Page 1

Erlwein

LITHOSTAR Multiline

Replacements of Parts

System

SP

Unit not including shock wave system

03127011

Print No.:

Replaces: n.a.

RXL2-120.841.02.01.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 09.05

2005

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 2 of 72

Medical Solutions

Page 3

Table of Contents 3

1- 0Table of Contents

1 _______ Prerequisites ___________________________________________________ 5

Documents required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required measurement and adjusting devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Disposal information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service information on the Intranet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 _______ Overview of Measures___________________________________________ 10

Component N11 (in control cabinet A12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Collimator component N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

VIDEOMED DI-M component. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Memoskop component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Multispot component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Laser light localizer component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unit/control console component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Generator component. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ultrasound option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 _______ PC Board Replacement __________________________________________ 21

Component N 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Board D1, (new type) host computer or when replacing the battery. . . . . . . . . . . . . 21

Board D1, (old type) host computer or when replacing the battery. . . . . . . . . . . . . . 22

Board D4xx, Motor controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Board D 5, A/D converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SMP bus board D10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Board D11, backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Board D 21, power supply M16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Board D4, power supply, respiratory and ECG triggering. . . . . . . . . . . . . . . . . . . . . 27

Collimator N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing the collimator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Replacing electric components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adjustment test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Control position of the collimator blades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

VIDEOMED DI-M component. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Board D1, analog board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Board D3, analog board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Unit/control console component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Board D32, distributor board, supporting frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

I.I. supply Z96 "Röderstein" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tableside control panel (NBF), board D41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recoding for use on the control console, board D41 . . . . . . . . . . . . . . . . . . . . . . . . 32

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

System unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Board D51, ADC/DUEP plug-in board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 3 of 72

Page 4

4 Table of Contents

4 _______ Potentiometers and Reference Switches ___________________________ 34

Overview of the potentiometers and reference switches . . . . . . . . . . . . . . . . . . . . . . . . 34

Basic information on the replacement and adjustment of potentiometers, reference switch-

es and motor encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

General replacement and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Checking, replacement and/or adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cone drive TL, reference switch S8 and potentiometer r8 . . . . . . . . . . . . . . . . . . . . . . . 41

Checking the toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Checking the travel range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Checking the travel range with US probe (optional) . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cone drive TR, reference switch S 9 and potentiometer r9 . . . . . . . . . . . . . . . . . . . . . . 43

Setting the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Checking the travel range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Longitudinal system Y drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Transverse system, X drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

C-arm orbital drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Shock head mount W system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5 _______ Checking / Replacing the Lifting Columns R / L ______________________ 56

Checking potentiometers r1/r2 and reference switches S1 and S25 . . . . . . . . . . . . . . . 56

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Removing the lifting column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installing the new lifting column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6 _______ Working on the Motor Drives _____________________________________ 62

7 _______ Working on the Orbital Drive _____________________________________ 63

Removing the am4 drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing the toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Installing the am4 drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8 _______ Appendix______________________________________________________ 70

9 _______ Changes to Previous Version _____________________________________ 71

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 4 of 72

Medical Solutions

Page 5

Prerequisites 5

1Prerequisites

2-

• Observe the EMC meaures for systems with serial number starting with 06022 (EMC =

electromagnetic compatibility).

• Observe ESD protective measures (ESD = electrostatically sensitive device).

• Ensure that the EMC shielding is reinstalled correctly after removing it to replace or

check boards.

• Check the connection pins when inserting boards and connectors.

• Remove the system covers for the area of the system being serviced and reinstall them

after the service work is completed.

NOTICE

Protective conductor test and backup:

¹ When service work is completed, perform a protective

conductor test and a backup of the new parameters.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 5 of 72

Page 6

6 Prerequisites

Documents required 0

• SAFETY NOTES RA0-000.012.29...

• LITHOSTAR Multiline Startup Instructions RXL2-120.034.01...

• LITHOSTAR Multiline wiring diagram set J1042

• Operation of the service software RXL2-120.113.01...

• Setting the software parameters RXL2-120.032.01...

• Jumper log 31 27 011 EBP 01S

• Start-up Instructions RXL2-120.034.01...

• MEMOSKOP Service Instructions RX57-029.061.01...

• VIDEOMED DI/DI-M Service Instructions RX52-022.061.01...

• MULTISPOT 2000 Setting Instructions RX57-091.032.01...

• POLYDOROS LX 30/50 Troubleshooting Instructions RX63-020.072.01...

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 6 of 72

Medical Solutions

Page 7

Prerequisites 7

Required measurement and adjusting devices 0

• Special tool, PLCC extractor 99 00 549 LE999

• 96-pin extension board, short 85 73 628 G5206

• 2x96-pin extension board 73 94 943 EE999

• 1x64-pin extension board

(This board can also be used on the 48-pin connectors)

21 67 179 N2030

• Service PC (for details see Intranet service laptop for CSEs)

• Serial PC connection cable, 5m 99 00 440 RE999

• Multimeter (Class 0.1%; Ri > 10 M), e. g., Fluke 8060 A 97 02 101 Y4290

• Oscilloscope, e.g., Fluke Scope Meter 73 92 074

• ESD tools according to ARTD, Part 3

• Standard service equipment kit

• A stretching belt or similar device (approximately 4.5 m long and

25 mm wide), must be purchased locally.

• 5 mm Allen wrench with guide pin

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 7 of 72

Page 8

8 Prerequisites

Disposal information 0

When disposing of boards and components no longer required, adhere to the Disposal

Instructions RXL2-120.163.01... .

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 8 of 72

Medical Solutions

Page 9

Prerequisites 9

Service information on the Intranet 0

The most recent information is available on the Intranet.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 9 of 72

Page 10

10 Overview of Measures

2Overview of Measures

3-

Component N11 (in control cabinet A12) 0

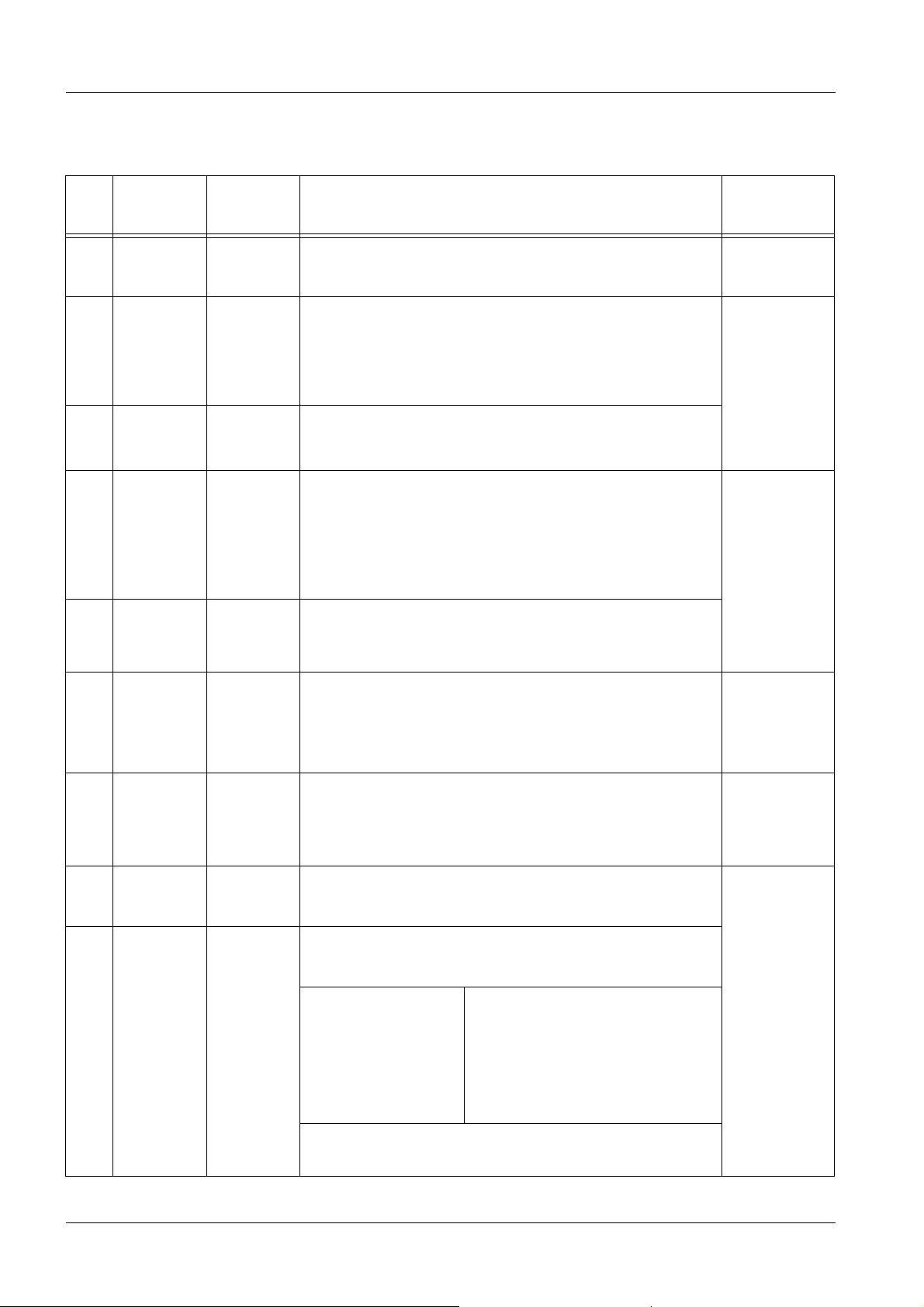

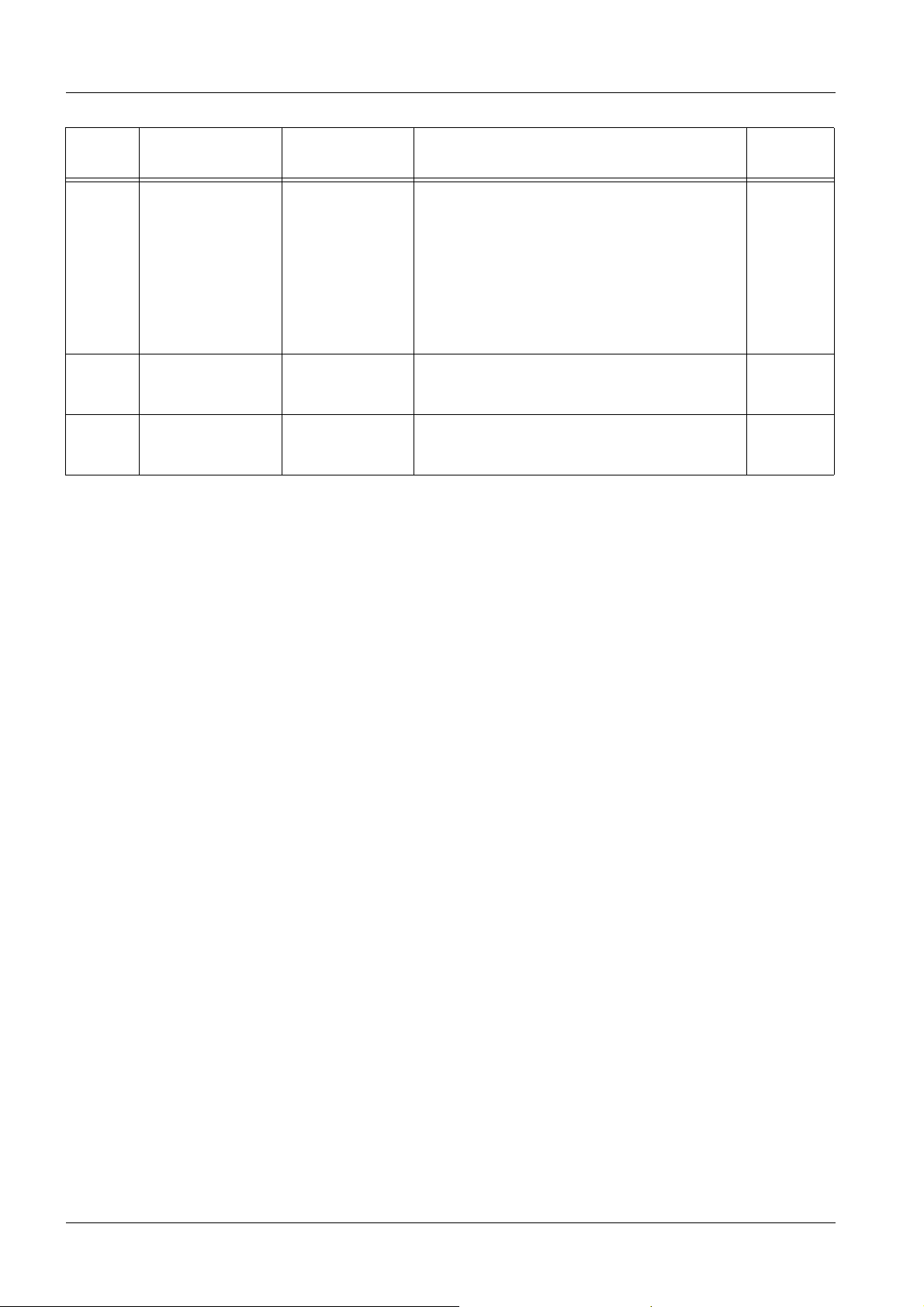

BoardPart no. Name Remarks regarding replacement

- Tool tip

Fuses Replace according to wiring diagram J1042-3A n.a.

D1 71 28 841

J1042

Host computer

Check switches according to wiring diagram excerpt in

Appendix. (Appendix / p. 70)

Wiring diagram 1042-21-4

Set time, restore the parameters, download software

30 82 138 Battery Set time, restore parameters

D1 31 25 825

J1042

Host computer

Activate battery: Solder in jumper X26-X27; check

jumpers/switches; jumper log

Wiring diagram J1042-21

Replace Proms, set time, restore the parameters,

download software

31 46 073

Battery Set time, restore parameters

B2905

Detail info

(Board D1,

(new type)

host computer or

when replacing the

battery/p.2

1).

(Board D1,

(old type)

host computer or

when replacing the

battery/p.2

2)

D2 31 25 643

J1042

D4 89 49 588

G5334

D5 31 25 528

J1042

D5 37 82 714

J1042

XCS

controller

Motor

controller

A/D converter

A/D

converter

Check jumpers/switches; replace Proms; jumper log,

wiring diagram J1042-22

Change EMC shielding plate, if present, from old to

new board

Check jumpers/switches;

replace Proms

Check jumpers; replace Proms

Check U

, setting on D8 with R220 (Board D 5,

ref

- Board backward-compatible

(starting with HOST Software VA00D)

- May only be operated with Prom:

- J1 Part no. 47 81 857 J1042

- J2 Part no. 47 81 865 J1042

n.a.

(Board D4xx,

Motor

controller / p.

24)

A/D

converter / p.

24)

Check jumpers; replace Prom; check U

setting on

ref

D8 with R220

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 10 of 72

Medical Solutions

Page 11

Overview of Measures 11

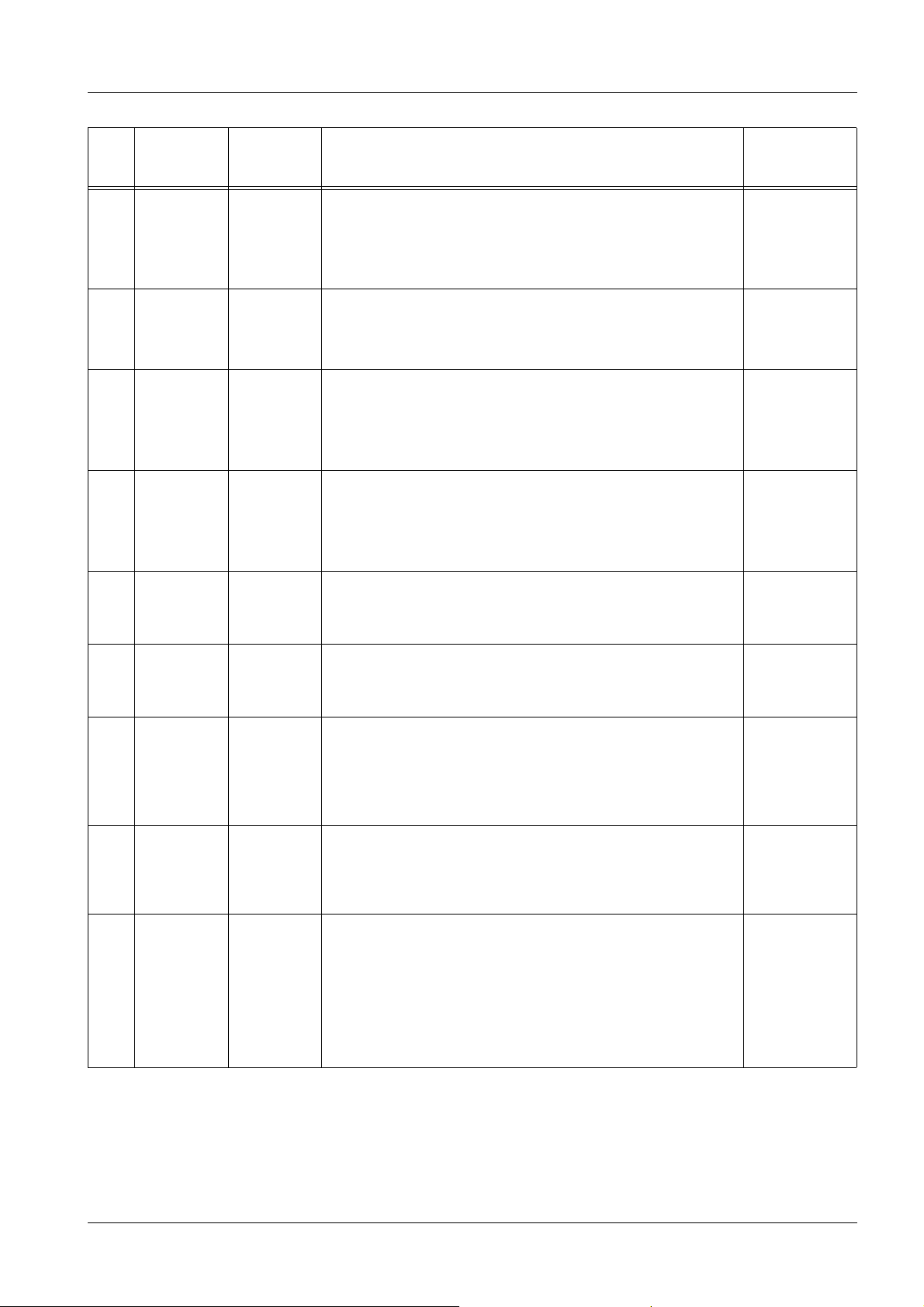

BoardPart no. Name Remarks regarding replacement

- Tool tip

D6 31 25 569

J1042

COM

controller

Check jumpers/switches; replace Proms; jumper log,

wiring diagram J1042-26

Change EMC shielding plate, if present, from old to

new board

D7 89 49 505

G5334

Motor

output

No special attention necessary n.a.

stages

D8 31 73 911

B3305

+5V

power

supply

Set the reference voltage U

R220; test point U

: D5.X31 (0V; X30)

ref

= 5.120V +/- 5 mV with

ref

Prior to installing the board, set potentiometer R220 to

the lowest value

D10 11 14 839

G5347

Bus board starting with serial no. 7000: Transfer the jumper from

the old board to the new board. Jumper log

X112.4 - X110.4. The plug must connect 1-5

D11 31 25 692

J1042

Backplane Check the fuses/jumpers

Jumper log, wiring diagram J1042-31/

Detail info

n.a.

n.a.

(SMP bus

board

D10 / p. 25)

(Board D11,

backplane /

p. 26)

D21 31 25 577

J1042

D25 88 21 068

G1005

D26 88 21 068

G1005

D4 84 37 337

K2013

Power

supply

M16

ECG/QRS

separation

Dig. memory

Respiration Analog Gate

Power

supply

D25/D26

Check the fuses,

wiring diagram J1042-6A/6B

Check the fuse,

wiring diagram J1042-45 jumper

Note: Do not change the potentiometer setting!

Check the jumper,

jumper log, wiring diagram J1042-46

Note: Do not change the potentiometer setting!

Check fuses F1/F2,

wiring diagram J1042-44

(Board D 21,

power supply

M16 / p. 26)

n.a.

n.a.

(Board D4,

power supply, respiratory and

ECG

triggering / p.

27)

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 11 of 72

Page 12

12 Overview of Measures

Collimator component N 0

• Collimator N is maintenance-free and should be replaced in the event of a mechanical

malfunction. An adjustment test must be performed following replacement ((Replacing

electric components / p. 28)).

• In case of electronics errors, parts will be replaced according to spare parts list

RX74-020.081.10....

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 12 of 72

Medical Solutions

Page 13

Overview of Measures 13

VIDEOMED DI-M component 0

When servicing or replacing the VIDEOMED DI-M, adhere to the Service Instructions

RX52-022.061.01...

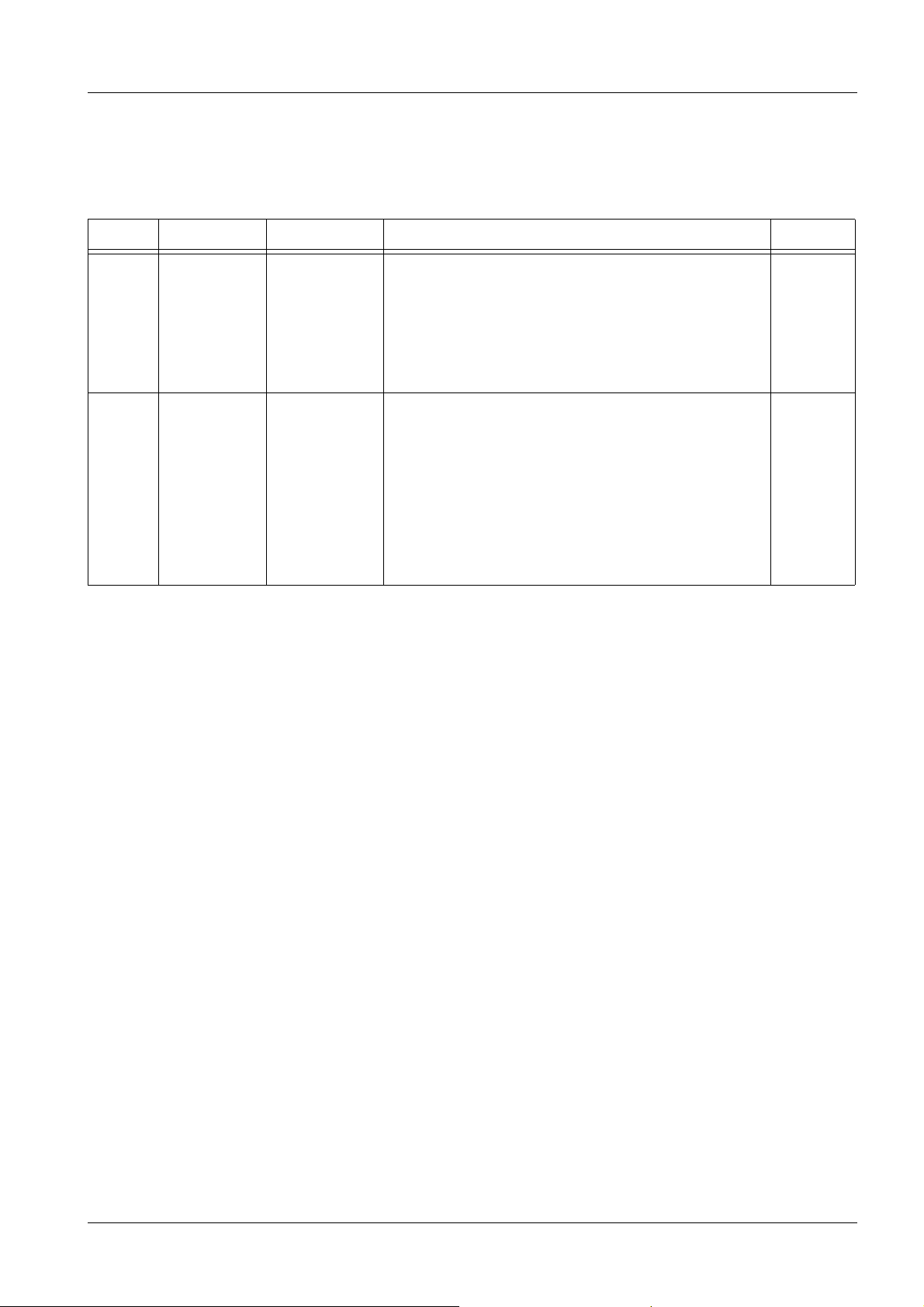

Board Part no. Name Remarks regarding replacement / tool tips Info

D1 30 97 727

X2170

D3 30 97 651

X2170

Analog board Remove the resistor between X902 and X903,

refer to the service note "Adapting a

MEMOSKOP"

Digital

control

board

"Load Default Value" is possible the first time only

with the switch, not with the service software.

Select the LITHOSTAR measurement field;

perform a dose rate check;

perform an IQ test

For 33 cm I.I. only:

select horizontal and vertical image reversal

(Board

D1, analog

board / p.

30)

n.a.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 13 of 72

Page 14

14 Overview of Measures

Memoskop component 0

Use Service Instructions RX57-029.061.01... when working on the Memoskop.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 14 of 72

Medical Solutions

Page 15

Overview of Measures 15

Multispot component 0

Use the Setting Instructions RX57-091.032.01... when working on the Multispot 2000.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 15 of 72

Page 16

16 Overview of Measures

Laser light localizer component 0

The complete laser light localizer unit is replaced. It can be converted from battery operation to rechargeable battery pack operation (refer to Instructions RXL2-120.033.03...).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 16 of 72

Medical Solutions

Page 17

Overview of Measures 17

Unit/control console component 0

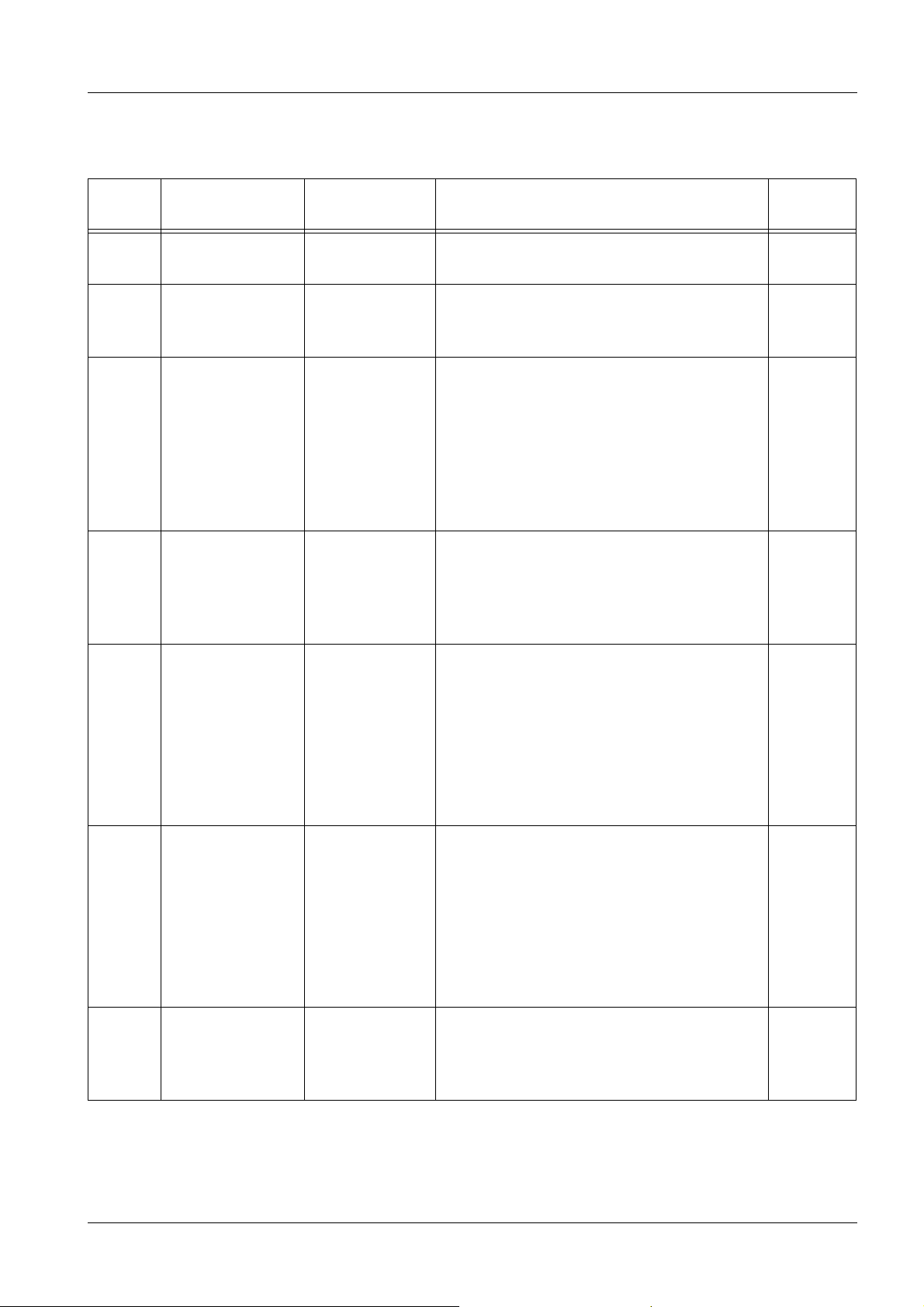

Board Part no. Name Remarks regarding replacement - tool

tips

D7 ... 89 49 505 G5334 Motor output

stage

D31 31 25 585 J1042 Base frame,

distributor

board

D32 31 25 676 J1042 Support frame,

distributor

board

Z96 31 36 194 X2134 I.I. power sup-

ply,

operator panel

No special attention necessary n.a.

Check jumper log, wiring diagram

J1042-51

No special attention

necessary

Check fuses F2 and F3; wiring diagram

J1042-6

Detail

info

n.a.

(Board

D32, distributor

board,

supporting

frame / p.

31)

(I.I. supply Z96

"Röderst

ein" / p. 3

1)

n.a. 31 23 879 J1042 Tableside con-

trol

D51 31 25 627 J1042 ADC/DUEP

plugin board in

the PC

r3-6, 8 30 28 009 B0611 Potentiometer

Completely replaced!

check the switch,

jumper log, wiring diagram J1042-61

Check jumpers, switches;

replace Prom;

jumper log, wiring diagram J1042-71

n.a.

(Tableside control panel

(NBF),

board

D41 / p. 3

2)

(Board

D51,

ADC/DU

EP

plug-in

board / p.

33)

(a)

Potentio

meters /

p. 35)

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 17 of 72

Page 18

18 Overview of Measures

Board Part no. Name Remarks regarding replacement - tool

tips

am 1/2 70 54 422 F0721 Lifting column

n.a.

n.a. 31 23 994 J1042 Shock wave

release

n.a. 47 82 707 J1042 System floor

Replace completely, no special attention

necessary

Replace completely; n.a.

switch

Detail

info

(Checking /

Replacing the

Lifting

Columns

R /

L/p.56)

n.a.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 18 of 72

Medical Solutions

Page 19

Overview of Measures 19

Generator component 0

The following instructions should be used when working on the generator.

LITHOSTAR Multiline Serial no. ≤ 6073 RX63-020.034.12...

Serial no. > 7000 POLYDOROS SX RXL2-120.034.05...

Serial no. > 7000 POLYDOROS LX RXL2-120.034.02...

Troubleshooting

Instructions

Troubleshooting

Instructions

When replacing the image intensifier, X-ray tube or camera, use the Start-up instructions

for the specific component. In addition, adjust the system in accordance with the adjust-

ment instructions, "Isocenter Adjustment" RXL2-120.071.01....

POLYDOROS LX RX63-020.072.01...

POLYDOROS SX RX63-055.072.01...

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 19 of 72

Page 20

20 Overview of Measures

Ultrasound option 0

Use Start-up Instructions RXL2-120.091.10.01... when working on the ultrasound system.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 20 of 72

Medical Solutions

Page 21

PC Board Replacement 21

3PC Board Replacement

4-

Component N 11 0

NOTE

Refer to wiring diagram J1042-3A for the rated current values of

the different fuses listed in this chapter.

Board D1, (new type) host computer or when replacing the battery 0

78 28 841 J 1042, refer to wiring diagram J1042-21-4

30 82 138 battery 3.0 V

Follow items A + B + D when replacing board D1.

Follow items A + C + D when replacing the battery.

• If possible, perform a backup of all current parameters and data.

A

(Refer to Operation of the Service Software RXL2-120.113.01. Chap. 3-3)

• Read out the counter values for

shock counter generator shock counter shockwave

shock counter spark-gap shock counter total

shock counter US probe (starting with Rev. 05)

and document them in the operating log (Logbook, Reg. 8).

• Remove board D1 from electronics rack N11.

B

• Change EMC shielding plate, if present, from old to new board.

• Set or check the switches on the new board.

• Switch settings, see wiring diagram excerpt in the Appendix to this manual.

C

• Measure the battery voltage; U

> 2.7 V is normal.

batt

• If the battery voltage is < 2.7 V, replace the battery.

• Desolder the old battery and replace it with a new one.

D

• Measure the battery voltage; U

> 2.7 V is normal.

batt

• If the battery voltage is < 2.7 V, replace the battery.

• Insert board D1.

• After switching on the system:

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 21 of 72

Page 22

22 PC Board Replacement

- Establish a connection between the service PC and D1 X10

- Start the service software (Refer to the service software operating instructions

RXL2-120.113...)

- Enter the current time and date "Realtime Clock"

- Execute a download of "Host Software, Parameter file" in the Data menu

- Execute a restore of the "Customer Data", "System Data" parameters in the

Data menu

- Call up "Technical Info" and "Service Data" in the Info menu with "Load from

File" and save by selecting "Put to Unit".

- Call up "Parameters" in the Adjustment menu

- Select "Interface Shockwavesystem" from the Parameter group

- The value 00 must appear in the "Value" column for:

Reset shock counter generator / Reset shock counter shockwave

Reset shock counter spark-gap / Reset shock counter total

Reset shock counter US probe (starting with Rev. 05)

• If necessary, reset the values in the Value column

(Reset with "FF"/normal operation with "00", refer to "Setting the software parameters" RXL2-120.032.01..)

NOTE

The Appendix of this manual contains a layout of the new D1

board. When board D1 is replaced, this layout is to be attached to

the LITHOSTAR Multiline wiring diagram.

Board D1, (old type) host computer or when replacing the battery 0

31 25,825 J 1042, refer to wiring diagram J1042-21-4

31 46 073 B 2905 battery 3.6 V

Follow items A + B + D when replacing board D1.

Follow items A + C + D when replacing the battery.

• If possible, perform a backup of all current parameters and data.

A

(Refer to Operation of the Service Software RXL2-120.113.01. Chap. 3-3)

• Read out the counter values for

shock counter generator shock counter shockwave

shock counter spark-gap shock counter total

shock counter US probe (starting with Rev. 05)

and document them in the operating log (Logbook, Reg. 8).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 22 of 72

Medical Solutions

Page 23

PC Board Replacement 23

• Remove board D1 from electronics rack N11.

B

• Change EMC shielding plate, if present, from old to new board.

• Set or check the switches on the new board.

• Replace Proms J66/J67.

• Solder in jumper X26 - X27 to activate the battery.

C

• Measure the battery voltage; U

• If the battery voltage is < 3.0 V, replace the battery.

• Desolder the old battery and replace it with a new one.

D

• Measure the battery voltage; U

> 3.0 V is normal.

batt

> 3.0 V is normal.

batt

• If the battery voltage is < 3.0 V, replace the battery.

• Insert board D1.

• After switching on the system:

- Establish a connection between the service PC and D1 X10

- Start the service software (Refer to the Service Software Operating Instructions RXL2-120.113...)

- Enter the current time and date "Realtime Clock"

- Execute a download of "Host Software, Parameter file" in the Data menu

- Execute a restore of the "Customer Data", "System Data" parameters in the

Data menu

- Call up "Technical Info" and "Service Data" in the Info menu with "Load from

File" and save by selecting "Put to Unit".

- Call up "Parameters" in the Adjustment menu

- Select "Interface Shockwavesystem" from the Parameter group

- The value 00 must appear in the "Value" column for:

Reset shock counter generator / Reset shock counter shockwave

Reset shock counter spark-gap / Reset shock counter total

Reset shock counter US probe (starting with Rev. 05)

• If necessary, reset the values in the Value column

(Reset with "FF"/normal operation with "00", refer to "Setting the software parameters" RXL2-120.032.01..)

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 23 of 72

Page 24

24 PC Board Replacement

Board D4xx, Motor controller 0

89 49 588 G 5334 Refer to jumper log wiring diagram J 1042-24

• Set or check jumpers

• Check switch S2 (S2 defines the board as D4A, B or C).

NOTICE

PAL modules

¹ The PAL modules J5, J31 and J32 on the replacement

board must be removed and destroyed. Only the original

PAL modules of the old board D4 may be used.

• Replace Prom J38.

• Mark the board according to its location.

• Insert the board and switch the system on.

• Check the operating voltage at test point X10 +5 V +/- 250 mV (0V, X11).

Board D 5, A/D converter 0

31 25 528 J1042, Refer to jumper log, wiring diagram J 1042-25

37 83 714 J1042

NOTICE

Risk of short circuit! Do not use the 96-pin extension board 81 33

944 X1454 to extend the front plug D5.X2.

¹ Use only the short 96-pin extension board, part no. 85 73

628 G5206.

• Remove the front plug X2; remove board D5.

• Set or check jumpers.

• Check the Proms J1/J2 and replace them, if necessary.

• Insert the board and set front plug X2 to the short extension; switch on the system.

• Check the reference voltage U

Mp X31 - X30 (0V). If necessary, set it with potentiometer R220 on board D8.

Checking the A/D converter

= 5.120 V ± 5 mV by connecting a DVM to board D5 at

ref

• Measure and record the voltage value for every actual value potentiometer (r1 ... r6)

(Mp X10 ... X15).

• Read out and record the value of the ADC value for the corresponding potentiometer

with the service PC in the Diagnostic, Monitoring menu.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 24 of 72

Medical Solutions

Page 25

PC Board Replacement 25

• Ensure that the relevant voltage value corresponds to the ADC value.

Conversion:

Voltage value (mV) = ADC value (bit) x 5mV/bit -> +/ - 20 mV tolerance

Voltage value (mV))

ADC value (bit) =

Example:

Measured value at D5 M

mV

Calculated value ADC value (bit) =

- Compare with recorded ADC value

-> the ADC value in bits for this channel is correct as long as the values do

not deviate from one another by more than +/- 4 bits.

Check the calculation: 587 bit x 5 mV/bit = 2935 mV +/- 20 mV

___________________

5mV/bit

X = 2935

p

2935 mV

___________ =

5 bit/mV

-> +/ - 4 bit tolerance

= 587 bit

• Switch off the system, remove the extension board and reconnect the front plug X2.

• Switch the system on.

• Check the operation of the various drives.

SMP bus board D10 0

11 14 839 G5347, wiring diagram J 1042-30

• Remove the cable connections from module N11.

• Remove the boards according to ESD guidelines and remove module N11 from the

cabinet.

• Replace board D10.

• Reinstall module N11 in reverse order.

• When installing the EMC shielding plate, ensure that the cables fit in the recesses pro-

vided and are not damaged.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 25 of 72

Page 26

26 PC Board Replacement

• Attach the exposed cable shielding with clamps.

Starting with serial no. 7001:

Transfer the jumper from the old board to the new board. X112.4 - X110.4

The plug must connect 1-5. (Refer to the jumper log).

Board D11, backplane 0

31 25 577 J1041, wiring diagram J 1042-31

• Remove the cable connections from module N11.

• Remove the boards according to ESD guidelines and remove module N11 from the

cabinet.

• Replace board D11.

• Reinstall module N11 in reverse order.

• When installing the EMC shielding plate, ensure that the cables fit in the recesses pro-

vided and are not damaged.

• Attach the exposed cable shielding with clamps.

• Check or set the jumper positions according to the jumper log or wiring diagram.

• Check the fuses F10...F16 according to the wiring diagram.

Board D 21, power supply M16 0

31 25 577 J1042, wiring diagram J 1042-41

• Check fuses F1 and F2.

• Replace the board.

• Switch the system on.

• Check LEDs V10... V16 and operating voltages.

Supply voltage of the magnetic brakes LED V10

MP X3.3/4 +25 V to +29 V regulated

Gnd X3.1/2

Supply voltage of function switches and safety circuits LED V11

MP X2.10 +23 V to +26 V regulated

Gnd X2.6

Supply voltage of the DUEP interface to the image memory LED V12

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 26 of 72

Medical Solutions

Page 27

PC Board Replacement 27

MP X2.1 +8.5 to +9.5 V regulated

Gnd X2.2

Supply voltage of the collimator LED V13

MP X4.4 +27 V to +35 V

Gnd X4.2

Supply voltage of the large drives (K1/K2 are energized) LED V14

MP X15 +28 V to +35 V

Gnd X14

Supply voltage of the small drives (K3 is energized) LED V15

MP X17 +28 V to +35 V

Gnd X16

Supply voltage of the Com controller (DUEP) LED V16

MP X2.9 +14 V to +15.5 V regulated

Gnd X2.6

Board D4, power supply, respiratory and ECG triggering 0

84 37 337 K2013, wiring diagram J 1042-44

• Check fuses F1 and F2.

• Measure the operating voltage (place the board on the extension)

+ 12 V ± 10% (X1.d/b/z4) LED V4 The - 5V are not used in the

- 12 V ± 10% (X1.d/b/z4) LED V11

GND (X1.d/b/z4)

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 27 of 72

LITHOSTAR Multiline

.

Page 28

28 PC Board Replacement

Collimator N 0

Fig. 1: Strain relief

Replacing the collimator 0

• Unpack the collimator.

• Remove the two colored screws from the transport bracket on the side of the blades

close to the focus.

• Check the adjustment of the leaves close to the focus with the template.

• Attach the collimator to the tube unit.

• If plug X1 has a connector shell, unscrew it, cut it open, remove it.

• Plug the X1 plug into the collimator and bolt it

• Attach the cable at the panel using strain relief clamps ((1/Fig.1/p.28)).

• Perform the adjustment test when you replace the entire collimator.

Replacing electric components 0

• Switch off the system

• Replace the electric components according to the spare parts list and perform the ad-

justment test.

D1/S2.5

OFF Collimator without prefiltration

ON Collimator with prefiltration

(On D1X7, check that the cable for the drive is connected)

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 28 of 72

Medical Solutions

Page 29

PC Board Replacement 29

Adjustment test 0

• Set DIP switch S2.4 to "OFF".

• Close the "height" and "width" collimator blades completely by hand.

• Remove the prefilter (if present).

• Move the iris blades to an opening of 70 x 70 mm (measure at the iris blades).

• Switch the system back on or reinsert fuse F1 on D1.

• Switch DIP switch S2.4 to "ON" for initialization.

The system will initialize. DIP switch S2.4 should remain "ON" during operation.

• The height and width blades will open or close to the 44mm format (± 0.75%) x 44 mm

(± 0.75%) at a SID of 125 cm (35 mm x 35 mm at 100 cm SID).

Control position of the collimator blades 0

• Install the cassette holder. Do not insert a film cassette.

• Move the system into the mid-range position.

• Release fluoroscopy.

• A radiation field of comparable size

44 mm (± 0.75%) x 44 mm (± 0.75%) - is visible on the monitor at a SID of 125 cm.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 29 of 72

Page 30

30 PC Board Replacement

VIDEOMED DI-M component 0

Board D1, analog board 0

30 97 727 X2170 wiring diagram X 2170-10

• Starting with revision level 01, the 620 ohm resistor between test points X902 and X903

should be removed.

Board D3, analog board 0

30 97 651 X2170 wiring diagram X 2170-13

• Select the "Multiline" measurement field from the specific parameters (refer to the Ser-

vice Instructions RX52-022.061.01...).

• Check the dose setting according to Start-up Instructions RXL2-120.034.01...).

• Perform an IQ test

• For 33 cm I.I. only:

Select "H-image reverse" and "V-image reverse" in the specific parameters and

transfer them individually to the system (Refer to the Service Instructions

RX52-022.061.01...).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 30 of 72

Medical Solutions

Page 31

PC Board Replacement 31

Unit/control console component 0

Board D32, distributor board, supporting frame 0

31 25 676 J1042, wiring diagram J1042-52/52A

• Plug in and check the connection cables according to the wiring diagram.

• Check connection (X56) and the operation of the tube assembly fan.

• Check the operation of service switch S 58.

• Check the operation LED’s V14 to V18 for the magnetic brake by moving the associat-

ed drive (The LED lights up when the brake is released).

I.I. supply Z96 "Röderstein" 0

31 36 194 X2134, wiring diagram X2134

• Replace the board and the power transistor at the same time.

• Check fuses F2 and F3.

• Check the operating voltage 27 V ± 10% for V11 "ON"; Tp 27 V → Tp 0.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 31 of 72

Page 32

32 PC Board Replacement

Tableside control panel (NBF), board D41 0

31 23 879 J1042, wiring diagram J1042-61

Board D41 is coded in the factory to "Patient table basic unit".

Recoding for use on the control console, board D41 0

• Place the tableside control panel with the membrane keyboard side on a level surface.

• Remove four screws (M 2.5x16) from the lower part of the housing.

• Carefully lift off the lower housing.

Four metal spacers are lying loosely on the PC board.

• Set or check the DUEP slave address of switch S3 according to the application and the

wiring diagram:

Address 7: Tableside control panel

(NBF) basic unit (patient table) factory

setting

Address 2: Tableside control panel

(NBF) basic unit control console

Fig. 2: S3 Switch

Assembly 0

• Center the four metal spacers on the contact surfaces and insert the four screws

(M2.5x16) in the holes in the lower part of the housing.

• Join the housing parts together so that one of the screws can be inserted through the

hole of the grounding tape.

The metal spacers must not move during assembly.

• Tighten the screws.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 32 of 72

Medical Solutions

Page 33

PC Board Replacement 33

System unit 0

30 10 175 JE002

• Replace the system unit, if necessary, according to the Repair Instructions

RXL2-120.091.02... .

Board D51, ADC/DUEP plug-in board 0

31 25 627 J1042, wiring diagram J1042-71

Refer also to Repair Instructions "Replacement of the system unit" RXL2-120.091...

• Set and check the jumpers and Proms according to the jumper or wiring diagram.

• Check the 7-segment display

(Refer to the error list RXL2-120-072.03...).

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 33 of 72

Page 34

34 Potentiometers and Reference Switches

4Potentiometers and Reference Switches

5-

Overview of the potentiometers and reference switches 0

Fig. 3: Overview of potentiometers and reference switches

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 34 of 72

Medical Solutions

Page 35

Potentiometers and Reference Switches 35

Basic information on the replacement and adjustment of potentiometers, reference switches and motor encoders

Fig. 4: Replacing the potentiometer

General replacement and adjustment 0

0

a) Potentiometers

• Move the unit so that the set screw becomes accessible ((M/Fig.4/p.35)).

• Switch the system off.

• Remove the Allen 1.5 mm set screw on the connecting piece of the potentiometer shaft

((M/Fig.4/p.35)).

• Remove the potentiometer retaining plate ((ISK 3 mm/Fig.4/p.35)).

• Remove the adjustment wheel ((E/Fig.4/p.35)) and the retaining parts from the po-

tentiometer shaft.

• Desolder the connection wires from the potentiometer and solder them to the new po-

tentiometer in the same order.

• Install the potentiometer in the reverse order. Do not tighten the set screw yet (Allen 1.5

mm).

• Switch the system on.

• Move the drive in "unregulated motion" with the service PC (Adjustment, Calibration) in

mm steps so that the corresponding reference switch is actuated (refer to

(Fig.5/p.36)). Check with DVM at D5.X2.A1...A11, 0V=X30.

NOTE

The potentiometer values are set in accordance with ADC values.

• Exit "unregulated motion" and select the "ADC value" for the corresponding drive in Di-

agnostic, Monitoring.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 35 of 72

Page 36

36 Potentiometers and Reference Switches

• Set the ADC value to the corresponding value using the adjustment wheel

((E/Fig.4/p.35)) (Refer to the detailed description for the corresponding potentiome-

ter).

• Retighten the set screw on the potentiometer shaft.

• Reset board D1 with S1.

• Check the drive function. No errors may be displayed.

• If reference switch errors continue to be displayed after adjusting the potentiometer (Er-

rors 0020-002B), check the A/D converter on board D5 according to (Board D 5, A/D

converter / p. 24).

b) Reference switches

NOTE

A 24 V lamp may be used to check switch functions instead of an

oscilloscope.

• Switch the system off.

• Remove the reference switch in question and remove the switch rocker.

• Replace the switch and wire.

• Reinstall the switch with the switch rocker and check the operation of the switch rocker.

• Switch the system on.

Fig. 5: Replacing the reference switch

Connect an oscilloscope (or lamp ≥ 24 V) to the input of board D5 X2 a... to check the

reference switch function (GND: X30/X40) (refer to the Overview circuit diagram for the

respective reference switch J1042-8...).

• Move the corresponding drive far enough so that the reference position is reached on

the service PC (Diagnostic; Monitoring) (Refer to the chapter on adjusting the drives).

• Adjust the reference switch by moving it in the X direction. The switch should activate

within the mechanical limits of the switching hysteresis ((Fig.5/p.36)).

Check it using the service PC (Diagnostic; Monitoring; Refswitch; Y; X; 0; W; ZL; ZR;

TL; TR) or on the oscilloscope (lamp ≥ 24 V).

Move the drive over the reference switch position several times to check.

• Check the drive function.

• Move the activator of the drive up to approx. 1 cm in front of the reference switch.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 36 of 72

Medical Solutions

Page 37

Potentiometers and Reference Switches 37

• Continue to move toward the switch in inching mode ((Fig.5/p.36)).

In addition, check the status of the reference switch on the service PC (Diagnostic,

Monitoring).

• If the switch is activated from both sides, check the switching hysteresis for both sides.

No errors may be displayed.

Overview of the switching hysteresis

• The test points of the actual value potentiometers and reference switches on board D5

are shown in the wiring diagram J1042-8x.

Fig. 6: Overview of the switching hysteresis

The switch can be ON or OFF within the range "X".

For the actual value potentiometers and reference switch test points on board D5, refer to

wiring diagram J1042-8x.

c) Checking synchronization of the actual value potentiometers to the motor encoder

NOTE

Adjustment of the MC position with the ADC position

- When the system is switched ON or board D1 is reset with button S1, the value of

"MC position" is adjusted to the value of the "ADC position.“ (initialized).

- If the ADC position deviates from the MC position, the error "428x AD / MC position

comparison failure / x“ is displayed (x corresponds to the number of the drive).

Reason for the error message

- Potentiometer Actual value Rx not synchronous to the motor encoder Bx.

Maximum acceptable differences in the ADC/MC positions

ZL, ZR = 25 in 1/10 mm W = 30 in 1/10 mm X = 30 in 1/10 mm Y = 30 in 1/10 mm

Starting with software VA00D (Software Upgrade Rev. 3), the physical limits of the drive are monitored.

O = 90 in 1/100° TL = 18 in 1/10 mm TR = 175 in 1/100°

Checking the display for the corresponding drive in the service PC

"MC position" and "ADC position" are displayed on the service PC (Diagnostic, Monitoring).

• Move the respective drive into an end position.

• Reset board D1 with button S1.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 37 of 72

Page 38

38 Potentiometers and Reference Switches

• Check the respective adjustment for the drive ("MC position" to "ADC position") on the

service PC (Diagnostic, Monitoring).

• Move the drive to the opposite end stop in 5 steps.

• Perform a check at the service PC.

NOTE

Procedure for tensioning the toothed belt:

If the deviations of the ADC/MC positions are greater than the maximum acceptable deviations, the drives must be checked. If there

are errors in the lifting columns and/or the cone drive, they must

be replaced, since the actual value potentiometer cannot be adjusted.

• Loosen the screws at the idler pulley of the corresponding potentiometer toothed belt.

• Tighten the toothed belt by shifting the idler pulley and retighten the retaining plate.

• Reset board D1 with button S1.

• Perform a functional check as described above.

• Loosen the idler pulley again if shifting the idler pulley does not adjust the belt ade-

quately.

• Remove the retaining plate for the toothed belt end stop.

• Open the clamping piece of the toothed belt, shorten the belt by removing 4 teeth (2

teeth each parallel), insert the belt and reassemble completely.

• Perform a functional check as described above (check hysteresis of the reference

switch).

Error display:

„Antriebe stehen außerhalb der physikalischen Betriebsgrenzen"

"Drives are located outside of physical limits"

"Moteurs endehors des limites physiques"

"Los Motores se eneuentran fuera de los limites fisicos"

Error Cause:

Remedy:

• One of the drives (O, W, X, Y, Z, TL, TR) is in the ADC position in

the area of the hardware proximity switch outside the operating

range (Monitoring) (ZL, ZR = 50 in 1/10 mm; W, X, Y = 40 in 1/10

mm; O = 100 in 1/100°; TL = 20 in 1/10 mm; TR = 400 in 1/100 °)

• Check the respective drive using the service PC (Diagnostic, Moni-

toring).

• Move the drive into the mid-range position (inside the operating

limits) in "unregulated mode" (Avoid collisions).

• Reset board D1 with button S1.

• Perform a functional check. If necessary, repeat the check of the

display ("MC/ADC position") for the corresponding drive in the service PC. If there is no improvement, adjust the toothed belt.

Error display:

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 38 of 72

Medical Solutions

Page 39

Potentiometers and Reference Switches 39

„Gerät befindet sich außerhalb der Betriebsgrenzen“

"Unit is outside the operating limits"

"L appereil est en dehors des limites d utilisation"

"Equipo se halla fuera de los limites de servicio"

Error Cause: - After exiting service mode "Unregulated motion" or

- when changing the Uro table, (switching over from Lithotripsy

mode<-> Urology mode) O, W, X, Y, Z, TL, TR

• At least one drive is outside the respective operating limits. (Refer

above for the drive values)

Remedy:

• Move drives to the basic position or ascending position (inside the

operating limits) using the →0← button.

• Perform a functional check. If necessary, repeat the check of the

display ("MC/ADC position") for the corresponding drive in the service PC.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 39 of 72

Page 40

40 Potentiometers and Reference Switches

Checking, replacement and/or adjustment 0

Reference switches S3..6, S8, S9 or actual value potentiometers r3..6, r8, r9

NOTICE

Make the following preparations according to the respective work step:

Danger of collision!

¹ Move the drives to a mid-range position to avoid collision

when moving the system in "unregulated motion" mode.

¹ The shock wave head (W drive) is in the park position!

• Connect the service PC to board D1 X10.

• The ADC values, position values and reference switch settings can be read out in the

"Diagnostic, Monitoring" menu.

• As an alternative, you can proceed as follows:

- Remove the EMC shielding plate at the front of N11.

The test points on board D5 are now accessible from the front.

The test points of the ACTUAL value potentiometers are shown in wiring diagram J

1042-25.

- Remove the front plug X2 of board D5 and reconnect it using the short 96-pin extension board 85 73 628 G5206.

(service accessory for the engineer).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 40 of 72

Medical Solutions

Page 41

Potentiometers and Reference Switches 41

Cone drive TL, reference switch S8 and potentiometer r8 0

• Connect an oscilloscope to D5.X2.a21 (for S8) (0 V to X30); 5 V/div., 0.1 s/div.

• Switch the system on.

• Move the shock wave head into the therapy position.

• Check the reference voltage, if necessary set it with R220 on D8. (U

mV; check on D5 MP X31, 0V at X30) ADC Value = 102

NOTICE

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 5.120 V ± 5

ref

= 5.120 V ±

ref

• Connect the DVM to D5.X2.a22 (0 V at X30).

• Check the function of potentiometer r8.

• Perform the check in normal mode.

• Check the potentiometer voltage at reference switch S8 = "On". U

at D5.X22 and 0 V at D5.X30; ADC value = 102

= 512 mV ± 5 mV

ref

• Check the switching hysteresis of reference switch S8 according to (Fig.7/p.41) in

"Monitoring".

Fig. 7: Switching hysteresis S8

Checking the toothed belt 0

• Check the toothed belt according to Service Instructions Shock Wave System

RXL2-120.841.01.

Checking the travel range 0

• The shock wave head is in the therapy position.

• The C-arm is in the + 30° fluoroscopy position.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 41 of 72

Page 42

42 Potentiometers and Reference Switches

X • Release fluoroscopy FL.

¹ The cone drive moves to the front end position. Safety limit switch S40 must not

be activated.

¹ The service PC (Diagnostic, Monitoring) display indicates: ADC value = MC

position 600 +/- 1 bit.

• Release a shock wave.

¹ The cone drive travels back to MCESWL position 470 ± 1 bit.

• Uncouple the W drive.

• The cone longitudinal drive travels

- Cone drive serial no. < 2000 to the MC position 300 ± 1 bit

- Cone drive serial no. > 2000 to the MC position 360 ± 1 bit

Checking the travel range with US probe (optional) 0

Prerequisite: - US probe inserted - Shock wave head in therapy position

• Use the cone longitudinal forward button on the US tableside control panel to move the

cone drive to the front end position.

¹ The LED on the US tableside control panel lights up.

¹ The service PC (Diagnostic, Monitoring) display indicates: ADC value = MC

position 600 ± 1 bit.

• Release shock waves.

¹ The cone drive travels back to MCESWL position 470 ± 1 bit.

• Use the cone longitudinal back button to move the cone drive to the back end position.

¹ The LED on the US tableside control panel lights up.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 42 of 72

Medical Solutions

Page 43

Potentiometers and Reference Switches 43

Cone drive TR, reference switch S 9 and potentiometer r9 0

NOTE

Only perform if the ultrasound option is available.

• Connect the oscilloscope to D5.X2.a23 (for S9) (0 V to X30); 5 V/div, 0.1 s/div.

• Switch the system on.

• Move the shock wave head into the therapy position.

• Check the reference voltage, if necessary set it with R220 on D8. (U

mV; check on D5 MP X31, 0V at X30)

NOTICE

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 5.120 V ± 5

ref

= 5.120 V ±

ref

• Connect a DVM to D5.X2.a24 (0 V at X30).

• Check the function of potentiometer r9.

Prerequisite: US probe not inserted.

• Move to the reference position in Normal mode using the tableside control panel.

Use the "Cone rotation right or left" key for this.

¹ The cone rotation drive travels to the 0° position and stops.

¹ The 0° marks on the toothed ring and the lifting cylinder line up.

(If in "unregulated motion" mode, readjust the cone rotation )

¹ The position is displayed on the US tableside control panel.

• When reference switch S9 is actuated, the DVM should display a reading of 2.560 V ± 2

mV. ADC value = 512

• Check the switching hysteresis of the reference switch S9 according to (Fig.8/p.43).

Fig. 8: Switching hysteresis S9

Setting the parameters 0

Refer to the "Parameter Groups" section of the "Service software, Software parameter /

Monitoring" instructions RXL2-120.032.02..

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 43 of 72

Page 44

44 Potentiometers and Reference Switches

Checking the travel range 0

Prerequisite: US probe is inserted.

• Move the US probe +90° and -90° by pressing the "Cone rotation left or right" key.

• Check the angular position on the US tableside control panel display.

• Safety limit switch S42 must not be actuated in the ± 90° setting.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 44 of 72

Medical Solutions

Page 45

Potentiometers and Reference Switches 45

Longitudinal system Y drive 0

Adjusting belt tension

Fig. 9: Measurement_1

Fig. 10: Measurement_2

• Move the unit left to the end stop.

• The distance from the center of roller (1/Fig.9/p.45) to the end stop (1/Fig. 10 / p. 45)

is 420 ± 5mm.

• Attach the spring balance (3/Fig. 10 / p. 45) and lift it with a force of 20 N + 5 N.

• It must be possible to raise the belt 3 mm + 1 mm (2/Fig. 10 / p. 45).

• If the belt tension varies from this, readjust it.

Adjusting reference switch S6 (Prerequisite: potentiometer r6 functioning correctly)

• Remove the cover of the cable inlet.

• Remove the metal shutter on the left and right at the back of the unit base frame.

• Switch the system on.

• Move the Y drive in inching mode to display "00" on the control monitor or on the ser-

vice PC (Diagnostic, Monitoring) Y Length ADC position in 1/10mm display to "000".

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 45 of 72

Page 46

46 Potentiometers and Reference Switches

• Adjust the reference switch S6 so that switching is assured within the stated tolerance

range indicated (refer to (Replacing reference switches) and (Switching hystereses

S6)).

• Reset the system on board D1 with S1.

• Move the drive over the reference switch position several times to check.

Replacing reference switch S6 and potentiometer r6

Switch adjustment

• Switch the system on.

• Bring the orbital drive into approx. 0° position.

• Bring the X drive into the mid-range position.

• Bring the shock wave head (W drive) into the park position.

• Select "unregulated motion" mode for the Y drive.

• Approach number 3 of the 5 reference points on the back of the unit base frame from

the left.

(Reference edge is the right outer side of the cable inlet, refer to (Fig. 11 / p. 46)).

Fig. 11: Reference edge

• Align the reference edge and the reference mark.

• Replace reference switch S6 (refer to (b) Reference switches / p. 36)).

• Check the potentiometer voltage for reference switch S6 = On U

(D5.X15 0V = D5 X30) ADC value = 512.

NOTICE

After replacement or for potentiometer deviations:

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 2.560 V + 2 mV

REF

= 5.120 V ±

ref

• If needed, replace the potentiometer according to (a) Potentiometers / p. 35).

• Reference switch is adjusted and closed.

• Loosen the set screw on potentiometer R6.

• Set the potentiometer value to ADC value = 512 by turning the adjustment wheel

((E/Fig.4/p.35)).

• Tighten the set screw.

• Reset board D1 with button S1.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 46 of 72

Medical Solutions

Page 47

Potentiometers and Reference Switches 47

• Check the switching hysteresis of the reference switch S6 according to (Fig. 12 / p. 47).

Fig. 12: Switching hysteresis S6

• Move to the end positions on the left or right in the Uro mode.

- The safety limit switches S64/S65 must not be activated.

- The unit movement must stop on the left at - 320 mm ± 2 mm and on the right at + 320

± 2 mm (control monitor display).

• Move to the left or right end positions in Litho mode (shock wave head in therapy posi-

tion). The safety limit switches S76/S77 must not be activated.

The unit movement must stop on the left at - 25 mm ± 2 mm and on the right at +25 ± 2

mm (control monitor display).

• If necessary, reattach the metal shutter on the left and right onto the back of the base

frame.

When doing this, be sure to correctly position the mounting holes and to use the upper

threads of the metal shutter.

• Reattach the cover of the cable inlet.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 47 of 72

Page 48

48 Potentiometers and Reference Switches

Transverse system, X drive 0

Adjusting belt tension

Fig. 13: Screws

Fig. 14: Reference value

(Checking the belt tension with a spring balance is not possible when the system is

assembled)

• The unit should not have any play transversally to the patient.

• To readjust, loosen the 4 fastening screws (1/Fig. 13 / p. 48) (two screws are not visi-

ble) and adjust with the adjustment screw ((2/Fig. 13 / p. 48)); reference value for ad-

justment: 30 mm ((1/Fig. 14 / p. 48)).

• Retighten the 4 mounting screws (1/Fig. 13 / p. 48).

Adjusting reference switch S5

(Prerequisite: potentiometer r5 functioning correctly)

• Switch on the system.

• Move the X drive in inching mode to display "20" mm on the control monitor or on the

service PC (Diagnostic, Monitoring) X Length ADC position in 1/10mm display to "200".

• Adjust the reference switch S5 so that switching is assured within the stated tolerance

range (refer to (Fig.5/p.36)).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 48 of 72

Medical Solutions

Page 49

Potentiometers and Reference Switches 49

• Reset the system on board D1 with S1.

• Move the drive over the reference switch position several times to check.

Replacing reference switch S5 and potentiometer r5

Fig. 15: Transverse system_X_drive

• Switch the system on.

• Bring the orbital drive into approx. 0° position.

• Bring the Y drive into the mid-range position (basic system).

• Bring the shock wave head (W drive) into the park position.

• Select "unregulated motion" mode for the X drive.

• Move the unit carrier to the front far enough so that the front edge of the front plate is 23

mm ± 0.5 mm in front of the rail edge. ((Fig. 15 / p. 49))

• Replace reference switch S5 (refer to (b) Reference switches / p. 36)).

Check the potentiometer voltage for reference switch S5 = On; U

D5.X14 and 0V at D5.X30. ADC value = 780

NOTICE

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 3.900 V + 2 mV at

ref

= 5.120 V ±

ref

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 49 of 72

Page 50

50 Potentiometers and Reference Switches

Fig. 16: Switching hysteresis S5

After replacement or for potentiometer deviations:

• Replace the potentiometer according to (a) Potentiometers / p. 35).

• Reference switch is adjusted and closed.

• Loosen the set screw on potentiometer R5.

• Set the potentiometer value to ADC value = 780 by turning the adjustment wheel

((E/Fig.4/p.35)).

• Tighten the set screw.

• Reset board D1 with button S1.

• Check the switching hysteresis of reference switch S5 according to (Fig. 16 / p. 50) Fig.

9.

• Move to the front or back end positions in Uro mode.

- The safety limit switches S67/S66 must not be activated.

- Unit movement must stop at the front at +120 ± 2 mm and at the back at - 350 ± 2

mm.

(control monitor display).

• Move to the back end position in Litho mode (shock wave head in therapy position).

- The safety limit switch S78 must not respond

- Restricted unit movement must stop at - 30 ± 2 mm to the back.

(control monitor display).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 50 of 72

Medical Solutions

Page 51

Potentiometers and Reference Switches 51

C-arm orbital drive 0

Adjusting belt tension

• The adjustment of the belt tension is described in "Working on the orbital drive" (Work-

ing on the Orbital Drive / p. 63) in this manual.

Fig. 17: C_arm_orbital

Adjusting the S4 reference switch

(Prerequisite: potentiometer r4 functioning correctly)

• Switch the system on.

• Move the orbital drive in inching mode to the mechanical indicator "+ 30°" on the ser-

vice PC (Diagnostic, Monitoring); and the C-arm to the ADC position in 1/10 mm display to "+ 3000".

Fig. 18: Adjusting S4

• Adjust reference switch S4 so that switching is assured within the stated switching hys-

teresis tolerance range (refer to (Fig.5/p.36) and (Fig. 18 / p. 51)).

• Reset the system on board D1 with S1.

• Move the drive over the reference switch position several times to check.

Replacing reference switch S4 or potentiometer r4

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 51 of 72

Page 52

52 Potentiometers and Reference Switches

• Connect a DVM to D5.X13 (0 V an X30).

• Connect an oscilloscope to D5.X2.a7 (0 V toX40) ; 5 V/div, 0,1 s/div.

• Switch the system on.

• Bring the X drive and the Y drive into mid-range position.

• Bring the shock wave head (W drive) into the park position.

• Select "unregulated motion" mode for the O drive.

• Bring the arm into +30° position.

• Align the reference edge of the unit cover and the reference mark (arrow)

((Fig. 17 / p. 51)).

• Replace reference switch S4 (refer to (b) Reference switches / p. 36)).

• Check the potentiometer voltage for the reference switch S4 = On U

mV (D5.X13 0V = D5 X30) ADC value = 966

NOTICE

After replacement or for potentiometer deviations:

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 4.830 V ± 2

REF

= 5.120 V ±

ref

• If necessary, replace the potentiometer according to (a) Potentiometers / p. 35).

• Reference switch is adjusted and closed.

• Loosen the set screw on potentiometer R4.

• Set the potentiometer value to ADC value = 966 by turning the adjustment wheel

((E/Fig.4/p.35)).

• Tighten the set screw.

• Reset board D1 with button S1.

• Check the switching hysteresis of the reference switch S4 according to drawing

((Fig. 18 / p. 51)).

• Move to the +30° or -10° end position with the tableside control.

- The safety limit switches S70/S71 must not be activated.

- When the 0° position keys on the tableside control are activated, the orbital drive

moves into the vertical position (check the position indicated on the control monitor

and at the reference mark).

- Fluoroscopy is enabled in the + 30° / 0° / -10° positions.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 52 of 72

Medical Solutions

Page 53

Potentiometers and Reference Switches 53

Shock head mount W system 0

Adjusting belt tension

Fig. 19: Adjusting belt tension

• Move the W drive to the uppermost position.

• Switch the system off.

• Loosen the 4 fastening screws ((1/Fig. 19 / p. 53)) (two screws are not visible) and set a

value of 28 mm ((2/Fig. 19 / p. 53)) with the two adjustment screws ((3/Fig. 19 / p. 53)).

• Retighten the 4 mounting screws.

Adjusting reference switch S3 and potentiometer r3

• Switch the system on.

• Move the shock wave system into the therapy position.

• Attach the adjustment phantom (switch S28 has switched).

• Check the isocenter in the + 30 degree or - 10 degree position and, if necessary, adjust

according to the "Isocenter adjustment" instructions " RXL2-120.071.01....

(Perform only the work necessary for shock head replacement).

NOTICE

Isocenter

¹ The isocenter is the starting point for the adjustment of

the reference switch or of the actual value potentiometer.

• Adjust reference switch S3 so that switching is assured within the stated switching hys-

teresis tolerance range (refer to (Fig.5/p.36) and (Fig. 20 / p. 54)).

The shock wave head is located in the isocenter.

Replacing reference switch S3 and potentiometer r3

• Switch the system on.

• Bring the X drive and the Y drive into mid-range position (basic position)..

• Bring the orbital drive into +30°.

• Select "unregulated motion" mode for the W drive.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 53 of 72

Page 54

54 Potentiometers and Reference Switches

• Bring the shock head into the therapy position.

• Attach the adjustment phantom and adjust the isocenter (refer to Isocenter Adjustment

RXL2-120.071.01...)

• Replace reference switch S3 (refer to (b) Reference switches / p. 36)).

• Check the potentiometer voltage for reference switch S3 = ON; Uref = 4.770 V ± 2 mV

(D5.X12 0V = D5.X30) ADC value = 954.

NOTICE

Fig. 20: Replacing S3

After replacement or for potentiometer deviations:

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 5.120 V ±

ref

• If necessary, replace the potentiometer according to (a) Potentiometers / p. 35).

• Reference switch is adjusted and closed.

• The shock wave system is in the adjusted isocenter.

• Loosen the set screw on potentiometer R3.

• Set the potentiometer value to ADC value = 954 by turning the adjustment wheel

((E/Fig.4/p.35)).

• Tighten the set screw.

• Reset board D1 with button S1.

• Remove the adjustment device (switch S28 is open).

• Check the switching hysteresis of reference switch S3 according to (Fig. 20 / p. 54).

• Move to the "Coupling or park position" end positions.

- The safety limit switches S69/S68 must not be activated.

• Check the isocenter according to "Isocenter adjustment" RXL2-120.071.01....

• Check the Litho park position S79 (release of the X/Y travel range for Uro mode).

• Move to the park position of the W drive; contact S79 must be closed. If necessary,

check "Switch ON" with the DVM on board D32 X41 PIN 3 and at ground GND.

• Install the URO insert.

• Move to the basic →0← position.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 54 of 72

Medical Solutions

Page 55

Potentiometers and Reference Switches 55

• The system may now be moved outside the "Litho Position". (X = -130 / + 70; Y = ± 320)

• Safety limit switches S 76/77 as well as S 78 must not be activated.

(Refer to circuit diagram J1042-7).

• Remove the Uro insert and move to the →0← basic position.

The system will only allow travel in the "Litho Position".

• Move the W drive out of the park position.

Switch S79 must open in the MC position - 430 ± 2 mm and switches S 76; S77; S78

must be activated. If necessary, check "Switch ON" with the DVM on board D32 X41

PIN 3 and at ground GND.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 55 of 72

Page 56

56 Checking / Replacing the Lifting Columns R / L

5Checking / Replacing the Lifting Columns R / L

6-

Checking potentiometers r1/r2 and reference switches S1 and S25

• Connect an oscilloscope to D5.X2.a1/a3 (for S1/2) (0 V at X30); 5 V/div, 0.1s/div.

• Switch the system on.

• Install the Uro insert.

• Check the reference voltage, if necessary set it with R220 on D8. (U

mV; check on D5 MP X31, 0V at X30)

NOTICE

Changing the reference voltage

¹ When changing the reference voltage D5 U

5 mV, check the switching hysteresis for all drives.

= 5.120 V ± 5

ref

= 5.120 V ±

ref

• Connect a DVM to D5.X2.a2/a4 (0 V at X30).

• Check the functions of potentiometers R1/2.

• Perform the check in normal mode.

• Adjust the table height with the tableside control (NBF).

• Check the potentiometer voltage at reference switches S1/2 = "On" U

mV at D5.X10/X11 and 0 V at D5.X30. ADC value = 742

= 3.710 V ± 2

ref

0

• Check the switching hysteresis of the reference switch S1/2 according to

(Fig. 21 / p. 56).

Fig. 21: Switching hysteresis S1_S2

NOTE

It is not possible to adjust potentiometers r1/r2 or reference

switches S1/S2. The corresponding lifting column must be replaced if there are defects or malfunctions.

• Move the system into the basic position→0← with the tableside control.

• The position indicator on the control monitor will display the value "1033". Check this

with the service PC (MC position) in 1/10 mm (display "10330" / control monitor Z =

1033).

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 56 of 72

Medical Solutions

Page 57

Checking / Replacing the Lifting Columns R / L 57

Fig. 22: Lifting column

Preliminary

remarks:

NOTICE

Fig. 23: Removing cover

To avoid replacing the lifting columns unnecessarily, troubleshoot

thoroughly and localize errors accurately.

Removing the lifting column

¹ When removing the lifting column, use a support

(wooden plank) approx. 80 cm to 95 cm high and with a

load capacity of approx. 40 kg to support the tabletop.

The engineer must obtain this item locally.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions

09.05 CS PS 24

Page 57 of 72

Page 58

58 Checking / Replacing the Lifting Columns R / L

Preparation 0

• Switch on the system and install the Uro insert.

• Loosen the four cover screws of the front, gray base frame cover and pull the plate out

to the side (refer to (Fig. 23 / p. 57)).

• Move the unit into the left or right end position. Disconnect the L/R cables of the lifting

columns from the cable harness in the base frame.

• Move the tabletop to the max. height.

• Remove the table extensions.

• Remove all covers of the lifting column affected ((Fig. 22 / p. 57))

• Remove the holding brackets of the covers by removing the screws.

• Unscrew the holder of the energy chain on the left lifting column.

• To remove the tabletop, push the support (wood plank) between the base frame and ta-

ble.

• Slowly move the table down onto this support until the weight is taken off the column.

NOTICE

Lifting column

¹ Do not retract the lifting column any further after lower-

ing the table onto the support.

• Switch the system off.

• Remove the 4 M8 Allen screws at the top of the column being replaced.

• Disconnect the plug for the power supply to the motor on the column that is not being

replaced.

• Switch the system on.

• Select "unregulated motion" with System-Logon-Adjustment-Calibration " as per the

"Operating the Service Software" instructions RXL2-120.113.01....

• Select the lifting column drive ZR or ZL.

NOTICE

Danger of collision!

¹ The system is now in "unregulated operation". The

movement sequences and the unit movements are no

longer monitored. Use caution to prevent collision hazards.

• Retract the column using the "Table down" button on the tableside control panel.

• Switch the system off.

LITHOSTAR Multiline RXL2-120.841.02.01.02 Siemens AG

09.05 CS PS 24

Page 58 of 72

Medical Solutions

Page 59

Checking / Replacing the Lifting Columns R / L 59

Removing the lifting column 0

• Disconnect the plug from the actual value acquisition of the lifting columns (board D31

X10/ X11).

• Disconnect the motor power supply plug.

• Unlock and remove the motor encoder plug.

Fig. 24: Allen_screws_A

• Turn the lifting column drive shaft by hand until the Allen screws of the drive shaft are

accessible from above ((Fig. 24 / p. 59)).

• Remove the 2.5 mm Allen set screws ((1/Fig. 24 / p. 59) and (1/Fig. 25 / p. 59)).

If necessary, remove "Loctite" using a heat gun.

• Remove the mounting screws on the base of the lifting column (Fig. 4) and remove the

column.

NOTE

• Remove the drive shaft bearing to replace the cables ((Fig. 26 / p. 60)).

• Remove the strain relief on the two cables for the lifting column.

• Remove the mounting screws on the base of the lifting column ((Fig. 24 / p. 59)) and re-

move the column.

Fig. 25: Allen_screws_B

Ensure that the encoder on the motor shaft does not become damaged.

Siemens AG RXL2-120.841.02.01.02 LITHOSTAR Multiline

Medical Solutions