Siemens LMS14 User Manual

Release 6

CC1U7471en

28.01.2015

Building Technologies Division

Albatros²

Boiler management unit LMS14...

User Manual

The LMS14… and this User Manual are intended for use by OEMs which integrate the boiler management unit

in their products.

2/617

Building Technologies Division User Manual LMS14… CC1U7471en

28.01.2015

3/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

Contents

1 Summary ....................................................................................................... 13

1.1 Supplementary documentation ...................................................................... 13

1.2 Target group of users .................................................................................... 14

1.3 Product range summary ................................................................................ 15

1.3.1 Topology ........................................................................................................ 15

1.3.2 Operating options .......................................................................................... 16

2 Safety notes ................................................................................................... 17

2.1 Notes on product liability ............................................................................... 17

2.1.1 Use of high-efficiency pumps ........................................................................ 18

2.1.2 High-voltage test ............................................................................................ 18

2.2 Environmental compatibility ........................................................................... 19

2.3 Lifecycle ......................................................................................................... 19

2.4 Standards and certificates ............................................................................. 19

2.5 Typographical conventions ............................................................................ 20

2.5.1 Safety notes ................................................................................................... 20

3 Mounting and installation ............................................................................... 21

3.1 Safety regulations .......................................................................................... 21

3.1.1 Electrical connection of ionization probe ....................................................... 21

3.1.2 Electrical connection on 2-phase systems .................................................... 22

3.2 Boiler management unit LMS14… ................................................................. 23

3.3 Basic diagram LMS14… ................................................................................ 25

3.4 Basic unit LMS14… complete (Basic) ........................................................... 26

3.4.1 Terminals of LMS14… complete (Basic) ....................................................... 27

3.4.2 Assignment of terminal X30 ........................................................................... 28

3.4.3 List of terminals of LMS14… complete (Basic) .............................................. 29

3.5 Basic unit LMS14... complete (Medium) ........................................................ 30

3.5.1 Terminals of LMS14… complete (Medium) ................................................... 31

3.5.2 Assignment of terminal X30 ........................................................................... 32

3.5.3 List of terminals of LMS14… complete (Medium) .......................................... 33

3.6 Basic unit LMS14... complete (Deluxe) ......................................................... 34

3.6.1 Terminals of LMS14… complete (Deluxe) ..................................................... 35

3.6.2 Assignment of terminal X30 ........................................................................... 36

3.6.3 List of terminals of LMS14… complete (Deluxe) ........................................... 37

3.7 Cable AGU2.110x109 .................................................................................... 38

3.8 Parameter stick AGU2.56xx109 .................................................................... 39

4 Commissioning .............................................................................................. 40

4.1 Basic units ..................................................................................................... 40

4/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

5 Handling ......................................................................................................... 41

5.1 Operation and display .................................................................................... 41

5.2 Overview of settings ....................................................................................... 42

6 The settings in detail .................................................................................... 124

6.1 Time of day and date ................................................................................... 124

6.1.1 Summer-/wintertime changeover ................................................................. 124

6.2 RF link .......................................................................................................... 125

6.2.1 Binding ......................................................................................................... 125

6.2.2 List of wireless devices ................................................................................ 126

6.3 Time programs ............................................................................................. 128

6.3.1 Switching points ........................................................................................... 128

6.3.2 Standard program ........................................................................................ 128

6.4 Holidays ....................................................................................................... 129

6.5 Heating circuits ............................................................................................ 131

6.5.1 Operating mode ........................................................................................... 131

6.5.2 Compensation variants ................................................................................ 132

6.5.3 Occupancy button (presence button) ........................................................... 134

6.5.4 Operating level ............................................................................................. 134

6.5.5 Setpoints ...................................................................................................... 135

6.5.6 Heating curve ............................................................................................... 136

6.5.7 ECO function ................................................................................................ 139

6.5.8 Flow temperature setpoint limits .................................................................. 142

6.5.9 Room thermostat ......................................................................................... 143

6.5.10 Delay heat request ....................................................................................... 147

6.5.11 Room model ................................................................................................. 149

6.5.12 Room influence ............................................................................................ 150

6.5.13 Room temperature control and limitation ..................................................... 152

6.5.14 Heating limit room controller ........................................................................ 152

6.5.15 Boost heating ............................................................................................... 153

6.5.16 Quick setback .............................................................................................. 154

6.5.17 Optimum start/stop control ........................................................................... 156

6.5.18 Heating up gradient room model .................................................................. 157

6.5.19 Raising the Reduced setpoint ...................................................................... 157

6.5.20 Continuous pump operation ......................................................................... 159

6.5.21 Frost protection for the room ........................................................................ 160

6.5.22 Frost protection for the heating circuit in Heating mode .............................. 160

6.5.23 Overtemperature protection for the pump heating circuit ............................. 161

6.5.24 Locking signals ............................................................................................ 162

6.5.25 Forced signals .............................................................................................. 162

6.5.26 Overtemperature protection for the mixing heating circuit ........................... 162

6.5.27 Pulse lock ..................................................................................................... 163

5/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.5.28 Flow temperature alarm ............................................................................... 163

6.5.29 Locking signals ............................................................................................ 164

6.5.30 Forced signals ............................................................................................. 164

6.5.31 Mixing valve control ..................................................................................... 165

6.5.32 Floor curing function .................................................................................... 167

6.5.33 Forced signal and locking signal ................................................................. 170

6.5.34 Buffer storage tank/primary controller ......................................................... 170

6.5.35 Speed-controlled pump ............................................................................... 171

6.5.36 Operating level changeover via input H ....................................................... 174

6.5.37 Operating mode changeover via input H ..................................................... 174

6.5.38 Behavior in the case of burner cycling ......................................................... 175

6.5.39 2-speed heating circuit pump ...................................................................... 175

6.5.40 2-speed boiler pump .................................................................................... 176

6.6 Cooling circuit 1 ........................................................................................... 177

6.6.1 Operating mode ........................................................................................... 177

6.6.2 Setpoints ...................................................................................................... 177

6.6.3 Room temperature limitation ....................................................................... 178

6.7 DHW heating ............................................................................................... 179

6.7.1 DHW mode .................................................................................................. 180

6.7.2 Setpoints ...................................................................................................... 181

6.7.3 Holiday program .......................................................................................... 182

6.7.4 DHW release ............................................................................................... 183

6.7.5 Priority ......................................................................................................... 185

6.7.6 Locking signals ............................................................................................ 185

6.7.7 Forced signals ............................................................................................. 185

6.7.8 Pump overrun .............................................................................................. 186

6.7.9 Legionella function ....................................................................................... 186

6.7.10 Circulating pump .......................................................................................... 190

6.7.11 Frost protection for the circulation pipe ....................................................... 191

6.7.12 Operating mode changeover via input H ..................................................... 192

6.8 Consumer circuit and swimming pool circuit ............................................... 193

6.9 Swimming pool ............................................................................................ 194

6.9.1 Setpoints ...................................................................................................... 194

6.9.2 Priority ......................................................................................................... 194

6.9.3 Overtemperature protection ......................................................................... 195

6.9.4 Plant hydraulics ........................................................................................... 195

6.10 Primary controller/system pump .................................................................. 196

6.10.1 Limitations of the flow temperature setpoint ................................................ 196

6.10.2 Mixing valve control ..................................................................................... 197

6.10.3 Plant hydraulics ........................................................................................... 198

6.11 Boiler ........................................................................................................... 199

6.11.1 Release threshold Outside temperature ...................................................... 199

6/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.11.2 Full charging of buffer storage tank ............................................................. 199

6.11.3 Setpoints ...................................................................................................... 200

6.11.4 Setpoint manual control ............................................................................... 202

6.11.5 Frost protection for the boiler ....................................................................... 203

6.11.6 PID control algorithm ................................................................................... 204

6.11.7 Boiler/burner control ..................................................................................... 205

6.11.8 Overtemperature protection ......................................................................... 206

6.11.9 Minimum limitation of boiler temperature ..................................................... 207

6.11.10 Minimum limitation of return temperature .................................................... 209

6.11.11 Boiler pump .................................................................................................. 210

6.11.12 Electronic temperature controller ................................................................. 211

6.11.13 Limitation of boiler temperature increase ..................................................... 212

6.11.14 Speed control ............................................................................................... 214

6.11.15 Output data .................................................................................................. 220

6.11.16 Fan ............................................................................................................... 221

6.11.17 Controller delay ............................................................................................ 223

6.11.18 Dynamic switching differentials .................................................................... 225

6.11.19 Delay heat request special operation ........................................................... 229

6.11.20 Flue gas supervision .................................................................................... 230

6.11.21 Static pressure supervision .......................................................................... 234

6.11.22 Dynamic pressure supervision ..................................................................... 237

6.11.23 Water pressure sensor ................................................................................. 241

6.11.24 Filling/flow supervision ................................................................................. 243

6.11.25 Quick shutdown of burner ............................................................................ 245

6.11.26 Limitation of output ....................................................................................... 246

6.11.27 Electronic limit thermostat ............................................................................ 248

6.11.28 Electronic safety limit thermostat (SLT) ....................................................... 249

6.11.29 Energy meter ............................................................................................... 255

6.11.30 Deaeration function ...................................................................................... 256

6.11.31 Input configuration dynamic pressure supervision ....................................... 258

6.11.32 Input configuration flow supervision ............................................................. 258

6.11.33 Additional settings for static pressure supervision ....................................... 259

6.11.34 Additional settings for dynamic pressure supervision .................................. 259

6.12 Special boiler functions ................................................................................ 260

6.12.1 Change of operating mode .......................................................................... 260

6.12.2 Loading the setpoint/actual value ................................................................ 260

6.12.3 Automatic heat generation lock .................................................................... 261

6.12.4 Manual heat generation lock ........................................................................ 261

6.12.5 Generation of common flow temperature setpoint ....................................... 262

6.12.6 Generation of boiler temperature setpoint ................................................... 262

6.12.7 Boiler control ................................................................................................ 263

6.12.8 Heat output limits ......................................................................................... 264

7/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.12.9 2-position controller ..................................................................................... 264

6.12.10 Protective boiler startup ............................................................................... 265

6.12.11 Keeping the boiler hot .................................................................................. 267

6.12.12 Alternative setting of output ......................................................................... 267

6.13 Cascaded systems ...................................................................................... 268

6.13.1 Addressing devices ..................................................................................... 268

6.13.2 Cascade master .......................................................................................... 269

6.13.3 Operating mode ........................................................................................... 270

6.13.4 Control ......................................................................................................... 271

6.13.5 Boiler sequence ........................................................................................... 272

6.13.6 Minimum limitation of return temperature .................................................... 274

6.13.7 Supervision of temperature differential ........................................................ 275

6.14 Extra heat source ........................................................................................ 275

6.15 Solar ............................................................................................................ 276

6.15.1 General ........................................................................................................ 276

6.15.2 Sensors ....................................................................................................... 277

6.15.3 Charging controller (dT) ............................................................................... 279

6.15.4 Maximum charging temperature, maximum safety temperature ................. 281

6.15.5 Priority ......................................................................................................... 282

6.15.6 Collector start function ................................................................................. 284

6.15.7 Frost protection for the collector .................................................................. 286

6.15.8 Overtemperature protection for the collector ............................................... 287

6.15.9 Recooling ..................................................................................................... 289

6.15.10 Evaporation temperature of medium ........................................................... 291

6.15.11 Speed control .............................................................................................. 292

6.15.12 Yield measurement ...................................................................................... 293

6.15.13 Hours run ..................................................................................................... 293

6.16 Solid fuel boiler ............................................................................................ 294

6.16.1 General ........................................................................................................ 294

6.16.2 Operating mode ........................................................................................... 295

6.16.3 Setpoints ...................................................................................................... 297

6.16.4 Control of the boiler/burner .......................................................................... 298

6.16.5 Overtemperature protection ......................................................................... 302

6.16.6 Frost protection ............................................................................................ 303

6.16.7 Frost protection for the solid fuel boiler ....................................................... 304

6.16.8 Configuration errors ..................................................................................... 304

6.16.9 Sensor error ................................................................................................. 304

6.17 Buffer storage tank ...................................................................................... 305

6.17.1 Release/control of heat source .................................................................... 305

6.17.2 Automatic locks ........................................................................................... 305

6.17.3 Charging solar/solid fuel boiler .................................................................... 307

6.17.4 Recooling ..................................................................................................... 308

8/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.17.5 Plant hydraulics ............................................................................................ 308

6.17.6 Return diversion ........................................................................................... 309

6.17.7 Partial charging ............................................................................................ 310

6.17.8 Full charging ................................................................................................ 311

6.17.9 Frost protection for the buffer in Heating mode ........................................... 311

6.17.10 Heat transfer to the DHW storage tank ........................................................ 312

6.18 DHW storage tank ........................................................................................ 314

6.18.1 Types of heat request .................................................................................. 314

6.18.2 DHW charging with one sensor ................................................................... 314

6.18.3 DHW charging with 2 sensors ...................................................................... 315

6.18.4 DHW charging with thermostat .................................................................... 315

6.18.5 Release ........................................................................................................ 316

6.18.6 Charging control ........................................................................................... 318

6.18.7 Limitation of charging time ........................................................................... 319

6.18.8 Charging pump/diverting valve .................................................................... 319

6.18.9 Discharging protection ................................................................................. 320

6.18.10 Overtemperature protection ......................................................................... 321

6.18.11 Frost protection for the DHW storage tank .................................................. 321

6.18.12 Recooling ..................................................................................................... 322

6.18.13 Electric immersion heater ............................................................................ 323

6.18.14 DHW push .................................................................................................... 326

6.18.15 Excess heat draw ......................................................................................... 328

6.18.16 Plant hydraulics ............................................................................................ 328

6.18.17 Speed-controlled pump ................................................................................ 329

6.18.18 Heat transfer ................................................................................................ 331

6.18.19 Stratification storage tank/intermediate circuit ............................................. 332

6.19 Storage tank systems .................................................................................. 334

6.19.1 Control of storage tank with sensor ............................................................. 334

6.20 Stratification storage tank ............................................................................ 336

6.20.1 Stratification storage tank with control to the boiler temperature flow .......... 338

6.20.1.1. Full charging of stratification storage tank ................................................... 340

6.20.1.2. Recharging the stratification storage tank .................................................... 341

6.20.2 Stratification storage tank with control to the DHW charging temperature via

setpoint compensation ................................................................................................. 342

6.20.2.1. Full charging of stratification storage tank ................................................... 344

6.20.2.2. Recharging the stratification storage tank .................................................... 347

6.20.3 Stratification storage tank with direct control to the DHW charging

temperature .................................................................................................................. 348

6.20.3.1. Full charging of stratification storage tank ................................................... 349

6.20.3.2. Recharging the stratification storage tank .................................................... 351

6.21 Instantaneous water heater ......................................................................... 352

6.21.1 Control ......................................................................................................... 352

6.21.2 DHW consumption (flow) ............................................................................. 352

9/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.21.3 DHW consumption (gradient) ...................................................................... 353

6.21.4 Keep hot function ......................................................................................... 354

6.21.5 Times ........................................................................................................... 355

6.21.6 Overrun ........................................................................................................ 355

6.21.7 Speed-controlled pump ............................................................................... 356

6.21.8 Configuration ............................................................................................... 357

6.21.9 Setpoint readjustment .................................................................................. 370

6.23 Configuration ............................................................................................... 378

6.23.1 Manual setting/adaption of partial diagrams ................................................ 381

6.23.2 Heating circuits/cooling circuit ..................................................................... 381

6.23.3 DHW storage tank ....................................................................................... 382

6.23.4 DHW separate circuit ................................................................................... 385

6.23.5 Boiler ........................................................................................................... 388

6.23.6 Boiler pump ................................................................................................. 390

6.23.7 Solar ............................................................................................................ 395

6.23.8 Combi storage tanks .................................................................................... 396

6.23.9 Relay outputs QX ........................................................................................ 397

6.23.10 Sensor inputs BX ......................................................................................... 403

6.23.11 Inputs H1/H3/H4/H5/H6/H7 ......................................................................... 405

6.23.12 Extension modules ...................................................................................... 414

6.23.13 EX extension modules 1/2/3 ........................................................................ 416

6.23.14 QX extension modules 1/2/3 ....................................................................... 418

6.23.15 BX extension modules ................................................................................. 423

6.23.16 H2 extension modules 1/2/3 ........................................................................ 425

6.23.17 PWM output/10 V output UX2/UX3 ............................................................. 433

6.23.18 PWM output P1 ........................................................................................... 435

6.23.19 Types of sensors/readjustments .................................................................. 436

6.23.20 Building model ............................................................................................. 437

6.23.21 Setpoint compensation ................................................................................ 439

6.23.22 Frost protection for the plant ........................................................................ 440

6.23.23 Control of flue gas damper .......................................................................... 441

6.23.24 Pump/valve kick ........................................................................................... 441

6.23.25 Pressure measurements H1, H2 and H3 ..................................................... 442

6.23.26 Saving the sensors ...................................................................................... 444

6.23.27 Plant diagrams ............................................................................................. 463

6.23.28 Device data .................................................................................................. 467

6.23.29 External space heating ................................................................................ 468

6.23.30 Partial diagrams ........................................................................................... 469

6.24 LPB system ................................................................................................. 470

6.24.1 Address/power supply ................................................................................. 470

6.24.2 Errors/maintenance/alarm ........................................................................... 472

6.24.3 Central functions .......................................................................................... 473

10/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.24.4 Clock ............................................................................................................ 478

6.24.5 Outside temperature .................................................................................... 478

6.25 Faults ........................................................................................................... 479

6.25.1 Message ...................................................................................................... 479

6.25.2 Acknowledgements ...................................................................................... 479

6.25.3 Error message functions .............................................................................. 480

6.25.4 History .......................................................................................................... 483

6.26 Maintenance/special mode .......................................................................... 484

6.26.1 Maintenance functions ................................................................................. 484

6.27 Special operating modes ............................................................................. 485

6.28 Parameter stick AGU2.56... ......................................................................... 493

6.28.1 Wrong use and risks .................................................................................... 493

6.28.2 Checks made by the LMS14... ..................................................................... 493

6.28.3 Examples of potential risks .......................................................................... 494

6.28.4 Reducing potential risks ............................................................................... 494

6.28.5 Spare part business ..................................................................................... 495

6.28.6 General notes on risks and problems .......................................................... 496

6.28.7 Operation via the boiler ................................................................................ 497

6.28.8 Parameter setting state ................................................................................ 501

6.28.9 Conditions for the transfer of data between LMS14... and parameter stick . 502

6.29 Input/output test ........................................................................................... 504

6.29.1 Output test relay ........................................................................................... 505

6.29.2 Input test sensors ......................................................................................... 508

6.29.3 Input test H1/H2/H3/H4/H5/H6/H7 ............................................................... 509

6.29.4 Input test EX (extension modules) ............................................................... 509

6.30 Operating state ............................................................................................ 510

6.30.1 Messages ..................................................................................................... 510

6.31 Diagnostics of cascaded system .................................................................. 515

6.32 Diagnostics of heat sources ......................................................................... 516

6.32.1 Process values ............................................................................................. 516

6.33 Diagnostics of consumers ............................................................................ 517

6.34 Burner control .............................................................................................. 518

6.34.1 Prepurging ................................................................................................... 518

6.34.2 Ignition ......................................................................................................... 519

6.34.3 Operation ..................................................................................................... 520

6.34.4 Postpurging .................................................................................................. 521

6.34.5 Configuration ................................................................................................ 522

6.34.6 Fan control ................................................................................................... 525

6.34.7 Chimney drying ............................................................................................ 526

6.34.8 Setpoint filter for fan speed control .............................................................. 527

6.34.9 Configuration ................................................................................................ 531

6.35 Program sequence of burner control (function) ........................................... 535

11/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

6.35.1 Program selection ........................................................................................ 535

6.35.2 Forced intermittent operation ....................................................................... 535

6.35.3 Burner control program ................................................................................ 535

6.35.4 Burner capacities ......................................................................................... 536

6.35.5 Sequence diagram for burner capacities ≤120 kW and Release QAA fan

param [4337.1] = ON ................................................................................................... 537

6.35.6 Sequence diagram for burner capacities >120 kW and Release QAA fan

param [4337.1] = ON ................................................................................................... 538

6.35.7 Sequence diagram for burner capacities ≤120 kW and Release QAA fan

param [4337.1] = OFF ................................................................................................. 539

6.35.8 Sequence diagram for burner capacities >120 kW and Release QAA fan

param [4337.1] = OFF >120 kW” ................................................................................. 540

6.35.9 Repetition counter ....................................................................................... 544

6.35.10 Description of sequence diagrams .............................................................. 545

6.35.11 Fan speed control ........................................................................................ 551

6.35.12 Filter for fan speed setpoint (OEM) ............................................................. 552

6.36 PWM limitation ............................................................................................. 556

6.36.1 Supervising air supply by monitoring current fan speed .............................. 556

6.37 Chimney drying ............................................................................................ 558

6.38 Fan parameters settable as load values via QAA75…/AVS37… ................ 559

6.38.1 Limitation of ionization current ..................................................................... 566

6.38.2 Ionization current maintenance ................................................................... 567

6.39 Modulating pump ......................................................................................... 568

6.39.1 Modulation of heating circuit pump .............................................................. 568

6.39.2 Behavior when burner cycles ...................................................................... 570

6.39.3 Limitation of boiler temperature differential ................................................. 571

6.39.4 Conditions for limiting the boiler’s temperature differential .......................... 572

6.39.5 Limitation dependent on pump modulation .................................................. 572

6.39.6 Limitation to the maximum differential ......................................................... 573

6.39.7 Limitation to the nominal differential ............................................................ 574

6.40 List of displays ............................................................................................. 575

6.40.1 Error code list .............................................................................................. 575

6.40.2 Maintenance code ....................................................................................... 578

6.41 Lockout/local reset ....................................................................................... 579

6.41.1 Lockout ........................................................................................................ 579

6.41.2 Local reset via the reset button ................................................................... 579

6.42 Remote reset ............................................................................................... 580

6.42.1 Additional activation of remote reset capability ........................................... 580

6.42.2 Restrictions in connection with remote reset ............................................... 580

6.43 Production ................................................................................................... 581

6.43.1 Monitoring mains voltage/mains frequency ................................................. 583

7 Plant diagrams ............................................................................................. 584

7.1 Basic diagrams ............................................................................................ 584

12/617

Building Technologies Division User Manual LMS14… CC1U7471en

Contents 28.01.2015

7.2 Extra functions ............................................................................................. 585

8 Technical data .............................................................................................. 586

8.1 LMS14… basic unit ...................................................................................... 586

8.1.1 General data ................................................................................................ 586

8.1.2 Environmental conditions ............................................................................. 586

8.1.3 Electrical connection data, mains voltage connections ................................ 587

8.1.4 Electrical connection data, extra-low voltage connections (PELV) .............. 589

8.1.4.3. Inputs B7/BX4 .............................................................................................. 589

8.1.4.4. Inputs B3/B38 .............................................................................................. 590

8.1.4.5. Inputs BX1/BX2/BX3 .................................................................................... 590

8.1.4.6. Input B9 ........................................................................................................ 590

8.1.4.7. Input H1 ....................................................................................................... 590

8.1.4.8. Input H3 ....................................................................................................... 591

8.1.4.9. Input H4 ....................................................................................................... 591

8.1.4.10. Input H5 ....................................................................................................... 591

8.1.4.11. Input H6 ....................................................................................................... 592

8.1.4.12. Input H7 ....................................................................................................... 592

8.1.4.13. Input for reset (EK) ....................................................................................... 592

8.1.5 PWM fan/Hall connection facility .................................................................. 592

8.1.6 PWM pump connection P1 .......................................................................... 593

8.1.7 PWM output/10 V output UX2/UX3 .............................................................. 593

8.1.8 Control of diverting valve ............................................................................. 593

8.1.9 BSB users .................................................................................................... 594

8.1.10 Outputs for LED flame and LED fault (X30) ................................................. 594

8.1.11 Cross-sectional area sensors ...................................................................... 594

8.2 Parameter stick AGU2.56xx109 ................................................................... 595

8.3 Sensor characteristics .................................................................................. 596

8.3.1 NTC 1k ......................................................................................................... 596

8.3.2 NTC 10k ....................................................................................................... 597

8.3.3 Pt1000 .......................................................................................................... 597

8.3.4 NTC 20k ....................................................................................................... 598

9 List of figures ................................................................................................ 599

13/617

Building Technologies Division User Manual LMS14... CC1U7471en

1 Summary 28.01.2015

1 Summary

The present User Manual describes handling and configuration of the following

products for OEMs:

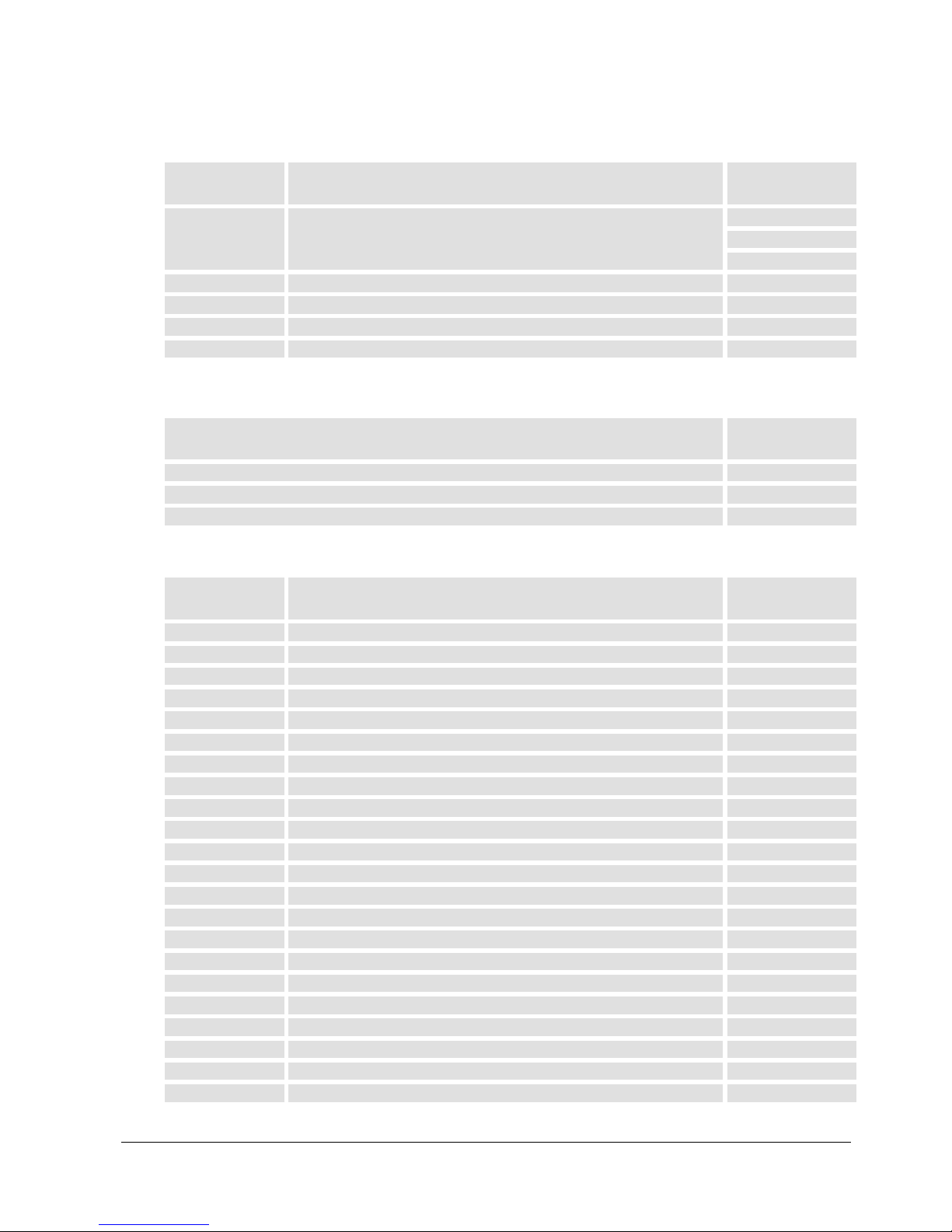

Product no.

(ASN)

Description

Documentation

no.

LMS14... Boiler management unit

CC1E7471

CC1U7471

CC1U7472

AGU2.560... Parameter stick for LMS..., can be read out CC1U7471

AGU2.561... Parameter stick for LMS..., writable CC1U7471

AGU2.563... Parameter stick for direct programming of the LMS... CC1U7471

AGU2.564... Parameter stick for spare part programming of the LMS... CC1U7471

1.1 Supplementary documentation

Description

Documentation

no.

Environmental Declaration LMS... CC1E7471

Data Sheet LMS… N7471

Product range overview LMS…

Q7471

For more information about accessories, refer to the following documents:

Product no.

(ASN)

Description

Documentation

no.

LMS15... Boiler management unit CC1U7472

Product range Product range overview Albatros² CE1Q2359

System

Albatros

2

system

CE1P2359_08

Partial Diagrams

Albatros

2

Hydraulic Partial Diagrams and Extra Functions

CE1P2359_10

AGU2.550... Extension ClipIn for LMS... CC1N7492

AGU2.551... Extension ClipIn for PWM (DC 0...10 V) CC1N7493

AGU3.6... Gas/air mixer CC1N7211

AGU3.7... Gas/air mixer CC1N7214

AVS13.399... Wireless outside sensor CE1U2354

AVS14.390... Wireless repeater CE1U2354

AVS37.294... Operating unit (Clear-text) CE1U2353

AVS37.390... Operating unit (Basic) CE1U2358

AVS71.390... Wireless module CE1U2354

AVS71.393... Wireless module BSB CE1U2358

AVS75.390... Extension module CE1U2353

AVS75.391... Extension module CE1U2354

OCI345.06/101 LPB ClipIn CC1U2355xx_04

QAA55.110... Room unit basic CE1U2353

QAA75.610... Room unit wire CE1U2353

QAA75.611... Room unit wire, with backlit display CE1U2353

QAA78.610... Room unit wireless CE1U2353

QAC34/101 Outside sensor NTC 1k CC1Q1701

14/617

Building Technologies Division User Manual LMS14... CC1U7471en

1 Summary 28.01.2015

Product no.

(ASN)

Description

Documentation

no.

QAD36/101 Strap-on temperature sensor NTC 10k CC1Q1808

QAZ36.522/109 Immersion temperature sensor NTC 10k CC1Q1843

QAZ36.526/109 Immersion temperature sensor NTC 10k CC1Q1843

OCI430... Interface module for PC-LMS... connection CC1N7635

OCI700 Service tool CC1E5655

TQG42...

Ignition module, combined with connection line for LMS14..., suitable

for VGU smart gas valves

CC1N7630

VGU7xS... Combination gas valves CC1N7668

VGU8xS... Combination gas valves CC1N7668

ACS420 Software for OCI430... ---

ACS432 Parameter stick manager CC1J7474

ACS435 Setup manager CC1J7471

ACS700 Remote supervision software/parameterization software for OCI700 Software CD

LMS14... are digital boiler management units (BMUs) for use with gas-fired

appliances equipped with premix burners. They are used for startup, control and

supervision of premix burners with capacities from <10 kW to 1 MW in intermittent

operation with direct ignition of the main flame.

The OEM must make certain that the LMS14… are suited for the application in

question.

The LMS14... provide all supervisory and control functions required for burner

operation, space heating and DHW heating. They also offer modular system

extensions in the form of integrated communication interfaces. Output modulation

is performed via a PWM-controlled fan with pneumatic gas-air ratio control.

1.2 Target group of users

Target group of users are OEMs

LMS14…

15/617

Building Technologies Division User Manual LMS14... CC1U7471en

1 Summary 28.01.2015

1.3 Product range summary

1.3.1 Topology

Remote

Servi ce tool

Mobile, SMS, Pager , Fax ,

WEB

Tel e f on

Networ k

Tel e f on

SMS

OCI 611

OCI7. ..

ACS700

BSB : Boiler S ystem Bus

Service Unit

(RU)

HMI

HMI

(RU)

Basic Uni t

LMS...

Extens ion

mod. AVS75…

(max. 3)

BSB- W

LPB : Local Process Bus

Basic Unit

LMS... / RVS...

LPB

Servi ce tool

OCI4 30

ACS420

7471z01e/1210

OCI345. ..

Room Unit

Figure 1: Product range summary – wired

Remote

Service tool

Mobile , SMS, Pager , Fax,

WEB

Tel ef o n

Networ k

Tel e fo n

SMS

OCI6 11OCI700

RF

Modul

ACS700

BSB : Boiler System Bus

Room Unit

RF

Repeater

RF

Tou ts id e

BSB-RF

Service Unit

(RU)

HMI

(RU)

Wireless

Wireless

Wireless

Basic Unit

LMS...

Extension

mod. AVS75...

(max. 3)

BSB -W

LPB : Local Process Bus

Basic Unit

LMS.../ RVS...

LPB

Service tool

OCI430

ACS420

7471z02e/1210

OCI345...

Figure 2: Product range summary – wireless

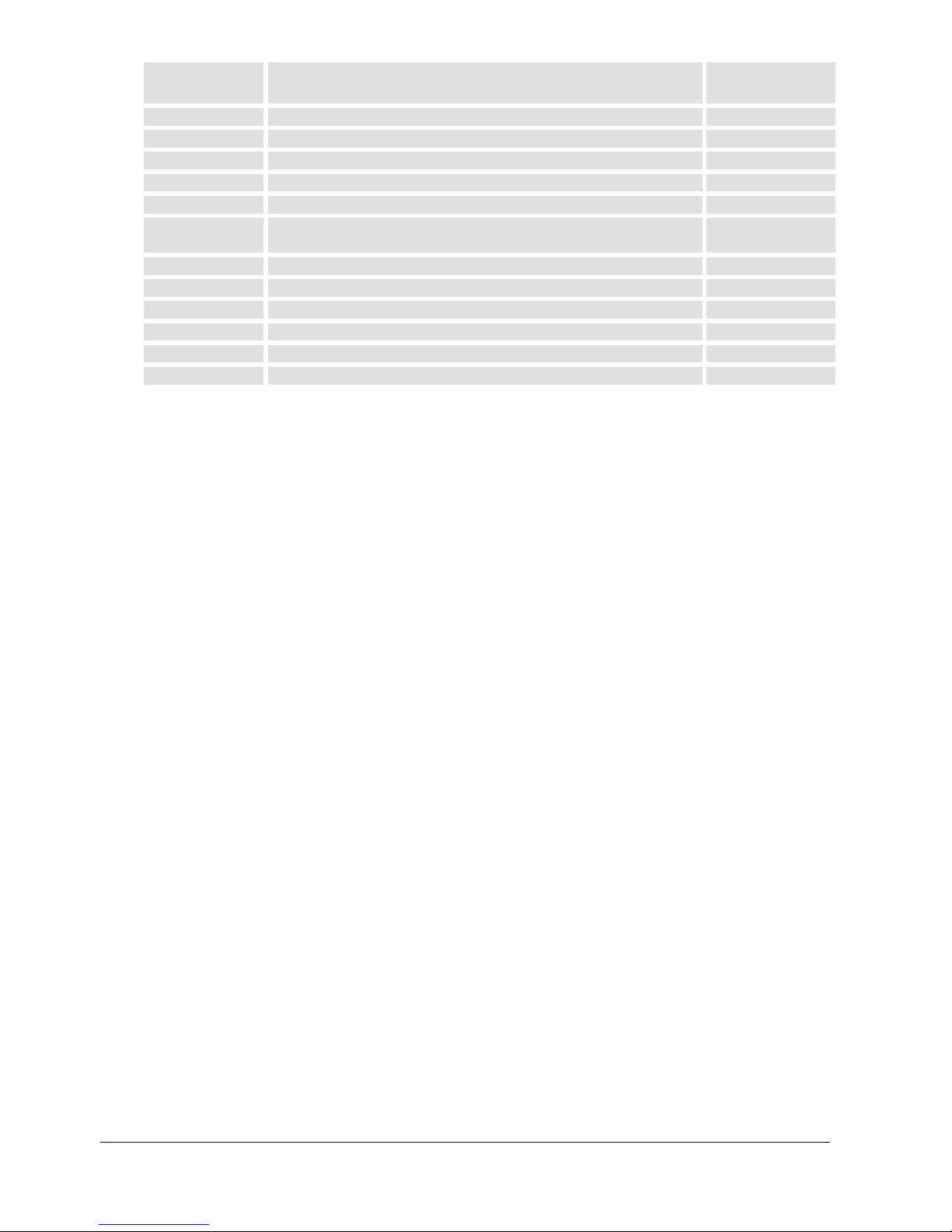

Wired

Wireless

16/617

Building Technologies Division User Manual LMS14... CC1U7471en

1 Summary 28.01.2015

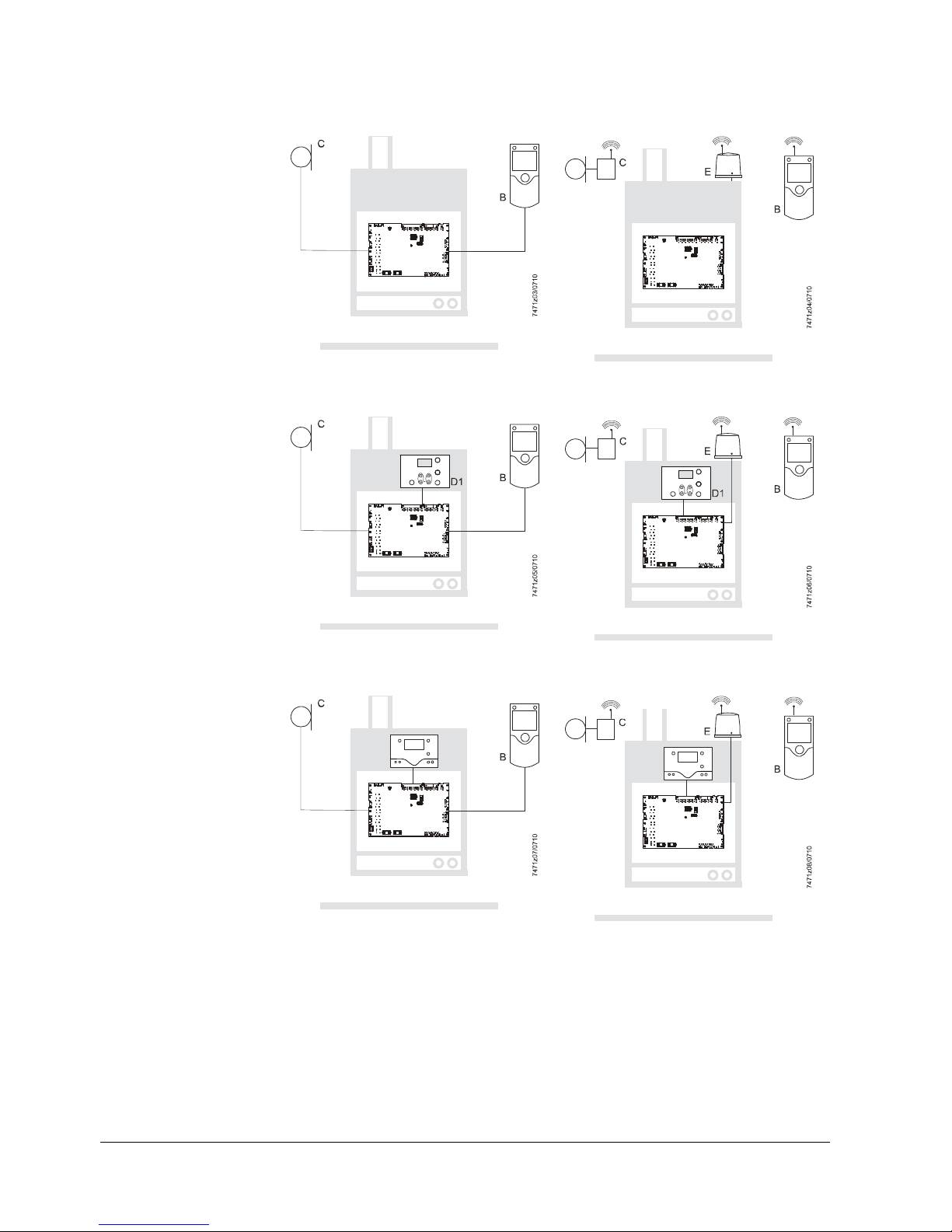

1.3.2 Operating options

Wired Wireless

A

T

A

T

Wired Wireless

A

T

Reset

+

A

T

Reset

+

Wired Wireless

A

T

D

A

T

D

Key

A Basic unit LMS14...

B Room unit QAA55.../QAA75.../QAA78...

C Outside sensor AVS13...

D Operator unit AVS37.294... (Clear-text)

D1 Operator unit AVS37.390... (Basic)

E RF module AVS71...

Operation via room unit

Operation via operator unit

Basic (optionally with

additional room unit)

Operation via operator unit

Clear-text (optionally with

additional room unit)

17/617

Building Technologies Division User Manual LMS14... CC1U7471en

2 Safety notes 28.01.2015

2 Safety notes

2.1 Notes on product liability

The LMS14… may only be used in building services plant and only in compliance

with the applications covered by this document

When employing the products, all requirements specified in chapters Handling and

Technical data must be satisfied

Local safety regulations (installation, etc.) must be complied with

The units must not be opened. If not observed, warranty by Siemens becomes void

Danger!

Do not open, interfere with or modify the units!

All activities (mounting, installation, service work, etc.) must be performed by

qualified personnel

Before performing any work in the connection area of the LMS14…, disconnect the

unit from mains supply (all-polar disconnection). Ensure that the plant cannot be

inadvertently switched on again and that it is indeed dead. If not disconnected,

there is a risk of electric shock

Ensure protection against electric shock by providing adequate protection for the

unit’s terminals

After any kind of activity (mounting, installation, service work, etc.), check to ensure

that wiring is in an orderly state, that all safety functions are performed correctly

and that the parameter settings are correct

Fall or shock can adversely affect the safety functions. Such units must not be put

into operation, even if they do not exhibit any damage

AC 230 V terminals that are not used must be protected by dummy plugs fitted by

the burner manufacturer

Never connect or disconnect the stepper motors (WX1 connected to X16 or

X16a) when live. If not observed, the built-in driver stage can be damaged

Siemens will not assume liability for damage resulting from unauthorized

interference!

If fuses inside the LMS15… are blown, the unit must be returned to Siemens. The

mains fuse (FB01/FB02) may be replaced once

. Since overcurrents can damage

relays, a plant safety check must be made.

Electromagnetic emissions must be checked on an application-specific basis!

The choice of applications and scope of functions covered by this User Manual

shall serve as a guideline. The correct operation of the plant must be checked

and proven by function tests made on the heating appliance and the relevant

plant!

Danger!

At the OEM’s request, the quick connector for the mechanical STB (SLT = safety limit

thermostat) on the printed circuit board can be bridged ex factory. In that case, the

mechanical SLT would be deactivated. When using a mechanical SLT, the resistor

must always be removed. LMS14... with different type numbers must never be mixed

up.

18/617

Building Technologies Division User Manual LMS14... CC1U7471en

2 Safety notes 28.01.2015

2.1.1 Use of high-efficiency pumps

When using high-efficiency pumps or pumps with integrated electronics, the

resulting switch-on currents can adversely affect the relays’ service life. For this

reason, use of these types of pump is permitted only if authorized in writing by

Siemens.

2.1.2 High-voltage test

Caution!

When making 100% inspections to DIN EN 60335-1, Addendum A, only AC

voltage may be applied. If tests are conducted with DC voltage, the LMS14...

might be damaged.

19/617

Building Technologies Division User Manual LMS14... CC1U7471en

2 Safety notes 28.01.2015

2.2 Environmental compatibility

The units contain electrical and electronic components and must not be disposed of

together with domestic waste.

Local and currently valid legislation must be complied with!

2.3 Lifecycle

The LMS14… have a designed lifetime* of 250,000 burner startup cycles which, under

normal operating conditions in Heating mode, correspond to approx. 10 years of usage

(starting from the production date indicated on the type field).

This lifetime is based on the endurance tests in the standard EN 298.

A summary of the conditions has been published by the European Control

Manufacturers Association (Afecor) (www.afecor.org

).

The designed lifetime is based on usage of the LMS14… as specified in the

manufacturer’s Data Sheet and User Manual. After reaching the designed lifetime in

terms of the number of burner startup cycles, or the respective time of usage, the

LMS14… are to be replaced by authorized personnel.

* The designed lifetime is not identical with the warranty time specified in the Terms of

Delivery

2.4 Standards and certificates

Conformity to EEC directives

- Electromagnetic compatibility EMC (immunity)

- Directive for gas-fired appliances

- Low-voltage directive

2004/108/EC

2009/142/EC

2006/95/EC

ISO 9001:2008

ISO 14001:2004

OHSAS 18001:2007

Identification code to EN 298: 2003 chapter 4: F M C L B N

Disposal

20/617

Building Technologies Division User Manual LMS14... CC1U7471en

2 Safety notes 28.01.2015

2.5 Typographical conventions

2.5.1 Safety notes

This User Manual contains instructions which must be observed to ensure your

personal safety and to prevent damage to equipment and property. The instructions

and notes are highlighted by warning triangles, arrows or information symbols and are

presented as follows, depending on the hazard level:

Danger

means that death, severe personal injury or substantial

property damage will occur if adequate precautionary

measures are not taken.

Warning

means that death, severe personal injury or substantial

property damage can occur if adequate precautionary

measures are not taken.

Caution

means that minor personal injury or property damage

can occur if adequate precautionary measures are not

taken.

Note draws your attention to important information on the

product, on product handling, or to a special part of the

documentation.

Reference refers to further information given in other pieces of

documentation or in chapters of this document.

Only qualified personnel are allowed to install and operate the equipment. Qualified

personnel in the context of the safety-related notes contained in this document are

persons who are authorized to commission, ground and tag devices, systems and

electrical circuits in compliance with established safety practices and standards.

Note the following:

The LMS14… may only be used on applications covered by the technical description.

The use of unsuitable or incorrectly installed accessories can lead to personal injury or

damage to property.

When using the unit in connection with third-party products or components, following

must be noted:

- The technical data of the LMS14… must be observed; in addition to static data,

consideration must be given to dynamic data, such as switch-on and switch-off

currents, surge currents, etc.

- EMC-specific properties or retroactive effects can adversely affect the unit’s life and

reliability and must be checked by the customer

- The OEM as the system integrator must ensure compliance with the relevant

regulations and make certain the correct fuses are used

- Siemens assumes no responsibility for the system

The products can only function correctly and safely if shipped, stored, set up and

installed correctly, and operated and maintained as specified.

Qualified personnel

Correct use

21/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

3 Mounting and installation

3.1 Safety regulations

Prior to installation, disconnect power

The low-voltage and mains voltage terminals are arranged on different sides of the

unit

Warning!

Never run ionization probe cable and mains cables in the same trunk.

This unit does not provide any separate line protection for supply cables

running to external loads (field supply)!

The cable insulation must always be appropriate for the rated voltage

concerned.

If supply voltages (including a 24 V extra-low voltage) are fed to external loads,

the cross-sectional areas used must always be suitable for the rated value of

the upstream overcurrent protective device.

Always observe the relevant local regulations in this regard.

Warning!

When making the wiring, the AC 230 V section must be strictly segregated

from the extra low-voltage section, thus ensuring protection against

electric shock and electromagnetic interference

In connection with the (safety) limit thermostat, observe the safety-related

notes given in chapter Electronic safety limit thermostat (SLT)

Make certain that spliced individual wires cannot touch neighboring

terminals. Fit suitable ferrules

Always run the high-voltage ignition cables separate from the unit and

other cables while observing the greatest possible distances

Danger!

Compliance with DIN EN 60335 and DIN EN 60730-2-5 must be ensured

The electrical wiring inside the boiler must conform to national and local

regulations

Degree of protection IP40 as per DIN EN 60529 for burner controls must be

ensured by the burner or boiler manufacturer through correct installation

of the LMS14...

3.1.1 Electrical connection of ionization probe

It is important to achieve practically disturbance- and loss-free signal transmission:

Never run the ionization probe cable together with other cables

- Line capacitance reduces the magnitude of the flame signal

- Use a separate cable

Observe the permissible length of the ionization probe cable (refer to chapter

Technical data in the relevant pieces of documentation)

Locate ignition electrode and ionization probe such that the ignition spark cannot

arc over to the ionization probe (risk of electric shock)

Locate the ionization probe and its connections such that adequate protection

against direct or indirect contact with active parts is ensured in every unfavorable

position allowed under correct usage conditions. If not observed, there is a risk of

electric shock

Electrical installation

22/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

3.1.2 Electrical connection on 2-phase systems

When operating the LMS14 on 2-phase systems, the following points must be observed:

You must adhere to the mains voltage and mains frequency values specified in the

technical data

The components you connect to the LMS14 (gas valve, igniter, etc.) must be

suitable for 2-phase operation

Make sure to connect the phases correctly.

There is a phase angle of 120° between the phases. Therefore, the sequence in

which the phases are connected does make a difference.

Connecting them incorrectly can result in an excessively low ionization current and

lead to "loss of flame" faults.

To ensure they are connected correctly, we recommend following the procedure

described below:

1. The characteristic ionization current for a particular type of boiler must be

determined by the OEM in 1-phase operation and documented in the Service

Manual.

This value can be read by referring to the Ionization current (8329) line in the

Diagnostics heat source menu.

2. When commissioning a boiler on a 1-phase system, it is essential to check the

Ionization current (8329).

If it is the same as or higher than the value in the Service Manual, the phases

have been connected correctly.

If the Ionization current (8329) is lower than the value in the Service Manual,

the phases have been connected incorrectly and must be swapped round.

23/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

3.2 Boiler management unit LMS14…

When mounting the PCB on a metal plate, the clearance between the lower edge

of the PCB and the metal plate must be a minimum of 12 mm (as per DIN EN

60335 minimum 8 mm air and creepage path to the end of the wires or the

solder fillets).

- Spacers must be made of electrically non-conductive material!

- When using metal screws for fixing, the head diameter must be 7.5 mm!

- If 2 metal screws are screwed into a spacer from both sides, an air path of 8 mm

must be observed or solid insulation of 2 mm must be provided (as per

DIN EN 60335)!

Caution!

Mounting (general information)

Currently valid national safety regulations must be complied with!

Inside the boiler, the unit must be fitted in a housing ensuring degree of

protection IP40 as a minimum requirement

Depending on the location and environmental conditions, higher degrees of

protection may be required

When mounted, the maximum permissible ambient temperature must never be

exceeded

Condensation water must not drip on the LMS14… or enter the unit, neither in

operation nor when service work is carried out

Ignition equipment

Note!

In terms of switching performance, any type of external ignition module used must be

approved by Siemens!

Electric ignition sparks generate high-frequency energy which can adversely affects

radio and television reception. The high-voltage cable running to the ignition electrode

acts as a transmit antenna. For this reason, application-specific tests must be made to

confirm that adequate distances are observed. High-frequency energy is also of

capacitive and inductive nature, that is, not wire-bound. This must be taken into

consideration when laying the cables.

The ignition cable used must satisfy the technical requirements of the ignition

module and should be run to the ignition electrode as directly as possible, with

no loops in between.

It must never be laid parallel or very close to other electrical cables.

24/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

Connections and wiring

When making the wiring, ensure that the protective extra low-voltage side is

strictly separated from other sections, thus providing protection against electric

shock and making certain that EMC will not be adversely affected! The

connectors’ predefined coding must be observed! Make the connections only

when the components are disconnected from power! AC 230 V terminals that are

not used must be covered by dummy plugs to ensure protection against electric

shock! A multipole isolator is required to disconnect the unit from mains supply.

For wiring the bus users, cables specified by Siemens are mandatory!

External signal sources (air pressure switch, room thermostat, DHW flow switch, etc.)

should have gold-plated silver contacts.

Both ionization probe and ignition electrode must be protected against electric shock.

Since the line to the ionization probe must be well insulated against ground, that line

together with the ionization probe must be protected against condensation and very

damp surroundings.

Warning!

Connector X17 for the burner ground must be connected as directly as

possible to protective earth (PE) of the mains cable and to X1 or X1a, pin 2, at

the mains input of the LMS14...

The burner’s housing must also be connected to the protective earth of the

mains cable.

The safety regulations for protective earth wiring must be complied with in all

cases.

Neutral point is the protective earth terminal of the mains cable.

The way protective earth is wired has a considerable impact on whether the

emission limits as per DIN EN 60335 are adhered to and on the unit’s EMC

performance inside the boiler.

Tests made by the customer

If the boiler or burner manufacturer wants to make additional insulation and high-

voltage tests, prior approval by Siemens is required!

As regards Directive 2004/108/EC (EMC): Once this component has been installed

in the equipment, evidence and explanatory information must be provided to

demonstrate that the relevant requirements have been met.

Engineering

The flow sensor (B2) and the return sensor (B7) are safety-related

components!

They must meet the requirements of DIN EN 14459:2007 Annex K while also

adhering to EN 15502-1:2012 Section 5.7.8.3.2 b).

Air circulation around the LMS14… must be ensured, enabling the unit to dissipate

the heat produced by its controller

The unit has been designed for use inside equipment of safety class I and must be

installed accordingly

Power may be switched on only when the unit is completely mounted. Otherwise,

there is a risk of electric shock at the terminals and through the cooling slots

The unit must not be exposed to drip water

Mains cables must be run completely separate from low-voltage cables (sensors),

observing a minimum distance of 100 mm

Mounting location

The LMS14… has been designed for mounting inside the burner or inside a control

panel. Protection against electric shock must be ensured!

25/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

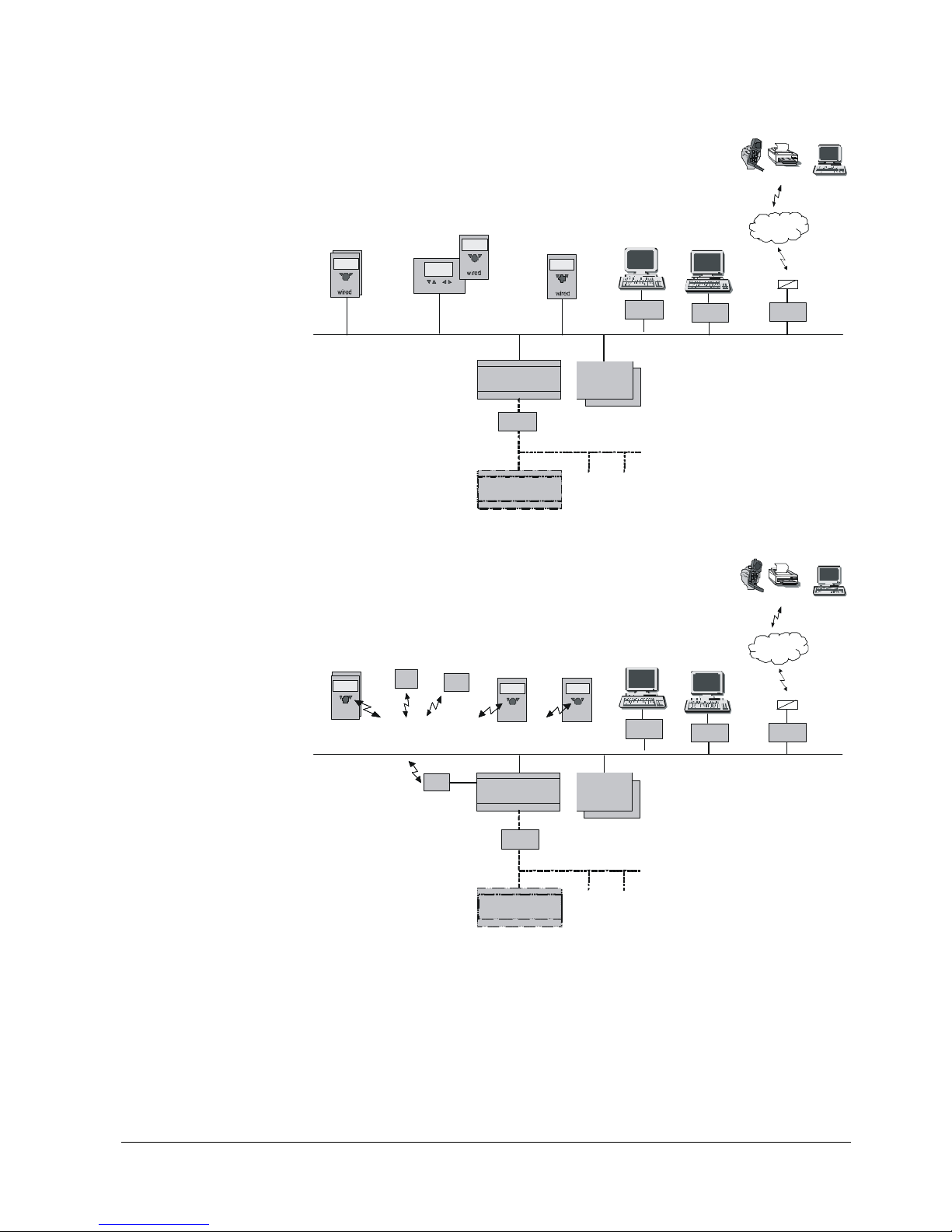

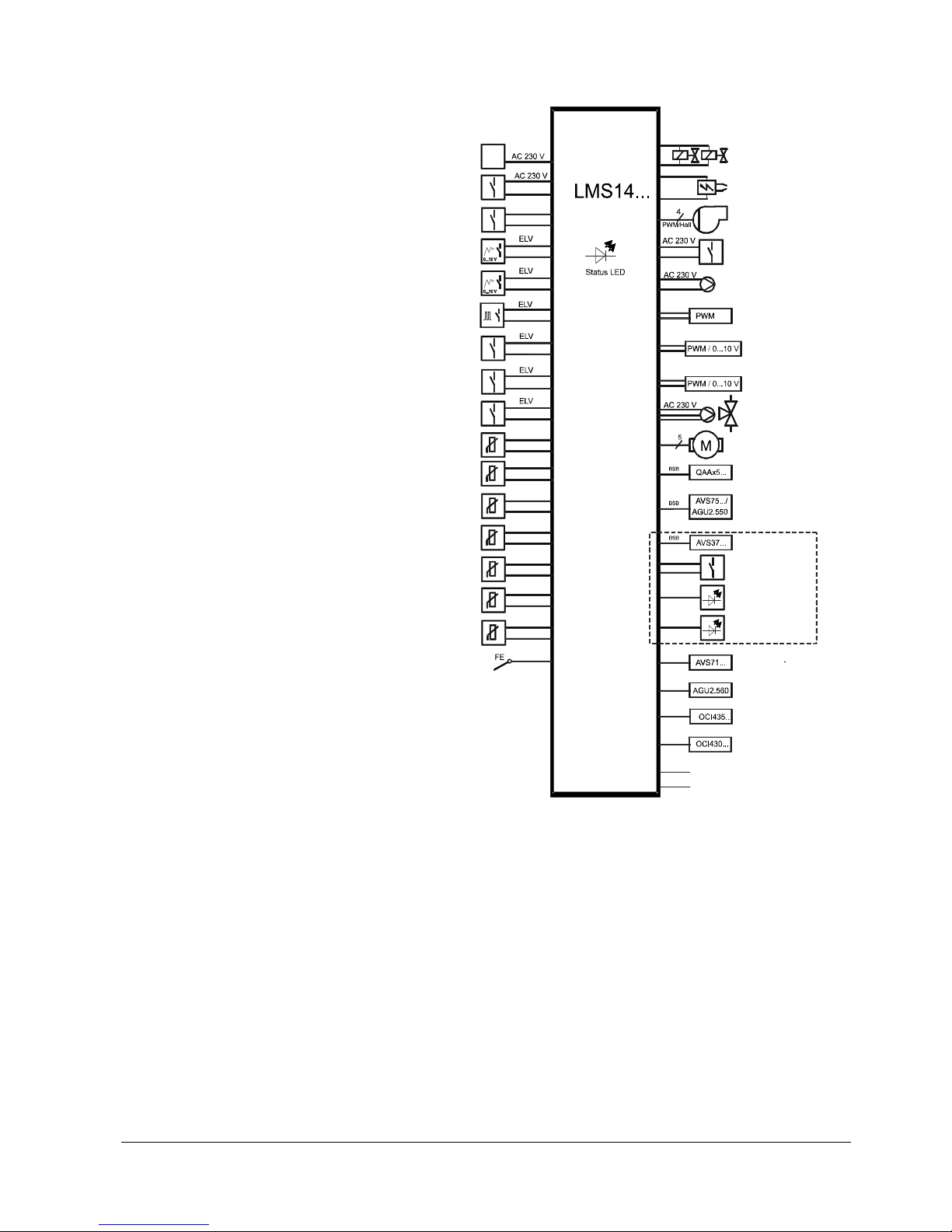

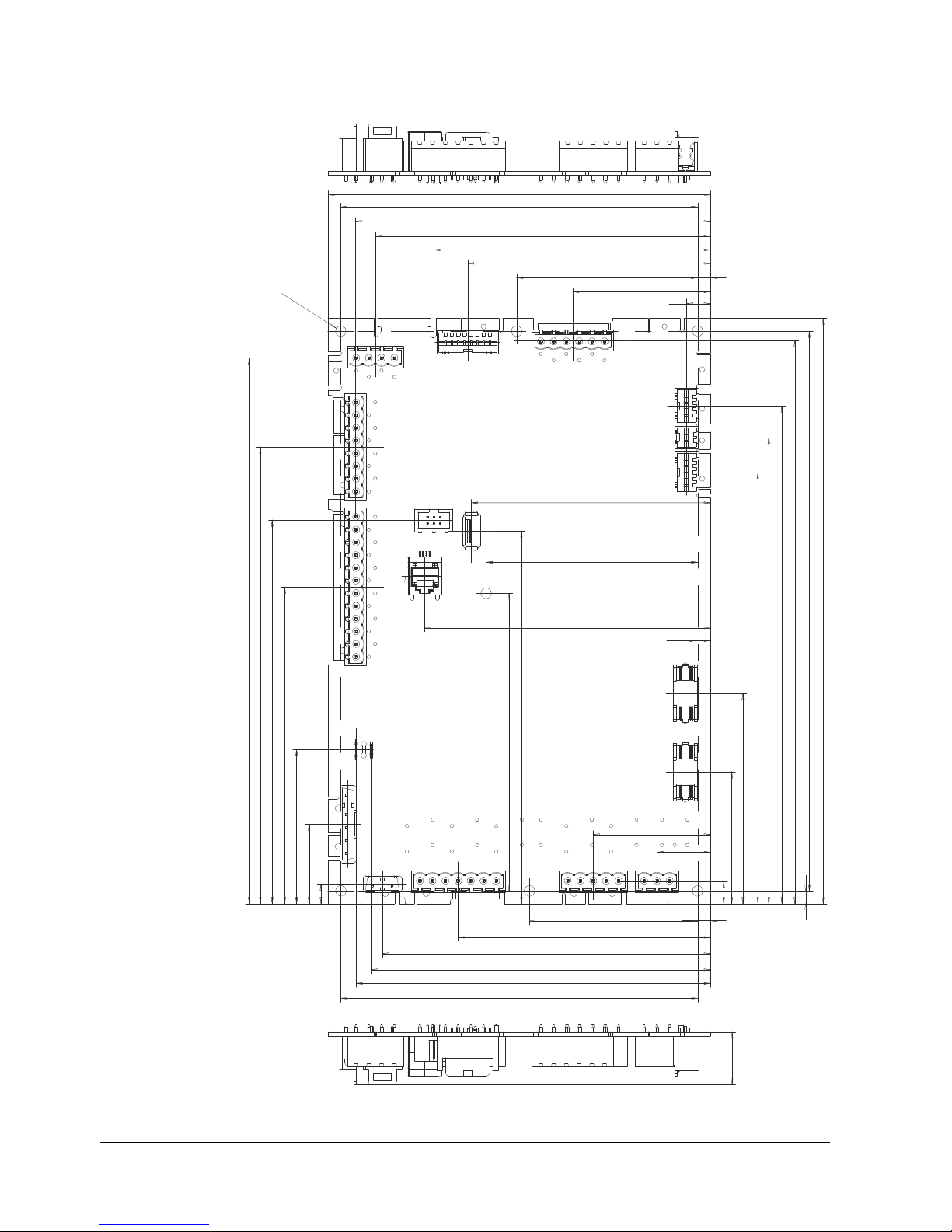

3.3 Basic diagram LMS14…

7471a44e/1214

Mains voltage

Lockout

(Safety temperature limiter,

Temperature li miter)

Lockout r eset butt on

Programmable analog /

digital input

Programmable analog /

digital input

Programmable frequenzy /

digital input

Programmable digital

input

Gas pressure switch or programmable

digital input

Air pressure switch or

progr amm able d igital

input

Boiler flow sensor

DHW sensor 1

Outside sensor

Multifunction sensor

Multifunction sensor

Multifunction sensor

Boiler return sensor /

multifunction sensor

Flame supervision

(continuous)

L1, N, PE / L1, L2, PE

(L1 / N )

replaceable

(S)TB / TB

Reset

H1

H3

H4

H5

H6

H7

B2

B3 / B38

B9

BX1

BX2

Bx3

Return flow B7 / BX4

Threshold programmable /

Dual or single electrode operation

Fuel valve

AC 230 V

Ignition module

AC 230 V

Variable Geschwindigkeit

PWM fan

AC 230 V

Multifunction

outpur

Heating circuit pump

Analog output

Analog output

Analog output

DHW pump 1

or diverting valve

Unipolar / bipolar

stepper motor

(diverting valve)

Room unit S / 1 / 2 / 3

Extension module 1 / 2 / 3

Operator unit

Reset

LED interference

LED flame

Radio module

Parameter stick

LPB module

PC tool

Line A UX1 (fuse )

Line A UX2 (fuse )

QX1

QX2

P1

UX2

UX3

QX3

QX4

Figure 3: Basic diagram

The diagram shows the full scope of functions of the LMS14… system.

The actual functions are to be determined based on the respective

execution/configuration.

26/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

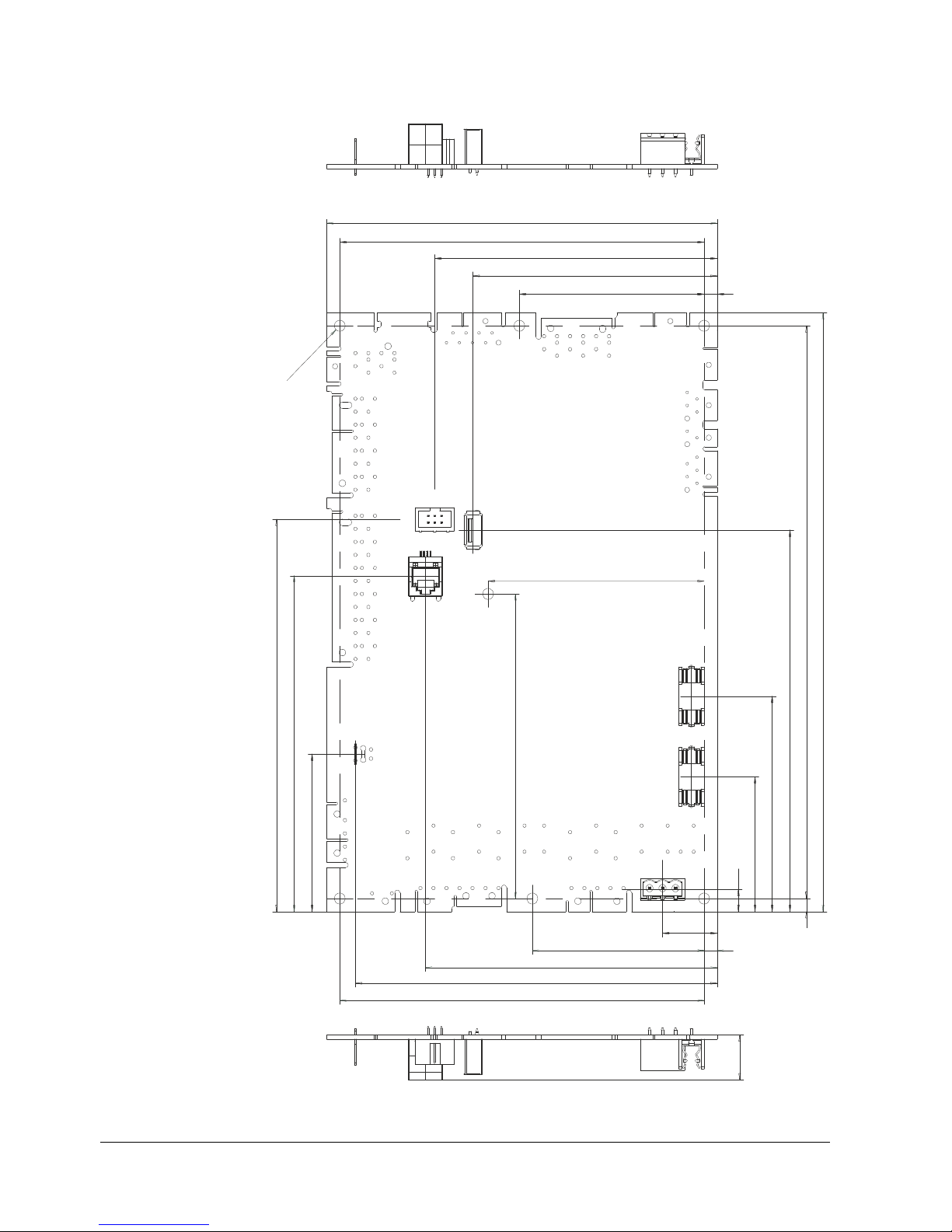

3.4 Basic unit LMS14… complete (Basic)

Dimensions in mm

150

140

108,5

93,8

71

5

Ø

4

,

2

(

7

x

)

83

117

150,7

129

60,5

82,7

146,5

220

230

8,6

51,8

5

21

5

66

112,1

139

140

17,2

7471m27/0514

Figure 4: Dimensions of basic unit complete (Basic)

27/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

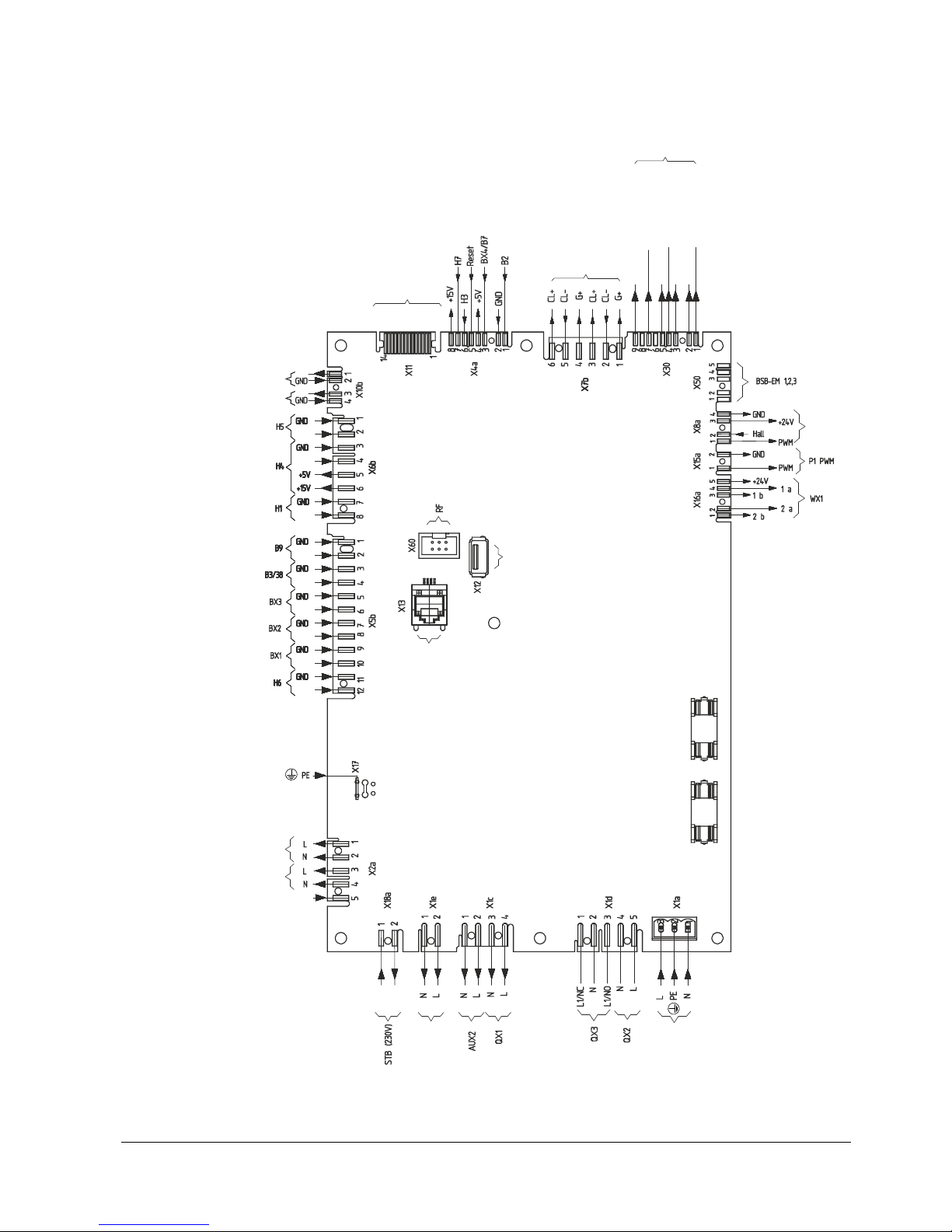

3.4.1 Terminals of LMS14… complete (Basic)

LED flame

LED interference

Reset

Identification port

+12 V

CL+

GND

BSB operator unit

Fan PWM

AUX1 / fan

Mains supply

Ionization

Ignition module

Fuel valve

OCI430

AGU2.56...

BSB bus room unit

OCI345...

7471a4 1e/1214

UX2

UX3

Figure 5: Terminals of LMS14… complete

28/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

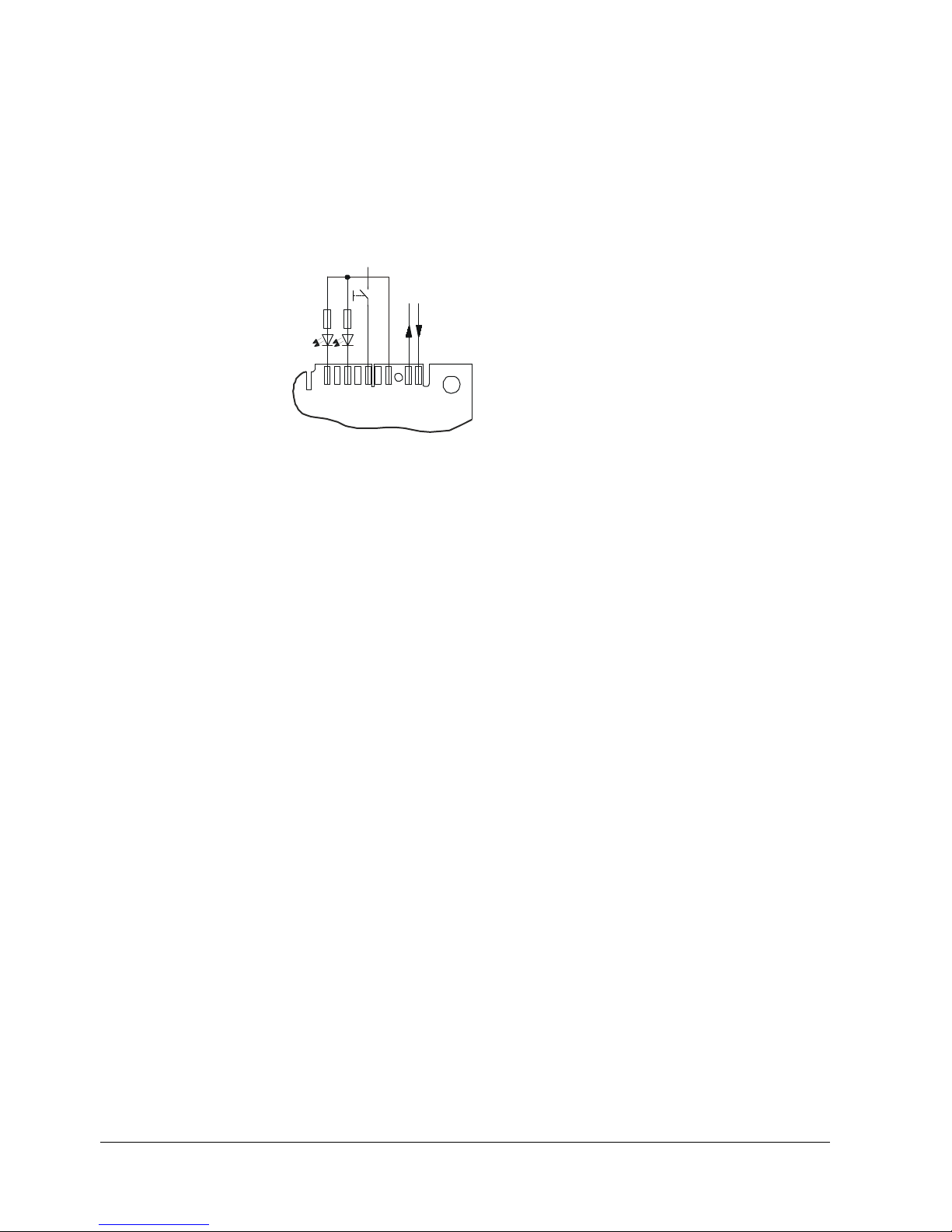

3.4.2 Assignment of terminal X30

7471m22e/1214

LED flame

LED interference

CL+

GND/CL-

Rv = external

Status LEDs

Uex t 12 V

987654321

X30

Rv

Rv

GND

ET

Figure 6: Assignment of terminal X30

29/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015

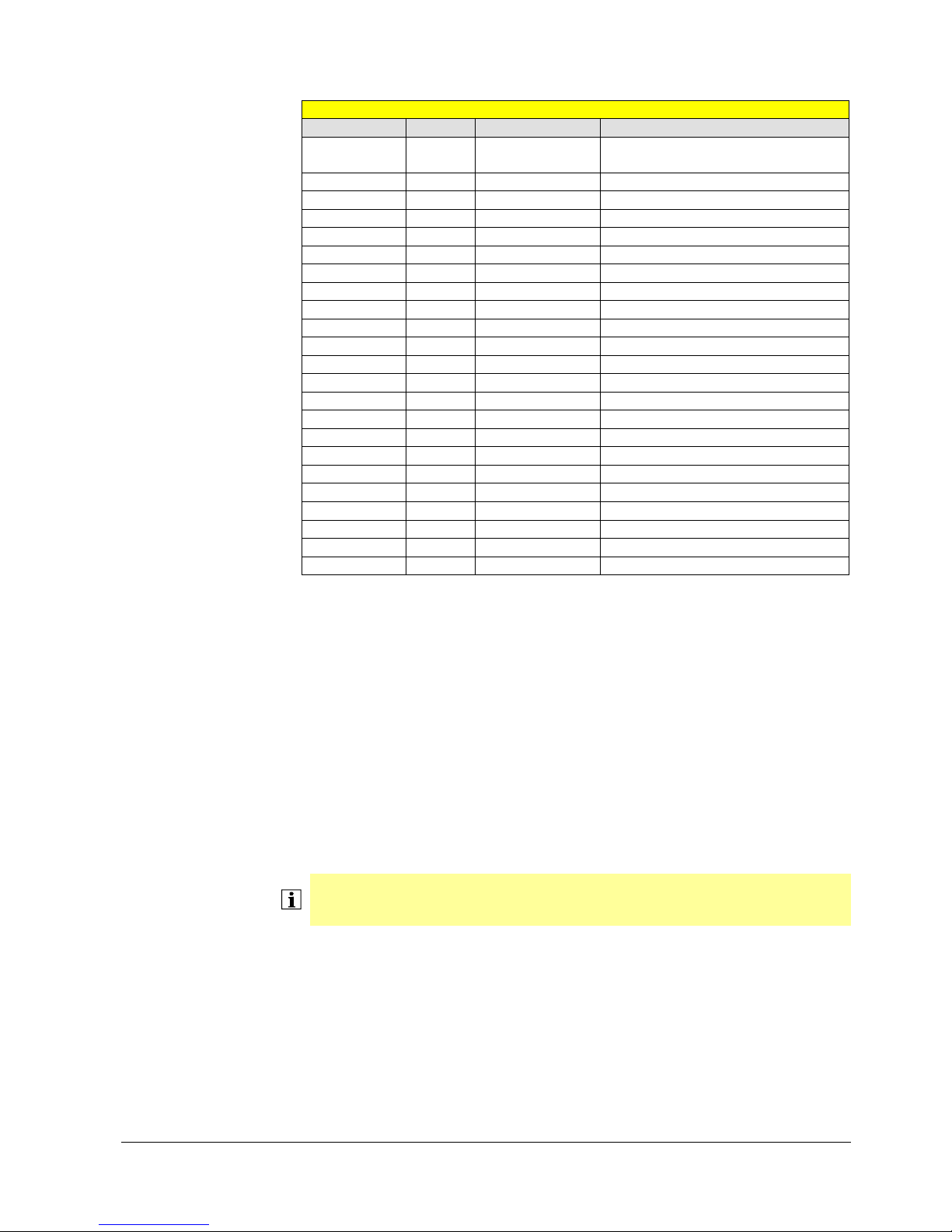

3.4.3 List of terminals of LMS14… complete (Basic)

LMS14... standard (Basic)

Terminal Mating connector

marking Number

of pins

Supplier Type/coding

X1a 3 Wieland 25.320.3353.0 green

X1c 4 Lumberg 3636 04K02

X1d 5 Lumberg 3636 05K02

X1e 2 Lumberg 3636 02K10

X2a 5 Lumberg 3636 05K22

X4a 8 Lumberg 3515 08K20

X5b 12 Lumberg 3636 12K01

X6b 8 Lumberg 3636 08K10

X7b 6 Lumberg 3636 06K09

X8a 4 Lumberg 3515 04K06

X10b 4 Lumberg

3515 04K26

X11 14 Lumberg 302299 14 uncoded

X12 4 Molex 48037-2200 uncoded

X13 6/4 Uncoded

X15a 2 Lumberg 3516 02K05

X16a 5 Lumberg 3515 05K25

X17 1 Uncoded

X18a 2 Lumberg 3636 02K05

X30 9 Lumberg 3515 09K15

X50 5 Lumberg 3515 05K23

X60 2x3 Uncoded

Key to LMS14… complete (Basic)

AUX... Auxiliary output

B2 Boiler sensor

B3 DHW sensor

B7 Boiler return sensor

B9 Outside sensor

B38 DHW outlet sensor

BX... Sensor input

H... Function input

P1 PWM output

QX... Relay output

STB Safety limit thermostat (SLT)

UX... PWM output / 10 output

WX1 Stepper motor output

Note!

The connector designations only specify coding and type. When ordering, also

consider the requirements placed on the material (e.g. filament test) and design.

30/617

Building Technologies Division User Manual LMS14... CC1U7471en

3 Mounting and installation 28.01.2015