Page 1

LITHOSTAR Multiline

System

Installation Instructions

SP

for Subcontractors and Siemens Technicians

© Siemens AG 2004

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

English

Print No.: RXL2-120.812.01.02.02 Doc. Gen. Date: 10.04

Replaces: RXL2-120.812.01.01.02

Page 2

0 - 2 Revision

Chapter Page Revision

all all 02

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery.

Revisions to hardcop y documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempting installation or service procedures.

LITHOSTAR Multiline RXL2-120.812.01 Page 2 of 4 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 3

Contents 0 - 3

Page

1 _______General Remarks_______________________________________________ 1 - 1

Items included in the Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Text Emphasis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Replacement of damaged or Lost Screws . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Yellow enameled Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Test Equipment and Tools (Service Tools Cataloque). . . . . . . . . . . . . . . . . .1 - 2

Installation auxiliary devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

2 _______System Installation _____________________________________________2 - 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Preinstallation work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Options: Monitor trolley and/or Patient monitor . . . . . . . . . . . . . . . . . . . 2 - 1

Polydoros LX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Polydoros SX 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Installing and Connecting the High Voltage Charger . . . . . . . . . . . . . . . . . . 2 - 3

Installing and Connecting the Cooling Unit . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Setting Up the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Installing the Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Installing the Components for the System Controller . . . . . . . . . . . . . . . . . .2 - 9

Setting Up the Console Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Positioning/Connecting the Monitors . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Positioning the Keyboard and the PC Mouse . . . . . . . . . . . . . . . . . . . .2 - 9

Connecting the Footswitch, Tableside Control Console,

Shock Wave Trigger Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Back panel of the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Positioning/Connecting the Operating System Unit (PC) . . . . . . . . . . . . . 2 - 10

Cover the cable outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Positioning/Connecting DICOM Connect (Option). . . . . . . . . . . . . . . . . 2 - 10

Positioning/Connecting the Multiformat Camera (Option) . . . . . . . . . . . . . 2 - 11

Positioning/Connecting the Diamentors (Option) . . . . . . . . . . . . . . . . . 2 - 11

Installing the TV camera on the 23" I.I. . . . . . . . . . . . . . . . . . . . . . . . . 2 - 12

Installing the TV camera on the 33" I.I. . . . . . . . . . . . . . . . . . . . . . . . . 2 - 12

Checking the temperature of the image intensifier . . . . . . . . . . . . . . . . . . 2 - 12

Installing the Collimator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 13

Installing the Diamentor (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 13

3 _______Connections with POLYDOROS LX 30 _____________________________3 - 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Connections and cable locations in the A12 electronics cabinet . . . . . . . . . . . . 3 - 2

Siemens AG RXL2-120.812.01 Page 3 of 4 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 4

0 - 4 Contents

Page

Connections/cable locations in the generator cabinet (Part A) . . . . . . . . . . . . . 3 - 3

Connections of the options and their cable locations in the A12

electronics cabinet and generator AC . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Connections and cable locations in the A12 electronics cabinet

and in the control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Connections/cable locations in the A13 shock wave cabinet. . . . . . . . . . . . . .3 - 11

Connections/Cable Locations in the Generator Cabinet (Part. B) . . . . . . . . . . .3 - 13

Connections/harness locations in the generator cabinet (Part C) . . . . . . . . . . .3 - 16

Fastening of plug, Sonoline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 20

4 ______ Connections with POLYDOROS SX 65 _____________________________4 - 1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Connections and cable locations in the A12 electronics cabinet. . . . . . . . . . . . 4 - 2

Overview of cable run in the power cabinet . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Connections/harness locations in the generator cabinet (Part A) . . . . . . . . . . . 4 - 4

Connections of the options and their cable positions in the A12

electronics cabinet and generator AC . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Connections and cable locations in the A12 electronics cabinet

and in the control console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Connections/cable locations in the A13 shock wave cabinet. . . . . . . . . . . . . .4 - 11

Overview of cable run in the power cabinet . . . . . . . . . . . . . . . . . . . . . .4 - 13

Connections/cable locations in the generator cabinet . . . . . . . . . . . . . . . . .4 - 14

Overview of cable run in the power cabinet . . . . . . . . . . . . . . . . . . . . . .4 - 18

Connections/harness locations in the generator cabinet (Part C) . . . . . . . . . . .4 - 19

Monitoring devices and indicators for radiation protection . . . . . . . . . . . . . . .4 - 20

Fastening of plug, Sonoline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 24

5 ______ Final Work Steps _______________________________________________5 - 1

Attaching the remaining panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Adapting the Other Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

6 ______ Changes to previous version _____________________________________6 - 1

LITHOSTAR Multiline RXL2-120.812.01 Page 4 of 4 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 5

General Remarks 1

Items included in the Shipment 1

The system was prestaged, tested and programmed in the factory with all components.

System start-up and the function checks required should be performed in accordance with

Start-up Instructions, RXL2-120.034.01.

The system is operational once installation and start-up have been completed.

The system is shipped in the following sections:

• LITHOSTAR Multiline - basic unit.

• Generator power unit cabinet, equipped with components and boards.

• H1 HF high voltage transformer.

• Two standard cabinets.

• Control console.

• Accessories/cover panels.

Requirements 1

- The preinstallation work steps must have been completed in accordance with Planning

Guide (PG) RXL2-120.021.01.

- Prior to the installation, the power line connection must be completed and provided

with a system breaker, an emergency OFF switch, and ground fault detector as

specified in the Planning Guide (PG) RXL2-120.021.01.

- The hardware for mounting the unit to the floor (Liebig expansion bolts /mounting plate)

must be installed per Installation Instructions RXL2-120.038.01...

- The condition of the access route within the building, as well as the condition of the

room in which the unit is to be installed, must be in compliance with the project

drawings and the data listed under the ”General Installation and Conditions of

Shipment - Med. Technology Division”.

1 - 1

Text Emphasis 1

• ”Cautions” are information provided with special emphasis when there is the potential

for damage to the equipment.

• ”Notices” are information provided with special emphasis to facilitate proper use of the

equipment or proper execution of a procedure.

• All texts referring to adjustments or installation steps marked with symbol” ” have to

be confirmed by the subcontractor or the Siemens engineer in the installation protocol

(register 3 of logbook).

p

Replacement of damaged or Lost Screws 1

• Damaged or lost screws may be replaced only with steel screws which meet the

requirements of DIN 267 and must be rated in the specified hardness class.

• All Allen screws used must be classified as hardness class 8.8.

Siemens AG RXL2-120.812.01 Page 1 of 4 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 6

1 - 2 General Remarks

Safety notes 1

• The general safety notes for medical products must be observed in the performance of

work and checks.

Yellow enameled Parts 1

• All parts of the unit and of components that are painted with yellow/red enamel are

shipping brackets which may be removed only in accordance with the Installation

Instructions.

Test Equipment and Tools (Service Tools Cataloque) 1

• Tool kit for Installation engineers

• Torque wrench (20 to 100 Nm)

• Digital Multimeter

Installation auxiliary devices 1

Transport carr iage roller set 11 53 654 G5338

The roller set must be ordered if the system

is not installed by the "Erlangen carrier".

Materials 1

• Loctite 221 20 48 874 RV090

• Oil f or high voltage transf ormer H1

for refilling only , if required

99 00 952

LITHOSTAR Multiline RXL2-120.812.01 Page 2 of 4 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 7

General Remarks 1 - 3

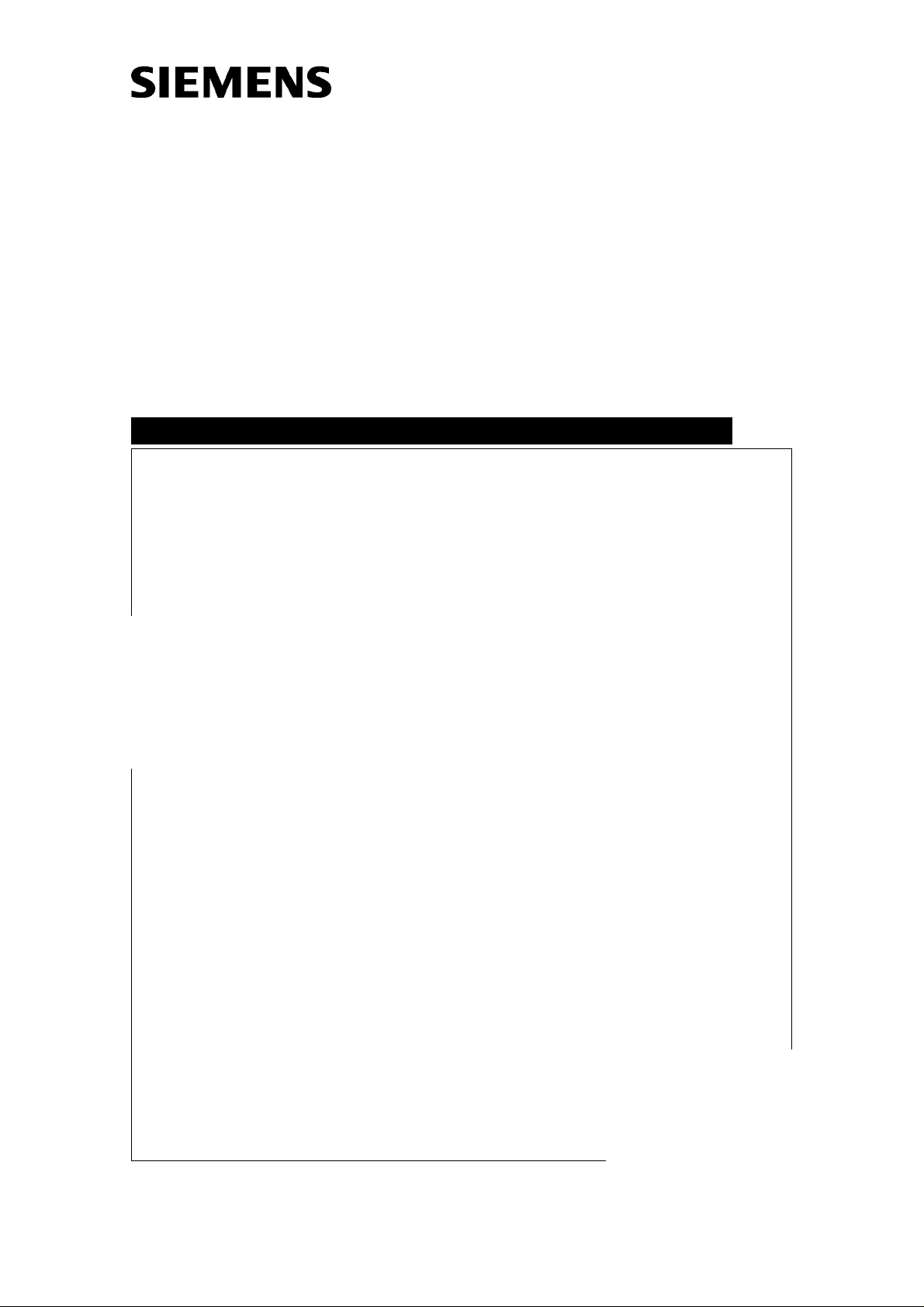

Component Overview 1

SC

3rd Monitor (Option)

PCMonitor

DICOM

Monitor

(Option)

Patient monitor

(Option)

Monitor I + II

Ultrasound unit

(Option)

Operating

system

unit

Multispot

or DICOM

Connect

(Options)

Diamentor

(Option)

Polydoros LX

AC

”HPE”

charger

N12

Shock

wave

controller

Cooling

unit

Water

prepara-

tion

A13

VIDEO-

MED

-DIM-

Image

storage

N11

System

controller

M16

Power

supply

A12

Siemens AG RXL2-120.812.01 Page 3 of 4 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 8

1 - 4 General Remarks

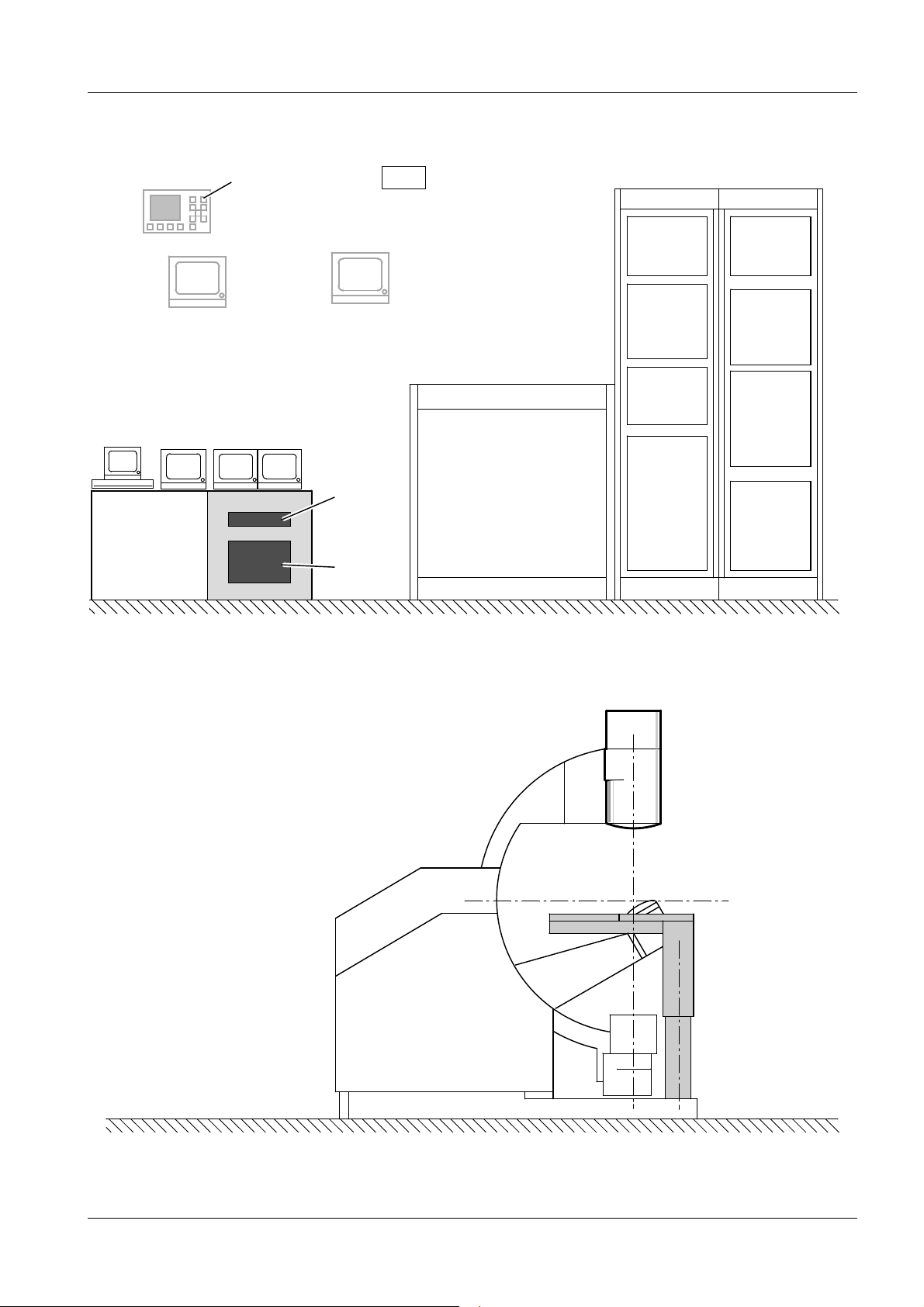

Component Overview 1

SC

3rd Monitor (Option)

PCMonitor

DICOM

Monitor

(Option)

Patient monitor

(Option)

Monitor I + II

Ultrasound unit

(Option)

Operating

system

unit

Multispot

or DICOM

Connect

(Options)

Diamentor

(Option)

Polydoros SX

AC

”HPE”

charger

N12

Shock

wave

controller

Cooling

unit

Water

prepara-

tion

A13

VIDEO-

MED

-DIM-

Image

storage

N11

System

controller

M16

Power

supply

A12

LITHOSTAR Multiline RXL2-120.812.01 Page 4 of 4 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 9

System Installation 2

Preparation 2

Preinstallation work 2

2 - 1

p

p

p

p

• Check the condition of the table installation plate (floor plate).

• Check the cable feed-throughs for cabinets, system control console, and the unit for

usability.

Options: Monitor trolley and/or Patient monitor 2

• Check the cable feed-throughs for the Patient monitor for usability.

• Make sure that there is sufficient space for a Patient monitor.

Siemens AG RXL2-120.812.01 Page 1 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

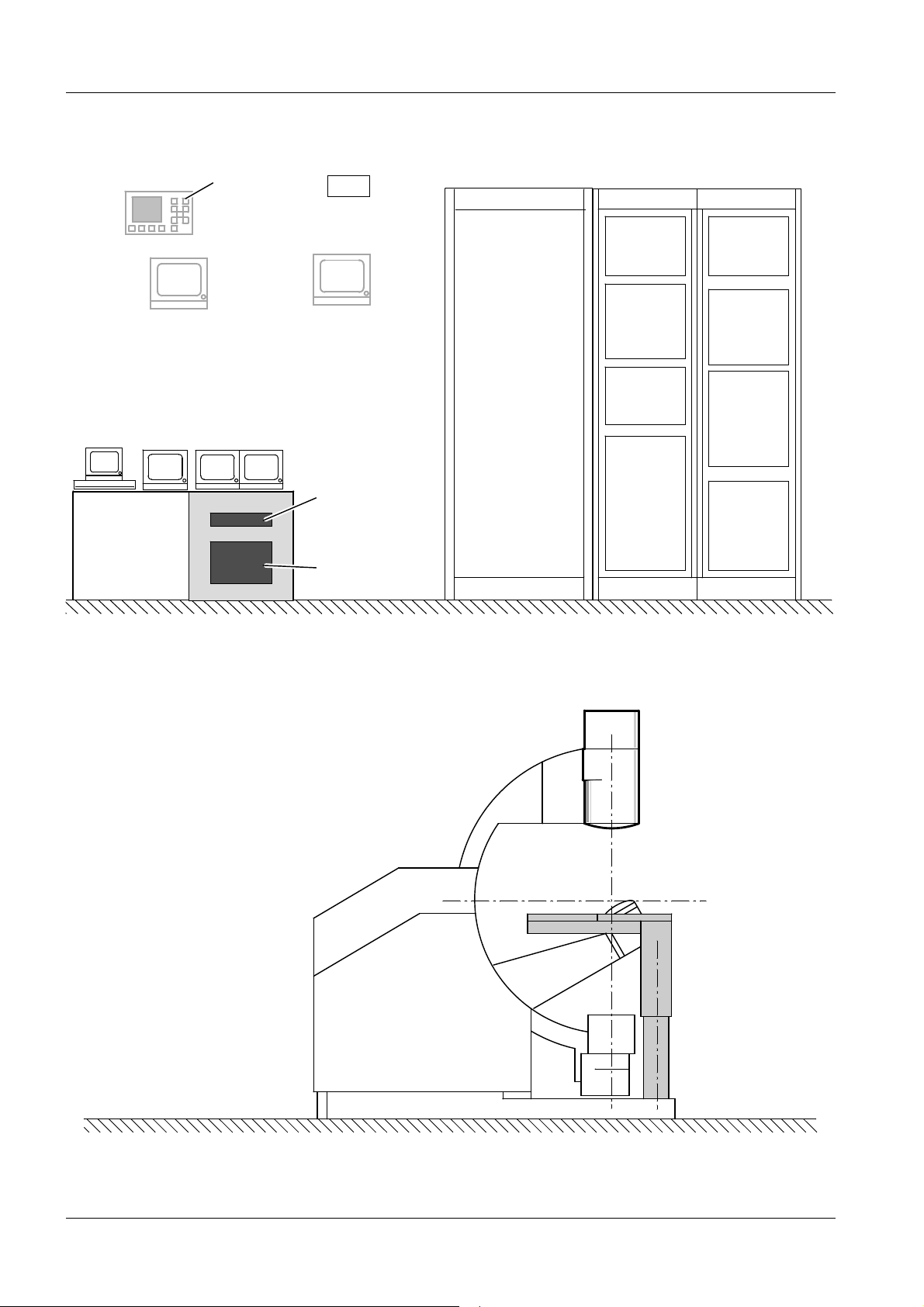

Page 10

2 - 2 System Installation

Cable lead-in

(on both sides)

Polydoros

SX 65

N12

N11

Polydoros

LX 30

M16

Mounting holes

AC

Fig. 1 Fig. 2

A13

A12

Cable lead-in from below

Generator and Cabinet Installation

Hand grip indentations

(on both sides)

2

Cable

lead-in from

the back

NOTICE

Do not insert the H1 high-voltage transformer until the generator

is cabled in the power cabinet.

With the exception of the cooling unit and the high voltage charger, the cabinets are

shipped from the factory completely assembled and are individually crated.

We recommend setting up and bolting down the generator according to the project plan or

Figure 1 before installing the remaining cabinets.

Polydoros LX 2

• Mark on the floor and drill the four mounting holes for the generator cabinet at its

intended location using the supplied template.

• Drill the holes and insert the Liebig anchors that are included in the shipment (Fig. 2).

• Remove all transport safety brackets from the generator.

• Take the generator off the pallet.

• If necessary, knock out the cable inlet in the generator cabinet for interconnections with

the adjacent cabinet. Install the edge protection strip (service package).

• Mount the generator in place b y inserting the 4 hex bolts into the Liebig screw anchors.

LITHOSTAR Multiline RXL2-120.812.01 Page 2 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 11

System Installation 2 - 3

1

4

2

Fig. 3

3

Polydoros SX 65 2

• Move the power cabinet into its location.

• Attach the top of the cabinet to the wall with retaining brackets to prevent the cabinet

from tilting.

p

• If required, the cabinet can also be bolted to the floor.

• If required, remove the cover for the corresponding cable inlet on the generator cabinet.

• Mov e cabinets A12 and A13 to their location according to the project plan or the above

example (Fig. 1).

• The splash guard has to be installed between the control cabinet A 12 and the shoc k

wave cabinet A13. If necessary , turn it around.

• Install the side walls of the cabinets.

• Within the scope of validity of the UL regulations (e.g. USA) the metal case should not be

removed due to fire protection.

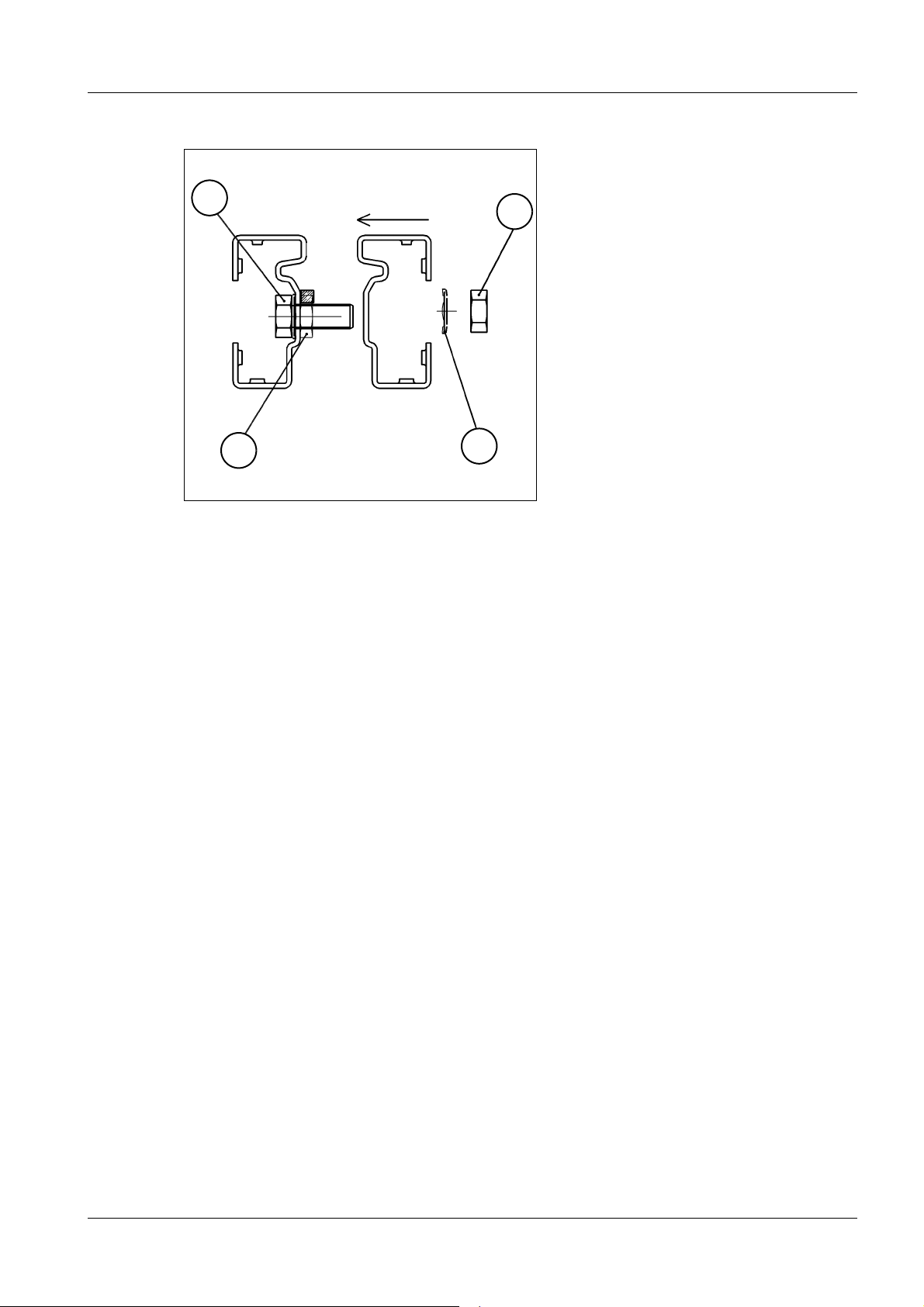

• Install the enclosed screw (1/Fig. 3) with nut (2/Fig. 3) to a cabinet to connect the cabinet.

Then move the second cabinet to its position and tighten with nut (4/Fig. 3) and flat

washer (3/Fig. 3).

• Move the cabinets to their final position and bolt them to the wall and the floor.

Installing and Connecting the High Voltage Charger 2

• Unpack the charging unit, place it on the rails provided in the shock wave cabinet above

the electronics unit N12 and secure it on the front using 4 screws.

• Connect the power line cable at N12 (1 on L1, 2 on N and ge/gn on PE).

• Plug in the cable from the N12, K108 to the charger controller on the charger.

Siemens AG RXL2-120.812.01 Page 3 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 12

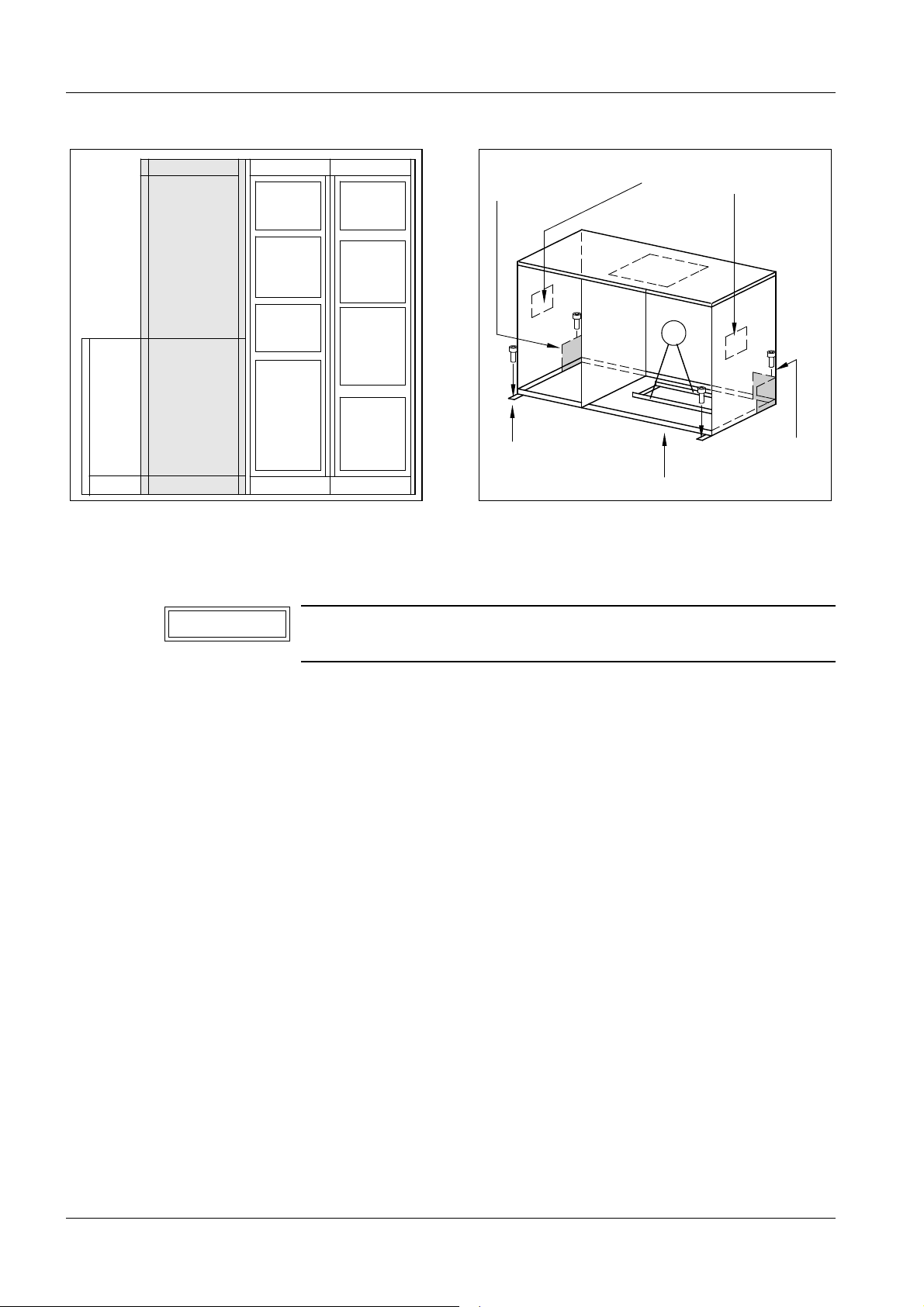

2 - 4 System Installation

a

ca. 1200

ca. 2300

b

ca. 1100

ca. 2400

2

Fig. 4 Fig. 5

c

ca. 1100

ca. 2620

Installing and Connecting the Cooling Unit 2

• Place the cooling system on the rails provided in the shock wave cabinet A13 (under the

N12 electronics unit), slide it into position and secure it on the front using two screws.

• Insert the hoses in the appropriate connections according to marking, and ensure that

they lock into position.

• Plug the power line connector for the cooling system into the socket on the electronics

unit at N12.X3.

• Connect the protective conductor between the cooling system and the shock wave

cabinet.

CAUTION

To avoid the risk of excessive heat build-up, make sure that the

ventilation inside and outside the cabinet is always sufficient.

Setting Up the Unit 2

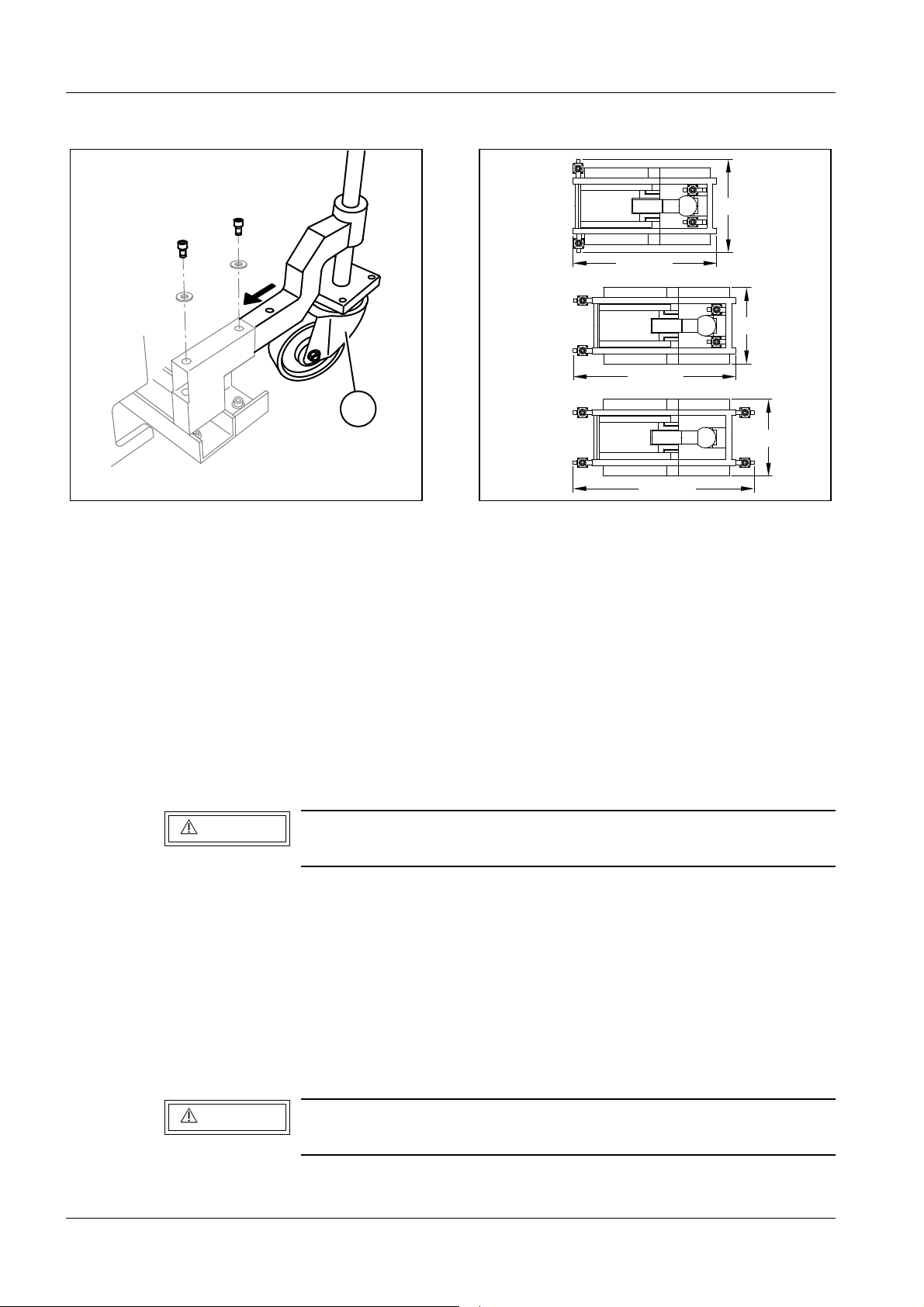

• Place the four transport rollers (2/Fig. 4) onto the transport carriage on the yellow

shipping frame at (c/Fig. 5) and bolt them in place.

• Remove the shipping pallet from the unit.

Lift the unit with the help of the spindles and pull the transportation pallets out to the side.

• Depending on the dimensions of the transport route, it may be necessary to reposition

the rollers on the carriage (Pos. a or b in Fig. 5) and bolt them in place.

For this reason, the unit should be lowered on an appropriate wooden base.

CAUTION

When lowering the unit, the cable harnesses must not be damaged.

• Move the unit to its installation location and place it next to the mounting plate.

LITHOSTAR Multiline RXL2-120.812.01 Page 4 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 13

System Installation 2 - 5

Fig. 6 Fig. 7

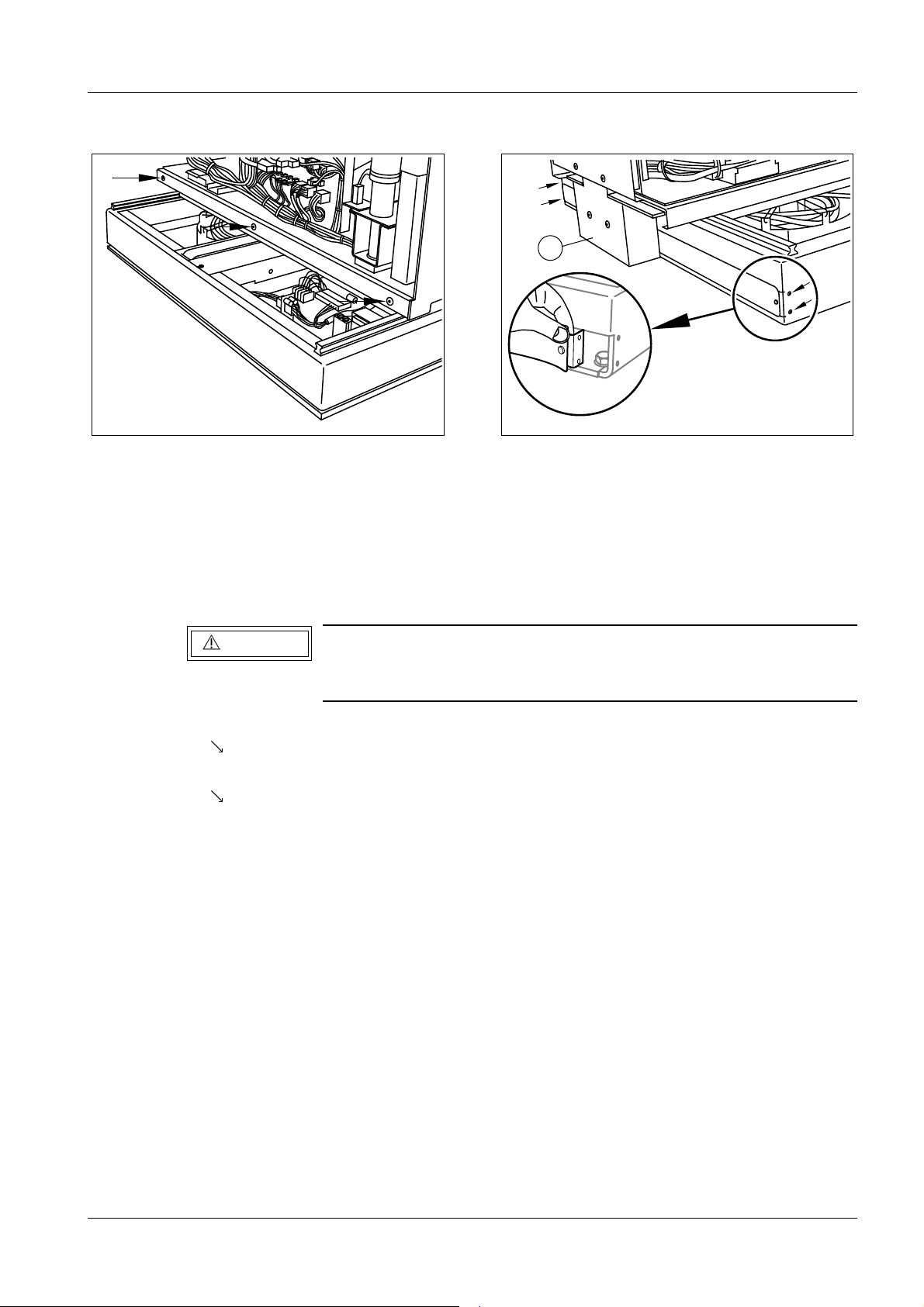

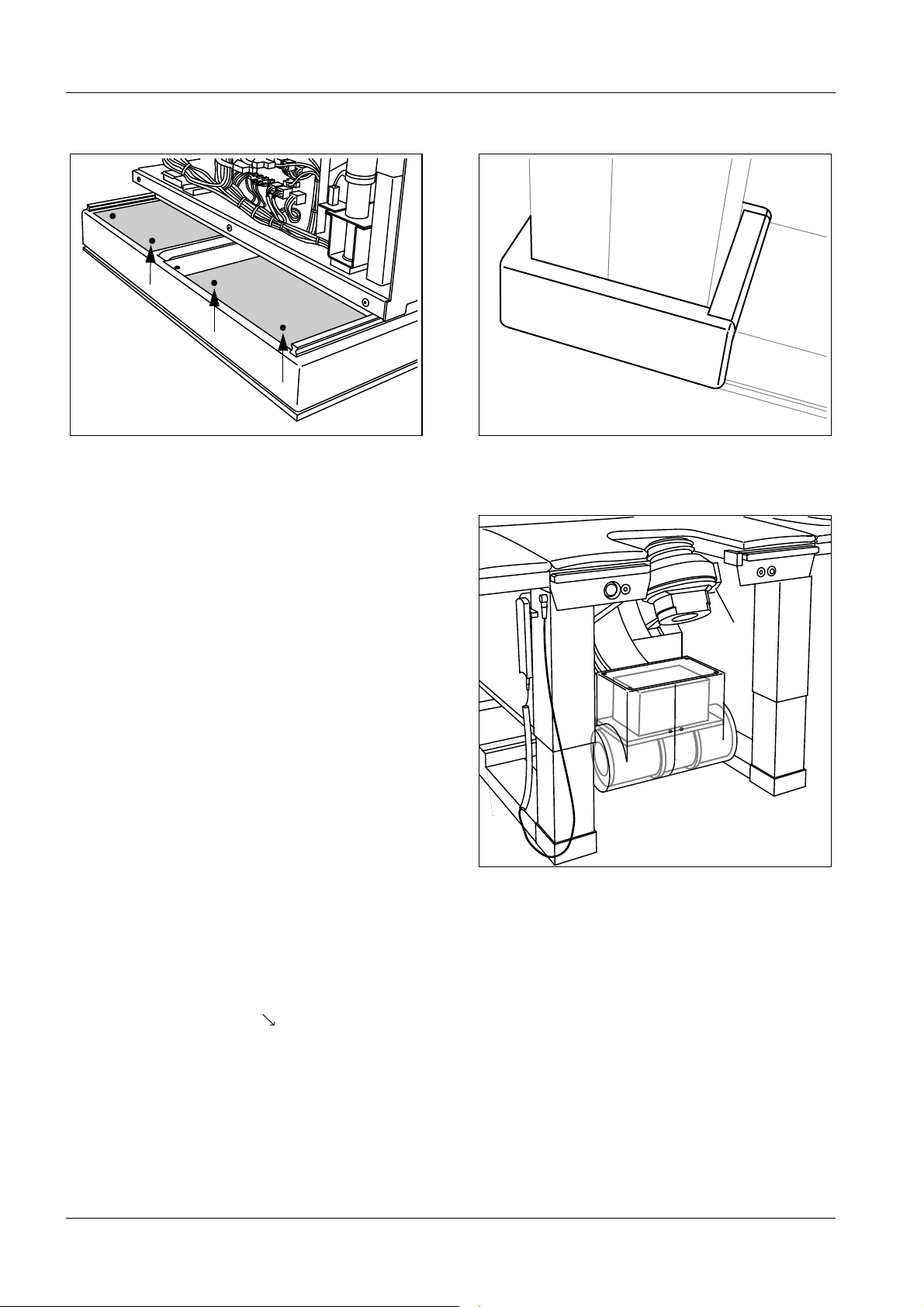

• Put the insulation plates on top of the thoroughly cleaned mounting plate (Fig. 6)

(the drill holes for the equipment must not be covered).

• Uncoil the four cable harnesses that are permanently connected to the unit and lay them

out (Fig. 7).

• Guide the free ends of the cable harnesses into the opening in the mounting plate, and

into the corresponding cabinets via the cable conduits.

NOTICE

The cable harnesses are color-coded:

- blue for the shock wave cabinet

- green for the control cabinet

- yellow for the generator

The correspondingly color-coded target connections are located

in the cabinets.

Siemens AG RXL2-120.812.01 Page 5 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 14

2 - 6 System Installation

8 x

4 x

Fig. 8 Fig. 9

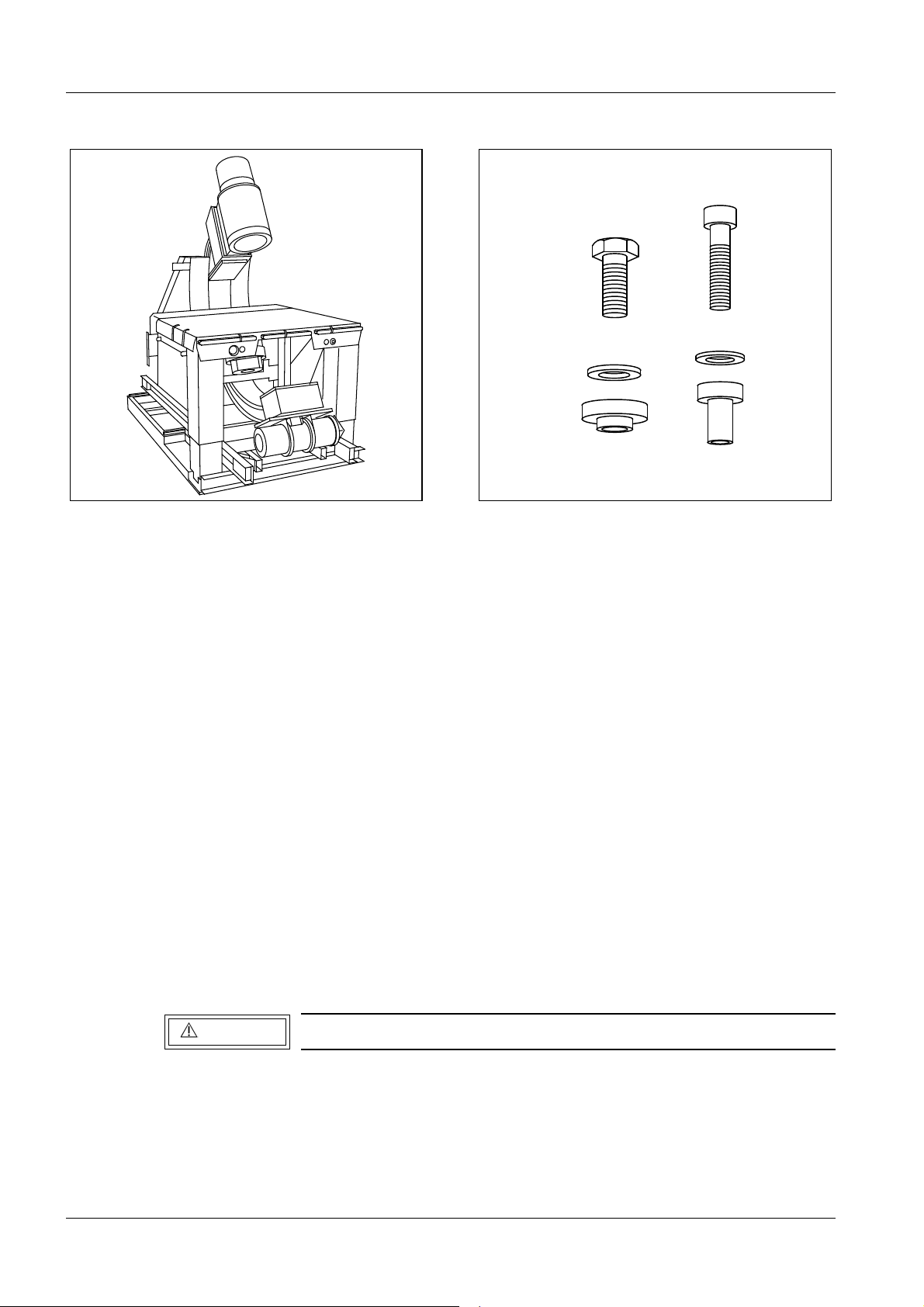

• Move the unit so that it is positioned correctly over the mounting plate and so that it is

level i.e., lower all four transport rollers evenly (Fig. 8).

• Mount the unit using 12 bolts and insulating sleeves on the floor. Apply Loctite 221 on the

bolt threads to secure them (Fig. 9):

- 8x Recessed socket head M 8 x 4 tighten to 24 Nm, ± 10%

- 4x Hex head M10 x 25

(The bolts are contained in the box with service materials.)

• Remove the entire transport device.

• Remove the yellow shipping brackets on the W-drive.

• Measure the resistance to ensure that the unit is electrically isolated on the mounting

plate.

• Carefully feed through the cable harnesses. Store any excess cable lengths. Roll them

up without kinks.

Do not place any excess cable or cable loops in the unit frame, since they may come into

contact with the moving energy chain and become damaged.

Do not block the movement of the energy chain.

CAUTION

Excess cable lengths may not be stored in the cabinets.

• Remove the transport safety bracket from the I.I. collision protection.

LITHOSTAR Multiline RXL2-120.812.01 Page 6 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 15

System Installation 2 - 7

K

Fig. 10 Fig. 11

Installing the Covers 2

For all visible surfaces, special paneling screws with 2.5 Allen sockets have been provided.

• The required scre ws and washers are already counted out and packed in plastic bags.

CAUTION

Before installing the covers, connect eac h metal co ver to gr ound;

the connections are provided in the unit and on the cover panels

themselves.

• Secure the two lateral strips on the unit base frame with three paneling screws for each

( /Fig. 10).

• Install the rear metal roll-down sash in the unit base frame on the left and the right

( /Fig. 11); for this, the mounting brackets must be installed on the inside of the frame.

• Attach the cover (K/Fig. 11) for the cable routing using two paneling screws.

Siemens AG RXL2-120.812.01 Page 7 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 16

2 - 8 System Installation

Fig. 12 Fig. 13

A

B

Fig. 14

• At this point you have to route the SONOLINE cables (see chapter 3, page 18 or

chapter 4, page 22) if the ultrasound option is being installed.

• Insert the two-part base frame cover and mount it in place using four paneling screws for

each part ( /Fig. 12).

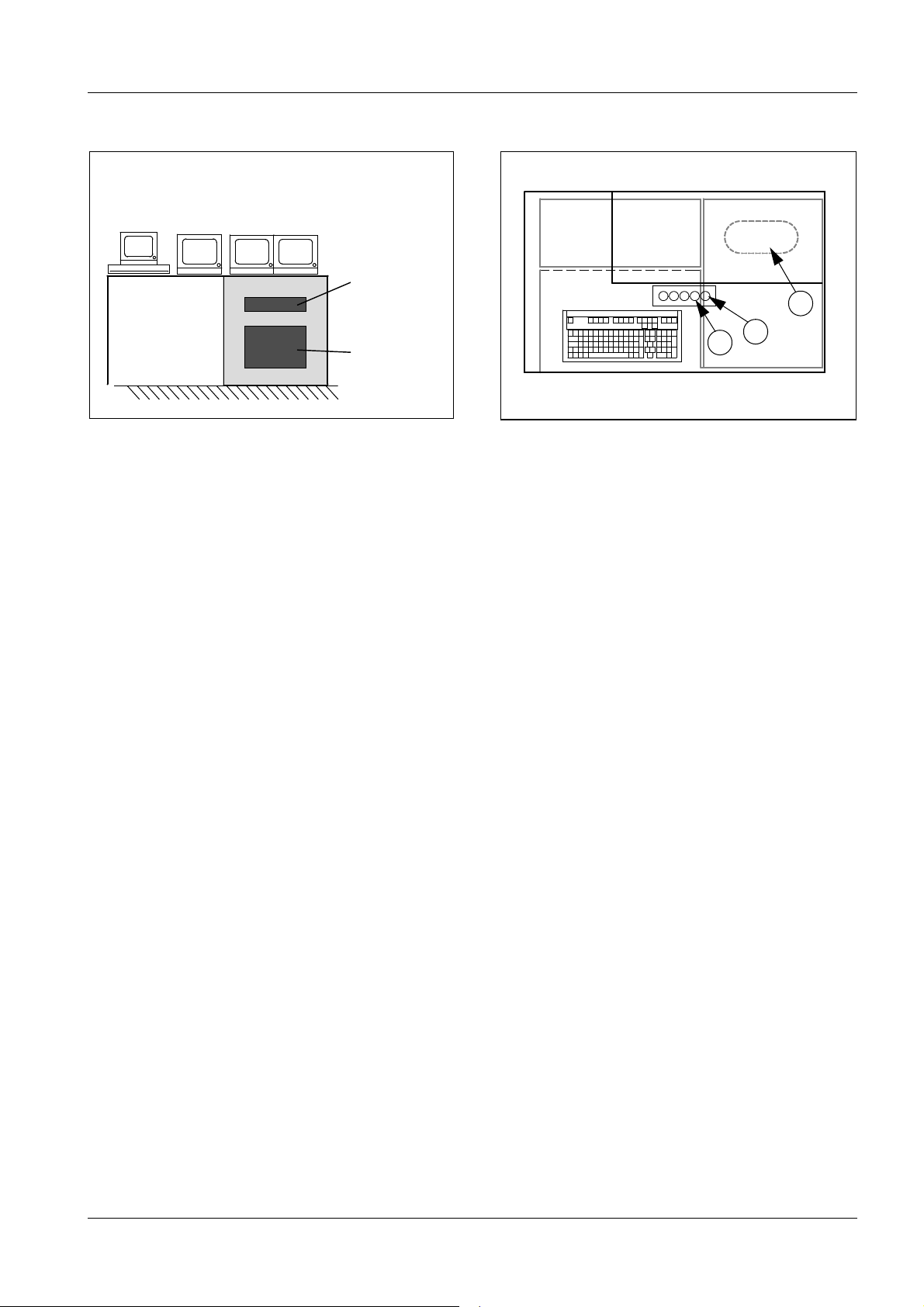

• Install the kick plates on both table legs and fasten them together (Fig. 13).

• Attach the paneling to the underside of the shock head support (A/Fig.14).

• In the front section of the base frame (B/Fig. 14), use black plastic plugs to seal the two

holes for mounting the transport carriage.

LITHOSTAR Multiline RXL2-120.812.01 Page 8 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 17

System Installation 2 - 9

PCMonitor

Fig. 15 Fig. 16

DICOM

Monitor

(Option)

Monitor I + II

Operating

system

unit

Multispot

or DICOM

Connect

(Options)

Installing the Components for the System Controller 2

Setting Up the Console Table 2

The cable outlet (A/Fig. 16) is set up at the factory for downward cable feed-through.

However, it is possible to route the cables to the back by punching out one of the perforated openings.

p

• Route the cable from the control console table to the control cabinet.

A

C

B

• If the Diamentor option is present, route the Diamentor cable from the electronics cabinet

to the console table.

Positioning/Connecting the Monitors 2

• Place the monitors on the control console table as shown in Fig. 15 and connect them

per their designations.

Positioning the Keyboard and the PC Mouse 2

• Place the keyboard and the PC mouse on the control console table.

• Connect the cable to the keyboard.

Connecting the Footswitch, Tableside Control Console, Shock Wave Trigger Mechanism 2

• Connect the tableside control without the holder (optional) (B/Fig. 16) and the (C/Fig. 16)

shock wave release control to the console table.

• Connect the footswitch for fluoroscopy (optional) either to the console table or to the unit:

- Right back panel of the unit,

- Under the foot support at the control console table.

• Connect the tableside control with the holder to the unit.

• Connect the unit footswitch (optional) on the right in back of the unit.

Siemens AG RXL2-120.812.01 Page 9 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 18

2 - 10 System Installation

1 Keyboard port

X51

7

2

4

2 Mouse port

4 Monitor power line connector

6 Monitor port

7 Power line connector

X50 Respirator-ECG signal interface

X51 DUEP port

X50

LM - Control Unit

Fig. 17

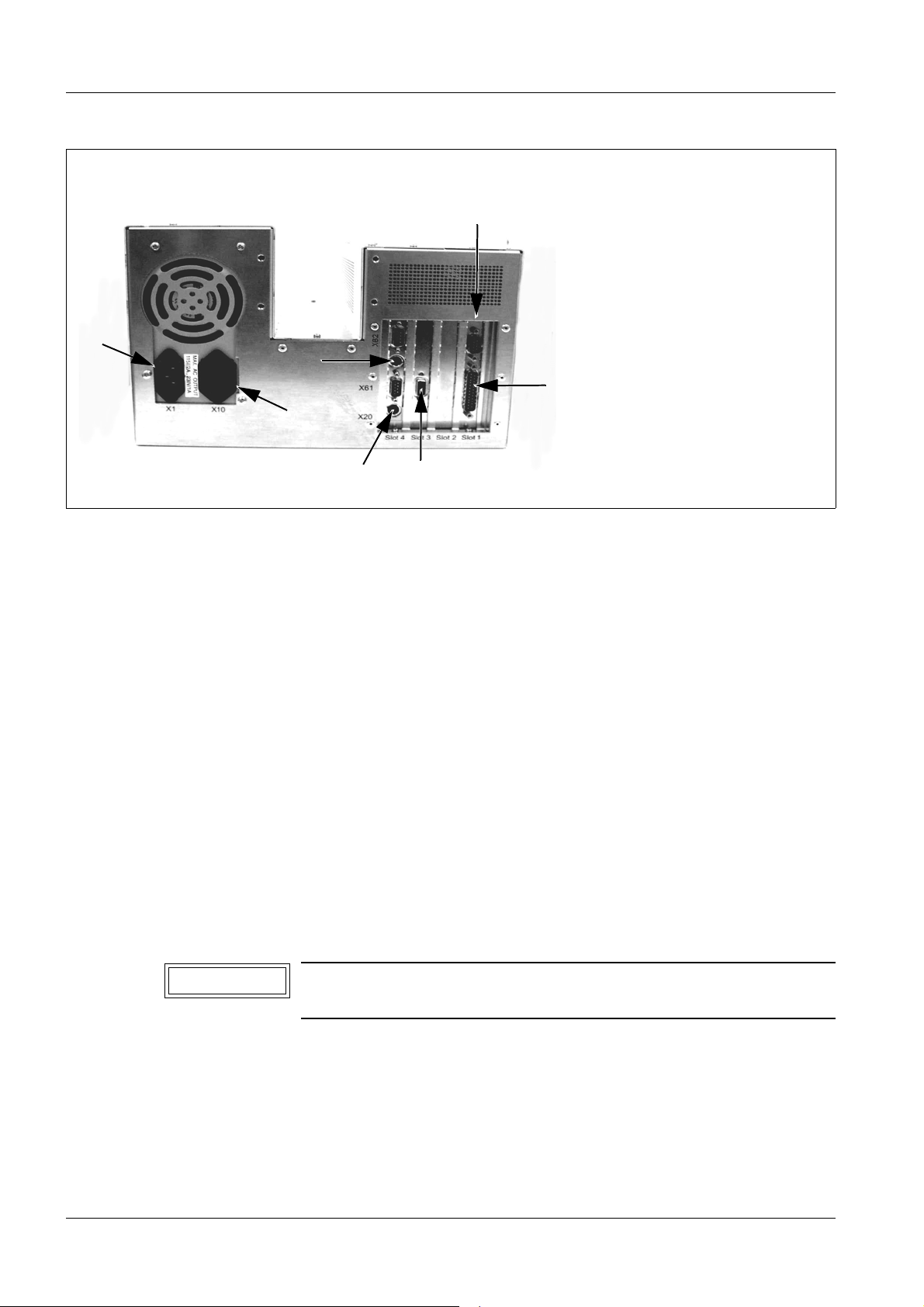

Back panel of the PC 2

Positioning/Connecting the Operating System Unit (PC) 2

• Open the door on the console table and pull out the PC slide-out shelf.

• Position the operating system unit on PC slide-out shelf and secure it from below.

• Connect the cables for the mouse, the keyboard, the monitors and the DUEP cable at the

• Connect the power line cable to the operating system unit.

• Insert the slide-out shelf. Pay attention to the cable routing in the console.

Cover the cable outlet 2

• In areas where UL regulations apply,(e.g. USA) you must cover the cable outlet with the

Positioning/Connecting DICOM Connect (Option) 2

1

PC (Fig. 17).

extra aluminum sheet located in the operating console as fire protection.

6

• Perform installation and startup according to the manual RXL2-120.814.02..

NOTICE

LITHOSTAR Multiline RXL2-120.812.01 Page 10 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

DICOM can be built into the LITHOSTAR Multiline only if no

MULTISPOT is installed.

Page 19

System Installation 2 - 11

Positioning/Connecting the Multiformat Camera (Option) 2

• Connect the Multispot per the designations and place it on the console table as shown in

Fig.15 and tighten the screws. The cables can be found in the console table (power,

video, control cable).

NOTICE

The two Allen screws in the base of the Multispot have to extend

into the drilled holes of the intermediate plate in the operating

cabinet. Depending on the customer's request, the drilled holes

on the front or on the back can be used.

Positioning/Connecting the Diamentors (Option) 2

• Plug the power cable into the multiple socket outlet of the console desk (slide-out-shelf).

• Lead the cable up through the free opening.

• Connect the cable routed from the measuring chamber of the Diamentor via the adapter

cable supplied.

• Connect the cable routed from power supply unit at the Diamentor.

• Position the Diamentor on the console desk.

Siemens AG RXL2-120.812.01 Page 11 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 20

2 - 12 System Installation

2

1

Fig. 18

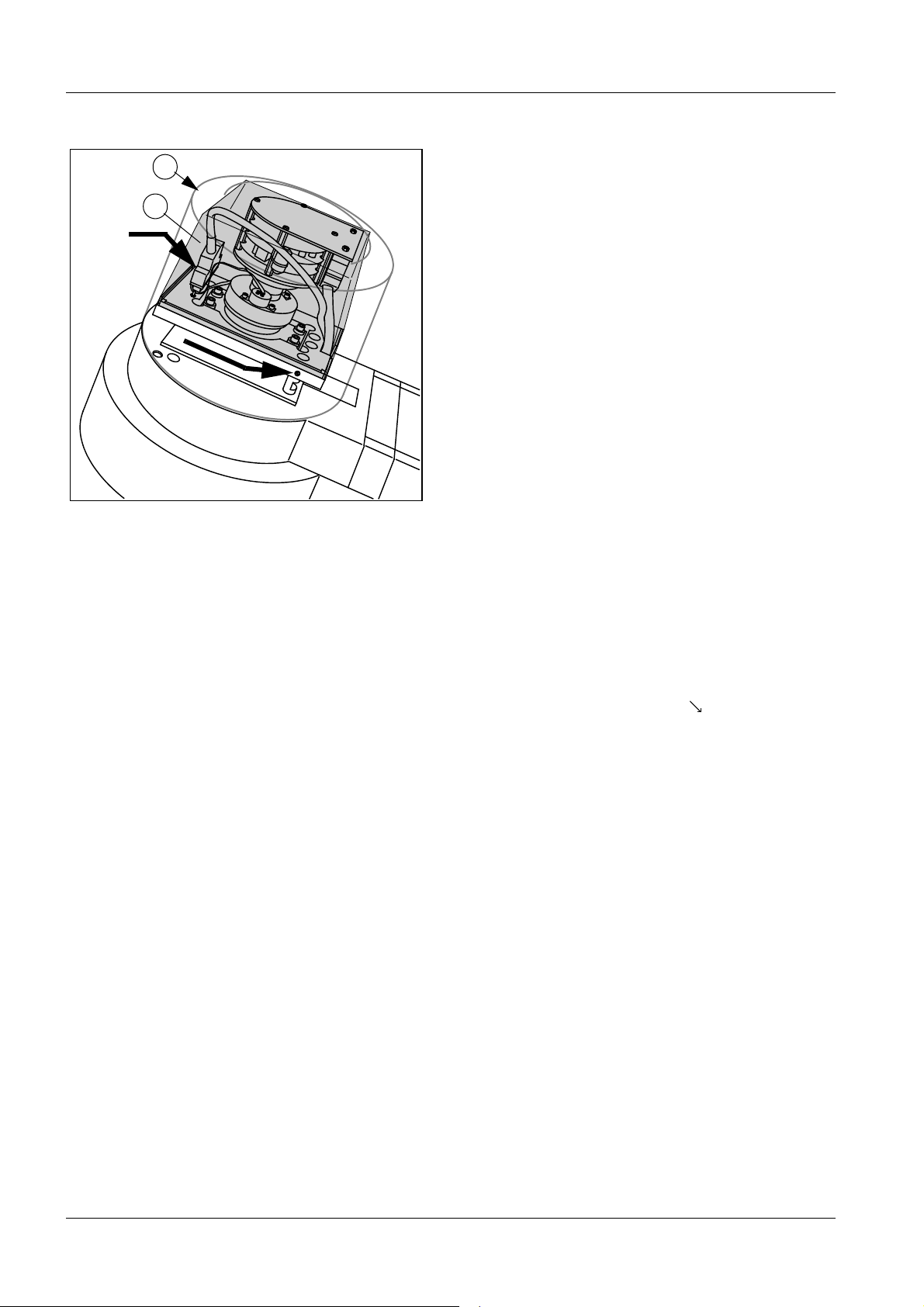

Installing the TV camera on the 23" I.I. 2

• Remove the housing (1/Fig. 18) from the TV camera.

• Remove the cover of the I.I. optics (black lid).

• Remove the set screws on the longer sides of the TV camera.

• Place the TV camera on the I.I. and mount it with the two set screws ( /Fig. 18).

• Plug in the two connection cables on the TV camera and secure them (Fig. 18).

• Clamp the shielding of the camera cable D115.X2 under the clamp.

• Reinstall the TV camera housing (1/Fig. 18) but do not secure it.

• Connect the protective conductor to the white cover (2/Fig. 18).

• Place the white cover (2/Fig. 18) over the TV camera and secure it together with the

housing.

• Use the white plastic plugs to cover the holes.

Installing the TV camera on the 33" I.I. 2

• The camera has been pre-installed at the factory.

Checking the temperature of the image intensifier 2

• Check the temperature indicators of the image intensifier according to the installation

instructions regarding temperature checks with SIRECON units and OPTILIX tubes in

RXD0-000.038.01... The results of the evaluation are recorded in the image quality

protocol (IQC) during start-up.

LITHOSTAR Multiline RXL2-120.812.01 Page 12 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 21

System Installation 2 - 13

1

1

2

Fig. 19 Fig. 20

Installing the Collimator 2

• Unpack the collimator.

• Remove the screws from the transport brackets at the side of the blades close to the

focus.

• Check the adjustment of the blades close to the focus with the template.

• Attach the collimator to the tube unit.

• Plug in connector X1 on the collimator.

• Secure the wire to the panel using strain relief clamps (1/Fig. 19).

• Connect the plug.

Installing the Diamentor (Option) 2

• Remove the cover from the collimator.

• Insert the measuring chamber and lead the cable out through the opening (1/Fig. 20).

• Reattach the cover to the collimator.

• Plug the two connectors together and fix the cable with the cable ties (2/Fig. 20).

Siemens AG RXL2-120.812.01 Page 13 of 14 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 22

2 - 14 System Installation

Installing the Simomed N44 monitor (OPTIONAL)

NOTICE

Refer also to installation instructions RX53-020.031.06..

• Remove the monitor housing.

• Slide the monitor onto the holder of the monitor trolley. The monitor should lock into

position.

• Tighten the two rear screws.

• Connect the cables according to the labels.

• Clamp the shielding of the BAS lead under the clamp of the VIDEO

cable.

IN

• Establish the protective conductor connections.

• Reinstall the monitor housing.

System with Polydoros LX chapter 3

System with Polydoros SX chapter 4

LITHOSTAR Multiline RXL2-120.812.01 Page 14 of 14 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 23

Connections with POLYDOROS LX 30 3

3 - 1

Cables in zipper hose

Cables fixed to the object

Control console

green

Fig. 1

General information 3

The cable harnesses are enclosed in zipper hoses and are color coded.

The specific target connection points for the harnesses have the same color coding in the

cabinets:

X-ray

generator

Shock wave

cabinet

AC

A13

A12

Patient

monitor

Option

Electronics

cabinet

Green

3rd Monitor

Option

Unit

Ultra-

sound unit

Option

Blue

yellow

X-ray generator, AC: yellow

Shock wave cabinet, A13: blue

Electronics cabinet, A12: green

- The conductor and cable shields have to be connected at the ends with the

corresponding clip.

CAUTION

Do not open the connector housing on the cable between the

camera and the VIDEOMED DI-M (D8.X1) under any circumstances.

• Do not shorten the harness.

• Whenever possible, avoid overlapping or looping harnesses in the system and

particularly in the cabinets. Do not store excess cable lengths in the cabinets

(EMC reasons).

• Be careful that the cable harnesses do not get caught in the swing-out frames.

• Water hoses 5 and 8 may only be shortened by max. 5 m.

CAUTION

Do not step on the hoses. Avoid small loops and kinks as this

may damage them.

Siemens AG RXL2-120.812.01 Page 1 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 24

3 - 2 Connections with POLYDOROS LX 30

Connections and cable locations in the A12

electronics cabinet

(green cable harnesses)

• Fasten the 3 cable harnesses (green) with the cable clip on the rail that

VIDEOMED

-DIM-

8

7

is installed at the bottom of the electronics cabinet.

right - cable harness,green, from control console

centre - cable harness,green, from unit (K3, K4....)

left - cable harness, green, from unit (K8, K9....)

• Secure the braided shield of the zipper hoses to the locations provided.

3

Image Storage

N11

System

Controller

9

M16

Power Supply

5

10

• Route the cables in the A12 electronics cabinet as shown in the adjacent

Fig. 2 and connect them according to table 1 and 3.

The numbers or letters (e.g. ) are located in the cable lists on the

4

following pages.

• Prior to routing the system cables, remove the EMC shielding plate at

N11 D11.

6

4

D21

4

X15

X4

X14

A12

L1

L1.1

L1.2

L2

X3

Cable harness, green, from the control console

Cable harness, green, from unit (K3, K4....)

Cable harness, green, from unit (K8, K9....)

3rd monitor on monitor trolley (optional)

Video cable 3rd monitor

Mounting rail for cable harness

Fig. 2

LITHOSTAR Multiline RXL2-120.812.01 Page 2 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 25

Connections with POLYDOROS LX 30 3 - 3

X6

A.. D

A

X41

E

X200

D110

D115

D100

K32/K31

D200

C

SNT

X3

D220

X4

H1

X5

X9

D160

F1

F2

F3

K20

K30

Fig. 3

B

D

M16

D165

Connections/cable locations in the generator cabinet (Part A) 3

• Route the cable harnesses in the generator cabinet as shown in Fig. 3 above,

and connect them as indicated in Tables 1 and 2:

Multiline power line connections

• Connect the power harness for the Multiline in the M16 at terminal strip K30 ( /Fig. 3)

(see also the POLYDOROS LX Wiring Diagram, X2169-11):

- K30.L1, L2, L3 (is switched over the GS breaker with generator ON).

- K30. N and K30. terminal pins ( /Fig. 3).

• Strain-relieve the power harness (shielding under the clamp).

B

B

D

Siemens AG RXL2-120.812.01 Page 3 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 26

3 - 4 Connections with POLYDOROS LX 30

AC Generator - A12 Electronics Cabinet - A13 Shock Wave Cabinet Connections

Type cable/

connection

2

4 x 4 mm

+

Gnd, shielded

1 x 6 mm

2

Function

MULTILINE

power supply

Protective con-

Generator

AC

M16.k30,

L1, L2, L3, N

M16.k30, M16,

A12 Cabinet A13 Cabinet ok

B 5

M16.X1 , N

F7, F8, F9

D 5

ductor

9 pole Canon XCS D200.X3 VDIM.D5.X13

9 pole Canon Act. value

D100.X200 N11.D6.X8

C 7

E 6

interface

3 x 1.5 mm

shielded

1 x 6 mm

2

2

,

A13 Power

supply

Protective con-

M16.X2.

L3, N, PE

M16, base

5 2

N12.X1.

L, N, PE

5 2

ductor

Canon Controller N11.D11.k104 N12.k104

Tab. 1

1)

Connections and cable position in cabinet A13 see fig. page 3-11

4 2

1)

1)

1)

System Operating Console - Generator Connections

This cable is located in the “System control console-Electronics Cabinet” zipper hose

Type of cable/

connector

Function

In Control

Console

in AC Generator ok

15 pole, Canon System ON/OFF Door D160.X9

Tab. 2

Connecting the XCS harnesses and

C E

• Pull the XCS harnesses (coming from the electronics cabinet) on the left side into the

power cabinet, guide them up and connect them on boards D100.X200 and D200.X3

C

per their designations (Fig. 3).

• Strain- relieve the harnesses using cable ties.

Control console connections

• Plug in the control console harness on board D160.X9 as shown in Table 2

A

( /Fig. 3).

• Strain- relieve the harness on the side using cable ties.

A

E

LITHOSTAR Multiline RXL2-120.812.01 Page 4 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 27

Connections with POLYDOROS LX 30 3 - 5

Power and voltage supply connection, protective conductor connection in A12

Type of cable/connection Function

1 x 16 mm

2

Protective conductor Device PE M16.PE

Cable harness in the middle

3 x 1.5 mm

harness in the middle

4 x 2.5 mm

harness in the middle

3 x 1.5 mm

on the right

1 x 6 mm

2

, shielded cable

2

, shielded cable

2

, shielded cable

2

Power connection

Z96

Voltage supply of

the output stages

Power connection

control console

Protective conductor PE control console M16.PE

Right cable harness

Tab. 3

Device /

control console

Cabinet A12 ok

Device X11.1, 2, 3 M16.X2

L1, N, PE

Device K1 M16/D21.

X14, L1.2

Socket control console

M16.X2

L2, N, PE

5

5

4

5

5

Siemens AG RXL2-120.812.01 Page 5 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 28

3 - 6 Connections with POLYDOROS LX 30

Connections of the options and their

cable locations in the A12

VIDEOMED

-DIM-

8

7

Image Storage

10

6

N11

System

Controller

9

4

electronics cabinet and generator AC

• Attach the special cables for the 3rd monitor to the

rail at the bottom of the electronics cabinet A12.

Install the cables as shown in Fig. 4 and connect

them according to table 4.

Patient monitor connection

• Position the patient monitor in the location provided

per the project planning guide (e.g. ceiling support).

• Plug the cable into the "SYNC" connector of the

patient monitor.

• Connect the patient monitor to its own power supply,

i.e. one that is independent of the LITHOSTAR

Multiline.

CAUTION

Do not establish any protective

conductor connections to the

LITHOSTAR.

9

3

M16

Power Supply

5

A12

Rail for cable harness

Fig. 4

Cable harness, green, from the operating console

Cable harness, green, from the unit (K3, K4....)

Cable harness, green, from the unit (K8, K9....)

3rd monitor on the monitor trolley (option)

Video cable 3rd monitor

LITHOSTAR Multiline RXL2-120.812.01 Page 6 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 29

Connections with POLYDOROS LX 30 3 - 7

Connections for the Options in the A12 Electronics Cabinet or in the AC Generator

Type of cable /

connector

3 x 1.5 mm

1 x 4 mm

2

2

Function Optional Unit

Line voltage 3rd Monitor * A12/M16.X2.L2, N, PE

Protective conduc-

Monitor trolley A12/M16

A 5

In the A12 Cabinet or

in the AC Generator

tor

Coax cable Video Monitor trolley A12/Monitor 3

Radiation ON display

Monitor trolley AC/D160.X6 see

generator wiring

in

diagram X2169-11

K14 ECG control Patient monitor "SYNC" A12/N11/D11.k14

Tab. 4

A

* The monitor cable contains more cable than necessary for connecting the

LITHOSTAR Multiline. Roll up the additional cables and place them in the control

cabinet.

ok

5

9

Siemens AG RXL2-120.812.01 Page 7 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 30

3 - 8 Connections with POLYDOROS LX 30

Connections and cable locations in the

A12 electronics cabinet

VIDEOMED

-DIM-

8

7

Image Storage

10

6

N11

System

Controller

9

4

and in the control console

(cable harness, green)

• Route the cables in the A12 electronics cabinet,

as shown in Fig. 5 and connect them as shown in

Table 5, 6 and 7.

VIDEOMED connection:

• Remove the XCS cables X11 and X12 from the D5

board.

• Remove the EMC shielding on the Videomed.

• Route the camera connector D8.X1similar to the video

cable underneath the rack and connect it to the

backplane as shown in Table 5.

Remove board D1 for this purpose.

• Attach the cable with a cable clip to the rack above the

shield.

• Attach the EMC shielding on the Videomed.

• Connect the XCS cables X11 and X12 on the D5 board.

8

3

M16

Power Supply

4

5

A12

Cable harness, green, from the control console

Cable harness, green, from the unit (K3, K4....)

Cable harness, green, from the unit (K8, K9....)

3rd monitor on the monitor trolley (option)

Video cable 3rd monitor

Mounting rail for cable harness

Fig. 5

LITHOSTAR Multiline RXL2-120.812.01 Page 8 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 31

Connections with POLYDOROS LX 30 3 - 9

Unit - A12 Electronics Cabinet Connections (left Cable Harness, green)

Type of cable /

connector

Function In Unit In Cabinet ok

12 pole connector, k8 Motor controller I D32.X54 N11/D11.K8

12 pole connector, k9 Motor controller II D32.X55 N11/D11.K9 3)

Special connector Control and

power supply

for the collimator

Special Camera Camera,

Collimator,

Z66.X1

D115.X2

N11/D6.X3

M16/D21.X4

VIDEOMED DI-M

D8.X1 on back-

4)

plane

Special Dose measurement

chamber

(optional Diamentor)

Tab. 5

Measurement

chamber collimator

Diamentor

(Control console)

3) Remove EMC shielding on the D6 board

Insert cable

Reattach the EMC shielding and make sure that the cable is in the

recess of the EMC cover.

4) After connecting D8.X1, install the EMI shielding plate.

(refer also to VIDEOMED connection in Chapter 3 page 8).

9

9

6

4

8

Unit - A12 Electronics Cabinet Connections (center Cable Harness, green)

Type of cable /

connector

4 pole connector k7 Power supply for the

Function In Unit In Cabinet ok

D31.X34 M16/D21.X3

magnetic brakes

37 pole connector k3 Incremental sensor D31.X30 N11/D11.K3

37 pole connector k4 Actual values D31.X31 N11/D11.K4

37 pole connector k5 Switches and DÜP D31.X32 N11/D11.K5

50 pole connector k6 Motor and magnetic

D31.X33 N11/D11.K6

brake control

9 pole connector k12 Zoom selection N11/D11.K12

9 pole connector k13 Respirator sensor

D27.X1 N11/D11.K13

connection

Tab. 6

4

4

4

4

4

4

9

Siemens AG RXL2-120.812.01 Page 9 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 32

3 - 10 Connections with POLYDOROS LX 30

System Control Console - Electronics Cabinet Connections (right Cable Harness, green)

Type of cable /

connection

Function In Control Console In A12 Cabinet ok

25 pole, Canon Controller Slide-out shelf N11/D11.K11

9 pole, Canon 4 channel

ECG - monitor

Coax video cable Video input

Monitor 1

in

Coax video cable Video input

Monitor 2

in

Coax video cable Video connection

Monitor 1

⇒ Monitor 3

Coax video cable Hardcopy input MULTISPOT

9 pole, Canon Hardcopy control MULTISPOT

Tab. 7

4 channel

ECG - monitor

1.Video monitor

Monitor 1

in

2.Video monitor

Monitor 2

in

3.Video monitor

Monitor 1

Monitor 3

out

in

N11/D11.K103A

MEMOSKOP,X11

MEMOSKOP,X12

9)

o to 3rd

7)

monitor if

configured

9)

MEMOSKOP, X10

9)

MEMOSKOP, X4

• connect to the monitor , only if a third monitor is present. 7)

8)

8)

10)

8)

8)

4

9

10

10

10

10

10

• Options 9)

• The coaxial cab le should be attached with a cable clip to the rail in the electronics

cabinet A12. Electrically Isolate the coaxial plug from the rack of the cabinet.

10)

• Check the switch positions on the back of the monitors and ensure that the setting is as

follows:

- Video signal to 0.3 V.

- If no third monitor is present, terminate both monitors at 75 Ohms.

- If a third monitor is present, set the output of the first monitor to high.

• Reattach the EMC shielding plate on the N11 D11. Make sure that all the cables are in

the recesses and will not get damaged when reattaching the shielding plate.

• After connecting the MEMOSKOP cabling, reinst all the MEMOSKOP cover.

The cable shielding must be under the corresponding clamp.

8)

LITHOSTAR Multiline RXL2-120.812.01 Page 10 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 33

Connections with POLYDOROS LX 30 3 - 11

Connections/cable locations in the A13

shock wave cabinet

3

HPE″

Charger

1

N12

Shock Wave

Controller

2

Cooling Unit

(cable harness, blue)

• Attach the blue cable harness in the shock wave

cabinet A13 on the front and back cabinet rack at pos.

6 and 7 with cable clips. Refer to Fig. 6. Attach the

braided shield of the zipper hose to the plate provided

at pos. 8 /9.

• Route the cables for the A13 shock wave cabinet as

shown in the Fig. left and connect them as shown in

Table 8.

• Secure the cables leading to N12 with cable ties on

the right side of position 50/52.

Make sure the conductors to D19 and D91 have

sufficiently long.

• For connecting the cables to the charger you have to

tilt M12 toward the front. Use cable ties to secure the

cables on the right side of position 67/68.

• Connect the hoses for the water connections at the

input/output point in the shock wave cabinet per

their designations or as shown in connection Table 8

and secure them with hose clamps.

3

Fig. 6

Water

Preparation

3

A13

• Make sure there are no kinks in the hoses and that

they are secured.

Connection point

for blue cable har-

NOTICE

The hoses must not be shortened

by more than 5 m, if required

Siemens AG RXL2-120.812.01 Page 11 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 34

3 - 12 Connections with POLYDOROS LX 30

o

Connection, Unit - A13 Shock Wave Control Cabinet (blue cable harness)

Type of cable /

connector

Function In Unit In Cabinet ok

Special Trigger lead X2, Power unit N12.X2

“ Test lead U/2 X5, Power unit N12.D91.X2

“ Test lead U

“ Test lead I

meß

meß

X4, Power unit N12.D91.X2

X3, Power unit N12.D91.X3

EK20 special Fan power supply X40, Power unit N12.K4

EK20 special Coupling X12, coupling assembly N12.K5

9 pole, Canon Coding X13, Power unit N12.K103

9 pole, Canon Shock head sensors X11, Shock wave head N12.K101

9 pole, Canon Coding Shock wave head N12.K102

Special K26 charger lead X1, Power unit Charger

1 x 4 mm

2

Protective conductor Power unit PE, Charger

Type of hose

Water Cooling system intake Shock wave head 5 Exchanger

2

5)

2

5)

2

5)

2

2

2

2

2

2

6)

1

6)

1

3

Water Cooling system return Shock wave head 8 Exchanger

Tab. 8

5) Allow enough cable length so that the boards can be unplugged with the

cables still connected.

6) - T o connect these cab les, swing the N12 out tow ards the front.

- Check that the screw connections of the high

voltage connector K26 are tightened securely

(refer to Fig. 7 on the left).

- Insert the connector of high voltage cable K26 on

the bottom of the charger until it locks audibly int

position.

- The connection (jumper) between and 0V

must be present.

Fig. 7

3

LITHOSTAR Multiline RXL2-120.812.01 Page 12 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 35

Connections with POLYDOROS LX 30 3 - 13

X41

A... D

D100

X200

D115

K32/K31

F

G

H

D200

X3

D110

K30

D220

M16

D165

Z

SNT

X9

D160

X6

X

X4

X5

H1

K20

F2

F1

F3

L

I

Fig. 8

Connections/Cable Locations in the Generator Cabinet (Part. B) 3

• Route the cables in the generator cabinet as shown in Fig. 8 above, and connect them in

accordance with Table 9:

• Install the yellow cable harness in the generator cabinet below M16. Connect the

shielding of the zipper hose to the bolt in M16 ( /Fig. 8). To strain-relieve the zipper

hose, attach it with a cable tie to the left intermediate plate of the cabinet near the floor

L

( /Fig. 8).

Rotating anode cable connection

• Route the rotating anode cable (internally required length approx. 1 m) up along the right

side in the frame of the generator cabinet to the anode starter ( /Fig. 8).

• Connect the braided shielding (external shielding) of the end of the lead to the right side

of the starter unit under one of the clamps ( /Fig. or 1/Fig. 9).

F

• Connect the red cable (inner shielding) to (3/Fig. 9).

• Strain-relieve the cable using cable ties (2/Fig. 9).

• Connect the rotating anode cable to the breaker of the anode starter ( /Fig. 8):

I

F

F

On breaker, contact: K31/R2 K31/R4 K32/R2

Anode cable leads: I / 1 0 II / 2

Siemens AG RXL2-120.812.01 Page 13 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 36

3 - 14 Connections with POLYDOROS LX 30

K32

K31

Fig. 9 Fig. 10

Generator - Unit Connections (Cable Harness, yellow)

Type of Cable Function Generator System ok

Stator cable

3 x 0.75 mm

2

Rotating anode drive Anode starter

K31.R2, R4, K32.R2

2 x HSK HV power supply HV-Transf. H1.API X-ray tube

1 x 6 mm

2

3 x 0.25 mm

2

Protective conductor - bolts

(on M16 under K20)

Oil pressure switch D160.x6.1 u. x6.3

shielding at

X

F

X-ray tube I, 0, II

H

I

X-ray tube

X

X-ray tube

Iontomat No function on the

Polydoros LX

Tab. 9

Connecting the H1 High Voltage Transformer

• Remove the inverter cover and open the bayonet connectors (1/Fig. 10).

• Change the position of the transformer mount (Fig. 10) and swing it out.

• Place the high voltage transformer on the transformer mount.

• Route the high voltage harnesses up to the high voltage transformer (3/Fig. 11).

• Check the oil level in the high voltage receptacles (approximately 1 cm); if necessary,

refill with oil (part no. 44 10 023 RV090 1 liter).

• Insert the high voltage plug without silicone disk but with silicone gasket into the correct

receptacle of H1 (Workstation 1).

LITHOSTAR Multiline RXL2-120.812.01 Page 14 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 37

Connections with POLYDOROS LX 30 3 - 15

t

-

• Slide the H1 high voltage transformer into the generator cabinet.

• Change the position of the transformer mount (Fig. 10), lift it, and lock in the bayonet

connectors (1/Fig. 10) of the mount.

• Connect the high voltage cable shielding to (Z/Fig. 8) (if the shielding is not accessible in

the clamping area, remove the outer insulation).

The clamps are located in the generator service packet.

• Use cable ties to strain-relieve the cab les

(3/Fig. 11).

• Carefully remove the plastic guard plate for board

D220 with symbols (1/Fig. 11).

• Connect the protective conductor strap to the

H1. (2/Fig. 11).

• Attach the (primary) leads H1.U1 and H1.V1 of the

inverter module per the designation onto H1

(3/Fig. 12).

Fig. 11

• Route the cable connected to D220.X41

(4/Fig. 11/12) down to the D160 board and connec

it to X44.

• Clamp the braided shield of the cable under the

clamp (5/Fig. 11).

• Use cable ties to strain-relieve the cab le at H1

(6/Fig. 12).

• Plug the flat cable X1 from board D100 to

connector X1 on board D220 (7/Fig. 12) and strain

relieve it on the co ver (shielding underneath the

strain relief).

• Reinstall the guard with the symbols

(1/Fig. 11).

• Check the nuts on the protective conductor studs

(8/Fig. 12) and tighten them, if necessary .

Fig. 12

Siemens AG RXL2-120.812.01 Page 15 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 38

3 - 16 Connections with POLYDOROS LX 30

D110

D110

F1

F1

F2

F2

F3

F3

K20

K20

H1

H1

K30

K30

D220

D220

D115

D115

K3

K32/K31

D165

D165

X6

X6

A... D

A... D

X9

X9

K

K

X41

X41

D100

D100

SNT

SNT

D160

D160

X200

X200

D200

D200

X3

X3

X4

X4

X5

X5

Fig. 13

J

J

M16

M16

Connections/harness locations in the generator cabinet (Part C) 3

• Route the harnesses in the generator cabinet as shown in Fig. 13 above, and connect

them in accordance with Table 10:

Generator power line connection

Nominal Line Voltage: 400 V ± 10%.

• Secure the screw type terminals from the service packet to the conductors of the power

cable. If the power cable diameter is small enough, turn the clamps 180° (both curvatures opposite to each other).

• Insulate the harness terminals that have been installed using heatshrink tubing.

• Remove the cover over the knife breakers F1, F2 and F3 ( /Fig. 13) at the M16 of the

generator.

• Connect the power line leads L1, L2, L3, N, PE to the fuses F1, F2, F3

(connection /Fig. 13) and to terminal strip K20. N and .

J

J

J

• Strain-relieve the power cable on the bottom plate of POLYDOROS LX. Do not allow this

to connect to any existing shielding on the power cable.

• Reinstall the cover over the knife breakers.

LITHOSTAR Multiline RXL2-120.812.01 Page 16 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 39

Connections with POLYDOROS LX 30 3 - 17

Fig. 14

Generator - Periphery

Type of Cable Function G enerator ok

Power line cable

3/N/Gnd

2 x 0.75 mm

2 x 0.75 mm

Tab. 10

2

2

System

power line connection

Radiation protection

Radiation buzzer

Radiation display

M16.

F1, F2, F3, N,

9)

M16.D160.X6 Door contact

9)

M16.D160.X6 Radiation indicator

J

Main distributor

L1, L2, L3, N,

K

K

lamps

9) Option

Connecting the options

K

Pilot lights and radiation protection indicators

At the customer's request or when country-specific regulations require (e.g. DHHS), the

following pilot lights and displays can be connected in the POLYDOROS LX to D160.X6

1

( /Fig. 14):

• Door contact for blocking the exposure release. If a door contact is required, it must be

connected in series with the oil pressure switch.

(Have the door contact activated e.g. by the examination room door.)

• External radiation indicator lamp

• Remove the corresponding jumper and connect the function according to wiring diagram

X2169-11. If necessary, pull the left part of the D160.X6 plug out from the side.

Siemens AG RXL2-120.812.01 Page 17 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 40

3 - 18 Connections with POLYDOROS LX 30

Ultrasound option

Tab. 11

NOTICE

Type of Cable Function

1 x 4 mm

3 x 0.75 mm

shielded

Canon

9 pole

Fiber optic

cable

Video Rear panel w/o function

For 230 V Sonoline line voltage

- Connect the cables to the power line terminal NK 1, 2, 3 (Fig. 15)

- Shielding see A/Fig. 15

2

Unpack and assemble the SONOLINE according to the instructions.

Ultrasound

system

Protective conductor

2

Voltage supply Rear panel refer to text

Control cable Ultrasound

Communication Rear panel N11 .D6

Rear panel Protective

conductor

terminal

D31.X28

tableside control

Multiline ok

Unit Cabinet A12

For 115 V Sonoline line voltage

(the required parts are located in the 115 V power supply packet)

- Attach the supplied grounded instrument connector (female connector) and the nozzle

to the 115 power supply cable routed into the case frame by the customer.

- Connect the grounded instrument connector (male connector) and the nozzle to the

power line cable from the corrugated hose.

- Plug the two grounded instrument connectors together (corrugated hose - power

supplies).

• Connect the protective conductor to the clamp (figure 15).

• Connect the control cable to D31.X28 (figure 15). This is possible only after moving the

system.

• Route the fiber optic and video cables to the control cabinet. (Refer to the installation

instructions for fiber optic cables /module RX0-000.038.02...).

• Route the video cable into the control cabinet (not used).

• Connect the ultrasound tableside control to SONOLINE.

• Connect the ultrasound probe and place the probe in its holder.

• Move board D6 slightly away from N11 to facilitate this.

• Plug the fiber optic cable into N11 on board D6 (according to color code). Secure the

fiber optic cable with cable clamps to the right side of the cabinet.

• Connect the corrugated hose to the Sonoline.

LITHOSTAR Multiline RXL2-120.812.01 Page 18 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 41

Connections with POLYDOROS LX 30 3 - 19

Power

cable

connector

Clamp for power

cable (A)

D31

Fig. 15

Corrugated

hose from

SONOLINE

Protective conductor

Cable outlet to cabinets

Clamp for corrugated hose

Siemens AG RXL2-120.812.01 Page 19 of 20 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 42

3 - 20 Connections with POLYDOROS LX 30

1

2

Fig. 16

Fastening of plug, Sonoline 3

• Remove the existing screw at point (1/Fig. 17).

• Screw in the mounting screw according to Fig. 17. The clamp (2/Fig. 17) prevents

loosening the plug connection without tools.

• Tighten the counternut (1/Fig. 17).

NOTE

CE approval is valid for the entire system only. If the ultrasound

unit is removed, then this does not retain the required CE approval.

LITHOSTAR Multiline RXL2-120.812.01 Page 20 of 20 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 43

Connections with POLYDOROS SX 65 4

4 - 1

Cables in zipper hose

Cables fixed at the object

Control console

green

Fig. 1

General information 4

The harnesses are enclosed in zipper hoses and are color coded. The specific target connection points for the harnesses have the same color coding in the cabinets:

X-ray

generator

AC

Shock wave

cabinet

A13

A12

Patient

monitor

Option

Electronics

cabinet

Green

3rd Monitor

Option

Unit

Ultra-

sound unit

Option

Blue

yellow

X-ray generator, AC: yellow

Shock wave cabinet, A13: blue

Electronics cabinet, A12: green

- The conductor and cable shields have to be connected at the ends with the

corresponding clip.

CAUTION

Do not open the connector housing on the cable between the

camera and the VIDEOMED DI-M (D8.X1) under any circumstances.

• Do not shorten the harness.

• Whenever possible, avoid overlapping or looping harnesses in the system and

particularly in the cabinets. Do not store excess cable lengths in the cabinets (EMC)

reasons).

• Be careful that the cable harnesses do not get caught in the swing-out frames.

• Water hoses 5 and 8 may only be shortened by max. 5 m.

CAUTION

Do not step on the hoses. Avoid small loops and kinks as this

may damage them.

Siemens AG RXL2-120.812.01 Page 1 of 24 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 44

4 - 2 Connections with POLYDOROS SX 65

Connections and cable locations in the A12

electronics cabinet

(green cable harnesses)

• Attach the 3 cable harnesses (green) with the cable clip to the rail that is

VIDEOMED

-DIM-

8

7

installed at the bottom of the electronics cabinet.

right - cable harness,green, from operat. console

center - cable harness,green, from unit (K3, K4....)

left - cable harness, green, from unit (K8, K9....)

• Secure the braided shield of the zipper hoses to the locations provided.

4

Image Storage

N11

System

Controller

9

M16

Power Supply

5

10

• Route the cables in the A12 electronics cabinet as shown in the adjacent

Fig. 2 and connect them according to tables 1 and 3.

The numbers or letters (e.g. ) are located in the cable lists on the

4

following pages.

• Prior to routing the system cables, remove the EMC shielding plate at

N11 D11.

6

4

D21

4

X15

X4

X14

A12

L1

L1.1

L1.2

L2

X3

Cable harness, green, from the control console

Cable harness, green, from unit (K3, K4....)

Cable harness, green, from unit (K8, K9.....)

3rd monitor on monitor trolley (optional)

Video cable 3rd monitor

Mounting rail for cable harness

Fig. 2

LITHOSTAR Multiline RXL2-120.812.01 Page 2 of 24 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 45

Connections with POLYDOROS SX 65 4 - 3

Overview of cable run in the power cabinet 4

Route the cable in the power cabinet from the

left or right only.

C

X3

L

M9

17

DIA

A

16

E

K5

K32

L

K31

H

8

M16

T2

D

B

Fig. 3

Siemens AG RXL2-120.812.01 Page 3 of 24 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

J

Page 46

4 - 4 Connections with POLYDOROS SX 65

Connections/harness locations in the generator cabinet (Part A) 4

• Route the harnesses in the generator cabinet as shown in Fig. 3 above, and connect

them as indicated in Tables 1 and 2:

Multiline power line connections

• Connect the power cables for the Multiline in M16 ( /Fig. 3) (refer also to the Multiline

• Strain-relieve the power harness.(shielding under the clamp)

AC Generator - A12 Electronics Cabinet - A13 Shock Wave Cabinet Connections

Type cable/

connection

2

4 x 4 mm

Gnd, shielded

1 x 6 mm

+

2

circuit diagram J1042-10):

Connection to contactor K4

L1

→ T1

L2

→ T2

→ T3

L3

→ K30.N

N

PE

→ Bolt on M16

Function

MULTILINE

power supply

Protective con-

Generator

AC

M16,

L1, L2, L3, N

M16.k30, M16,

ductor

D

B

A12 Cabinet A13 Cabinet ok

B 5

M16.X1 , N

F7, F8, F9

D 5

9 pole Canon XCS D 320.X3 VDIM.D5.X13

9 pole Canon Act. value

D100.X200 N11.D6.X8

C 7

E 6

interface

3 x 1,5 mm

shielded

1 x 6 mm

2

2

,

A13 Power

supply

Protective con-

M16.X2.

L3, N, PE

M16, base

5 2

N12.X1.

L, N, PE

5 2

ductor

Canon Controller N11.D11.k104 N12.k104

Tab. 1

1)

Connections and cable position in the cabinet A13, refer to the fig. on page 3-11.

4 2

System Operating Console - Generator Connections

This cable is located in the “System operating console-Electronics Cabinet” zipper hose

Type of cable/

connector

Function

In Control

Console

in AC Generator ok

15 pole, Canon System ON/OFF Door D160.X9

Tab. 2

1)

1)

1)

LITHOSTAR Multiline RXL2-120.812.01 Page 4 of 24 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 47

Connections with POLYDOROS SX 65 4 - 5

Connecting the XCS harnesses and

C E

• Pull the XCS harnesses (coming from the electronics cabinet) on the right side into the

frame of the power cabinet, guide them up and connect them on boards D100.X200

and D320.X3 per their designations (Fig. 3).

C

• Strain-relieve the harnesses using cable ties.

Control console connections

• Plug in the control console harnesses on board D160.X9 as shown in Table 2

A

( /Fig. 3).

• Strain-relieve the harnesses on the side using cable ties.

Power and voltage supply connection, protective ground wire connection in A12

Type of cable/connection Function

1 x 16 mm

2

Protective conductor device PE M16.PE

Cable harness in the middle

2

3 x 1.5 mm

, shielded cable

harness in the middle

2

4 x 2.5 mm

, shielded cable

harness in the middle

2

3 x 1.5 mm

, shielded cable

on the right

1 x 6 mm

2

Power connection

Z96

Voltage supply of

the output stages

Power connection

control console

Protective conductor PE operating

right cable harness

Device /

operating console

Cabinet A12 ok

device X11.1, 2, 3 M16.X2

L1, N, PE

device K1 M16/D21.

X14, L1.2

socket

operating console

M16.X2

L2, N, PE

M16.PE

console

E

5

5

4

5

5

Tab. 3

Siemens AG RXL2-120.812.01 Page 5 of 24 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 48

4 - 6 Connections with POLYDOROS SX 65

Connections of the options and their

cable positions in the A12

VIDEOMED

-DIM-

8

7

Image Storage

10

6

N11

System

Controller

9

4

electronics cabinet and generator AC

• Attach the special cables for the 3rd monitor to the

rail at the bottom of the electronics cabinet.

Install the cables as shown in Fig.4 and connect

them according to table 4.

Patient monitor connection

• Position the patient monitor in the location provided

per the project planning guide (e.g. ceiling support).

• Plug the cable into the "SYNC" connector of the

patient monitor.

• Connect the patient monitor to its own power supply,

i.e. one that is independent of the LITHOSTAR

Multiline.

CAUTION

Do not make any direct ground

wire connections to the

LITHOSTAR.

9

4

M16

Power Supply

5

A12

Mounting rail for cable harness

Fig. 4

Cable harness, green, from the operating console

Cable harness, green, from the unit (K3, K4....)

Cable harness, green, from the unit (K8, K9....)

3rd monitor on the monitor trolley (option)

Video cable 3rd monitor

LITHOSTAR Multiline RXL2-120.812.01 Page 6 of 24 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 49

Connections with POLYDOROS SX 65 4 - 7

Connections for the Options in the A12 Electronic Cabinet or in the AC Generator

Type of cable /

connector

3 x 1.5 mm

2

Function Optional Unit

Power supply

3rd Monitor * A12/M16.X2.L2, N, PE

A 5

In the A12 Cabinet or

in the AC Generator

voltage

1 x 4 mm

2

Protective conduc-

Monitor trolley A12/M16

tor

Coax cable Video Monitor trolley A12/Monitor 3

in

Radiation display Monitor trolley AC/D160.X61 refer to

generator wiring

diagram X2206-11

K14 ECG control Patient monitor "SYNC" A12/N11/D11.k14

Tab. 4

A

* The monitor cable contains more cable than necessary for connecting the

LITHOSTAR Multiline. Roll up the additional cables and place them in the control

cabinet.

ok

5

9

Siemens AG RXL2-120.812.01 Page 7 of 24 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 50

4 - 8 Connections with POLYDOROS SX 65

Connections and cable locations in the

A12 electronics cabinet

VIDEOMED

-DIM-

8

7

Image Storage

10

6

N11

System

Controller

9

4

and in the control console

(cable harness, green)

• Route the cables in the A12 electronics cabinet, as

shown in Fig.5 and connect them as shown in Table 5,

6 and 7.

VIDEOMED connection:

• Remove the XCS cables X11 and X12 from the D5

board.

• Remove the EMC shielding on the Videomed.

• Route the camera connector D8.X1similar to the video

cable underneath the rack and connect it to the

backplane as shown in Table 5.

Remove board D1 for this purpose.

• Attach the cable with a cable clip to the rack above the

shield.

• Attach the EMC shielding.

• Reinstall the XCS cables X11 and X12 on the D5

board.

8

4

M16

Power Supply

4

5

A12

Cable harness, green, from the control console

Cable harness, green, from the unit (K3, K4....)

Cable harness, green, from the unit (K8, K9....)

3rd monitor on the monitor trolley (option)

Video cable 3rd monitor

Mounting rail for cable harness

Fig. 5

LITHOSTAR Multiline RXL2-120.812.01 Page 8 of 24 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 51

Connections with POLYDOROS SX 65 4 - 9

Unit - A12 Electronic Cabinet Connections (left Cable Harness, green)

Type of cable /

connector

Function In Unit In Cabinet ok

12 pole connector, k8 Motor controller I D32.X54 N11/D11.K8

12 pole connector, k9 Motor controller II D32.X55 N11/D11.K9 3)

Special connector Control and

Power supply

for the collimator

Special Camera Camera,

Collimator,

Z66.X1

D115.X2

N11/D6.X3

M16/D21.X4

VIDEOMED DI-M

D8.X1 on the back-

4)

plane

Special Dose measurement

chamber (optional)

Measurement

chamber colli-

Diamentor

(Control console)

mator

Tab. 5

3) Remove the EMC shielding plate on the D6 board

Insert the cable

Reattach the EMC shielding plate and make sure that the cable is in the

recess of the EMC cover.

4) After connecting the D8.X1, reinstall the EMI shielding plate.

(Refer also to VIDEOMED connection in chapter 4, page 8.)

9

9

6

4

8

Unit - A12 Electronics Cabinet Connections (center Cable Harness, green)

Type of cable /

connector

4 pole connector k7 Power supply for the

Function In Unit In Cabinet ok

D31.X34 M16/D21.X3

magnetic brakes

37 pole connector k3 Incremental sensor D31.X30 N11/D11.K3

37 pole connector k4 Actual values D31.X31 N11/D11.K4

37 pole connector k5 Switches and DÜP D31.X32 N11/D11.K5

50 pole connector k6 Motor and magnetic

D31.X33 N11/D11.K6

brake control

9 pole connector k12 Zoom selection N11/D11.K12

9 pole connector k13 Respirator sensor

D27.X1 N11/D11.K13

connection

Tab. 6

4

4

4

4

4

4

9

Siemens AG RXL2-120.812.01 Page 9 of 24 LITHOSTAR Multiline

Medical Solutions Rev. 02 10.04 CS PS 24 System

Page 52

4 - 10 Connections with POLYDOROS SX 65

System Control Console - Electronics Cabinet Connections (right Cable Harness, green)

Type of cable /

connection

Function In Control Console In A12 Cabinet ok

25 pole, Canon Controller Slide-out shelf N11/D11.K11

9 pole, Canon 4 channel

ECG - monitor

Coax video cable Video input

Monitor 1

in

Coax video cable Video input

Monitor 2

in

Coax video cable Video connection

Monitor 1

⇒ Monitor 3

Coax video cable Hardcopy input MULTISPOT

9 pole, Canon Hardcopy control MULTISPOT

Tab. 7

4 channel

ECG - monitor

1st Video monitor

Monitor 1

in

2nd Video monitor

Monitor 2

in

3rd Video monitor

Monitor 1

Monitor 3

out

in

N11/D11.K103A

MEMOSKOP,X11

MEMOSKOP,X12

9)

o to 3rd

7)

monitor if

configured

9)

MEMOSKOP, X10

9)

MEMOSKOP, X4

8)

8)

10)

8)

8)

4

9

10

10

10

10

10

connect to the monitor, only if a third monitor is present. 7)

Options 9)

The coaxial cable should be attached with a cable clip to the rail in the electronics

10)

cabinet A12. Electrically isolate the coaxial plug from the rack of the cabinet.

• Check the switch positions on the back of the monitors and ensure that the setting is as

follows:

- Video signal to 0.3 V.

- If no third monitor is present, set both monitors to 75 Ohms.

- If a third monitor is present, set the output of the first monitor on high.

• Reattach the EMC shielding plate on the N11 D11. Make sure that all the cables are in

the recesses and will not get damaged when reattaching the shielding plate.

• After connecting the MEMOSKOP cabling, reinstall the MEMOSK OP cov er panel.

The cable shielding must be under the corresponding clamp .

8)

LITHOSTAR Multiline RXL2-120.812.01 Page 10 of 24 Siemens AG

System Rev. 02 10.04 CS PS 24 Medical Solutions

Page 53

Connections with POLYDOROS SX 65 4 - 11

Connections/cable locations in the A13

shock wave cabinet

4

HPE″

Charger

1

N12

Shock Wave

Controller

2

Cooling Unit

(blue cable harness)

• Attach the blue cable harness in the shock wave

cabinet A13 on the front and rear cabinet rack at pos.

6 and 7. with cable clips. Refer to Fig. 6. Attach the

braided shield of the zipper hose on the plate

provided at pos. 8/9.

• Route the cables for the A13 shock wave cabinet as

shown in the Fig. left and connect them as shown in

Table 8.

• Secure the cables leading to N12 with cable ties on

the right side of position 50/52.

Make sure the conductors to D19 and D91 are

sufficiently long.

• For connecting the cables to the charger, you have to

tilt M12 toward the front. Use cable ties to secure the

cables on the right side of position 67/68.

• Connect the hoses for the water connections at the