Page 1

Erlwein

LITHOSTAR MODULARIS

Troubleshooting Guide

System

SP

Troubleshooting Guide

05531103

Print No.:

Replaces: SPL1-130.840.01.04.02

SPL1-130.840.01.05.02

© Siemens AG

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

English

Doc. Gen. Date: 04.05

2000

Page 2

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service procedures.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 2 of 138

Medical Solutions

Page 3

Table of Contents 3

1- 0Table of Contents

1 _______ General ________________________________________________________ 7

Safety Information and Protective Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Applicability and Regulations for the Country Organizations . . . . . . . . . . . . . . . . . . . 7

Required Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Required Aids and Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Product-specific Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modularis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modularis Vario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 _______ LITHOSTAR MODULARIS Error List _______________________________ 13

Info, E00 and E99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Water System, E10-E12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Water System, E14-E15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Controls, E20-E21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controls, E22-E25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Controls, E26-E29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Monitoring, E31-E34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Monitoring, E40-E48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Monitoring, E49-E54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

High Voltage Circuit, E60 - E67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

High Voltage Circuit, E68 - E74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

High Voltage Circuit, E75 - E78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Internal Errors, E80-E89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ultrasound, E90-E93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Displays on the D3 Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Text on the Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

"Chip card invalid" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

LITHOSTAR MODULARIS SIEMENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Missing Isocenter Cross on the Ultrasound System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3 _______ Service Software _______________________________________________ 31

(Hyper) Terminal Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

German WINDOWS 95/98/NT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

English Windows 95/98/NT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Working with the (Hyper) Terminal Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Select Option: h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Select Option: p . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Select Option: d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Select Option: e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Select Option: t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Select Option: c. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Select Option: a/b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 3 of 138

Page 4

4 Table of Contents

Select Option: i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Select Option: u . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Select option: r. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Select Option: s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Software Download with Windows 95 / 98 / NT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Select Option: 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Text after Replacing the D3 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

LITHOSTAR MODULARIS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 _______ LITHOSTAR MODULARIS ________________________________________ 49

LITHOSTAR MODULARIS Parts Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Shock Wave Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Shock Wave Head Cover Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Removing the Shock Wave Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Installing the Shock Wave Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Replacing the Isocenter Phantom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cooling Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Checking the Cooling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Replacing the Cooling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Filling the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Filling the Coupling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Emptying the Cooling System with the Old Pump (2/Fig. 10) . . . . . . . . . . . . . . . . . . 60

Emptying the Cooling system with the New Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Emptying the Coupling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Hose Pump Head in the Coupling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Removing the Hose Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Installing the Hose Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Hose Pump Head in the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing the Hose Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installing the Hose Pump Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

IWAKI Cooling Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Charging Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

High Voltage Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cables in the Corrugated Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Air Suction Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Up to support arm serial number 0050 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Beginning with support arm serial number 0051 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

D3 Board or Chip Card Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Notice for LITHOSTAR MODULARIS with the Gold Card: . . . . . . . . . . . . . . . . . . . . 76

Replacing the D3 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

D3 Board Expansion (Ultrasound) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Pressure Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Potentiometer for Angulation Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Angulation Drive (C-Arm Drive). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 4 of 138

Medical Solutions

Page 5

Table of Contents 5

SIREMOBIL Iso-C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Adjusting the S1/S2 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Setting the Cam on the LITHOSTAR MODULARIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Balancing Spring for the Support Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Support Arm Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Rotary Joint Latch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Replacing the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Sector Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Curved Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Final Work Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5 _______ Isocenter with X-Ray ____________________________________________ 97

LITHOSTAR MODULARIS up to Support Arm Serial Number 0050 . . . . . . . . . . . . . . . 97

Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Adjusting the 0° Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Adjusting the 20° Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Final Work Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

LITHOSTAR MODULARIS beginning with Support Arm Serial Number 0051 . . . . . . 103

Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Adjusting the 0° Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Adjusting the 20° Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Final Work Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

LITHOSTAR MODULARIS as a "LithoShare" Procedure. . . . . . . . . . . . . . . . . . . . . . . 107

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6 _______ Isocenter with Ultrasound_______________________________________ 108

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Checking the Target on the Sonoline G20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Checking Image Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Checking the Target on the Sonoline Adara. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Checking Image Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Checking the Target on the Sonoline Prima . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Checking Image Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7 _______ Memoskop Programming _______________________________________ 129

Standard Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

8 _______ Ultrasound Device MUP Menu ___________________________________ 130

Selecting the MODULARIS Crosshairs on the SONOLINE G20 . . . . . . . . . . . . . . . . . 130

Ultrasound Localization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Selecting the MODULARIS Crosshairs on the SONOLINE Adara. . . . . . . . . . . . . . . . 131

Ultrasound Localization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Selecting the MODULARIS Crosshairs on the SONOLINE Prima . . . . . . . . . . . . . . . . 132

Ultrasound Localization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 5 of 138

Page 6

6 Table of Contents

Overview of Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Read out the Software Version G20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Reading Out the Adara Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Reading Out the Prima Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

9 _______ Changes to Previous Version ____________________________________ 137

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 6 of 138

Medical Solutions

Page 7

General 7

1General

2-

Safety Information and Protective Measures 0

• Observe the safety measures described .

CAUTION

When performing service work and tests, observe:

¹ the product-specific safety information in the docu-

ments, as well as the general safety information contained in ARTD, Part 2.

¹ Disconnect the power cable when working on the sys-

tem.

¹ Disconnect the power cable when working on the sys-

tem.

¹ When working with the power on, observe the general

safety regulations.

¹ Observe ESD guidelines.

¹ Switch off the system prior to replace boards or assem-

blies.

¹ After completing all service work and reattaching the

cover panels, perform the ground wire measurement as

specified in ARTD-002.731.17.

¹ Ground wire resistance may not exceed 0.2 Ohms.

¹ When servicing the power-on assembly (replacing the

power-on assembly or the power cable), the equivalent

leakage current must be measured and documented.

¹ Tests and adjustments performed with radiation on are

identified by the radiation warning symbol x.

¹ Radiation protection must be worn during these types of

adjustments (refer to ARTD, Part 2).

Applicability and Regulations for the Country Organizations 0

Equivalent Leakage Current Measurement

The equivalent leakage current must be measured where applicable under the requirements of DIN VDE 0751, Part 1.

Where DIN VDE 0751 does not apply, the country organizations should comply with the

following regulations (refer to ARTD - 002.731.17, as well as the safety-technical regulations for installation and maintenance).

The local national regulations apply primarily for the country organizations.

In the event that there are no existing local regulations, the following provisions should be

observed in the interest of the safety of customers, patients, employees and third parties

as well as the company.

Initial Measured Value

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 7 of 138

Page 8

8 General

The equivalent leakage current measurement was performed at the factory and the value

measured was entered in Test Protocol 1. The measurement was made at the line voltage

and line frequency indicated in Test Protocol 1.

If the on-site line voltage or line frequency differs from the information indicated upon

delivery of the Modularis Uro Plus, the values given are invalid. The values should be

marked invalid (crossed out with the comment "invalid values" and the service engineer

should sign and date this copy).

In this case, the equivalent leakage current must be measured again. The value may not

exceed 1 mA according to DIN VDE 0751, Part 1.

The initial value measured must be documented.

Repeat measurements

When service or repair work is performed on the primary power supply circuit (e.g. repairs

to the power-on circuit), the equivalent leakage current test must be repeated. The values

measured in the subsequent test may not exceed the threshold value of 1 mA as specified

in VDE 0751, Part 1. In addition, they may not exceed the initial measured value by more

than 50%. If the value exceeds this threshold, the system must be repaired. The value

measured must be documented.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 8 of 138

Medical Solutions

Page 9

General 9

Required Tools and Test Equipment 0

NOTE

The specified articles are listed in the SCT (Catalog Service Tools)

if nothing else is indicated (the STC is a component of the Spare

Parts Catalog).

• Standard service equipment

• Service PC, see intranet, service laptop for CSEs

• PC connection cable, 5 m 99 00 440 RE999

• ESD equipment

• Bender safety tester 97 06 979 Y0526

• Digital voltmeter, e.g. FLUKE 187 99 94 831Y4290

• Shock wave pressure test unit 30 95 408 J1008

• Adapter for C-head 98 17 347 J1008

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 9 of 138

Page 10

10 General

Required Aids and Documents 0

• SIREMOBIL Iso-C Service Instructions SPR2-230.061.01..

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 10 of 138

Medical Solutions

Page 11

General 11

Product-specific Information 0

This document is valid for the established Lithostar Modularis and the new "low end lithotripter" called the Modularis Vario. Overview of difference between the two units:

Modularis 0

• (1) Shock wave head C with 120 mm focus depth.

• (2) Length of therapy arm incl. shock head = 1800 mm.

• (3) Energy charging unit with spark gap technology.

• (4) Docking technology implemented with docking plate.

Modularis Vario 0

• (1) Shock wave head C plus with a focus depth of 140 mm (*1) including an adapted

isocenter phantom.

• (2) Length of therapy arm incl. shock head = 900 mm.

• (3) Energy charging unit with fast high voltage switch (*2).

• (4) Docking technology implemented with docking mandrel.

Fig. 1: Modularis

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 11 of 138

Page 12

12 General

Fig. 2: Modularis Vario

*1 The shock wave head C

Modularis unit. In this case, it is not different in every way. All new Modularis units will be

shipped with shock wave head C

with a 140-mm focal depth is upgradable for the normal

plus

(July 2003, except USA ).

plus

*2 The spark gap will no longer be used in the Multiline and Modularis Lithotripters. Beginning July 2003, all charging units will be equipped with the "Fast High Voltage Switch".

This switch is not a consumable and not a spare part. Thus the only spare part is the

charging unit.

NOTE

By observing the above mentioned differences, all known technical information is usable for the established Modularis and the

Modularis Vario.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 12 of 138

Medical Solutions

Page 13

LITHOSTAR MODULARIS Error List 13

2LITHOSTAR MODULARIS Error List

3-

NOTE

Error messages from the SIREMOBIL Iso-C have not been listed.

(Refer to the SIREMOBIL Iso-C service documents

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 13 of 138

Page 14

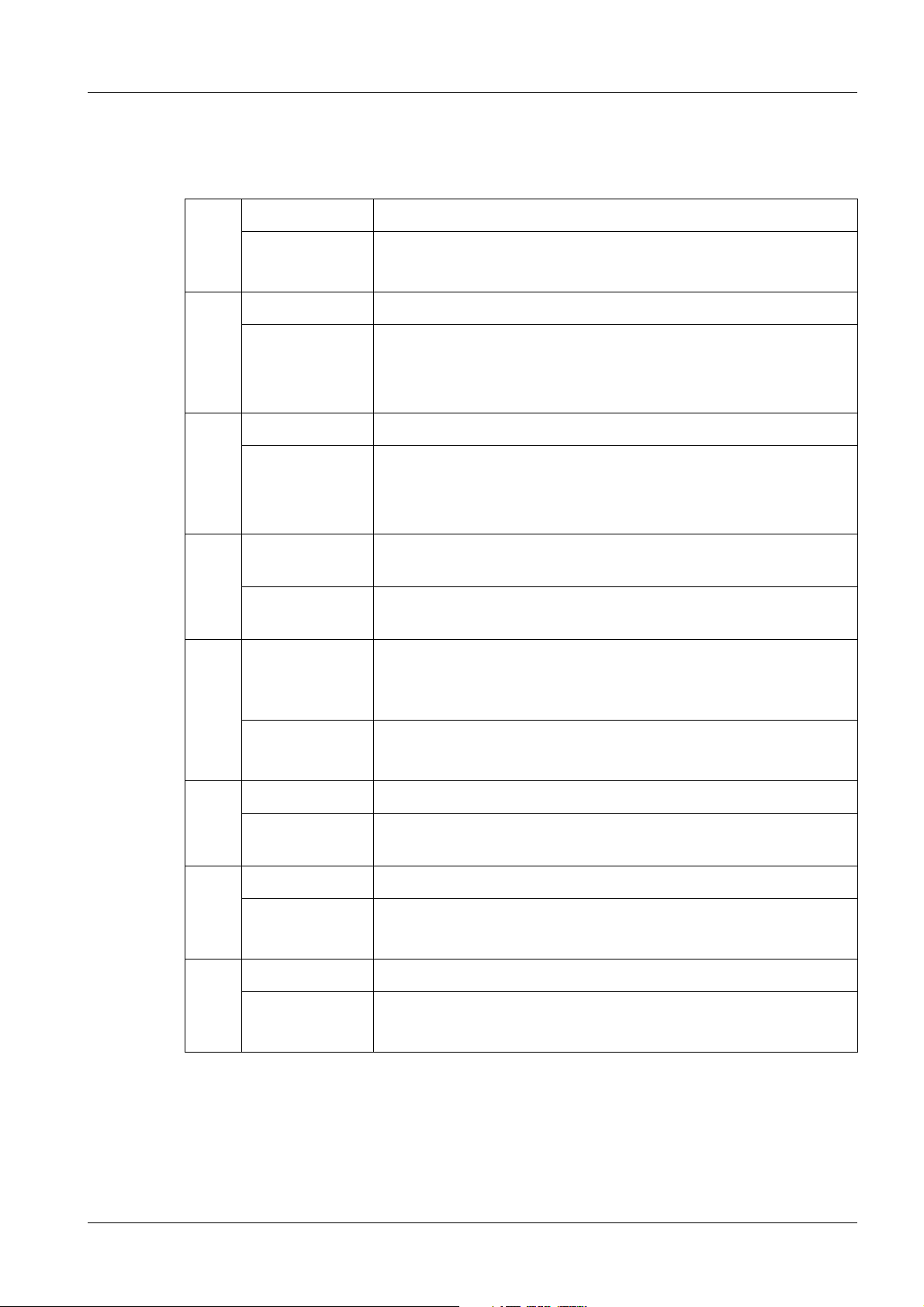

14 LITHOSTAR MODULARIS Error List

Info, E00 and E99 0

E00 Error Text: System was switched on.

Possible

cause/action:

E99 Error Text: The system was switched off without deleting the therapy data.

Possible

cause/action:

Press the Reset button.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 14 of 138

Medical Solutions

Page 15

LITHOSTAR MODULARIS Error List 15

Water System, E10-E12 0

LITHOSTAR MODULARIS circuit diagram J1048, pages 13 and 14.

E10 Error Text: Cooling system losing water.

Possible

cause/action:

Is water running out of the hoses?

P

switch o.k.?

min

D3.X3 board connection o.k.?

Fill the cooling system.

E11 Error Text: Maximum pressure in the cooling system exceeded.

Possible

cause/action:

Pressure switch P

Are the hoses blocked, kinked?

P

switch o.k.?

max

responded.

max

D3.X3 board connection o.k?

Is the cooling unit operating?

Check the fill level in the cooling system.

E12 Error Text: Minimum pressure in the cooling system exceeded.

Possible

cause/action:

Pressure switch P

Is water running out of the hoses and hose connections?

Air in the cooling system?

responded.

min

Check the fill level in the cooling system.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 15 of 138

Page 16

16 LITHOSTAR MODULARIS Error List

Water System, E14-E15 0

E14 Error Text: Water level too low in the water reservoir tank.

Possible

cause/action:

E15 Error Text: Coupling pressure not o.k.

Possible

cause/action:

Not enough water in the tank.

Float switch in the tank o.k.?

D3.X3 board connection o.k.?

Completely fill the coupling bellows, deselect automatic pressure regulation, and drain the water.

Repair any leaks.

Refill the water in the reservoir tank.

Pressure sensor on the shock head o.k.?

If water can still be pumped out, the sensor is probably defective (refer to "Working with the Terminal Program: Show Diagnostic Data").

Suction hose correctly inserted in the coupling bellows?

Return hose kinked?

D3.X8 board connection o.k.?

Fill the coupling system.

If the error occurs only with obese patients, the suction hose in

the coupling bellows may be kinked.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 16 of 138

Medical Solutions

Page 17

LITHOSTAR MODULARIS Error List 17

Controls, E20-E21 0

If the control panel is dark: check fuse F5 on the D3 board.

E20 Error Text: No contact with the control unit (this error is visible only when

reading out the error log with the service PC).

Possible

cause/action:

E21 Error Text: X-ray button on the control unit activated with switch-on.

Possible

cause/action:

X5 connection cable correctly connected to the control unit?

Check the F5 fuse on the D3 board.

If the error occurs after replacing the D3 board: is X35 connector properly connected?

X-ray button stuck?

Control unit o.k.?

Cable o.k.?

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 17 of 138

Page 18

18 LITHOSTAR MODULARIS Error List

Controls, E22-E25 0

E22 Error Text: QRS signal from ECG unit missing, i.e. no ECG triggering pos-

sible.

Possible

cause/action:

E23 Error Text: Motor for C-Arm movement in LITHOSTAR MODULARIS

Possible

cause/action:

Trigger cable connected to ECG unit?

ECG triggering selected on the control unit? Trigger cable

plugged in on D3.X70?

drawing too much current.

C-Arm moving freely?

SIREMOBIL Iso-C cable connected?

Brake in SIREMOBIL Iso-C can be released, i.e. is the motor

not locked?

Brake connection cable in SM Iso-C o.k.? (D3.X38 - SM Iso-C)

Motor connection cable o.k. (board D3.X36)?

D3 board?

Motor connection cable o.k. (D3.X36 board)?

Settings for the SIREMOBIL Iso brakes o.k.? (Angulation and

orbital in 0°. LITHOSTAR MODULARIS not coupled. Attach a

spring balance at the handle near the I.I. Release the angulation brake and pull with the spring balance. The C-Arm must

move when the spring balance indicates a value from 20N-30N

- preferably close to 20 N. Settings are made at the position

where the angulation motor is coupled. Wrench size 30 mm,

coupling must be removed). Also refer to SPR2-230.061.01...

chapter 7.

D3 board?

E24 Error Text: C-Arm blocked.

No change on the actual value potentiometer in LITHOSTAR

MODULARIS.

Possible

cause/action:

E25 Error Text: C-Arm potentiometer not working.

Possible

cause/action:

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

C-Arm moving freely?

Potentiometer o.k.?

Correct tension on the belt?

Connection cable to potentiometer o.k.? (D3.X38)

Check the setting of the SIREMOBIL angulation brake (see

E23)

Potentiometer connected?

Check the D3.X30 connector!

Connect the cable to the potentiometer.

Page 18 of 138

Medical Solutions

Page 19

LITHOSTAR MODULARIS Error List 19

Controls, E26-E29 0

E26 Error Text: ECG option not installed.

Possible

cause/action:

E27 Error Text: Control unit.

Possible

cause/action:

E28 Error Text: C-Arm pivots in the wrong direction.

Possible

cause/action:

E29 Error Text: Shock wave release button sticking.

Possible

cause/action:

Warning message only.

Key sticking.

Replace control panel.

Cables connected incorrectly to the potentiometer or the

motor?

Correct tension on the belt?

Check the setting of the SIREMOBIL angulation brake (see

E23).

Check control unit. Circuit diagram J1048 - 25.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 19 of 138

Page 20

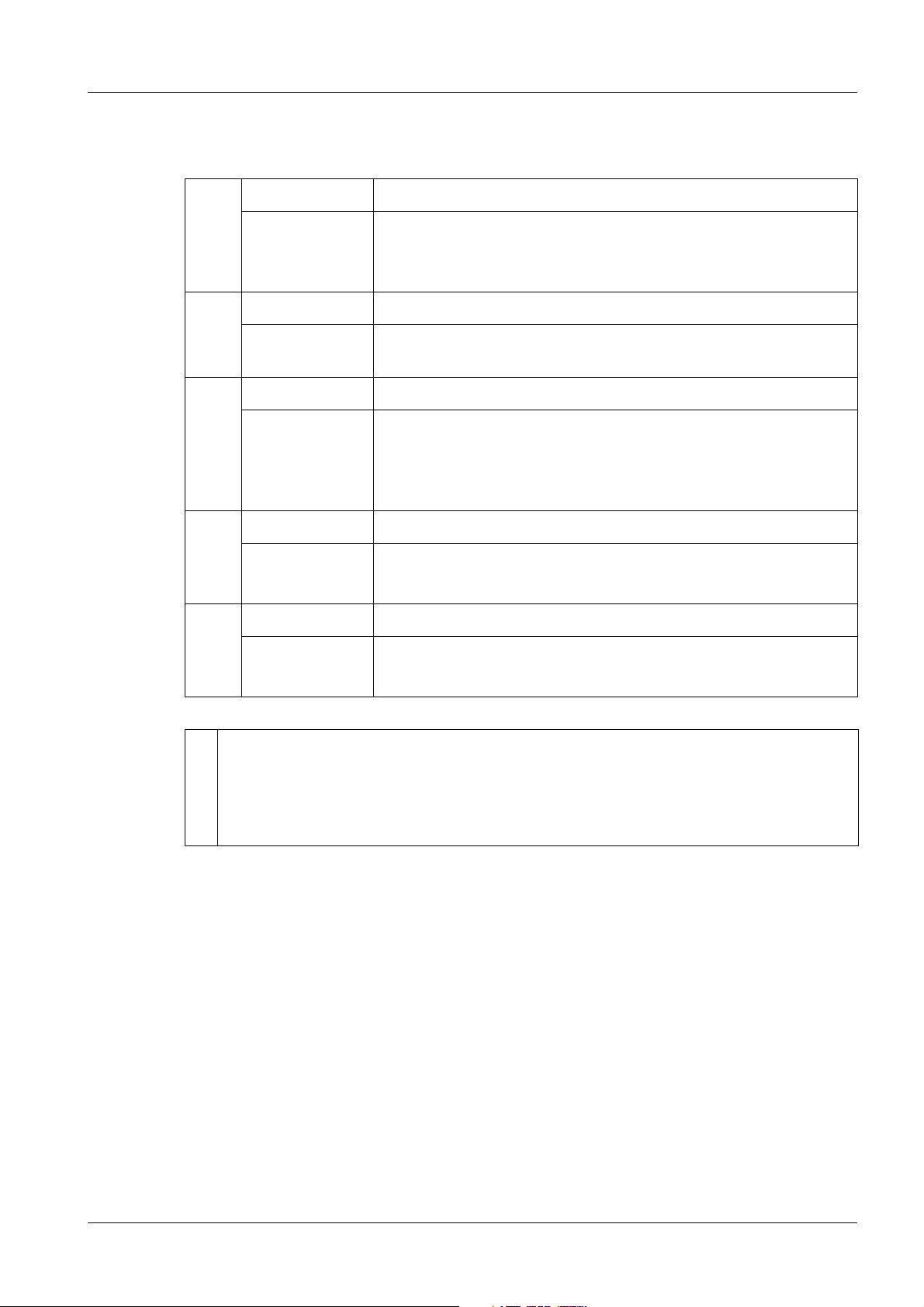

20 LITHOSTAR MODULARIS Error List

Monitoring, E31-E34 0

E31 Error Text: Temperature sensor supplying incorrect data.

Possible

cause/action:

E32 Error Text: The temperature at the shock wave head has exceeded the

Possible

cause/action:

E34 Error Text: Temperature cannot be determined: could not access the ADC

Possible

cause/action:

Temperature sensor o.k.?

D3.X2 connection cable o.k.?

The temperature difference can be read out on the service PC.

maximum value.

Let the shock wave head cool down, but do not switch the system off!

Check to ensure that the cooling unit is operating.

If the M1 cooling pump is running, the pump head may need to

be replaced.

If the error reoccurs, check the function of the cooling unit.

when converting the analog values from the temperature sensor.

Voltage supply for the temperature sensors outside acceptable

range.

D3.X2 connection cable o.k.?

D3 board?

Read out the temperature with the service PC.

Refer also to error 45.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 20 of 138

Medical Solutions

Page 21

LITHOSTAR MODULARIS Error List 21

Monitoring, E40-E48 0

E40 Error Text: Cooling pump fuse defective.

Possible

cause/action:

E41 Error Text: M1 cooling pump defective.

Possible

cause/action:

E42 Error Text: Coupling pump defective.

Possible

cause/action:

E43 Error Text: Fuse for coupling pump defective.

Possible

cause/action:

E44 Error Text: 5 volt power supply defective.

Possible

cause/action:

E45 Error Text: 18 volt power supply defective.

Possible

cause/action:

F2 fuse on D3 board o.k.?

M1 motor o.k.? Circuit diagram J1048 - 13

D3.X7 connection cable o.k.?

M2 motor o.k.? Circuit diagram J1048 - 13

D3.X7 connection cable o.k.?

F3 fuse on D3 board o.k.?

Replace D3 board.

LED VCC18 on D3 board o.k.? Circuit diagram J1048 - 11

D3.X8 connection cable o.k.?

Check the power supply for the pressure sensors!

E46 Error Text: 17 volt power supply defective

Possible

cause/action:

E47 Error Text: Valve and card terminal fuse defective?

Possible

cause/action:

E48 Error Text: Reference for temperature sensors defective.

Possible

cause/action:

LED VCC17 on D3 board o.k.?

Replace D3 board.

Short circuit?

F4 fuse on D3 board? Circuit diagram J1048 - 13

Check valve (coupling circuit).

Check card terminal.

Replace temperature sensors.

Replace D3 board.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 21 of 138

Page 22

22 LITHOSTAR MODULARIS Error List

Monitoring, E49-E54 0

E49 Error Text: Reference potentiometer defective.

Possible

cause/action:

E50 Error Text: -5 volt power supply defective.

Possible

cause/action:

E52 Error Text: Battery voltage for battery-buffered RAM and real-time clock

Possible

cause/action:

E53 Error Text: Incorrect data in the battery-buffered RAM.

Possible

cause/action:

Short circuit in potentiometer for C-arm movement or potentiometer for ultrasound probe (only if option is available)?

D3.X38, D3.X28 connection cable (ultrasound option) o.k.?

Circuit diagram J1048 - 16/17.

Use the service PC to read the current potentiometer (menu

"d").

For troubleshooting when the ultrasound option is available:

Remove the board for the ultrasound option and cables X28

and X29 from the D3 board.

Replace D3 board.

too low.

Replace the lithium battery on the D3 board.

Normal occurrence during initial startup or after replacing the

lithium battery.

Check the lithium battery!

Replace the D3 board.

Perform a software download!

E54 Error Text: Clock stopped (this message is also displayed when the bat-

tery is replaced)

Possible

cause/action:

D3.X31 - XP7 connection cable present under the cover?

Set the clock!

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 22 of 138

Medical Solutions

Page 23

LITHOSTAR MODULARIS Error List 23

High Voltage Circuit, E60 - E67 0

LITHOSTAR MODULARIS circuit diagram J1048 - 12.

E60 Error Text: Charging current too low during the charging process.

Possible

cause/action:

Check the line voltage!

Replace the charging / energy unit!

E61 Error Text: Overvoltage in the charging unit.

Possible

cause/action:

System OFF

- 10 minute pause - System ON.

Replace the charging / energy unit!

E62 Error Text: Overtemperature in the charging unit.

Possible

cause/action:

Heat in the LITHO MODULARIS?

System OFF - 10 minute pause - System ON.

Replace the charging / energy unit!

E63 Error Text: Capacitor defective in the charging / energy unit (out of toler-

ance).

Possible

Replace the charging / energy unit!

cause/action:

E64 Error Text: Default voltage not attained.

Current voltage after frequency converter (U

) is greater

nom

than selected voltage.

1

Possible

cause/action:

Check the fiber optic cable!

Replace the charging / energy unit!

)

E65 Error Text: Charging voltage too high during the charging process.

Possible

Replace the charging / energy unit!

cause/action:

E66 Error Text: Default voltage incorrect.

1

Possible

cause/action:

Check the fiber optic cable!

Replace the charging / energy unit!

)

E67 Error Text: No ignition of spark gap after trigger pulse (several times).

1

Possible

cause/action:

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Check the fiber optic cable!

Replace the spark gap!

)

Page 23 of 138

Page 24

24 LITHOSTAR MODULARIS Error List

High Voltage Circuit, E68 - E74 0

E68 Error Text: Charging current too high during charging process.

Possible

cause/action:

E69 Error Text: Repeated self-ignition of the spark gap.

Possible

cause/action:

E70 Error Text: Charging current too low after ignition!

Possible

cause/action:

E71 Error Text: Charging current too high after ignition.

Possible

cause/action:

E72 Error Text: No communication possible with the charging / energy unit.

Possible

cause/action:

Replace the charging / energy unit!

Replace the spark gap!

Check the high voltage cable connections!

Check the high voltage connector!

Replace the shock wave head!

Check the high voltage cable!

Check the high voltage connector!

Replace the shock wave head!

Check the line voltage at the charging / energy unit!

Replace the fuse in the charging / energy unit!

Check the fiber optic cable!

1

)

Replace the charging / energy unit!

E73 Error Text: Message: Constancy limit reached.

Possible

cause/action:

E74 Error Text: Constancy limit reached.

Possible

cause/action:

1

) Before replacing the charging / energy unit, check the fiber optic cable (LWL):

For user information only.

Approx. 10-15 treatments still possible, then error 74 appears.

The constancy limit has been reached.

• Replace the following parts:

- shock wave head

- spark gap and

In addition, replace the water in the entire system!

• Disconnect the fiber optic cable at both ends and check by holding it up to the light

or

• Place it on the Clk (U5) of the D3 board and check whether light is visible.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 24 of 138

Medical Solutions

Page 25

LITHOSTAR MODULARIS Error List 25

High Voltage Circuit, E75 - E78 0

E75 Error Text: Chip card terminal error (documented in error log only).

Possible

cause/action:

E76 Error Text: Chip card expired

Possible

cause/action:

E77 Error Text: Chip card communication error

Possible

cause/action:

E78 Error Text: Charging process too long.

Possible

cause/action:

E79 Error Text: Short circuit - call Service

Possible

cause/action:

Check revision level for D3 board: Rev. 00 - 02: replace D3

board. Rev. 03 and higher: replace chip card reading device.

Wrong card or card incorrectly inserted.

Insert a new card.

Check revision level for D3 board: Rev. 00 - 02: replace D3

board. Rev. 03 and higher: replace chip card reading device

Cable? If the error reoccurs after replacing the D3 board, is the

X33 connector properly connected?

Line voltage o.k.?

Replace the charging / energy unit!

High voltage cable or energy unit defect

Replace the cable or the energy unit!

1

) Before replacing the charging / energy unit, check the fiber optic cable (LWL):

• Disconnect the fiber optic cable at both ends and check by holding it up to the light

or

• Place it on the Clk (U5) of the D3 board and check whether light is visible.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 25 of 138

Page 26

26 LITHOSTAR MODULARIS Error List

Internal Errors, E80-E89 0

E80 Error Text: Flash memory defective.

Possible

cause/action:

E81 Error Text: CMOS pulse counter incorrect.

Possible

cause/action:

E82 Error Text: Pulse counter backup incorrect

Possible

cause/action:

E83 Error Text: CMOS chip card data incorrect

Possible

cause/action:

E85 Error Text: Measurement acquisition incorrect.

Possible

cause/action:

E86 Error Text: Flash memory defective

Not applicable for the user.

Read out the memory and perform a reset at the next opportunity.

If this error occurs repeatedly, D3 board must be replaced.

If this error occurs repeatedly, D3 board must be replaced.

Possible

cause/action:

E89 Error Text: Watchdog responded.

Possible

cause/action:

Not applicable for the user.

Read out the memory and perform a reset at the next opportunity.

If this error occurs repeatedly, D3 board must be replaced.

Appears each time a reset is performed with the S3 switch on

D3 board.

This error may occur if the system is switched off during initialization.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 26 of 138

Medical Solutions

Page 27

LITHOSTAR MODULARIS Error List 27

Ultrasound, E90-E93 0

E90 Error Text:

Possible

cause/action:

E91 Error Text:

Possible

cause/action:

E92 Error Text: The two potentiometers have different values.

Possible

cause/action:

E93 Error Text: Erroneous US values.

Possible

cause/action:

No connection from LITHOSTAR to SONOLINE

Potentiometer skips.

Cable from potentiometer to D3 board ok? Potentiometer

defect?

Fig. 3:

Dampness on the potentiometer.

C-MOS has lost values. Adjust the potentiometer (point "U" in

the service menu).

Check the default values (see SPL1-130.038.01...).

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 27 of 138

Page 28

28 LITHOSTAR MODULARIS Error List

Displays on the D3 Board 0

Once the system is turned on, different symbols are displayed chronologically on the D3

board display .

Display Possible cause/action

0 System o.k. (only with the ultrasound localization option and if a communica-

tion was set up to the ultrasound device.)

d Software download.

1 Data transfer, the decimal point is blinking.

4 The receiving file is being checked.

5 Software download time too long.

7 Everything o.k. (only if no ultrasound localization option is available or if the

ultrasound device is turned off.)

- The service switch is set to normal mode - only for boards that still have no

software.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 28 of 138

Medical Solutions

Page 29

LITHOSTAR MODULARIS Error List 29

Text on the Console 0

"Chip card invalid" 0

• This message is displayed when:

- the gold card is still logged on a different LITHOSTAR MODULARIS

- D3 board was replaced and the "init counter" on the gold card is already set to 3.

- the card is defective.

In the normal mode, check whether the LED 174 on the D3 board blinks temporarily and

then remains lit when turning it on.

LITHOSTAR MODULARIS SIEMENS 0

This message is displayed when too many errors occur. In this case, use the service PC

to generate an error log.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 29 of 138

Page 30

30 LITHOSTAR MODULARIS Error List

Missing Isocenter Cross on the Ultrasound System 0

There is no communication between the ultrasound system and the LITHOSTAR MODULARIS.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 30 of 138

Medical Solutions

Page 31

Service Software 31

3Service Software

4-

(Hyper) Terminal Program 0

The Windows (Hyper) Terminal program is used to retrieve error codes, settings, shock

wave counts, etc. from the LITHOSTAR MODULARIS and to save them to diskette. The

error log and therapy data can only be deleted from the CPU board using this (Hyper) Terminal program. This program is usually located under Accessories in Windows.

The following provides a short overview of the connection procedure.

The standard cable (99 00 440 RE999) is used as the connection cable between the service PC and the LITHOSTAR MODULARIS.

NOTE

Due to the numerous versions and languages for WINDOWS, the

connection procedure is described in German and English.

If there are problems, use the Help function in the (Hyper) Terminal program.

The "Courier New" font is recommended for reading data stored on the diskette.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 31 of 138

Page 32

32 Service Software

German WINDOWS 95/98/NT 0

Fig. 4: German_Windows 95_98_NT

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 32 of 138

Medical Solutions

Page 33

Service Software 33

English Windows 95/98/NT 0

Fig. 5: English_Windows 95_98_NT

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 33 of 138

Page 34

34 Service Software

Working with the (Hyper) Terminal Program 0

Once you create a connection between the service PC and the LITHOSTAR MODULARIS, press the "h" key to display the following text:

You will be notified if the software version is not compatible with the hardware version.

Refer to document SPL1-130.038.01... (Intranet) for default values.

Fig. 6:

The following will be displayed if the software version is not compatible with the hardware

version:

Fig. 7:

Select Option: h 0

• Press the"h" key to display the input menu.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 34 of 138

Medical Solutions

Page 35

Service Software 35

Select Option: p 0

• Press the "p" key to display the following text:

Fig. 8:

The total number of shock waves released are displayed. The counters for the shock

head / capacitor / spark gap can be reset to zero.

Always perform this procedure when replacing one of these parts, i. e. the "spark gap"

counter must be reset to zero if the charging unit is replaced.

Select Option: d 0

Press the "d" key to display the following text

Fig. 9:

Sensors (C-grade) Displays the temperature at the shock wave head in Celsius. The

difference between both temperature values may not exceed a

maximum of 3° C.

HV (V) Displays the voltage at the high-voltage capacitor. If there is no

connection to the charging unit (i.e. fiber optic cable is removed),

the value is 20460.

P-bellows (mV) Displays the pressure in the coupling bellows. P-automatic

selected and rinse ended: Q 500 mV - 2000 mV o.k.

C-arm pot. (mV) Current voltage at the potentiometer for the angulation motor.

US pot. 1/2 (mV) Current voltage at the potentiometer for the US applicator. Accept-

able difference: 50. When US localization is not available, the

value is 9995.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 35 of 138

Page 36

36 Service Software

Select Option: e 0

• Press the "e" key to display the following text:

Fig. 10:

• The number of errors in the error log is displayed (e.g. 100 error messages).

• The last 250 errors (maximum) are displayed in blocks of 20. Between these blocks is

the line "press space to continue, "x" to exit".

• To have a better overview, system power-up is shown with the code E00.

• The oldest error has the number 1; the most recent error is all the way at the top.

• The line "last watchdog error code" is internal information.

• The errors can only be deleted in the system after all error numbers have been viewed.

Select Option: t 0

• Press the "t" key to display the following text:

Fig. 11:

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 36 of 138

Medical Solutions

Page 37

Service Software 37

Displays all days for which therapy data exists, as well as the number of patients. To

select the day: enter month/day/year.

• The following data is displayed for each treatment (max 40):

- each increase in energy level

- the number of shock waves for each of the energy levels (energy levels between 0.1

and 1.0 will be summarized in steps of 0.1)

- any errors that occurred

- the text output can be temporarily stopped at any time with the "Space" key.

Entering "A" is recommended only for saving all data to a diskette.

The data cannot be deleted until they have been read (on a workday).

Selecting delete will erase all therapy data.

Fig. 12:

• Example:

- 1:0012 - 12 shock waves triggered with an energy step of 0.1-1.0 (energy steps between 0.1 and 1.0 are summarized in intervals of 0.1).

- **E60 - error 60 has occurred.

- 32:0041 - 41 shock waves triggered with energy steps of 3.2.

- **E60 - error 60 has occurred again.

Fig. 13:

Once all of the therapy data for a day is listed, the above text will be displayed. Press the

"d" key to delete all therapy data.

Select Option: c 0

• Press the "c" key to display the following text:

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 37 of 138

Page 38

38 Service Software

Fig. 14:

Text: 4: 531...0 G init=2 .... ..... 04/13 ... 418

Explan.: *1 *2 *3 *4 *5 *6 *7 *8

• *1: sequential number of the card inserted.

• *2: serial number of the card.

• *3: a "gold" card was inserted, i.e. the input slot is closed.

• *4: init counter in the above example is init=2, i.e. the gold card was logged onto two dif-

ferent D3 boards.

• *5: n.a.

• *6: n.a.:

Card ejected

• *7: Date of ejection

• *8: System shock wave counter value when card was ejected

Card in system

• *7: Text: "Card locked to unit"

• *8: ............

Text: 5: 531...1 P 89956 0 0 04/13 ... 418

Explan.: *1 *2 *3 *4 *5 *6 *7 *8

• *1: sequential number of the card inserted

• *2: serial number of the card

• *3: a "pay per use" card was inserted

• *4: shock waves still present on the card

• *5: internal system card counter

• *6: number of shock waves registered on inserting the ppu card

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 38 of 138

Medical Solutions

Page 39

Service Software 39

Card ejected • *7: Date of ejection

• *8: System shock wave counter value when card was ejected

Card in system

• *7: Text: "Card locked to unit"

• *8: ............

Select Option: a/b 0

NOTE

• Press the"a" key to reduce the time by 50 ms, i.e. from 1200 ms to 1150 ms.

• Press the"b" key to increase the time by 50 ms, i.e. from 1200 ms to 1250 ms.

If there are problems decoupling the angulation motor, the motor follow-up time for relaxing the coupling can be changed. Time < 300 and > 5000 cannot be selected.

You do not have to save changes.

Select Option: i 0

• Press the "i" key to display the following text:

Fig. 15:

After pressing the "1" key and then the "h" key, the display for "selection option i now

"reads": installed".

Select Option: u 0

• Press the "u" key to display the following text:

Fig. 16:

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 39 of 138

Page 40

40 Service Software

• If the potentiometer has to be adjusted (i.e., after the D3 board is replaced or after the

D3 ultrasound addition), proceed as follows:

• Push the probe receiver all the way to the front so that the space between the probe and

the isocenter phantom is very small when the isocenter phantom is raised.

• After pressing the "j" key, the following appears after "actual value": established value

(max. 500).

Fig. 17:

Fig. 18:

CAUTION

The following values can be altered only if approval is granted by

Erlangen.

¹ The correct values can be found in document

SPL1-130.038.01... (Intranet).

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 40 of 138

Medical Solutions

Page 41

Service Software 41

Fig. 19:

Explanation:

The displayed position (distance and position) of the objects on the ultrasound image is

calculated from the time difference between sending a signal and receiving the echo. The

standard speed of sound in the human body is 1540 m/sec. However, this speed can vary

depending on which tissue is being examined.

The position of the isocenter can be adjusted to ensure that the position of the cross

matches the actual stone position on the ultrasound monitor.

This is possible with:

Fig. 20:

Fig. 21:

Every probe can be set to one of three settings:

Threshold value,

The point at which the "scale high" value is used (default 100 mm).

Fig. 2

Scale low, Fig. 2 Correction factor (default 7.7%) between 0 mm and the "threshold

value" (this value is useful for thin patients).

Scale high, Fig. 2 Correction factor (default 7.7%) between the "threshold value" and

end (this value is useful for obese patients).

Selecting the keys "t, l, h" (depending on the application) reduces the value. Select T, L, H

to increase the value.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 41 of 138

Page 42

42 Service Software

Select option: r 0

• Press the "r" key to change the "pulse rate"

- Selection: Fixed 2 Hz (USA) or variable 1/1.5/2 Hz

• After pressing the "h" key, display for "selection option r" shows the pulse rate that has

been set.

Select Option: s 0

CAUTION

Software downloads are possible only if the software and hardware are compatible.

The system and service PC may not be turned off during a software download.

¹ If this occurs, the D3 board must be replaced.

• Press the "s" key to display the following text:

Fig. 22:

After "1" has been entered, the software download must start within 60 seconds. If the 60

seconds elapses without starting the download, reselect "h" from the entry menu, reselect

"s", etc.

Once the software download is complete, check that the values in the "ultrasound localization" menu for the applicators are identical to those in document SPL1-130.038.01..

(Intranet). If this is not the case, make the appropriate changes.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 42 of 138

Medical Solutions

Page 43

Service Software 43

Software Download with Windows 95 / 98 / NT 0

Fig. 23: Software Download with Windows 95_98_NT

Do not select "capture text file" when downloading the software.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 43 of 138

Page 44

44 Service Software

Select Option: 0 0

• Press the "o" key to switch from the right side to the left side of the table. This may be

done only if the table has also been mechanically modified, refer to MODULARIS Uro

Installation and Startup Instructions. After pressing the "h" key, the display for "option o

selection" will show which table was selected. The configuration shipped is the right table (Fig. 25 / p. 44).

Fig. 24:

Fig. 25: Left/right side version

Text after Replacing the D3 Board 0

• Press the "h" key to display the following text (the software is installed).

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 44 of 138

Medical Solutions

Page 45

Service Software 45

Fig. 26:

• Press the "n" key to display the following text.

Fig. 27:

• Press 1 or 2 and follow the instructions.

Fig. 28:

NOTE

This procedure cannot be undone!

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 45 of 138

Page 46

46 Service Software

Fig. 29:

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 46 of 138

Medical Solutions

Page 47

Service Software 47

LITHOSTAR MODULARIS Control Panel 0

Fig. 30:

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 47 of 138

Page 48

48 Service Software

Fig. 31:

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 48 of 138

Medical Solutions

Page 49

LITHOSTAR MODULARIS 49

4LITHOSTAR MODULARIS

5-

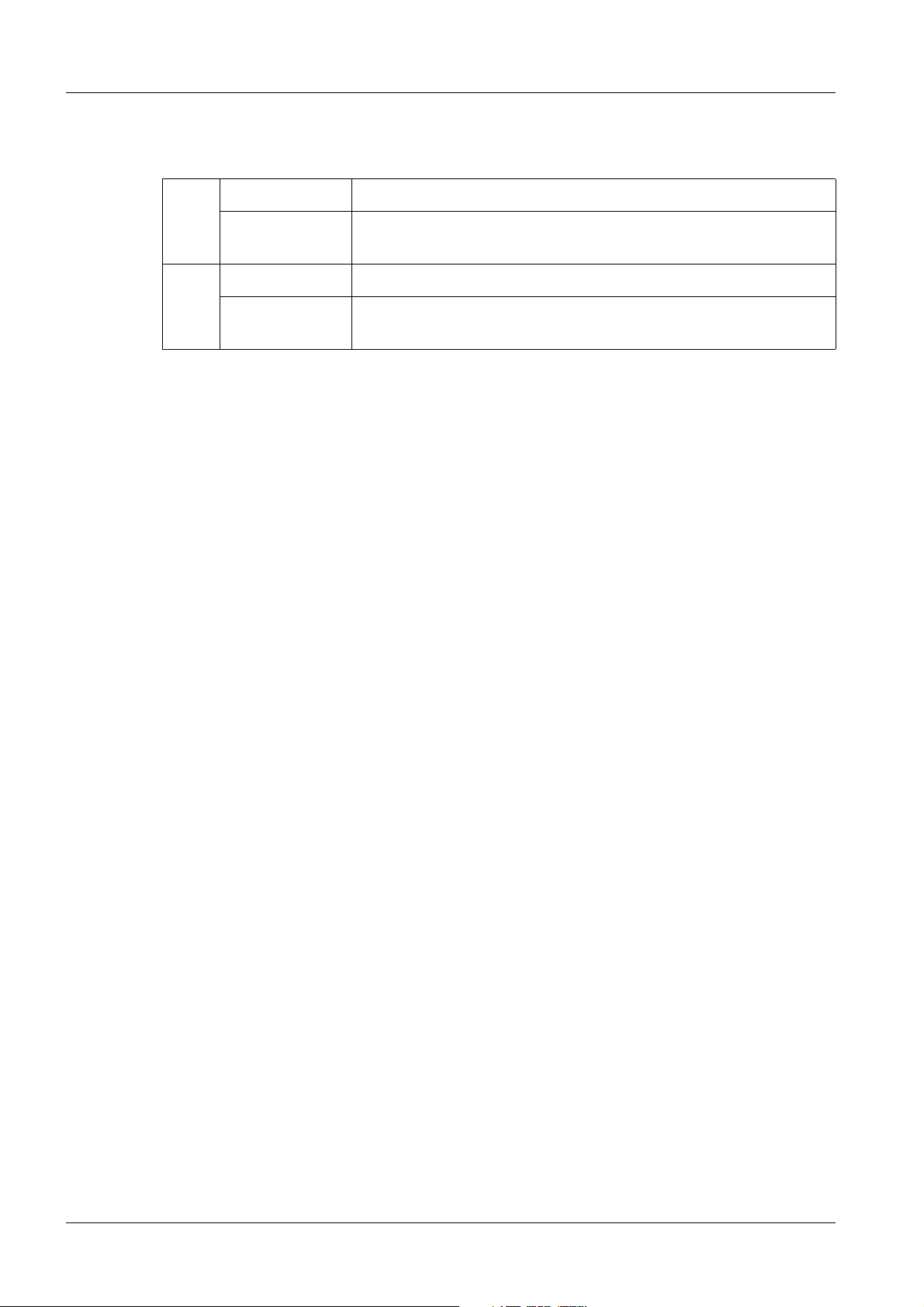

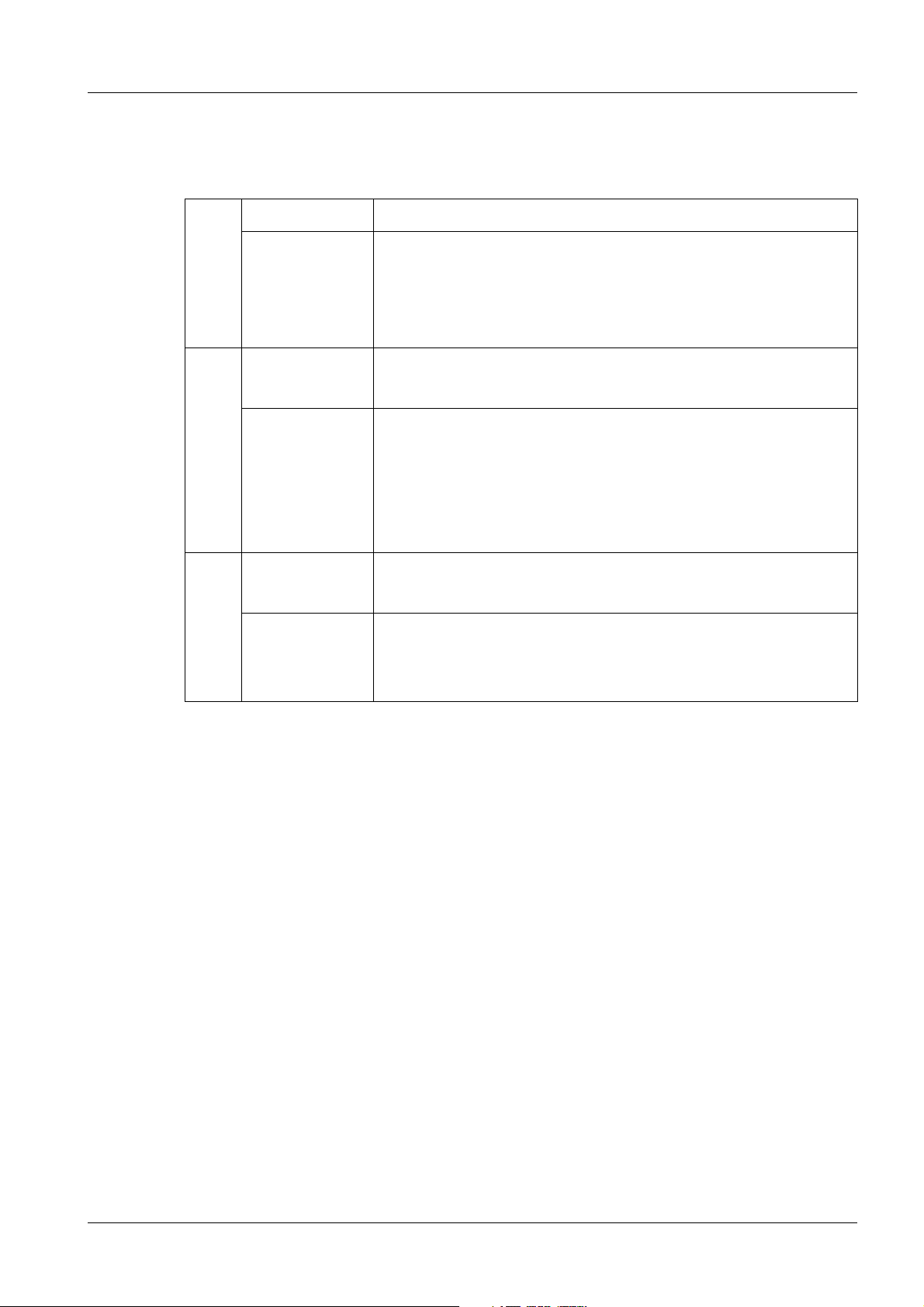

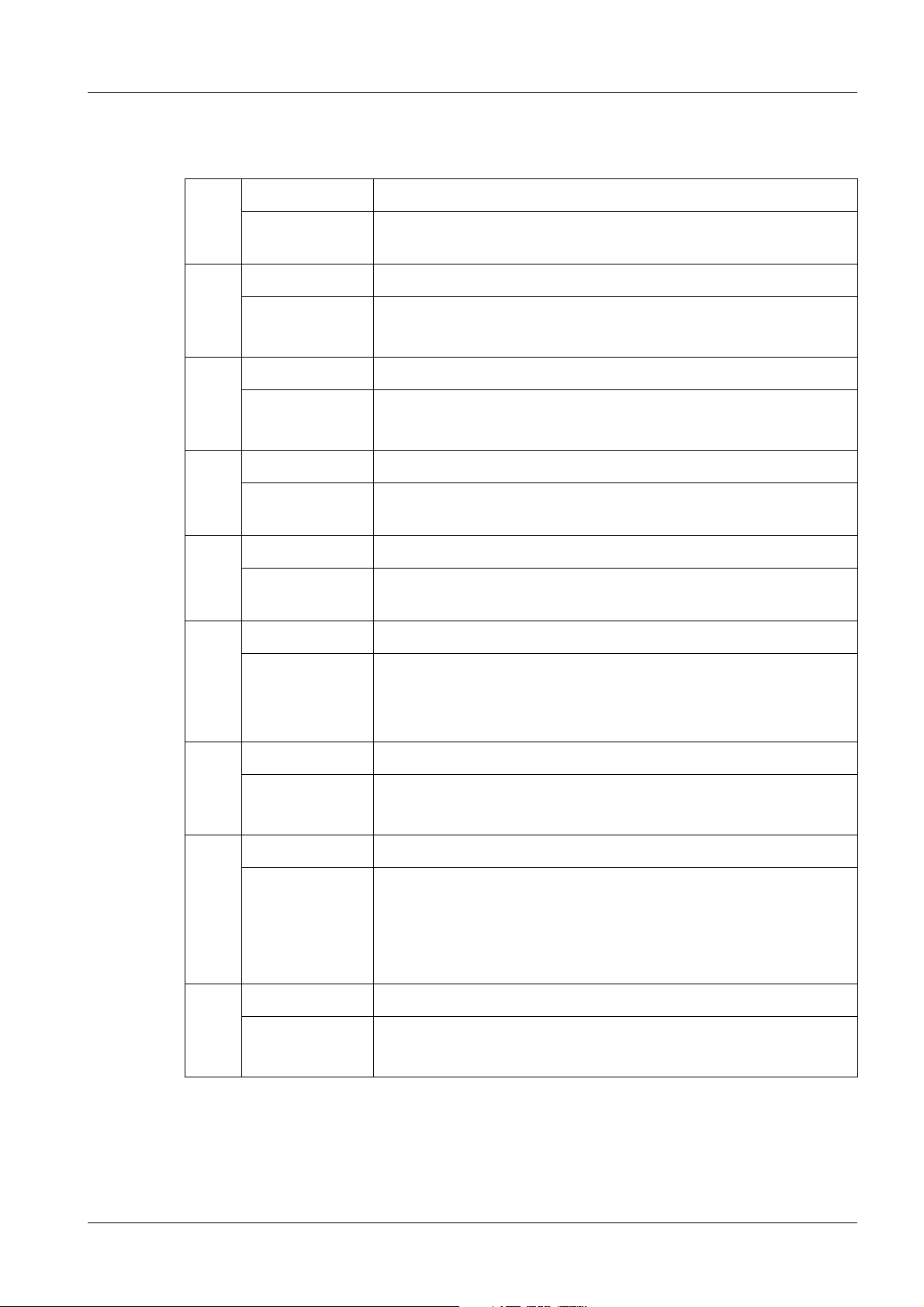

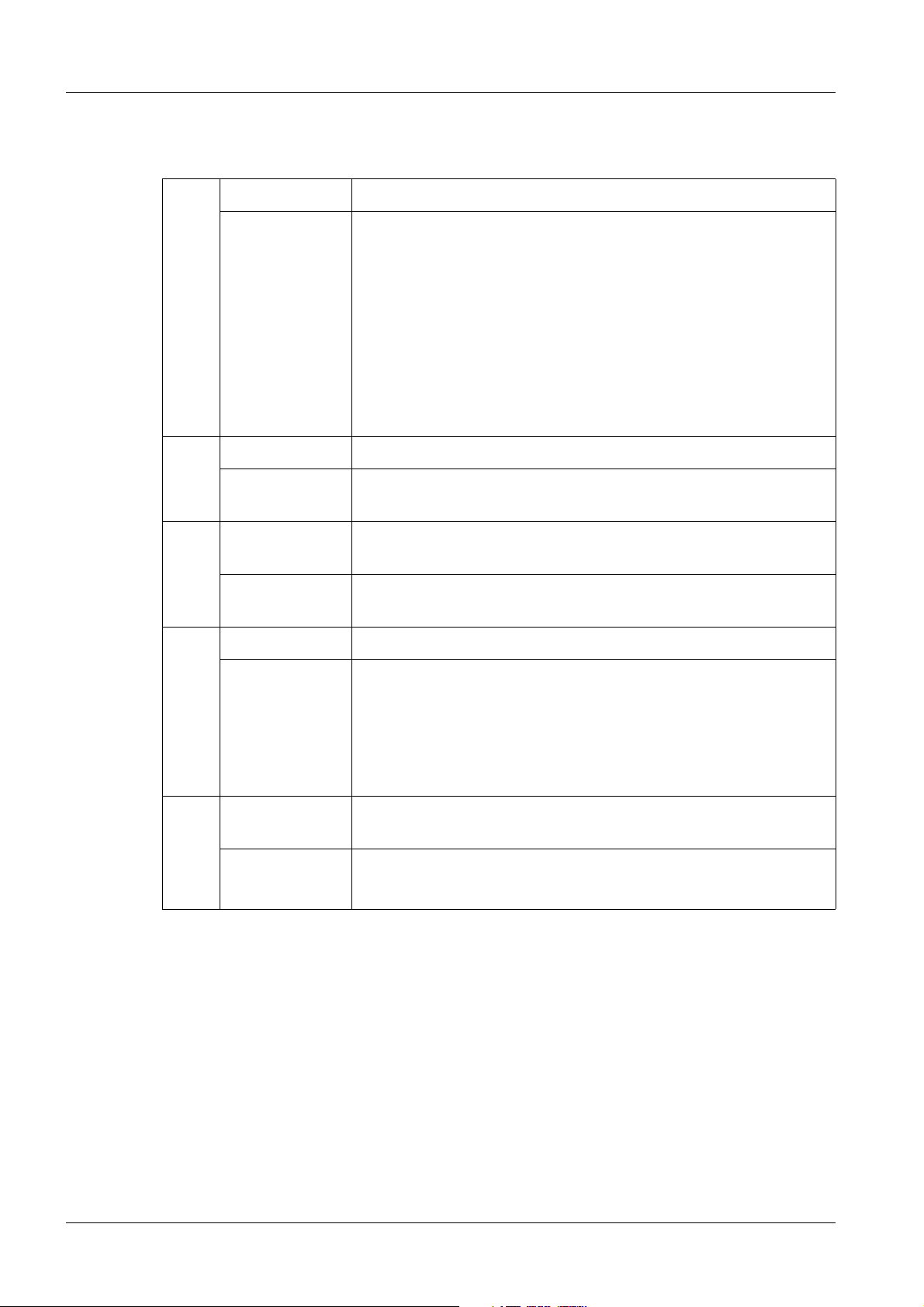

LITHOSTAR MODULARIS Parts Overview 0

Assembly Comments Regarding Replacement

Function Item No.

Shock wave head C 16 11 008 Refer to description: Replace the Water, Also

Replace the M1 Pump Head, Reset the Counter to

Zero

The shock wave head is shipped without the coupling bellows

Coupling bellows C 47 78 705 The clamping strap must be ordered separately!

Shock wave head

C plus

70 41 358 Refer to description: Replace the Water, Also

Replace the M1 Pump Head, Reset the Counter to

Zero

The shock wave head is shipped without the coupling bellows

Coupling bellows

70 41 416 The clamping strap must be ordered separately!

C plus

High voltage cable 11 81 523 Refer to description, "Cables in Corrugated Tub-

ing"

High voltage connector 11 81 622 Refer to description,

Charging Unit 11 58 000 Refer to description,

Cooling Unit 47 78 002 Refer to description, Filling in the "Dates in the

Startup" box.

Pump 47 73 847

70 41 101

Coupling pump; Refer to description, Cooling

Pump; Refer to description,

Temperature Sensor 55 31 277 Refer to description, "Cables in Corrugated Tub-

ing"

Pressure Sensor 55 31 243 Refer to description, "Cables in Corrugated Tub-

ing"

D3 Board 55 31 053 Refer to description,

Battery for D3 Board 31 46 073

Control Unit 55 31 129 No special instructions required

Perform a function test following replacement

Transformer and D1

Board

55 31 111 Make a note of the jumpers for the line voltage

230 V: 3 -5, 200V: 2 - 6, 120 V:1 - 5 and 4 - 7, 100

V: 1 -6 and 2 - 7

D1 Power Supply

55 31 301 Check fuses

Board

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 49 of 138

Page 50

50 LITHOSTAR MODULARIS

Angulation motor 55 31 392 Refer to description,

MODULARIS Support

55 31 020 Refer to description,

Arm

Articulated Joint Lock 55 31 608 Refer to description,

Potentiometer 70 50 433 Refer to description,

SIREMOBIL Switch 10 70 721 Refer to description,

CPL Adjustment

Adapter.

47 78 754 Version A usable for C-head only

As of version B adaptable for C and C plus

Isocenter Phantom

Fig. 32: Parking the phantom

Fig. 33: Phantom work

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 50 of 138

Medical Solutions

Page 51

LITHOSTAR MODULARIS 51

Shock Wave Head 0

Shock Wave Head Cover Panels 0

• Switch the system off. Remove the cover panels on the system unit by removing the

screws.

• Remove the water reservoir tank and drain the remaining water.

• Reinstall the water reservoir tank.

• Switch the system on. Position the support arm in the horizontal position.

• Set S2 service switch on the D3 board to position 2 (service on).

• Select "service" on the control unit and then "coupling circuit".

• Press the corresponding key for "empty" (S6) on the control unit until the coupling bel-

lows is located next to the lens.

• Switch the system off.

• Only the equipment with ultrasound localization:

- Unscrew the two placement parts for the ultrasound.

- Ensure that the screw lengths are correct when tightening them.

• Remove the mounting screws (I/Fig. 33 / p. 50) for the upper cover panel on both sides

of the shock head.

• Push the buttons in the direction of the arrow on both sides of the isocenter phantom

(Fig. 33 / p. 50) and at the same time flip back the isocenter phantom (Fig. 32 / p. 50).

• Detach the upper cover panel, remove it towards the front.

• Push the buttons on both sides of the isocenter phantom in the direction of the arrow

(Fig. 32 / p. 50) and at the same time flip up the isocenter phantom (Fig. 33 / p. 50).

• If required, remove the 3 paneling screws from both lower cover panels and remove the

cover panels.

• Reinstall the cover panels in the reverse order after completion of all work.

Fig. 34: Removing swh

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 51 of 138

Page 52

52 LITHOSTAR MODULARIS

Fig. 35: swh socket

Removing the Shock Wave Head 0

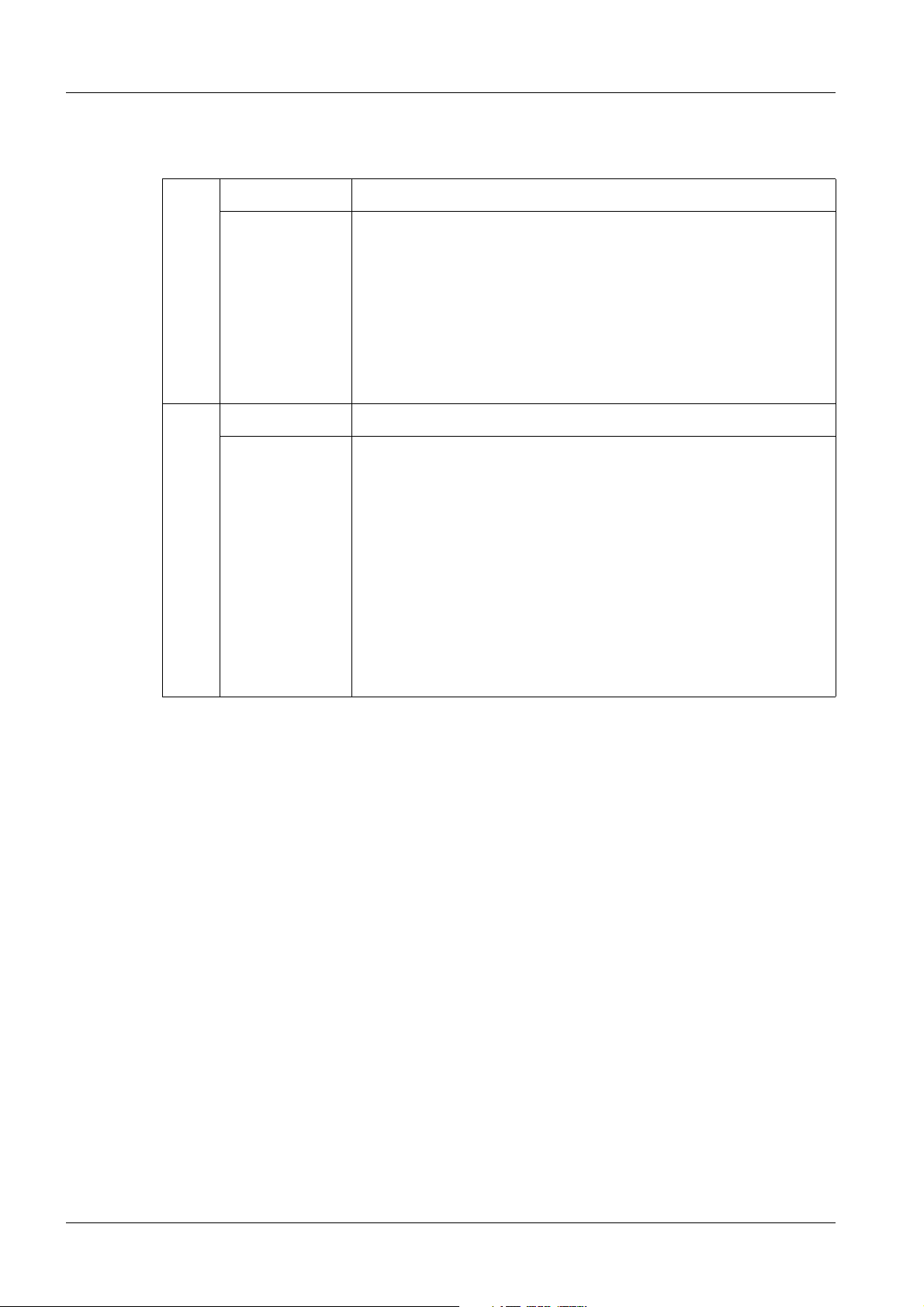

System configuration n =

several

Replace the

shock wave

head

• Remove the cover panels on the shock wave head (refer to "Shock Wave Head Cover

• Remove the coupling bellows, carefully pulling the small pin out of the air suction hose

1 LITHOSTAR MODULARIS and 1

SIREMOBIL Iso-C

Up to support arm S0050

For adjustment of isocenter on the

shock wave head; refer to chapter

"Isocenter with X-ray, up to Support

Arm Serial Number 0050".

Beginning with Support Arm S0051

For adjustment of isocenter on the

SIREMOBIL Iso-C; refer to chapter

"Isocenter with X-ray, beginning with

Support Arm Serial Number 0051".

Panels").

inside the coupling bellows (refer also to (Fig. 39 / p. 55) and (Fig. 40 / p. 55)).

1 LITHOSTAR MODULARIS and n SIREMOBIL Iso-C

It is important to follow this work flow to

avoid having to readjust the isocenter on

all SIREMOBILEs!

• Prior to replacing the shock wave head,

view the isocenter (the three C-Arm positions) and if possible, save it or make a

hardcopy.

• Replace the shock wave head.

• Check the isocenter; the setting must be

identical to that of the defective shock wave

head. If an adjustment is necessary, it must

be made using the shock wave head setting; refer to chapter "Isocenter with X-ray,

up to Support Arm Serial Number 0050".

• Loosen the four screws (V/Fig. 34 / p. 51) on the isocenter phantom using an Allen key

with a ball end, but do not remove them.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 52 of 138

Medical Solutions

Page 53

LITHOSTAR MODULARIS 53

• Flip the isocenter phantom toward the front and completely remove it (this may be diffi-

cult).

- If the isocenter phantom has a serial number (2/Fig. 34 / p. 51), it can be removed by

using two screw pulleys (1/Fig. 34 / p. 51) on the shock wave head.

• Open the Y8 valve (Fig. 42 / p. 58), i.e. switch the Y8 lever from horizontal = closed, to

vertical = open.

• Switch the system on.

• Set the S2 service switch on the D3 board to position 2 (service on).

• Select "service" on the control unit and then "cooling unit".

• Press the corresponding key for "empty" on the control unit until no more water flows

out.

• Set the S2 service switch on the D3 board to position 1 (service off).

• Switch the system off.

• Remove the 2 Allen screws (U/Fig. 35 / p. 52) underneath the shock wave head.

• Remove the screw (SL/Fig. 38 / p. 54) with the ground wire on the shock wave head.

• Wait at least 10 minutes after switching the system off. Then push the high-volt-

age connector down until the openings (O/Fig. 38 / p. 54) are accessible.

• Loosen the Allen screws in the openings (O/Fig. 38 / p. 54), but do not remove them.

• Disconnect all the water hoses at both interfaces of the shock wave head.

• Remove the shock wave head towards the front.

NOTE

Fig. 36: swh tube

There may be water remaining in the shock wave head.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 53 of 138

Page 54

54 LITHOSTAR MODULARIS

Fig. 37: swh sensor

Fig. 38: swh adjustment

Installing the Shock Wave Head 0

• Shorten both hoses at the shock wave head corresponding to the dimensions in

(Fig. 36 / p. 53).

• Check that the spring-mounted temperature sensor (T/Fig. 37 / p. 54) is seated correct-

ly in the groove.

• Insert the air suction hose centrally through the shock wave head (L/Fig. 40 / p. 55).

• Install the new shock wave head from above and insert the water hoses; when doing

this, ensure that the hose marked in red (R/Fig. 38 / p. 54) is located next to the

high-voltage connector and that the air suction hose underneath the shock wave head

is neither kinked nor caught in the shock wave head.

• Attach the shock wave head with the Allen screws (O/Fig. 38 / p. 54) that are visible

through the opening.

• Push the high-voltage connector as far up as possible until the openings

(O/Fig. 38 / p. 54) are covered again.

• Reattach the screw (SL/Fig. 38 / p. 54) with the ground wire.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 54 of 138

Medical Solutions

Page 55

LITHOSTAR MODULARIS 55

• Retighten the 2 Allen screws (U/Fig. 35 / p. 52) underneath the shock wave head.

• Place the isocenter phantom on top so that it is flush and secure it with the four screws

(V/Fig. 34 / p. 51) (use an Allen key with a ball end for this).

Fig. 39: swh air

Fig. 40: swh air tube

• Insert the air suction hose (L) as shown in (Fig. 39 / p. 55) and (Fig. 40 / p. 55) carefully

over the pin (ST) in the coupling bellows. Tie a knot to secure it (Fig. 39 / p. 55).

• Install the coupling bellows; when doing this, ensure that the pin (ST/Fig. 40 / p. 55) for

attachment of the hose is positioned at the highest point and is seated correctly in the

clamp.

• Replace the hose pump head for cooling pump M1 (refer to the section "Hose Pump

Head in the Coupling System"). (Not necessary if the IWAKI pump is installed).

• Fill the cooling system (refer to the section "Filling the Cooling System").

• Fill the coupling system (refer to the section "Filling the Coupling System").

• Check the isocenter as described in (Isocenter with X-Ray / p. 97).

• Select "service" and then "coupling system" on the control unit.

• Activate the corresponding key for "empty" (S6) on the control unit until the coupling

bellows is located next to the lens.

• Reinstall the covers of the shock wave head according to the procedure for removal.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 55 of 138

Page 56

56 LITHOSTAR MODULARIS

• Adjust the S2 service switch on the D3 board to position 1 (service off).

• Select "rinse" on the control unit and activate the cycle (ends automatically).

• Read out the counter for the shock wave head and record the value in the Operating

Protocol (in Register 4).

• Reset the counter (Service Software / p. 31).

• Connect the service PC to the board as described in (Service Software / p. 31).

• Read out both temperature values on the service PC; the difference may not exceed a

maximum of 3° C.

• Trigger shock waves: both temperature values should increase closely in parallel (DT e

3° C).

• Reattach the system cover.

• Perform a function test.

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 56 of 138

Medical Solutions

Page 57

LITHOSTAR MODULARIS 57

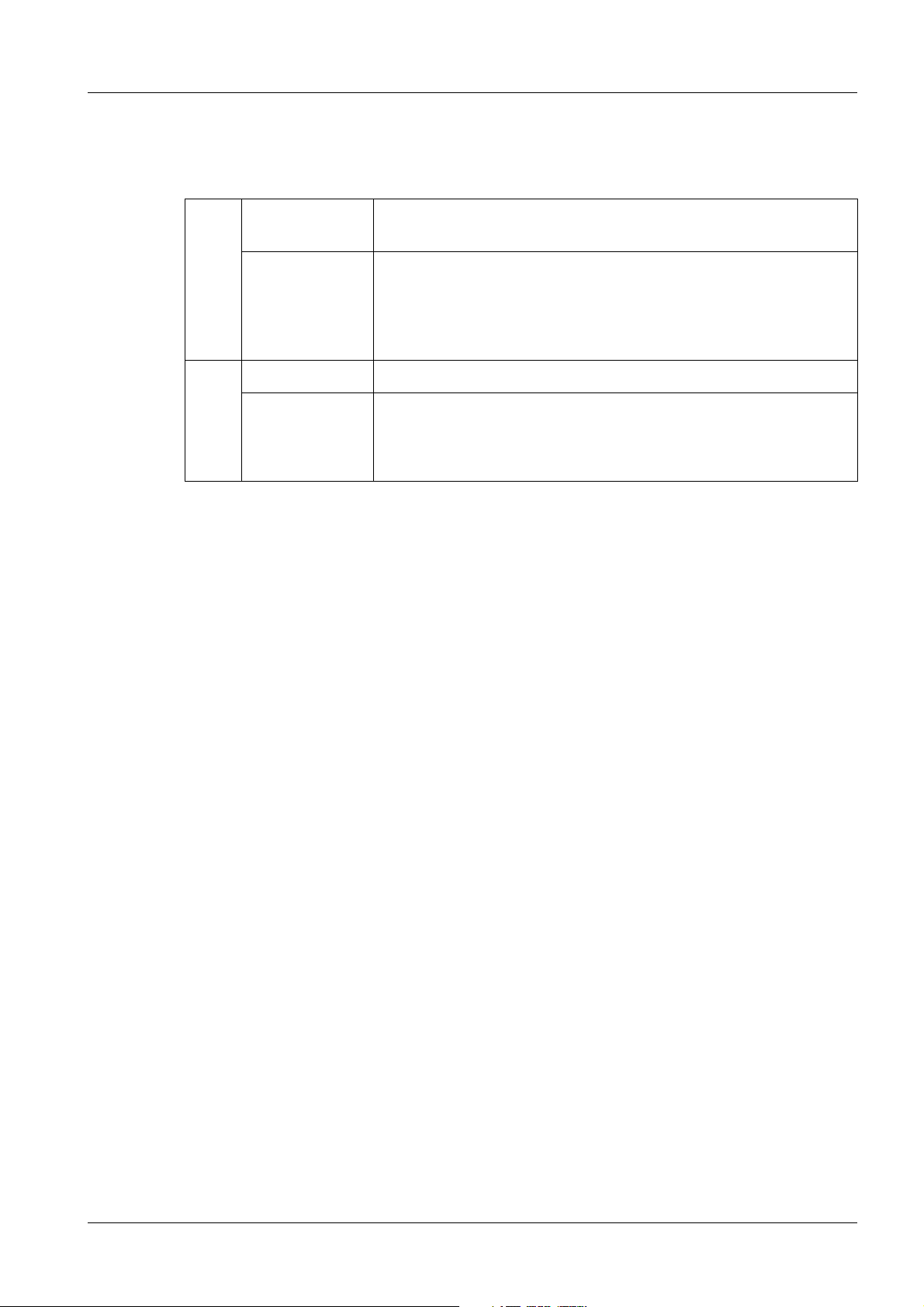

Replacing the Isocenter Phantom 0

System configuration n =

several

Replace the

isocenter

phantom

1 LITHOSTAR MODULARIS and 1

SIREMOBIL Iso-C

Up to support arm S0050

For adjustment of isocenter on the

shock wave head, refer to chapter

(LITHOSTAR MODULARIS up to

Support Arm Serial Number

0050/p.97)

Beginning with support arm S0051

For adjustment of isocenter on the

SIREMOBIL Iso-C, refer to chapter

(LITHOSTAR MODULARIS beginning with Support Arm Serial Number 0051 / p. 103).

1 LITHOSTAR MODULARIS and n SIREMOBIL Iso-C

It is important to follow this work flow to

avoid having to readjust the isocenter on

all SIREMOBILEs!

• Prior to replacing the isocenter phantom,

view the isocenter (the three C-Arm positions) and if possible, save it or make a

hardcopy.

• Replace the isocenter phantom.

• Check isocenter; the setting must be identi-

cal to that of the defective isocenter phantom. If an adjustment is necessary, it must

be made via the shock wave head setting;

refer to chapter (LITHOSTAR MODULARIS

up to Support Arm Serial Number

0050 / p. 97).

Fig. 41: Old pump

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 57 of 138

Page 58

58 LITHOSTAR MODULARIS

Fig. 42: New pump

Fig. 43: Bleeder valve

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 58 of 138

Medical Solutions

Page 59

LITHOSTAR MODULARIS 59

Cooling Unit 0

Checking the Cooling Unit 0

• Disconnect both cables at the B1 temperature switch (located on the cooling unit under-

neath the D3 board and the fiber optic connections).

• Connect both cables.

• Switch the system on.

• The fan and compressor in the cooling unit start up.

- If not, check the power supply.

- If o.k., replace the cooling unit.

• Switch the system off.

• Reconnect both cables.

Replacing the Cooling Unit 0

• Empty the coupling system and cooling system according to the instructions.

• Replace the cooling unit.

• Fill the coupling system and cooling system according to the instructions.

• Fill in the "Date of start up" box on the cooling unit label.

Filling the Cooling System 0

• Remove the system cover panels.

• Fill the water reservoir tank with distilled water.

• Switch the system on.

• Position the support arm in the horizontal position.

• Open the bleeder valve (cap K/Fig. 43 / p. 58) in the cooling unit by two turns (it should

remain open).

• Adjust the S2 service switch on the D3 board to position 2 (service on).

• Open the Y8 valve (Fig. 41 / p. 57) / (Fig. 42 / p. 58); i.e. switch the Y8 lever from hori-

zontal = closed to vertical = open.

• Select "service" on the control unit and then "cooling unit".

• Press the corresponding key for "fill" on the control unit until the water flowing from the

return line in the water reservoir tank is free of air bubbles. (the M1 hose pump will run

as long as required, V188 on the D3 board goes on).

• Close the Y8 valve (Fig. 41 / p. 57) / (Fig. 42 / p. 58); i.e. switch the Y8 lever from verti-

cal - open to horizontal = closed.

• Set the S2 service switch on the D3 board to position 1 (service off).

• Switch the system off.

• Reattach the system cover panels.

Siemens AG SPL1-130.840.01.05.02 LITHOSTAR MODULARIS

Medical Solutions

04.05 CS PS 24

Page 59 of 138

Page 60

60 LITHOSTAR MODULARIS

Filling the Coupling System 0

• Remove the system cover panels.

• Fill the water reservoir tank with distilled water, if necessary.

• Switch the system on and position the support arm in the horizontal position

• Set the S2 service switch on the D3 board to position 2 (service on).

• Select "service" on the control unit and then "coupling system".

• Press the corresponding key for "fill" (S6) on the control unit until the coupling bellows

rounds out slightly.

• Check whether the air suction hose inside the coupling bellows is actually secured at

the top position (Installing the Shock Wave Head / p. 54) (Fig. 39 / p. 55).

• Set the S2 service switch on the D3 board to position 1 (service off).

• Select "rinse" on the control unit and activate the cycle; this function ends automatically.

• If air bubbles are visible in the coupling bellows, start the "rinse" cycle again.

• Switch the S2 service switch on the D3 board to position 2 (service on).

• Select "service" and then "coupling system" on the control unit.

• Press the corresponding key for "empty" (S6/Fig. 33 / p. 50) on the control unit until the

coupling bellows is located next to the lens.

• Switch the system off.

• Fill the water reservoir tank up to the fill line (Fig. 41 / p. 57) / (Fig. 42 / p. 58) with dis-

tilled water.

• Set the S2 service switch on the D3 board to position 1 (service off).

• Switch the system on. The "rinse" cycle will be activated automatically and the coupling

bellows will fill.

• Switch the system off.

• Fill the water reservoir tank with distilled water.

• Reattach the system cover panels.

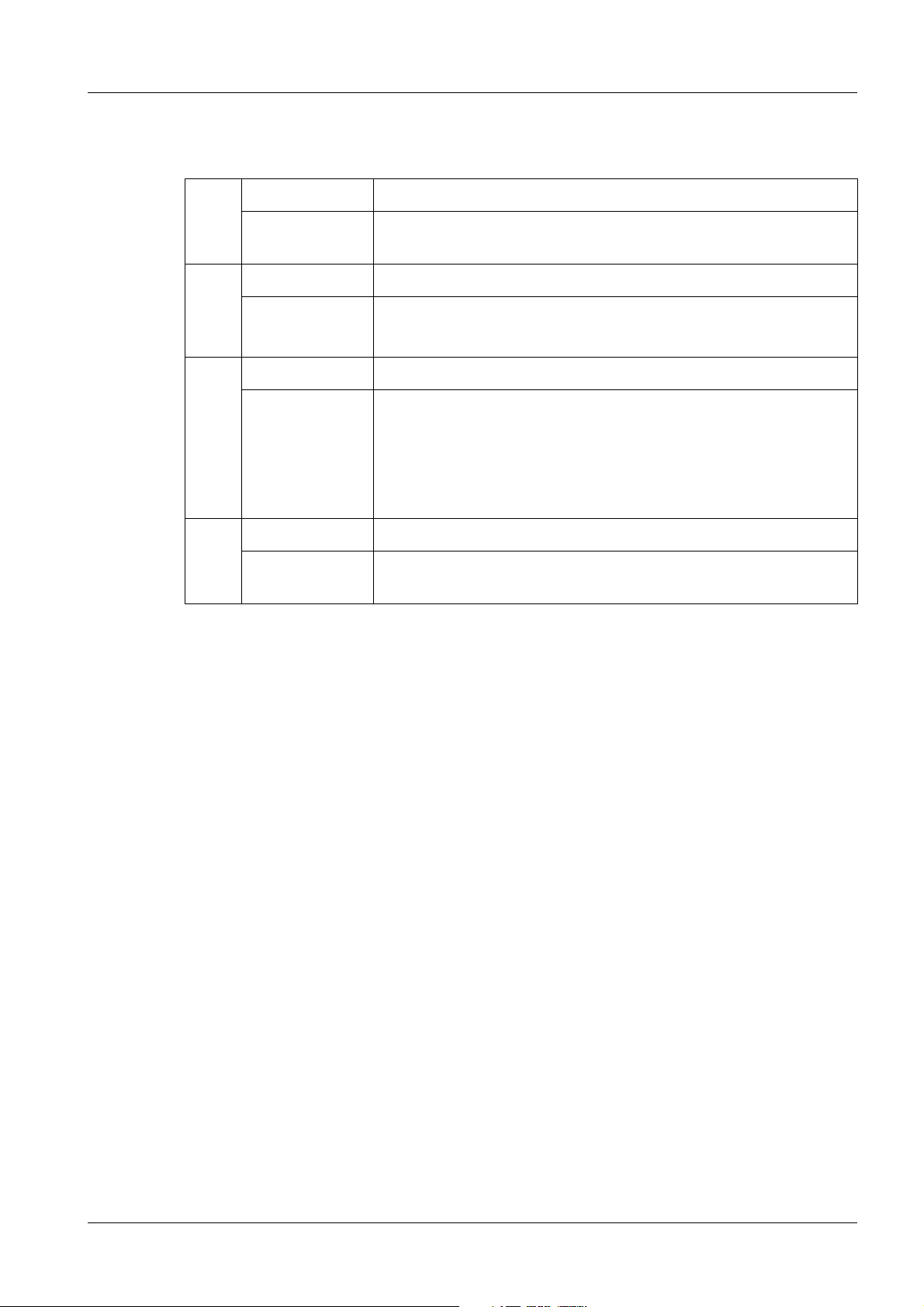

Emptying the Cooling System with the Old Pump (2/Fig. 10) 0

• Remove the system cover panels.

• Remove the water reservoir tank and empty the water.

• Insert the return hose into the water reservoir tank.

• Position the support arm in the horizontal position.

• Open the Y8 valve (Fig. 41 / p. 57), i.e. switch the Y8 lever from horizontal = closed to

vertical = open.

• Switch the system on.

• Set the S2 service switch on the D3 board to position 2 (service on).

• Select "service" on the control unit and then "cooling unit".

• Press the corresponding key for "empty" on the control unit until no more water flows.

• Set the S2 service switch on the D3 board to position 1 (service off).

LITHOSTAR MODULARIS SPL1-130.840.01.05.02 Siemens AG

04.05 CS PS 24

Page 60 of 138

Medical Solutions

Page 61

LITHOSTAR MODULARIS 61

• Switch the system off.

Emptying the Cooling system with the New Pump 0

(3/Fig. 42 / p. 58)

• Remove the system cover panels from the basic unit.

• Remove the water reservoir tank and empty the water.

• Insert the return hose into the water reservoir tank.

• Position the support arm in the horizontal position.

• Open the Y8 valve (Fig. 42 / p. 58), i.e. switch the Y8 lever from horizontal = closed to

vertical = open.

• Exchange the two water connections on the cooling pump. (The two black-marked hos-

es are not connected).

• Switch the system on.

• Set the S2 service switch on the D3 board to position 2 (service on).

• Select "service" and then "cooling unit" on the control unit.

• Press the corresponding key for "empty" on the control unit until the water stops.

• Set the service switch on the D3 board to position 2 (service off).

• Switch the system off.

• Properly connect the two water connections to the cooling pump. (Both black-marked

hoses must be reconnected).

Emptying the Coupling System 0

• Remove the system cover panels on the basic unit.

• Remove the water reservoir tank and empty the water.

• Switch the system on.

• Position the support arm in the horizontal position.

• Set the S2 service switch on the D3 board to position 2 (service on).

• Select "service" and then "coupling system" on the control unit.