Page 1

User Guide

Document No. 125-1902

June 26, 2018

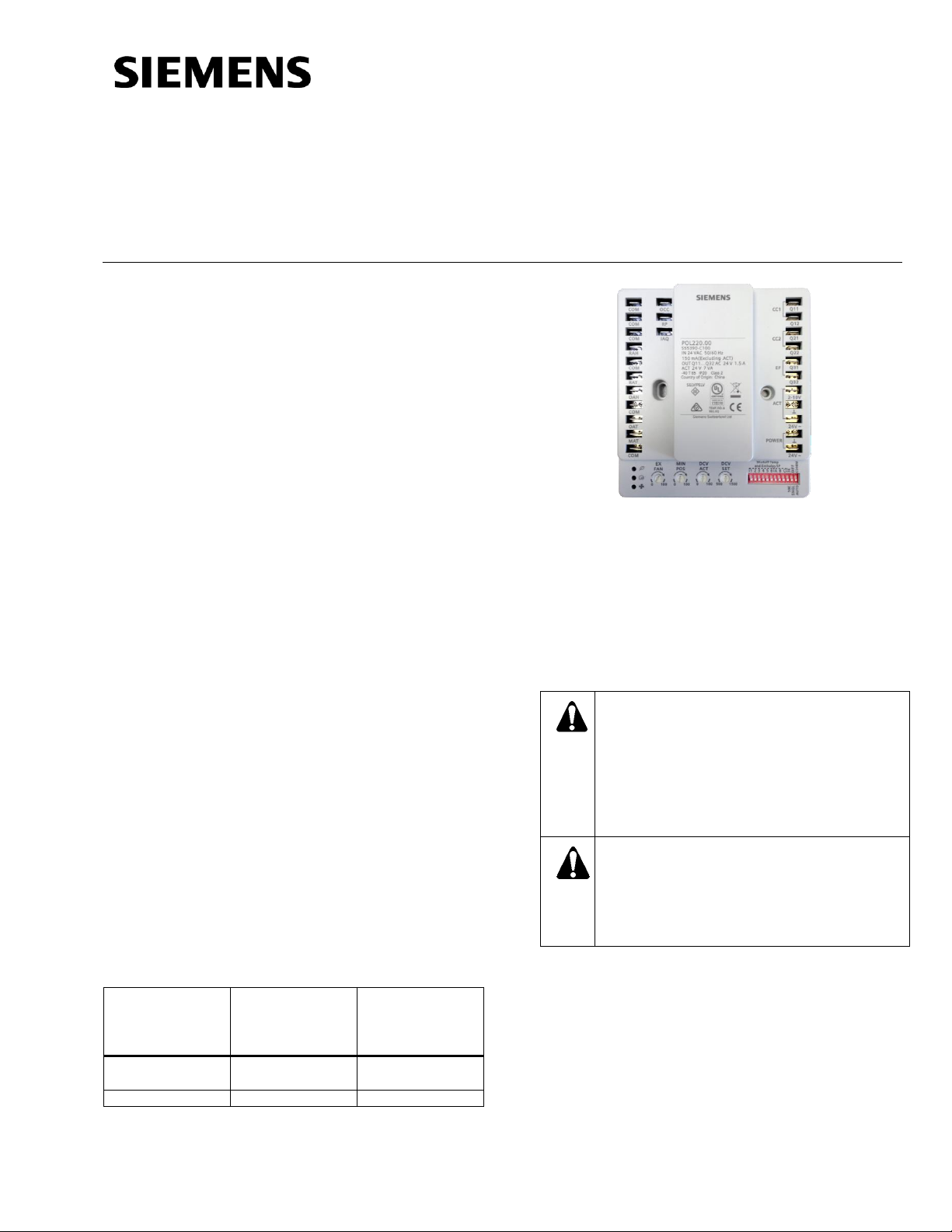

POL220 Series Economizer Controller

Page 1 of 16

Product Description

The Economizer Controller allows the use of

unconditioned outside air to cool a building. The

Free Cooling air determination is based on customer

temperature and humidity selections, as well as

optional Demand Control Ventilation (DCV)

strategies with CO2 level selection.

Features

• Economizer control provides “free cooling”

based on single or dual dry bulb temperature, or

combination temperature + humidity sensors.

• Wide temperature shut-off setpoint range

selection and Btu/lb selection range selectable

by DIP switches.

• Potentiometers allow accurate adjustment of

DCV, exhaust fan levels, and minimum damper

position.

• Versions with remote minimum position damper

adjustments accept either 0 to 10 Vdc or 135

Ohm potentiometer signals.

• Used with Siemens OpenAir® damper actuators.

• Flexible sensor inputs accept 10K or 3K

standard NTC sensors, or Siemens QFM2160U

combination temperature/humidity 0 to 10V

sensor for enthalpy control.

• LED Indication when in Free Cooling operation,

DCV operation and exhaust fan operation as

well as during sensor failure.

• Quick installation and easy commissioning.

• Two-stage cooling control.

• Occupancy input with default capability.

• Quick connect I/O with 1/4” spade connections.

• Anti-freeze protection.

• Brownout protection.

Product Numbers

Economizer

Controller

Single

Economizer

Controller

Multi-pack (20)

Remote

Potentiometer

Input Type

POL220.05

POL220.00

BSG61

(0-10 Vdc)

POL220.10

POL220.15

LVC2 (135Ω)

Item Number 125-1902, Rev. GA

Contents

• Economizer Controller

• Two No. 6 3/4” self-tapping screws

Accessory

985-960 Jumper Accessory

Warning/Caution Notations

CAUTION/ATTENTION

Equipment damage or loss of data may

occur if you do not follow a procedure as

specified.

Risque de dégâts matériels ou de perte de

données, en cas de non-respect des

procédures à suivre.

WARNING/AVERTISSEMENT

Personal injury may occur if you do not

follow a procedure as specified.

Risque de blessures graves en cas de

non-respect des procédures à suivre.

Prerequisites

For proper Economizer Controller operation, read

this User Guide carefully, and follow the instructions

in the Economizer Controller Start-up/

Commissioning Mode section. Failure to do so may

result in damage to the product or create a

hazardous condition. Installation of this controller

must be performed by a trained HVAC service

technician.

Page 2

Document No. 125-1902

User Guide

June 26, 2018

Page 2 of 16 Siemens Industry, Inc.

Basic Economizer Control Modes

1. Control Mode 1: Fixed Dry-bulb

(Single dry-bulb)

Outside air and mixed air temperature sensors

are used.

2. Control Mode 2: Differential Dry-bulb

(Dual Dry-Bulbs)

Outside air, return air, and mixed air

temperature sensors are used.

3. Control Mode 3: Combination Fixed Enthalpy

and Fixed Dry-bulb Control

Outside air temperature and humidity sensors,

and mixed air temperature sensors are used.

4. Control Mode 4: Combination of Differential

Enthalpy and Fixed Dry-bulb

Outside air temperature and humidity sensors,

return air temperature and humidity sensors,

and mixed air temperature sensors are used.

Specifications

Electrical Ratings:

Input Voltage: 24 Vac ±25%; 50/60 Hz (Class 2).

Nominal Power Consumption (at 24 Vac, 60 Hz):

4 VA.

Relay Contact Rating at 30 Vac (maximum power

from Class 2 input only): 1.5A run, 3.5A inrush.

NOTE:

All inputs and outputs must be 24 Vac Class 2.

Ambient Ratings:

Temperature: -40°F to 149°F (-40°C to 65°C).

Humidity: 5 to 95 percent RH (non-condensing).

Inputs:

Combination Temperature/Humidity Sensor

(QFM2160U): 5-wire (18, 20, or 22 AWG cable)

connection.

Dry Bulb Temperature Sensor 10K Ohm Type II

NTC (QAM2030.010) or 3K NTC: 2-wire

(18, 20, or 22 AWG cable) connection.

DCV (CO2) Sensor (QPA2000): 3- wire

(18, 20, or 22 AWG cable)

0 to 10 Vdc control signal

Outputs:

Actuator (GCA151.1P GMA151.1P, GQD151.1P):

4-wire (18 AWG)

Actuator Signal: 2 to 10 Vdc.

Actuator Input Resistance: 100K ohm.

The controller provides 7 VA max. to operate the

damper actuator.

Exhaust Fan: Contact closure.

Auxiliary Equipment:

• RDY2000 Commercial Thermostat

• LVC2 (135 Ω) Control Board for remote minimum

damper positioning (POL220.10 and POL220.15)

• BSG61 (0-10 Vdc) for remote minimum damper

positioning (POL220.00 and POL220.05)

Wire the electrical connections using 1/4” female,

insulated spade connections.

Approvals:

UL listed per UL873.

CE

RCM

cUL Listed per CSA – C22.2 No. 24

Suitable for plenum installation

UL/NEMA Type 1

Dimensions: 5.10” × 4.70” × 1.10”

(130 mm × 120 mm × 28 mm)

Weight: 0.49 lbs (221 g)

Required Tool

Phillips Screwdriver

Expected Installation Time

15 minutes

Installation

Mount the controller to sheet metal ductwork or a

panel using two self-tapping screws (provided). The

mounting location must protect the controller from

the elements and ultraviolet rays.

Page 3

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 3 of 16

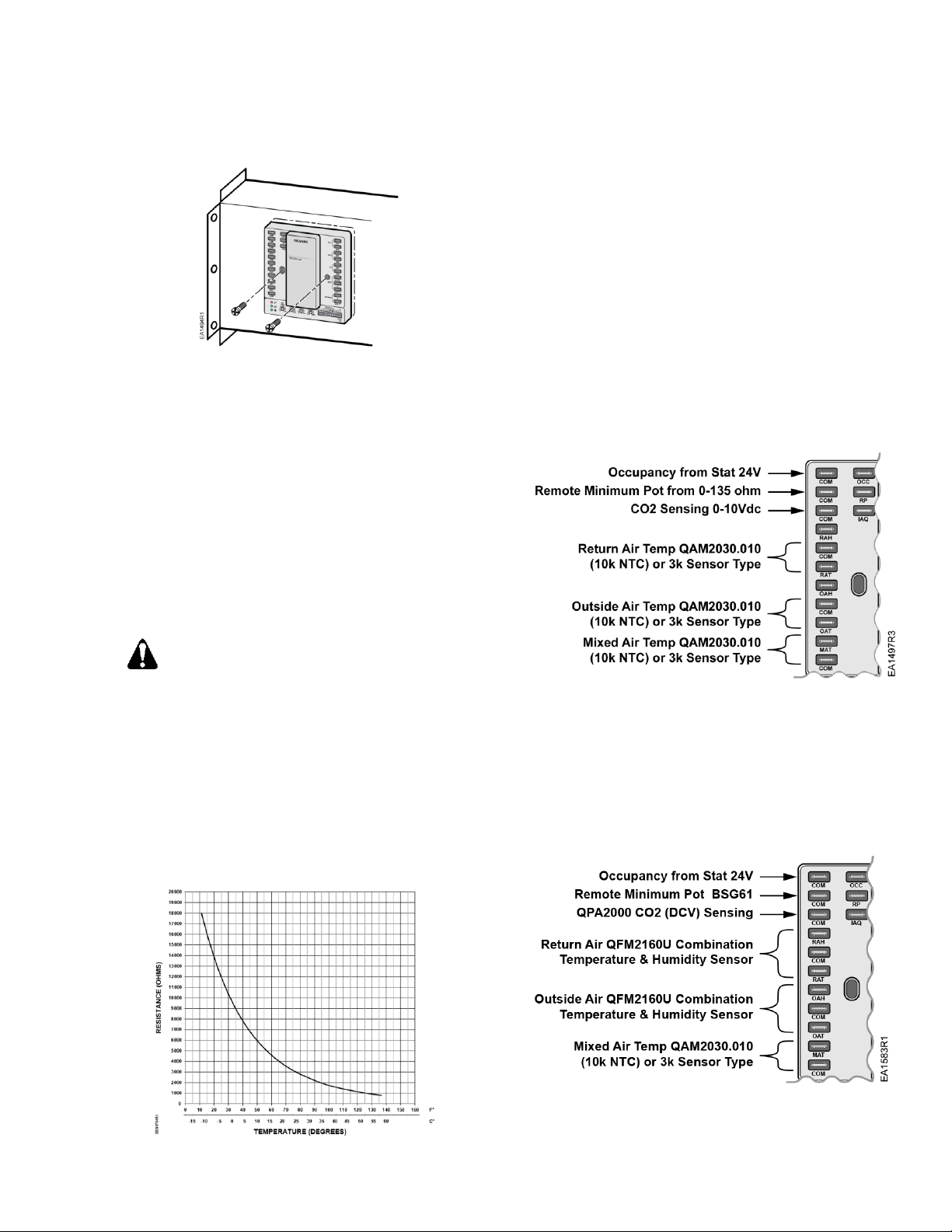

Figure 1. Controller Mounted to Ductwork.

Outdoor, Return Air, and Mixed Air

Sensor Operating and Mounting

Instructions

Location and Mounting

The Economizer Controller accepts signals from

either the QAM2030.010 (10K, Type II) dry bulb

temperature sensor, or 3K NTC temperature sensor.

It provides single or differential temperature based

economizer control or the QFM2160U combination

temperature/humidity sensor for single or dual

enthalpy-based economizer control.

CAUTION/ATTENTION:

Do not mix sensors.

Temperature sensors must all be either

10K Ohm Type II NTC, or 3K NTC.

Ne mélangez pas de détecteurs.

Les détecteurs de température doivent

tous être l'un ou l'autre le Type II d'Ohm

de 10 Ko NTC, ou 3 Ko NTC.

For differential dry bulb operation, use two

QAM2030.010 (10K Type II NTC) or 3K NTC

temperature sensors.

Figure 2. 3K NTC Curve.

NOTE: 3K NTC sensors must follow this curve.

Sensor Mounting

1. Mount the sensor in any orientation, exposing it

to freely circulating air, using the two mounting

screws provided with the sensor. Choose a

location that protects it from rain, snow, and

direct sunlight.

2. Connect the appropriate Type II NTC 10K or 3K

sensor for:

o Outside Air: Connect to the OAT and COM

terminals of the device.

o Return Air (Differential): Connect to the RAT

and COM terminals of the device.

o Mixed Air: Connect to the MAT and COM

terminals of the device.

Figure 3. Type II NTC 10K or 3K Sensor Connections.

3. Connect the QFM2160U Combination

Temperature/Humidity sensor for Enthalpy

control.

o Outside Air: Connect to the OAT, COM, and

OAH terminals of the device.

o Return Air (Differential): Connect to the

RAT, COM, and RAH terminals of the

device.

Figure 4. QFM2160U Combination

Temperature/Humidity Sensor Connections.

Page 4

Document No. 125-1902

User Guide

June 26, 2018

Page 4 of 16 Siemens Industry, Inc.

NOTE: QFM2160U Combination Temperature/

Humidity Sensors must be powered by an

external 24 Vac power supply.

CO2 Sensor – Demand Control

Ventilation (DCV)

1. Mount the QPA2000 CO2 Sensor in an area with

unobstructed air circulation. See QPA…Series

Indoor Air Quality Room Sensors Installation

Instructions (129-435).

2. Connect the sensor to the IAQ and COM

terminals of the controller. See Figure 4.

NOTE: CO2 sensors must be powered by an

external 24 Vac power supply.

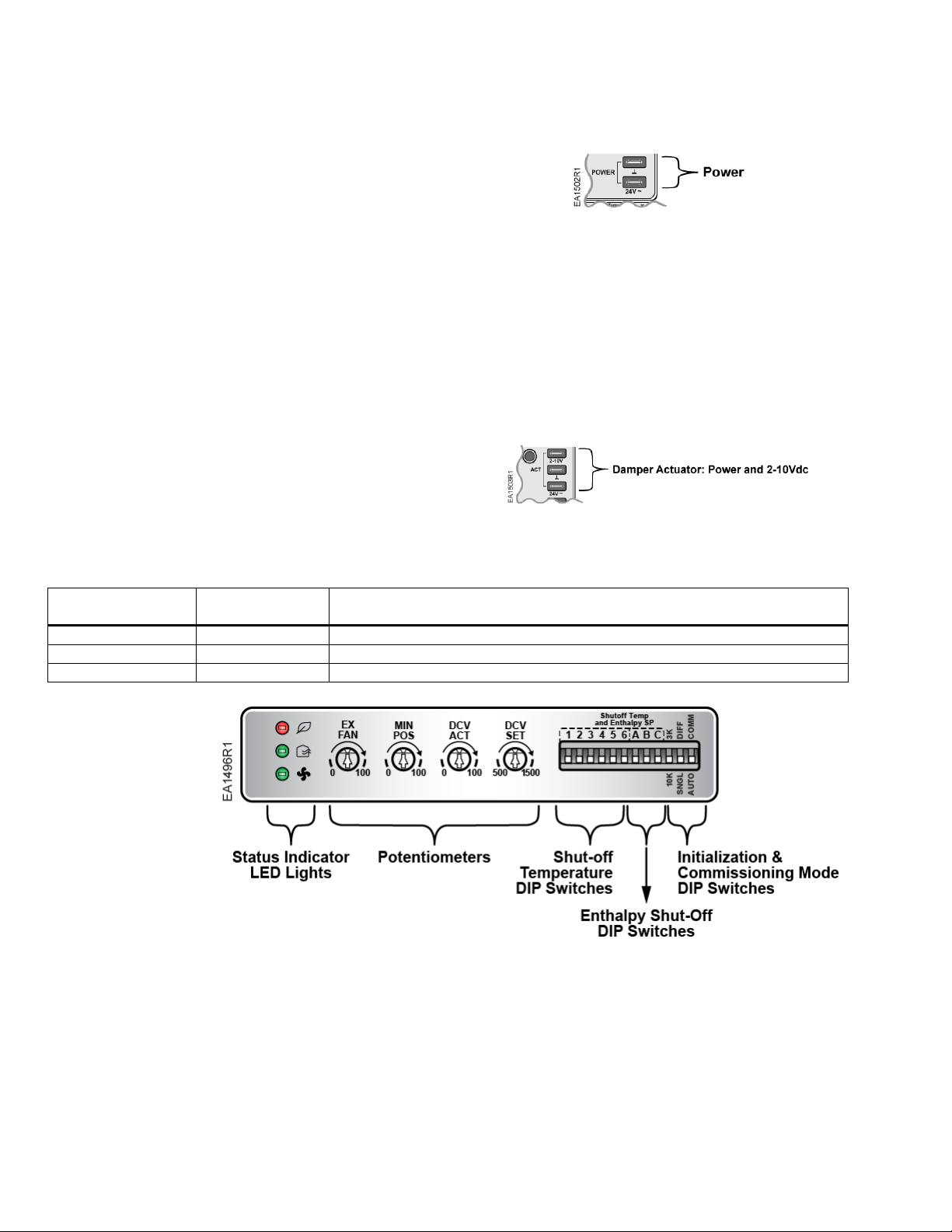

Powering the Economizer

Controller

To power the Economizer Controller, connect a

24 Vac external power supply source.

Figure 5. Connecting to Power Supply Source.

Damper Actuator Connection to the

Economizer Controller

1. Connect the appropriate Siemens OpenAir

Damper Actuator to the controller actuator input

as shown.

2. Select the appropriate modulating (2 to 10 Vdc)

spring return damper actuator to operate the

Economizer damper. See Table 1.

Figure 6. Damper Actuator Connections.

Table 1. Damper Actuator Selection.

Damper Actuator

Part Number

Torque Rating

Description

GQD151.1P

20 lb-in

Spring Return, 2 to 10 Vdc Signal, Plenum-rated

GMA151.1P

62 lb-in

Spring Return, 2 to 10 Vdc Signal, Plenum-rated

GCA151.1P

160 lb-in

Spring Return, 2 to 10 Vdc Signal, Plenum-rated

Figure 7. Economizer Control Adjustments.

Page 5

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 5 of 16

Economizer Controller

Startup/Commissioning Mode

Factory default settings:

All DIP switches are in the OFF (down position).

NOTE:

Use a small, flat-blade screwdriver to select DIP

switches. Ensure that the switches are fully in the

ON or OFF position.

All potentiometers are in the middle position (arrow

pointing upwards).

Initialization

1. Connect the sensor inputs and other auxiliary

equipment.

2. Use the DIP switch to select a 3K or 10K sensor

(see Figure 7).

3. Use the DIP switch to select Single (SNGL) or

Differential (DIFF) mode (see Figure 7).

4. Apply power to the controller (see Figure 5).

5. The controller will perform up to a 20-second

auto detection to determine the type of sensor

input(s).

If you experience a transient power failure during

initialization, the compressors will not suddenly

restart because the outputs are deactivated.

Commissioning Mode

This Commissioning mode (COMM) adjusts the

Minimum Position of the outside air damper. In the

Commissioning mode, the damper will be overridden

by Effective MIN POS, or DCV ACT, whichever is

greater.

Effective MIN POS is determined by either the

onboard MIN POS potentiometer or the Remote MIN

POS potentiometer:

Move the DIP switch on the bottom of the controller

to the COMM position (see Figure 7) to enter the

Commissioning mode. When the Free Cooling LED

and DCV LED blink red, this indicates that the

controller is in the Commissioning mode. CC1 and

CC2 are energized in the Commissioning mode, and

the exhaust fan responds to the outside air damper.

Determining Required Airflow

The Consulting Engineer defines the minimum

damper position by the minimum outdoor airflow

required in the building during the occupied period.

To determine the minimum amount of outside air to

bring in the building, use these basic guidelines:

• The OA rate can be calculated by this formula:

OA

% =

MAT−RAT

OAT−RAT

A minimum 10°F temperature differential

between OA and RA must be maintained;

otherwise, this formula doesn’t work well.

OR

• An airflow measuring station can be used to

directly tune the outdoor airflow volumetric rate

to designed value. OA rate can be calculated

from formula 𝑂𝐴% =

OAV

SAV

=

OAV

OAV+RAV

, where

minimum differential temperature between OA

and RA is not required.

Setting Minimum Position in Commissioning

Mode

If a Remote Positioning Potentiometer is being

used:

1. Turn the MIN POS potentiometer to the fully

closed, 0 position.

2. Turn the DCV ACT potentiometer to the fully

closed, 0 position

3. Adjust the Remote MIN POS Potentiometer until

the designed OA flow rate is met.

4. After the Remote MIN POS Potentiometer

adjustment is complete, turn the DCV ACT

potentiometer until designed DCV OA flow rate

is met. The DCV ACT setting should be greater

than the Remote MIN POS Potentiometer

setting.

5. When these adjustments are completed, set

the DIP switch to AUTO to resume normal

operation.

If the onboard MIN POS Potentiometer is being

used:

1. Turn the Remote MIN POS Potentiometer to the

fully closed, 0 position.

2. Turn the DCV ACT potentiometer to the fully

closed, 0 position,

3. Turn the MIN POS potentiometer until designed

OA flow rate is met.

4. After MIN POS adjustment is complete, turn the

DCV ACT potentiometer until designed DCV OA

flow rate is met. The DCV ACT should be

greater than MIN POS.

5. After all MIN POS and DCV ACT adjustments

are completed, set the DIP switch to AUTO to

resume normal operation.

Page 6

Document No. 125-1902

User Guide

June 26, 2018

Page 6 of 16 Siemens Industry, Inc.

Selecting the Shut-off Temperature and

Enthalpy Setpoint

The damper will be open and will allow for free

cooling below the temperature shut-off setpoint

selected from one of the six DIP switches located on

the bottom right corner of the controller cover (see

Figure 7).

The numbered DIP switches correspond to the shutoff temperature values (see Table 2). When all of the

DIP switches are in the down position and no

number is selected (factory default), the default

temperature shut-off setpoint value is 75°F.

Table 2. Shut-off Temperature Values.

Default

1 2 3 4 5

6

75°F

50°F

55°F

60°F

65°F

70°F

80°F

For Economizer operation based on both

temperature and humidity, the enthalpy shut-off

setpoint value may be selected from the following

lettered DIP switches. When the three DIP switches

are in the down position, the default enthalpy shutoff value is 28 Btu/lb.

Table 3. Enthalpy Shut-Off Values.

Default

A B C

28 Btu/lb

22 Btu/lb

24 Btu/lb

26 Btu/lb

For further assistance in determining these shut-off

setpoint values, see ASHRAE 90.1.2014 for a

guideline for shutoff control types for specific climate

zones.

Selecting Single or Differential

(Dual) Sensors

Basic Economizer Control Modes

Control Mode 1: Fixed Dry-bulb (Single Dry-Bulb)

• OA temperature sensor and MA temperature

sensor are used.

• Set the DIP switch to SNGL (single) mode. See

Figure 7.

• The outside-air dry-bulb temperature is

compared to a shut-off dry-bulb temperature. If

the outside-air dry-bulb temperature is below the

shut-off dry-bulb temperature, then the outside

air is used to meet all or part of the cooling

demand.

Control Mode 2: Differential Dry-bulb (Dual DryBulbs)

• OA temperature sensor and RA temperature

sensor, MA temperature sensors are used.

• Set the DIP switch to DIFF (Differential) mode.

See Figure 7.

• The outside-air dry-bulb temperature is

compared with the return-air dry-bulb

temperature. If the outside-air dry-bulb

temperature is less than the return-air dry-bulb

temperature, then the outside air is used to meet

all or part of the cooling demand.

Control Mode 3 - Combination Fixed Enthalpy and

Fixed Dry-bulb Control

• OA temperature and Humidity sensor, and MA

temperature sensor are used.

• Set the DIP switch to SNGL (Single) mode. See

Figure 7.

• Determine the shut-off setpoint by a combination

of two parameters:

- Enthalpy shut-off SP

- Dry-bulb shut-off SP

• Determine if the outside air can be used for Free

cool:

If the outside-air enthalpy is lower than the shutoff enthalpy setpoint, and the outside air dry bulb

temperature is lower than the shut-off dry bulb

setpoint, then the outside air can be used.

Control Mode 4 - Combination of Differential

Enthalpy and Fixed Dry-bulb

• OA temperature and humidity sensor, and return

temperature and humidity sensor, and MA

temperature sensor are used.

• Set the DIP switch to DIFF (Differential) mode.

See Figure 7.

• Determine if outside air can be used for Free

cooling: If outside-air enthalpy is lower than the

return air enthalpy, and the outside air dry bulb

temperature is lower than the dry bulb

temperature shut- off setpoint, then outside air

can be used.

Demand Control Ventilation Setpoint

(DCV Only)

The controller will modulate the outside air damper

based on the CO2 level through the ppm value

selected by the DCV SET potentiometer between

the range of 500 and 1500 ppm, on the controller, as

shown in Figure 7.

To disable the DCV, turn the DCV ACT

potentiometer counter-clockwise to 0%.

If a CO2 sensor is not used with the controller, the

OA damper will modulate based on the Free Cooling

logic.

If the CO2 sensor has failed, the damper will be

controlled by the Free Cooling logic.

Page 7

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 7 of 16

Exhaust Fan Operation and Setting

Figure 8. Relay Connection.

The exhaust fan contacts are 24V dry contacts only,

and are labeled Q31 and Q32. An external line

voltage contactor is required to operate the exhaust

fan.

If the EX FAN potentiometer is turned fully counterclockwise to 0%, the EX FAN feature is disabled.

This feature allows the exhaust fan operation to be

disabled instead of being operated at constant ON.

The exhaust fan shut-off point is selected by setting

the EX FAN potentiometer to the desired level. See

Figure 7.

When the damper position reaches the exhaust fan

setpoint, the exhaust fan relay will be energized. A

Green exhaust fan LED indicates that the exhaust

fan is ON.

Cooling Stage Operation

Figure 9. Cooling Stage Operation.

The Economizer Controller accepts inputs for singleand two-stage cooling inputs, and reroutes to the

RTU through the relay connection CC1 and CC2.

The operation of the cooling stages is determined by

the availability of Free Cooling provided by the

economizer operation mode. SeeTable 4.

Based on the use of Free Cooling, the operating

modes are as follows:

• Y1 is Stage 1 Cooling Demand.

• Y2 is Stage 2 Cooling Demand.

• Free Cooling is always the first cooling stage.

• The Cool Stage 1 call from the Commercial

Thermostat (Y1) energizes the CC1 input to the

Economizer Controller.

• The Cool Stage 2 call from the Commercial

Thermostat (Y2) energizes the CC2 input to the

Economizer Controller.

Table 4. Cooling Stage I/O Logic.

Economizer

Y1

Thermostat

Y2

Thermostat

Cooling

Stage 1

Cooling

Stage 2

OFF

ON

ON

ON

ON

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF*

ON

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

* If OAT<56°F, then Relay 2 is always OFF to

disable Cooling Stage 2. Otherwise, if both stages of

cooling (Y1 and Y2) are ON for more than 5

minutes, Y2 remains ON, and the OAT is greater

than 56°F, then Relay 2 will energize to allow Y2

pass-through to enable Cooling Stage 2.

Remote Positioning Potentiometer

BSG61, 0 to 10 Vdc for POL220.00 and

POL220.05

The BSG61 Remote Positioning Potentiometer can

be used to remotely set the minimum damper

position and connect the RP and COM terminals of

the device.

Figure 10. RP and OCC Terminals.

This input offsets the damper minimum position

setting (MIN POS).

NOTE: The BSG61 Remote Positioning

Potentiometer must be powered by an

external 24 Vac power supply.

When the remote potentiometer is installed, set the

MIN POS potentiometer to 0%; the damper position

will receive positioning signals from the BSG61

Remote Potentiometer.

Page 8

Document No. 125-1902

User Guide

June 26, 2018

Page 8 of 16 Siemens Industry, Inc.

LVC2, 135 Ohm for POL220.10 and POL220.15

The LVC2 Control Board can be used to remotely

set the minimum damper position and connect the

RP and COM terminals of the device.

Figure 11. RP and OCC Terminals.

This input offsets the damper minimum position

setting (MIN POS).

When the remote potentiometer is installed, set the

MIN POS potentiometer to 0%; the damper position

will receive positioning signals from the LVC2

Control Board.

Occupancy Input

The Economizer Controller can input an occupancy

signal from the commercial thermostat on inputs

OCC and COM. If an occupancy signal is not

available, order Jumper Accessory 985-960, and

connect to these inputs to default the occupancy

status to ON.

When OFF, the minimum damper position is 0%.

LED Fault Detection and Diagnostics

Table 5. LED Pattern Summary.

Status

Free Cooling

LED

Demand Control

Ventilation LED

Exhaust Fan

LED

Commissioning mode

Red Blinking

Red Blinking

Power-Start-up

Orange

Orange

Green

MA/OA Sensor failure in SNGL mode

Red On

MA/OA/RA Sensor failure in DIFF mode

Red On

MIN POS potentiometer Failure

Red On

CO2 Sensor failure when DCV is enabled

Red On

DCV SET/DCT ACT potentiometer failure

Red On

DCV SET position is inappropriate

Fast Red Blinking

Brownout

Red On

Red On

Failure to detect valid FC Sensor mix during

initialization

Red On

Application

Figure 12. Connected Economizer System Components Location Example.

Page 9

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 9 of 16

Wiring Guide

Figure 13. Two-Stage Cooling System with Single Dry-Bulb Changeover Control Mode.

Page 10

Document No. 125-1902

User Guide

June 26, 2018

Page 10 of 16 Siemens Industry, Inc.

Figure 14. Two-Stage Cooling System with Dual Dry-Bulb Changeover Control Mode.

Page 11

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 11 of 16

Figure 15. Two-Stage Cooling System with Single Enthalpy Changeover Control Mode.

Page 12

Document No. 125-1902

User Guide

June 26, 2018

Page 12 of 16 Siemens Industry, Inc.

Figure 16. Two-Stage Cooling System with Dual Enthalpy Changeover Control Mode.

Page 13

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 13 of 16

Figure 17. Optional CO2 Sensor and Remote Potentiometer LVC2, 135 Ohm.

Figure 18. Optional CO2 Sensor and Remote Potentiometer BSG61, 0 to 10 Vdc.

The installation is now complete.

Page 14

Document No. 125-1902

User Guide

June 26, 2018

Page 14 of 16 Siemens Industry, Inc.

Dimensions

Figure 19. Dimensions in Inches (Millimeters).

Troubleshooting

WARNING/AVERTISSEMENT:

Do not open the actuator.

Ne pas ouvrir le servomoteur !

Symptom

Reason

Solution

The Economizer Controller/

Mechanical

Cooling is not operating

No input power

Use a multi-meter to check if there is 24 Vac +/- 25% (18 Vac – 30 Vac) at

the POWER terminals.

If there is no voltage or if the voltage is significantly low, check the

transformer output voltage at the RTU. If 24 volts is not present at the

transformer secondary side, check the primary line voltage to the

transformer.

If the line voltage is not present at the transformer primary side, check the

primary power to the RTU, fuses, circuit breaker, and so on.

Brownout

If voltage is below 18 Volts, the Economizer Controller may be in Brownout

Protection mode. This mode disables all of the relay outputs.

When the power is back to 18 Vac or higher, the Economizer Controller and

RTU will operate normally.

Y1/Y2 signal is missing

from the thermostat

Mechanical Cooling doesn’t run until there is cooling demand (Y1/Y2 Active).

Check the wiring from CC1, Q11 and CC2, Q21 terminals to the commercial

thermostat. 24V should present between CC1.Q11/CC2.Q21 and COM.

24 Vac~ and 24 Vac ┴

are incorrectly wired

24 Vac power supply has polarity when all devices are powered by the same

24 Vac transformer; reversing polarity may cause a short circuit that can

damage the system.

Follow the transformer polarity mark; check the wring of 24V~ (or G or 24V+)

and ensure that they are tied to the same polar of 24 Vac power supply;

while checking the wiring of ┴ (or G0 or 24V- or COM) and ensure that they

are all tied to another polar of 24 Vac power supply.

Page 15

Document No. 125-1902

User Guide

June 26, 2018

Siemens Industry, Inc. Page 15 of 16

Symptom

Reason

Solution

Free Cooling LED is solid

RED

Mixed Air (MA) sensor error

Check the MA sensor, it must be either a 10K Type II NTC, or 3K NTC

sensor.

Outside Air (OA)/Return Air

(RA) sensor error

Check the OA sensor. If in DIFF mode, check the RA sensor too. The

following sensor signals are valid:

• 10K Type II NTC temperature

• 3K NTC temperature

• 0–10V temperature and 0–10V humidity

• 10K Type II NTC temperature and 0-10V humidity

• 3K NTC temperature and 0-10V humidity

In Differential (DIFF) mode, OA and RA sensors must be of the same

sensor type.

MIN POS potentiometer has

been damaged by excessive

force

Check if MIN POS potentiometer has been damaged; if so, replace the

Economizer Controller.

Sensor Auto Detection error

Ensure that the sensors have been correctly wired prior to controller

power-up. Power-up the active sensors first, or power-up the controller

and the active sensors simultaneously. Otherwise, the controller may not

capture the sensor type in time.

Don’t change the DIP switch settings (10K/3K or SNGL/DIFF) when the

controller is running. The controller must be rebooted after any changes to

the sensor or sensor setting for the new sensor configuration to be

implemented.

DCV LED is solid RED

CO2 sensor error

Check the CO2 sensor signal; the valid signal must be 0-10V.

DCV ACT or DCT SET

potentiometer has been

damaged by excessive force

Check if DCV ACT or DCT SET potentiometer has been damaged by

excessive force; if so, replace the Economizer Controller.

DCV ACT is not being

turned to the 0 position

The DCV feature should not be enabled, but it was not turned off. Adjust

the DCV ACT potentiometer to full CCW position if you are not using

DCV.

Exhaust Fan LED is not

working

The Ex FAN potentiometer

hasn’t been set up correctly,

or has been damaged by

excessive force.

In its full CCW position, the EX FAN control is disabled; therefore, the

Exhaust Fan LED is OFF, and the EF relay is inactive. To use this feature,

the EX FAN potentiometer must be turned to a non-zero position.

If the EX FAN control is enabled, but the Exhaust Fan doesn’t work

correctly, check if the EX FAN potentiometer has been damaged. If so,

replace the Economizer Controller.

Both Free Cooling and DCV

red LEDs are blinking

The Economizer Controller

is set to COMM mode

The Economizer Controller is set to COMM mode, and must be set back

to AUTO mode to resume normal operation.

DCV red LED is blinking

The DCV feature is enabled,

but the DCV ACT

potentiometer is improperly

set.

Ensure that the DCV ACT is greater than the MIN POS setting.

The controller has no alarm,

but the Free Cooling LED

never turns on even though

the OA seems to be suitable

for Free Cooling

Shut-off SP setting error

The shut-off temperature and/or enthalpy setpoint is incorrectly set up.

Consult an HVAC professional to set up the shut-off setpoint correctly.

OA temp is too low

The OAT is too low; therefore, there is no cooling demand. This could

possibly enable anti-freeze protection.

OA temp is too high or too

humid

In DIFF mode, even though OA temperature is lower than RA

temperature, if both OA and RA temperatures exceed the high limit, Free

Cooling will turn off.

In Differential Enthalpy control mode, even though OA enthalpy is lower

than RA enthalpy, if both OA and RA enthalpy exceed the high limit, Free

Cooling will turn off.

Page 16

Document No. 125-1902

User Guide

June 26, 2018

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. OpenAir is a registered trademark of Siemens Schweiz AG. Other products or company names mentioned herein

may be the trademarks of their respective owners. © 2018 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089

USA

+ 1 847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them

to sbt_technical.editor.us.sbt@siemens.com

Document No. 125-1902

Printed in the USA

Page 16 of 16

• Link to EULA and OSS Read Me File:

http://w3.usa.siemens.com/buildingtechnologies/us/en/legal_information/Pages/eula-and-oss.aspx

FCC NOTE:

This device complies with Part 15 of the FCC Rules. Changes or modifications not expressly approved by Siemens

Industry Inc. could void the user’s authority to operate the equipment.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

Loading...

Loading...