Siemens LAE10, LFE10 Quick Manual

Landis & Staefa Division CC1N7781E June 01, 1999 1/8

7

781

Flame Safeguards

LAE10

LFE10

Series 02

Supplementary data sheets 7712 and 7713

Flame safeguards for burners with intermittent operation.

For safety reasons - self-test of flame supervision circuit, etc. - at least one controlled

shutdown is required every 24 hours.

For flame supervision systems for continuous operation, refer to data sheet 7783.

The LAE10 is used for the supervision and indication of oil flames, the LFE10

for gas and oil flames.

The LAE10 / LFE10 and this data sheet are intended for use by OEMs which

integrate the flame safeguards in their products.

The LAE10 is designed for the supervision of oil flames in connection with selenium

photocell detectors RAR...

The LFE10 is suited for the supervision of gas flames and luminous or blue-burning oil

flames in connection with UV detectors QRA... or a flame rectification probe.

Both types of flame safeguards are used primarily in conjunction with the LEC1 burner

control on the following applications:

– Dual-supervision of burners

Supervision of the main flame or of the pilot and main flame by two identical or

different types of flame detectors

– Supervision of forced draught oil / gas burners

Supervision of the flame with different types of detectors, depending on the

operating mode

– Multi-flame supervision

Plants with several burners whose flames must be supervised individually by one or

several detectors, whose startup and supervision, however, should or must be

carried out centrally and simultaneously by only one burner control

– The flame safeguards can also be used in connection with other types of burner

controls provided the given combination and selected circuitry do not impair the

burner control’s safety functions

– The flame safeguards are also used as flame indication units in combustion plant

with manual startup

ISO 9001

Use

2/8 CC1N7781E June 01, 1999 Landis & Staefa Division

To avoid injury to persons, damage to property or the environment, the

following warning notes should be observed!

It is not permitted to open, interfere with or modify the units!

• Before performing any wiring changes in the connection area of the LAE10 / LFE10,

the flame safeguard must be completely isolated from the mains supply!

• Check the wiring and all safety functions!

• Ensure that the drop out delay time of relay «d» does not exceed 50 ms (also refer

to «Connection examples»)!

• The relevant national safety regulations must be complied with!

• Locate the ignition and detector electrodes such that the ignition spark cannot arc

over to the detector electrode!

→ Risk of electric overloads

• Locate and adjust the flame detector such that only the flame to be supervised will

be detected

• Protect the UV cell adequately against UV radiation emitted by

– halogen lamps

– welding equipment

– special lamps

– ignition sparks

– high energy x-rays and gamma rays

• Installation and commissioning work may only be carried out by qualified staff!

• Observe the permissible lengths and shielding of the detector cables!

→ Refer to «Technical data»!

• Always run the ignition cables separate from the unit and other cables while

observing the greatest possible distances!

• Before putting the flame safeguard into operation, check the wiring carefully!

The LAE10 / LFE10 are of plug-in design and consist of power section, flame signal

amplifier, flame relay, an auxiliary relay for controlling the UV detector or the flame

simulation test, and a flame indication lamp located in the unit cover behind a viewing

window.

The electrical circuit is intrinsically safe in compliance with the relevant regulations

and - in connection with LEC1 burner controls - is tested in respect of proper

functioning each time the burner is started up.

The flame safeguards can be mounted in any position directly on the burner, in

control panels, or on the front of a panel.

There are two types of plug-in bases available, designed for cable entry from the front,

the side or below.

Two earth terminals provide looping facilities for the earth connections of other burner

plant components such as ignition transformers (the flame safeguards themselves are

double-insulated!).

The plug-in bases - like the housing - are made of impact-proof and heat-resistant

plastic.

For illustrations of the bases and other notes, refer to «Base versions» and

«Dimensions».

– LAE10:

Automatic light simulation test by increasing the sensitivity of the amplifier during

the burner off and purge times, as programmed by the LEC1 burner control

– LFE10:

Automatic testing of the UV detector by increasing the operating voltage of the UV

tube during the burner off and purge times, as programmed by the LEC1 burner

control

Warning notes

Engineering notes

Mounting notes

Installation notes

Mechanical design

Special features

Landis & Staefa Division CC1N7781E June 01, 1999 3/8

– UV detector QRA... (refer to data sheet 7712)

– Selenium photocell detectors RAR7 and RAR8 (refer to data sheet 7713)

– Flame rectification probe

Flame supervision by making use of the electrical conductivity of the flame in

conjunction with the rectifying effect is only possible with gas and blue-flame

burners.

Since the flame signal amplifier responds only to the d.c. component of the flame

signal (ionization current), a short-circuit across the detector electrodes cannot

simulate a flame signal.

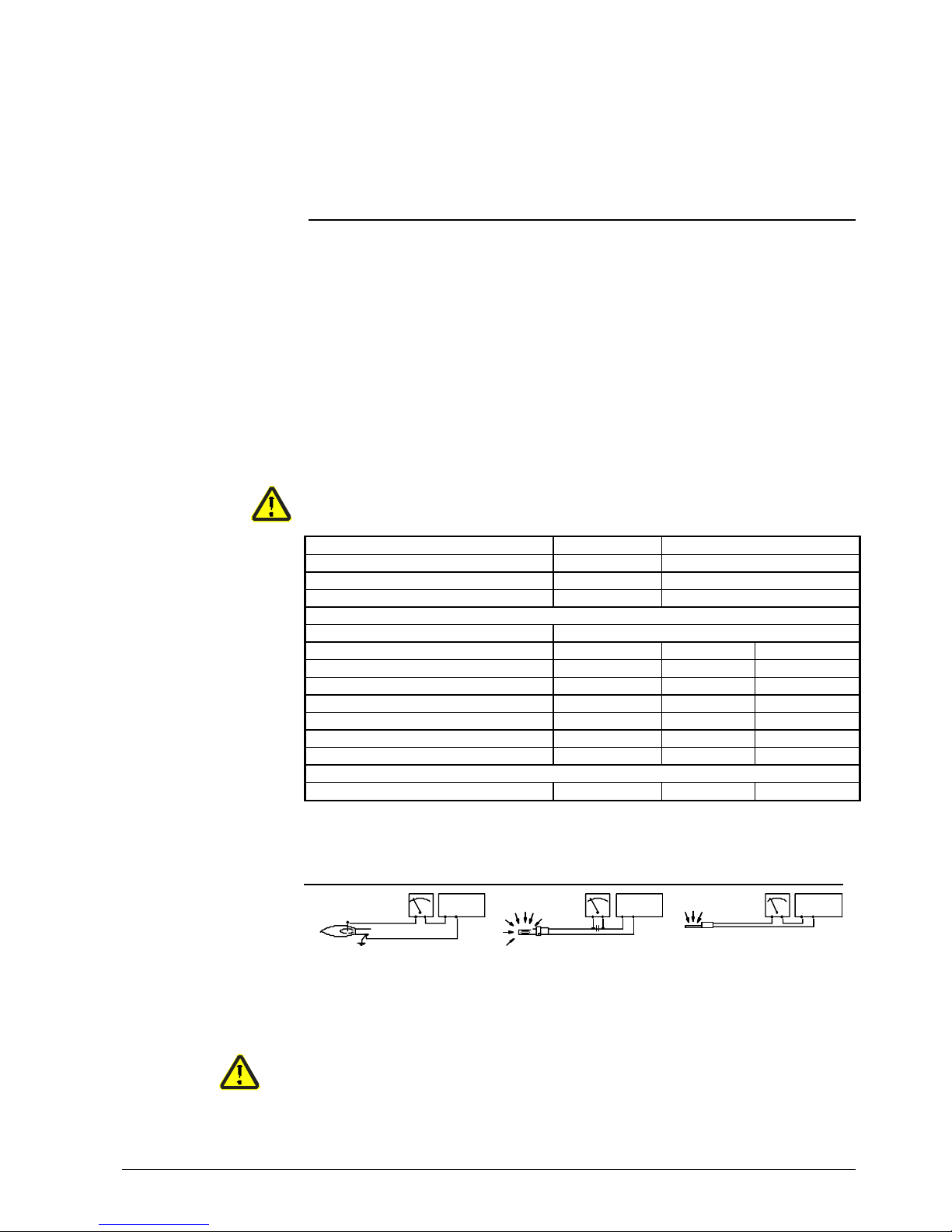

CE conformity Mains voltageAC 220 V -15 %...AC 240 V +10 %

According to the directives of the European Union AC 100 V -15 %...AC 110 V +10 %

Electromagnetic compatibility EMC

89 / 336 EEC incl. 92 / 31 EEC Mains frequency 50...60 Hz ±6 %

Directive for gas appliances 90 / 396 EEC

Low voltage directive 73 / 23 EEC Prefuse (external) max. 10 A (slow)

Environmental conditions Power consumption 4.5 VA

Transport IEC 721-3-2

Climatic conditions class 2K2 Max. contact rating 2 A

Temperature range -20...+60 °C

Humidity < 95 % r.h. Degree of protection IP 40

Mechanical conditions class 2M2 provided cable entry is in

Operation IEC 721-3-3 compliance with IP 40

Climatic conditions class 3K5

Temperature range -20...+60 °C Mounting orientation optional

Humidity < 95 % r.h.

Condensation, formation of ice and ingress

of water are not permitted!

LAE10 LFE10

Weight without plug-in base 305 g 395 g

Weight with normal plug-in base 380 g 470 g

Weight with high plug-in base 415 g 505 g

Flame supervision Series 02

LFE10 LFE10 LAE10

Rectification probe UV detector Selenium cell

Required min. detector current in µA

- At AC 100 V and AC 220 V min. 8 150 8

- At AC 110 V and AC 240 V min. 9 200 8

Max. possible detector current in µA

- At AC 100...110 V and AC 220...240 V approx. 100 approx. 650 approx. 25

Perm. length of connecting cables 20 m ¹) 20 m ¹) 20 m ²)

¹) In case of greater distances, use low-capacitance cable (total max. 2 nF), such as single-core RG62

²) Run detector cables separately, at least 5 cm away from other cables and, in case of greater distances, use

selenium photocell detector RAR8

A

C

FE

M

QRA...

Illumination of flame

Electrolytic capacitor 100 µF, DC 10 V

Detector electrode

Microammeter

UV detector

Ignition may affect the ionization current!

Remedy: exchange the connections on the primary side of the ignition transformer

Flame detectors

Technical data

Measurement circuits

FE

M

+-

LFE10

810

QRA...

A

M

+-

LFE10

109

C

-

+

A

M

+-

910

LAE10

77 81a07 / 119 8

-

+

+

Loading...

Loading...