Siemens LDS 6 Operating Instructions Manual

LDS 6

In-situ Laser Gas Analyzer

•

Operating Instructions

LDS 6 In-situ Laser Gas Analyzer

01/2009

Operating Instructions • 01/2009

Continuous Gas Analysis

General Information

1

Technical Information

2

Installation Guidelines

3

Operation

4

Alarms

5

Maintenance and Service

6

Spare Parts List

7

Technical Data

8

Dimensional Drawings

9

ESD guidelines

A

List of Abbreviations

B

Continuous Gas Analysis

In Situ Laser Gas Analyzers

LDS 6

Operating Instructions

01/2009

A5E00295894-05

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

Ordernumber: A5E00295894

Ⓟ 04/2009

Copyright © Siemens AG 2004,

2007, 2008, 2009.

Technical data subject to change

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

5

Content

1 General Information

................................................................................................................................... 7

1.1 Information for our

Customers .......................................................................................................7

1.2 General Information

.......................................................................................................................7

1.3 Special Information and

Warnings.................................................................................................8

1.4 Warranty Conditions ......................................................................................................................8

1.5 Delivery Information .......................................................................................................................8

1.6 Standards and Regulations............................................................................................................8

2 Technical Inf

ormation ................................................................................................................................ 9

2.1 General Description

.......................................................................................................................9

2.2 Design..........................................................................................................................................13

2.3 Operating Principle ......................................................................................................................19

2.4 Configuration Examples...............................................................................................................20

2.5 Measurement Princ

iple ................................................................................................................21

3 Installation Guidelines

.............................................................................................................................. 25

3.1 Safety Information........................................................................................................................25

3.2 General Installation Information

...................................................................................................28

3.3 Electrical Connections .................................................................................................................29

3.3.1 Power Supply Connections

..........................................................................................................29

3.3.2 Hybrid Cable Connection.............................................................................................................31

3.3.3 Signal Cable Connection

.............................................................................................................32

3.3.4 Pin Assignment of LDS 6 .............................................................................................................34

3.4 Three Channel System ................................................................................................................35

3.4.1 External Power Suppl

y.................................................................................................................35

3.4.2 Three Channel Hybrid Cable Connec

tion....................................................................................36

3.5 Flange Installation Requirements

................................................................................................37

3.6 Installation of

Flanges ..................................................................................................................37

4 Operation

................................................................................................................................................. 41

4.1 General ........................................................................................................................................41

4.2 Input Sequence of Data

...............................................................................................................44

4.3 Analyzer Functions ......................................................................................................................47

4.3.1 Summary of Analyzer Functions..................................................................................................47

4.3.2 Analyzer Status............................................................................................................................49

4.3.3 Calibration

....................................................................................................................................51

4.3.4 Measuring Ranges.......................................................................................................................52

4.3.5 Parameters...................................................................................................................................52

4.3.6 Configuration................................................................................................................................55

Content

LDS 6

6 Operating Instructions, 01/2009, A5E00295894-05

4.4 Watch Dog................................................................................................................................... 64

5 Alarms ..................................................................................................................................................... 65

5.1 Alarm Response.......................................................................................................................... 65

5.2 Maintenance Request Alarm....................................................................................................... 67

5.3 Faults Alarm ................................................................................................................................ 68

5.4 Transmission Alarm .................................................................................................................... 69

5.5 Limit Alarm

.................................................................................................................................. 69

5.6 Function control alarm

................................................................................................................. 69

6 Maintenance and Servi

ce ........................................................................................................................ 71

6.1 General about Maintenance and Servi

ce.................................................................................... 71

6.2 Cleaning the Central Unit

............................................................................................................ 71

6.3 Cleaning the Wedge Windows

.................................................................................................... 71

6.4 Calibration Verification ................................................................................................................ 72

6.5 Reconfiguration of Temperature Compens

ation......................................................................... 73

6.6 Reconfiguration of Press

ure Compensation ............................................................................... 74

6.7 Reconfiguration of the Path Length

............................................................................................ 75

7 Spare Parts List....................................................................................................................................... 77

7.1 Compatibility of detectors

with central units................................................................................ 77

7.1.1 Detector Labels ........................................................................................................................... 77

7.1.2 Central Unit Label

s...................................................................................................................... 78

7.2 Spare Parts Lists......................................................................................................................... 79

7.3 Ordering Instructions................................................................................................................... 81

7.4 Repair/Upgrade........................................................................................................................... 81

8 Technical

Data......................................................................................................................................... 83

8.1 Central Unit

................................................................................................................................. 83

8.2 Hybrid and Sensor Cables

.......................................................................................................... 87

8.3 Purging........................................................................................................................................ 88

9 Dimensional Dra

wings ............................................................................................................................. 89

A ESD guidelin

es ........................................................................................................................................ 93

A.1 ESD guidelines............................................................................................................................ 93

B List of Abbre

viations ................................................................................................................................ 95

B.1 List of Abbreviations

.................................................................................................................... 95

Index........................................................................................................................................................ 99

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

7

General Information

1

1.1 Information for our Customers

Before beginning work with this device, please study this manual carefully! It contains

important information and data whose observation ensures proper device function and saves

you servicing costs. The manual will help you to operate the device more easily and

efficiently, allowing you to achieve reliable results.

1.2 General Information

The product described in this manual has left the factory in a high quality and tested

condition. In order to preserve this condition and to operate this product correctly and safely,

it may only be used in the manner described by the manufacturer. Furthermore, proper

transportation, storage, installation, operation and maintenance of the device is vital for

ensuring correct and safe operation.

This manual contains the information required for the intended use of the described product.

It is addressed to technically qualified personnel who are specially trained or who have the

relevant knowledge of automation technology (measuring and control systems).

Knowledge and technically correct implementation of the safety notes and warnings

contained in this manual are required for safe installation and commissioning, as well as for

safety during the operation and maintenance of the described product. Only qualified

personnel have the required professional knowledge for correctly interpreting the generally

valid safety notes and warnings in this manual in each specific case and to act accordingly.

This manual is an inherent part of the scope of delivery, despite the fact that it can be

ordered separately for logistic reasons.

Due to the variety of technical details, it is not possible to consider every single detail for all

versions of the described product and for every conceivable case in the set-up, operation,

maintenance and use in systems. For further information, or in the case of problems which

are not covered in enough detail in this document, please request the required information

from your local or responsible Siemens regional office.

Note

In particular, before using the device for new research and development applications, we

recommend that you first contact your Siemens representative or our application department

to discuss the application in question.

General Information

1.3 Special Information and Warnings

LDS 6

8 Operating Instructions, 01/2009, A5E00295894-05

1.3 Special Information and Warnings

This manual provides you with information on using, installing, operating, and maintaining

the device.

Pay particular attention to all special information and warnings. Information of this type is set

apart from the rest of the text and is marked with the corresponding pictograms. This

information provides you with useful tips and helps to avoid faulty operation.

1.4 Warranty Conditions

We expressly point out that the product quality is exclusively and conclusively described in

the sales contract. The content of this product documentation is neither a part of a previous

or existing agreement, promise or legal relationship, nor is it intended to modify these. All

obligations on the part of Siemens AG are contained in the respective sales contract, which

also contains the complete and solely applicable liability provisions. The provisions defined

in the sales contract for the responsibility for defects are neither extended nor limited by the

remarks in this document.

1.5 Delivery Information

The respective scope of delivery is listed on the shipping documents – enclosed with the

delivery – in accordance with the valid sales contract.

When opening the packaging, please observe the corresponding information on the

packaging material. Check the delivery for completeness and undamaged condition. In

particular, you should compare the Order No. on the rating plates with the ordering data, if

available.

If possible, please retain the packaging material, since you can use it again in case of return

deliveries.

1.6 Standards and Regulations

As far as possible, the harmonized European standards were the basis for the specification

and production of this device. If no harmonized European standards have been applied, the

standards and regulations for the Federal Republic of Germany are valid.

When this product is used beyond the scope of these standards and regulations, the valid

standards and regulations of the country of the operating company apply.

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

9

Technical Information

2

2.1 General Description

Overview

LDS 6 is a diode laser gas analyzer with a measuring principle based on the specific light

absorption of different gas components. LDS 6 is suitable for fast and non-contact

measurement of gas concentrations or temperatures in process or flue gases. One or two

signals from up to three measuring points are processed simultaneously by one central

analyzer unit. The in-situ cross-duct sensors at each measuring point can be separated up to

700 m from the central unit by using fiber-optic cables. The sensors are designed for

operation under harsh environmental conditions and contain a minimum of electrical

components.

Figure 2-1 LDS 6, typical installation with transmitted-light sensors

Technical Information

2.1 General Description

LDS 6

10 Operating Instructions, 01/2009, A5E00295894-05

Benefits

The in-situ gas analyzer LDS 6 is characterized by a high availability and unique analytical

selectivity, and by a broad scope of suitable applications. LDS 6 enables the measurement

of one or two gas components or – if desired – the gas temperature directly in the process:

● With high levels of dust load

● In hot, humid, corrosive, explosive, or toxic gases

● In applications showing strong varying gas compositions

● Under harsh environmental conditions at the measuring point

● Highly selective, i.e. mostly without cross-sensitivities

LDS 6 properties:

● Little installation effort

● Minimum maintenance requirements

● Extremely rugged design

● High long-term stability through built-in, maintenance-free reference gas cell, field

calibration is unnecessary

● Real-time measurements

Moreover, the instrument provides warning and failure messages upon:

● Need for maintenance

● Erroneous reference function

● Bad signal quality

● Exceeding of a lower or upper alarm level for the measured variable

● Transmitted amount of light exceeding an upper or lower limit

Technical Information

2.1 General Description

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

11

Application

The LDS 6 laser gas analyzer is suitable for a wide range of applications. The most common

of them are:

● Process optimization

● Continuous emission monitoring for all kinds of fuels (oil, gas, coal, and others)

● Process measurements in power utilities and any kind of incinerator

● Process control

● Explosion protection

● Measurements in corrosive and toxic gases

● Quality control

● Environmental protection

● Plant and operator safety

Sectors

● Power plants

● Steel works

● Cement industry

● Chemical and petrochemical plants

● Automotive industry

● Waste incinerators

● Glass and ceramics production

● Research and development

Special applications

In addition to the standard applications, special applications are available upon request.

Technical Information

2.1 General Description

LDS 6

12 Operating Instructions, 01/2009, A5E00295894-05

Essential characteristics

● Integrated calibration adjustment with an internal reference cell

● Negligible long-term drifts of zero and span

● Dynamic background correction for varying dust loads

● Isolated signal outputs, 4 to 20 mA

● User-friendly, menu-driven operation

● Selectable time constants (response time)

● Two user levels with individual access codes for prevention of unwanted and

unauthorized operations

● Operation according to NAMUR recommendations

● Monitoring of overall optical transmission

● Remote preventive maintenance and servicing via Ethernet/modem

● Straightforward replacement of the central unit, since connections can easily be removed

● Sensor and central unit housing free of wear and corrosion

● Easy operation with a numerical keypad and menu prompting

Certified versions for emission monitoring

The LDS 6 is available as certified instrument for emission monitoring of NH3, NH3/H2O, H2O,

HCl, HCl/H

2

O. The certificates are issued by TÜV for Germany and MCERTS for the United

Kingdom. For conducting regular linearity and calibration checks, test kits for ammonia,

water and HCl should be used. These kits can be ordered separately as instrument

accessories. For new analyzer orders, the NH

3

, NH3/H2O and H2O kits named "Version 2"

must be ordered. In case of doubt or for already installed analyzers, please contact Siemens

for spotting the correct kit version.

Technical Information

2.2 Design

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

13

2.2 Design

The gas analyzer LDS 6 consists of a central unit and up to three in-situ sensors. The

connection between the central unit and the sensors is established by a so-called hybrid

cable, which contains optical fibers and copper wires. An additional cable connects the

transmitter and receiver parts of the cross-duct sensor.

Central unit

The central unit is housed in a 19" rack with 4 holders for mounting in a hinged frame in

racks with or without telescopic rails.

The LDS 6 operates as an independent unit powered by a 100-240 V AC main power supply.

Figure 2-2 CentralUnit

Technical Information

2.2 Design

LDS 6

14 Operating Instructions, 01/2009, A5E00295894-05

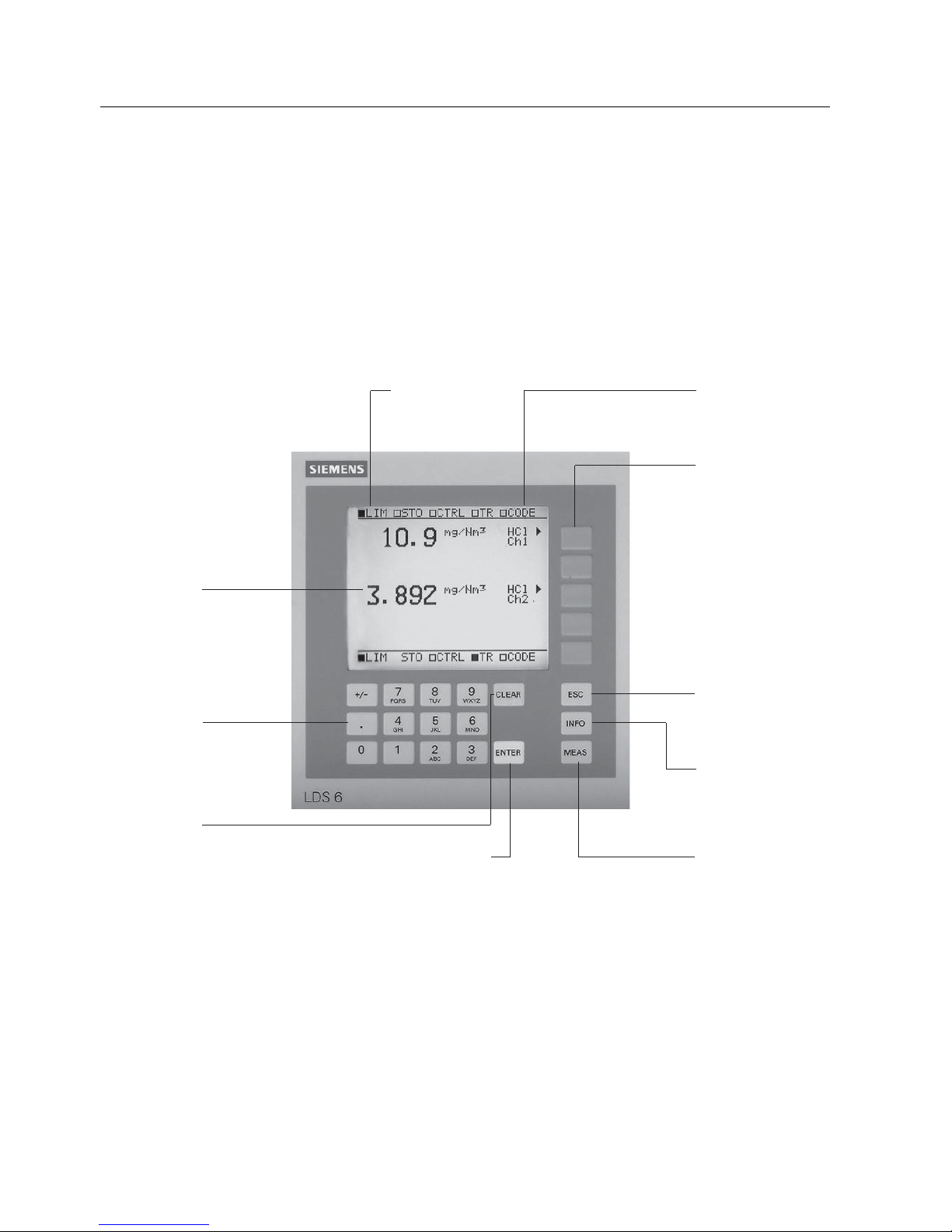

Display and control panel

● Large LCD field for simultaneous display of measurement result and device status

● Contrast of the LCD field is adjustable via the menu

● LED background illumination of the display with energy-saving function

● Easy-to-clean membrane touch pad with softkeys

● Menu-driven operation for parameterization and diagnostics

● Operation support in plain text

6WDWXVOLQHWRLQGLFDWH

WKHGHYLFHVWDWXV

/('EDFNOLWJUDSKLF

GLVSOD\DQGPHPEUDQH

WDFWLOHWRXFKNH\ERDUG

7ZRFRGHOHYHOV

DFFRUGLQJWR1$085

0($6NH\

WRUHWXUQGLUHFWWR

PHDVXUHPHQWPRGH

0HQXGULYHQ

RSHUDWRUFRQWURO

ZLWKILYHVRIWNH\V

(6&NH\

WRFDQFHOHQWULHV

,1)2NH\

IRUKHOSLQSODLQWH[W

&/($5NH\

WRGHOHWHWKH

GLJLWVHQWHUHG

1XPHULFNH\SDG

IRUHQWHULQJGLJLWV

1XPHULFGLVSOD\

RIFRQFHQWUDWLRQV

(17(5NH\

WRDGRSW

WKHQXPEHUV

Figure 2-3 LDS 6 central unit, membrane keyboard and graphic display

Technical Information

2.2 Design

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

15

Inputs and outputs

● One to three measurement channels with hybrid connections for the sensors at the

measuring points

● Two analog inputs per channel for process gas temperature and pressure

● Two analog outputs per channel for gas concentration(s) or for gas temperature and

concentration For selected versions, the transmission can be read out as an alternative.

● Six freely configurable binary inputs per channel for signalling faults or maintenance

requests from external temperature or pressure transducers or sensor purging failure.

● Six freely configurable binary outputs per channel (signalling of faults, maintenance

requirements, function control, transmission limit alarms, concentration limit alarms, store

analog output)

Communication

Network connection: Ethernet (10Base-T) for remote diagnostics and maintenance.

The LDS 6 can be operated remotely via the Ethernet port with a PC running

Windows 95/98/ME or Windows NT/2000/XP. It is also possible to connect the LDS 6 via

modem to the public telephone net. In that case an LDS 6 LAN modem kit is required. Any

external connection requires the optional software LDSComm (LDS Communication Client)

to be installed on the remote computer. All aspects of LDS 6 can be controlled in this way.

For the operation of the LDS 6 using LDSComm software refer to the LDSComm Manual

(A5E02183317).

Maintenance and fault messages

LDS 6 outputs different warnings via relays:

● Need for maintenance (measured value is not influenced)

● Operating error (measured value might be influenced)

Technical Information

2.2 Design

LDS 6

16 Operating Instructions, 01/2009, A5E00295894-05

Cross-duct sensors

Figure 2-4 Sensor CD 6, transmitter or receiver unit

● In-situ cross-duct sensors, configured as transmitter and receiver unit, connected via

sensor cable

● Connection to the LDS 6 central unit by a so-called hybrid cable, max. length 700 m

● Stainless steel, partially painted

● IP65 degree of protection for sensor

● Adjustable flanges with flange connection

DN 65/PN 6, ANSI 4"/150 lbs

● Optional flameproof window flanges with dimensions: DN 65/PN 6, DN 80/PN 16, ANSI

4"/150 lbs, other process interfaces available on request

● Purging facilities on the process and the sensor sides, configurable application with

purging gas connections for:

– Instrument air

– Purging air blower

– Steam

– Nitrogen

– Process gases to which the pressure equipment directive cat. 2 does not apply

● In combination with high-pressure window flanges, purging with instrument air or nitrogen

is possible

● Fast connectors for cleaning the measurement openings and the sensor window

Technical Information

2.2 Design

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

17

● Optional: Ex-protected version according to

ATEX II 1GD T135 °C EEx ia IIC T4, Cert. No. DEMKO 06 ATEX 139648X. Certificates

according to IEC and TIIS are also available

● Sensor types CD 6 and CD 6C are compliant with the pressure equipment directive

Note

The sensors are described in detail in separate manuals which is part of their delivery.

ATEX sensors

The sensors are also available in an ATEX version - see also separate user manual. These

have very low power electronics and are intrinsically safe. For use in areas with potentially

explosive atmosphere a barrier box must be installed additionally.

For further information regarding the ATEX option please refer to the separate ATEX manual

for LDS 6.

Parts in contact with the process gases

The sensors normally do not come into contact with the process gas, since purging with a

gaseous media is applied at the process side. Stainless steel purging gas tubes in front of

the sensor windows immerse slightly into the process gas and thus limit the purging volume.

Special materials such as Hastelloy, plastics (PP) and ceramics are available on request.

Technical Information

2.2 Design

LDS 6

18 Operating Instructions, 01/2009, A5E00295894-05

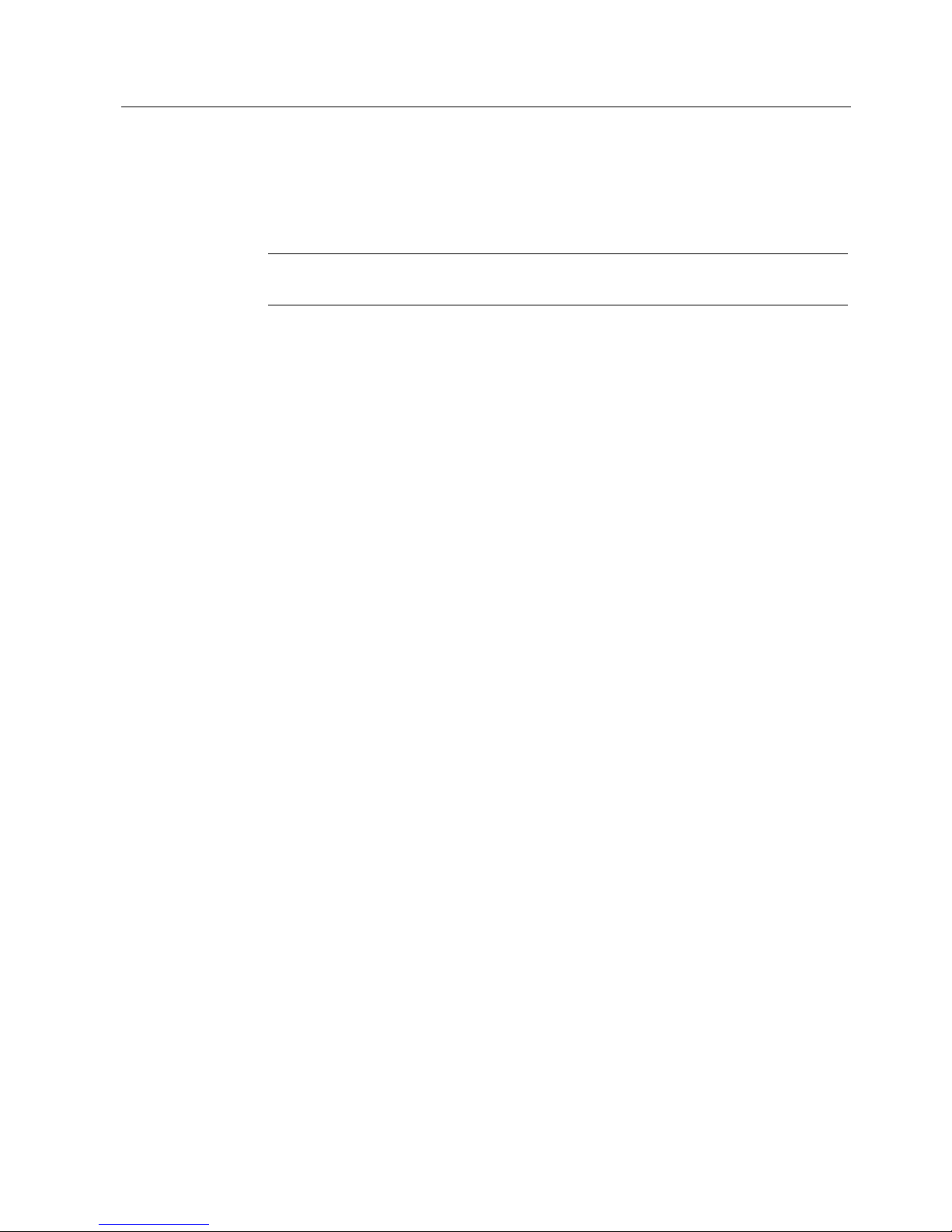

Hybrid and sensor cables

A combination of fiber-optic cables and twisted copper wires connects the sensors to the

central unit. The hybrid cable connects the central unit with the transmitter unit of the sensor,

the sensor cable connects the transmitter and receiver units of the sensor.

2

1

3

1 Twisted pair of wires

2 Multimode fiber

3 Singlemode fiber

Figure 2-5 Connections of the hybrid cable

For installation in EEx-protected environments, the legislative regulations have to be

complied with, such as the spatial separation of intrinsically-safe from non-intrinsically-safe

cables.

● Max. 700 m between central unit and measuring point

● Hybrid and sensor cables

– Multimode fiber-optic cable, provided with SMA connections for transmission of the

measured signal

– Two-wire copper cable, in twisted pair version, for +24 V supply of the detector

electronics (+12 V in the case of EEx-suitable instruments)

● Additionally for the hybrid cable:

– Single-mode fiber-optic cable, configured double-sided with E2000 connectors for

transmission of laser light

● Rugged cable sheath for mounting in open cable ducts or ductworks

● Sheath material: oil-resistant polyurethane

Technical Information

2.3 Operating Principle

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

19

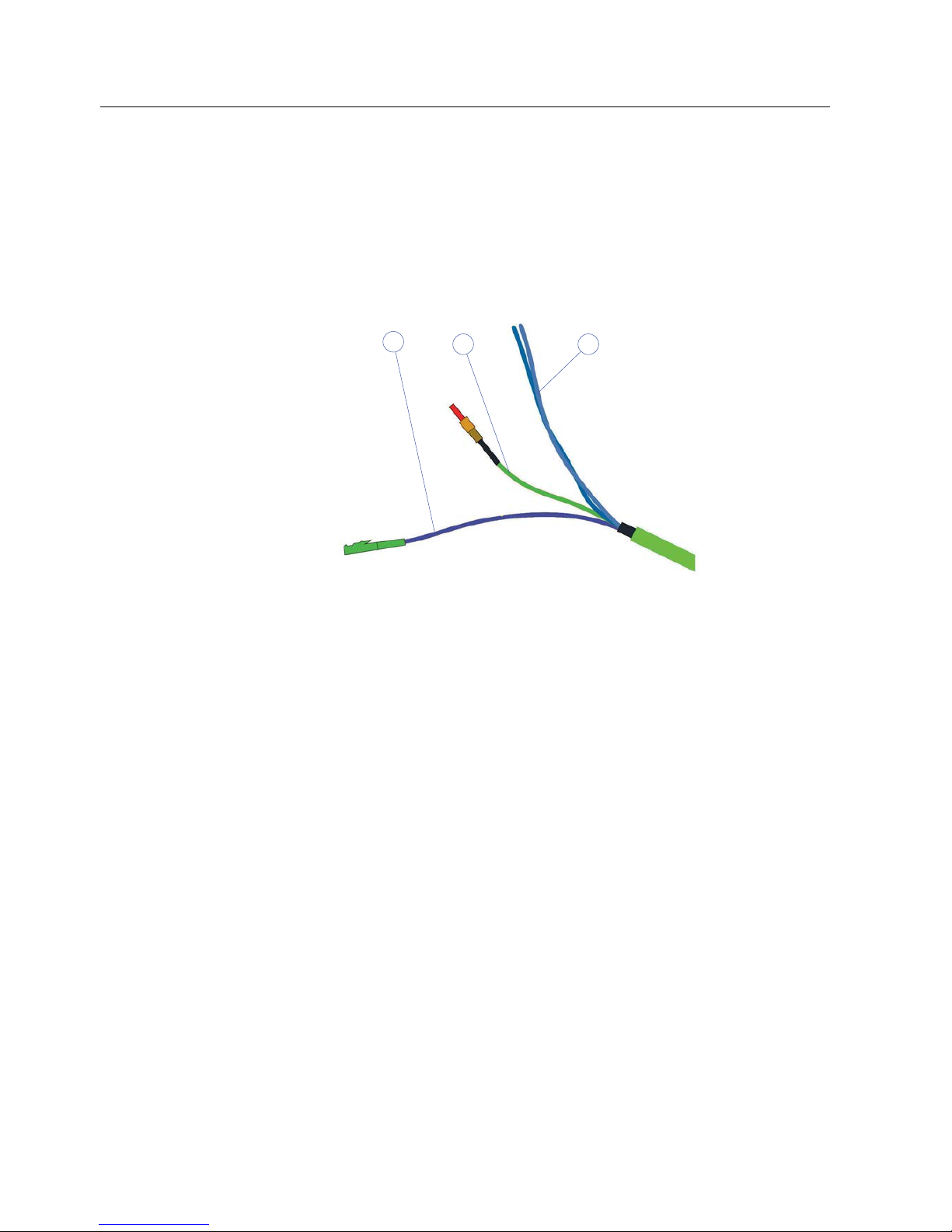

2.3 Operating Principle

LDS 6 is a gas analyzer employing single-line molecular absorption spectroscopy. A diode

laser emits a beam of near-infrared light, which passes through the process gas and is

detected by a receiver unit. The wavelength of the laser diode output is tuned to a gasspecific absorption line. The laser continuously scans this single absorption line with a very

high spectral resolution.

The result is a fully resolved single molecular line which is analyzed in terms of absorption

strength and line shape. The influence of cross-sensitivities on the measurement is

negligible, since the quasi-monochromatic laser light is absorbed very selectively by only one

specific molecular line in the scanned spectral range.

3

7

3

7

3

7

3

7

3

7

0HDVXUHG

YROXPH

(2

&KDQQHO

/DVHU

FRQWURO

'LRGH

ODVHU

2SWRFRXSOHU

5HIHUHQFH

FHOO

&38DQG

GLVSOD\

6LJQDO

SURFHVVLQJ

/DVHUOLJKW

(OHFWULFDOVLJQDOV

5HIOHFWHG/('OLJKW

&HQWUDOXQLW +\EULGFDEOHV 0HDVXUHPHQWSDWK

(2

(2

(2

0HDVXUHG

YROXPH

0HDVXUHG

YROXPH

&KDQQHO

&KDQQHO

(2

(2

Figure 2-6 Basic design of the LDS 6

Technical Information

2.4 Configuration Examples

LDS 6

20 Operating Instructions, 01/2009, A5E00295894-05

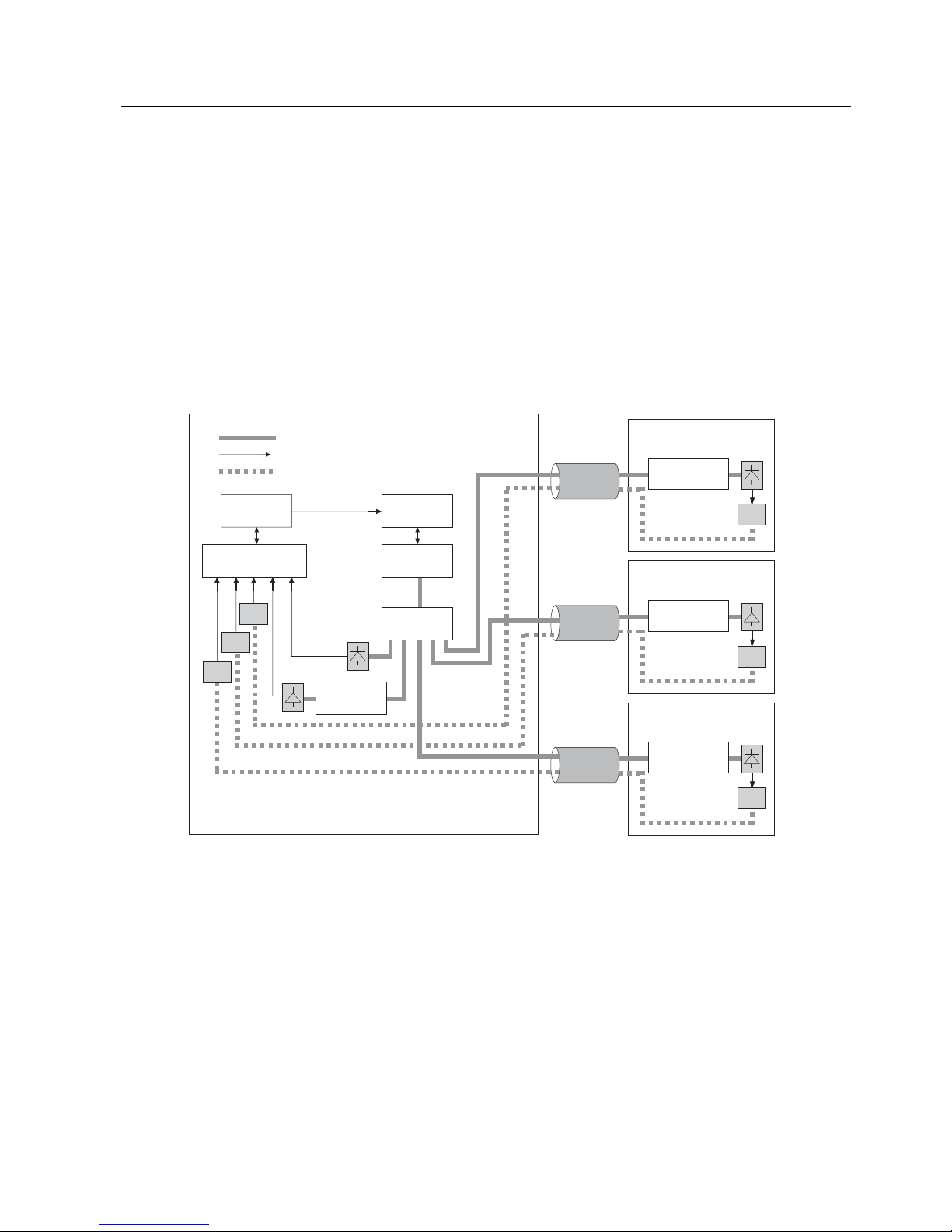

2.4 Configuration Examples

A feature of the in-situ analytical procedure is that the physical measurement takes place

directly in the stream of process gas, and usually also directly in the actual process gas line.

All process parameters such as gas matrix, pressure, temperature, moisture, dust load, flow

velocity and mounting orientation can influence the measuring properties of the LDS 6 and

must therefore be systematically investigated for each new application.

&HQWUDOXQLW

+\EULGFDEOH

PD[OHQJWKP

6XSSOHPHQWDU\FKDQQHORSWLRQ

6XSSOHPHQWDU\FKDQQHORSWLRQ

7UDQVPLWWHUXQLW

5HFHLYHU

3URFHVVIODQJH

6HQVRUFRQQHFWLQJFDEOH

0HDVXUHPHQW

SDWKOHQJWK

*DVFRQFHQWUDWLRQ

)OXHJDV

FRPSRVLWLRQ

6WHDP

'XVWORDG

*DVYHORFLW\

*DVWHPSHUDWXUH

*DVSUHVVXUH

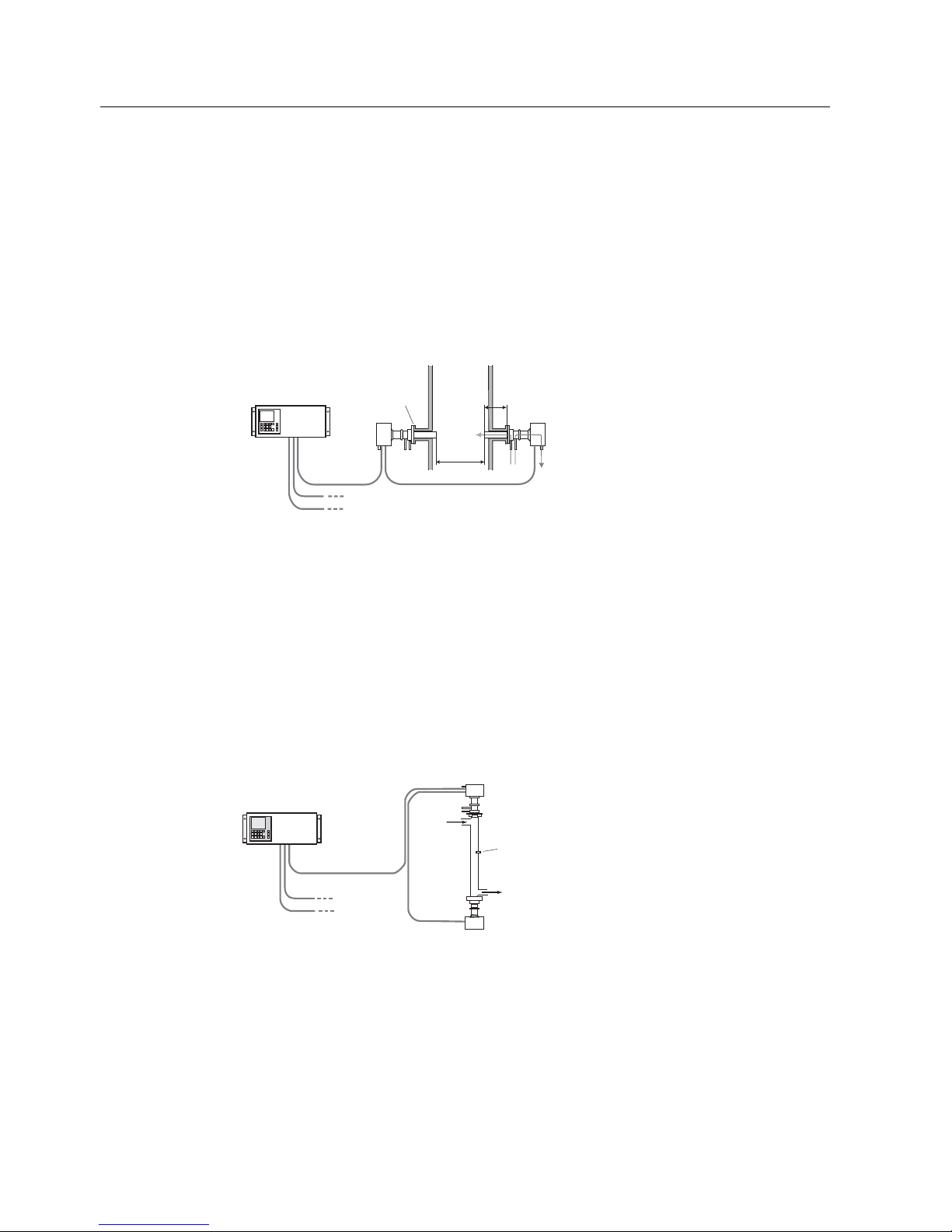

Figure 2-7 Typical transmitted light setup of LDS 6, in-situ

A feature of the standard applications defined in the ordering data of the LDS 6 is that the

typical process conditions are well-known and documented, and that the guaranteed

measuring properties can be proven by reference installations. If you cannot find your

application among the standard applications, please contact Siemens. We will be pleased to

check your possible individual application of the LDS 6. You can find an application

questionnaire on the LDS product sites on the Internet.

To avoid contamination of sensor openings on the process side, clean gaseous purging

media are used such as instrument air, N

2

or steam. Purging air tubes on the sensor heads,

which slightly penetrate into the process gas stream, define the effective measuring path

length.

7UDQVPLWWHUXQLW

&HQWUDOXQLW

5HFHLYHU

6DPSOHJDV

RXWOHW

6DPSOH

JDV

LQOHW

7HPSHUDWXUH

VHQVRU

+\EULGFDEOH

PD[OHQJWKNP

6XSSOHPHQWDU\

FKDQQHORSWLRQ

6XSSOHPHQWDU\

FKDQQHORSWLRQ

6HQVRUFRQQHFWLQJFDEOH

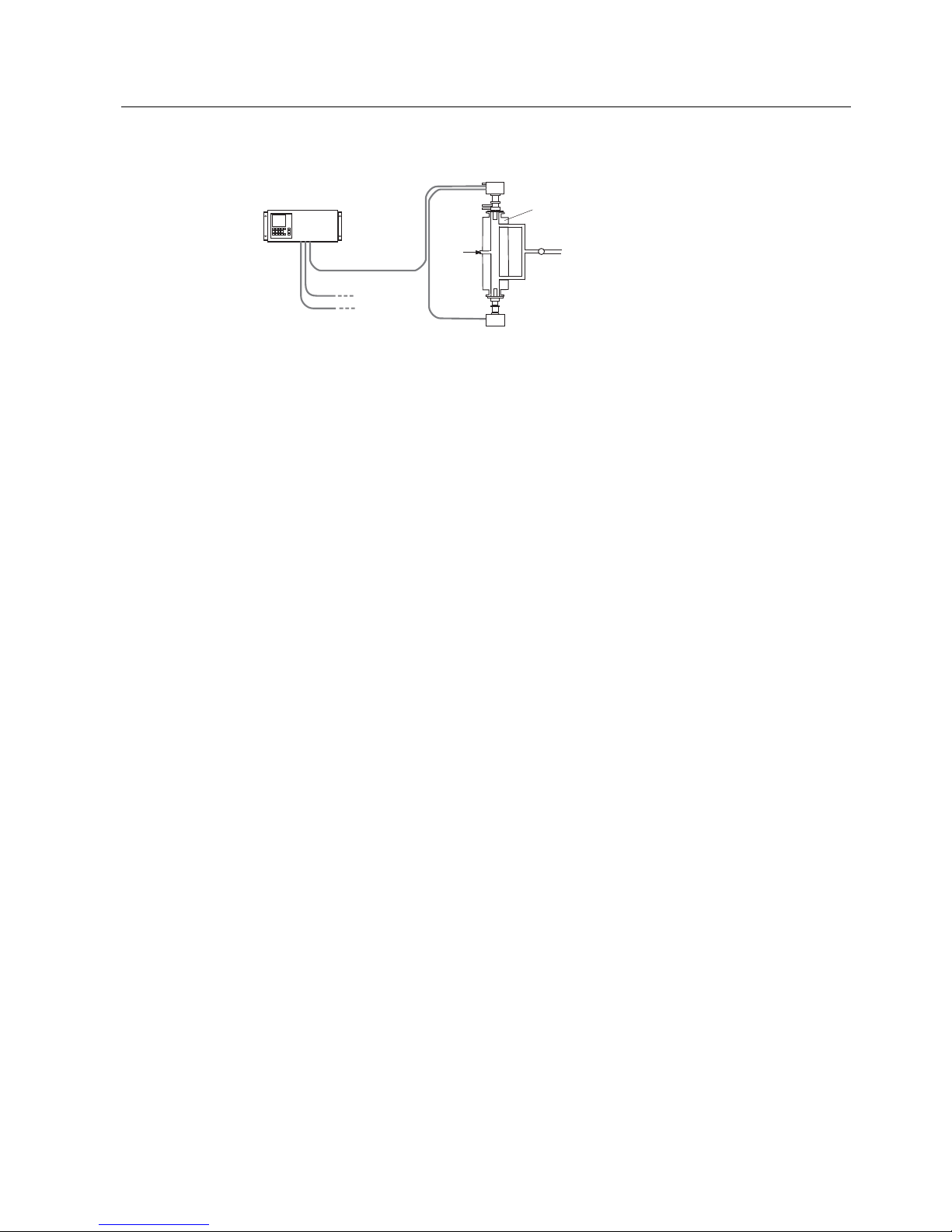

Figure 2-8 Typical transmitted light setup of LDS 6, in bypass

The LDS 6 can measure in both the transverse and longitudinal directions of the process gas

flow. In certain cases, the process conditions make it necessary to condition the sample gas

stream in a bypass line with respect to process temperature, pressure and/or optical path

length. Further treatment of the process gas, such as drying or dust precipitation, is usually

not necessary.

Technical Information

2.5 Measurement Principle

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

21

7UDQVPLWWHUXQLW

&HQWUDOXQLW

5HFHLYHU

6DPSOHJDVLQOHW

3XPS

+\EULGFDEOH

PD[OHQJWKP

6XSSOHPHQWDU\

FKDQQHORSWLRQ

6XSSOHPHQWDU\

FKDQQHORSWLRQ

6HQVRUFRQQHFWLQJFDEOH

+HDWLQJ

RSWLRQ

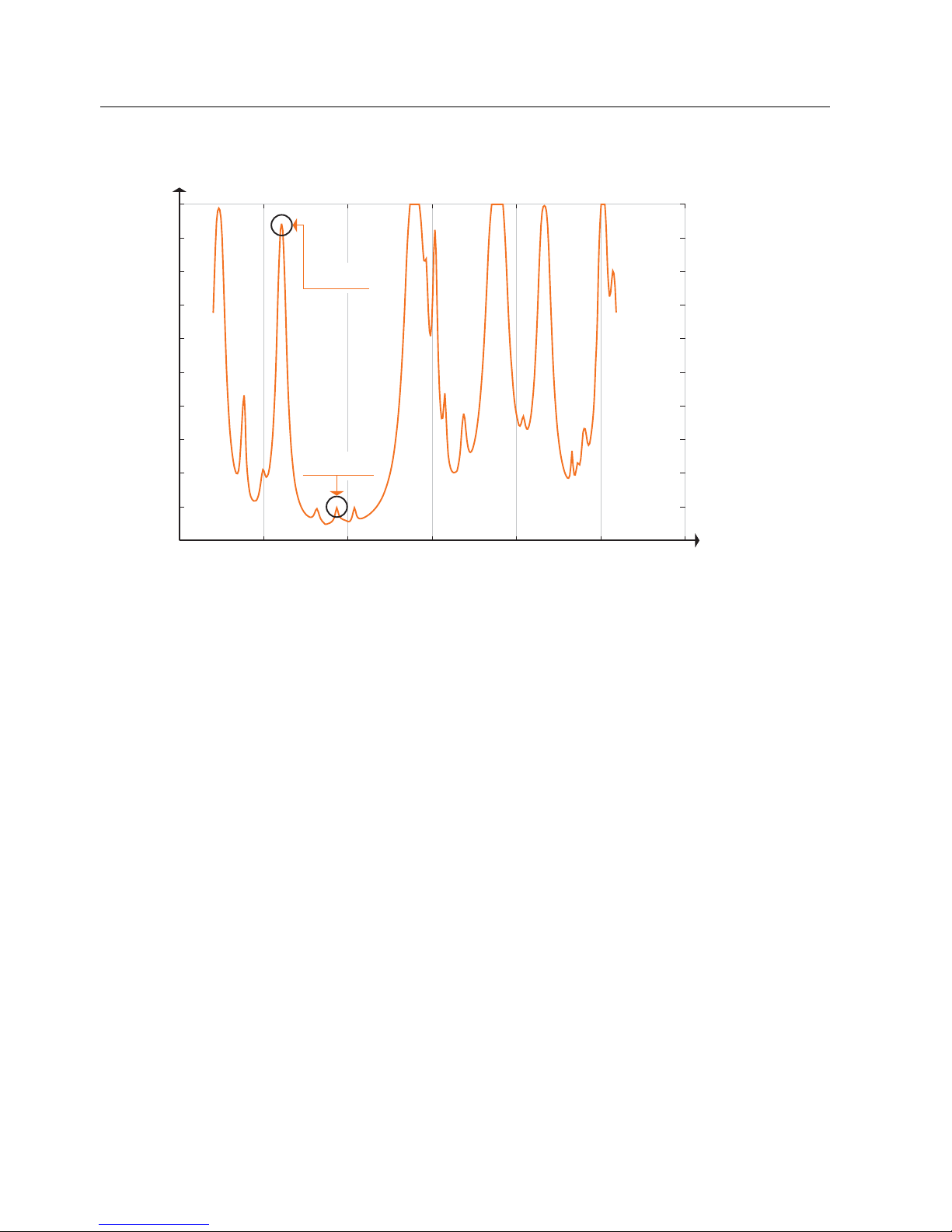

Figure 2-9 Measuring configuration of LDS 6 with heated flow cell

2.5 Measurement Principle

Mode of operation

The operation of LDS 6 is based on the fact that light propagating through a gas mixture will

be absorbed according to Beer-Lambert's law at certain narrow wavelength bands. This is

where the gases possess molecular transitions forming narrow absorption lines.

The light source in LDS 6 is a semi-conductor laser tuned to an appropriate absorption line

for the gas to be measured. The laser light is spectrally much narrower than the gas

absorption line and this, together with a proper choice of absorption line, will result in low

interference from other gases.

The light is modulated, both in frequency and in amplitude, to facilitate detection on the

second harmonic as well as elimination of contribution from spectrally broad absorption

originating from dust, smoke, etc.

LDS 6 is connected to the measuring points by fiber optics. The laser light is guided by a

single-mode fiber from the central unit to the transmitter unit of the in-situ sensor. The sensor

consists of a transmitter and a receiver; the distance between them defines the

measurement path. In the receiver box, the light is focused onto a suitable detector. The

detector signal is then converted into an optical signal and transmitted via a second optical

fiber to the central unit, where the concentration of the gas component is determined from

the detected absorption signal.

LDS 6 usually measures a single gas component by means of the absorption capacity of a

single fully resolved molecular absorption line. The absorption results from conversion of the

radiation energy of the laser light into the internal energy of the molecule. In the working

range of the LDS 6, both rotation-vibration transitions and electronic transitions – such as

with O

2

– can be triggered.

In some specific cases, two components can be measured simultaneously if their absorption

lines are so close to each other that they can be detected within the laser spectrum by one

single scan (for example water (H

2

O) and ammonia (NH3)).

Technical Information

2.5 Measurement Principle

LDS 6

22 Operating Instructions, 01/2009, A5E00295894-05

Relative absorption

Wavelength [μm]

1.543 1.5435 1.544 1.5445 1.545 1.5455 1.546

0.1

0.0

0.2

0.3

0.4

0.5

0.6

0.7

0.8

H2O 15%

NH3 5ppm

1.0

0.9

Figure 2-10 Absorption spectra of water and ammonia

Moreover, in some applications it is possible to determine the gas temperature as a

measured value. In this case, the ratio of the absorbance of two characteristic lines of the

same molecule measured at the same time in the same volume gives the actual temperature

in the process gas.

Typical measurable gases for LDS 6 are:

● Oxygen (O

2

) for low and high pressure

● Oxygen + temperature

● Hydrogen fluoride (HF) + water

● Hydrogen chloride (HCl) + water

● Ammonia (NH

3

) + water

● Water vapor (H

2

O)

● Carbon monoxide (CO)

● Carbon dioxide (CO

2

)

● CO + CO

2

By using an internal reference cell normally filled with the gas measured, the stability of the

spectrometer is permanently checked in a reference channel.

By doing so, the continuous validity of the calibration is ensured without the need to carry out

external recalibration using bottled test gases or reference gas cells.

Technical Information

2.5 Measurement Principle

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

23

/DVHUOLQH

$EVRUSWLRQOLQH

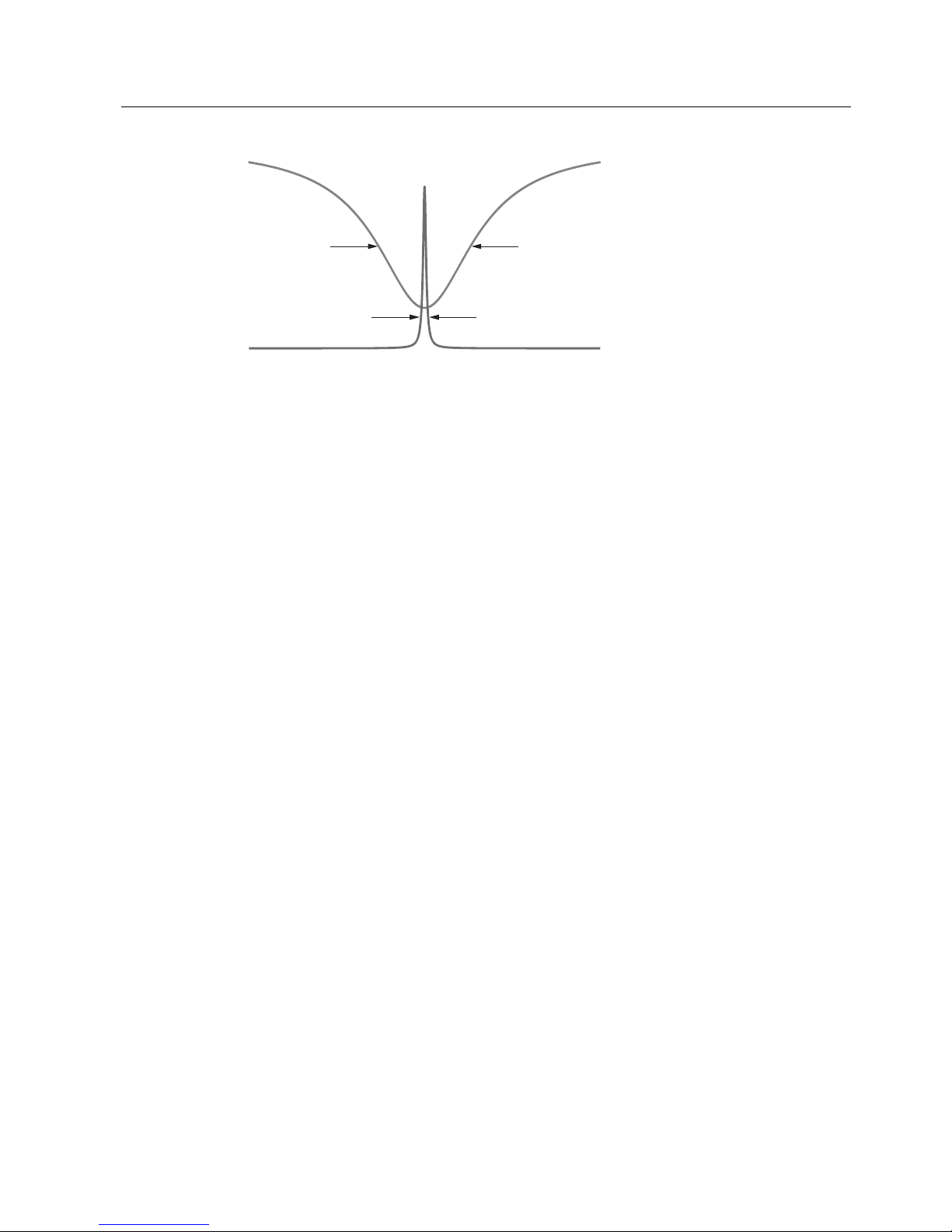

Figure 2-11 Typical spectral bandwidth of an absorption line compared to the bandwidth of the laser

light

Influences on the measurement

Dust load

As long as the laser beam is able to generate a suitable detector signal, the dust load of the

process gases does not influence the analytical result. By applying a dynamic background

correction, measurements can be carried out without any negative impact. Under good

conditions, particle densities up to 100 g/Nm

3

can be handled by the LDS 6. Varying dust

loads are compensated by scanning the laser over the gas absorption line and the current

background. At a scan position next to the absorption line, the instrument can "see" only

absorption caused by the dust load where at the line center the signal is composed of the

molecular absorption and the continuous, unspecific background absorption. With the

wavelength modulation technique, the actual measured transmission is always compared

with the baseline. After signal processing, phase-sensitive application delivers a signal only

from the molecular line free of background.

The influence of a high dust load is complex and depends on the path length and particle

size. The optical damping increases at longer path lengths. Smaller particles also have a

large influence on the optical damping. With a combination of high dust load, long path

length and small particle size, the technical support at Siemens should be consulted.

Temperature

The temperature influence on the absorption line strength is compensated by a correction

factor determined during calibration. A temperature signal can be fed into the instrument

from an external temperature sensor. This signal is then used to correct the influence of the

temperature on the observed line strength. If the temperature of the sample gas remains

constant, it is alternatively possible to carry out a static correction using a preset value.

At high temperatures there may be noticeable broadband IR radiation of gas and dust, or

flames may occasionally occur in the measurement path. In this case the detector is

protected by an optical bandpass filter to prevent saturation by the strong background

radiation.

Technical Information

2.5 Measurement Principle

LDS 6

24 Operating Instructions, 01/2009, A5E00295894-05

Pressure

The gas pressure can affect the line shape of the molecular absorption line. LDS 6 uses a

special algorithm to adapt the line shape. Additionally, an external pressure signal can be fed

to the instrument to provide complete compensation for the pressure influence including the

density effect.

Cross-interferences

Since LDS 6 derives its signal from a single fully resolved molecular absorption line, crossinterferences with other gases are quite unlikely. LDS 6 is therefore able to measure the

desired gas components very selectively. In special cases, the composition of the process

gas might have an influence on the shape of the absorption line features. This influence is

compensated by analyzing the full shape of the detected signal curve applying specific

algorithms.

Optical path length

The absorption values analyzed by the LDS 6 are typically small. As a result of BeerLambert’s law, the absorption of laser light depends on the optical path length within the gas.

Therefore, the precision in determining the effective optical path length in the process might

limit the overall precision of the measurement.

As the sensor openings toward the process normally need to be purged to keep them clean

over a long period of time, the thickness of the mixing zone between the purging medium

and the process gas and its concentration distribution need to be considered. In a typical insitu installation with some meters of path, the influence of the purging gas on the effective

path length can be neglected.

Path length and dust load are mutually influencing: the higher the dust load in the process,

the shorter the max. possible path length.

Note

Individual requirements for the measuring point can make the utilization of special sensor

equipment necessary. The possibilities for adapting the sensors are:

• Different purging media, such as instrument air, ambient air, nitrogen or steam

• Different purging modes on process and sensor sides

• Special materials of purging tubes and/or sensor flanges

• Cooling or heating of the sensors

• EEx-proof sensor configurations

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

25

Installation Guidelines

3

3.1 Safety Information

It is essential that you observe the given information and warnings!

Electrical Safety

DANGER

Certain parts inside the gas analyzer LDS 6 carry dangerous voltages.

The housing must be closed and grounded before switching on the analyzer.

Death, personal injury and/or damage to persons and/or property may result if this is not

observed.

LDS 6 and CD 6 meet all regulations specified in the present EU regulations

(LVD regulation 2006/95/EC and EMC regulation 2004/108/EC).

The device can be used in an industrial environment.

Laser Safety

All lasers used by LDS 6 are of class 1. The emitted laser light is in most cases invisible

(near infrared) and the intensity is low enough so that the unprotected eye is not damaged

under normal circumstances. LDS 6 has warning labels at appropriate positions according to

DIN EN 60825-1.

CAUTION

This device emits laser beams.

To avoid damage to your eyes never look directly into the laser beam.

If this rule is not followed there is a chance that damage to the unprotected eye may occur

if you look directly into the laser beam particularly when using focusing optics (e. g.

binoculars).

Installation Guidelines

3.1 Safety Information

LDS 6

26 Operating Instructions, 01/2009, A5E00295894-05

Heat Safety

Some metal parts and piping placed near the sensors are at elevated temperatures. The

reason is high temperature purging - either from steam or from air.

CAUTION

The sensors are designed for work at elevated temperatures, particularly when a purging

system is in operation. Even after operation these parts cool off slowly.

For any work around these sensors be sure to wear protective gloves.

If this rule is not followed serious burns of the unprotected skin may happen.

Pressure Safety

The sensor is tested at a pressure of 600 kPa. This pressure value should not be exceeded

in operational conditions.

WARNING

Should pressures higher than 600 kPa occur in the process, this can lead to destruction of

the sensors and their environment. In worst case process media may break free and pollute

the environment.

Avoid under any circumstances process pressures higher than 600 kPa.

If this rule is not followed, death, injuries and/or damage to property and environment can

occur.

Explosion Protection - II 1GD T135 °C EEx ia IIC T4 IP65

The LDS 6, with a central unit and sensors interconnected with optical fibers, is explosion

safe. Only a limited, low energy part of the electronics is located at the measurement site.

The distance between the central unit and the sensors can be several hundred meters. The

LDS 6 system is available in an Ex version and is then delivered with an approval for use in

hazardous environments. The ATEX certificate is a system certificate and is only valid if LDS

6 is installed according to the instructions given in the certificate.

Installation Guidelines

3.1 Safety Information

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

27

Approval

The concept of the Ex approval is that the central unit is unchanged from a standard unit and

that a special Ex sensor pair (CD 6 Ex) is used in the hazardous zone. In addition to this an

explosion protection barrier is added before entry into the hazardous zone. An absolute

condition for the approval is that the equipment is set up according to the drawing, ADM

3040 3050, please refer to the separate ATEX manual for LDS 6.

The protection is as follows:

Cross Duct Sensor -

II 1G Ex ia IIC T4 II 1D IP65 T135 °C.

Central (Barrier) Unit -

II (1)G Ex [ia] IIC II (1)D Ex [iaD].

● Equipment Group: Group II - Surface.

● Equipment Category: Category 1G D - Zone 0. Flammable material can be present

continuously, frequently or for long periods, in gas and dust.

● Type of protection: EEx ia. The equipment present in the hazardous area is intrinsically

safe.

● Explosion group: IIC. This corresponds to a gas group containing Acetylene and

Hydrogen.

● Temperature class: T4. The maximum surface temperature on the equipment is 135 °C

(275 °F) and the ignition temperature of the gas or vapor is between 135 °C (275 °F) and

200 °C (392 °F).

● The sensor housing protection is IP65 and the ambient temperature must be between

-30 °C (-22 °F) and +60 °C (140 °F) .

Liability

Following commissioning, the total responsibility is with the owner.

Installation Guidelines

3.2 General Installation Information

LDS 6

28 Operating Instructions, 01/2009, A5E00295894-05

3.2 General Installation Information

Mounting Conditions

The central unit LDS 6 should be placed on a location which is dust-free and as free as

possible from vibrations. The distance between the central unit and the measurement point,

i.e. the sensor, may not exceed 1000 meters (3,280 ft) for the non ATEX version and

600 m (1,970 ft) for the ATEX version.

During operation the permissible surrounding air temperature is 5 °C (41 °F) to 45 °C

(113 °F), with a relative humidity of maximum 85% non-condensing, around the central unit.

Also ensure that the unit is not exposed to direct solar radiation. If these conditions can’t be

fulfilled the LDS 6 must be installed in a cabinet with controlled environment.

Note

As condensing is normally a problem when moving the device from outside to inside a

building it is recommended that the device should be adapted to room climate for a couple of

hours before starting it.

The back of the unit must be freely accessible. There should be at least 10 cm (4 ") of free

space behind the LDS 6 to accommodate the signal and hybrid cables. To meet the safety

requirements for air convection and cooling there must be a free space of at least 5 cm (2 ")

above and at least 3 cm (1 1/4 ")below LDS 6.

For detailed information on the sensor installation, please refer to the sensor manual

corresponding to your system setup.

Installation Guidelines

3.3 Electrical Connections

LDS 6

Operating Instructions, 01/2009, A5E00295894-05

29

Hybrid Cables

The hybrid cables should be installed such that they are protected from mechanical wear

such as sharp edges or moving parts. During installation always keep the protective tube in

such a position that the single mode fiber connector is protected from dust. The operating

temperature for the cables is -40 to +80°C (-40 to 176 °F) and the installation temperature is

-20 to +80°C (-4 to 176 °F). The bending radius of the cables may never be smaller than

100 mm (4 ").

Note

Throughout the entire installation, keep the fiber ends protected by the protective tubes;

observe that these should only be removed by authorized personnel.

There are three kinds of cables used for the LDS 6 depending on the application:

● Hybrid cables for all types of systems except oxygen. These are installed between the

LDS 6 and the transmitter sensor.

● Hybrid cables for oxygen systems only, also installed between the LDS 6 and the

transmitter sensor.

● Loop cables, same for all systems, are installed between the transmitter sensor and the

receiver sensor.

3.3 Electrical Connections

3.3.1 Power Supply Connections

WARNING

The respective country-specific standards for the installation of power systems with rated

voltages below 1000 V must be followed. Failure to observe these regulations may result in

death, personal injury and/or damage to property.

General

● Check that the local voltage agrees with that specified on the label on the analyzer.

● The cable must be tested according to IEC 60227 or IEC 60245 and must be suitable for

70 °C (158 °F).

● The power cable must be routed separately from the hybrid cables.

Installation Guidelines

3.3 Electrical Connections

LDS 6

30 Operating Instructions, 01/2009, A5E00295894-05

Detachable Cord

● The analyzer is supplied with an appliance plug which may only be connected to the

power supply by qualified personnel. The cross-section of the conductors must be at least

1 mm

2

. The phase conductor must be connected to the identified position (L).

● Only detachable power supply cords tested by an accepted third party Lab accredited for

the region where the unit is to be used is allowed. This cord must be suitable for the rated

current and limited in length. This flexible cord must also be suitable for an ambient

temperature of 70 °C (158 °F) and is not allowed to be mounted in building installations.

● As the kind of appliance inlet is only suitable for 70 °C (158 °F) ambient temperature the

power cord must be kept away with suitable means from surfaces of more than 70 °C

(158 °F) at max. rated operation conditions.

● It is not allowed to install a switch within the power supply cord.

Electrical Protection

● A circuit-breaker shall be part of the installation. It must be provided in the immediate

vicinity of the analyzer (see rating plate for loading capacity). It must also be labeled to

correlate with the instrument.

Loading...

Loading...