Page 1

COMOS Plant Manager

From Integrated Engineering to Integrated Operations

Issue 3/2012

3D visualization

Acquisition of VRcontext

strengthened COMOS

portfolio

Chemical

Industry

Reference Evonik

Power Plant

Industry

Reference BWSC

Interview

with Dirk Wegg about trends

in the oil & gas industry

Page 2

“ The results delivered by COMOS meet

our expectations. COMOS very quickly

provided significant and quantifiable

improvements in productivity and

reductions in project times.”

Lili Sun, Sr. Vice President, Sinopec Engineering Incorporation

2 COMOS Plant Manager | 3/2012

Page 3

Editorial

Dear readers,

At this time, the plant management of the

future is being discussed by experts at many

conferences and trade fairs. These events

provide the ideal platform for exchanging information on trends, requirements, the latest

developments, and innovative practical solutions in the process industry. For example,

plant designers and owner operators came

together at the Digital Plant Conference

2012 in September and examined the topic

of holistic plant management throughout the

entire life cycle of an industrial plant. In the

scope of this event, we had the opportunity

to announce the takeover of 3D experts

VRcontext by Siemens.

The acquisition and integration of the successful VRcontext product Walkinside represents a valuable addition to our COMOS soft-

ware range in the areas of 3D visualization

and training software. Apart from the familiar

2D solutions, we can therefore now offer fast

access to 3D engineering data from the basic

and detail engineering stages. Along with realistic 3D visualization and easy operation,

the powerful software impresses with data

management in real time and a capability to

handle very large data volumes. You can read

more about COMOS Walkinside on pages six

and seven of this edition of the COMOS Plant

Manager.

In this issue, we also report on the successful

use of COMOS by our customers Evonik in the

chemical industry and BWSC in the power

plant industry. Read about the latest benefits

provided by our service and support system

and our extended training program. Of course,

Doc COMOS has another useful tip for you.

This time, it relates to executing a query faster. In the Event Calendar, you will find events

at which we can discuss the efficient management of your plant together. Take advantage of the opportunity and speak to us. Your

regional COMOS contact partner will be happy to make an individual appointment to talk

to you in detail about your specific requirements.

I hope you enjoy reading this issue of

COMOS Plant Manager.

Yours,

Andreas Geiss

Vice President COMOS Industry Solutions

Andreas Geiss

Vice President

COMOS Industry Solutions

3 COMOS Plant Manager | 3/2012

Page 4

Contents

Contents

In this issue you can read about:

05 3D visualization and training software

Acquisition of VRcontext strengthened

COMOS portfolio

07 Chemical Industry: Reference Evonik

Standardization supports accelerated

plant design

10 Power Plant Industry: Reference BWSC

Design of power plants in interdisciplinary

database

12 Interview with Dirk Wegg about

trends in the oil & gas industry

“Data-centric development and operation

of plants with COMOS could potentially

solve an industry problem that has plagued

us for decades.”

15 News

Mobile plant management, Service

and support newsletter, Sales and service

partners for Romania, Best IT company in

Denmark, Event Calendar, Training

program expanded, Tips & tricks

4 COMOS Plant Manager | 3/2012

Page 5

3D visualization and training software

COMOS portfolio significantly strengthened

by the acquisition of 3D experts VRcontext

On September 26, 2012, at the Digital Plant congress in Würzburg,

the acquisition of VRcontext S. A. on October 1, 2012 was officially announced. With this acquisition, Siemens has acquired one of the world‘s

leading experts in 3D visualization and training software. This further

strengthens Siemens‘ established position in the industrial software

market. The market-leading software Walkinside will be integrated in

the COMOS product portfolio.

From the start of the new fiscal year, the

product will be available under the trade

name “ COMOS Walkinside” and will expand

the extensive portfolio with powerful 3D visualization throughout the entire plant lifecycle.

The Walkinside software is currently used in

more than 200 companies for the visualization

of complex data models, primarily in the oil

and gas industry; for plant operation and

maintenance; and for simulation and training.

Even today, COMOS Walkinside can provide

considerable added value, particularly in

plant operation and maintenance. By linking

the geometric objects of the VR model with

the engineering data from COMOS, they can

be used throughout all phases of the plant

lifecycle. Attractive and realistic visualization

of the current status of the plant is possible

through direct access to all information, independent of the 3D system. This allows maintenance and servicing work to be planned,

5 COMOS Plant Manager | 3/2012

»

Page 6

3D visualization and training software

“The integration of the Walkinside 3D visualization and training software of our

long-standing partner VRcontext into our industrial software portfolio will benefit

our customers significantly. Using intelligent 3D models can make plant engineer-

ing and operation safer and more efficient in many sectors of the industry,” states

Eckard Eberle, CEO of the Siemens Industrial Automation Systems Business Unit.

simulated and executed efficiently in the 3D

model based on constantly up-to-date and

consistent data. In addition to this, it is also

possible to access information linked to a

COMOS object (work permits, data sheets,

maintenance intervals, etc.) at any time.

COMOS Walkinside offers a combination that

is unique on the market, with simple operation and realistic visualization along with permanent availability of the plant data. This

ensures efficient data management in real

time, as well as the ability to handle the largest possible data volumes. Even extremely

complex models, such as those produced for

complete offshore drilling platforms or FPSO

(Floating Production Storage Offloading)

units, allow a virtual walkthrough in real

time.

COMOS Walkinside also finds profitable application in the training of field operators. The

software allows personnel to be trained realistically in the virtual model of the real plant

while the plant itself is still under construction. These training scenarios include the fast

locating of objects or components in the

plant, the planning and execution of maintenance work, and the simulation of faults. In

“multiple avatar mode“, this training allows

the participation of the entire operations

team together in the same virtual model. This

avoids the high costs involved in sending

staff to a plant that is still under construction.

At the same time, staff can be prepared efficiently under safe environmental conditions

for their later deployment.

With the integration of Walkinside in the

COMOS portfolio, customers profit from even

greater productivity and additional benefits

throughout the entire value chain of plant

management. The skills brought together in

COMOS Walkinside will also be integrated increasingly in development and support, etc.

and therefore increase the investment protection for customers.

You will find more information on

the advantages of COMOS Walkinside

in the video

6 COMOS Plant Manager | 3/2012

(6:35 minutes)

Page 7

Chemical Industry: Reference Evonik

Standardization supports

accelerated plant design

Effective planning of chemical plants through optimized engineering

The chemical company Evonik has been pursuing a holistic approach

to plant design for some years. Strictly defined xml files within a very

modular working environment act as the core of this concept. All data

is saved in a central database. The company is currently developing standards for P&ID creation with the target of unified and accelerated plant

design.

Researchers and engineers at Evonik cooperate very closely on a global basis in order to

facilitate the rapid market launch of innovative products. Nevertheless, the design of correspondingly tailored production plants generally still takes several years. This planning

period can only be minimized if the individual

planning phases are merged more closely and

overlapped more intensively. In this context,

the utilization of information generated within the scope of basic engineering throughout

the further planning process represents a suitable approach. Using a procedural guideline,

P&ID (piping and instrumentation) flow diagrams can be generated from the process

flow diagrams created during this phase. The

guideline is to cover approximately 80 percent

of the information contained in a flow diagram. The earlier initial P&ID flow diagrams

are available, the faster can initial plant costs

be calculated.

Standardization in basic

engineering

The design of chemical plants can be accelerated by means of an extensively applied standardization concept. Analyses implemented at

Evonik Industries show that the share of imperatively individually planned plant parts is way

lower than expected. The implementation of

standardizations in the still very complex field

of P&ID creation therefore represented an obvious lever. Time expenditures both in terms of

The design of tailored chemical production

plants generally still takes several years.

»

7 COMOS Plant Manager | 3/2012

Page 8

Chemical Industry: Reference Evonik

As one of the world‘s leading companies in the specialty chemicals industry, Evonik Industries employs

the COMOS software solution for plant designing.

planning and plant cost calculation can be significantly minimized through the introduction

of standards. “Initial considerations regarding

standardized P&ID creation were already discussed 20 years ago. However, we had to

shelve these considerations as no suitable software tools for the realization of such standardization were available back then”, recalls Dr.

Dorothea Schwarz, project manager at Evonik

Industries AG.

Holistic software solution for knowhow bundling

Over the course of time and with various software developments for plant planning, this situation has changed. Meanwhile, the chemical

company employs the COMOS software solution for plant design by Siemens. Amongst

other things, it is used for the creation of P&ID

flow diagrams for individual users. This objectoriented software is based on a uniform database. With its engineering block technology, it

represents the core of the standardization concept. These e-blocks consist of a query tree

and a graphical component, which adapts to

the answer behavior. The planners are thus reliably guided through the decision process on

the basis of blocks. At the end of the process

chain, a flow diagram is generated in which

every line, measurement, and apparatus is interlinked with a procedural decision. These decisions partially go into great detail. Yet, especially more complex units and genuine

“know-how goodies”, which constitute the

specific Evonik knowledge, require manual reworking. As the standardized queries are carried out very time-efficiently, ample leeway is

available for such reworks. The e-blocks form

an integral part of the general planning database and are seamlessly integrated in the

COMOS working environment. Furthermore,

data consistency is ensured at all times. As the

e-blocks can be very easily supplemented by

further information, every decision can be immediately assessed with regard to costs. This

facilitates the rapid identification of “expensive” versions.

User-friendly interface for eased

planning

The plant engineers are currently working

with a prototype developed by the chemical

company. This prototype features a query tree

structure, which is based on an expert system.

For P&ID planning, the engineers answer concrete questions on specific subjects via a userfriendly interface, for example “Is an inflow

armature in the feed supply required?” or

“How many feed supplies in the column are

required?”. Traffic light colors indicate whether further planning decisions have to be made

by the user. Defined e-blocks are incorporated

in the P&ID flow diagrams in accordance with

the plant engineers’ answers. All prepared

planning steps can be immediately graphically

implemented and displayed by the software.

All decisions are documented and can be revoked, if required.

Time savings with basic planning

The application of the developed standards resulted in a considerably optimized P&ID creation process at Evonik Industries. What took

up half a day in the past can now be realized

“We expect significantly

reduced planning times from the

application of the COMOS e-block

technology,” states Dr. Dorothea

Schwarz, project manager at

Evonik Industries AG.

within roughly 45 minutes. “We expect significantly minimized engineering times from the

application of the COMOS e-block technology.

These time savings are then invested in the

development of intelligent solutions which »

8 COMOS Plant Manager | 3/2012

Page 9

Chemical Industry: Reference Evonik

Countering the impending loss of

innovative strength

The uniform database of COMOS

supports interdisciplinary workflows on the basis of consistent

data throughout all phases of

the plant lifecycle.

are matched to our customers’ requirements

even more closely,” comments Dr. Schwarz.

Furthermore, the uniform database supports

interdisciplinary workflows and smoother coordination between the individual departments. “Long-term success in this highly innovative business necessitates rapid inventions to

outdistance copyists,” emphasizes Dr. Schwarz.

Plant planning as a basis for staff

development

At Evonik Industries, plant designing not only

implies the cooperation of various colleagues

all around the globe for the realization of customized plants. The company’s approach to

plant design also includes the qualification of

young colleagues for future tasks in the Evonik group, for example as plant engineers.

Correspondingly, these persons are only assigned to the field of plant designing for a

limited period. The resulting constant staff

fluctuation has to be compensated accordingly. “It is therefore all the more important to

ensure the rapid productivity of our young

colleagues in this situation. From our point of

view, e-blocks can decisively contribute to

time savings for basic engineering and to a

faster utilization of the young engineers’ creative potential,” Dr. Schwarz concludes.

Particularly in Germany, companies are facing

the problem of demographic development.

Many sectors suffer from skilled labor shortage and companies have to deal with the

great difficulty of recruiting and qualifying

suitable young professionals for specific tasks.

This may lead to a future loss of innovative

strength in research and development departments. This trend is further aggravated by the

fact that many highly competent senior employees will leave the companies in the coming years due to age. The companies will then

have to deal with a considerable loss of

knowledge as the know-how of these staff

members was frequently only documented insufficiently. This would inevitably result in

higher costs and reduced competitiveness.

High R&D investments and shorter

time-to-market

Also the chemical company Evonik is facing

this trend. As one of the world‘s leading companies in the specialty chemicals industry, the

permanent development of innovative products and applications represents a strategic

main task. Correspondingly, investments for

research and development amounted to approximately 365 million Euros in 2011. Roughly

2,400 staff members work in the company‘s

research and development (R&D) departments at more than 35 sites worldwide. Over

700 staff members of this headcount work in

process technology and engineering alone.

Moreover, the company conducts many joint

research activities with other companies, universities and scientific-technical institutions.

These major R&D expenditures are reflected

by more than 24,000 patents and applications. The chemical company‘s research and

development processes are based on very

close cooperation with its customers to ensure the development of demand-based products. These innovative products have to be

produced and launched as fast as possible in

order to remain competitive. The time pressure regarding the required production plants‘

planning and realization is correspondingly

high.

The standardization of P&ID planning

with the help of the COMOS software offers

considerable time savings.

9 COMOS Plant Manager | 3/2012

Page 10

Power Plant Industry: Reference BWSC

BWSC designs power plants on

an interdisciplinary database

Today, all system design at BWSC (Burmeister & Wain Scandinavian

Contractor) is handled in a single database rather than several closed

systems. The result is a more dynamic and effective design process with

fewer errors.

All BWSC’s power plants are today designed

using an interdisciplinary software tool. This

has reduced the number of errors and increased productivity, but it has also required

changes to the work processes in the machinery room. When the EPC (Engineering Procurement Construction) company designs a

power plant, it is no longer a lengthy process

in which the mechanical and electrical engineers do their design work in separate closed

systems, laboriously exchanging CAD drawings or spreadsheets by e-mail. Since the

North Zealand turnkey supplier invested in

the COMOS software tool, all system design

has been carried out in a single database.

When the mechanical engineer creates a

pump, the system automatically creates an

electrical object containing e.g. supply and

control signals for the pump, and the electrical engineer can then continue working on

that object.

When one of the engineers updates his data,

the data is simultaneously updated elsewhere »

By Morten Lund, Ingeniøren

Diesel Engine Power Plant in Kenya, which BWSC designed with the software solution COMOS

in the system. In that way, all parties involved

in the design always know what changes the

other engineers are making. The result is a

more dynamic and effective design process

which reduces the number of spreadsheets,

the number of e-mails exchanged and the

number of errors. “We achieve a better quality. We make fewer errors and in that way also

cut down on the amount of time spent. We

get more work done in less time,” says Technical Manager at BWSC, Claus Albrechtsen, although he is unable to tell exactly how much

money is being saved.

Speaking the same language

As the first large customer in Denmark, BWSC

purchased COMOS from Siemens Industry

Software five years ago. The reason for the

purchase was a growing dissatisfaction with

the company’s existing system, which did not

function optimally as a combined database

system. The mechanical department had one

design program, the electrical department

another, and the instrumentation department

a third. The individual departments used their

own designs and exchanged data via Excel

sheets, which was not a viable solution in the

long run. BWSC therefore began looking for a

system that would enable the company’s 60

design engineers to speak one and the same

digital language.

“We now have an open, object-oriented database system in which everyone works in parallel and with parallel data. What is clever

10 COMOS Plant Manager | 3/2012

Page 11

Power Plant Industry: Reference BWSC

about the system is that if you have a pump,

there will also be a motor with controls and a

supply signal. The minute the mechanical engineer invents his pump, the system supports

him by saying: “Remember the electrical supply and don’t forget to attach some measurement instruments.” The other groups of engineers then add their details,” says Mads Broge

Richelsen, Systems Manager at BWSC with responsibility for COMOS.

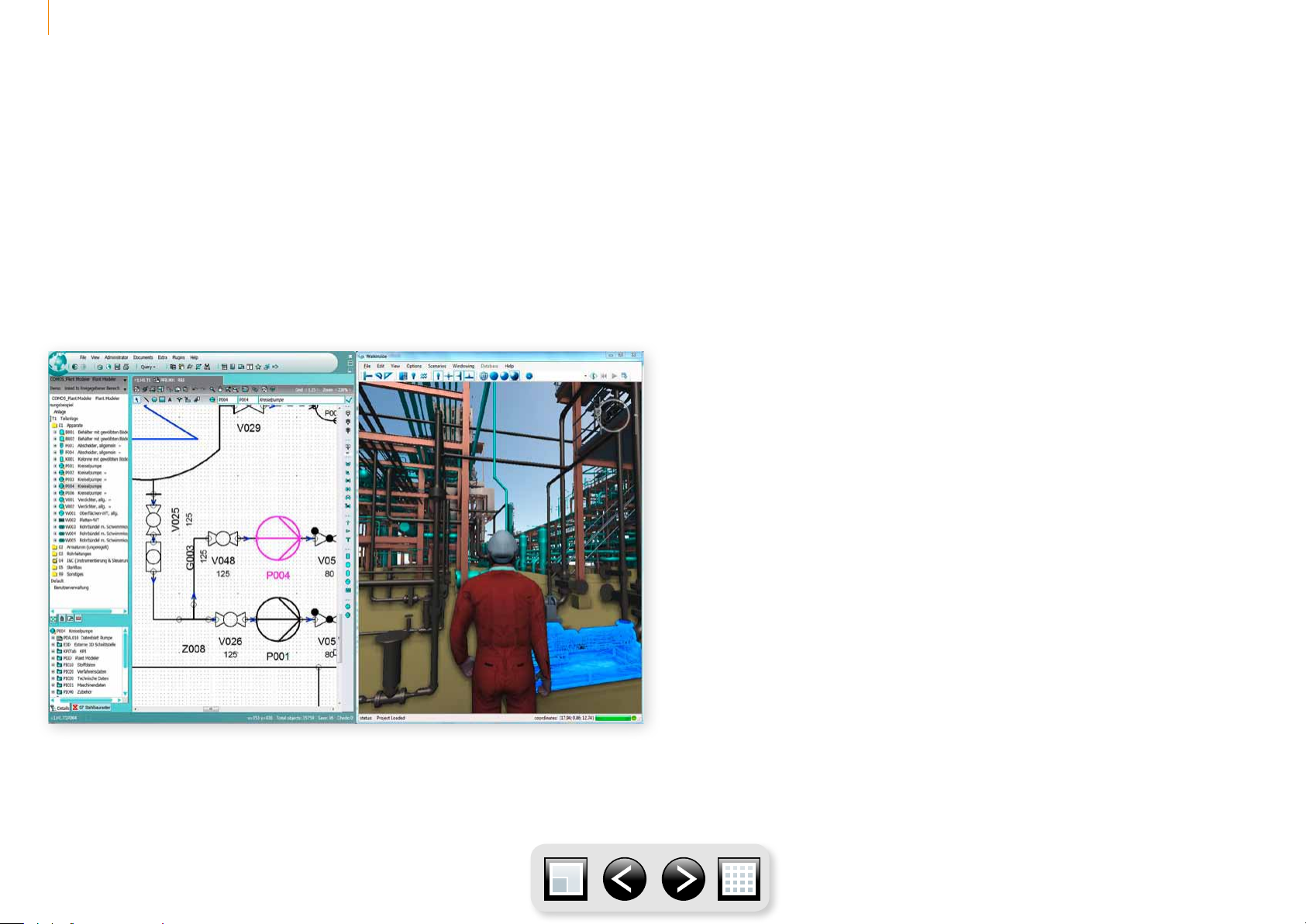

The engineers cannot make 3D drawings in

COMOS; they still work in the two-dimensional world. However, it is possible to synchronize the 2D diagrams with the 3D model, and

the system also enables direct linking to the

system in the procurement department and

to the different user manuals for the components. Previously, the 3D designer first had to

search for a data sheet for the component,

and when he eventually found it, he had to

sit and model everything manually. Now we

make sure in advance that we have matched

the catalogs for the 2D and 3D worlds so that

the objects we use in the 3D world contain

the same data and characteristics as in the 2D

world,” Claus Albrechtsen explains.

The systems had to be adapted

The above may sound as if the transition to

COMOS was painless; as if the implementation was planned to the last detail and everything fell into place so that the engineers

could go home somewhat happier at the end

of the first working week. The last statement

may be true, but Claus Albrechtsen freely acknowledges that the project – like many other change processes in a company – involved

a certain amount of daring and anarchy when

BWSC’s engineers had to learn to use COMOS.

“To be honest, you just dive in. And you make

sure all the practical details are in order. I’d

like to be able to say that all our work processes were in place, but that wasn’t the

case. The process was the same for us as for

everyone else: you discover that you have to

adjust your systems to the program, and we

spent the first many years doing that,” Claus

Albrechtsen rationalizes and adds: “The man-

agement doesn’t simply lean back and say:

“Now we’ve figured it all out.” Everyone has

to provide input, and then you gradually develop some procedures that work. We’re

working on that all the time. We’re far from

having finished exploiting the possibilities a

system like COMOS offers.”

Completely valid data

One of the challenges in day-to-day working

life is the necessity to work with completely

valid data. It is a clever system, of course,

that enables the electrical engineer to immediately start designing the supply for the

pump, which the mechanical engineer has

entered into the system, but what if the mechanical engineer merely entered his first

wild guesses? And what if the mechanical engineer changes his choice of pump because

he has made a mistake or changes his mind?

Process engineers and electrical engineers of BWSC are working with the object-oriented software COMOS incl.

a single database. The electric motor marked in the tree structure on the left of the picture is the same motor in the

process flow diagram and the electrical diagram.

In this case you risk duplicating your work because the electrical engineer then has to start

again from scratch.

BWSC has therefore incorporated status fields

in the system, for example for signals, piping,

and other equipment. The status field indicates to the other engineers how far the design has progressed. In that way, the data is

validated, and it becomes easier for the users

to grasp the many components, which easily

add up to 4,000-6,000 signals for a power

plant project, according to Mads Broge

Richelsen.

11 COMOS Plant Manager | 3/2012

Page 12

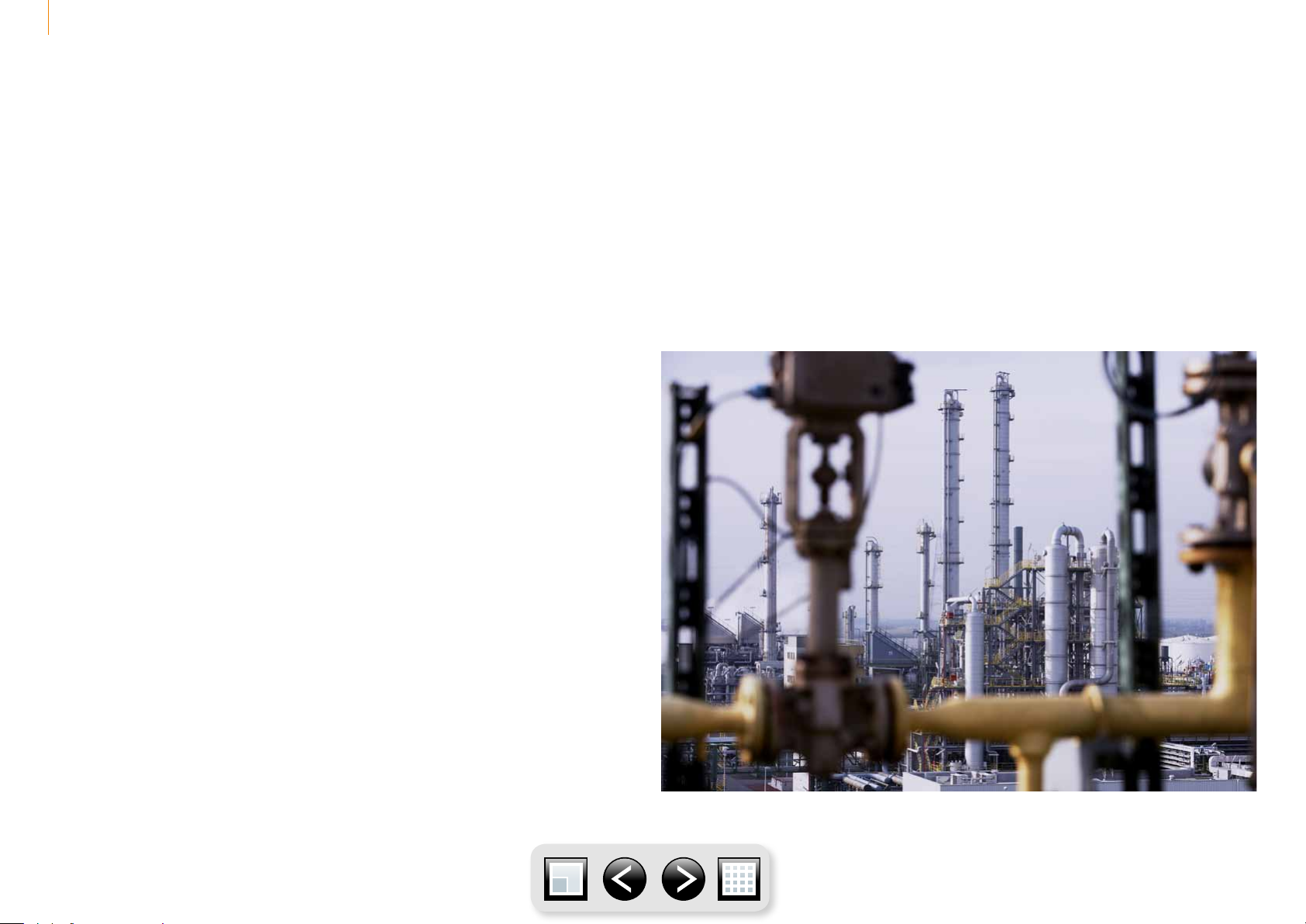

Interview with Dirk Wegg about trends in the oil & gas industry

Interview with Dirk Wegg about

trends in the oil & gas industry

The oil & gas industry represents dynamic development and innovation. COMOS Plant Manager

spoke to Dirk Wegg, General Manager of the Blue

Chip Energy Program at Siemens Industry Software, about trends, challenges, and solutions in

this marketplace.

COMOS Plant Manager: Hello Mr. Wegg, can

you tell us about the developments you are currently witnessing in the oil and gas industry?

Dirk Wegg: The demand for energy in industrialized and newly industrializing countries is

steadily increasing. However, over the coming

years, the global community will not yet be

able to meet this demand with renewable or

alternative energy sources. In fact, over the

next 20 to 30 years, raw materials such as oil

and gas will play an increasingly important

role in terms of energy supply. Having said

this, deposits which are easily exploited have

been virtually exhausted. To this end, ever

greater risks have to be taken in order to extract oil and gas from remote areas. As such,

deep sea drilling activities are commonplace

these days and initial projects exploring ex-

traction in areas with extreme climatic conditions, such as in the Barents Sea north of Norway and Russia, are currently underway.

Extracting the raw materials, and the plant

equipment needed for this, is correspondingly

more costly and complex. At the same time,

the economical and political pressure under

which the plant operators are placed continues to increase. Indeed, the issue of personal

and environmental safety remains a key focus.

There will be ever more official rules and regulations to comply with. Furthermore, additional time pressures are placed on companies

these days. In the past, a whole decade could

pass between the discovery of raw material

resources and their extraction - however, the

process must now take place in a significantly

shorter time period.

»

12 COMOS Plant Manager | 3/2012

Page 13

Interview with Dirk Wegg about trends in the oil & gas industry

COMOS Plant Manager: What requirements

arise from this for plant management?

Dirk Wegg: Basically, fewer employees must

be able to manage increased plant complexity

easily and quickly. Due to the huge quantity of

data gathered and the corresponding need to

prepare this data, which serves as a basis for

economical and technical decisions, implementing optimum plant management is essential. However, this requires high-performance

engineering tools throughout all phases of the

plant lifecycle – ranging from engineering to

handover and plant operation.

COMOS Plant Manager: What are the consequences for plant engineering?

Dirk Wegg: EPC (Engineering Procurement &

Construction) companies are now placed under significant pressure in terms of quality

and time. They must design highly-specialized technical plants to meet individual requirements faster than ever before. Today, a

great deal of time can only be saved by implementing parallel operational processes in

plant engineering. In order to benefit from

“Only when the right data is available at the

right time and place that risk can be further

controlled and costs thereby minimized.”

such savings, collaboration spanning trades

and companies is essential. This calls for corresponding tools, such as the object-oriented

COMOS software, which offers just such a

software solution, thanks to its uniform data

platform. The software enables interoperabil-

ity using the open system architecture and as

a uniform software solution, now ensures

optimum bidirectional data exchange between different applications and disciplines.

In terms of the future, the software will continue to be improved, developing in line with

ISO 15926 and utilizing the latest interface

technologies. Especially in terms of the

handover from plant engineer to owner operator, there is still large scope for improvement.

COMOS Plant Manager: What challenges do

owner operators face, both now and in the

future?

Dirk Wegg: Financial pressures on operators

will continue to rise. In order to make savings, the widest range of measures for optimization will be adopted. Such measures

range from having fewer staff on the extraction site and extend to putting risk-based

maintenance strategies in place as part of the

maintenance operations. At the same time,

operators must continuously adapt and improve their plant documentation in line with

new regulations and provisions. Efficient data

management is absolutely essential for all

these measures and requirements, for it is

only when the right data is available at the

right time and place that risk can be further

controlled and costs thereby minimized.

»

13 COMOS Plant Manager | 3/2012

Page 14

Interview with Dirk Wegg about trends in the oil & gas industry

3D visualization with the software

solution COMOS Walkinisde

COMOS Plant Manager: So what does an efficient data management system involve?

Dirk Wegg: Successful plant management of

the future is based on a data-centric approach, which makes traditional documentbased working methods a thing of the past.

The more complex plants become, the more

effort it takes and the more difficult it is to

manage plant documentation in the traditional sense and keep it up-to-date. The solution definitely lies in managing engineering

data in a uniform system. Updates are automatically included and replicated within all

relevant processes. This ensures the as-built

condition of the plant is always available in

digital format. The COMOS software solution

offers precisely such an efficient data management system and indeed, is already being

used successfully in a number of applications

across the oil and gas industry.

COMOS Plant Manager: Occasionally,

COMOS has been criticized for not offering

sufficient 3D visualization options.

Dirk Wegg: Firstly, COMOS provides standard

interfaces for 3D CAE systems which can

identify and solve inconsistencies between

2D and 3D visualizations. These systems are

being continually further developed and enhanced. Secondly, the topic of 3D visualization is being addressed in COMOS, in particular with the acquisition of VRcontext.

Furthermore, fully integrating Walkinside

software into the range has added further

depth to this focus. Over the last few years,

the 3D visualization software Walkinside,

with its intuitive user interface, has made a

name for itself in the oil and gas industry and

is relied upon by large, globally leading companies. Combined with COMOS as a global

data center, this enables easy, menu-assisted

access for users to all relevant information

which has already been generated in the Ba-

sic and Detail Engineering phases. This enables the operator to be guided through

efficient preparation and planning of maintenance and servicing tasks, for example. As

such, owner operators can use the software

as an ideal way of training staff, in preparation for their deployment on a drilling platform. This results in significantly increased

plant availability, combined with maximum

safety levels during operation.

COMOS Plant Manager: Mr. Wegg,

thank you for the interview.

14 COMOS Plant Manager | 3/2012

Page 15

NEWS

NEWS

Mobile plant management with

COMOS Mobile Document Review

An ever increasing number of users are enjoying the benefits of engineering software

for mobile plant management. Modern web

and sharepoint technologies offer users

increasing flexibility in terms of global collaboration, help to improve the quality of

information, enhance efficiency, and save

time.

Siemens has now extended its plant management software COMOS by the inclusion of a

solution for mobile data and document utilization in the form of an iPad app entitled

COMOS Mobile Document Review. Users can

now edit, review, and release plant documentation, and manage revision status anywhere,

anytime with the aid of editing and redlining

features – whether on business trips, in meetings or during tours of inspection. Documents from the COMOS database are transmitted via a web server in pdf format to the

COMOS user’s iPad where they are edited of-

fline. Available redlining functions include

freehand drawing, insertion of comments

and integration of photos taken on site. Once

redlining has been completed, a pdf is created and the file returned to the COMOS database for further processing.

The COMOS App is intuitive to use and can

be operated without any prior knowledge

of COMOS engineering software. All newly

loaded documents are immediately visible

and their management is simplified by the

use of favorites functions. The App is available in Chinese, German, English and French,

and can be downloaded free of charge from

the Apple App Store. It works best on the

2nd or 3rd generation iPad.

Information video

(1:18 minutes)

15 COMOS Plant Manager | 3/2012

Page 16

NEWS

Service and Support newsletter for

fast and personalized information

The Siemens IA&DT Service and Support online portal has been expanded with new and very useful features

for COMOS customers. Apart from being able to create an individual newsletter, users also have access to a

download area, FAQ documents, and manuals.

COMOS customers now have the opportunity

of putting together their own individual Service and Support newsletter. This newsletter is

sent by e-mail and provides them with fast and

up-to-date information on the previously selected topics, for example, updates and service

packs. To be able to put together an individual

Service and Support newsletter, the user must

already be registered in the online portal or

must register there. Users can then select the

product they would like to be informed about

and the type of document. For the “Plant Engineering Software COMOS” users can select

from the document types “Downloads”, “FAQs”,

“Manuals” and “Current product information”.

As soon as new information relating to the selected topics is published in the online portal,

users will be sent an e-mail keeping them up to

date with all innovations.

In the Service and Support online portal the

COMOS customer now has new helpful functions available. Among other things, the download area provides the user with a list of the

most important technical information on

COMOS. The list is updated monthly. The FAQ

area gives the user access to informative documents on a variety of topics, for example “Data

exchange between SIMATIC PCS 7 and COMOS”.

All manuals from COMOS version 9.2 onwards

are available for download.

Service and Support

Online Portal

Presentation: Create an individual newsletter

16 COMOS Plant Manager | 3/2012

Page 17

NEWS

COMOS sales and service

partners for Romania

Since 2005, the FIWA group has been

working worldwide as a certified Siemens

partner for SIMATIC PCS 7 and the chemicals industry. The Romanian branch of the

engineering company (SC FIWA RO SRL)

has also been operating since August 2012

as a sales and service partner for the

COMOS software solution.

Focusing on the oil and gas, pharmaceuticals,

environmental technology, foodstuff, steel,

chemicals and petrochemicals industries, SC

FIWA RO SRL offers a wide range of engineering services in Romania. These include plant

engineering design and implementation in the

sectors of process automation, process control,

MSR technology, weighing technology, electrical engineering, building technology, communications and security technology, software development, and data processing technology.

The company has made a name for itself in recent years through successful projects with

companies such as Siemens IMOL, SC OMV

PETROM SA, and SC CONTINENTAL SRL. Due to

the extremely good customer relationship with

SC OMV PETROM SA and their many years of

ex perience in the oil and gas industry as well

as their partnership with Siemens, they

seemed the obvious partner for COMOS in Romania. ”With SC FIWA RO SRL, we have gained

an expert partner in Romania, who is familiar

with local conditions and develops and implements excellent engineering solutions,” says

Steffen Rosa, Global Partner Manager COMOS

at Siemens Industry Software.

Best IT company

in Denmark

The IT magazine ComputerWorld

names Siemens Industry Software A/S

as the best IT company in Denmark.

On September 20, 2012, the company

received the award from the magazine. In addition to being named the

best IT company in Denmark, the company also won the awards for the best

basis software, software, and growth

comet.

Event Calendar

2012:

Discover the COMOS software solutions

in 2012 at following events. We will inform you at these events about the latest

news about COMOS. We appreciate your

visit. more ... »

17 COMOS Plant Manager | 3/2012

Page 18

NEWS

COMOS training

program expanded

Training courses have been complemented

by six further courses

The range of COMOS training courses has

been complemented by six further courses.

We would like to introduce three of these

courses in a little more detail below. In the

Basic, Cabinet Layout, and MRO (Maintenance

Repair Overhaul) courses, up to six participants per course will be introduced to specific course content in a very practice-oriented

way. The COMOS Basic Training contains the

fundamentals of working with the COMOS

software, while the Cabinet Layout Training is

aimed at experienced COMOS users from the

area of electrical engineering. The new MRO

training course is aimed at maintenance engineers, and it presents options for optimizing

maintenance tasks. To achieve maximum

learning success, the experienced COMOS instructors give special attention during the

courses to participants‘ needs. You can find

out more about the content of the courses by

clicking on the relevant course.

All COMOS training courses can also be

booked locally for specific customers around

the world. You can request information on

other training courses via the e-mail address

training. COMOS @siemens.com Information

on COMOS training courses is also available

on the Internet.

Training course descriptions

1. COMOS Basic Training

COMOS Basic Training is aimed at planning

engineers, drafters, or trainee COMOS administrators. It covers the philosophy of COMOS,

the handling of technical documentation,

and specific objects for electrotechnical planning.

more ... »

2. COMOS Cabinet Layout Training

This is intended as advanced training for experienced users with knowledge gained from

COMOS Electrical Engineering Training. This

course introduces methods and tools for

planning control cabinets. The focus is on

creating views, synchronizing these views,

and working with the COMOS rail editor.

more ... »

3. COMOS MRO Training

(Maintenance Repair Overhaul)

The COMOS MRO (Maintenance Repair Overhaul) Training is aimed at users and trainee

COMOS administrators. Participants learn

about the basic functionalities of COMOS for

working with the interface. Different maintenance methods and documents are then introduced and created.

more ... »

18 COMOS Plant Manager | 3/2012

Page 19

NEWS

Tips and Tricks – ask Doc COMOS

Sometimes a little information has a big

effect. In this rubric of the COMOS Plant

Manager, Doc COMOS answers your questions and gives you tips on how to work

with the COMOS software solution even

more efficiently. Today Doc COMOS answers the following question:

“How could I realize a query

even faster?”

Doc COMOS will introduce in two videos

the search method “database query”, which

helps save time.

The first video shows the two different

methods to do a query. In both methods,

the amount of data is equal. With the method of the “classic query” (video sequence of

the first 45 seconds) it takes around 10 seconds to request, interprete, and display the

information. Much more faster you could

receive the information by the search method “database query” (video sequence from

second 45). Even with the same amount of

information, this type of query needs only

approx. one second compared to the “classic

query” to request, interprete, and display the

information.

Video 1

(1:21 Minuten)

The second video is presenting how to create a “database query”. The video shows

the different working steps:

1. Open an empty “Query”

2. Select “Database search”

3. The configuration field of the “database

query“ will be opened

4. Define the “start object” by drag & drop

5. Define the searched settings (e.g.

Property, Attribute or FreeProperty)

6. Specify the settings by further definition

(e. g. Name, Lable, or Description)

7. Define the searched value

(in our sample it is G125)

8. Link to “AND operation”. In the configuration field the fixed settings are linked to

“AND operations”

9. Again, define the searched settings

(e.g. Property, Attribute, or FreeProperty)

10. Specify the settings by further definition

of the “Attribute name” (in the sample we

enter “PIA055”)

11. Define the searched value

(in our sample it is “7”)

12. Link to “OR operation”. The different

configuration fields are linked to

“OR operations”

13. A new configuration field will

be opened. Enter the requested

information in the fields (in our

sample it is “Property, Name, =

und G55”).

14. To start the query, click the

“Search” button

15. The requested information will

be shown

16. Only the defined data sets will be

taken from the database. In our

sample we have a “Query: 16/16”.

Video 2 (1:43 Minuten)

19 COMOS Plant Manager | 3/2012

Page 20

sendsend

Feedback

Your opinion is important to us!

My contact details:

We would like to continuously improve the quality of the COMOS Plant Manager.

Therefore the feedback of the readers is very important to us.

Which article suits you well and which article did not fit your expectations? Do you have

special contents we should report about? Please send us your feedback. Either you tick one

of the faces

my expectations, or you write us your comments in the specified field. Afterwards click

the send button and your feedback is on the way to us. Thank you for your cooperation.

Do you want to receive more content details about an article? Just click the

listed article and fill in the contact details. Click the send button and we will immediately

contact you to answer your questions.

= very good article, = article was interesting, = article did not fit

behind the

3D visualization and training software

Chemical Industry: Reference Evonik

Power Plant Industry: Reference BWSC

Interview with Dirk Wegg

COMOS Mobile Document Review

Service and Support newsletter

COMOS sales and service partner in Romania

Best IT company in Denmark

Event Calendar 2012

Training program expanded

Tips & tricks

Company ________________________________________________________

Street/no. ________________________________________________________

Postal code/city ________________________________________________________

Salutation Mrs. Mr.

Title ________________________________________________________

First name ________________________________________________________

Family name ________________________________________________________

Telephone ________________________________________________________

E-mail ________________________________________________________

I received the COMOS Plant Manager from third party. Please include me in

the COMOS Plant Manager distribution list:

E-mail* ________________________________________________________

My e-mail address changed.

Please send me the COMOS Plant Manager in the future to following address:

E-mail* ________________________________________________________

Please delete my e-mail address from the COMOS Plant Manager distribution list

Comment field:

I hereby agree that my personal data will be used by Siemens and/or

Siemens subcontractors exclusively in connection with the requested

services. I herewith consent to any further disclosure of my personal

data by Siemens Industry if such disclosure is mandatory by law or a court

judgement.*

*Required field

20 COMOS Plant Manager | 3/2012

Page 21

Impress

COMOS Plant Manager

3/2012

COMOS Plant Manager

From Integrated Engineering to Integrated Operations

Issue 3/2012

3D visualization

Acquisition of VRcontext

strengthened COMOS

portfolio

Chemical

Industry

Reference Evonik

Power Plant

Industry

Reference BWSC

Interview

with Dirk Wegg about Trends

in the Oil & Gas Industry

Publisher

Siemens AG

Industry Sector

Industry Automation Division

Industrial Automation Systems

I IA AS PA CIS MK

Karl-Legien-Str. 190

D-53117 Bonn, Germany

www.siemens.com/ COMOS

COMOS Industry Solutions

VP Andreas Geiss

Editor

Ingo Kaiser, Siemens AG, I IA AS PA CIS MK

Karl-Legien-Str. 190

D-53117 Bonn, Germany

Phone: +49 (0) 228 64805-210

Fax: +49 (0) 228 64805-125

ingo.kaiser@siemens.com

Editorial Committee

Mareike Blettner, Ingo Kaiser

COMOS Plant Manager is published quarterly.

© 2012 by Siemens Aktiengesellschaft

Munich and Berlin

All rights reserved by the publisher.

The following products are registered

trademarks of Siemens AG:

COMOS, SIMATIC, SIMATIC Automation Designer,

SIMATIC IT, SIMATIC PCS 7, TIA

The marks mentioned are registered trademarks of

the respective owner. If trademarks, trade names,

technical solutions, or similar are not listed above,

this does not imply that they are not registered.

The information provided in this magazine contains

merely general descriptions or characteristics of

performance, which in the case of actual use do not

always apply as described or which may change as

a result of further development of the products. An

obligation to provide the respective characteristics

shall exist only if expressly agreed in the terms of

contract.

Picture credits:

Digitalstock · BWSC · Fotolia · Evonik Systems · Siemens

www.siemens.com/ COMOS

Loading...

Loading...