Siemens Lithostar Multiline Repair Instructions

LITHOSTAR Multiline

Repair Instructions

Repair Instructions

SP

Titel der Unterlage hier eintragen

Shock wave system

© Siemens AG 1996

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: RXL2-120.841.01.02.02 Doc. Gen. Date: 09.05

Replaces: RXL2-120.841.01.01.02

0 - 2 Revision

Chapter Page Revision

all all 02

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery.

Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempting installation or service procedures.

LITHOSTAR Multiline RXL2-120.841.01 Page 2 of 4 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

Contents 0 - 3

Page

1 _______General _______________________________________________________ 1 - 1

Measurement instruments required . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Technical documents required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Reading/deleting the shot counter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Overview of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Removing the shock wave head cover . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Removing the coupling bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Attaching the coupling bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Installing the shock wave head covers . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Filling/venting the cooling circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Filling the coupling circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

2 _______Replacing board W11 ___________________________________________ 2 - 1

Board W11 with AS00 and AS01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Board W11 as of AS02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

3 _______Replacing the coupling control W12 _______________________________ 3 - 1

4 _______Replacing the pressure transducer sensor B3/W4 ___________________ 4 - 1

5 _______Replacing the shock wave head and cone drive _____________________ 5 - 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Cone drive replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 3

Checking the toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Replacing the cone tube cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

6 _______Replacing the Shock Wave Generator______________________________ 6 - 1

Removing the old shock wave generator . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Installing the new shock wave generator . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Replacing the trigger transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

7 _______Replacing the water pump and filter _______________________________ 7 - 1

Replacing the water pump M15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Replacing the filter holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

8 _______Replacing the sensor module ____________________________________ 8 - 1

Board W11 with AS00 and AS01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Board W11 as of AS02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

9 _______Setting the monitoring on board D19 ______________________________ 9 - 1

Determining voltage value X3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Siemens AG RXL2-120.841.01 Page 3 of 4 LITHOSTAR Multiline

Medical Solutions Rev. 02 09.05 CS PS 24

0 - 4 Contents

Page

Setting the voltage values on MP3 and MP4 . . . . . . . . . . . . . . . . . . . . . . 9 - 2

10 _____ Monitoring times on board D91 __________________________________10 - 1

Determining the current charging time (t

Setting the monitoring time (t

+ 40 ms) . . . . . . . . . . . . . . . . . . . . . .10 - 2

meas.

) . . . . . . . . . . . . . . . . . . . . .10 - 1

meas.

11 _____ Changes to previous version ____________________________________11 - 1

LITHOSTAR Multiline RXL2-120.841.01 Page 4 of 4 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

General 1

Safety notes

1 - 1

CAUTION

Tests or adjustments performed with radiation ON are identified by the radiation warning

symbol .

Radiation protection regulations must be observed and radiation protection clothing must

be worn during these types of adjustments.

Observe ESD regulations.

When performing all service work and tests, please note the product-specific safety information contained in the instructions, as

well as the general safety information contained in ARTD Part 2.

Measurement instruments required 1

NOTICE

• Oscilloscope e.g. Fluke Scope Meter 73 92 074

• Digital Multimeter e.g. Fluke 187 99 94 831

• Shock wave pressure test device 30 95 408

• Adapter 70 41 028

Unless otherwise specified, the articles mentioned are listed in

the STC (Service Tools Catalog). The STC is a component of the

Spare Parts Catalog.

Technical documents required 1

• Disposal instructions RXL2-120.163.01

• Isocenter Adjustment RXL2-120.071.01

• Shock Wave Pressure and Position Control SPL2-120.074.01

Reading/deleting the shot counter 1

Shot counter: Reading

Deleting

Documentation of the shot counters

Monitoring (Service Software Multiline)

→

Instructions RXL2-120.113.01...

Parameter (Service Software Multiline)

→

Interface: Shock wave System

Instructions: RXL2-120.032.01...

Operating record (Logbook)

→

Siemens AG RXL2-120.841.01 Page 1 of 10 LITHOSTAR Multiline

Medical Solutions Rev. 02 09.05 CS PS 24

1 - 2 General

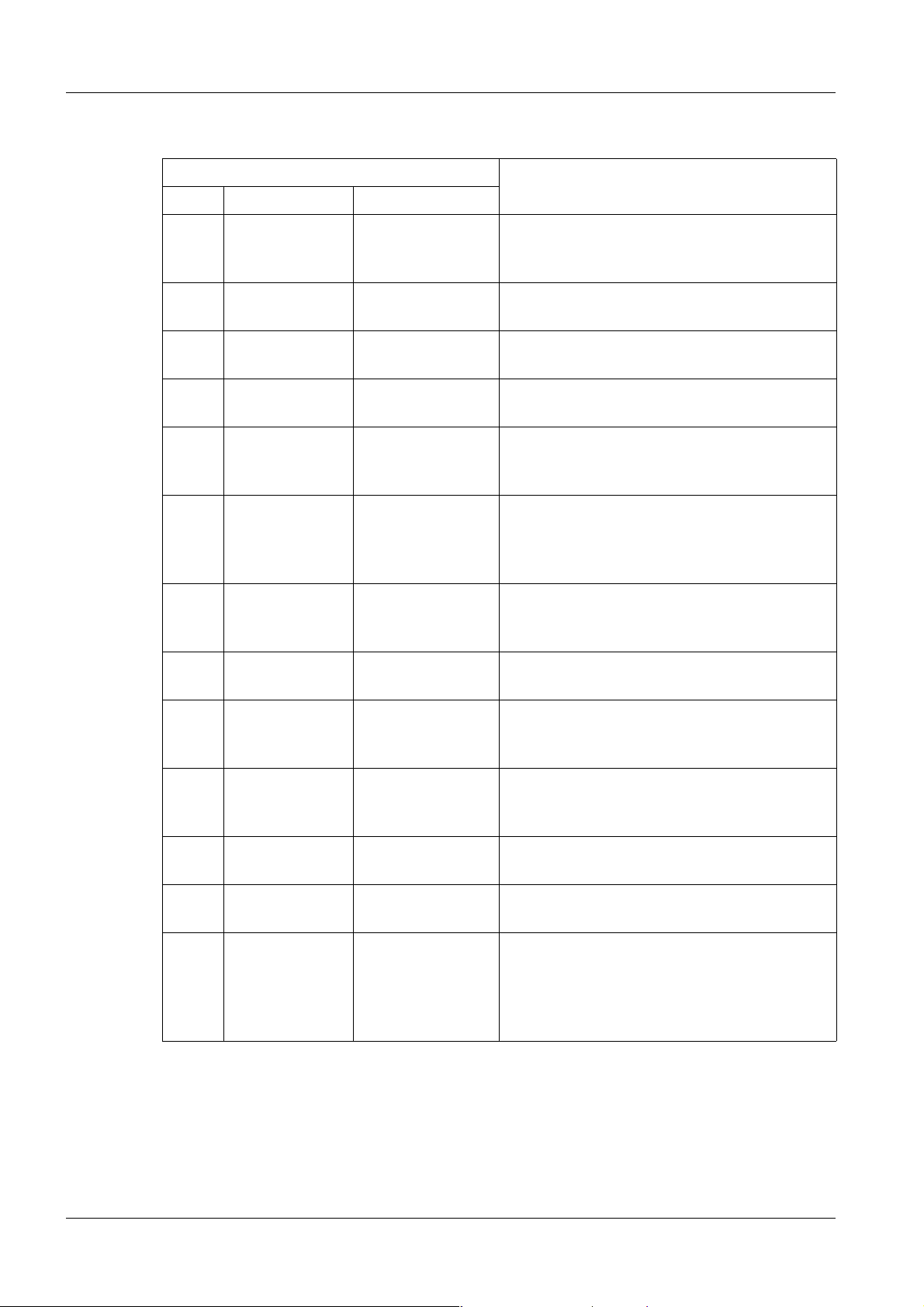

Overview of components 1

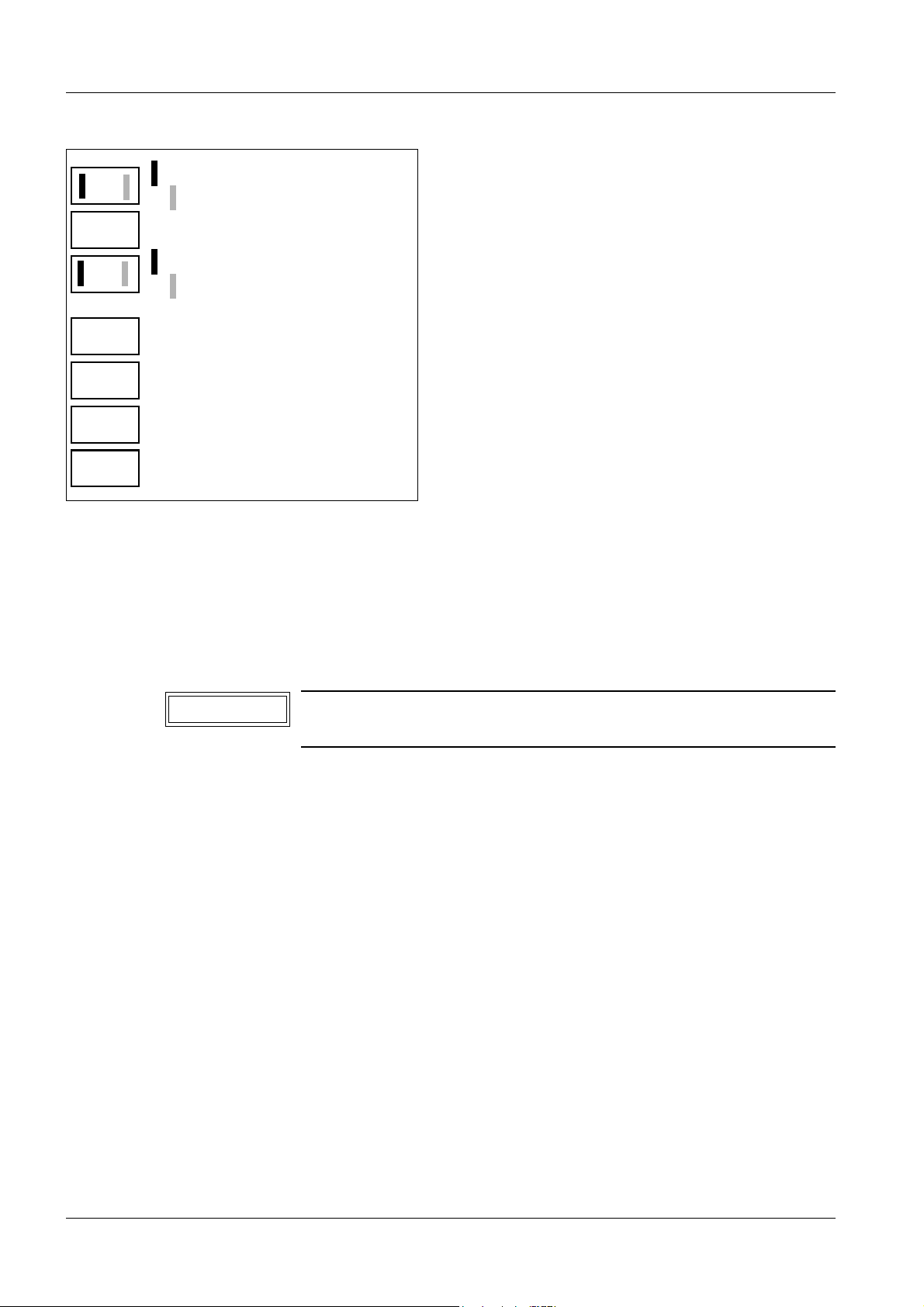

Module

Function Part number

D1 Power supply 11 64 032 X1767 0V = Z6

Set +15 V

Set - 15 V

D12 Trigger electro-

nics

D19 Monitoring 16 65 194 J1038 Check settings and adjust if necessary:

D91 Energy monito-

ring

W11A Cooling circuit 16 65 533 J1011 Check flow rate setting and adjust with R5 if

W12 Coupling

control

W15 Charging device

control

87 98 547 J1009 No special attention required

Refer to wiring diagram J1029-39

88 57 245 J1005 Check settings and adjust if necessary:

Refer to wiring diagram J1029-91

necessary:

Refer to wiring diagram J1029-31

16 65 277 J1029 Check prom's and jumpers,

Check setting and adjust if necessary:

Refer to wiring diagram J1029-33, jumper

log

16 65 558 J1038 Check proms and jumpers,

Refer to wiring diagram J1029-10, jumper

log

Comments on replacement

+15 = Z10 -15V = Z32

± 0.1 V with R2

± 0.1 V with R5

W16 Interface 16 65 368 J1038 Check proms and jumpers,

Refer to wiring diagram J1029-10

Sensor module

shock wave

head

B3/W4 Pressure trans-

ducer sensor

B3/W4

M15 Water pump 30 95 044 J1029 Check flow and set 25

M18 Charging device 46 81 326 B3305 Check setting of board D91

N70 Shock wave

generator

30 92 603 J1035 Check setting on boards W11A and W12

30 93 551 J1029 Check setting on board W12

± 3 liters on W11A

with R5

Documentation of the “System counter”

11 78 230 J1003 Check setting of board D91,

note counter reading of the “Shock wave/

Spark gap counter” and perform reset.

Perform pressure measurement according

to instructions SPL2-120.074.01

LITHOSTAR Multiline RXL2-120.841.01 Page 2 of 10 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

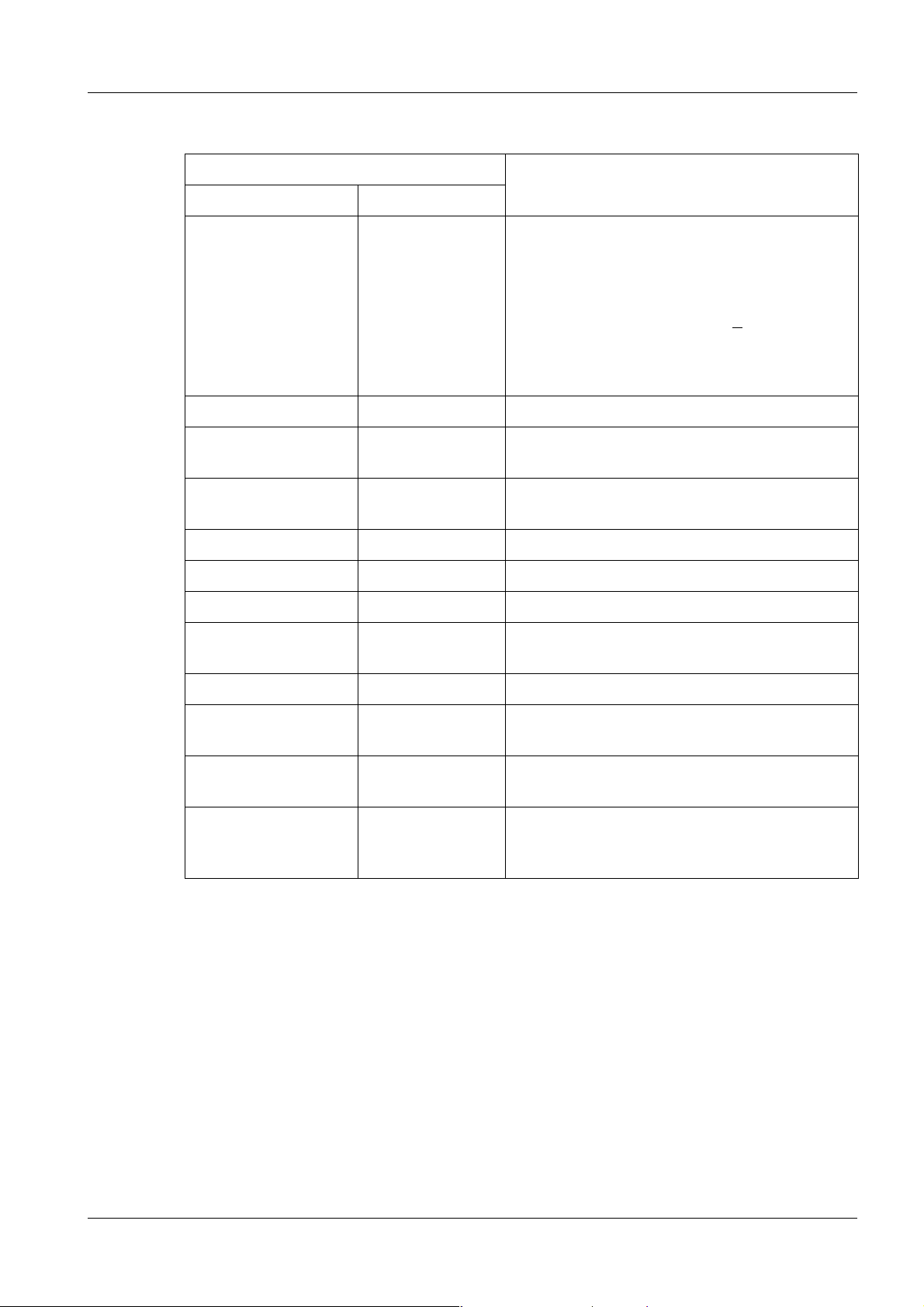

General 1 - 3

Module

Function Part number

Spark gap 89 56 112 J1003 Do not touch the ceramic body.

Record counter reading of the "Shock wave/

Spark gap counter” and perform reset

To prime the spark gap select the highest

energy level and release 500 +

waves

If errors occur, reset these and release further

shock waves

Cooling unit 46 94 022 B3104 Fill the cooling circuit acc. to Chapter 1

Shock wave head 30 92 223 J1035 The shock wave head is delivered without

coupling bellows

Comments on replacement

10 shock

Cone drive 16 69 275 J1035,

30 92 728 J1035

Filter insert 70 52 012 F0428 Fill the cooling circuit acc. to Chapter 1

Filter complete 30 95 010 J1029 Fill the cooling circuit acc. to Chapter 1

Pressure switch S4 30 93 528 J1029 Fill the cooling circuit acc. to Chapter 1

Solenoid valve Y1 77 60 341 B1805 Fill the cooling circuit acc. to Chapter 1

Use the water connections of the old valve

Flow meter 70 54 257 F0423 Fill the cooling circuit acc. to Chapter 1

High voltage socket 30 92 009 J1035 Remove shock wave head cover acc. to Chap-

ter 1

Coupling bellows 47 78 465 J1035 After replacement, fill the coupling circuit acc.

to Chapter 1

Ultrasound cap

assembly

30 92 207 J1035

⎯

⎯

Siemens AG RXL2-120.841.01 Page 3 of 10 LITHOSTAR Multiline

Medical Solutions Rev. 02 09.05 CS PS 24

1 - 4 General

Normal mode

S2

Empty coupling bellows*

R998

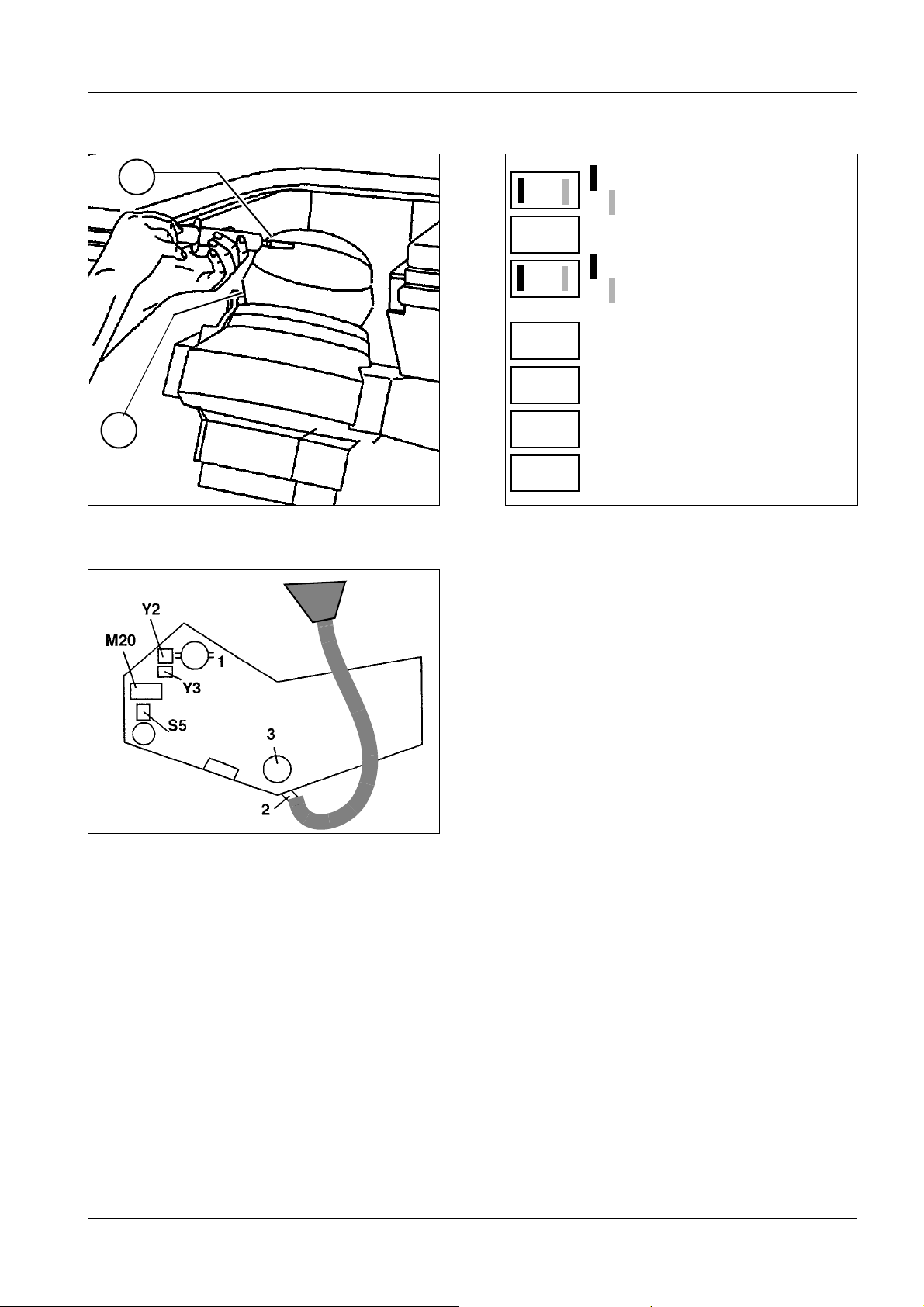

Fig. 1

S1

S3

R71

R85

R49

Button on: Fill coupling bellows *

Function only

Normal mode

Service mode

Offset

Coupling pressure sensor B1

Lift min.

(V22)

Lift max.

(V23)

Offset

Filling level sensor B3/W4

*

if S3

at service

mode position

W12

Removing the shock wave head cover 1

• System ON.

Actuate the following switches on board W12 (Fig. 1):

S3 in SERVICE MODE position.

S2 in EMPTY COUPLING BELLOWS position (valve Y3 opened).

NOTICE

More water remains on the lens with the new coupling bellows,

therefore, use caution when removing it.

• Move the shock wave head into working position.

• Switch module N12 off with S1.

• Remove the left side cover on the unit.

On systems:

up to and including serial no.06032:

• Loosen hoses 5 and 8 on the water

interface in the shock wave cabinet.

On systems:

from serial no. 06033:

• Connect the service hoses to the T

• Connect the service hoses to hose

connections 5 and 8 coming from the

unit and place the ends in a collecting vessel.

connector of the water interface in the

shock wave cabinet and place the ends

in a collecting vessel.

LITHOSTAR Multiline RXL2-120.841.01 Page 4 of 10 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

General 1 - 5

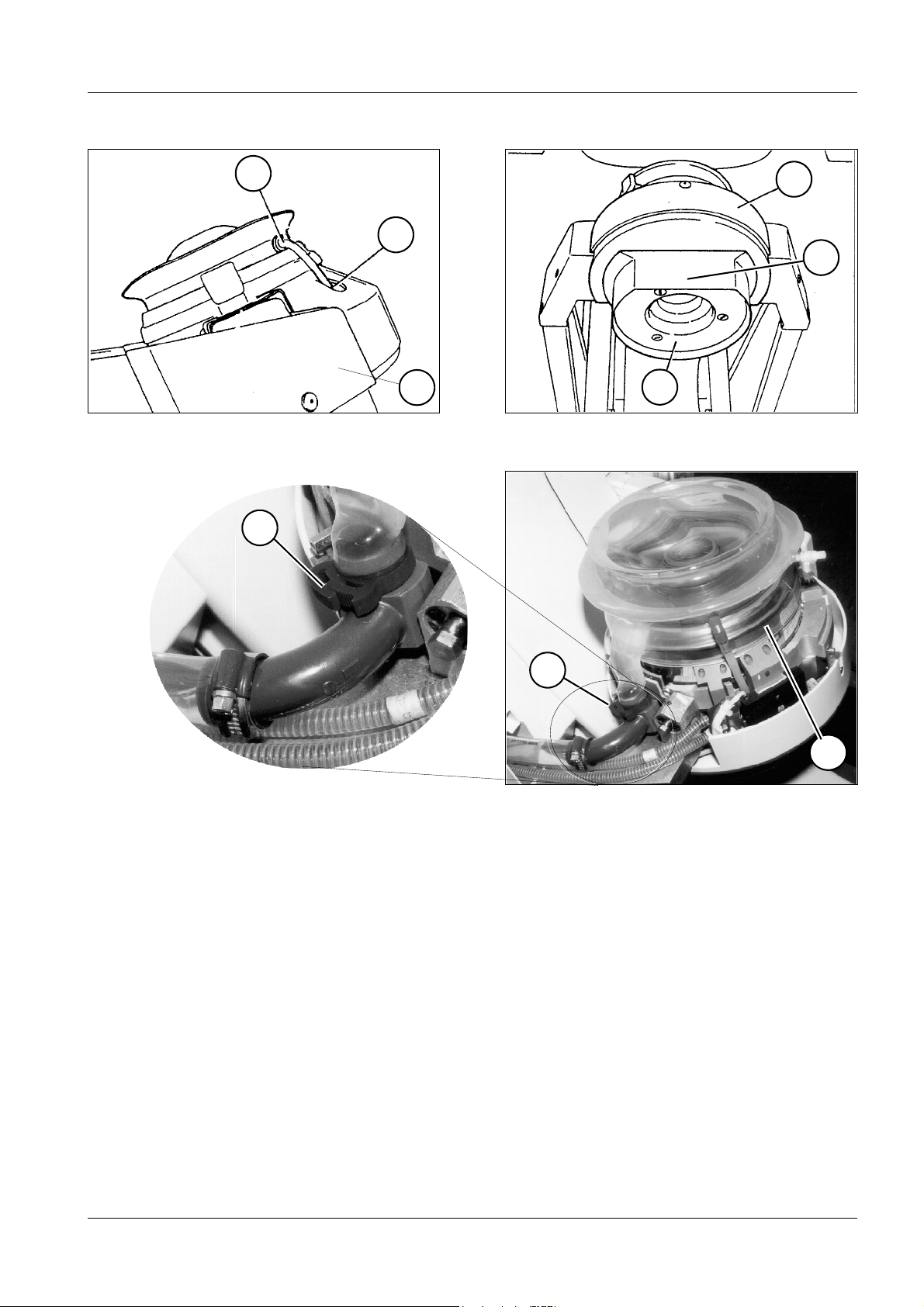

1

2

4

Fig. 2 Fig. 3

8

5

7

6

8

Detail

Fig. 4

• Remove the cover from the upper cover (2/Fig. 2) for the elbow pipe.

• Remove the elbow pipe (1/Fig. 2) from the coupling bellows.

• Remove the upper cover (5/Fig. 3).

• Remove the middle cover (7/Fig. 3).

• Remove the lower cover (6/Fig. 3).

Removing the coupling bellows 1

• Remove the shock wave head cover.

• Remove the covering (as shown in 4/Fig. 2).

• Remove the clamp (as shown in 8/Fig. 4).

9

• Remove the water connection of the coupling bellows.

Siemens AG RXL2-120.841.01 Page 5 of 10 LITHOSTAR Multiline

Medical Solutions Rev. 02 09.05 CS PS 24

1 - 6 General

• Remove the tensioning band found below the collar (9/Fig. 4), to do so, bend the collar

upwards.

• Remove the coupling bellows from the shock wave head.

CAUTION

There is still water on the lens.

Attaching the coupling bellows 1

• Dry the lens, if necessary, so that the coupling bellows can be attached more easily.

• Mount the coupling bellows, and ensure its correct position.

The connection for the pressure sensor (elbow) in the coupling bellows must be

congruent with the lens opening.

• Thread the tensioning band through the guide so that the closure on the tensioning band

is on the opposite side of the water connection.

• Place the water connection of the coupling bellows onto the connecting piece, using the

hose clamp (8/Fig. 4) to secure it.

• Reinstall the cover and the shock wave head covering (4/Fig. 2).

Installing the shock wave head covers 1

• Attach the central cover.

• Position and secure the upper cover.

• Reconnect water hoses 5 and 8 to the interface in the shock wave cabinet or remove the

service hoses.

• Switch on module N12.

• Fill the cooling circuit and the coupling circuit according to Chapter 1.

• System OFF.

• Reattach the lower cover (6/Fig. 3).

• Reattach the left side cover on the unit.

LITHOSTAR Multiline RXL2-120.841.01 Page 6 of 10 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

General 1 - 7

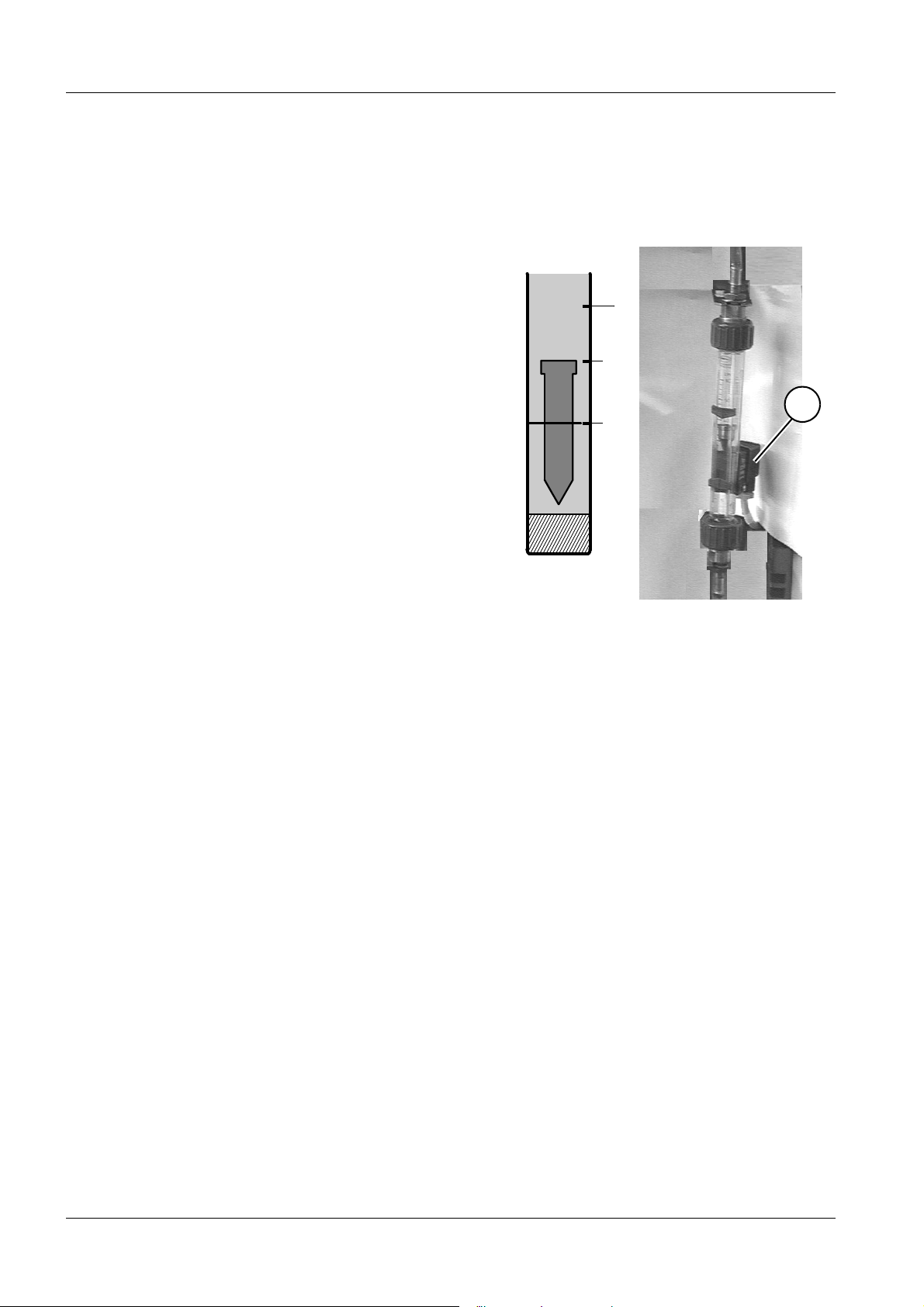

1

2

Fig. 5

Filling/venting the cooling circuit 1

CAUTION

• Fill the water canister with sterile water (deionized water is not sterile. Refer to

Speedinfo RX17-96).

• Hook the filled canister in the cabinet onto the transport holder.

NOTICE

• Open the red cap on the fast venting valve.

• Open the pump outlet quick coupling (1/Fig. 5). If service hoses are available, then these

can be connected to the T piece of the water interface (2/Fig. 5).

• Switch on module N12 with switch S1; the cooling circuit will now be filled and vented.

• Switch off the module N12 with switch S1.

• Connect pump quick coupling or remove service hoses.

• Switch on the module N12 with switch S1.

Each time the cooling circuit is opened, it must be filled or vented.

The canister must not be closed tightly due to venting. Board W11

must be set as described in Chapter 2 of this manual. When using

the Iwaki pump, the cooling circuit must be opened in order for

the pump to draw in.

• If pump M15 and valve Y1 begin to oscillate, i.e. if they constantly switch on and off, then

pull the plug of valve Y1 briefly several times until pump M15 runs evenly.

Siemens AG RXL2-120.841.01 Page 7 of 10 LITHOSTAR Multiline

Medical Solutions Rev. 02 09.05 CS PS 24

1 - 8 General

• Allow the air bubbles to escape from both cooling circuits by alternately pressing one

circuit closed for approx. 10 min. with a hose clamp at the cooling unit (OT and Litho) and

increasing the flow with R5 on board W11A to 40l/h (+3l/h).

• During venting, move the shock wave head several times from the park position into the

working position and back again to facilitate removal of air bubbles.

• After the cooling circuit is vented, i.e.

once air bubbles can no longer be seen

in the flow meter, set the flow back to

25 l/h (+3l/h) with R 5 on board W11A.

• If necessary, set switch S1 (a/Fig. 6) on

the flow meter to approx. 20 l/h.

The LED V3 on board W 11A must light

up after ending the filling and emptying

process.

• Disconnect the mains plug of the cooling

devices.

• Connect a multimeter to measurement

point X3 on board W11A, from AS02 Mp

X2.3, (0V on board D1.X3) and measure

the value.

The value must not change by more

than 50 mV within 10 minutes.

Fig. 6

25l

a

20l

• If the deviation is larger, check whether there are still air bubbles in the system.

• Check the system for leaks.

• Close the red cap of the fast venting valve.

• Reconnect the mains plug of the cooling unit.

LITHOSTAR Multiline RXL2-120.841.01 Page 8 of 10 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

General 1 - 9

Filling the coupling circuit 1

B

A

R998

Fig. 7 Fig. 8

• Press the coupling bellows together.

• Insert and secure the elbow pipe (A/Fig. 7).

S2

S1

S3

R71

R85

R49

Normal mode

Empty coupling bellows*

Buttonon:Fill coupling bellows*

Functions only

Normal mode

Service mode

Offset

Cplg. pressure sensor B1

Min. lift

(V22)

Max. lift

(V23)

Offset

Fill status sensor B3/W4

*

if S3

is in the service

position

W12

Fig. 9

• Move switch S2 (Fig. 8) on board W12 into the

NORMAL MODE position

¹ Valve Y3 is closed

• With button S1 on board W12 (Fig. 8), fill the

coupling bellows with enough water so that the air

collected in the coupling bellows can be removed.

B3/W4

• Remove the air in the coupling bellows using a

syringe without a needle (B/Fig. 7).

• Move switch S2 into the EMPTY COUPLING

BELLOWS position on board W12.

¹ Valve Y3 is open

• Once the coupling bellows has completely collapsed, check the water level. It should be

between the two lines shown in (1/Fig. 9).

- Small quantities of water can be removed or replenished with the syringe.

• Move switches S3 and S2 back into the normal mode position on board W12.

Siemens AG RXL2-120.841.01 Page 9 of 10 LITHOSTAR Multiline

Medical Solutions Rev. 02 09.05 CS PS 24

1 - 10 General

This page intentionally left blank.

LITHOSTAR Multiline RXL2-120.841.01 Page 10 of 10 Siemens AG

Rev. 02 09.05 CS PS 24 Medical Solutions

Loading...

Loading...