Page 1

Industry Sector, IA&DT

SCE Training Curriculum for

for Integrated Automation Solutions

Totally Integrated Automation (TIA)

Siemens Automation Cooperates with Education

TIA Portal Module 090-010

WinCC Advanced with Runtime and TP700 Comfort Panel

SCE Training Curriculum Page 1 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 2

Industry Sector, IA&DT

Suitable SCE Trainer Packages for these training curriculums

SIMATIC controllers

SIMATIC S7-300 with CPU 314C-2PN/DP

Order no.: 6ES7314-6EH04-4AB3

SIMATIC S7-300 with CPU 314C-2PN/DP (upgrade)

Order no.: 6ES7314-6EH04-4AB4

SIMATIC S7-300 with CPU 315F-2PN/DP

Order no.: ES7315-2FH14-4AB1

SIMATIC ET 200S with CPU IM151-8 F PN/DP

Order no.: 6ES7151-8FB00-4AB1

SIMATIC HMI

SIMATIC TP700 Comfort Panel - Color

Order no.: 6AV2133-4AF00-0AA0

SIMATIC STEP 7 Software for Training

SIMATIC STEP 7 Professional V11 - Single license

Order no.: 6ES7822-1CC01-4YA5

SIMATIC STEP 7 Professional V11 - Classroom license (up to 12 users)

Order no.: 6ES7822-1AA01-4YA5

SIMATIC STEP 7 Professional V11 - Upgrade license (up to 12 users)

Order no.: 6ES7822-1AA01-4YE5

SIMATIC STEP 7 Professional V11 - Student license (up to 20 users)

Order no.: 6ES7822-1AC01-4YA5

Please note that these training packages are replaced with successor packages when necessary.

An overview of the currently available SCE packages is provided under: HUsiemens.com/sce/tpUH

Advanced Training

For regional Siemens SCE advanced training courses, please get in touch with your regional SCE contact

person siemens.com/sce/contact

Additional information regarding SCE

siemens.com/sce

Information regarding usage

This SCE training curriculum for the end-to-end automation solution Totally Integrated Automation (TIA) was

prepared for the program "Siemens Automation Cooperates with Education (SCE)" specifically for training

purposes for public educational facilities and R&D facilities. Siemens AG does not guarantee the contents.

This document curriculum is to be used only for initial training on Siemens products/systems; i.e., it can be

copied entirely or partially and given to those being trained for usage within the scope of their training.

Distributing or copying this training curriculum and sharing its contents is permitted within public training and

advanced training facilities for training purposes.

Exceptions require written permission from the Siemens AG contact person: Roland Scheuerer

roland.scheuerer@siemens.com.

Offenders will be held liable. All rights including translation are reserved, particularly if a patent is granted or a

utility model or design is registered. Usage for industrial customer courses is expressly prohibited. We do not

consent to the training curriculums being used commercially.

We wish to thank the Michael Dziallas Engineering Corporation and all other involved persons for their support

during the preparation of this document.

SCE Training Curriculum Page 2 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 3

Industry Sector, IA&DT

SEITE:

1. Preface.......................................................................................................................................................... 5

2. Notes on programming for SIMATIC S7-300 ................................................................................................ 7

2.1 SIMATIC S7-300 automation system ......................................................................................................... 7

2.2 STEP 7 Professional V11 (TIA Portal V11) programming software ........................................................... 7

2.3 Operator control and monitoring with WinCC ............................................................................................. 8

3.0 Project description ........................................................................................................................................ 9

3.1 Hardware configuration ............................................................................................................................... 9

3.2 Plant description ....................................................................................................................................... 10

3.3 Task .......................................................................................................................................................... 11

3.4 Configuration ............................................................................................................................................ 11

4. Inserting a TP700 Comfort Panel into the color mixing station project ....................................................... 12

4.1 Loading and re-saving a project template ................................................................................................ 13

5. WinCC user interface ................................................................................................................................. 25

5.1 Project tree ............................................................................................................................................... 26

5.2 Menu bar and buttons ............................................................................................................................... 26

5.3 Working area ............................................................................................................................................ 27

5.4 Tools ......................................................................................................................................................... 27

5.5 Properties window .................................................................................................................................... 28

5.6 Details view ............................................................................................................................................... 28

5.7 Layout ....................................................................................................................................................... 29

6. Device configuration of the TP700 Comfort Panel...................................................................................... 30

6.1 Setting the IP address .............................................................................................................................. 31

6.2 Setting the panel as PROFINET IO device............................................................................................... 32

7. Configuring screens .................................................................................................................................... 33

7.1 Root screen .............................................................................................................................................. 34

7.2 Tank 1 screen ........................................................................................................................................... 44

7.3 Tank 2 screen ........................................................................................................................................... 47

7.4 Tank 3 screen ........................................................................................................................................... 47

7.5 Testing configuration in Runtime .............................................................................................................. 48

8. Settings on the TP700 Comfort Touch Panel ............................................................................................. 50

8.1 Setting the date and time .......................................................................................................................... 51

8.2 Setting transfer properties ........................................................................................................................ 52

8.3 Assigning PROFINET device names ........................................................................................................ 53

8.4 Reboot ...................................................................................................................................................... 53

8.5 Transfer mode .......................................................................................................................................... 54

8.6 Configuring a connection .......................................................................................................................... 55

9. Display and operating objects ..................................................................................................................... 56

9.1 Layers ....................................................................................................................................................... 56

9.2 Basic objects............................................................................................................................................. 57

9.3 Enhanced objects ..................................................................................................................................... 59

10. Display and operating objects in the "Color mixing station" project ............................................................ 60

10.1. Configuring display and operating objects in the “Tank 1” screen ............................................................ 60

SCE Training Curriculum Page 3 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 4

Industry Sector, IA&DT

10.2 Configuring display and operating objects in the “Tank 2” and “Tank 3” screens .................................... 76

10.3 Objects in the root screen ......................................................................................................................... 78

10.4 Configuring objects in the permanent window .......................................................................................... 97

11. Configuring alarms .................................................................................................................................... 101

11.1 Analog alarms ......................................................................................................................................... 101

11.2 Alarm window ......................................................................................................................................... 103

11.3 Testing alarm configuration in Runtime .................................................................................................. 104

12. Configuring recipes ................................................................................................................................... 105

12.1 Adding recipes ........................................................................................................................................ 105

12.2 Specifying data records .......................................................................................................................... 106

12.3 Creating "Recipe input" and "Select recipe" screens .............................................................................. 106

12.4 Selecting a recipe in Runtime ................................................................................................................. 111

12.5 Entering new recipes in Runtime ............................................................................................................ 112

13. Configuring user administration ................................................................................................................ 113

13.1 Setting up user groups ............................................................................................................................ 113

13.2 Creating users ........................................................................................................................................ 114

13.3 Assigning authorizations ......................................................................................................................... 115

13.4 Testing user administration in Runtime .................................................................................................. 118

SCE Training Curriculum Page 4 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 5

Industry Sector, IA&DT

Additional Functions for

PLC Programming

Module 30

Basics of PLC

Programming

Module 10, Module 20

PROFIBUS PROFINET

Module 60 Module 70

AS-Interface

Module 50

Safety/Security

Systems

Module 80

Drives

Module 100

Process Visualization

(HMI) Module 90

Sensor Technology

Module 110

Simulation SIMIT

Module 150

More Programming

Languages

Module 40

1. Preface

Regarding its content, module 010-090 is part of the training unit 'Process visualization' and

demonstrates how to configure WinCC visualization between the TP700 panel and the SIMATIC S7-300

controller.

Training objective:

This module describes the most important functions of the WinCC Advanced V11 software.

Typical tasks are performed in a sample plant.

"Open" and "Save as" of a STEP 7 project

SCE Training Curriculum Page 5 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Inserting an HMI station

WinCC Advanced V11 interface

Configuring display and operating objects

Configuring alarms

Creating recipe management

Setting up user administration

Requirements:

To successfully work through this module, the following knowledge is assumed:

Proficiency in working with Windows

Basics of PLC programming with the TIA Portal

(e.g. module 020-010 - ‘Startup’ Programming of SIMATIC S7-300 with TIA Portal V11)

Blocks for SIMATIC S7-300

(e.g. module 030-010 – Block Types for SIMATIC S7-300 )

Timer and counter blocks for SIMATIC S7-300

(e.g. module 030-020 – IEC Timers and IEC Counters for SIMATIC S7-300 )

Page 6

Industry Sector, IA&DT

1 PC

2 STEP 7 Professional

and WinCC Advanced

(TIA Portal V11 SP2)

3 Ethernet connection

5 SIMATIC HMI

TP700 Comfort Panel

4 S7-300 with

CPU 315F-2 PN/DP

Hardware and software needed

1 PC Pentium 4, 1.7 GHz 1 (XP) – 2 (Vista) GB RAM, free disk storage approx. 2 GB

Operating system Windows XP Professional SP3/Windows 7 Professional/Windows 7

Enterprise/Windows 7 Ultimate/Windows 2003 Server R2/Windows Server 2008 Premium SP1,

Business SP1, Ultimate SP1

2 Software STEP 7 Professional V11 SP2 (Totally Integrated Automation (TIA) Portal V11) and

WinCC Advanced V11 SP2

3 Ethernet connection between PC and CPU 315F-2 PN/DP

4 SIMATIC S7-300 PLC, e.g. CPU 315F-2PN/DP with 16DI/16DO signal module.

The inputs have to be brought out to a panel.

5 SIMATIC HMI TP700 Comfort Panel

SCE Training Curriculum Page 6 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 7

Industry Sector, IA&DT

2. Notes on programming for SIMATIC S7-300

2.1 SIMATIC S7-300 automation system

The SIMATIC S7-300 automation system is a modular microcontroller system for the low and medium

performance range.

A comprehensive range of modules is available to optimally adapt the system to the automation task.

The S7 controller consists of a power supply, a CPU, and input and output modules for digital and

analog signals.

If necessary, communication processors and function modules are also used for special tasks such as

stepper motor control.

The programmable logic controller (PLC) uses the S7 program to monitor and control a machine or a

process. The I/O modules are queried via the input addresses (%I) and addressed via the output

addresses (%Q) in the S7 program.

The system is programmed with the STEP 7 software.

2.2 STEP 7 Professional V11 (TIA Portal V11) programming software

STEP 7 Professional V11 (TIA Portal V11) software is the programming tool for the following automation

systems

- SIMATIC S7-1200

- SIMATIC S7-300

- SIMATIC S7-400

- SIMATIC WinAC

STEP 7 Professional V11 provides the following functions for plant automation:

- Configuration and parameter assignment of the hardware

- Specification of the communication

- Programming

- Testing, commissioning, and servicing with operational/diagnostic functions

- Documentation

- Creation of visualizations for SIMATIC Basic Panels using the integrated WinCC Basic software.

- Visualization solutions for PCs and other panels can also be created with other WinCC software

packages

Support is provided for all functions in a comprehensive online help system.

SCE Training Curriculum Page 7 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 8

Industry Sector, IA&DT

2.3 Operator control and monitoring with WinCC

System description

Since processes are becoming more and more multi-layered and the demands regarding the

functionality of machines and plants are rising, the operator needs a powerful tool to control and monitor

production systems. An HMI (Human Machine Interface) system represents the interface between the

human being (operator) and the process (machine/system). The controller has the actual control over

the process. There is an interface between the operator and WinCC (at the HMI panel) and an interface

between WinCC and the controller.

WinCC is the software that you use to handle all necessary configuration tasks. WinCC Advanced V11 is

the software for process visualization.

WinCC handles the following tasks:

• Representing the process

The process is represented on the HMI device. If, for example, a state changes in the process, the

display is updated on the HMI device.

• Operating the process

The operator can operate the process via the graphical user interface. The operator can, for example,

enter a setpoint for the controller or start a motor.

• Generating alarms

If critical process states occur in the process, an alarm is triggered automatically; for example, if a

specified limit is exceeded.

• Logging process values and alarms

The HMI system is able to log alarms and process values. Thus, the process can be documented and

you can still access older production data at a later time.

• Documenting process values and alarms

Alarms and process values can be read out by the HMI system as a log. For example, you can output

the production data at the end of a shift.

• Managing process parameters and machine parameters

The HMI system is able to store parameters for processes and machines in recipes. You can transfer

these parameters from the HMI panel to the controller, for example, in a single step in order to change

production to another product type.

SCE Training Curriculum Page 8 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 9

Industry Sector, IA&DT

3.0 Project description

3.1 Hardware configuration

In our sample program for a color mixing station, we use a programming device with WinCC Advanced

V11 and WinCC Advanced V11 simulation.

The color mixing station is controlled using a SIMATIC S7-300. The operator uses a Touch Panel

(TP700) to operate the process via the graphical user interface.

The operator can, for example, enter a setpoint for the controller or start a motor.

The programming device, the SIMATIC S7-300 controller and the TP700 operator panel are

interconnected via the Ethernet interface.

The color mixing station is connected to the controller via digital and analog inputs and outputs.

PC for configuration

TP700 as HMI device

Note

WinCC Advanced Runtime simulation can also be used to represent the TP700 Touch Panel on the

programming device.

SCE Training Curriculum Page 9 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 10

Industry Sector, IA&DT

Auto-Man START T1 supply T1 drain T2 supply T2 drain T3 supply T3 drain Reservoir Motor

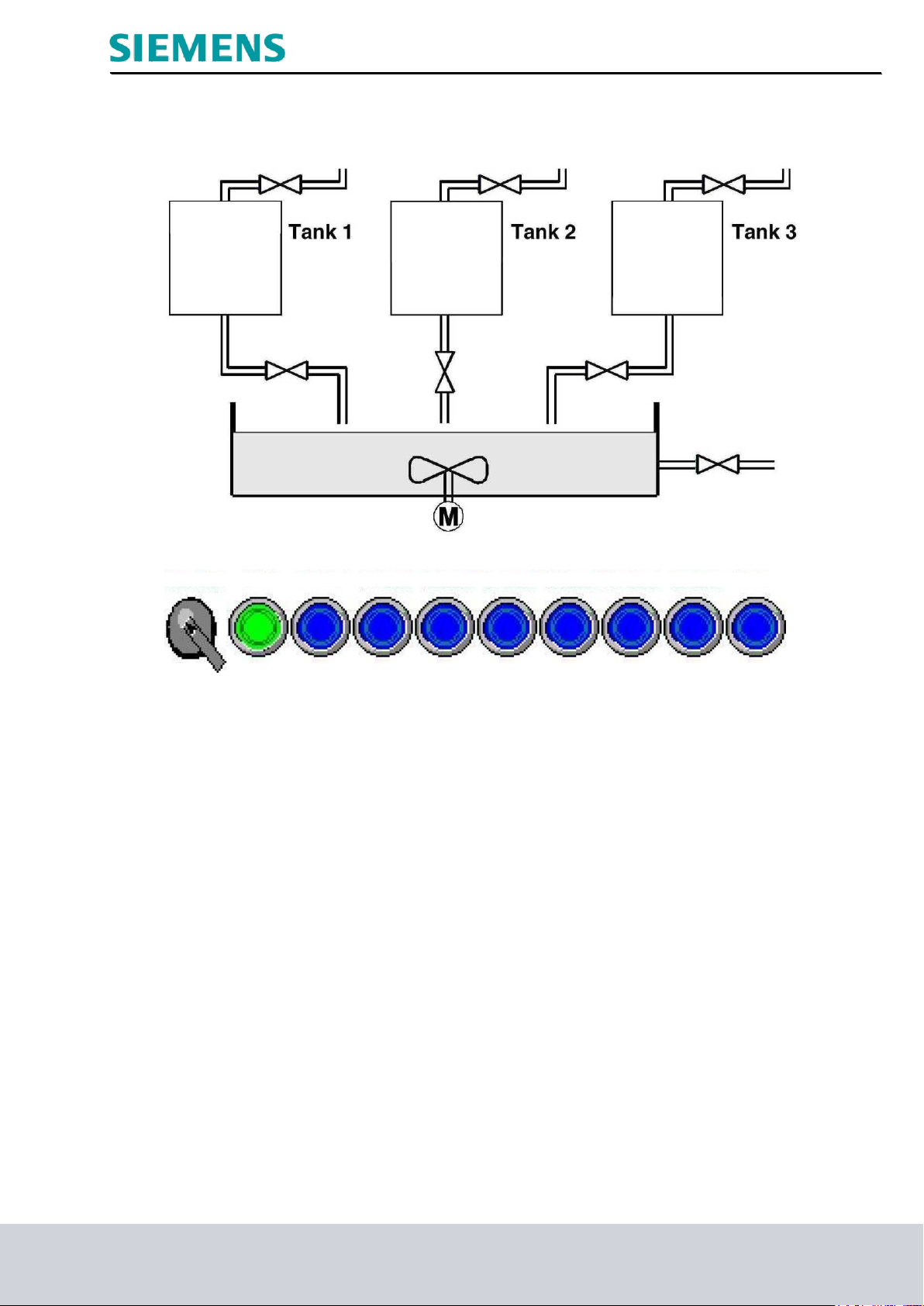

3.2 Plant description

A color mixing station is controlled using a SIMATIC S7-300 in automatic or in manual mode. In

"Automatic" mode, the three tanks are filled using a two-point control mechanism.

At minimum fill level, the supply valve of the corresponding tank is opened automatically and only closed

once the maximum fill level is reached.

The preset program is run when the Start button is pressed.

First, the drain valves are opened and the corresponding default quantities are filled into the reservoir

from the separate tanks.

After the drain valves are closed, the mixer motor is started.

At the end of the mixing process and after a short rest period, the drain valve of the reservoir opens and

the finished color mixture is discharged.

The start function is enabled as soon as the reservoir is empty.

The light in the start button is lit and a new color mixing process can be started.

In "Manual" mode, the automatic draining process is terminated; all valves and the mixer motor can then

be operated manually.

The lights in the buttons for manual operation are lit.

Note

The default quantities and time periods are determined by the program.

If another color mixing process is to be started, the default quantities and time periods must be changed

in the program or a new program must be loaded to the controller.

SCE Training Curriculum Page 10 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 11

Industry Sector, IA&DT

3.3 Task

In the case of the color mixing station, the program was modified using the programming device every

time the mixing ratio had to be changed. Since these modifications are not only time-consuming but also

risky if input is incorrect, the decision was made to add a TP700 Comfort Touch Panel to the color

mixing station.

Using the panel, the following requirements are to be met:

- It should now be possible to operate the color mixing station via the panel as well.

- The fill levels of the tanks and of the reservoir are to be indicated as bars and also as numerical

values.

- The movement of the mixer motor is to be represented graphically.

- The default quantities are to be entered using the panel.

- The minimum and maximum fill levels of the three tanks are to be displayed on separate tank

screens.

- Switching between the operating modes is also to be performed using the panel, and the respective

operating mode will be displayed on the panel.

- The finished mixtures are to be stored as recipes in the panel and need only be selected by the

operator.

- The fill levels are monitored and alarms are to be generated in the event of danger.

- A password must be entered in order to operate the color mixing station.

- Communication of the TP700 Comfort Panel with SIMATIC S7-300 controller is to take place via the

Ethernet interface.

3.4 Configuration

The STEP 7 Professional V11 configuration software and WinCC Advanced V11 are used to create a

process visualization for the color mixing station on the programming device. The process values are

represented with screens and screen objects. Default values can be transferred to the controller using

operator controls. Communication between the HMI panel and the machine or the process takes place

by means of tags via the controller. The value of a tag is written to a memory area (address) in the

controller, where it is read by the HMI panel.

The process visualization is saved and transferred from the programming device to the TP700

Comfort HMI panel after generation.

After the panel is powered up, the process can be monitored and the plant can be operated.

SCE Training Curriculum Page 11 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 12

Industry Sector, IA&DT

4. Inserting a TP700 Comfort Panel into the color mixing station project

The 'Totally Integrated Automation Portal V11' software is used for project management and

programming.

Components such as control, visualization, and networking of the automation solution are created,

assigned parameters, and programmed here using a standard interface.

Online tools are available for the error diagnostics.

In the following section, a project is to be opened for SIMATIC S7-300, the project is to be stored under

a different name and adapted to the new requirements:

The central tool is the ‘TIA Portal V11’, which is opened with a double-click.

SCE Training Curriculum Page 12 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 13

Industry Sector, IA&DT

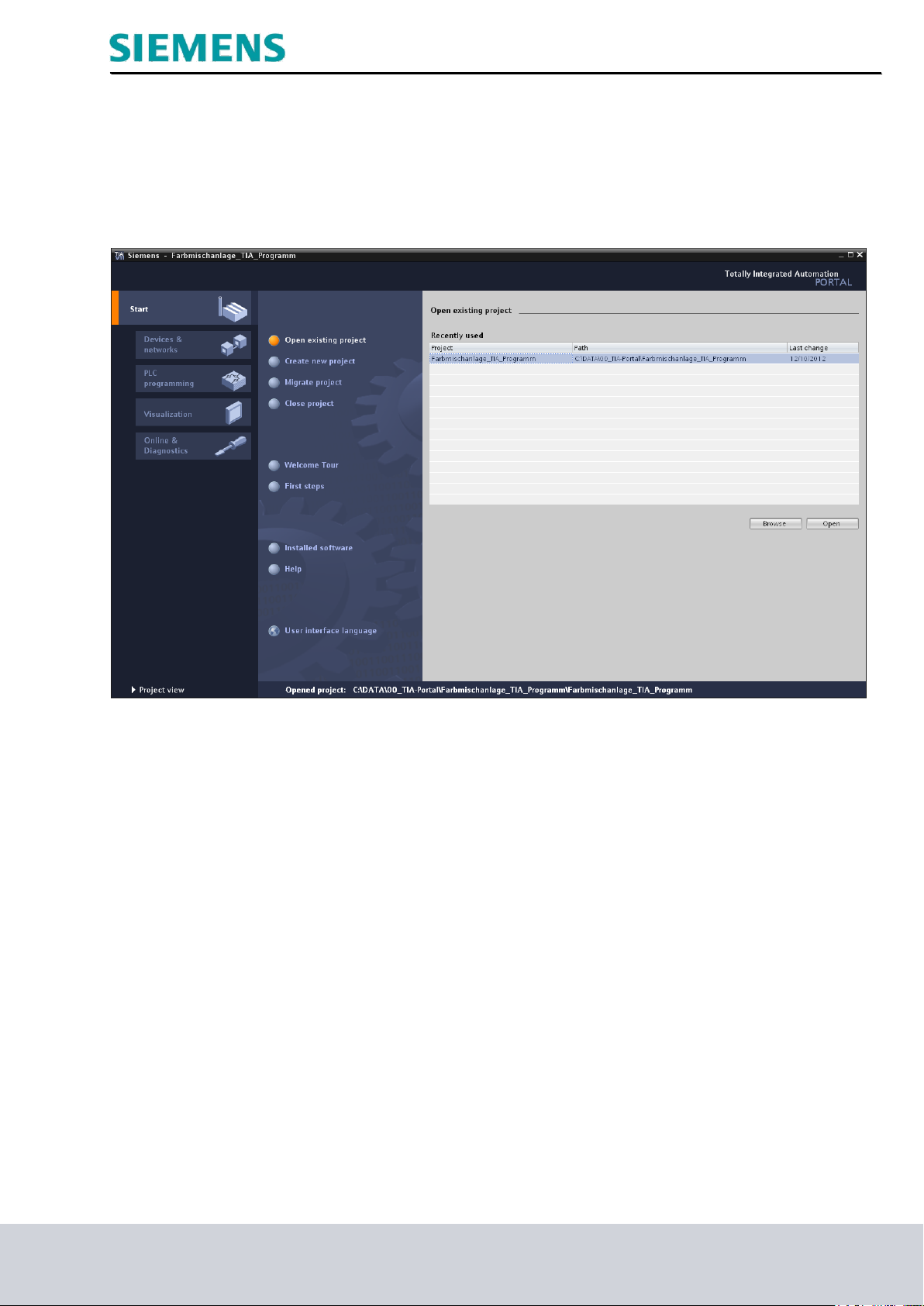

4.1 Loading and re-saving a project template

The project "Color mixing station_TIA_Program" from Module 090-010 will now be opened as a

template for this program.

SCE Training Curriculum Page 13 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 14

Industry Sector, IA&DT

‘First steps’ for configuring are now suggested.

Click ’Open the project view‘.

SCE Training Curriculum Page 14 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 15

Industry Sector, IA&DT

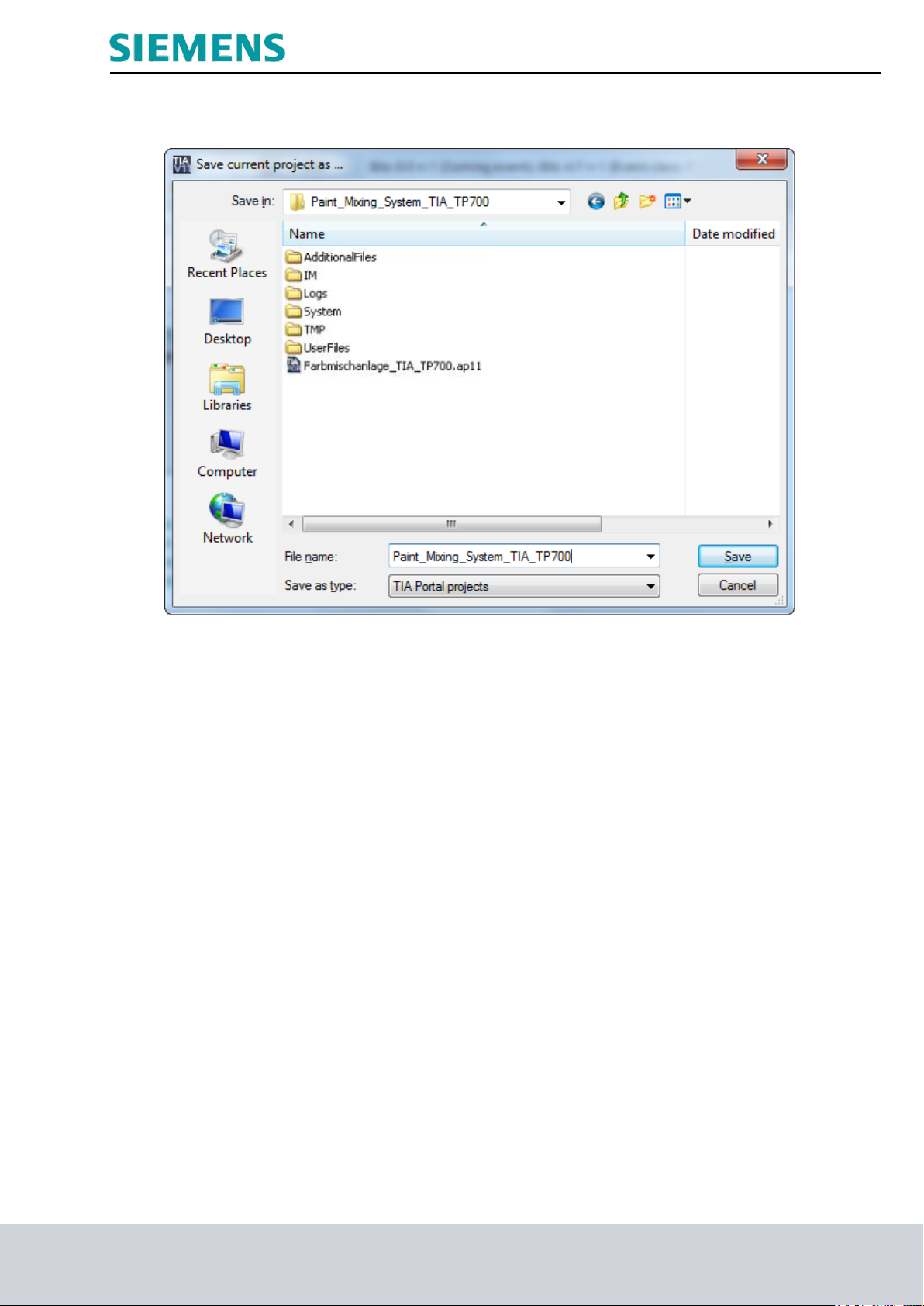

Start by saving the project under a different name.

In the Project menu, click "Save as".

SCE Training Curriculum Page 15 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 16

Industry Sector, IA&DT

‘Save’ the project under the new name ‘Color mixing station_TIA_TP700’.

SCE Training Curriculum Page 16 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 17

Industry Sector, IA&DT

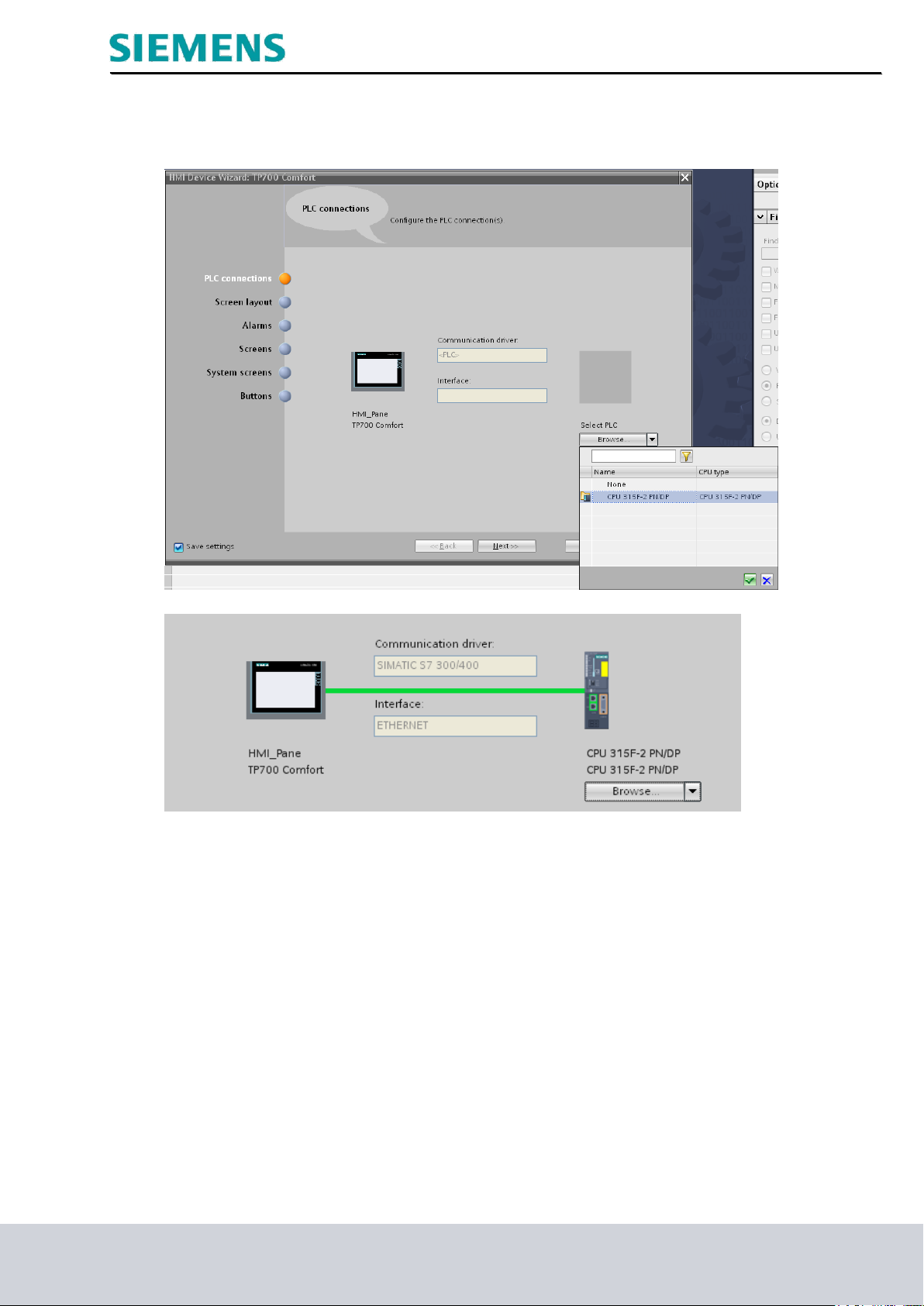

To set up a new panel in the project, double-click 'Add new device' to open the selection window.

Under HMI, SIMATIC Comfort Panel, select the 7" Display Panel “TP700 Comfort”.

Enter the device name and set the check mark for "Start device wizard".

Click "OK".

SCE Training Curriculum Page 17 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 18

Industry Sector, IA&DT

Under PLC, first select the "CPU 315F-2 PN/DP".

Then, click "Next".

SCE Training Curriculum Page 18 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 19

Industry Sector, IA&DT

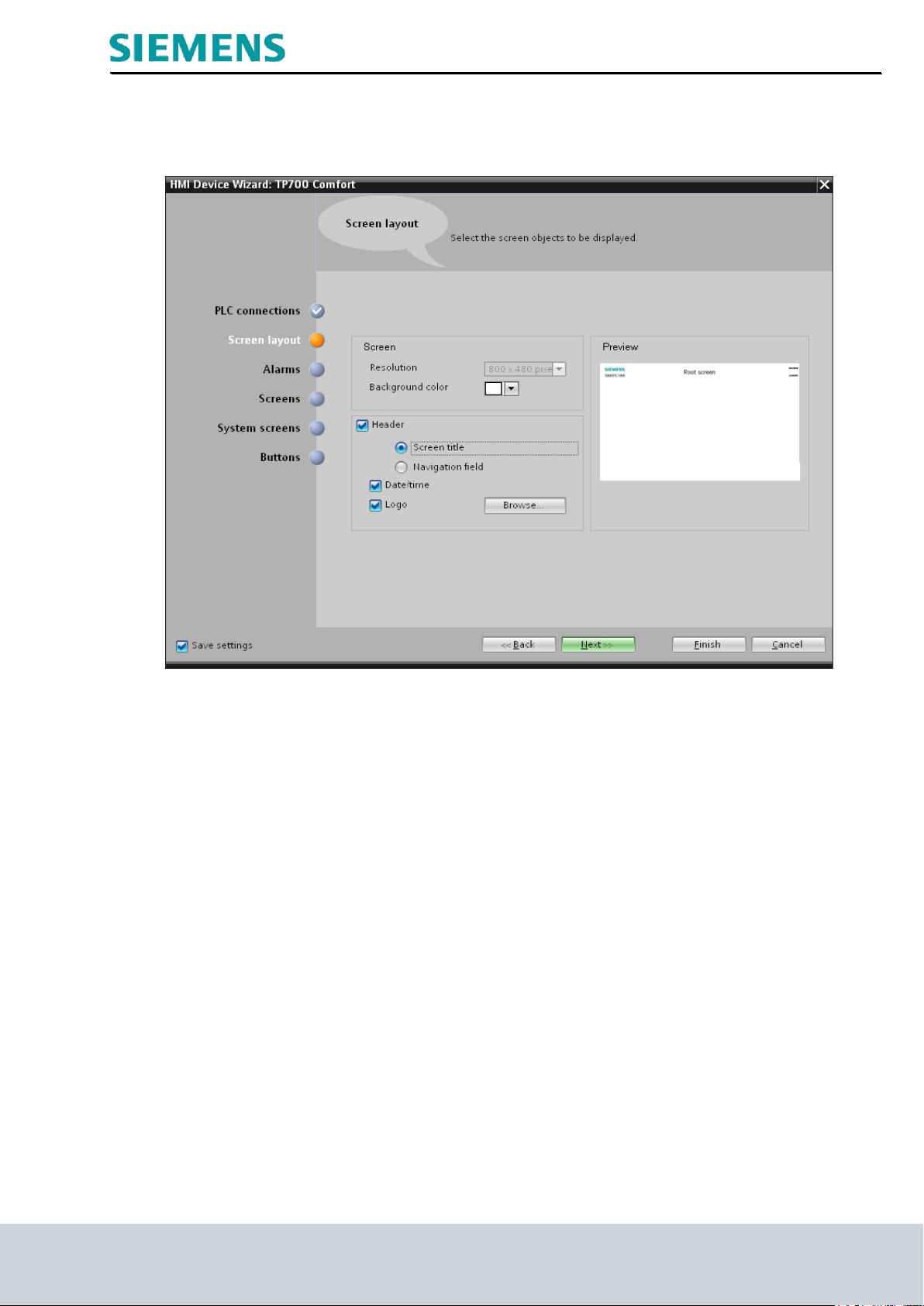

Under Screen layout, change the background color to "White" and make the settings for "Header".

Now, click "Next".

SCE Training Curriculum Page 19 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 20

Industry Sector, IA&DT

Set the check marks for Alarms.

Then, click "Next".

SCE Training Curriculum Page 20 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 21

Industry Sector, IA&DT

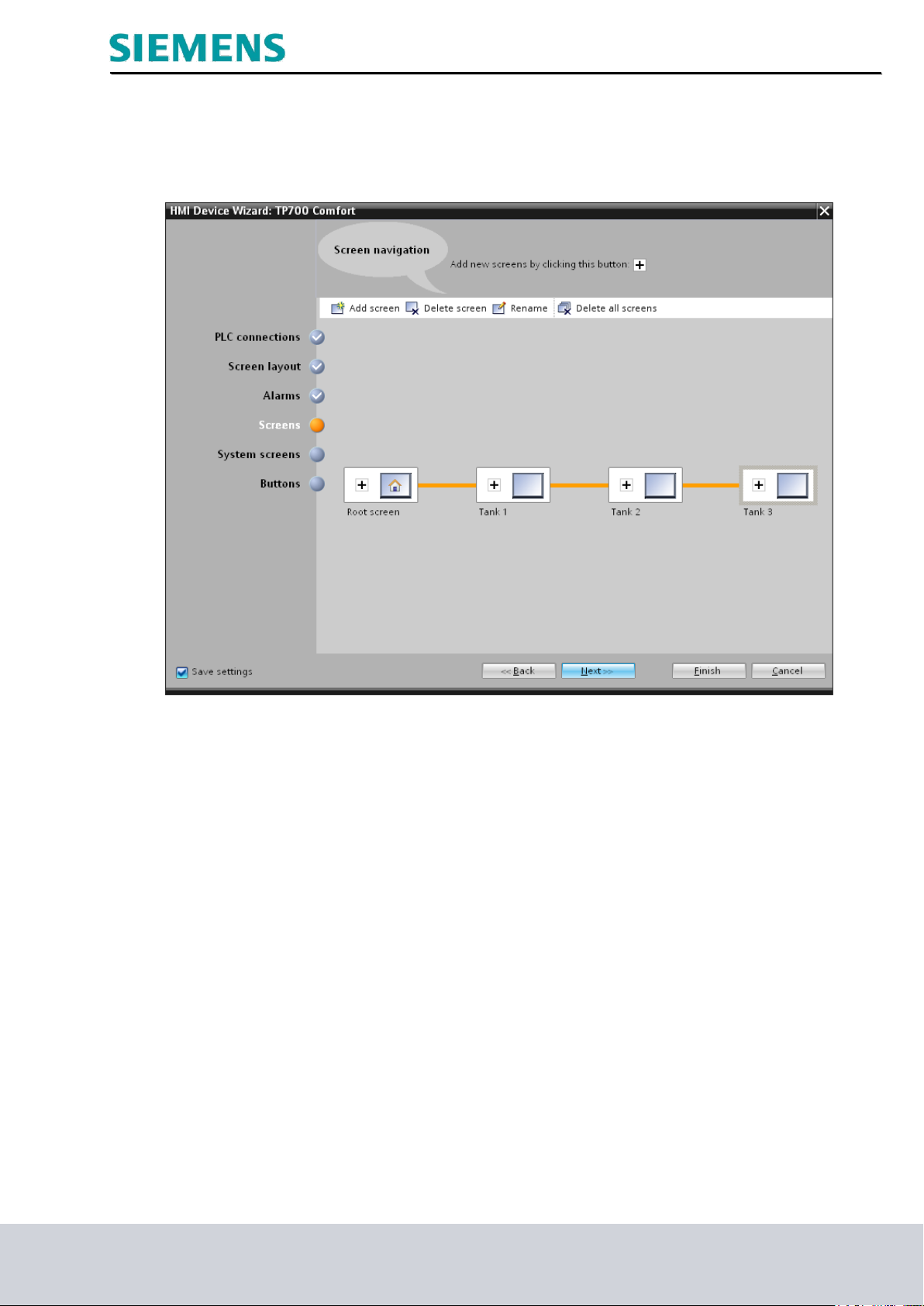

A screen menu structure can be set up under Screen navigation.

For our example, four screens will suffice to begin with.

Assign the names "Root screen, Tank 1, Tank 2, Tank 3".

After that, click "Next".

SCE Training Curriculum Page 21 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 22

Industry Sector, IA&DT

Select the system screens.

Then, click "Next".

SCE Training Curriculum Page 22 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 23

Industry Sector, IA&DT

To conclude, predefined system buttons can also be positioned.

Remove all check marks.

Now, click "Finish".

SCE Training Curriculum Page 23 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 24

Industry Sector, IA&DT

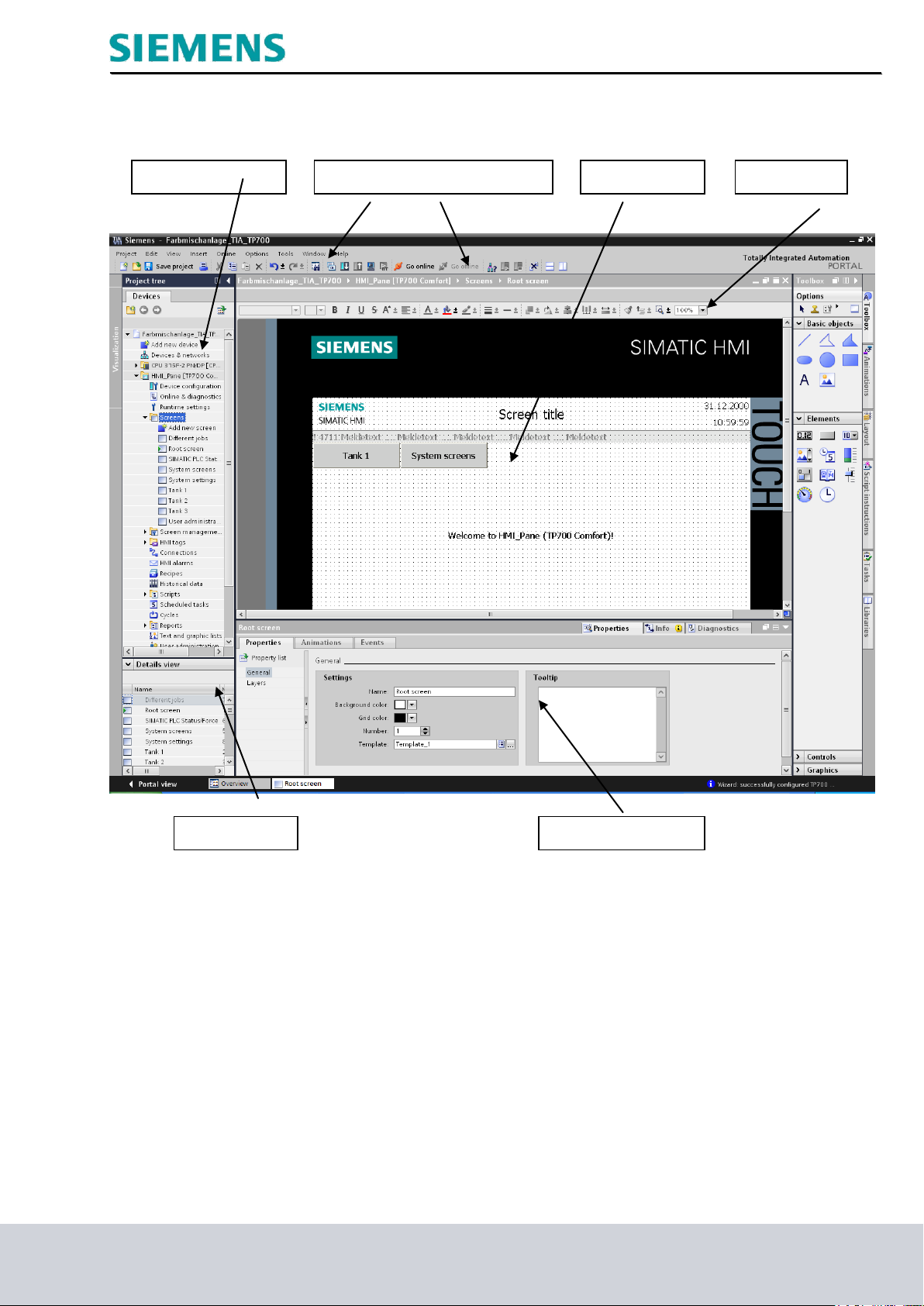

The WinCC interface now opens with the root screen.

SCE Training Curriculum Page 24 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 25

Industry Sector, IA&DT

Project tree

Menu bar and buttons

Details view

Properties window

Tools

Working area

5. WinCC user interface

SCE Training Curriculum Page 25 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 26

Industry Sector, IA&DT

5.1 Project tree

The project tree window is the central control point for project editing.

All components and all available editors of a project are displayed in a tree structure in the project

window and can be opened there.

Each editor is assigned a symbol that identifies the associated object. Only elements supported by the

selected HMI device are displayed in the project window.

In the project window, you can access the HMI device settings.

5.2 Menu bar and buttons

The menus and the toolbars provide all the functions needed to configure the HMI device. If a

corresponding editor is active, editor-specific menu commands and toolbars are displayed.

If you point to a command with the mouse, a corresponding tooltip is provided for each function.

SCE Training Curriculum Page 26 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 27

Industry Sector, IA&DT

5.3 Working area

The objects of the project are edited in the working area. All WinCC elements are arranged around the

working area.

In the working area, we edit the project data either in tabular form (for example, tags) or graphically (for

example, a process screen).

A toolbar is located in the upper part of the working area.

Fonts, font colors and functions such as rotate, align, etc. can be selected here.

5.4 Tools

In the Tools window, a selection of objects is provided that can be inserted into screens, such as graphic

objects and operator control. In addition, the Tools window includes graphics with preassembled graphic

objects and collections of faceplates.

Objects are dragged to the working area.

SCE Training Curriculum Page 27 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 28

Industry Sector, IA&DT

5.5 Properties window

In the properties window, you edit the properties of objects; for example, the color of screen objects.

The properties window is available only in certain editors.

In the properties window, the properties of the selected object are displayed arranged according to

categories. As soon as you exit an input field, the value changes become effective.

If you enter an invalid value, this field is highlighted in color.

To obtain information on the valid data range, for example, view the tooltip.

In addition, animations and events of the selected object are configured in the properties window; in this

case, for example, a screen change when the button is released.

5.6 Details view

The details view displays additional information on the object selected in the project tree.

SCE Training Curriculum Page 28 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 29

Industry Sector, IA&DT

5.7 Layout

Settings for the working area such as the zoom view, level selection and grid functions can be made in

the layout window. Animations, instructions, tasks and libraries of the relevant object can be selected

using additional tabs.

SCE Training Curriculum Page 29 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 30

Industry Sector, IA&DT

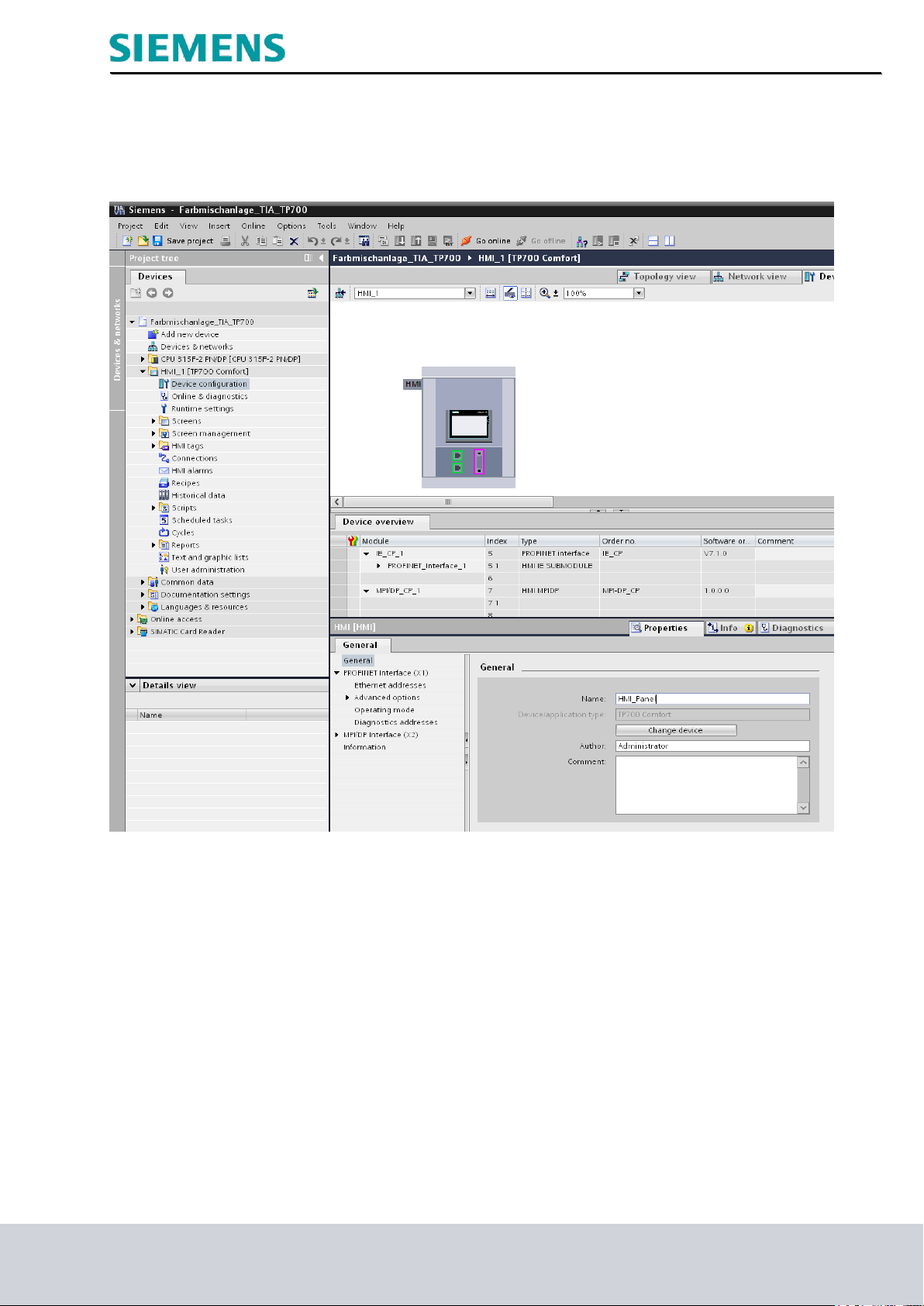

6. Device configuration of the TP700 Comfort Panel

To open, double-click the device configuration of the HMI_Panel [TP700 Comfort].

SCE Training Curriculum Page 30 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 31

Industry Sector, IA&DT

6.1 Setting the IP address

Select the Ethernet interface of the panel and set the IP address 192.168.0.140 under Ethernet

addresses.

SCE Training Curriculum Page 31 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 32

Industry Sector, IA&DT

6.2 Setting the panel as PROFINET IO device

Set the check mark for IO-Device under Operating mode and select the CPU 315F-2 PN/DP

PROFINET interface_1.

Click “Save project”.

Close the device configuration of the panel.

SCE Training Curriculum Page 32 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 33

Industry Sector, IA&DT

7. Configuring screens

A screen can consist of static and dynamic elements. Static elements, such as text and graphics, are not

updated by the controller.

Dynamic elements are connected to the controller and visualize current values from the controller’s

memory. Visualization can be in the form of alphanumeric displays, trends or bars. Dynamic elements

are also inputs on the HMI device that are written to the controller’s memory. Tags are used for the

connection with the controller.

To begin with, the four automatically generated screens are to be configured for our color mixing station.

Root screen

This screen is already set up automatically and is also defined as start screen.

The entire plant is displayed here.

You can switch the operating mode or start the mixing process, the manual operation of the mixer motor

and the opening of the drain valve using buttons.

The motion of the mixer and the states of the valves are displayed in graphic form.

The filling capacities of the individual admixtures are indicated via input fields.

Jumping to other screens should also be possible.

The "System screens" button can be used to make system settings on the panel, for example.

Tank 1

The valves from Tank 1 can be operated in manual mode in the Tank 1 screen. The maximum and

minimum filling capacity can be set on the sliders. The supply and drain valve can be opened or closed

using buttons (Open valve).

The valves are displayed in graphic form and change their color in the open state.

The fill level is displayed in red. When the maximum fill level has been reached, the supply valve is

closed in automatic mode. If the tank is completely full, the supply valve cannot be opened.

Other buttons are used to switch to other tanks or to the root screen.

Tank 2, Tank 3

The Tank 2 and Tank 3 screens are structured like the Tank 1 screen.

The valves and the fill level of Tank 2 are displayed in green.

The valves and the fill level of Tank 3 are displayed in blue.

SCE Training Curriculum Page 33 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 34

Industry Sector, IA&DT

7.1 Root screen

Open the root screen of the HMI_Panel [TP700 Comfort] with a double-click.

Permanent overview area

The automatically generated screens contain a permanent window in the upper section.

The permanent area (overview) is also displayed in all newly added screens.

SCE Training Curriculum Page 34 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 35

Industry Sector, IA&DT

In the permanent window, change the screen title to Color mixing station under General and the

Position & size and Margins of the text field under Layout.

SCE Training Curriculum Page 35 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 36

Industry Sector, IA&DT

Root screen display area

In the root screen, delete the text field in the center of the screen and the Tank 1 button.

Under Layout, change the Position & size of the System screens button.

SCE Training Curriculum Page 36 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 37

Industry Sector, IA&DT

Configuring screen changes

In each screen, a screen change to the other three screens should be possible using buttons.

In WinCC, the screen names need only be dragged from the project window to achieve this. The buttons

are then generated automatically.

Under Layout, change the Position & size of the Tank 1 button.

SCE Training Curriculum Page 37 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 38

Industry Sector, IA&DT

Insert the Tank 2 button and change the Position & size under Layout.

Insert the Tank 3 button and change the Position & size under Layout.

Make sure to save the project occasionally.

SCE Training Curriculum Page 38 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 39

Industry Sector, IA&DT

Inserting a graphic view

Drag a graphic view to the working area of the root screen.

SCE Training Curriculum Page 39 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 40

Industry Sector, IA&DT

You can now choose graphics from the list in the properties window of the graphic view

You can use the buttons to create new graphics from files or OLE objects.

The selected graphic appears in the preview window and can be inserted.

You have two options for inserting graphics.

First option

Click Create new graphic from file.

SCE Training Curriculum Page 40 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 41

Industry Sector, IA&DT

Select the file "Plant.bmp" from the Color Mixing Station_TIA templates directory.

Confirm your selection with Open.

SCE Training Curriculum Page 41 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 42

Industry Sector, IA&DT

Second option

Click Create new graphic from OLE object.

Select Create from File and click Browse.

Select the image "Plant.bmp" and click Open.

In the next window, confirm your selection with OK

SCE Training Curriculum Page 42 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 43

Industry Sector, IA&DT

.

Under Layout, change the Position & size of the graphic view.

Remember to save the project!

SCE Training Curriculum Page 43 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 44

Industry Sector, IA&DT

7.2 Tank 1 screen

Open the Tank 1 screen with a double-click.

Delete the text field in the center of the screen and the Tank 2 button.

SCE Training Curriculum Page 44 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 45

Industry Sector, IA&DT

Under General, change the name of the button to Root screen

and adjust the Position & size of the button under Layout.

Insert the Tank1.bmp image as graphic view.

SCE Training Curriculum Page 45 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 46

Industry Sector, IA&DT

Copy the buttons Tank 2 and Tank 3 from the root screen and insert these in the Tank 1 screen.

SCE Training Curriculum Page 46 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 47

Industry Sector, IA&DT

Repeat the work steps for the Tank 2 and Tank 3 screens.

7.3 Tank 2 screen

7.4 Tank 3 screen

SCE Training Curriculum Page 47 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 48

Industry Sector, IA&DT

7.5 Testing configuration in Runtime

Select the HMI_Panel and click the "Start simulation" button.

Root screen

Tank 1 screen

SCE Training Curriculum Page 48 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 49

Industry Sector, IA&DT

Tank 2 screen

Tank 3 screen

Test the function of the buttons in all screens

SCE Training Curriculum Page 49 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 50

Industry Sector, IA&DT

8. Settings on the TP700 Comfort Touch Panel

The most important panel settings have already been made in the device configuration of the panel in

the WinCC project.

Select the HMI_Panel [TP700 Comfort] and click the Load to device button.

These settings are written to the panel during loading.

The most important settings can also be made directly on the panel.

The Touch Panel TP700 runs under the Windows CE operating system and can be operated, like all

touch panels, directly on the screen. To make operation easier, you should use a touch pen or connect a

mouse to the panel's USB port.

The desktop and the Loader window appear after the panel starts up.

At the bottom edge of the screen, there is a taskbar which you can use to start programs or adjust

program settings, like with other Windows systems.

Loader buttons:

Transfer: Data transfer becomes active and data can be read in from WinCC flexible.

Start: Runtime is started and the process visualization appears on the panel.

Control Panel: Windows CE Desktop opens.

Taskbar: The taskbar opens.

SCE Training Curriculum Page 50 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 51

Industry Sector, IA&DT

8.1 Setting the date and time

Use the Control Panel button to set the date and time.

The Windows CE desktop opens.

Use the Date/Time button to make the settings.

Set the time zone, date and time. Click OK to confirm.

SCE Training Curriculum Page 51 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 52

Industry Sector, IA&DT

8.2 Setting transfer properties

On the desktop, press the icon

Select PN/IE under Channel.

Select the Enable Transfer check box and the Remote Control check box.

The settings in the Transfer Settings window have nothing to do with the connection settings in the

WinCC project.

This means, for example, that data can be transferred between the TP700 Panel and WinCC using the

Ethernet interface, and that communication between the panel and the SIMATIC S7 controller can take

place using the MPI interface.

In our example, data is transferred between the TP700 Panel and WinCC and communication takes

place between the panel and the SIMATIC S7 controller by means of the Ethernet interface.

To set the IP address on the panel, click Properties to edit or check the network settings.

To set the MPI or PROFIBUS address on the panel, click Properties to edit or check the bus settings

after the selection of the interface.

Select the PN/IE interface.

Click OK to confirm.

SCE Training Curriculum Page 52 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 53

Industry Sector, IA&DT

8.3 Assigning PROFINET device names

Double-click the PROFINET icon on the desktop. Select the PROFINET IO enabled check box and

enter hmixbpanel5650 as the device name of the panel.

8.4 Reboot

The panel can be booted under the OP Properties.

All the settings are applied after the reboot.

SCE Training Curriculum Page 53 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 54

Industry Sector, IA&DT

8.5 Transfer mode

After the “reboot”, the panel is automatically set to transfer mode.

If the panel already contains a configuration, Runtime is started after a few seconds.

Connecting to host… appears in the Transfer window.

SCE Training Curriculum Page 54 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 55

Industry Sector, IA&DT

8.6 Configuring a connection

Until now, we have worked in our project without access to the SIMATIC S7 controller.

We also want to display fill levels and enter fill quantities on our panel.

For operating and display objects that access the process values of a controller, a connection to the

controller has to be configured first.

Here, you specify how and via which interface the panel communicates with the controller.

Double-click Connections in the project window.

All parameters have already been set by the settings in the device configuration.

Save the project.

The bus error LED on the CPU goes out after successful loading to the panel.

Note

To create a new connection, double click the free field in the first column.

Change the connection parameters of the newly created connection.

SCE Training Curriculum Page 55 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 56

Industry Sector, IA&DT

9. Display and operating objects

Display and operating objects are graphic elements used to design process screens.

All display and operating objects behave dynamically in Runtime.

In addition, you can make the properties of objects dynamic.

An example of this is the graphic of a tank whose fill level changes in the display depending on the

corresponding process value.

Another example of the dynamic behavior of an object is a button that triggers a specific function.

Essentially, you can assign dynamic properties to any graphic object.

You have the following configuration options:

- The appearance of the object changes: color and flash behavior.

- The object moves on the screen.

- The object is shown or hidden.

The following additional options are available for operator controls:

- An object is enabled or locked for operating.

- Operator input, such as clicking an object, triggers an event. The configured response to this event

is to work through a function list.

9.1 Layers

Layers and nesting of objects within levels are used for the differential display and editing of screen

objects.

A screen has 32 layers. Objects can be inserted at every layer. The assignment of an object to a layer

determines the nesting of an object in the screen. Objects of layer 0 are located in the screen

background, while objects of layer 31 are located in the foreground.

The objects are also staggered within each layer.

In the creation of a process screen, the objects of an individual layer are arranged by default in the order

of their configuration. The first object inserted is located at the very rear of the layer. Each further object

is placed one position further to the front.

It is possible to change the position of objects to each other within the layer.

There is always one active layer. When you add new objects to a screen, these are assigned to the

active layer as standard. The number of the active layer is indicated in the "Layer" toolbar. The active

layer is highlighted in color in the layer pane.

When you open a screen, all 32 layers of the screen are always displayed.

You can use the layer pane after opening the screen to hide all layers except the active layer. You then

explicitly edit objects of the active layer.

SCE Training Curriculum Page 56 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 57

Industry Sector, IA&DT

Symbol

Object

Notes

"Line"

You can choose straight, rounded or arrow-shaped line ends

"Polyline"

A "polyline" consists of linked paths and may have any number of vertices.

The vertices are numbered in the order of their creation. You can modify or

delete vertices individually. You can choose straight, rounded or arrowshaped line ends for the polyline. The polyline is an open object. Even if the

start and end points have the same coordinates, the area they enclose

cannot be filled in.

"Polygon"

The vertices of a polygon are numbered in the order of their creation. You

can modify or delete vertices individually. You can fill a polygon with a color

or a pattern.

"Ellipsis"

You can fill an ellipsis with a color or a pattern.

"Circle"

You can fill a circle with a color or a pattern.

"Rectangle“

You can set any rounding for the vertices of a rectangle. You can fill a

rectangle with a color or a pattern.

"Text field"

In a text field, you display one row or multiple rows of text and assign font

colors and fonts to this text. You can fill a text field with a color or a pattern.

"I/O field"

An I/O field can be assigned the following functions in Runtime:

Output of tag values

Input of values by the operator; the input values are stored in a tag

Combined input and output; in this case, the operator can edit the

output tag values and thus reset them.

You can define limits for the tag values shown in the I/O field.

If you want to hide the operator input in Runtime, configure "Hidden input".

"Date/time

field"

A date/time field may have the following functions in Runtime:

Output of the date and time

Combined input and output; in this case, the operator can edit the

output values and thus reset the date or time.

The system time or corresponding tags can be used as the source for the

date and time.

You can choose to have the date displayed in detail (e.g. Tuesday,

December 31, 2003) or in short form (12/31/2003).

9.2 Basic objects

SCE Training Curriculum Page 57 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 58

Industry Sector, IA&DT

Symbol

Object

Notes

“Graphic I/O

field”

A graphic I/O field can be assigned the following functions in Runtime:

Output of entries of a graphic list

Combined input and output; in this case, the user can select a graphic

from the graphic list and thus change the content of the graphic I/O

field.

Example of its use as output field:

To indicate the status of a valve in Runtime, the graphic I/O field outputs the

image of a closed or open valve.

"Symbolic I/O

field"

A symbolic I/O field can be assigned the following functions in Runtime:

Output of text list entries

Combined input and output; in this case, the user can select a text from

the text list and thus change the content of the symbolic I/O field.

Example of its use as combined input and output field:

To control a motor in Runtime, the user selects the "Motor OFF" or "Motor

ON" text from the text list. The motor is started or stopped depending on the

selection; the symbolic I/O field shows the respective state of the motor

(motor OFF/Motor ON).

"Graphic view"

The graphic view is used to show graphics created with third-party graphic

programs in a screen. The follow graphic formats can be displayed: "*.emf",

"*.wmt", "'.dib", "'.bmp", "*.jpg", "'.jpeg", "'.gif' and "*.tif“.

You can use the graphic view to insert graphics of other graphic programs

and OLE (Object Linking and Embedding) objects. OLE objects can be

opened and edited directly from the properties window of the graphic view in

the graphics program in which they were created.

"Button"

The operator uses the button to control a process. Functions and scripts

can be configured on the button.

"Switch"

In Runtime, the switch is used to input and display two states, such as ON

and OFF, or pressed and not pressed. The switch can be labeled with text

or graphics to display the state of the switch in Runtime.

"Bar"

A value from the controller is displayed in Runtime in the form of a bar in a

scaled graph. You can use a bar to display changes in fill level, for example.

Note

Depending on the HMI device which you are configuring, some of the objects from the Tools window

are available either with restricted functionality or not at all.

Objects that are not available in the Tools window are grayed out and cannot be selected.

SCE Training Curriculum Page 58 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 59

Industry Sector, IA&DT

Symbol

Object

Description

"SIider”

The operator can use the slider to read and input numerical values as

follows.

As indicating element, the position of the slider shows the current

value from the controller

To input widths, the operator moves the slider to the required

position.

The slider can only be configured with vertical sliding direction.

"Clock"

In Runtime, the clock is used to display the system time in either analog

or digital format on the HMI device.

"Status/Force"

Status/Force gives the operator direct read and write access from the

HMI device to individual address areas in the connected SIMATIC S7 or

SIMATIC S5.

"Sm@rtClient

view"

The operator can use Sm@rtClient view to monitor and operate another

HMI device of the plant.

"HTML browser"

The operator can use the HTML browser to view websites.

"User view"

In WinCC flexible, you can protect the operation of screen objects using

passwords. In Runtime, the user view allows an administrator to manage

the users on the HMI device.

Users that do not have administrator rights can change their passwords

in Runtime.

"Pointer

instrument"

In Runtime, you can use the pointer instrument to display numerical

values using a pointer position. It is possible to configure the appearance

of the pointer instrument. You can, for example, change the background

graphic or the scale design.

"Trend view"

You can use the trend view to simultaneously display multiple trends with

values from the controller or from a log. The axes of the trend view can

be configured (scales, units etc.).

"Recipe view"

The operator can use the recipe view to display, edit and manage data

records in Runtime.

"Alarm view"

The operator can use the alarm view to display selected alarms or alarm

events from the alarm buffer or alarm log in Runtime.

"Alarm window"

The operator can use the alarm window to display selected alarms or

alarm events from the alarm buffer or alarm log in Runtime. You can only

configure the alarm window in the template.

"Alarm indicator"

The alarm indicator signals to the operator that alarms that need to be

acknowledged have arrived and have not yet been acknowledged.

You can only configure the alarm indicator in the template.

9.3 Enhanced objects

SCE Training Curriculum Page 59 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 60

Industry Sector, IA&DT

10. Display and operating objects in the "Color mixing station" project

10.1. Configuring display and operating objects in the “Tank 1” screen

A bar, two sliders and two buttons are configured to begin with.

Afterwards, the supply and drain valves are to be animated in color.

Configuring the bar view

You are going to configure a bar to display the current fill level of Tank 1.

Drag a bar to the Tank 1 screen.

SCE Training Curriculum Page 60 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 61

Industry Sector, IA&DT

Specify 1000 as the maximum value.

Select the tag "CONTENT_T1" as process tag from the PLC tags of the color mixing station.

The WinCC tag "CONTENT_T1" was automatically generated.

SCE Training Curriculum Page 61 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 62

Industry Sector, IA&DT

To make additional settings, double-click Default tag table in the project window.

Set the acquisition cycle of the tag to 100 ms. The tag is now updated every 100 ms. The movement of

the bar, i.e. the fill level of the tank, is now animated in the display.

Note

The communication influences the cycle time of the SIMATIC S7 300 controller. When there are a large

number of tags, it is advisable to consider precisely the acquisition cycle of each tag.

SCE Training Curriculum Page 62 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 63

Industry Sector, IA&DT

In the Properties window under Appearance, change the color assignments of the foreground color to

Red and the bar background to White.

Under Limits, remove the check mark for “Lines”.

Under Scales, remove the check mark for “Show scale”.

SCE Training Curriculum Page 63 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 64

Industry Sector, IA&DT

Under Layout, change the position and bar size.

The bar alignment is set by default to Top.

The bar to display the fill level in the Tank 1 screen is now complete.

SCE Training Curriculum Page 64 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 65

Industry Sector, IA&DT

Configuring sliders

A slider is configured to set the minimum fill level.

From the Tools window, under Enhanced objects, drag the slider to the "Tank 1“ screen.

Enter 450 as maximum value and 10 as minimum value, and select the tag " low_level" as process tag

from the FB call "tank1" of the DB1 of the color mixing station.

Note

In WinCC, you can also access the tag declaration in a data block.

SCE Training Curriculum Page 65 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 66

Industry Sector, IA&DT

Under General, enter “MIN” as the title.

Under Layout, change the position and size of the slider.

Under Text format, change the font size to Tahoma, 15px bold.

Insert a second slider to set the maximum fill level in Tank 1.

Change the minimum value to 550 and the maximum value to 990, and select the tag “high_level” as

process tag from the FB call “tank1” of the DB1.

Under Layout, enter “MAX” as the title.

Position the slider to X600 and Y80 and change the size to 100 x 260.

Under Text format, change the font size.

SCE Training Curriculum Page 66 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 67

Industry Sector, IA&DT

The Tank 1 screen now looks like this.

Three tags have now been created automatically.

Set the acquisition cycle of the newly created tags to 100 ms.

Remember to save the project!

SCE Training Curriculum Page 67 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 68

Industry Sector, IA&DT

Configuring buttons

We configure a button for opening the valves.

From the Tools window, under Basic objects, drag a button to the “Tank 1” screen.

Under General, select the Text On check box and enter the text.

Caution! Do not press the Enter key after entering the text; otherwise, a new line will be created.

SCE Training Curriculum Page 68 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 69

Industry Sector, IA&DT

Change the background color to White and select a font size.

Set the position and the size.

Open the Events tab.

Under Press, select the function "SetBitWhileKeyPressed" in the function list.

Select “manual_supply_tank1” as tag from DB1.

SCE Training Curriculum Page 69 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 70

Industry Sector, IA&DT

The button should be operable only in manual mode.

In other words, it should only be possible to operate the button if the tag “H3_MAN” has the value 1.

Open the Animation tab.

Under Display, select Add new animation.

Under Animations, select the Control enable.

Select "H3_MAN" as tag from the PLC tags.

Under Control enable, set the status to Enabled.

For Single bit, select the bit position 0.

Create a new animation appearance.

The button should change color in manual mode; i.e. when the tag “H3_MAN” has the value 1. To make

the color change visible, change the foreground color to white and the background color to blue under

Appearance.

SCE Training Curriculum Page 70 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 71

Industry Sector, IA&DT

Copy and insert the button.

Change the text to “Drain valve”, and the position to X320, Y320.

Under Press Events, select the tag “manual_drain_tank1”.

The tag list now contains three more tags that have been automatically created.

SCE Training Curriculum Page 71 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 72

Industry Sector, IA&DT

Displaying the valve function in color

The switching states of the valves should be visible through a color change.

Click the Layout tab. First, enlarge the zoom factor of the view and select the screen section of the valve.

Then, go to the Tools tab. Under Basic objects, select the Polygon.

Trace the valve by clicking with the mouse on each corner and finish with a double-click.

Due to the grid function, the polygon will be somewhat larger than in the graphic.

The size and position will be adjusted in the properties.

SCE Training Curriculum Page 72 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 73

Industry Sector, IA&DT

In the Properties, under Appearance, set the fill color to Yellow.

Change the position and size so that the graphic and polygon fit together.

SCE Training Curriculum Page 73 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 74

Industry Sector, IA&DT

Create a new animation Appearance and use the tag Supply_T1.

Enter the value 1 as range and change the background color to red.

Copy and insert the polygon. Rotate the polygon by 90 degrees and position it below the tank (button for

rotating by 90 degrees is in the toolbar at the top).

Use the tag “DRAIN_T1” for the color change in the appearance.

The tag list now contains two more tags that have been automatically created.

Remember to save the project!

SCE Training Curriculum Page 74 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 75

Industry Sector, IA&DT

Testing “Tank 1” in Runtime

Load the project to the panel and test the functions in the "Tank 1" screen.

Note

If the reservoir is filled, the drain valve cannot be opened.

You first have to drain the reservoir using the “MANUAL_DRAIN_RES” (I1.6).

If you set the acquisition cycle of all tags to 100 ms, the actuation of the buttons and the valve function

will be updated faster.

SCE Training Curriculum Page 75 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved

SCE_EN_090-010_R1209_ WinCC Advanced with Runtime and TP700 Comfort Panel

Page 76

Industry Sector, IA&DT

10.2 Configuring display and operating objects in the “Tank 2” and “Tank 3” screens

The “Tank 2” and “Tank 3” screens are structured like the “Tank 1” screen.

In the “Tank 2” screen, the fill level of the tank and the valve function are to be displayed in green and

the tags for Tank 2 will be used, for example “CONTENT_T2”.

In the “Tank 3” screen, the fill level of the tank and the valve function are to be displayed in blue and the

tags for Tank 3 will be used, for example “CONTENT_T3”.

Configure the tank screens by either repeating the work steps as for the “Tank 1” screen and using a

different color and tag assignment, or copying the objects of the "Tank 1" screen and inserting these in

the “Tank 2” and “Tank 3” screens.

You can select and copy multiple objects using SHIFT + mouse click.

Afterwards, switch to the "Tank 2" or "Tank 3" screen and insert the objects.

After inserting the objects, you need only change the color assignments and recreate or reassign the

tags.

With bars and valves, the size and position also have to be adapted to the background graphic.

Check the created tags and test the objects of the screens in Runtime.

SCE Training Curriculum Page 76 of 118 To be used only at Educational and R&D Facilities

TIA Portal Module 090-010, Edition 03/2013 Unrestricted / © Siemens AG 2013. All Rights Reserved