Siemens IL205AT, IL207AT, IL208AT, IL206AT Datasheet

IL205AT/206AT/207AT/

208AT

PHOTOTRANSISTOR

FEATURES

• High Current Transfer Ratio, I

V

=5 V

CE

IL205AT, 40 – 80%

IL206AT, 63 –125%

IL207AT, 100 – 200%

IL208AT, 160 – 320%

• High BV

CEO

, 70 V

• Isolation Voltage, 2500 VAC

=10mA,

F

RMS

• Industry Standard SOIC-8 Surface

Mountable Package

• Standard Lead Spacing, .05"

• Available in Tape and Reel (suffix T)

(Conforms to EIA Standard RS481A)

• Compatible with Dual Wave, Vapor Phase

and IR Reflow Soldering

• Underwriters Lab File #E52744

(Code Letter P)

SURFACE MOUNT OPTOCOUPLER

Package Dimensions in Inches (mm)

.120±.005

.240

(6.10)

(3.05±.13)

Pin One ID

.004 (.10)

.008 (.20)

.192±.005

(4.88±.13)

.050 (1.27)

.021 (.53)

.154±.005

C

L

(3.91±.13)

.016 (.41)

typ.

TOLERANCE: ±.005 (unless otherwise noted)

SMALL OUTLINE

Anode

1

Cathode

2

NC

3

NC

4

.015±.002

(.38±.05)

.008 (.20)

.020±.004

(.15±.10)

2 plcs.

40°

5° max.

R.010

(.25) max.

(1.49±.13)

8

NC

7

Base

6

Collector

5

Emitter

7°

.058±.005

.125±.005

(3.18±.13)

Lead

Coplanarity

±.0015 (.04)

max.

DESCRIPTION

The IL205AT/206AT/207AT/208AT are optically

coupled pairs with a Gallium Arsenide infrared LED

and a silicon NPN phototransistor. Signal information,

including a DC level, can be transmitted by the

device while maintaining a high degree of electrical

isolation between input and output. The IL205/6/7/8

come in a standard SOIC-8 small outline package

for surface mounting which makes them ideally

suited for high density applications with limited

space. In addition to eliminating through-holes

requirements, this package conforms to standards

for surface mounted devices.

A specified minimum and maximum CTR allows a

narrow tolerance in the electrical design of the

adjacent circuits. The high BV

a higher safety margin compared to the industry

of 70 volts gives

CEO

standard 30 volts.

Maximum Ratings

Emitter

Peak Reverse Voltage .......................................6.0 V

Continuous Forward Current .......................... 60 mA

Power Dissipation at 25°C .............................90 mW

Derate Linearly from 25°C .......................1.2 mW/°C

Detector

Collector-Emitter Breakdown Voltage ................70 V

Emitter-Collector Breakdown Voltage ..................7 V

Collector-Base Breakdown Voltage ...................70 V

Power Dissipation ........................................150 mW

Derate Linearly from 25°C .......................2.0 mW/°C

Package

Total Package Dissipation at 25°C Ambient

(LED + Detector) ...................................... 240 mW

Derate Linearly from 25°C .......................3.3 mW/°C

Storage Temperature .....................–55°C to +150°C

Operating Temperature .................–55°C to +100°C

Soldering Time at 260°C............................... 10 sec.

Semiconductor Group 4–1

Characteristics (T

Emitter

Forward Voltage V

Reverse Current I

Capacitance C

Detector

Breakdown Voltage

Collector-Emitter BV

Emitter-Collector BV

Collector-Emitter V

Dark Current I

Collector-Emitter

Capacitance C

Package

DC Current Transfer CTR

IL205AT 40 80

IL206AT 63 125

IL207AT 100 200

IL208AT 160 320

DC Current Transfer CTR

IL205AT 13 25

IL206AT 22 40

IL207AT 34 60

IL208AT 56 95

Collector-Emitter I

Saturation Voltage V

Isolation Test Voltage V

Equivalent DC

Isolation Voltage 3535 VDC

Capacitance,

Input to Output C

Resistance,

Input to Output R

Switching Time t

Specifications subject to change.

=25°C)

A

Symbol Min. Typ. Max. Unit Condition

F

R

O

CEO

ECO

CEOdark

CE

DC

DC

CE sat

IO

IO

IO

, t

ON

OFF

1.3 1.5 V IF=10 mA

0.1 100 µAVR=6.0 V

25 pF VR=0

70 V IC=100 µA

710 V IE=100 µA

550nA IF=0

10 pF VCE=0

%I

%I

0.4 IF=10 mA

2500 VAC

0.5 pF

100 GΩ

3.0 µsIC=2 mA,

RMS

=10 V,

CE

=10 mA,

F

V

=5 V

CE

=1 mA,

F

V

=5 V

CE

=2.0 mA,

C

=100 Ω,

R

E

=10 V

V

CE

10.95

V

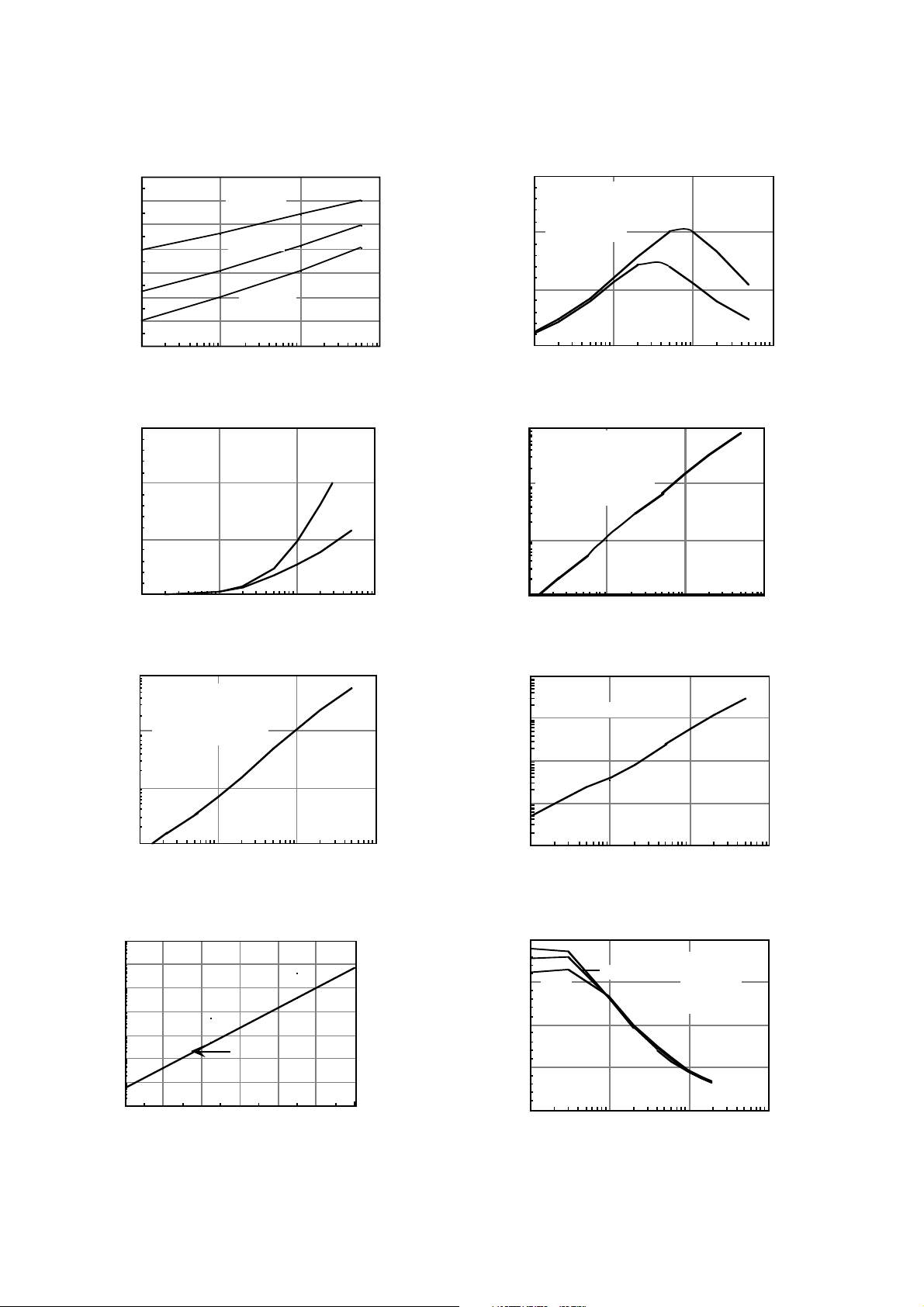

Figure 1. Forward voltage versus forward current

C

C

C

V

V

C

1.4

1.3

1.2

1.1

1.0

0.9

0.8

VF - Forward Voltage - V

0.7

IF - Forward Current - mA

Ta = -55°C

Ta = 25°C

Ta = 85°C

Figure 2. Normalized non-saturated and

saturated CTRce versus LED current

1.5

Normalized to:

Vce = 10 V

IF = 10 mA

1.0

Ta = 25°C

0.5

100101.1

0.0

NCTRce - Normalized CTRce

.1 1 10 100

IF - LED Current - mA

Vce = 5

Vce = 0.4 V

Figure 3. Collector-emitter current versus

LED current

150

Ta = 25°

100

50

Current - mA

Ice - Collector-emitter

0

.1 1 10 100

Figure 5. Normalized collector-base photocurrent

versus LED current

10

IF - LED Current - mA

Normalized to:

Vce = 10

Vce = 0.4 V

Vcb = 9.3 V

IF = 10 mA

1

Ta = 25 °C

.1

NIcb - Normalized Icb

.01

.1 1 10 100

IF - LED Current - mA

Figure 4. Normalized collector-base photocurrent

versus LED current

100

Normalized to:

Vcb = 9.3 V

IF = 1 mA

10

Ta = 25 °C

1

NIcb - Normalized Icb

.1

.1 1 10 100

IF - LED Current - mA

Figure 6. Collector-base photocurrent versus

LED current

1000

Current - µA

Icb - Collector-base

Ta = 25°C

Vcb = 9.3 V

100

10

1

.1

.1110100

IF - LED Current - mA

Figure 7. Collector-emitter leakage current

versus temperature

5

10

4

10

3

10

2

10

1

10

0

10

-1

10

Iceo - Collector-Emitter - nA

-2

10

Ta - Ambient Temperature - °C

Vce = 10V

TYPICAL

100806040200-20

Figure 8. Normalized saturated HFE versus

base current and temperature

2.0

1.5

1.0

0.5

Saturated HFE

NHFE(sat) - Normalized

0.0

1 10 100 1000

70°

25°

Vce = 0.4 V

50°

Ib - Base Current - µA

Normalized to:

Ib = 20µA

Vce = 10

Ta = 25 °C

Semiconductor Group 4–2

Loading...

Loading...