Page 1

LITHOSTAR Multiline

Disposal Instructions

SP

Environmental protection measures

© Siemens AG 1995

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 3 English

Print No.: RXL2-120.163.01.03.02 Doc . Gen. Date: 04.97

Replaces: RXL2-120.163.01.02.02

Page 2

0 - 2 Revision

Chapter Page Revision

01 - 403

11 - 202

21 - 203

3 1 - 10 03

41 - 202

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 2 of 4 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 3

Contents 0 - 3

Page

1 _______General_______________________________________________________1 - 1

General inf o rmatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

2 _______Outline _______________________________________________________2 - 1

Disposal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Materials/components subject to mandatory disposal . . . . . . . . . . . . . . . . .2 - 2

3 _______Disassembly and Disposal_______________________________________3 - 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Insulating oil in HV battery charger

(when scrapping only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Coolant in the cooling unit

(when scrapping only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Protective measures, storage and handling . . . . . . . . . . . . . . . . . . . . . 3 - 1

Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

Lithium battery in the MEMOSKOP . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Lithium battery in control frame N11. . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Buffer battery in POLYDOROS LX . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Battery in POLYDOROS SX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Lithium battery in the SONOLINE . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Battery in the SIRECUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

Battery in the laser light localizer . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Insulating oil (

High-voltage generator (POLYDOROS LX and SX). . . . . . . . . . . . . . . . . 3 - 5

Shock wave generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

X-ray tube assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Lead and components containing lead . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

X-ray tube assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Collimator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Grid and centering cross on the I.I. . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Grid on the cassette holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Implosive vacuum components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

X-ray tube assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Image intensifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

System PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

MULTISPOT 2000, optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 9

when scrapping only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

4 _______Changes as compared to previous version _________________________4 - 1

Siemens AG Register 3 RXL2-120.163.01 Page 3 of 4 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 4

0 - 4 Contents

Page

This page intentionally left blank.

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 4 of 4 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 5

General 1

General information 1

The regulation regarding electronic scrap presently being formulated requires that manufacturers of systems and equipment dispose of the hazardous materials and components

contained in them. Proper disposal procedures for hazardous waste apply not only when

scrapping the system but also when replacing hazardous materials while the system is

operational.

The list of hazardous materials b y p roduc t locat ed on pa ge 2-1 of t hese in structions gi v es

an outline of the assemblies and components subject to mandatory disposal procedures.

To assist you in locating t he assemb l ies/co mponents containi ng hazardous s ubst ances in

the system, we have included disposal information and illustrations on page 2-2.

The disposal information contained in these instructions applies when scrapping the system or when replacing components and parts containing substances hazardous to the

environment.

1 - 1

Siemens AG Register 3 RXL2-120.163.01 Page 1 of 2 LITHOSTAR Multiline

Medical Engineering Rev. 02 04.97 TD SP 1

Page 6

1 - 2 General

This page intentionally left blank.

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 2 of 2 Siemens AG

Rev. 02 04.97 TD SP 1 Medical Engineering

Page 7

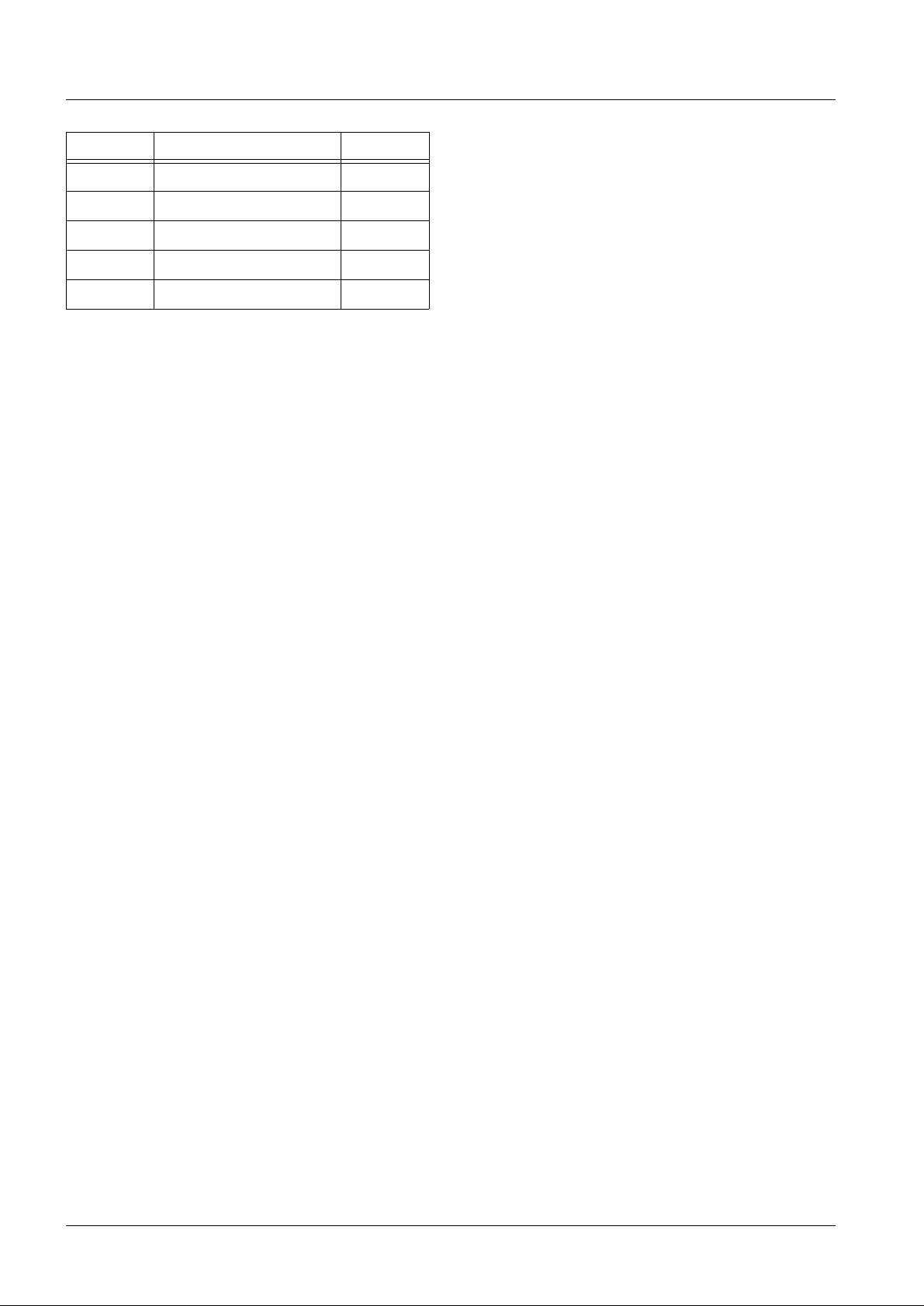

Outline 2

Disposal list 2

2 - 1

Component

Assembly

Location

Battery charger Shock wave cabinet A13 Oil ~ 2 ltr. Page 3-1

Cooling unit Shock wave cabinet A13

Battery

Control cabinet/

MEMOSKOP/Board D1

Harmful

substances/

Hazard

1

Coolant:

2

R134A

3

Lithium 1 Page 3-2

Quan-

tity

0.88 lb

0.4 kg

Page 3-1

Mea-

sure

Control cabinet/

Battery

Control frame

4

Lithium 1 Page 3-2

N11Board D1

Buffer battery

in component J32

High-voltage generator

Shock wave generat.

POLYDOROS LX

Board D200

POLYDOROS LX / SX

Basic unit

HV capacitor

5

Lithium 1 Page 3-3

Transformer

6

oil PCB-free

Oil

7

inflammable

~15 ltr. Page 3-5

~2 ltr . Page 3-6

Lead Page 3-6

X-ray tube asse mbly C-arm, lower secti o n

Oil Page 3-6

8

Implosion of

X-ray tube

1 Page 3-7

Collimator X-ray tube assembly Lead 1 Page 3-6

Grid

Centering cross

Image intensifier

Image intensifier

Grid Cassette holder Lead 1 Page 3-7

Image intensifier with

Videomed

C-arm, upper section

PC monitor Control console

FL double monitor Control console Impl. of tube 1 Page 3-8

Physiolog. monitor

optional

MULTISPOT,

optional

FL monitor

System PC, keyboard

and mouse

Control console

Control console

Monitor trolley or ceiling

mounted support

Control console Battery 1 Page 3-9

SONOLINE monitor SONOLINE

Battery SONOLINE Lithium 1 Page 3-4

9

10

Lead 1 Page 3-7

11

Implosion of

12

X-ray tube

Implosion of

13

picture tube

14

Implosion of

15

picture tube

Implosion of

16

1 Page 3-7

1 Page 3-8

1 Page 3-8

1 Page 3-8

picture tube

Implosion of

17

picture tube

18

Implosion of

19

picture tube

20

1 Page 3-8

1 Page 3-8

Siemens AG Register 3 RXL2-120.163.01 Page 1 of 2 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 8

2 - 2 Outline

Component

Location

Assembly

SIRECUST monitor SIRECUST

Battery SIRECUST Lithium 1 page 3-4

Buffer batter y

POLYDOROS SX in

CPU unit

Battery Laser light localizer dep. on model 4 page 3-4

21

22

23

24

Harmful

substances/

Hazard

Implosion of

picture tube

Quan-

tity

1 page 3-8

Lithium 1 page 3-3

Materials/components subject to mandatory disposal 2

234

17

24

12

11

10

1

23

13

5

6

14

15

Mea-

sure

20

7

8

19

9

21

18

16

22

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 2 of 2 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 9

3 - 1

Preparation 3

• Make sure that the unit and the on-si te power supply are switched off.

• Ensure that the system and the on-site power distr ibutor cannot be switched on again.

Battery

charger

Cooling

unit

6,(0(16

Insulating oil in HV battery charger

(when scrapping only) 3

• Remove the front cover of the shock wave cabinet.

• Take out the battery charger.

• Pour out or draw off the oil of th e charger into a suitable

container.

• The oil removed must be disposed of by a qualified

recycling company.

Coolant in the cooling unit

(when scrapping only)

Procedure 3

• Disassemble the cooling unit

• Pour the coolant, fluorocarbon R134a, into a suitable

container.

• The liquid removed must be disposed of by a qualified

recycling company.

Protective measures, storage and handling 3

• Technical protective measures:

- If vapors or mist can accumulate, ensure s ufficient

ventilation or exhaust to comply wi th specified

thresholds.

- Avoid inhaling high vapor concentrat ions.

- Since mist and vapor are heavier than air and di splace

the oxygen, avoid narrow or low worki ng positions.

Exhaust must be provided at the lowest wor king

positions.

- Keep the liquid away from heat and sources of ignition,

since it can decompose into toxic by-products i f held

near open flames or placed on red-hot surfaces.

3

• Individual protective measur es:

- Use respiratory equipment in closed or ins ufficiently

ventilated rooms.

- Use safety glasses for eye protection .

- Use gloves made of chlorbutyl rubber to protec t hands.

- Use lightweight protective clothes and skin protection.

• Work hygiene

- Do not inhale the vapors.

- Do not allow the liquid to contact ey es or hands.

Fig. 1 Shockwave cabinet

Siemens AG Register 3 RXL2-120.163.01 Page 1 of 10 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 10

3 - 2 Disassembly and Disposal

'

MEMOSKOP

/LWKLXPEDWWHULH

0HPRVNRS

9

*

-

9

9

9

Lithium battery

;

Control frame N11

7

1HW]EDX

JUXSSH

0

D1

/LWKLXPEDWWHULH

Lithium battery

;

'

Batteries 3

• Remove the front panel of the cont rol cabinet (Fig. 2).

• Remove the front panel of the genera tor cabinet (Fig. 3)

Lithium battery in the MEMOSKOP 3

• Remove the front cover of the MEMOSKOP in the

control cabinet (Fig. 2) by removing the screws.

• Remove board D1 from the MEMOSKOP and place it on

a flat surface.

• Remove the lithium battery from position J 144 on board

D1 and have a qualified recycling company dispose of it.

Lithium battery in control frame N11 3

• Remove board D1 from control frame N11 in the control

cabinet and place it on a flat surface (Fig. 2).

• Remove the lithium battery from position G4 on boar d

D1 and have a qualified recycling company dispose of it.

Fig. 2

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 2 of 10 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 11

Disassembly and Disposal 3 - 3

X14

X1

XCS

X3

X4

Buffer battery

V1 V2

X5

X13

Fig. 3 POLYDOROS LX

3XIIHUEDWWHULH

HQWKDOWHQ

SIEMENS

11 72 720 X2169 D200 E2

DATA

MODEM

'

D200

D100

D110

D115

D200

J32 J11 J28

X5

X2

D291

D160

X9

X5

T2

H1

K20

F1F2F3

D220

K30

M16

Buffer battery

Buffer battery in POLYDOROS LX 3

• Remove board D200 from the generator

cabinet and place it on a flat surf ace (Fig.

3).

• Remove component J32 containing the

buffer battery from board D200. (Fig. 3).

• Have the component containing the buffer

battery disposed of by a qualif ied recycling

company.

Battery in POLYDOROS SX 3

• Remove the battery from the CPU HD unit

and have a qualified recycling company

dispose of it (Fig.4).

Fig. 4 POLYDOROS LX

Siemens AG Register 3 RXL2-120.163.01 Page 3 of 10 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 12

3 - 4 Disassembly and Disposal

Lithium battery in the SONOLINE 3

• Remove the side panel from the

SONOLINE:

• Remove the lithium battery from t he

SONOLINE and have it disposed of

by a qualified recycling company.

Battery

Fig. 5 SONOLINE

Battery in the SIRECUST 3

• Remove the battery from the back of

the SIRECUST and have it disposed

of by a qualified recycling company.

Fig. 6 SIRECUST

Battery

Battery in the laser light localizer 3

• Remove the battery from the laser light l ocalizer and have it disposed of by a qualif ied

recycling company .

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 4 of 10 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 13

Disassembly and Disposal 3 - 5

Cover with installed parts

24 pan head screws distributed

on the periphery

Trough filled with transformer oil

Fig. 7 High-voltage generator

Insulating oil (when scrapping only) 3

High-voltage generator (POLYDOROS LX and SX) 3

• Remove the high-voltage generator H1fr om the generator cabinet (Fig. 3)

• Loosen the 24 pan head screws on the high-voltage generator (Fig.7).

• Lift the cover with the install ed parts from the trough of the high-voltage generator and

allow the oil to run into the trough .

• Pour the oil from the trough into a su itable container and have it disposed of by a

qualified recycling co mpany.

Siemens AG Register 3 RXL2-120.163.01 Page 5 of 10 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 14

3 - 6 Disassembly and Disposal

Collimator

X-ray tube assem.

Shock wave generator

Fig. 8

Shock wave generator 3

• Remove the panels of the basic unit.

• Remove the shock wave generator fro m the basic unit (Fig. 8, left).

• Open the shock wave generator by removing the screws and take out the high-voltage

capacitor filled with oil.

• Have the entire high-voltage capaci tor disposed of by a qualified recycli ng company or

send it back as returned goods to SIEMENS AG, Medical Enginee ring Group, for

reprocessing.

X-ray tube assembly 3

• Remove the covers of the tube assembly by remo ving the screws.

• Remove the collimator fr om the tube assembly (Fig.8, right) by removin g the screws.

• Remove the tube assembly filled with oi l from the C-arm and send it back as returned

goods to SIEMENS AG, Medical Engineering Group for reprocessing.

Lead and components containing lead 3

X-ray tube assembly 3

• Due to the lead content of the screens, the tube asse mbly must be sent back as returned

goods to SIEMENS AG, Medical Engineering Group for reprocessing.

Collimator 3

• Due to the lead content of the blades, the col limator previously removed from the t ube

assembly must be sent back as returned goods to SIEMENS AG, Medical Engineeri ng

Group for reprocessing.

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 6 of 10 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 15

Disassembly and Disposal 3 - 7

Cover

Image Intensifier

Grid Centering cross

Fig. 9

Grid and centering cross on the I.I. 3

• Remove the grid and centering cross atta ched to the I.I. input (Fig. 9).

• Have the grid and the centering cross di sposed of by a qualified recyc ling company

(Fig. 9).

Grid on the cassette holder 3

• Remove the grid from the cassette hold er and have it disposed of by a qual ified recycling

company.

Implosive vacuum components 3

X-ray tube assembly 3

• Due to the vacuum X-ray tube, the tube assembly must be sent back as previously

described to SIEMENS AG, Medical Engineering Group for reprocessing.

Image intensifier 3

• Remove the side panels of the I.I. by r emoving the screws (Fig. 9, left)

• Remove the I.I. from the C-arm (Fig. 9, ri ght)

and send it back as returned goods to SIEMENS AG, Medical Engineering Group for

reprocessing.

Siemens AG Register 3 RXL2-120.163.01 Page 7 of 10 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 16

3 - 8 Disassembly and Disposal

FL Monitor

SIRECUST

Monitor

PC Monitor

Keyboard

FL double monitor

Mouse

Physiolog. monitor

System PC

Multispot 2000

(if

present)

Fig. 10

Monitors 3

• Send the PC monitor to SIEMENS AG, Medical

Engineering or to a q ualified recycli ng company.

• Send the FL double monitor as returned goods to

SIEMENS AG, Medical Engineering or to a qualified

recycling company.

• Send the FL monitor to SIEMENS AG, Medical

Engineering, or to a qualified recycling company.

• Send the physiological monitor, i f present, to the

Lucius & Baer company or to a qualified recyc ling

company.

• Have the entire SIRECUST system, including the built-

in monitor, disposed of by a quali fied recycling

company or send it as returned goods to SIEMENS

AG, Medical Engineering Group.

• Send the SONOLINE monitor as returned goods to

SIEMENS AG, Medical Engineering Group, or have it

disposed of by a qualified recyc ling company.

Monitor

Fig. 11

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 8 of 10 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 17

Disassembly and Disposal 3 - 9

System PC 3

• Turn over the sy stem PC (Fig. 10) together with the keyboard and the mouse to

SIEMENS AG, Medical Engineering Group or to a qualified recycling company.

MULTISPOT 2000, optional 3

• Send the MULTISPOT 2000 (Fig. 10), if present, to the Hertel company, Electronics

Recycling, Nuremberg, or to SIEMENS AG, Medical Engineering Group.

Siemens AG Register 3 RXL2-120.163.01 Page 9 of 10 LITHOSTAR Multiline

Medical Engineering Rev. 03 04.97 TD SP 1

Page 18

3 - 10 Disassembly and Disposal

This page intentionally left blank.

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 10 of 10 Siemens AG

Rev. 03 04.97 TD SP 1 Medical Engineering

Page 19

Changes as compared to previous version 4

Chapter 0 Cover page ad apted; page containi ng re vi sion le vel and table of contents

expanded

Chapter 1 Layout changed

Chapter 2 Table and figure changed

Chapter 3 Fig. 4 new; text changes and additions

Chapter 4 Changed in accordance with the new revision level

4 - 1

TD SP 1 / Schlee

TD SP 2 / Wendt

SMS Iselin / Weiss Costa

Siemens AG Register 3 RXL2-120.163.01 Page 1 of 2 LITHOSTAR Multiline

Medical Engineering Rev. 02 04.97 TD SP 1

Page 20

4 - 2 Changes as compared to previous version

This page intentionally left blank.

LITHOSTAR Multiline Register 3 RXL2-120.163.01 Page 2 of 2 Siemens AG

Rev. 02 04.97 TD SP 1 Medical Engineering

Loading...

Loading...