Page 1

SiemensUrdaneta

POLYMOBIL III/Plus

Troubleshooting Guide

System

SP

Serial numbers 20,000 and higher

1018780010187803

Print No.:

Replaces: SPR8-125.840.10.03.02

SPR8-125.840.10.04.02

© Siemens

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 05.09

2007

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with

or authorized by Siemens or one of its affiliates are directed to contact one of the local

offices of Siemens or one of its affiliates before attempting installation or service procedures.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 2 of 104

Page 3

Table of Contents 3

0Table of Contents

1 _______ General ________________________________________________________ 6

Safety Notes, Notes and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety information and protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Tools, measurement and auxiliary devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 _______ Overview______________________________________________________ 12

POLYMOBIL III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

D916 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

D922, filament inverter, ON/OFF switching circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 15

U1 power supply unit 5 V ± 5% / 15 V ± 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

U2 power supply unit 12.5 V ± 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D98 Display board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D1/ Measurement circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

C1/ Inverter capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pre-load and discharge resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Status of the LEDs (optimum condition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

POLYMOBIL Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

D916 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

D927 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

U1 power supply unit 5 V ± 5% / 15 V ± 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

U2 power supply unit 12.5 V ± 10% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D952 capacitor charging circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D971 (capacitor bank). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

D98 Display board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C1 main inverter capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

K22 switch-on relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Discharge resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Status of the LEDs (optimum condition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 _______ Error Messages ________________________________________________ 26

POLYMOBIL III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Error 1 - Loss of the + 15 V dc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Error 3 - Oil pressure rise or overheating of the tube . . . . . . . . . . . . . . . . . . . . . . . . 26

Error 4 - Static short circuit of the main inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error 6 - IH heating measured < IH of preheating. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error 7 - IH heating measured > IH allowed by software . . . . . . . . . . . . . . . . . . . . . 28

Error 8 - kV measured < > 0 in idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Error 9 - mA measured < > 0 in idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Error 11 - Voltage too high in the capacitor bank . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Error 12 - Noise in the static short circuit signal in the heating inverter . . . . . . . . . . 29

Error 13 - Voltage in the capacitor bank is low during charge process . . . . . . . . . . . 30

Error 15 - Static short circuit, heating inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Error 22 - short circuit, heating inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Error 23 - Tube current limitation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Error 25 - Preparation timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 3 of 104

Page 4

4 Table of Contents

Error 31 - kV limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Error 34 - Tube current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Error 35 - Short circuit in the main inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Error 36 - Short circuit in the heating inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Error 37 - Regulation failure in the kV loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Error 38 – Regulation failure in the mA loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Error 39 - Exposure timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Error 41 - The exposure has not finished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Error 42 - Heating current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Error 92 - RAM failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Error 93 - Failure in the initial verification of the + 15 V DC. . . . . . . . . . . . . . . . . . . . 35

Error 94 - Difference between doubler signal and voltage level. . . . . . . . . . . . . . . . . 36

Error 95 - Precharge Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Error 96 - Failure of Channel D (KV_NOM) in A/D converter . . . . . . . . . . . . . . . . . . 36

Error 97 - Failure of Channel B (JR_NOM) in A/D converter. . . . . . . . . . . . . . . . . . . 36

Error 98 - Failure of Channel C (Ih_NOM) in A/D converter . . . . . . . . . . . . . . . . . . . 36

POLYMOBIL Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

"Pause" error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Error 1 - Loss of the + 15 V dc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Error 3 - Oil pressure rise or overheating of the tube . . . . . . . . . . . . . . . . . . . . . . . . 37

Error 4 - Static short circuit of the main inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Error 6 - IH heating measured < IH of preheating . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Error 7 - IH heating measured > IH allowed by software . . . . . . . . . . . . . . . . . . . . . . 38

Error 8 - kV measured < > 0 in idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Error 9 - mA measured < > 0 in idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Error 11 - Voltage too high in the capacitor bank. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Error 12 - Noise in the static short circuit signal in the heating inverter. . . . . . . . . . . 40

Error 13 - Voltage in the capacitor bank is low during charge process . . . . . . . . . . . 40

Error 15 - Static short circuit, heating inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Error 22 - Short circuit, heating inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Error 23 - Tube current limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Error 24 - The anode does not get up to its startup speed . . . . . . . . . . . . . . . . . . . . 42

Error 25 - Preparation timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Error 28 - Starter short circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Error 31 - kV limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Error 34 - Tube current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Error 35 - Short circuit in the main inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Error 36 - Short circuit in the heating inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error 37 - Regulation failure in the kV loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error 38 – Regulation failure in the mA loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error 39 - Exposure timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Error 41 - The exposure has not finished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Error 42 - Heating current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Error 92 - RAM failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Error 93 - Failure in the initial verification of the + 15 V DC. . . . . . . . . . . . . . . . . . . . 46

Error 96 - Failure of Channel D (KV_NOM) in A/D converter . . . . . . . . . . . . . . . . . . 46

Error 97 - Failure of Channel B (JR_NOM) in A/D converter. . . . . . . . . . . . . . . . . . . 47

Error 98 - Failure of Channel C (Ih_NOM) in A/D converter . . . . . . . . . . . . . . . . . . . 47

4 _______ Service programs_______________________________________________ 48

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 4 of 104

Page 5

Table of Contents 5

Activation of the service programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

POLYMOBIL III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Service programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

POLYMOBIL Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Service programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5 _______ Measurements _________________________________________________ 59

POLYMOBIL Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

High-voltage circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Filament heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Line voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Measuring KV and JR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Capacitor charging circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Rotating anode starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

kV Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Testing the filament circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Testing and setting the mAs counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Coincidence of light and radiation fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

POLYMOBIL III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Checking the maximum main inverter frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Oscillating current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Checking the high-voltage kV

Checking the filament and tube current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Setting the maximum filament frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Checking the tube current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Checking the kV and tube current (IR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Checking the mAs values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Adjusting the mAs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Coincidence of light and radiation fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

NOM

and kV

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

ACT

6 _______ Changes to previous version ____________________________________ 103

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 5 of 104

Page 6

6 General

Safety Notes, Notes and Symbols 0

1- 1General

DANGER

WARNING

CAUTION

NOTICE

DANGER indicates an immediate danger that if disregarded

will cause death or serious physical injury.

¹

WARNING indicates a possible danger that if disregarded

can cause death or serious physical injury.

¹

CAUTION used with the safety alert icon indicates a possible

danger that if disregarded will or can lead to minor or moderate physical injury and/or damage to property.

¹

NOTICE used without the safety alert icon indicates a possible danger that if disregarded can or will lead to an undesirable outcome or state other than death, physical injury or

property damage.

¹

NOTE

NOTE is used to indicate information that explains the proper

way to use devices or to carry out a process, i.e., provides

pointers and tips.

X Warning about ionizing radiation or radioactive substances. Tests and adjustments that

must be performed with the radiation switched on are indicated by this radiation warning

icon.

V Dangerous electrical voltage > 25 VAC or > 60 VDC.

C Caution! General hazard warning.

E ESD: Warning about electrostatically sensitive components.

P Report icon. Used to indicate entries in certificates.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 6 of 104

Page 7

General 7

Safety information and protective measures 1.1

WARNING

WARNING

Risk of death, injury or material damage.

Strictly follow

- the product-specific safety information, the general safety

information in the document TD00-000.860.01... and the

safety information according to ARTD Part 2.

¹ Non-compliance can lead to death, injuries, or material

damage.

X-ray radiation!

When working on the system where radiation has to be

released, comply with all radiation protection directives and

the rules for radiation protection according to

ARTD-002.731.02.

¹ Non-compliance can lead to illnesses, irreversible

damage to body cells and to genetic make-up, severe

injuries, or death.

¹ Use available radiation protection devices.

¹ Wear radiation protection clothing (lead apron).

¹ Maintain the greatest possible distance from the radia-

tion source.

¹ Release radiation only if necessary.

¹ Set radiation activity as low as possible (low KV and

mAs values).

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 7 of 104

Page 8

8 General

WARNING

POLYMOBIL Plus! (with X3 connected!)

To avoid electrical shock from components under voltage,

also be aware that:

The capacitor bank might still carry a charge. Do not attempt

to work on the system while this condition exists.

After switching off the system, approximately 450 VDC may

still be present in the system even after disconnecting the

line voltage plug. Within 10 minutes, this voltage will drop to

approximately 10 V.

¹ Inspect LEDs V40 and V41 on D927, which is dis-

charged with the bank.

¹ Measure the voltage between the chassis and the right

side of F5 (D927) --> X3 connected!

¹ Before beginning any service work, wait until the volt-

age drops to approx. 10V within approx. 10 minutes;

the LEDs V1 to V10 on D 971 are then off (each of them

represents the voltage in one condenser).

¹ If one or more fuses on the D 971 have responded, high

voltage may still be present at the affected capacitor

even after a prolonged period of time.

¹ If connector X3 or X9 on D 927 or D 952 are not inserted

or there is a defect in the circuit, the capacitor bank will

not discharge. This can cause life-threatening voltage

to be present in the system even after a prolonged

period of time.

¹ Refer to the POLYMOBIL III/ Plus “Replacement of

parts, SPR8-125.841.10... ".

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 8 of 104

Page 9

General 9

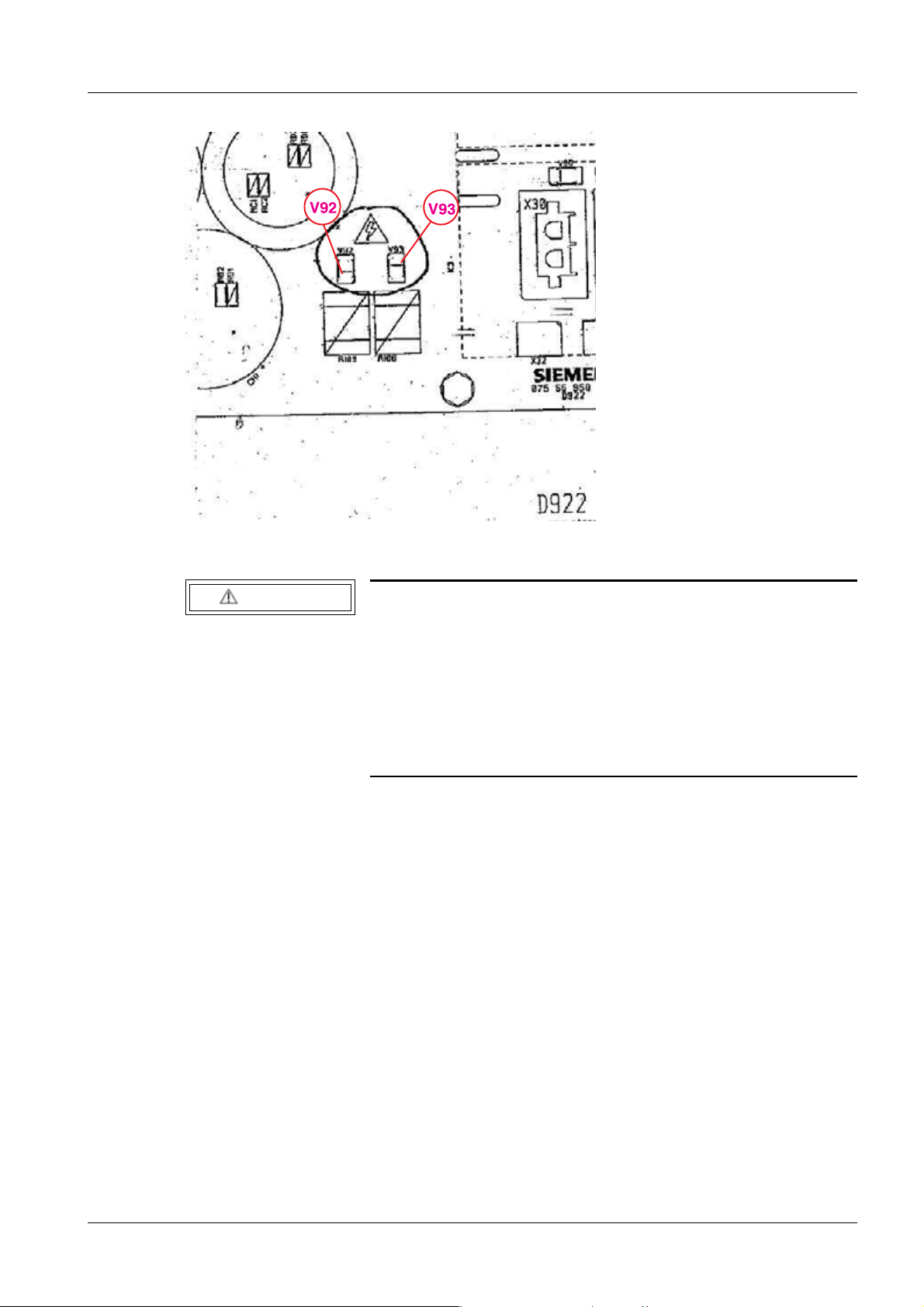

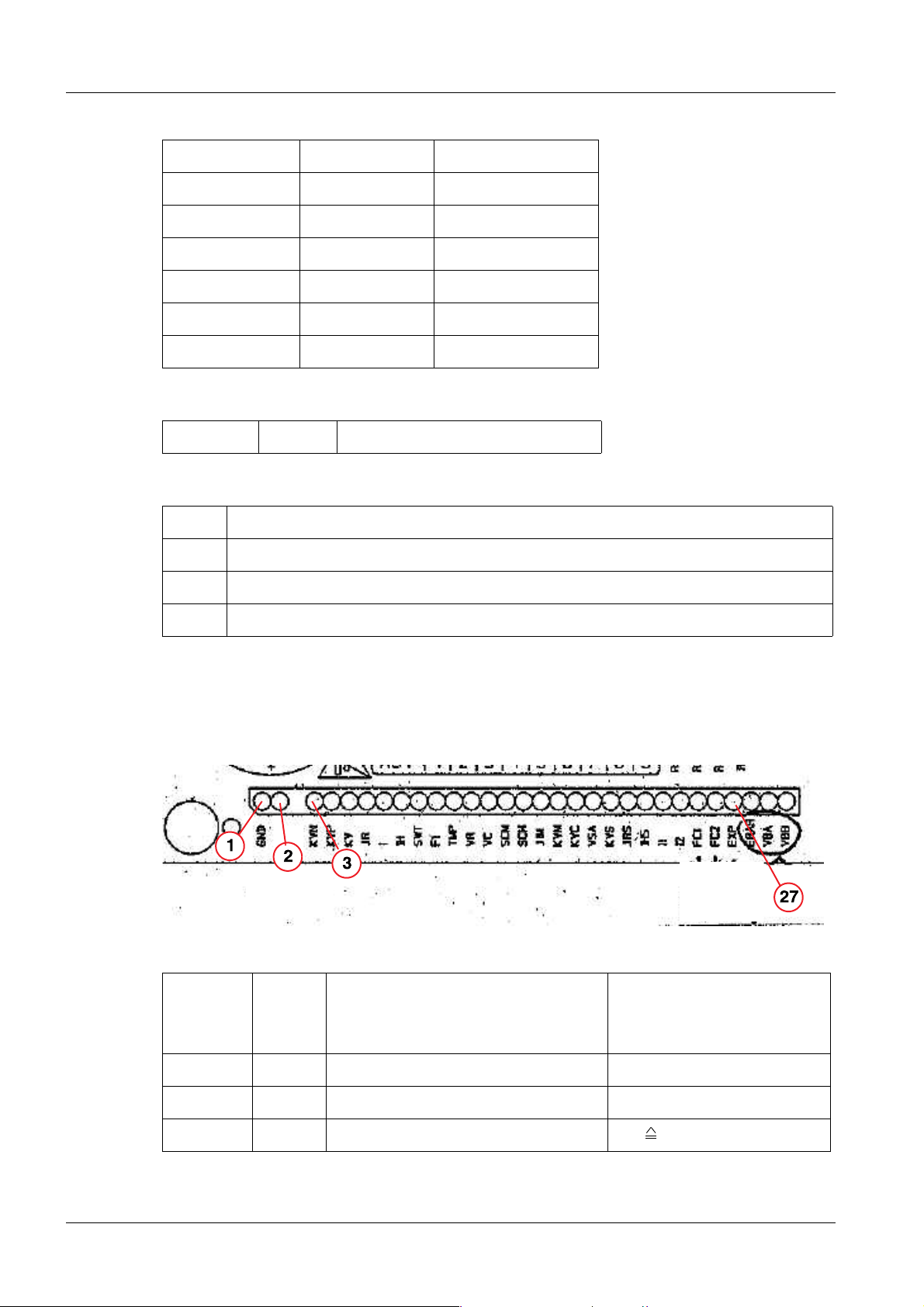

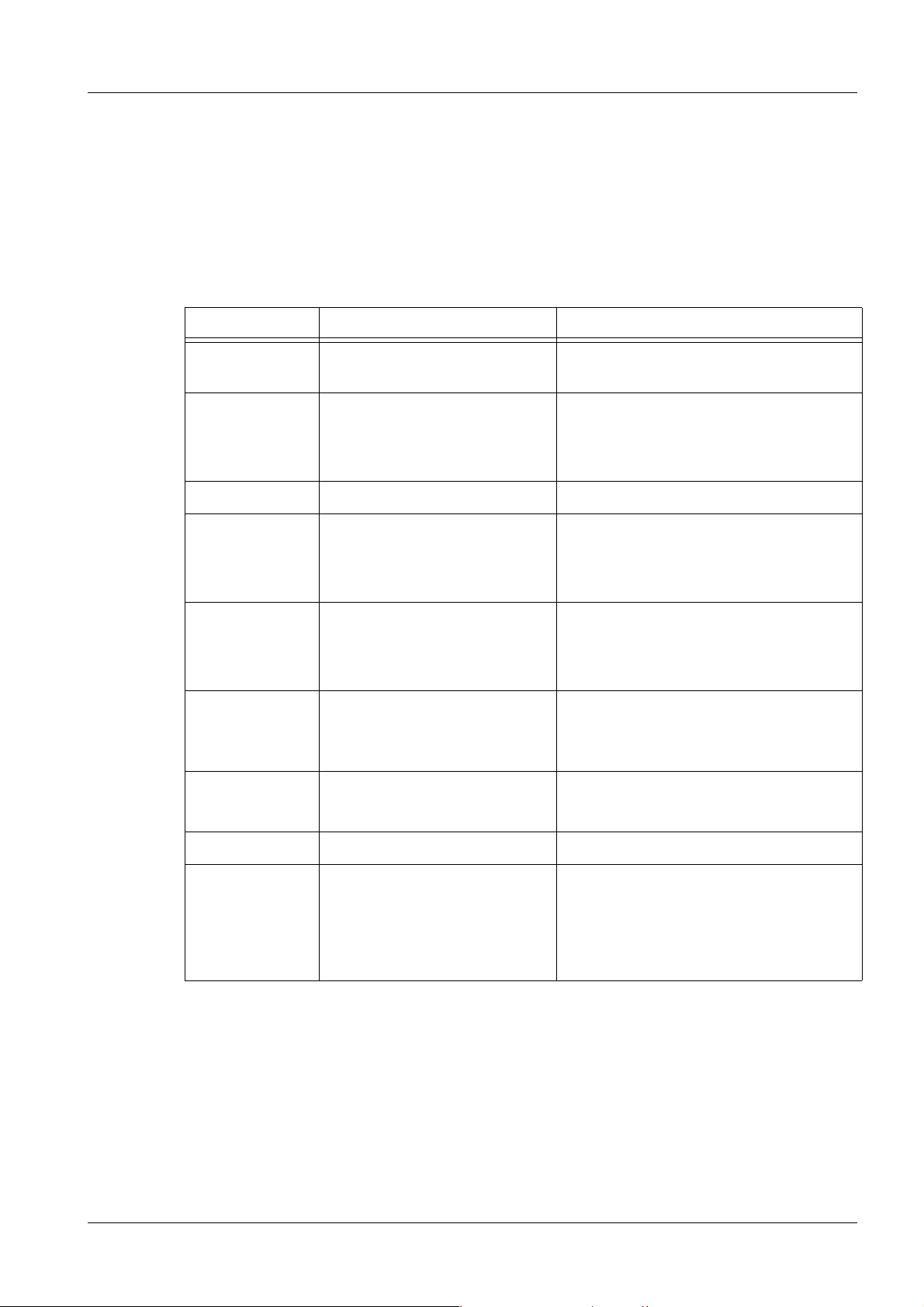

Fig. 1: D922_V92_V93

WARNING

POLYMOBIL III! To avoid electrical shock from components

under voltage, also be aware that:

After the system is switched off, around 300 V direct voltage

are present in the control console for the main inverter.

¹ Before beginning any service work, wait until the volt-

age drops to approx. 12V within approx. 1.5 minutes;

the LED‘s V92 and V93 on D922 are then off. V92: - 330

V, V93: + 330 V, see (Fig.1/p.9).

• Connect the POLYMOBIL Plus / III only to a line voltage supply (receptacle) that com-

plies with the requirements of VDE 0107 or corresponds to the local national standards.

• In general, switch off the system and disconnect the power cable from the mains prior to

any service work.

• Remove or insert boards with the generator switched OFF only; observe ESD guide-

lines when handling boards.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 9 of 104

Page 10

10 General

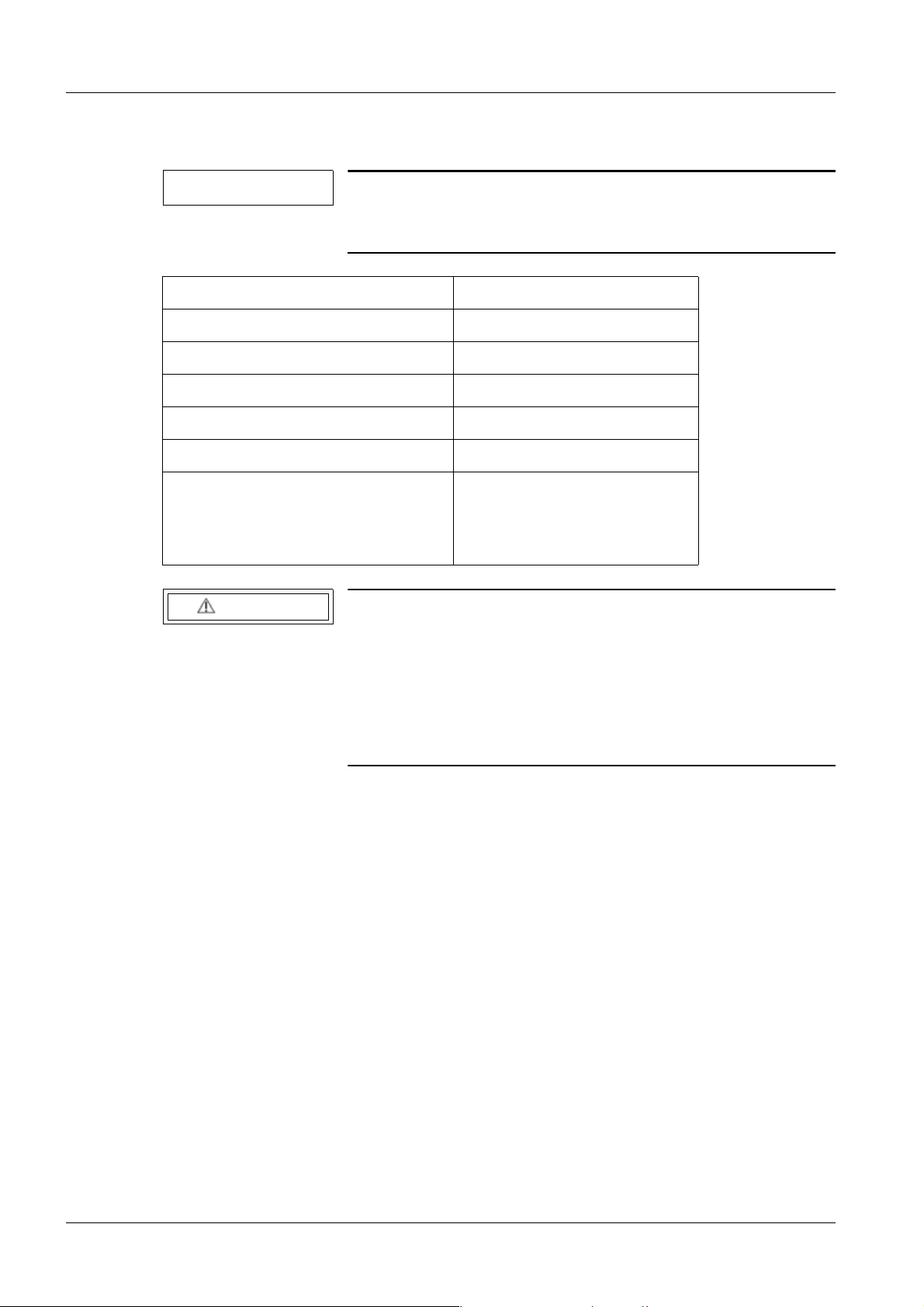

Tools, measurement and auxiliary devices 1.2

NOTE

All tools, measurement and auxiliary devices with the exception of those marked " * " are listed along with their specifications in the STC (Service Tools Catalog).

Standard service kit* n/a

Digital multimeter n/a

2-channel memory oscilloscope n/a

mAs meter n/a

Protective conductor meter n/a

Equivalent leakage current meter n/a

Current transformer (50 A : 50 mA)*

Part no. 31 51 289

In addition, a metal film resistor with

10 Ohms; 0.5 W; 1% is required*

Refer also to Speed Info 06/91

WARNING

Dangerous electrical voltage present during service work!

Risk of death or serious physical injury.

¹ The oscilloscope must be connected to ground before

measurements are performed. A TEK video isolator

and the trigger set must be used whenever there is a

risk of ground loops distorting the measurement

results (see ARTD-002.731.22...).

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 10 of 104

Page 11

General 11

Cleaning 1.3

• The unit must always be switched off and disconnected from the mains before clean-

ing. Use only water to clean the unit or a lukewarm solution consisting of water and a

household cleaning agent.

• Do not use abrasive cleaning agents or organic solvents such as benzene, alcohol, or

spot remover.

• Do not spray water on the unit.

• For additional information, refer to the Operating Instructions.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 11 of 104

Page 12

12 Overview

2- 2Overview

NOTICE

To check the assemblies, remove the upper covers, the handles, and the lower front cover of the switchbox.

¹ Follow the Replacement Instructions,

SPR8-125.841.10...

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 12 of 104

Page 13

Overview 13

POLYMOBIL III 2.1

D916 0

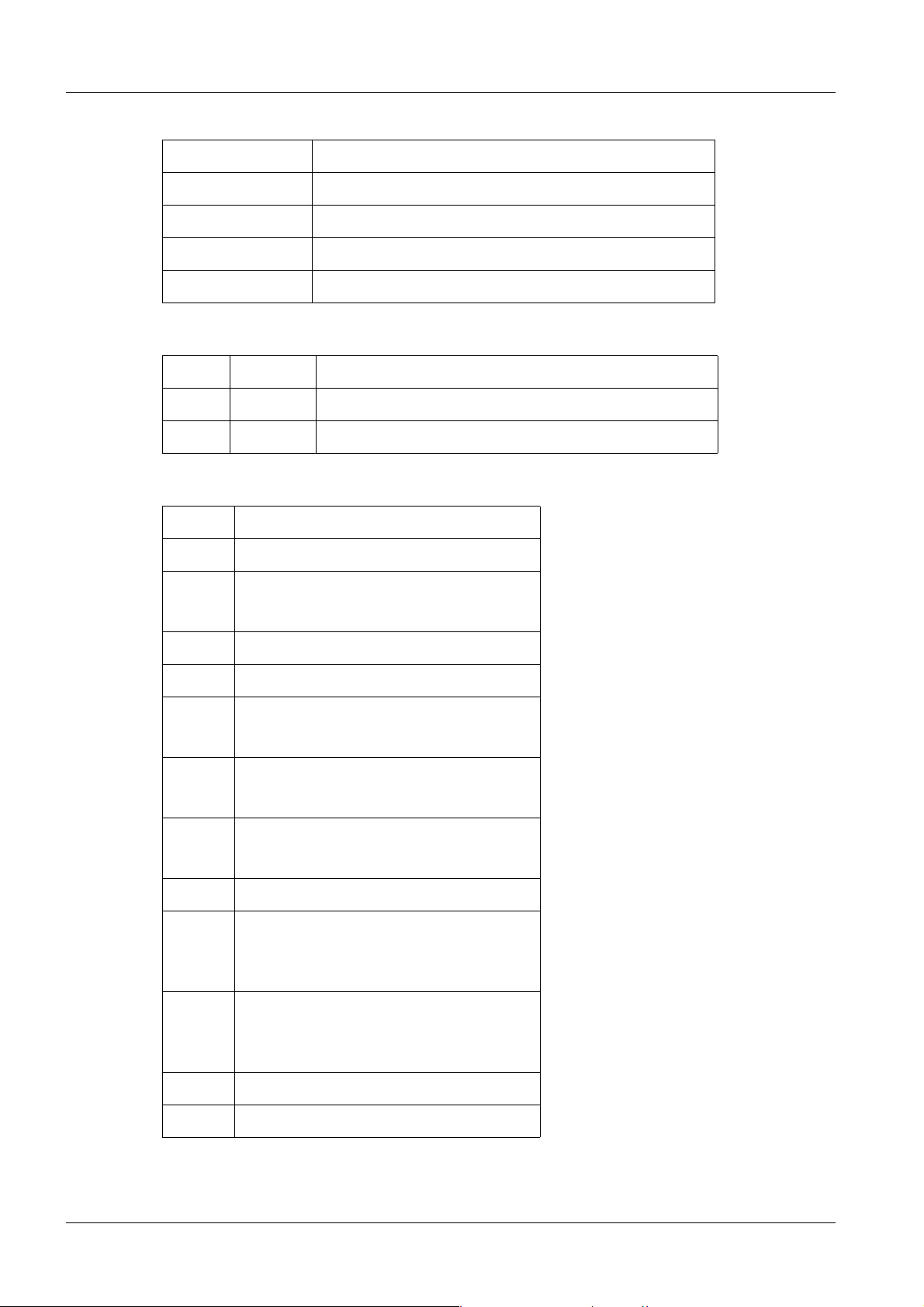

D916 CPU, control and measurement value acquisition

Overview D916:

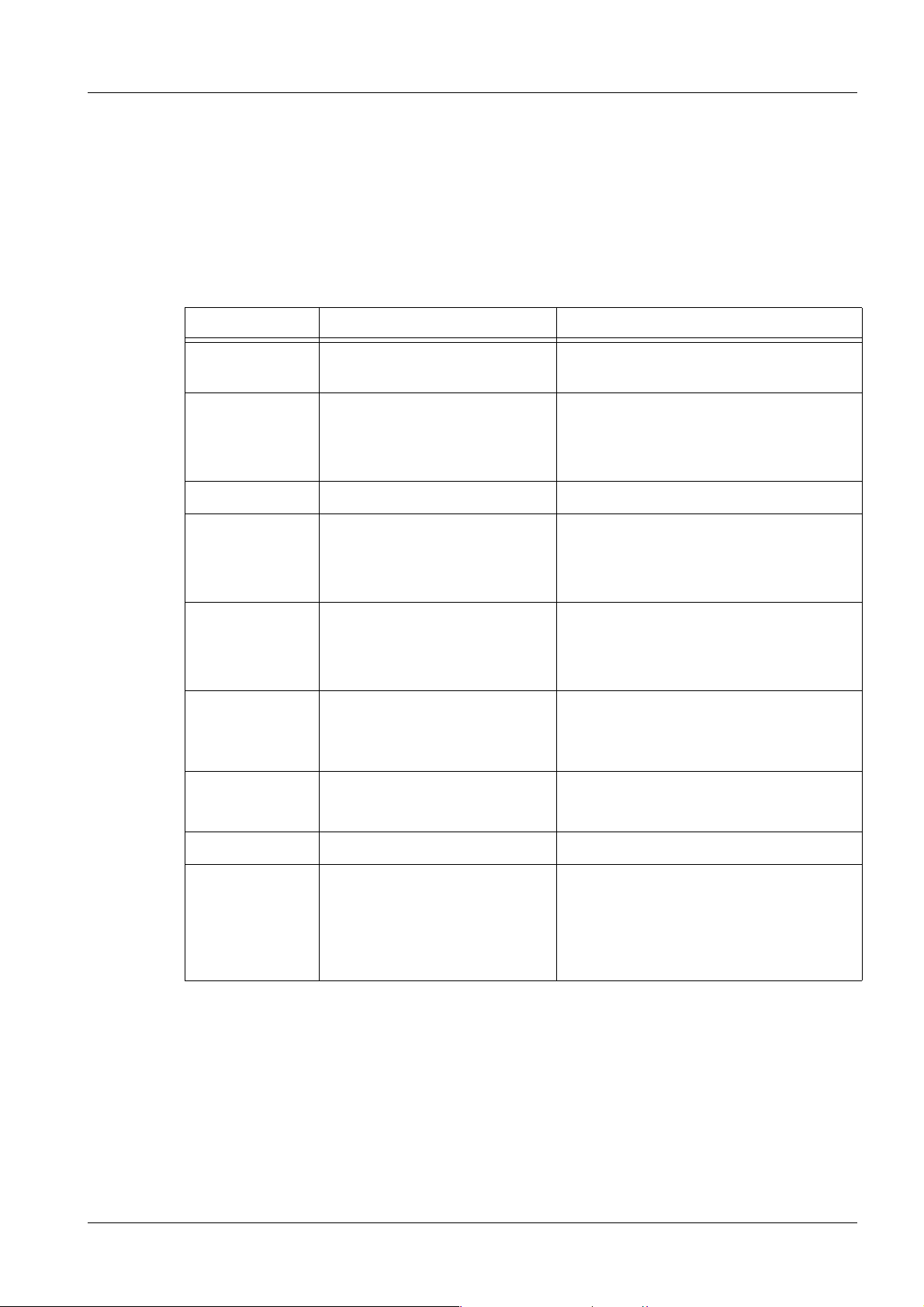

Name Function / Information Value

V24 This blinks when the software

is working

P1 This adjusts the mAs counter Adjusted service program 14:

P2 Not used n/a

P3 Adjustment of the maximum

frequency of the heating converter

P4 Adjustment of the maximum

frequency of the main inverter

P5 Adjustment of heating current Test point "I" Resonance, pre-adjust-

SW2B Operating modes:

n/a

320 kHz

(test point F1 adjusted in the factory)

Service Program 9:

80 kHz ± 1 kHz

(Test point "FC1")

Service Program 7:

24.5 kHz ± 0.5 kHz

(test point "FC2")

ment:

test point "IH" fine tuning

Normal: Position 1

Normal / service

SW1 For factory use only Do not use

SW3 Button

Operating modes:

Activation/reset

Power connector D916.X15:

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 13 of 104

Service: Position 2

SW2B in position 2: Press

= Service Mode

SW2B in position 1: Press

= Normal Mode

Page 14

14 Overview

D916.X15 Pin Color

1 black Ground (+ 5 V)

3 black Ground (+ 5 V)

4 red + 5 V ± 5 %

5 brown +15 V ± 10%

6 blue Ground (+/- 15 V)

7 yellow -15 V ± 10%

LED D916:

V24 ON Blinking during exposure

Potentiometers D916:

P1 OFFSET of mAs converter. Set at the factory - Do not change!

P3 Filament inverter frequency

P4 Main inverter frequency

P5 Adjustment/setting of filament heating circuit

Reset - switch

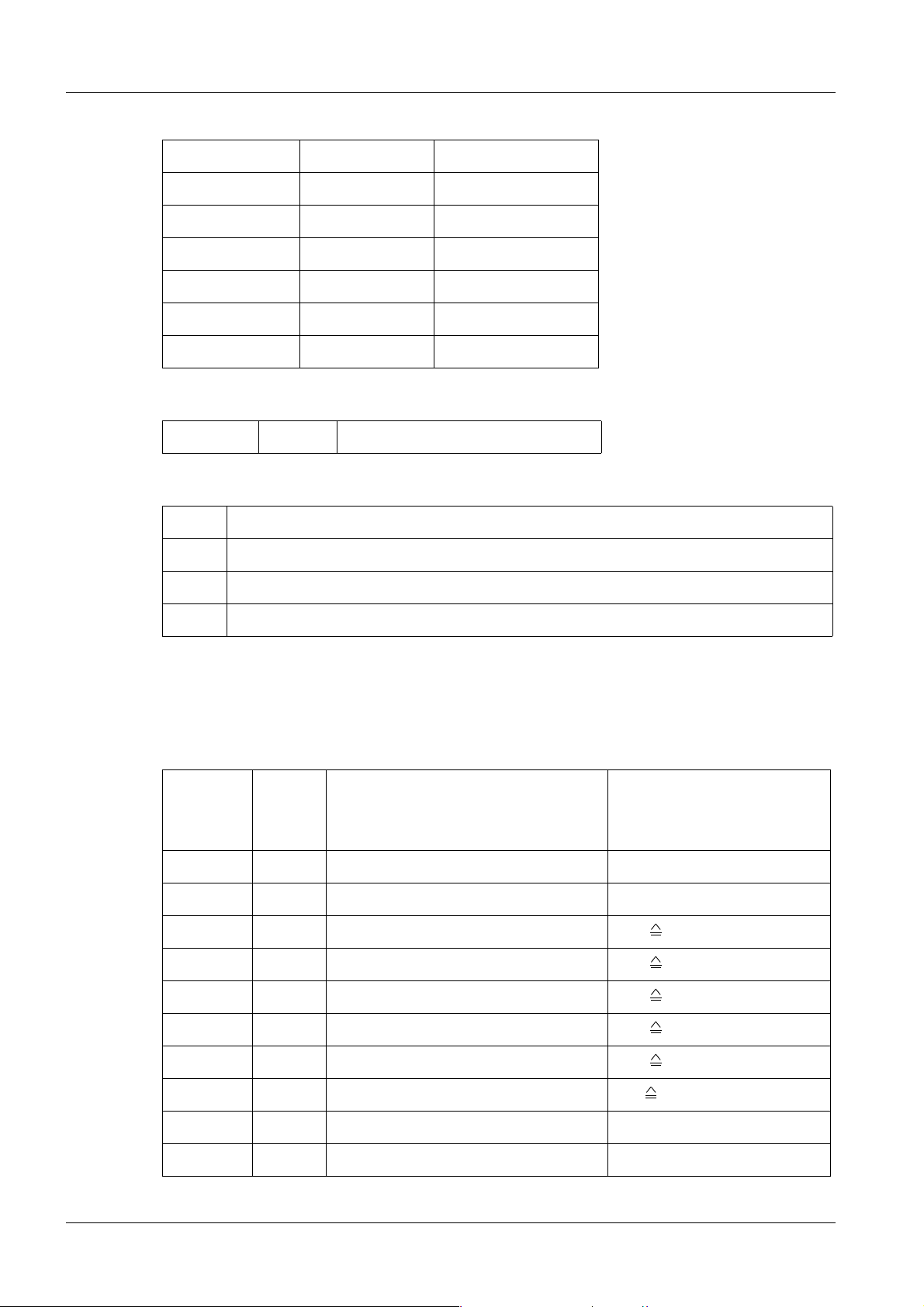

Test points D916 CPU

Fig. 2: D916_test points

Left to

right

TP Function/information Measurement

Range

1 GND Mass measurement n/a

2 GND Mass measurement n/a

3 KVN Negative branch 1 V 10 k V

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 14 of 104

Page 15

Overview 15

4 KVP Positive branch 1 V 10 k V

5 KV “Kv Ist” in tube 1 V 30 k V

6 JR Tube current 1 V 10 mA

7 I Heating resonant current 1 V 1 A (primary)

8 IH Heating current 1 V 1.2 A (secondary)

9 SWT Switching to regulate tube current High = kV > 70% “KV soll”

10 F1 mAs integration frequency max. 5V/ 320 kHz

11 TMP Single tank temperature

12 VR Reference voltage 5 V - dc ± 0.01

13 VC Capacitor bank voltage 1 V 100 V

14 SCM Main inverter short circuit Error 35 and 4

15 SCH Heating inverter short circuit Error 22, 36, 15 and 12

16 JIM Tube overcurrent (heating or rays) Error 23 or Error 34

17 KVM KV overvoltage (positive or negative

branch)

18 KVC Main inverter resonance current 1 V 50 A

19 VSA Not used n/a

20 KVS "KV soll" (kv selected) 1 V 30 kV

21 JRS "Soll tube current" (mA required) 1 V 10 mA

22 IHS "Soll heating current" (ih required) 1 V 1.2 As

25 FC1 Current inverter frequency

26 FC2 Main inverter frequency

27 EXP High = no exposure (kV regulator

disabled) Low = Exposure

Error 31

D922, filament inverter, ON/OFF switching circuit 0

LED:

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 15 of 104

Page 16

16 Overview

V86 +15 V for inverter frequency OK and 24 V presence

V85 24 V presence

V15 Auxiliary voltage OK

V3 Collimator On

V93, V92 DC voltage BUS

Fuses:

F1 15 AT Phase line fuse

F2 15 AT Neutral line fuse

F3 1 AT +24 voltage fuse

Measurement points:

VP 0V

0V24 Ground 24V

P24V +24V

HIP5 +5V

GNDA Ground 5V

HIER Error drivers heating current

(ground for tester GNDA)

HID1 control TRANSISTOR High

(ground for tester GNDA)

HID2 control TRANSISTOR Low

(ground for tester GNDA)

FAUX Hz generation auxiliary supplies

HVD1 Control transistors High and Low of the

other branch (Main Inverter)

(ground for tester GNDC)

HVD2 Control transistors Low and High of the

other branch (Main Inverter)

(ground for tester GNDC)

HVRS Reset of the drivers of Main Inverter

HVER Error in the drivers of Main Inverter

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 16 of 104

Page 17

Overview 17

U1 power supply unit 5 V ± 5% / 15 V ± 10% 0

Fuse: 2 A T

U2 power supply unit 12.5 V ± 10% 0

Fuse: 5 A T

D98 Display board 0

The display board shows the selected mAs and KV values. By pressing the membrane keyboard button, you can change the ON/OFF, KV, and mAs values.

D1/ Measurement circuit 0

The D1 measurement board of the high voltage main circuit represent KV and mA values

to the CPU.

C1/ Inverter capacitor 0

The C1 capacitor is the capacitive portion of the main inverter. The C1 single tank belongs

to the high voltage circuit.

Pre-load and discharge resistors 0

The pre-load and discharge resistors are responsible for the switch-on current and the discharge of the capacitor within 10 minutes after the system has been switched off, from

approximately 400VDC to a level below 10VDC.

Status of the LEDs (optimum condition) 0

a) POLYMOBIL III OFF, line voltage plug connected:

D922: LED V85 24V presence

b) POLYMOBIL III ON, standby

D922: LED V86 ON 15V and 24V presence

LED V85 ON 24V presence

LED V15 ON Auxiliary voltage OK

LED V93 ON DC bus voltage

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 17 of 104

Page 18

18 Overview

LED V92 ON DC bus voltage

LED V3 OFF ON, if collimator button is pushed

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 18 of 104

Page 19

Overview 19

POLYMOBIL Plus 2.2

D916 0

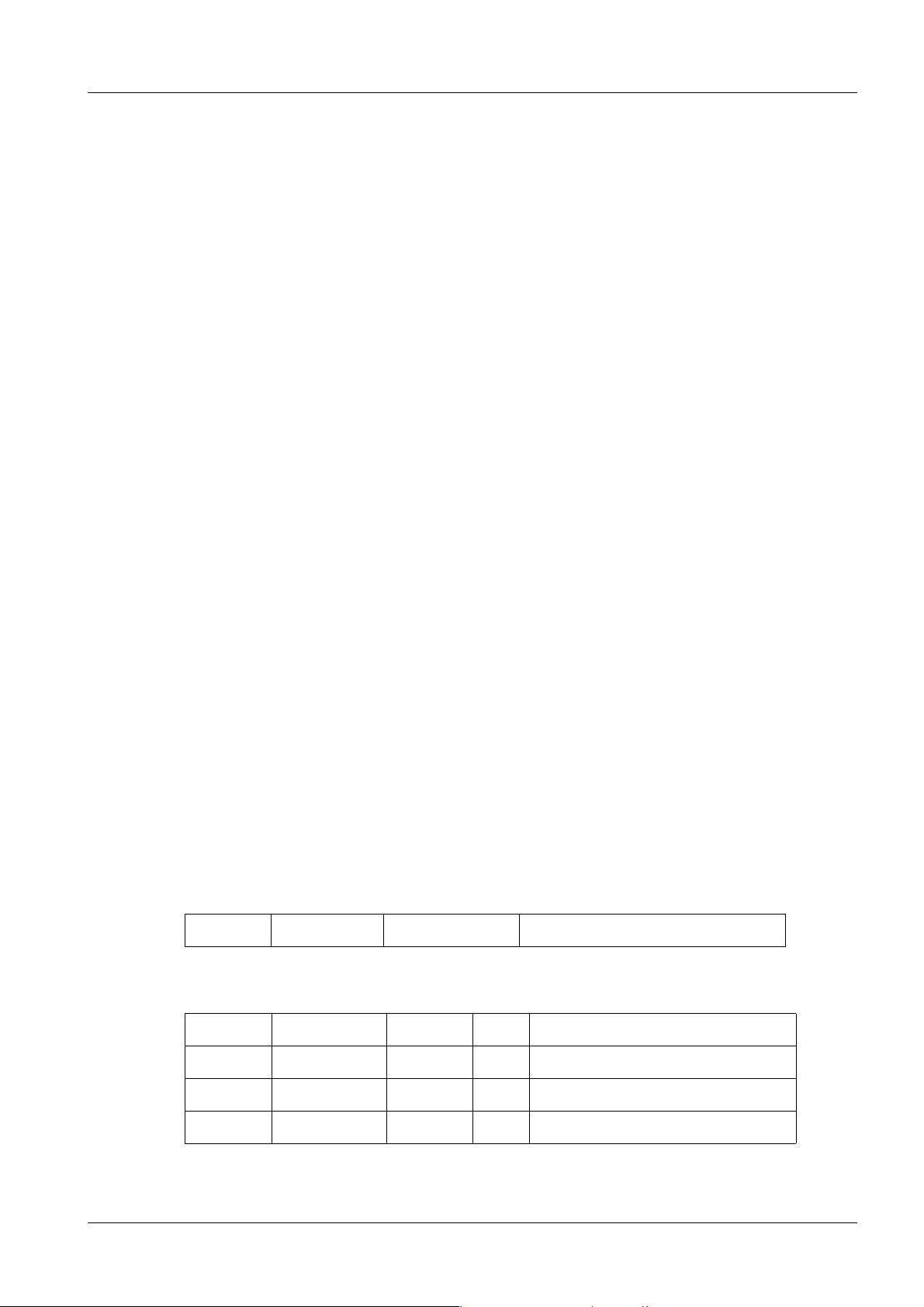

D916 CPU, control and measurement value acquisition

Overview D916:

Name Function / Information Value

V24 This blinks when the software

is working

P1 This adjusts the mAs counter Adjusted service program 14:

P2 Not used n/a

P3 Adjustment of the maximum

frequency of the heating converter

P4 Adjustment of the maximum

frequency of the main inverter

P5 Adjustment of heating current Test point "I" Resonance, pre-adjust-

SW2B Operating modes:

n/a

320 kHz

(test point F1 adjusted in the factory)

Service Program 9:

80 kHz ± 1 kHz

(Test point "FC1")

Service Program 7:

18 kHz ± 0.5 kHz

(test point "FC2")

ment:

test point "IH" fine tuning

Normal: Position 1

Normal / service

SW1 For factory use only Do not use

SW3 Button

Operating modes:

Activation/reset

Power connector D916.X15:

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 19 of 104

Service: Position 2

SW2B in position 2: Press

= Service Mode

SW2B in position 1: Press

= Normal Mode

Page 20

20 Overview

D916.X15 Pin Color

1 black Ground (+ 5 V)

3 black Ground (+ 5 V)

4 red + 5 V ± 5 %

5 brown +15 V ± 10%

6 blue Ground (+/- 15 V)

7 yellow -15 V ± 10%

LED D916:

V24 ON Blinking during exposure

Potentiometers D916:

P1 OFFSET of mAs converter. Set at the factory - Do not change!

P3 Filament inverter frequency

P4 Main inverter frequency

P5 Adjustment/setting of filament heating circuit

Reset - switch

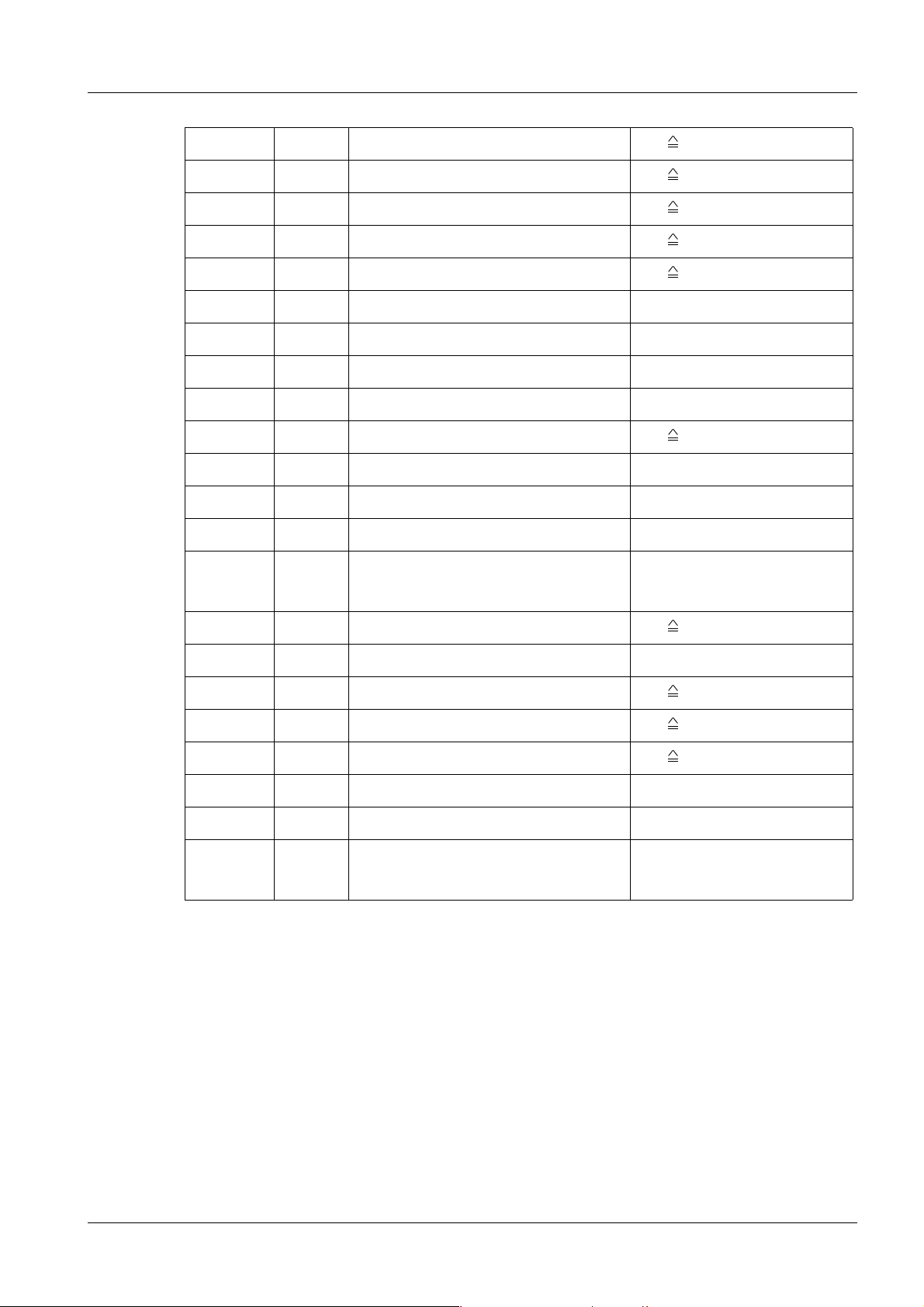

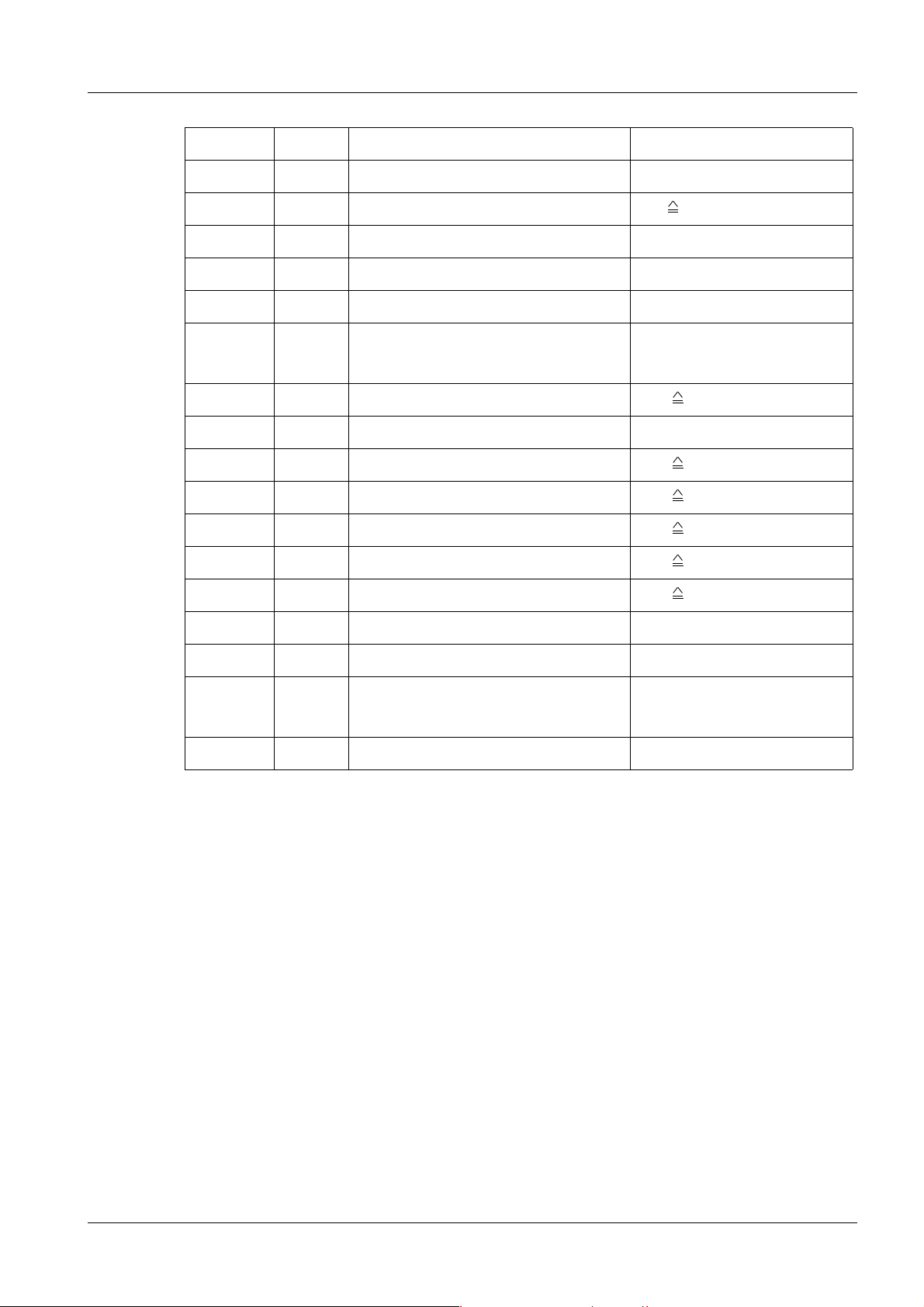

Test points D916 CPU

Left to

right

Range

1 GND Mass measurement n/a

2 GND Mass measurement n/a

3 KVN Negative branch 1 V 10 k V

4 KVP Positive branch 1 V 10 k V

5 KV “Kv Ist” in tube 1 V 30 k V

TP Function/information Measurement

6 JR Tube current 1 V 100 mA

7 I Heating resonant current 1 V 1 A (primary)

8 IH Heating current 1 V 1.2 A (secondary)

9 SWT Switching to regulate tube current High = kV > 70% “KV soll”

10 F1 mAs integration frequency max. 5V/ 320 kHz

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 20 of 104

Page 21

Overview 21

11 TMP Single tank temperature

12 VR Reference voltage 5 V - dc ± 0.01

13 VC Capacitor bank voltage 1 V 100 V

14 SCM Main inverter short circuit Error 35 and 4

15 SCH Heating inverter short circuit Error 22, 36, 15, and 12

16 JIM Tube overcurrent (heating or rays) Error 23 or Error 34

17 KVM KV overvoltage (positive or negative

branch)

18 KVC Main inverter resonance current 1 V 50 A

19 VSA Not used n/a

20 KVS "KV soll" (kv selected) 1 V 30 kV

21 JRS "Soll tube current" (mA required) 1 V 100 mA

Error 31

22 IHS "Soll heating current" (ih required) 1 V 1.2 As

23 I1 "Motor current" (stator 1 rewinding) 1 V 4 A

24 I2 "Motor current" (stator 2 rewinding) 1 V 4 A

25 FC1 Current inverter frequency

26 FC2 Main inverter frequency

27 EXP High = no exposure (kV regulator

disabled) Low = Exposure

28 ERAR Starter signal Error 28

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 21 of 104

Page 22

22 Overview

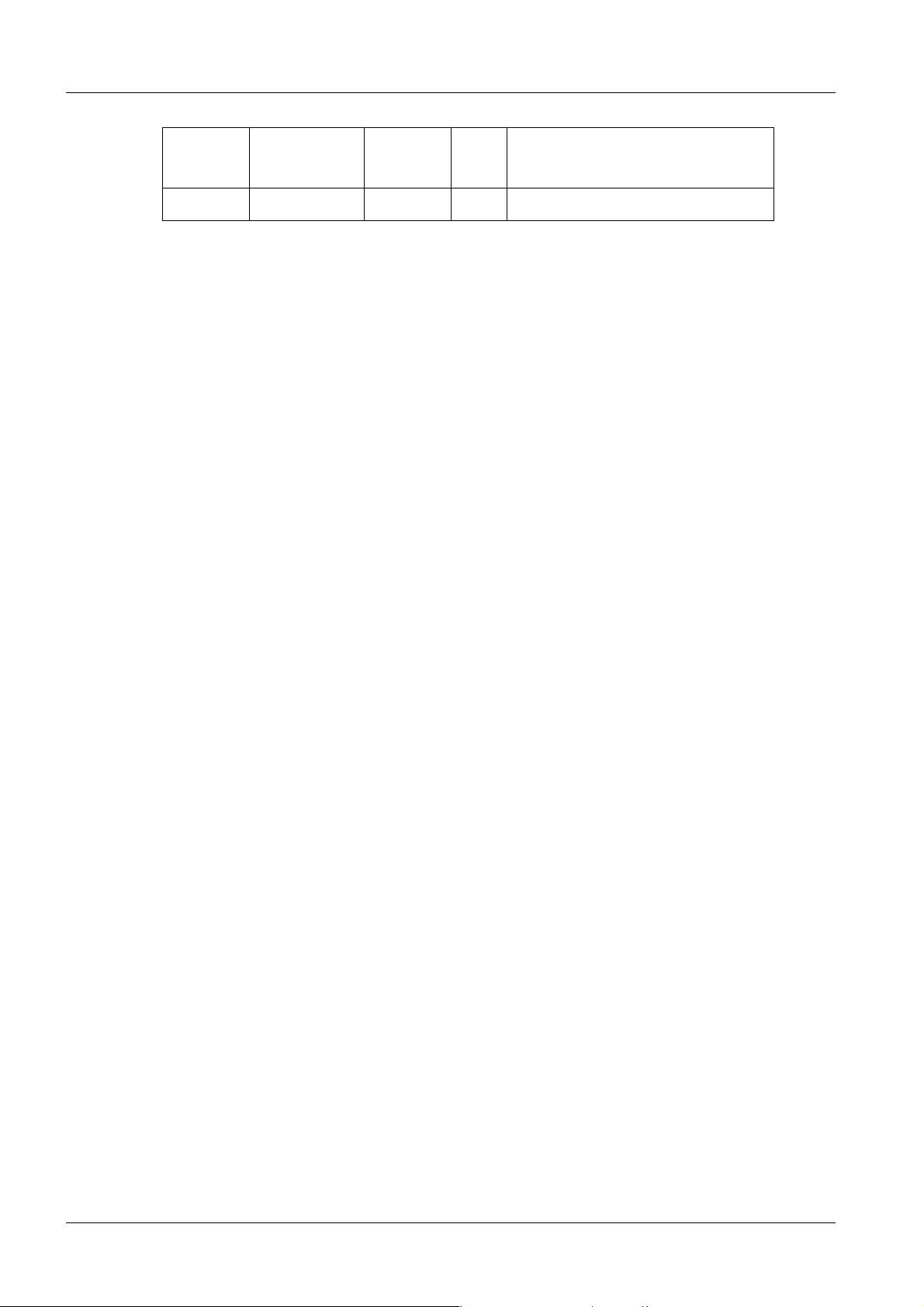

D927 0

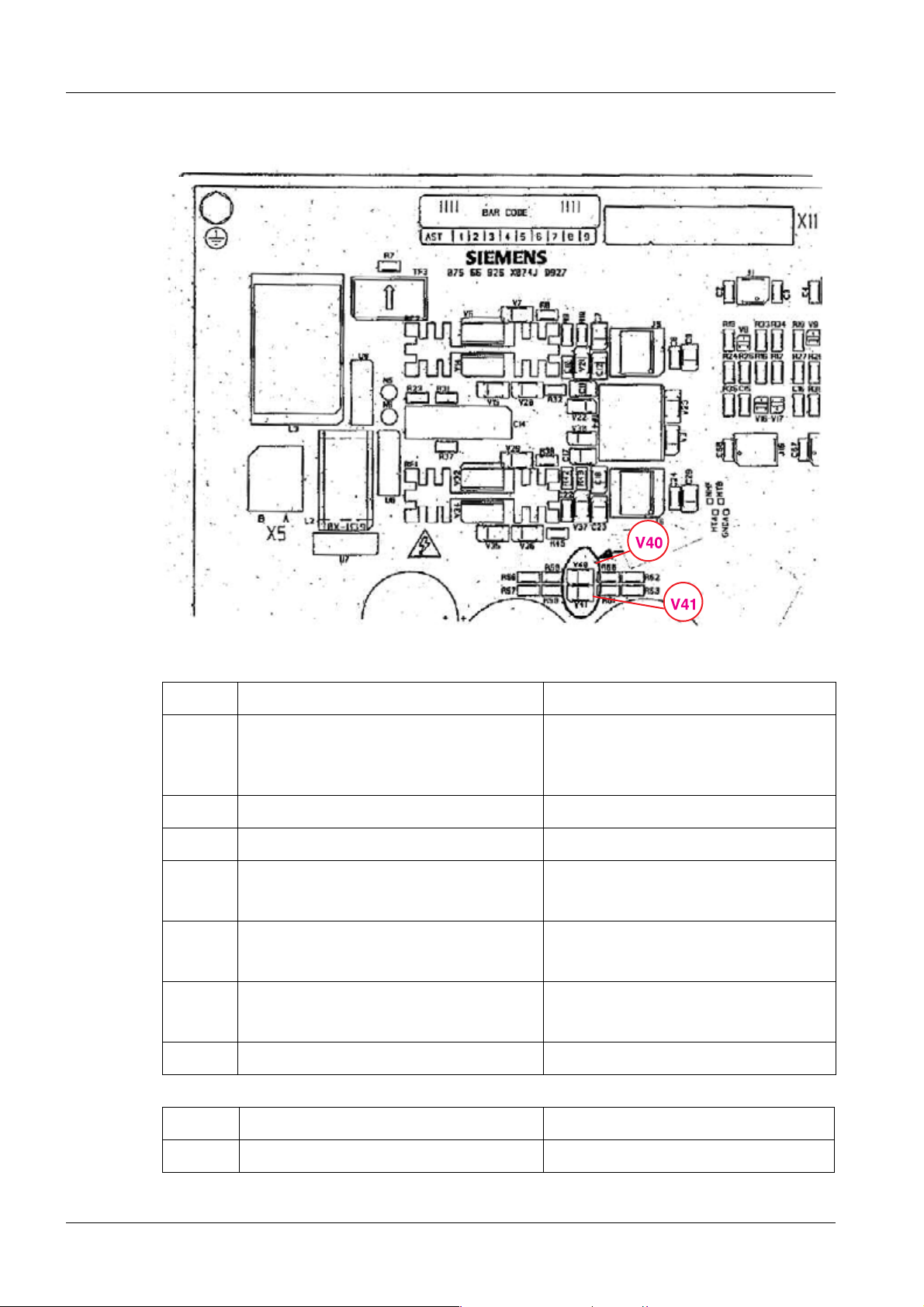

Fig. 3: D927_V40_V41

Name Function / Information Value

P1 Collimator voltage adjustment Adjusted to obtain > 180 lux in light

field

(Approx. 25 V in connector X7).

V12 Presence of + 24 V DC n/a

V5 Enables + 15 V DC n/a

V40 Capacitor bank

Voltage indication

V41 Capacitor bank

Voltage indication

V46 Internal power supplies

are working

V59 Collimator on n/a

n/a

n/a

n/a

Fuse value referring to

F3 1 AT (250 V ∼ / slow) n/a

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 22 of 104

Page 23

Overview 23

F5 6 AF (500 V DC / fast) n/a

F6 20 AF (500 V DC / fast) n/a

F7 15 AF (250 V ∼ / slow) Line voltage

F8 15 AF (250 V ∼ / slow) Line voltage

U1 power supply unit 5 V ± 5% / 15 V ± 10% 0

Fuse: 2 A T

U2 power supply unit 12.5 V ± 10% 0

Fuse: 5 A T

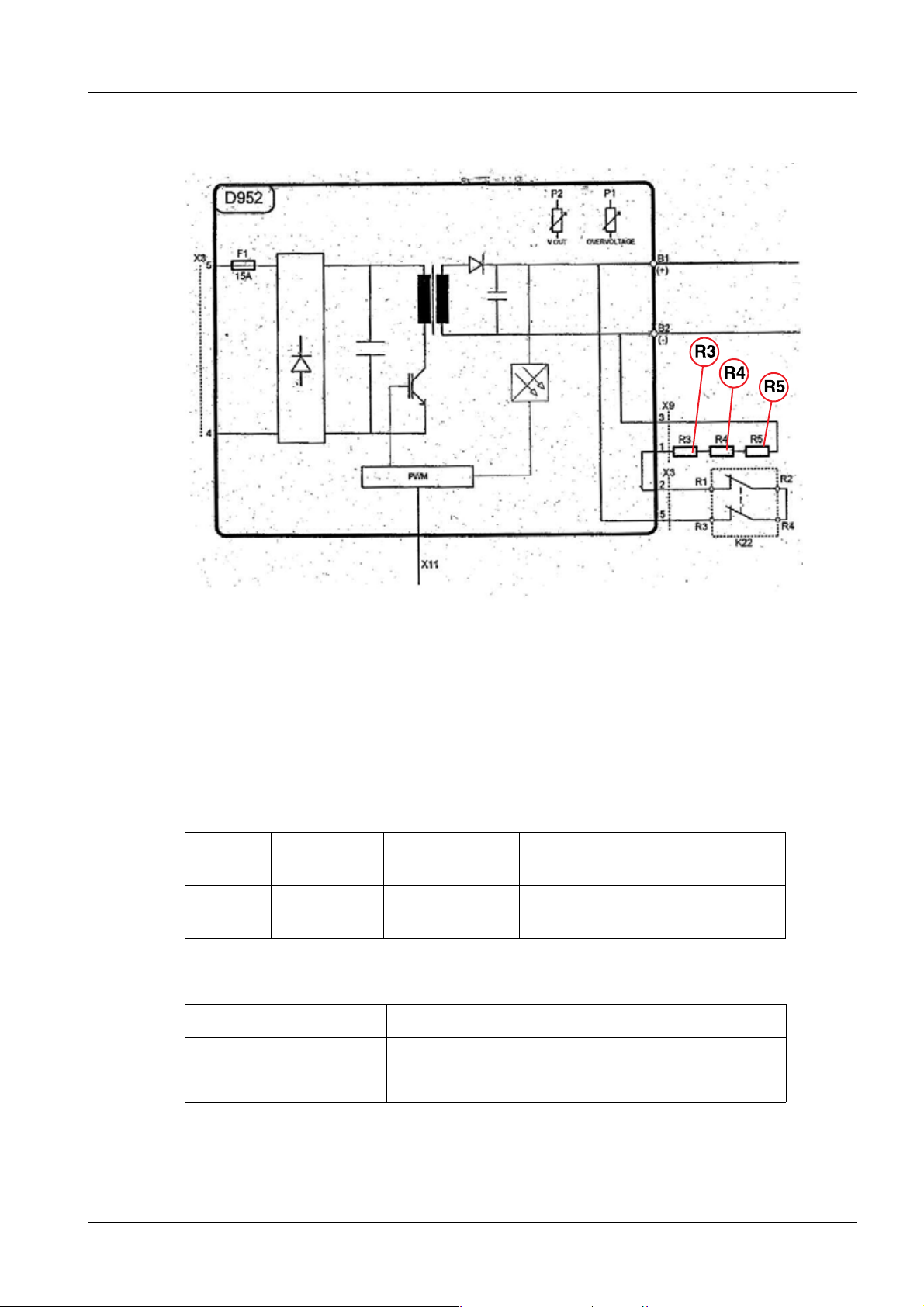

D952 capacitor charging circuit 0

LED:

Vin (V8) ON Line voltage OK

VDC (V1) ON Capacitor voltage present (the voltage can also be consider-

ably lower than 450 V)

V31 Charging cycle (OFF --> not charging) / (ON --> charging)

V30 Error indication (OFF --> OK) / (ON --> with errors)

V32 Enable charger (ON --> enable charging) / (OFF --> disable)

Fuse:

F1 15 AT

(250 V ∼ / delayed)

Test points:

ERR Error output charging error

VC Capacitor voltage 1 V : 100 V

Charging circuit

IC Capacitor charging current

FR1 Charging circuit frequency (dependent on the line voltage and VC)

GND Ground

CAR Signal to enable the charger

NCBC CAR enable and charging

OK Signal to indicate the full charge

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 23 of 104

Page 24

24 Overview

D971 (capacitor bank) 0

LED:

Name Function / Information Value

V1 - 10 C1 - C10 (10mF) charged > 40V Yellow LEDs ON

Fuse value referring to

F1-F10 20 A (500 V DC / fast) C1 - C10 individual capacitor

F12 20 A (500 V DC / fast) Capacitor bank input

F11 100 A (500 V DC / high speed) Capacitor bank output

D98 Display board 0

The display board shows the selected mAs and KV values. By pressing the membrane keyboard button, you can change the ON/OFF, KV, and mAs values.

C1 main inverter capacitor 0

6.8 µV ±10 %

C2 0

C2 is the capacitor used to accelerate the rotor (phase shift); it is connected to the XCAP

connector.

K22 switch-on relay 0

Connects and disconnects the discharge resistors.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 24 of 104

Page 25

Overview 25

Discharge resistors 0

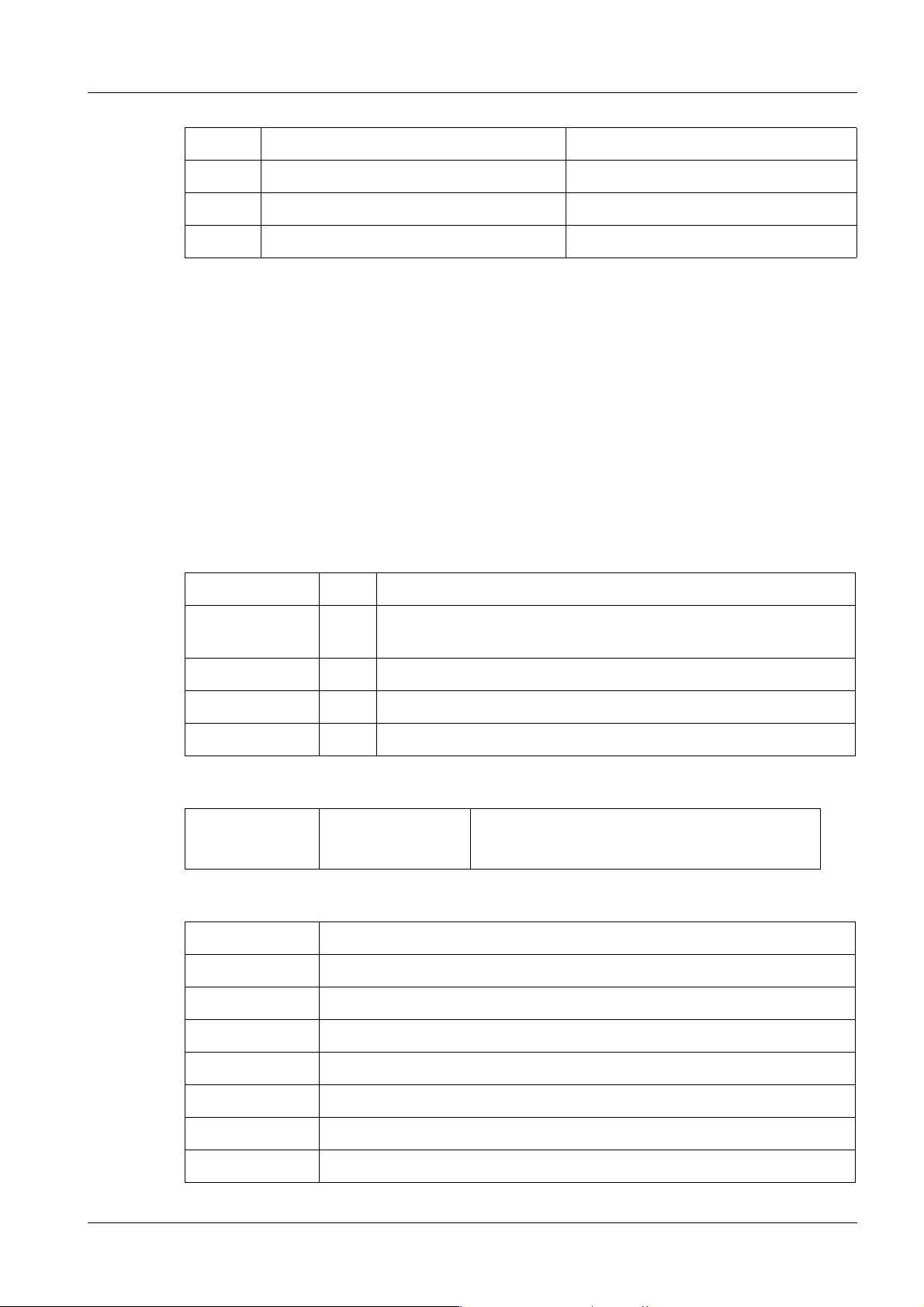

Fig. 4: R3_R4_R5

R3, R4 and R5 --> 510 Ohm ± 5%.

They have to be screwed down tight to prevent their being damaged.

Status of the LEDs (optimum condition) 0

a) POLYMOBIL Plus OFF, line voltage plug connected:

D952: LED 450 VDC (V1) glows for 10 minutes following

shutdown

D971: all LEDs glows for 10 minutes following

shutdown

b) POLYMOBIL Plus ON, standby

D952: LED Vin (V8) ON

LED 450 VDC (V1) ON

D971: all LEDs ON

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 25 of 104

Page 26

26 Error Messages

POLYMOBIL III 0

3- 3Error Messages

Error 1 - Loss of the + 15 V dc 0

Error 1 + 15 V missing

System status:

Standby

Explanation:

Action:

• Check X15 (D916):

- Pin 1, 3: 0V

- Pin 4 : 5V

- Pin 5: +15V

- Pin 6: 0V

- Pin 7: -15V

• Check the U1 power supply and the cable connection at the

U1.

Error 3 - Oil pressure rise or overheating of the tube 0

Error 3 Oil pressure rise or overheating of the tube

System status:

Standby

Explanation:

Action:

• Check the oil switch.

(Normal tube condition = switch closed)

¹ Warning: let the tube cool off before testing!

• Check the connections and the cable between the switch

and the D916 X8-9 and X8-8.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 26 of 104

Page 27

Error Messages 27

Error 4 - Static short circuit of the main inverter 0

Error 4 Static short circuit of the main inverter

System status:

Standby

Explanation:

Action:

• Check the power supplies U1 / U2 and the connections to

the main inverter.

¹ Some other possible causes are: capacitor C1 or

D922 may be defective.

• Disconnect capacitor C1.

- Warning: Turn off the equipment. Wait 10 minutes for it

to discharge. Turn it back on.

- If the error disappears, then it might be the tube, C1, the

cables and/or the connections to the tube.

Error 6 - IH heating measured < IH of preheating 0

Error 6 IH heating measured < IH of preheating

System status:

Standby

Explanation:

Action:

• Compare IH and IHS in D916 to make sure they are not the

same.

• Check the frequency of the heating inverter in the D916

TP - FC1.

• Check the form of the resonance current at the TP-I D916

(use Service Program 9).

¹ Possible causes are a bad cable connection from

D916 to D1(X8) (high resistance) to the single tank, a

defective heating inverter on board D922, a defective

heating transformer (single tank), the filament in the

single tank is defective, the D916 and/or the D922 are

defective, or the tube is defective.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 27 of 104

Page 28

28 Error Messages

Error 7 - IH heating measured > IH allowed by software 0

Error 7 IH heating measured > IH allowed by software.

System status:

Standby

Explanation:

Action:

• Before inhibition, IHM exceeds 3.75V; i.e. 4.25A max.

allowed.

• Check the form of the resonance current in the TP-I D916.

¹ Some possible causes are bad cable connections

from D916 to D1 (X8), or D916 and/or D922 are defective, or the tube is defective (filament).

Error 8 - kV measured < > 0 in idle 0

Error 8 kV measured < > 0 in idle

System status:

Standby

Explanation:

Action:

• Check the cable connections D916 to D1 (X8).

¹ Some other possible causes may be: the CPU D916

and/or the D922 and/or the tube are defective.

Error 9 - mA measured < > 0 in idle 0

Error 9 mA measured < > 0 in idle

System status:

Standby

Explanation:

Action:

• Check the cable connections, especially the ones between

the tube and the CPU D916 (X8).

¹ Some other possible causes may be: the CPU D916

or the tube is defective.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 28 of 104

Page 29

Error Messages 29

Error 11 - Voltage too high in the capacitor bank 0

Error 11 Voltage too high in the capacitor bank.

System status:

Standby

Explanation:

D916 (CPU) detects overvoltage (> 440 V) in the capacitor

bank. After the system is switched on, the capacitor bank voltage is about 440 V (VC). This voltage is reduced to 1% of its

former level and the reduced voltage can be measured on

board D916, TP VC.

Action:

• Check the VC test point of the D916 and check the voltage

directly in the capacitor bank VC (possible point: HVVC in

D922).

Error 12 - Noise in the static short circuit signal in the heating inverter 0

Error 12 Noise in the static short circuit signal in heating

System status:

Standby

Explanation:

Action:

• Check the SCH test point on the D916 (a high level means

a short circuit).

• Check the cable connection between the D916 CPU and the

power board D922.

• Switch off the system and disconnect X5 on the power

board D922. Switch on the system. .

¹ If Error 6 appears, the CPU D916 should be OK.

Check D922, cable connection to the single tank.

¹ If Err 12 is still displayed, replace D916 CPU.

• If the Err 12 disappears, the D916 CPU is OK.

• Then look over the possible problems on the power board

D922, the tube and the wiring.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 29 of 104

Page 30

30 Error Messages

Error 13 - Voltage in the capacitor bank is low during charge process 0

Error 13 Voltage in the capacitor bank is low during charge process

System status:

Standby

Explanation:

The voltage in the capacitor bank is lower than the voltage

expected from the CPU. The capacitor bank voltage after the

system is switched on is about 400V (VC) and divided on board

100:1 to be monitored from the CPU (Vc).

Action:

• Check the cable connection between the CPU and the D922

(X20).

• Check the VC test point of the D916, and check the voltage

directly in the capacitor bank VC (possible point: HVVC on

D922).

Error 15 - Static short circuit, heating inverter 0

Error 15 Static short circuit, heating inverter

System status:

Standby

Explanation:

Action:

• Check the SCH test point of the D916 (a high level means a

short circuit of the heating inverter).

• Switch off the system and disconnect X5 on the power

board D922. Switch on the system. .

¹ If Error 6 appears, the CPU D916 should be OK.

Check D922, cable connection to the single tank.

¹ If Err 15 is still displayed, replace D916 CPU.

¹ If Err 15 disappears, then the D922 is OK.

• Use Service Program 9 and check the maximum frequency

of the heating inverter (refer to document "Replacement of

parts" SPR8-125.841.10..).

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 30 of 104

Page 31

Error Messages 31

Error 22 - short circuit, heating inverter 0

Error 22 Short circuit, heating inverter

System status:

Preparation

Explanation:

Action:

• Check the SCH test point of the D916 (a high level means a

short circuit of the heating inverter).

• Check cable connection to the tube.

• Switch off the system and disconnect X5 on the power

board D922. Switch on the system.

¹ If Error 6 appears, the CPU D916 should be OK.

Check D922, the cable connection to the single tank,

and the single tank.

¹ If Err 22 is still displayed, replace D916 CPU.

¹ If Err. 22 disappears, then the D922 is OK.

• Short circuit outside the tube, look over the connections and

wiring that go to the tube.

• Use Service Program 9

and check the maximum frequency of the heating inverter.

Error 23 - Tube current limitation 0

Error 23 Tube current limitation

System status:

Preparation

Explanation:

Action:

• Check the JIM test point of the D916 (a high level means a

tube current error).

• Use Service Program 9

and check the filament current of the tube (refer to document "Replacement of parts" SPR8-125.841.10...).

¹ It is possible that the filament inside the tube is defec-

tive.

¹ It is possible that the filament current in preparation is

bad. Adjust with the potentiometer P5 on the D916.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 31 of 104

Page 32

32 Error Messages

Error 25 - Preparation timeout 0

Error 25 Preparation timeout

System status:

Preparation

Explanation:

This error occurs when preparation time (hand switch, first step)

exceeds 15 seconds without an exposure being taken.

Action:

• If this error occurs without the hand switch being activated

for more than 15 seconds, then check the connection

between the hand switch and the CPU.

It may be bad or the CPU may be defective.

Error 31 - kV limit 0

Error 31 kV limit

System status:

Exposure

Explanation:

Action:

• Check the KVM test point of the D916 (a high level means

an error).

• Check the signal cable connection between the tube and the

D916.

• Check the maximum frequency of the main inverter (Service

Program 7, refer also to document "Replacement of parts"

SPR8-125.841.10...).

• Check the filament current (Service Program 9), refer also

to document "Replacement of parts" SPR8-125.841.10...).

¹ Possible defects: the D916 or the D1 may be defective.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 32 of 104

Page 33

Error Messages 33

Error 34 - Tube current limit 0

Error 34 Tube current limit

System status:

Exposure

Explanation:

Action:

• Check the JIM test point of the D916 (A high level means a

tube current error).

• Use Service Program 9 and check the filament current and

the maximum frequency of the heating inverter (refer to document "Replacement of parts" SPR8-125.841.10...).

¹ It is possible that the filament inside the tube is defec-

tive.

¹ It is possible that the filament current in preparation is

bad. Adjust with the potentiometer P5 on the D916.

• Analyze to see if other error messages appear, especially

with high or low KV’s.

¹ A short-circuit problem may exist in the tube.

Error 35 - Short circuit in the main inverter 0

Error 35 Short circuit in the main inverter

System status:

Exposure

Explanation:

Action:

• Check the SCM test point in D916 (a high level means a

short circuit error); it is possible the tube is defective.

• Check the cable connections between the D916 and the

D922 (X20).

• Check the cable connections between the D922 and the

tube XoutA XoutB.

• Check C1.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 33 of 104

Page 34

34 Error Messages

Error 36 - Short circuit in the heating inverter 0

Error 36 Short circuit in the heating inverter

System status:

Exposure

Explanation:

Action:

• Check SCH signal in the D916 (A high level means a short

circuit).

• Check the maximum filament frequency and the signal in

test point I (Service Program 9), (refer to the document

"Replacement of parts" SPR8-125.841.10...)

• Check the cable connections between the D922 (X5) and

the tube.

¹ Possible defect: D922

Error 37 - Regulation failure in the kV loop 0

Error 37 Regulation failure in the kV loop

System status:

Exposure

• kV_actual (KV) is in a different range than kV_nominal

(KVS).

• Check the connections between the D916 (X8) and the

tube.

¹ The D916 may be faulty.

¹ Check heating current adjustment, using P5 (very

important if D916 will be replaced!) - see “Replacement of Parts”, SPR8-125.841.10...

Error 38 – Regulation failure in the mA loop 0

Error 38 Regulation failure in the mA loop

System status:

Exposure

• i_actual (JR) is in a different range than kV_nominal (JRS).

• Check the connections between the D916 (X8) and the

tube.

¹ The D916 may be faulty.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 34 of 104

Page 35

Error Messages 35

Error 39 - Exposure timeout 0

Error 39 Exposure timeout

System status:

Exposure

• Check the frequency of the heating inverter at the D916 test

point FC1 (Service Program 9).

¹ The system interrupts the exposure. This may occur

when the mAs integrator fails in the D916.

Error 41 - The exposure has not finished 0

Error 41 The exposure has not finished.

System status:

Exposure

• The exposure switch is released during exposure.

¹ If the interruption was caused by another problem, it

may be a kV and/or mA regulation failure. Also see

errors Err 37 and Err 38.

Error 42 - Heating current limit 0

Error 42 Heating current limit

System status:

Exposure

• Check the JIM test point on the D916.

• Check heating current (Service program 9). It is possible

that the potentiometer P5 is not properly adjusted (the preparation current is too low).

Error 92 - RAM failure 0

Error 92 RAM/D916 failure.

System status:

Init

• Replace D916

Error 93 - Failure in the initial verification of the + 15 V DC 0

Error 93 Failure in the initial verification of the + 15 V DC

System status:

Init

• Check the voltages of U1 and D916 X15.

- + 15 V D916 X15 Pin 5 - 6

- - 15 V D916 X15 Pin 6 - 7

- + 5 V D916 X15 Pin 4 - 3

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 35 of 104

Page 36

36 Error Messages

Error 94 - Difference between doubler signal and voltage level 0

Error 94 Difference between doubler signal and voltage level

System status:

Init

• Check cable X10

• Check cable X in D922 that comes from filter

• Check mains resistance

Error 95 - Precharge Error 0

Error 95 Precharge Error

System status:

Init

Explanation: Voltage below 80V after 9 seconds

• Check mains resistance.

• Check cable X in D922 that comes from filter.

Error 96 - Failure of Channel D (KV_NOM) in A/D converter 0

Error 96 Failure of Channel D (KV_NOM) in A/D converter

System status:

• Failure of CPU Channel D (KV_NOM) in A/D converter.

Init

¹ The CPU D916 is faulty.

Error 97 - Failure of Channel B (JR_NOM) in A/D converter 0

Error 97 Failure of Channel B (JR_NOM) in A/D converter

System status:

Init

• Failure of CPU Channel B (JR_NOM) in A/D converter.

¹ The CPU D916 is faulty.

Error 98 - Failure of Channel C (Ih_NOM) in A/D converter 0

Error 98 Failure of Channel C (Ih_NOM) in A/D converter

System status:

Init

• Failure of CPU Channel C (Ih_NOM) in A/D converter.

¹ The CPU D916 is faulty.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 36 of 104

Page 37

Error Messages 37

POLYMOBIL Plus 3.1

"Pause" error 0

Pause Message: "Pause"

System status:

Standby

Explanation: This message appears when the temperature of

the capacitor charging circuit board has exceeded a defined

value (caused by a number of exposures being taken within a

short time).

Action:

• Wait until the temperature has dropped.

• Error: If this message ("Pause") does not go away or if it

appears immediately after the unit is switched on, the D952

board may need to be replaced.

Error 1 - Loss of the + 15 V dc 0

Error 1 + 15 V missing

System status:

Standby

• Check X15 (D916):

- Pin 1, 3: 0V

- Pin 4: 5V

- Pin 6: 0V

- Pin 7: -15V

• Check the U1 power supply and the cable connection at the

U1.

Error 3 - Oil pressure rise or overheating of the tube 0

Error 3 Oil pressure rise or overheating of the tube

System status:

Standby

• Check the oil switch.

(Normal tube condition = switch closed)

¹ Warning: let the tube cool off before testing!

• Check the connections and the cable between the switch

and the D916 X8-9 and X8-8.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 37 of 104

Page 38

38 Error Messages

Error 4 - Static short circuit of the main inverter 0

Error 4 Static short circuit of the main inverter

System status:

Stand-by

• Check the power supplies U1 / U2 and the connections to

the main inverter.

¹ Some other possible causes are: capacitor C1 or

D927 may be defective.

• Disconnect capacitor C1.

- Warning: Turn off the equipment. Wait 10 minutes for it

to discharge. Turn it back on.

- If the error appears again, it may be that the D961 is

faulty.

- If the error disappears, then it might be the tube, the C1,

the cables, and/or the connections to the tube.

Error 6 - IH heating measured < IH of preheating 0

Error 6 IH heating measured < IH of preheating

System status:

Standby

• Compare: IH and IHS are not the same.

• Check the frequency of the heating inverter in the D916

TP - FC1.

• Check the form of the resonance current at the TP-I D916

(use service program 9).

¹ Some possible causes are a bad connection (high

resistance), faulty heating transformer, bad filament,

faulty D916 and/or D927 and/or the tube.

Error 7 - IH heating measured > IH allowed by software 0

Error 7 IH heating measured > IH allowed by software

System status:

Standby

• Before inhibition, IHM exceeds 4.26V, i.e. 5.12A

• Check the form of the resonance current in the TP-I D916.

¹ Some possible causes are bad cable (resistance),

faulty D916 and/or D927 and/or the tube

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 38 of 104

Page 39

Error Messages 39

Error 8 - kV measured < > 0 in idle 0

Error 8 kV measured < > 0 in idle

System status:

Standby

• Check the cables, especially the ones between the tube and

the CPU (connector X8).

¹ Some other possible causes may be: the CPU D916

and/or the D927 and/or the tube are defective.

Error 9 - mA measured < > 0 in idle 0

Error 9 mA measured < > 0 in idle

System status:

Standby

• Check the cables, especially the ones between the tube and

the CPU (connector X8).

¹ Some other possible causes may be: the CPU D916

is faulty or the tube is faulty.

Error 11 - Voltage too high in the capacitor bank 0

Error 11 Voltage too high in the capacitor bank or capacitor loader

D952 is faulty.

System status:

Standby

Explanation:

D916 (CPU) detects overvoltage (> 440 V) in the capacitor

bank. After the system is switched on, the capacitor bank voltage is about 440 V (VC). This voltage is reduced to 1% of its

former level and the reduced voltage can be measured on

board D916, TP VC.

Action:

• Check the VC test point of the D916 and check the voltage

directly in the capacitor bank VC (possible points: between

the earth and fuse F5 located on D927).

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 39 of 104

Page 40

40 Error Messages

Error 12 - Noise in the static short circuit signal in the heating inverter 0

Error 12 Noise in the static short circuit signal in heating

System status:

Standby

• Check the SCH test point on the D916 (a high level means

a short circuit).

• Check the cable connection between the D916 CPU and the

power board D927.

• Switch off the system and disconnect X5 on the power

board D927. Switch on the system.

¹ If the Err 12 disappears, the D916 CPU is OK.

Then look over the possible problems on the power

board D927, the tube and wiring.

Error 13 - Voltage in the capacitor bank is low during charge process 0

Error 13 Voltage in the capacitor bank is low during charge

System status:

Standby

Explanation:

The voltage in the capacitor bank is lower than the voltage

expected from the CPU. The capacitor bank voltage after the

system is switched on is about 440V (VC) and divided on board

100:1 to be monitored from the CPU (Vc).

Action:

• Check the connection between the CPU and the D952

(X20) and the connection between the D927 and the D952

(X3).

• Check the Vc test point of the D916 and the voltage directly

in the capacitor bank (possible points: between the earth

and fuse F5 located on D927).

¹ If VC and Vc are close to 440 V and 4.4 V, then D916

may be faulty.

¹ If VC is close to 440 V but Vc is not at 4.4 V, then either

the D952 or the D916 may be bad.

¹ If they are not close, then the D952 may be faulty.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 40 of 104

Page 41

Error Messages 41

Error 15 - Static short circuit, heating inverter 0

Error 15 Static short circuit, heating inverter

System status:

Standby

• Check the SCH test point of the D916 (a high level means a

short circuit of the heating inverter).

• Switch off the system and disconnect X5 on the power

board D927. Switch on the system.

¹ If Error 6 appears, the CPU D916 should be OK.

Check D927, cable connection to the single tank.

¹ If Err 15 is still displayed, replace D916 CPU.

¹ If Err15 disappears, then the D927 is OK.

• Use Service Program 9 and check the maximum frequency

of the heating inverter (refer to document "Replacement of

parts" SPR8-125.841.10...).

Error 22 - Short circuit, heating inverter 0

Error 22 Short circuit, heating inverter

System status:

Preparation

• Check the SCH test point of the D916 (a high level means a

short circuit).

• Check cable connection to the tube.

• Switch off the system and disconnect X5 on the power

board D922. Switch on the system.

¹ If Error 6 appears, the CPU D916 should be OK.

Check D927, the cable connection to the single tank,

and the single tank.

¹ If Err 22 is still displayed, replace D916 CPU.

¹ If Err. 22 disappears, then the D927 is OK.

• Short circuit outside the tube, look over connections and

wiring that go to the tube.

• Use Service Program 9

and check the maximum frequency of the heating inverter.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 41 of 104

Page 42

42 Error Messages

Error 23 - Tube current limitation 0

Error 23 Tube current limitation

System status:

Preparation

• Check the JIM test point of the D916 (A high level causes

the error).

• Use Service Program 9

and check the filament current of the tube (refer to document "Replacement of parts" SPR8-125.841.10...).

¹ It is possible that the filament inside the tube is bad.

¹ It is possible that the filament current in preparation is

bad (very high or very low). Adjust the potentiometer

P5 of the D916.

Error 24 - The anode does not get up to its startup speed 0

Error 24 The anode does not reach its startup speed

System status:

Preparation

• Check the I1 and I2 test points of D916.

• Check the connection to C2, the phase shift capacitor, the

XCap, and the X6 connector.

• Check the connection between the power board D927 X11

and CPU D916 X11.

• Check F5 6AT on the power board D927.

• Check F6 20AT on the power board D927.

Error 25 - Preparation timeout 0

Error 25 Preparation timeout

System status:

Preparation

• This error occurs when preparation time (hand switch, first

step) exceeds 15 seconds without an exposure being taken.

¹ If this error occurs without the hand switch being acti-

vated for more than 15 seconds, then check the connection between the hand switch and the CPU.

It may be bad or the CPU may be defective.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 42 of 104

Page 43

Error Messages 43

Error 28 - Starter short circuit 0

Error 28 Starter short circuit

System status:

Preparation

• Check the phase displacement capacitor (C2).

• Check the winding resistances of the stator (X6 - 3 - X6 - 1

should be close to 83 Ohms, X6 - 3 and C2 should be close

to 174 Ohms).

¹ Possible defects: the D927, C2 and check the cable

connection to the starter within the tube.

Error 31 - kV limit 0

Error 31 kV limit

System status:

Exposure

• Check the KVM test point of the D916 (a high level means

an error).

• Check test point KVC of the D916.

• Check the signal cable connection between the tube and the

D916.

• Check the maximum frequency of the main inverter (Service

Program 7), refer also to document "Replacement of parts"

SPR8-125.841.10...).

• Check the filament current (Service Program 9), refer also

to document "Replacement of parts" SPR8-125.841.10...).

¹ Possible defects: the D916 or the D900 may be defec-

tive.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 43 of 104

Page 44

44 Error Messages

Error 34 - Tube current limit 0

Error 34 Tube current limit

System status:

Exposure

• Check the JIM test point on the D916.

¹ It is possible that the potentiometer P5 is not properly

adjusted, thus causing the heating current in preparation to be very high.

• If an error exists in the entire range of kV during the expo-

sure, especially at low kVs, a problem must exist inside the

tube.

• Use Service Program 9 and check the filament current and

the maximum frequency of the heating inverter (refer to document "Replacement of parts" SPR8-125.841.10...).

¹ It is possible that the filament inside the tube is defec-

tive.

¹ It is possible that the filament current in preparation is

bad. Adjust with the potentiometer P5 on the D916.

• Analyze to see if other error messages appear, especially

high voltage ones.

¹ A short-circuit problem may exist in the tube.

Error 35 - Short circuit in the main inverter 0

Error 35 Short circuit in the main inverter

System status:

Exposure

• Check the SCM test point in D916.

¹ If a persistent error appears in the entire kV range dur-

ing the exposure, especially at low kVs, the tube may

be faulty.

• Check the connections between the D916 and the D961

(X20).

• Check the connections between the D961 and the tube

(U - V)/X4.

• Check C1.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 44 of 104

Page 45

Error Messages 45

Error 36 - Short circuit in the heating inverter 0

Error 36 Short circuit in the heating inverter

System status:

Exposure

• Check SCH signal in the D916 (A high level means a short

circuit).

• Check the maximum filament frequency and the signal in

test point I (Service Program 9), (refer to the document

"Replacement of parts" SPR8-125.841.10...)

• Check the connections between the D927 (X5) and the

tube.

¹ The D927 may be faulty.

Error 37 - Regulation failure in the kV loop 0

Error 37 Regulation failure in the kV loop

System status:

Exposure

• kV_actual (KV) is in a different range than kV_nominal

(KVS).

• Check the connections between the D916 (X8) and the

tube.

¹ The D916 may be faulty.

¹ Check heating current adjustment, using P5 (very

important if D916 will be replaced!) - see “Replacement of Parts”, SPR8-125.841.10...

Error 38 – Regulation failure in the mA loop 0

Error 38 Regulation failure in the mA loop

System status:

Exposure

• i_actual (JR) is in a different range than kV_nominal (JRS).

• Check the connections between the D916 (X8) and the

tube.

¹ The D916 may be faulty.

Error 39 - Exposure timeout 0

Error 39 Exposure timeout

System status:

Exposure

• Check the frequency of the heating inverter at the D916 test

point FC1 (Service Program 9).

¹ The system interrupts the exposure. This may occur

when the mAs integrator fails in the D916.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 45 of 104

Page 46

46 Error Messages

Error 41 - The exposure has not finished 0

Error 41 The exposure has not finished.

System status:

Exposure

• The exposure switch is released during exposure.

¹ If the interruption was caused by another problem, it

may be a kV and/or mA regulation failure. Also see

errors Err 37 and Err 38.

Error 42 - Heating current limit 0

Error 42 Heating current limit

System status:

Exposure

• Check the JIM test point on the D916.

• Check heating current (Service program 9). It is possible

that the potentiometer P5 is not properly adjusted (the preparation current is too low).

Error 92 - RAM failure 0

Error 92 RAM failure.

System status:

Init

• Replace D916

Error 93 - Failure in the initial verification of the + 15 V DC 0

Error 93 Failure in the initial verification of the + 15 V DC

System status:

Init

• Check the voltages of U1 and D916 X15.

- + 15 V D916 X15 Pin 5 - 6

- - 15 V D916 X15 Pin 6 - 7

- + 5 V D916 X15 Pin 4 - 3

Error 96 - Failure of Channel D (KV_NOM) in A/D converter 0

Error 96 Failure of Channel D (KV_NOM) in A/D converter

System status:

Init

• Failure of CPU Channel D (KV_NOM) in A/D converter.

¹ The CPU D916 is faulty.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 46 of 104

Page 47

Error Messages 47

Error 97 - Failure of Channel B (JR_NOM) in A/D converter 0

Error 97 Failure of Channel B (JR_NOM) in A/D converter

System status:

Init

• Failure of CPU Channel B (JR_NOM) in A/D converter.

¹ The CPU D916 is faulty.

Error 98 - Failure of Channel C (Ih_NOM) in A/D converter 0

Error 98 Failure of Channel C (Ih_NOM) in A/D converter

System status:

Init

• Failure of CPU Channel C (Ih_NOM) in A/D converter.

¹ The CPU D916 is faulty.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 47 of 104

Page 48

48 Service programs

General 0

4- 4Service programs

Activation of the service programs 0

• Turn off the unit.

• Take off the cover.

• Move the SW2B service switch to position 2 on the D916.

• Turn on the unit.

• "Pr 1" will appear on the display.

• For the selection of the required program, use mAs+ / mAs-

• To enter, press the collimator light button. To exit, press it again.

While we are in service programming, the X-rays are disabled.

To quit the service mode, move SW2B to position 1 and press the Reset button SW3, or

turn the POLYMOBIL OFF and then ON again.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 48 of 104

Page 49

Service programs 49

POLYMOBIL III 4.1

Service programs 0

Program 2 - exposure counter

Program 2

• Press the collimator light button to enter.

• Read the exposure counter on the display.

• Press the collimator light button to exit.

NOTE:

A reset is not possible. In the event that the tube is changed, make a note

of the start triggers.

Program 3 - error buffer

Program 3

• Press the collimator light button to enter.

• Show the last 20 errors on the display.

• On the left, the position it occupies is shown.

• On the right, the error code is indicated.

• The most recent errors are shown at the top of the list.

• To go backwards, use the "mAs-" key.

• Press the collimator light button to exit.

Program 4 - deletion of error buffer

Program 4

• Press the collimator light button to enter.

• To delete, press the "kV+" button for approximately 4 seconds.

• Press the collimator light button to exit.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 49 of 104

Page 50

50 Service programs

Program 5 - Change of initial values (kV and mAs) or last value

Program 5

• Press the collimator light button to enter.

• Press kV+, kV- and/or mAs+/mAs- to select the values.

• To save the values, press the collimator light button.

Program 6 - maximum values of kV and mAs

Program 6

• Press the collimator light button to enter.

• To limit the maximum values, select with kV+, kV- and/or mAs+/mAs-.

• To save the values, press the collimator light button.

Program 7 - maximum main inverter frequency

Program 7

• Press the collimator light button to enter.

• On the display, "ADJF" will appear.

• The maximum frequency can be measured at TP FC2 on the D916

CPU.

• Press the exposure switch to obtain the maximum frequency.

• To adjust, use the P4 potentiometer of the D916.

• The adjustment will be carried out until the following value is reached

on the D916 - P4 TP FC2: 24.5 kHz ± 0.5 kHz.

• Press the collimator light button to exit.

Program 8 - Collimator ON/OFF with exposure switch

Program 8

• Press the collimator light button to enter.

• Collimator OFF/ON will appear on the display.

• To start: press the exposure switch. To brake: release the exposure

switch.

• Press the collimator light button to exit.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 50 of 104

Page 51

Service programs 51

Program 9 - heating current testing

Program 9

• Press the collimator light button to enter.

• "FIL 3" will appear on the display. There should be 3 A of current.

• Press the exposure switch. The filament current will increase to 3.7 A

and "FIL 3.7" will appear on the display.

• Press the collimator light button to exit.

Program 10 - AutoOff ON/OFF (available but not used)

Program 10

• Press the collimator light button to enter.

• Can be used, and changed:

- “OFF” no autooff

- “ON” autooff is running

Program 11 - exposure points or half points

Program 11

• Press the collimator light button to enter.

• "ON" or "OFF" will appear on the display.

• ON = 47 steps (manufacturer's default); OFF = 24 steps

• To change it, press the mAs+ or mAs- keys.

• To save what you have selected, press the collimator light button ON.

Program 12 - firmware version

Program 12

• Press the collimator light button to enter.

• "POL 101" will appear on the display.

• To exit, press the collimator light button.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 51 of 104

Page 52

52 Service programs

Program 13 - eliminate the buzzers

Program 13

• Press the collimator light button to enter.

• "BEP x" will appear on the display.

• To change it, press the mAs+ or mAs- keys.

¹ 3 different buzzer volumes are available.

• To save what you have selected, press the collimator light button.

Program 14 - adjustment of mAs V/F converter

Program 14

• Press the collimator light button to enter.

• "F1 On" will appear on the display.

• The maximum frequency can be measured at TP F1 on the D916

CPU.

• To adjust, use the P1 potentiometer of the D916. Adjust to 320 kHz.

¹ Take care with that adjustment, the frequency must be VERY

CLOSE to 320 kHz!

• To exit, press the collimator light button.

Program 15 - one resonance pulse

Program 15

• Press the collimator light button to enter.

• "P OFF" will appear on the display.

• Put the oscilloscope tester KVC on the D916 CPU.

• Press the exposure switch; one resonance pulse is obtained, see

(Fig.5/p.53).

• To exit, press the collimator light button.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 52 of 104

Page 53

Service programs 53

Fig. 5: Program 15

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 53 of 104

Page 54

54 Service programs

POLYMOBIL Plus 4.2

Service programs 0

Program 1 - formatting the capacitor bank

Program 1

• Press the collimator light button to enter.

• After starting up this service program, the message "CAP 150"

appears on the display.

• The voltage increases from 150 V to 440 V DC. The program remains

in each stage for approximately 6 minutes. The system stays at 440 V

DC (last stage) for approximately 1 hour, showing "CAP END".

• Press the light to exit.

NOTE:

If the voltage is over 150 V, the program begins first by discharging and

then starts the charging process.

Program 2 - exposure counter

Program 2

• Press the collimator light button to enter.

• Read the exposure counter on the display.

• Press the collimator light button to exit.

NOTE:

A reset is not possible. In the event that the tube is changed, make a note

of the start triggers.

POLYMOBIL III/Plus SPR8-125.840.10.04.02 Siemens

05.09 CS SD SP/ CO

Page 54 of 104

Page 55

Service programs 55

Program 3 - error buffer

Program 3

• Press the collimator light button to enter.

• Show the last 20 errors on the display.

• On the left, the position it occupies is shown.

• On the right, the error code is indicated.

• The latest errors are shown at the top of the list.

• To go backwards, use the "mAs-" key.

• Press the collimator light button to exit.

Program 4 - deletion of error buffer

Program 4

• Press the collimator light button to enter.

• To delete, press the "kV+" button for approximately 4 seconds.

• Press the collimator light button to exit.

Program 5 - change of initial values (kV and mAs) or last value

Program 5

• Press the collimator light button to enter.

• Press kV+, kV- and/or mAs+/mAs- to select the values.

• To save the values, press the collimator light button.

Program 6 - maximum values of kV and mAs

Program 6

• Press the collimator light button to enter.

• To limit the maximum values, select with kV+, kV- and/or mAs+/mAs-.

• To save the values, press the collimator light button.

Siemens SPR8-125.840.10.04.02 POLYMOBIL III/Plus

05.09 CS SD SP/ CO

Page 55 of 104

Page 56

56 Service programs

Program 7 - Maximum main inverter frequency

Program 7

• Press the collimator light button to enter.

• On the display, "ADJF" will appear.

• The maximum frequency can be measured at TP FC2 on the D916

CPU.

• Press the exposure switch to obtain the maximum frequency.

• To adjust, use the P4 potentiometer of the D916.

• The adjustment will be carried out until the following value is reached

on the D916 - P4 TP FC2: 18 kHz ± 0.5 kHz.

• Press the collimator light button to exit.

Program 8 - checking the anode rotation starter

Program 8

• Press the collimator light button to enter.

• ROT 220 will appear on the display.

• To start: press the exposure switch. To brake: release the exposure

switch.

• Press the collimator light button to exit.

Program 9 - heating current testing

Program 9

• Press the collimator light button to enter.

• "FIL 3" will appear on the display. There should be 3 A of current, see

(Fig. 29 / p. 82).

• Press the exposure switch. The filament current will increase to 5 A

(see (Fig. 30 / p. 83) and "FIL 5" will appear on the display.

• Press the collimator light button to exit.