Page 1

GAMMA instabus

Technical product information

July 2008

Switching actuator, submodule N 512/21 5WG1 512-1AB21

3x AC 230/400V, 16A, C-load, load-check

Product and functional description

output individually which switching state it is to assume

on a bus voltage failure and after the bus voltage recovery: as before bus voltage failure, ON or OFF.

Application program

The N 512/11 switching actuator needs the application

program "07B0 A15 Switching Actuator 981B01". This

controls the outputs of the main module as well as the

outputs of all connected submodules via their 6-pole

interface.

In bus mode, a communication object can be available

for each actuator output - for switching, for manual

override, for a forced control, for a logical combination

and for status query. Furthermore, if required, timelimited switching instead of permanent switching on can

be enabled for each channel via an optional "Night

mode" object (e.g. for lighting while cleaning), if need be

with a warning before switching off by multiple switching the output on and off (flashing). It can also be selected whether all a module's outputs are to be set jointly

The switching actuator submodule N 512/21 is a 3 MU

(module units) wide device for DIN-rail mounting in Nsystem dimensions, with 3 switching outputs (relay contacts) for AC 230/400V, 16A, C-load, each with load current measurement and monitoring (load-check). A submodule cannot be operated stand-alone or be directly

connected to the bus. But it can be connected via a special 6-pole bridging connector either with a switching

actuator main module or with another submodule which

is already connected to a main module (see figure 1).

The submodule electronics are supplied by bus voltage

via the 6-pole bridging connector.

In total up to 4 switching actuator submodules can be

connected in series to a switching actuator main module,

so that a main module, if need be, can be extended simply from a 3-fold to a 6-, 9-, 12- or 15-fold switching

actuator and thus be matched flexibly to the number of

loads to be switched.

It is indicated by flashing of the corresponding green LED

A to E on the top of the main module if more submodules are set than are actually connected or if the set

submodule type does not correspond with the submodule type actually connected or if a submodule is

detected as faulty.

and thus identically or whether each output is to be set

separately and individually.

Amongst others, the application program includes optional detection and monitoring of the load current for

each output on load failure and/or overload, simultaneous switching of all 3 outputs (3-phase switching), conversion of a speed given as a percentage value into 1- to

3-stage switching commands (fan speed control), conversion of a valve setting given as a percentage value

into a pulse width modulated (PWM) switching command (thermal drive control), a switching cycle and

operating hours count with threshold monitoring for

each output and an integrated 8-bit scene control, in

which each output can be incorporated into up to 8 scenes.

To load the application program, the Engineering Tool

Software (ETS) is required as version 3.0 f or higher.

: If the N 512/11 application program is "unloaded"

Note

with the ETS, then you will no longer be able to activate

direct mode, i.e. the LED status display and local switching of the outputs using the buttons on the front panel

of the actuator are disabled. Only after reloading the

application program can you re-enable the status display

and direct mode.

Behavior in case of mains failure / recovery

Because the electronics of a submodule are fed from the

bus (via the 6-pole interface to the main module), a

mains failure then leads solely to a failure of the submodule if the bus voltage also fails as the result of a

mains failure. However, it can be set for each submodule

Siemens AG N 512/21, 4 pages Technical manual

Industry Sector, Building Technologies

Electrical Installation Technology © Siemens AG 2008 Update: http://www.siemens.com/gamma

P.O. Box 10 09 53, D-93009 Regensburg Subject to change without further notice

2.4.3.3/1

Page 2

GAMMA instabus

Technical product information

July 2008

Switching actuator, submodule N 512/21 5WG1 512-1AB21

3x AC 230/400V, 16A, C-load, load-check

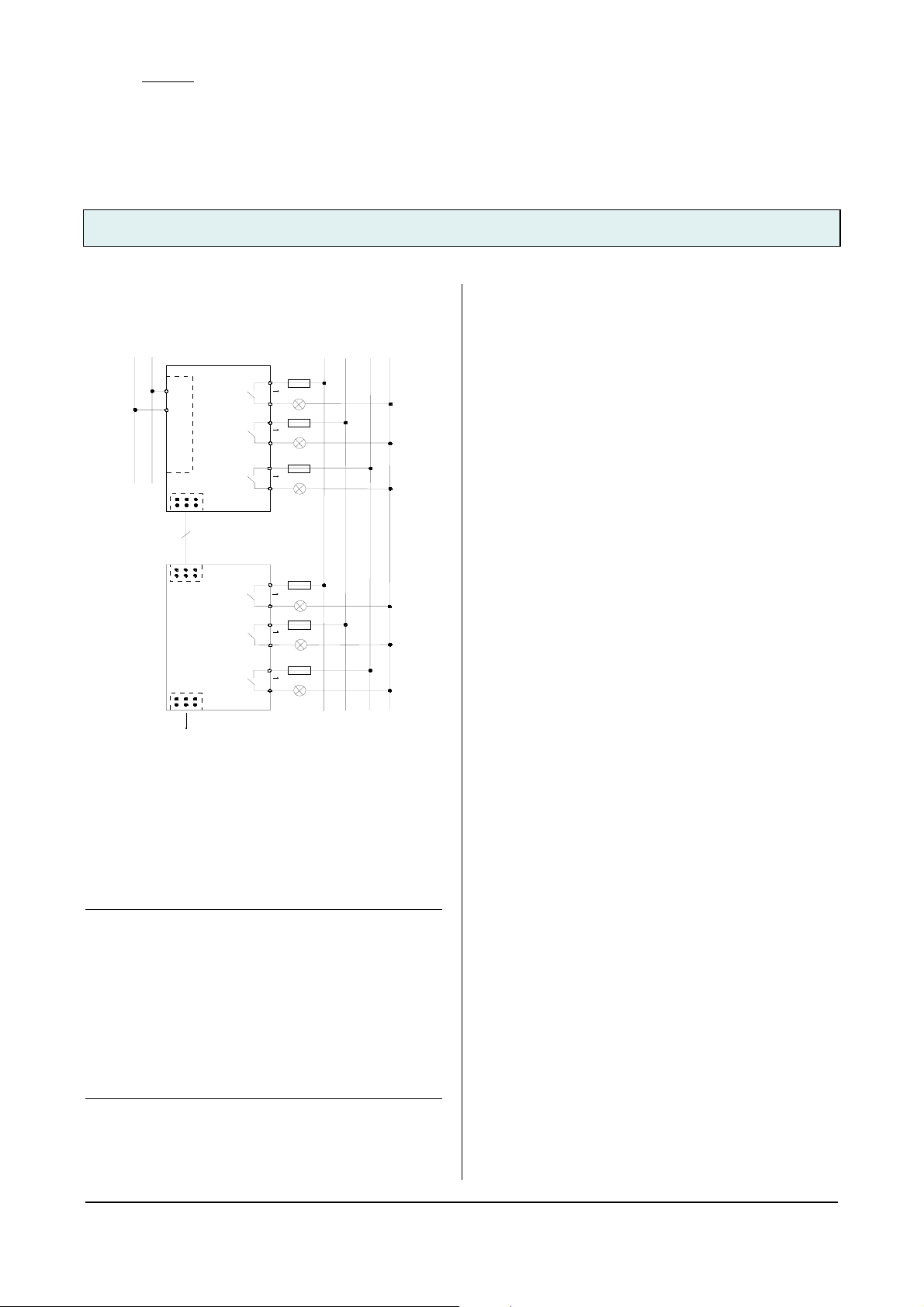

Connection example

Schaltaktor, Hauptmodul

Switching actuator, main module

N 512/11

Ausgang 1

Output 1

t

i

n

u

r

e

g

l

n

p

i

X

l

p

p

Ausgang 2

N

o

u

k

K

o

Output 2

n

c

a

s

s

u

u

B

B

Ausgang 3

Output 3

L1

1

L2

2

L3

3

L3

N

L2

L1

A

6

Schaltaktor, Erweit erung

Switching actuator, submodule

N 512/21

Ausgang 1

Output 1

Ausgang 2

Output 2

Ausgang 3

Output 3

L1

1

L2

2

L3

3

B

C ... E

Figure 1. Connection example

Installation notes

• The device can be used for permanent installation in

dry interior rooms and for insertion in distribution

boards or miniature housings.

V

DANGER

• The device must be mounted and commissioned by an

authorised electrician.

• When connecting the device, it should be ensured that

the device can be isolated.

• The device must not be opened.

• For planning and construction of electric installations,

the relevant guidelines, regulations and standards of

the respective country are to be considered.

• With the last submodule no bridging connector must

be plugged into the jack for a further submodule on

the right submodule side.

Technical data

Power supply

• Bus voltage: via the 6-pole bridging connector

• Bus current per submodule: typically 1 mA

• Power dissipation: if all outputs = OFF: 0.03 W,

at max. load and all outputs = ON: approx. 3.5 W

Outputs

• 3 switching outputs, potential-free relay contacts:

- rated voltage: AC 230/400 V, 50/60 Hz

- rated current: 16 AX (200 µF) to DIN EN 60669-1,

16 A in AC1 mode (cos ϕ = 0.8) and in AC3 mode

(cos ϕ = 0.45) as to DIN EN 60947-4-1,

- DC switching capacity: 16A at 24V DC

- Min. switching capacity: 100 mA at 12V AC

- Incandescent lamp load: max. 3,680 W

- LV halogen lamps, inductive transformer: 2,000 W

- LV halogen lamps, electronic transformer: 2,500 W

- Number of OSRAM ballasts for T5/T8:

QTI 1x28/54W: 56, QTP 1x36W: 31,

QT-M 1x26-42W:21, QTP 2x58W: 9,

QT-FQ 1x80W: 9

- Mech. lifetime: > 1,000,000 switching cycles

- Electr. lifetime: > 100,000 at AC1, > 30,000 at AC3

- Load current measuring range: 0.1...20 A, sinusoidal

- Load current frequency range: 50/60 Hz, +/- 5 Hz,

- Measuring accuracy: +/- 9 % of the current measured

value and +/- 130 mA,

- Max. relay position changes per output and evenly

distributed per minute with simultaneous switching of

all relays: 20 with 3 outputs, 10 with 6 outputs, 7 with

9 outputs, 5 with 12 outputs, 4 with 15 outputs

Operating elements

• none

Display elements

• none

Connections

• Output circuits: screw-type terminals,

insulation strip length 7... 9 mm.

The following conductor cross-sections are permitted:

- 0.5... 4.0 mm² single-core,

- 0.5... 2.5 mm² finely stranded without / with connec-

tor sleeve.

• Each L-conductor connection to the N 512/11 must be

fused with a circuit-breaker of characteristic B or C for

a max. nominal current of 16 A!

• Submodule: 6-pole jack for bridging connector.

Technical manual N 512/21, 4 pages Siemens AG

Industry Sector, Building Technologies

Update: http://www.siemens.com/gamma © Siemens AG 2008 Electrical Installation Technology

Subject to change without further notice P.O. Box 10 09 53, D-93009 Regensburg

2.4.3.3/2

Page 3

GAMMA instabus

Technical product information

July 2008

Switching actuator, submodule N 512/21 5WG1 512-1AB21

3x AC 230/400V, 16A, C-load, load-check

Mechanical data

• Housing: plastic

• Dimensions: DIN rail mounted device in N dimensions,

width 3 module units (1 module unit = 18 mm)

• Weight: approx. 225 g (inclusive of bridging connec-

tor)

• Fire load: approx. 2800 kJ

• Installation: Snap-on mounting on DIN rail

EN 60715-TH35-7.50

Electrical safety

• Degree of pollution (according to IEC 60664-1): 2

• Type of protection (according to EN 60529): IP 20

• Overvoltage category (according to IEC 60664-1): III

• Device complies with: EN 50090-2-2 and EN 60669-2-1

EMC requirements

• Complies with EN 50090-2-2, EN 50428 and

EN 60669-2-1

Environmental conditions

• Climatic withstand capability: EN 50090-2-2

• Ambient operating temperature: - 5 ... + 45 °C

• Storage temperature: - 25 ... + 70 °C

• Relative humidity (not condensing): 5 % to 93 %

Markings

• none (no device with bus interface)

CE mark

• In accordance with the EMC guideline (residential and

functional buildings), low voltage guideline

Location and function of connectors

A1

A2

A3

Figure 2. Connectors

A1 Jack for connection of a switching actuator sub-

module to a switching actuator main module or to a

preceding submodule

A2 Jack for connection of a further switching actuator

submodule

A3 Screw-type terminals of outputs 1...3

Installation and wiring

Mounting / dismounting the device

see figure 3 and 4

B2

:

B1

Figure 3. Mounting the device

Siemens AG N 512/21, 4 pages Technical manual

Industry Sector, Building Technologies

Electrical Installation Technology © Siemens AG 2008 Update: http://www.siemens.com/gamma

P.O. Box 10 09 53, D-93009 Regensburg Subject to change without further notice

2.4.3.3/3

Page 4

GAMMA instabus

Technical product information

July 2008

Switching actuator, submodule N 512/21 5WG1 512-1AB21

3x AC 230/400V, 16A, C-load, load-check

C2

C1

Figure 4. Dismounting the device

C3

Connecting a switching actuator submodule: see figure 5

Snap the switching actuator submodule on to the rail

and push it to the left against the switching actuator

main module or against the switching actuator submodule. Connect both devices using the bridging connector supplied.

Space for notices

AB C

Figure 5. Connecting a switching actuator submodule

General notes

• Any faulty devices should be returned to the local

Siemens office.

• If you have further questions about the product,

please contact our Technical Support:

℡ +49 (0) 180 50 50-222

" +49 (0) 180 50 50-223

! www.siemens.com/automation/support-request

Technical manual N 512/21, 4 pages Siemens AG

Industry Sector, Building Technologies

Update: http://www.siemens.com/gamma © Siemens AG 2008 Electrical Installation Technology

Subject to change without further notice P.O. Box 10 09 53, D-93009 Regensburg

2.4.3.3/4

Loading...

Loading...