Page 1

Copyright 2005 by Siemens AG

A5E00409892-01

Product Information on the Reference Manual

Programmable Logic Controllers S7-300 Module Data Release 3

1 Position Decoder Module SM 338; POS-INPUT;

(6ES7338-4BC01-0AB0)

Order number

6ES7338-4BC01-0AB0

Characteristics

The position decoder module SM 338; POS-INPUT is distinguished by the

following features:

• 3 inputs for the connection of maximum three absolute value encoders (SSI)

and 2 digital inputs to freeze the encoder values

• Direct reaction possible to encoder values in moving systems

• Processing of acquired encoder values of the SM 338 in user program

• Supports clocked operation

• Type of encoder value acquisition (see chapter 1.1.2.1) can be selected:

– Free running

– Clocked

• 24 VDC rated input voltage

• Non-isolated against the CPU

• Fast mode selectable; with faster encoder recording and compressed

checkback interface

Fast mode is available as of SM 338; POS-INPUT firmware version V2.0.0 and

as of STEP 7 V5.3+SP2 selectable.

Page 2

2

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Supported encoder types

The following encoder types are supported by the SM 338; POS-INPUT:

• Absolute value encoder (SSI) with 13-bit message length

• Absolute value encoder (SSI) with 21-bit message length

• Absolute value encoder (SSI) with 25-bit message length

Supported data formats

The SM 338; POS-INPUT supports the gray code and binary code data formats.

Firmware update

1)

You can use STEP 7 HW Config firmware update to load POS-INPUT in the

operating system memory of the SM 338 in order to extend the functionality and

trouble-shooting.

Note

The old firmware is deleted with the start of the firmware update. If the firmware

update is interrupted or canceled for any reason, the SM 338; POS-INPUT is no

longer functional. Restart the firmware update and wait until it has been

successfully completed.

1)

The function is only possible in distributed configuration if the header module (slave interface) supports the

necessary system services

Page 3

3

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1 Synchronous Operation

Warning

The basics of synchronous operation are described in a separate manual.

Hardware requirements

For the synchronous operation of the SM 338, you require:

• CPU which supports clocked operation

• DP master which supports the equidistant bus cycle

• Slave interface (IM 153-x) which supports synchronous operation

Characteristics

Depending on the system parameterization, the SM 338 works in either

non-synchronous or synchronous mode.

In synchronous operation, the data exchange between DP master and SM 338 is

synchronous to the PROFIBUS DP cycle.

In synchronous operation all 16 bytes of the checkback interface are consistent.

If synchronicity is lost due to faults or failure or delay of Global Control (GC), the

SM 338 goes back into synchronous operation in the next cycle without error

response.

If synchronicity is lost, the checkback interface is not updated.

Page 4

4

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

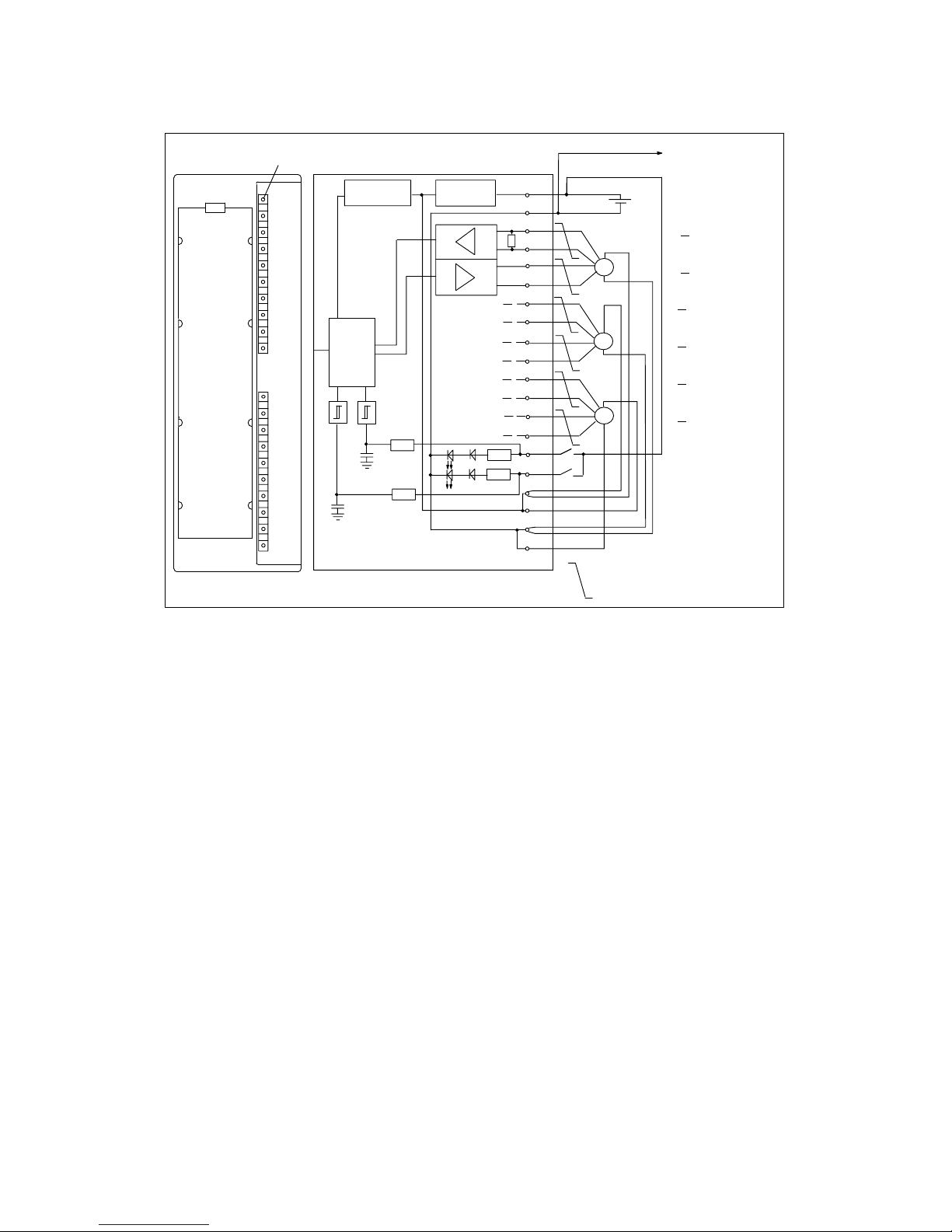

1.1.1 Terminal Connection Diagram and Block Diagram

Fault indicator – red

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

L+

24V

OD (Data)

OD (Data)

OC (Clock)

OC (Clock)

1D (Data)

1D (Data)

1C (Clock)

1C (Clock)

2D (Data)

2D (Data)

2C (Clock)

2C (Clock)

DI 0 (DigitalDI 1 input)

DC24V (encoder)

DC24V (encoder)

M (encoder)

M (encoder)

SSI

SSI

SSI

Short-circuit

protection

Voltage monitoring

SF

S7-300 Backplane bus

Logic

M

RS 422

Twisted pair cables

DI 0

DI 1

Connection to the

ground of the CPU

Figure 1-1 Module View and Block Diagram of the SM 338; POS-INPUT

Wiring rules

Please observe the following important rules of the wiring of the module:

• The ground of the encoder supply is connected non-isolated to the ground of

the CPU. Thus, connect pin 2 of the SM 338 (M) with low impedance with the

ground of the CPU.

• The encoder lines (pins 3 to 14) must be twisted pairs and shielded. Apply the

shield to both sides.

For the shield connection to the SM 338, use the shield connection element

(order number 6ES7390-5AA00-0AA0).

• If the output current (900 mA) of the encoder supply is exceeded, then you

must connect an external power supply.

Page 5

5

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1.2 Functions of the SM 338; POS INPUT

1.1.2.1 Encoder value acquisition

The absolute value encoder transfers its encoder values in messages to the

SM 338. The transfer of the message is initiated by the SM 338.

• In non-synchronous operation, the encoder values are acquired while it is free

running.

• In synchronous operation the encoder values are acquired synchronized to the

PROFIBUS DP cycle at each Ti.

Free running encoder value acquisition

The SM 338 always initiates the transfer of a message after the end of the

parameterized monoflop time.

Asynchronous to these free running messages, the SM 338 processes the

acquired encoder values during the cycle of its updating rate (see Technical Data).

Thus, in the case of free running encoder value acquisition, encoder values of

different ages result. The difference between the maximum and minimum age is

the jitter (see Technical Data).

Synchronous encoder values acquisition

Synchronous encoder values acquisition is automatically set if, in the DP master

system, the equidistant bus cycle is activated and the DP Slave is synchronized to

the DP cycle.

The SM 338 initiates the transfer of a message in each PROFIBUS DP cycle

at the time Ti.

Synchronous to the PROFIBUS DP cycle, the SM 338 processes the transferred

encoder values.

Page 6

6

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1.2.2 Gray/Dual Converter

In the Gray setting, the encoder values provided by the absolute value encoder in

gray code is converted into Dual code. In the Dual setting, encoder values

provided by the absolute value encoder remain unchanged.

Warning

If you have selected the Gray setting, the SM 338 always converts the entire

encoder value (13, 21, 25 bits). As a result, preceding special bits affect the

encoder values and following bits could be falsified under certain circumstances.

1.1.2.3 Transferred Encoder Value and Normalization

The transferred encoder value contains the encoder position of the absolute value

encoder. Depending on the encoder used, additional bits which are located before

and after the encoder position are also transferred in addition to the encoder

position.

So that the SM 338 can detect the encoder position, make the following settings:

• Normalization, places (0..12), or

• Normalization, units / revolution

Normalization, places

The normalization determines the position of the encoder values in the checkback

interface.

• If “Places” = 1, 2....12, this indicates that the following non relevant bits in the

encoder values are removed and the encoder value is right justified in the

address range (see following example).

• If “Places” = 0, this indicates that the following bits are retained and available

for evaluation.

This can be useful if you use an absolute value encoder which transfers

information in the following bits (see manufacturer information) and you want to

evaluate these (see also chapter 1.1.2.2).

Parameter units / revolution

A maximum of 13 bits are available for the units/revolution. According to the

“Places” data, the resulting number of units/revolution is automatically displayed.

Page 7

7

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Example of normalization of an encoder value

You are using a single-turn encoder with 29 units= 512 units/ revolution

(resolution/360°).

In STEP 7 you have set the following parameters:

• Absolute encoder: 13 bits

• Normalization: 4 places

• Units / revolution: 512

Before the normalization: cyclically acquired encoder values 100

0

31

0000000000000000000000000

XXXX

00100

11

0000

Transferred bits

Relevant bits

After the normalization: encoder values 100

0

31

0000000000000000000000000 001001100000000

Relevant bits

Double data word

Double data word

Result: Bits 0 to 3 (4 places, marked with “x”) are omitted.

1.1.2.4 Freeze Function

The freeze function “freezes” the current encoder values of the SM 338. The

freeze function is coupled to the digital inputs DI 0 and DI 1 of the SM 338.

The freeze is triggered by an edge change (rising edge) on DI 0 or DI 1. A frozen

encoder value is identified by the bit 31 (output address) being set. With a digital

input you can freeze one, two or three encoder values.

You must switch on the freeze function, i.e. set the corresponding parameters in

STEP 7. The freeze function is not possible in fast mode.

The encoder values are retained until the freeze function is ended and can thus be

evaluated dependent on the event.

Page 8

8

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Ending the freeze function

The freeze function must be ended at every encoder input. You acknowledge the

function in the user program by setting the bit 0, 1 or 2 depending on the channel

with the STEP 7-Operation T PAB “xyz” (for a program example,

see chapter 1.1.4).

After exiting, bit 31 of the corresponding encoder value is again deleted and the

encoder values are again updated. A renewed freezing of the encoder values is

again possible as soon as you have deleted the acknowledgment bit in the output

address of the module.

In synchronous operation the acknowledgment is processed at time To. From this

point in time a renewed freezing of the encoder values can take place via the

digital inputs.

Warning

The freeze function is automatically acknowledged if you newly parameterize the

corresponding channel with different parameters (see 1.1.3 chapter).

If the parameters remain identical, the freeze function remains unaffected.

1.1.3 SM 338; POS-INPUT Parameterization

You parameterize the SM 338; POS-INPUT with STEP 7. You must perform

parameter assignment in STOP mode of the CPU.

As soon as you have set all the parameters, download the parameters from the

programming device to the CPU. On a transition from STOP to ³ RUN mode, the

CPU then transfers the parameters to the SM 338.

The parameters cannot be changed by the user program.

Page 9

9

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Parameters of the SM 338; POS-INPUT

You will find an overview of the parameters that you can set and their default

settings for the SM 338 in the table below.

The default settings apply if you have not performed parameter assignment in

STEP 7 (default setting bold).

Table 1-1 Parameters of the SM 338; POS-INPUT

Parameter

values Range Note

Enable

• Fast mode Yes/no

Release parameter.

Affects all 3 channels.

Enable

• Diagnosis interrupt Yes/no

Release parameter.

Affects all 3 channels.

Absolute value encoder

(SSI)

1)

none; 13 bits; 21 bits; 25 bits none: The encoder input is

switched off.

Code type

1)

Gray; Binary Code provided by encoder.

Baud rate

1) ,3)

125 kHz; 250 kHz; 500 kHz; 1 MHz Data transfer rate of the SSI

position decoder. Observe the

relationship between the cable

length and baud rate (see

Technical Data)

Monoflop time

1),2),3)

16 ms; 32 ms; 48 ms; 64 ms The monoflop time is the

minimum time interval between

2 SSI message frames.

The parameterized monoflop

time must always be greater than

the monoflop time of the absolute

value encoder.

Normalization

• Places

• Units / revolution

4)

0 to 12

2 to 8192

Normalizing right justifies the

encoder values of the encoder

absolute; non-relevant places are

discarded.

Switching on freeze off; 0; 1 Designation of the digital input

whose rising edge causes a

freezing of the encoder value.

1)

See technical data of the absolute value encoder

2)

The monoflop time is the time interval between 2 SSI message frames. The parameterized monoflop

time must be greater than the monoflop time of the absolute value encoder (see technical data of the

manufacturer). The time 2 (1 / baud rate) is added to the value parameterized in HW config. At a

baud rate of 125 kHz with a parameterized monoflop time of 16 ms, an effective monoflop time of 32 ms

is actually achieved.

3)

The following restriction applies to the monoflop time of the absolute value encoder:

(1 / baud rate) < Monoflop time of the absolute value encoder < 64 ms + 2 (1 / baud rate)

4)

to the power of two

Warning

Please note that in non synchronous operation the baud rate and the monoflop

time affect the accuracy and actuality of the encoder values.

In synchronous operation the baud rate and the monoflop time affect the accuracy

of the freeze function.

Page 10

10

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1.4 SM 338; POS-INPUT Addressing

Data range for the encoder values

The inputs and outputs of the SM 338 are addressed as of the initial module

address. The input and output address is determined at the configuration of the

SM 338 in STEP 7.

Input Addresses

Table 1-2 SM 338; POS-INPUT: Input Addresses

Encoder input

Input address (from the configuration) + address offset

0 ”Initial module address”

1 ”Module start address” + 4 bytes address offset

2 ”Module start address” + 8 bytes address offset

Structure of the double data word in Standard Mode

For each encoder input the double data word is made up as follows:

Freeze

0 = encoder value is not frozen. The value is constantly updated.

1 = encoder value is frozen. The value remains constant until

acknowledgment.

25 bit sensor value in gray or binary code

31 024

Page 11

11

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Structure of the double data word in Fast Mode

For each encoder input the double data word is made up as follows:

25 bit sensor value in gray or binary code

1 = Group error (sensor error, ext. auxiliary voltage error)

30 02427

Status digital input

1 = Parameter assignment error

1 = Ready for operation (checkback value valid)

In the double data word of channel 0, the status of the I0 is set in bit 27 (status

digital input) and in the double data word of channel 1, the status of the digital input

I1 is set.

The bit is always = 0 in the double data word of channel 2.

Output Address im Standard Mode

Acknowledging the freeze function:

Bit 0 = encoder input 0

Bit 1 = encoder input 1

Bit 2 = encoder input 2

Initial module address

07

Reading out data areas

You can read out the data areas in your user program with the STEP 7-Operation

L PED “xyz”.

Example of access to encoder values and use of the freeze function

You want to read out and evaluate the value of the encoder at the encoder inputs.

The module start address is 256.

No output data are supported in fast mode.

Page 12

12

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

AWL Explanation

L PED 256 //

T MD 100 //

U M 100.7 //

= M 99.0 //

L PED 260 //

T MD 104 //

U M 104.7 //

= M 99.1 //

L PED 264 //

T MD 108 //

U M 108.7 //

= M 99.2 //

L MB99//

T PAB 256 //

Read encoder value in the address range for

encoder input 0

Store encoder value in marker double word

Acquire and store freeze status for later

acknowledgment

Read encoder value in the address range for

encoder input 1

Store encoder value in marker double word

Acquire and store freeze status for later

acknowledgment

Read encoder value in the address range for

encoder input 2

Store encoder value in marker double word

Acquire and store freeze status for later

acknowledgment

Load and acknowledge freeze condition

(SM 338: output address 256)

Afterwards you can further process the encoder values from the marker range

MD 100, MD 104 and MD 108. The encoder value is contained in bits 0 to 30 of

the marker double word.

Page 13

13

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1.5 Diagnosis of the SM 338; POS-INPUT

The SM 338 makes diagnostic messages available, i.e., all diagnostic messages

are always provided by the SM 338 without your assistance.

Actions following diagnostic message in STEP 7

Each diagnostic message leads to the following actions:

• The diagnostic message is entered in the diagnosis of the module and

forwarded to the CPU.

• The SF LED on the module lights.

• If you have programmed “Enable Diagnostic Interrupt” in STEP 7, a diagnostic

interrupt is triggered and OB 82 is called.

Reading out diagnostic messages

You can read out detailed diagnostic messages by means of SFCs in the user

program (refer to the Appendix “Diagnostic Data of Signal Modules”).

You can view the cause of the error in STEP 7, in the module diagnosis (refer to

online Help for STEP 7).

Diagnostic message via SF LED

The SM 338 indicate errors for you by means of their SF LED (group error LED).

The SF LED lights as soon as a diagnostic message is triggered by the SM 338. It

goes out when all errors have been rectified.

The group fault (SF) LED also lights up in case of external errors (short circuit of

encoder supply), independent of the operating status of the CPU (if power is on).

The SF LED lights up temporarily at startup during the self test of the SM 338.

Page 14

14

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Diagnostic messages of the SM 338; POS INPUT

The table below gives an overview of the diagnostic messages for the SM 338.

Table 1-3 Diagnostic messages of the SM 338; POS INPUT

Diagnostics Message

LED Scope of the Diagno-

stics

Module problem SF Module

Internal malfunction SF Module

External malfunction SF Module

Channel error present SF Module

External auxiliary supply missing SF Module

Module not parameterized. SF Module

Wrong parameters SF Module

Channel information available SF Module

Time monitoring triggered SF Module

Channel error present SF Channel

(encoder input)

Configuring/parameter assignment error SF Channel

(encoder input)

External channel error (encoder fault) SF Channel

(encoder input)

Page 15

15

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Causes of errors and remedial measures

Table 1-4 Diagnostics Messages of the SM 338, Causes of Errors and Remedial Measures

Diagnostics

Message

Possible Error Cause Remedy

Module fault An error detected by the module has

occurred.

Internal error Module has detected an error within

the automation system.

External error Module has detected an error outside

of the automation system.

Channel error present Indicates that only specific channels

are faulty .

External auxiliary

supply missing

The power supply L+ to the module is

missing

Feed supply L+

Module not

parameterized

Module requires information whether it

should work with parameters preset by

the system or with your parameters.

Message present after network active

until transfer of the parameters by the

CPU complete; parameterize module if

necessary.

Wrong parameters One parameter or the combination of

parameters is not plausible

Reassign module parameter

Channel information

present

Channel error present; module can

provide additional channel information.

Watchdog tripped Temporary high electromagnetic

interference

Eliminate interference

Channel error present An error detected by the module has

occurred at the encoder input.

Configuration /

parameterization error

Illegal parameter had been transferred

to module

Reassign module parameter

External channel error

(encoder error)

Broken wire in encoder cable, encoder

cable not connected or encoder

defective.

Check connected encoder

Page 16

16

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1.6 Interrupts of the SM 338; POS INPUT

Introduction

In this Section, the interrupt behavior of the SM 338; POS-INPUT is described.

The SM 338 can trigger diagnostic interrupts.

The OBs and SFCs mentioned below can be found in the online Help for STEP 7,

where they are described in greater detail.

Enabling interrupts

The interrupts are not preset – in other words, they are inhibited without

appropriate parameter assignment. Assign parameters to the Interrupt Enable in

STEP 7 (refer to Section 1.1.3).

Diagnostic interrupt

If you have enabled diagnostic interrupts, then incoming active error events (initial

occurrence of the error) and departing error events (message after

troubleshooting) are reported by means of interrupts.

The CPU interrupts execution of the user program and processes the diagnostic

interrupt block (OB 82).

In the user program, you can call SFC 51 or SFC 59 in OB 82 to obtain more

detailed diagnostic information from the module.

The diagnostic information is consistent until such time as OB 82 is exited. When

OB 82 is exited, the diagnostic interrupt is acknowledged on the module.

Page 17

17

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

1.1.7 Technical Specifications of the 338; POS-INPUT

Dimensions and Weight

Dimensions B x H x T

(mm)

40 x 125 x 120

Weight Approx. 235 g

Voltages, Currents, Potentials

Rated load voltage L+

• Range

• Reverse polarity

protection

24 VDC

20.4 ... 28.8 V

No

Isolation no, only against shield

Permitted potential

difference

• between input

(M connection) and

central grounding point

of the CPU

1 VDC

Encoder supply

• Output voltage

• Output current

L+ –0.8 V

max. 900 mA, short

circuit–proof

Current dissipation

• From the backplane

bus

• From the load voltage

L+ (no load)

max. 160 mA

max. 10 mA

Power dissipation of the

module

typ. 3 W

Encoder inputs POS INPUT 0 to 2

Position decoding absolute

Difference signals for SSI

data and SSI clock

according to RS422

Data transfer rate and cable

length of absolute value

encoders (twisted pair and

shielded)

• 125 kHz max. 320 m

• 250 kHz max. 160 m

• 500 kHz max. 60 m

• 1 MHz max. 20 m

Message duration of the

SSI transmission

• 125 kHz

• 250 kHz

• 500 kHz

• 1 MHz

13 bits 21 bits 25 bits

112 ms 176 ms 208 ms

56 ms 88 ms 104 ms

28 ms 44 ms 52 ms

14 ms 22 ms 26 ms

Monoflop time

2

16 ms, 32 ms, 48 ms, 64 ms

Digital inputs DI 0, DI 1

Isolation no, only against shield

Input voltage 0-Signal: –3 V ... 5 V

1-Signal: 11 V ... 30.2 V

Input current 0-Signal: v2 mA

(quiescent current)

1-Signal: 9 mA (typ.)

Input delay 0 > 1: max. 300 ms

1 > 0: max. 300 ms

Maximum repeat frequency 1 kHz

Connection of a two–wire

BEROS, type 2

Possible

Shielded line length 600 m

Unshielded line length 32 m

Status, Interrupts, Diagnostics

Interrupts

• Diagnostic interrupt Parameters can be

assigned

Status display of digital

inputs

Group error/fault

LED (green)

LED (red)

Inaccuracy of the encoder value

Free running encoder value acquisition

(Standard Mode)

• Maximum age

1)

(2 × Message duration)

+ monoflop time

+ 580 ms

• Minimum age

1)

Message duration

+ 130 ms

• Jitter

Message duration

+ monoflop time

+ 450 ms

Update rate Evaluation of the message

every 450 ms

Free–wheeling sensor value detection (Fast Mode)

• Maximum age

1)

(2 × Message duration)

+ monoflop time

+ 400 ms

• Minimum age

1)

Message duration+

100 ms

• Jitter Message duration+

monoflop time + 360 ms

Update rate Evaluation of the message

every 360 ms

Synchronous encoder value acquisition

• Age Encoder value at time T

i

of

the current PROFIBUS DP

cycle

Page 18

18

Product Information on the Reference Manual Programmable Logic Controllers S7-300 Module Data Release 3

A5E00409892-01

Inaccuracy of the frozen encoder value (freeze)

Free running encoder value acquisition

• Maximum age

1)

(2 × Message duration)

+ monoflop time

+ 580 ms

• Minimum age

1)

Message duration

+ 130 ms

• Jitter

Message duration +

monoflop time + 450 ms

Synchronous encoder value acquisition

• Jitter

Max (message

durationn + param.

Monoflop time n)

n = 0, 1, 2, (Channel)

Isochrone time of the module

In Standard Mode TWE 850 ms

TWA 620 ms

ToiMin 90 ms

TDPMin 1620 ms

In Fast Mode TWE 700 ms

TWA 0 ms

ToiMin 0 ms

TDPMin 900 ms

1)

Age of the encoder values determined by the

transfer process and the processing

2)

The following restriction applies to the monoflop

time of the absolute value encoder:

(1 / baud rate) < Monoflop time of the absolute

value encoder < 64

ms + 2 x (1 / baud rate)

Loading...

Loading...