Page 1

Extractor hood

siemens-home.bsh-group.com/welcome

siemens-home.com/welcome

>HQ@,QVWUXFWLRQVIRULQVWDOODWLRQDQGXVH

Register

your

product

online

Page 2

en

Table of contents

[en]Instructions for installation use

INSTRUCTION MANUAL.......................................................... 2

d na

8Intended use

8 Intended use................................................................... 2

Intended use

Read these instructions carefully. Only then

( Important safety information ........................................3

7 Environmental protection ............................................. 5

Ç Operating modes ........................................................... 5

1 Operating the appliance................................................ 5

2 Cleaning and maintenance ........................................... 8

3 Trouble shooting.......................................................... 10

4 Customer service ........................................................ 10

INSTALLATION INSTRUCTIONS........................................... 11

( Important safety information ......................................12

K General information..................................................... 13

5 Installation.................................................................... 16

INSTRUCTION MANUAL

Produktinfo

Additional information on products, accessories,

Additional information on products, accessories, replacement

parts and services can be found at www.siemens-home.bsh-

replacement parts and services can be found at

group.com and in the online shop www.siemens-home.bsh-

www.siemens-home.com and in the online shop

group.com/eshops

www.siemens-eshop.com

will you be able to operate your appliance

safely and correctly. Retain the instruction

manual and installation instructions for future

use or for subsequent owners.

The appliance can only be used safely if it is correctly installed according to the safety instructions. The installer is responsible for ensuring that the appliance works perfectly at its installation location.

This appliance is intended for domestic use

and the household environment only. The

appliance is not intended for use outside. Do

not leave the appliance unattended during

operation. The manufacturer is not liable for

damage which is caused by improper use or

incorrect operation.

This appliance is intended for use up to a maximum height of 2000 metres above sea level.

This appliance may be used by children over

the age of 8 years old and by persons with

reduced physical, sensory or mental

capabilities or by persons with a lack of

experience or knowledge if they are

supervised or are instructed by a person

responsible for their safety how to use the

appliance safely and have understood the

associated hazards.

Children must not play with, on, or around the

appliance. Children must not clean the

appliance or carry out general maintenance

unless they are at least 15 years old and are

being supervised.

Keep children below the age of 8 years old at a safe distance from the appliance and power cable.

Check the appliance for damage after unpacking it. Do not connect the appliance if it has been damaged in transport.

This appliance is not intended for operation with an external clock timer or a remote control.

2

Page 3

(Important safety

information

Important safety information

:Warning

Danger of suffocation!

Packaging material is dangerous to children.

Never allow children to play with packaging

material.

:Warning

Danger of death!

Risk of poisoning from flue gases that are

drawn back in.

Always ensure adequate fresh air in the room

if the appliance is being operated in exhaust

air mode at the same time as room airdependent heat-producing appliance is being

operated.

Room air-dependent heat-producing

appliances (e.g. gas, oil, wood or coaloperated heaters, continuous flow heaters or

water heaters) obtain combustion air from the

room in which they are installed and discharge

the exhaust gases into the open air through an

exhaust gas system (e.g. a chimney).

In combination with an activated vapour

extractor hood, room air is extracted from the

kitchen and neighbouring rooms - a partial

vacuum is produced if not enough fresh air is

supplied. Toxic gases from the chimney or the

extraction shaft are sucked back into the living

space.

■ Adequate incoming air must therefore

always be ensured.

■ An incoming/exhaust air wall box alone will

not ensure compliance with the limit.

Safe operation is possible only when the

partial vacuum in the place where the heatproducing appliance is installed does not

exceed 4 Pa (0.04 mbar). This can be

achieved when the air needed for combustion

is able to enter through openings that cannot

be sealed, for example in doors, windows,

incoming/exhaust air wall boxes or by other

technical means.

Important safety information en

In any case, consult your responsible Master

Chimney Sweep. He is able to assess the

house's entire ventilation setup and will

suggest the suitable ventilation measures to

you.

Unrestricted operation is possible if the vapour

extractor hood is operated exclusively in the

circulating-air mode.

:Warning

Risk of fire!

■ Grease deposits in the grease filter may

catch fire.

Clean the grease filter at least every

2 months.

Never operate the appliance without the

grease filter.

Risk of fire!

■ Grease deposits in the grease filter may

catch fire. Never work with naked flames

close to the appliance (e.g. flambéing). Do

not install the appliance near a heatproducing appliance for solid fuel (e.g.

wood or coal) unless a closed, nonremovable cover is available. There must

be no flying sparks.

Risk of fire!

■ Hot oil and fat can ignite very quickly. Never

leave hot fat or oil unattended. Never use

water to put out burning oil or fat. Switch off

the hotplate. Extinguish flames carefully

using a lid, fire blanket or something similar.

Risk of fire!

■ When gas burners are in operation without

any cookware placed on them, they can

build up a lot of heat. A ventilation

appliance installed above the cooker may

become damaged or catch fire. Only

operate the gas burners with cookware on

them.

Risk of fire!

■ Operating several gas burners at the same

time gives rise to a great deal of heat. A

ventilation appliance installed above the

cooker may become damaged or catch fire.

Never operate two gas burners

simultaneously on the highest flame for

longer than 15 minutes. One large burner of

more than 5 kW (wok) is equivalent to the

power of two gas burners.

3

Page 4

en Important safety information

:Warning

Risk of burns!

The accessible parts become very hot when in

operation. Never touch hot parts. Keep

children at a safe distance.

:Warning

Risk of injury!

■ Components inside the appliance may have

sharp edges. Wear protective gloves.

Risk of injury!

■ Items placed on the appliance may fall

down. Do not place any objects on the

appliance.

Risk of injury!

■ The light emitted by LED lights is very

dazzling, and can damage the eyes (risk

group 1). Do not look directly into the

switched on LED lights for longer than

100 seconds.

:Warning

Risk of electric shock!

■ A defective appliance may cause electric

shock. Never switch on a defective

appliance. Unplug the appliance from the

mains or switch off the circuit breaker in the

fuse box. Contact the after-sales service.

Risk of electric shock!

■ Incorrect repairs are dangerous. Repairs

may only be carried out and damaged

power cables replaced by one of our

trained after-sales technicians. If the

appliance is defective, unplug the appliance

from the mains or switch off the circuit

breaker in the fuse box. Contact the aftersales service.

Risk of electric shock!

■ Do not use any high-pressure cleaners or

steam cleaners, which can result in an

electric shock.

Causes of damage

Caution!

Risk of damage due to corrosion. Always

switch on the appliance while cooking to avoid

condensation. Condensate can produce

corrosion damage.

Always replace faulty bulbs to prevent the remaining bulbs from overloading.

Risk of damage due to ingress of humidity into the electronic circuitry. Never clean operator controls with a wet cloth.

Surface damage due to incorrect cleaning. Clean stainless steel surfaces in the direction of the grain only. Do not use any stainless steel cleaners for operator controls.

Surface damage due to strong or abrasive cleaning agents. Never use strong and abrasive cleaning agents.

Risk of damage from returning condensate. Install the exhaust duct in such a way that it falls away from the appliance slightly (1° slope).

4

Page 5

Environmental protection en

7Environmental protection

Environmental protection

Your new appliance is particularly energy-efficient. Here you can find tips on how to save even more energy when using the appliance, and how to dispose of your appliance properly.

Saving energy

■ During cooking, ensure that there is a sufficient

supply of air so that the extractor hood can work

efficiently and with a low level of operating noise.

■ Adjust the fan speed to the intensity of the cooking

fumes. Only use intensive mode where this is

required. A lower fan speed means that less energy

is consumed.

■ If there are intensive cooking fumes, select a higher

fan speed in good time. If cooking fumes have

already spread in the kitchen, the extractor hood

must be operated for longer.

■ Switch off the extractor hood if you no longer require

it.

■ Switch off the lighting if you no longer require it.

■ Clean and, if required, replace the filter at regular

intervals in order to increase the effectiveness of the

ventilation system and to prevent the risk of fire.

ÇOperating modes

Operating modes

Exhaust air mode

The air which is drawn in is cleaned

by the grease filters and conveyed to

the exterior by a pipe system.

Note: The exhaust air must not be conveyed into a

functioning smoke or exhaust gas flue or into a shaft

which is used to ventilate installation rooms which

contain heat-producing appliances.

■ Before conveying the exhaust air into a non-

functioning smoke or exhaust gas flue, obtain the

consent of the heating engineer responsible.

■ If the exhaust air is conveyed through the outer wall,

a telescopic wall box should be used.

Air recirculation

The air which is drawn in is cleaned by

the grease filters and an activated

carbon filter, and is conveyed back into

the kitchen.

Environmentally-friendly disposal

Dispose of packaging in an environmentally-friendly manner.

This appliance is labelled in accordance with

European Directive 2012/19/EU concerning

used electrical and electronic appliances

(waste electrical and electronic equipment WEEE). The guideline determines the

framework for the return and recycling of used

appliances as applicable throughout the EU.

Note: To bind odours in air recirculation mode, you

must install an activated carbon filter. The different

options for operating the appliance in air recirculation

mode can be found in the brochure. Alternatively, ask

your dealer. The required accessories are available

from specialist retailers, from customer service or from

the Online Shop.

1Operating the appliance

Operating the appliance

These instructions apply to several appliance variants. It is possible that individual features are described which do not apply to your appliance.

Note: Switch on the extractor hood when you start

cooking and switch it off again several minutes after you

have finished cooking. This is the most effective way of

removing the kitchen fumes.

5

Page 6

en Operating the appliance

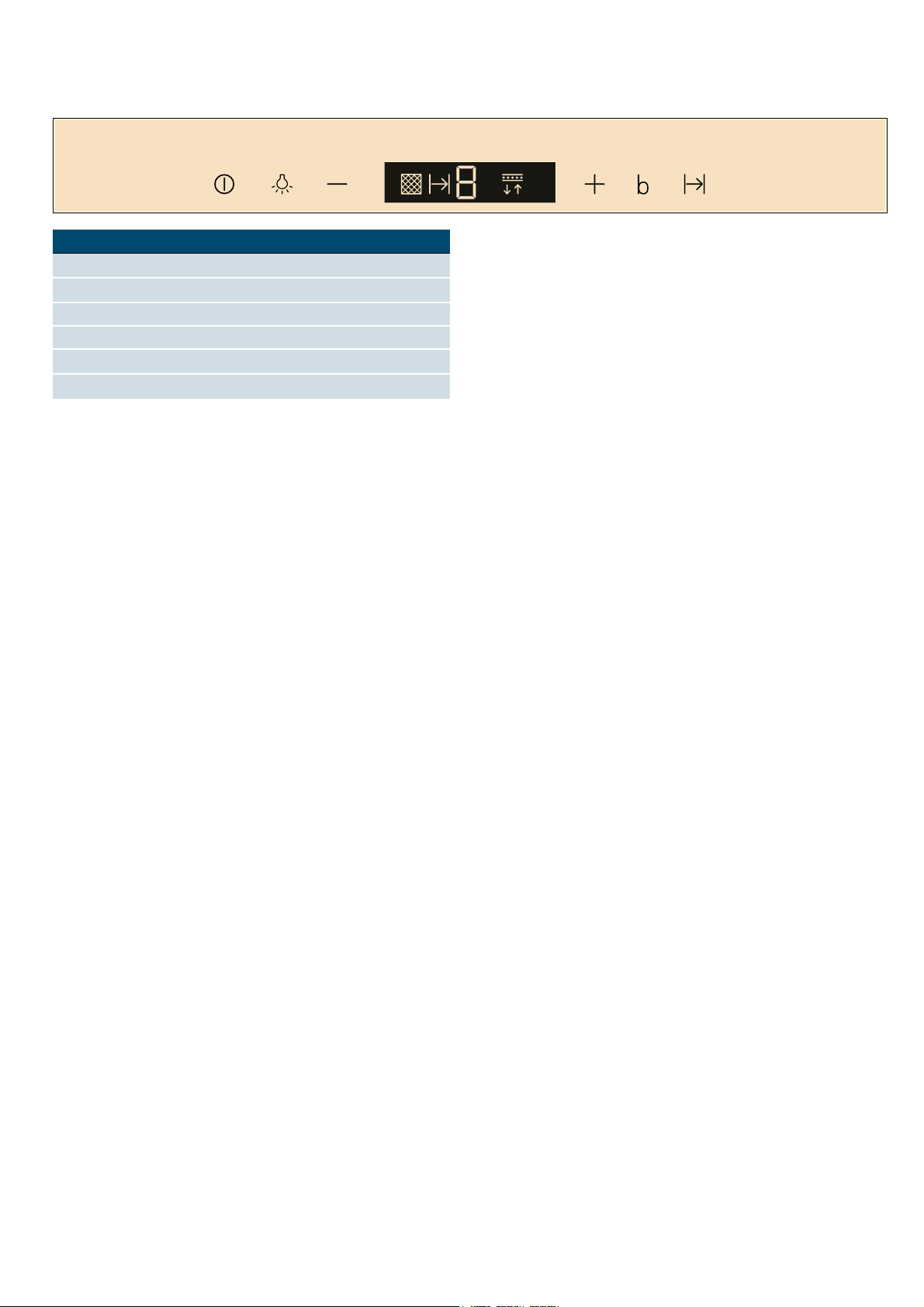

Control panel model 1

LQW

Explanation

Fan on/off

#

Light on/off/dimming

=

- Reduces the fan settings/fan run-on time

+ Increases the fan settings/intensive setting 1, 2

Boost function (short-term maximum power)

&

Fan run-on

x

Setting the fan

Switching on

■ Pull out the filter pull-out and touch the # symbol.

The fan will start at setting ƒ.

■ Touch the + or - symbol to alter the fan speed.

Note: When the filter pull-out is pushed in, only fan

settings ‚, ƒ and „ can be selected.

Switching off

Touch the # symbol. Slide in the filter pull-out.

Intensive setting

You can use the intensive setting if there is a large build-up of odours and fumes/vapours.

Touch the + symbol whilst the fan is at setting „.

This activates intensive setting ‚ 2. Touch the +

symbol once again to activate intensive setting ƒ2.

After approximately six minutes, the electronics automatically reduce the fan to a lower setting . If you want to end the intensive setting before the preset time expires, touch the - symbol until the required fan setting is reached.

Boost function

The boost function is a short-term maximum power setting which can be activated at any fan setting.

Touch the & symbol. After approximately 20 seconds, the fan switches back to the previously set fan setting.

Lighting

The lighting can be switched on and off independently of the fan.

Touch the

= symbol.

Setting the brightness

Press and hold the = symbol until the desired brightness is reached.

Saturation display

When the metal grease filters or the activated charcoal filter are/is saturated, an audible signal sounds for approximately four seconds after the fan is switched off.

In addition, the corresponding symbol appears on the display:

■ Metal grease filter:!

■ Activated charcoal filter: "

If you have not yet done so, the metal grease filters should be cleaned or the activated charcoal filter changed.

For instructions on how to clean the metal grease filters, please refer to the section Cleaning and maintenance.

The saturation indicators can be reset while they are flashing. To do this, touch the - symbol.

Switching over the indicator for circulating-air mode

For circulating-air mode, the electronic control must be switched over accordingly:

■ The extractor hood must be connected and switched

off.

■ Touch and hold the # and x symbols at the same

time, until the ™" indicator lights up for circulatingair mode "Starter Set". Repeatedly pressing and

holding this button combination causes the ’"

indicator to light up for the "CleanAir" circulating-air

module.

■ Repeatedly pressing and holding this button

combination switches the electronic control back

over to ducted operation (! indicator).

Fan run-on time

Touch the x symbol or slide in the filter pull-out while the extractor hood is operating.

After approximately 10 minutes, the fan will switch off automatically.

6

Audible signal

Switching on the audible signal

When the fan is switched off, press and hold the # and + symbols simultaneously for approximately three seconds. An audible signal sounds as an acknowledgement.

Switching off the audible signal

Repeat the "Switching on the audible signal" process.

Page 7

Control panel model 2

Operating the appliance en

DXWR

Explanation

#

=

&

!

Fan on/off

Light on/off/dimming

Boost function (short-term maximum power)

Automatic mode with fan run-on

-|||+ Range of fan settings

Setting the fan

Switching on

■ Pull out the filter pull-out and touch the # symbol.

The fan will start at setting ƒ.

■ Slide your finger across the settings range ||| to

alter the fan speed.

Note: When the filter pull-out is pushed in, only fan

settings ‚, ƒ and „ can be selected.

Switching off

Touch the # symbol. Slide in the filter pull-out.

Intensive setting

You can use the intensive setting if there is a large build-up of odours and fumes/vapours.

Slide your finger to the right across the III settings range. Intensive settings ‚ 2 and ƒ2 can be selected.

After approximately six minutes, the electronics

automatically reduce the fan to a lower setting . If you

want to end the intensive setting before the preset time

expires, slide your finger to the left across the III

settings range until the required fan setting is reached.

Boost function

The boost function is a short-term maximum power setting which can be activated at any fan setting.

Touch the & symbol. After approximately 20 seconds, the fan switches back to the previously set fan setting.

Fan run-on time

If you slide in the filter pull-out, the run-on time will be activated for as long as the extractor hood is operating.

After approx. 10 minutes, the fan switches off automatically.

LQW

Automatic mode

Switching on

■ Touch the # symbol.

The fan starts at setting ƒ.

■ Touch the ! symbol.

The optimum fan setting ‚, ƒ or „ is automatically

set via a sensor.

Switching off

Touch the ! or # symbol to switch automatic mode off.

The fan switches off automatically if the sensor no longer detects a change in the air quality of the room.

Automatic mode can run for a maximum of 4 hours.

Sensor control

In automatic mode, a sensor in the extractor hood detects the intensity of the cooking and roasting odours. Depending on the sensor setting, the fan automatically switches to another fan setting.

Default sensitivity setting: „

Lowest sensitivity setting: ‚

Highest sensitivity setting: †

If the sensor control responds too quickly or too slowly, it can be changed accordingly:

1. When the fan is switched off, hold the ! symbol

for approximately four seconds. The setting is

displayed.

2. The sensor control setting can be changed by

sliding your finger to the right or to the left across the

||| settings range.

3. To confirm the entry, hold the ! symbol for

approximately four seconds.

Lighting

The lighting can be switched on and off independently of the fan.

Touch the = symbol.

Setting the brightness

Press and hold the = symbol until the desired brightness is reached.

7

Page 8

en Cleaning and maintenance

Saturation display

When the metal grease filters or the activated charcoal filter are/is saturated, an audible signal sounds for approximately four seconds after the fan is switched off.

In addition, the corresponding symbol appears on the display:

■ Metal grease filter:!

■ Activated charcoal filter: "

If you have not yet done so, the metal grease filters should be cleaned or the activated charcoal filter changed.

For instructions on how to clean the metal grease filters, please refer to the section Cleaning and maintenance.

The saturation indicators can be reset while they are flashing. To do this, touch the - symbol.

Switching over the indicator for circulating-air mode

For circulating-air mode, the electronic control must be switched over accordingly:

■ The extractor hood must be connected and switched

off.

■ Touch and hold the # and ! symbols at the

same time, until the ™" indicator lights up for

circulating-air mode "Starter Set". Repeatedly

pressing and holding this button combination

causes the ’" indicator to light up for the

"CleanAir" circulating-air module.

■ Repeatedly pressing and holding this button

combination switches the electronic control back

over to ducted operation (! indicator).

Audible signal

Switching on the audible signal

When the fan is switched off, press and hold the # and + symbols simultaneously for approximately three seconds. An audible signal sounds as an acknowledgement.

Switching off the audible signal

Repeat the "Switching on the audible signal" process.

2Cleaning and maintenance

Cleaning and maintenance

:Warning

Risk of burns!

The appliance will become hot during operation,

especially near the bulbs. Allow the appliance to cool

down before cleaning.

:Warning

Risk of electric shock!

Penetrating moisture may result in an electric shock.

Clean the appliance using a damp cloth only. Before

cleaning, pull out the mains plug or switch off the circuit

breaker in the fuse box.

:Warning

Risk of electric shock!

Do not use any high-pressure cleaners or steam

cleaners, which can result in an electric shock.

:Warning

Risk of injury!

Components inside the appliance may have sharp

edges. Wear protective gloves.

Cleaning agents

To ensure that the different surfaces are not damaged by using the wrong cleaning agent, observe the information in the table. Do not use any of the following:

■ Harsh or abrasive cleaning agents,

■ Cleaning agents with a high alcohol content,

■ Hard scouring pads or cleaning sponges,

■ High-pressure cleaners or steam cleaners.

Wash new sponge cloths thoroughly before use.

Follow all instructions and warnings included with the cleaning agents.

8

Page 9

Cleaning and maintenance en

Area Cleaning agent

Stainless steel Hot soapy water:

Clean with a dish cloth and then dry with a

soft cloth.

Clean stainless steel surfaces in the grind

direction only.

Special stainless steel cleaning products are

available from our after-sales service or from

specialist retailers. Apply a very thin layer of

the cleaning product with a soft cloth.

Painted surfaces Hot soapy water:

Clean using a damp dish cloth and dry with a

soft cloth/towel.

Do not use any stainless steel cleaners.

Aluminium and plastic Glass cleaner:

Clean with a soft cloth.

Glass Glass cleaner:

Clean with a soft cloth. Do not use a glass

scraper.

Controls Hot soapy water:

Clean using a damp dish cloth and dry with a

soft cloth/towel.

Risk of electric shock caused by penetrating

moisture.

Risk of damage to the electronics from penetrating moisture. Never clean operating controls with a wet cloth.

Do not use any stainless steel cleaners.

In the dishwasher:

Note: If the metal mesh grease filters are cleaned in the

dishwasher, slight discolouration may occur. This has

no effect on the function of the metal mesh grease

filters.

■ Do not clean heavily soiled metal mesh grease filters

together with utensils.

■ Place the metal mesh grease filters loosely in the

dishwasher. The metal mesh grease filters must not

be wedged in.

Removing metal grease filter

1. Open the lock and fold down the metal grease filter.

While doing this, place your other hand under the

metal grease filter.

2. Take the metal grease filter out of the holder.

Cleaning the metal mesh grease filters

These instructions apply to several appliance variants. It is possible that individual features are described which do not apply to your appliance.

:Warning

Risk of fire!

Grease deposits in the grease filter may catch fire.

Clean the grease filter at least every 2 months.

Never operate the appliance without the grease filter.

Notes

■ Do not use any aggressive, acidic or alkaline

cleaning agents.

■ When cleaning the metal mesh grease filters, also

clean the holder for the metal mesh grease filters in

the appliance using a damp cloth.

■ The metal mesh grease filters can be cleaned in the

dishwasher or by hand.

By hand:

Note: You can use a special grease solvent for

stubborn dirt. It can be ordered via the Online Shop.

Notes

– Grease may accumulate in the bottom of the

metal grease filter.

– Hold the metal grease filter level to prevent

grease from dripping out.

3. Clean the metal grease filter.

Installing the metal mesh grease filter

1. Insert the metal mesh grease filter.

While doing this, place the other hand under the

metal mesh grease filter.

2. Fold the metal mesh grease filter upwards, locking it

in place.

■ Soak the metal mesh grease filters in a hot soapy

solution.

■ Clean the filters with a brush and then rinse them

thoroughly.

■ Leave the metal mesh grease filters to drain.

9

Page 10

en Trouble shooting

3Trouble shooting

Trouble shooting

Malfunctions often have simple explanations. Please read the following notes before calling the after-sales service.

:Warning

Risk of electric shock!

Incorrect repairs are dangerous. Repairs may only be

carried out and damaged power cables replaced by

one of our trained after-sales technicians. If the

appliance is defective, unplug the appliance from the

mains or switch off the circuit breaker in the fuse box.

Contact the after-sales service.

Malfunction table

Problem Possible cause Solution

The appliance

does not work

--------

The plug is not

plugged in.

Connect the appliance to the

electricity supply

Power cut Check whether other kitchen

appliances are working

Faulty fuse Check in the fuse box to make

sure that the fuse for the

appliance is OK

4Customer service

Customer service

When calling us, please give the product number (E

no.) and the production number (FD no.) so that we can

provide you with the correct advice. The rating plate

with these numbers can be found inside the appliance

(remove the metal mesh grease filter to gain access).

You can make a note of the numbers of your appliance and the telephone number of the after-sales service in the space below to save time should it be required.

E no. FD no.

After-sales serviceO

Please be aware that a visit by an after-sales engineer will be charged if a problem turns out to be the result of operator error, even during the warranty period.

Please find the contact data of all countries in the enclosed customer service list.

To book an engineer visit and product advice

GB 0344 892 8999

Calls charged at local or mobile rate.

IE 01450 2655

0.03 € per minute at peak. Off peak 0.0088 €

per minute.

LED lights

Defective LED lights may be replaced by the manufacturer, their customer service or a qualified technician (electrician) only.

:Warning

Risk of injury!

The light emitted by LED lights is very dazzling, and can

damage the eyes (risk group 1). Do not look directly

into the switched on LED lights for longer than 100

seconds.

Rely on the professionalism of the manufacturer. You can therefore be sure that the repair is carried out by trained service technicians who carry original spare parts for your appliances.

Accessories

(not included in the scope of delivery)

Note: These instructions apply to several appliance

models. It may be the case that an optional accessory

that is listed does not apply for your appliance.

Note: Observe the installation instructions in the

accessory.

Accessory Order number

Basic equipment:

Starter set for circulating-air mode

Easy-change filter for starter set

Basic equipment:

CleanAir air recirculation module

Throw-away filter for CleanAir recirculation mod-

ule

Lowering frame:

Appliance width: 60 cm LZ46600

Lowering frame:

Appliance width: 90 cm LZ49600

Installation set:

Upper cabinet: 90 cm LZ49200

--------

LZ45650

LZ45610

LZ46800

LZ46810

10

Page 11

INSTALLATION INSTRUCTIONS

Customer service en

Installation instructions

These instructions apply to several appliance variants. It is possible that individual features are described which do not apply to your appliance.

■ This appliance is installed in a upper cabinet.

■ Follow the enclosed installation instructions for

additional special accessories (e.g. for circulating-air

mode).

■ The surfaces of the appliance are sensitive. Avoid

damaging them during installation.

Appliance width 60 cm:

[

[

[

[

[

Appliance width 90 cm:

PP

PP

[

[

[

[

[

[

11

Page 12

en Important safety information

(Important safety

information

Important safety information

Read these instructions carefully. Only then will you be able to operate your appliance safely and correctly. Retain the instruction manual and installation instructions for future use or for subsequent owners.

The appliance can only be used safely if it is correctly installed according to the safety instructions. The installer is responsible for ensuring that the appliance works perfectly at its installation location.

The width of the extractor hood must correspond at least with the width of the hob.

For the installation, observe the currently valid building regulations and the regulations of the local electricity and gas suppliers.

When conveying the exhaust air, official and legal regulations (e.g. state building regulations) must be followed.

:Warning

Risk of death!

Risk of poisoning from flue gases that are

drawn back in. The exhaust air must not be

conveyed into a functioning smoke or exhaust

gas flue or into a shaft which is used to

ventilate installation rooms that contain

heating appliances. If the exhaust air is to be

conveyed into a non-functioning smoke or

exhaust gas flue, you must obtain the consent

of the heating engineer responsible.

Room air-dependent heat-producing

appliances (e.g. gas, oil, wood or coaloperated heaters, continuous flow heaters or

water heaters) obtain combustion air from the

room in which they are installed and discharge

the exhaust gases into the open air through an

exhaust gas system (e.g. a chimney).

In combination with an activated vapour

extractor hood, room air is extracted from the

kitchen and neighbouring rooms - a partial

vacuum is produced if not enough fresh air is

supplied. Toxic gases from the chimney or the

extraction shaft are sucked back into the living

space.

■ Adequate incoming air must therefore

always be ensured.

■ An incoming/exhaust air wall box alone will

not ensure compliance with the limit.

Safe operation is possible only when the

partial vacuum in the place where the heatproducing appliance is installed does not

exceed 4 Pa (0.04 mbar). This can be

achieved when the air needed for combustion

is able to enter through openings that cannot

be sealed, for example in doors, windows,

incoming/exhaust air wall boxes or by other

technical means.

:Warning

Danger of death!

Risk of poisoning from flue gases that are

drawn back in.

Always ensure adequate fresh air in the room

if the appliance is being operated in exhaust

air mode at the same time as room airdependent heat-producing appliance is being

operated.

In any case, consult your responsible Master

Chimney Sweep. He is able to assess the

house's entire ventilation setup and will

suggest the suitable ventilation measures to

you.

Unrestricted operation is possible if the vapour

extractor hood is operated exclusively in the

circulating-air mode.

:Warning

Danger of death!

Risk of poisoning from flue gases that are

drawn back in. If installing a ventilation system

in a room with a heat-producing appliance

connected to a chimney/flue, the electricity

supply to the hood must be equipped with a

suitable safety switch.

12

Page 13

General information en

:Warning

Risk of fire!

Grease deposits in the grease filter may catch

fire. The specified safety distances must be

observed in order to prevent an accumulation

of heat. Observe the specifications for your

cooking appliance. If gas and electric hobs

are operated together, the largest specified

distance applies.

Only one side of the appliance may be

installed directly next to a high-sided unit or a

wall. The distance between the appliance and

wall or high-sided unit must be at least 50

mm.

:Warning

Risk of injury!

■ Components inside the appliance may have

sharp edges. Wear protective gloves.

Risk of injury!

■ The appliance may fall down if it has not

been properly fastened in place. All

fastening components must be fixed firmly

and securely.

Risk of injury!

■ The appliance is heavy. To move the

appliance, 2 people are required. Use only

suitable tools and equipment.

:Warning

Risk of electric shock!

Components inside the appliance may have

sharp edges. These may damage the

connecting cable. Do not kink or pinch the

connecting cable during installation.

KGeneral information

General information

Exhaust air mode

:Warning

Risk of death!

Risk of poisoning from flue gases that are drawn back

in. The exhaust air must not be conveyed into a

functioning smoke or exhaust gas flue or into a shaft

which is used to ventilate installation rooms that contain

heating appliances. If the exhaust air is to be conveyed

into a non-functioning smoke or exhaust gas flue, you

must obtain the consent of the heating engineer

responsible.

If the exhaust air is conveyed through the outer wall, a telescopic wall box should be used.

Exhaust duct

Note: The appliance manufacturer does not provide any

warranty for faults attributable to the pipe section.

:Warning

Risk of electric shock!

It must always be possible to disconnect the

appliance from the electricity supply. The

appliance must only be connected to a

protective contact socket that has been

correctly installed. If the plug is no longer

accessible once the appliance has been

installed, or a fixed connection is required, the

installation must have an all-pole isolating

switch with a contact gap of at least 3 mm.

Only an electrician may install the fixed

connection. We recommend installing a

residual-current circuit breaker (RCCB) in the

appliance's power supply circuit.

:Warning

Danger of suffocation!

Packaging material is dangerous to children.

Never allow children to play with packaging

material.

■ The appliance achieves its optimum performance by

means of a short, straight exhaust air pipe and as

large a pipe diameter as possible.

■ As a result of long, rough exhaust air pipes, many

pipe bends or pipe diameters that are smaller than

150 mm, the optimum extraction performance is not

achieved and fan noise is increased.

■ The pipes or hoses for laying the exhaust air line

must consist of non-combustible material.

Round pipes An inner diameter of 150 mm, but at least 120 mm, is recommended.

Flat ducts The inner cross-section must correspond to the diameter of the round pipes.

150 mm diameter, approx. 177 cm

120 mm diameter, approx. 113 cm

■ Flat ducts should not have any sharp deflections.

■ Use sealing strips for different pipe diameters.

2

2

13

Page 14

en General information

Electrical connection

:Warning

Risk of electric shock!

Components inside the appliance may have sharp

edges. These may damage the connecting cable. Do

not kink or pinch the connecting cable during

installation.

The required connection data can be found on the rating plate inside the appliance; to do this, remove the metal mesh grease filter.

Length of the cable: approx. 1.30 m

This appliance complies with the EC interference suppression regulations.

:Warning

Risk of electric shock!

It must always be possible to disconnect the appliance

from the electricity supply. The appliance must only be

connected to a protective contact socket that has been

correctly installed. If the plug is no longer accessible

once the appliance has been installed, or a fixed

connection is required, the installation must have an allpole isolating switch with a contact gap of at least

3 mm. Only an electrician may install the fixed

connection. We recommend installing a residual-current

circuit breaker (RCCB) in the appliance's power supply

circuit.

1. Make the cut-out for the exhaust air pipe. To do this,

make an opening in the top or back panel of the

fitted unit with an additional recess for the power

cord.

PP

2. If the cabinet base is in place, remove it. Mark the

fastening points on the inside of the cabinet and use

a bradawl to make indentations where the holes are

to be. To help you mark the fastening points, use the

fastening piece provided.

PP

Preparing the units

■ The fitted unit must be level and have sufficient load-

bearing capacity.

■ The max. weight of the extractor hood is 18 kg.

Appliance dimensions and safety clearances

■ Observe the appliance's dimensions.

■ Comply with the safety clearances.

If the installation instructions for the gas cooking

appliances specify a different distance, the largest

distance must always be provided for.

The fitted unit must be heat-resistant up to 90 °C.The

fitted unit must still be sturdy after the cut-outs have

been made.

To install the extractor hood in a wall-hanging

cupboard, the extractor hood must be provided with the

following dimensions:

Width 600 mm

Depth Min. 320 mm

Depth Min. 350 mm with lowering frame

Height Min. 420 mm

Height Min. 600 mm with CleanAir air recirculation

module

Wall thickness 16 mm or 19 mm

PLQ

PP

14

Page 15

General information en

Body wall thickness: 16 mm

1. Screw the mounting pieces to the body on the left

and right. ¨

2. Remove the tabs from the bottom of the mounting

pieces. ©

$

PP

%

[

Body wall thickness: 19 mm

1. Fold out the tabs on both of the mounting pieces. ¨

2. Screw the mounting pieces to the body on the left

and right. ©

3. Remove the tabs from the bottom of the mounting

pieces. ª

Preparing the appliance

1. Connect the power cord provided to the

appliance.¨

2. Use the strain relief to secure the power cord in

place.©

$

%

$

%

PP

&

PP

[

15

Page 16

en Installation

5Installation

Installation

Sliding the appliance up into place

1. Slide the appliance up into place and make sure it is

positioned correctly. ¨

2. Measure the distance between the appliance and

the wall, and mark this on the filler strip.

3. If required, shorten the filler strip to the required

dimension. ©

$ %

&

3. Carefully remove the appliance.

Sliding out the appliance

Note: Before you remove the appliance, protect the hob

with a piece of polystyrene from the packaging.

1. Use a flat-blade screwdriver to push in the fastening

bolt, and turn it 90° until it locks into place. ¨

2. Push in the fastening bolt gently with your fingers,

and turn it until it comes out of the housing along

with the spring.©

Pull gently on the fastening bolt; before you do this,

take hold of the appliance from beneath with the

other hand. ª

4. Screw in the filler strip fully.

[

5. Push in the fastening bolt and turn it 90°.

Note: The fastening pieces on the left and right of

the appliance must be able to move.

16

Page 17

Installation en

Final fitting stage

1. Slide the appliance up into place. ¨

2. Lock the fastening bolts on the left and right. ©

3. Fit the protective caps on the left and right. ª

$

%

&

2. Shorten the spacer to the required dimension and

insert it into the slot specified.

4. Establish the electrical connection.

Note: The extractor hood's housing can be concealed

within the upper cabinet. In doing so, you must observe

the following:

■ The intermediate floor must not be placed on the

extractor hood's housing.

■ The front panel must not be secured to the housing.

■ Access must be available in order to change the

filter and for the after-sales service.

Appliance width 90 cm:

You must also screw the appliance to the wall-hanging cupboards either side of it.

Connecting the pipes

Note: If an aluminium pipe is used, smooth the area

where it is to be connected before you connect it.

Exhaust air pipe, dia. 150 mm (recommended size)

Fit the exhaust air pipe directly to the air-pipe connector and seal the joint.

Exhaust air pipe, dia. 120 mm

1. Fit the reducing connector directly to the air-pipe

connector.

2. Attach the exhaust air pipe to the reducing

connector.

3. Seal both joints appropriately.

Removing the appliance

1. Disconnect the electrical connection.

2. Disconnect the pipes.

3. Remove the metal grease filter.

4. Remove the protective caps from the fastening

elements.

Changing the filter pull-out's limit stop

On some versions of the appliance, the limit stop for the

filter pull-out can be changed. Spacers are included

with these appliances in order to position the

appliance's handle strip flush with the fitted unit.

1. Pull the filter pull-out towards you.

5. Remove the appliance; see section entitled

"Removing the appliance".

17

Page 18

Page 19

Page 20

BSH Hausgeräte GmbH

Carl-Wery-Straße 34, 81739 München, GERMANY

www.siemens-home.com

siemens-home.bsh-group.com

0DQXIDFWXUHGE\%6++DXVJHUlWH*PE+XQGHU7UDGHPDUN/LFHQVHRI6LHPHQV$*

*9001087137*

9001087137 960211

Loading...

Loading...