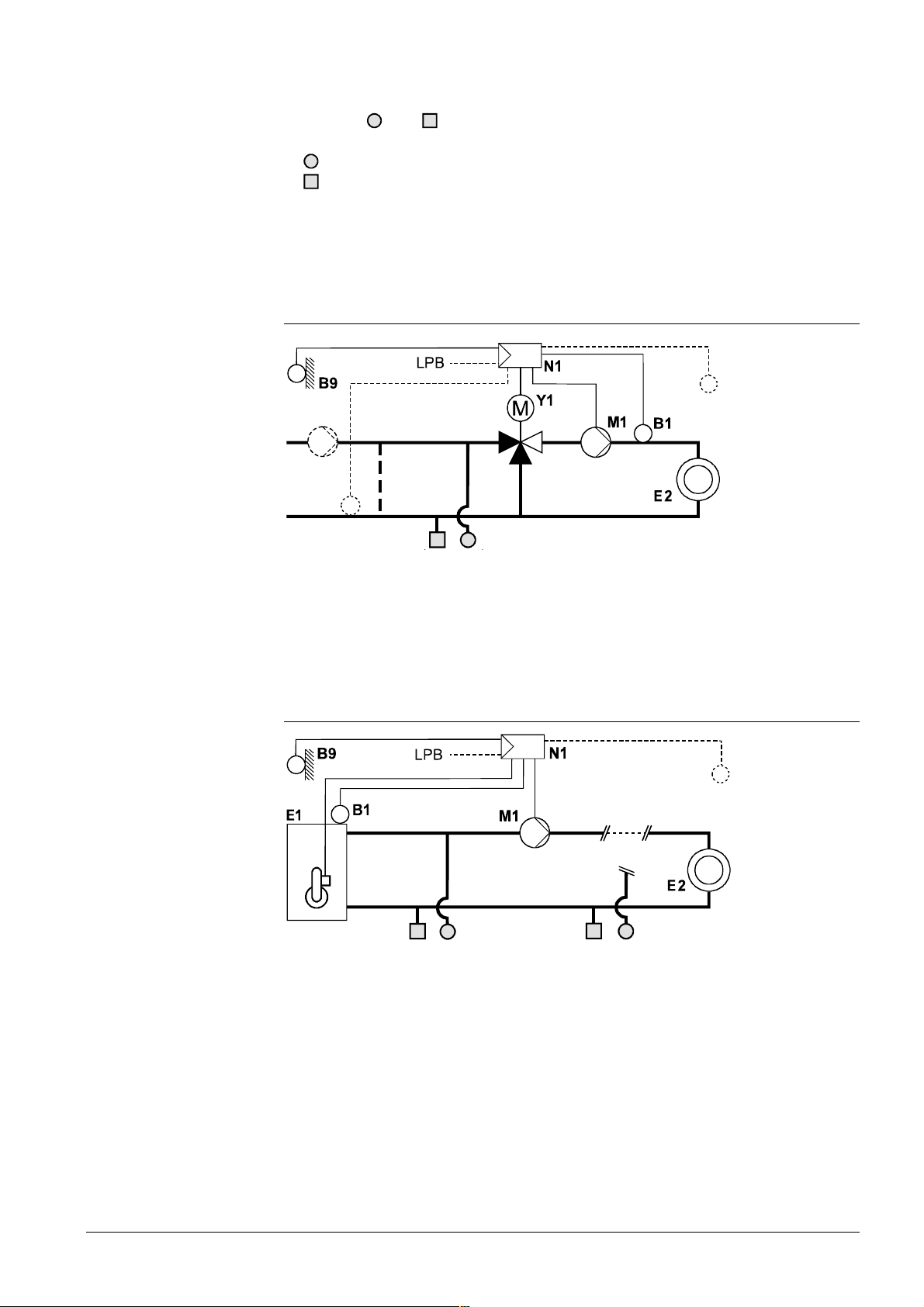

Notes on the plant diagrams with the different types of space heating and d.h.w. circuits

are given in the following sections:

• Symbols

and indicate where and how the space heating circuit is connected to

the d.h.w. circuit. where:

representing the flow

representing the return

• The numbers beneath these symbols indicate the type of d.h.w. circuit with which the

heating circuit can be combined

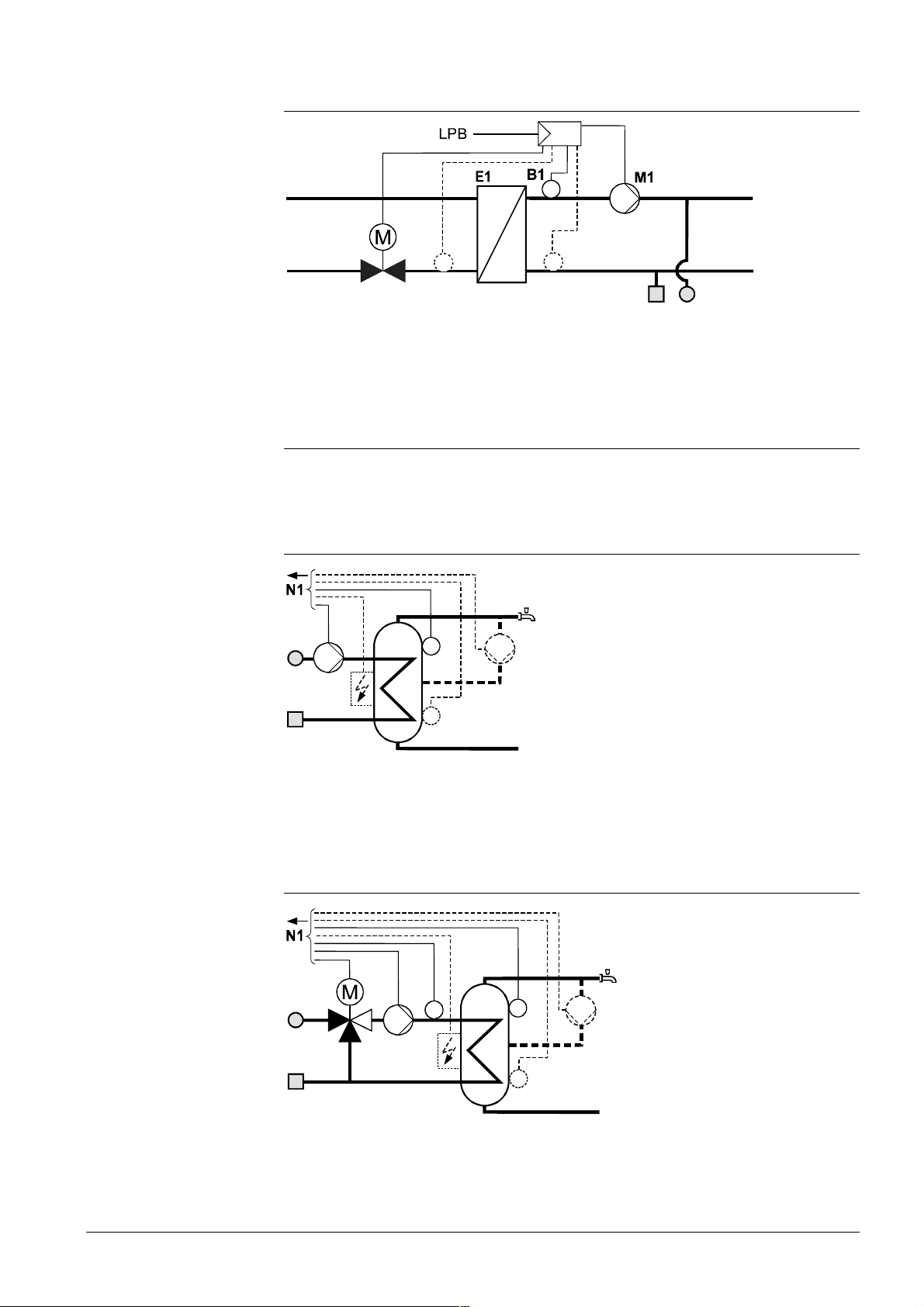

3.2.2 Heating circuit type 1 – space heating with mixing

valve

A6/B5

B7

2524S01

1, 2, 4 0, 5

Space heating with weather-compensated flow temperature control. 3-position control

acting on the mixing valve of the heating zone.

Outside temperature signal from own sensor or data bus. With or without room influence. Heating up and setback according to the heating program.

3.2.3 Heating circuit type 2 – space heating with boiler

A6/B5

2524S02

1, 2 3 0, 5

Space heating with own boiler, with weather-compensated boiler temperature control.

2-position control acting on the burner.

Outside temperature signal from own sensor or data bus. With or without room influence. Heating up and setback according to the heating program.

17/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 18

3.2.4 Heating circuit type 3 – space heating with district heat

N1

A6/B5

Y1

B7

B71

2524S03

2, 4 1 3 0, 5

Space heating with district heat connection, with weather-compensated flow temperature control acting on the valve in the primary return of the district heat connection.

Outside temperature signal from own sensor or data bus. With or without room influence. Heating up and setback according to the heating program.

3.2.5 Heating circuit type 4 – precontrol with mixing valve

B7

2524S04

1, 2 0, 5

Precontrol with demand-dependent control of the main flow temperature. 3-position

control acting on the mixing valve in the main flow.

Heat demand signal from data bus. No heating program.

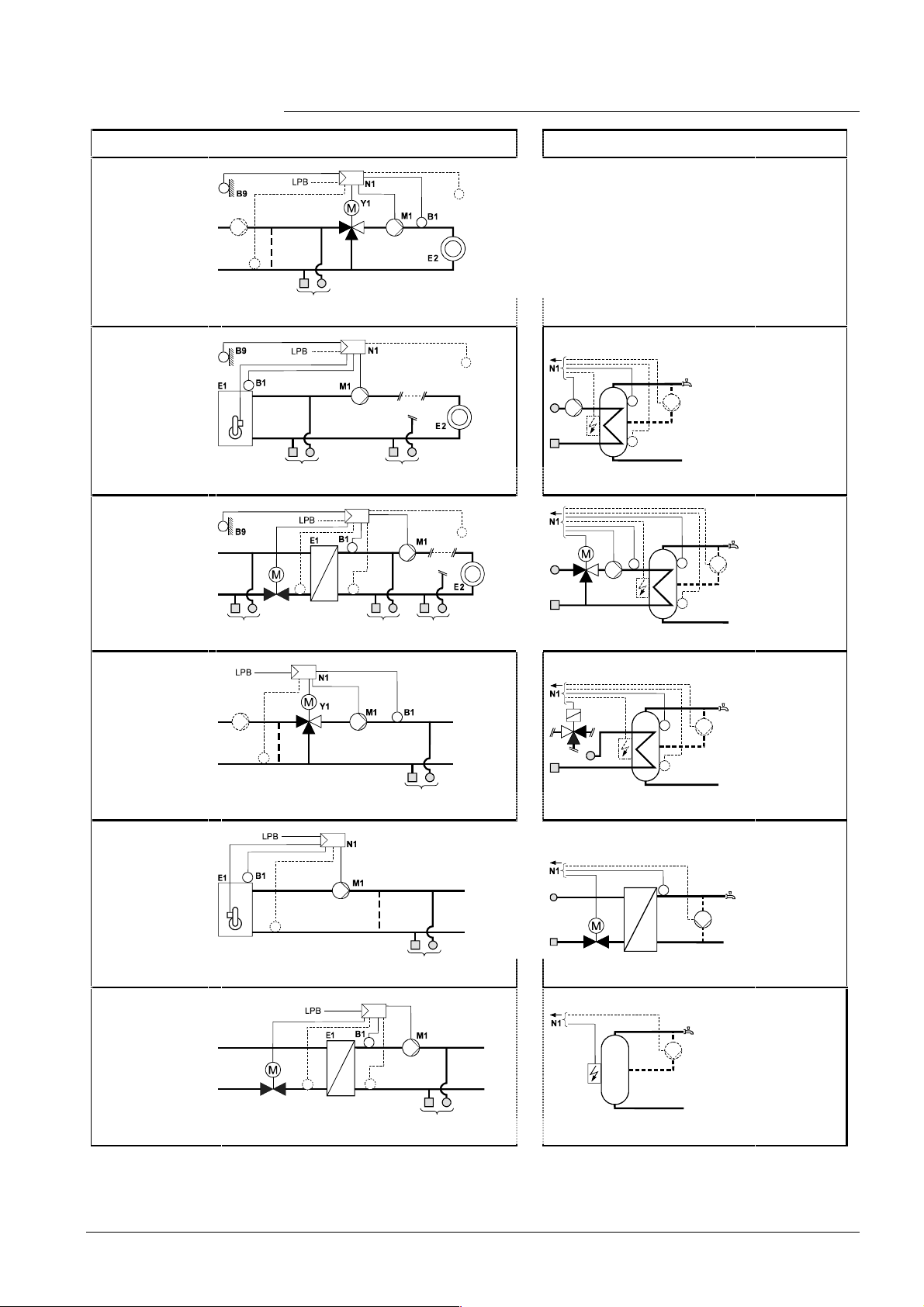

3.2.6 Heating circuit type 5 – precontrol with boiler

B7

1, 2, 4 0, 5

Precontrol with demand-compensated control of the boiler temperature. 2-position control acting on the burner.

Heat demand signal from data bus. No heating program.

2524S05

18/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 19

3.2.7 Heating circuit type 6 – precontrol with district heat

N1

Y1

2524S06

B7

Precontrol with district heat connection, with demand-compensated control of the secondary flow temperature acting on the valve in the primary return.

Heat demand signal from data bus. No heating program.

B71

1, 2 0, 5

3.2.8 D.h.w. plant type 0 – no d.h.w.

The RVL471 does not provide d.h.w. heating.

3.2.9 D.h.w. plant type 1 – d.h.w. storage tank with charging

pump

M3

B31

M4

K6

B32

Charging of d.h.w. storage tank through control of the charging pump. Acquisition of the

d.h.w. temperature with one or 2 sensors or thermostats. Circulating pump and electric

immersion heater are optional.

2524S07

3.2.10 D.h.w. plant type 2 – d.h.w. storage tank with mixing

valve

Y7

M3

B3

K6

B31

M4

B32

Charging of d.h.w. storage tank through control of the mixing valve according to own

temperature sensor in the storage tank flow. Acquisition of the d.h.w. temperature with

one or 2 sensors or thermostats. Circulating pump and electric immersion heater are

optional.

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

2524S08

19/118

Page 20

3.2.11 D.h.w. plant type 3 – storage tank with diverting valve

Y3

B31

M4

K6

B32

2524S09

Charging of the d.h.w. storage tank through control of the diverting valve. Acquisition of

the d.h.w. temperature with one or 2 sensors or thermostats. Circulating pump and

electric immersion heater are optional.

3.2.12 D.h.w. plant type 4 – instantaneous d.h.w. heating via

heat exchanger

N1

B3

Y7

D.h.w. heating via heat exchanger (instantaneous d.h.w. heating) through control of the

2-port valve in the heat exchanger’s primary return. Acquisition of the d.h.w. temperature in the heat exchanger’s secondary flow. Circulating pump is optional, but strongly

recommended.

M4

2524S10

3.2.13 D.h.w. plant type 5 – only electric immersion heater

M4

K6

2524S11

Charging of d.h.w. storage tank only through release of the electric immersion heater.

No control of d.h.w. heating by the controller. Circulating pump is optional.

A6 Room unit QAW50 or QAW70 E2 Consumer (space)

B1 Flow / boiler sensor LPB Data bus

B3 D.h.w. flow sensor K6 Electric immersion heater

B31 Storage tank sensor / thermostat 1 M1 Heating circuit pump / circulating pump

B32 Storage tank sensor / thermostat 2 M3 Charging pump

B5 Room sensor M4 Circulating pump

B7 Return sensor (primary circuit) N1 Controller RVL471

B71 Return sensor (secondary circuit) Y1 Heating circuit mixing valve

B9 Outside sensor Y3 Diverting valve

E1 Heat source (boiler / heat converter) Y7 D.h.w. mixing valve

20/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 21

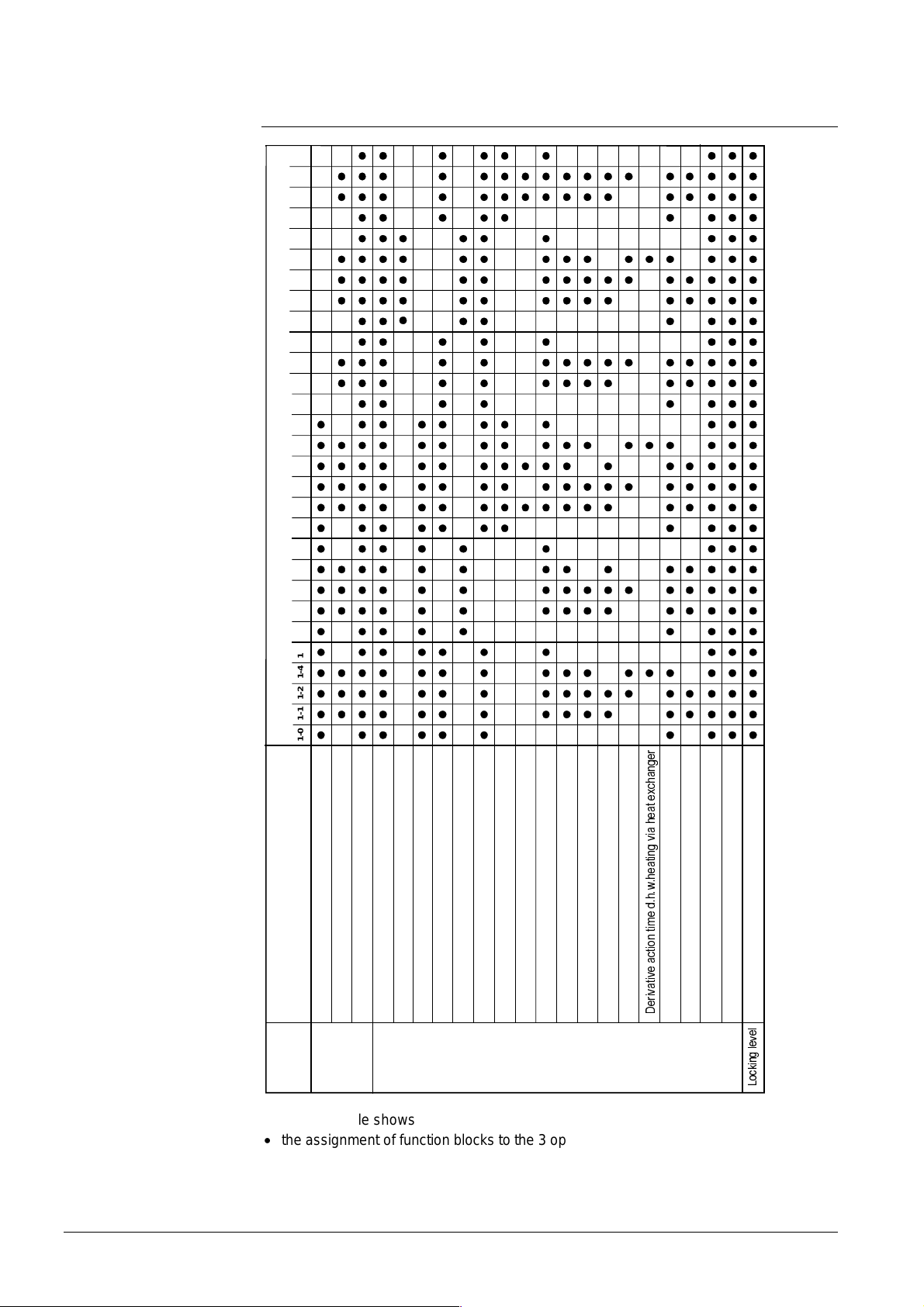

3.2.14 Summary of plant types and plant combinations

0, 5

0, 5

0, 5

0, 5

Plant types with regard to heating circuit D.h.w. plant types

1

Space heating with

mixing zone 3position control,

acting on mixing

valve

Space heating with

own boiler:

2

Space heating with

own boiler 2-position

contro l, acting on

burner

Possible d.h.w. combinations:

3

Space heating with

district heat

3-position control,

acting on valve

Possible d.h.w. combinations:

A6/B5

B7

2524S01

Õ 1, 2, 4

A6/B5

2524S02

Õ 1, 2 3 0, 5

N1

Y1

B7

B71

2, 4 1 3 0, 5

A6/B5

2524S03

--

--

--

0

No d.h.w. heating

1

D.h.w. heating

M3

B31

M4

K6

B32

2524S07

through control

of the charging

pump.

2

M4

2524S08

D.h.w. heating

through control

of the mixing

valve.

Y7

B3

M3

K6

B31

B32

4

Precontrol with mixing zone, heat demand signal via data

bus

Possible d.h.w. combinations:

5

Precontrol with

boiler, heat demand

signal v ia data bus

Possible d.h.w. combinations:

6

Precontrol with district heat, heat demand signal via data

bus

Possible d.h.w. combinations:

B7

Õ 1, 2

B7

Õ 1, 2, 4

N1

Y1

B7

B71

Õ 1, 2

--

Y3

B31

2524S04

K6

B32

M4

--

B3

2524S05

Y7

M4

--

M4

2524S06

K6

2524S11

3

D.h.w. heating

through control

of the diverting

valve

2524S09

4

D.h.w. heating

via heat exchanger

through control

of the valve

2524S10

5

D.h.w. heating

via electric

immersion

heater only

21/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 22

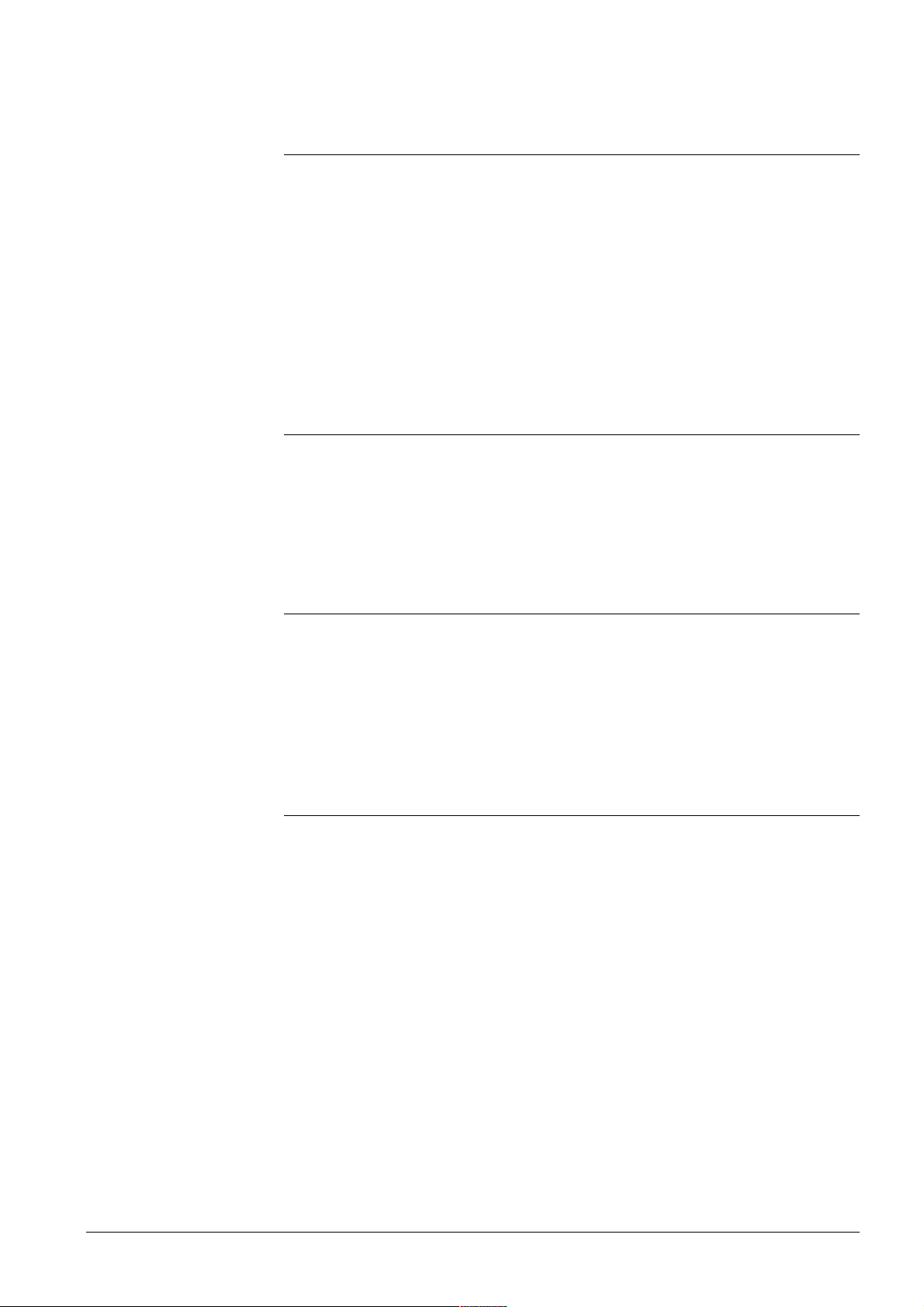

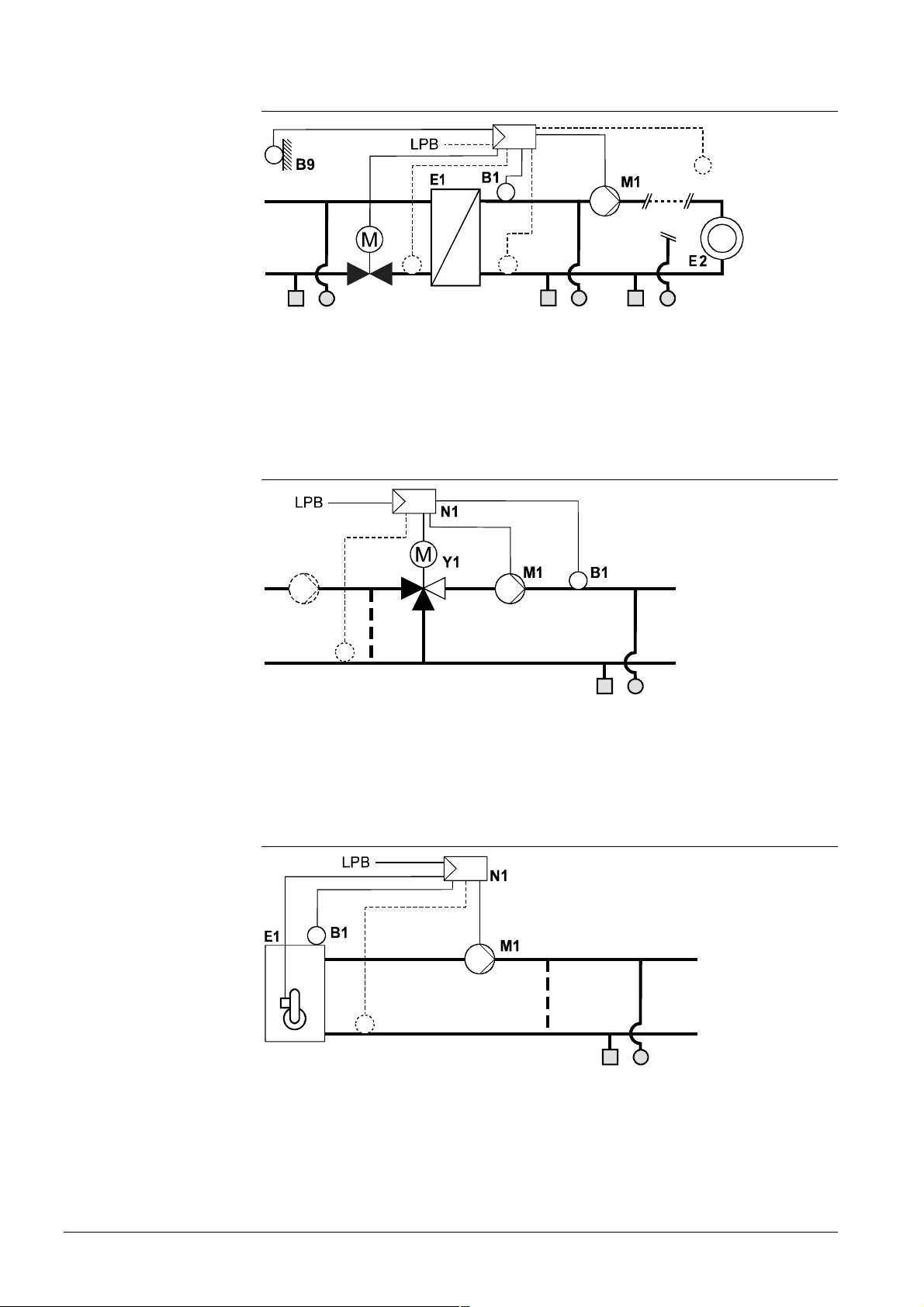

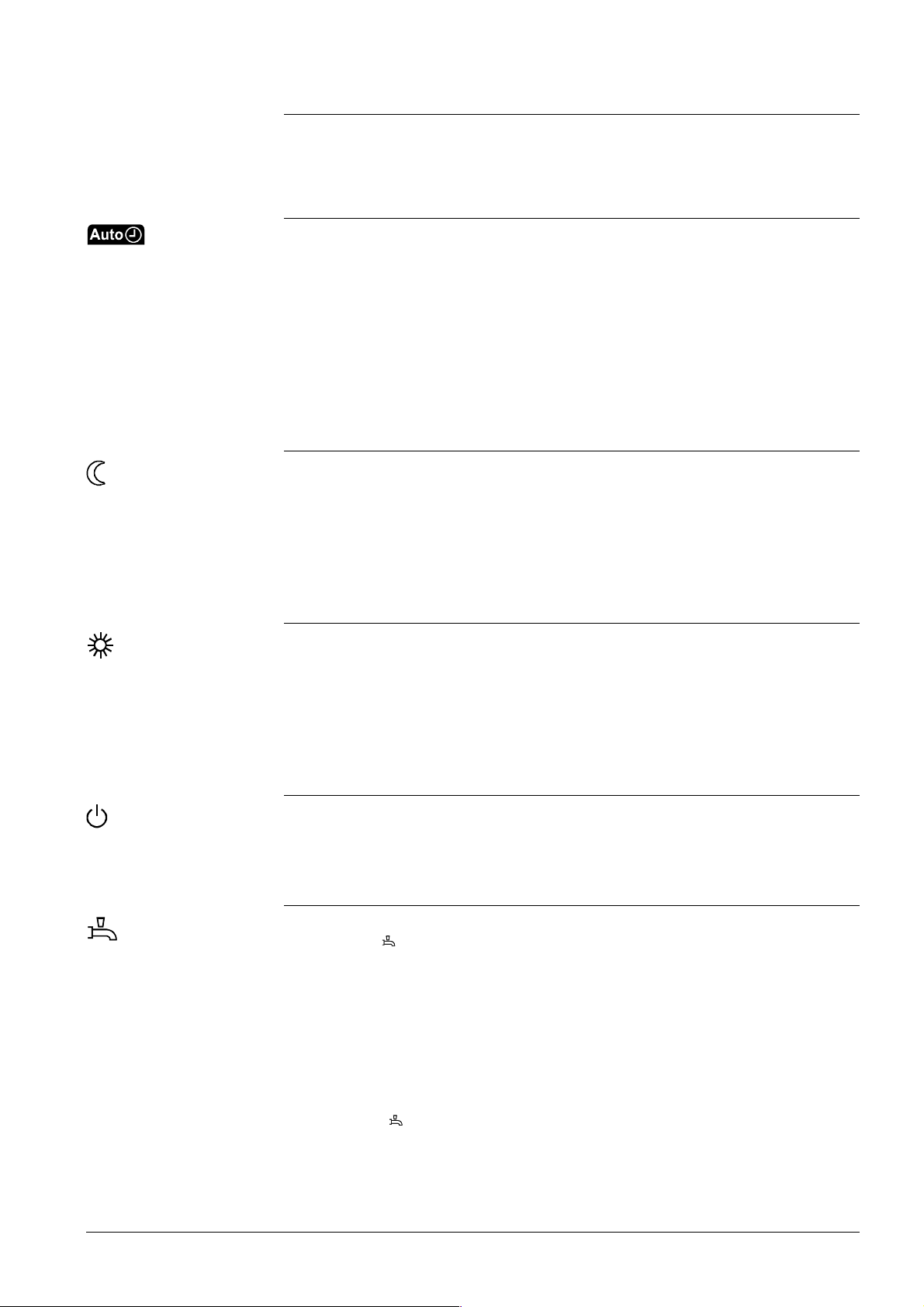

3.3 Setting levels, function blocks and plant

types

Combination of plants

2524T01e

1-0 1-1 1-2 1-4 1-5 2-0 2-1 2-2 2-3 2-5 3-0 3-1 3-2 3-3 3-4 3-5 4-0 4-1 4-2 4-5 5-0 5-1 5-2 5-4 5-5 6-0 6-1 6-2 6-5

Enduser general

Plant type

Function block

Enduser space heating

Enduser d.h.w.

Level

Enduser

Cascad e s l ave

Space heating

Setpoint limitation of return temperatu re

District heating

3-positio n actu ato r heati ng ci rc uit

Boiler

Max. limitat i on of d.h . w. re turn te mperature

Basic settings d.h.w.

Release of d.h.w. charging

D.h.w. s to rage tank

D.h.w. priority and flow temperature setpoint

3-position d.h.w. actuator

Heating

engineer

The above table shows

• the assignment of function blocks t o t he 3 op erat ing leve ls

• the function blocks activ at ed wit h the d ifferen t p lan t ty pes

U

H

J

Q

D

K

F

[

H

W

D

H

K

D

L

Y

J

Q

L

W

D

H

K

Z

K

G

H

P

L

W

Q

R

L

W

F

D

H

Y

L

W

D

Y

L

U

H

Multifunctional relay

Time switch pro gram 3

Legionella function

'

Service fu nct io ns and gene ra l set tin gs

Locking function s

O

H

Y

H

O

J

Q

L

N

F

R

/

22/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 23

3.4 Heating circuit ope rating modes

The heating circuit operating mode is selected on the controller by pressing the respective button. Also, the operating mode can be changed by bridging terminals H1-M.

3.4.1 Automatic operation

• Automatic changeover from NORMAL to REDUCED temperature, and vice versa,

according to the 7-day program entered

• Automatic changeover to holiday mode, and back, according to the holiday schedule

entered

• Demand-dependent switching of the heating system according to the room and outside

temperature while giving consideration to the building’s thermal inertia (ECO function)

• Remote operation via room unit (optional)

• Frost protection is ensured

3.4.2 Continuously REDUCED heating

• Continuous heating to the REDUCED temperature

• With ECO function

• No holiday mode

• Remote operation from a room unit not possible

• Frost protection is ensured

3.4.3 Continuously NORMAL heating

• Continuous heating to NORMAL temperature

• No ECO function

• No holiday mode

• Remote operation via room unit not possible

• Frost protection is ensured

3.4.4 STANDBY

• Heating is switched off, but is ready to operate

• Frost protection is ensured

3.5 D.h.w. operati ng modes

D.h.w. heating is switched on and off by pressing the respective button:

• ON (button

operating mode and control. D.h.w. heating to the NORMAL or REDUCED setpoint

can be provided as follows:

− According to the entered switching program 2

− According to the entered heating circuit program (–1 h)

− Continuously (24 hours a day)

During the entered holiday period, d.h.w. heating and the circulating pump are deactivated when using controllers with no bus connection (with data bus, depending on

the setting made).

• OFF (button

tion of plant types x–4 and x–5)

is lit): D.h.w. heating takes place independent of the heating circuit’s

dark): No d.h.w. heating. Frost protection is ensured (with the excep-

23/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 24

3.6 Manual operation

The RVL471 can be switched to manual operation. In this case, the control will be

switched off. In manual operation, the various actuating devices behave as follows:

• Heating circuit mixing valve: This mixing valve is not under voltage, but can be manually driven to any position by pressing the manual buttons

= opening). The heating circuit pump / circulating pump is continuously running.

• Boiler: The 2 burner stages are continuously on. The manual button

switch the second stage on and off. Pump M1 is continuously running

• D.h.w. charging pump: The charging pump is continuously running

• D.h.w. changeover valve: The diverting valve is always in the ”Heating circuit” position

• D.h.w. slipper / seat valve: This valve is driven to the fully closed position, in which

case the closing time is five times the set running time. Then, it is deactivated

• Circulating pump M4: Continuously running

• Electric immersion heater K6: Continuously released

• Multifunctional relay: Continuously energized

Manual operation also negates any overriding of the controller's operating mode

(bridging of H1–M).

( = closing,

can be used to

3.7 Plant type and operating mode

Depending on the selected type of plant, the following operating modes are available:

Plant type

1–0 YES YES YES YES NO YES

1–1, 1–2, 1–4, 1–5 YES YES YES YES YES YES

2–0 YES YES YES YES NO YES

2–1, 2–2, 2–3, 2–5 YES YES YES YES YES YES

3–0 YES YES YES YES NO YES

3–1, 3–2, 3–3, 3–4, 3–5 YES YES YES YES YES YES

4–0 YES NO NO NO NO YES

4–1, 4–2, 4–5 YES NO NO NO YES YES

5–0 YES NO NO *) NO YES

5–1, 5–2, 5–4, 5–5 YES NO NO *) YES YES

6–0 YES NO NO NO NO YES

6–1, 6–2, 6–5 YES NO NO NO YES YES

*)

Depending on the boiler's operating mode:

Boiler with automatic shutdown: NO

Boiler with manual shutdown: YES

24/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 25

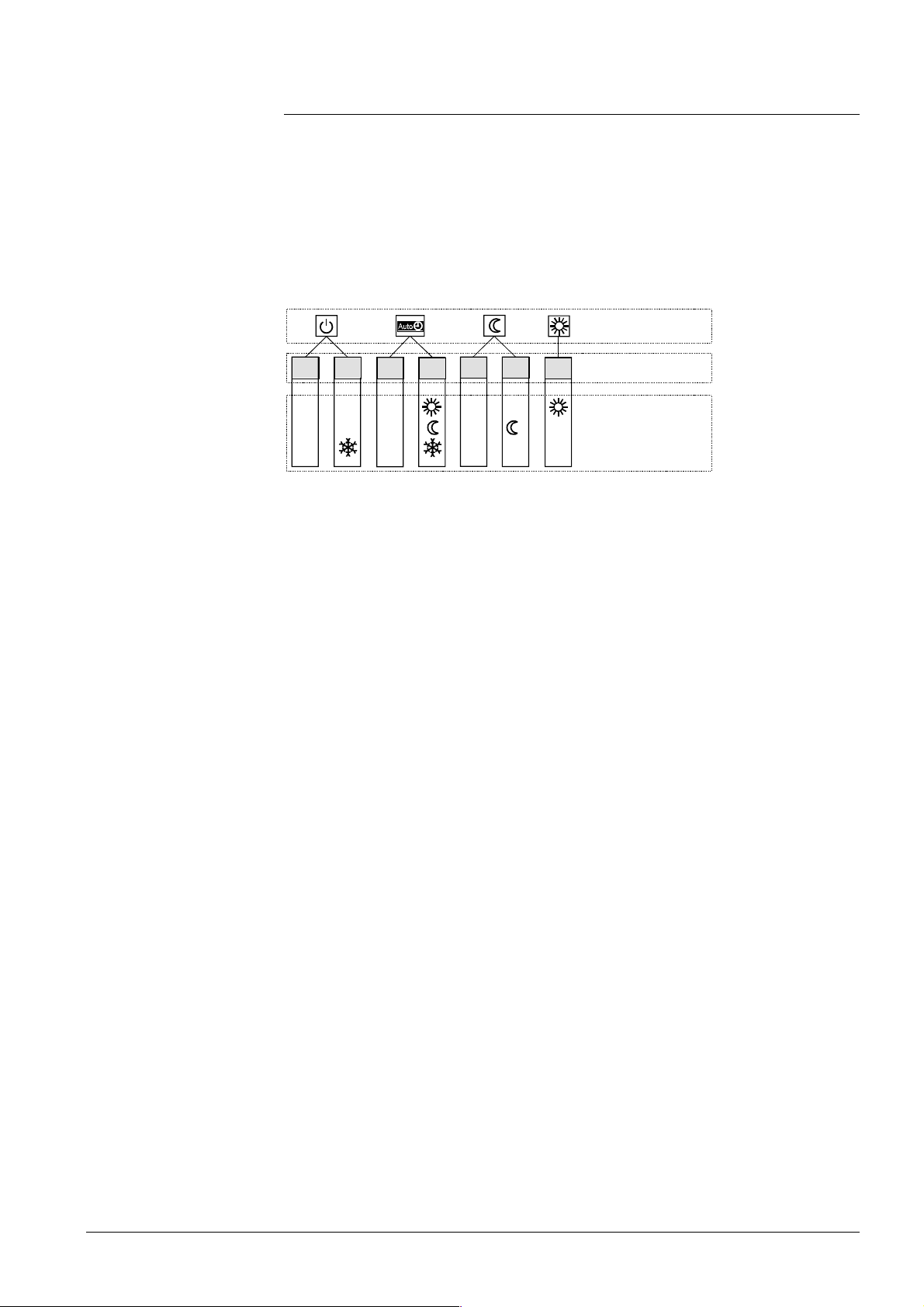

3.8 Operating state and operational level

The user selects the required heating circuit operating mode by pressing the respective

button. Each operating state has a maximum of 2 operating states – with the exception

of operating mode "Continuously NORMAL heating" (only one operating state possible).

When the ECO function is active, and in the case of quick setback, the operating state

is always OFF.

When the operating state is ON, there is a maximum of 3 operational levels, depending

on the operating mode. The operational level is determined by the heating program and

the holiday program.

Operat i n g mo de

OFF

ON

OFF

ON

OFF ON

ON

Operating stat e

Operational le v e l

2522B03e

25/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 3 Fundamentals 23.10.2002

Page 26

4 Acquisition of measured values

4.1 Room temperature (A6, B5)

4.1.1 Measurement

The following choices exist:

• A room temperature sensor QAA24 can be connected to terminal B5

• A room unit QAW50 or QAW70 can be connected to terminal A6

• 2 units can be connected to the terminals. In this case, the RVL471 can ascertain the

average of the 2 measurements. The other room unit functions will not be affected by

averaging

4.1.2 Handling faults

If there is a short-circuit or open-circuit in one of the 2 measuring circuits, the control

responds as follows, depending on the room temperature source (setting on operating

line 65):

• No sensor (operating line 65 = 0):

A short-circuit or open-circuit has no impact on the control. An error message will not

be generated

• Room unit sensor QAW... (operating line 65 = 1):

In the event of a short-circuit or open-circuit, the control continues to operate with the

room model, depending on the function. An error message will be generated

• Room temperature sensor QAA24 (operating line 65 = 2):

In the event of a short-circuit or open-circuit, the control continues to operate with the

room model, depending on the function. An error message will be generated

• Average value (operating line 65 = 3):

In the event of a short-circuit or open-circuit in one of the 2 measuring circuits, the

control continues to operate with the normally working measuring circuit. An error

message will be generated.

In the case of a short-circuit or open-circuit in both measuring circuits, the control continues to operate with the room model, depending on the function. 2 error messages

will be generated

• Automatic mode (operating line 65 = A):

Since the controller itself decides how it acquires the room temperature, error messages cannot be generated.

4.1.3 Room model

The RVL471 features a room model. It simulates the progression of the room temperature. In plants with no measurement of the room temperature, it can provide certain

room functions (e.g. quick setback).

For more detailed information, refer to section 10.4.4, "Room model temperature".

4.2 Flow and boiler temperatur e (B1)

4.2.1 Measurement

The flow or boiler temperature is acquired with one or 2 sensors. 2 sensors connected

in parallel are used to ascertain the average value. The temperature sensors used must

always have a sensing element LG-Ni

26/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 4 Acquisition of measured values 23.10.2002

Page 27

4.2.2 Handling faults

A short-circuit or open-circuit in the measuring circuit is identified and indicated as a

fault. In that case, the plant responds as follows:

• Plants with 3-position control:

Heating circuit pump / circulating pump M1 continues to run and the mixing valve will

close

• Plants with 2-position control:

The heating circuit pump / circulating pump M1 continues to run and the burner will

shut down

4.3 Outside temperature (B9)

4.3.1 Measurement

The outside temperature is acquired with the outside sensor. This can be a QAC22 or

QAC32:

• QAC22: Sensing element LG-Ni 1000

• QAC32: Sensing element NTC 575 at 20 °C

The controller automatically identifies the type of sensor used.

In interconnected plants, the outside temperature signal is made available via LPB.

Controllers having their own sensor pass the outside temperature signal to the data

bus.

DW&

4.3.2 Handling faults

If there is a short-circuit or open-circuit in the measuring circuit, the controller responds

as follows, depending on the outside temperature source:

• Controller not connected to the data bus (LPB):

The control operates with a fixed value of 0 °C outside t emperature. An error message

will be generated

• Controller connected to the data bus (LPB):

If the outside temperature is available via data bus, it will be used. An error message

will not be generated (this is the normal state in interconnected plants!). If there is no

outside temperature available on the data bus, however, the control uses a fixed value

of 0 °C outside temperature. In that case, an error message will be generated.

4.4 Primary return temperature (B7)

4.4.1 Measurement

The primary return temperature is acquired with a sensor having a sensing element LGNi 1000

primary return temperature and for limitation of the temperature differential (DRT limitation).

In interconnected plants, the primary return temperature with plant type 1–x can be

acquired via data bus. Controllers with plant type 1–0 and connected sensor pass the

return temperature signal to the data bus.

7KLVPHDVXUHGYDOXHLVUHTXLUHGIRUPLQLPXPDQGPD[LPXPOLPLWDWLRQRIWKH

4.4.2 Handling faults

If there is a short-circuit or open-circuit in the measuring circuit, and if the controller

requires the return temperature, it responds as follows:

27/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 4 Acquisition of measured values 23.10.2002

Page 28

• If there is a return temperature from a controller of the same segment available on the

data bus, it is used (only with plant type 1–x). No error message will be generated

since this is the normal state in interconnected plants

• However, if there is no return temperature available on the data bus, the return temperature limitation functions will be deactivated and an error message generated

4.5 Secondary return temperature (B71)

4.5.1 Measurement

The secondary return temperature is acquired with a sensor having a sensing element

LG-Ni 1000

6–x), together with the primary return temperature.

7KLVPHDVXUHGYDOXHLVUHTXLUHGIRU'57OLPLWDWLRQSODQWW\SHV±[DQG

4.5.2 Handling faults

If there is a short-circuit or open-circuit in the measuring circuit, and if the controller

requires the return temperature, DRT limitation will be deactivated. An error message

will be generated

4.6 D.h.w. flow temperatu re (B 3)

4.6.1 Measurement

The d.h.w. flow temperature is acquired with a sensor having a sensing element

LG-Ni 1000

4.6.2 Handling faults

If there is a short-circuit or open-circuit in the measuring circuit, the d.h.w. will no longer

be heated. The charging pump is deactivated and the actuating device (slipper or seat

valve) is shut.

An error message will be generated.

4.7 D.h.w. storage tank temperature (B31, B32)

4.7.1 Measurement

The storage tank temperature can be acquired as follows:

• With one or 2 sensors having a sensing element LG-Ni 1000

• With one or 2 thermostats

This means that there are 2 measuring circuits.

RU

4.7.2 Handling faults

The controller's response to faults in the measuring circuits depends on the type of

d.h.w. demand (setting on operating line 126):

• One d.h.w. storage tank temperature sensor (operating line 126 = 0):

In the event of a short-circuit or open-circuit in one of the 2 measuring circuits, the

controller continues to work with the other measuring circuit, if possible. An error message will not be generated.

28/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 4 Acquisition of measured values 23.10.2002

Page 29

If no valid measured value is obtained from either of the measuring circuits, an error

message will be generated. The d.h.w. will no longer be heated and the charging pump

is deactivated.

Exception: With plant type x–2, the d.h.w. storage tank is always charged when sensor

B3 (d.h.w. flow) works normally

• 2 d.h.w. storage tank temperature sensors (operating line 126 = 1):

In the event of a short-circuit or open-circuit in one of the 2 measuring circuits, the

controller continues to work with the other measuring circuit. An error message will be

generated.

If no valid measured value is obtained from either of the measuring circuits, 2 error

messages will be generated. The d.h.w. will no longer be heated and the charging

pump is deactivated.

Exception: With plant type x–2, the d.h.w. storage tank is always charged when sensor

B3 (d.h.w. flow) works normally

• One d.h.w. storage tank thermostat (operating line 126 = 2):

If, in measuring circuit B31, there is neither an open-circuit (thermostat open) nor a

short-circuit (thermostat closed), an error message will be generated. The d.h.w. will no

longer be heated and the charging pump is deactivated.

Exception: With plant type x–2, the d.h.w. storage tank is always charged when sensor

B3 (d.h.w. flow) works normally

• 2 d.h.w. storage tank thermostats (operating line 126 = 3):

If, in the measuring circuits, there is neither an open-circuit (thermostat open) nor a

short-circuit (thermostat closed), an error message will be generated. The controller

will continue to work with the measuring circuit that operates correctly.

If, in both measuring circuits, there is neither an open-circuit (thermostat open) nor a

short-circuit (thermostat closed), 2 error messages will be generated. The d.h.w. will no

longer be heated and the charging pump is deactivated.

Exception: With plant type x–2, the d.h.w. storage tank is always charged when sensor

B3 (d.h.w. flow) works normally

29/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 4 Acquisition of measured values 23.10.2002

Page 30

5 Function block "Enduser space heat-

ing"

This function block contains settings that the enduser himself can make.

5.1 Operating lines

Line Function, par amet er Unit Factory

1 Setpoint of NORMAL heating °C 20.0 0...35

2 Setpoint of REDUCED heating °C 14.0 0...35

3 Setpoint of holiday mode / frost protection °C 10.0 0...35

4 Weekday for th e heating program 1-7 1...7, 1-7

5 1. Third heating period, start of NORMAL heating hh:mm 06:00 --:-- / 00:00...24:00

6 1. Third heat i ng per i od, start of REDUCED heating hh:mm 22:00 --:-- / 00:00...24:00

7 2. Third heating period, start of NORMAL heating hh:mm --:-- --:-- / 00:00...24:00

8 2. Third heat i ng per i od, start of REDUCED heating hh:mm --:-- --:-- / 00:00...24 :00

9 3. Third heating period, start of NORMAL heating hh:mm --:-- --:-- / 00:00...24:00

10 3. Third he at i ng per i od, start of REDUCED heating hh:mm --:-- --:-- / 00:00...24 :00

11 Holiday period 1...8

12 Date of first day of holiday dd:MM --:-- --:-- / 01.01. ... 31.12.

13 Date of last day of holiday dd:MM --:-- --:-- / 01.01. ... 31.12.

14 Heat i ng cu rv e, f low tem pe r at ure s et poin t TV 1 at

an outside temperature of 15 °C

15

Heating cu rv e, flo w tem pe rat ur e set po in t TV2 at

an outside temperature of –5 °C

°C 30 20...70

°C 60 20...120

setting

Range

5.2 Setpoints

5.2.1 General

The setpoints of the NORMAL and the REDUCED room temperature and of frost protection for the plant / holiday mode are entered directly in °C room temperature. They

are independent of whether or not the control uses a room temperature sensor.

Caution

5.2.2 Frost protection for the building

The lowest valid room temperature setpoint always corresponds to at least the setpoint

of holiday mode / frost protection (setting on operating line 3), even if lower values have

been entered as the setpoints of the NORMAL and the REDUCED room temperature

(settings on operating lines 1 and 2).

If a room sensor is used and the room temperature falls below the holiday / frost protection setpoint, ECO – if available – will stop OFF until the room temperature has risen

1 °C above the holiday / frost protection setpoint.

5.3 Heating program

The heating program of the RVL471 provides a maximum of 3 heating periods per day;

also, every weekday may have different heating periods.

The entries to be made are not the switching times, but the periods of time during which

the NORMAL room temperature shall apply. Usually, these periods of time are identical

to the building's occupancy times. The actual switching times for the change from the

REDUCED to the NORMAL room temperature, and vice versa, are calculated by the

optimization function. (Precondition: Optimization is activated).

30/118

Siemens Building Technologies Basic Documentation RVL471 CE1P2524E

HVAC Products 5 Function block "Enduser space heating" 23.10.2002

Page 31

Using the setting "1-7" on operating line 4, it is possible to enter a heating program that

applies to all weekdays. This simplifies the settings: If the weekend times differ, enter

the times for the entire week first, and then change days 6 and 7 as required.

The settings are sorted and overlapping heating periods combined.

5.4 Holiday program

A maximum of 8 holiday periods per year can be programmed. At 00:00 of the first day

of the holiday period, changeover to the setpoint for frost protection / holiday mode

takes place. At 24:00 of the last day of the holiday period, the RVL471 will change to

NORMAL or REDUCED heating in accordance with the time switch settings.

The settings of each holiday period will be cleared as soon as the respective period has

elapsed.

Holiday periods may overlap. It is not necessary to observe a certain order. Depending