Page 1

SENTRON 3WL / 3VL

Library for SIMATIC PCS 7 V1.0

Function Manual

•

11/2008

SIMATIC

Page 2

Page 3

Library SENTRON 3WL / 3VL for

SIMATIC PCS 7

Function Manual

Introduction

Information about the library

Description of blocks

Configuration Manual

Technical specifications

Technical support

1

2

3

4

5

6

V1.0

11/2008

A5E02316914A-01

Page 4

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E02316914A-01

Ⓟ 11/2008

Copyright © Siemens AG 2008.

Technical data subject to change

Page 5

Table of contents

1 Introduction................................................................................................................................................ 7

1.1 General ..........................................................................................................................................7

1.2 Further documentation

1.3 Installing the library

1.4 Hardware configuration

1.4.1 Incorporating v

2 Information about

2.1 Overview of the blocks.................................................................................................................13

2.2 General information about OS ty

2.2.1 Faceplates....................................................................................................................................13

2.2.2 Symbols .......................................................................................................................................15

3 Description of

3.1 Diagnostics block DIA_WLVL ......................................................................................................17

3.1.1 Calling OBs

3.1.2 Called blocks................................................................................................................................18

3.1.3 Function .......................................................................................................................................18

3.1.4 Message behavior........................................................................................................................18

3.1.5 Error behavior ..............................................................................................................................19

3.1.6 I/O access error ...........................................................................................................................19

3.1.7 Module fault..................................................................................................................................19

3.1.8 Read diagnostics data of 3WL / 3VL

3.1.9 Start-up characteristics ................................................................................................................20

3.1.10 Block parameters .........................................................................................................................20

3.2 Driver module DRV

3.2.1 Calling OBs

3.2.2 Called blocks................................................................................................................................23

3.2.3 Function .......................................................................................................................................23

3.2.4 Message behavior........................................................................................................................26

3.2.5 Assignment of the cycli

3.2.6 Addressing and modul

3.2.7 Processing the diagnostics data of the 3WL dev

3.2.8 Start-up characteristics ................................................................................................................29

3.2.9 Block parameters .........................................................................................................................29

3.2.10 Description of symbols and faceplates ........................................................................................60

the library .................................................................................................................... 13

blocks................................................................................................................................ 17

ia GSD file..............................................................................................................8

..................................................................................................................................18

..................................................................................................................................22

...................................................................................................................7

........................................................................................................................7

..................................................................................................................8

picals ........................................................................................13

...........................................................................................19

_3WL.............................................................................................................22

c process image......................................................................................27

e driver .....................................................................................................28

ice ....................................................................28

3.3 Driver module DRV

3.3.1 Calling OBs

3.3.2 Called blocks................................................................................................................................96

3.3.3 Function .......................................................................................................................................96

3.3.4 Message behavior........................................................................................................................99

3.3.5 Assignment of the cycli

3.3.6 Addressing and modul

3.3.7 Processing the diagnostics data of the 3VL device ...................................................................102

3.3.8 Start-up characteristics ..............................................................................................................102

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

..................................................................................................................................96

_3VL..............................................................................................................95

c process image....................................................................................100

e driver ...................................................................................................101

3

Page 6

Table of contents

3.3.9 Block parameters ...................................................................................................................... 102

3.3.10 Description of symbols and faceplates ..................................................................................... 111

4 Configuration

4.1 Interconnections on COM15 for 3WL

4.1.1 24V DC voltage ......................................................................................................................... 126

4.1.2 Other voltage lev

4.2 Interconnections on COM10 for 3VL

4.2.1 Connection for c

4.2.2 Connection for motorized operating mechanism

4.3 Connection on COM20 for

4.3.1 COM20 pin assignment............................................................................................................. 130

4.3.2 Connecting the optional motorized op

4.4 Configuring a meas

4.4.1 Creating the PLC program

4.4.2 Connection to WinCC................................................................................................................ 135

5 Technical specif

6 Technical su

Figures

Figure 1-1

Figure 1-2 Selection of basic type for 3WL .................................................................................................... 8

Figure 1-3 Selection of basic type for 3VL ..................................................................................................... 9

Catalog path for incorporating via GSD file................................................................................... 8

Manual............................................................................................................................. 125

........................................................................................ 125

els .................................................................................................................. 127

......................................................................................... 128

ommunication ................................................................................................. 128

...................................................................... 129

3VL................................................................................................. 130

erating mechanism to COM20 ...................................... 131

uring point .................................................................................................. 132

........................................................................................................ 132

ications......................................................................................................................... 139

pport .................................................................................................................................. 141

Figure 1-4 Properties of the 3WL / 3VL device directly connected to the DP master system...................... 10

Figure 1-5 Properties of the 3WL / 3VL device following a Y link ................................................................ 11

Figure 2-1 Section of the overview display................................................................................................... 13

Figure 2-2 Trend setting on the icon............................................................................................................. 14

Figure 2-3 Icons in Graphics Designer......................................................................................................... 15

Figure 3-1 Symbol with 1 measurement....................................................................................................... 61

Figure 3-2 Faceplate for standard view........................................................................................................ 63

Figure 3-3 Faceplate for measurements view, current tab........................................................................... 65

Figure 3-4 Faceplate for measurements view, voltage tab .......................................................................... 66

Figure 3-5 Faceplate for measurements view, active power/energy tab...................................................... 67

Figure 3-6 Faceplate for measurements view, reactive power/energy tab .................................................. 68

Figure 3-7 Faceplate for measurements view, apparent power tab............................................................. 69

Figure 3-8 Faceplate for measurements view, miscellaneous tab............................................................... 70

Figure 3-9 Faceplate for diagnosis view, warnings tab ................................................................................ 71

Figure 3-10 Faceplate for diagnosis view, trip reason tab.............................................................................. 72

Figure 3-11 Faceplate for diagnosis view, setpoints tab ................................................................................ 74

Figure 3-12 Faceplate for maintenance view, maintenance 1 tab ................................................................. 76

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

4 Function Manual, 11/2008, A5E02316914A-01

Page 7

Table of contents

Figure 3-13 Faceplate for maintenance view, maintenance 2 tab ..................................................................77

Figure 3-14 Faceplate for maintenance view, operation tab...........................................................................79

Figure 3-15 Faceplate for protect. para view, parameter set A.......................................................................80

Figure 3-16 Faceplate for protect. para view, parameter set B.......................................................................82

Figure 3-17 Faceplate for protect. para view, additional tab...........................................................................84

Figure 3-18 Faceplate for ext. protect. para view, current tab ........................................................................85

Figure 3-19 Faceplate for ext. protect. para view, voltage tab........................................................................86

Figure 3-20 Faceplate for ext. protect. para view, reactive power tab ............................................................87

Figure 3-21 Faceplate for ext. protect. para view, frequency tab....................................................................88

Figure 3-22 Faceplate for setpoints view, current tab .....................................................................................89

Figure 3-23 Faceplate for setpoints view, voltage tab.....................................................................................90

Figure 3-24 Faceplate for setpoints view, frequency tab ................................................................................91

Figure 3-25 Faceplate for setpoints view, active power tab............................................................................92

Figure 3-26 Faceplate for setpoints view, apparent/reactive power tab .........................................................94

Figure 3-27 Faceplate for message suppression view....................................................................................95

Figure 3-28 Symbol with 1 measurement......................................................................................................111

Figure 3-29 Faceplate for standard view.......................................................................................................113

Figure 3-30 Faceplate for measurements view.............................................................................................115

Figure 3-31 Faceplate for diagnosis view......................................................................................................116

Figure 3-32 Faceplate for maintenance view, maintenance 1 tab ................................................................118

Figure 3-33 Faceplate for maintenance view, operation tab.........................................................................119

Figure 3-34 Faceplate for protect. para view, protect. para tab ....................................................................120

Figure 3-35 Faceplate for protect. para view, additional tab.........................................................................121

Figure 3-36 Faceplate for ext. protect. para view..........................................................................................122

Figure 3-37 Faceplate for setpoints view ......................................................................................................123

Figure 3-38 Faceplate for message suppression view..................................................................................124

Figure 4-1 COM15 interconnection at 24V DC voltage...............................................................................126

Figure 4-2 COM15 interconnection at other voltage levels.........................................................................127

Figure 4-3 Connection for communication ..................................................................................................128

Figure 4-4 Connection for motorized operating mechanism .......................................................................129

Figure 4-5 COM20 connection to SENTRON VL ........................................................................................130

Figure 4-6 Driver block in CFC chart (not connected).................................................................................132

Figure 4-7 Compile program .......................................................................................................................133

Figure 4-8 Generate module driver .............................................................................................................133

Figure 4-9 Driver block in CFC chart connected .........................................................................................134

Figure 4-10 Basing the block icons on the plant hierarchy ...........................................................................135

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

5

Page 8

Table of contents

Figure 4-11 Creating block icons out of plant hierarchy ............................................................................... 136

Figure 4-12 Create block icons when compiling OS .................................................................................... 136

Figure 4-13 Link picture component with measuring point........................................................................... 137

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

6 Function Manual, 11/2008, A5E02316914A-01

Page 9

Introduction

1.1 General

The Library SENTRON 3WL / 3VL for SIMATIC PCS 7 software package is used to connect

the circuit breakers SENTRON 3WL and 3VL to a SIMATIC PCS 7 process control system

and contains the following components:

● Block library with:

– DIA_WLVL: diagnostic block

– DRV_3WL: PCS 7 block for recording measurements, setpoints, protective

– DRV_3VL: PCS 7 block for recording measurements, setpoints, protective

– User objects and operating blocks for operating and observing measured data on the

● Online help in German and English

● Manual in German and English

The block library can be used in in the PCS 7 versions V6.1 SP1, V7.0 and V7.0 SP1.

1

parameters, etc. of a 3WL circuit-breaker

parameters, etc. of a 3VL circuit breaker

OS

1.2 Further documentation

You can find further details in the following manuals:

● Manual for SENTRON WL and SENTRON VL circuit-breakers with communication

capability

● SENTRON WL Operating Manual

● SENTRON VL Operating Manual

1.3 Installing the library

To start the installation, please insert the CD in the CD-ROM drive on your PG/PC and

launch the "Setup.exe" program. All the other information you need will be provided during

the installation process. Please also read the information in the readme file.

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

7

Page 10

Introduction

1.4 Hardware configuration

1.4 Hardware configuration

The driver concept for 3WL / 3VL supports operation of the circuit-breaker as a DP slave

directly connected to the DP master system as well as connected following a Y-link DPV0 or

DPV1.

The circuit-breakers in this setup can be incorporated using a GSD file.

NOTICE

In such cases ensure that the circuit-breaker's I/O data is within the control's process

image. This is absolutely essential to the driver generator's functionality.

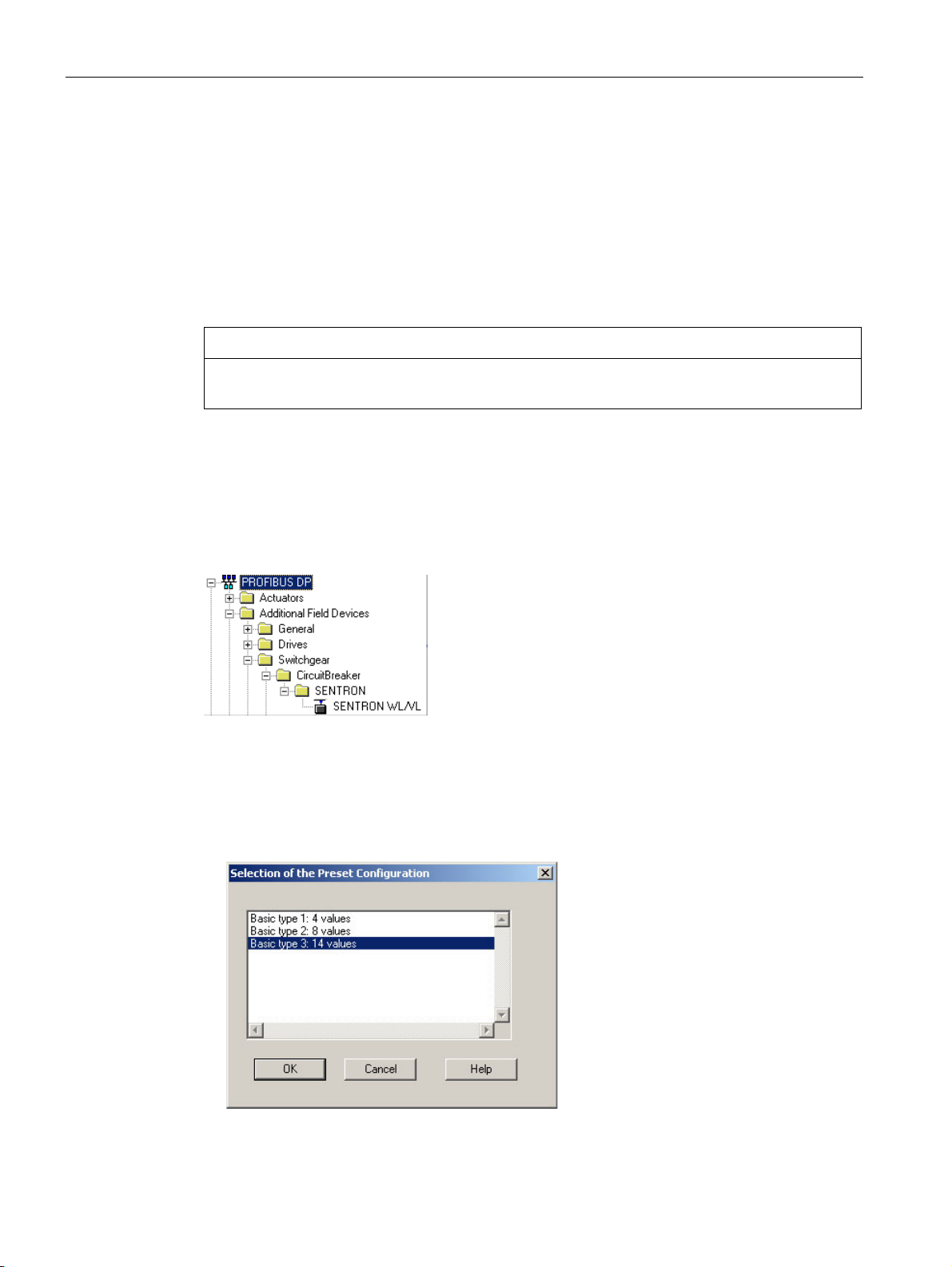

1.4.1 Incorporating via GSD file

If the 3WL / 3VL device is incorporated via GSD SIEM80C0.gsd, it is entered in the hardware

configuration catalog under PROFIBUS-DP → Other field devices → Switchgear:

Figure 1-1 Catalog path for incorporating via GSD file

The following I/O configuration applies for 3WL:

● Outputs: 2 bytes of digital control data

● Inputs: 44 bytes of binary status (2 bytes) and measurements with property bytes (42

bytes)

Figure 1-2 Selection of basic type for 3WL

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

8 Function Manual, 11/2008, A5E02316914A-01

Page 11

Introduction

1.4 Hardware configuration

This configuration corresponds to basic type 3 for 3WL. This basic type must be set to

ensure operation.

The following I/O configuration applies for 3VL:

● Outputs: 2 bytes of digital control data

● Inputs: 14 bytes of binary status (2 bytes) and measurements with property bytes (12

bytes)

Figure 1-3 Selection of basic type for 3VL

This configuration corresponds to basic type 1 for 3VL. This basic type must be set to ensure

operation.

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

9

Page 12

Introduction

1.4 Hardware configuration

Configuration in HW config.

In the HW config., 3WL / 3VL is installed with the corresponding GSD file (see above) and

with basic type 3 and/or 1.

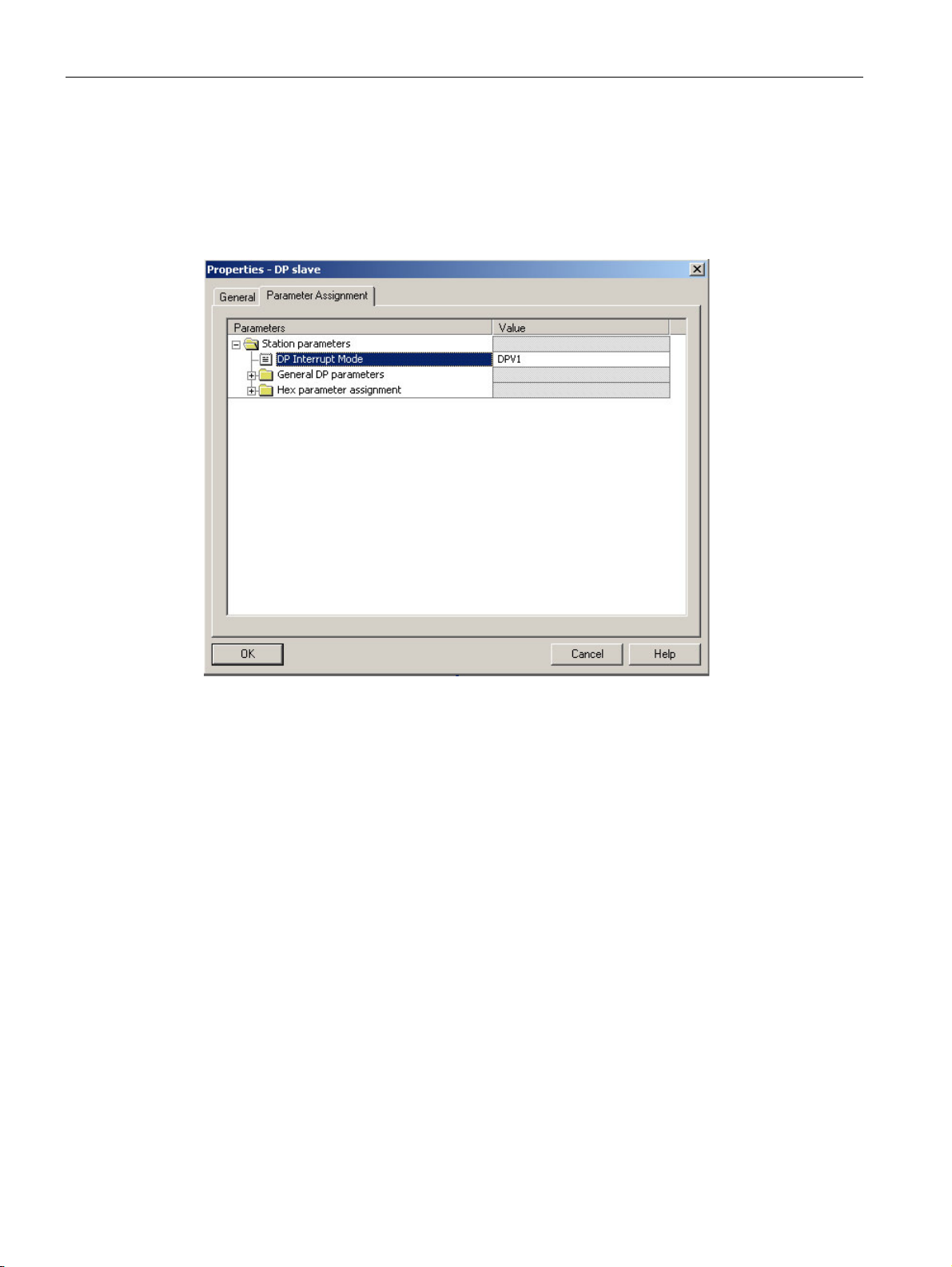

Figure 1-4 Properties of the 3WL / 3VL device directly connected to the DP master system

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

10 Function Manual, 11/2008, A5E02316914A-01

Page 13

Introduction

1.4 Hardware configuration

If 3WL / 3VL is connected following a Y-link DPV0 or DPV1, 3WL / 3VL must be configured

in the HW config. as a DPV0 slave. All acyclic services and interrupts are deactivated. This

means that the device no longer outputs diagnostic interrupts and data records can no

longer be read from the device. For details of the effect that this has on the response of the

blocks, refer to

Section 3 Description of the blocks (Page 17).

Figure 1-5 Properties of the 3WL / 3VL device following a Y link

The start addresses of inputs and outputs must be located in the partial process image that

is assigned to the watchdog interrupt OB in which the driver block is called.

The LADDR parameter input of the driver block must be connected to the start address of

the inputs of the 3WL / 3VLdevice.

The assignment of the cyclic interface is included in the description of the driver block.

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

11

Page 14

Introduction

1.4 Hardware configuration

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

12 Function Manual, 11/2008, A5E02316914A-01

Page 15

Information about the library

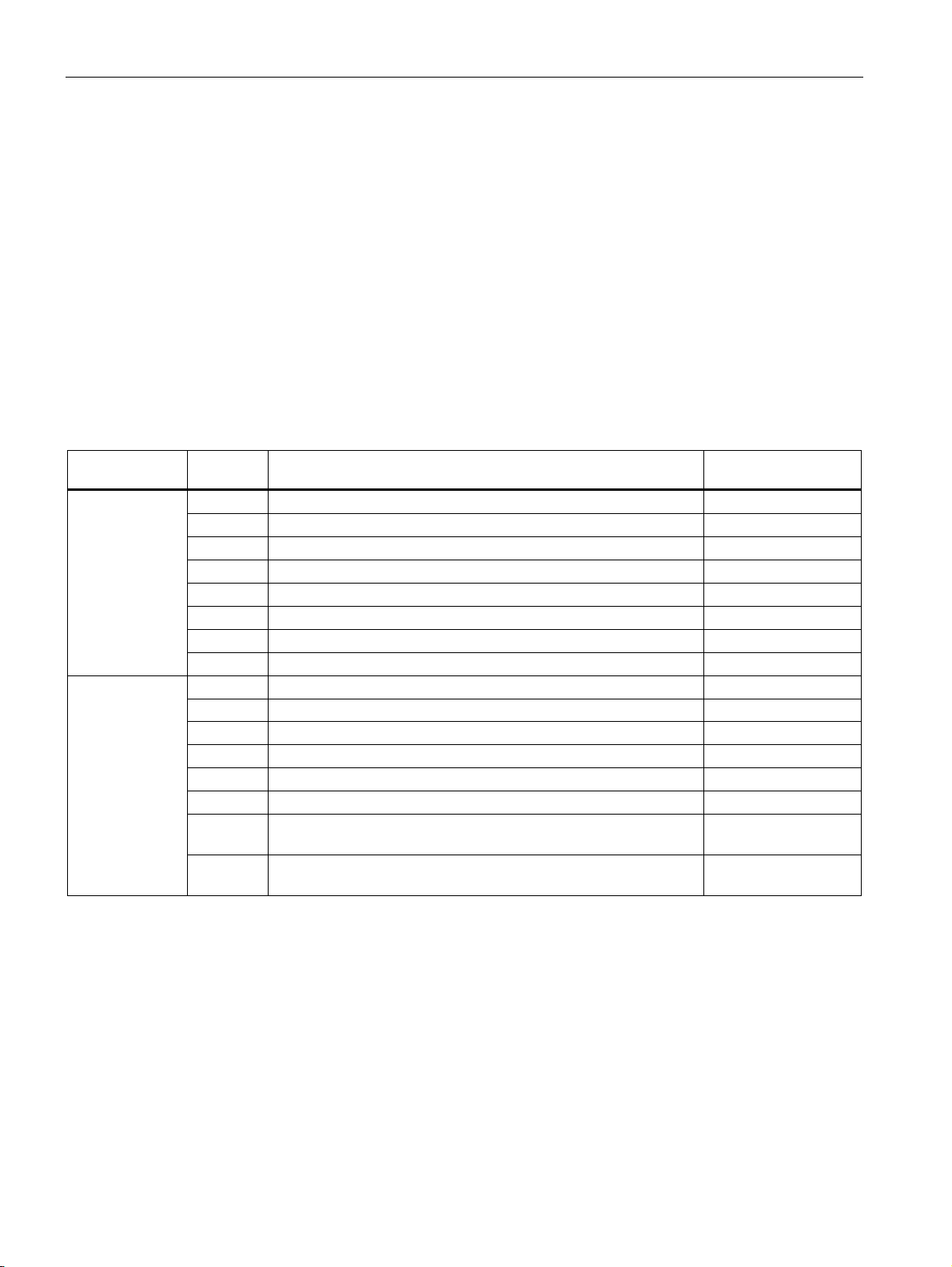

2.1 Overview of the blocks

The library contains the following blocks:

Name Function Number

DIA_WLVL Diagnostic block FB1742

DRV_3WL PCS 7 driver block FB1741

DRV_3VL PCS 7 driver block FB1740

2.2 General information about OS typicals

2.2.1 Faceplates

Faceplates are configured with the Graphics Designer using the templates and PCS 7specific standard views (Trend, Batch, and Alarm) provided by the Faceplate Designer. If

other user objects and functions are required, they can be added.

2

Overview

The faceplates described are provided as functional and tested examples and can be

adapted by the user.

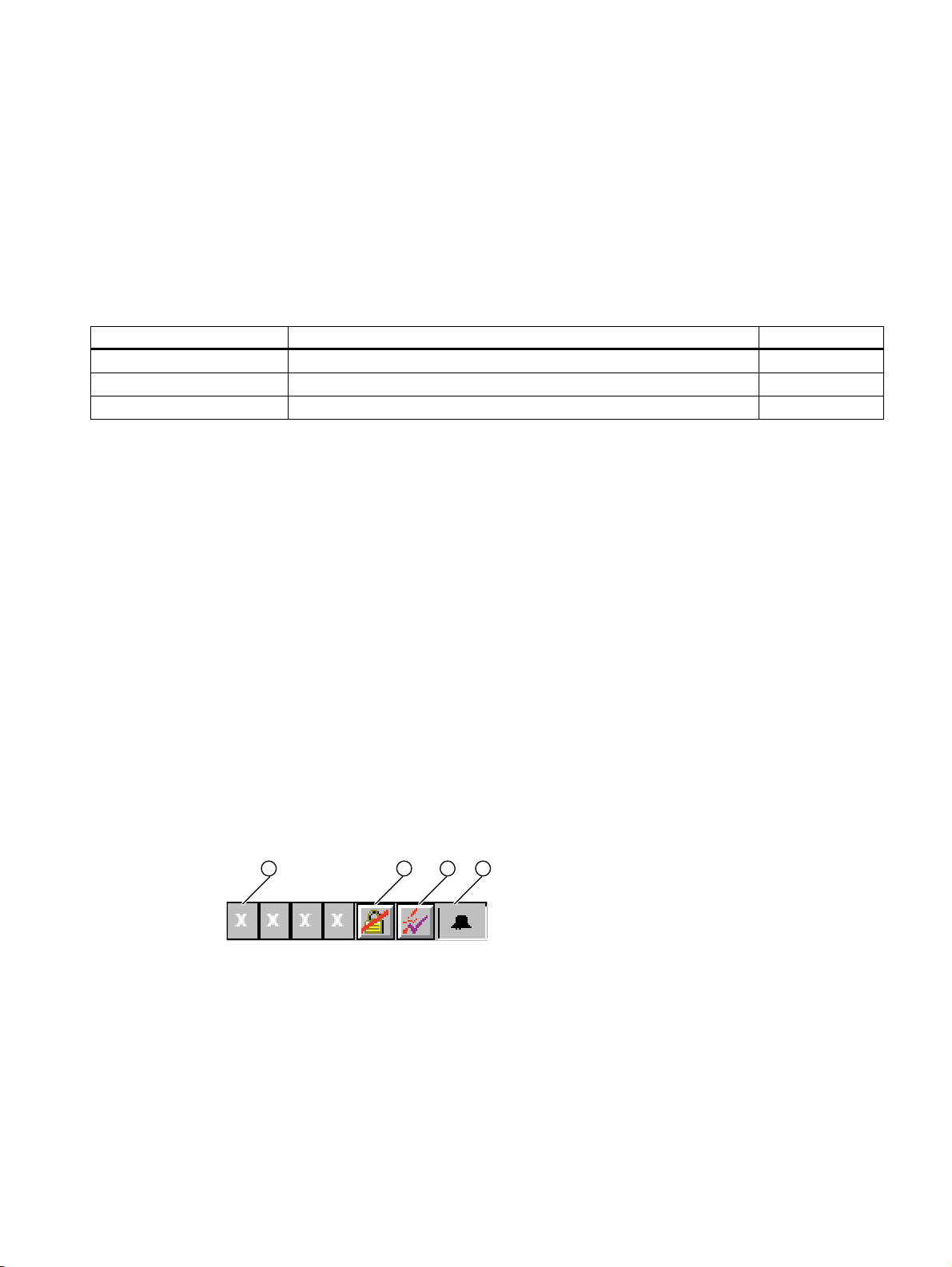

Two icons and a group/loop display with all the necessary displays are provided for the

driver block. The relevant group display is called using the icons.

The display forms part of the @PG_DRV_3WL_OVERVIEW.pdl / @PL_DRV_3WL.pdl

(and/or @PG_DRV_3VL_OVERVIEW.pdl / @PL_DRV_3VL.pdl) basic displays.

(1) Group display

(2) Message lock (MSG_LOCK)

(3) Message acknowledgment

(4) Message suppression (QMSG_SUP)

Figure 2-1 Section of the overview display

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

13

Page 16

Information about the library

2.2 General information about OS typicals

Trend (@PCS7_trend.pdl)

The "ReturnPath" and "StandardTrend" properties must be parameterized on the icon to

incorporate a trend in a faceplate.

• StandardTrend

:

• ReturnPath:

2: Online values with 5 min time axis

> 2: Archive values with time axis of the value entered (in

min)

.AVGCUR Structural element name starting with a full stop

: Separators

CO_GREEN Color for trend

, Separators between two online values

Figure 2-2 Trend setting on the icon

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

14 Function Manual, 11/2008, A5E02316914A-01

Page 17

Information about the library

2.2 General information about OS typicals

2.2.2 Symbols

The process display icons are based on the process symbols provided by the Faceplate

Designer. The diagrams are schematic diagrams.

Template pictures @PCS7Typicals_SENTRON.pdl / @Template_SENTRON.pdl

The icons can be found in the template diagrams @PCS7Typicals_SENTRON.pdl and

@Template_SENTRON.pdl.

When using the "Create/Update Block Icons" function, PCS 7 accesses the file

@PCS7Typicals_SENTRON.pdl .

When manually copying the icons into a process display, you must use the icons from the

@Template_SENTRON.pdl file.

Different variants of block icons

There may be several variants of block icons for one measuring point. These variants are

distinguished by the "type" attribute: The value of this attribute describes the variant. For

example, if you look at a variant of the block icon for a valve, you will find the value

"@Valve/2". You use the part of the value displayed after the "/" to control which variant of

the block icon is produced. You therefore have to enter this part in the object properties for

the block instance. If you do not enter any parameters in the object properties for the block

instance, the standard block icon is produced automatically: This is the block icon with the

"/1" label for the "type" attribute, e.g. "@Valve/1".

Only one version is however supplied per circuit breaker type with the library.

Connection to the measuring point

There is one icon for the driver block that is linked to the associated measuring point using

the "Connect picture block to tag structure" function.

The icons contain the following visible information:

(1) Tag name

(2) Maximum phase current

(3) Group display (EventState)

(4) Circuit breaker in manual (M) / automatic (A)

(5) Circuit breaker state

Figure 2-3 Icons in Graphics Designer

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

15

Page 18

Information about the library

2.2 General information about OS typicals

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

16 Function Manual, 11/2008, A5E02316914A-01

Page 19

Description of blocks

The library consists of the blocks described below:

Diagnostic block (Page 17) DIA_WLVL

●

● Driver block (Page 22) DRV_3WL

● Driver block (Page 95) DRV_3VL

3.1 Diagnostics block DIA_WLVL

FB1742

The DRV_3WL and DRV_3VL driver blocks have a shared diagnostics block DIA_WLVL.

Description of block:

● Calling OBs (Page 18)

● Called blocks (Page 18)

● Function (Page 18)

3

See also

● Message behavior (Page 18)

● Error behavior (Page 19)

● I/O access error (Page 19)

● Module fault (Page 19)

● Read diagnostics data of 3WL / 3VL (Page 19)

● Start-up characteristics (Page 20)

● Block parameters (Page 20)

Driver module DRV_3WL (Page 22)

Driver module DRV_3VL (Page 95)

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

17

Page 20

Description of blocks

3.1 Diagnostics block DIA_WLVL

3.1.1 Calling OBs

The block must be installed in the processing sequence in the following OBs (occurs

automatically in the CFC):

OB1 Cyclic program

OB82 Diagnostic interrupt

OB83 Insert/remove module interrupt

OB85 Program error

OB86 Rack failure

OB100 Warm restart

Installation is performed automatically by means of the function "Generate Module Driver"

3.1.2 Called blocks

The block calls the following blocks:

SFC6 RD_SINFO

SFC51 RDSYSST

3.1.3 Function

The DIA_WLVL block is responsible for diagnosis of the 3WL / 3VL device.

If a 3WL / 3VL is directly connected to the DP master system, the block evaluates the acyclic

events that are relevant for 3WL / 3VL (start-up, DP station failure, module fault), generates

quality code and diagnostic information for the MOD_PAX0 block and provides the driver

block with status information via parameter output OMODE.

In the case of operation following a Y link DPV1, diagnostic information cannot be supplied

to the driver block. The block evaluates start-up, DP station failure and module faults and

provides the driver block with this information via parameter output OMODE.

This block is not used in the case of connection following Y link DPV0.

3.1.4 Message behavior

The block has no message behavior. The messages for DP station failure and module fault

are generated by the MOD_PAX0 block (in the case of direct connection to the DP master

system) or PADP_L00 (in the case of connection following the Y link DPV0) or OB_DIAG1 (in

the case of connection following the Y link DPV1).

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

18 Function Manual, 11/2008, A5E02316914A-01

Page 21

Description of blocks

3.1 Diagnostics block DIA_WLVL

3.1.5 Error behavior

Failure of the DP master or DP slave has already been determined by the previous

OB_DIAG1 block and evaluated by the RACKF, SUBN1ERR and SUBN2ERR inputs.

In the event of an error, the output OMODE features the identifier for "higher-ranking error"

(OMODE = 16#40xxxxxx).

3.1.6 I/O access error

From the viewpoint of the I/O configuration, 3WL / 3VL is a "compact" DP slave, i.e. it always

has a fixed I/O configuration. It can therefore be assumed that if an I/O access error occurs,

the entire DP slave must have failed (which is reported shortly afterwards).

I/O access errors are not evaluated any further, for this reason.

3.1.7 Module fault

Following a restart and when ACC_ID = TRUE, the module addressed with LADDR is

checked. SZL ID xC91 is read for this purpose. If the module addressed with LADDR does

not exist, the output QMODF is set and the identifier for "higher-ranking error" is entered for

the OMODE output (OMODE=16#40xxxxxx).

3.1.8 Read diagnostics data of 3WL / 3VL

If the 3WL / 3VL outputs a diagnostics alarm, system function RDSYSST (SFC51) will

activate reading of the device-specific diagnostics data.

The device-specific diagnostics data is also read out using the system function RDSYSST

(SFC51) following a CPU restart and rack start-up.

Since 3WL / 3VL following a Y link switches over to DPV0 mode, the device-specific

diagnostics data cannot be read.

The read information is transferred to the MOD_PAX0 block and the driver block where it is

evaluated.

It is also read if a request is output by the driver block at the "DIAG_REQ" input. This occurs

if:

● MAINT_MC ! = 0

● R_MAINT = 1

● Cyclically at DIAREQ_T ! = 0.0 min

The diagnostics data can also be displayed on a Maintenance Station (MS).

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

19

Page 22

Description of blocks

3.1 Diagnostics block DIA_WLVL

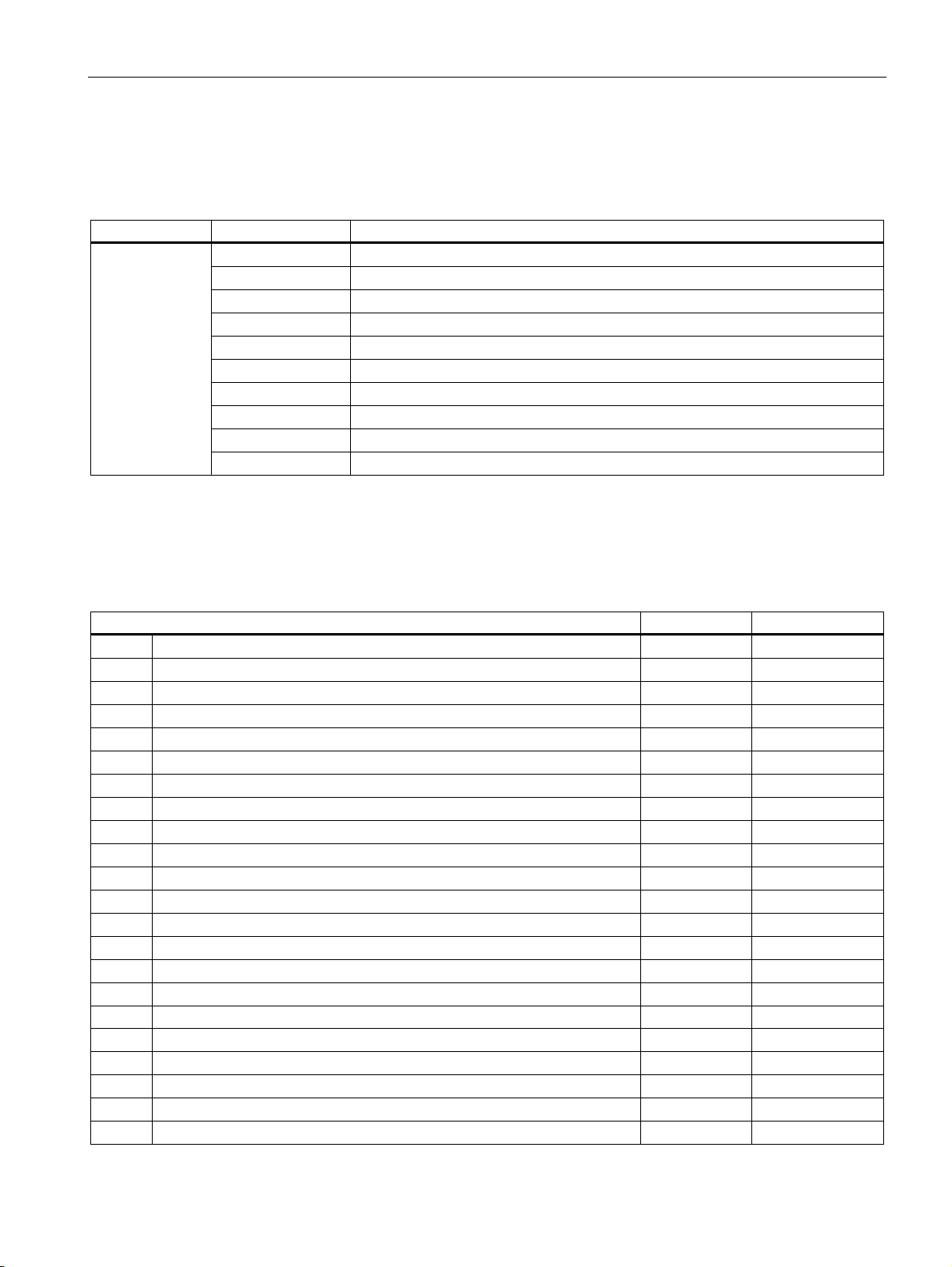

Diagnostic events are assigned to maintenance status as follows:

Diagnostic event Maintenance status QUALITY PA_DIAG

Perform visual inspection on main contacts Maintenance

requirement is

medium

Immediate maintenance of main contacts

Maintenance

requirement is high

16#68 16#0020_0000

16#24 16#0100_0000

3.1.9 Start-up characteristics

In OB100, the identifier for "Start up" is entered for output OMODE (OMODE=16#xx01xxxx).

3.1.10 Block parameters

The as-supplied state of the block displayed in CFC is shown in the "I/O" column: I/O name

bold = I/O is visible, normal = I/O is invisible.

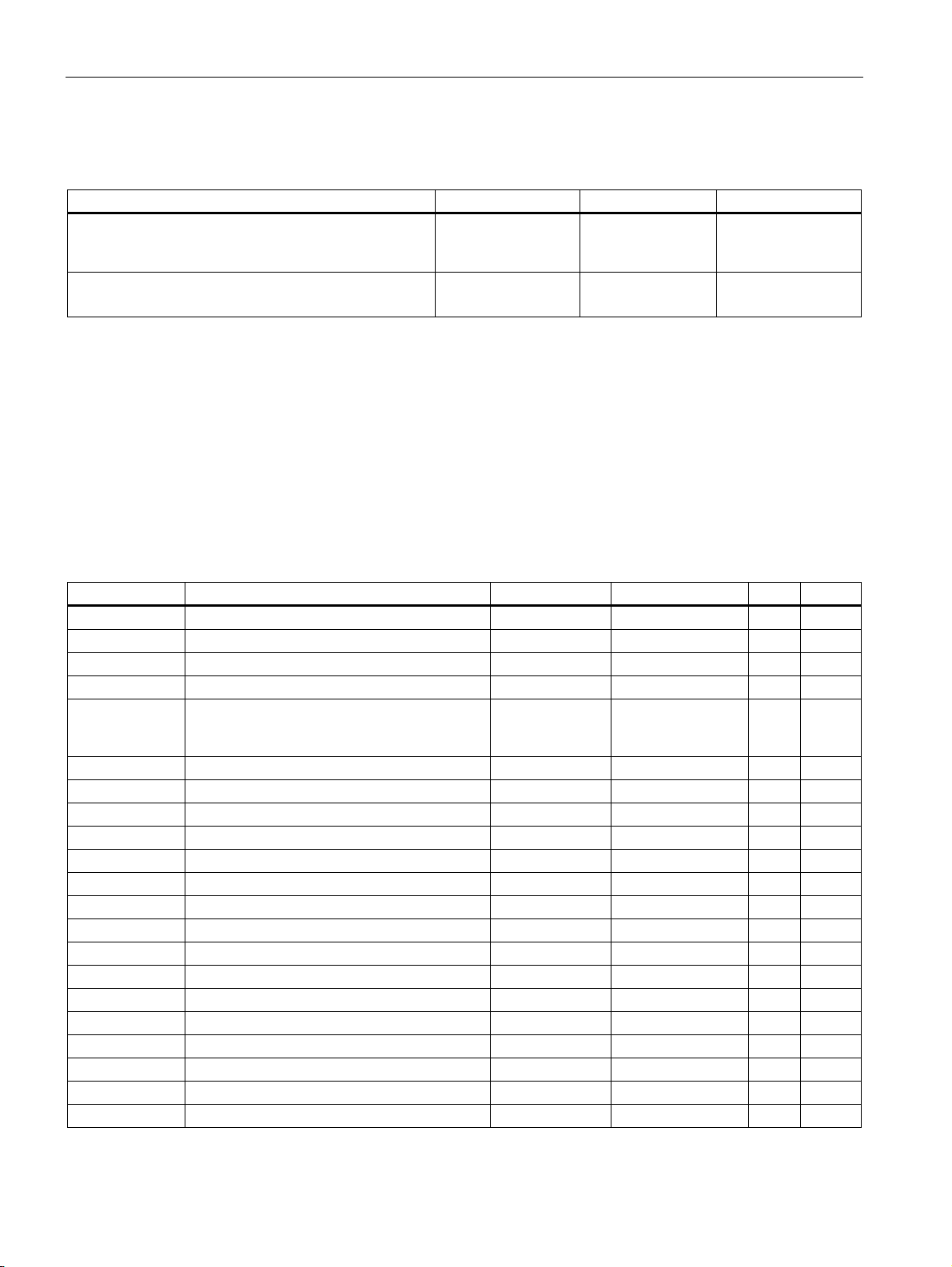

I/O (parameter) Comment Data type Default Type OCM

EN_DIAG 1 = Enable read diagnostic data BOOL FALSE I

MODE Parameter OMODE of DRV_WLVL WORD 0 I

LADDR Logical address of module INT 0 I

DADDR Diagnostic address of module INT 0 I

DPA_LINK Device connection:

0 = DP-MASTER,

1 = DP/PA-LINK

SUBN_TYP 1 = External DP interface BOOL FALSE I

SUBN1_ID ID of Primary Subnet BYTE 16#FF I

SUBN2_ID ID of Redundant Subnet BYTE 16#FF I

RACK_NO Rack number BYTE 0 I

RACKF 1 = Rack failure BOOL FALSE I

SUBN1ERR 1 = Slave 1 Failure BOOL FALSE I

SUBN2ERR 1 = Slave 2 Failure BOOL FALSE I

ACC_ID 1 = Accept new mode settings BOOL TRUE IO

DIAG_REQ 1 = Read diagnostic information BOOL FALSE I

QERR 1 = Error BOOL FALSE O

QMODF 1 = Module Failure BOOL FALSE O

QRACKF 1 = Rack failure BOOL FALSE O

RACK1ERR 1 = DP slave system failure (primary) BOOL FALSE O

RACK2ERR 1 = DP slave system failure (redundant) BOOL FALSE O

QUALITY Quality code of process value BYTE 0 O

OMODE Status MODE DWORD 0 O

BOOL FALSE I

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

20 Function Manual, 11/2008, A5E02316914A-01

Page 23

Description of blocks

3.1 Diagnostics block DIA_WLVL

I/O (parameter) Comment Data type Default Type OCM

PA_DIAG Diagnostic information for maintenance DWORD 0 O

QDIAG_INF Diagnostic information WORD 0 O

Structure of OMODE

Byte Value Meaning

Byte 3 16#80: Valid data

16#40: Invalid data

Byte 2 16#01: Cold restart (OB100)

Byte 1; 0 16#0000 Irrelevant

Higher-level fault

Structure of QDIAG_INF

VALUE Meaning

0 Everything ok

1 Perform visual inspection on main contacts

2 Immediate maintenance of main contacts

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

21

Page 24

Description of blocks

3.2 Driver module DRV_3WL

3.2 Driver module DRV_3WL

FB1741

Description of block:

● Calling OBs (Page 22)

● Called blocks (Page 23)

● Function (Page 23)

● Message behavior (Page 26)

● Assignment of the cyclic process image (Page 27)

● Addressing and module driver (Page 28)

● Processing the diagnostics data of the 3WL de

● Start-up characteristics (Page 29)

● Block parameters (Page 29)

● Description of symbols a

See also

Diagnostics block DIA_WLVL (Page 17)

Driver module DRV_3VL (Page 95)

3.2.1 Calling OBs

The OB watchdog interrupt in which the block is installed (e.g. OB32). Also in OB100

(performed automatically in CFC, see start-up characteristics).

vice (Page 28)

nd faceplates (Page 60)

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

22 Function Manual, 11/2008, A5E02316914A-01

Page 25

Description of blocks

3.2 Driver module DRV_3WL

3.2.2 Called blocks

The block calls the following blocks:

SFB35 ALARM_8P

SFB52 RDREC

SFB53 WRREC

SFC1 READ_CLK

SFC6 RD_SINFO

SFC20 BLKMOV

SFC21 FILL

3.2.3 Function

The DRV_3WL block is used for measurement acquisition and control and it forms the

interface to the OS.

Automatic / manual mode switch over

Automatic and manual mode are available for operating the driver block. When in manual

mode, the user can control the circuit breaker position (ON / OFF) of the faceplate in WinCC.

When in automatic mode, the corresponding buttons are locked (cannot be operated) in the

faceplate and the circuit breaker is controlled by input parameters which can be connected in

the CFC (AUTO_ON / AUTO_OFF) and therefore by the AS program.

The user can define the mode in which the block is to run in the faceplate or in a block

parameter (AUT_L).

The setting at the LIOP_SEL input determines which of the parameters is currently active.

NOTICE

If an error occurs (monitoring error, Local turn off, Tripped) the block changes to Forced

manual. If the pending error state is acknowledged with one of the RESET buttons, the

block goes into the specified mode again.

If Automatic mode is specified by the AS program (LIOP_SEL = 1, AUT_L = 1) the

commands present at AUTO_ON or AUTO_OFF are always output.

Under certain circumstances this means that resetting error states may cause a switching

operation of the circuit breaker. If this is not desired the user must configure the AS

program accordingly.

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

23

Page 26

Description of blocks

3.2 Driver module DRV_3WL

Switching the circuit breaker on/off

The user can use the driver block to switch the circuit breaker.

It is important to note here that the ON state means "main contacts closed" and the OFF

state means "main contacts open".

The circuit breaker cannot be switched on or off in certain states:

It must not be switched on when:

• there is a monitoring error

• the block is in maintenance mode

• write protection applies

• the circuit breaker is already on

• the circuit breaker has tripped

• the circuit breaker has been switched off locally

• the circuit breaker is not ready for an On command

(QMON_ERR = 1)

(MAINT = 1)

(QWR_PROT = 1)

(QON = 1)

(QTRIP = 1)

(QLOC_OFF = 1)

(RDY_ON = 0)

It must not be switched off when:

• there is a monitoring error

• the block is in maintenance mode

• write protection applies

• the circuit breaker is already off

• the circuit breaker has tripped

• the circuit breaker has been switched off locally

Resetting Tripped and Local turn off states

If the block is in one of the two states, it has to be reset before an On command can be

output again. The faceplate features a corresponding button for the user for this RESET.

CAUTION

Before the circuit breaker is switched back on, the reason for tripping/switching off must be

established and possible error causes must be rectified.

NOTICE

If such a state is reset the response of the mode must be observed as it may cause a

switching operation of the circuit breaker under certain circumstances.

(QMON_ERR = 1)

(MAINT = 1)

(QWR_PROT = 1)

(QOFF = 1)

(QTRIP = 1)

(QLOC_OFF = 1)

See Automatic / Manual mode switchover

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

24 Function Manual, 11/2008, A5E02316914A-01

Page 27

Description of blocks

3.2 Driver module DRV_3WL

Feedback monitoring

When monitoring is activated (MONITOR = On), switching commands (ON / OFF) and the

resetting of trips are time monitored. If the expected state is not reached after an operation

and within the monitoring time (TIME_MON), the block outputs a message and goes into a

resetting state (QMON_ERR).

NOTICE

If the monitoring error is reset the response of the mode must be observed as it may cause

a switching operation of the circuit breaker under certain circumstances.

See Automatic / Manual mode switchover

The faceplate features an appropriate RESET button for resetting this state again.

Measured value acquisition

The block reads measured values from the cyclic process image.

When operating 3WL on the DP master system directly, the block also reads data record 94

with the system function block RDREC (SFB52).

The data record is read in a defined cycle. The interval at which the data record can be read

can be set in seconds using the input parameter CYCLE_T. The default setting is 60

seconds. A cycle of 0 seconds or less means that this data record is not read.

Time synchronization

Data record 68 writes the current time in cycles in order to transfer the current time to the

circuit breaker. This cycle can be set in seconds using the TIME_SYNC_T parameter.

Diagnostics and maintenance

In order to display the current state of the circuit breaker, modules present, statistics

information and diagnostic messages, the module reads the status word from the process

image and data records 91 and 92.

The process image is called in cycles. The user can request the data records in the faceplate

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

via operations. The diagnostic messages are updated in cycles when messages are present.

WARNING

During maintenance work on the circuit breaker, maintenance mode must be activated!

At the same time, the circuit breaker must be locked locally to prevent it being switched

back on.

Maintenance specifications apply to the circuit breakers (in accordance with EN 50 110-1,

DIN VDE 0105-100 and BGV A2).

25

Page 28

Description of blocks

3.2 Driver module DRV_3WL

Protect. parameter and extended protect. parameter

This data, which comes from data records 128 and 129, is updated for the display in the

faceplate if requested by the operator.

These parameters cannot be written.

Setpoints

These parameters can be read and written from the faceplate.

3.2.4 Message behavior

DRV_3WL issues the following messages:

Message block Message

number

MSG_EVID1

MSG_EVID2

1 Overload tripping (L) AH

2 Instantaneous short-circuit (I) AH

3 Short-time-delay short-circuit (S) AH

4 Ground fault (G) AH

5 Trip as a result of extended protection function AH

6 Overload in neutral conductor AH

7 Overload warning present WH

8 An activated setpoint value has been exceeded WH

1 An alarm signal is currently present WH

2 Error time synchronization WH

3 Local turn off of circuit breaker / tripped AH

4 Load shedding warning WH

5 Perform visual inspection on main contacts WH

6 Immediate maintenance of main contacts AH

7 Monitoring error AS Control System

8 Forbidden switching command for auto mode - switching

Message text Message class

Fault

AS Control System

command ignored

Fault

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

26 Function Manual, 11/2008, A5E02316914A-01

Page 29

Description of blocks

3.2 Driver module DRV_3WL

Auxiliary values

EV_ID Auxiliary value Block parameters

MSG_EVID1

-

MSG_EVID2

1 AUX_PR01

2 AUX_PR02

3 AUX_PR03

4 AUX_PR04

5 AUX_PR05

6 AUX_PR06

7 AUX_PR07

8 AUX_PR08

9 AUX_PR09

10 AUX_PR10

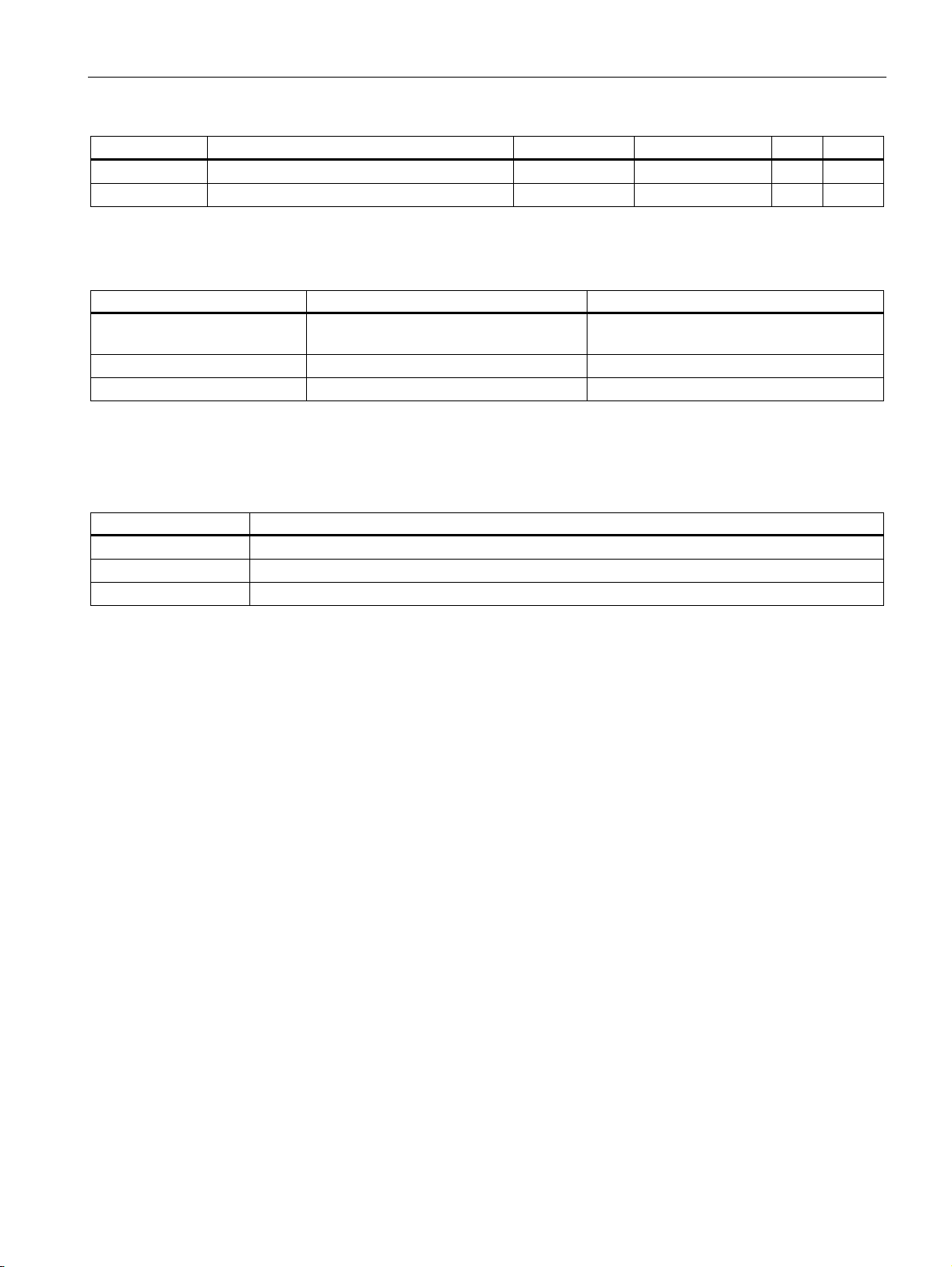

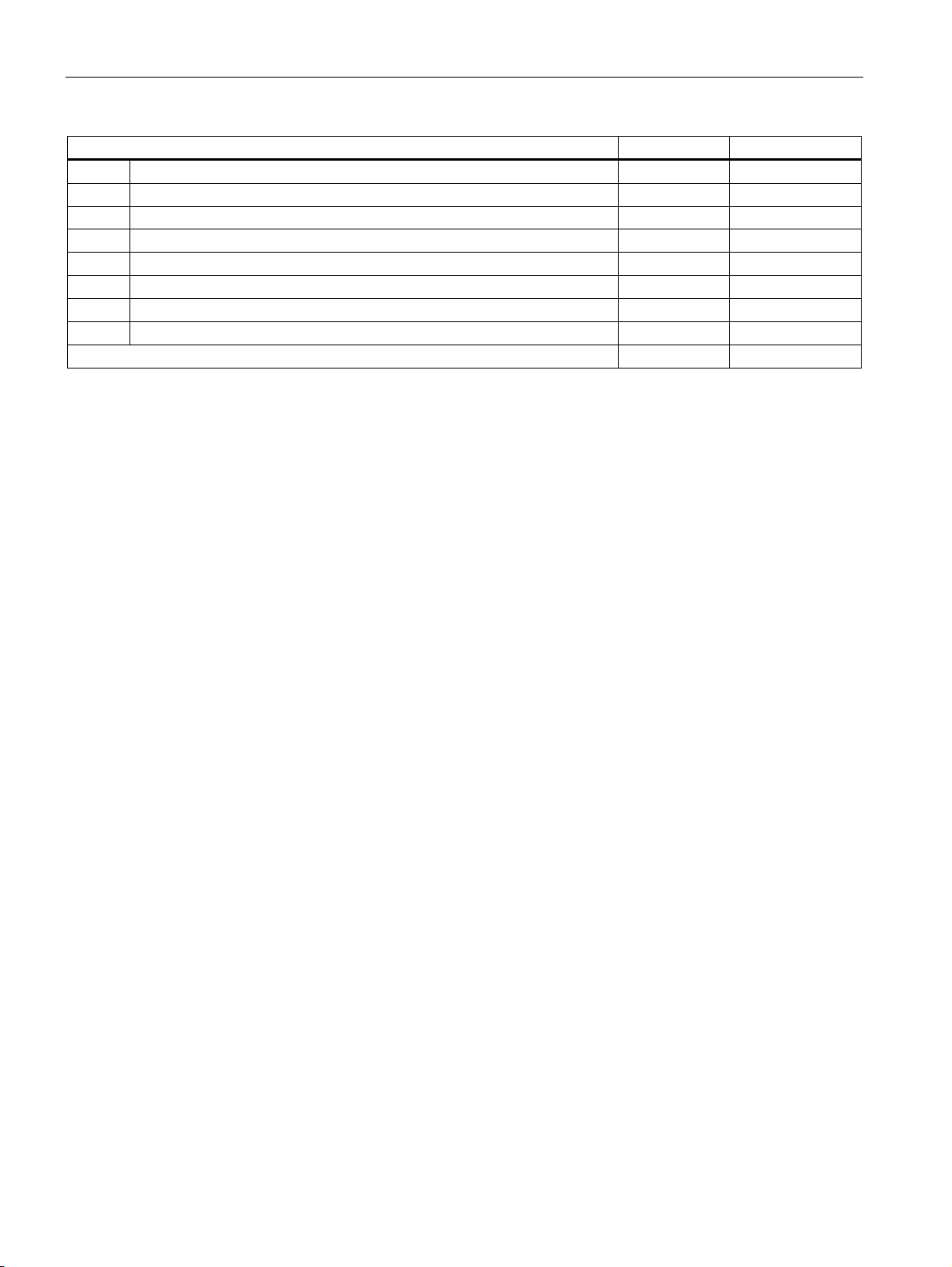

3.2.5 Assignment of the cyclic process image

Only basic type 3 is supported in the default setting.

Name Inputs Outputs

0 / 1 Control bytes 2

0 / 1 Binary status information 2

2 / 3 Current in phase 1 2

4 / 5 Current in phase 2 2

6 / 7 Current in phase 3 2

8 / 9 Max. current in phase under highest load 2

10 / 11 Current in neutral conductor 2

12 / 13 Phase-to-phase voltage L12 2

14 / 15 Phase-to-phase voltage L23 2

16 / 17 Phase-to-phase voltage L31 2

18 / 19 Neutral-point star voltage L1N 2

20 / 21 Neutral-point star voltage L2N 2

22 / 23 Neutral-point star voltage L3N 2

24 / 25 Mean value of power factors of 3 phases 2

26 / 27 Total active energy of 3 phases 2

28 / 29 Total apparent power of 3 phases 2

30 EB of current phase 1 1

31 EB of current phase 2 1

32 EB of current phase 3 1

33 EB of max. current in phase under highest load 1

34 EB of current in neutral conductor 1

35 EB of phase-to-phase voltage L12 1

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

27

Page 30

Description of blocks

3.2 Driver module DRV_3WL

Name Inputs Outputs

36 EB of phase-to-phase voltage L23 1

37 EB of phase-to-phase voltage L31 1

38 EB of neutral-point star voltage L1N 1

39 EB of neutral-point star voltage L2N 1

40 EB of neutral-point star voltage L3N 1

41 EB of mean value of the three power factors 1

42 EB of total active energy 1

43 EB of total apparent power 1

Number of bytes 44 2

3.2.6 Addressing and module driver

The I/O addresses of 3WL must lie completely within the process image of the CPU. In the

CFC chart, the LADDR input is connected to the base address of the 3WL device.

Procedure:

Select input parameter → right mouse button → Interconnection to

address... → Entere.g. EW512

If 3WL is directly connected to the DP master system, the module driver connects block

outputs OMODE, QRACKF and QMODF to inputs MODE00, RACKF and MODF of the block

MOD_PAX0 and the module driver connects input DIAG_INF to output QDIAG_INF of

diagnostics block DIA_WLVL.

In the case of operation following a Y-Link DPV1, the module driver connects block inputs

MODE, RACKF and DIAG_INF to outputs OMODE, QRACKF and QDIAG_INF of

diagnostics block DIA_WLVL.

In the case of operation following a Y-Link DPV0, the module driver connects block inputs

MODE and RACKF to outputs OMODE00 and QRACKF of block PADP_L00.

The block input BASADR is parameterized with the logical base address of the 3WL device

by the module driver.

The block input BASADR_OUT is parameterized with the start address of the outputs of the

3WL device by the module driver.

The input DPA_LINK is parameterized with the connection mode of the 3WL device by the

module driver.

● DPA_LINK = 0 -> Directly connected to the DP master

● DPA_LINK = 1 -> Connected following a DP/PA link

3.2.7 Processing the diagnostics data of the 3WL device

If 3WL is directly connected to the DP master system, the block processes the diagnostic

information that is supplied to it from the DIA_WLVL diagnostics block via the input

DIAG_INF.

The user has the possibility of setting the cycle for cyclic reading of the diagnostics data

record at the "DIAREQ_T" input. At DIAREQ_T = 0.0 minutes no cyclic reading takes place.

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

28 Function Manual, 11/2008, A5E02316914A-01

Page 31

Description of blocks

3.2 Driver module DRV_3WL

3.2.8 Start-up characteristics

On starting, messages are deactivated (OB100).

3.2.9 Block parameters

The as-supplied state of the block displayed in CFC is shown in the "I/O" column: I/O name

bold = I/O is visible, normal = I/O is invisible.

I/O (parameter) Comment Data type Default Type OCM

MODE Parameter OMODE of DIA_WLVL DWORD 0 I

RACKF 1 = Rack failure BOOL FALSE I

LADDR Base address of 3WL module WORD 0 I

BASADR Base address of 3WL module INT 0 I

BASADR_OUT Base address of 3WL module for outputs INT 0 I

DPA_LINK Device connection: 0 = DP-MASTER,

1 = DP/PA-LINK

MSG_LOCK 1 = Messages locked BOOL FALSE I x

RUNUPCYC Lag: Number of run up cycles INT 0 I

SAMPLE_T Sample time [s] REAL 0.0 I

CYCLE_T Cycle time of cyclic reading of DRs [s] REAL 60.0 I

TIME_SYNC_T Cycle time of time synchronization [min] REAL 10.0 I

DIAREQ_T Cycle time of reading diagnostic

information [min]

DR94_K 1 = kWh inputs for real and reactive energy

of DR 94 are used

MONITOR 1 = Monitoring activated BOOL TRUE I

TIME_MON Monitoring time [s] REAL 10.0 I

DIAG_INF Diagnostic info for driver WORD 0 I

ALT_SYM 1 = Alternative symbols BOOL FALSE I

MANOP_EN 1 = Operator may input MANUAL BOOL TRUE I

AUTOP_EN 1 = Operator may input AUTO BOOL TRUE I

LIOP_SEL 1 = Linking, 0 = Operator active BOOL FALSE I

AUT_L Linkable input for MANUAL/AUTO mode BOOL FALSE I

AUTO_ON AUTO mode: Switch off (open the main

contacts)

AUTO_OFF AUTO mode: Switch on (close the main

contacts)

MSG_EVID1 Message ID message block 1 DWORD 0 I

MSG_EVID2 Message ID message block 2 DWORD 0 I

SUP_OVLD_WRN 1 = Active message suppression BOOL FALSE I x

SUP_SP_EXCEED 1 = Active message suppression BOOL FALSE I x

SUP_WRN 1 = Active message suppression BOOL FALSE I x

SUP_LD_SHED 1 = Active message suppression BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE O

BOOL FALSE I x

BOOL FALSE I

BOOL FALSE I

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

29

Page 32

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

RP_NORM_I DR 130: Real power in normal direction REAL 0.0 I x

RP_NORM_I_QC Quality code of RP_NORM_I BYTE 0 I

RP_NORM_I_OFF DR 130: Real power in normal direction

OFF

RP_NORM_I_NA DR 130: Real power in normal direction

not available

RP_REV_I DR 130: Real power in reverse direction REAL 0.0 I x

RP_REV_I_QC Quality code of RP_REV_I BYTE 0 I

RP_REV_I_OFF DR 130: Real power in reverse direction

OFF

RP_REV_I_NA DR 130: Real power in reverse direction

not available

PF_CAP_I DR 130: Power factor capacitive REAL 0.0 I x

PF_CAP_I_QC Quality code of PF_CAP_I BYTE 0 I

PF_CAP_I_OFF DR 130: Power factor capacitive OFF BOOL FALSE I x

PF_CAP_I_NA DR 130: Power factor capacitive not

available

PF_IND_I DR 130: Power factor inductive REAL 0.0 I x

PF_IND_I_QC Quality code of PF_IND_I BYTE 0 I

PF_IND_I_OFF DR 130: Power factor inductive OFF BOOL FALSE I x

PF_IND_I_NA DR 130: Power factor inductive not

available

T_RP_NORM_I DR 130: Delay time for real power in

normal direction

T_RP_NORM_I_QC Quality code of T_RP_NORM_I BYTE 0 I

T_RP_NORM_I_OFF DR 130: Delay time for real power in

normal direction OFF

T_RP_NORM_I_NA DR 130: Delay time for real power in

normal direction not available

T_RP_REV_I DR 130: Delay time for real power in

reverse direction

T_RP_REV_I_QC Quality code of T_RP_REV_I BYTE 0 I

T_RP_REV_I_OFF DR 130: Delay time for real power in

reverse direction OFF

T_RP_REV_I_NA DR 130: Delay time for real power in

reverse direction not available

T_PF_CAP_I DR 130: Delay time for power factor

capacitive

T_PF_CAP_I_QC Quality code of T_PF_CAP_I BYTE 0 I

T_PF_CAP_I_OFF DR 130: Delay time for power factor

capacitive OFF

T_PF_CAP_I_NA DR 130: Delay time for power factor

capacitive not available

T_PF_IND_I DR 130: Delay time for power factor

inductive

T_PF_IND_I_QC Quality code of T_PF_IND_I BYTE 0 I

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

30 Function Manual, 11/2008, A5E02316914A-01

Page 33

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

T_PF_IND_I_OFF DR 130: Delay time for power factor

inductive OFF

T_PF_IND_I_NA DR 130: Delay time for power factor

inductive not available

OVER_FRQ_I DR 130: Over frequency REAL 0.0 I x

OVER_FRQ_I_QC Quality code of OVER_FRQ_I BYTE 0 I

OVER_FRQ_I_OFF DR 130: Over frequency OFF BOOL FALSE I x

OVER_FRQ_I_NA DR 130: Over frequency not available BOOL FALSE I x

T_OVER_FRQ_I DR 130: Delay time for over frequency REAL 0.0 I x

T_OVER_FRQ_I_QC Quality code of T_OVER_FRQ_I BYTE 0 I

T_OVER_FRQ_I_OFF DR 130: Delay time for over frequency

OFF

T_OVER_FRQ_I_NA DR 130: Delay time for over frequency not

available

UNDER_FRQ_I DR 130: Under frequency REAL 0.0 I x

UNDER_FRQ_I_QC Quality code of UNDER_FRQ_I BYTE 0 I

UNDER_FRQ_I_OFF DR 130: Under frequency OFF BOOL FALSE I x

UNDER_FRQ_I_NA DR 130: Under frequency not available BOOL FALSE I x

T_UNDER_FRQ_I DR 130: Delay time for under frequency REAL 0.0 I x

T_UNDER_FRQ_I_QC Quality code of T_UNDER_FRQ_I BYTE 0 I

T_UNDER_FRQ_I_OFF DR 130: Delay time for under frequency

OFF

T_UNDER_FRQ_I_NA DR 130: Delay time for under frequency

not available

CUR_THD_I DR 130: THD current REAL 0.0 I x

CUR_THD_I_QC Quality code of CUR_THD_I BYTE 0 I

CUR_THD_I_OFF DR 130: THD current OFF BOOL FALSE I x

CUR_THD_I_NA DR 130: THD current not available BOOL FALSE I x

T_CUR_THD_I DR 130: Delay time for THD current REAL 0.0 I x

T_CUR_THD_I_QC Quality code of T_CUR_THD_I BYTE 0 I

T_CUR_THD_I_OFF DR 130: Delay time for THD current OFF BOOL FALSE I x

T_CUR_THD_I_NA DR 130: Delay time for THD current not

available

VOLT_THD_I DR 130: THD voltage REAL 0.0 I x

VOLT_THD_I_QC Quality code of VOLT_THD_I BYTE 0 I

VOLT_THD_I_OFF DR 130: THD voltage OFF BOOL FALSE I x

VOLT_THD_I_NA DR 130: THD voltage not available BOOL FALSE I x

T_VOLT_THD_I DR 130: Delay time for THD voltage REAL 0.0 I x

T_VOLT_THD_I_QC Quality code of T_VOLT_THD_I BYTE 0 I

T_VOLT_THD_I_OFF DR 130: Delay time for THD voltage OFF BOOL FALSE I x

T_VOLT_THD_I_NA DR 130: Delay time for THD voltage not

available

CREST_F_I DR 130: Crest factor REAL 0.0 I x

CREST_F_I_QC Quality code of CREST_F_I BYTE 0 I

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

31

Page 34

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

CREST_F_I_OFF DR 130: Crest factor OFF BOOL FALSE I x

CREST_F_I_NA DR 130: Crest factor not available BOOL FALSE I x

FORM_F_I DR 130: Form factor REAL 0.0 I x

FORM_F_I_QC Quality code of FORM_F_I BYTE 0 I

FORM_F_I_OFF DR 130: Form factor OFF BOOL FALSE I x

FORM_F_I_NA DR 130: Form factor not available BOOL FALSE I x

T_CREST_F_I DR 130: Delay time for crest factor REAL 0.0 I x

T_CREST_F_I_QC Quality code of T_CREST_F_I BYTE 0 I

T_CREST_F_I_OFF DR 130: Delay time for crest factor OFF BOOL FALSE I x

T_CREST_F_I_NA DR 130: Delay time for crest factor not

available

T_FORM_F_I DR 130: Delay time for form factor REAL 0.0 I x

T_FORM_F_I_QC Quality code of T_FORM_F_I BYTE 0 I

T_FORM_F_I_OFF DR 130: Delay time for form factor OFF BOOL FALSE I x

T_FORM_F_I_NA DR 130: Delay time for form factor not

available

RP_DEM_I DR 130: Demand real power REAL 0.0 I x

RP_DEM_I_QC Quality code of PR_DEM_I BYTE 0 I

RP_DEM_I_OFF DR 130: Demand real power OFF BOOL FALSE I x

RP_DEM_I_NA DR 130: Demand real power not available BOOL FALSE I x

AP_DEM_I DR 130: Demand apparent power REAL 0.0 I x

AP_DEM_I_QC Quality code of AP_DEM_I BYTE 0 I

AP_DEM_I_OFF DR 130: Demand apparent power OFF BOOL FALSE I x

AP_DEM_I_NA DR 130: Demand apparent power not

available

T_RP_DEM_I DR 130: Delay time demand of the real

power

T_RP_DEM_I_QC Quality code of T_RP_DEM_I BYTE 0 I

T_RP_DEM_I_OFF DR 130: Delay time demand of the real

power OFF

T_RP_DEM_I_NA DR 130: Delay time demand of the real

power not available

T_AP_DEM_I DR 130: Delay time demand of the

apparent power

T_AP_DEM_I_QC Quality code of T_AP_DEM_I BYTE 0 I

T_AP_DEM_I_OFF DR 130: Delay time demand of the

apparent power OFF

T_AP_DEM_I_NA DR 130: Delay time demand of the

apparent power not available

RAP_DEM_I DR 130: Demand reactive power REAL 0.0 I x

RAP_DEM_I_QC Quality code of RAP_DEM_I BYTE 0 I

RAP_DEM_I_OFF DR 130: Demand reactive power OFF BOOL FALSE I x

RAP_DEM_I_NA DR 130: Demand reactive power not

Available

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

32 Function Manual, 11/2008, A5E02316914A-01

Page 35

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

RAP_NORM_I DR 130: Reactive power in normal

direction

RAP_NORM_I_QC Quality code of RAP_NORM_I BYTE 0 I

RAP_NORM_I_OFF DR 130: Reactive power in normal

direction OFF

RAP_NORM_I_NA DR 130: Reactive power in normal

direction not available

T_RAP_DEM_I DR 130: Delay time demand of the

reactive power

T_RAP_DEM_I_QC Quality code of T_RAP_DEM_I BYTE 0 I

T_RAP_DEM_I_OFF DR 130: Delay time demand of the

reactive power OFF

T_RAP_DEM_I_NA DR 130: Delay time demand of the

reactive power not available

T_RAP_NORM_I DR 130: Delay time for reactive power in

normal direction

T_RAP_NORM_I_QC Quality code of T_RAP_NORM_I BYTE 0 I

T_RAP_NORM_I_OFF DR 130: Delay time for reactive power in

normal direction OFF

T_RAP_NORM_I_NA DR 130: Delay time for reactive power in

normal direction not available

RAP_REV_I DR 130: Reactive power in reverse

direction

RAP_REV_I_QC Quality code of RAP_REV_I BYTE 0 I

RAP_REV_I_OFF DR 130: Reactive power in reverse

direction OFF

RAP_REV_I_NA DR 130: Reactive power in reverse

direction not available

AP_I DR 130: Apparent power REAL 0.0 I x

AP_I_QC Quality code of AP_I BYTE 0 I

AP_I_OFF DR 130: Apparent power OFF BOOL FALSE I x

AP_I_NA DR 130: Apparent power not available BOOL FALSE I x

T_RAP_REV_I DR 130: Delay time for reactive power in

reverse direction

T_RAP_REV_I_QC Quality code of T_RAP_REV_I BYTE 0 I

T_RAP_REV_I_OFF DR 130: Delay time for reactive power in

reverse direction OFF

T_RAP_REV_I_NA DR 130: Delay time for reactive power in

reverse direction not available

T_AP_I DR 130: Delay time for apparent power REAL 0.0 I x

T_AP_I_QC Quality code of T_AP_I BYTE 0 I

T_AP_I_OFF DR 130: Delay time for apparent power

OFF

T_AP_I_NA DR 130: Delay time for apparent power not

available

CUR_OVER_I DR 130: Over current REAL 0.0 I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

33

Page 36

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

CUR_OVER_I_QC Quality code of CUR_OVER_I BYTE 0 I

CUR_OVER_I_OFF DR 130: Over current OFF BOOL FALSE I x

CUR_OVER_I_NA DR 130: Over current not available BOOL FALSE I x

CUR_GRD_I DR 130: Earth fault current REAL 0.0 I x

CUR_GRD_I_QC Quality code of CUR_GRD_I BYTE 0 I

CUR_GRD_I_OFF DR 130: Earth fault current OFF BOOL FALSE I x

CUR_GRD_I_NA DR 130: Earth fault current not available BOOL FALSE I x

CUR_N_I DR 130: Over current N-phase REAL 0.0 I x

CUR_N_I_QC Quality code of CUR_N_I BYTE 0 I

CUR_N_I_OFF DR 130: Over current N-phase OFF BOOL FALSE I x

CUR_N_I_NA DR 130: Over current N-phase not

available

CUR_DEM_I DR 130: Demand of the current REAL 0.0 I x

CUR_DEM_I_QC Quality code of CUR_DEM_I BYTE 0 I

CUR_DEM_I_OFF DR 130: Demand of the current OFF BOOL FALSE I x

CUR_DEM_I_NA DR 130: Demand of the current not

available

T_CUR_OVER_I DR 130: Delay time for over current REAL 0.0 I x

T_CUR_OVER_I_QC Quality code of T_CUR_OVER_I BYTE 0 I

T_CUR_OVER_I_OFF DR 130: Delay time for over current OFF BOOL FALSE I x

T_CUR_OVER_I_NA DR 130: Delay time for over current not

available

T_CUR_GRD_I DR 130: Delay time for over current

ground

T_CUR_GRD_I_QC Quality code of T_CUR_GRD_I BYTE 0 I

T_CUR_GRD_I_OFF DR 130: Delay time for over current

ground OFF

T_CUR_GRD_I_NA DR 130: Delay time for over current

ground not available

T_CUR_N_I DR 130: Delay time for over current N-

phase

T_CUR_N_I_QC Quality code of T_CUR_N_I BYTE 0 I

T_CUR_N_I_OFF DR 130: Delay time for over current N-

phase OFF

T_CUR_N_I_NA DR 130: Delay time for over current N-

phase not available

UNBAL_CUR_I DR 130: Phase unbalance current REAL 0.0 I x

UNBAL_CUR_I_QC Quality code of UNBAL_CUR_I BYTE 0 I

UNBAL_CUR_I_OFF DR 130: Phase unbalance current OFF BOOL FALSE I x

UNBAL_CUR_I_NA DR 130: Phase unbalance current not

available

T_UNBAL_CUR_I DR 130: Delay time for phase unbalance

current

T_UNBAL_CUR_I_QC Quality code of T_UNBAL_CUR_I BYTE 0 I

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

34 Function Manual, 11/2008, A5E02316914A-01

Page 37

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

T_UNBAL_CUR_I_OFF DR 130: Delay time for phase unbalance

current OFF

T_UNBAL_CUR_I_NA DR 130: Delay time for phase unbalance

current not available

T_CUR_DEM_I DR 130: Delay time for demand of the

current

T_CUR_DEM_I_QC Quality code of T_CUR_DEM_I BYTE 0 I

T_CUR_DEM_I_OFF DR 130: Delay time for demand of the

current OFF

T_CUR_DEM_I_NA DR 130: Delay time for demand of the

current not available

UNDER_VOLT_I DR 130: Under voltage REAL 0.0 I x

UNDER_VOLT_I_QC Quality code of UNDER_VOLT_I BYTE 0 I

UNDER_VOLT_I_OFF DR 130: Under voltage OFF BOOL FALSE I x

UNDER_VOLT_I_NA DR 130: Under voltage not available BOOL FALSE I x

T_UNDER_VOLT_I DR 130: Delay time for under voltage REAL 0.0 I x

T_UNDER_VOLT_I_QC Quality code of T_UNDER_VOLT_I BYTE 0 I

T_UNDER_VOLT_I_OFF DR 130: Delay time for under voltage OFF BOOL FALSE I x

T_UNDER_VOLT_I_NA DR 130: Delay time for under voltage not

available

UNBAL_VOLT_I DR 130: Phase unbalance voltage REAL 0.0 I x

UNBAL_VOLT_I_QC Quality code of UNBAL_VOLT_I BYTE 0 I

UNBAL_VOLT_I_OFF DR 130: Phase unbalance voltage OFF BOOL FALSE I x

UNBAL_VOLT_I_NA DR 130: Phase unbalance voltage not

available

T_UNBAL_VOLT_I DR 130: Delay time for phase unbalance

voltage

T_UNBAL_VOLT_I_QC Quality code of T_UNBAL_VOLT_I BYTE 0 I

T_UNBAL_VOLT_I_OFF DR 130: Delay time for phase unbalance

voltage OFF

T_UNBAL_VOLT_I_NA DR 130: Delay time for phase unbalance

voltage not available

OVER_VOLT_I DR 130: Over voltage REAL 0.0 I x

OVER_VOLT_I_QC Quality code of OVER_VOLT_I BYTE 0 I

OVER_VOLT_I_OFF DR 130: Over voltage OFF BOOL FALSE I x

OVER_VOLT_I_NA DR 130: Over voltage not available BOOL FALSE I x

T_OVER_VOLT_I DR 130: Delay time for over voltage REAL 0.0 I x

T_OVER_VOLT_I_QC Quality code of T_OVER_VOLT_I BYTE 0 I

T_OVER_VOLT_I_OFF DR 130: Delay time for over voltage OFF BOOL FALSE I x

T_OVER_VOLT_I_NA DR 130: Delay time for over voltage not

available

RD_DR69 Read data record 69 (status of the

modules)

RD_DR91 Read data record 91 (statistic and

maintenance)

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

REAL 0.0 I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE I x

BOOL FALSE IO x

BOOL FALSE IO x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

35

Page 38

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

RD_DR92 Read data record 92 (diagnostics) BOOL FALSE IO x

RD_DR128 Read data record 128 (metering and ext.

protective function)

RD_DR129 Read data record 129 (protective function) BOOL FALSE IO x

RD_DR130 Read data record 130 (setpoints) BOOL FALSE IO x

WR_DR130 Write data record 130 (setpoints) BOOL FALSE IO x

AUT_ON_OP Operator input: Mode 1 = AUTO,

0 = MANUAL

AUX_PR01 Auxiliary value 01 ANY IO

AUX_PR02 Auxiliary value 02 ANY IO

AUX_PR03 Auxiliary value 03 ANY IO

AUX_PR04 Auxiliary value 04 ANY IO

AUX_PR05 Auxiliary value 05 ANY IO

AUX_PR06 Auxiliary value 06 ANY IO

AUX_PR07 Auxiliary value 07 ANY IO

AUX_PR08 Auxiliary value 08 ANY IO

AUX_PR09 Auxiliary value 09 ANY IO

AUX_PR10 Auxiliary value 10 ANY IO

MAN_OFF Operator input: Switch off (open the main

contacts)

MAN_ON Operator input: Switch on (close the main

contacts)

RESET Operator input trip reset BOOL FALSE IO x

RES_MONERR Operator input reset monitoring error BOOL FALSE IO x

ACK_TRIP A current trip is acknowledged and reset BOOL FALSE IO x

DEL_TRIP Delete trip and event log BOOL FALSE IO x

R_VAL_MEM Reset all min./max. value memories

(except temperatures)

R_TEMP Reset min./max. temperatures BOOL FALSE IO x

R_MAINT Reset all resettable maintenance

information and counters

MAINT 1 = Maintenance mode BOOL FALSE IO x

QERR 1 = Error BOOL FALSE O x

QMON_ERR 1 = Monitoring error BOOL FALSE O x

QBAD 1 = Bad process value BOOL FALSE O x

QMSG_SUP 1 = Message suppression active BOOL FALSE O x

QMSG_ERR 1 = Message error BOOL FALSE O

QMANOP 1 = Operator enabled for MANUAL BOOL FALSE O x

QDIAG_REQ 1 = Read diagnostic information BOOL FALSE O

QAUTOP 1 = Operator enabled for AUTO BOOL FALSE O x

QOFF_OP 1 = Operator enabled for "OFF" BOOL FALSE O x

QON_OP 1 = Operator enabled for "ON" BOOL FALSE O x

QRES_OP 1 = Operator enabled for "RESET" BOOL FALSE O x

BOOL FALSE IO x

BOOL FALSE IO x

BOOL FALSE IO x

BOOL FALSE IO x

BOOL FALSE IO x

BOOL FALSE IO x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

36 Function Manual, 11/2008, A5E02316914A-01

Page 39

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

QDR_OP 1 = Operator enabled for data record

actions

QOP_ERR 1 = Operator error BOOL FALSE O

QMAN_AUT 1 = AUTO, 0 = MANUAL mode BOOL FALSE O x

MSG_STAT1 Message block 1: STATUS output WORD 0 O

MSG_STAT2 Message block 2: STATUS output WORD 0 O

MSG_ACK1 Message block 1: ACK_STATE output WORD 0 O

MSG_ACK2 Message block 2: ACK_STATE output WORD 0 O

QERR_WR 1 = An error occurred during writing DRs BOOL FALSE O

QERR_RD 1 = An error occurred during reading DRs BOOL FALSE O

QWR_STAT Status of DR writing WORD 0 O

QRD_STAT Status of DR reading WORD 0 O

STATUS Binary status information WORD 0 O

STATUS_QC Quality code of STATUS BYTE 0 O

CUR_L1 Current in phase 1 REAL 0.0 O x

CUR_L1_QC Quality code of CUR_L1 BYTE 0 O

CUR_L2 Current in phase 2 REAL 0.0 O x

CUR_L2_QC Quality code of CUR_L2 BYTE 0 O

CUR_L3 Current in phase 3 REAL 0.0 O x

CUR_L3_QC Quality code of CUR_L3 BYTE 0 O

CUR_MAX Current max. L1, L2, L3 REAL 0.0 O x

CUR_MAX_QC Quality code of CUR_MAX BYTE 0 O

CUR_N Current in phase N (trip unit) REAL 0.0 O x

CUR_N_QC Quality code of CUR_N BYTE 0 O

U_L1_L2 Voltage line-to-line L1-L2 (A-B) REAL 0.0 O x

U_L1_L2_QC Quality code of U_L1_L2 BYTE 0 O

U_L2_L3 Voltage line-to-line L2-L3 (B-C) REAL 0.0 O x

U_L2_L3_QC Quality code of U_L2_L3 BYTE 0 O

U_L3_L1 Voltage line-to-line L3-L1 (C-A) REAL 0.0 O x

U_L3_L1_QC Quality code of U_L3_L1 BYTE 0 O

U_L1_N Voltage star point L1-N (A-N) REAL 0.0 O x

U_L1_N_QC Quality code of U_L1_N BYTE 0 O

U_L2_N Voltage star point L2-N (B-N) REAL 0.0 O x

U_L2_N_QC Quality code of U_L2_N BYTE 0 O

U_L3_N Voltage star point L3-N (C-N) REAL 0.0 O x

U_L3_N_QC Quality code of U_L3_N BYTE 0 O

PF_AVG Power factor average REAL 0.0 O x

PF_AVG_QC Quality code of PF_AVG BYTE 0 O

ACT_W Active energy in normal direction REAL 0.0 O x

ACT_W_QC Quality code of ACT_W BYTE 0 O

KVA_TOT Apparent power total REAL 0.0 O x

KVA_TOT_QC Quality code of KVA_TOT BYTE 0 O

BOOL FALSE O x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

Function Manual, 11/2008, A5E02316914A-01

37

Page 40

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

POS_CB Position of circuit breaker BYTE 0 O x

QDISCON 1 = Disconnected BOOL FALSE O x

QOP_POS 1 = Operating position BOOL FALSE O

QTEST_POS 1 = Test position BOOL FALSE O

QNO_CB 1 = Circuit breaker not present BOOL FALSE O x

ST_CB Status of circuit breaker BYTE 0 O x

QNOT_RDY 1 = Circuit breaker not ready BOOL FALSE O

QOFF 1 = Main contacts disconnected BOOL FALSE O

QON 1 = Main contacts closed BOOL FALSE O

QTRIP 1 = Circuit breaker has tripped BOOL FALSE O

QLOC_OFF 1 = Local turn off of circuit breaker BOOL FALSE O x

QRDY_ON 1 = Ready to switch on BOOL FALSE O

QUNV_REL 1 = Voltage applied to undervoltage

release

QSPR_CHAR 1 = Storage spring is charged BOOL FALSE O

QOVLD_WRN 1 = Overload warning present BOOL FALSE O

QSP_EXCEED 1 = An activated setpoint value has been

exceeded

QWRN 1 = A warning signal is currently present BOOL FALSE O

QWR_PROT 1 = Write operations are prohibited BOOL FALSE O

QFREE_COM15 1 = Status of the free user input on the

COM15 module

LST_TRIP Reason for last trip BYTE 0 O

QTR_OVLD 1 = Overload tripping (L) BOOL FALSE O

QTR_ISC 1 = Instantaneous short-circuit (I) BOOL FALSE O

QTR_STD_C 1 = Short-time-delay short-circuit (S) BOOL FALSE O

QTR_GF 1 = Ground fault (G) BOOL FALSE O

QTR_EXT_F 1 = Trip as a result of extended protection

function

QTR_OVLD_N 1 = Overload in neutral conductor BOOL FALSE O

QLD_SHED 1 = Load shedding warning BOOL FALSE O

E_TIME_SYC 1 = Error time synchronization BOOL FALSE O

STON_GFNA Short time on / Ground fault off BOOL FALSE O x

STON_GFOFF_QC Quality code of STON_GFOFF BYTE 0 O

STON_GFOFF_NA Short time on / Ground fault off not

available

STON_GFOFF_STOFF_GFON Short time off / Ground fault off BOOL FALSE O x

STOFF_GFON_QC Quality code of STOFF_GFON BYTE 0 O

STOFF_GFON_NA Short time off / Ground fault on not

available

N_ACT_LD DR 91: Number of switch actions under

load

N_ACT_LD_QC Quality code of N_ACT_LD BYTE 0 O

BOOL FALSE O

BOOL FALSE O

BOOL FALSE O

BOOL FALSE O

BOOL FALSE O x

BOOL FALSE O x

WORD 0 O x

Library SENTRON 3WL / 3VL for SIMATIC PCS 7

38 Function Manual, 11/2008, A5E02316914A-01

Page 41

Description of blocks

3.2 Driver module DRV_3WL

I/O (parameter) Comment Data type Default Type OCM

N_ACT_LD_NA DR 91: Number of switch actions under

load not available

N_ACT_TRP DR 91: Number of switch actions caused

by a trip

N_ACT_TRP_QC Quality code of N_ACT_TRP BYTE 0 O

N_ACT_TRP_NA DR 91: Number of switch actions caused

by a trip not available

N_ACT_CC DR 91: Number of switch actions

(complete cycle on/off)

N_ACT_CC_QC Quality code of N_ACT_CC BYTE 0 O

N_ACT_CC_NA DR 91: Number of switch actions

(complete cycle on/off) not available

OP_HOURS DR 91: Operating hours (breaker on and

current > 0)

OP_HOURS_QC Quality code of OP_HOURS BYTE 0 O

OP_HOURS_NA DR 91: Operating hours (breaker on and

current > 0) not available

LAST_CHG DR 91: Date of the last parameter change DATE_AND_

LAST_CHG_QC Quality code of LAST_CHG BYTE 0 O

LAST_CHG_NA DR 91: Date of the last parameter change

not available

N_SC_TRP DR 91: Number of short circuit trips (SI) WORD 0 O x

N_SC_TRP_QC Quality code of N_SC_TRP BYTE 0 O

N_SC_TRP_NA DR 91: Number of short circuit trips (SI)

not available

N_OVL_TRP DR 91: Number of overload trips (L) WORD 0 O x

N_OVL_TRP_QC Quality code of N_OVL_TRP BYTE 0 O

N_OVL_TRP_OFF DR 91: Number of overload trips (L) OFF BOOL FALSE O x

N_OVL_TRP_NA DR 91: Number of overload trips (L) not

available

N_EF_TRP DR 91: Number of earth fault trips (G) WORD 0 O x

N_EF_TRP_QC Quality code of N_EF_TRP BYTE 0 O

N_EF_TRP_NA DR 91: Number of earth fault trips (G) not

available

S_I2T_L1 DR 91: Sum of I2T-values L1 REAL 0.0 O x