Siemens LFL Series, LFL1.133-110V, LFL1.333-110V, LFL1.335-110V, LFL1.635-110V Technical Instructions

Technical Instructions

Document No. 7451US

LFL...

Rev. 2 November 15, 2004

LFL Series

Burner Flame Safeguard Control

The LFL… is a compact electro-mechanical

primary flame safeguard control designed to

provide burner sequencing, automatic ignition and continuous flame monitoring fo

r

gas, oil, and dual fuel, single burner applications.

The LFL… is applicable for on-off, multistage or modulating burners. The LFL… is

designed for direct main burner ignition,

intermittent or interrupted pilot operation.

The LFL… integrates the flame amplifier,

purge timer and sequencer in a single control. Flame supervision is accomplished

using UV sensor or flame rod detection.

Features

• Primary flame safeguard control

• Visual sequence indication

• Optional combustion air blower control

• Optional postpurge

• Preignition interlock

• Continuous flame monitoring,

including extraneous light detection

• UV sensor functional test

• Proven air switch function

• Proven high fire purge interlock

• Proven low fire ignition interlock

• Direct main burner ignition,

intermittent or interrupted pilot operation

• Integrated flame amplifier

• UV sensor or flame rod detector

• Lockout alarm terminal

• Local and optional remote reset

• Burner off – economy position

(fully closed air damper interlock)

• Unit fuse and spare fuse provided

Contents

Control Interface .................................................2

Installation...........................................................2

Ordering information...........................................3

Wiring base.........................................................3

Specifications .....................................................4

Specifications continued.....................................5

Description of oper controls ................................6

Ladder diagram external connections.................7

Sequence Dial OPERATION ..............................8

Sequence Dial FAULT and LOCKOUT...............9

Sequence Chart................................................10

Dimensions.......................................................11

11.15.2004

Siemens Building Technologies

HVAC Products

Control interface

2/12

Siemens Building Technologies HVAC Products

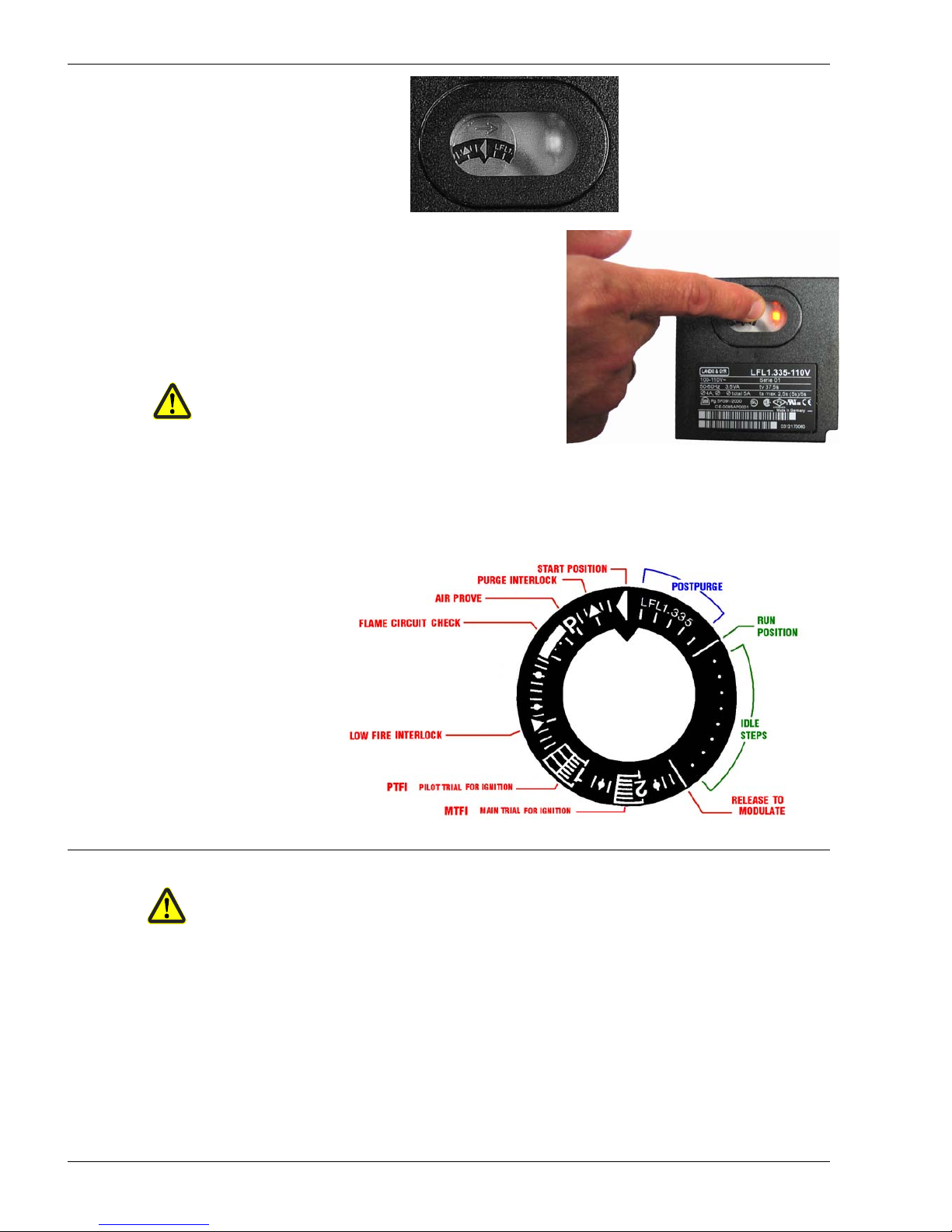

Indicator dial visible

through front window

Lockout indicator light

visible through front

window

The LFL… reset button

is integrated with the front window.

During a lockout condition,

pressing the window resets the LFL...

Pressing

* the window or remote reset

during normal operation will lockout the LFL…

*Do not hold reset button for more than

10 seconds! (Local or remote) , exceeding

10 seconds will damage control !

Manually press the lockout reset button.

Do NOT use any tools or pointed objects.

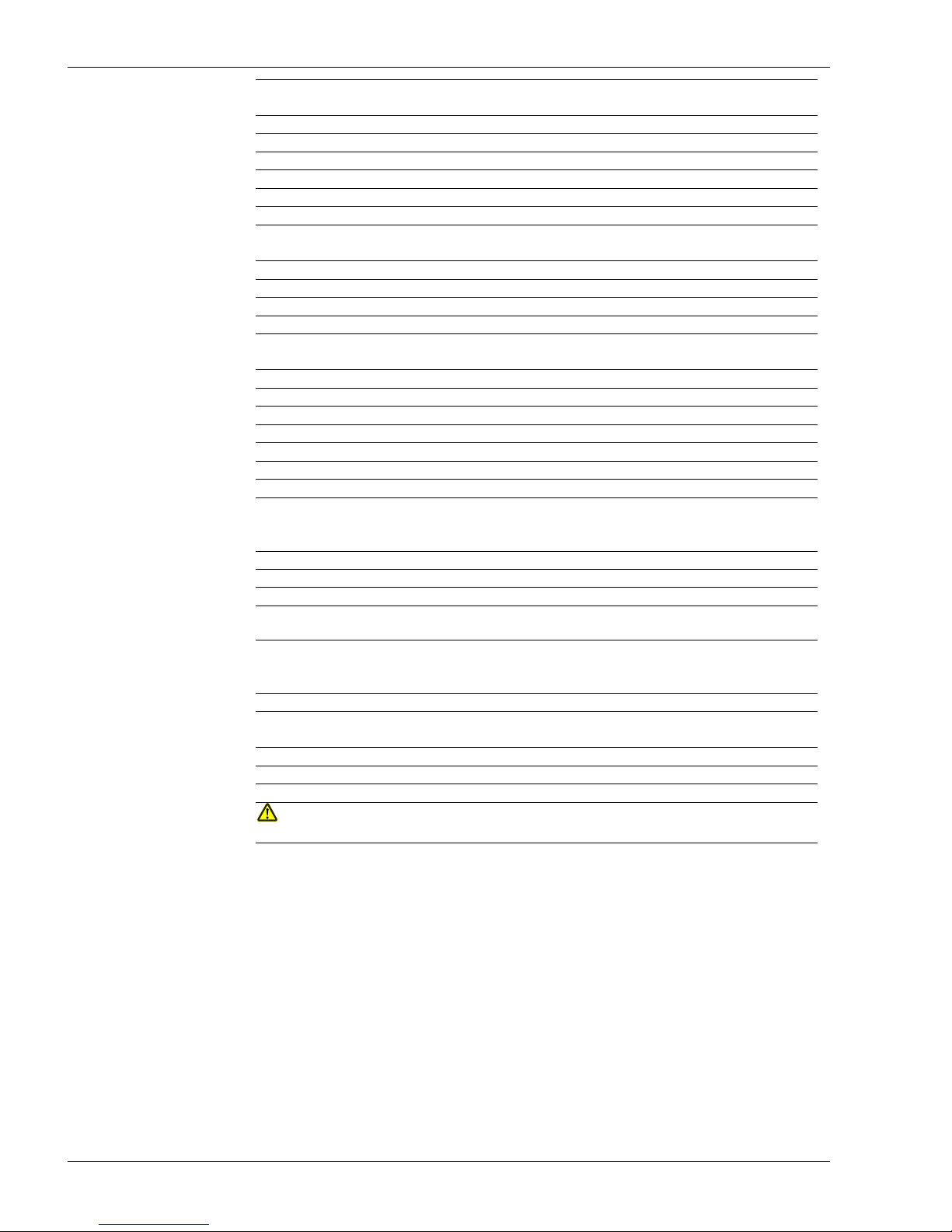

Indicator dial provides symbolic information about the program sequence, the type of fault,

and the point in the sequence where the fault occurred.

The LFL…

sequence is

fixed and

cannot be

manually

manipulated.

Installation

• All installation and commissioning work must be performed by qualified personnel.

• The LFL… must be mounted in an electrical enclosure, typically in the control panel.

• All wiring must comply with applicable electrical codes standards and regulations.

• Before performing any wiring to the LFL…, remove and isolate all power.

• High voltage AC wiring must not be installed in the same conduit

as the flame detector wiring.

• Maximum 10 A slow external fuse is required.

• The LFL is not adversely affected by electromagnetic resonance.

• Ground the LFL… wiring base.

• Do not open or modify the LFL...

• When UV flame supervision is used, other sources of radiation, such as halogen

lamps, welding equipment, ignition sparks can produce erroneous flame signals.

11.15.2004

Ordering Information

Table 1 Product Numbers

110 Vac 50/60 Hz *

LFL1.133-110V LFL1.333-110V LFL1.335-110V LFL1.635-110V

220 Vac 50/60 Hz *

LFL1.133 LFL1.335 LFL1.635

Timing description

Pre-purge time 7.5 sec 26 sec 31 sec 55 sec

Pilot trial for ignition (PTFI) 2.5 sec 4 sec 4 sec

Main trial for ignition (MTFI) 2.5 sec 4 sec

Interval from the beginning of MTFI

until release to modulation

2.5 sec 10 sec 10.5 sec

Post purge time 12 sec 15 sec 12 sec

Flame failure response time (FFRT) 1 sec

*All times listed above are for 60 Hz operation. (Times for 50 Hz operation will be 20% longer.)

Description Product Number

LFL Control unit Refer to Table 1 above

(without wiring base)

Wiring base AGM410490550

Flame sensor

UV (shown) QRA 4.U

forward looking 3/4” NPT

UV Refer to

QRA2… , QRA10 … Technical Instruction 7712

Flame rod By others

Wiring Base

The wiring base provides the following:

• 24 Terminals ______________

• 3 Ground connections __________________--

• 3 Neutral connections,

connected to terminal 2

3/12

Siemens Building Technologies CC1N7451en

HVAC Products 11.15.2004

Specifications

Supply voltage

100 Vac –15 % ... 110 Vac +10 % 50/60 Hz ±6 %

220 Vac –15 % ... 240 Vac +10 % 50/60 Hz ±6 %

Internal fuse 6.3 A (slow)

External fuse Maximum 10 A (slow)

Weight – LFL 2.2 lb

Weight – Wiring base 0.25 lb

Power consumption 3.5 VA

Mounting orientation No restrictions

General

Terminal 1 Line Maximum 5 A total load

Terminal 2 Neutral N/A

Terminal 3 Alarm 1 A pilot duty

Terminals 4 to 5 Limit string N/A

Terminals 6 and 7 Combustion Air

Blower

Motor 4 FLA, 24 LRA or 1.6 A pilot duty

Terminals 8, 9, 10, 11 Damper actuator N/A

Terminals 12, 13, 14 Air flow interlock N/A

Terminal 16 Ignition transformer 4 A

Terminal 17 Pilot fuel valve Motor 4 FLA, 24 LRA or 1.6 A pilot duty

Terminal 18 Main fuel valve Motor 4 FLA, 24 LRA or 1.6 A pilot duty

Terminal 19 Main fuel valve Motor 4 FLA, 24 LRA or 1.6 A pilot duty

Terminal 20 Damper actuator N/A

Terminal ratings

110V

UL File: MH26134 Standard: UL372

CSA Certificate: 1370843 Standard: CAN/CSA-C22.2 No 199-M89

FM File: J.I. 3003560 Standard: FM7610

110V & 220V

CE File: CE-0085AP0001 Standard: DIN EN 298

FCC Compliant Part 15 Class B - Emissions

Approvals

Vibration 0.5G Environment

Operation temperature range -5...+140 °F < 95 % relative humidity

Storage temperature range -58...+140 °F < 95 % relative humidity

Condensation, formation of ice and ingress

of water are not permitted!

Environmental

ratings

4/12

Siemens Building Technologies HVAC Products

11.15.2004

Loading...

Loading...