CE1P2522E

30.03.2000

Siemens Building Technologies

Landis & Staefa Division

RVL470 and RVL469

Heating Controllers

Basic Documentation

Edition: 2.1

Controller series: B

1996 Siemens Building Technologies Ltd.

S

iemens Building Technologies AG

L

andis & Staefa Division

G

ubelstrasse 22

C

H-6301 Zug

T

el. 041 - 724 11 24

F

ax. 041 - 724 35 22

h

ttp://www.landisstaefa.com

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Contents

TOC-I

Contents

1. Summary.........................................................................................................1

1.1. RVL470 and RVL469.......................................................................................1

1.2. Brief description and key features....................................................................1

1.3. Type summary.................................................................................................1

1.4. Equipment combinations..................................................................................1

1.4.1. Suitable sensors ..............................................................................................1

1.4.2. Suitable room units..........................................................................................2

1.4.3. Suitable actuators............................................................................................2

1.4.4. Communication................................................................................................2

1.4.5. Documentation.................................................................................................2

2. Use..................................................................................................................3

2.1. Types of plant ..................................................................................................3

2.2. Types of buildings............................................................................................3

2.3. Types of heating systems................................................................................3

2.4. Functions .........................................................................................................3

3. Fundamentals.................................................................................................5

3.1. Key technical features......................................................................................5

3.1.1. Plant types with regard to the heating circuit....................................................5

3.1.2. Function blocks................................................................................................5

3.2. Plant types.......................................................................................................5

3.2.1. Plant type 1 – "Space heating with a mixing valve"..........................................5

3.2.2. Plant type 2 – "Space heating with a boiler".....................................................6

3.2.3. Plant type 3 – "Space heating with district heat"..............................................6

3.2.4. Plant type 4 – "Pre-control with a mixing valve"...............................................6

3.2.5. Plant type 5 – "Pre-control with a boiler"..........................................................7

3.2.6. Plant type 6 – "Pre-control with district heat" ...................................................7

3.3. Plant types and function blocks........................................................................7

3.4. Operating modes .............................................................................................8

3.4.1. Automatic mode...............................................................................................8

3.4.2. Continuous REDUCED heating .......................................................................8

3.4.3. Continuous NORMAL heating..........................................................................8

3.4.4. Standby............................................................................................................8

3.4.5. Manual operation.............................................................................................8

3.4.6. Plant type and operating mode........................................................................9

3.5. Operational status and operational level..........................................................9

4. Acquisition of measured values.................................................................10

4.1.1. Room temperature (A6, B5)...........................................................................10

4.1.1.1. Measurement.................................................................................................10

4.1.1.2. Handling of faults...........................................................................................10

4.1.1.3. Room model...................................................................................................10

4.1.2. Flow and boiler temperature (B1)...................................................................10

4.1.2.1. Measurement.................................................................................................10

4.1.2.2. Handling of faults...........................................................................................11

4.1.3. Outside temperature (B9) ..............................................................................11

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

TOC-II

Contents

Landis & Staefa Division

4.1.3.1. Measurement ................................................................................................ 11

4.1.3.2. Handling of faults........................................................................................... 11

4.1.4. Primary return temperature (B7).................................................................... 11

4.1.4.1. Measurement ................................................................................................ 11

4.1.4.2. Handling of faults........................................................................................... 11

4.1.5. Secondary return temperature (B71)............................................................. 12

4.1.5.1. Measurement ................................................................................................ 12

4.1.5.2. Handling of faults........................................................................................... 12

5. Function block "End-user 1"...................................................................... 13

5.1. Operating lines.............................................................................................. 13

5.2. Setpoints....................................................................................................... 13

5.2.1. General ......................................................................................................... 13

5.2.2. Frost protection for the building..................................................................... 13

5.3. Heating program............................................................................................ 13

5.4. Holiday program............................................................................................ 14

6. Function block "End-user 2"...................................................................... 15

6.1. Operating lines.............................................................................................. 15

6.2. Time of day and date..................................................................................... 15

6.3. Indication of faults ......................................................................................... 15

7. Function block "Plant type"....................................................................... 17

7.1. Operating line................................................................................................ 17

7.2. General ......................................................................................................... 17

8. Function block "Space heating"................................................................ 18

8.1. Operating lines.............................................................................................. 18

8.2. ECO function................................................................................................. 18

8.2.1. Compensating variables and auxiliary variables............................................ 18

8.2.2. Heating limits................................................................................................. 19

8.2.3. Mode of operation ......................................................................................... 19

8.2.3.1. Switching the heating off............................................................................... 19

8.2.3.2. Switching the heating on............................................................................... 20

8.2.4. Operating modes and operational statuses................................................... 20

8.3. Room temperature source............................................................................. 20

8.4. Optimization .................................................................................................. 20

8.4.1. Definition and purpose .................................................................................. 20

8.4.2. Fundamentals................................................................................................ 21

8.4.2.1. With a room temperature sensor................................................................... 21

8.4.2.2. Without a room temperature sensor.............................................................. 21

8.4.3. Process......................................................................................................... 21

8.4.4. Room model temperature.............................................................................. 21

8.4.5. Optimum stop control.................................................................................... 22

8.4.6. Quick setback................................................................................................ 22

8.4.7. Optimum start control.................................................................................... 23

8.4.8. Boost heating ................................................................................................ 23

8.5. Room functions ............................................................................................. 24

8.5.1. Maximum limitation of the room temperature ................................................ 24

8.5.2. Room temperature influence......................................................................... 25

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Contents

TOC-III

8.6. Heating curve.................................................................................................25

8.6.1. Purpose .........................................................................................................25

8.6.2. Basic setting...................................................................................................25

8.6.2.1. Settings with the bar ......................................................................................26

8.6.2.2. Settings on operating lines.............................................................................26

8.6.2.3. Selection of setting.........................................................................................26

8.6.3. Deflection.......................................................................................................26

8.6.4. Parallel displacement of heating curve ..........................................................27

8.6.5. Display of setpoints........................................................................................27

8.7. Generation of setpoint....................................................................................28

8.7.1. Weather-compensated control.......................................................................28

8.7.2. Demand-compensated control.......................................................................28

9. Function block "Three-position actuator heating circuit"..........................29

9.1. Operating lines...............................................................................................29

9.2. Limitations......................................................................................................29

9.2.1. Limitations of the flow temperature................................................................29

9.2.2. Setpoint increase...........................................................................................29

9.3. Three-position control....................................................................................30

9.4. Excess mixing valve temperature ..................................................................30

9.5. Locking of pulses...........................................................................................30

10. Function block "Boiler"...............................................................................31

10.1. Operating lines...............................................................................................31

10.2. Operating mode.............................................................................................31

10.3. Limitations......................................................................................................31

10.3.1. Maximum limitation of the boiler temperature ................................................31

10.3.2. Minimum limitation of the boiler return temperature.......................................32

10.4. Two-position control.......................................................................................32

10.4.1. Control with a single-stage burner .................................................................32

10.4.2. Control with a two-stage burner.....................................................................33

10.4.2.1. Setting parameters.........................................................................................33

10.4.2.2. Control 33

10.4.3. Frost protection for the boiler......................................................................... 34

10.4.4. Protective boiler startup.................................................................................34

10.4.5. Protection against boiler overtemperatures....................................................35

10.5. Operating mode of pump M1 .........................................................................36

11. Function block "Setpoint of return temperature limitation" ....................37

11.1. Operating line.................................................................................................37

11.2. Description.....................................................................................................37

11.3. Minimum limitation of the return temperature.................................................37

11.3.1. Acquisition of the measured values ...............................................................37

11.3.2. Mode of operation..........................................................................................37

11.3.3. Mode of operation with a single unit (with no bus).........................................38

11.3.4. Mode of operation in interconnected plants ...................................................38

11.3.4.1. Central impact of limitation.............................................................................38

11.3.4.2. Local impact of limitation................................................................................ 38

12. Function block "District heat" ....................................................................39

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

TOC-IV

Contents

Landis & Staefa Division

12.1. Operating lines.............................................................................................. 39

12.2. Limitations..................................................................................................... 39

12.2.1. Secondary flow temperature.......................................................................... 39

12.2.2. Maximum limitation of primary return temperature........................................ 39

12.2.2.1. Purpose39

12.2.2.2. Generation of maximum limit value............................................................... 39

12.2.2.3. Function40

12.2.3. Maximum limitation of the return temperature differential (DRT limitation).... 40

12.2.3.1. Function40

12.2.3.2. Purpose40

12.2.4. Integral action time........................................................................................ 41

12.2.5. Minimum limitation of stroke (suppression of hydraulic creep)...................... 41

12.2.6. Flow limitation................................................................................................ 41

13. Function block "Service functions and general settings"....................... 42

13.1. Operating lines.............................................................................................. 42

13.2. Display functions........................................................................................... 43

13.2.1. Flow temperature setpoint............................................................................. 43

13.2.2. Heating curve................................................................................................ 44

13.3. Commissioning aids...................................................................................... 44

13.3.1. Simulation of outside temperature................................................................. 44

13.3.2. Relay test...................................................................................................... 45

13.3.3. Sensor test.................................................................................................... 45

13.3.4. Test of H-contacts......................................................................................... 46

13.4. Auxiliary functions ......................................................................................... 46

13.4.1. Frost protection for the plant ......................................................................... 46

13.4.2. Flow alarm..................................................................................................... 46

13.4.3. Manual overriding of operating mode (contact H1)........................................ 47

13.4.4. Pump overrun................................................................................................ 47

13.4.5. Pump kick...................................................................................................... 48

13.4.6. Winter- / summertime changeover ................................................................ 48

13.4.7. Gain of locking signal.................................................................................... 48

13.4.7.1. Fundamentals................................................................................................48

13.4.7.2. Uncritical locking signals............................................................................... 48

13.4.7.3. Critical locking signals................................................................................... 48

13.5. Entries for LPB.............................................................................................. 49

13.5.1. Source of time of day .................................................................................... 49

13.5.2. Source of outside temperature...................................................................... 50

13.5.3. Addressing of devices................................................................................... 50

13.5.4. Bus power supply.......................................................................................... 51

13.5.5. Bus loading characteristic ............................................................................. 51

14. Function block "Contact H2" ..................................................................... 52

14.1. Operating line................................................................................................ 52

14.2. Description .................................................................................................... 52

15. Function block "External inputs" .............................................................. 53

15.1. Operating lines.............................................................................................. 53

15.2. Contact H2.................................................................................................... 53

15.3. Hours run counter.......................................................................................... 53

15.4. Software version............................................................................................ 53

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Contents

TOC-V

15.5. Identification number of room unit..................................................................53

15.6. Radio clock, elapsed time since last reception...............................................53

16. Function block "Locking functions"..........................................................54

16.1. Operating line.................................................................................................54

16.2. Locking the settings on the software side ......................................................54

16.3. Locking the settings for district heat on the hardware side ............................54

17. Communication............................................................................................55

17.1. Combination with room units..........................................................................55

17.1.1. General..........................................................................................................55

17.1.2. Combination with room unit QAW50..............................................................55

17.1.2.1. Overriding the operating mode.......................................................................55

17.1.2.2. Setting knob for room temperature readjustments.........................................55

17.1.3. Combination with room unit QAW70..............................................................55

17.1.3.1. Overriding the operating mode.......................................................................56

17.1.3.2. Setting knob for room temperature readjustments.........................................56

17.1.3.3. Effect of the individual QAW70 operating lines on the RVL470.....................56

17.1.3.4. Overriding the QAW70 entries from the RVL470...........................................57

17.1.4. Combination with SYNERGYR central unit OZW30.......................................57

17.2. Communication with other devices ................................................................57

18. RVL469..........................................................................................................58

18.1. Features and function....................................................................................58

18.2. Technical design............................................................................................58

18.2.1. Type of plant.................................................................................................. 58

18.2.2. Operation with a partner ................................................................................58

18.2.3. Handling errors ..............................................................................................59

18.2.3.1. Wrong addressing..........................................................................................59

18.2.3.2. Missing or wrong partner ...............................................................................59

18.2.4. Passive mode ................................................................................................59

19. Handling .......................................................................................................60

19.1. Operation.......................................................................................................60

19.1.1. General..........................................................................................................60

19.1.1.1. Operating elements........................................................................................60

19.1.1.2. Display 61

19.1.1.3. Operating instructions....................................................................................61

19.1.2. Analog operating elements ............................................................................61

19.1.2.1. Buttons and displays for selecting the operating mode..................................61

19.1.2.2. Heating curve.................................................................................................61

19.1.2.3. Setting knob for room temperature readjustments.........................................61

19.1.2.4. Buttons and displays for manual operation....................................................61

19.1.2.5. Display of positioning commands...................................................................62

19.1.2.6. Display "Heating operates"............................................................................62

19.1.3. Digital operating elements..............................................................................62

19.1.3.1. Operating line principle..................................................................................62

19.1.3.2. Buttons 62

19.1.3.3. Block skip function .........................................................................................62

19.1.3.4. Info button...................................................................................................... 63

19.1.4. Setting levels and access rights.....................................................................63

19.1.4.1. Setting levels..................................................................................................63

19.1.4.2. Access rights..................................................................................................63

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

TOC-VI

Contents

Landis & Staefa Division

19.2. Commissioning.............................................................................................. 63

19.2.1. Installation instructions.................................................................................. 63

19.2.2. Operating lines.............................................................................................. 63

19.2.2.1. Setting the operating line "Plant type" ........................................................... 63

19.2.2.2. Setting the other operating lines.................................................................... 64

19.2.2.3. Operating lines for functional checks............................................................. 64

19.3. Installation..................................................................................................... 64

19.3.1. Location......................................................................................................... 64

19.3.2. Mounting choices .......................................................................................... 64

19.3.3. Wiring............................................................................................................ 64

20. Engineering ................................................................................................. 65

20.1. Connection terminals..................................................................................... 65

20.1.1. Low voltage side............................................................................................ 65

20.1.2. Mains voltage side......................................................................................... 65

20.2. Connection diagrams .................................................................................... 66

20.2.1. Basic connections on the low voltage side.................................................... 66

20.2.2. Basic connections on the mains voltage side................................................ 66

21. Mechanical design ...................................................................................... 67

21.1. Basic design.................................................................................................. 67

21.2. Dimensions.................................................................................................... 67

22. Technical data ............................................................................................. 68

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Summary

1/68

1. Summary

1.1. RVL470 and RVL469

This Basic Documentation covers two types of heating controllers, the RVL470 and the

RVL469. The RVL470 is described in every detail, not so the RVL469.

The RVL469 contains functions of the RVL470 and is therefore integrated in the present

Basic Documentation. But only the section “RVL469” refers to the specific functionality

of the RVL469 (functions that differ from those of the RVL470). In all the other chapters

and sections, the RVL469 will not be specifically mentioned.

1.2. Brief description and key features

•

The RVL470 is a multi-functional heating controller for use in residential and nonresidential buildings. It is suited for weather-compensated flow temperature control of

heating zones with or without room temperature influence or for demand-compensated control of heat generating equipment (pre-control)

•

It is used in plants with own heat generating equipment or with a district heat connection

•

The RVL470 is capable of communicating with other units via LPB (Local Process

Bus)

•

The RVL470 has 6 types of plants pre-programmed. When a certain plant type is selected, all functions and settings required for that particular plant will be activated

•

For the direct setting of the heating curve, the proven bar is used, but digital adjustment of the heating curve is also possible. For readjustment of the room temperature,

a setting knob is used (L&S standard)

•

All other parameters are set digitally using the operating line principle (L&S standard)

•

Operating voltage AC 230 V, CE conformity, overall dimensions to DIN 43700

(144

*

144 mm)

1.3. Type summary

The

RVL470

is a compact controller requiring no plug-in modules or cards.

1.4. Equipment combinations

1.4.1. Suitable sensors

•

For water temperatures:

Suitable are all types of temperature sensors that use a sensing element LGNi 1000 Ω at 0 °C. The following types are presently available:

–

Clamp-on temperature sensor QAD22

–

Immersion temperature sensor QAE22...

–

Immersion temperature sensor QAP21.3 with integrated connecting cable

•

For the room temperature:

Suitable are all types of temperature sensors that use a sensing element LGNi 1000 Ω at 0 °C. The following type is presently available:

–

Room temperature sensor QAA24

•

For the outside temperature:

–

Outside sensor QAC22 (sensing element LG-Ni 1000 Ω at 0 °C)

–

Outside sensor QAC32 (sensing element NTC 575 Ω at 20 °C)

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

2/68

Summary

Landis & Staefa Division

1.4.2. Suitable room units

•

Room unit QAW50

•

Room unit QAW70

1.4.3. Suitable actuators

All Landis & Staefa actuators with the following features can be used:

•

Electric or electro-hydraulic actuators with a running time of 0.5 to 14.5 minutes

•

Suitable for three-position control

•

Operating voltage AC 24 V ... AC 230 V

1.4.4. Communication

Communication is possible with the following types of units:

•

All controllers made by Landis & Staefa with LPB communication capability

•

SYNERGYR central unit OZW30 (software version 3.0 or higher)

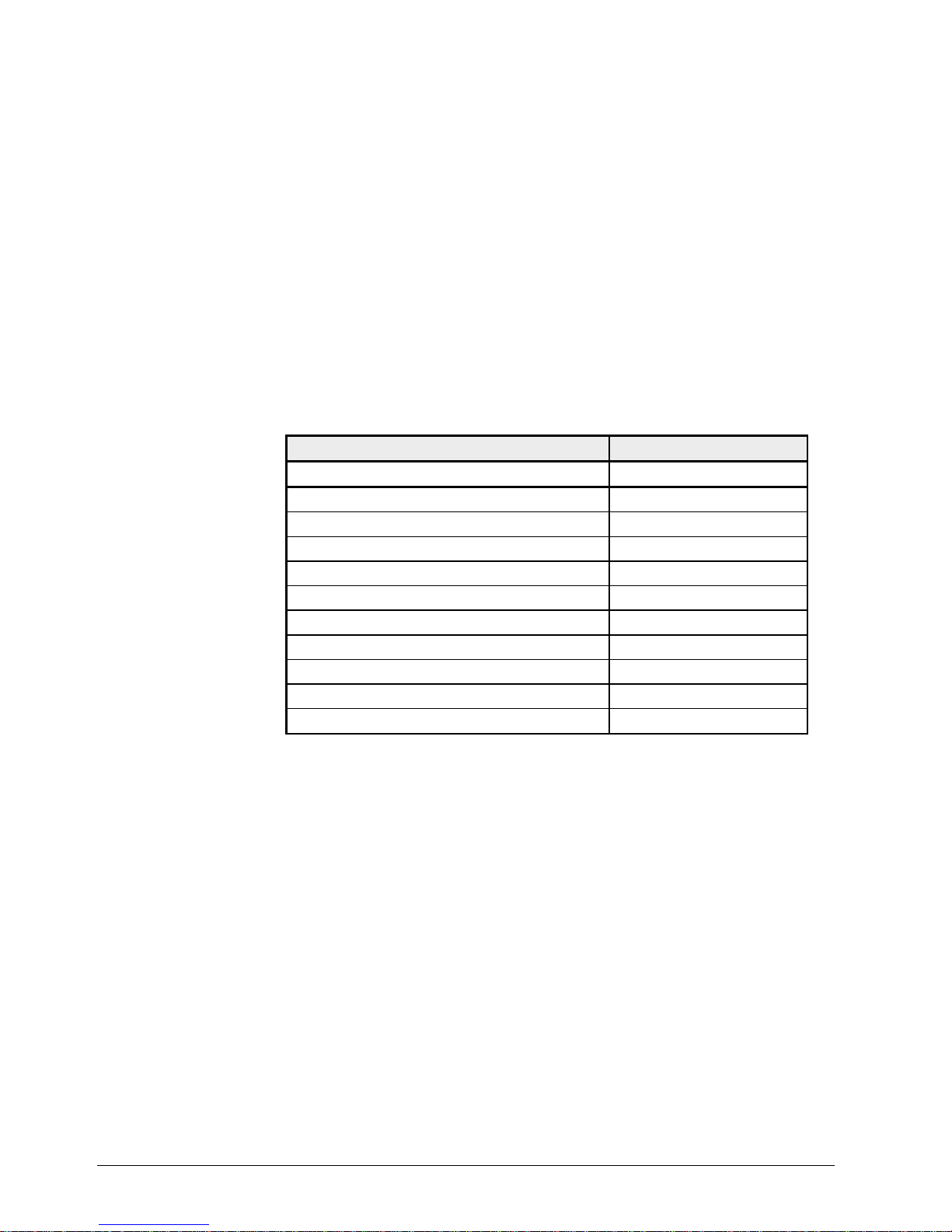

1.4.5. Documentation

Type of documentation Ordering number (for English)

Data sheet RVL470 CE1N2522E

Data sheet RVL469 CE1N2527E

Operating Instructions RVL470 4 319 2634 0

Operating Instructions RVL469 74 319 0008 0

Installation Instructions RVL470 4 319 2643 0

Installation Instructions RVL469 74 319 0017 0

Data sheet QAW50 CE2N1635E

Data sheet QAW70 CE2N1637E

Data sheet "LPB Basic System Data" CE1N2030E

Data sheet "LPB Basic Engineering Data" CE1N2032E

Basic documentation "LPB System engineering“ CE1P2370E

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Use

3/68

2. Use

2.1. Types of plant

Basically, the RVL470 is suitable for all types of heating plants that use weathercompensated flow temperature control. In addition, it can be used for demandcompensated control of the main flow. Examples:

•

Heating zones with own heat generation

•

Heating zones with a direct or indirect district heat connection

•

Main groups with own heat generation

•

Main groups with a direct or indirect district heat connection

•

Large plants comprising heat generation and several heating zones

2.2. Types of buildings

Basically, the RVL470 is suitable for all types of buildings that use weathercompensated heating control, but is designed specifically for use in:

•

Multi-family houses

•

Single-family houses

•

Small to medium-size non-residential buildings

2.3. Types of heating systems

The RVL470 is suitable for use with all standard heating systems, such as:

•

Radiators

•

Convectors

•

Underfloor heating systems

•

Ceiling heating systems

•

Radiant panels

2.4. Functions

The RVL470 is used if one or several of the following functions is / are required:

•

Weather-compensated flow temperature control

•

Flow temperature control through a modulating seat or slipper valve, or boiler temperature control through direct control of a single- or two-stage burner

•

Optimum start / stop control according to the selected weekly program

•

Quick setback and boost heating according to the selected weekly program

•

ECO function: demand-dependent switching of the heating system based on the type

of building construction and the outside temperature

•

Weekly program for building occupancy with a maximum of three setback periods per

day and daily varying occupancy schedules

•

Entry of eight holiday periods per year

•

Automatic summer- / wintertime changeover

•

Display of parameters, actual values, operational statuses and fault status signals

•

Communication with other units via the LPB

•

Remote operation with the help of a room unit and external switches

•

Service functions

•

Frost protection for the plant, the boiler and the building

•

Minimum or maximum limitation of return temperature

•

DRT limitation (limitation of the temperature differential)

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

4/68

Use

Landis & Staefa Division

•

Minimum and maximum limitation of flow temperature

•

Maximum limitation of room temperature

•

Periodic pump run

•

Pump overrun

•

Maximum limitation of the rate of setpoint increase

•

Flow alarm

For application examples, refer to section "3. Fundamentals".

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Fundamentals

5/68

3. Fundamentals

3.1. Key technical features

The RVL470 offers two key technical features:

•

The controller has six plant types preprogrammed

•

The settings are combined in the form of function blocks

3.1.1. Plant types with regard to the heating circuit

In terms of the heating circuit, the following plant types are available:

•

Plant type 1 – "Space heating with a mixing valve"

•

Plant type 2 – "Space heating with a boiler"

•

Plant type 3 – "Space heating with district heat"

•

Plant type 4 – "Pre-control with a mixing valve"

•

Plant type 5 – "Pre-control with a boiler"

•

Plant type 6 – "Pre-control with district heat"

3.1.2. Function blocks

The following function blocks are available:

•

Function block "End-user 1"

•

Function block "End-user 2"

•

Function block "Plant type"

•

Function block "Space heating"

•

Function block "Three-position actuator for heating circuit"

•

Function block "Boiler"

•

Function block "Setpoint of return temperature limitation"

•

Function block "Settings for plant type 3"

•

Function block "Service functions and general settings"

•

Function block "Contact H2"

•

Function block "Contact H2 and general displays"

•

Function block “Locking functions”

For each function block, the required settings are available in the form of operating

lines. A description of the individual functions is given below, for each function block and

line.

3.2. Plant types

The RVL470 has six types of plant ready programmed, whereby the functions are assigned to each type of plant, as required. When commissioning a plant, the respective

plant type must be selected.

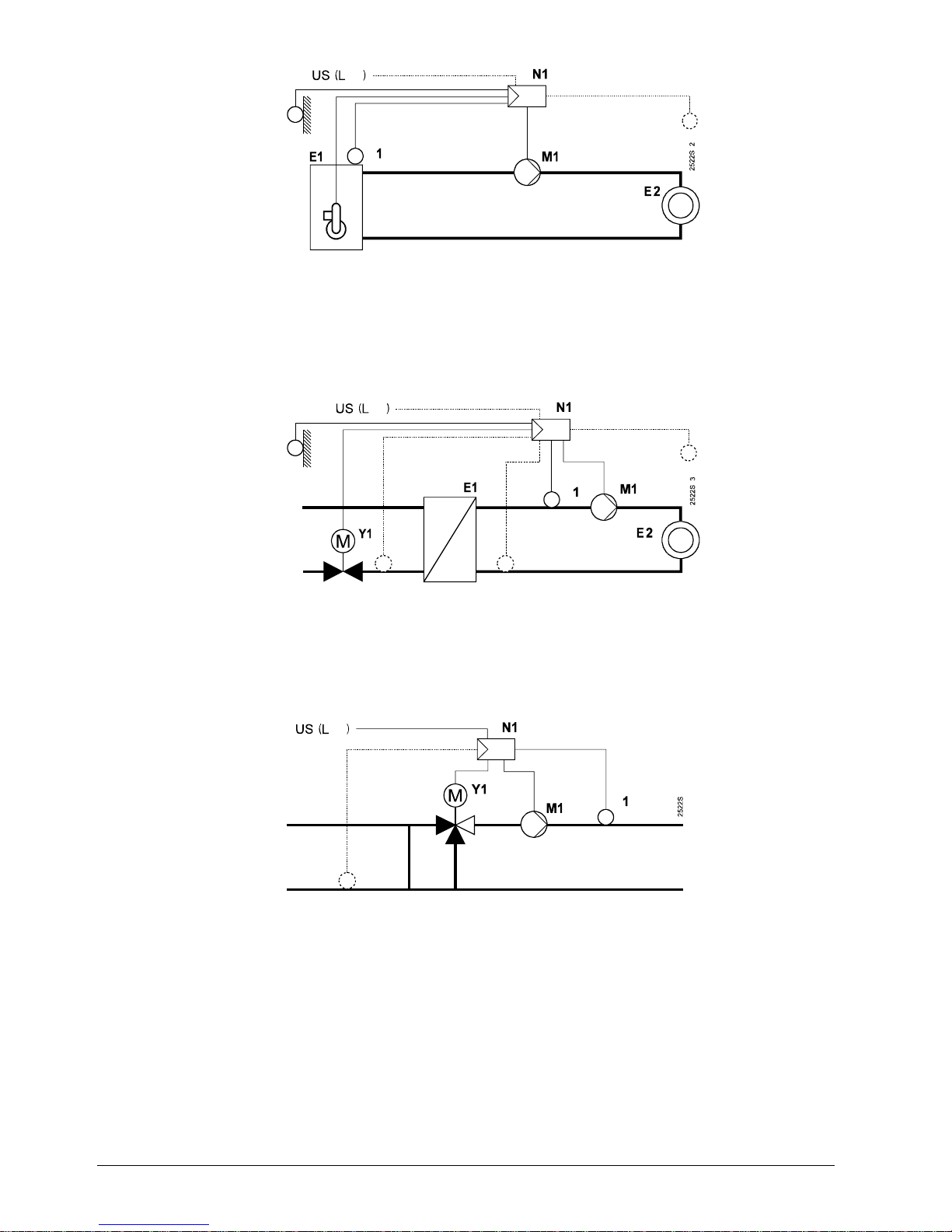

3.2.1. Plant type 1 – "Space heating with a mixing valve"

B9

A6/B5

B7

Space heating with weather-compensated flow temperature control. Three-position

control through the heating zone's mixing valve. Outside temperature signal from own

outside sensor or data bus. With or without room temperature influence. Heating-up and

setback according to the heating program.

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

6/68

Fundamentals

Landis & Staefa Division

3.2.2. Plant type 2 – "Space heating with a boiler"

B9

A6/B5

Space heating with own boiler, with weather-compensated boiler temperature control.

Two-position control through a burner.

Outside temperature signal from own outside sensor or data bus. With or without room

temperature influence. Heating-up and setback according to the heating program.

3.2.3. Plant type 3 – "Space heating with district heat"

B9

A6/B5

B7 B71

Space heating with a district heat connection, with weather-compensated flow temperature control through the valve in the primary return of the district heat connection.

Outside temperature signal from own outside sensor or data bus. With or without room

temperature influence. Heating-up and setback according to the heating program.

3.2.4. Plant type 4 – "Pre-control with a mixing valve"

B7

Pre-control with demand-compensated control of the main flow temperature. Threeposition control through the mixing valve in the main flow.

Heat demand signal from the data bus. No heating program.

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Fundamentals

7/68

3.2.5. Plant type 5 – "Pre-control with a boiler"

B7

Pre-control with demand-compensated boiler temperature control. Two-position control

through the burner.

Heat demand signal from the data bus. No heating program.

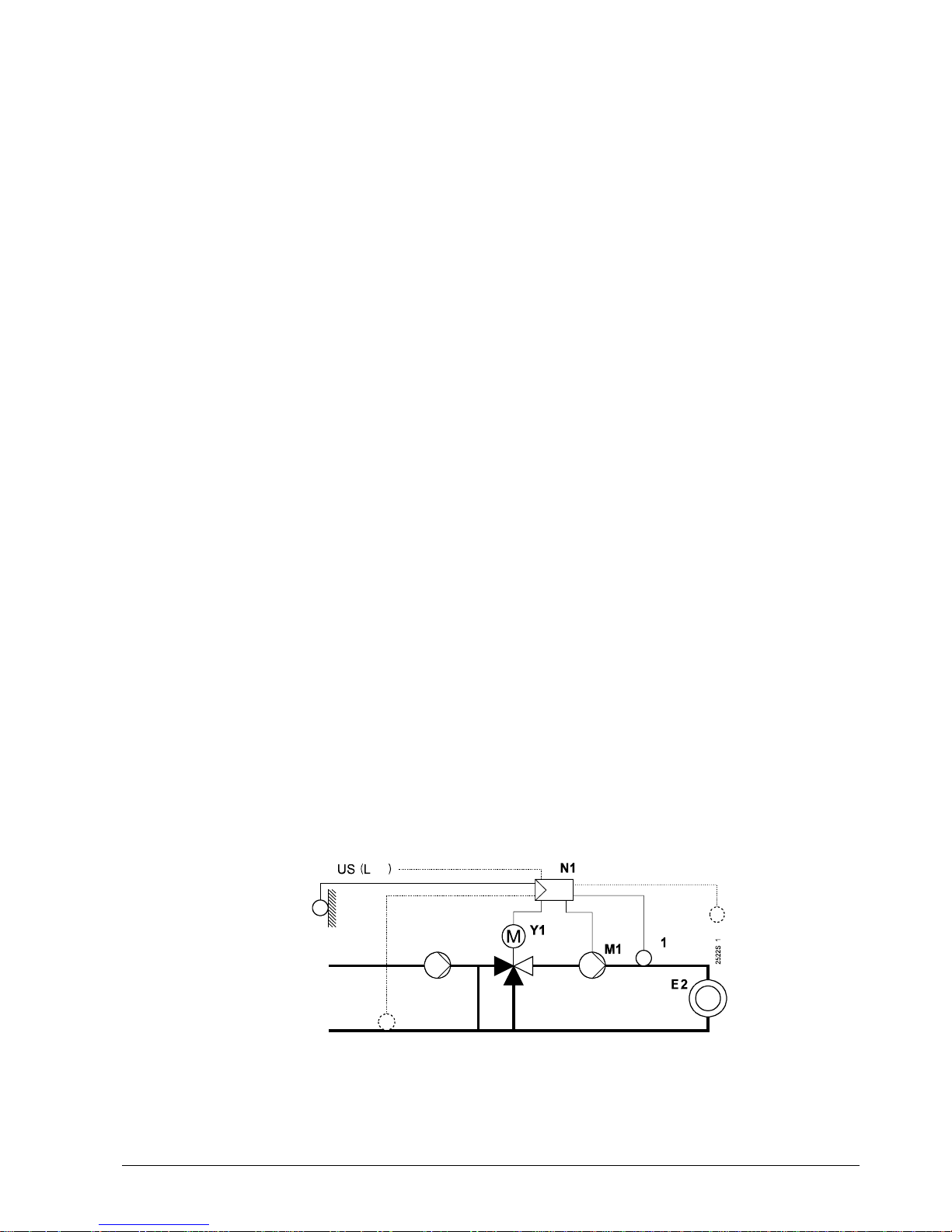

3.2.6. Plant type 6 – "Pre-control with district heat"

B7 B71

2522S06

Pre-control with a district heat connection, with demand-compensated control of the

secondary flow temperature through the valve in the primary return.

Heat demand signal from the data bus. No heating program.

A6 Room unit QAW50 or QAW70 E1 Heat generating equipment

B1 Flow / boiler temperature sensor (boiler / heat exchanger)

B5 Room temperature sensor E2 Load (space)

B7 Return temperature sensor (primary circuit) LPB Data bus

B71 Return temperature sensor (secondary circuit) M1 Heating circuit pump/circulating pump

B9 Outside sensor N1 Controller RVL470

Y1 Heating circuit mixing valve

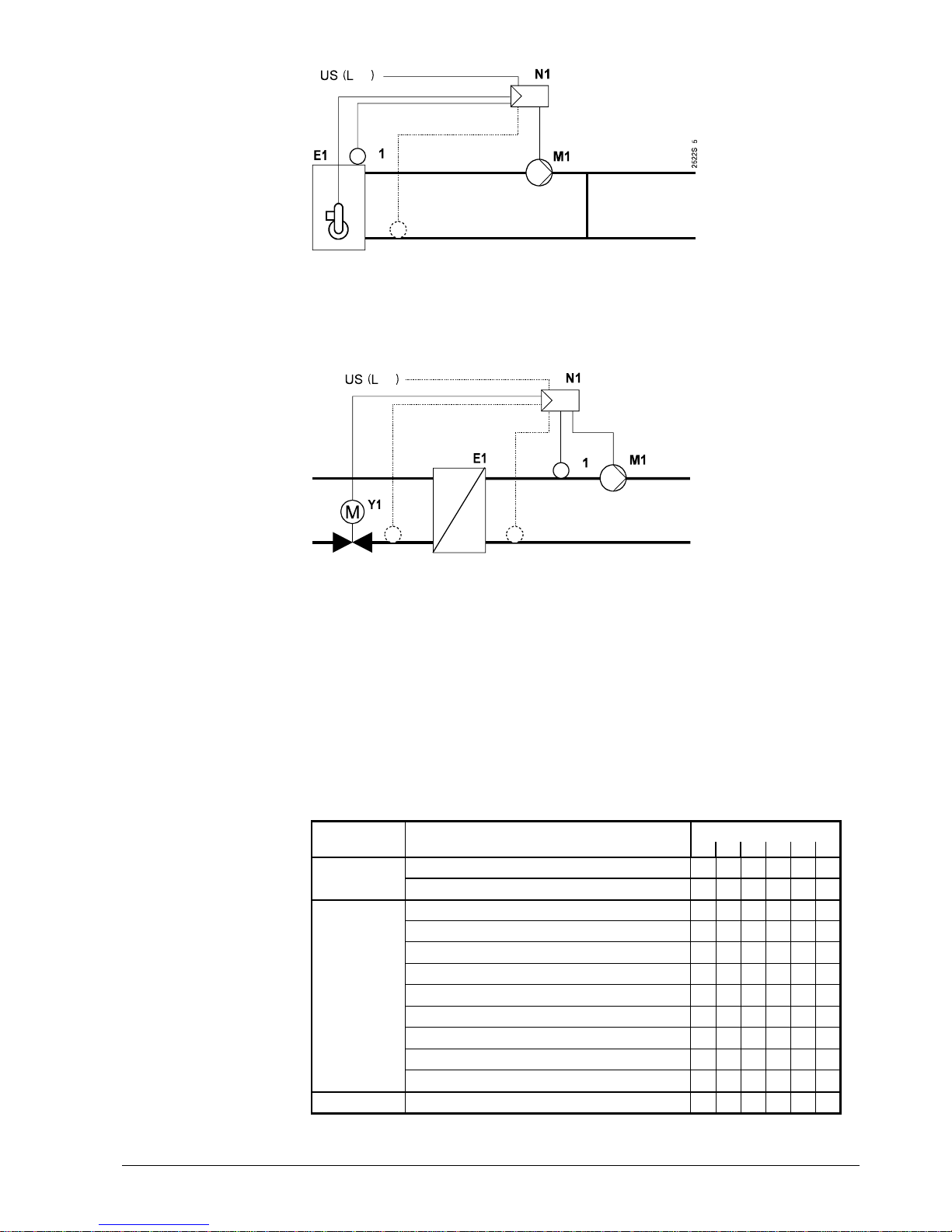

3.3. Plant types and function blocks

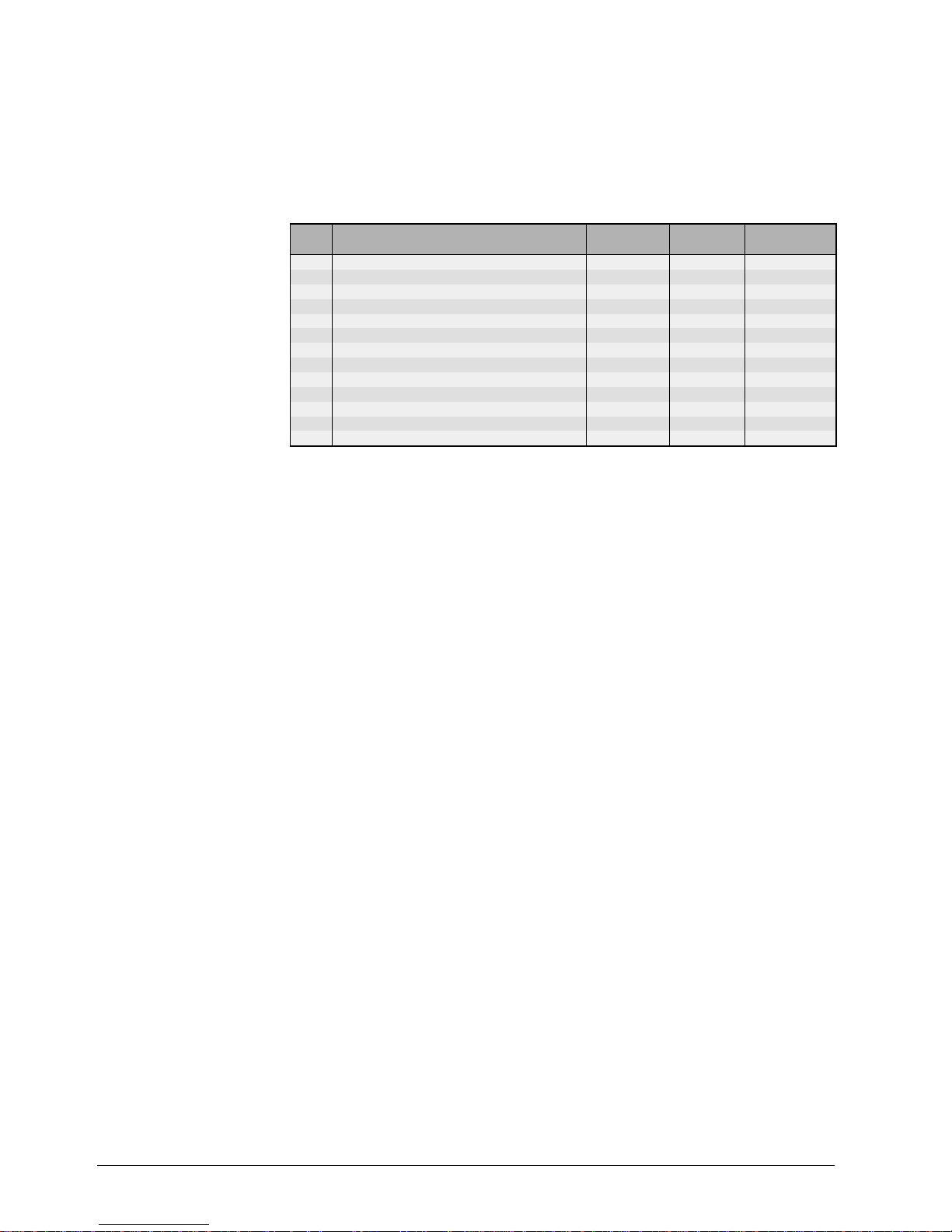

Plant typeLevel Function block

123456

End-user 1

zzz

End-user

level

End-user 2

zzzzzz

Plant type

zzzzzz

Space heating

zzz

Three-position actuator for heating circuit

zzzz

Boiler

zz

Setpoint of return temperature limitation

z zzzz

Settings for plant type 3

zz

Service functions and general settings

zzzzzz

Contact H2

zzzz

Heating engineer level

Contact H2 and general displays

zzzzzz

Locking level Locking functions

zzzzzz

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

8/68

Fundamentals

Landis & Staefa Division

The block diagram shows

•

the function blocks assigned to the three operational levels

•

the function blocks activated with the different plant types

3.4. Operating modes

The operating mode is selected on the controller by pressing the respective button.

Also, the operating mode can be changed by bridging terminals H1–M.

3.4.1. Automatic mode

•

Automatic changeover from NORMAL to REDUCED temperature, and vice versa,

according to the entered weekly program

•

Automatic changeover to holiday mode, and back, according to the entered holiday

schedule

•

Demand-dependent switching of the heating system in function of the room and outside temperature while giving consideration to the building's thermal inertia (ECO

function)

•

Remote operation from a room unit (optional)

•

Frost protection is assured

3.4.2. Continuous REDUCED heating

•

Continuous heating to the REDUCED temperature

•

With ECO function

•

No holiday mode

•

Remote operation from a room unit not possible

•

Frost protection is assured

3.4.3. Continuous NORMAL heating

•

Continuous heating to NORMAL temperature

•

No ECO function

•

No holiday mode

•

Remote operation from a room unit not possible

•

Frost protection is assured

3.4.4. Standby

•

Heating is switched off, but is ready to operate

•

Frost protection is assured

3.4.5. Manual operation

The RVL470 can be switched to manual operation. In that case, the control will be

switched off.

In manual operation, the various regulating units behave as follows:

•

Heating circuit slipper valve / seat valve: this mixing valve is not under voltage, but

can be manually driven to any position by pressing the manual buttons

( = clos-

ing,

= opening).

The heating circuit pump/circulating pump M1 is continuously running.

•

Boiler: the two burner stages are continuously on. The manual button can be used

to switch the second stage on and off.

The heating circuit pump/circulating pump M1 is continuously running.

Manual operation also negates any overriding of the controller's operating mode (bridging H1–M).

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Fundamentals

9/68

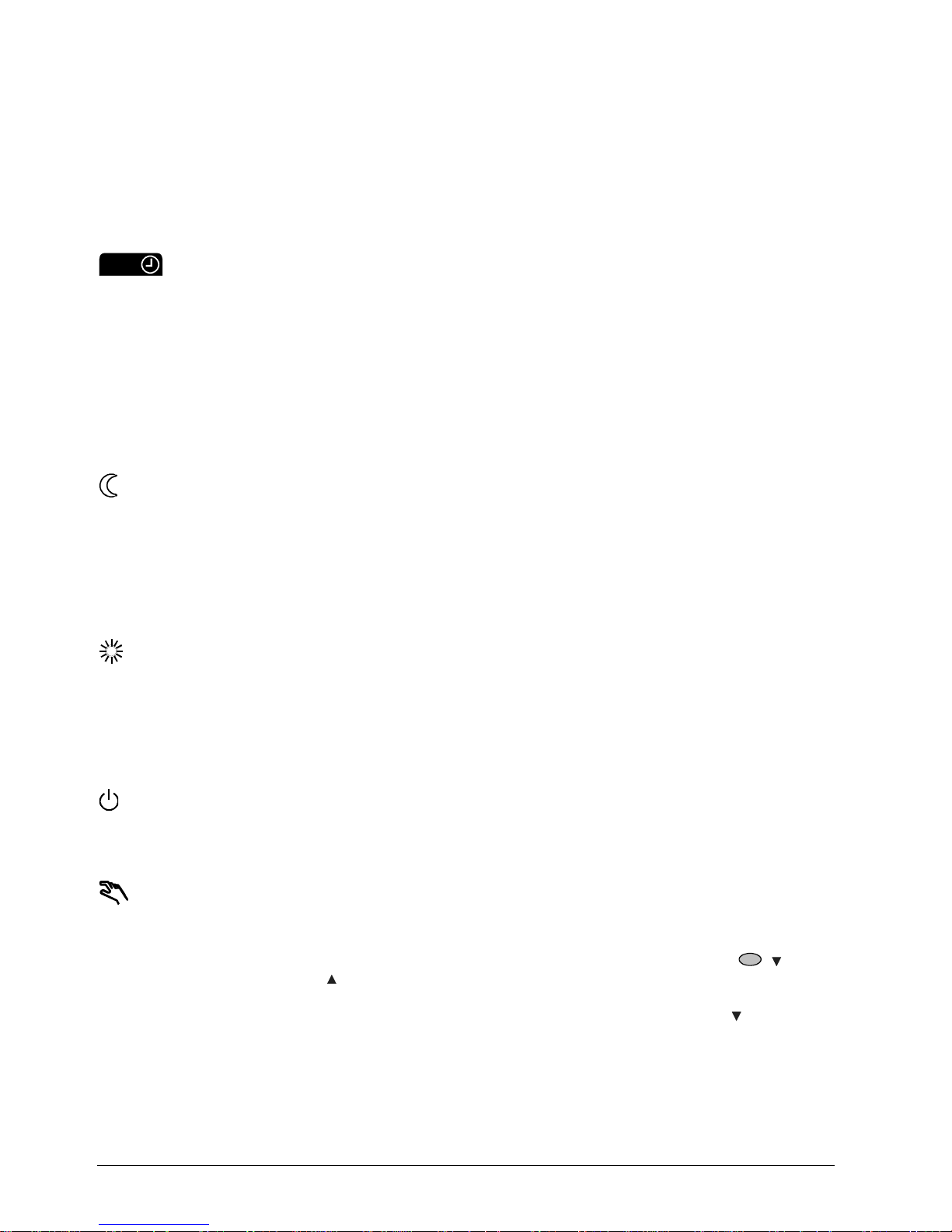

3.4.6. Plant type and operating mode

Depending on the type of plant selected, the following operating modes are available:

Plant type

1 YES YES YES YES YES

2 YES YES YES YES YES

3 YES YES YES YES YES

4 YES NO NO NO YES

5 YES NO NO *) YES

6 YES NO NO NO YES

*) Depending on the boiler's operating mode:

Boiler with automatic shutdown: NO

Boiler without manual shutdown: YES

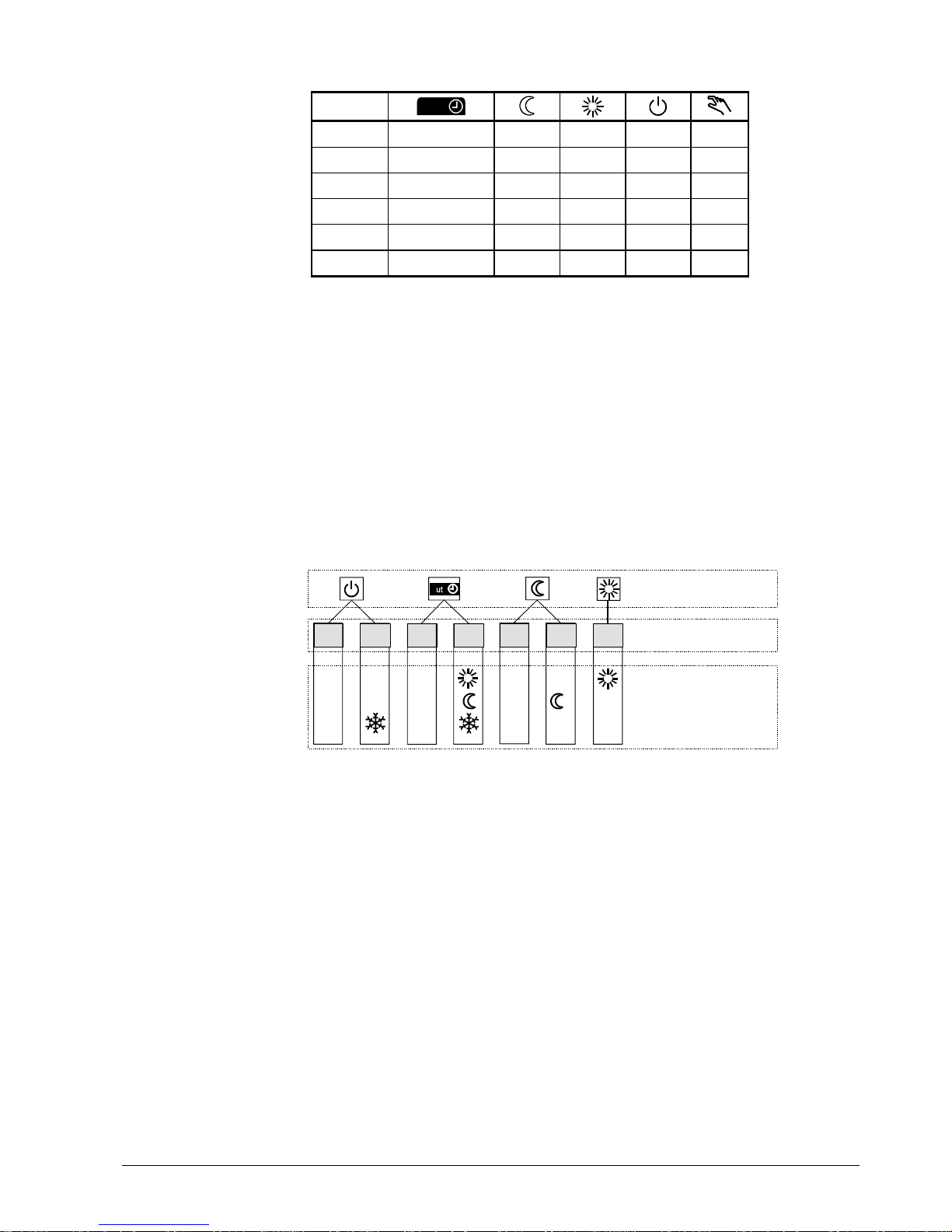

3.5. Operational status and operational level

The user selects the required operating mode by pressing the respective button. Each

operating mode has a maximum of two operational statuses – with the exception of operating mode "Continuously NORMAL heating" (only one operational status possible).

When the ECO function is activated and in the case of quick setback, the operational

status is always OFF.

When the operational status is ON, there is a maximum of three operational levels, depending on the operating mode. The operational level is determined by the heating program and the holiday program.

OFF

ON

OFF

ON

OFF ON

ON

Opera t i ng mode

Operationa l statu s

Operat ional level

2522B03e

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

10/68

Acquisition of measured values

Landis & Staefa Division

4. Acquisition of measured values

4.1.1. Room temperature (A6, B5)

4.1.1.1. Measurement

The following choices exist:

•

A room temperature sensor QAA24 can be connected to terminal B5

•

A room unit QAW50 or QAW70 can be connected to terminal A6

•

A unit can be connected to each of the two terminals. In that case, the RVL470 can ascer-

tain the average of the two measurements.

The other room unit functions will not be affected by averaging

4.1.1.2. Handling of faults

If there is a short-circuit or an interruption in one of the two measuring circuits, the control will respond as follows:

•

No sensor (operating line 65 = 0):

A short-circuit or open-circuit has no impact on the control. A fault status message will

not be generated

•

Room unit sensor QAW... (operating line 65 = 1):

In the event of a short-circuit or open-circuit, the control continues to operate depending on the function of the room model. A fault status message will be generated

•

Room temperature sensor QAA24 (operating line 65 = 2):

In the event of a short-circuit or open-circuit, the control continues to operate depending on the function of the room model. A fault status message will be generated

•

Average value (operating line 65 = 3):

In the event of a short-circuit or open-circuit in one of the two measuring circuits, the

control continues to operate with the normally working measuring circuit. A fault

status message will be generated.

In the case of a short-circuit or open-circuit in both measuring circuits, the control

continues to operate depending on the function of the room model. Two fault status

messages will be generated

•

Automatic mode (operating line 65 = A):

Since the controller itself decides how it acquires the room temperature, no fault

status messages can be generated

4.1.1.3. Room model

The RVL470 features a room model which simulates the development of the room temperature. In plants with no measurement of the room temperature, it can provide certain

room functions (e.g. quick setback).

For more details, refer to section "8.4.4. Room model temperature".

4.1.2. Flow and boiler temperature (B1)

4.1.2.1. Measurement

The flow or boiler temperature is acquired with one or two sensors. Two sensors connected in parallel are used to ascertain the average value. The temperature sensors

used must always have a sensing element LG-Ni 1000 Ω.

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Acquisition of measured values

11/68

4.1.2.2. Handling of faults

A short-circuit or interruption in the measuring circuit is identified and displayed as a

fault. In that case, the plant will respond as follows:

•

Plants with mixing valve control:

The heating circuit pump/circulating pump M1 continues to run and the mixing valve

will close

•

Plants with boiler control:

The heating circuit pump/circulating pump M1 continues to run and the burner will

shut down

4.1.3. Outside temperature (B9)

4.1.3.1. Measurement

The outside temperature is acquired by the outside sensor, which may be a QAC22 or

QAC32:

QAC22: sensing element LG-Ni 1000 Ω at 0 °C

QAC32: sensing element NTC 575 Ω at 20 °C

The controller automatically identifies the type of sensor used. In interconnected plants,

the outside temperature signal is made available via LPB. Controllers having their own

sensor pass the outside temperature signal to the data bus.

4.1.3.2. Handling of faults

If there is a short-circuit or an interruption in the measuring circuit, the control will respond as follows:

•

In the event of a short-circuit:

If an outside temperature is made available via LPB, it is used. If none is available, the

control uses a fixed value of 0 °C outside temperature. A fault status signal is always

generated

•

In the event of an interruption:

If the controller requires an outside temperature and it is made available via LPB, it is

used. There will be no fault status signal in that case (this is the usual status in interconnected plants!). If, however, there is no outside temperature made available via

LPB, the control uses a fixed value of 0 °C. In that case, a fault status signal will be

delivered

4.1.4. Primary return temperature (B7)

4.1.4.1. Measurement

The primary return temperature is acquired with a sensor having a sensing element LGNi 1000 Ω at 0 °C. This measured value is required for minimum and maximum limitation of the primary return temperature and for limitation of the temperature differential

(DRT limitation).

In interconnected plants, the primary return temperature with plant type 1 can be acquired via the data bus. Controllers with plant type 1 and connected sensor pass the

primary return temperature signal to the data bus.

4.1.4.2. Handling of faults

If there is a short-circuit or an interruption in the measuring circuits, the control will respond as follows:

•

If, on the data bus, there is a return temperature from a controller of the same segment available, it is used (only with plant type no. 1). No fault status message will be

generated since this is the normal status in inconnected plants

•

If, on the data bus, there is no return temperature available, the return temperature

limitation functions will be deactivated and a fault status message generated

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

12/68

Acquisition of measured values

Landis & Staefa Division

4.1.5. Secondary return temperature (B71)

4.1.5.1. Measurement

The secondary return temperature is acquired with a sensor having a sensing element

LG-Ni 1000 Ω at 0 °C. This measured value is required for limitation of the temperature

differential (DRT limitation) (plant types 3 and 6), together with the primary return temperature.

4.1.5.2. Handling of faults

If there is a short-circuit or open-circuit in the measuring circuit, and if the controller requires the return temperature, DRT limitation will be deactivated and a fault status message generated.

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Function block "End-user 1"

13/68

5. Function block "End-user 1"

This function block contains settings that the end-user himself can make.

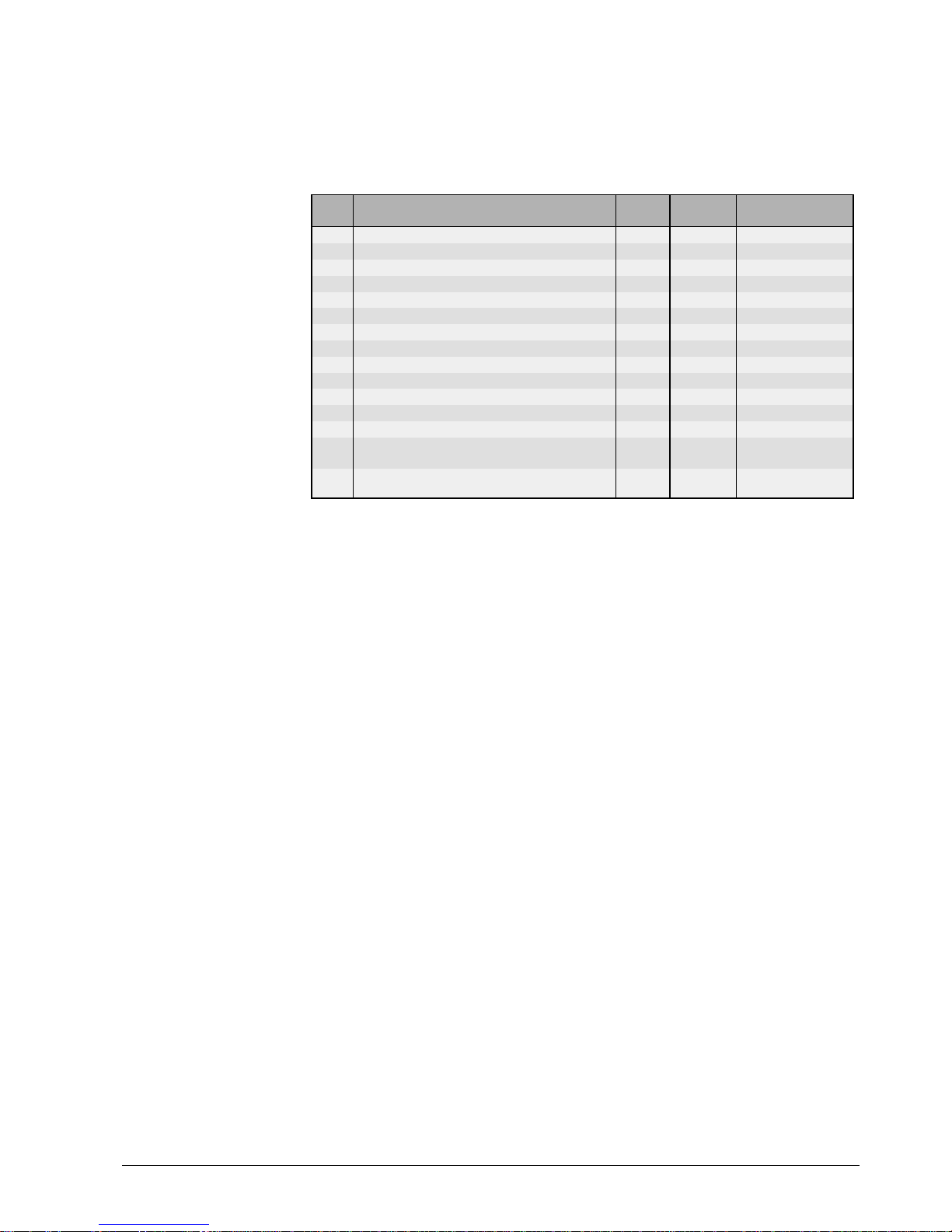

5.1. Operating lines

Line Function, parameter Unit Factory

setting

Range

1

Setpoint for NORMAL heating °C 20.0 0...35

2

Setpoint for REDUCED heating °C 14.0 0...35

3

Setpoint for frost protection / holiday mode °C 10.0 0...35

4

Weekday 1-7 1...7, 1-7

5

1st heating period, start of NORMAL heating hh:mm 06:00 --:-- / 00:00...24:00

6

1st heating period, start of REDUCED heating hh:mm 22:00 --:-- / 00:00...24:00

7

2nd heating period, start of NORMAL heating hh:mm --:-- --:-- / 00:00...24:00

8

2nd heating period, start of REDUCED heating hh:mm --:-- --:-- / 00:00. ..24:00

9

3rd heating period, start of NORMAL heating hh:mm --:-- --:-- / 00:00...24:00

10

3rd heating period, start of REDUCED heating hh:mm --:-- --:-- / 00:00...24:00

11

Holiday period 1...8 1...8

12

Date of first day of holidays dd:MM --:-- 00.00. ... 31.12.

13

Date of last day of holidays dd:MM --:-- 00.00. ... 31.12.

14

Heating curve, flow setpoint TV1 at 15 °C outside

temperature

°C 30 20...70

15

Heating curve, flow setpoint TV2 at –5 °C outside

temperature

°C 60 20...120

5.2. Setpoints

5.2.1. General

The setpoint of the NORMAL and the REDUCED temperature and of frost protection for

the plant / holiday mode are entered directly in °C room temperature. They are independent of whether or not the control uses a room temperature sensor.

5.2.2. Frost protection for the building

The lowest valid room temperature setpoint always corresponds to at least the setpoint

of frost protection / holiday mode (setting on operating line 3), even if lower values have

been entered as the setpoints of the NORMAL and the REDUCED temperature (settings on operating lines 1 and 2).

If a room temperature sensor is used and the room temperature falls below the holiday /

frost protection setpoint, ECO – if available – will stop OFF until the room temperature

has risen 1 °C above the holiday / frost protection setpoint.

5.3. Heating program

The heating program of the RVL470 provides a maximum of three heating periods per

day. Also, every weekday may have different heating periods.

Note:

The entries to be made are not switching times, but periods of time during which the

NORMAL temperature shall apply. Usually, these periods of time are identical to the

building's occupancy times. The actual switching times for the change from the

REDUCED to the NORMAL temperature, and vice versa, are calculated by the optimization function, provided it is activated. Using the setting "1-7" on operating line 4, it is

possible to enter a heating program that applies to all days of the week. This simplifies

the settings: if the weekend settings differ from the other weekday settings, first enter

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

14/68

Function block "End-user 1"

Landis & Staefa Division

the times for the entire week, then make the settings for days 6 and 7.

The entries are sorted and overlapping heating periods combined.

5.4. Holiday program

A maximum of eight holiday periods per year can be programmed. At 00:00 of the first

day of the holiday period, changeover to the setpoint of frost protection / holiday mode

takes place. After 24:00 of the last day of the holiday period, the RVL470 will change to

NORMAL or REDUCED mode in accordance with the time switch settings.

The settings of each holiday period will be cleared as soon as the respective period has

elapsed. The holiday periods may overlap. It is not necessary to observe a certain order.

The holiday program is only activated in AUTO mode.

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Function block "End-user 2"

15/68

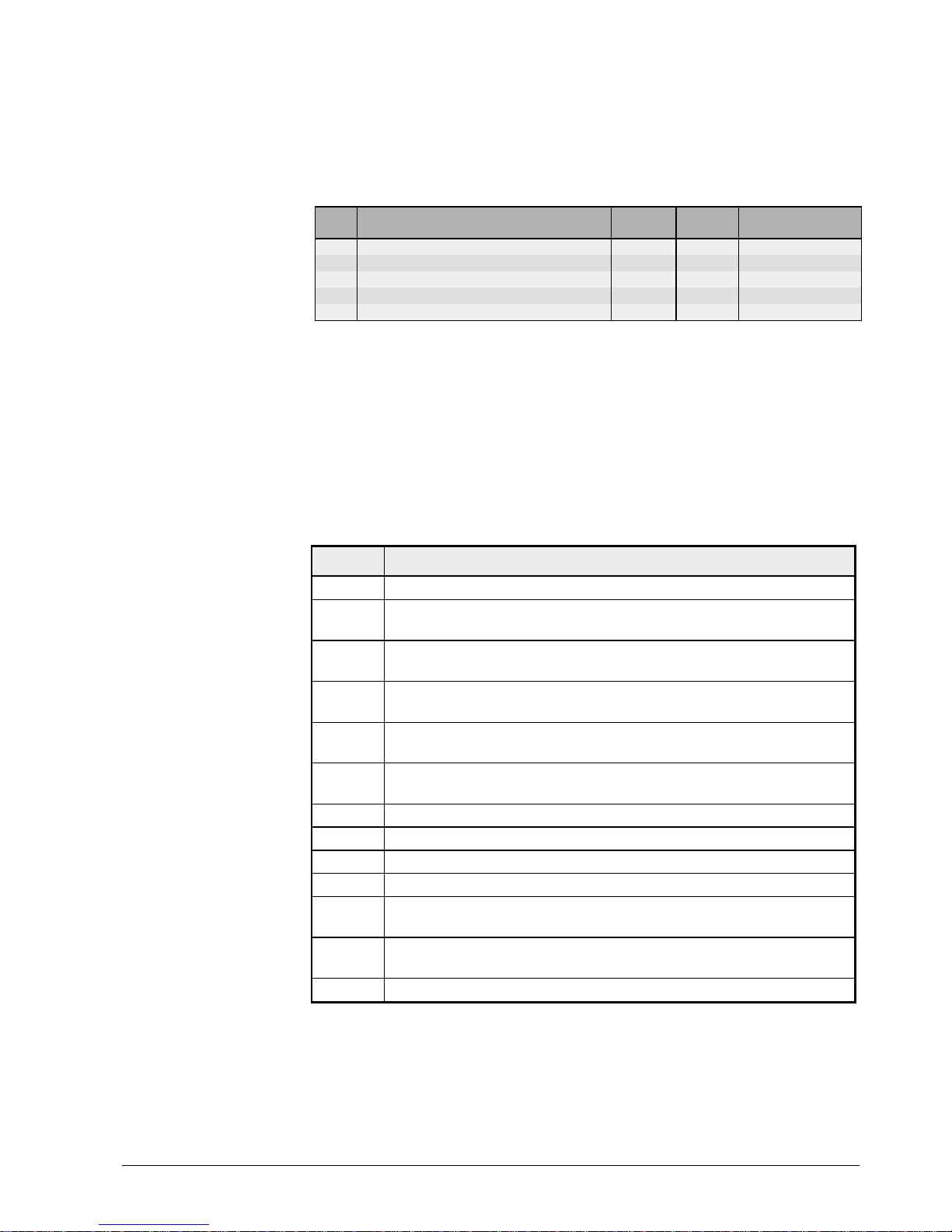

6. Function block "End-user 2"

This function block contains settings that the end-user himself may make, as well as

fault indication.

6.1. Operating lines

Line Function, parameter Unit Factory

setting

Range

38

Time of day hh:mm 00:00...23:59

39

Weekday 1...7

40

Date dd:MM 1.01. ... 31.12.

41

Year yyyy 1995...2094

50

Faults 0...255

6.2. Time of day and date

The RVL470 has a yearly clock to enter the time of day, weekday and date.

The changeover from summer- to wintertime, and vice versa, is automatic. Should the

respective regulations change, the changeover dates can be adjusted (refer to

section "13. Function block "Service functions and general settings"").

6.3. Indication of faults

The following faults are indicated:

Number Fault

10 Interruption or short-circuit in the outside sensor's measuring circuit (B9)

30 Interruption or short-circuit in the flow or boiler temperature sensor's

measuring circuit (B1)

40 Interruption or short-circuit in the measuring circuit of the return tem-

perature sensor in the primary circuit (B7)

42 Interruption or short-circuit in the measuring circuit of the return tem-

perature sensor in the secondary circuit (B71)

60 Interruption or short-circuit in the room temperature sensor's measuring

circuit (B5)

61 Interruption or short-circuit in the measuring circuit of the room unit's sen-

sor (A6)

62 Wrong room unit connected

81 Short-circuit on the LPB

82 Same bus address exists on the data bus (LPB) several times

100 Two time masters on the LPB

120 Flow alarm (for explanation, refer to function block "Service functions",

operating line 171)

140 Inadmissible bus address or inadmissible plant type (if RVL470 is used

with LPB)

142 Wrong partner unit (with RVL469 only)

If a fault occurs, the LCD displays

ERROR

.

In interconnected plants, the address (device and segment number) of the controller

causing the fault is indicated on all the other controllers, but no address is displayed on

the controller causing the fault.

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

16/68

Function block "End-user 2"

Landis & Staefa Division

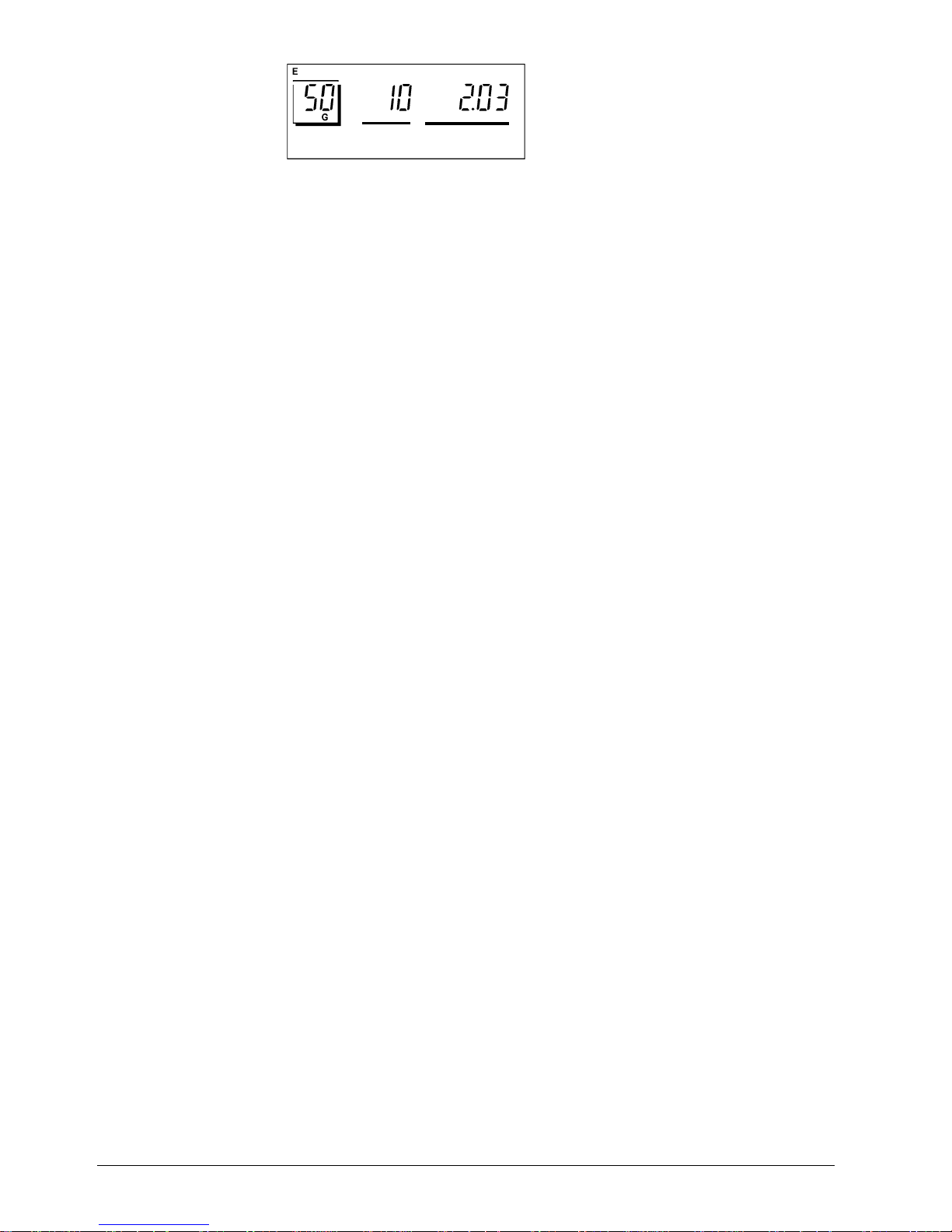

Example of display in interconnected plants:

2522Z05

50

10

2

03

= line number

= error code

= device number

= segment number

The fault status signal disappears only after rectification of the fault. There will be no

acknowledgment.

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Function block "Plant type"

17/68

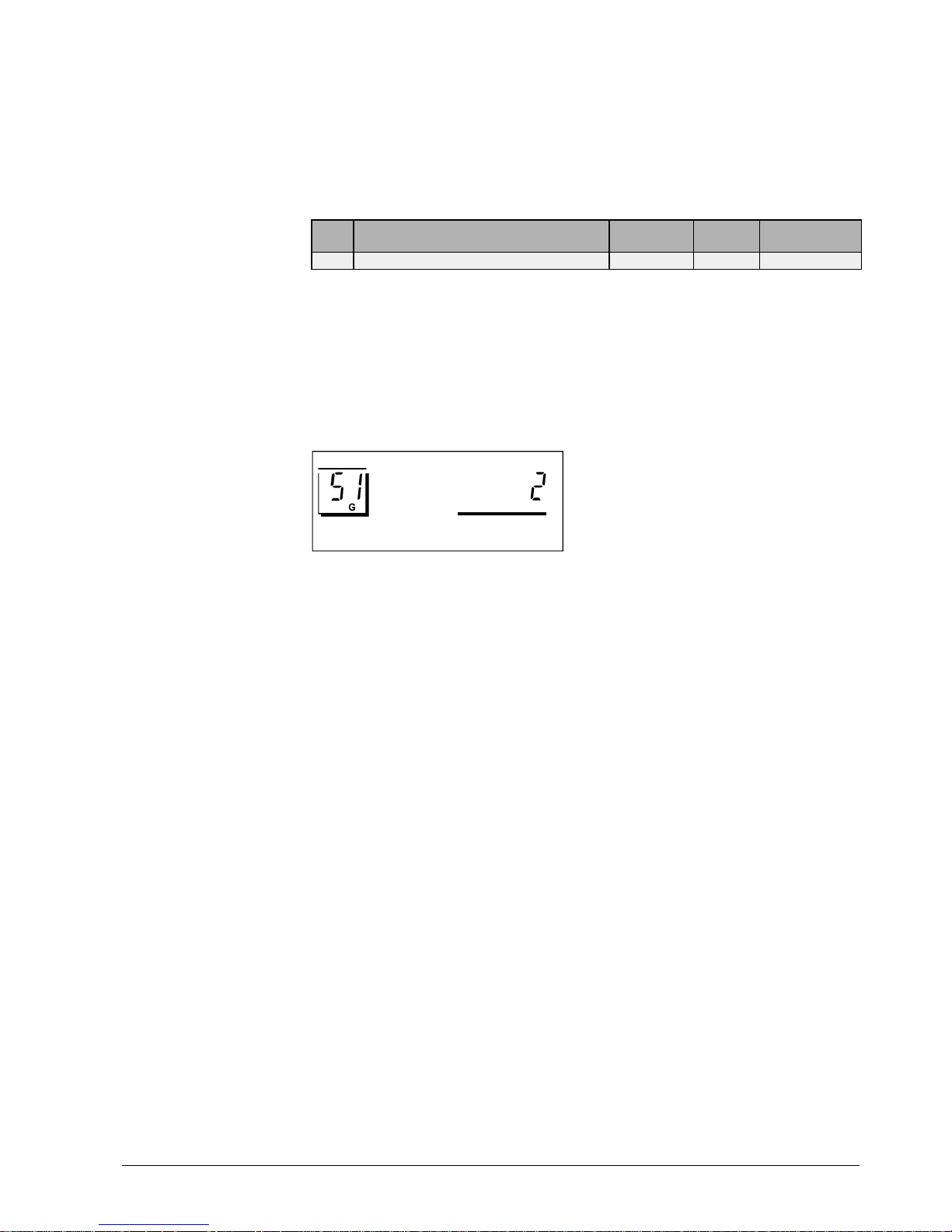

7. Function block "Plant type"

This function block only contains the entry of the type of plant.

7.1. Operating line

Line Function, parameter Unit Factory

setting

Range

51

Plant type 1 1...6

7.2. General

When commissioning the plant, the respective plant type must be entered first. This ensures that the functions required for the specific type of plant, the parameters and operating lines for the settings and displays will be activated.

All plant-specific variables and operating lines that are available for the other plant types

will then be dead.

Example (selection of plant type no. 2):

2522Z18

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

18/68

Function block "Space heating"

Landis & Staefa Division

8. Function block "Space heating"

This function block provides the ECO function, the optimization functions with boost

heating and quick setback, as well as the room temperature influence.

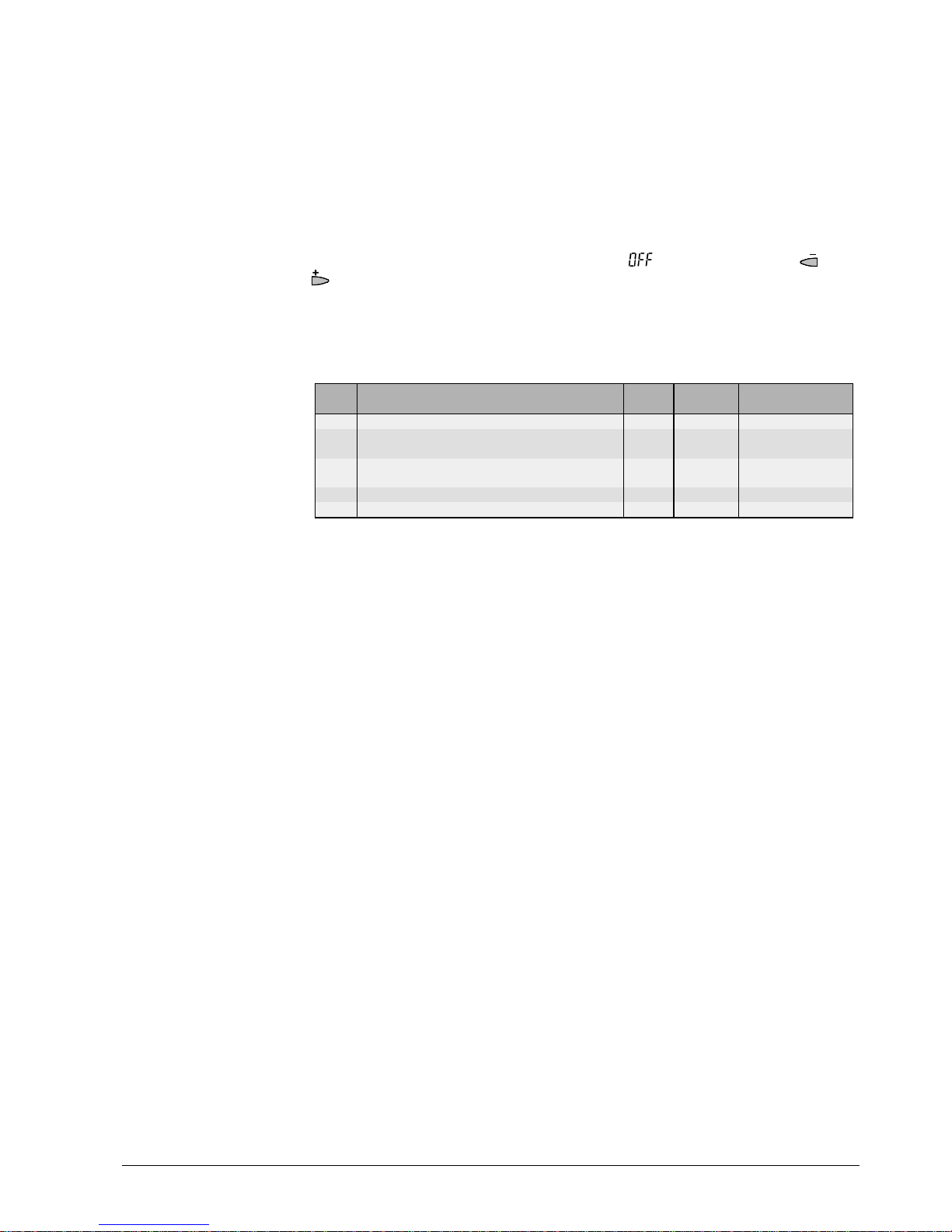

8.1. Operating lines

Line Function, parameter Unit Factory

setting

Range

61

Heating limit for NORMAL heating (ECO day) °C 17.0 --.- / −5...+25

62

Heating limit for REDUCED heating (ECO night) °C 5.0 --.- / –5...+25

63

Building time constant h 20 0...50

64

Quick setback 1 0 / 1

65

Source of the room temperature A 0 / 1 / 2 / 3 / A

66

Type of optimization 0 0 / 1

67

Maximum heating-up time hh:mm 00:00 00:00...42:00

68

Maximum optimum shutdown h:mm 0:00 0:00...6:00

69

Maximum limitation of room temperature °C --.- --.- / 0...35

70

Gain factor for room temperature influence 4 0...20

71

Boost of room temperature setpoint °C 5 0...20

72

Parallel displacement of heating curve °C 0.0

−4.5...+4.5

73

Type of heating curve adjustment 0 0...2

8.2. ECO function

The ECO function controls the heating system depending on demand. It gives consideration to the development of the room temperature depending on the type of building

construction as the outside temperature varies. If the amount of heat stored in the

building is sufficient to maintain the room temperature setpoint currently required, the

ECO function will switch the heating off.

Using the ECO function, the heating system operates only, or consumes energy only

when required.

8.2.1. Compensating variables and auxiliary variables

The ECO function takes into account the development of the outside temperature and

the heat storage capacity of the building.

The following variables are taken into consideration:

•

The building time constant. This is the measure of the type of building construction

and indicates how quickly the room temperature in the building would change if the

outside temperature was suddenly changed. The following guide values can be used

for setting the building time constant: 10 hours for light, 25 hours for medium, and 50

hours for heavy building structures

•

The actual outside temperature (TA)

•

The composite outside temperature (TAM); it is the mean value of

–

the actual outside temperature and

–

the outside temperature filtered by the building time constant

In comparison with the actual outside temperature, the composite outside temperature is attenuated. Hence, it represents the effects of short-time outside temperature

variations on the room temperature as they often occur during intermediate seasons

(spring time and autumn)

•

The attenuated outside temperature (TAD). It is generated by filtering twice the actual

outside temperature by the building time constant. This means that, in comparison

with the actual outside temperature, the attenuated outside temperature is considerably dampened.

This ensures that no heating will be provided in the summer when, under normal circumstances, the heating would be switched on because the outside temperature

drops for a few days.

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Function block "Space heating"

19/68

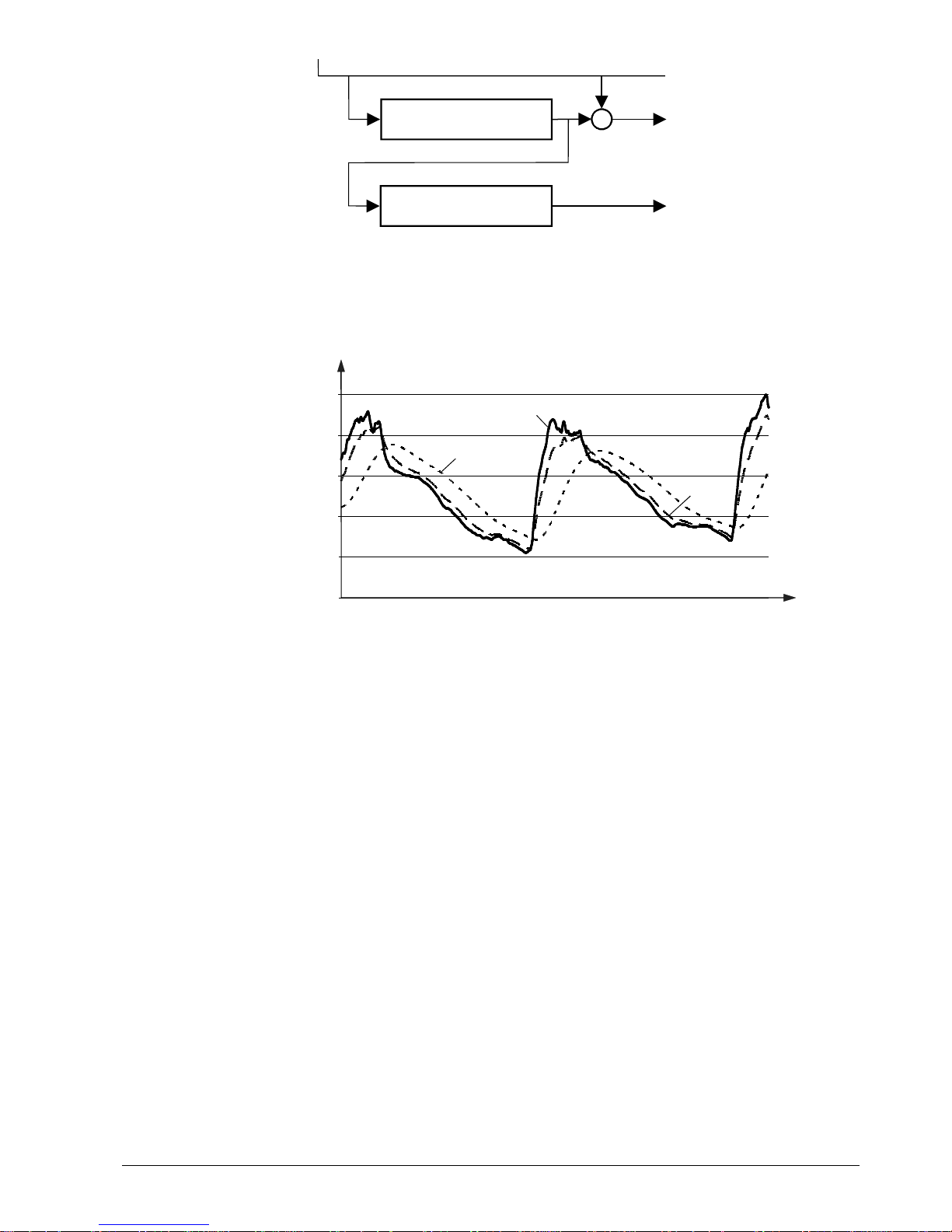

TA (B9 or BUS)

2522B02e

T

A

k

t

k

t

T

AD

T

AM

Generation of the composite and attenuated outside temperature

TAActual outside temperature

T

AD

Attenuated outside temperature

T

AM

Composite outside temperature

kt Building time constant

0

5

10

15

20

25

T

AD

T

AM

t

2522D17

T

A

T

A

Development of the actual, composite and attenuated outside temperature

TAActual outside temperature

T

AD

Attenuated outside temperature

T

AM

Composite outside temperature

tTime

8.2.2. Heating limits

Two heating limits can be set:

•

"ECO day" for NORMAL heating

•

"ECO night" for the lower temperature level; this may be REDUCED heating or OFF

(holidays / frost protection)

In both cases, the heating limit is the outside temperature at which the heating shall be

switched on and off. The switching differential is 1 °C.

8.2.3. Mode of operation

8.2.3.1. Switching the heating off

The heating will be switched off when

one

of the three following conditions is satisfied:

•

The actual outside temperature exceeds the current ECO heating limit

•

The composite outside temperature exceeds the current ECO heating limit

•

The attenuated outside temperature exceeds the "ECO day" heating limit

In all these cases, it is assumed that the amount of heat entering the building envelope

from outside or the amount of heat stored in the building structure will be sufficient to

maintain the required room temperature level.

When the ECO function has switched the heating off, the display shows

ECO

.

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

20/68

Function block "Space heating"

Landis & Staefa Division

8.2.3.2. Switching the heating on

The heating will be switched on again only when

all

three of the following conditions are

satisfied:

•

The a c t ual o u t s i d e temperature has fallen 1 °C below the current ECO heating limit

•

The composite outside temperature has fallen 1 °C below the current ECO heating

limit

•

The attenuated outside temperature has fallen 1 °C below the "ECO day" heating limit

8.2.4. Operating modes and operational statuses

The ECO function is provided depending on the operating mode:

Operating mode or operational status ECO function Actual heating limit

Automatic mode Active ECO day or ECO night

Continuously REDUCED heating Active ECO night

Continuously NORMAL heating Inactive –

STANDBY Active ECO-night

Frost protection / holiday mode Active ECO-night

Manual operation Inactive –

8.3. Room temperature source

The room temperature source can be selected on operating line 65.

The following settings are possible:

Operating line 65 Room temperature source

0 No room temperature sensor

1 Room unit connected to terminal A6

2 Room temperature sensor connected to terminal B5

3 Average value of devices connected to terminals A6 and B5

A Automatic selection

Line 65 also displays the room temperature source effectively used by the controller

(indicated by ACTUAL):

ACTUAL = 0 Controller uses no sensor

ACTUAL = 1 Controller uses the room unit connected to terminal A6

ACTUAL = 2 Controller uses the room temperature sensor connected to

terminal B5

ACTUAL = 3 Controller operates with the average value delivered by the devices

connected to terminals A6 and B5

8.4. Optimization

8.4.1. Definition and purpose

Operation is optimized. EN 12098 defines optimization as "automatic shifting of the

switch-on and switch-off points aimed at saving energy". This means that

•

switching on and heating up as well as switching off are controlled such that during

building occupancy times the required room temperature level will always be ensured

•

the smallest possible amounts of energy will be used to achieve this objective

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Function block "Space heating"

21/68

8.4.2. Fundamentals

It is possible to select or set:

•

The type of optimization: either with a room temperature sensor/room unit or based on

the room model

•

The maximum limit value for the heating-up time

•

The maximum limit value for optimum shutdown

•

Quick setback: yes or no

To perform the optimization function, the controller makes use of the actual room temperature – acquired by a room temperature sensor or room unit – or the room model.

8.4.2.1. With a room temperature sensor

Using a room temperature sensor or room unit, it is possible to have optimum start control

and

optimum stop control. To be able to optimally determine the switch-on and

switch-off points, optimization needs to "know" the building's heating up and cooling

down characteristics, always in function of the prevailing outside temperature. For this

purpose, optimization continually acquires the room temperature and the respective

outside temperature. It captures these variables via the room temperature sensor and

the outside sensor and continually adjusts the forward shift of the switching points. In

this way, optimization can also detect changes made to the building and to take them

into consideration.

The learning process always concentrates on the first heating period per day.

8.4.2.2. Without a room temperature sensor

When no room temperature sensor is used, the room model

only

allows optimum start

control.

Optimization operates with fixed values (no learning process), based on the set maximum heating up time and the room model.

8.4.3. Process

HP

T

Rw

T

Rx

T

Rw

T

Rw

T

Rw

Hp Heating program T

Rw

Room temperature setpoint of NORMAL heating

tTime T

Rw

Room temperature setpoint of REDUCED heating

t1 Forward shift for early shutdown

∆

T

Rw

Setpoint boost (only with boost heating)

t2 Forward shift for start of heating-up T

Rx

Actual value

t3 Quick setback TR Room temperature

T

Rw

Setpoint

8.4.4. Room model temperature

To ascertain the room temperature generated by the room model, a distinction must be

made between two cases:

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

22/68

Function block "Space heating"

Landis & Staefa Division

•

The RVL470 is not in quick setback mode:

The room temperature generated by the room model is identical to the actual room

temperature setpoint

•

The RVL470 is in setback mode:

The room temperature generated by the room model is determined according to the

following formula:

t

3 * kt

Room model temperature TRM [°C] = (TRw – TAM ) * e

Development of the room temperature as generated by the room model

2522D18

t

1

T

Rw

T

RM

T

Rw

T

Rw

e 2.1828 (basis of natural logarithms)

k

t

Building time constant in hours

t Time in hours

t

1

Quick setback

T

AM

Composite outside temperature

T

R

Room temperature

T

RM

Room model temperature

T

Rw

Setpoint of the normal room temperature

T

Rw

Setpoint of the reduced room temperature

8.4.5. Optimum stop control

During the building’s occupancy times, the RVL470 maintains the setpoint of NORMAL

heating. Toward the end of the occupancy time, the control switches to the REDUCED

setpoint. Optimization calculates the changeover time such that, at the end of occupancy, the room temperature will be 0.5 °C below the setpoint of NORMAL heating (optimum shutdown).

By entering 0 hours as the maximum optimum shutdown, optimum stop control can be

deactivated.

8.4.6. Quick setback

When changing from the NORMAL temperature to a lower temperature level

(REDUCED or holidays / frost), the heating will be shut down. And it will remain shut

down until the setpoint of the lower temperature level is reached.

•

When using a room temperature sensor, the effective actual value of the room temperature is taken into account

•

When using no room temperature sensor, the actual value is simulated by the room

model

The duration of quick setback is determined according to the following formula:

T

Rw

– T

AM

t [ h ] = 3 * kt * ( – ln

––––––––––– )

T

Rw

– T

AM

Siemens Building Technologies Basic Documentation RVL470 CE1P2522E / 30.03.2000

Landis & Staefa Division

Function block "Space heating"

23/68

where:

ln Natural logarithm

kt Building time constant in hours

t Duration of setback

TAM Composite outside temperature

TRw

Setpoint of the NORMAL room temperature

TRw

Setpoint of the REDUCED room temperature

8.4.7. Optimum start control

During the building’s non-occupancy times, the RVL470 maintains the setpoint of

REDUCED heating. Toward the end of the non-occupancy time, optimization switches

the control to boost heating. This means that the selected boost will be added to the

room temperature setpoint. Optimization calculates the changeover time such that, at

the start of occupancy, the room temperature will reach the setpoint of NORMAL heating.

When the room temperature is simulated by the room model, that is, when using no

room temperature sensor, the forward shift in time is calculated as follows:

t [ min ] = ( T

Rw

– TRM ) * 60

where:

tForward shift

TRw

Setpoint of the NORMAL room temperature

T

RM

Room model temperature

Optimum start control with the room model takes place only if a quick setback was previously effected.

Optimum start control can be deactivated by entering 0 hours as the maximum heatingup period.

8.4.8. Boost heating

For boost heating, a room temperature setpoint boost can be set. After changeover to

the NORMAL temperature, the higher room temperature setpoint applies, resulting in an

appropriately higher flow temperature setpoint.

t

2522D08

T

R

T

Rw

T

Rx

T

Rw

T

Rw

T

Rw

tTime

T

R

Room temperature

T

Rw

Setpoint of NORMAL room temperature

T

Rw

Setpoint of REDUCED room temperature

T

Rx

Actual value of the room temperature

T

Rw

Room temperature setpoint

∆

T

Rw

Boost of room temperature setpoint (with boost heating)

Duration of boost:

•

When using a room sensor, boost heating is maintained until the room temperature

has reached the setpoint of normal heating. Then, that setpoint is used again

CE1P2522E / 30.03.2000 Basic Documentation RVL470 Siemens Building Technologies

24/68

Function block "Space heating"

Landis & Staefa Division

•

When using no room sensor, the room model calculates how long boost heating will

be maintained. The duration is determined according to the following formula:

T

Rw

– T

RM1

k

t

t1 [ h ] = 2

*

––––––––––––

*

––––

T

Rw

– T

Rw

20

The duration of the boost is limited to two hours.

t

2522D19

T

RM

T

R

t

1

T

RM1

T

Rw

T

Rw

T

Rw

T

Rw

k

t

Building time constant in hours

tTime

t

1

Duration of room temperature setpoint boost (with boost heating)

T

R

Room temperature

T

Rw

Setpoint of the NORMAL room temperature

T

Rw

Setpoint of the REDUCED room temperature

T

RM

Room model temperature

T

RM1

Room model temperature at the start of boost heating

T

Rw

Room temperature setpoint

∆

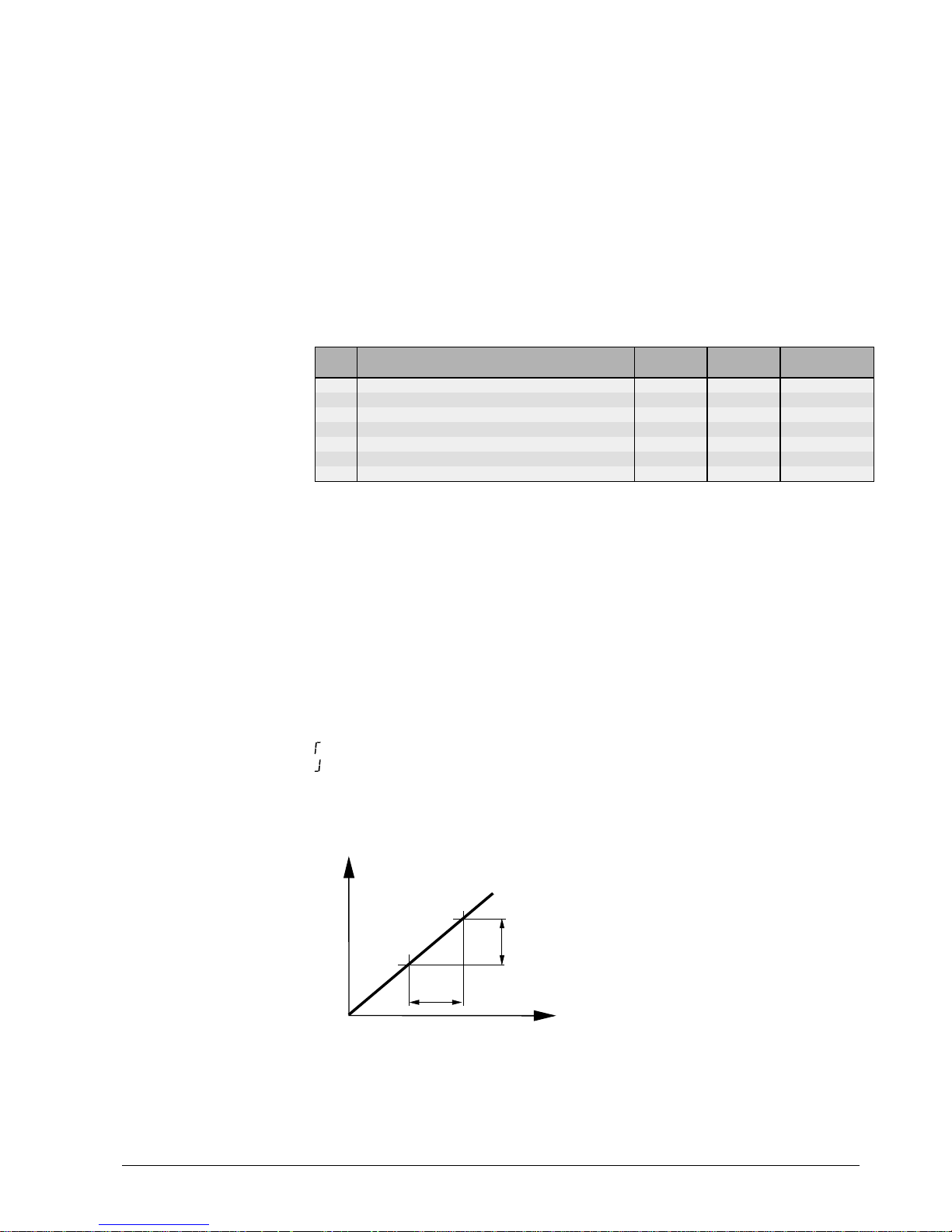

T