Siemens LMU54 Series,LMU64 Series Basic Documentation

HVAC Products

LMU54... / LMU64...

Boiler Management Unit (BMU)

Basic Documentation

Software version 2. 08

CC1P7494en

07.11.2002

Siemens Building Technologies

Safety notes

Caution: The present Basic Documentation describes the broad range of applications and functions

offered by the LMU... and shall serve as a guideline. The correct functioning of the unit must

be checked and confirmed by functional tests on the boiler and / or on the relevant plant!

• Degree of protection IP 40 to EN 60 529 for burner controls must be ensured by the burner or boiler

manufacturer by adequately mounting the LMU...

• In the geographical areas where DIN standards apply, mounting and installation must be in compliance

with the relevant VDE requirements, especially DIN / VDE 0100, 0550 and DIN / VDE 0722!

• The electrical wiring inside the boiler must conform to country-specific and local regulations!

• Where (S)LTs are required, refer to the safety-related notes given in section «Electronic (S)LT»!

• It must be ensured that spliced individual wires cannot get in contact with adjacent terminals.

Use adequate ferrules!

• Prior to commissioning, check wiring and parameterization carefully!

The boiler manufacturer is responsible for the correct parameterization of the LMU..., which must be in

compliance with the relevant standards and regulations!

• When commissioning the plant, check all safety functions!

• Before performing any wiring changes or other work in the connection area of the LMU…, completely

isolate the unit from the mains supply!

• Lay high-voltage ignition cable completely separate from all other cables!

• Ensure protection against electric shock hazard on the LMU… and on all electrical connections

through appropriate mounting!

• There is no absolute protection against incorrect use of the RAST5 connectors.

For this reason, check the correct connector assignments prior to commissioning the plant!

• The burner manufacturer must ensure protection against electric shock hazard on all AC 230 V terminals

by fitting dummy plugs!

• When wiring the unit, AC 230 V mains voltage and extra low-voltage must always be run strictly

separate to warrant protection against electric shock hazard!

− DIN EN 60335

− DIN EN 60730-2-5

• Protect the mains-powered ionization probe against electric shock hazard!

The LMU… is a safety device!

• Do not open, interfere with or modify the unit!

• Siemens is not liable for damage resulting from unauthorized interference!

• In the event of blown fuses inside the LMU..., return the unit to Siemens!

(Customer may replace mains fuse F1 only once)

• Electromagnetic emissions must be checked on an application-specific basis!

To ensure the safety and reliability of the LMU..., the following points must also be observed:

− Condensation, formation of ice and ingress of water are not permitted!

If such conditions have occurred, make certain the unit is completely dry before switching on!

− Static charges must be avoided as they can damage the unit’s electronic components when touching them

Recommendation: Use ESD equipment !

2/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 07.11.2002

Contents

1 Overview ..........................................................................................10

− Brief description..........................................................................10

1.1 System concept ..................................................................................10

1.2 Features............................................................................................11

− Safety functions ..........................................................................11

− Supervision / protective functions for the plant .................................11

− Auxiliary modules (clip-in) .............................................................11

− DHW .........................................................................................12

− Heating circuit.............................................................................12

− System application ......................................................................12

− Operation / service......................................................................12

− Parameterization.........................................................................13

− Mains transformer........................................................................13

− Other features .............................................................................13

1.3 Product range.....................................................................................13

1.4 Field of use ........................................................................................13

− Target market .............................................................................13

− Heating plants .............................................................................13

− Heat generating equipment ...........................................................13

1.5 Notes on product liability......................................................................14

1.6 Notes on environmental protection........................................................14

− Disposal notes ............................................................................14

2 Product range overview ....................................................................15

3 Functions ..........................................................................................17

3.1 Burner control ....................................................................................17

− Program selection .......................................................................17

− EEPROM...................................................................................17

− Forced intermittent operation ........................................................17

− Burner control program ................................................................17

− Sequence diagram ......................................................................18

− Capacity range < 70 kW ............................................................18

− Capacity range 70...120 kW.......................................................18

− Capacity range > 120 kW..........................................................19

− Description of sequence diagrams..............................................19

− Sequence times.......................................................................20

− Standby..................................................................................20

− Startup ...................................................................................20

− Shutdown................................................................................22

− Home run ................................................................................22

− Special cases (deviations).........................................................22

− LMU... plausibility checks of the speed parameters .......................24

− Parameterization of speed feedback signal..................................24

− Fan parameters accessible via QAA ...........................................25

− The different capacity ranges .....................................................26

− Setting the fan parameters during startup and shutdown................27

− Speed readjustment .................................................................28

3.2 Selection of the compensation variants..................................................30

3/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

− Heating circuits ...........................................................................30

− Room setpoint ............................................................................ 32

− Configuration of the heating circuits ...............................................34

− DHW circuit................................................................................ 35

3.3 Acquisition of actual values .................................................................. 37

− Assignment of analog sensors ...................................................... 37

− Temperatures ............................................................................. 37

− Display of ionization current ..........................................................38

3.4 Supervisory functions .......................................................................... 39

− Temperature limiter function......................................................... 39

− Flue gas temperature supervision.................................................. 39

− Plausibility check of sensor ....................................................... 39

− Function................................................................................. 39

− Electronic (S)LT ..........................................................................40

− Handling faults ........................................................................ 40

− Flow switch / water pressure supervision ........................................42

− Function of flow switch.............................................................. 42

− Function of pressure switch....................................................... 42

− Pressure sensor.......................................................................... 42

− Static supervision..................................................................... 43

− Dynamic supervision ................................................................ 44

− Load limitation............................................................................ 45

− Speed limitation.......................................................................... 48

− Limitation of ionization current....................................................... 48

3.5 Boiler control...................................................................................... 49

− Frost protection for the boiler........................................................ 49

− Controller delay .......................................................................... 49

− Controller delay due to parameterization..................................... 49

− Controller delay due to SLT criterion........................................... 50

− Controller configuration ................................................................50

− Transfer of setpoint / actual value ...............................................50

− Determining the controller coefficients ........................................ 50

− Heat output limits..................................................................... 51

− Boiler temperature control............................................................ 52

− 2-position control ..................................................................... 52

− Minimum boiler pause time........................................................ 52

− Boiler cycling protection............................................................... 52

− Dynamic switch-off differential.................................................... 53

− Modulating control, conventional................................................ 54

3.6 Hydraulic system management (HSM)................................................... 55

− Frost protection for the plant ......................................................... 55

3.7 Consumer management (CM) .............................................................. 56

− Determining the demands for heat .................................................56

− Priorization of demands for heat ................................................ 56

− Determining the temperature demand............................................ 57

− Temperature limitation ..............................................................58

− Summer / winter (S / W) changeover.............................................. 59

3.8 Electronically controlled PWM heating circuit pump .................................61

− General...................................................................................... 61

− Introduction................................................................................ 61

− Notes ..................................................................................... 61

4/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

− Task of ∆T control with PWM pump ...............................................61

− First stage Maximum limitation of the flow temperature..................62

− Second stage ∆T limitation........................................................62

− Third stage ∆T supervision ........................................................63

− PWM pump control......................................................................63

− H-Q chart (example) .................................................................63

− Adaption of modulating pump to the heating plant.........................64

− Parametes of the PWM pump (OEM).............................................64

− Preset parameters .......................................................................64

− Activation of PWM pump via a configuration byte.............................65

− Parameters of the PWM pump (installer) ........................................66

− Parameters for temperatures ........................................................66

− PID controller coefficients of delta-T supervision ..............................67

− Summary of all ∆T parameters ......................................................67

− Behavior in different operating modes ............................................68

− Pump overrun..........................................................................68

− Normal operation (heating operation) ..........................................68

− Reduced (setback) operation .....................................................68

− Shutdown mode.......................................................................68

− Heating up phase.....................................................................68

− DHW operation ........................................................................69

3.9 Heating circuit control..........................................................................70

− Attenuated outside temperature .................................................70

− Composite outside temperature ...................................................71

− Type of building construction .....................................................71

− Heating curves .........................................................................72

− Generating the demands for heat ..................................................73

− Time switch.............................................................................74

− Room thermostat .....................................................................75

− RU .........................................................................................75

− Combinations of RU and room thermostat / time switch.................76

− ECO functions ............................................................................77

− S / W changeover.....................................................................77

− Automatic 24-hour heating limit ..................................................77

− Quick setback constant (KON) ......................................................78

− Generating the temperature demands .............................................78

− With fixed value control or emergency operation...........................78

− With weather compensation.......................................................78

4 Clip-in AGU2.500... for additional heating circuit.................................79

− Functions ...................................................................................79

− General...................................................................................79

− Hydraulic diagrams......................................................................79

− Sensor inputs (analog inputs)........................................................79

− Inputs / outputs...........................................................................79

− Interfaces for the LMU... ...............................................................80

− Sensor.......................................................................................80

− Frost protection ...........................................................................80

− Overtemperature protection..........................................................80

− Mixing circuits..........................................................................80

− Determining the flow temperature setpoint ......................................80

− Handling the locking signal........................................................80

5/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

− Handling the forced signal......................................................... 80

− Flow temperature control.............................................................. 80

− Pump control.............................................................................. 81

− Pump control with pump circuits .................................................81

− Pump control with mixing circuits ............................................... 81

− Pump overrun ..........................................................................81

− Pump kick............................................................................... 81

− Mixing valve control .....................................................................81

− Position of mixing valve in the idle state...................................... 81

− Functional test ............................................................................ 81

5 Clip-in module OCI420... for communication via LPB.......................... 82

− Functions ................................................................................... 82

− General .................................................................................. 82

− Inputs / outputs ...........................................................................82

− Interfaces to LMU... .....................................................................82

5.1 Connection of LMU... to ALBATROS via OCI420 (LPB clip-in) .................. 82

5.1.1 Additional heating circuit extensions via ALBATROS controllers................ 82

− Automatic changeover of operating mode .......................................83

− Giving consideration to heat demand from the RVA… ......................83

− Locking and forced signals when connecting to the LPB................... 83

5.1.2 External DHW heating by ALBATROS controllers ................................... 83

− Type of priority of DHW heating .................................................... 84

5.1.3 Multiboiler plants with LMU (cascade applications).................................. 84

− Separate DHW circuit in cascade applications................................. 85

− Operation with the RVA65... ......................................................... 85

5.1.4 System functions ................................................................................ 86

− Uniform system time.................................................................... 86

− Error / diagnostic messages from the LMU...................................... 86

− Outside sensor, outside temperature sensor................................... 88

− Assignment of address numbers................................................ 88

− Setting the LPB device and segment address................................. 88

6 Clip-in function module AGU2.51x ..................................................... 89

− Functions ................................................................................... 89

− General .................................................................................. 89

− Outputs...................................................................................... 89

− Number of available outputs ......................................................89

− Inputs........................................................................................ 90

− Digital input ............................................................................. 90

− Analog input ............................................................................ 90

− Predefined setpoint (temperature demand) ..................................90

− Predefined output .................................................................... 91

− Sensor input “Pressureless header”............................................ 91

7 DHW control (BWR) .......................................................................... 93

− Boiler temperature setpoint during DHW heating with storage tank

systems ..................................................................................... 93

− DHW temperature control............................................................. 94

− Compensation variants............................................................. 94

− Position of diverting valve.......................................................... 95

− Storage tank systems............................................................... 95

− Stratification storage tank.......................................................... 96

6/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

− Instantaneous DHW system ........................................................ 100

− Notes ................................................................................... 100

− Hydraulic diagram.................................................................. 100

− Operating mode........................................................................ 100

− Outlet temperature control (FS-DHW is closed).......................... 100

− Comfort control (after FS-DHW opening)................................... 100

− Aqua-booster system.................................................................. 103

− Hydraulic diagram.................................................................. 103

− Operating mode........................................................................ 103

− Outlet temperature control .......................................................103

− Comfort control ......................................................................103

− Legionella function .................................................................... 104

7.1 Special functions .............................................................................. 105

− Forced signals .......................................................................... 105

− Parameterization....................................................................... 105

− Via PC tool ACS420 and OCI490... .......................................... 105

− Via QAA73... / AGU2.310........................................................ 105

− Via AGU2.361 / AGU2.303...................................................... 106

− Programmable input of the LMU... ............................................... 106

− Modem function..................................................................... 106

− Warm air curtain function ........................................................ 106

− Programmable output of the LMU... ............................................. 107

− Status output......................................................................... 107

− Alarm output ..........................................................................107

− Operational status signal......................................................... 107

− Switching off the external transformer ....................................... 108

− Pump output second heating circuit.......................................... 108

− DHW circulating pump............................................................ 108

− Actuating device with warm air curtain function activated............. 108

− Pump of pressureless header .................................................. 108

− Basic function of controller clip-in module.................................. 108

− Actuating device with full DHW charging activated...................... 108

− Actuating device when analog signal exceeds threshold ..............109

− Power concept.......................................................................... 109

8 Basic diagram................................................................................. 110

8.1 LMU... ............................................................................................. 110

9 Connection diagrams...................................................................... 111

9.1 LMU... ............................................................................................. 111

9.2 DHW stepper motor (bipolar).............................................................. 112

9.3 AGU2.104A109................................................................................ 112

9.4 AGU2.500A109................................................................................ 113

9.5 AGU2.500A209................................................................................ 114

9.6 OCI420A109 .................................................................................... 115

9.7 OCI420A209 .................................................................................... 116

9.8 AGU2.51x ........................................................................................ 117

9.9 Connecting cable between OCI490... and PC .......................................118

9.10 Mounting, electrical installation and service.......................................... 119

− Mounting (general) .................................................................... 119

− Mounting the LMU5x............................................................... 119

7/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

− Ignition device...........................................................................119

− Terminals and wiring .................................................................119

− Testing by the customer.............................................................120

10 Technical data ................................................................................121

10.1 LMU................................................................................................121

− General....................................................................................121

− Electrical connection data ........................................................... 122

− Cable lengths (LMU... Ö HMI and LMU... Ö Clip-in).................126

− Connectors ..............................................................................126

10.2 Clip-in .............................................................................................127

10.2.1 AGU2.500........................................................................................127

− Outputs....................................................................................127

− Electrical connections................................................................127

− Input........................................................................................127

10.2.2 AGU2.51x........................................................................................127

− Outputs....................................................................................127

− Electrical connections................................................................127

− Input........................................................................................127

10.3 External components ........................................................................128

− RAST5 connectors ....................................................................128

− Mains transformer .....................................................................128

− Fan with DC 24 V motor.............................................................128

− Fan with DC motor operating on mains voltage..............................128

11 Dimensions....................................................................................129

11.1 LMU5x... .........................................................................................129

11.2 LMU6x... .........................................................................................130

11.3 AGU2.500A109 / AGU2.51xA109 .......................................................131

11.4 AGU2.500A209................................................................................132

11.5 OCI420A109....................................................................................133

11.6 OCI420A209....................................................................................134

11.7 Mounting plate for clip-in module ........................................................135

12 Parameter list / legend of parameter bit fields LMU... ........................ 136

12.1 Parameter list...................................................................................136

− Parameter list LMU....................................................................136

− Temperatures........................................................................136

− Switching differentials.............................................................137

− Controller functions ................................................................137

− Controller times .....................................................................138

− Controller coefficients.............................................................138

− Pressures .............................................................................138

− Burner control fan ..................................................................139

− Burner control sequence.........................................................139

− Burner control identification.....................................................140

− Operating data......................................................................140

− MCI......................................................................................140

− LPB .....................................................................................140

12.2 Lockout position storage....................................................................141

− Phase designations / numbers ....................................................141

8/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

12.3 Legend of parameter bit fields LMU..................................................... 142

− Controller functions ................................................................ 142

− Burner control program........................................................... 145

− Operating modes ................................................................... 147

− LPB...................................................................................... 147

13 Glossary of abbreviations ................................................................148

− Constants................................................................................. 148

− Variables.................................................................................. 148

14 Addendum: Hydraulic diagrams BMU............................................... 149

14.1 Hydraulic diagrams ........................................................................... 149

− Basic diagrams......................................................................... 149

− Pump circuit extensions via AGU2.500......................................... 151

− Mixing circuit extensions via AGU2.500... ..................................... 153

− Zone extensions........................................................................ 156

− Heat generation manager........................................................... 162

14.2 Assignment of hydraulic diagrams to the outputs of the LMU…............... 166

9/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products Contents 07.11.2002

1 Overview

Brief description

QAA73...

LMU... are Boiler Management Units (BMUs) of digital design for use with gas-fired

appliances equipped with premix burners.

They are used for the startup, control and supervision of premix burners having the

capacity ranges < 70 kW, 70 - 120 kW or > 120 kW in intermittent operation and with

direct ignition of the main flame.

The LMU... provide all supervisory and control functions required for burner, heating and

DHW operation and make possible modular system extensions via integrated

communication interfaces.

Output modulation is accomplished via a PWM-controlled fan, and pneumatic fuel / air

ratio control with the help of a gas valve.

1.1 System concept

LMU...

QAC34...

Room thermostat /

time switch

Human Machine Interface

AGU2.303...

(HMI)

AGU2.350...

Building automation /

remote management

OCI / ACS

Service tool

Modulating room unit

RVA47... RVA46...

LPB

RVA65...RVA63... RVA66...

LPB

Clip-in

Auxiliary modules

OCI420

AGU2.500

AGU2.51x

0...10 V

4...20 mA

AGU2.361...

AGU2.310...

AGU2.362...

7494b01E/0702

10/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 1 Overview 07.11.2002

1.2 Features

Below, the full functionality of the LMU... is described. For information on the scope of

functions of a specific unit, refer to the relevant version / configuration.

Safety functions

Supervision / protective

functions for the plant

• Gas burner control conforming to EN 298 for intermittent operation

• Integrated boiler / burner control for space heating and DHW operation

• Sequence control depending on the boiler’s capacity: < 70 kW, 70 - 120 kW, or > 120 kW.

Boiler capacities up to about 600 kW can be handled (depending on the type of fan /

gas valve used)

• Integrated electronic (safety) limit thermostat

• Integrated limit thermostat function

• Direct ignition of the main flame by means of

− integrated single-pole high-voltage ignition (with the choice of single-electrode

operation)

− external AC 230 V ignition control (optional)

• Continuous (analog) ionization current supervision with optional indication of flame

intensity

• Gas valve control AC 230 V (RAC optional)

• Number of start repetitions can be programmed

• Quick startup (especially in connection with instantaneous DHW systems)

• Fan supervision

• Optimization of combustion (optional)

• Control of an AC 230 V fan (DC 24 V fan optional)

• Ignition load precontrol via speed readjustment

• Adaptive postpurge level of fan speed

• Load limitation (fan limitation by minimum / maximum speed and / or flame signal)

• Number of fan feedback pulses can be selected

• Flame stabilization time

• Boiler cycling protection via minimum boiler off time

• Dynamic switch-off differentials for space heating (Hz) and DHW (Bw) operation

• Pump and diverting valve kick

• Frost protection functions for the plant, the boiler, DHW and the room

• Water pressure supervision (pressure sensor with static and / or dynamic supervision,

contact for pressure switch, flow switch)

• Flue gas temperature supervision

Auxiliary modules

(clip-in)

• OCI420 clip-in for communication, LPB interface for ALBATROS system world

• AGU2.500 clip-in for additional heating circuit

• AGU2.51x clip-in function module

- inputs: NTC, 10 kΩ

digital input

0(4)...20 mA

DC 0...10 V

- outputs: max. 3 relays AC 230 V

11/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 1 Overview 07.11.2002

DHW

• Integrated DHW systems with specific algorithms for storage tank, stratification

storage tank, instantaneous and aquabooster systems

• Instantaneous DHW heating systems with optional comfort function

• DHW heating with charging pump / diverting valve

• Diverting valve control via stepper motor control, N.O. contact with continuous phase

or changeover contact

• DHW control with sensor or thermostat

• Control of DHW circulating pump with QAA73...-V1.4

Heating circuit

System application

• Integrated weather-compensated pump heating circuit

• PWM-controlled heating circuit pump with specific algorithms to ensure most effective

condensation, improved overall efficiency and enhanced room comfort (optional)

• Additional weather-compensated heating circuit for single-user applications via

modular clip-in add-on module AGU2.500 (pump or mixing heating circuit) with

independent minimum / maximum limitation and heating curve.

Independent time switch program in connection with the QAA73...

• Automatic summer / winter changeover

• Automatic 24-hour heating limit (with no RU connected)

• Quick setback (with no RU connected)

• Compensation variants with room thermostat / time switch (single- or dual-channel

time switch)

• Compensation variants with room controls via integrated interface based on

OpenTherm (QAA73... / QAA53...)

• Integrated interface on OpenTherm basis

• Communication capability via the Local Process Bus (LPB) by means of clip-in

module

• Consistent system architecture of RVA… controllers

• Optional remote supervision

• Connection via LPB clip-in module to

− RVA46... zone controllers

− RVA47... cascade controllers

− RVA63... boiler and heating circuit controllers

− RVA65... energy managers for solar, wood, etc.

− RVA66... boiler and heating circuit controllers

− OCI6... communication interface for remote supervision (in connection with

appropriate ACS… software)

1)

Operation / service

• Modular and flexible concept of operating units AGU2.3...; optionally with housings for

flush panel mounting, degree of protection IPX4D (splash-proof) and LCD model with

clock function and backlit display

• Chimney sweep function

• Controller stop function for output adjustment

• Error messages with lockout storage and fault history

• Display and interrogation of all relevant process parameters via operating units,

QAA73... and PC tool

• Counter for the number of startups and the number of operating hours

• Maintenance functions with service message

1)

• Automatic plant configuration (identification of RU, connected HMI, sensors, etc.)

1) Planned; on request

12/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 1 Overview 07.11.2002

Parameterization

• Via PC tool ACS420

• Via room unit QAA73...

• Via operating units AGU2.3...

• Via specific final production test tool ACS421

Mains transformer

Other features

• Mains transformer integrated in the unit

An additional external transformer is not absolutely required (only when using a fan

operating on DC 24 V, or in the case of stepper motor control).

• Multifunctional housing with mechanical attachment facility for maximum 2 clip-in

modules

− Integrated exchangeable main fuse AC 230 V

− Integrated installer interface via RAST5 connector

• Optional extensions with up to 2 flexible clip-in modules that can be matched to

individual customer needs

• Programmable relay output (AC 230 V) for specific functions

• Programmable digital input for specific functions

• Housing / clip-in modules of advanced design made of recyclable plastic

1.3 Product range

Target market

Heating plants

Heat generating

equipment

Refer to chapter 2, «Product range overview».

1.4 Field of use

The LMU... are designed for use by OEMs. They are supplied directly to the boiler

manufacturer and enhance both the functionality and the level of outfit of gas-fired

boilers.

Suited for all types of standard heating systems such as radiator or underfloor heating

systems in the residential sector (one-family houses or blocks of flats).

Primarily for use with:

• Premixing or condensing gas-fired appliances with modulating burners using PWM

DC fans and pneumatic fuel / air ratio control, in intermittent operation and with direct

ignition of the main flame

• Capacity ranges < 70 kW, 70...120 kW, or > 120 kW

• Heating boilers or combi boilers with DHW storage tanks or instantaneous DHW

heaters

13/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 1 Overview 07.11.2002

1.5 Notes on product liability

• The units may only be used in building services plant in accordance with the

applications and features described above

• When using the products, all requirements specified in chapter «Technical data» must

be observed

• The local safety regulations must be complied with

1.6 Notes on environmental protection

Disposal notes

The LMU... contains electrical and electronic components and may not be disposed of

together with household waste. Local and currently valid legislation must be

observed!

14/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 1 Overview 07.11.2002

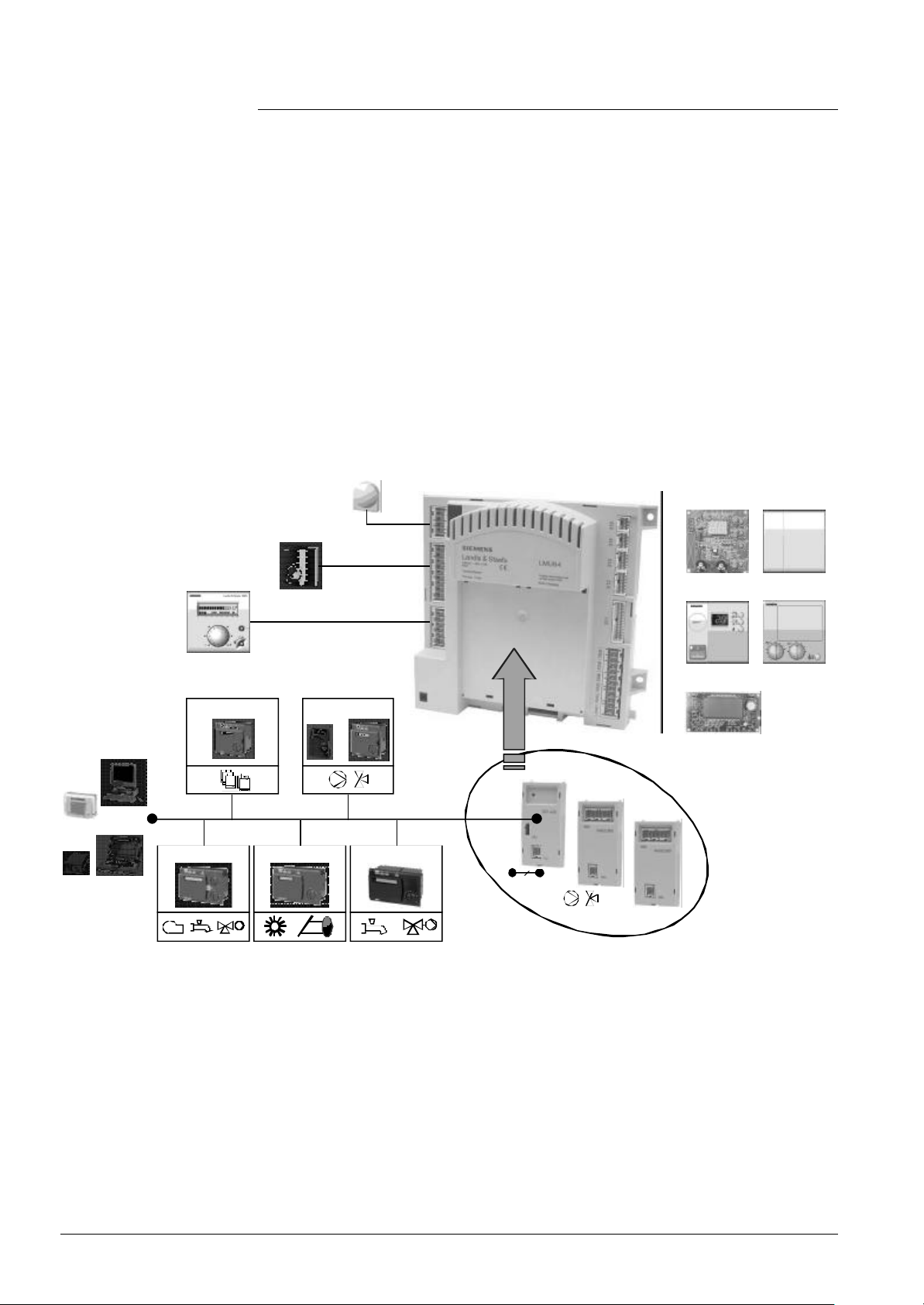

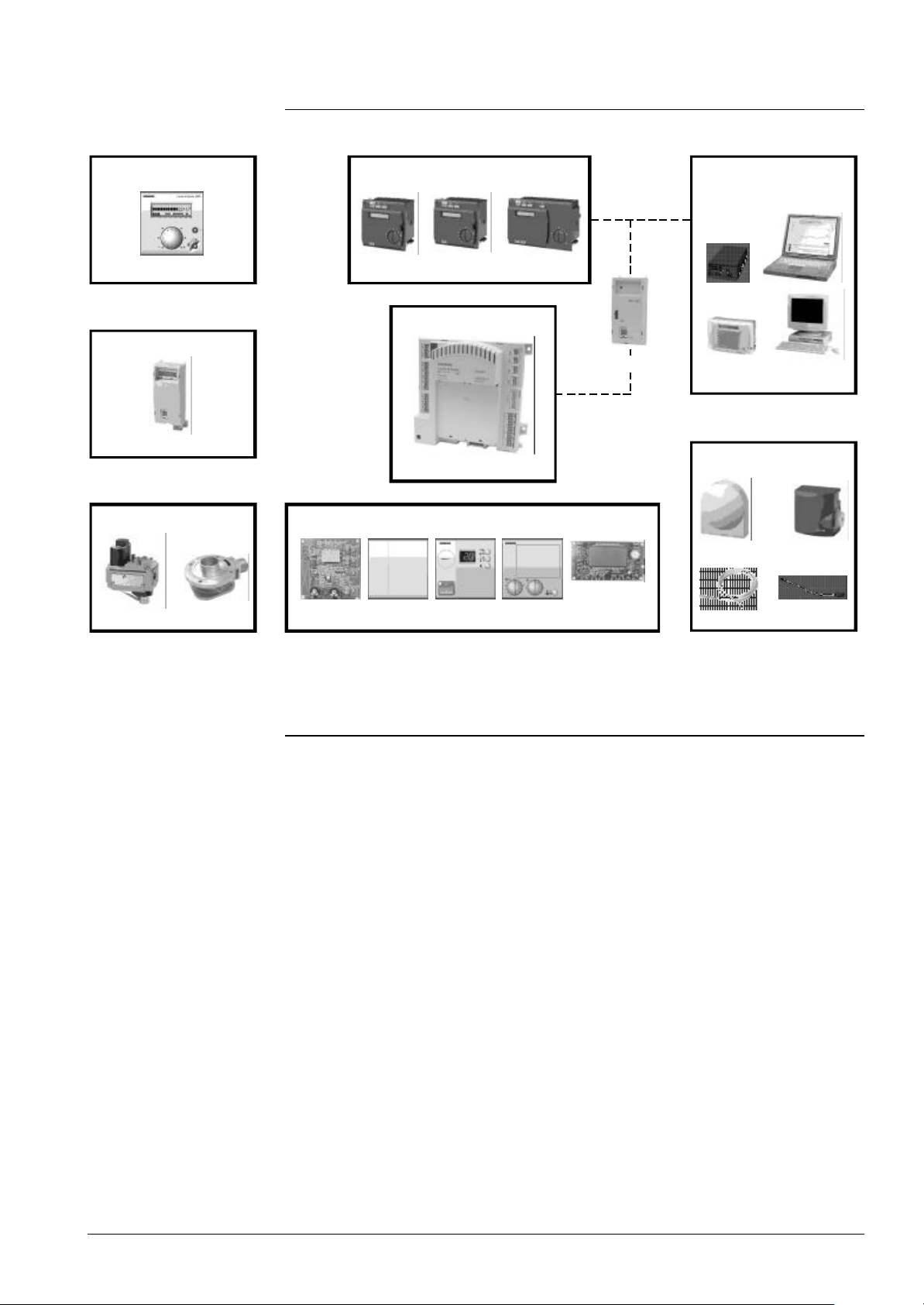

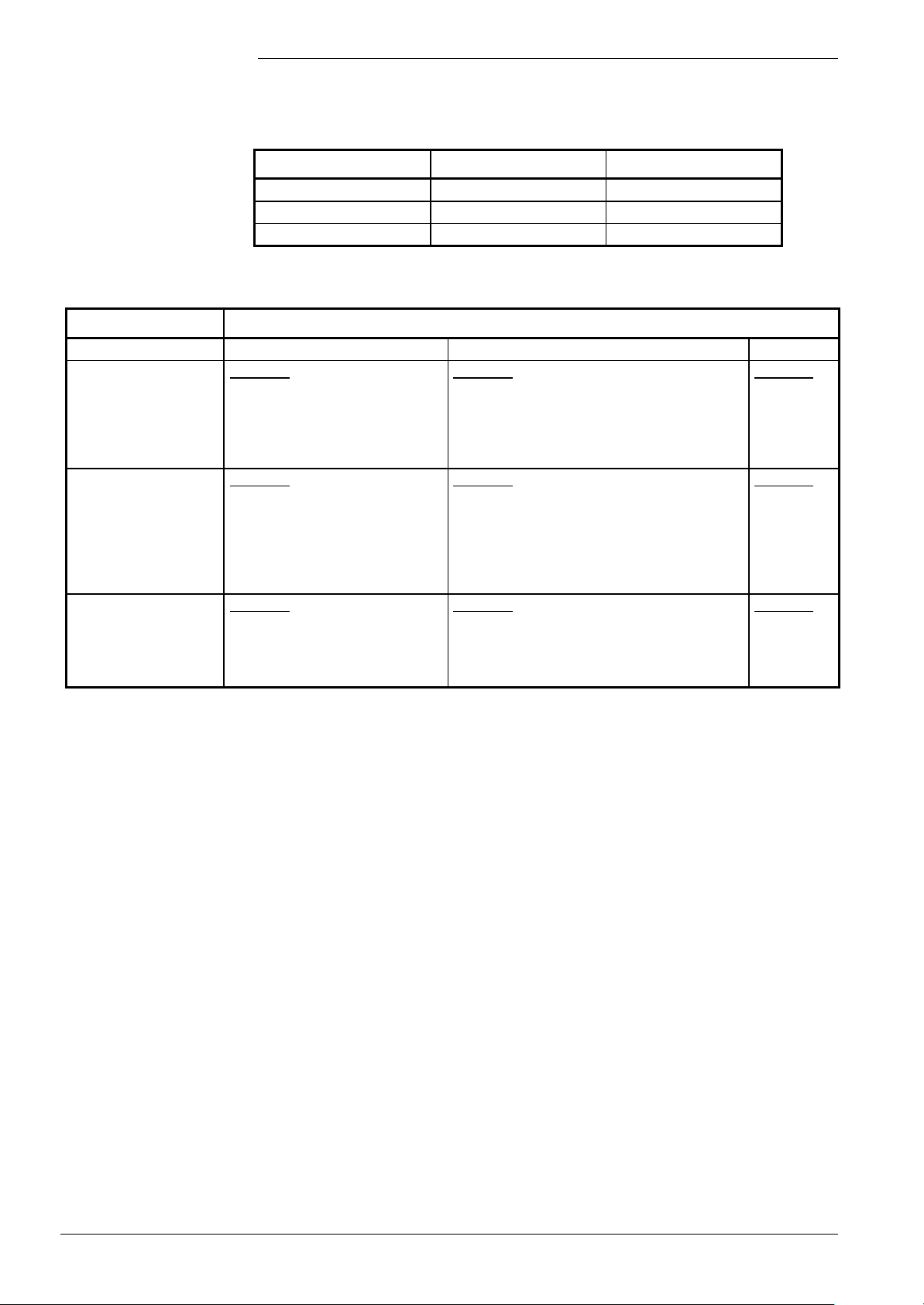

2 Product range overview

7494b02E/0802

Room units

QAA73...

Clip-in modules

AGU2.5xx

Gas valves / Mixer

AGU3.6...

Controllers

RVA46... RVA47... RVA...

BMU

OCI420...

LMU...

HMI

AGU2.350 AGU2.361 AGU2.362AGU2.303 AGU2.310

Service remote

management

ACS6... / OCI6...

Temp. sensors

QAC34...

QAZ36...

QAL36...VDU...

QAD36...

BMU

Controller

Service tool

The following units and accessories are designed for use with the ALBATROS range:

Type of unit Description Documentation no.

LMU54... BMU (without housing, without combustion optimization) CC1P7494

LMU64... BMU (with housing, without combustion optimization) CC1P7494

1)

1)

REA02... Room thermostat (RAA20) CE1N3002

REA11... Room temperature controller CE1P2274

RVA46... Heating controller CE1P2372

RVA47... Cascade controller for modulating gas-fired CE1P2379

heating boilers

RVA63... Heating circuit controller CE1P2373

RVA65... Heat energy manager CE1P2392

RVA66... Heating circuit or primary controller with DHW control CE1P2378

2)

2)

2)

OCI490A109 PC interface for ACS42X... -ACS420 Software for OCI490A109

ACS421 Final production test software

Remote supervision

ACS... Operating software CE1B2530

OCI6... Central communication unit CE1N2530 / 2531

15/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 2 Product range overview 07.11.2002

2)

2)

Room units

QAA73... RU for boiler control with OpenTherm interface CE1P2284

QAA53... RU for boiler control with OpenTherm interface CE1Q2282

Clip-in modules

Gas valve

Sensor

AGU2.500A109 Clip-in for additional heating circuit

AGU2.500A209 Clip-in for additional heating circuit (printed circuit board version)

AGU2.511A109 Clip-in function module, voltage relay

AGU2.513A109 Clip-in function module, current relay

AGU2.514A109 Clip-in function module, sensor relay

AGU2.515A109 Clip-in function module, digital input relay

OCI420A109 Clip-in for communication LPB interface

OCI420A209 Clip-in for communication LPB interface (printed circuit board version)

VDUxxx Compact gas control loop with pneumatic fuel / air CC1N7662

ratio control

AGU3.6... Gas / air mixing device (pressure side) --

QAC34/101 Outside sensor NTC 1kΩ CE1Q1811

QAD36/101 Strap-on temperature sensor NTC 10 kΩ -QAK36... Screwed immersion temperature sensor NTC 10 kΩ --

QAL36.225 Universal temperature sensor NTC 10 kΩ CE1Q1842

QAZ36.522/109 Cable temperature sensor NTC 10 kΩ, cable length 2 m CE1Q1843

QAZ36.526/109 Cable temperature sensor NTC 10 kΩ, cable length 6 m CE1Q1843

2)

2)

Operating section

Cable

AQL21.30 Holding spring for QAL36.225, 30 mm -AQL21.42 Holding spring for QAL36.225, 42 mm --

AGU2.350A109 Dummy cover, housing for flush panel mounting,

degree of protection IPx4D

AGU2.361A109 Operating section for boiler, housing for flush panel mounting,

degree of protection IPx4D

AGU2.362A109 Operating section for heating circuit, housing for flush panel mounting,

degree of protection IPx4D

AGU2.303B109 Operating section, type of printed circuit board

AGU2.310A109 Operating unit with LCD (printed circuit board version)

AGU2.100A109 Connecting cable LMU... Ö AGU2.303 / AGU2.361 / AGU2.310

AGU2.101A109 Connecting cable AGU2.361 Ö AGU2.362

AGU2.102A109 Connecting cable AGU2.361 Ö control panel mounting QAA73...

AGU2.103A109 Connecting cable service interface AGU2.361 Ö QAA73...

1) 2)

1) 2)

1) 2)

1) 2)

AGU2.104A109 Connecting cable LMU... Ö Clip-in module AGU2.500 / OCI420

1)

1)

1)

1)

1)

2)

1)

Refer to Operating Instructions CC1B7494

2)

On request

16/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 2 Product range overview 07.11.2002

3 Functions

3.1 Burner control

Program selection

EEPROM

Forced intermittent

operation

Parameterization enables certain parts of the burner control program to be changed,

thus permitting a number of different burner control sequences.

The burner control sequences are distinguished by their capacity ranges in which the

boilers shall operate.

In accordance with the standards, there are 3 different capacity ranges:

• < 70 kW

• 70...120 kW

• > 120 kW

For all capacity ranges, there are additional parameterization choices available,

enabling the burner control’s sequence and times to be matched to specific

requirements.

The EEPROM of the LMU... is used to store the burner control’s program sequence and

lockout positions.

Also, control parameters and other setting values are filed in EEPROM.

Forced intermittent operation ensures that the burner control initiates shutdown after no

more than 24 hours of continuous operation.

This enables the burner control to perform the internal self-tests included in the startup

and shutdown sequence.

Burner control program

The burner control’s program ensures orderly operation of the unit including startup and

shutdown as well as flame supervision.

The sequence can be altered by changing certain parameters.

If there are deviations from the defined sequence, or in the case of a reset, the program

initiates safety shutdown (home run) and then - depending on the setting made lockout, restart or start prevention.

The program sequence is controlled in accordance with the program’s phases. The

individual phases are grouped and include startup, operation, shutdown and home run.

After a reset (power on), the burner starts its home run. Depending on the available

(parameterized) input / output signals or program times (e.g. prepurging), the individual

program phases will be either executed or skipped.

The burner control’s program is designed for intermittent operation. To verify orderly

functioning (detection of faults), a complete program cycle is required.

In the «Standby» position, the burner control is ready to operate and waits for a heat

demand signal from the controller, or it demands start prevention (no release).

The burner control maintains the «Operation» position until no more heat is demanded

by the controller - but for no more than 24 hours. On completion of that period of time,

the burner control will automatically enforce intermittent operation.

17/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

Sequence diagram

Capacity range < 70 kW

HMI

display:

Phase

Heat demand

Flame

Ignition

BV

LP (2)

LP (3)

LP (4)

NoG_Max

N_Vor

-N_Vor_Delta

+N_VL_Delta

N_VL

+N_ZL_Delta

N_ZL

-N_ZL_Delta

N_TL

-N_TL_Delta

NoG_Null

7494f01e/0801

22 0 1 2 3 654

PH_TNB

Home run

TLOTNB

PH_TLO PH_TNN

Standby

TNN tsa1 tsa2

PH_

STANDBY

PH_

STARTVER

PH_

STANDBY

THL1

PH_

THL1_1

dependent on

10 Hz

11 Bw

12 Hz+Bw

tsa

Operation

tv TBRE TW1 TW2 tvz tsa1 tsa2 tn

PH_TV PH_TBRE PH_TW1 PH_TW2 PH_TVZ

PH_

TSA1_1

PH_

THL2

PH_

TSA2_1

PH_

Z

THL2

PH_

ti

MODULATION

PH_

THL2

PH_

THL2

PH_

THL2_1

PH_TI

PH_

Z

THL2

PH_

THL2

ZZ

ZZ

parameter

setting

dependent on

parameter

setting

dependent on

20 2 4 7 21 99

tsa

PH_TN_1

THL1 (TW1)

PH_

PH_TW1

THL1_2

PH_

TSA1_2

PH_

THL2

Z Z

PH_

THL2

PH_

TSA2_2

PH_

TSA1_2

THL2 tn

PH_

PH_TN_2

THL2_2

Z

Z

ZZ

parameter

setting

ZZZZ

dependent on

parameter

setting

dependent on

parameter

setting

dependent on

parameter

setting

ZZZZ

PH_

STOER

Capacity range 70...120 kW

HMI

display:

Phase

Heat demand

Flame

Ignition

BV

LP (2)

LP (3)

LP (4)

NoG_Max

N_Vor

-N_Vor_Delta

+N_VL_Delta

N_VL

+N_ZL_Delta

N_ZL

-N_ZL_Delta

N_TL

-N_TL_Delta

NoG_Null

7494f02e/0201

PH_TNB

22

Home run

TLOTNB

PH_TLO PH_TNN

0 1

Standby

TNN tsa1 tsa2

PH_

STANDBY

PH_

STARTVER

PH_

STANDBY

3

2

tv TBRE

THL1

PH_

PH_TV PH_TBRE PH_TW1 PH_TW2 PH_TVZ

THL1_1

TW1

Z

R

dependent on

parameter

setting

10 Hz

11 Bw

654

12 Hz+Bw

tsa

Operation

TW2 tvz tsa1 tsa2 tn

PH_

TSA1_1

PH_

THL2

Z

PH_

TSA2_1

PH_

THL2

ti

PH_TI

PH_

THL2

Z

Z

PH_

PH_

THL2

THL2

R

PH_

MODULATION

PH_

THL2

20 2 4 7 21 99

PH_

PH_TN_1

THL2_1

Z

R

ZZ

RR

dependent on

parameter

setting

ZZ

ZZ

R

ZZ

RR

dependent on

parameter

setting

ZZ

THL1 (TW1)

PH_

PH_TW1

THL1_2

dependent on

parameter

setting

tsa

PH_

TSA1_2

PH_

THL2

Z Z

TSA2_2

PH_

THL2

PH_

TSA1_2

PH_

THL2_2

PH_TN_2

PH_

STOER

THL2 tn

PH_

Z

Z

ZZ

R

dependent on

parameter

setting

ZZ

dependent on

parameter

setting

ZZ

R

Z

RR

Logic on

Logic off

On deviation

transition to home run

Deviation leads to lockout

On deviation transition to

specified or following

phase

Control

Permitted range

Prohibited range

-> Home run

Prohibited range

-> Lockout

Control signal

Ideal signal

Transition criterion

Triggering forced prepurging

Z

Repetition can be parameterized,

R

then lockout

18/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

Repetition can be parameterized,

Sequence diagram

Capacity range > 120 kW

HMI

display:

Phase

Heat demand

Flame

Ignition

BV

LP (2)

LP (3)

LP (4)

NoG_Max

N_Vor

-N_Vor_Delta

+N_VL_Delta

N_VL

+N_ZL_Delta

N_ZL

-N_ZL_Delta

N_TL

-N_TL_Delta

NoG_Null

7494f03e/0201

PH_TNB

Logic on

Logic off

On deviation

transition to home run

PH_

THL2

PH_

TSA2_1

ZZ

Z

10 Hz

11 Bw

12 Hz+Bw

Operation

PH_

ti

MODU-

PH_TI

LATION

PH_

THL2

20 2 4 7 21 99

PH_

THL2

PH_

THL2_1

dependent on

parameter

setting

PH_TN_1

ZZ

THL1 (TW1)

PH_

THL1_2

dependent on

parameter

setting

Permitted range

Prohibited range

-> Home run

Prohibited range

-> Lockout

22

Home run

TLOTNB

PH_TLO PH_TNN

0 1

Standby

TNN tsa1 tsa2

PH_

PH_

STANDBY

STARTVER

PH_

STANDBY

3

2

tv TBRE

THL1

PH_

PH_TV PH_TBRE PH_TW1 PH_TW2 PH_TVZ

THL1_1

dependent on

parameter

setting

TW1

654

tsa

TW2 tvz tsa1 tsa2 tn

PH_

TSA1_1

PH_

Z

THL2

dependent on

parameter

setting

Deviation leads to lockout

On deviation transition to

specified or following

phase

Control

PH_TW1

tsa

PH_

TSA1_2

PH_

Z Z

THL2

dependent on

parameter

setting

Z

R

THL2 tn

PH_

PH_

TSA2_2

THL2_2

PH_

THL2

PH_

TSA1_2

ZZ

dependent on

parameter

setting

Control signal

Ideal signal

Transition criterion

Triggering forced prepurging

then lockout

PH_TN_2

PH_

STOER

Z

Z

ZZ

Description of sequence

diagrams

The burner control’s program is subdivided into different phases. Each phase is

identified by a certain output and input configuration of the burner control.

For the precise sequence of signals, refer to the sequence diagrams.

Signal sequences not shown in the sequence diagrams are summarized under «Special

cases».

The times given in the sequence diagrams are distinguished as follows:

UPPERCASE LETTERS (e.g. «THL1») constants stored in ROM

Lowercase letters (e.g. «tsa») parameters stored in EEPROM

With regard to the speed feedback signal, the following nominal levels are used:

N_Vor, N_VL, N_ZL, N_TL

Prepurging Nominal load

1)

Previously «Full load» (VL)

1)

Ignition load Partial load

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

19/171

According to the sequence diagram, there is a permitted tolerance band with an upper

and a lower limit for each level (e.g. «N_ZL»), which is defined via parameter

«N_XX_Delta».

The relevant sequence phases (refer to the sequence diagrams) are queried for these

limits.

Example: Ignition load upper limit = «N_ZL» + «N_ZL_Delta»

lower limit = «N_ZL» - «N_ZL_Delta»

These limit values are complemented by «NoG_Null» and «NoG_Max» (refer to the

sequence diagrams).

«NoG_Max» is the maximum speed that must never be reached. «NoG_Null» is the low

speed that must be crossed when changing to standby.

Sequence times

Time

Min.

(s)

TNB 0.2 21.0 Lockout position Afterburn time

TLO 0.2 51.0 Lockout position Open LP

TNN 0.2 51.0 Lockout position Down to speed = 0

THL1 0.2 51.0 Lockout position First fan runup time

THL2 0.2 51.0 Lockout position Second fan runup time

tv 0 51.0 Switching Prepurging

TBRE 0.2 51.0 Lockout position Brake time until ignition load is reached

TW1 0.2 51.0 Lockout position

tvz 0.2 5.0 Switching Preignition time

TSA 1.8 9.8

tsa1 0.2 9.6

tsa2 0.2 TSA-tsa1

ti 0.2 10 Switching Interval operation

tn 0 51.0 Switching Postpurging

1)

Lockout position or start repetition, depending on the flame signal and the parameter;

various parameterization choices (refer to relevant description)

2)

With parameterization with abortion of safety time in the case of flame detection, the times

of «tsa1» and «tsa2» are derived from the time of establishment of flame. It should be

noted, however, that «TSA» can never be exceeded

Max.

(s)

Response

Description

at end of

Waiting for internal sequence, speed

readjustment and optimization of

combustion

1)

2)

1)

2)

1)

Ignition safety time

Ignition safety time with ignition

Ignition safety time without ignition

The following phases (with associated times in parentheses) are relevant with one

startup / shutdown cycle:

Standby

• PH_STANDBY (unlimited): Burner control waits for a heat demand signal from the

controller

• PH_STARTVER: No external or internal release, relevant diagnostic code is delivered

Startup

The change from «Standby» to «Operation» is the startup triggered by a heat demand

signal from the controller.

If startup takes place with prepurging, startup will commence with the «PH_THL1_1»

phase; if no prepurging is used, with the «PH_THL1_2» phase.

20/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

• PH_THL1_1 (THL1): Maximum fan runup time to prepurging level. With «tv» > 0 or in

case of demanded forced prepurging

• PH_THL1_2 (THL1): Maximum fan runup time to ignition level. With «tv» = 0 and no

demanded forced prepurging

• PH_TV (tv): Prepurging phase

• PH_TBRE (TBRE): Maximum period of time for reaching the ignition level after

prepurging (reaching the speed band for the ignition load)

• PH_TW1 (TW1): Maximum waiting time until the following functions are performed:

− Internal safety tests: These tests are started the moment the startup phase

commences and already run in the background during the preceding phases

− Combustion optimization: Optimization of combustion deactivated or stepper motor

in start position

− Speed readjustment: Checkback signal delivered when the required speed for the

ignition load is reached for the first time

• PH_TVZ (tvz): Preignition time (can be parameterized, but minimum is 0.2 seconds)

• PH_TSA1_1; PH_TSA2_1; PH_TSA1_2; PH_TSA2_2; (TSA): Ignition safety time. If,

on completion of this period of time, there is no flame (also after several reignition

attempts), the burner control will initiate lockout or make a restart, depending on the

parameter settings made.

With parameterization with abortion of the safety time in the case of flame detection,

«TSA» can be shortened via flame establishment (refer to «PH_TSA1_2»,

«PH_TSA2_2»).

Parameterization choice 1:

• PH_TSA1_1 (tsa1, max. TSA): First part of the safety time with ignition switched on.

The fuel valve is open

• PH_TSA2_1 (TSA - tsa1, max. TSA): Second part of the safety time with ignition

switched off. The fuel valve is open

Parameterization choice 2:

• PH_TSA1_2 (max. TSA): First part of the safety time with ignition switched on.

Once a flame signal is detected, the change to the «PH_TSA2_2» phase (switching

ignition off) takes place. If there is no establishment of flame, the burner control stays

in the «PH_TSA1_2» phase until the end of «TSA» is reached

• PH_TSA2_2 (0.2 seconds, can be run through several times during «TSA»):

Second part of the safety time with ignition switched off. The fuel valve is open. 0.2

seconds after the change to the «PH_TSA2_2» phase, the flame signal is checked. If,

in that case, the flame has been lost, an immediate reignition attempt is made by

returning to the «PH_TSA1_2» phase.

This procedure can repeat itself until the end of «TSA» is reached.

If the flame is still present, the change to the «PH_TI» phase takes place.

Operation:

Start of the operating position is the «PH_TI» phase. If interval «ti» is not required, it

cannot be parameterized to 0 but only to a minimum of 0.2 seconds.

• PH_TI; (ti), interval required for stabilization of the flame

• PH_MODULATION; (unlimited), controller operation. In this phase, the controller

result is output

21/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

Shutdown

The change from the operating position to «Standby» is made when there is no more

demand for heat and is divided into «Shutdown» and «Home run».

«Shutdown» consists of postpurging, which can be deactivated.

With postpurging, there is a choice of 2 operating modes the difference being the way

the fan is controlled.

Parameterization choice 1:

• PH_THL2_1 (0.2 s): Change during postpurging, to the level of the last operating

command

• PH_TN1 (tn): Postpurging to the level of the last operating command

Parameterization choice 2:

• PH_THL2_2 (THL2): Change during postpurging, to the level of prepurging

• PH_TN2 (tn): Postpurging to the level of prepurging

Home run

Special cases (deviations)

The home run is used to bring about the change to the «Standby» position.

Normally, the home run is made on completion of «Shutdown».

After extraordinary events (refer to the sequence diagram), or in the case of a reset, the

home run brings the unit back to its basic position («Standby»).

In the case of a new demand for heat, the home run triggers a faster startup sequence.

This is accomplished by a shorter «TNN» followed by a direct change from the

«PH_TNN» phase to the «PH_THL1_1/2» phase. This means that the «Standby» state

will be skipped.

• PH_TNB (TNB): Permitted afterburn time

• PH_TLO (TLO): Permitted period of time with «LP» closed (if present) or speed >

«N_TL-N_TL_Delta»

• PH_TNN (TNN): Permitted period of time at speed > «NoG_Null»

• Forced prepurging: In the case of a reset after lockout and after power ON, forced

prepurging with the «LmodVOr» parameter is initiated, which takes place in the

«PH_TV» phase and which lasts 21 seconds, or «tv», if «tv» > 21 seconds.

The deviations marked with «Z» in the sequence diagram cause the burner control to

perform forced prepurging in the next startup phase.

• Repetition at the end of «TSA»: In the event no flame is established at the end of

«TSA», there is a choice of lockout or repetition can be triggered by changing to the

home run. The number of repetitions is limited and can be selected via the

«RepZaehler» parameter.

However, the general conditions of the different adjustable capacity ranges must be

observed (refer to the table further below).

• In the event of loss of flame during operation, the burner control initiates lockout or

changes to home run with restart, depending on the capacity range (refer to the table

further below)

• Prepurging: Can be deactivated by using the setting 0 seconds. In that case - as

shown on the sequence diagram - a change from the «PH_THL1_1» phase to the

«PH_TW1» phase will take place

• Preignition time: If parameter «tvz» is set to 0 (no ignition prior to «TSA»), the

«PH_TVZ» phase takes no more than 0.2 seconds (minimum time)

• Forced intermittent operation: After 24 hours of continuous operation at the latest,

forced intermittent operation is triggered, which ensures a regular shutdown to the

«PH_STANDBY» phase.

The timer for forced intermittent operation is reset in the «PH_STANDBY» phase.

Quick startup with forced intermittent operation is not possible.

22/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

• Safety time (TSA): As described above, the behavior of the burner control in the 2

1 SW run

different modes can be parameterized: Abortion of the safety time with flame

detection, and evaluation of the flame at the end of the safety time.

It must be noted that in the case of single-electrode operation, it is always «Evaluation of

the flame at the end of the safety time» that must be parameterized.

• Postpurging: Can be parameterized in 2 different ways, namely as postpurging on

the prepurging level, or as postpurging with the control used last. The duration of

postpurging is adjusted via «tn» (also see above)

• Start prevention: Certain internal or external events can trigger start prevention. In

that case, the burner control changes to the «PH_STARTVER» phase. The reason for

start prevention is given via the diagnostic code

The reason can be one of the following (examples):

− Open-circuit or short-circuit of flame detector

− No «GP» signal (depending on the parameterization)

− Open «LP» input (depending on the parameterization)

− Temperature limiter has cut out

Some of the functions that give rise to start prevention can be deactivated via

parameterization.

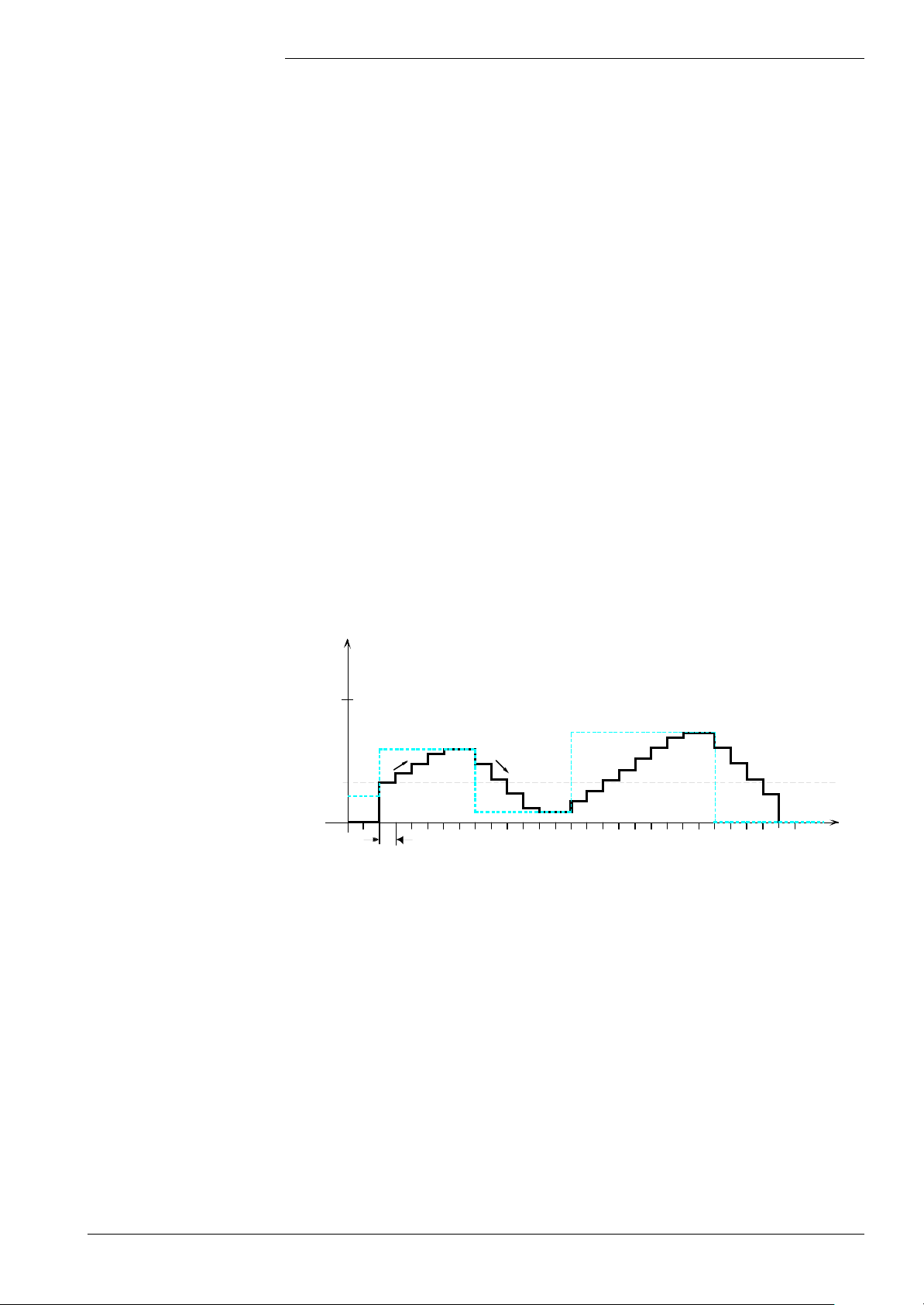

• Ramps: Fan control can be limited by a ramp. To do this, a number of

parameterization choices are available.

The rate of signal change towards a higher or lower speed is limited via parameter

(VmLauf, VmLaufBetr, VmLab, VmLabBetr).

In all phases - with the exception of «PH_MODULATION» - parameters «VmLauf»

and «VmLab» apply to the rate of change of fan control up or down.

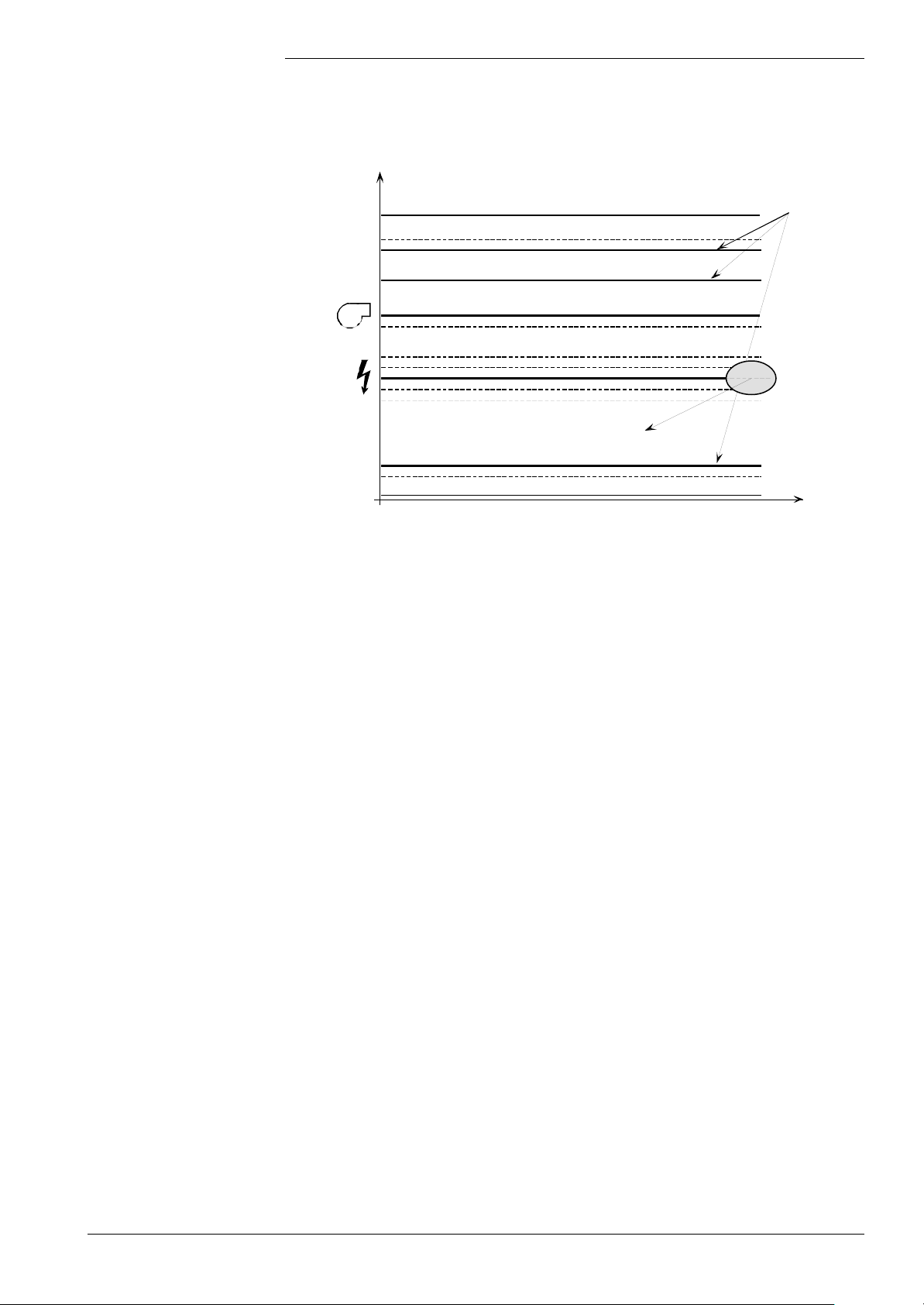

PWM

100 %

Setpoint

Ramp (DOWN)

Threshold

value

Control value following the setpoint while considering the threshold value and the ramps

Ramp (UP)

7494d21E

In the «PH_MODULATION» phase, the increase of fan control is limited by the smaller

of the 2 parameters «VmLaufBetr» and «VmLauf».

The decrease is limited by the smaller of the 2 parameters «VmLab» and «VmLabBetr».

Also, when controlling the fan, a threshold value is to be considered. It is predefined by

the «LmodStart» parameter.

As long as the setpoint is lower than the threshold value, the fan will not be controlled. It is

controlled only - using the threshold value - when the setpoint is at least equal to the

threshold value.

23/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

If the setpoint lies above the threshold value, starting from the threshold value, the

control value will approach the setpoint in accordance with the maximum slope (ramp)

defined by parameters «VmLauf» and «VmLaufBetr».

If the setpoint lies below the current control value, the control value will approach the

setpoint in accordance with the ramp (VmLab, VmLabBetr). This also applies in the case

the setpoint is lower than the threshold value.

If the setpoint equals zero, which means that the fan shall be switched off, first the

control value will be reduced in accordance with the ramp until it is smaller than or equal

to the threshold value. Only then will the control value be reduced to zero.

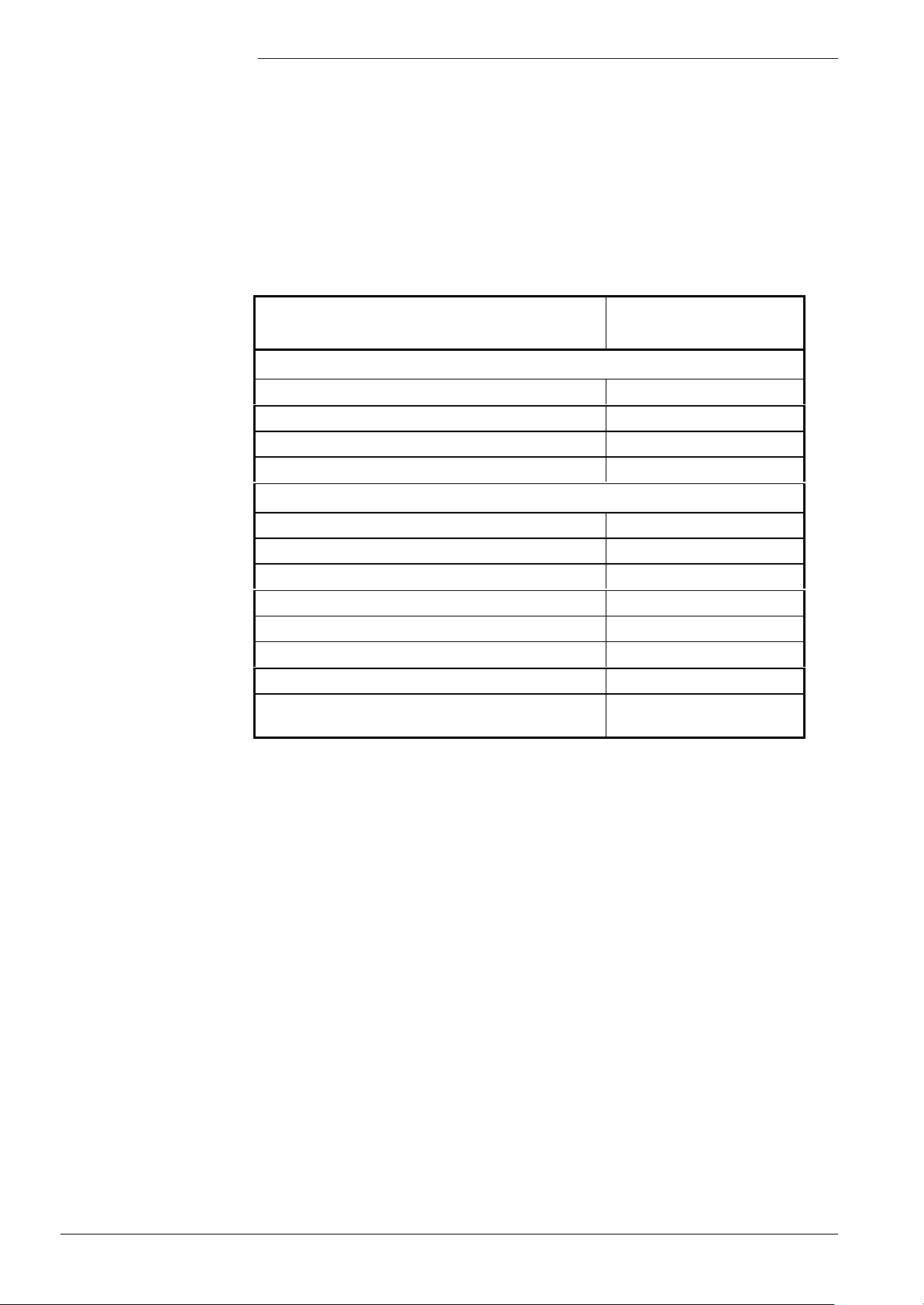

LMU... plausibility checks

of the speed parameters

Fault Display of fault on the

PC tool

Check PWM control values of the fan for plausibility in relation to other parameters:

LmodZL > LmodVL 218

LmodTL > LmodZL 219

LmodNull > LmodTL 220

Check speed parameters of the fan for plausibility in relation to other parameters:

N_TL > N_VL 221

N_VOr > NoG_Max 222

N_VL + N_VL_Delta > NoG_Max 223

N_ZL + N_ZL_Delta > N_VL + N_VL_Delta 224

N_VOr - N_VOr_Delta < NoG_Null 225

N_ZL - N_ZL_Delta < N_TL - N_TL_Delta 226

N_TL - N_TL_Delta < NoG_Null 227

N_Nachstell_Delta ≥ N_ZL_Delta

or N_Nachstell_Delta ≥ N_Vor_Delta

503

Parameterization of

speed feedback signal

24/171

The fan’s speed feedback signal can be parameterized.

Parameter: Fan pulses (in «FaEinstellFlags3»)

Available choices : 2, 3 or 4 pulses per revolution

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

Fan parameters

accessible via QAA

Under certain conditions, the fan parameters for ignition load, partial load and full load

can also be set via the QAA73... (parameter «FaEinstellFlags3»).

Since these fan parameters are safety-related and – as a general rule – safety-related

values cannot be readjusted via the QAA73..., following applies:

• The relevant parameters will be copied and the new parameters filed in the nonsafety-related range

• Changeover between the 2 parameter groups can be parameterized via a safetyrelated flag (FaEinstellFlags3)

Changeover to the QAA fan parameters is only permitted under certain preconditions:

1. Capacity range < 70 kW.

2. Changeover only possible on the OEM level or higher.

For the new parameters, the usual fan parameter checks are made (same as with the

previous parameter group).

Listing of both parameter groups:

Parameters on QAA Safety-related parameters

LmodZL_QAA LmodZL

LmodTL_QAA LmodTL

LmodVL_QAA LmodVL

Note

N_ZL_QAA N_ZL

N_TL_QAA N_TL

N_VL_QAA N_VL

When setting these parameters, the following general conditions must be observed:

QAA parameters : CRC-protected parameter:

LmodZL_QAA ≤ LmodZL

LmodVL_QAA ≤ LmodVL

LmodTL_QAA ≥ LmodTL

N_ZL_QAA ≤ N_ZL

N_VL_QAA ≤ N_VL

N_TL_QAA ≥ N_TL

When, in the following, reference is made to one of the safety-related parameters, it is

also possible that the corresponding QAA parameter is meant (depending on the

parameterization).

25/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

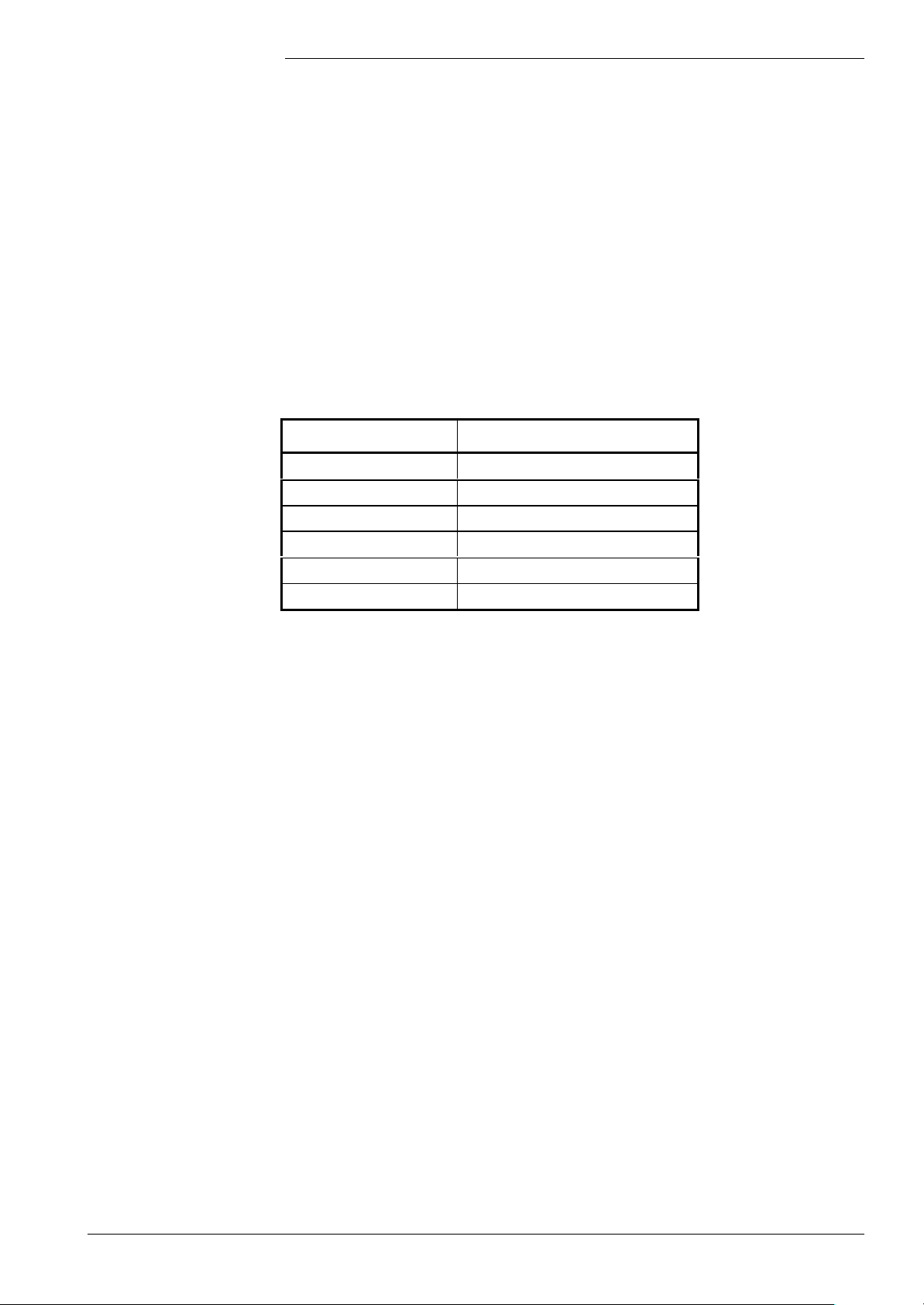

The different capacity

ranges

In compliance with the standards, a differentiation must be made with regard to the

responses in the sequence diagram for the different boiler capacity ranges.

Parameter «FaProgFlags1» can be used to select the 3 following ranges:

FaProgFlags1 (Bit7) FaProgFlags1 (Bit6) Capacity range

0 0 < 70 kW

0 1 70...120 kW

1 0 > 120 kW

From these 3 capacity ranges, the following differences emerge:

Capacity range

Subject < 70 kW 70 - 120 kW > 120 kW

Air supply failure during

prepurging, ignition or in

operation:

1)

Failure during

establishment of flame:

2)

Response:

Home run; during the safety time and

in operation also forced prepurging.

During prepurging, immediate lockout.

Response:

Shutdown on first occurrence, restart

permitted (number of restarts can be

parameterized). Then lockout; also

forced prepurging.

Repetition counter is reset in phase

Response:

Home run on first occurrence, one restart permitted

(number 0 / 1 can be parameterized). Then lockout;

also forced prepurging.

During prepurging, immediate lockout.

Repetition counter is reset in the «PH_TI » phase.

Response:

Shutdown on first occurrence, one restart permitted

(number 0 / 1 can be parameterized). Then lockout;

also forced prepurging.

Repetition counter is reset in the «PH_TI » phase.

Response:

Lockout

position

4)

Response:

Lockout

position

4)

«PH_TI ».

Loss of flame during

operation:

3)

Response:

Shutdown

Response:

Shutdown on first occurrence, one restart permitted

(number 0 / 1 can be parameterized). Then lockout;

also forced prepurging.

Repetition counter is reset in the «PH_TI » phase.

Response:

Lockout

position

4)

1)

With the LMU...: Failure of speed supervision or speed feedback signal below the valid

range.

Relevant phases: PH_TV, PH_TW1, PH_TW2, PH_TVZ, PH_TSA1_1, PH_TSA2_1,

PH_TSA1_2, PH_TSA2_2, PH_TI, PH_MODULATION

2)

With the LMU...: No flame at the end of the safety time. Relevant phases: PH_TSA1_1,

PH_TSA2_1, PH_TSA1_2, PH_TSA2_2

3)

With the LMU...: Loss of flame during phases «PH_TI» and «PH_MODULATION»

4)

Accomplished by parameterizing the specified value for the start repetitions to 0

26/171

Siemens Building Technologies Basic Documentation LMU54... / LMU64... CC1P7494en

HVAC Products 3 Functions 07.11.2002

Setting the fan parameters

during startup and shutdown

Parameter LMU...

Speed

[min-1]

NoG_MAX

Signal

PWM [%]

To visualize the following description, also refer to the sequence diagram of the LMU…

and the following graph.

Speed limitation

KonfigRg5)

N_VL*

(N_VL_Delta)

N_VL_QAA*

NhzMax

N_Vor

(N_Vor_Delta)

(N_ZL_Delta)

N_Nachstell_Delta

N_ZL* LmodZL*

N_Nachstell_Delta

(N_ZL_Delta)

N_ZL_QAA*

N_TL*

(N_TL_Delta)

N_TL_QAA*

NoG_Null

* Depending on parameter «FaEinstellFlags3»

LmodVL*

LmodVL_QAA*

PhzMax

LmodVor

LmodZL_QAA*

LmodTL*

LmodTL_QAA*

LmodNull

Fan control and speed parameters

First, set the speed limits while speed readjustment is switched off.

For that purpose, set the fan control parameters («LmodZL», «LmodVor», etc.) to the

values required from the combustion point of view (with the medium flueway and at

mains voltage).

Then, also determine the associated fan speeds from the fan characteristic and

parameterize them accordingly («N_ZL», «N_Vor», etc.).

In a first approach, set the limit values for the permitted bands very wide

(«N_ZL_Delta», «N_Vor_Delta», etc.).

The values of fan control and fan speed can now be optimized.

MAX

MAX

MIN

Boiler

Boiler

Heating

OFF

Extra function «Speed readjustment»

(optional)

N_Nachstell Kon1

N_Nachstell_Lern