Siemens LME21.230A2, LME11.230A2, LME21.130A2, LME21.330A1, LME21.330A2 Installation Manuals

...

CC1N7101en

27.11.2008

Building Technologies

HVAC Products

7

101

Burner Controls LME...

Burner controls for the supervision of 1- or 2-stage gas or gas / oil burners of

small to medium capacity, operation, with or without fan in intermittent.

The LME… and this Data Sheet are intended for use by OEMs which integrate the

burner controls in their products.

Use, features

LME… burner controls are used for the startup and supervision of 1- or 2-stage gas or

gas / oil burners in intermittent operation. The flame is supervised by an ionization

probe or flame detector QRA… with ancillary unit AGQ3…A27 for gas / oil forced draft

burners or blue–burning flames with blue-flame detectors QRC...

In terms of housing dimensions, the LME... are identical with the LGB… and LMG…

burner controls (refer to «Type summary»).

- For gas burners with or without fan to EN 298: 2003

- For gas burners with fans conforming to EN 676

- For oil burners to EN 230: 2005

- Undervoltage detection

- Air pressure supervision with functional check of the air pressure switch during

startup and operation

- Electrical remote reset facility

- Multicolor indication of fault status and operational status messages

- Limitation of the number of repetitions

- Accurate control sequence thanks to digital signal handling

- Controlled intermittent operation after 24 hours of continuous operation

Supplementary documentation

Product Range Overview LME…............................................................................ Q7101

Use

Features

2/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

Warning notes

To avoid injury to persons, damage to property or the environment, the following

warning notes must be observed!

Do not to open, interfere with or modify the unit!

• All activities (mounting, installation and service work, etc.) must be performed by

qualified staff

• Before making any wiring changes in the connection area, completely isolate the

plant from mains supply (all-polar disconnection). Ensure that the plant cannot be

inadvertently switched on again and that it is indeed dead. If not observed, there is

a risk of electric shock hazard

• Ensure protection against electric shock hazard by providing adequate protection

for the burner control’s connection terminals

• Check the connecting lines of the air pressure switch for short-circuits (connection

terminals 3, 6 and 11)

• Press the lockout reset button / operation button of LME... or the AGK20… lockout

reset button extension only manually (applying a force of no more than 10 N) without using any tools or pointed objects

• Fall or shock can adversely affect the safety functions. Such units must not be put

into operation, even if they do not exhibit any damage

• Each time work has been carried out (mounting, installation, service work, etc.),

check to ensure that wiring is in an orderly state and make the safety checks as

described in «Commissioning notes»

Engineering notes

• When used in connection with actuators, there is no position feedback signal from

the actuator to the burner control

• When used in connection with actuators, the requirements of applicable norms and

regulations must be observed

• The running times of the actuators must match the burner control’s program. An

additional safety check of the burner control together with the actuators is required

• When substituting burner controls type LGB… or LMG… by LME…, the AGQ1… or

AGQ2… ancillary unit must be replaced by the AGQ3…A27

Mounting notes

• Ensure that the relevant national safety regulations are complied with

3/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

Installation notes

• Always run the high ignition cables separate from the unit and other cables while

observing the greatest possible distance

• Do not mix up live and neutral conductors

• Install switches, fuses, earthing, etc., in compliance with local regulations

• The connection diagrams show the burner controls with earthed neutral conductor.

In networks with non-earthed neutral conductor and ionization current supervision,

terminal 2 must be connected to the earth conductor via an RC unit (type reference

ARC 4 668 9066 0). It must be made certain that local regulations are complied

with (e.g. protection against electric shock hazard) since AC 120 V (50 / 60 Hz) or

AC 230 V (50 / 60 Hz) mains voltage produces peak leakage currents of 2.7mA

• Make certain that the maximum permissible current rating of the connection termi-

nals will not be exceeded

• Do not feed external mains voltage to the control outputs of the unit. When testing

the devices controlled by the burner control (fuel valves, etc.), the LME… must not

be connected

• In the case of burners with no fan motor, an AGK25 must be connected to terminal

3 of the unit, or else the burner cannot reliably be started up

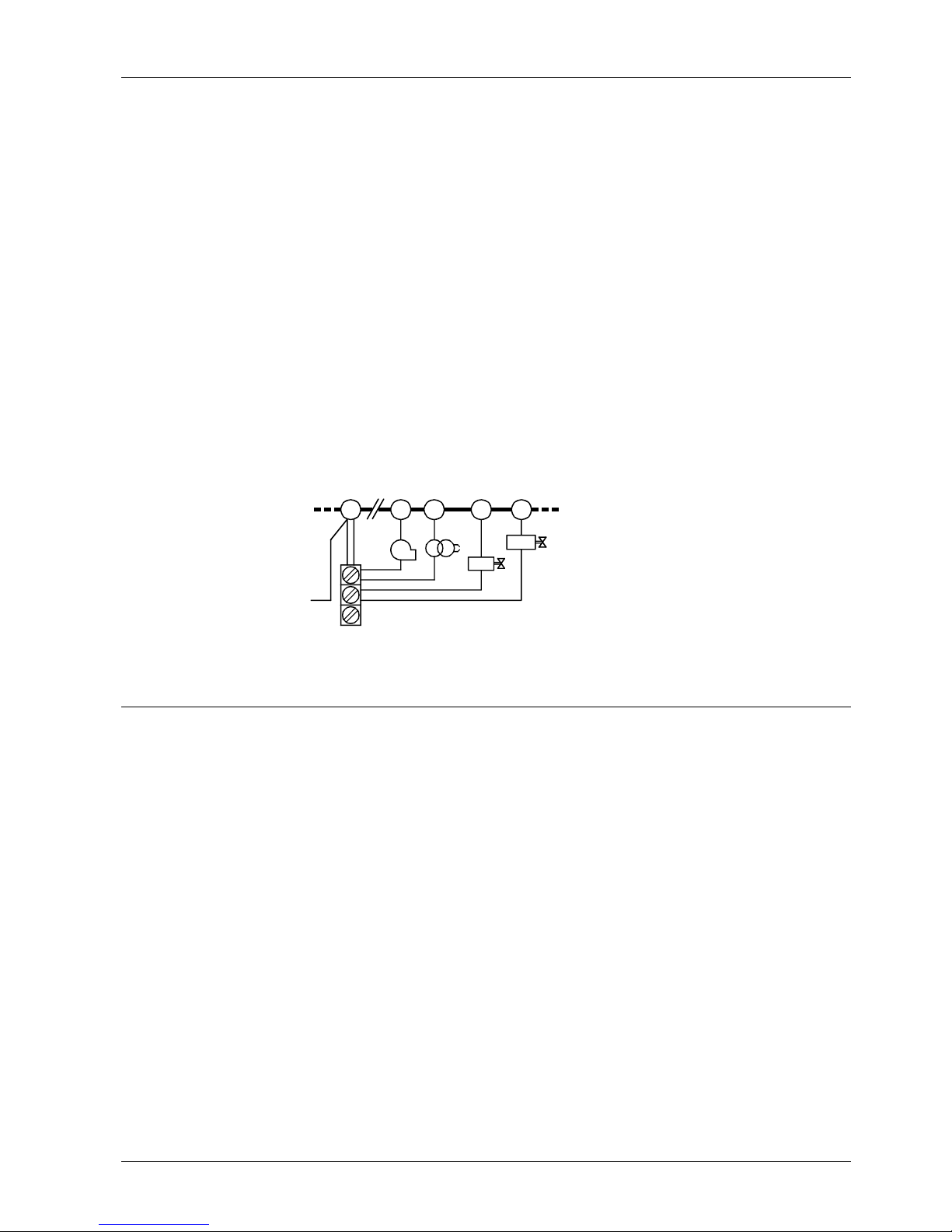

• For safety reasons, feed the neutral conductor to terminal 2. Connect the burner

components (fan, ignition transformer and fuel valves) to the neutral distributor as

shown below in figure. The connection between neutral conductor and terminal 2 is

prewired in the base

Example

23

7

4

5

BV2

BV1

Z

M

N

7101a05/0804

Correct wiring of neutral conductors!

Electrical connection of flame detectors

It is important to achieve practically disturbance- and loss-free signal transmission:

• Never run detector cables together with other cables

– Line capacitance reduces the magnitude of the flame signal

– Use a separate cable

• Observe the permissible length of the detector cables (refer to «Technical data»)

• The ionization probe is not protected against electric shock hazard

• Locate the ignition electrode and the ionization probe such that the ignition spark

cannot arc over to the ionization probe (risk of electrical overloads) and that it cannot adversely affect the supervision of ionization

• Insulation resistance

– Must be a minimum of 50 MΩ between ionization probe and ground

– Soiled detector holders reduce the insulation resistance, thus supporting cree page currents

• Earth the burner in compliance with the relevant regulations; earthing the boiler

alone does not suffice

Legend

BV... Fuel valve

M Fan motor

Z Ignition transformer

4/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

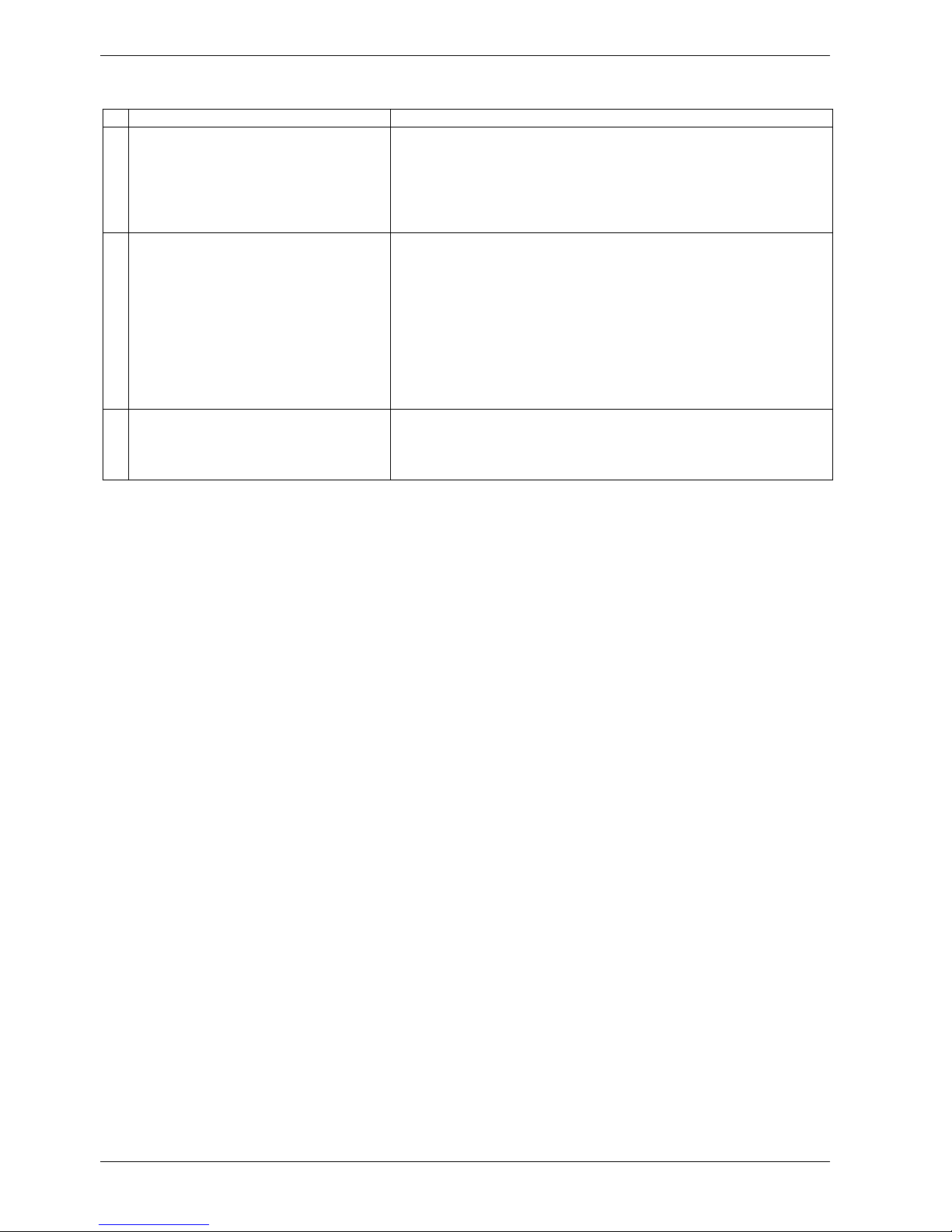

Commissioning notes

• When commissioning the plant for the first time or when doing maintenance work,

make the following safety checks:

Safety check to be carried out Anticipated response

a) Burner startup with previously inter-

rupted line to the flame detector

LME11… / LME41.051...:

Max. 3 repetitions

LME2… / LME41.052... / LME41.053... / LME41.054... / LME41.071...

/ LME41.09... / LME44...:

Lockout at the end of «TSA»

b) Burner operation with simulated loss of

flame. For that purpose, cut off the fuel

supply

LME11… / LME41.051...:

• Establishment of flame at the end of «TSA» → Max. 3 repetitions

• No establishment of flame at the end of «TSA» → Lockout

LME2… / LME44...:

Lockout

LME41.052... / LME41.053... / LME41.054... / LME41.071... /

LME41.09...:

Repetition

c) Burner operation with simulated air

pressure failure

Immediate lockout

LME41...:

Safety shutdown / restart

5/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

Standards and certificates

Conformity to EEC directives

- Electromagnetic compatibility EMC (immunity)

- Directive for gas-fired appliances

- Low-voltage directive

- Directive for pressure devices

2004/108/EC

90/396/EEC

2006/95/EC

97/23/EC

ISO 9001: 2000

Cert. 00739

ISO 14001: 2004

Cert. 38233

Identification code to EN 298 / EN 230

LME11…

F M C L X N

LME21… / LME22… / LME23…

F T L L X N

LME41...

A M C L X N

LME44…

A B L L X N

Type

LME11.230A2

--- x x ---

LME11.330A2

--- x x x

LME21.130A1

x x x ---

LME21.130A2

x x x x

LME21.230A2

x x x x

LME21.330A1

x x x ---

LME21.330A2

x x x x

LME21.350A1

x x x ---

LME21.350A2

x x x x

LME21.550A2

x x x x

LME22.131A2

x x x x

LME22.231A2

x x x x

LME22.232A2

x x x x

LME22.233A2

x x x x

LME22.331A1

x x x ---

LME22.331A2

x x x x

LME22.333A2

x x x ---

LME23.331A2

x x x x

LME23.351A2

x x x x

LME41.051A2

--- x x ---

LME41.052A2

--- x x ---

LME41.053A2

--- x x ---

LME41.054A2

--- x x ---

LME41.071A2

--- x x ---

LME41.091A2

--- x x ---

LME41.092A2

--- x x ---

LME44.056A2

--- x x x

LME44.057A1

--- x x ---

LME44.057A2

--- x x x

Service notes

• Use the KF8872 service adapter for short periods of time only

6/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

Life cycle

Burner controls has a designed lifetime* of 250,000 burner startup cycles which, under

normal operating conditions in heating mode, correspond to approx. 10 years of usage

(starting from the production date given on the type field). This lifetime is based on the

endurance tests specified in standard EN230 / EN298 and the table containing the

relevant test documentation as published by the European Association of Component

Manufacturers (Afecor) (www.afecor.org

).

The designed lifetime is based on use of the burner controls according to the manufacturer’s Data Sheet. After reaching the designed lifetime in terms of the number of

burner startup cycles, or the respective time of usage, the burner control is to be replaced by authorized personnel.

* The designed lifetime is not the warranty time specified in the Terms of Delivery

Disposal notes

The unit contains electrical and electronic components and must not be disposed of

together with domestic waste.

Local and currently valid legislation must be observed.

Mechanical design

• Units of plug-in design like their predecessor types LGB... and LMG... (refer to

«Dimensions»)

• The housing is made of impact-proof, heat-resistant and flame-retarding plastic. It

is of plug-in design and engages audibly in the base

• The housing accommodates the

- microcontroller for the control sequence and the control relays for load control

- electronic flame signal amplifier (ionization)

- lockout reset button with its integrated 3-color signal lamp (LED) for operational

status and fault status messages and the socket for connecting the OCI400 inter face adapter or the AGK20... lockout reset button extension

• Multicolor indication for operational status and fault status messages

• Transmission of operational status and fault status messages and detailed service

information via additional OCI400 interface adapter and ACS410 PC Windows

software

• Burner capacity unlimited (thermal output on startup ≤ 120 kW)

• 3 repetitions in the event of loss of flame during operation (LME11… /

LME41.051…)

• Repetition in the event of loss of flame during operation (LME41.052… /

LME41.053… / LME41.054… / LME41.071… / LME41.091… / LME41.092…)

LME...

Indication and

diagnostics

Versions

7/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

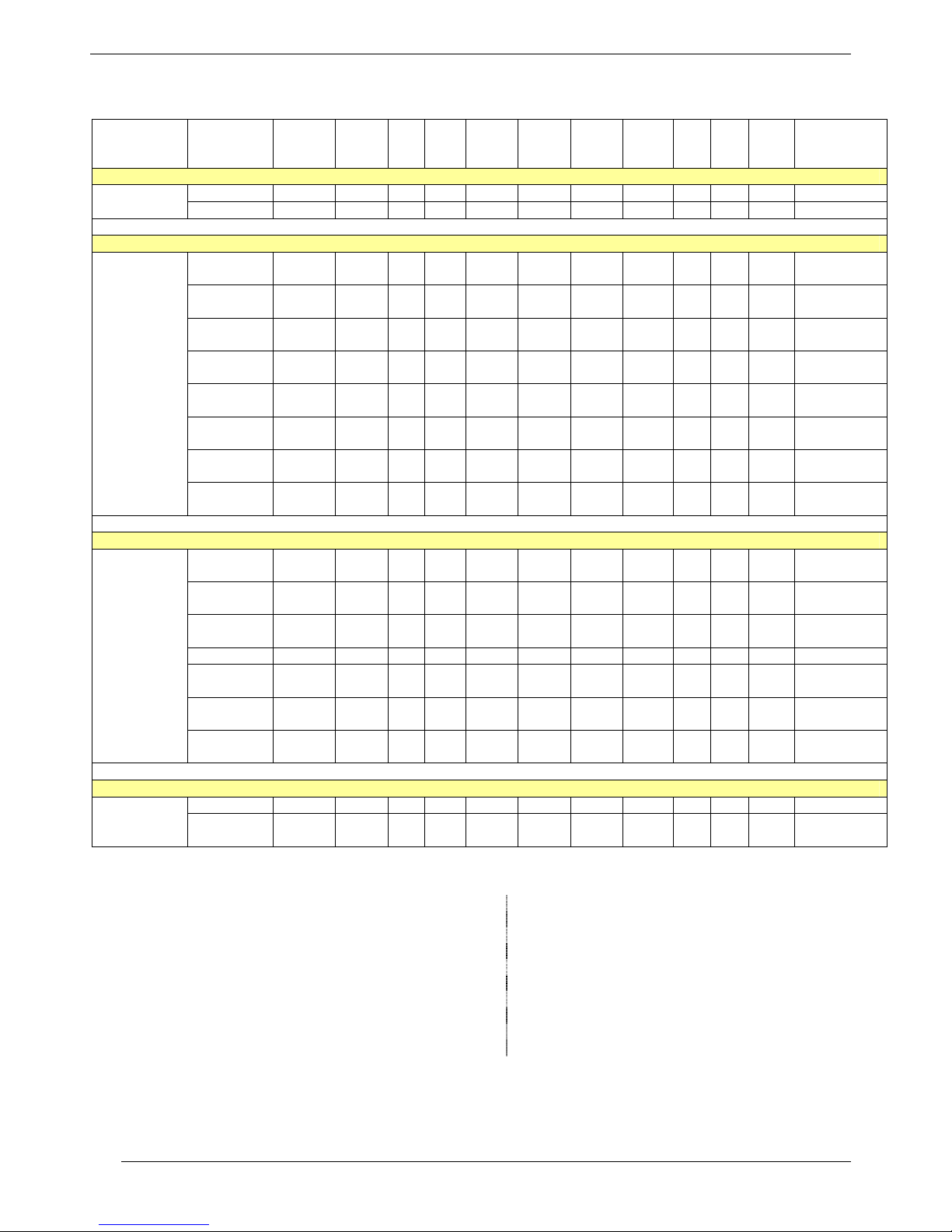

Type summary (other types of burner controls on request)

The type references given below apply to the LME… burner control without plug-in

base and without flame detector. For ordering information on plug-in bases and other

accessories, refer to «Ordering».

Flame detector

Type

reference

Main

voltage

tw

approx.

s

t1

min.

s

TSA

max.

s

t3n

approx.

s

t3

approx.

s

t4

approx.

s

t10

min.

s 3)

t11

min.

s 1)

t12

min.

s 1)

Repetition

For

replacing of

Burner controls for 1-stage burners (up to 120 kW output)

LME11.230A2

AC230V

2.5 20 3 2 2 --- 5 --- --- 3x

---

Ionization probe

(ION)

LME11.330A2

AC230V

2.5 30 3 2 2 --- 5 --- --- 3x

---

Burner controls for 2-stage burners, without actuator control

LME21.130A1

AC 120 V

2.5 7 3 2 2 8 5 --- --- ---

LGB21.130A17

LME21.130A2

AC 230 V

2.5 7 3 2 2 8 5 --- --- ---

LGB21.130A27

LMG21.130B27

LME21.230A2

AC 230 V

2.5 20 3 2 2 8 5 --- --- ---

LGB21.230A27

LMG21.230B27

LME21.330A1

AC 120 V

2.5 30 3 2 2 8 5 --- --- ---

---

LME21.330A2

AC 230 V

2.5 30 3 2 2 8 5 --- --- ---

LGB21.330A27

LMG21.330B27

LME21.350A1

AC 120 V

2.5 30 5 4 2 10 5 --- --- ---

LGB21.350A17

LME21.350A2

AC 230 V

2.5 30 5 4 2 10 5 --- --- ---

LGB21.350A27

LMG21.350B27

Ionization probe

(ION) or flame

detector

QRA...

4)

with

AGQ3...A27

LME21.550A2

AC 230 V

2.5 50 5 4 2 10 5 --- --- ---

LGB21.550A27

Burner controls for 2-stage burners, with actuator control

LME22.131A2

AC 230 V

2.5 7 3 2 3 8 3 12 12 ---

LGB22.130A27

LMG22.130B27

LME22.231A2

AC 230 V

2.5 20 3 2 3 8 3 12 12 ---

---

LME22.232A2

AC 230 V

2.5 20 3 2 3 8 3 16.5 16.5 ---

LGB22.230A27

LMG22.230B27

LME22.233A2

AC 230 V

2.5 20 3 2 3 8 3 30 30 --- LMG22.233B27

LME22.331A1

AC 120 V

2.5 30 3 2 3 8 3 12 12 ---

---

LME22.331A2

AC 230 V

2.5 30 3 2 3 8 3 12 12 ---

LGB22.330A27

LMG22.330B27

Ionization probe

(ION) or flame

detector

QRA... 4) with

AGQ3...A27

LME22.333A2

AC 230 V

2.5 30 3 2 3 8 3 30 30 ---

---

Burner controls for 2-stage burners, with actuator control

LME23.331A2

AC 230 V

2.5 30 3 2 3 8 3 12 12 --- LGB32.330A27

Blue flame

detector QRC…

LME23.351A2

AC 230 V

2.5 30 5 4 1 10 3 12 12 ---

LGB32.350A27

Legend

tw Waiting time 1) Max. running time available for actuator «SA»

TSA Safety time The actuator running time must be shorter

t1 Prepurge time 2) t22 + response time of flame relay

t3 Preignition time 3) Max. 65 s

t3n Postignition time 4) Only used for AC 230 V

t4 Interval between ignition «Off» and «BV2»

t10 Specified time for air pressure signal

t11 Programmed opening time for actuator «SA»

t12 Programmed closing time for actuator «SA»

t22 2nd safety time

8/25

Building Technologies CC1N7101en

HVAC Products 27.11.2008

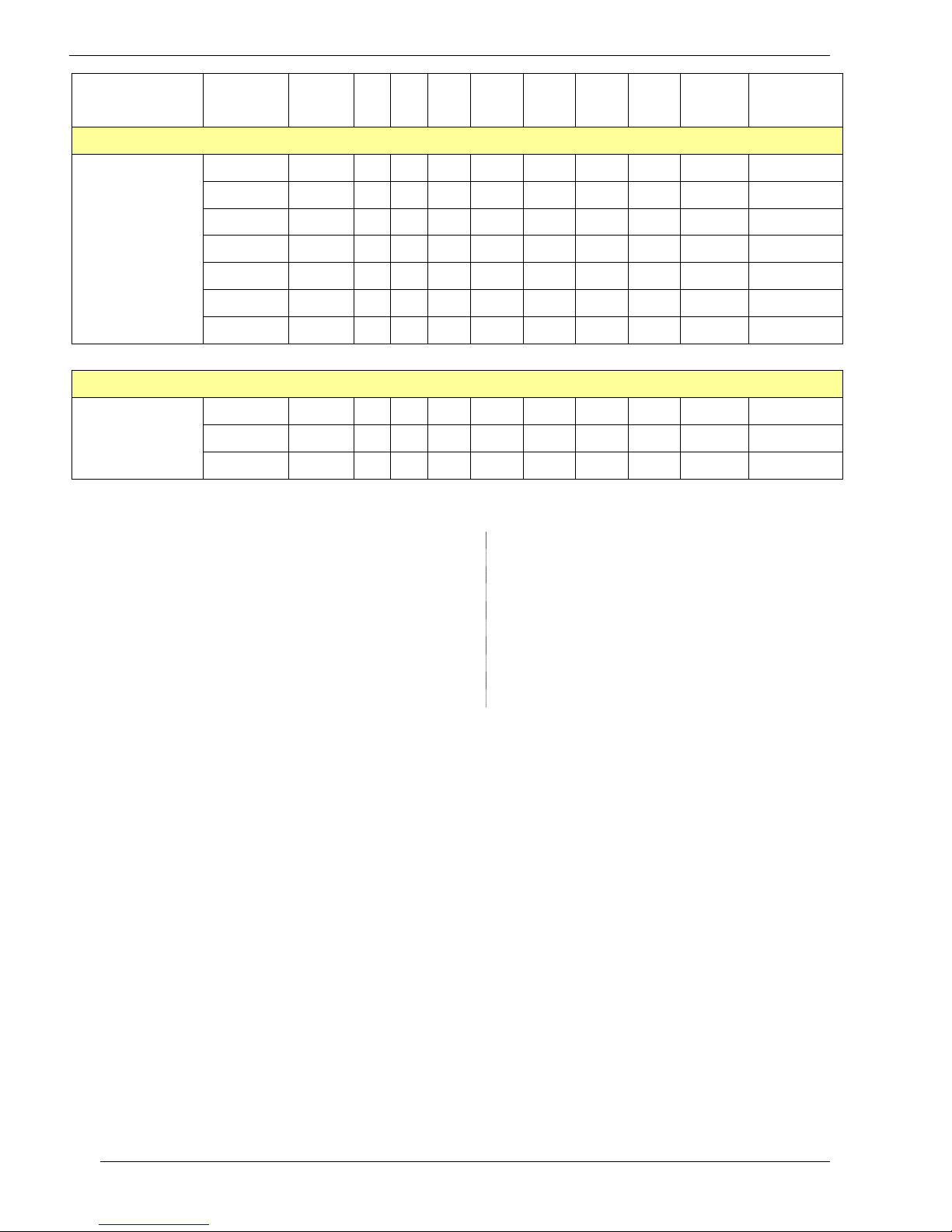

Type summary (other types of burner controls on request) [cont´d]

Flame detector

Type reference

Main

voltage

tw

min.

s

t1´

min.

s

TSA

max.

s

t3n

approx.

s

t3

approx.

s

t4

approx.

s

t22

approx. s Repetition For replacing of

Burner controls for atmospheric burners

LME41.051A2

AC 230 V

2,5 1 5 4 1 --- --- 3x ---

LME41.052A2

AC 230 V

2,5 1 5 4 10 --- --- X ---

LME41.053A2

AC 230 V

2,5 10 5 4 1 --- --- X ---

LME41.054A2

AC 230 V

2,5 1 5 4 1 --- --- X ---

LME41.071A2

AC 230 V

2,5 10 10 9 1 --- --- X ---

LME41.091A2

AC 230 V

2,5 1 10 9 10 --- --- X ---

Ionization probe (ION)

or flame detector

QRA...

4)

with

AGQ3...A27

LME41.092A2

AC 230 V

2,5 1 10 9 1 --- --- X ---

Burner controls for atmospheric burners

LME44.056A2

AC 230 V

16 9 5 4 2 10 5 --- LGB41.255A27

LME44.057A1

AC 120 V

16 9 5 4 2 10 8 --- LGB41.258A17

Ionization probe (ION)

or flame detector

QRA...

4)

with

AGQ3...A27

LME44.057A2

AC 230 V

16 9 5 4 2 10 8 --- LGB41.258A27

Legend

tw Waiting time 1) Max. running time available for actuator «SA»

TSA Safety time The actuator running time must be shorter

t1´ Purge time 2) Max. 65 s

t3 Preignition time 3) Max. 65 s

t3n Postignition time 4) Only used for AC 230 V

t4 Interval between ignition «Off» and «BV2»

t10 Specified time for air pressure signal

t11 Programmed opening time for actuator «SA»

t12 Programmed closing time for actuator «SA»

t22 2nd safety time

Loading...

Loading...