Page 1

Erlwein

POLYDOROS SX/LX

Maintenance Protocol

POLYDOROS

Generator

Customer:

Address:

AX

Department:

Room:

Contact person:

Telephone:

Cust. specific no.:

Cust. no.:

Date.:

The instructions RX63-055.831.02.02.02 are required for

this protocol

Print No.:

Replaces: RX63-055.832.02.01.02

RX63-055.832.02.02.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 04.05

2002

Page 2

Cust.-No.: Date: Protocol

1Protocol

SIEMENS Office:

Address:

Region:

Country:

Contact person:

Tel.:

CSE in charge:

Tel.:

Remarks Regarding the Protocol:

The protocol is valid as proof of quality for one check that must be performed on the system / component in one year.

The check must be performed in the specified intervals.

The results of the check are entered in this protocol.

The chapter numbers in front of the checkpoints indicate the corresponding chapters in

the particular instructions (see cover page).

The protocol must be completely filled out by the Customer Service Engineer, i.e.:

• All boxes must be filled out. If a box does not apply to the system or if no entry needs to

be made, check the “n.a.“ box.

• Enter the customer number (Cust. No.:) and the date of the check in the header of each

page so that each page can be allocated to a customer and to a check date.

• If there are complaints, the IVKs for the component about which a complaint has been

made as well as the type of complaint must be entered in the “Open Points“ table provided for this. Correction of these open points also must be documented in this table

with the date and a signature. If there are no open points, check “No“ and document this

with the date and a signature.

• If movable components (also test phantoms that are part of the system) that can be

used in different systems are used for the check, they must be entered in the “Movable

Components“ table provided for this.

• The measurement values for the measurements that must be performed during the

check must also be entered in the open spaces / tables provided for them.

• After completing the check, Page 3 of this protocol must be filled out and signed.

POLYDOROS SX/LX RX63-055.832.02.02.02 Siemens AG

04.05 CS PS 211

Page 2 of 10

Medical Solutions

Page 3

Protocol Date: Cust.-No.:

Further Processing and Archiving of the Protocol

The protocol is a document and thus must be archived. After completing the test, it must

be filed in the corresponding register in the “System Owner Manual“ binder. If needed, a

copy can be handed to the customer.

System:

Serial No.:

Software Version:

Number of the Service Contract:

Type of Maintenance:

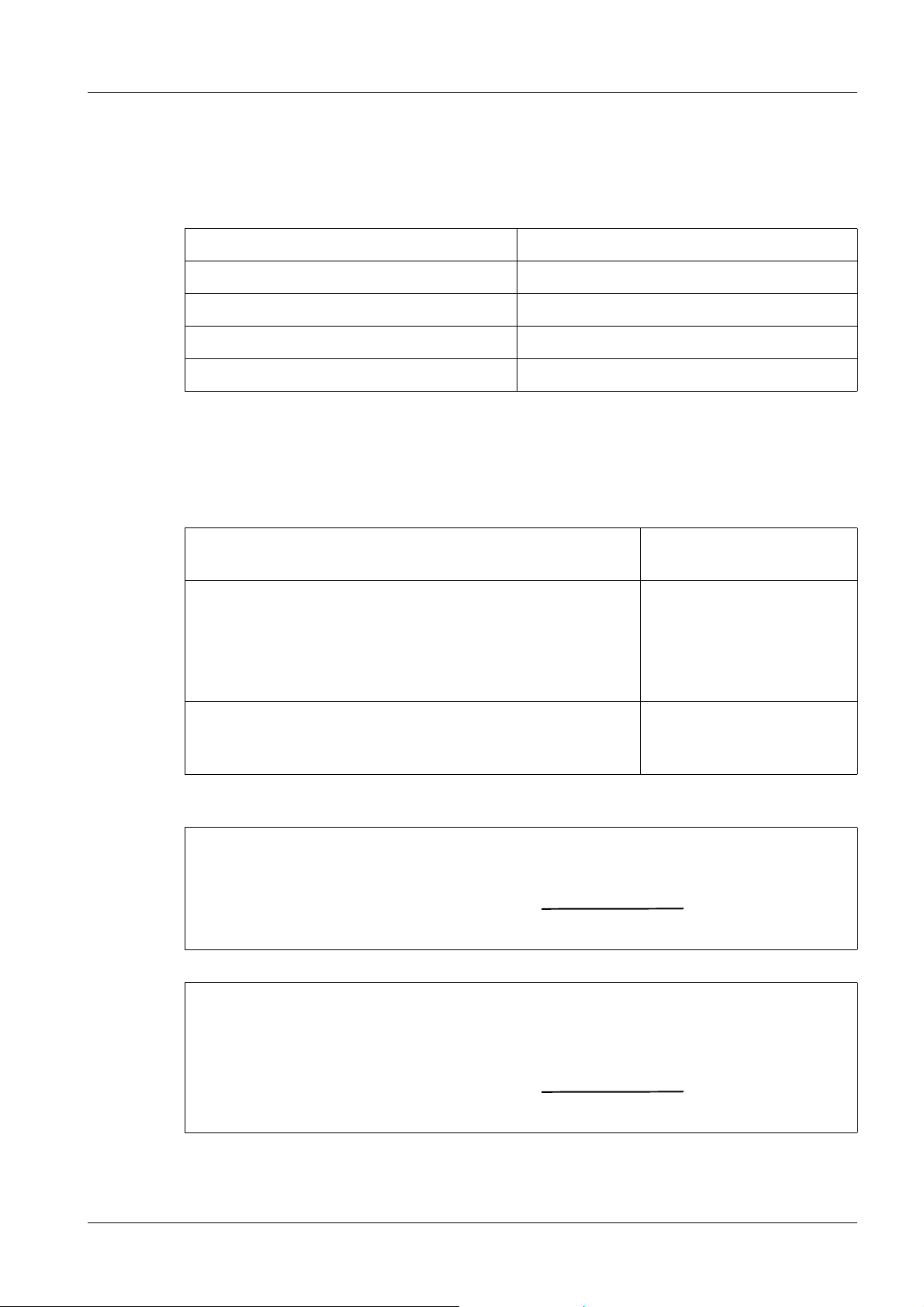

Evaluating the Condition of the System / Component

The system has no deficiencies. The image quality test

resulted in no differences from required reference values.

The system / component has slight deficiencies that have

no affect on continued operation of the system. However

they should be corrected preventively.

The image quality test resulted in no differences from

required reference values.

The system / component has serious deficiencies. For

safety reasons, continued operation of the system is permitted only after successfully correcting the deficiencies.

After completing all work steps, an evaluation was performed.

Signature:

Date: Name:

The operator or a person assigned for this has taken note of this evaluation.

(if national regulations require this)

Signature:

Date: Name:

Siemens AG RX63-055.832.02.02.02 POLYDOROS SX/LX

Medical Solutions

04.05 CS PS 211

Page 3 of 10

Page 4

Cust.-No.: Date: Protocol

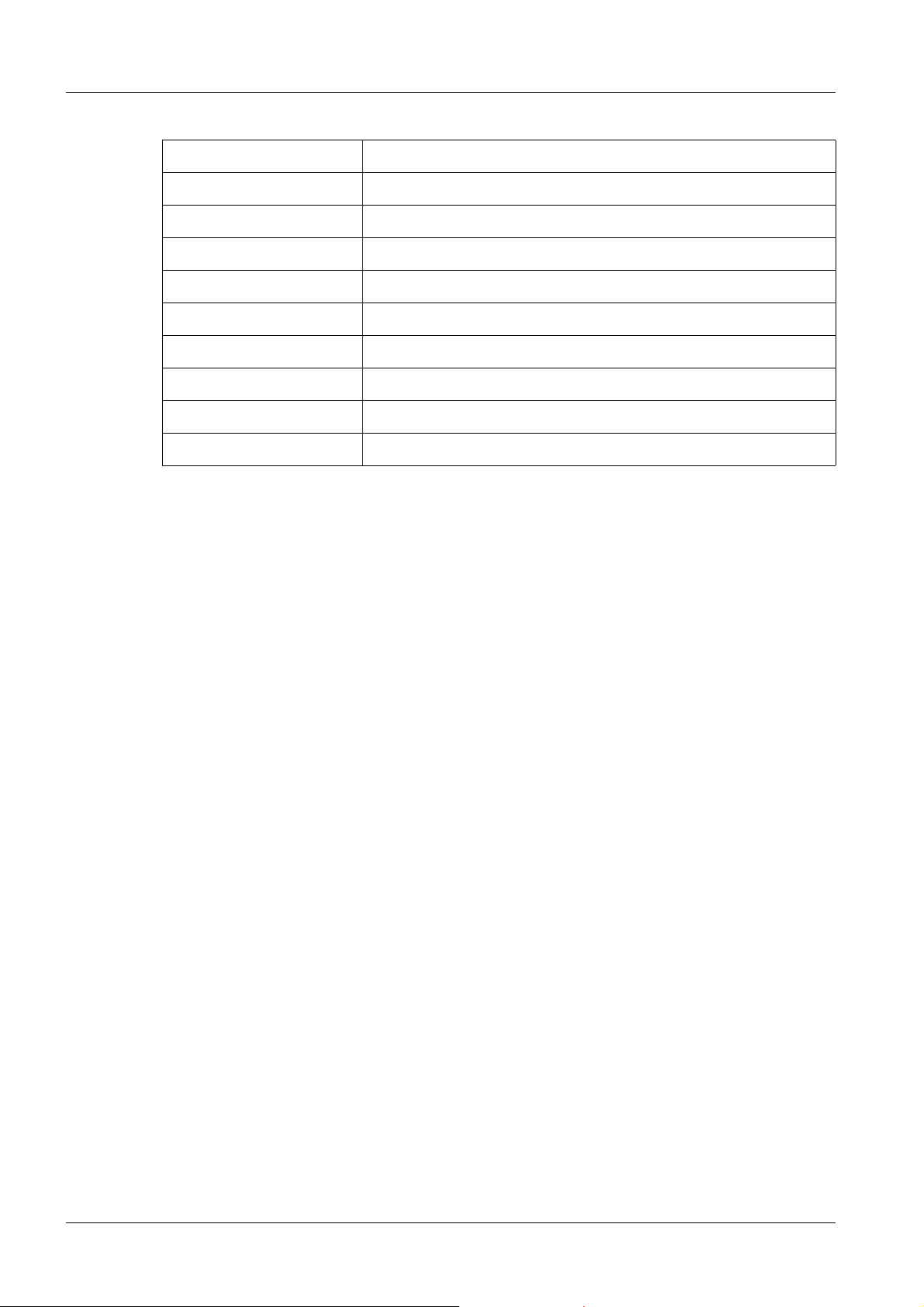

Explanation of Abbreviations in the Protocol

Abbrev. Explanation Abbrev. Explanation

SI Safety Inspection PMF Preventive Maintenance, Operat-

ing Value Check, Function Check

SIE Electrical Safety Inspection Q System Quality, Image Quality

SIM Mechanical Safety Inspec-

QIQ Image Quality

tion

PM Preventive Maintenance QSQ System Quality Check

PMP Periodic Preventive Mainte-

SW Software Maintenance

nance

PMA Preventive Maintenance

CSE Customer Service Engineer

Adjustments

Additional activities performed

Only activities that are not described in the instructions for the system / component need

to be listed.

Date:

Additional activities performed:

OK not OKn.a.

Open Points:

Yes: No: Signature:

Date: Name:

If “Yes“, enter the component with the IVK and the open point (only the number) in the

table. After completing maintenance, record this in the table.

IVK Component Open Points Completed

Date Signature

POLYDOROS SX/LX RX63-055.832.02.02.02 Siemens AG

04.05 CS PS 211

Page 4 of 10

Medical Solutions

Page 5

Protocol Date: Cust.-No.:

Measuring Devices queried electronically:

Yes: No: Signature:

Date: Name:

If the measurement devices are queried electronically, for example with a Scout Mobile

Device, entry of the measuring devices in the table can be skipped.

Measuring Devices Type Serial No. Date Used Next Cali-

bration

Due

Movable Components:

Yes: No: Signature:

Date: Name:

If “Yes“, enter the movable component with which the check was performed along with the

with the Serial No. in the table.

Movable components (also test phantoms that are part of the system) are parts that can

be used on different systems).

Component Serial No.

Siemens AG RX63-055.832.02.02.02 POLYDOROS SX/LX

Medical Solutions

04.05 CS PS 211

Page 5 of 10

Page 6

Cust.-No.: Date: Protocol

OK not n.a.

OK

1 Prerequisites / Notes

1.1 Requirements

1.2 Notes

1.2.1 Safety Information

1.2.1.1 General Safety Information

1.2.1.2 Product-specific Safety Information

1.2.2 Product-specific Remarks

1.2.2.1 Notes Regarding Maintenance

1.2.3 General Remarks

1.2.3.1 Maintenance time / interval

1.2.3.2 Tolerance Data

1.2.3.3 Maximum Torque Values in Nm

1.2.3.4 Explanation of Abbreviations in the Maintenance Certificate

1.2.3.5 DHHS Regulations

2 General Visual Check

2.1 Visual Inspection

SI Checking the cover panels

SI Required operator documents present

SI Checking the cable corrugated hoses

SI Checking the cable corrugated hoses (of mobile components)

SI Checking the radiation protective panels

SI Checking warning labels

Maintenance of component was performed completely:

Signature:

Date: Name:

2.2 Tables and Warning Labels

4 POLYDOROS SX/LX

4.1 Special Requirements

4.2 Inspection and Maintenance

4.2.1 General Information

PM Cleaning

POLYDOROS SX/LX RX63-055.832.02.02.02 Siemens AG

04.05 CS PS 211

Page 6 of 10

Medical Solutions

Page 7

Protocol Date: Cust.-No.:

OK not n.a.

OK

4.2.2 Generator Control Console

PM Cleaning

4.2.3 Error Log

PM Evaluating the Error Log

4.2.4 Checking the High Voltage Cables

SI Check the shielding on the HV cables.

4.2.5 Replacing the Batteries with PL SX 65/80 with XCU HD Unit, Part No.: 38

27 123

PMP Battery replacement performed (required annually) with the PL SX 65/80

Startup Date / Date of Last Replacement

4.2.6 Direct Technique Radiation Displays

SI Checking the Direct Technique Radiation Displays

4.2.7 Indirect Technique Radiation Displays

SI Checking the Indirect Technique Radiation Displays

4.2.8 IONTOMAT Limit

SI Checking the IONTOMAT Limit

4.2.9 Dose Rate IQ Initial Values

4.2.10 Indirect Technique Dose Rate

QIQ Indirect Technique IQ Initial Values

4.2.11 Direct Technique Dose Rate

QIQ Direct Technique IQ Initial Values

4.2.12 Conditioning the X-Ray Tube(s)

PMA Conditioning the tube(s) (test shots)

PM Check of the max. generator power

4.2.13 IQ Final Test with Indirect Technique

QIQ IQ Final Test

..

DD MM YYYY

4.2.14 IQ Final Test with Direct Technique

QIQ IQ Final Test

4.2.15 IONTOMAT Fields

PM Selecting and checking the sensitivity of the IONTOMAT fields

PM Checking IONTOMAT linearity

Maintenance of component was performed completely:

Signature:

Date: Name:

Siemens AG RX63-055.832.02.02.02 POLYDOROS SX/LX

Medical Solutions

04.05 CS PS 211

Page 7 of 10

Page 8

Cust.-No.: Date: Protocol

OK not n.a.

OK

5 Final Work Steps

5.2 Inspection and Maintenance

SIE Performing the Ground Wire Check

Maintenance of component was performed completely:

Signature:

Date: Name:

6 Changes to Previous Version

POLYDOROS SX/LX RX63-055.832.02.02.02 Siemens AG

04.05 CS PS 211

Page 8 of 10

Medical Solutions

Page 9

Protocol Date: Cust.-No.:

Generator

Generator Tables 0

Indirect Technique 0

Tab. 1 Fluoroscopy kV and mA

Fluoro kV mA No fluoro

Prior to conditioning the tube

After conditioning the tube

Direct Technique 0

Tab. 2 Work Station 1

Work Station 1 kV mAs not configured

Prior to conditioning the tube

After conditioning the tube

Tab. 3 Work Station 2

Work Station 2 kV mAs not configured

Prior to conditioning the tube

After conditioning the tube

Tab. 4 Work Station 3

Work Station 3 kV mAs not configured

Prior to conditioning the tube

After conditioning the tube

Tab. 5 Iontomat Fields

Iontomat Fields Left Center Right not configured

Work Station 1 mAs mAs mAs

Work Station 2 mAs mAs mAs

Work Station 3 mAs mAs mAs

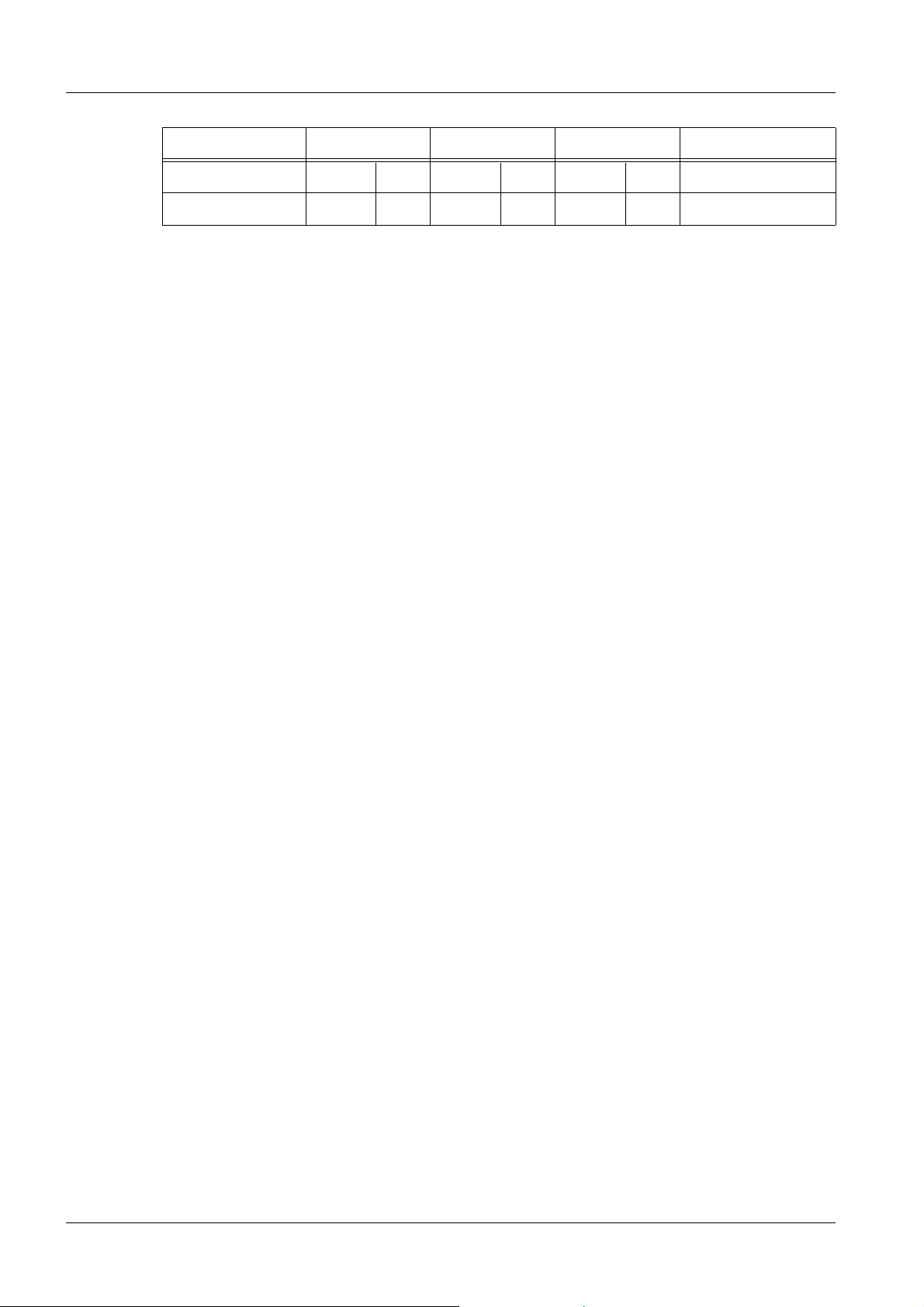

Tab. 6 Linearity

Linearity 0.3 Cu 0.6 Cu 0.9 Cu not configured

Work Station 1 mAs mAs mAs

Siemens AG RX63-055.832.02.02.02 POLYDOROS SX/LX

Medical Solutions

04.05 CS PS 211

Page 9 of 10

Page 10

Cust.-No.: Date: Protocol

Linearity 0.3 Cu 0.6 Cu 0.9 Cu not configured

Work Station 2 mAs mAs mAs

Work Station 3 mAs mAs mAs

POLYDOROS SX/LX RX63-055.832.02.02.02 Siemens AG

04.05 CS PS 211

Page 10 of 10

Medical Solutions

Loading...

Loading...