Siemens LR200 Quick Start Manual

Quick Start Manual May 2008

sitrans

LR200 (HART)

SITRANS LR200 (HART) with Siemens LUI Interface: Quick Start Manual

This manual outlines the essential features and functions of the SITRANS LR200 (HART). We

strongly advise you to acquire the detailed version of the manual so you can use your device to

its fullest potential. The complete manual can be downloaded from the SITRANS LR200

product page of our web site at: www.siemens.com/LR200

from your local Siemens Milltronics representative.

Questions about the contents of this manual can be directed to:

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.smpi@siemens.com

Copyright Siemens Milltronics

Process Instruments Inc. 2008.

Disclaimer of Liability

All Rights Reserved

We encourage users to purchase authorized bound manuals, or to view electronic versions as designed and

authored by Siemens Milltronics Process Instruments Inc. Siemens Milltronics Process Instruments Inc. will not be

responsible for the contents of partial or

whole reproductions of either bound or

electronic versions.

While we have verified the contents of this manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The contents of

this manual are regularly reviewed and corrections are included in subsequent editions. We

welcome all suggestions for improvement.

Technical data subject to change.

. The printed manual is available

English

MILLTRONICS is a registered trademark of Siemens Milltronics Process Instruments Inc.

Technical Support

Support is available 24 hours a day.

To find your local Siemens Automation Office address, phone number, and fax number, go to:

www.siemens.com/automation/partner:

• Click on the tab Contacts by Product then find your product group (+Process Automation

> +Process Instrumentation > +Level Measuring Instruments).

• Select the team Tech nica l Support. Click on Next.

• Click on a continent, then a country, followed by a city. Click on Next.

For on-line technical support go to: www.siemens.com/automation/support-request

• Enter the device name (SITRANS LR200) or order number, then click on Search, and

select the appropriate product type. Click on Next.

• Enter a keyword describing your issue. Then either browse the relevant documentation,

or click on Next to email a description of your issue to Siemens Technical Support staff.

Siemens A&D Technical Support Center: phone +49 180 50 50 222

fax +49 180 50 50 223

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-1

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to

protect the product and the connected equipment. These warning notices are accompanied by

a clarification of the level of caution to be observed.

1)

English

WARNING: relates to a caution symbol on the product, and means that failure to

observe the necessary precautions can result in death, serious injury, and/or

considerable material damage.

WARNING

in death, serious injury, and/or considerable material damage.

1)

: means that failure to observe the necessary precautions can result

Note: means important information about the product or that part of the operating manual.

FCC Conformity

US Installations only: Federal Communications Commission (FCC) rules

WARNING: Changes or modifications not expressly approved by Siemens

Milltronics could void the user’s authority to operate the equipment.

Notes:

• This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

• This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference to radio communications, in which case the user will

be required to correct the interference at his own expense.

SITRANS LR200

WARNING: SITRANS LR200 is to be used only in the manner outlined in this manual,

otherwise protection provided by the equipment may be impaired.

Note:

• This product is intended for use in industrial areas. Operation of this equipment in a

residential area may cause interference to several frequency based communications.

SITRANS LR200 is a 2-wire 6 GHz pulse radar level transmitter for continuous monitoring of

liquids and slurries in storage and process vessels including high temperature and pressure, to

a range of 20 m (66ft).

The device consists of an electronic circuit coupled to the antenna and either a threaded or

flange type process connection.

1)

This symbol is used when there is no corresponding caution symbol on the product.

Page EN-2 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

Communication is via HART1). Signals are processed using Process Intelligence.

Specifications

For a complete listing, see the SITRANS LR200 (HART) Instruction Manual. For Approvals

information, please refer to the device nameplate and the process device tag.

Ambient/Operating Temperature

Notes:

• Process temperature and pressure capabilities are dependent upon information on the

process device tag. The reference drawing listed on the tag can be downloaded from the

Siemens website at: www.siemens.com/LR200

• Maximum temperature is dependent on the process connection, antenna materials, and

vessel pressure. See

Maximum Process Temperature Chart

Process Pressure Temperature derating curves are available in the full manual.

ambient temperature (surrounding enclosure)

–40 °C to +80 °C (–40 °F to +176 °F)

process temperature

PP rod:

–40 °C to +80 °C (–40 °F to +176 °F)

PTFE rod or SS horn:

–40 °C to +200 °C (–40 °F to +392 °F)

Power

.

on page 22, for more details.

device

nameplate

process device

tag

English

General Purpose:

Non-incendive (FM/US only):

Intrinsically Safe:

Flameproof:

Increased Safety:

Explosion-proof (FM/CSA US/Canada only):

Approvals

•General CSA

• Radio Europe (R&TTE), FCC, Industry Canada

1)

HART® is a registered trademark of HART Communication Foundation.

US/C

, FM, CE

Nominal 24 V DC at

max. 550 Ohm loop

resistance.

Nominal 24 V DC at

max. 250 Ohm loop

resistance.

(continued on next page)

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-3

• Hazardous Flameproof (Europe)

Increased Safety (Europe)

Explosion proof (US/Canada)

1)

2)

3)

English

Note: Use appropriate conduit seals to maintain IP or NEMA rating.

Approvals (continued)

• Hazardous

Non-incendive (US)

Intrinsically Safe

(Europe) ATEX II 1 G, EEx ia IIC T4

(US/Canada) FM/CSA: (barrier required)

Class I, Div. 1, Groups A, B, C, D

Class II, Div. 1, Groups E, F, G

Class III T4

(Australia) ANZEX Ex ia IIC T4

(Tamb = –40 to +80 °C) IP67

(International) IECEX TSA 04.0020X T4

• Marine Lloyd’s Register of Shipping

ABS Type Approval

4)

FM: (barrier not required)

Class I, Div. 2, Groups A, B, C, D T5

5)

ATEX II 1/2 G, EEx dm ia IIC T4

ATEX II 1/2 G, EEx em ia IIC T4

FM/CSA: (barrier not required)

Class I, Div. 1, Groups A, B, C, D

Class II, Div. 1, Groups E, F, G

Class III T4

Programmer (infrared keypad)

Siemens Milltronics Infrared IS (Intrinsically Safe) Hand Programmer for hazardous and all

other locations (battery is non-replaceable with a life expectancy of 10 years in normal use).

• approval ATEX II 1 G, EEx ia IIC T4, certificate SIRA 01ATEX2147

• FM/CSA: Class I, Div. 1, Groups A, B, C, D

• ambient temperature −20 to 40 °C (−5 to 104 °F)

• interface proprietary infrared pulse signal

• power 3 V lithium battery

• weight 150 g (0.3 lb)

• color black

• Part Number 7ML1930-1BK

1)

See

Flameproof wiring

2)

See

Increased safety wiring

3)

See

Explosion-proof wiring (FM/CSA US/Canada only)

4)

See

Non-incendive wiring (FM/US only)

5)

See

Intrinsically Safe wiring

Page EN-4 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

on page 9.

on page 10.

on page 10.

on page 11.

on page 11.

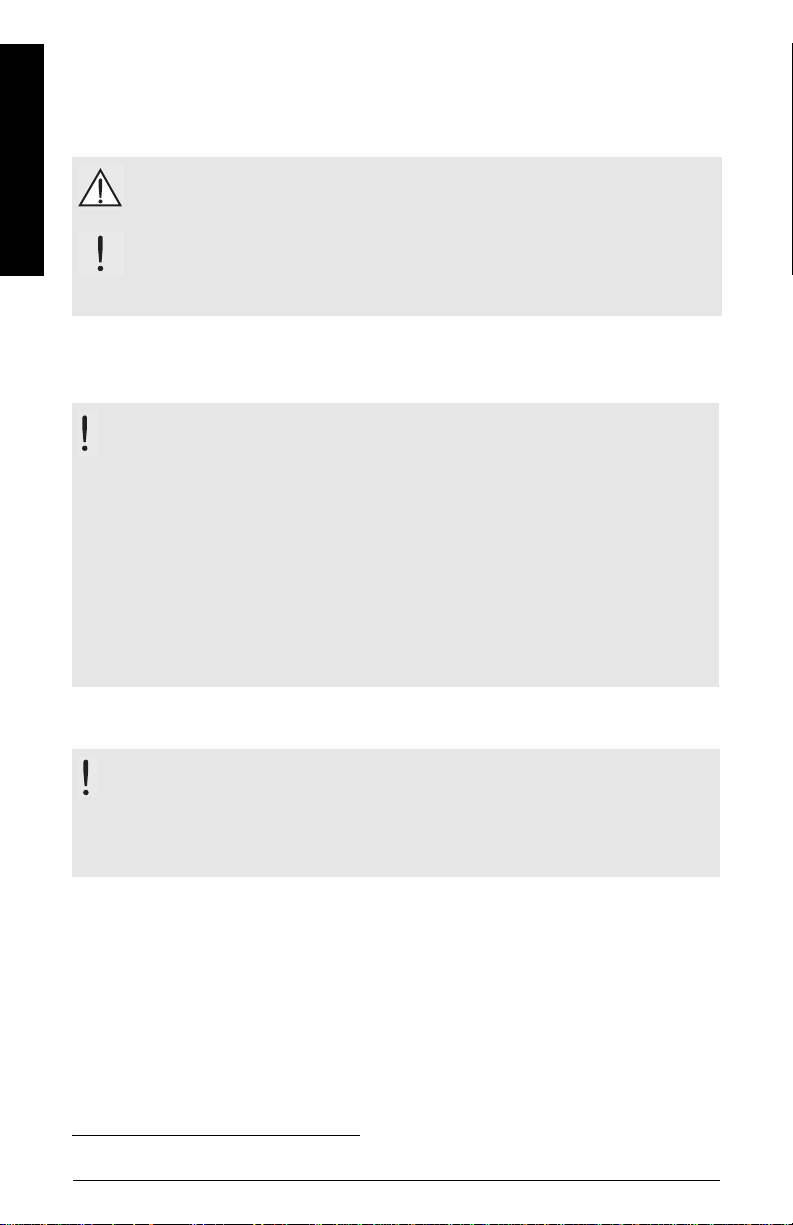

Pressure Application

WARNINGS:

• This product is designated as a Pressure Accessory per Directive 97 / 23 / EC, and

is not

intended for use as a safety device.

• Never attempt to loosen, remove, or disassemble process connection or

instrument housing while vessel contents are under pressure.

• Improper installation may result in loss of process pressure.

Installation

WARNINGS:

• Installation shall only be performed by qualified personnel and in

accordance with local governing regulations.

• Materials of construction are chosen based on their chemical compatibility (or

inertness) for general purposes. For exposure to specific environments, check

with chemical compatibility charts before installing.

Notes:

• The Process Device Tag shall remain with the process pressure boundary assembly1). In

the event the device package is replaced, the Process Device Tag shall be transferred to

the replacement unit.

• SITRANS LR200 units are hydrostatically tested, meeting or exceeding the requirements

of the ASME Boiler and Pressure Vessel Code and the European Pressure Equipment

Directive.

1)

English

Installation guidelines

• Provide easy access for viewing the display and programming via the hand programmer.

• Provide an environment suitable to the housing rating and materials of construction.

• Provide a sunshield if the device will be mounted in direct sunlight.

1)

The process pressure boundary assembly comprises the components that act as a barrier against

pressure loss from the process vessel: that is, the combination of process connection body and

emitter, but normally excluding the electrical enclosure.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-5

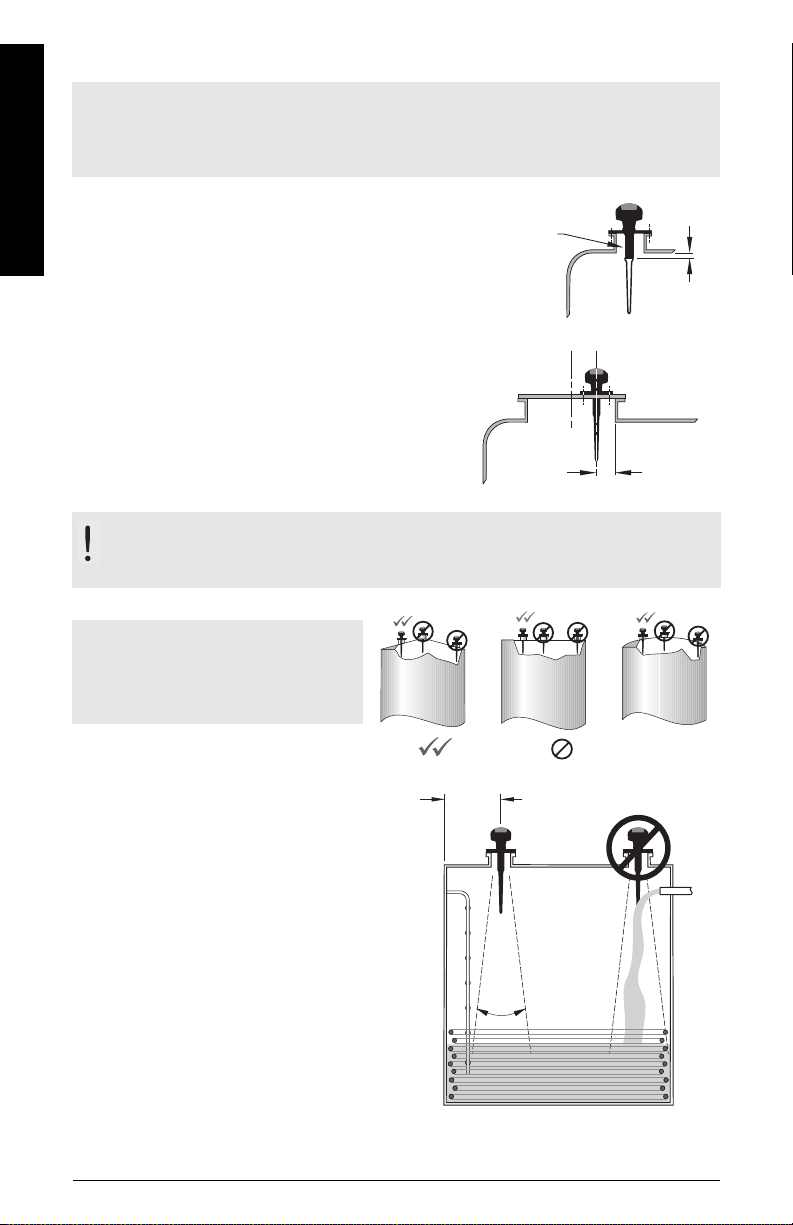

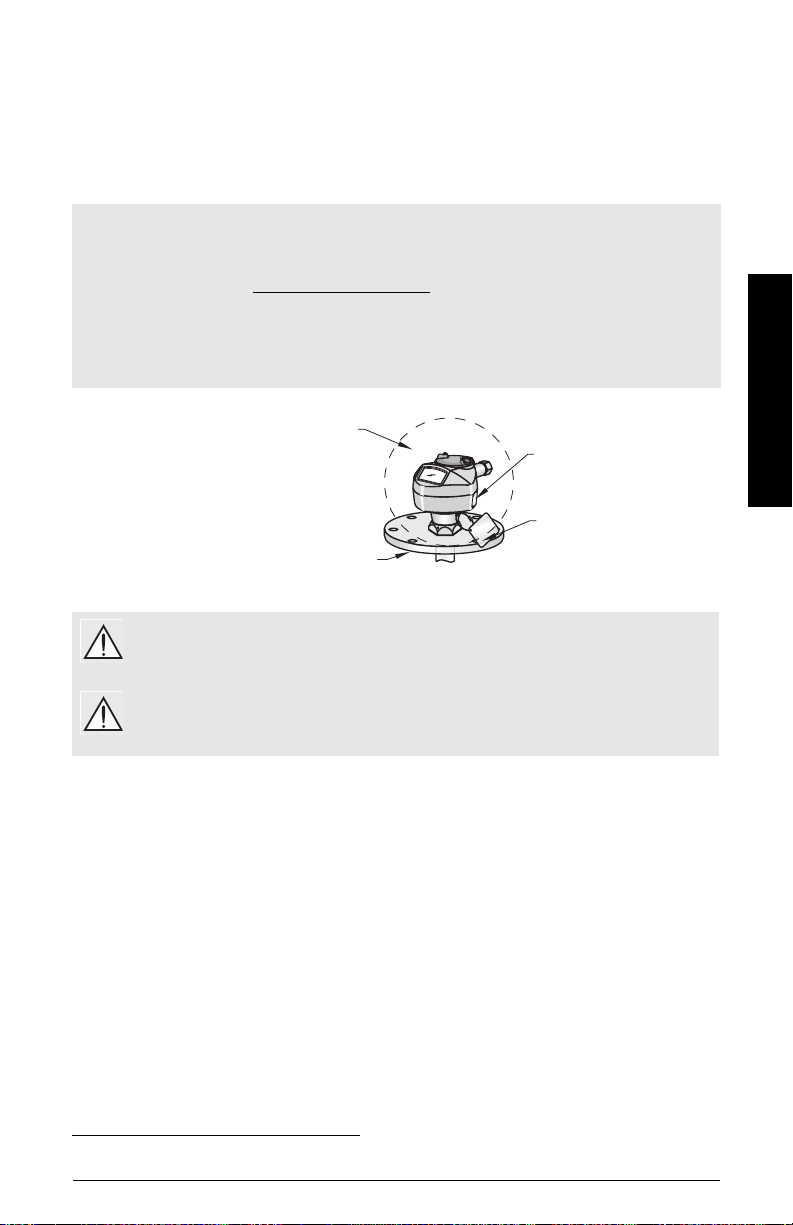

Nozzle design

Notes:

• For nozzles 100 mm (4") in length or shorter use the 100 mm (4") shield.

• For nozzles 250 mm (10") in length or shorter use the 250 mm (10") shield.

• For details on other applications, please see the full manual.

English

• The end of the shield section should protrude a minimum

of 10 mm (0.4”) to avoid false echoes being reflected from

the nozzle.

Location on a manhole cover

• A manhole cover is typically a covered nozzle with a

diameter 610 mm (24”) or greater.

• For optimum signal conditions, locate the antenna

off-center, typically 100 mm (4") from the side.

Nozzle location

WARNING: For vessels with conical or parabolic tops, avoid mounting the

instrument at the centre. (The concavity of the top can focus echoes into the centre,

giving false readings.)

shield

10 mm

(0.4")

100 mm (4")

Note: Under certain circumstances, it

may be acceptable to mount the device

at the centre of a flat-topped tank.

Please discuss this with your local

Siemens representative.

• Keep emission cone free of interference

from ladders, pipes, I-beams or filling

streams.

• Locate the antenna away from the side

wall, to avoid interference from indirect

echoes.

• Make allowance for the emission cone

spreading, to avoid interference with

vessel walls or obstructions.

Coni

Conical

preferred

beam

angle

20

Fl at

Flat

undesirable

min. 300 mm (1ft)

per 3 m (10’) of vessel

height

emission

cone

o

Parabolic

Page EN-6 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

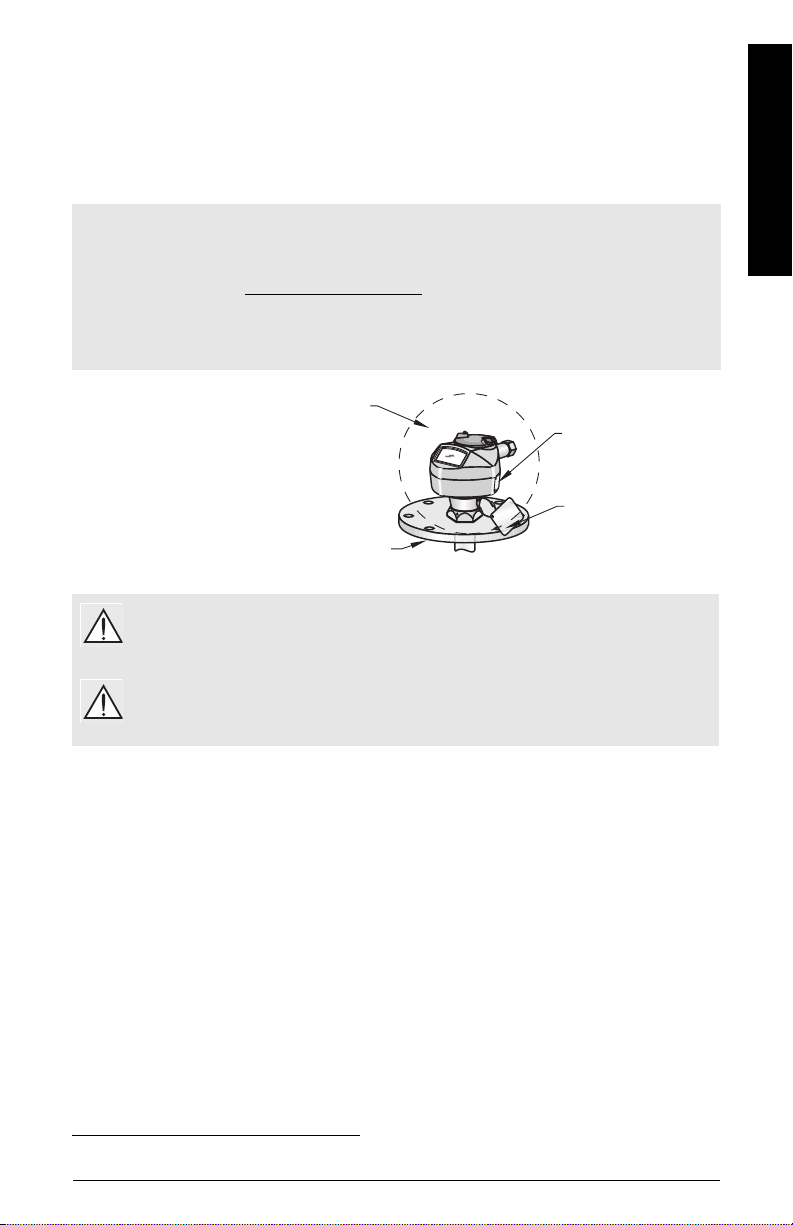

Installation instructions

Notes:

• There is no limit to the number of times the device can be rotated.

• Orient the front or back of the device towards the closest vessel wall.

• Do not rotate the enclosure after programming and device configuration (a polarity shift

of the transmit pulse may cause an error).

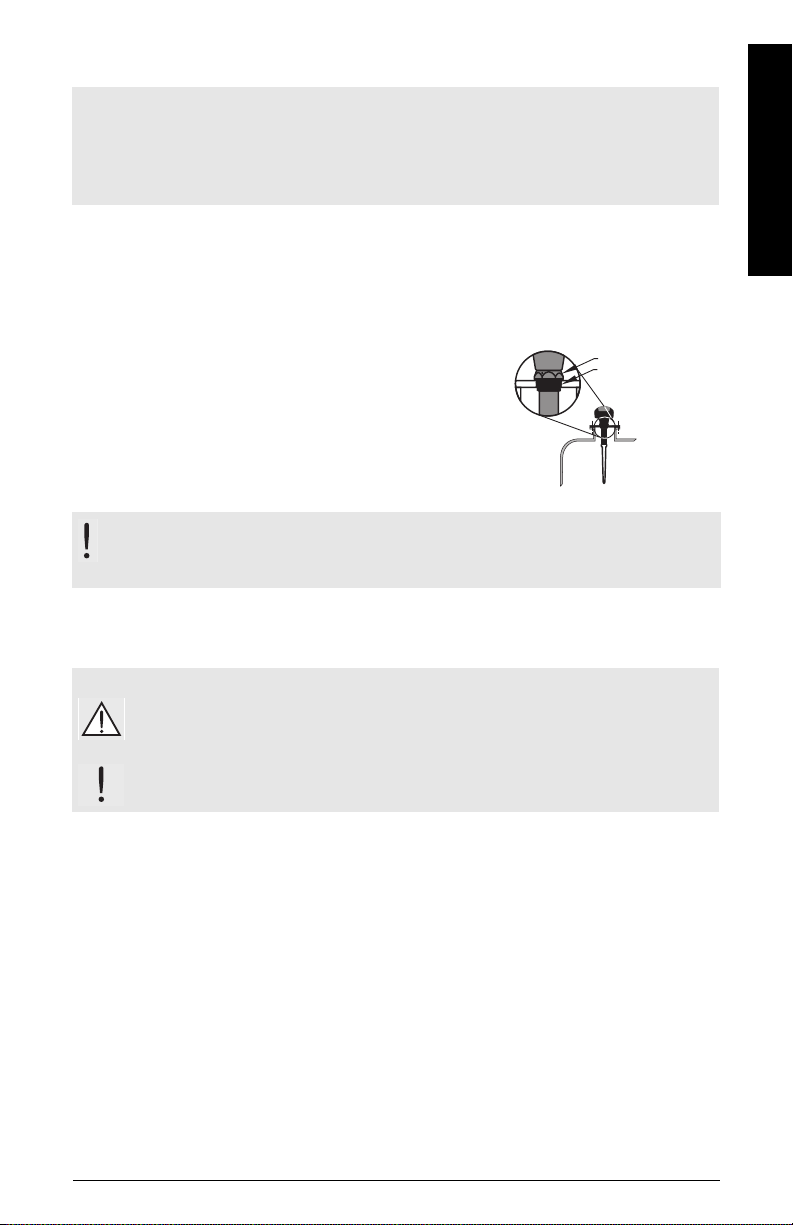

Threaded Version

1) Before inserting the device into its mounting connection, check to ensure the threads are

matching to avoid damaging them.

2) Screw the device into the process connection, and hand

tighten. For pressure applications, use PTFE tape or

other appropriate thread sealing compound, and tighten

the process connection beyond hand-tight (max. torque

40 N·m (30 ft.lbs).

3) To rotate the enclosure, first loosen the three set-screws

securing the locking ring. After positioning the

enclosure, retighten the screws.

locking ring

secured by three

2 mm Allen setscrews

threaded

connection

Flanged Version

WARNING: The user is responsible for the selection of bolting and gasket materials

which will fall within the limits of the flange and its intended use, and which are

suitable for the service conditions.

Wiring

Power

English

WARNINGS:

The DC input terminals shall be supplied from a source providing electrical

isolation between the input and output, in order to meet the applicable safety

requirements of IEC 61010-1.

All field wiring must have insulation suitable for rated voltages.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-7

Connecting SITRANS LR200

WARNINGS:

• Check the device nameplate and process device tag, to verify the approval rating.

• Use appropriate conduit seals to maintain IP or NEMA rating.

English

• Read

Notes:

• For detailed wiring instructions, please refer to the full Instruction Manual.

• Use twisted pair cable: AWG 22 to 14 (0.34 mm

• Separate cables and conduits

1) Use a 2 mm Allen key to loosen the lid-lock set screw

2) Strip the cable jacket for approximately 70 mm (2.75") from the end of the cable, and

3) Connect the wires to the terminal as shown: the polarity is identified on the terminal

4) Ground the device according to local regulations.

5) Tighten the gland to form a good seal.

6) Close the lid and secure the locking ring before programming and device configuration.

Instructions specific to hazardous area installations

2

may be required to conform to standard instrumentation

to 2.5 mm2).

on page 13.

wiring practices, or electrical codes.

2 mm lid-lock set screw.

then unscrew the cover.

thread the wires through the gland.

block.

Do not rotate the device after it has been configured, as this may cause an error.

cable shield

(if used)

Page EN-8 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

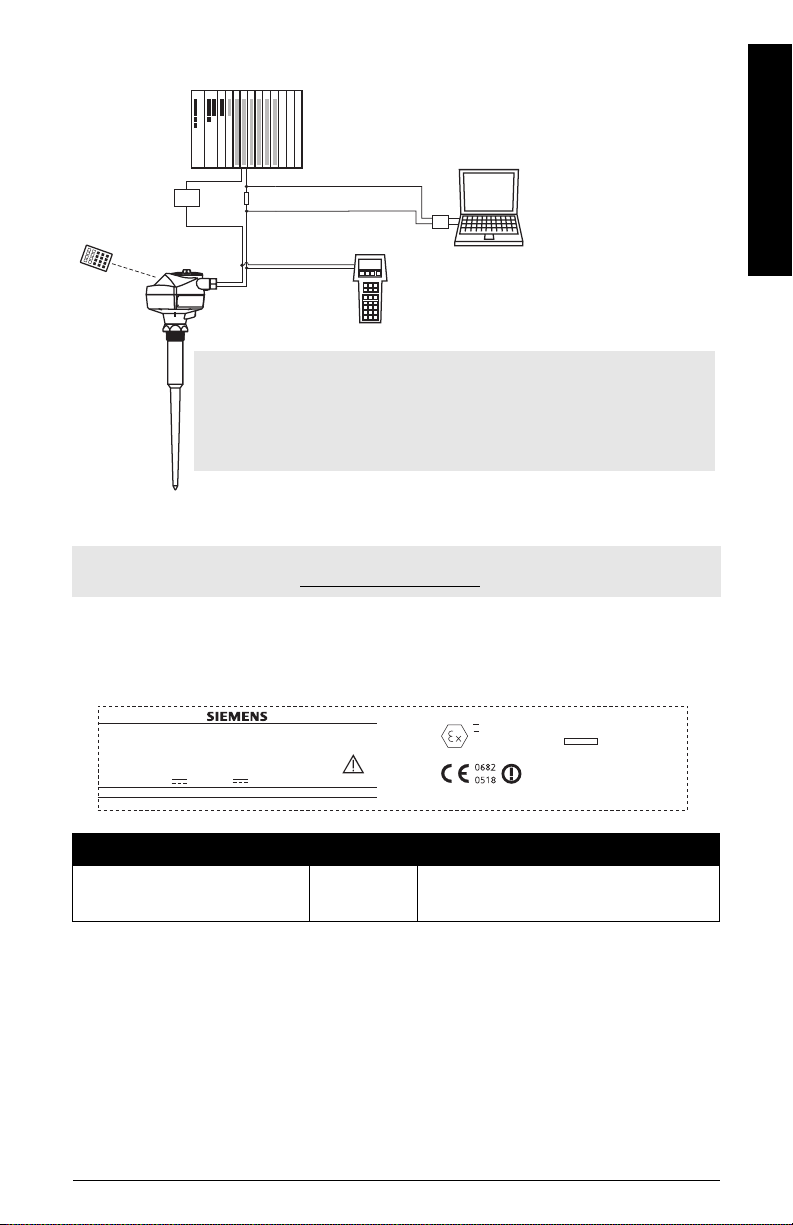

Connecting HART: typical PLC/mA configuration

active PLC

power

supply

SITRANS

LR200

R = 250 Ω

HART

modem

HART

communicator

Notes:

• Depending on the system design, the power supply may be separate

from the PLC, or integral to it.

• Loop resistance (total of cable resistance plus 250 Ohm [resistor]) must

be less than 550 Ohm for the device to function properly.

Wiring setups for hazardous area installations

Note: ATEX certificates and connection drawings listed below can be downloaded from the

product page of our website at: www.siemens.com/LR200.

There are five wiring options for hazardous area installations. In all cases, check the device

nameplate and process device tag to verify the approval rating.

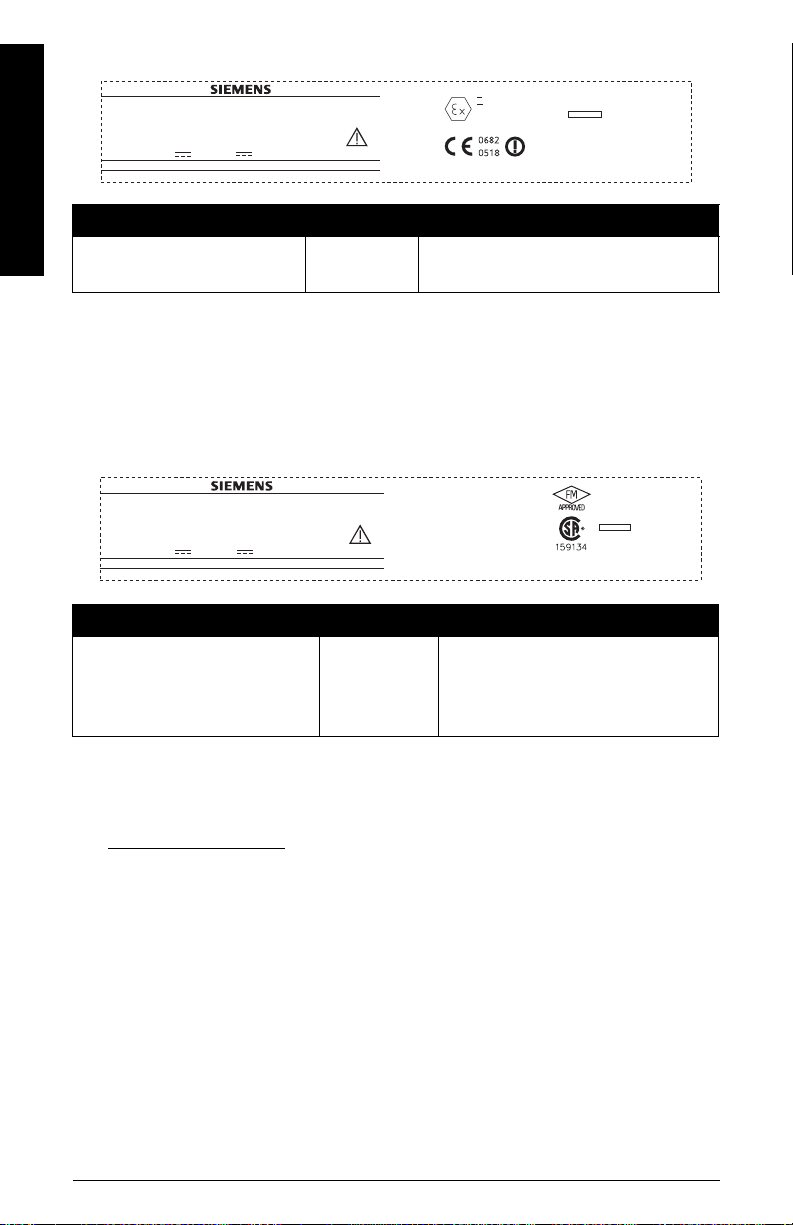

1. Flameproof wiring

English

SITRANSLR 200

7ML1234-56789-0ABC-D

SerialNo: GYZ/S1034567

Encl.:NEMA /TYPE 4X,6, IP67,IP68

Amb.Temp.:–40°Cto80 °C

PowerRating: 24V

Nom.,30 V

SiemensMilltronics ProcessInstruments Inc.,Peterborough

Madein Canada

Max.,4 -20mA

SIRA

II 1/2G

EEx dmia IIC T4

05ATEX1001X

HART

Um= 250V

Approval Rating Valid for: Reference

ATEX II 1/2 G, EEx dm ia IIC T4 Europe

• For power demands see

Curve 2 (Flameproof, Increased Safety, Explosion-proof)

page 23.

• For wiring requirements follow local regulations.

•See also

Instructions specific to hazardous area installations

certificate listed above.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-9

Flameproof/Increased Safety: ATEX Cer-

on page A-1.

tificate

on

on page 13 and the ATEX

2. Increased safety wiring

SITRANSLR 200

7ML1234-56789-0ABC-D

English

SerialNo: GYZ/S1034567

Encl.:NEMA /TYPE 4X,6, IP67,IP68

Amb.Temp.:–40°Cto80 °C

PowerRating: 24V

Nom.,30 V

SiemensMilltronics ProcessInstruments Inc.,Peterborough

Madein Canada

Max.,4 -20mA

SIRA

Approval Rating Valid for: Reference

ATEX II 1/2 G, EEx em ia IIC T4 Europe

• For power demands see

Curve 2 (Flameproof, Increased Safety, Explosion-proof)

page 23.

• For wiring requirements follow local regulations.

•See also

Instructions specific to hazardous area installations

certificate listed above.

Flameproof/Increased Safety: ATEX Certificate

3. Explosion-proof wiring (FM/CSA US/Canada only)

SITRANSLR 200

7ML1234-56789-0ABC-D

SerialNo: GYZ/S1034567

Encl.:NEMA /TYPE 4X,6, IP67,IP68

Amb.Temp.:–40°Cto80 °C

PowerRating: 24V

Nom.,30 V

SiemensMilltronics ProcessInstruments Inc.,Peterborough

Max.,4 -20mA

Madein Canada

Approval Rating Valid for: Reference

FM/CSA:

Class I, Div. 1, Groups A, B, C, D

Class II, Div. 1, Groups E, F, G

Class III T4

US/Canada

ClassI ;Div1; Group A,B, C,D

ClassII ;Div1; GroupE,F,G

ClassIII

Temp.Code:T4

P

erdrawing: 23650597

WARNING: Do Not Remove Cover While Circuits Are Live

FM/CSA Explosion Proof Connection

Drawing number 23650597

II 1/2 G

EEx emia IIC T4

05ATEX1001X

HART

Um= 250V

on page A-1.

on page 13 and the ATEX

FCCID: NJA-LR200

CANADA:267P-LR 200

HART

on

• For power demands see

Curve 2 (Flameproof, Increased Safety, Explosion-proof)

on

page 23.

• For wiring requirements (North America only) see the connection drawing listed above,

which can be downloaded from the product page of our website at:

www.siemens.com/LR200

.

Page EN-10 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

4. Non-incendive wiring (FM/US only)

7ML1234-56789-0ABC-D

SerialNo: GYZ/S1034567

Encl.:NEMA /TYPE 4X,6, IP67

Amb.Temp.:–40°Cto80 °C

PowerRating: 24V

Nom.,30V

SiemensMilltronics ProcessInstruments Inc.,Peterborough

Madein Canada

Max.,4-20mA

CANADA:267PFCCID:NJA-LR200

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions

1)This device may not cause harmful interference and

2)This device must accept any interference received,

including interference that may cause undesired operation

Class I, Div.2,

Group A,B,C,D

Temp.Code:T5

Approval Rating Valid for: Reference

FM:

Class I, Div. 2, Groups A, B, C, D T5

• For power demands, see

incendive)

on page 23.

US

Curve 1 (General Purpose, Intrinsically Safe, Non-

• For wiring requirements (North America only) see the connection drawing listed

above, which can be downloaded from the product page of our website at:

www.siemens.com/LR200

.

FM Non-Incendive Connection Drawing number 23650537

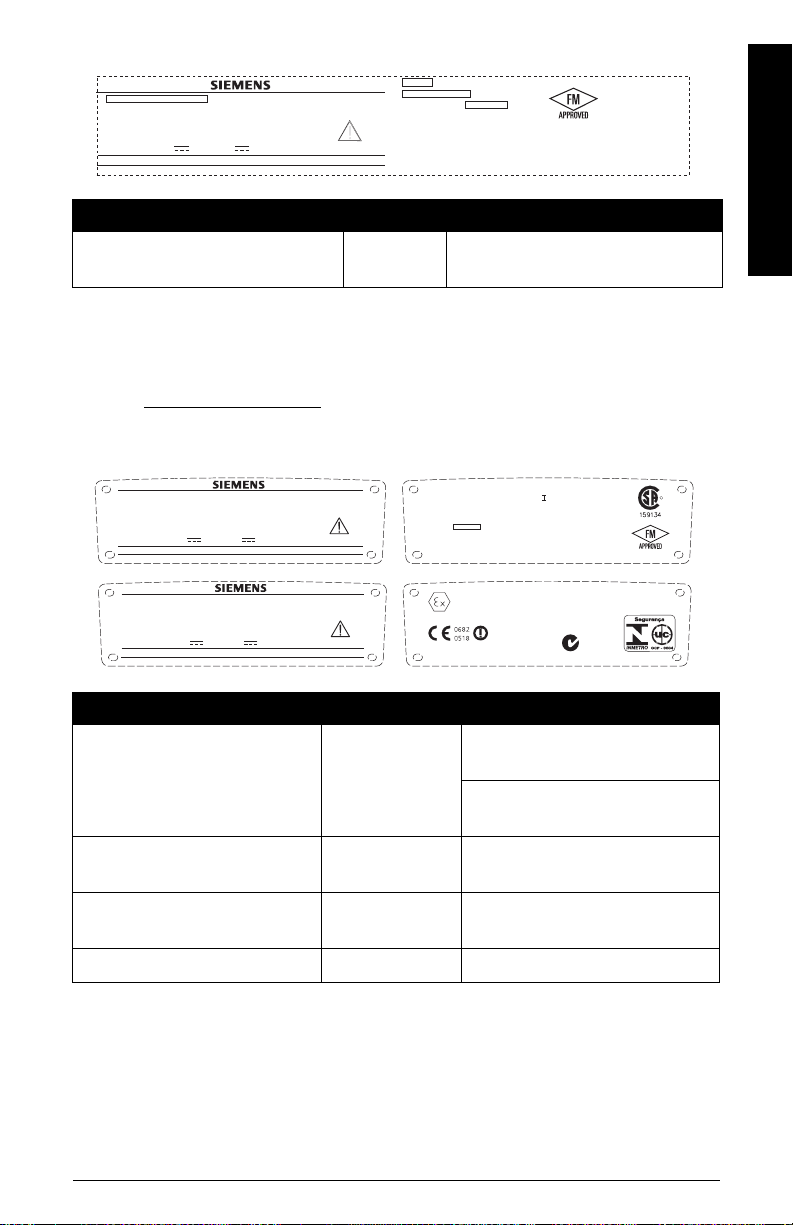

5. Intrinsically Safe wiring

SITRANS LR200

7ML1234-56789-0ABC-D

Serial No: GYZ / S1034567

Encl.: NEMA / TYPE 4X, 6, IP67, IP68

Amb.Temp.:– 40 °C to 80 °C

Power Rating: 24V

SITRANS LR200

7ML1234-56789-0ABC-D

Serial No: GYZ / S1034567

Encl.: NEMA / TYPE 4X, 6, IP67, IP68

Amb.Temp.:– 40 °C to 80 °C

Power Rating: 24V

Nom.,30 V

Siemens Milltronics Process Instruments Inc., Peterborough

Siemens Milltronics Process Instruments Inc., Peterborough

Made in Canada

Nom.,30 V

Made in Canada

Max.,4 -20mA

Max.,4 -20mA

Class I, Div 1, Group A, B, C, D

Class II, Div 1, Group E, F,G

Class III

Temp.Code: T4

HART

CSA per drawingA5E01003039

FM per drawing A5E01003040

WARNING: Possible Static Hazard, Do Not Rub Or Clean On Site

1GII

EEx ia IIC T4

SIRA 06ATEX2378X

HART 5.8 GHz

WARNING: PossibleStatic Hazard, Do Not Rub OrClean On Site.

Ui=30V

Ii = 120 mA

Pi = 0.8 W

Ci=15nF

Li = 0.1 mH

Vmax=30V

max = 120 mA

Pmax = 0.8 W

Ci=15nF

Li = 0.1 mH

IC: 267P-LR200

FCC ID: NJA-LR200

IECEx TSA 04.0020X

ANZEx 04.3016X

Ex ia IIC T4

N117

English

R

Approval Rating Valid for: Reference

FM/CSA:

Class I, Div. 1, Groups A, B, C, D

Class II, Div. 1, Groups E, F, G

US/Canada

Class III

ATEX II 1 G, EEx ia IIC T4 Europe

ANZEX Ex ia IIC T4

(Tamb = –40 to 80 °C) IP67

Australia

IECEX TSA 04.0020X International

• For power demands see

Curve 1 (General Purpose, Intrinsically Safe, Non-incendive)

page 23.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-11

FM Intrinsically Safe Connection

Drawing number A5E01003040

CSA Intrinsically Safe Connection

Drawing number A5E01003039

Intrinsically Safe: ATEX Certificate

on page A-5

on

• For wiring requirements:

N. America: See the connection drawings listed above, which can be

downloaded from the product page of our website at:

www.siemens.com/LR200

Europe: Follow local regulations.

Australia: Follow local regulations.

English

International: Follow local regulations.

• Use appropriate conduit seals to maintain IP or NEMA rating.

• Recommended intrinsically safe barriers are listed under

on page 12.

• Refer to

Instructions specific to hazardous area installations

certificate listed above.

.

Passive Shunt Diode Barriers

on page 13 and the ATEX

Note: Selecting a suitable PLC input module, power supply, or barrier requires knowledge

about Intrinsic Safety and the application. It is the responsibility of the installer to ensure that

the intrinsically safe installation complies with both the apparatus approval requirements and

the relevant national code of practice.

Passive Shunt Diode Barriers

Note: A well regulated supply voltage is required.

Manufacturer Part Number

MTL 787SP+ (Dual Channel)

MTL 7787P+ (Dual Channel)

Stahl 9001/01-280-100-10 (Single Channel)

Stahl 9002/01-280-110-10 (Dual Channel)

How to select a passive barrier for SITRANS LR200

To make sure that the barrier safety description is suitable for the LR200 Intrinsically Safe (IS)

input parameters, carry out the following calculations:

Re-e = max. end-to-end resistance of the barrier

Rloop = loop resistance (total of cable resistance plus e.g. sense resistance,

displays, and/or PLC inputs)

Vbarrier = value of any non-linear voltage drops due to the barrier

1) Determine the value for Re-e from the data sheet.

2) Calculate the total value for Rloop: by adding, for example, sense resistance, displays,

and/or PLC inputs.

3) Calculate Rworking = Re-e + Rloop.

Page EN-12 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

4) Determine the value of Vbarrier from the barrier data sheet (for example, voltage drops

due to diodes).

5) Calculate Vworking = Vsupply – Vbarrier.

Use the values for Vworking and Rworking to confirm that operation is within the shaded area

of the graph

Curve 1 (General Purpose, Intrinsically Safe, Non-incendive)

on page 23.

Notes:

• The following list is not exhaustive: there are many IS power supplies and barriers on the

market, which will work with the LR200.

• The PLC input modules and barriers listed below have all been tested and are functionally

compatible with the LR200.

Active barriers (repeating barriers)

Manufacturer Part Number

MTL 706

MTL 7206

Stahl 9001/51-280-110-14

Pepperl+Fuchs KSD2-CI-S-Ex

Pepperl+Fuchs KFD2-STC3-Ex1

MTL E02009 - verify

MTL E02010

Instructions specific to hazardous area installations

(Reference European ATEX Directive 94/9/EC, Annex II, 1/0/6)

The following instructions apply to equipment covered by certificate numbers

SIRA 06ATEX2378X, SIRA 05ATEX1001X:

1) For use and assembly, refer to the main instructions.

2) The equipment is certified for use as Category 1G equipment.

3) The equipment may be used with flammable gases and vapors with apparatus group IIC,

IIB, and IIA, and temperature classes T1, T2, T3, and T4.

4) The equipment is certified for use in an ambient temperature range of –40 °C to +80 °C.

5) The equipment has not been assessed as a safety related device (as referred to by

Directive 94/9/EC Annex II, clause 1.5).

6) Installation and inspection of this equipment shall be carried out by suitably trained

personnel in accordance with the applicable code of practice (EN 60079-14 and EN 6007917 in Europe).

English

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-13

7) The equipment is non-repairable.

8) The certificate numbers have an ‘X’ suffix, which indicates that special conditions for safe

use apply. Those installing or inspecting this equipment must have access to the

certificates.

9) If the equipment is likely to come into contact with aggressive substances, then it is the

English

responsibility of the user to take suitable precautions that prevent it from being adversely

affected, thus ensuring that the type of protection is not compromised.

Aggressive substances: e.g. acidic liquids or gases that may attack metals, or

solvents that may affect polymeric materials.

Suitable precautions: e.g. establishing from the material’s data sheet that it

is resistant to specific chemicals.

Activating SITRANS LR200

Power up the device. SITRANS LR200 automatically starts up in Measurement mode. (To

change the language displayed see

language)

on page 17.)

Selecting a listed option (for example, selecting a

The LCD Display

Measurement mode

1342

LEVEL

1)

((((normal operation)

[]

M

18.91

21.40 °C

DATA EXCH.

678

Fault present

S: 0 LOE

PROGRAM mode

Navigation view

• A visible menu bar indicates

the menu list is too long to

display all items.

• A deeper item band represents

a shorter menu list.

7 – text area displays a fault code and an error message

8 – service required icon appears

1 – toggle indicator for linear units or %

2 – selected operation: level, space, or distance

3 – measured value (level or volume, space, or distance)

4 – units

5 – bar graph indicates level

1)

6 – secondary region indicates on request

temperature, echo confidence, loop current, or distance

7 – text area displays status messages

8 – device status indicator

5

current

menu

item

band

menu

bar

LEVEL METER

QUICK START

SETUP

DIAGNOSTICS

SERVICE

electronics

1

current

item

number

current

item

pointer

1)

In response to a key press request: see

Page EN-14 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

Key functions in Measurement mode

on page 15.

Parameter view Edit view

parameter

number

parameter

value/

selection

parameter

name

MATERIAL

PREVIOUS

NEXT

1.1

LIQUID

EDITBACK

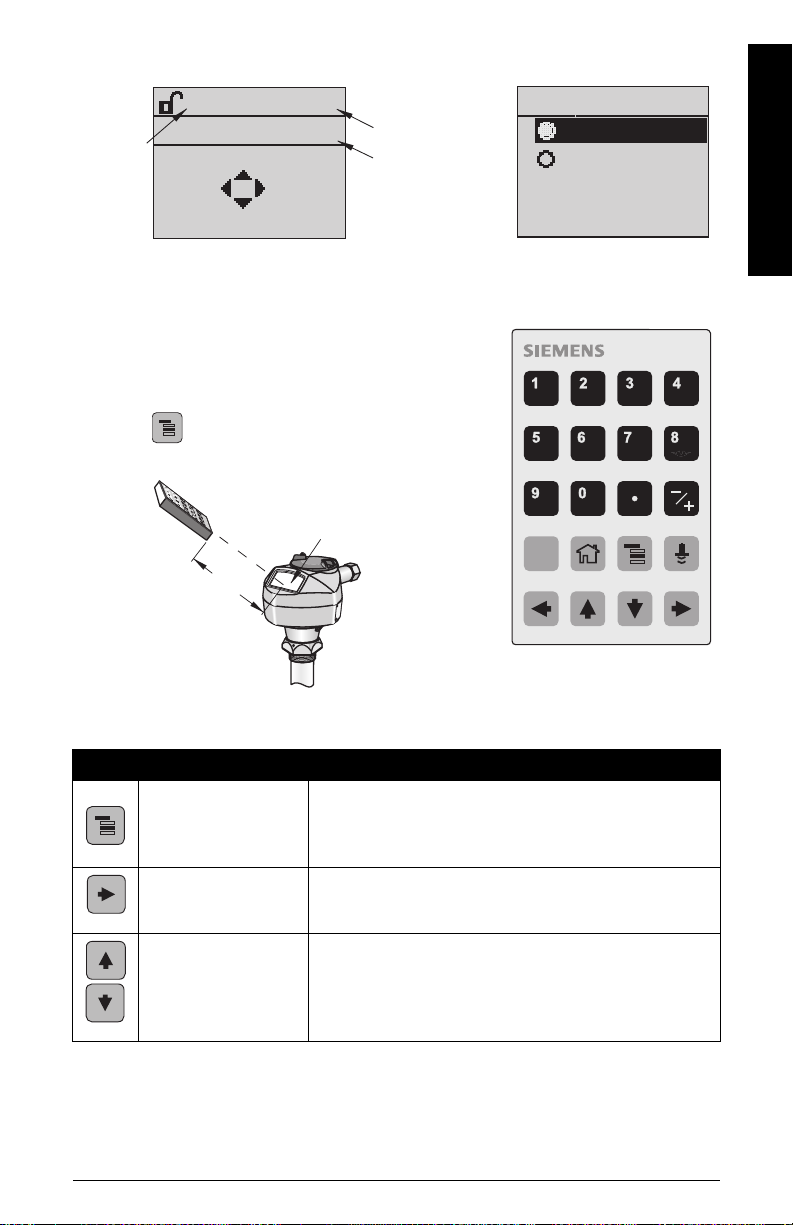

Handheld Programmer

(Part No. 7ML1930-1BK)

The programmer is ordered separately.

• Point the programmer at the display (from a maximum

distance of 300 mm [1 ft.]).

• Press Mode to toggle between Measurement

and PROGRAM mode.

handheld programmer

display

Max. 300 mm

(1 ft)

MATERIAL

LIQUID

LIQUID LOW DK

C

1.1

English

Key functions in Measurement mode

Key Function Result

Opens the menu level last displayed in this power cycle, or

Mode opens PROGRAM mode.

RIGHT arrow

opens PROGRAM

mode.

UP or DOWN arrow

toggles between linear

units and percent.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-15

menu level 1 if power has been cycled since exiting PRO-

GRAM mode or more than 10 minutes have elapsed since

PROGRAM mode was used.

Opens menu level 1.

LCD displays measured value in either linear units or per-

cent.

Key Function Result

Updates the loop current.

Updates internal

enclosure tempera-

English

ture reading.

Updates echo confi-

dence value.

Updates distance mea-

surement.

New value is displayed in LCD secondary region.

Programming SITRANS LR200

Note: SITRANS LR200 automatically returns to Measurement mode after a period of

inactivity in PROGRAM mode (between 15 seconds and 10 minutes, depending on the menu

level).

Settings can be modified locally via the Local User Interface or remotely via SIMATIC PDM.

The Local User Interface (LUI) consists of an LCD display and a handheld programmer.

•See

Quick Start Wizard via the handheld programmer

Quick Start Wizard via SIMATIC PDM

•See

on page 21.

Parameter menus

Note: For the complete list of parameters with instructions, see the full manual. It can be

downloaded from the product page of our website at: www.siemens.com/LR20 0.

on page 18.

Parameters are identified by name and organized into

function groups, then arranged in a 5-level menu

structure.

1. QUICK START

2. SETUP

3. DIAGNOSTICS

3.14. MEAS. VALUES

3.14.1. CURR. INTERN. TEMP.

Accessing parameters via the handheld programmer

1. Enter PROGRAM mode

a) Point the programmer at the display from a maximum distance of 300 mm (1 ft).

b) Press RIGHT arrow to open menu level 1.

Page EN-16 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

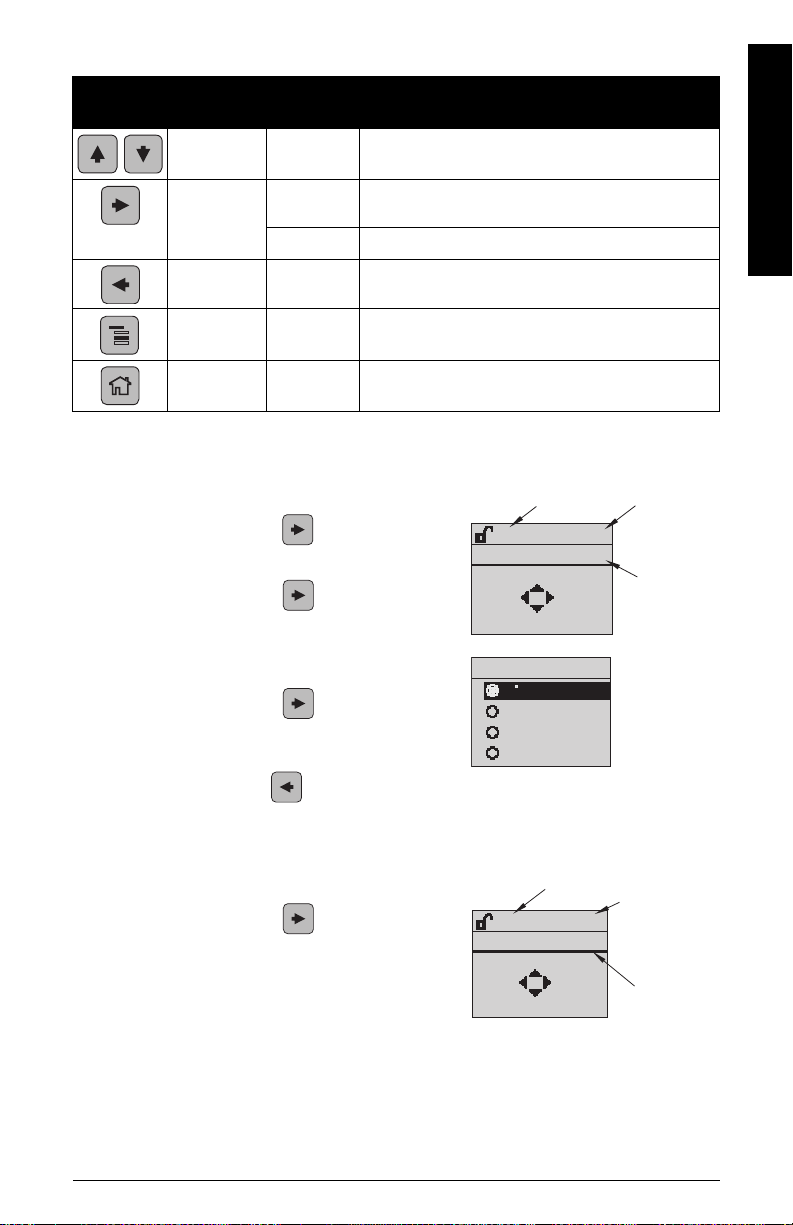

2. Navigating: key functions in Navigation mode

Key Name

UP or DOWN

arrow

RIGHT arrow

LEFT arrow

Mode

Home

Menu

level

menu or

parameter

menu

Function

• Scroll to previous or next menu or parameter.

• Go to first parameter in the selected menu

• or open next menu.

parameter • Open Edit mode.

menu or

parameter

menu or

parameter

menu or

parameter

• Open parent menu.

• Change to MEASUREMENT mode.

• Open menu level 1.

3. Editing in PROGRAM mode

Selecting a listed option (for example, selecting a language)

a) Navigate to Language (7).

b) Press RIGHT arrow to open parameter

view.

c) Press RIGHT arrow again to open Edit

mode. The current selection is highlighted.

parameter name

LANGUAGE

BACK

PREVIOUS

NEXT

ENGLISH

EDIT

7

parameter

number

current

selection

English

d) Scroll to a new selection.

LANGUAGE

7

ENGLISH

Press RIGHT arrow to accept it. The

LCD returns to parameter view and displays

the new selection.

GERMAN

FRENCH

SPANISH

e) Press LEFT arrow to return to the menu.

Changing a numeric value

a) Navigate to the desired parameter.

b) Press RIGHT arrow to open parameter

view. The current value is displayed.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-17

parameter name

LOW CALIB. 1.5

20.00 M

PREVIOUS

EDITBACK

NEXT

parameter

number

current

value

c) Press RIGHT arrow again to open Edit mode. The

current value is highlighted.

d) Key in a new value, and press RIGHT arrow to accept

it.

English

The LCD returns to parameter view and displays the new

selection.

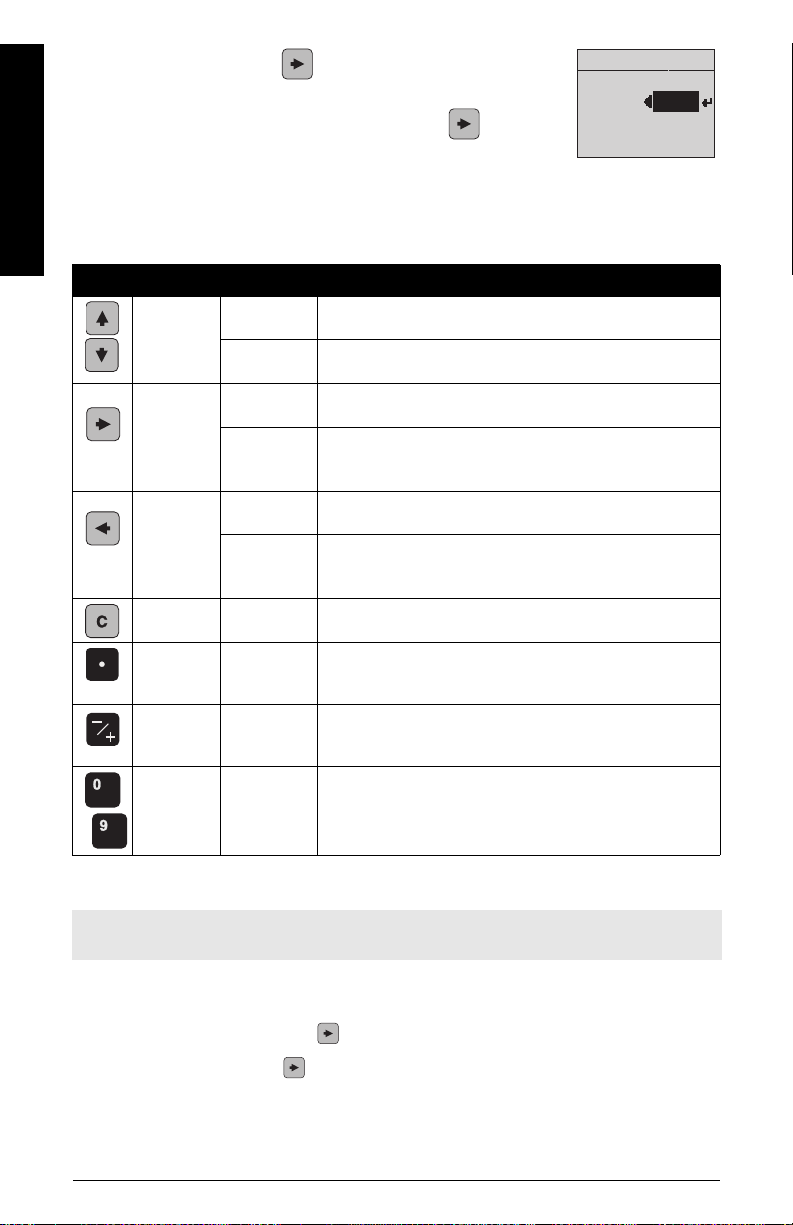

Key functions in Edit mode

Key Name Function

UP or

DOWN

arrow

RIGHT arrow

LEFT arrow

Clear

Selecting

options

Numeric

editing

Selecting

options

Numeric

editing

Selecting

options

Numeric

editing

Numeric

editing

LOW CALIB.

1.5

+20.00

• Scrolls to item.

• Increments or decrements digits

• Toggles plus/minus sign

• Accepts the data (writes the parameter)

• Changes from Edit to Navigation mode

• Moves cursor one space to the right

• or with cursor on Enter sign, accepts the data and changes

from Edit to Navigation mode

•Cancels Edit mode without changing the parameter

•Moves cursor to plus/minus sign if this is the first key

pressed

• or moves cursor one space to the left.

• Erases the display.

M20.00

Decimal

point

Plus/minus

sign

Numeral

to

Numeric

editing

Numeric

editing

Numeric

editing

• Enters a decimal point.

• Changes the sign of the entered value.

• Enters the corresponding character.

Quick Start Wizard via the handheld programmer

Note: Each time the Quick Start Wizard is initiated, the start-up settings are factory defaults.

The Wizard will not recall previous user-defined settings.

1. Quick Start

a) Point the programmer at the display (from a maximum distance of 300 mm [1 ft.]),

then press RIGHT arrow to activate PROGRAM mode and open menu level 1.

b) Press RIGHT arrow twice to navigate to menu item 1.1 and open parameter

view.

Page EN-18 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

c) Press RIGHT arrow to open Edit mode or DOWN arrow to accept default

values and move directly to the next item.

d) To change a setting, scroll to the desired item or key in a new value.

e) After modifying a value, press RIGHT arrow to accept it and press DOWN arrow

to move to the next item.

f) Quick Start settings take effect only after you select Ye s to Apply changes in

step 1.7.

1.1. Material

Options

LIQUID

LIQUID LOW DK (low dielectric liquid)

1.2. Response Rate

Sets the reaction speed of the device to measurement changes in the target range.

SLOW 0.1 m/minute

Options

MED 1.0 m/minute

FAST 10.0 m/minute

Use a setting just faster than the maximum filling or emptying rate (whichever is greater).

1.3. Sensor Units

Selects the units for the Quick Start variables (high and

low calibration point, and level, distance, or space).

Options

M, CM, MM, FT, IN

1.4. Operation

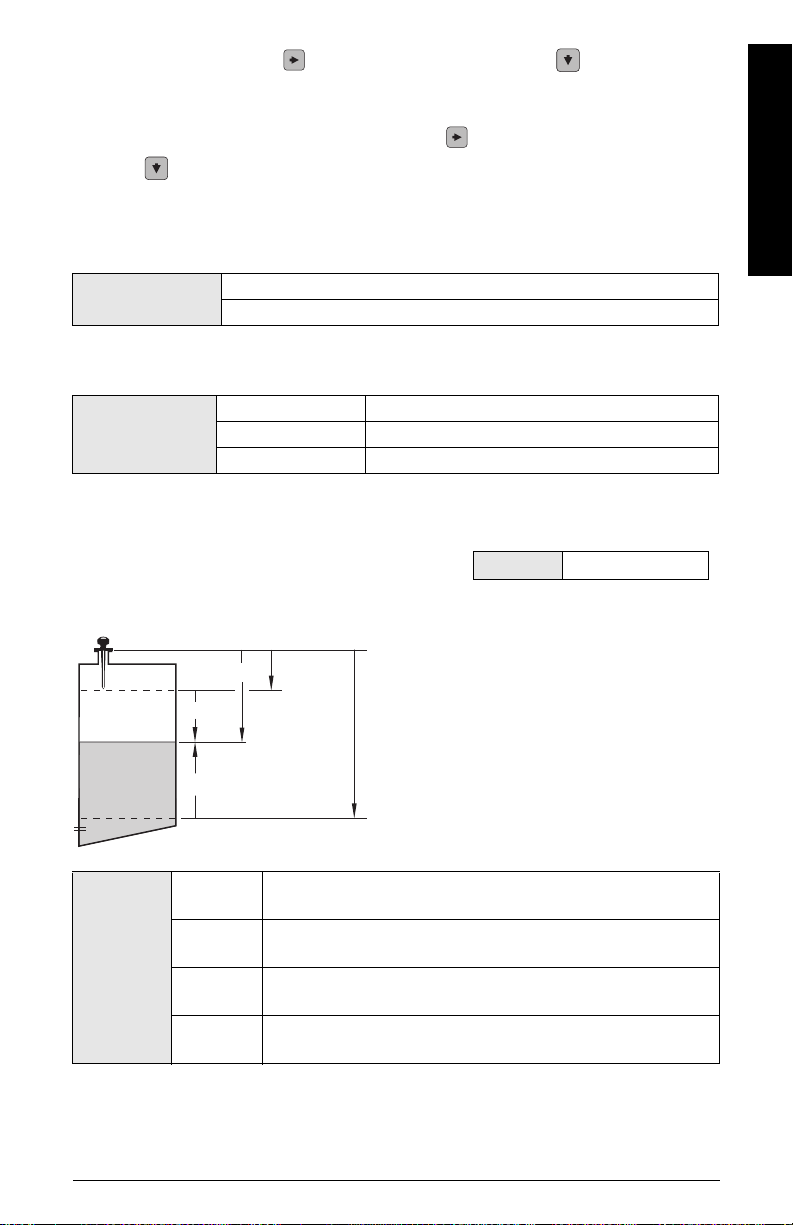

sensor

reference

point

space

distance

high cal.

point

English

level

low cal.

point

Operation

types

NO

SERVICE

LEVEL

SPACE

DISTANCE

The SITRANS LR200 stops updating measurements and associated loop current. Last valid measurement is displayed.

Distance to material surface referenced from Low Calibration

Point (process empty level).

Distance to material surface referenced from High Calibration

Point (process full level).

Distance to material surface referenced from Sensor Reference

Poi nt.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-19

1.5. Low Calibration Point

Distance from Sensor Reference to Low Calibration Point: usually process empty level.

Values

Range: 0.0000 to 20.000 m

1.6. High Calibration Point

Distance from Sensor Reference to High Calibration Point: usually process full level.

English

Values

Range: 0.0000 to 20.000 m

1.7. Apply? (Apply changes)

In order to save the Quick Start settings it is necessary to select Yes to apply changes.

Options

YES, NO

Display shows DONE when Quick Start is successfully completed.

Press Mode to return to Measurement mode. SITRANS LR200 is now ready to operate.

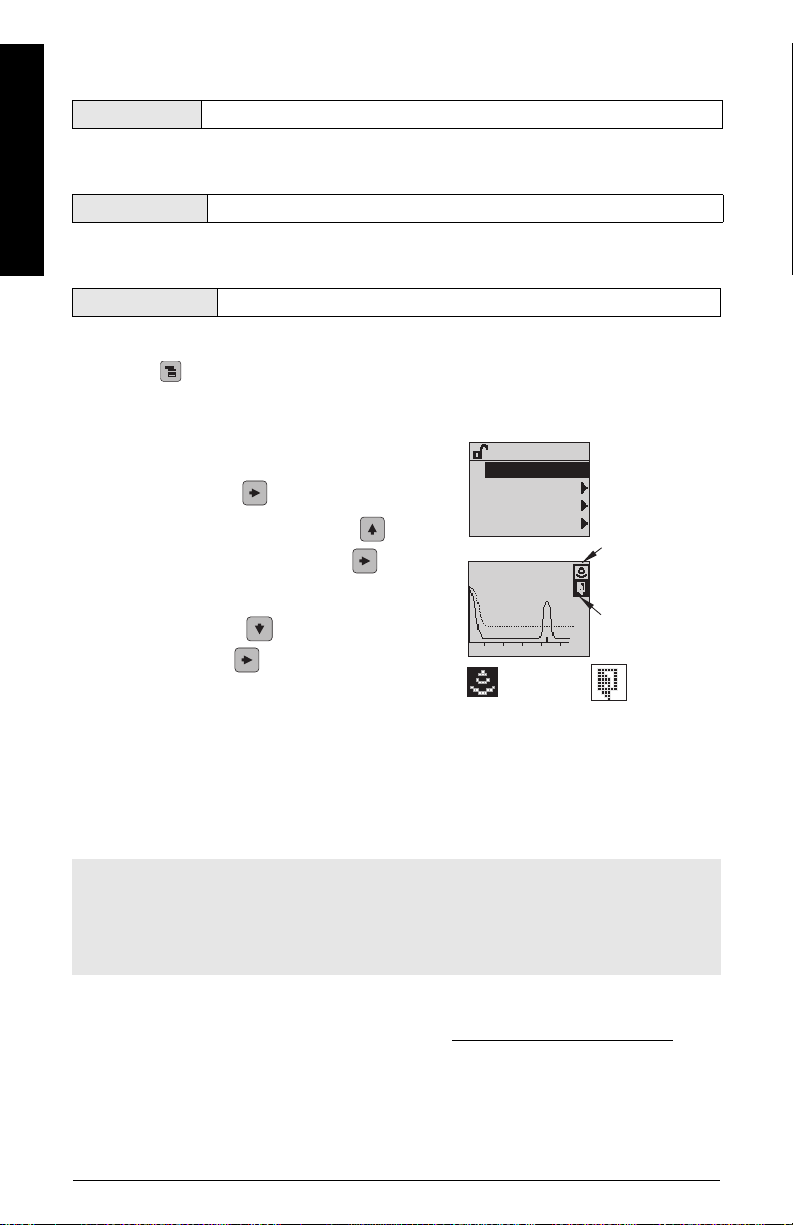

Requesting an Echo Profile

1) In PROGRAM mode, navigate to: Level Meter >

Diagnostics (3) > Echo Profile (3.1).

2) Press RIGHT arrow to request a profile.

3) In the Profile screen, press UP arrow to select

the Transmit icon, and RIGHT arrow to update

the profile.

4) Press DOWN arrow to select the Exit icon,

then RIGHT arrow to return to previous menu.

DIAGNOSTICS

ECHO PROFILE

MEAS. VALUES

REMAIN. DEV. LIFE

RE .MAIN SENS.LIFE

C:38 A:TF D:4.25

12345

transmit icon,

selected

3.1

transmit icon,

deselected

exit icon,

selected

exit icon,

deselected

SITRANS LR200 Communications: HART

• You will need the full manual to acquire the list of applicable parameters.

• We recommend that you use SIMATIC Process Device Manager (PDM) to program your

device.

SIMATIC PDM

Notes:

• SIMATIC PDM Rev. 6.0 SP3 or higher is recommended.

• SIMATIC PDM Rev. 5.2 SP1 is supported only for basic configuration and troubleshooting.

For advanced features such as the Quick Start wizard, Revision 6.0 SP3 or higher is

required.

SIMATIC PDM is a software package used to commission and maintain SITRANS LR200 and

other process devices. Please consult the operating instructions or online help for details on

using SIMATIC PDM. (You can find more information at: www.siemens.com/simatic-pdm

Products and Solutions > Products and Systems > Communications and Software > Process

Device Manager.)

Page EN-20 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

. Go to

Electronic Device Description (EDD)

• You can locate the EDD in Device Catalog, under Sensors/Level/Echo/Siemens

Milltronics/SITRANS LR200.

• Check the product page of our website at: www.siemens.com/LR200

to make sure you have the latest version of SIMATIC PDM, the most recent Service Pack

(SP) and the most recent hot fix (HF). If you need to install a new EDD see

new device

below.

, under Downloads,

Configuring a

Configuring a new device

Note: Clicking on Cancel during an upload from device to SIMATIC PDM will result in some

parameters being updated.

1. Check that you have the most recent EDD, and if necessary download it from the product

page listed above. Save the files to your computer, and extract the zipped file to an easily

accessed location. Launch SIMATIC PDM – Manager Device Catalog, browse to the

unzipped EDD file and select it.

2. Launch SIMATIC PDM and create a new project for LR200. Application Guides for setting

up HART devices with SIMATIC PDM can be downloaded from the product page of our

website at: www.siemens.com/LR200

3. Upload parameters to the PC/PG.

4. Configure the device via the Quick Start wizard (see below).

.

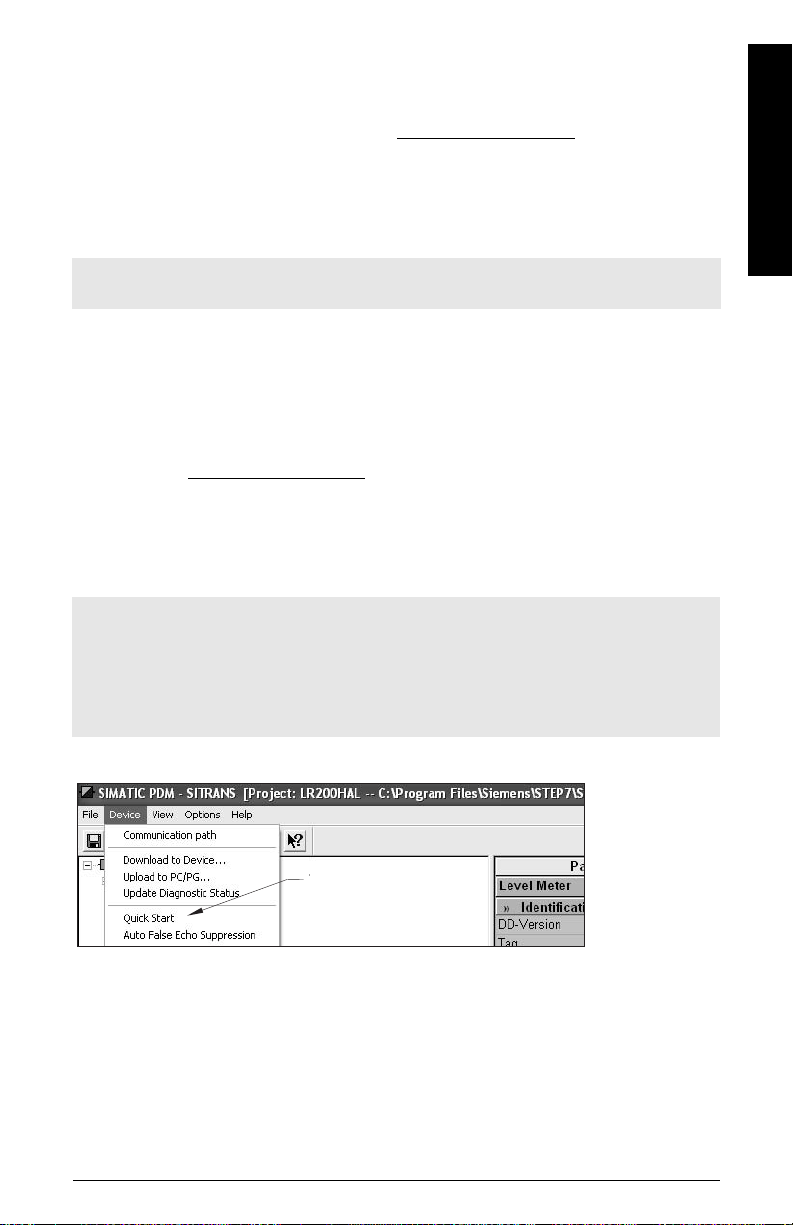

Quick Start Wizard via SIMATIC PDM

Notes:

• The Quick Start wizard settings are inter-related and changes apply only after you click on

Transfer at the end of step 5.

• Each time the Quick Start Wizard is initiated, the start-up settings are factory defaults.

The Wizard will not recall previous user-defined settings.

• Click on BACK to return and revise a setting or Cancel to exit the Quick Start.

English

Launch SIMATIC PDM, open the menu Device – Quick Start, and follow steps 1 to 5.

Quick

Start

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-21

Maintenance

SITRANS LR200 requires no maintenance or cleaning under normal operating conditions. If

cleaning becomes necessary under severe operating conditions:

1. Note the antenna material and the process medium, and select a cleaning solution that

will not react adversely with either.

2. Remove the device from service and wipe the antenna clean using a cloth and suitable

English

cleaning solution.

Unit Repair and Excluded Liability

For detailed information, please see the inside back cover.

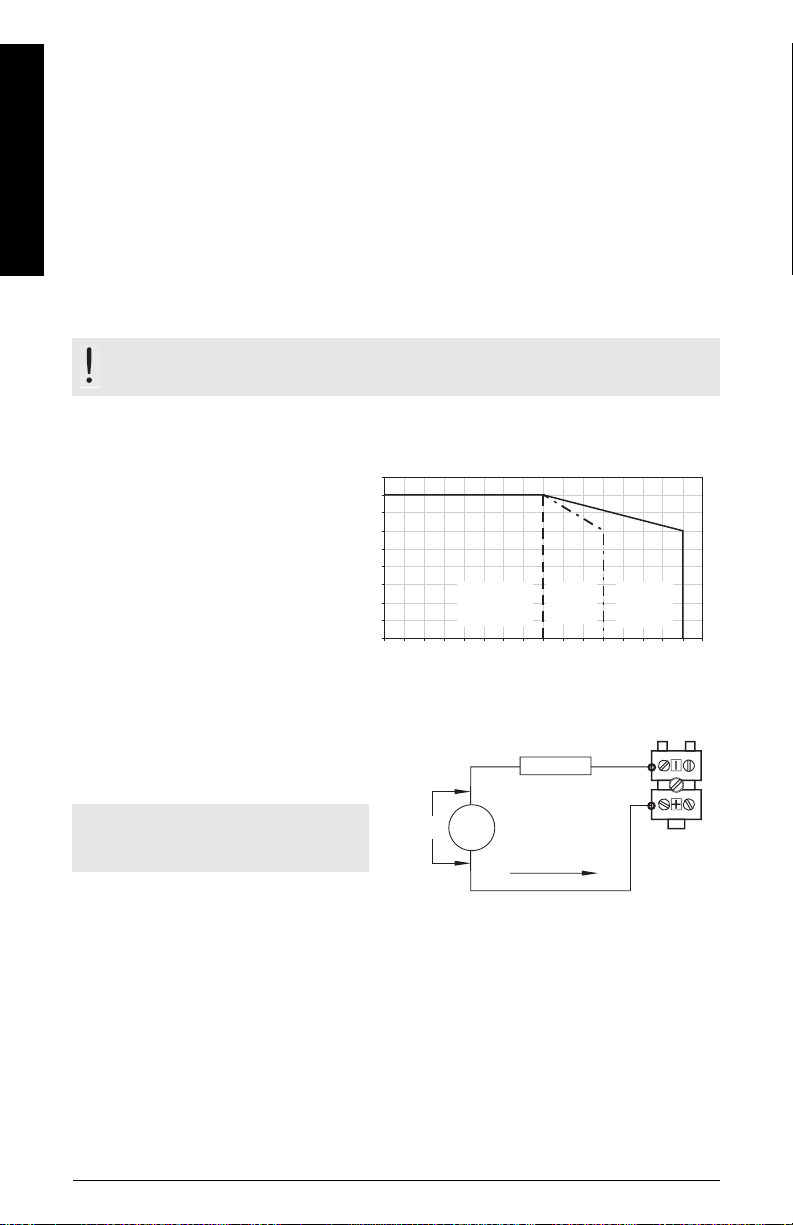

Maximum Process Temperature Chart

WARNING: Internal temperature must not exceed 80 °C (176 °F).

Maximum Flange and Process Temperatures versus allowable ambient

for flange adapter versions of SITRANS LR200

• The chart is for guidance only.

• It does not represent every

possible process connection

arrangement. For example, it will

NOT apply if SITRANS LR200 is

mounted directly on a metallic

vessel surface.

• It does not take into consideration

heating from direct sunshine

exposure.

• You can use parameter 3.14.1 to

monitor the current internal temperature.

90

80

C)

o

70

60

50

40

30

20

10

Ambient Temperature (

0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

Process Flange Surface Temperature (oC)

PP rod

temperature

(no flange)

flange

tempera-

ture

process

tempera-

ture

Loop power

Typical connection drawing

Note: Loop voltage is the voltage at the

terminals of the power supply (not the

voltage at the terminals of the device).

Page EN-22 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

loop

voltage

VL

power

supply

-

+

loop resistance

RL

loop current IL

LR200

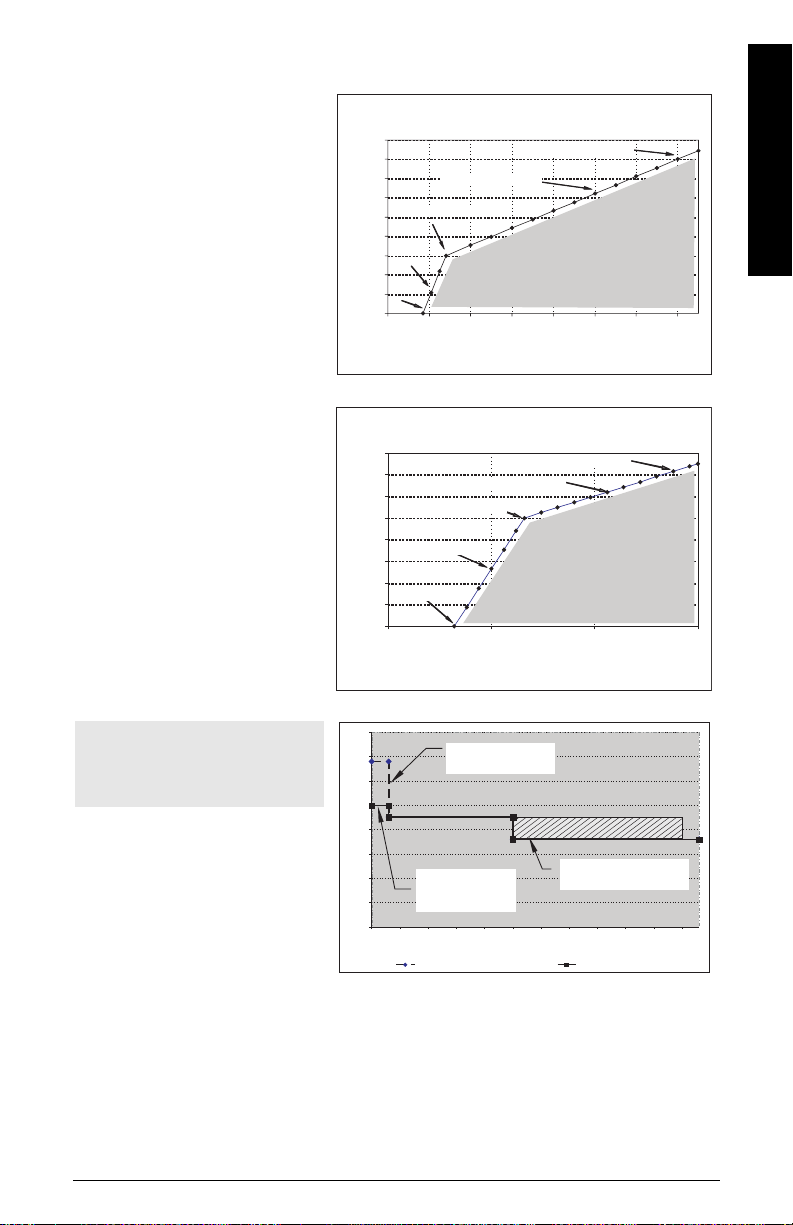

Allowable operating area

Curve 1 (General Purpose,

Intrinsically Safe, Non-

incendive)

Loop Voltage versus Loop

Resistance

Curve 2

(Flameproof,

Increased Safety, Explosionproof)

Loop Voltage versus Loop Resistance

Startup Curve

Note: At startup, it can take

anywhere from 25 to 55 seconds

for the device to report the actual

material level.

Power Supply Requirements

Curve 1: Power Supply Requirements

900

800

L

700

600

500

400

300

Loop Resistance - R

200

Loop Resistance – RL

100

0

RL=44.6*VL – 493.4

(17.8v, 300 ohms)

RL=272.7*VL – 4554.1

(16.7v, 0 ohms)

15 17 19 21 23 25 27 29

Loop Voltage – VL

Power Supply Requirements

Curve 2: Power Supply Requirements

400

350

L

300

RL=272.7*VL – 4554.1

250

200

(30.0v,845 ohms)

150

100

Loop Resistance - R

(16.7v, 0 ohms)

50

Loop Resistance – RL

0

15 20 25 30

(17.8v, 300 ohms)

Loop Voltage – VL

40

35

30

25

20

Current(mA)

15

Current (mA)

10

5

0

0 5 10 15 20 25 30 35 40 45 50 55

Loop Power Supply

(no Current Limit)

Loop Power

Supply with 25 mA

Current Limit

No Current Limit Current LimitedPower Supply

No current limit

(30.0v,845 ohms)

ALLOWABLE

OPERATING AREA

Loop Voltage- V

(Source Voltage)

RL=44.6*VL – 493.4

ALLOWABLE

OPERATING AREA

Loop Voltage - V

(Source Voltage)

actual material level

(example value 18 mA)

Time (secs)

Time (seconds)

L

L

Current-limited power

English

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Page EN-23

English

Notes

Page EN-24 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

SITRANS LR200 (HART) med Siemens LBI Interface: Quick Start manual

Denne manual opridser de væsentligste karakteristika og funktioner af SITRANS LR200

(HART). Vi anbefaler Dem kraftigt at anskaffe den detaljerede version af denne manual, så De

kan anvende apparatet fuldt ud. Den komplette manual kan downloades fra produktsiden for

SITRANS LR200 på vores website: www.siemens.com/LR200

Deres lokale Siemens Milltronics repræsentant.

Spørgsmål vedrørende indholdet af denne manual kan rettes til:

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

E-mail: techpubs.smpi@siemens.com

Copyright Siemens Milltronics

Process Instruments Inc. 2008.

Ansvarsfragåelse

Alle rettigheder forbeholdes

Vi opfordrer brugerne til at anskaffe de

autoriserede, indbundne manualer eller

læse de elektroniske versioner, der er

udarbejdet og skrevet af Siemens

Milltronics Process Instruments Inc.

Siemens Milltronics Process Instruments

Inc. påtager sig intet ansvar for indholdet af

delvise eller fuldstændige gengivelser af

indbundne eller elektroniske versioner.

Skønt vi har kontrolleret, at indholdet af denne

manual stemmer overens med de beskrevne

instrumenter, kan der stadig forekomme variationer.

Vi kan derfor ikke garantere en fuldstændig

overensstemmelse. Indholdet af denne manual

revideres jævnligt, og eventuelle rettelser inkluderes i

de efterfølgende udgaver. Vi modtager gerne forslag

til forbedringer.

Retten til ændringer af de tekniske data forbeholdes.

. Den trykte manual kan fås hos

Dansk

MILLTRONICS er et registreret varemærke, der tilhører Siemens Milltronics Process Instruments Inc.

Teknisk Support

Support er tilgængelig 24 timer i døgnet.

Adresse, telefon- og faxnummer på Siemens Automations lokale kontor kan findes på:

www.siemens.com/automation/partner:

• Klik på fanebladet Contacts by Product

produktgruppe (+Process Automation

Instrumentation

(Niveaumålingsinstrumenter)

• Vælg teamet Technical Sup port

• Klik på et kontinent, derefter et land og til slut en by. Klik på Next.

For on-line teknisk support, gå til: www.siemens.com/automation/support-request

• Indtast apparatets navn (SITRANS LR200) eller ordrenummeret, klik på Search

vælg den relevante produkttype. Klik på Next.

• Indtast et nøgleord, der beskriver problemet. Gennemløb derefter den relevante

dokumentation eller klik på Next for at e-maile en beskrivelse af problemet til personalet i

Siemens Tekniske Support.

Siemens A&D Technical Support Center: telefon +49 180 50 50 222

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Side DK-1

(Procesinstrumentering)

).

(Kontakter pr. produkt)

(Procesautomatisering)

> +Level Measuring Instruments

(Teknisk assistance)

fax +49 180 50 50 223

og find den relevante

> +Process

. Klik på Next

(Næste)

.

(Søg)

og

Sikkerhedsvejledning

De anførte advarsler skal overholdes for at sikre egen og andres sikkerhed samt for at

beskytte produktet og det tilknyttede udstyr. Advarslerne ledsages af en tydeliggørelse af

graden af forsigtighed, der bør overholdes.

ADVARSEL: vedrører et advarselssymbol på produktet og betyder, at en

manglende overholdelse af de nødvendige forholdsregler kan føre til død, alvorlig

personskade og/eller omfattende materielle skader.

ADVARSEL

forholdsregler kan føre til død, alvorlig personskade og/eller omfattende

materielle skader.

1)

: betyder, at en manglende overholdelse af de nødvendige

1)

Bemærk: betyder vigtige oplysninger om produktet eller denne del af brugsvejledningen.

FCC-overensstemmelse

Kun for installationer i USA: Regler fra Federal Communications

Dansk

Commission (FCC)

ADVARSEL: Ændringer eller modifikationer, der ikke er udtrykkeligt godkendt af

Siemens Milltronics, kan ophæve brugerens ret til at benytte udstyret.

Bemærkninger:

• Dette udstyr er blevet testet og fundet at overholde grænserne for et klasse A digitalt

udstyr i henhold til Afsnit 15 i FCC-reglerne. Disse grænser er beregnet til at yde en

rimelig beskyttelse mod skadelige interferenser, når udstyret anvendes i kommercielle

omgivelser.

• Dette udstyr frembringer, bruger og kan udstråle radiofrekvent energi, og kan, såfremt det

ikke installeres og bruges i overensstemmelse med instruktionsbogen, forårsage

interferens, der kan virke forstyrrende for radiokommunikationen. Brugen af dette udstyr i

et beboelsesområde vil sandsynligvis forårsage skadelig interferens med

radiokommunikationer, som brugeren i givet fald vil være nødsaget til at udbedre for egen

regning.

SITRANS LR200

ADVARSEL: SITRANS LR200 bør kun anvendes som beskrevet i denne manual, da

den beskyttelse, udstyret yder, ellers kan forringes.

Bemærk: Dette produkt er beregnet til anvendelse i industriområder. Brugen af dette udstyr i

et beboelsesområde kan forårsage interferens med forskellige frekvensbaserede

kommunikationer.

SITRANS LR200 er en totråds 6 GHz pulsradarniveautransmitter til kontinuert overvågning af

væsker og opslæmninger i lager- og procestanke, inklusive ved højt tryk og høj temperatur, i en

afstand af op til 20 m (66 ft).

Dette apparat består af et elektronisk kredsløb, der er koblet til antennen, og en

procestilslutning af enten gevind- eller flangetypen.

1)

Dette symbol anvendes, når der ikke er noget tilsvarende advarselssymbol på produktet.

Side DK-2 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

Kommunikationen foregår via HART.1) Signaler behandles ved hjælp af Process Intelligence.

Tekniske data

For en fuldstændig liste, se SITRANS LR200 (HART) Instruktionsbogen. For oplysninger om

godkendelser henvises der til apparatets typeskilt og procesudstyrskilt.

Omgivende temperatur/Driftstemperatur

Bemærkninger:

• De tilladelige procestemperaturer og –tryk afhænger af oplysningerne på

procesudstyrskiltet. Referencetegningen, der er angivet på dette skilt, kan downloades fra

Siemens' website på: www.siemens.com/LR200

• Den maksimale temperatur afhænger af procestilslutningen, antennematerialerne og

trykket i beholderen. Se

Diagram over maksimale procestemperaturer

yderligere detaljer. Kurver over procestryk- og temperaturreduktionen findes i den

komplette manual.

omgivende temperatur (omkring huset)

–40 °C til +80 °C (–40 °F til +176 °F)

procestemperatur

PP-stav:

–40 °C til +80 °C (–40 °F til +176 °F)

PTFE-stav eller SS-horn:

–40 °C til +200 °C (–40 °F til +392 °F)

Strømforsyning

.

på side 22 for

apparatets

typeskilt

procesudstyrskilt

Dansk

Almen brug:

Ikke-antændingsfarlig (kun FM/US):

Egensikker:

Flammesikker:

Forhøjet sikkerhed:

Eksplosionssikker (kun FM/CSA US/Canada):

Nominel 24 V dc med

max. 550 Ohm

sløjfemodstand.

Nominel 24 V dc med

max. 250 Ohm

sløjfemodstand.

Godkendelser

• Almen brug CSA

• Radio Europa (R&TTE), FCC, Industry Canada

1)

HART® er et registreret varemærke, der tilhører HART Communication Foundation.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Side DK-3

US/C

, FM, CE

(fortsættes på næste side)

• Risikoområder Flammesikker (Europa)

Forhøjet sikkerhed (Europa)

Eksplosionssikker (USA/Canada)

1)

ATEX II 1/2 G, EEx dm ia IIC T4

2)

ATEX II 1/2 G, EEx em ia IIC T4

3)

FM/CSA: (barriere ikke påkrævet)

Klasse I, Div. 1, Gruppe A, B, C, D

Klasse II, Div. 1, Gruppe E, F, G

Klasse III T4

Bemærk: Brug passende kabelrørstætninger for at bevare IP- eller NEMA-klassificeringen.

Godkendelser (fortsat)

Dansk

• Risikoområder

Ikke-antændingsfarlig (USA)

Egensikker

5)

(Europa) ATEX II 1 G, EEx ia IIC T4

(USA/Canada) FM/CSA: (barriere påkrævet)

Klasse I, Div. 1, Gruppe A, B, C, D

Klasse II, Div. 1, Gruppe E, F, G

Klasse III T4

(Australien) ANZEX Ex ia IIC T4

(Tomg = –40 til +80 °C) IP67

(Internationalt) IECEX TSA 04.0020X T4

• Maritimt Lloyd’s Skibsregister

ABS Typegodkendelse

4)

FM: (barriere ikke påkrævet)

Klasse I, Div. 2, Gruppe A, B, C, D T5

Programmeringsenhed (infrarødt tastatur)

Siemens Milltronics infrarøde IS (Intrinsically Safe - Egensikre) håndholdte

programmeringsenhed til risikoområder og alle andre steder (batteriet kan ikke udskiftes men

har en forventet levetid på 10 år ved normal brug).

• godkendelse ATEX II 1 G, EEx ia IIC T4, certifikat SIRA 01ATEX2147

FM/CSA: Klasse I, Div. 1, Gruppe A, B, C, D

• omgivende temperatur −20 til 40 °C (−5 til 104 °F)

• interface proprietært infrarødt pulssignal

• strømforsyning 3 V lithiumbatteri

• vægt 150 g (0,3 lb)

•farve sort

• Del nummer 7ML1930-1BK

1)

Se

Flammesikker elinstallation

2)

Se

Elinstallation med forhøjet sikkerhed

3)

Se

Eksplosionssikker elinstallation (kun FM/CSA US/Canada)

4)

Se

Ikke-antændingsfarlig elinstallation (kun FM/US)

5)

Se

Egensikker elinstallation

Side DK-4 SITRANS LR200 (HART) – QUICK START MANUAL 7ML19985XC81

på side 9.

på side 10.

på side 10.

på side 11.

på side 11.

Anvendelser under tryk

ADVARSLER:

• Dette produkt betegnes som trykbærende udstyr i henhold til direktivet 97 / 23 / EF

og er ikke

beregnet til brug som sikkerhedsanordning.

• Forsøg aldrig at løsne, afmontere eller adskille procestilslutningen eller

instrumenthuset, mens indholdet er under tryk.

• Ukorrekt installation kan medføre tab af procestryk.

Installation

ADVARSLER:

• Installationen må kun foretages af kvalificeret personale og under

overholdelse af de lokalt gældende regler.

• Konstruktionsmaterialerne er valgt på basis af deres kemiske kompatibilitet (eller

inerti) ved almindelig brug. Hvis de skal udsættes for særlige omgivelser, bør

foreneligheden kontrolleres i tabeller over kemisk kompatibilitet inden

installationen.

Bemærkninger:

• Procesudstyrskiltet skal forblive sammen med grænsefladen til procestrykket1). Såfremt

apparatpakken udskiftes, skal procesudstyrskiltet overføres til erstatningsenheden.

• SITRANS LR200 enhederne er hydrostatisk testet og opfylder eller er bedre end kravene i

ASME Boiler and Pressure Vessel Code samt det europæiske Trykudstyrsdirektiv.

1)

Installationsvejledning

• Sørg for en lettilgængelig adgang for aflæsning af displayet og programmering ved hjælp

af den håndholdte programmeringsenhed.

• Sørg for, at omgivelserne svarer til instrumenthusets klassificering og

konstruktionsmaterialer.

• Hvis apparatet skal monteres i direkte sollys, bør det forsynes med en solafskærmning.

Dansk

1)

Grænsefladen til procestrykket omfatter de komponenter, der fungerer som en barriere mod tryktab

fra procestanken: det vil sige kombinationen af procestilslutningsdelen og emitteren, men normalt

eksklusive den elektriske indkapsling.

7ML19985XC81 SITRANS LR200 (HART) – QUICK START MANUAL Side DK-5

Loading...

Loading...