Page 1

Erlwein

LITHOSTAR Multiline

Maintenance Instructions

System

SP

LITHOSTAR Multiline

The protocol RXL2-120.105.01.06.02 is required for

these instructions

Print No.:

Replaces: RXL2-120.101.01.05.02

RXL2-120.101.01.06.02

03127011

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 08.05

1995

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 2 of 52

Medical Solutions

Page 3

Table of Contents 3

0 Table of Contents

1 _______ General information______________________________________________ 5

Required Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Test and Auxiliary Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Tolerance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 _______ Inspection of exterior and inspection of surroundings ________________ 10

Inspection of exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Inspection of surroundings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unit movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 _______ Safety inspections ______________________________________________ 12

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 _______ Inspection for wear and replacement of parts _______________________ 19

Periodic preventive replacement of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inspection for wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unit/mechanical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Respiratory belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 _______ Maintenance ___________________________________________________ 22

Changing the water in the coupling circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Changing the water in the cooling circuit,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning the quick vent valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubricating and oiling the linear guides of the drives . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6 _______ System heat dissipation _________________________________________ 27

Cooling unit in the service cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cabinet ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

MEMOSKOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

X-ray tube assembly fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 _______ Operating value inspection_______________________________________ 31

Respiratory gate control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

ECG control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dose control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 3 of 52

Page 4

4 Table of Contents

8 _______ Functional inspections __________________________________________ 35

PC keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Triggering shock waves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Footswitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Unit footswitches - urology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Surveillance monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Tableside control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control PC mouse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 _______ Quality inspections _____________________________________________ 42

Component inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Television chain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Final result quality inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Log book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10 ______ System adjustment _____________________________________________ 44

Collimator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cassette holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Isocenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11 ______ Maintenance ___________________________________________________ 47

Unit and system cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Log book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

12 ______ Final Work Steps _______________________________________________ 49

Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Unit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13 ______ Changes to Previous Version _____________________________________ 51

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 4 of 52

Medical Solutions

Page 5

General information 5

1-

1 General information

1.1 Required Documents

• Isocenter Adjustment RXL2-120.071.01

• Spare Parts List RXL2-120.081..

• Start-up Instructions RXL2-120.815.01

• Planning RXL2-120.021..

• Maintenance Protocol RXL2-120.105.01.05.

• Image quality binder RXD0-000.064.01..

• Ultrasound Localizer Start-up RXL2-120.091.10...

• Shock Wave Pressure and Position Check SPL2-120.074.01...

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 5 of 52

Page 6

6 General information

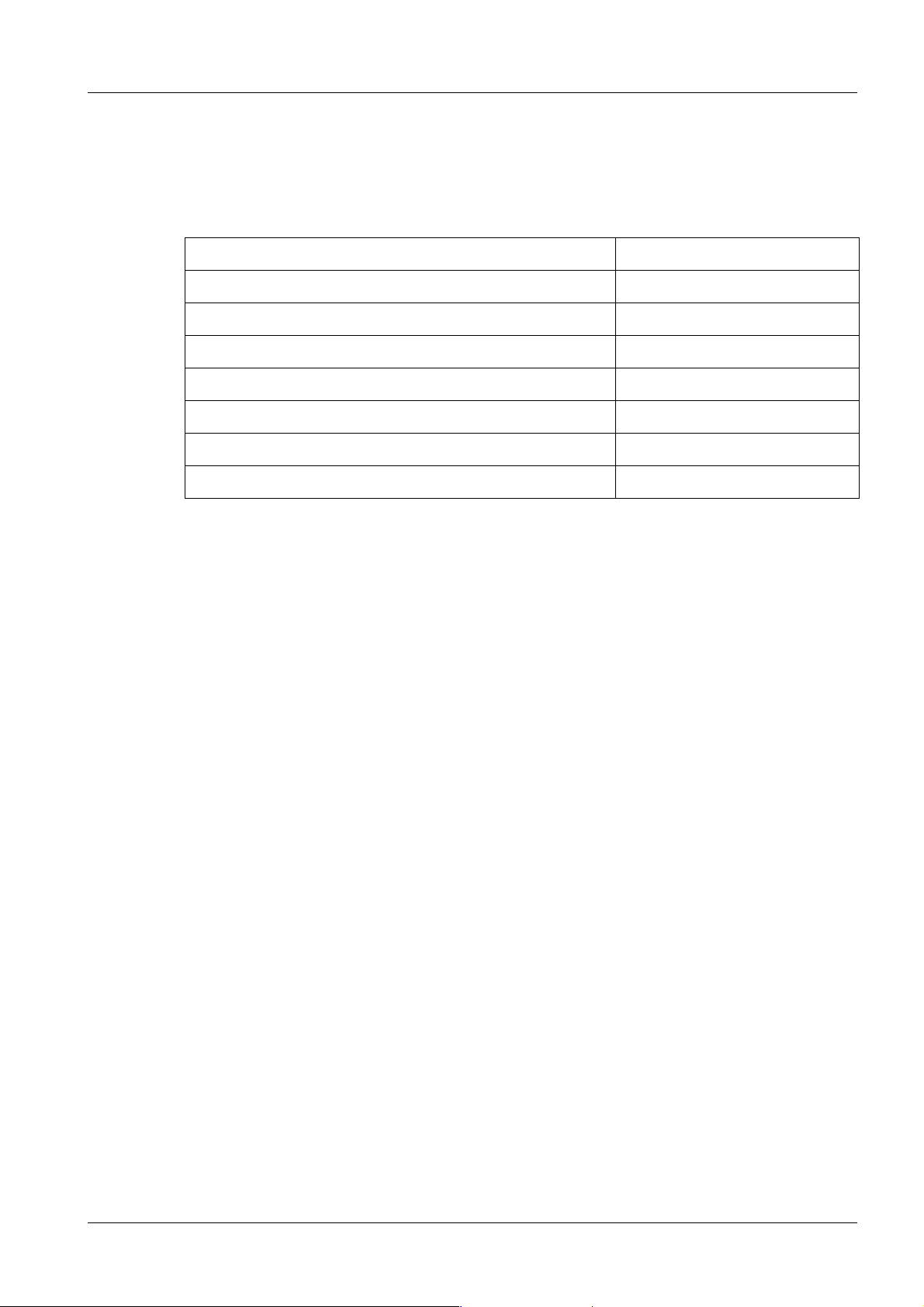

1.2 Test and Auxiliary Equipment

Tool For example Material no.:

• Protective conductor meter 44 15 899 RV 090

• Digital voltmeter Fluke 187 99 94 831

• Service PC with connecting cable according to ARTD

• Storage oscilloscope Fluke Scope Meter 73 92 074

• Dose meter DIADOS 97 17 612

PTW Nomex 97 08 637 Y0388

• Copper filter - set (10 x 0.3 mm) 44 06 120 RV 090

• 17-mm Cu strip (minimum contrast check) 11 67 662 G 5247

• 2.1-mm precision copper filter 99 00 598 XE 999

• ESD kits, ARTD 3 - Wrist band 34 63 874

- Cable 34 64 062

• TV dynamic test case 37 90 156 X 1963

• PTU pressure tester

- PTU adapter

30 95 408

70 41 028

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 6 of 52

Medical Solutions

Page 7

General information 7

1.3 Tools

NOTE

The indicated items are listed in the STC (Service Tools Catalog)

unless otherwise stated (the STC is a component of the Spare

Parts Catalog) with the exception of items marked with "*".

• Start-up tool kit

• High-pressure grease gun 28 84 609 RE 012

• 1 kg ”Longtime PD2” lubricant or

20 g ”Longtime PD2” lubricant

• 1 l turbo oil bottle HN 32 SRN 30 021

Squirt oiler 0.5 l

73 95 445 RH 999

34 91 271

37 83 359 J 1042

38 02 415

• Torque wrench (20 to 100 Nm) 44 30 906 RH 090

• for POLYDOROS: Installation material "washers" 88 67 665 X 1122

• 1 liter transformer oil as needed 99 00 945

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 7 of 52

Page 8

8 General information

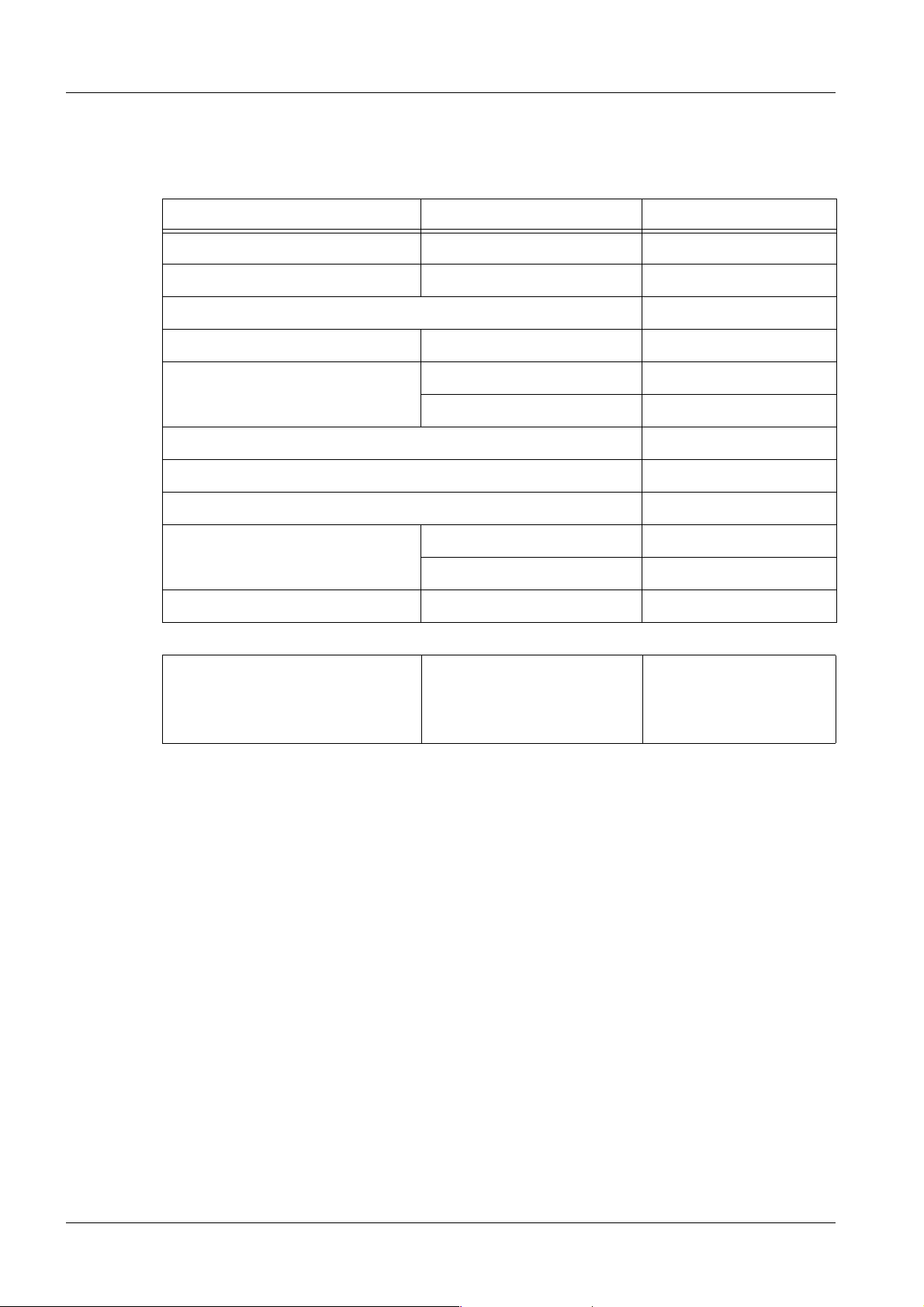

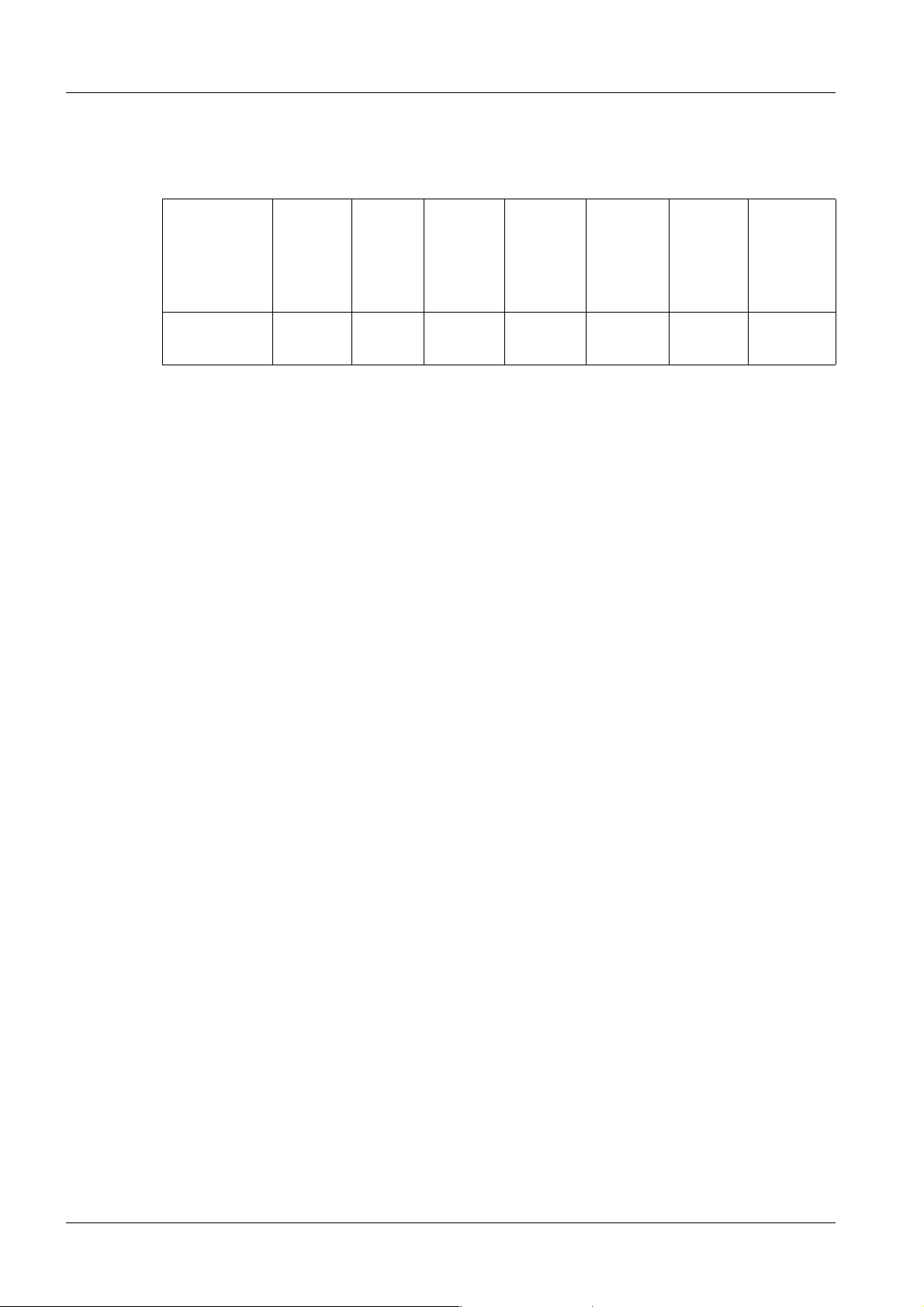

1.4 Tolerance data

General tolerances for linear dimensions in compliance with ISO 2768

Limit value

for the nominal range

Admissible

tolerance

These tolerances apply to all dimensions indicated in these instructions, unless other tolerances are specifically indicated after the value.

The tolerance for torque values is ± 10%.

over 3

mm to 6

mm

± 0.5

mm

over 6

mm to

30 mm

± 1 mm ± 1.5

over 30

mm to

120 mm

mm

over 120

mm to

400 mm

± 1.5

mm

over 400

mm to

1,000

mm

± 4 mm ± 6 mm ± 8mm

over

1,000

mm to

2,000

mm

over

2,000

mm to

4,000

mm

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 8 of 52

Medical Solutions

Page 9

General information 9

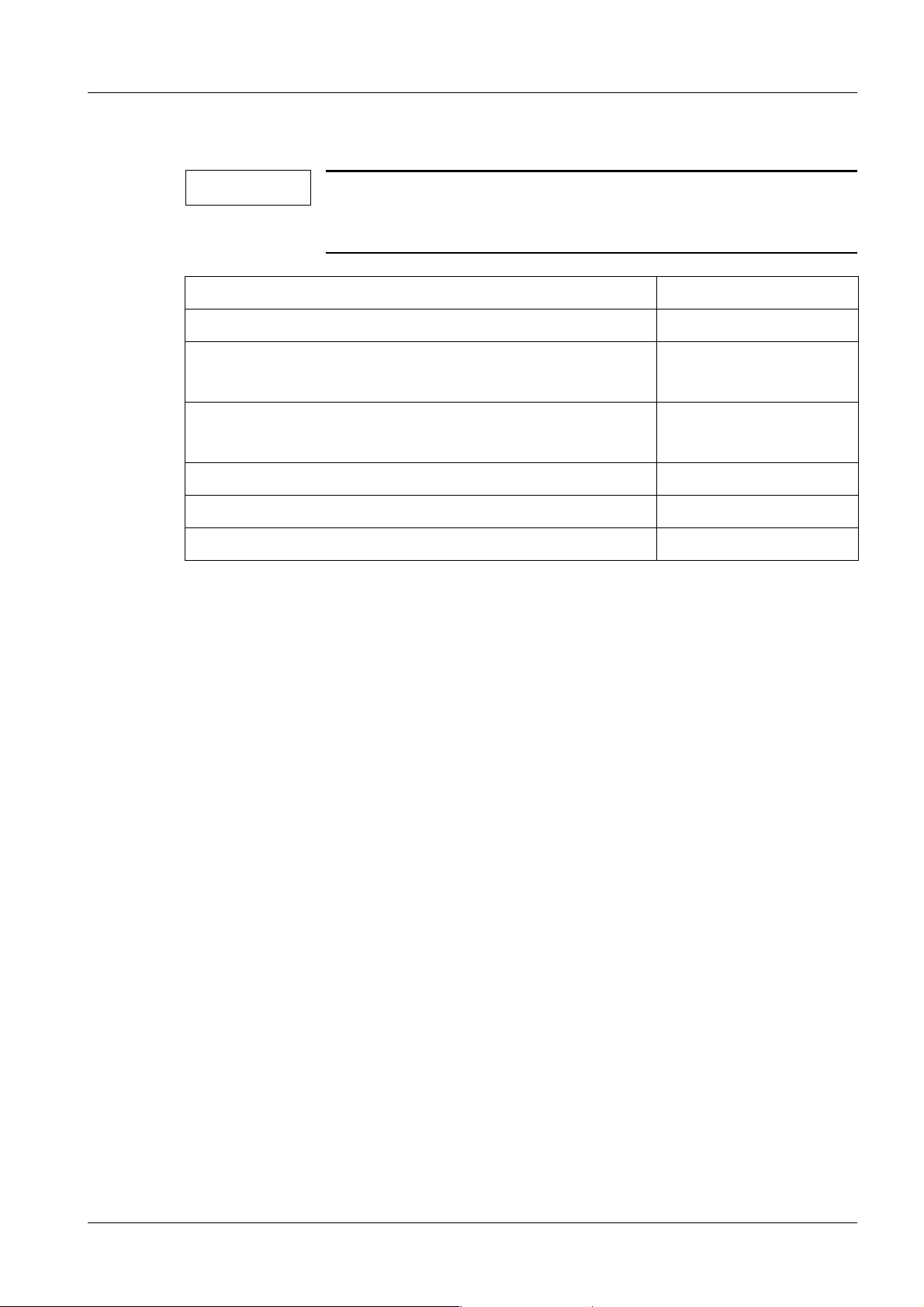

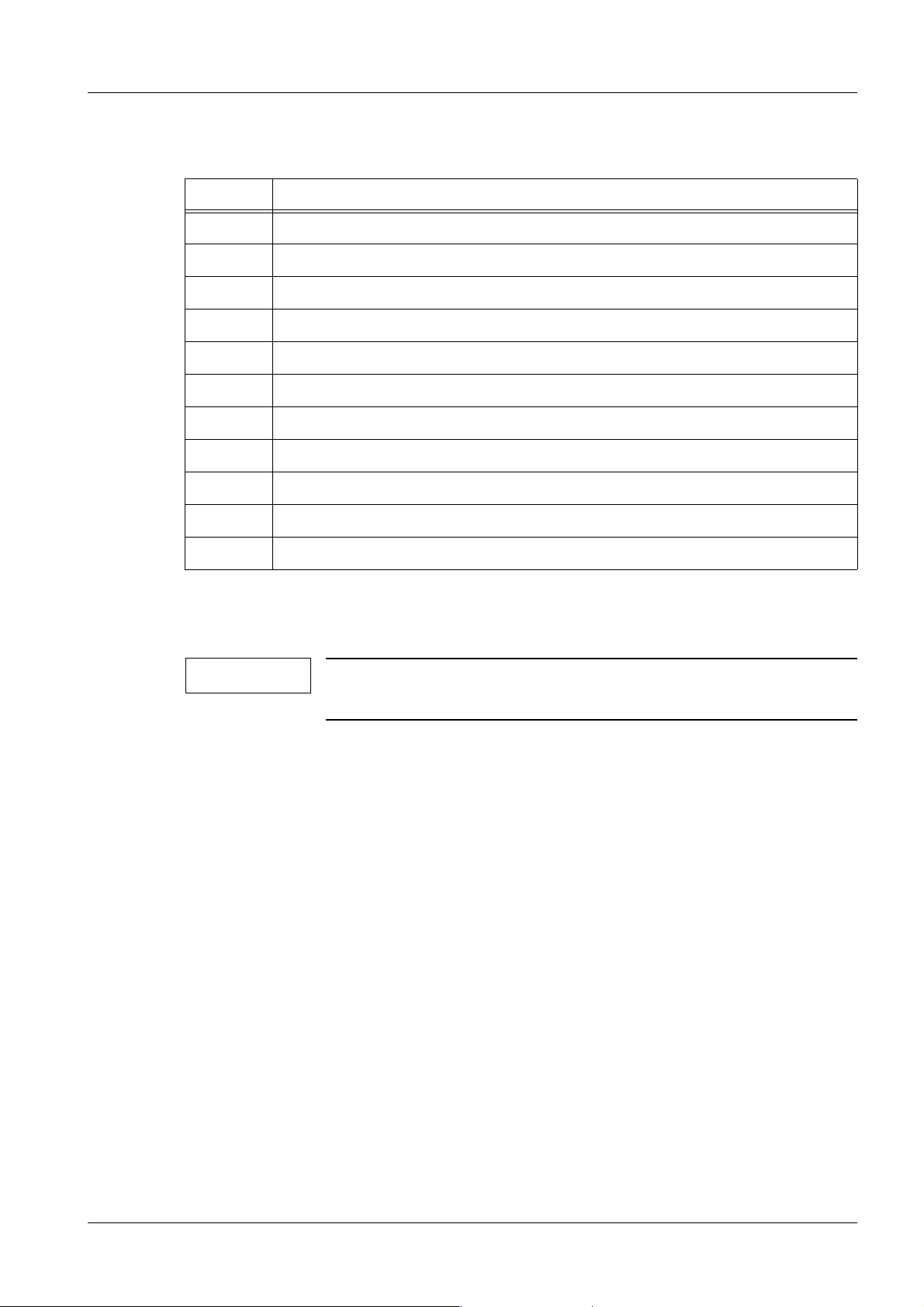

1.5 Abbreviations

Abbrev. Description

SI Safety Inspection

SIE Electrical Safety

SIM Mechanical Safety

PM Preventive Maintenance

PMP Periodic Preventive Maintenance

PMA Preventive Maintenance Adjustments

PMF Preventive Operating Value Check and Functional Check

Q Quality Check

QIQ Image Quality

QSQ System Quality Check

SW Software Maintenance

The steps identified by these abbreviations are part of the maintenance report and should

be checked off upon completion.

NOTE

Unless otherwise indicated, the maintenance interval is 12

months.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 9 of 52

Page 10

10 Inspection of exterior and inspection of surroundings

2-

2 Inspection of exterior and inspection of surroundings

2.1 Inspection of exterior

PMP Unit

PMP Cover

PMP Table pad

PMP Shock wave head/coupling bellows

PMP Image intensifier

PMP X-ray tube assembly cover

PMP Control PC

PMP Keyboard

PMP Mouse

• Check the entire system for mechanical damage.

• Replace or repair any defective parts.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 10 of 52

Medical Solutions

Page 11

Inspection of exterior and inspection of surroundings 11

2.2 Inspection of surroundings

2.2.1 Unit movements

PMP Patient monitor

PMP Monitor trolley

PMP Additional medical devices

• Ensure that there is free space around the unit to avoid collisions during unit movement.

• Mark the locations of the additional devices or secure the units.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 11 of 52

Page 12

12 Safety inspections

3-

3 Safety inspections

SI Remove the unit covers

• Remove the side covers of the unit.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 12 of 52

Medical Solutions

Page 13

Safety inspections 13

3.1 Electrical Safety

SI Emergency-off switch function

• Operate the emergency-off switch in the room.

- The system must switch off.

- The system cannot be turned on until the emergency-off switch is released and the

voltage supply is switched back on.

SI Function of the fault current circuit breaker

• Check the mechanical functioning of the fault current circuit breaker by operating the

built-in test button.

• Check electrical functioning according to ARTD-002.731.17.

SI Safety circuit switch function

• Check the safety circuit for the O-W-X-Y motor movements in table G1 using the

J1042-7 circuit diagram.

• After connecting and logging on to the service PC, the Adjustment/Calibration service

software program can be used to move the motor drives to the safety switches without

software monitoring.

(See Operating the Service Software)

• Use the tableside control panel to move the drives into the safety circuit while monitor-

ing the appropriate limit switch.

NOTE

- When checking the X-drive using the "urology insert", move the O-drive to the +10°

position to avoid risk of collision with the tube assembly housing. During "litho operation", move the shock wave head to the coupling position and move the X-drive to

S78 in a limited range.

- In the case of a Y-drive check using the urology insert, move the O-drive to the 0° position. Switches S64/65 for the large range must be activated. During "litho operation", switches S76/77 for the limited range must be activated.

NOTE

SI Lines and cables

Do not move to the mechanical end positions!

If the safety switches are actuated, you can move the drives out of

the safety zone by activating service button S59 on N11 or service

button S58 on D32 in the unit.

• Check the line and cable insulation for damage or kinks to the extent possible.

• Check charging line K26 for a secure connection and a good ground connection at the

charger and the shock wave generator.

SI HV cable shielding

DIN VDE 0750 Part 21 (IEC 601-2-7) Paragraph 16

The high voltage cables that can be touched and that conduct the tube current must be

provided with a flexible, conductible shielding that has a maximum resistance of 1 ohm/m.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 13 of 52

Page 14

14 Safety inspections

The shielding must be connected to both the metal housing of the X-ray generator and the

X-ray tube assembly.

Conduct a check using measurements as follows:

• Switch off the system contactor.

NOTE

Wait until the red LEDs on D110 are no longer lit (approx. 1 min.).

• Disconnect the high voltage cable from the socket at the HV generator and measure the

shielding mesh against protective ground. Move the cable, particularly at bends and

loops.

- High voltage cables with a shielding mesh resistance

exceeding the maximum of 1 ohm/m are to be replaced.

- Reinsert the cables

Only use transformer oil for inserting the high voltage plugs at the HV generator. Do not

use silicone washers!

Set of spare parts:

Installation material "washers" Part no. 88 67 665 X 1122

1 l transformer oil as needed Part no. 99 00 945

SI Time - radiation indicator

Check functioning of the radiation indicator and functioning of the different FL release buttons while the FL time display and/or time-out for fluoroscopy are running.

• Reset the fluoroscopy timer to zero.

X

X

X

• Move the filter (approx. 0.3 mm Cu) into the fluoro unit beam projection.

• Switch fluoroscopy ON at the fluoro unit.

The timer counts up.

Observe radiation protection regulations!

• Check the radiation indicator at the control monitor.

During fluoroscopy, a symbol for radiation release appears on the left of the control

monitor in the status field.

• Check functioning of the FL release buttons on the connection panel of the control con-

sole and the footswitch at the console and/or unit.

• During fluoroscopy and exposure, check functioning of the radiation indicator lamp on

monitor trolley N72 (optional) or the local radiation indicators.

After a total of 4.5 minutes, a signal generator must sound.

• Switch off the signal generator. Do not reset the FL timer.

After 9.5 minutes, the signal generator in the control console must sound.

• Switch off the signal generator. Do not reset the FL timer.

Fluoro must switch off within 10 minutes.

• Switch fluoroscopy OFF at the fluoro unit.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 14 of 52

Medical Solutions

Page 15

Safety inspections 15

• Reset the fluoroscopy timer to zero.

(See Start-up Instructions, paragraph 4-6)

SI Function switch of the generator

• Check functioning of the service switch on board D100 in the generator. When the ser-

vice switch is off, radiation release must be blocked (no activation of the inverter!)

• Check functioning of switch S2 on board D160. When S2 is in the OFF position, the line

contactor of the generator may not switch on. (Multiline, not operating)

NOTE

SI Protective conductor check

When the generator is switched off, there is still line voltage

present at the T1 transformer and the D160 switch-on circuit.

(See LX circuit diagram X2169-11 or SX circuit diagram X2206-11)

After switching off the generator, approx. 600 V DC is still available

for the inverter! This is indicated by LEDs V135 and V136 on board

D110.

(See LX circuit diagram X2169-16 or SX circuit diagram X2206-16)

The voltage dissipates within approx. 1.5 minutes to 0 V; the LEDs

go off at approx. 30 V.

• Test the protective conductor with the protective conductor tester according to

ARTD-002.731.17.

The protective conductor connection in the generator is the central protective

conductor.

(The protective conductor check must be performed again as a final step when the

system is closed!)

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 15 of 52

Page 16

16 Safety inspections

3.2 Mechanical Safety

SI Toothed belt of the W-drive

SI Toothed belt of the O-drive

• Visually inspect the toothed belts of the drive for wear.

• Cracks on the back or at the tooth base; replace toothed belts if necessary.

• Ensure that the clamping pieces of the toothed belts are secure.

SI X-ray tube assembly

SI Collimator

SI Image intensifier with camera head

• Ensure that the screw connections of the X-ray tube assembly on the C-arm are secure.

• Ensure that the collimator is securely attached to the X-ray tube assembly.

• To check the mounting of the collimator, remove the large rectangular cover of the radi-

ation protection housing and then reinstall it. The collimator may not rotate at the housing flange.

• To check the image intensifier mounting, remove its rubber cover and the protective

cover of the camera.

• Check the mounting of the image intensifier.

• Check the mounting of the camera at the image intensifier.

• Reinstall covers.

SI Unit mounting

SI Safety distance of the unit

• Use a torque wrench to check the attachment of the table to the base plate. Ensure that

8 x Allen screws (at the lifting columns) M8 x 40 with 24 Nm ± 10% 4 x external hexagons M10x25 are secure.

• Check the maneuverability ranges of the unit, the O-W -X-Y-Z-drive during lithotripsy

and urology operation. Maintain the safety distances in the end positions of the unit

movements.

SI Urology insert

• Insert the urology insert and ensure that it is secure.

• Ensure that S22 is properly switched.

• Adjust switch S22 if necessary.

• If needed, adjust both guide pieces of the urology insert. For this purpose, insert the

urology insert and press both guide pieces toward the outside.

• Tighten the screws.

SI Shock wave heads

• Check the maneuverability of the shock wave system support (W-drive) from the

parked position to the working position and back.

• Check the limited range by moving unit G1 in the table cutout.

SI Unit grip strip

• Ensure that the unit grip strip is secure.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 16 of 52

Medical Solutions

Page 17

Safety inspections 17

• Check the accessory parts for proper functioning.

SI Table extensions

• Ensure that the table extensions are securely mounted.

• Check the patient position detection (head/foot) for proper functioning and check the

patient position display on the control monitor.

SI US applicator

• Insert the US applicator in the shock wave head and secure it.

• Ensure that the US applicator is secure.

• Ensure that the US applicator module is undamaged. If there is damage, replace the

US applicator.

SI Cassette holder mounting

SI Exposure display on the control monitor

• Install the cassette holder and insert a cassette with film.

• Select 77kV, 100 mAs, 80% output on the control PC.

X

• Releasing an exposure:

- The radiation symbol must be displayed on the control PC during the exposure (X-ray

radiation).

- The buzzer (whistle) must be audible in the control PC for the duration of the exposure.

• Change the cassette and develop the film after every exposure.

• Ensure that the cassette holder is secure.

- When the cassette holder is lifted, the collision protection (yellow safety button

- ) must light up yellow.

SI Collision protection

• Check the collision protection of the X-ray tube assembly housing. Given blockage of

the X-ray tube assembly housing when moving the drives in the O-W-X-Y-Z direction,

the collision protection must stop the movement.

The yellow safety button on the unit lights up.

Given unit blockage (collision protection) during movement of a drive, this button can be

used to carry out the unit movement in the opposite direction. In the event of blockage, the

corresponding unit movement button blinks.

In the event of unit blockage (collision protection) during unit drive movement:

• The yellow safety button lights up.

• Move in the opposite direction of the unit blockage: Operate the safety button and the

button on the tableside control panel.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 17 of 52

Page 18

18 Safety inspections

Fast beeping

¹ Wrong direction - the unit is still moving into the blockage.

Slow beeping

¹ Correct direction - the unit is moving away from the blockage.

• Check the collision protection of the image intensifier. Given blockage of the X-ray tube

assembly housing when moving the drives in the O-W-X-Y-Z direction, the collision protection must stop the movement.

On the connection panel of the control console and the unit the yellow safety button

lights up.

• Interrupt the light barrier, if present.

Unit movements should not be possible.

Yellow danger buttons light up.

Remove any interruptions in the light barrier.

• Activate the safety cover on the shock wave head (L+R).

Unit movements should not be possible.

Yellow danger buttons light up.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 18 of 52

Medical Solutions

Page 19

Inspection for wear and replacement of parts 19

4-

4 Inspection for wear and replacement of parts

4.1 Periodic preventive replacement of parts

PMP Battery

• Check the battery on board D1 (≥ 2.7 V) and replace it at least once every 36 months.

• Document this in the operating data report/log book.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 19 of 52

Page 20

20 Inspection for wear and replacement of parts

4.2 Inspection for wear

4.2.1 Unit/mechanical components

PMP O-W-X-Y-Z drives

PMP O-drive toothed belt

PMP W-drive toothed belt

PMP X-drive toothed belt

PMP Y-drive toothed belt

PMP CL-drive toothed belt

PMP Z-drive plastic clutch

• Check the drives of the motors (in the O-W-X-Y-Z direction) for wear.

• Check the drive toothed belts (in the O-W-X-Y-CL directions) for wear and replace them

as needed. If the toothed belt of the cone lenght (CL) drive is worn, the cone drive must

be replaced.

(see the spare parts list).

• Ensure that the teeth of the toothed belt engage securely with the recesses of the drive

wheel.

• Check for wear on the plastic clutch between the motor axis and the drive axis of the

Z-drives.

PMP Actual value potentiometer

• Check the drive belts for the actual value potentiometer (O-W-X-Y drive) for wear and

replace them as needed

(see the spare parts list).

PMP Pressure tester

PMP PTU adapter-M

PMP Shock wave head

• Perform a pressure test at the shock wave head.

• Check and document the pressure value.

See Shock Wave Pressure and Position Check Service Instructions SPL2-120.074.01.

• Check functioning of switch S28 "adjustment aid attached".

(Blocking of the W-drive)

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 20 of 52

Medical Solutions

Page 21

Inspection for wear and replacement of parts 21

4.3 Respiratory belt

PMF Wear and tear

• Check the respiratory belt for damage/wear and tightness and replace it in the event of

damage.

(See the spare parts list).

PMP Contacts at the PS contactor (generator)

Due to the low impedance of the intermediate circuit, the power-on sequence occurs in

two steps. In the first step, the intermediate circuit capacitors are charged via the LS contactor. After the charging time, the switch-on damping circuit is bypassed with the PS contactor.

Given errors in the charging process or when disconnecting the PS contactor contacts

under load (fuses, FI switch, etc.), these can be overloaded.

• Switch off the system contactor.

NOTE

Wait until the red LEDs on D110 are no longer lit (approx. 1 min.).

• Disconnect the RC element from the PS contactor.

• Remove the spark quenching chamber from the PS contactor (remove 2 screws).

- In the case of an older POLYDOROS LX (< series no. 1020), the contactor must be

taken out in order to remove the spark quenching chamber.

The following is required for conversion:

- Cable deflector 31 57 141

- Holder for cable deflector 31 57 364

• Check the contacts for excessive melting loss.

• Reattach the spark quenching chamber.

• Reattach the RC element.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 21 of 52

Page 22

22 Maintenance

5-

5 Maintenance

5.1 Changing the water in the coupling circuit

Removing air pockets in the coupling bellows

PMA Shock wave head

The water in the coupling circuit is to be changed:

• Move switch S2 on board W12 to the "Empty coupling bellows" position (Y3 opens), see

the start-up instructions.

• Connect the service hose with a funnel to the water tank and insert the hose end into an

available container. The water tank is emptied.

• If the system parts are very dirty, clean them prior to refilling. (If necessary, remove the

tank, fill it halfway with water, and shake it to remove the dirt).

• After emptying the water tank, fill the coupling circuit in accordance with the start-up in-

structions.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 22 of 52

Medical Solutions

Page 23

Maintenance 23

5.2 Changing the water in the cooling circuit,

Checking flow and the water tank

Fig. 1: Quick vent valve Fig. 2: Flowmeter

5.2.1 Cleaning the quick vent valve

PMA Water preparation

PMA Water system: Cleaning the system parts

Contamination in the cooling circuit can settle in the quick vent valve (Fig.1/p.23) so

that the valve can no longer close properly and the water leaks.

• Disconnect the hose connections from the front and back of the filter housing and re-

move the hoses.

• Loosen the four fastening screws of the filter housing and remove the entire housing in-

cluding the installed quick vent valve.

NOTE

• Empty the water from the filter housing.

• Unscrew the cover of the vent valve. Use open-end wrench SW19 to provide

counter-support to the housing base. (If the cover cannot be loosened manually, carefully use water pump pliers to loosen it).

• Remove the cover and lift the float out of the housing.

Do no exert any pressure on the sides of the quick vent valve.

NOTE

The float (Fig.1/p.23) is accommodated in the cover and can fall

out of its holder during removal.

• Remove the float from the holder in the cover.

• Clean the sealing surfaces of the float holder and the vent hole (Fig.1/p.23) with flow-

ing water.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 23 of 52

Page 24

24 Maintenance

• Remove build-up in the float housing and rinse it out with water.

• Check the sealing ring (O ring) on the cover for damage and replace the complete quick

vent valve if necessary.

• Put the float back in the correct position in the holder and insert it in the housing.

• Manually tighten the cover. Use open-end wrench SW19 to provide counter-support to

the housing base.

• Install the filter housing from below and secure it again.

• Turn the top of the vent valve housing counter-clockwise to OPEN (approx. 1/8 rota-

tion).

• Connect the hoses to the front and back of the filter housing.

PMA Cooling circuit: Water replacement

PMA Cooling circuit: Flow/bubble-free

PMA Water tank: Check the level

The water in the cooling circuit is to be changed:

• Remove the water hoses at interfaces 5 and 8 at the water interface of the shock wave

cabinet.

• Open the seals with the matching ends of the hoses from the service cabinet and emp-

ty the cooling water into the prepared container.

• Fill the cooling system and set the flow according to the start-up instructions.

• Replace the water filter, part no. 70 52 012 F 0428, if necessary.

• Refill the water supply tank after the water has been changed.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 24 of 52

Medical Solutions

Page 25

Maintenance 25

5.3 Lubricating and oiling the linear guides of the drives

PMA Linear guide, longitudinal (lubricate)

PMA Linear guide, transverse (lubricate)

Use the high-pressure grease gun to lubricate the bearing blocks of the linear guides.

Y

X

1

Fig. 3: Longitudinal drive and transverse drive

• To access the front points to be lubricated (on the patient table), move the system to the

"gel position".

• Loosen and remove the bottom white cover plate on the front side under the orbital

drive by unscrewing the 5 screws (Allen 3 mm) (Fig.3/p.25).

The lubricating nipples of the bearing blocks are then accessible from the front, on the

bottom.

To access the back points to be lubricated, move the system to the "lift position".

The lubricating nipples of the bearing blocks are accessible from the back, on the bottom.

NOTE

After the linear guide has been lubricated, move the system to the "uro position" and then

move it several times to the end positions of the X and Y-drives to lubricate the linear

guide evenly.

Apply the grease gun axially in order to prevent damage to the lubricating nipples!

• Remove excess lubricant from the bearing blocks and linear guides.

Reattach the removed cover plate.

PMA Guide rail, W-drive (oil)

PMA Guide rails, orbital (oil)

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 25 of 52

Page 26

26 Maintenance

PMA Guide rails, orbital (oil)

PMA Gear wheel, O-drive (lubricate)

• Oil the guide rails of the O and W-drives via the dirt removal device and oil container.

O

W

1

Fig. 4: Orbital drive and W-drive

• Oil the guide rails integrated in the C-arm at the vertical drive. Mechanically clean the

dirt removal areas at the points indicated by arrows and apply a few drops of oil to the

oiling means (felt).

• Oil each drive on the right and left side.

• Oil the guide rails on the W drive, see arrows in ((Fig.4/p.26)) and fill the containers

between the running wheels of the shock generator cart with oil.

• Move the W-drive to the middle position.

• Use the oilcan to fill the containers at the top and bottom of the guide rail with oil.

• Lubricate the crown gears of the O-drive motor on the orbital drive (Fig.4/p.26).

• Remove old or excess lubricant.

• After oiling the W and O-drives, move them to the end positions several times to oil the

guide rails evenly.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 26 of 52

Medical Solutions

Page 27

System heat dissipation 27

6-

6 System heat dissipation

6.1 Cooling unit in the service cabinet

PMP Switching area

PMP Seals/leaks

• Check whether the thermostat of the cooling unit is responding.

- Mark the controller position for this purpose.

- Turn the thermostat to the left to set a lower temperature. This causes the cooling

unit to switch on.

- Turn the temperature controller back to the marked position.

• Check the complete cooling unit for leaks.

• Ensure that the intake and exhaust air slots at the cooling unit are dust-free. Clean them

if necessary.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 27 of 52

Page 28

28 System heat dissipation

6.2 Cabinet ventilation

PMP Intake air and ventilation shafts unobstructed

• Check whether the intake air and ventilation shafts are unobstructed when the cabinet

is closed in order to ensure a fresh-air supply.

• Remove any objects placed on the top of the cabinet!

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 28 of 52

Medical Solutions

Page 29

System heat dissipation 29

6.3 MEMOSKOP

PMP Cleaning the ventilation slots

• Remove dust from the bottom of the ventilation slots.

• Perform a functional check of the fan installed in MEMOSKOP.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 29 of 52

Page 30

30 System heat dissipation

6.4 X-ray tube assembly fan

PMP Function

PMP Cleaning the ventilation slots

• Check the X-ray tube assembly fan for proper functioning.

• Clean the ventilation slots at the X-ray tube assembly housing.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 30 of 52

Medical Solutions

Page 31

Operating value inspection 31

7-

7 Operating value inspection

7.1 Respiratory gate control

PMA Learning time, window

• Ensure proper functioning of the respiratory gate control at the physiological monitor.

NOTE

The boards cannot be adjusted due to the complicated measuring

setup!

• Perform a functional check in accordance with Start-up Instructions RXL2-120.815...

• Ensure proper functioning of the respiratory belt at both connection points.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 31 of 52

Page 32

32 Operating value inspection

7.2 ECG control

PMA Function

• Ensure proper functioning of the ECG control. For this purpose, attach electrodes to a

test person. The signal is displayed on the physiological monitor. A trigger is only released when a QRS complex is detected!

• Perform a functional check in accordance with Start-up Instructions RXL2-120.815...

(See the Triggering Shock Waves section).

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 32 of 52

Medical Solutions

Page 33

Operating value inspection 33

7.3 Dose control

QIQ Adjustment values

• Check the dose during fluoroscopy.

X

• (See Start-up Instructions RXL2-120.815... for the assigned value

see the test report).

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 33 of 52

Page 34

34 Operating value inspection

7.4 Generator

PMA Checking/setting the tube filament heating

Not necessary if the check according to the start-up instructions is within the tolerance!

X Observe radiation protection regulations!

In the case of POLYDOROS, the filament heating functions as a constant current regulator.

Filament vaporization increases the resistance. Given a constant filament current, the filament power and the filament temperature also increase. If the filament current is not corrected, filament vaporization accelerates.

An increase in filament temperature of approx. 2-3% reduces the service life of the tube

by half.

Keep prep. time (preparation) short!

Always push the exposure release button down fully.

Let go of the release button immediately following the exposure.

X

• Connect the oscilloscope to

POLYDOROS LX:

• Connect the oscilloscope to

POLYDOROS SX:

- CH 1 = D100.X18 (kV actual)

- CH 2 = D100.X61 (mA actual)

- Trig.ext. ( - ) = D100.X48 (SWR )

- CH 1 = D100.X61 (kV_ACT)

- CH 2 = D100.X64 (MA_ACT)

- Trig.ext. ( - ) = D100.X64 (SWR )

• Set the following for each focus: - 73 kV

-100 %

- Change the mAs value until an exposure time of approx. 100 ms is

displayed.

• Release an exposure.

• Evaluate the oscillogram.

- The high voltage should be ± 5 % of the set value within 10 ms.

- The tube current should be ± 5 % of the set value within 50 ms.

- It is favorable for the service life of the tube for the tube current to be below the set

value (max. 20%) during power-on.

- An initial brief spiked overshoot (e-function < 3 ms, depending on the length of the HV

cable) is the charging current of the HV capacitors and can be ignored (does not flow

over the tube and therefore does not affect dose).

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 34 of 52

Medical Solutions

Page 35

Functional inspections 35

8-

8 Functional inspections

8.1 PC keyboard

PMF Key functions

• Ensure proper functioning of all control keys on the keyboard in accordance with the op-

erating instructions.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 35 of 52

Page 36

36 Functional inspections

8.2 Triggering shock waves

PMF Triggering

• Check shock wave triggering with and without respiratory and ECG triggering.

(See the start-up instructions).

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 36 of 52

Medical Solutions

Page 37

Functional inspections 37

8.3 Footswitches

PMF Function

• Ensure proper functioning of the footswitch for fluoroscopy (Electrical Safety / p. 13)

section: Time - radiation indicator.

X

• Check the footswitch at the unit and control console.

(See the radiation indicator function).

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 37 of 52

Page 38

38 Functional inspections

8.4 Unit footswitches - urology

PMF Function

• Check all footswitch functions in accordance with the operating instructions.

• Check the cables and plug connections for damage.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 38 of 52

Medical Solutions

Page 39

Functional inspections 39

8.5 Surveillance monitor

PMF Basic settings

• Check the basic settings and functioning of the physiological monitor. Take the appro-

priate amplification into account when displaying the monitoring signals.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 39 of 52

Page 40

40 Functional inspections

8.6 Tableside control panel

PMF Function

• Connect the tableside control panel for the unit via connection points A/B on the unit.

• Ensure that all button functions are operating properly.

• Check the cables and plug connections for damage.

• Ensure proper functioning of the tableside control panel of the control console.

• Ensure proper functioning of the ultrasound tableside control panel.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 40 of 52

Medical Solutions

Page 41

Functional inspections 41

8.7 Control PC mouse

PMF Function

• Ensure proper movement of the mouse pointer on the control monitor.

• If necessary, remove the ball from the mouse and clean the sensor.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 41 of 52

Page 42

42 Quality inspections

9-

9 Quality inspections

9.1 Component inspection

9.1.1 Television chain

QSQ Image quality

• Use the image quality test to check the image quality of the television chain.

(See Start-up Instructions RXL2-120.815...).

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 42 of 52

Medical Solutions

Page 43

Quality inspections 43

9.2 Final result quality inspection

9.2.1 Log book

QSQ Compare/document check results

• Save the current system parameters and delete fault storage.

(See Operating the Service Software "Backup").

• Document the various counter values in the "Operational certificate" log book.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 43 of 52

Page 44

44 System adjustment

10-

10 System adjustment

10.1 Collimator

PMA Radiation field

PMA Fixed formats

• Check the predefined fixed collimator formats and adjust them if necessary in accor-

dance with the setting instructions.

• Check the settings of the collimator iris and adjust them if necessary in accordance with

the setting instructions.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 44 of 52

Medical Solutions

Page 45

System adjustment 45

10.2 Cassette holder

PMA Cassette center

• Check the centering of the cassette in the cassette holder with respect to the radiation

field.

• If necessary, adjust it in accordance with the setting instructions.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 45 of 52

Page 46

46 System adjustment

10.3 Isocenter

PMA Adjustment

• Check the isocenter at the table with the adjustment phantom and readjust it in the case

of deviations outside of the tolerance.

• Check the adjustment of the shock wave head.

(See "Adjusting the isocenter" in the adjustment instructions).

• If the ultrasound option is available, also check the isocenter with ultrasound. (See in-

structions RXL-120.091....).

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 46 of 52

Medical Solutions

Page 47

Maintenance 47

11-

11 Maintenance

11.1 Unit and system cabinets

PMP Cleaning the exterior

PMP Cleaning the interior

PMP Paint

• Clean the unit and the system cabinets

• Remove contamination from inside the cabinets

• Clean the fan and ventilation slots

• Repair paint damage as necessary, for the paint number

see Planning Guide RXL2-120.021.01.

• Clean the tube cone from the inside

(Only perform if the ultrasound option is available).

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 47 of 52

Page 48

48 Maintenance

11.2 Log book

PMP Completeness

• Check and document completed updates.

• Fill out the system papers, check them for completeness, and add any missing informa-

tion.

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 48 of 52

Medical Solutions

Page 49

Final Work Steps 49

12-

12 Final Work Steps

12.1 Covers

PMF Installing unit covers

• Reattach all covers and check them for damage.

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 49 of 52

Page 50

50 Final Work Steps

12.2 Unit function

PMF Functions when the system is closed

• Check all unit functions.

• Perform a functional check of the accessory parts (see the operating instructions).

- Replace them in the case of damage (see the spare parts list).

SI Protective conductor test

• Check the protective conductor when the system is closed in accordance with

ARTD-002.731.17.

(Also see the start-up instructions).

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 50 of 52

Medical Solutions

Page 51

Changes to Previous Version 51

13-

13 Changes to Previous Version

Toothed belt, cone lenght (CL) drive added to "Inspection for Wear."

Siemens AG RXL2-120.101.01.06.02 LITHOSTAR Multiline

Medical Solutions

08.05 CS PS 24

Page 51 of 52

Page 52

52 Changes to Previous Version

LITHOSTAR Multiline RXL2-120.101.01.06.02 Siemens AG

08.05 CS PS 24

Page 52 of 52

Medical Solutions

Loading...

Loading...