Page 1

POLYMOBIL III

Start-up Instructions

SP

from Serial No. 3000

© Siemens AG 2005

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: RXB8-115.034.02.03.02 Doc. Gen. Date: 04.05

Replaces: RXB8-115.034.02.02.02

Page 2

0 - 2 Revision

Chapter Page Rev.

All All 03

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery.

Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempting installation or service procedures.

POLYMOBIL III RXB8-115.034.02 Page 2 of 4 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 3

Contents 0 - 3

Page

1 _______Requirements__________________________________________________ 1 - 1

Emphasized texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Required tools and measurement devices . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Safety information and protective measures . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Important start-up information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Notes on the protective conductor resistance test . . . . . . . . . . . . . . . . . . . 1 - 4

Notes on device leakage current measurement. . . . . . . . . . . . . . . . . . . . . 1 - 6

Replacement for damaged or lost screws . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

2 _______Unpacking ____________________________________________________ 2 - 1

3 _______Checking and adapting the line voltage ____________________________3 - 1

Checking the nominal line voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Adaptation of the nominal line voltage. . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

4 _______Functional checks ______________________________________________ 4 - 1

Checking the control and display elements . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Checking the weight counterbalance . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Readjustment of the weight counterbalance with affixed accessories . . . . . . . . . 4 - 2

Checking the control elements on the double slot diaphragm. . . . . . . . . . . . . . 4 - 3

Checking the exposure release with high-voltage . . . . . . . . . . . . . . . . . . . . 4 - 3

Checking coincidence of light field and radiation field. . . . . . . . . . . . . . . . . . 4 - 4

Checking the exposure switch-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

5 _______Final work steps _______________________________________________ 5 - 1

Protective conductor test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Device leakage current measurement. . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

Last work steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

6 _______Start-up report _________________________________________________ 6 - 1

POLYMOBIL III Start-up report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

7 _______Electrical safety / reports ________________________________________ 7 - 1

Protective conductor resistance / report. . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Device leakage current / report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

8 _______Changes to previous version _____________________________________ 8 - 1

Siemens AG RXB8-115.034.02 Page 3 of 4 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 4

0 - 4 Contents

Page

This page intentionally left blank.

POLYMOBIL III RXB8-115.034.02 Page 4 of 4 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 5

Requirements 1

Emphasized texts 1

1 - 1

DANGER

WAR NING

CAUTION

NOTICE

DANGER indicates an immediate danger that if disregarded will

cause death or serious physical injury.

WARNING indicates a possible danger that if disregarded can

cause death or serious physical injury.

CAUTION used with the safety alert icon indicates a possible danger that if disregarded will or can lead to minor or moderate physical injury and/or damage to property.

NOTICE used without the safety alert icon indicates a possible

danger that if disregarded may or will lead to an undesirable

result or state other than death, physical injury or property damage.

NOTE

NOTE is used to indicate information which explains the proper

way to use devices or to carry out a process, i.e. which provides

hints and tips.

Icons 1

Tests and adjustments that must be performed with the radiation switched on are

indicated by this radiation warning icon.

This icon means "Dangerous electrical voltage".

Enter the result of tests marked with this icon in the test report at the end of these

instructions.

Siemens AG RXB8-115.034.02 Page 1 of 8 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 6

1 - 2 Requirements

Required tools and measurement devices 1

NOTE

All tools, measuring equipment and aids, with the exception of

those marked with "*", are listed and specified in the STC

(Service Tools Catalogue).

• Standard service tool kit*

• Ground wire tester

• Device leakage current measuring device

• Digital multimeter

Safety information and protective measures 1

WAR NING

Danger of injuries, death or material damage.

Note

- the product-specific safety notes in these instructions,

- the general safety information in the document

TD00-000.860.01...

and

- the safety information in accordance with ARTD Part 2.

WAR NING

Non-compliance can lead to death, to injuries or to

material damage.

X-ray radiation!

Non-compliance can lead to illnesses, irreversible damage to

body cells and the genotype, severe injuries and even death.

In work on the system in which radiation must be released, the

radiation protection directives and the rules for radiation protection according to ARTD 02.771.02 must be complied with.

Please note:

- Use available radiation protection devices.

- Wear radiation protection clothing (lead apron).

- Keep your distance from the radiation source as large as possible.

- Release radiation only if necessary.

- Set radiation activity as low as possible.

(Low kV and mAs values)

- Release radiation for as short a time as possible.

Checks in which radiation must be released are identified by the

radiation warning symbol.

POLYMOBIL III RXB8-115.034.02 Page 2 of 8 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 7

Requirements 1 - 3

DANGER

In work on the opened system there is a

! risk of electric shock !

• After the system is switched off around 300 V direct voltage are

present in the control console for the main inverter.

The yellow LED V35 on D920 lights up.

The voltage drops within approx. 1.5 minutes to approx. 12V; the

LED V35 goes out.

• Connect the POLYMOBIL III only to a mains supply (wall outlet) that corresponds in its

installation to the requirements according to VDE 0107 or the national regulations.

• Before any intervention switch the POLYMOBIL III off with the power OFF switch on the

control console and pull out the power plug!

• Install or remove components only with the generator switched off; when doing this,

observe ESD guidelines.

Important start-up information 1

• The POLYMOBIL III that has been completely tested and set up in the factory is ready for

use after start-up is completed.

• The POLYMOBIL III can be connected to a nominal line voltage of 110 V AC (± 10%) or

230 V AC (

exception is connection to a line voltage

+ 6 / - 10%). There is an automatic adaptation to the existing line voltage. An

≥ 240 V AC (see the "Adaptation of the nominal line voltage" section).

NOTE

• Observe the on-site fusing of the wall outlet:

- 10 A slow-blow (on-site) at 207 ... 243.8 V line voltage

- 16 A slow-blow (on-site) at 99 ... 121 V line voltage

• The power connection cable of the POLYMOBIL III is delivered

with a grounding type plug.

Fit national power connection plugs as required.

• After start-up, a test specified specifically for the country of use may have to be

performed; e.g. acceptance test according to RöV (Germany).

Acceptance test according to RöV (Germany):

Required measured values can be taken partially from the test report supplied with the

system.

Siemens AG RXB8-115.034.02 Page 3 of 8 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 8

1 - 4 Requirements

The following values measured in the factory are documented in the test report:

- Brightness of the light localizer

- Visual test of filter values

- Coincidence of light field and radiation field

- Accuracy of the X-ray tube voltage

- Checking the mAs values

- Reproducibility of radiation

Notes on the protective conductor resistance test 1

Observe the instructions in the safety rules for installation and repair

(ARTD-002.731.17 ...).

The protective conductor resistance of 0.2 ohms must not be exceeded.

Initial measurement

Perform the protective conductor test after completion of all work.

The measurement must be made according to DIN VDE 0751, Part 1 (see ARTD Part 2).

In this case the protective conductor resistance in the normal operating condition to all

conductive touchable parts of the system must be measured.

Make sure that control cables or data cables between the components of the system do

not imitate any protective conductor connection.

During the measurement, move the power cable and additional connection cables with

integrated protective conductor section by section to detect cable breaks.

The protective conductor resistance must not exceed 0.2 Ohms.

The values must be recorded as initial measurements in the report ’Protective conductor

resistance / report’ stating the measuring points.

Document the measuring procedure and the measuring instrument used (designation

and serial number).

POLYMOBIL III RXB8-115.034.02 Page 4 of 8 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 9

Requirements 1 - 5

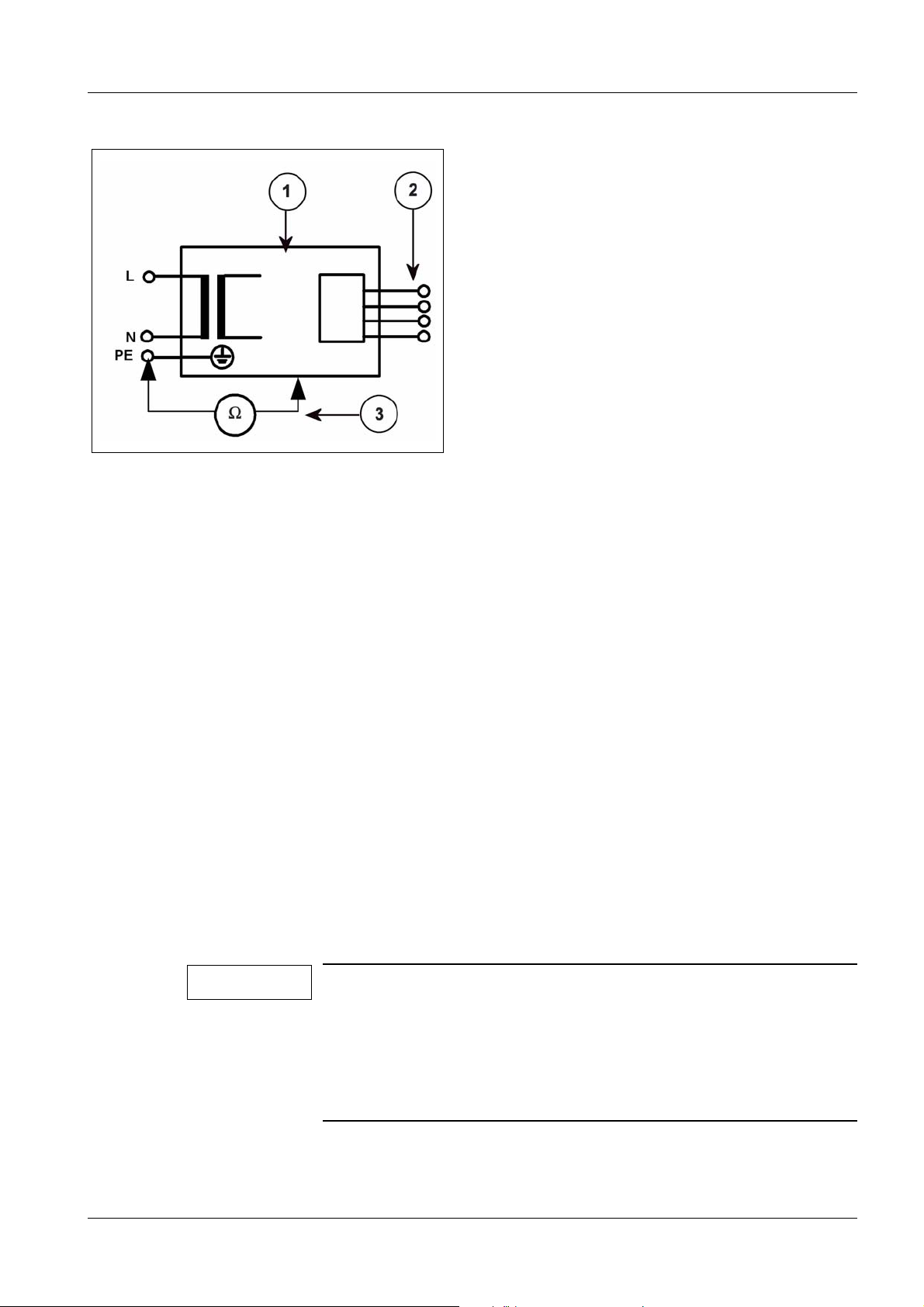

Fig. 1 Measuring circuit for measuring the protective conductor resistance in systems that are separated from the

power supply, according to DIN VDE 0751-1:2001-10, Fig. C2.

1 = System

2 = Application part (not present)

3 = Measuring arrangement (integrated in the measuring instrument)

Repeat measurement

In the case of maintenance or repair perform the protective conductor resistance measurement again.

Document and assess the values determined in the repeat measurement.

The measurement must be made according to DIN VDE 0751, Part 1

(see ARTD-002.731.17...). In this case the protective conductor resistance in the normal

operating condition to all conductive touchable parts of the system must be measured.

Make sure that control cables or data cables between the components of the system do

not imitate any protective conductor connection.

During the measurement, move the power cable and additional connection cables with

integrated protective conductor section by section to detect cable breaks.

The protective conductor resistance must not exceed 0.2 Ohms.

The values determined in the repeat measurement must be recorded and assessed in the

report ’Protective conductor resistance / report’, stating the measuring points.

Document the measuring procedure and the measuring instrument used (designation

and serial number).

NOTE

Evaluate the results by comparing the first measured value to the

corresponding values documented during preceding maintenance procedures or safety checks.

A sudden or unexpected increase of the measured values

may indicate a safety-relevant defect

- even if the limit value of 0.2 ohms is not exceeded

(protective ground wire or contacts).

Siemens AG RXB8-115.034.02 Page 5 of 8 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 10

1 - 6 Requirements

Notes on device leakage current measurement 1

Observe the instructions in the safety rules for installation and repair (ARTD-002.731.17).

WAR NING

Electrical voltage!

Non-compliance can lead to severe injuries and even death.

The device leakage current measurement may be

performed on systems of protection class I only after the

protective conductor test has been passed.

Initial measurement

Perform the device leakage current measurement after completion of all work.

Perform the measurement according to DIN VDE 0751, Part 1 (see ARTD-002.731.17...),

and record the determined value as the first measured value.

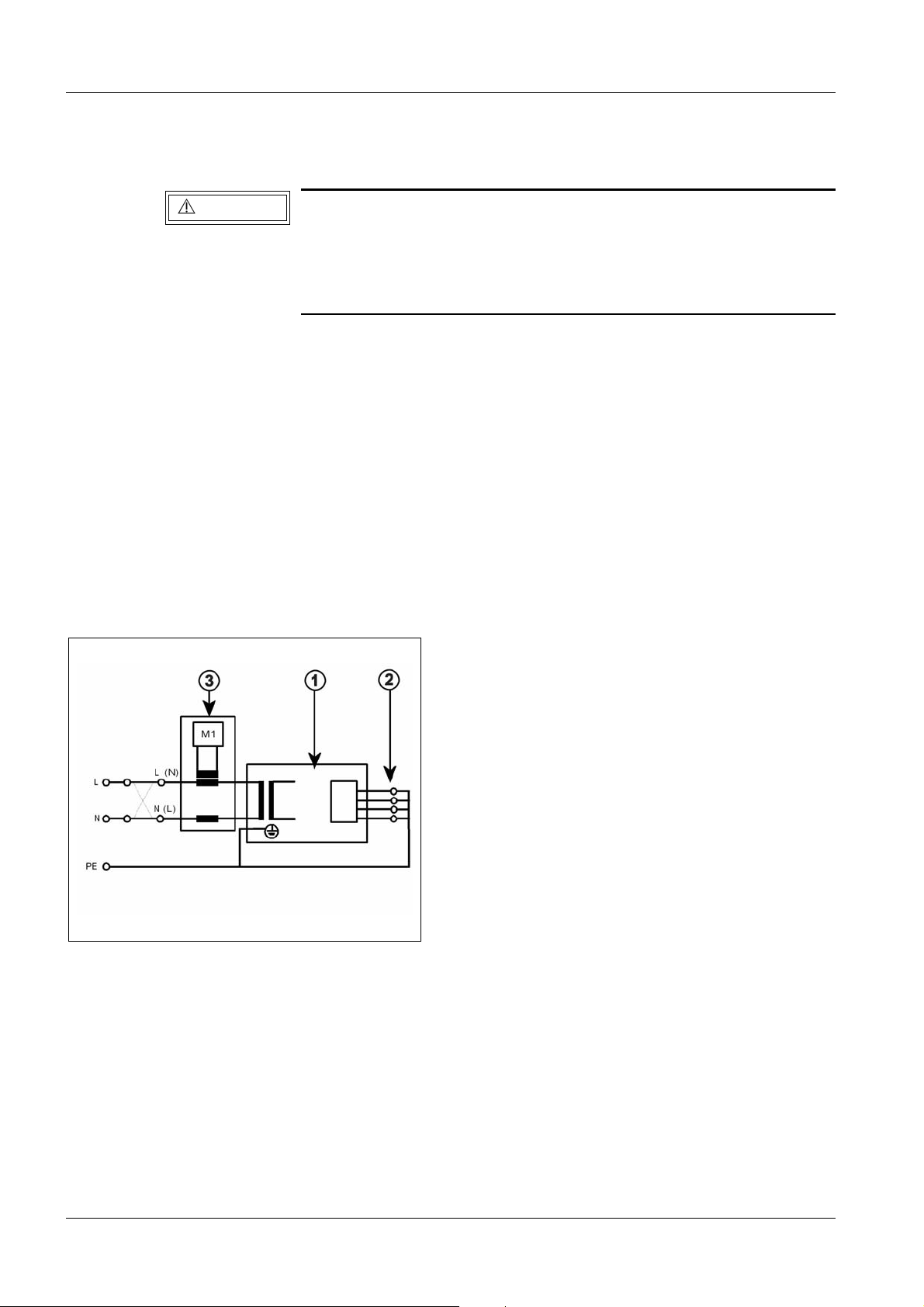

Measurement of the device leakage current according to the differential current method

(measuring arrangement according to Fig. 2) must be given preference, since no danger

for the person performing the measurement and other persons arises during the measurement.

However, please note the minimum resolution of the leakage current measuring instrument and any additional manufacturer's data restricting the use of the measuring instrument.

Fig. 2 Measuring circuit for measuring the device leakage current according to the differential current method

according to DIN VDE 0751-1:2001-10, Fig. C6 for protection class

1 = System

2 = Application part (not present)

3 = Measuring arrangement (integrated in the measuring instrument)

I.

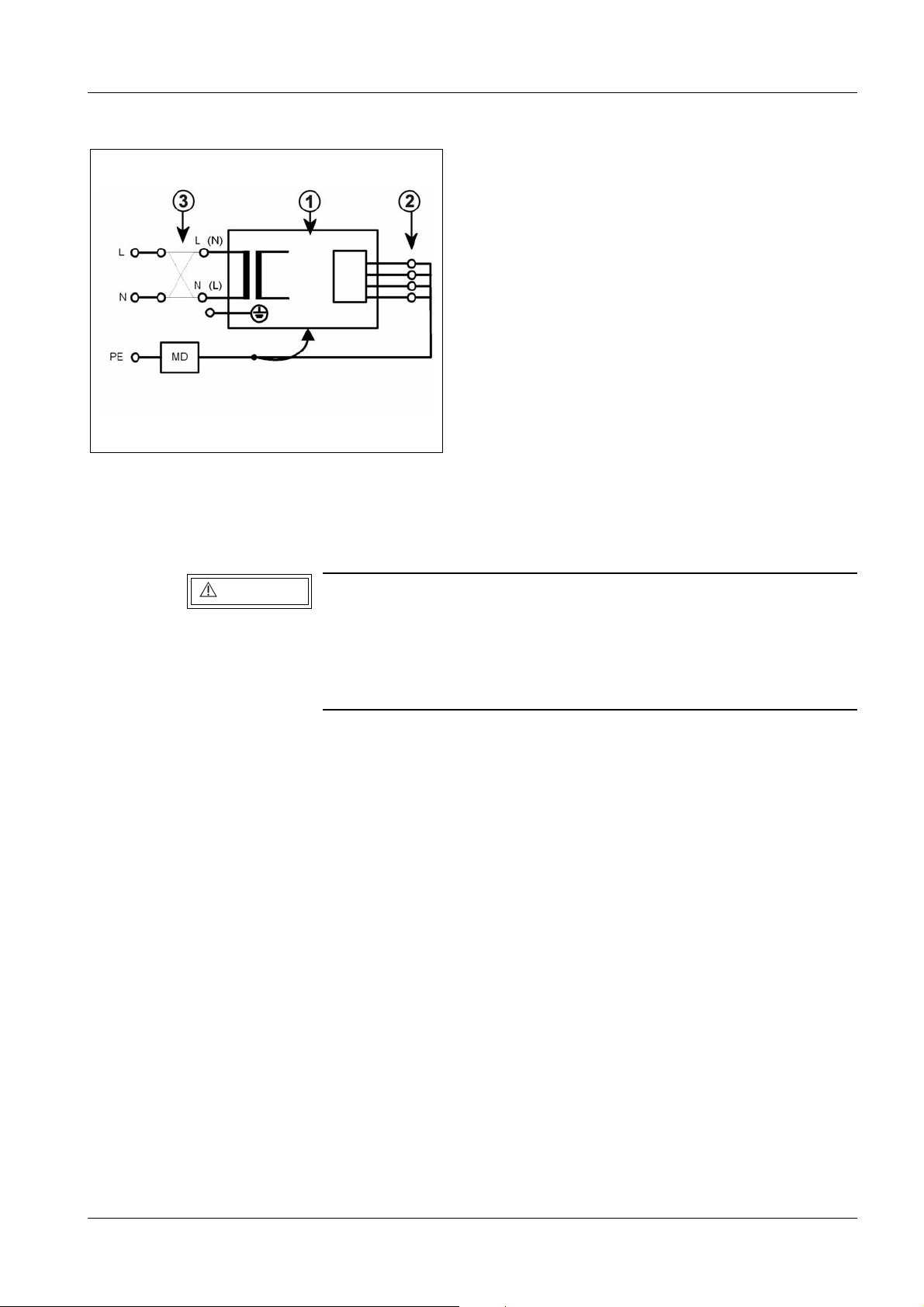

If the direct measurement of the device leakage current is used

(measuring arrangement according to Fig. 3), then the system must be set up insulated

during the measurement and must not be touched during the measurement.

POLYMOBIL III RXB8-115.034.02 Page 6 of 8 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 11

Requirements 1 - 7

Fig. 3 Measuring circuit for the direct measurement of the device leakage current

according to DIN VDE 0751-1:2001-10, Fig. C5 for protection class

1 = System

2 = Application part (not present)

3 = Measuring arrangement (integrated in measuring instrument)

I.

WAR NING

Electrical voltage!

Non-compliance can lead to severe injuries and even death.

No housing parts of the system may be touched during the measurement in the direct measurement of the device leakage current

(measuring arrangement according to Fig. 3).

Third-person access to the system must be prevented.

The system must be switched on during the measurement. Measuring instruments with

automated measuring sequences must therefore be set to manual measurement.

Enter the highest value as first measured value in the report ’Device leakage current /

report’.

This value must not exceed the permissible leakage current values according to

DIN VDE 0751-1:2001-10, Table F.1, line "Device leakage current for devices according to

remarks 1 and 3", of 2.5 mA.

Measure and record the current line voltage. If the measured line voltage deviates from

the nominal voltage, then correct the measured value to the value corresponding to a

measurement at the nominal value of the line voltage. Document this in addition.

Document the measuring procedure (differential measurement or direct measurement)

and the measuring instrument used (designation and serial number).

Repeat measurement

When service or repair work is performed on the primary power supply circuit (e.g. repairs

to the power-on circuit or replacement of the line filter), the device leakage current test

must be repeated.

The same measuring conditions as in the first measurement apply.

Siemens AG RXB8-115.034.02 Page 7 of 8 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 12

1 - 8 Requirements

Record and assess the highest value determined in the repeat measurement in the existing report ’Device leakage current / report’.

This value must not exceed the permissible leakage current values according to

DIN VDE 0751-1:2001-10, Table F.1, line "Device leakage current for devices according to

remarks 1 and 3", of 2.5 mA.

Measure and record the current line voltage. If the measured line voltage deviates from

the nominal voltage, then correct the measured value to the value corresponding to a

measurement at the nominal value of the line voltage. Document this in addition.

Document the measuring procedure (differential measurement or direct measurement)

and the measuring instrument used (designation and serial number).

NOTE

Evaluate the results by comparing the first measured value to the

corresponding values documented during preceding maintenance procedures or safety checks.

A sudden or unexpected increase of the measured values may

indicate that a fault has occurred in the primary circuit of the

power supply (damaged insulation, damage caused by humidity,

defective interference suppressor, etc.) - even if the limit value of

2.5 mA is not exceeded.

Replacement for damaged or lost screws 1

• Damaged or lost screws may be replaced only with screw types that meet specifications,

made of steel per DIN 267 and that have the specified hardness rating.

CAUTION

Replacement of screws.

All Allen screws used must basically have the strength class 8.8.

Cleaning 1

• Prior to cleaning the unit, the unit must always be switched off or disconnected from line

power.

• Clean the unit with just water or with a lukewarm, aqueous solution of water and a

common household cleaning agent.

• Do not use souring powders and no organic solvents or cleaning agents, e.g. cleaning

fluid, alcohol, spot remover, etc.

• Water spraying is not permitted.

• For further information, see the operator manual "Cleaning/Disinfecting".

POLYMOBIL III RXB8-115.034.02 Page 8 of 8 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 13

Unpacking 2

Fig. 1

2 - 1

• Bend the straps on the crate cover upwards and lift off the crate cover.

• Bend open the straps of the side walls and lift off the side walls.

• Place the side wall with the integrated ramp (1/Fig. 1) in front of the pallet and hook in the

fastening straps.

• Remove the plastic cover.

Siemens AG RXB8-115.034.02 Page 1 of 2 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 14

2 - 2 Unpacking

Fig. 2 Fig. 3

• Remove the protective covers on the single tank and the collimator.

• Unscrew the 4 hexagonal head screws (2/Fig. 2, width across flats 17 mm) remove the

bow (3/Fig. 2) and the U-rail (4/Fig. 2).

• Bring the foot pedal from the locked position (5/Fig. 2) into the maneuvering position

(6/Fig. 3). For further foot pedal positions refer to the operator manual.

• Remove the 2 hexagonal head screws and the bow (7/Fig. 2, width across flats 17 mm)

on the left and right of the stand carriage.

• Push the POLYMOBIL III over the rail (8/Fig. 3) and move it over the ramp (9/Fig. 3)

away from the pallet.

POLYMOBIL III RXB8-115.034.02 Page 2 of 2 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 15

Checking and adapting the line voltage 3

3 - 1

7 6 5 4 3 2 1

Fig. 1 Fig. 2

Checking the nominal line voltage 3

240 V

220 V

200 V

125 V

T1

110 V

100 V

4

0 V

3

• Measure the line voltage with the digital multimeter on-site at the wall outlet.

Record the line voltage.

Adaptation of the nominal line voltage. 3

NOTE

If the measured line voltage is

line voltage adaptation at T1!

• At the bottom of the control console loosen the hand screw and the protective conductor

cable shoe (accessible through the cassette compartment).

• Loosen the corrugated hose from the holding clamps.

• Lift the control console at the handle recesses and set it down on a table or similar base.

• Loosen the 4 Allen screws (1/Fig. 1, wrench size 4mm) and lift the cover upwards.

• Loosen the cheese-head screw (2/Fig. 2) and the 2 nuts (3/Fig. 2) and hinge the control

unit to the side.

• At the terminal block of the transformer T1 change the conductor connection from T1.6

(220 V) to T1.7 (240 V) (4/Fig. 2).

• Then close the control console in the reverse order, set it on the mobile stand, fasten it

with the hand screw and connect the protective conductor cable shoe.

≥ 240 V AC, then make a nominal

Siemens AG RXB8-115.034.02 Page 1 of 2 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 16

3 - 2 Checking and adapting the line voltage

This page intentionally left blank.

POLYMOBIL III RXB8-115.034.02 Page 2 of 2 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 17

Functional checks 4

4 - 1

NOTE

If malfunctions occur during these checks, refer to the

service instructions.

Checking the control and display elements 4

• Plug the power connection plug into the grounding type wall outlet.

• Press the ON button on the control console (5/Fig. 4).

During power up the system runs through an initialization phase with the following

conditions:

Initialization - - - - - -

kV mAs

Line voltage L

measurement kV mAs

Line voltage L

display kV mAs

Preferred data 60 10

i n - - -

i n 226 e.g. 226 V AC

kV mAs

The POLYMOBIL III is ready after the acoustic signal stops.

• Go through the mAs values from 0.32 . . . 200 mAs by pressing the ± mAs buttons

• Go through the kV values from 40 . . . 100 kV by pressing the ± kV buttons

NOTE

Exceeding the permissible setting data is not possible.

Siemens AG RXB8-115.034.02 Page 1 of 6 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 18

4 - 2 Functional checks

3

4

2

1

Fig. 1 Fig. 2

Checking the weight counterbalance 4

• Unlock the support arm (1/Fig. 1) and loosen the knob (2/Fig. 1).

It should be possible to move the support arm easily without affixed accessories over the

entire range and it should come to rest in every position.

Readjustment of the weight counterbalance with affixed accessories

Should the support arm not come to rest in every position with affixed accessories, then

readjust the spring tension for the weight counterbalance.

• Remove the cover on the stand (3/Fig. 1).

• Release completely the additional brake on the support arm (2/Fig. 1).

• Move the support arm into the horizontal position.

• Tighten the screw (4/Fig. 2) with a 17 mm fork wrench.

Adjust the spring tension so that there is equilibrium in the horizontal support arm

position, i.e. so that the forces for raising and lowering the tube assembly are the same.

4

POLYMOBIL III RXB8-115.034.02 Page 2 of 6 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 19

Functional checks 4 - 3

7

8

Fig. 3 Fig. 4

Checking the control elements on the double slot diaphragm. 4

• Check the light localizer in each case at the control console and at the double slot

diaphragm.

To do this press the button (6/Fig. 4 or 7/Fig. 3); the light localizer lamp lights up for

20 s

± 1s.

• Check the turning ability of the double slot diaphragm ± 45°.

• By turning the diaphragm setting knobs (8/Fig. 3) check the easy movement and

uniformity of the format setting (leaf pairs).

Checking the exposure release with high-voltage 4

• Close the double slot diaphragm.

Set 60 kV, 10 mAs.

• Pull out the exposure release switch (9/Fig. 4) completely.

9

6

5

10

• Release exposure.

The radiation indicator (10/Fig. 4) lights up for the duration of the exposure, an acoustic

signal sounds at the same time.

• Check that the cable of the exposure release switch (9/Fig. 4) rolls back in without

difficulty after it is pulled out.

Siemens AG RXB8-115.034.02 Page 3 of 6 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 20

4 - 4 Functional checks

Length

Marker

Side marker

Fig. 5

Checking coincidence of light field and radiation field 4

Procedure:

• Load a 24 cm x 30 cm or 10" x 12" cassette with film and place it on a table or similar

support.

• Set vertical SID of 100 cm or 40" to the top edge of the cassette with tape measure,

• Set a format of 18 cm x 24 cm or 8" x 10" with the knobs.

• Switch the light localizer on and align the cassette.

• Place a radio-opaque marker (e.g. washer, coin) on the cassette as shown in Fig. 5.

Position a washer as a side marker.

• Release exposure (60 kV, 10 mAs) and process the film.

• Make a note on the processed film of the following data using a waterproof felt tip pen:

-SID set

- Film size

- Radiation field size

POLYMOBIL III RXB8-115.034.02 Page 4 of 6 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 21

Functional checks 4 - 5

Y

1

Film

Light

Fig. 6

X

2

X

1

Radiation

Y

2

Evaluation:

• Measure the deviations (X1, X2, Y1, Y2) between the edges of the light field and the edg-

es of the radiation field on all four sides as shown in Fig. 6.

• Calculate the overall deviations in the X and Y direction (without regard to the mathemat-

ical sign).

• The length deviation (Σ Y) as well as the width deviation (Σ X) must be less than 1.6 cm in

each case.

Siemens AG RXB8-115.034.02 Page 5 of 6 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 22

4 - 6 Functional checks

Fig. 7 Fig. 8

• If the deviation is greater, loosen the 4 Allen screws (arrow/Fig. 7/Fig. 8) and shift the

collimator correspondingly.

Then tighten the screws on the collimator (arrow/Fig. 7/Fig. 8) again.

• Repeat the test procedure and readjust the collimator until the light and radiation field lies

inside the permissible tolerance (< 1.6 cm).

Checking the exposure switch-off 4

• Check the exposure switch-off in the following settings:

40 kV, 200 mAs (max. mA)

100 kV, 80 mAs (min. mA)

To d o

this:

Release exposure. The radiation indicator (10/Fig. 4) lights up.

The exposure must switch off after 5 s + 3.5 s.

The radiation indicator goes out, the acoustic signal stops.

NOTE

The exposure time depends on the level of the line voltage and

the quality of the mains.

POLYMOBIL III RXB8-115.034.02 Page 6 of 6 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 23

Final work steps 5

Fig. 1

5 - 1

Protective conductor test 5

Observe the notes on the protective conductor test in these instructions.

• Perform the protective conductor test while the system is closed according to

ARTD-002.731.17...

The protective conductor resistance may not exceed 0.2 ohms.

• The values must be recorded as initial measurements in the report ’Protective conductor

resistance / report’ (chapter 7 of these instructions), stating the measuring points.

• In addition document the measuring procedure and the measuring instrument used

(designation and serial number).

Device leakage current measurement 5

Observe the notes on the device leakage current measurement in these instructions.

• Perform the device leakage current measurement while the system is closed according

to ARTD-002.731.17.

The limit of 2.5 mA must not be exceeded.

WAR NING

Electrical voltage!

Non-compliance can lead to severe injuries and even death.

In the direct measurement of the device leakage current no housing parts of the system may be touched during the measurement.

Third-person access to the system must be prevented.

Siemens AG RXB8-115.034.02 Page 1 of 2 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

D

t

af

r

Page 24

5 - 2 Final work steps

• The system must be switched on during the measurement. Measuring instruments with

automated measuring sequences must therefore be set to manual measurement.

• Enter the highest value as first measured value in the report ’Device leakage current /

report’ (chapter 7 of these instructions).

• This value must not exceed the permissible leakage current values of 2.5 mA according

to DIN VDE 0751-1:2001-10, Table F.1, line "Device leakage current for devices

according to remarks 1 and 3".

• Transfer the current line voltage from the ’Start-up report’ into the report ’Device leakage

current / report’. If the current line voltage deviates from the nominal voltage, then correct

the measured value to the value corresponding to a measurement at the nominal value

of the line voltage. Document this in addition.

• Document the measuring procedure (differential measurement or direct measurement)

and the measuring instrument used (designation and serial number).

Reports 5

• Separate the completed 'Start-up report' (chapter 6 of these instructions) from these

instructions and file it in the system folder, "Certificates" register.

• Separate the completed reports 'Protective conductor resistance / report' and

’Device leakage current / report’ (chapter 7 of these instructions) from these instructions

and file them in the system folder , "Certificates" register.

• Complete the 'Installation Protocol' located on the system and send it (per fax) to the

address stated in the protocol.

Last work steps 5

• Wind the power connection cable onto the cable holder on the back of the control

console.

• Lock the support arm in the traveling position (Fig. 1) and check the forced locking of the

support arm.

POLYMOBIL III RXB8-115.034.02 Page 2 of 2 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

D

t

af

r

Page 25

Start-up report 6

POLYMOBIL III Start-up report 6

The Start-up report is arranged analogously to these Start-up instructions.

Article number / type number / serial number: . . . . . . . . . . . . . . . .

Customer: . . . . . . . . . . . . . . . . . . . . Customer number: . . . . . . . . . . . . . . .

6 - 1

1. Check of the nominal line voltage . . . . . . . . . .V

Instrument type: . . . . . . . . . . . . . .

Serial No.: . . . . . . . . . . . . . .

Calibrated up to: . . . . . . . . . . . . . .

2. Adaptation of the nominal line voltage at >

3. Checking the control and display elements ok

4. Checking the weight counterbalance ok

5. Checking the control elements on the double slot diaphragm. ok

6. Checking the exposure release with high-voltage ok

7. Coincidence of light field and radiation field ok

AC

240 VAC on T1

n.a. ok

ΣX: . . . . . . . . . . . cm

ΣY: . . . . . . . . . . . cm

8. Checking the exposure switch-off. ok

9. Protective conductor test

(measured values in separate report

’Protective conductor resistance / report’)

10. Device leakage current measurement

(measured values in separate report

’Device leakage current / report’)

Date: . . . . . . . . . . . . . . Engineer . . . . . . . . . . . . . . . .

ok

ok

Siemens AG RXB8-115.034.02 Page 1 of 2 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

D

t

af

r

Page 26

6 - 2 Start-up report

This page intentionally left blank.

POLYMOBIL III RXB8-115.034.02 Page 2 of 2 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

D

t

af

r

Page 27

Electrical safety / reports 7

Protective conductor resistance / report 7

System:

Material number:

Serial number:

Customer-spec. ident number

Protective conductor resistance

First measured value Repeat measurements value

Meas. point 1:

_____________

Meas. point 2:

_____________

Meas. point 3:

_____________

Meas. point 4

_____________

7 - 1

Meas. point 5

_____________

Meas. point 6

____________

Meas. point 7

____________

Meas. point 8

____________

(*1) Meas. circuit:

Meas. inst.

type:

Meas. inst.

Ser. No.:

Meas. inst.

calibrated up to:

Assessment:

Date:

n.a.

Name:

Signature

(*1) Meas. circuit: see Fig. 1, next page

Siemens AG RXB8-115.034.02 Page 1 of 6 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 28

7 - 2 Electrical safety / reports

Measuring circuit

Fig. 1 Measuring circuit for measuring the protective conductor resistance in systems that are separated from the

power supply, according to DIN VDE 0751-1:2001-10, Fig. C2.

1 = Measuring arrangement (measuring instrument)

2 = System

3 = Application part (if present)

Remarks:

Date Remarks Name Signature

POLYMOBIL III RXB8-115.034.02 Page 2 of 6 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 29

Electrical safety / reports 7 - 3

Device leakage current / report 7

System:

Material number:

Serial number:

Customer-spec. ident number

Device leakage current

Device leakage current

(highest

measured value)

[mA]

Line voltage

during the measurement

[V~]

Device leakage current

(corrected value)

[mA]

(*1) Meas. circuit:

Meas. inst.

type:

Meas. inst.

Ser. No.:

Meas. inst.

calibrated up to:

Assessment:

First measured

value

Repeat measurements value

Date:

Name:

Signature:

(*1) Meas. circuit: See Fig. 2 to Fig. 3, next page

Siemens AG RXB8-115.034.02 Page 3 of 6 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 30

7 - 4 Electrical safety / reports

Measuring circuit

Direct measurement.

Fig. 2 Measuring circuit for the direct measurement of the device leakage

current according to DIN VDE 0751-1:2001-10, Fig. C5

for protective class

1 = System

2 = Application part (if present)

3 = Measuring arrangement (integrated in the measuring

instrument)

I.

Differential measurement

Fig. 3 Measuring circuit for the measurement of the device leakage

current according to the differential current method

complying with DIN VDE 0751-1:2001-10, Fig. C6

for protective class

1 = System

2 = Application part (if present)

3 = Measuring arrangement (integrated in the measuring

instrument)

I.

POLYMOBIL III RXB8-115.034.02 Page 4 of 6 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 31

Electrical safety / reports 7 - 5

Remarks:

Date Remarks Name Signature

Siemens AG RXB8-115.034.02 Page 5 of 6 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 32

7 - 6 Electrical safety / reports

Date Remarks Name Signature

POLYMOBIL III RXB8-115.034.02 Page 6 of 6 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Page 33

Changes to previous version 8

Chapter 0 Cover page, revision level, table of contents changed

Chapter 1 New section 'Notes on the protective conductor resistance test'

inserted.

New section 'Notes on device leakage current measurement'

Chapter 5 Section 'Protective conductor test' changed

New section 'Device leakage current measurement' inserted.

New section 'Reports' inserted.

New section 'Last work steps' inserted.

Chapter 6 Start-up report for protective conductor test and

device leakage current measurement adapted.

Chapter 7 New chapter 'Electrical safety / reports' inserted.

8 - 1

All chapters Editorial changes made.

Siemens AG RXB8-115.034.02 Page 1 of 2 POLYMOBIL III

Medical Solutions Rev. 03 04.05 CS PS 24

Page 34

8 - 2 Changes to previous version

This page intentionally left blank.

POLYMOBIL III RXB8-115.034.02 Page 2 of 2 Siemens AG

Rev. 03 04.05 CS PS 24 Medical Solutions

Loading...

Loading...