Siemens LME7 Series, LME75, LME71, LME73 Technical Instructions

SCC Inc.

Technical Instructions LME-1000

June 11, 2019

www.scccombustion.com

L M E 7…

Burner Controls

Combustion Controls

IntentionallyLeftBlank

LME Series Technical Instructions

Document No. LME-1000

Table of Contents

Section 1: Overview

Introduction ........................................................................................................................... 1

LME7 System Builder ............................................................................................................. 2

Mounting ............................................................................................................................. 10

Important Safety Notes ........................................................................................................ 12

Approvals ............................................................................................................................. 13

Section 2: LME71 Wiring, Parameters, and Phase Diagrams

LME71 Wiring Diagrams ......................................................................................................... 1

LME71 Parameter List ............................................................................................................ 4

LME71 Phase Diagrams ........................................................................................................ 11

Section 3: LME73 Wiring, Parameters, and Phase Diagrams

LME73 Wiring Diagrams ......................................................................................................... 1

LME73 Parameter List ............................................................................................................ 4

LME73 Phase Diagrams .......................................................................................................... 9

Section 4: LME75 Wiring, Parameters, and Phase Diagrams

LME75 Wiring Diagrams ......................................................................................................... 1

LME75 Parameter List ............................................................................................................ 3

LME75 Phase Diagrams .......................................................................................................... 8

Section 5: Commissioning

Commissioning a New LME7 Burner Control .......................................................................... 1

Parameter Backups / Restores ............................................................................................... 2

Displaying the Flame Signal from the LME7 Burner Control.................................................... 3

Displaying the Actuator Position / PWM Blower Speed from the LME7 Burner Control .......... 4

Manually Adjusting the Actuator Position / PWM Blower Speed from the LME7 Burner

Control ............................................................................................................................. 4

AZL23 Display Unit Icons ........................................................................................................ 4

SCC Inc. Page 1 Table of Contents

Technical Instructions LME Series

Document No. LME-1000

Section 6: PWM Blowers

Introduction ........................................................................................................................... 1

PWM Blower Fundamentals ................................................................................................... 1

Centrifugal Blower Fundamentals .......................................................................................... 2

Blower Speed Monitoring ...................................................................................................... 3

Commissioning the LME7 when Using a PWM Blower............................................................ 5

Adjusting P0, P1, and P2 via the LME7 Built-in Display ........................................................... 7

Adjusting P0, P1, and P2 via the AZL23 Display Unit ............................................................... 8

Additional Tips for Burners with PWM Blowers ...................................................................... 9

Section 7: Troubleshooting

Troubleshooting Introduction ................................................................................................ 1

Complete Fault Code List ....................................................................................................... 3

Other Common Faults ............................................................................................................ 7

Section 8: Modbus

Introduction ........................................................................................................................... 1

Physical Connections.............................................................................................................. 1

Status LED .............................................................................................................................. 2

Tx/Rx LED ............................................................................................................................... 2

Modbus RTU Connection Details ............................................................................................ 3

BACnet MS/TP Connection Details ......................................................................................... 4

Using the OCI417 Configuration Utility ................................................................................... 5

Updating the OCI417.10 Firmware ......................................................................................... 7

Modbus Mapping ................................................................................................................... 8

BACnet Mapping .................................................................................................................. 11

Unused Inputs ...................................................................................................................... 13

Table of Contents Page 2 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

Section 9: ACS410

ACS410 Software Introduction ............................................................................................... 1

Software Installation .............................................................................................................. 2

Connecting to a PC ................................................................................................................. 3

Saving a Parameter Set to a PC .............................................................................................. 4

Uploading a Parameter Set to an LME7 .................................................................................. 5

Creating an LME7 Startup Report ........................................................................................... 6

Synchronizing the LME7 and PME Parameters ....................................................................... 7

Saving and Viewing Trends ..................................................................................................... 8

Viewing the Status Screen .................................................................................................... 10

Appendix A: Application Guide

Honeywell Modutrol IV Motor with the LME75 ...................................................................... 3

Two Flame Detectors ........................................................................................................... 13

SCC Inc. Page 3 Table of Contents

Technical Instructions LME Series

Document No. LME-1000

Intentionally Left Blank

Table of Contents Page 4 SCC Inc.

Section 1

Overview

Section 2

LME71 Wiring, Parameters,

and Phase Diagrams

Section 3

LME73 Wiring, Parameters,

Section 4

LME75 Wiring, Parameters,

Section 5

Commissioning

Section 6

PWM Blowers

Section 7

Troublesho

oting

Section 8

Modbus

Section 9

ACS410

Appendix A

Application Guide

and Phase Diagrams

and Phase Diagrams

Section 1

Overview

Section 2

LME71 Wiring, Parameters,

and Phase Diagrams

Section 3

LME73 Wiring, Parameters,

Section 4

LME75 Wiring, Parameters,

Section 5

Commissioning

Section 6

PWM Blowers

Section 7

Troubleshooting

Section 8

Modbus

Section 9

ACS410

Appendix A

Application Guide

and Phase Diagrams

and Phase Diagrams

LME Series Technical Instructions

Document No. LME-1000

Introduction

The LME7 burner control is ideally suited for use in industrial thermal process applications. The

LME7 is extremely flexible, and encompasses the following features:

• Accepts standard UV, self-check UV, or self-check IR scanners and/or flame rods

• Integral LED display

• Programmable purge times and safety times

• Programmable actuator positions for purge, ignition, and low fire

• Adjustable time overlap of spark ignition and pilot valve

• Adjustable time overlap of pilot and main gas valves

• Proof-of-closure (POC) switch monitoring

• Modbus RTU or BACnet MS/TP communication

• Optional gas valve proving function

• Password-protected access to OEM parameters

• Integrated actuator control

• Integrated PWM blower control

Figure 1-1: The Main Components of an LME7 System

SCC Inc. Page 1 Section 1

Technical Instructions LME Series

Document No. LME-1000

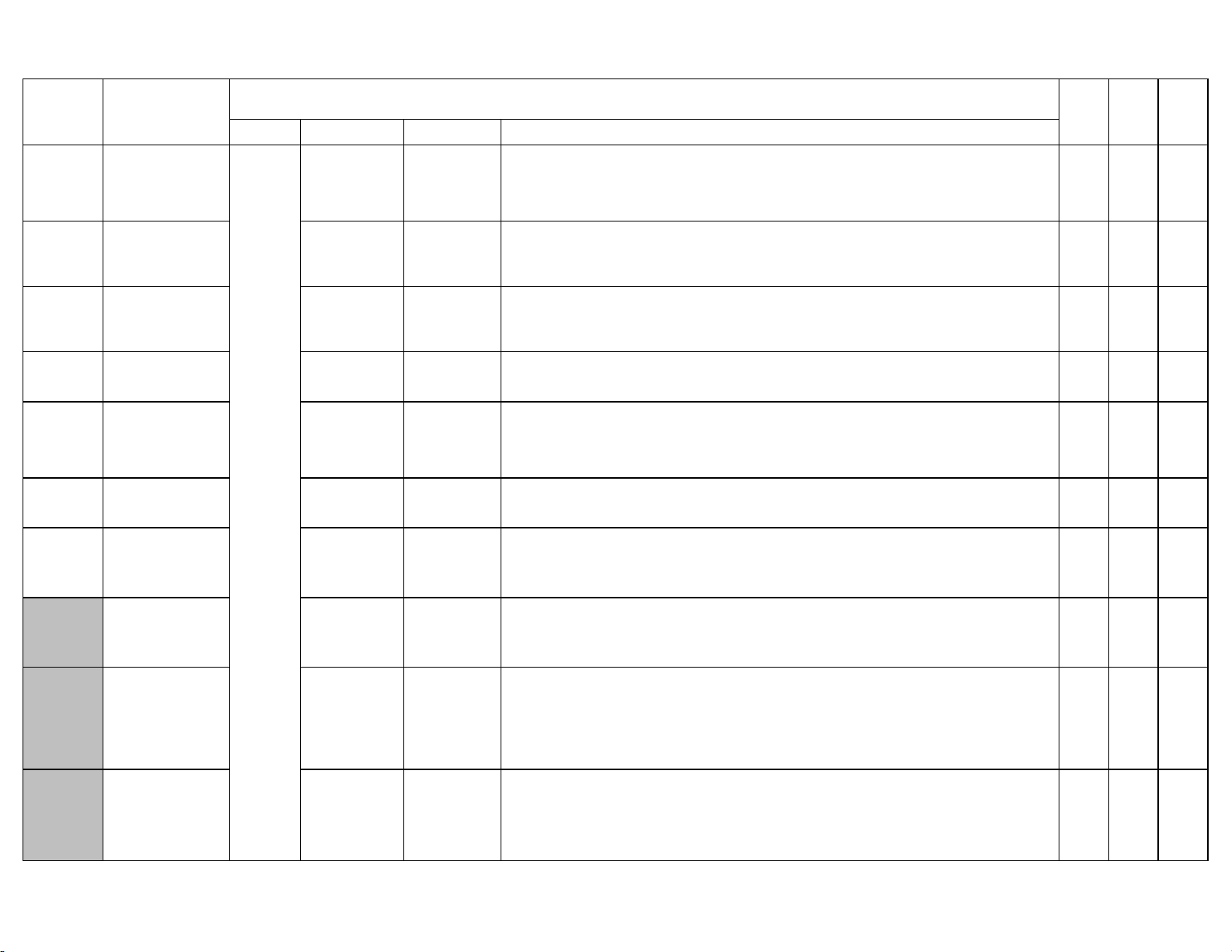

LME7 System Builder

The LME7 burner control system is comprised of many components. Use the following pages to

choose the components needed for your specific application.

Control Panel Components

Base Unit – Qty (1) Required

Choose one of the following LME7 base unit options. See page 10 for mounting information.

LME71.000A1

self-check scanner capability, 110V

Flame safeguard, with actuator control, without

Flame safeguard, without actuator control, without

LME73.000A1

self-check scanner capability, 110V

Flame safeguard, with actuator control, with self-

LME75.000A1

check scanner capability, 110V

Program Module – Qty (1) Required

Choose one of the following PME7 program modules. The program module contains the

program sequence used to operate the burner.

Base Unit

PME71.111A1

PME71.112A1 • •

PME71.901A1 • • • • • •

PME73.811A1

PME73.812A1 • • •

PME73.840A1 • • • • • •

PME75.811A1

PME75.812A1 • • • •

LME71.000A1

LME73.000A1

LME75.000A1

Controls Actuator

Actuator Control Can Be Disabled

• •

• • • • • •

• • • • • • •

Controls PWM Blower

Flame Rod

Non-Self-Checking UV Scanner

Self-Checking UV or IR Scanner

Valve Proving

Purge

•

• • •

• • •

Independent Ignition Position

Analog Input for Fire Rate

Section 1 Page 2 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

Plug Set – Qty (1) Required

The terminal plug set for the LME7 is sold separately. Each LME7 needs one plug set.

AGG3.710

Plug set containing all terminals for an LME7 system

LME7 Package - Optional

For convenience, the LME7 base unit, PME7 program module, and AGG3.710 plug set can be

ordered as a package that is shipped pre-assembled.

LME71.000A1 with PME71.111A1 program module

LME71.111A1PKG

and AGG3.710 plug set installed

LME71.000A1 with PME71.112A1 program module

LME71.112A1PKG

LME71.901A1PKG

LME73.811A1PKG

and AGG3.710 plug set installed

LME71.000A1 with PME71.901A1 program module

and AGG3.710 plug set installed

LME73.000A1 with PME73.811A1 program module

and AGG3.710 plug set installed

LME73.812A1PKG

LME73.840A1PKG

LME75.811A1PKG

LME75.812A1PKG

LME73.000A1 with PME73.812A1 program module

and AGG3.710 plug set installed

LME73.000A1 with PME73.840A1 program module

and AGG3.710 plug set installed

LME75.000A1 with PME75.811A1 program module

and AGG3.710 plug set installed

LME75.000A1 with PME75.812A1 program module

and AGG3.710 plug set installed

SCC Inc. Page 3 Section 1

Technical Instructions LME Series

Document No. LME-1000

Remote Display – Optional

Each LME7 can be equipped with a remote display that provides additional status information

not shown by the integral LED display on the LME7. Either the remote display or the ACS410

software are required to change parameter settings on the LME7. See page 11 for mounting

information and panel cutout dimensions.

AZL23.00A9

Backlit remote display

Remote Display Cable – Qty (1) Required if Using the AZL23.00A9 Remote Display

This cable is required when using an AZL23 display to connect the AZL23 to the LME7 base unit.

Pre-made 7 foot cable and adapter for connecting

TDCCOMBO

the AZL23 display to the LME7 base unit

Interface Modules and Accessories – Optional

A separate interface module is required for Modbus or BACnet MS/TP communication with the

LME7.

OCI417.10

Modbus and BACnet MS/TP interface module

TDC207

7 foot cable to connect OCI417.10 to LME7 base unit

Fuses - Optional

The LME7… base units do not have a built-in replaceable fuse. It is recommended to install an

external fuse on the incoming power to the LME7.

FUSE6.3A-SLOW

5-pack of 6.3A, 250V, 5x20mm, slow blow fuses

Section 1 Page 4 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

Actuators and Accessories

Actuator – Qty (1) Optional with LME73 and LME75 Burner Controls

SQM4… and SQM5… series actuators are available for use with the LME73 and LME75 burner

controls. For more information on SQM4… actuators, refer to Document No. N7817. For more

information on SQM5… actuators, refer to Document No. 155-517P25.

SQM4…

adjustable switches, zero and span adjustment

90-400 in-lb torque, NEMA 4 optional,

45-160 in-lb torque, NEMA 4 standard, up to three

SQM5…

auto/manual toggle switch, six adjustable position

switches, zero and span adjustment

Couplings – Optional

Zero-lash, flexible couplings are available for SQM… actuators. For more information, refer to

Document No. CPBK-1000.

Cxx…

Flexible couplings for SQM… actuators

Actuator Mounting Bracket Kits - Optional

Modular bracket kits are available to assist in mounting an SQM… actuator to a variety of valves

or dampers. A coupling is necessary when using a modular bracket kit. For more information,

refer to Document No. CPBK-2000.

BR-AS…

to a variety of valves or dampers

SCC Inc. Page 5 Section 1

Modular bracket kits for mounting SQM… actuators

Technical Instructions LME Series

Document No. LME-1000

Flame Scanners

Flame Scanners – Qty (1) Required Unless Using a Flame Rod

Four flame scanners are available for use with the LME7. For technical information about these

flame scanners, refer to Document No. N7711 for the QRA4.U, Document No. N7719 for the

QRI… flame scanners, and Document No. N7712 for the QRA75.A17.

Ultraviolet (UV) flame scanner, non-self-checking,

QRA4.U

forward viewing, with ¾” NPSM connection, for use

with LME71 or LME73 base units

QRA75.A17

QRI2A2.B180B

QRI2B2.B180B

Ultraviolet (UV) flame scanner, self-checking, side

viewing, for use with LME75 base units

Infrared (IR) flame scanner, self-checking, forward

viewing, for use with LME75 base units

Infrared (IR) flame scanner, self-checking, side

viewing, for use with LME75 base units

Flame Scanner Accessories

QRA75 Wiring Cable – Qty (1) Required per QRA75.A17 Flame Scanner

A pre-made 12 foot cable is required when using the QRA75.A17 flame scanner. For more

information, refer to Document No. N7712.

Pre-made 12 foot cable for use with the QRA75.A17

AGM23U

flame scanner. Supplied with 1/2” NPSM conduit

adapter

Section 1 Page 6 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

QRA75.A17 Accessories - Optional

Mounting accessories are available for the QRA75.A17 flame scanner. For more information,

refer to Document No. N7712.

Right angle adapter for mounting a QRA75 flame

AGG16.U

scanner. Comes with a 1” NPSM female thread

connection

Thermal barrier for use with the QRA75 flame

THERMAL-1X75

scanner along with accessory AGG16.U. Adapts a 1”

NPSM thread to a female 3/4” NPT connection

Magnifying lens with spring washer and O-ring for

AGG03

increased sensitivity, to be mounted inside thermal

barrier THERMAL-1X75

QRI… Accessories - Optional

Mounting accessories are available for both the forward viewing and side viewing QRI… flame

scanners. For more information, refer to Document No. N7719.

Kit for mounting forward viewing scanner

QRI2A2.B180B on a flame tube. Comes with clamp,

AGG2.110

mounting sleeve, thermal barrier with 3/4” NPSM

connection, and heat insulation glass

Pg9 thread to 1/2” NPSM conduit connection

AGG2.120

adapter for use with any QRI… flame scanner

Right angle adapter for mounting side viewing

AGG90.U

scanner QRI2B2.B180B on a flame tube. Comes

with 3/4” NPSM female thread connection

SCC Inc. Page 7 Section 1

Technical Instructions LME Series

Document No. LME-1000

Additional Flame Scanner Accessories – Optional

Additional accessories are available for flame scanners to prevent heat from getting to the

scanner. For more information, refer to Document No. N7711 and Document No. N7712.

Thermal barrier for use with the QRA4.U flame

scanner, and QRI2B2.B180B flame scanner when

THERMAL-

used with right angle adapter AGG90.U. Adapts a

75X75

3/4” NPSM thread to a female 3/4” NPT connection.

Rated for scanner tube temperatures up to 250 °F

Heat insulating lens with spring washer and O-ring,

for applications where the temperature at the

AGG02

scanner will exceed 176 °F. Can be mounted inside

thermal barriers THERMAL-75X75 or THERMAL-1X75

ACS410 Software for Laptop

The ACS410 software for the LME7 offers many features including parameter backups, startup

reports, and trending. The software may be downloaded at www.scccombustion.com.

ACS410 Cables – Qty (1) Required if Using the ACS410 Software

To use the ACS410 software, cables are necessary to connect the LME7 to a PC.

User-level PC interface module and cable. Permits

access to user level parameters only without the

ability to perform parameter backups

Service-level PC interface module and cable.

Permits access to user and service level parameters

and the ability to perform parameter backups

OCI410.20

OCI410.30

OEM-level PC interface module and cable. Permits

OCI410.40

access to all parameters and the ability to perform

parameter backups

Section 1 Page 8 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

Enclosures

Enclosures - Optional

A small NEMA 1 enclosure is available for use with any LME7… base unit. Three ½” conduit

knockouts are available on both the top and the bottom of the enclosure.

LME7-ENC-KT

NEMA 1 enclosure for any LME7… base unit

Trainers

Trainers - Optional

Training units are available to train OEMs and field technicians how to program and use the

various features of the LME75 burner control.

TR-L75-1A

LME75 training unit, 110 VAC

SCC Inc. Page 9 Section 1

Technical Instructions LME Series

Document No. LME-1000

Mounting

LME7 Controller

The LME7 must be mounted inside an enclosure that will protect it from dirt and moisture. The

unit should be mounted with three #8 screws (not provided). The panel, which the unit sits on,

should be drilled and tapped to accommodate these screws.

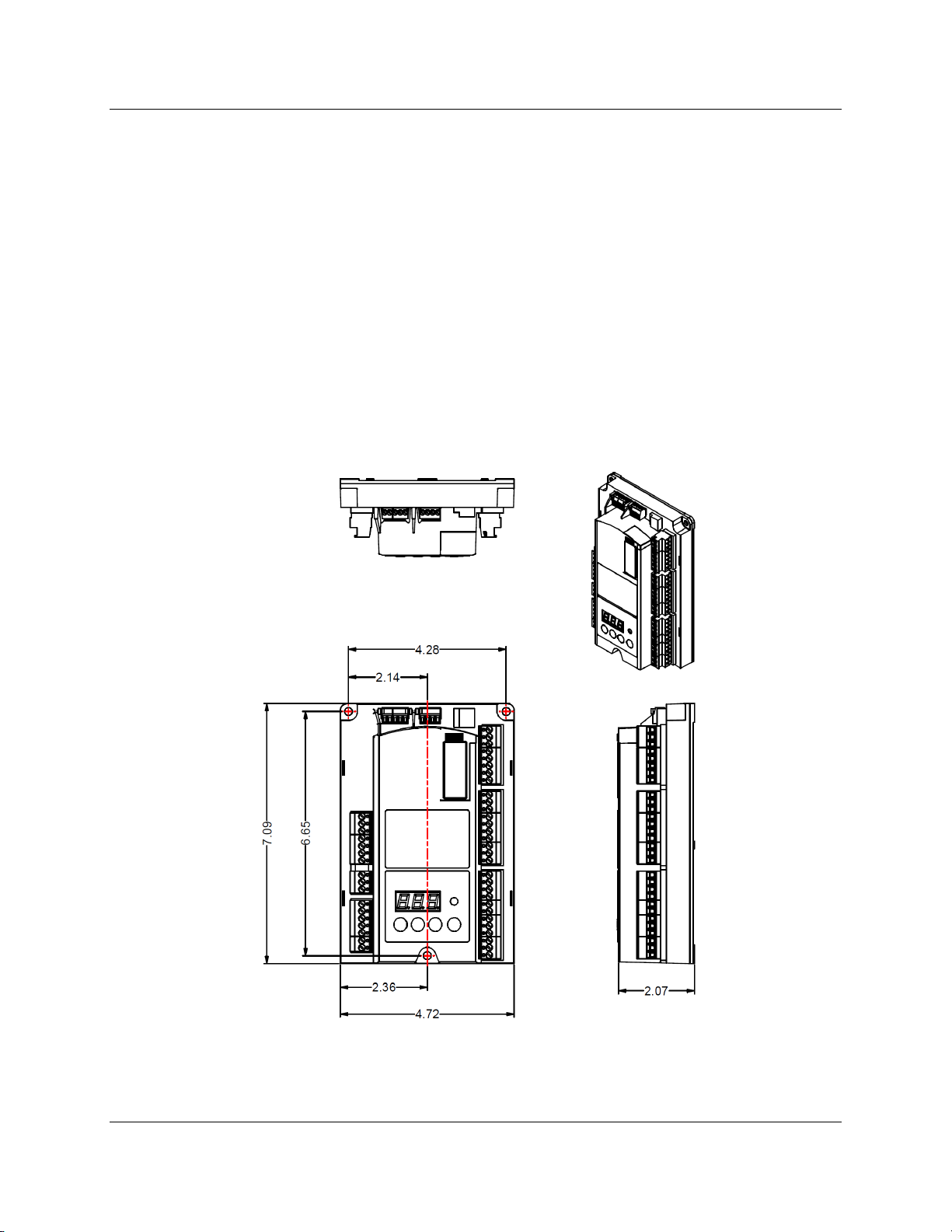

During the mounting process, consideration should be given to the various plugs and wires that

must be attached to the LME7. Electrical connections are made via plugs that are located in the

face of the unit with wires coming out to the top, left side, and right side of the unit. A space of

at least one inch is recommended above, to the left, and to the right of the LME7. The

recommended total space to leave for the LME7 is 8” x 6.75” x 3” because the overall

dimensions of the LME7 are 7.09” x 4.72” x 2.07”.

Figure 1-2: LME7 Dimensions (inches)

Section 1 Page 10 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

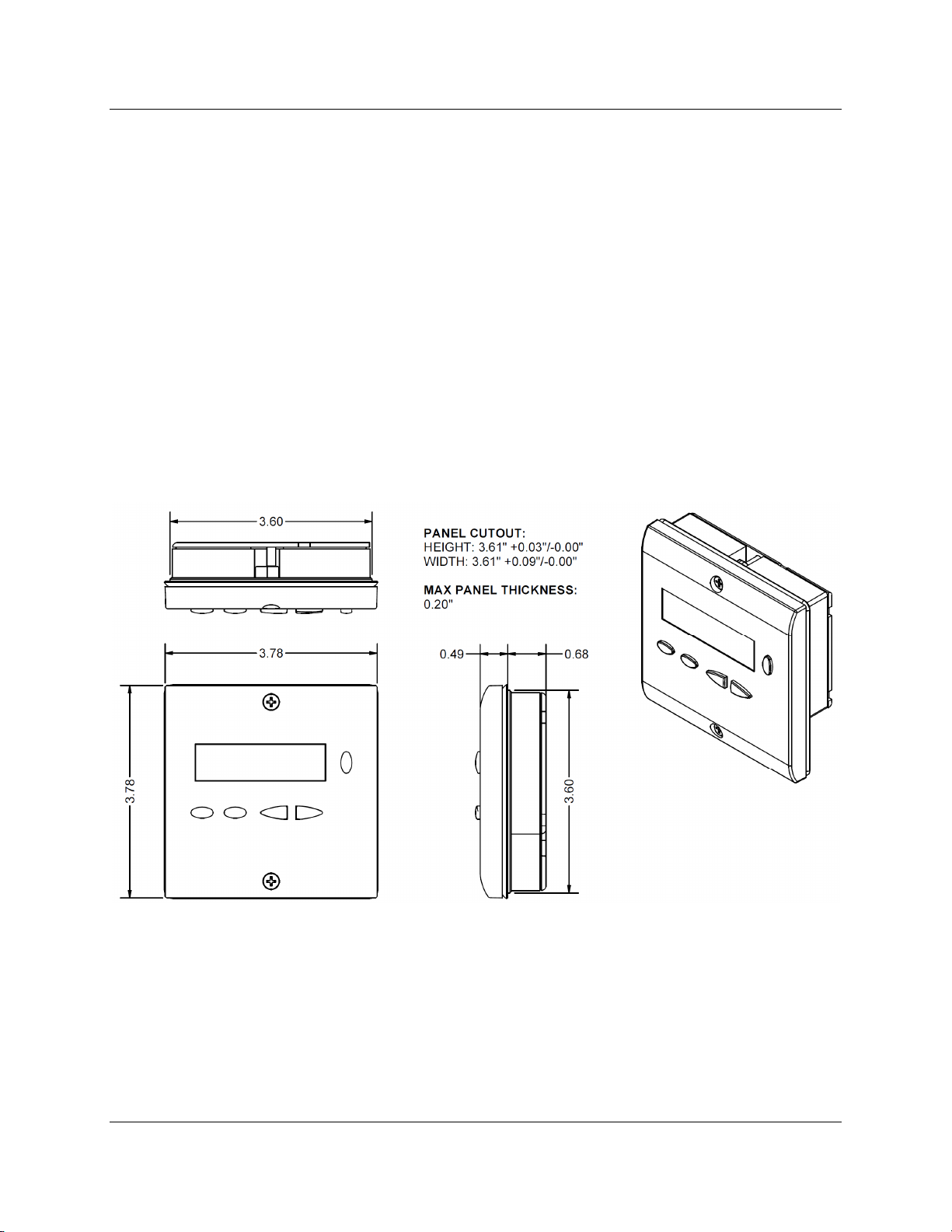

AZL23 Display

The AZL23 is designed to be mounted in a rectangular cutout through the face / door of an

electrical enclosure. It has one screw on the top and another on the bottom that engage small

plastic tabs which will swing out when the screw is tightened clockwise; the screw can be

loosened to retract the tab and increase clearance before tightening. The tab will pinch the

sheet metal of the enclosure door between itself and the AZL23 gasket. This facilitates easy

removal and replacement of the AZL23 since it is designed to be taken out of the enclosure face

and held in the hands for setup and commissioning.

The AZL23 connects to the LME7 at terminal X56 with cable TDCCOMBO. The AZL23 has an

IP54 rating when mounted in an electrical enclosure.

Figure 1-3: AZL23 Dimensions (inches)

SCC Inc. Page 11 Section 1

Technical Instructions LME Series

Document No. LME-1000

Important Safety Notes

• The LME7 is a safety device. Under no circumstances should the unit be modified or

opened. SCC Inc. will not assume responsibility for damage resulting from unauthorized

modification of the unit.

• All activities (mounting, installation, service work, etc.) must be performed by qualified

staff.

• Before performing any work in the connection area of the LME7, disconnect the unit

from the main supply (all-polar disconnection).

• Protection against electrical shock hazard on the LME7 and all other connected

electrical components must be ensured through good wiring and grounding practices.

• Fall or shock can adversely affect the safety functions of an LME7. Such units must not

be put into operation, even if they do not exhibit any apparent damage.

• Condensation and the entry of water into the unit must be avoided.

Section 1 Page 12 SCC Inc.

LME Series Technical Instructions

Document No. LME-1000

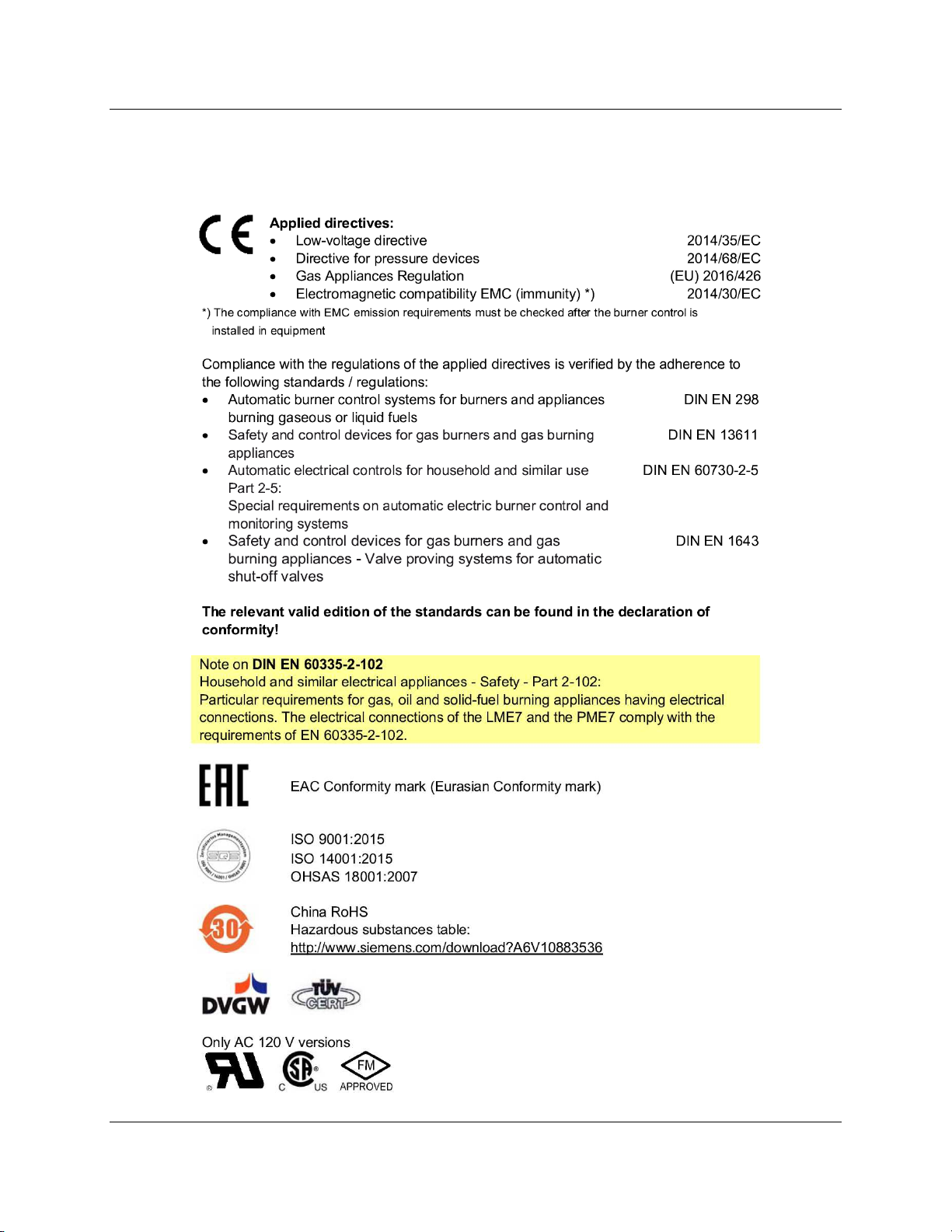

Approvals

The LME7 has the following standards and approvals:

SCC Inc. Page 13 Section 1

Technical Instructions LME Series

Document No. LME-1000

Intentionally Left Blank

Section 1 Page 14 SCC Inc.

Section 1

Overview

Section 2

LME71 Wiring,

Section 3

LME73 Wiring, Para

meters,

Section 4

LME75 Wiring, Parameters,

Section 5

Commissioning

Section 6

PWM Blowers

Section 7

Troubleshooting

Section 8

Modbus

Section 9

ACS410

Appendix A

Application Guide

Parameters, and

P

hase Diagrams

and Phase Diagrams

and Phase Diagrams

Section 1

Overview

Section

2 LME71 Wiring,

Parameters, and

Section 3

LME73 Wiring, Parameters,

Section 4

LME75 Wiring, Parameters,

Section 5

Commissioning

Section 6

PWM Blowers

Section 7

Troubleshooting

Section 8

Modbus

Se

ction 9

ACS410

Appendix A

Application Guide

hase Diagrams

P

and Phase Diagrams

and Phase Diagrams

LME Series

LME-1000

Technical Instructions

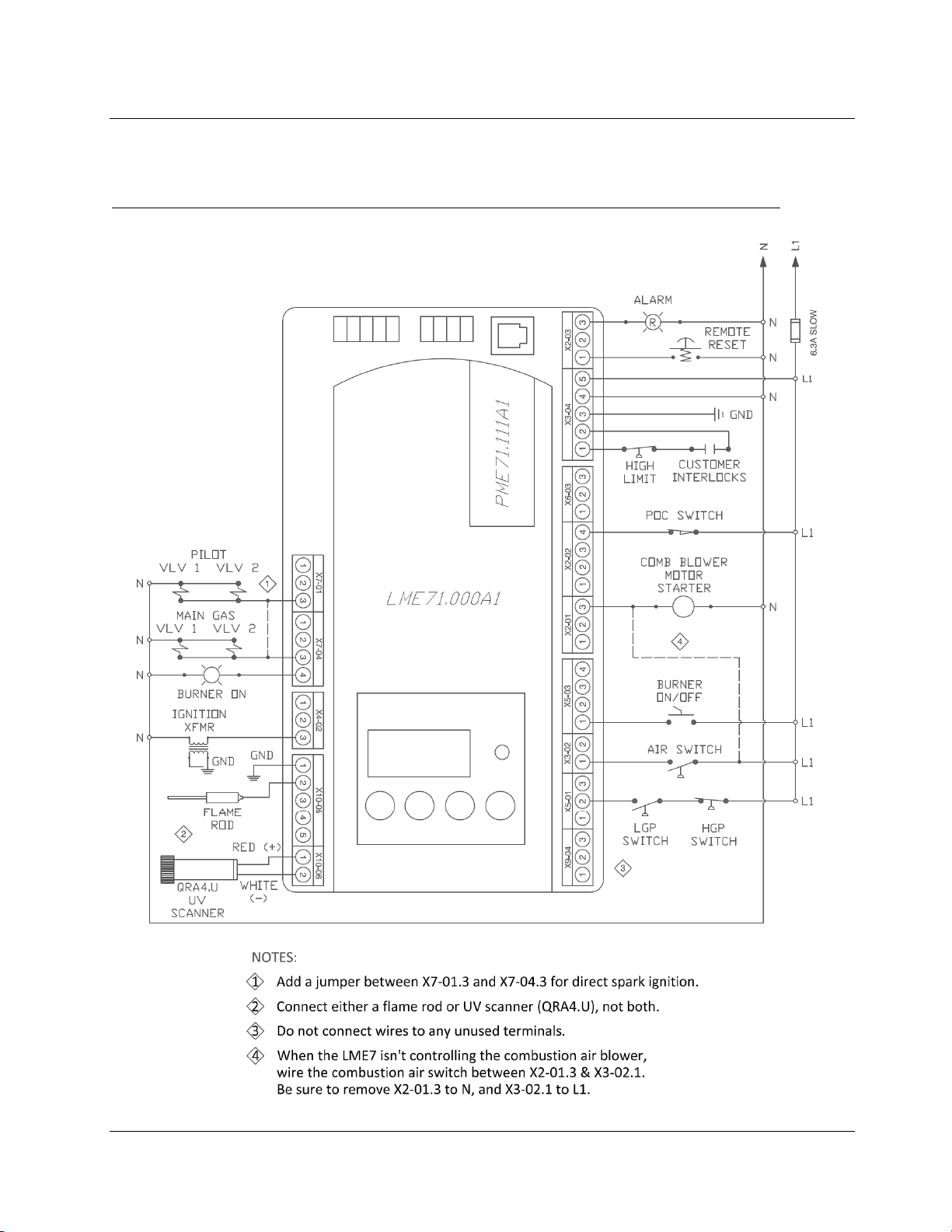

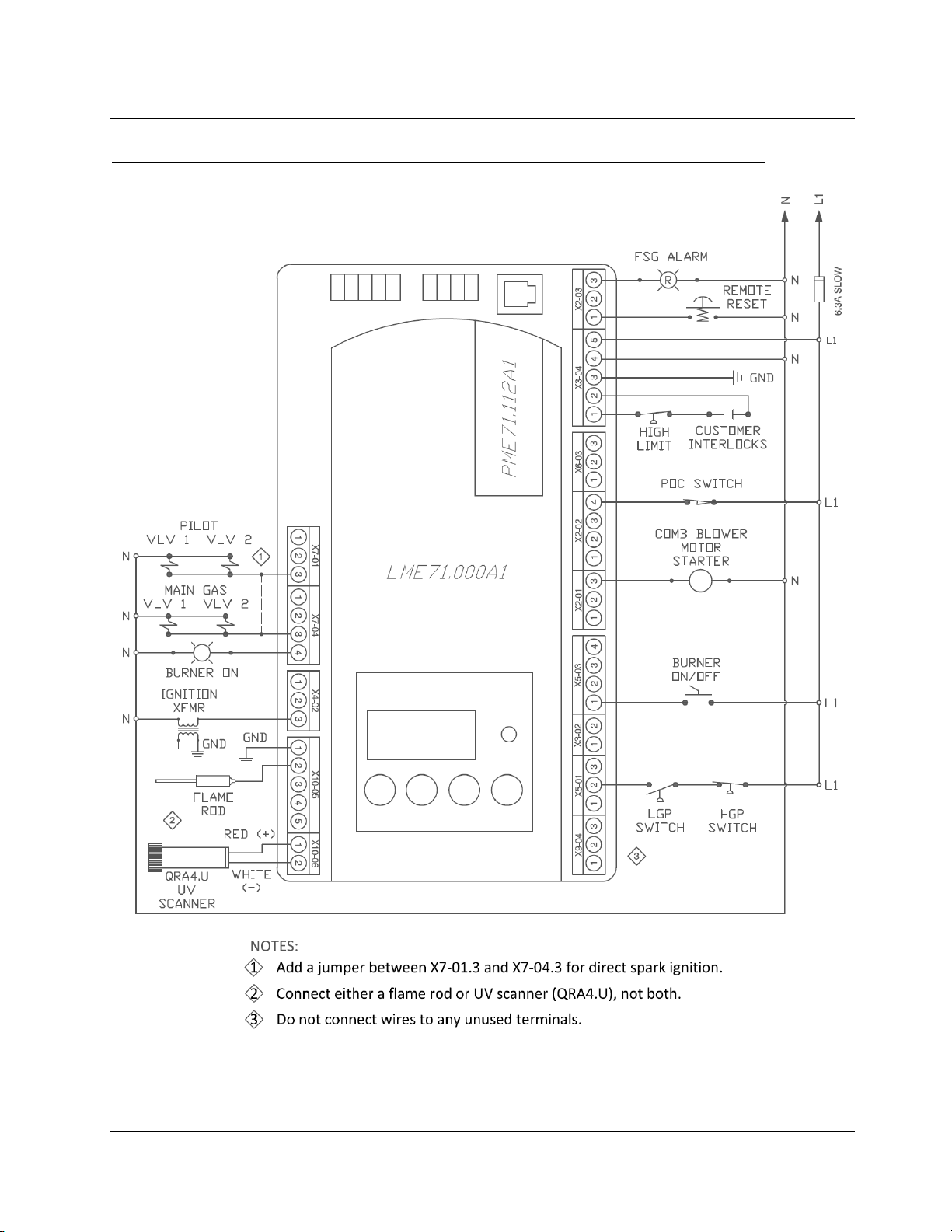

LME71 Wiring Diagrams

PME71.111A1 – Pilot or direct spark; with purge; no actuator control; no valve proving

SCC Inc. Page 1 Section 2

Technical Instructions L

Document No. LME-1000

u

PME71.112A1 – Pilot or direct spark; no purge; no act

ator control; no valve proving

ME Series

Section 2 Page 2 SCC Inc.

LME Series

LME-1000

Technical Instructions

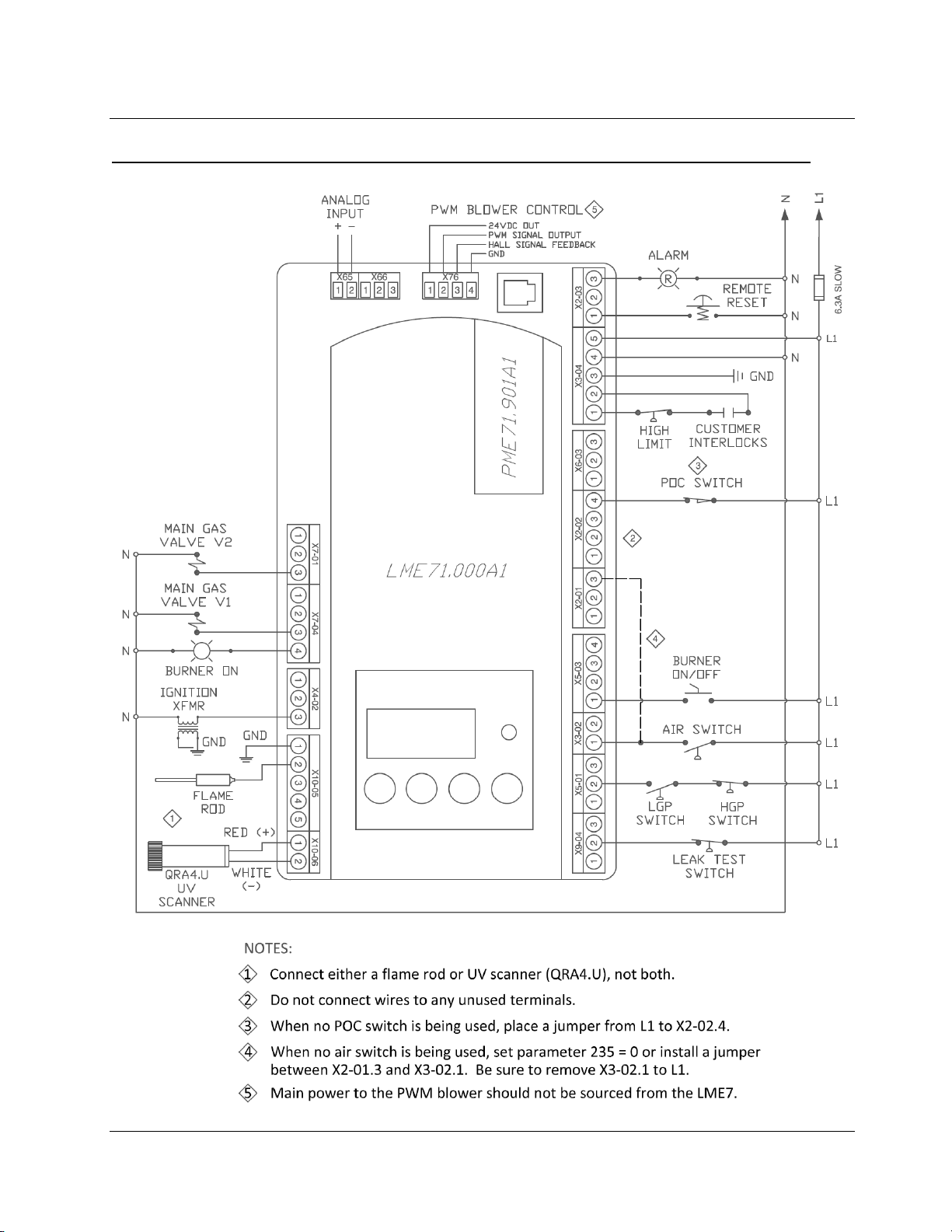

v

PME71.901A1 – PWM blower control; direct spark only;

alve proving; no actuator control

SCC Inc. Page 3 Section 2

LME Series

Used to perform parameter backups and restores.

display "rSt End".

000 Level: Parameter Backup / Restore / Change Passwords

LME71 Parameter List

Technical Instructions

LME-1000

Parameter

Number

041 Service Level PW 7173 Any 4 characters

042 OEM Level PW L7unI Any 5 characters

060 Backup / Restore S

Parameter Name

Shaded Parameters = Frequently Used

PW Level Default Range Description

The service level password can be changed here. It must be exactly 4 characters in length. Enter the

O

Backup - 0

Restore - 0

0-1

current password, then enter the new password twice to change it (c = current, n = new, r = repeat).

The OEM level password can be changed here. It must be exactly 5 characters in length. Enter the current

password, then enter the new password twice to change it (c = current, n = new, r = repeat).

Backup: Transfer LME7 parameters to PME7. Restore: Transfer PME7 parameters to LME7.

Set parameter to 1 and press the info button to begin the backup or restore. Once a parameter backup is

successful, the screen will display "bAC End". Once a parameter restore is successful, the screen will

100 Level: General Information / Display Mode

LEGEND - Password Level: S = Service; O = OEM; S/O = View - Service, Write - OEM; Info = Info Menu; Ser = Service Menu

102 Production Date Date that the LME7 was produced in the DD.MM.YY format.

103 Serial Number Serial number of the LME7.

Info

113 Burner ID Not set 0-99999999

140 Display Mode S

164 Startups

166 Total Startups Displays the total number of startups. Not resettable.

Info

170 Number of Relay Cycles

171 Max Relay Cycles Displays the maximum number of relay cycles allowed on the internal relays of the LME7.

111 - 1

112 - 1

901 - 4

Read only

Reset only

Read only

1-4

The burner ID can be viewed through the AZL23 but can only be set using the ACS410 software. The

burner ID must be all digits (no letters), from 1-8 digits in length. Typically the burner serial number is

used. This serves as an identifier for the parameter set. The burner ID must be set in order to perform a

parameter backup to a PC using the ACS410 software. Parameter backups to the PME7 program module

can be made without setting the burner ID.

Sets what will be displayed by the LME7 integral display.

1 = phase

2 = flame signal (QRA… flame scanner or flame rod)

3 = not used

4 = load

Displays the total number of startups. To reset this value, press and hold the info button until the value

begins to flash, then let go. The value will automatically change to 0. Press the info button again to

confirm the reset.

Displays the number of cycles on different internal relays in the LME7.

Index 00 = K12 relay cycles

Index 01 = K11 relay cycles

Index 02 = K2 relay cycles

Index 03 = K1 relay cycles

PME71.

111A1

PME71.

112A1

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

PME71.

901A1

SCC Inc. Page 4 Section 2

LME Series

Once the LME7 reaches phase 22 for the second time (between phases 24 and 30), this sets the length of

due to lack of air pressure. As soon as the switch is made, the sequence progresses.

opened. Sets the length of phase 38.

When activated, this forces the LME7 to shut the burner down every 24 hours of uninterrupted operation.

The burner will automatically restart afterwards. The purpose of the shutdown is to check and cycle safety

1 = activated

Technical Instructions

LME-1000

Parameter

Number

224

225 Prepurge Time

226 Pre-Ignition Time 3.087 sec 1.029-37.485 sec

230

231

234 Postpurge Time

235 Air Pressure Switch 0 0-1

237 POC Switch S 1 0-2

Parameter Name

Time Air Pressure

Switch

Pilot / Main

Stabilization Time

Pilot and Main Overlap

Time

Shaded Parameters = Frequently Used

PW Level Default Range Description

13.818 sec 0-13.818 sec

S/O

111 - 29.106 sec

901 - 19.404 sec

111 - 3.234 sec

112 - 3.234 sec

901 - 15.582 sec

9.996 sec 0-74.97 sec

111 - 19.404 sec

901 - 4.851 sec

0-1237 sec

3.234-74.97 sec

0-1237 sec Sets the postpurge time (length of phase 74).

LEGEND - Password Level: S = Service; O = OEM; S/O = View - Service, Write - OEM; Info = Info Menu; Ser = Service Menu

200 Level: Burner Control

time the LME7 will wait for air pressure switch input X3-02.1 to become energized before a lockout occurs

Sets the prepurge time (length of phase 30). The LME7 has a base prepurge time of 2.1 seconds. This

setting adds seconds to the base time.

The period of time that the ignition transformer (output X4-02.3) is energized before the main valves are

On PME71.111A1 and PME71.112A1, this setting defines the pilot stabilizing period if a pilot is used.

During this period, only the pilot valve is open. The spark is de-energized.

On PME71.901A1, this setting defines the main stabilizing period. During this time, only the main valves

are open. The spark is de-energized. Sets the length of phase 44.

When a fuel train with a pilot is used, this setting defines the overlap of the pilot (output X7-01.3) and the

main fuel valves (output X7-04.4). After this time expires, the pilot is de-energized. Sets the length of

phase 50.

This setting activates or deactivates the air pressure switch input X3-02.1.

0 = deactivated

1 = activated

This setting defines the function of POC switch input X2-02.4.

0 = deactivated

1 = activated (verify POC switch is closed on startup and shutdown)

2 = activated (verify POC switch is closed on startup and shutdown, and open during operation)

PME71.

111A1

PME71.

112A1

• •

• • •

• •

• •

• •

PME71.

901A1

•

•

•

239 Forced Intermittent 0 0-1

S/O

240 Repetition Flame 0

Index 00 = 0-2

Index 01 = 0-4

devices. The PME73.840A1 will recycle every 24 hours.

0 = deactivated

This sets the numbers of times a flame failure must occur before causing a lockout. Most North American

codes require 1.

Index 00 = flame failures during operation

Index 01 = flame failures during main trial for ignition

0 = no repetitions

1 = no repetitions

2 = 1 repetition

3 = 2 repetitions

4 = 3 repetitions

• •

• • •

SCC Inc. Page 5 Section 2

LME Series

Determines at which point during the burner's sequence that valve proving will be performed. Used in

1 = valve proving on shutdown

Determines at which point during the burner's sequence that valve proving will be performed. Used in

1 = valve proving on startup and shutdown

Flame Failure Response

Technical Instructions

LME-1000

Parameter

Number

241.00

241.01 Valve Proving Setup 1 1 0-1

241.02 Valve Proving Setup 2 0 0-1

242 VP Evacuation Time 2.646 sec 0-2.646 sec

243 VP Upstream Test 10.290 sec 1.029-37.485 sec

244 VP Fill Time 2.646 sec 0-2.646 sec

245 VP Downstream Test 10.290 sec 1.029-37.485 sec

247 Intermittent Pilot 0 0-1

Parameter Name

Valve Proving

Activation

Shaded Parameters = Frequently Used

PW Level Default Range Description

0 0-1

S/O

LEGEND - Password Level: S = Service; O = OEM; S/O = View - Service, Write - OEM; Info = Info Menu; Ser = Service Menu

This setting determines if gas valve proving (leak testing) will be performed. Gas valve proving can be

performed on startup, shutdown, or both depending on the settings of parameters 241.01 and 241.02.

0 = deactivated

1 = activated

conjunction with parameter 241.02.

0 = valve proving on startup

conjunction with parameter 241.01.

0 = valve proving according to parameter 241.01

If valve proving is performed, this specifies the length of time that the downstream valve (V2) is energized

(output X7-01.3). This will evacuate any gas that might exist between the gas valves. Sets the length of

phase 80.

If valve proving is performed, this specifies the length of time that both the upstream and downstream

valves are closed. If the pressure between the valves rises during this period (enough to open the NC

valve proving pressure switch), then the upstream valve is leaking and the LME7 will lockout. A longer

time period will produce a more sensitive test. Sets the length of phase 81.

If valve proving is performed, this specifies the length of time that the upstream valve (V1) is energized

(output X7-04.4). This will fill the volume between the main gas valves to line pressure. Sets the length of

phase 82.

If valve proving is performed, this specifies the length of time that both the upstream and downstream

valves are closed. If the pressure between the valves falls during this period (enough to close the NC valve

proving pressure switch), then the downstream valve is leaking and the LME7 will lockout. A longer time

period will produce a more sensitive test. Sets the length of phase 83.

Sets the type of pilot being used. If set to 1, the pilot valve will remain open from phase 40 to the end of

main operation (oP1).

0 = interrupted pilot

1 = intermittent pilot

PME71.

111A1

• •

PME71.

112A1

PME71.

901A1

•

•

•

•

•

•

•

Sets the flame failure response time (FFRT). The FFRT is the maximum length of time that the flame signal

can go away before a lockout occurs. This setting also doubles as the length of time the signal from the air

254

257 Trial for Ignition

Time

(FFRT)

1 0-1

111 - 4.116 sec

112 - 4.116 sec

901 - 2.205 sec

0-13.23 sec

pressure switch can go away before a lockout occurs. On PME71.901A1, the FFRT is fixed at 1 second.

0 = 1 second

1 = 3 seconds

On PME71.111A1 and PME71.112A1, this setting defines the overlap of the spark (output X4-02.3) and the

pilot valve (output X7-01.3) if a pilot is used.

On PME71.901A1, this setting defines the overlap of the spark (output X4-02.3) and the main valves.

After this time expires, the spark is de-energized. The LME7 has a base time of 0.3 seconds. This setting

adds seconds to the base time. Sets the length of phase 40.

• •

• • •

SCC Inc. Page 6 Section 2

Loading...

Loading...