Page 1

User Guide

i-3 V2 I/O Controller – Modbus

www.usa.siemens.com/i-3

3

Page 2

i-3® Control Technology V2

TM

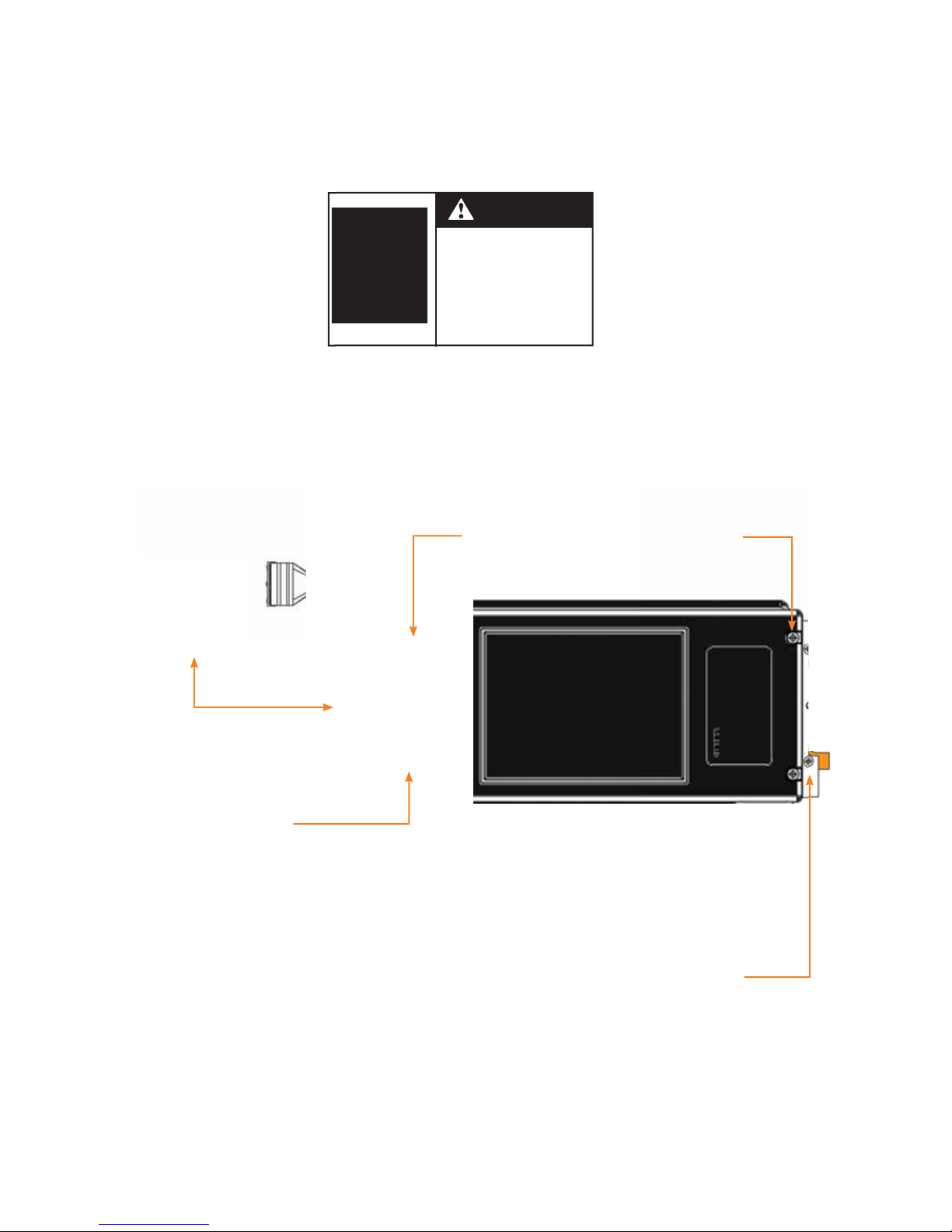

DANGER

Hazardous voltage.

Will cause death or

serious injury.

Keep out.

Qualifi ed personnel only.

Disconnect and lock off all

power before working on

this equipment.

Safety Precautions

(a) Only qualified persons familiar with

the construction and operation of this

equipment should perform work described

in this set of instructions. Such work

should be performed only after reading

this complete set of instructions.

(b) Follow safety related work practices, as

described in NFPA 70E, part II, at all times.

(c) Hazardous voltages in electrical

equipment can cause severe personal

injury or death. Energizing this equipment

for the first time after initial installation

or maintenance is potentially dangerous.

Inspection and maintenance should be

performed on this equipment and

equipment to which power has been

cut off, disconnected, and electrically

isolated so that no accidental contact

can be made with energized parts.

(d) Some types of electrical equipment will

cause harmonics in the electrical system

which may result in overheating. Consider

this condition when determining this

equipment loading, as possible de-rating

of equipment may be necessary.

Important

The information contained herein is

general in nature and not intended for

specific application purposes. It does not

relieve the user of responsibility to use

sound practices in application, installation,

operation, and maintenance of the

equipment purchased. Siemens reserves

the right to make changes in the

specifications shown herein or to make

improvements at any time without notice

or obligations. Should a conflict arise

between the general information

contained in this publication and the

contents of drawings or supplementary

material or both, the latter shall

take precedence.

Qualified Person

For the purpose of this manual and

product labels, a qualified person is

one who is familiar with the installation,

construction, operation or maintenance

of the equipment and the hazards

involved. In addition, this person has

the following qualifications:

(a) is trained and authorized to

de-energize, clear, ground, and tag

circuits and equipment in accordance

with established safety practices.

(b) is trained in the correct care and

use of protective equipment such as

rubber gloves, hard hat, safety glasses

or face shields, flash clothing, etc.,

in accordance with established

safety practices.

(c) is trained in rendering first aid.

Signal Words

The signal words “Danger,” “Warning”

and “Caution” used in this manual

indicate the degree of hazard that

may be encountered by the user.

These words are defined as:

Danger - Indicates an imminently

hazardous situation which if not

avoided, will result in death or

serious injury.

Warning - Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution - Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Dangerous Procedures

In addition to other procedures

described in this manual as dangerous,

user personnel must adhere to the

following warnings:

(a) Danger! High Voltage. Qualified

personnel only. Lock off all power to

this equipment before working inside.

Always work on de-energized equipment.

Always de-energize equipment before

performing any tests, maintenance

or repair.

y

Warning! Alwa

(b)

on the interrupting device after the closing

mechanism(s) are discharged.

(c) Caution! Always let an interlock device

or safety mechanism perform its function

without forcing or defeating the device.

(d) Caution! Hydrocarbon spray

propellants and hydrocarbon compounds

will cause degradation of certain plastics.

Contact your local Siemens representative

before using these products to clean or

lubricate components during installation

or maintenance.

s perform maintenance

Page 3

TM

i-3® Control Technology V2

Chapter 1 Introduction 2

Over

Chapter 2 i-3 V2 I/O Controller 3

Introduction 3

I/O

Power Supply 7

Fuse Element 7

Switch Element 7

Ribbon Cables 7

USB to RS-485 Converter 7

Chapter 3 Control Input 8

Mounting Bracket 8

- Removing Communication Interface Door 8

- Removing Cover 8

Chapter 4 Control Inputs/Outputs 9

Introduction 9

Switc

Common Input Types 10

Changing Input Types 11

Input/Output Mapping 11

Chapter 5 Communication Protocols 12

Introduction 12

Configuring i-3 I/O Controller 12

- Using Panel Configurator Tool Software 12

- Using Modbus Communication 12

SIPOD Status 13

view 2

Board 4

I/O Contr

Connecting Controller to a Modbus System (PC or Building Automation System) 12

oller Box 8

h Inputs 9

Appendix 18-

s Tables 18-19

A Modbus Addr

B Circuits (SIPODs) Modbus Address Table 20-21

C Modbus Coils, Discrete Inputs, Input Registers and Holding Registers Address Tables 22-44

D Dimming Instructions 45-47

E USB to RS485 Converter Driver Software Installations Instructions 48-52

F Recommended Input Devices 53-72

G Common Networking setups 73-74

Customer Support Information 75

These instructions do not purport all details or variations in equipment, nor to provide for every possible contingency to be met in

connection with installation, operation or maintenance. Should further information be desired or should particular problems arise

which are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the local Siemens sales office. The

contents of this instruction manual shall not become part of or modify any prior or existing agreement, commitment or relationship.

The sales contract contains the entire obligation of Siemens. The warranty contained in the contract between the parties is the sole

warranty of Siemens. Any statements contained herein do not create new warranties or modify the existing warranty.

es

1

Page 4

Chapter 1

Introduction

Overview

The purpose of this manual is to help users

develop safe and efficient procedures for

the installation, operation and maintenance

of the i-3 V2 I/O Modbus Controller.

The i-3 V2 I/O Controller is used to control

the operation of P1 Series with i-3 Control

Technology V2 Panel. The controller directs

SIPODs (Remotely Operated Contactors)

to switch ON/OFF. It also monitors the

contact status up to 42 branch circuits.

The i-3 V2 I/O Controller enables the P1

lighting panel to operate as a slave panel

to accept dry contact or wet digital inputs

and analog inputs or commands through

communications network by a Building

Automation System. It provides up to 20

two-wire dry or wet contact inputs and

two analog inputs which can be used to

control up to 42 outputs.

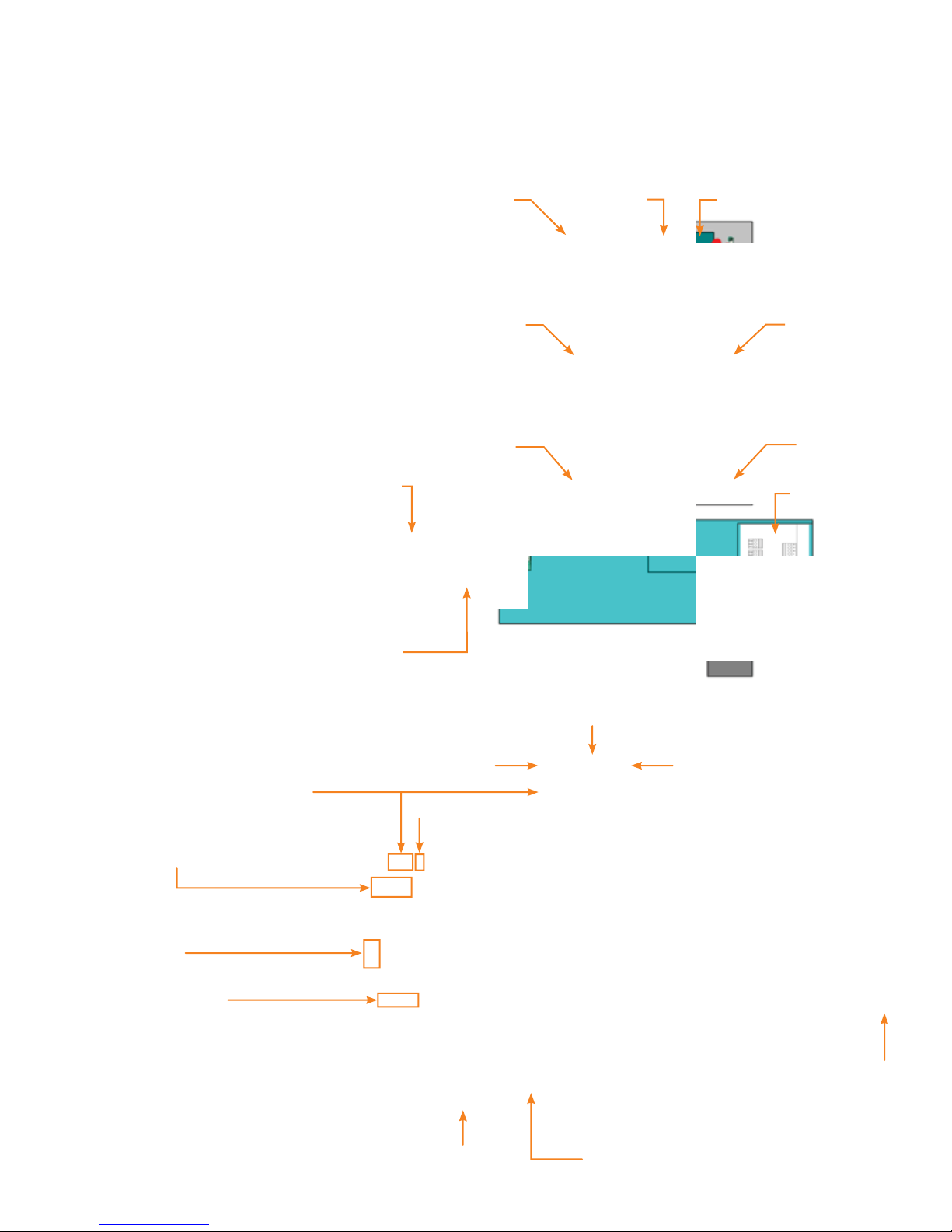

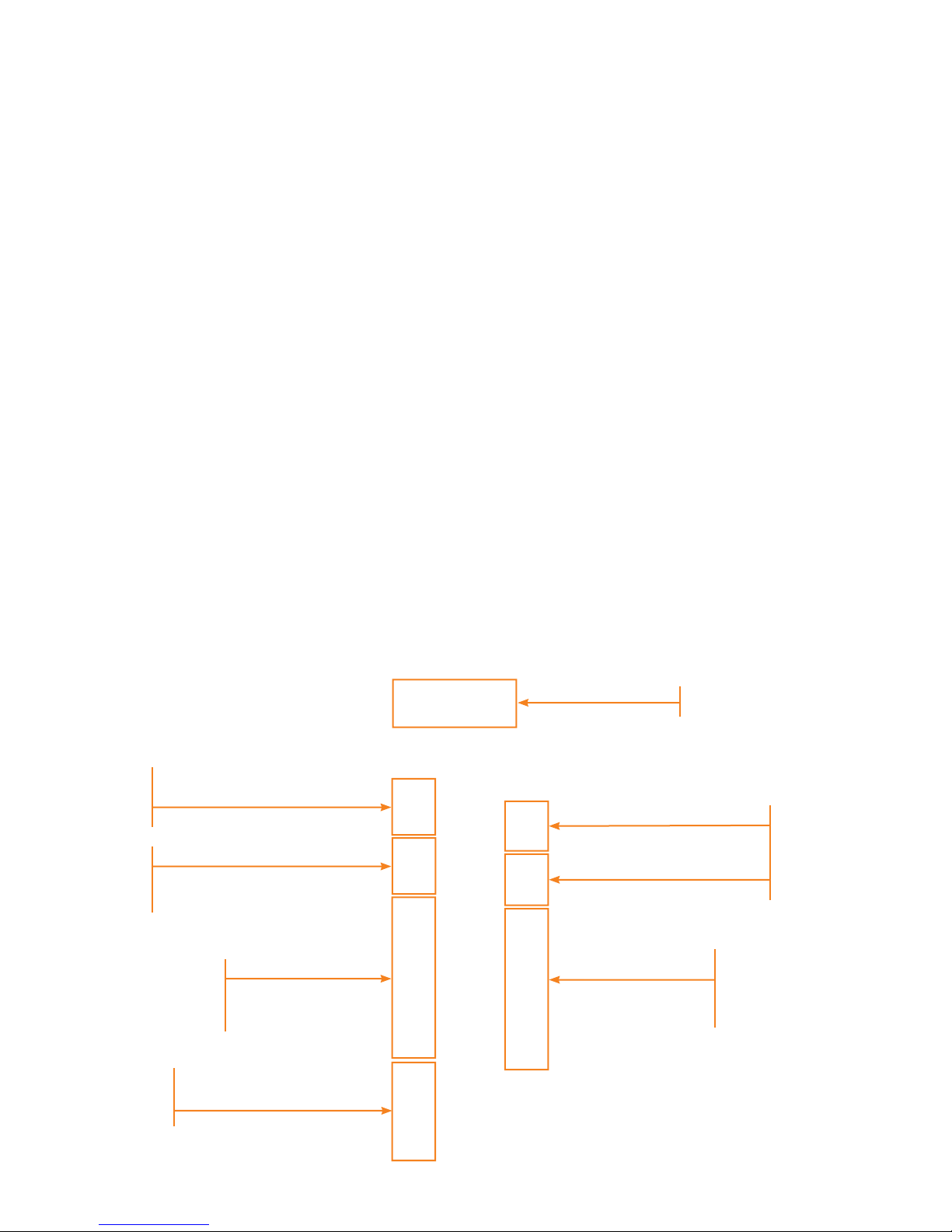

Figure 1.1

Single Slave Panel System Overview

PC or BAS

(Modbus

Interface)

RS485 to

RS232

converter

P1 Box

Data Rail

Ribbon

Cable

BQD SIPOD

Up to 21

Up to 21

I/O Board

Data Rail

Ribbon

Cable

Input

Terminals

Power

Supply

Front Panel Overview

Modbus

addressing switches

Connector

for Modbus

TCP/IP card

RS485 connections

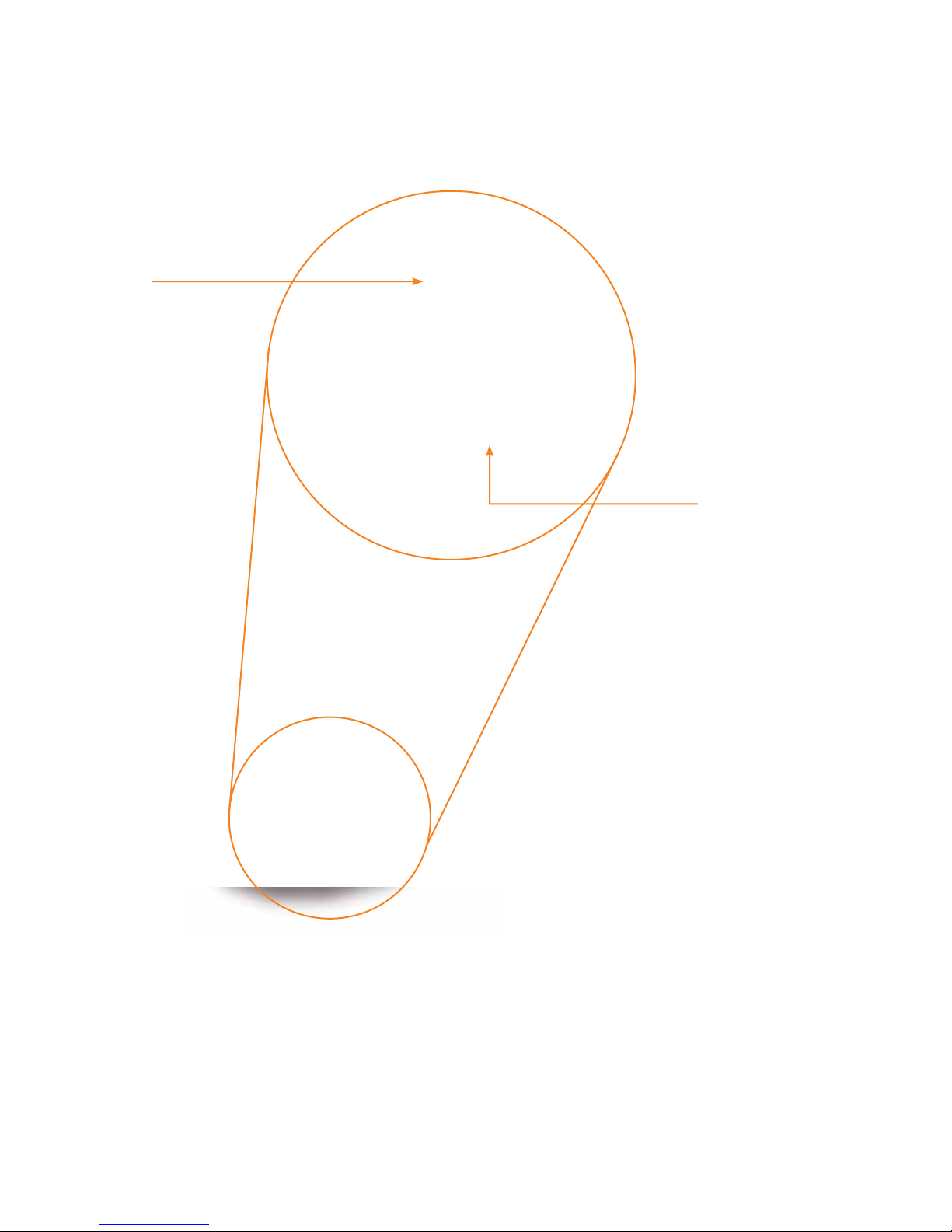

Figure 1.2

i-3 Controller Front View

Three way switch

All ON-AUTO-ALL OFF

Normal

operation

All SIPOD ON

Reset

Fuse Power switch

All SIPOD OFF

Note: The switch must

be on the “A

position during

commissioning and

normal operation.

UTO”

Ribbon

cable

2

Page 5

Chapter 2

i-3 V2 I/O Controller

Introduction

The i-3 V2 I/O Controller consists of

I/O printed circuit board, power supply,

fuse, switch, ribbon cables, mounting

bracket and I/O controller housing. This

chapter will discuss these individual

components in detail.

Three way switch

All ON-AUTO-ALL OFF

Modbus

addressing

switches

Connector

for Modbus

TCP/IP card

Reset

I/O Board

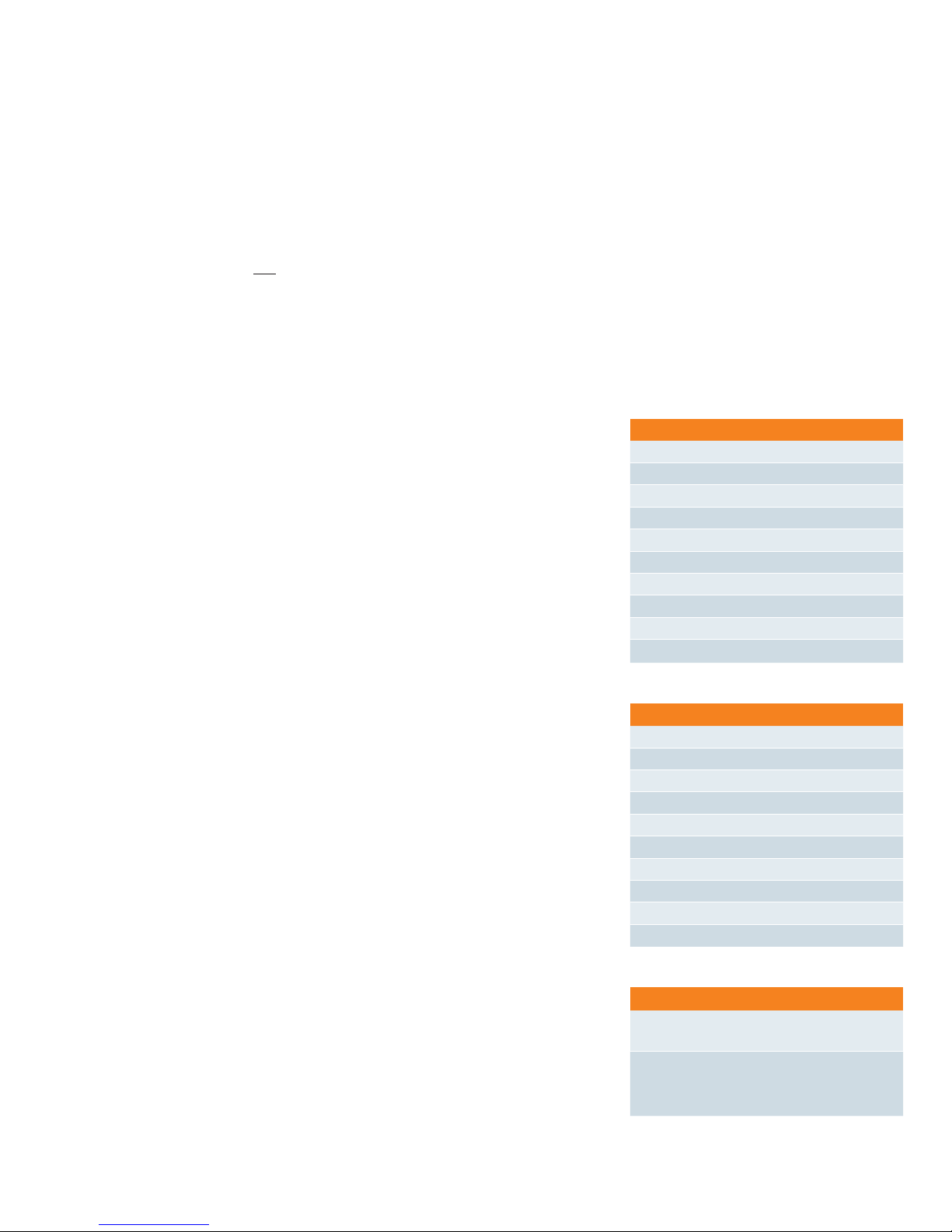

The main component of i-3 V2 I/O

Controller is the I/O printed circuit

board. Figure 2.1 below shows main

parts and features of I/O Board.

Ribbon cables

connectors

Modbus

RS-485

connection

Figure 2.1

I/O Board Layout

Communications

interface section

Power supply

connector

Input /Output

wiring section

3

Page 6

Chapter 2

i-3 V2 I/O Controller

Switch input terminals (digital inputs)

(TB1 – TB2)

There are 20 switch input terminals

available to be used to connect to external

dry or wet contact switching devices. They

are capable of accepting up to 20 two-wire

dry or wet contact inputs. Two ten-pin

pluggable connectors will be used to

connect the input wires to external

devices. A six pin pluggable connector

(TB3) is used to connect the contacts

common to the board (if the six location

on the connector are not sufficient; the

commons may be jumped together

outside of the board and one common

wire can be brought into the board).

The recommended wire is 18 AWG

stranded copper.

Analog outputs (TB5)

Two 0-10 VDC, 100 mA each to control

0-10 V dimmable ballasts.

Analog inputs (TB6)

Two analog inputs to connect the 0-10 V

output from light sensors.

24 VDC (TB4)

Power supply for sensors (light, motion,

etc.) as well as for wet contacts.

Firmware upgrade connector

This connection is used for Factory Service

and is not available to users.

Ribbon cable connector

There are two ribbon cable connectors

on the I/O Board that interface with the

data rails located on each side of the

P1 Series Lighting Panel. For safety

purposes, ribbon cables have a key feature

that prevents them from being connected

in the wrong orientation. A white mark

indicates the location of pin 1. In addition,

the pin 1 wire is black. The black wire must

be connected to pin 1 of the connector

where it lines up with the white mark.

Modbus addressing switches

Used to set the controllers Modbus address

in hexadecimal format.

Connector for Modbus TCP/IP

optional card

The Modbus TCP/IP optional card (Figure

2.2) cable plugs into this connector.

Figure 2.2

Modbus optional TCP card

Figure 2.3

I/O Board Wiring Section

Analog outputs

(Center pin is common)

Analog inputs

(Center pin is common)

Digital inputs 1 -10

Dry or wet contacts

Digital inputs common

Firmware upgrade connector

(Siemens use only)

24 VDC (+)

24 VDC (–)

Digital inputs 11 -20

Dry or wet contacts

4

Page 7

Chapter 2

i-3 V2 I/O Controller

USB-RS485 converter kit

Part No. 5WG1715-8XY02

Phoenix connector

Part No. 1984028

FTD chip

Part No. USB-RS485-WE-1800-BT

Figure 2.4

USB Converter Kit

5

Page 8

Chapter 2

i-3 V2 I/O Controller

Three way switch

All ON-AUTO-ALL OFF

Modbus

RS-485

connection

Figure 2.5

Modbus board

Reset button

Three-way switch (Figure 2.6)

This switch is used to determine the

method operation of all SIPODs. It has 3

positions, “All ON”, “Auto” and “All OFF.”

• “All ON” – Forces all SIPOD contacts to

be closed. In this position, the I/O Boar

prevent SIPODs from accepting any

remote commands.

Figure 2.6

Three-way Switch

• “Auto” – SIPODs can be controlled

emotely by a Building Automation

r

System (BAS) or any Modbus master.

• “All OFF” – Forces all SIPOD contacts

o be opened. In this position, the I/O

t

d

Board prevents SIPODs from accepting

any remote commands.

All ON Auto

RS-485 terminals

The RS-485 terminals are used to connect

i-3 V2 I/O Controller to a Modbus Building

Automation System (BAS). They also

enable users to configure the i-3 V2 I/O

Controller and perform various diagnostic

tests with the configuration software.

Reset button

This button resets (reboots) the controller.

All OFF

6

Page 9

Chapter 2

i-3 V2 I/O Controller

Power supply

The power supply is mounted under the

I/O printed circuit board. It uses one of the

3-phase buses as the main power source.

The power supply provides power to the

controller and all its functions.

Fuse

The fuse protects the wire to the power

supply and I/O Board from short circuits.

This fuse is a 2 Amps class CC fuse rated

for 600Vac or less. Figure 2.7 shows

the fuse housing. To replace the fuse use

LittleFuse KLDR002 or equivalent.

Power switch

An ON/OFF switch controls power to the

i-3 V2 controller. Be sure to turn the power

switch OFF prior to removing the fuse from

the controller.

Ribbon cables

A pair of 26-wire ribbon cables connect

the I/O Board and the data rails. They

provide two-way data communication

between the I/O Board and SIPODs. They

also provide power and ground.

2A Fuse

Figure 2.7

Power Switch and Fuse Housing

On/Off Switch

Each ribbon cable has identical connectors

on each end. A “keying” feature reduces

the risk of installing the connectors in the

wrong orientation.

USB to RS-485 converter

A USB to RS-485 converter should be

purchased to allow communication

between the i-3 V2 I/O Controller and

a personal computer. FTD Chip part

# USB-RS485-WE-1800-BT is recommended,

however Siemens is not responsible for the

part’s functionality.

A converter may be purchased from

Siemens – Part No. 5WG1 715-8XY02.

Users may also build a converter; see

Figure 2.4.

Figure 2.8

Ribbon Cable

7

Page 10

Chapter 3

Control Input

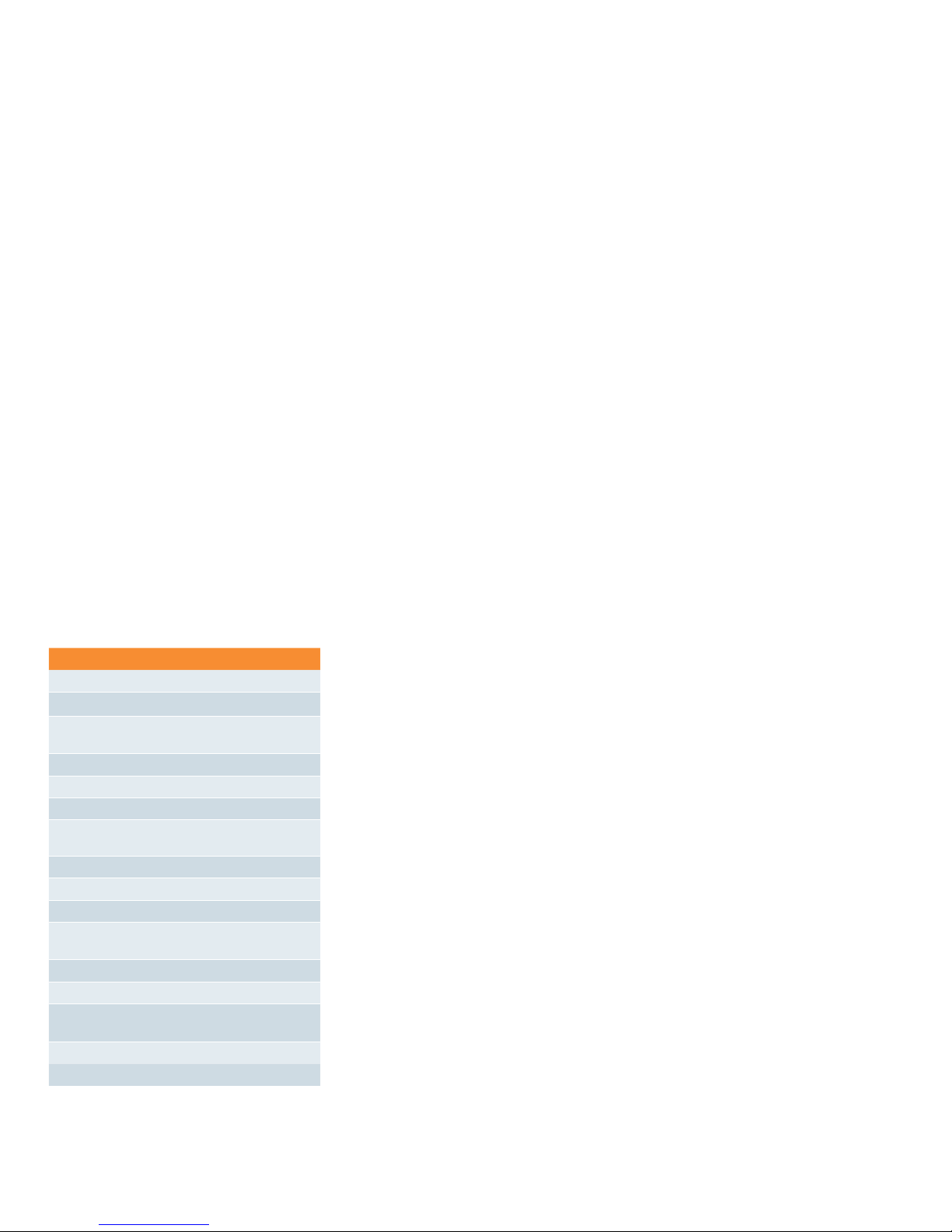

Mounting bracket

The mounting bracket is a “C” shape

steel plate that screws into the P1

panel mounting rails. This bracket holds

the controller.

I/O controller box

Removing the communication

interface door

The communication interface door

provides access to the communication

interface section without removing the

entire cover. Use the door handle shown

in Figure 3.1 to remove and install

the door.

DANGER

Hazardous voltage.

Will cause death or

serious injury.

Keep out.

Qualifi ed personnel only.

Disconnect and lock off all

power before working on

this equipment.

Door Handle

Removing the cover

Them I/O Controller cover must be removed

to access the input wiring section. Follow

the step-by-step instructions below to

remove the cover:

1. Disconnect and lock off all power

sources supplying this panel.

2. Remove P1 Panel trim and deadfront.

3. Remove the cover screws (4 total)

located as shown on Figure 3.1 to

remove the cover.

Cover screws (4)

“C” shape

mounting bracket

Communications

interface door

(shaded )

Figure 3.1

I/0 Controller Communication Interface Door

Controller

mounting screws (4)

8

Page 11

Chapter 4

Control Inputs/Outputs

Introduction

i-3 V2 I/O Controller provides a set of control

input terminals for wiring devices, such as

wall switches, photocells or occupancy

sensors. These terminals are located in the

input wiring section of the I/O printed

circuit board. There are two types of inputs

provided by these terminals:

• Switch inputs – The i-3 V2 I/O Contr

provides up to 20 input connections for

dry or wet (24 VDC) contacts (such as

wall switches, occupancy sensors, etc).

These contact inputs are capable of

acting either independently or in pairs

to turn ON and OFF. The controller can

accept up to 10 three-wire inputs or any

combination of two- and three-wire

inputs until its capacity is reached.

• Analog I/O – i-3 V2 I/O Contr

provides two analog input and two

analog output connections to control

0-10V dimming ballast.

There are two Analog Inputs (at TB6 on the

I/O Board) and two Analog Outputs (at TB5).

The Analog Inputs can be used to read any

0 to 10 Volt input value, and the Analog

Outputs can be used to drive out 0 to 10

volts ballast at a maximum of 100 mA each.

In a practical sense, this means that each

Analog Output can drive approximately 50

typical dimming ballasts (assuming each

ballast uses 2 mA – check your ballast

documentation for an actual determination).

Input / output connectors

oller

oller

The Analog Inputs can be used in any

situation where digital inputs are used.

They are specified by using input numbers

33 and 34, but whether they are “ON” or

“OFF” is more complex. For each analog

input, registers 20 and 21 give the input

value in the range 0-4095. Registers 36

and 37 specify values to be compared

to the Analog Inputs and comparison

operations, to determine whether the

Analog Input is ON or OFF.

Register 36 is the Compare definition for

Analog Input 1 (input number 33), and

contains the comparison value in the

bottom 12 bits (least significant, bits

0-11, range 0-4095). The high-order bit

(bit 15) in that register stands for “equal”

comparison, bit 14 stands for “less,” and bit

13 stands for “greater.” These three bits may

be combined to make “less or equal” or

“greater or equal” or “always ON” (all three

bits on). If all three bits are off, then the

Analog Input is never ON. Register 37

controls the comparison operation for

Analog Input 2 (input number 34).

Controlling the Analog Outputs: Registers

38 and 39 give the actual, read only values

of the Analog Outputs 1 and 2. Like all

Analog values, they are a number in the

range 0 to 4095, corresponding to 0 to 10

Volts. (NOTE: The actual output may be

limited by the circuitry to approximately

9.2 Volts.)

Registers 22 and 23 are for specifying

Analog Output 1 Set value and Analog

Output 2 Set value. These Set values are

intended to be used to drive the Analog

Outputs. However, whether these Set

values are used by the Analog Outputs

depends on the Analog Output Feed

registers, 32 and 33.

Each Analog Output’s actual output value

can be tied to an Analog Input or to register

22 or 23, but not both. The Analog Output

Feed registers determine this tie-in. Register

32 (Analog Output 1 Feed) contains the

number of the Input to be tied to the

Analog Output. This number is from 0 to

44, where 0 is “no connection” and 1-20

are digital inputs, while numbers of 33 and

34 are analog inputs 1 and 2. These two

analog inputs act as a digital inputs based

on the Analog compare register values.

Numbers 35 and 36 specify the analog

inputs and the feed is through the direct

values of the analog inputs. Numbers 37

and 38 specify the analog inputs and the

feed is through the difference of the Max

Voltage (4095) and the direct values of

the inputs.

Numbers 39 and 40 do not represent an

actual input, but instead ties this Analog

Output to register 22 or 23, respectively.

Register 33 is for specifying the Analog

Output 2 Feed. Numbers 42 and 42 specify

the use of the analog gain table. Numbers

43 and 44 specify the use of the PID loop

function with values E0 and E1 respectively.

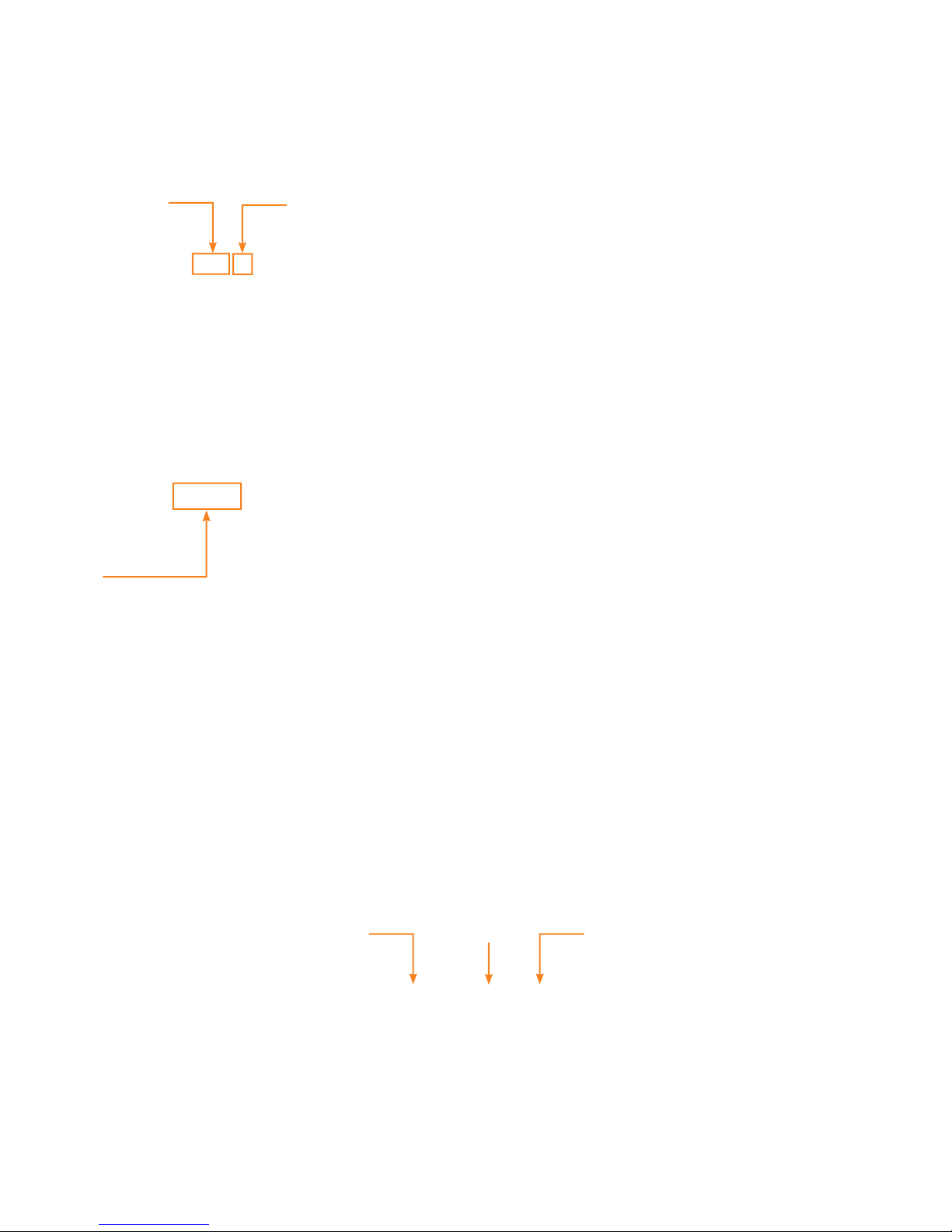

Common

Figure 4-1

Input / Output Connectors

Digital inputs Analog I/0

24 VDC

9

Page 12

Chapter 4

Control Inputs/Outputs

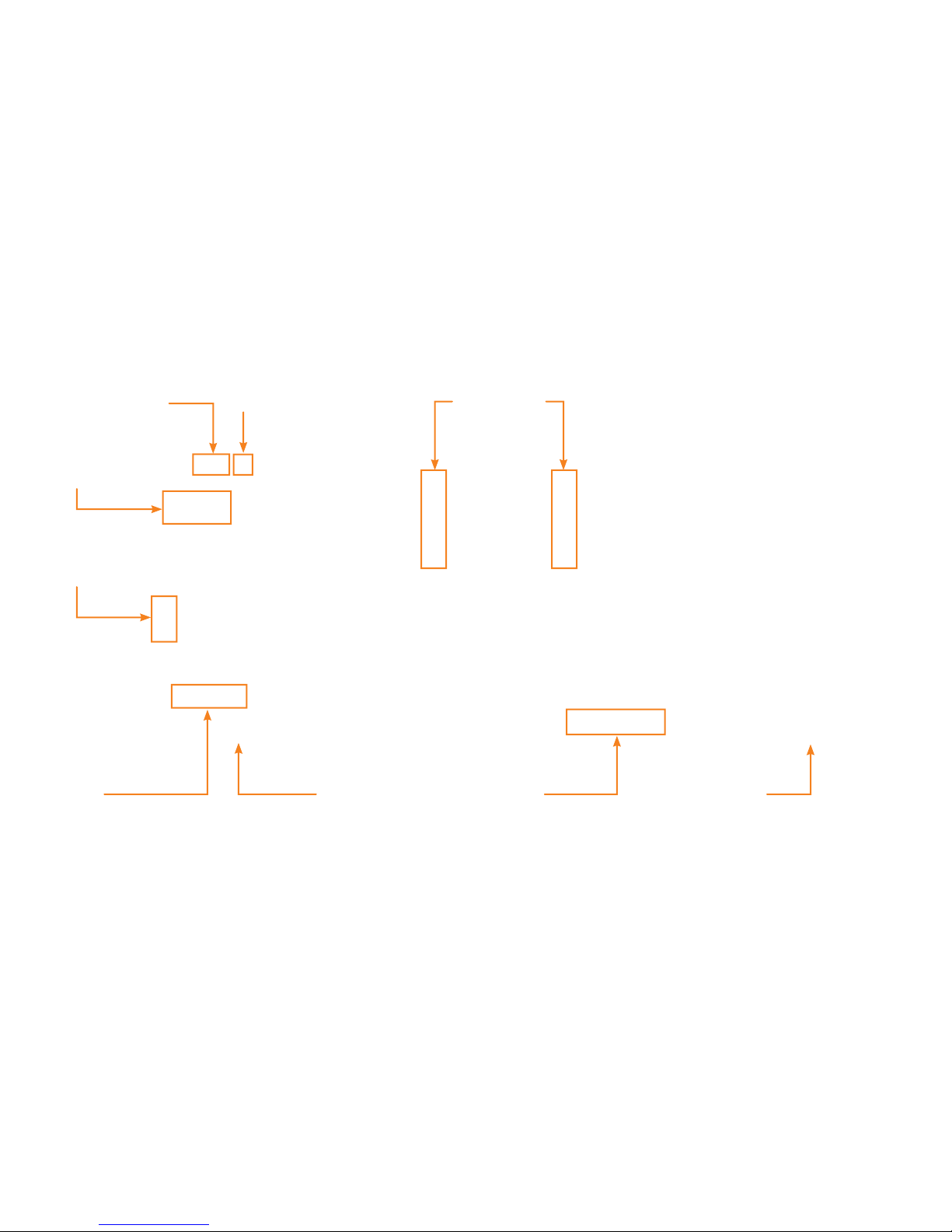

The diagram below illustrates the position of these input terminals in

i-3 V2 controller I/O board.

Analog outputs

Analog inputs

Digital inputs

Digital inputs

common

TB5

TB6

TB1

TB3

TB4

TB2

24 VDC

Digital inputs

Figure 4-2

Input Terminals in the Input Wiring Section

Common input types

Table 4-1 lists the typical input types supported by i-3 Control Technology V2 system.

Input Type Description Comments

0 Digital input maintain toggle switch (2-wire) If the value changes, then invert the state

1 Digit

2 Digital input maintain normally on switch (2-wire)

3 Digital input maintain normally on switch (2-wire) – blinking

4 Digital input maintain normally off switch (2-wire)

5 Digital input maintain normally off switch (2-wire) – blinking

6 Digital input momentary toggle switch (2-wire)

7 Digital input momentary toggle switch (2-wire) – blinking

8 Digital input momentary normally on switch (2-wire)

9 Digital input momentary normally off switch (2-wire)

10 Digital input dual-momentary switch (3-wire)

11 Digital input dual-momentary switch (3-wire) – blinking

Table 4-1

Common Input Types

10

al input maintain toggle switch (2-wire) – blinking if the value changes, then invert the state

Page 13

Chapter 4

Control Inputs/Outputs

Changing input types

All input types can be changed using

the Modbus communication protocol.

Refer to Modbus Map on page 14 for

more information.

Input/output mapping

Setting input/output mapping can

be accomplished using Modbus

communication protocol or the

configuration software.

Any given input to the I/O Board may be

connected to one output or to an output

group or zone (which is more than one

output). Refer to Modbus Map table in

Chapter 5 –Communication Protocols

under “Configuring i-3 V2 I/O Controller”

section for more information.

11

Page 14

Chapter 5

Communication Protocol

Introduction

The i-3 V2 I/O Controller provides

Modbus as the standard communication

protocol. A personal computer or Building

Automation System may be connected to

i-3 V2 I/O Controller using a twisted pair

serial cable wired to RS-485 terminal

located in the communication interface

section of I/O Board.

The i-3 V2 I/O Controller will act as a

Modbus Slave using Modbus RTU or

Modbus TCP/IP (optional) slave protocol

when interfacing with Building

Automation System. Modbus master

devices connected to the controller

can access (read) the data, making

configuration changes and initiating

control actions.

Connecting the controller to a

Modbus System (PC or Building

Automation) system

A twisted pair serial cable is used to

connect the i-3 V2 I/O Controller to a

personal computer or Building Automation

System. RS-485 to RS- 232 conversion

cable is required to connect to a personal

computer. This cable is connected to the

RS-485 terminal which is located in

the I/O Board communication interface

section as shown in Figure 5.1.

The RS-485 terminal is accessible through

Communication Interface Door without

removing the panel deadfront. See Figure

3.1 on page 8.

Configuring i-3 V2 I/O Controller

There are two methods of configuring

i-3 V2 I/O Controller: using The Panel

Configurator Software or Modbus

communications.

1. Using the i-3 V2 I/O Configurator

Software

Refer to “i-3 V2 I/O Configurator

Software Tool” section for instructions

on how to download this program from

our Web site.

2. Using Modbus Communication

Assigning a Modbus address

By default, i-3 V2 I/O Controller device

address is assigned as 126. If multiple

i-3 V2 I/O Controllers or other Modbus

devices are present on the same line,

each device must be assigned a unique

device address.

The Modbus address is programmed

with rotary switches located on the

electronic board.

See Appendix A – Modbus Address

Table for rotary switch settings.

Changing input types

To change input types, follow the steps:

1. Use either function code 6, preset

single register or 16: preset multiple

registers.

2. The register address for input types

ranges from 1792 (for input terminal 1)

to 1811 (for input terminal 20).

3. Assign the desired input type value,

which can be found in the Modbus Map

Table on page 10. For example, input

type “3” is digital input maintain

normally ON switch (2-wire).

RS-485

Terminal

Figure 5.1

i-3 I/O Controller Communication Interface

12

Page 15

Chapter 5

Communication Protocols

Creating output groups

An output group consists of a set of

SIPODs. To create an output group, follow

these steps:

1. Use either function code 6: preset single

register or 16: preset multiple registers.

2. The register addresses for output group

definition ranges from 256 (for output

group definition 1) to 380 (for output

group definition 125).

3. Assign the register value to create as

many output groups as desired. Note:

Each register is made up of two bytes:

the first byte represents the output

group number and the second byte is

the SIPOD number. For example, if the

register contains 0x0402, then the

output group is 4 (0-relative numbering)

and the SIPOD is 2. There can be

duplicate output groups and/or SIPODs

within the table. This means an output

group can contain more than one SIPOD,

and a SIPOD can be in more than one

output group.

Mapping input-to-output

By default, the factory assembled i-3

V2 Controller input-to-output mapping

is not set. Input-to-Output mapping can

be redefined as desired to meet the project

specification. To map input to output,

follow these steps:

1. Use either function code 6: preset single

register or 16: preset multiple registers.

2. Register address for input-to-output map

starts from 2048 for input terminal 1 to

2067 for input terminal 32.

3. Assign the register value for the desired

input maps. Note: Each entry (register)

in the table has two parts: a high order

byte that is either 0 (for an output

mapping) or 0x80 (for an output group

mapping), and a low-order byte that

specifies either an output (SIPOD)

number or an output group number.

The table is indexed by input number.

For example, if the fifth entry (register)

in the table is 0x0001, then input

number 5 is mapped to SIPOD 1. If the

tenth entry (register) is 0x8004, then

input number 10 is mapped to output

number 4.

Refer to Modbus Map table on page 14

for additional information.

Other configuration functions

Other functions, such as reading SIPOD

status, reading input status, setting up

SIPOD parameter, etc., are listed in the

Modbus Map table on page 14.

13

Page 16

Chapter 5

Communication Protocols

Modbus map (See Appendix C)

This section describes the Modbus

communication protocol employed by the

i-3 V2 I/O Controller in a Modbus network.

Please contact Technical Support at

1-800-333-7421 to obtain the most

current Modbus Map.

SIPOD Status

The first (high-order) byte of the SIPOD

Status Word contains:

+---------------------------------------------------+

| P | R | D | O | S | S | | |

| O | S | E | V | P | P | | || Control byte

| D | T | F | F | 1 | 2 | | |

+--------------------------------------------------+

SIPOD – SIPOD initiated message – set

when the message originates in the SIPOD

rather than the I/O Board.

RST – Reset flag – sent from the SIPOD

to the I/O Board in the first message after

a system reset.

DEF/FIN – Default/Finishing flag

This flag has two meanings – one if the

message originates in the SIPOD, and

another if the message originates in the

I/O Board. In a SIPOD message, it means (if

on) that the default values of parameters

have not yet been set – in particular, no

“SetParameter” message has been received

from the IO Board since the most recent

SIPOD reset.

In messages originating in the I/O Board,

the FIN flag indicates that no more data

will be sent to the SIPOD. It also indicates

that no more data will be accepted. No

data may be sent in a packet which has the

FIN flag set. The FIN flag is not currently

used, and is intended for situations where

there are multiple packets sent from the I/O

Board – not for single messages.

OVF – Command overflow flag

This flag indicates that at least one

command previously sent to the SIPOD was

ignored because there was no room

in the task queue. This means that

commands are being sent too quickly

for the SIPOD to handle them.

SP1 – Status of Pole 1

This is equal to 1 if the first pole is closed.

SP2 – Status of Pole 2 (for 2-pole PODs)

This is equal to q if the second pole is

closed.

The second (low-order) byte of the

SIPOD Status Word contains:

• Bit 7 (left-most bit) – Open/Closed flag

ON = Closed;

OFF = Open.

• Bit 6 – OIP – Open in process flag

• Bit 5 – CIP – Close in process flag

• Bit 4 – FAIL – Failure flag (failed to open

close)

or

•

Bit 3 – NAK flag (a previous message

was g

• Bit 2 – MxO – Maximum Opens per

minute

• Bit 1 – MxC – Maximum Closes per

minute

• Bit 0 – SQE – Sequence Error flag (a

pr

The Open/Closed flag is set based on the

Auxiliary Detector in the SIPOD. This is a

contact switch that mimics the operation

of the power contacts.

Note that the FAIL, NAK, and SQE flags

are sent only once, and then cleared. All

three of these flags mean that there was

a problem since the last time a status was

sent to the I/O Board – not necessarily

related to the previous message from the

I/O Board. For example, if the I/O Board

requests an Open, then a Close, then sends

GetStatus and the status contains

a FAIL flag, then either the Open or the

Close failed (or both), but the I/O Board

cannot determine which operation failed.

Timed inputs

Each register represents a 16-bit signed

value (-32766 to +32767), which gives

the number of minutes to time an input

when it is switched ON. The default is 0,

meaning “do not time this input”. The

maximum value is 32767 (about

22.75 days).

After this time, the input will be turned

“OFF” logically – that is, the switch may

be physically in the ON position, but any

SIPODs mapped to it will be turned off.

arbled)

reached

reached

evious message was out-of sequence)

NOTE: There is a built-in delay of up to

one minute, so setting this time to 1 will

result in the input turning “OFF” after a

minimum of one minute and maximum

of two minutes.

Putting 0 in this register means there is no

timing: that is, the switch is ON indefinitely

until operated OFF.

Timed SIPOD overrides

Each register represents a 16-bit signed

value (-32766 to +32767), which gives

the number of minutes to time a SIPOD

override. The default is 0, meaning “ there

is no override.” The maximum time is +

or - 32767 (about 22.75 days). A positive

value will turn the SIPOD ON for that

amount of time. A negative value means

the SIPOD will be turned OFF for that

amount of time.

For example, a value of +15 will turn the

SIPOD ON for 15 minutes. A value of -20

will turn the SIPOD OFF for 20 minutes. So

the absolute value of the register indicates

the time, and the sign of the register indicates ON or OFF.

After this time, the override will be

disabled logically. The SIPOD will return

to whatever state (ON/OFF) it would be

in if the override had not happened.

Putting 0 in this register means the

override is disabled. In other words,

overrides are always time-limited.

If the registers are read, they return the

value of the time left in the override and

indicate by being negative or positive

whether the SIPOD is turned OFF or ON.

IOB control word

As a safety precaution, there is a password

value required in the high-order byte of the

IOB Control Word to enable use of

any of the control bits. This is to prevent

accidental activation of the control bits

it is not meant to prevent unauthorized

access. The password value is 0xA0

(hexadecimal A0, decimal 160).

Note that the IOB Control Word always

returns 0 (0x0000) when read.

Bit 0 -- if ON, clears all statistics of the

IO Board

14

Page 17

Chapter 5

Communication Protocols

Bit 1 -- if ON, run the IOB Diagnostics

routine

Bit 2 -- if ON, reset the IO Board

Bit 3 -- if ON, restore defaults to the

parameters of the IO Board (but not the

Modbus device address) as well as the

Date and Time.

Bit 4 -- if ON, restore defaults to the

Output Groups Table (i.e., no output

groups defined) and the Input-Output

Mapping Table (i.e., 1-to-1 mapping of

32 digital inputs to the first 32 outputs)

Bit 5 -- If ON, restore defaults to the Input

Types Table (i.e., all digital input types set

to 0) and to Inputs Force (i.e., turn off

all forcing). In addition, the states of all

inputs are initialized.

Bit 6 -- If ON, indicates the IO Board should

go into Program Upgrade mode – stopping

all activity except for receiving memory

updates (allows reading/writing of the IOB

Memory Access Table and writing register

115 – the IOB Control Word)

Bit 7 -- If ON, cancels the Program Upgrade

mode (IO Board goes back into normal

mode – all normal functions are enabled)

To activate one or more of these bits, you

must add the password value and write the

word. For example, if you wish to reset

the IO Board, you must write 0xA004

(hexadecimal A004).

Input forcing

Using a combination of the Inputs On/Off

(registers 18 and 19) and the Inputs Force

(registers 16 and 17), the user can force

the state of individual and multiple inputs

to be either On or Off. The Force All

On/Off switch on the IO Board still has

the highest priority of action, but Input

Forcing is second to that switch when it

comes to priority of action.

The state of an input (On or Off) can be

read or written in registers 18 and 19.

However, writing to an input state has

no effect unless the corresponding bit in

registers 16 or 17 is set to 1. Therefore,

registers 16 and 17 act as a mask of

registers that are being forced, and

registers 18 and 19 act as forced states or

actual states of inputs, depending on the

mask registers.

Note that when an input is being forced,

the actual state of the input has no effect

whatsoever, until the forcing is turned

OFF for that input. This may lead to some

confusion, i.e., someone trying to toggle a

light switch and seeing nothing happen to

the lights.

Panel configurator tool software

To obtain this software, please contact

Siemens at 800-427-2256. Software will

be available for download online.

Input Logics

Registers 3584 through 3603 specify an

optional logic operation for each Input.

Each register contains a 0 (“OR”), 1

(“AND”), 2 (“NAND”), or 3 (“XOR”) in the

first byte and an input number (1-20 for

digital inputs or 33 analog input 1 or 34

for analog input 3) in the second byte. A

value of 0 in a register means that there is

no Logic operation to be applied. A Logic

operation allows the user to relate two

different inputs to a POD with an AND,

OR, NAND, or XOR logical connection.

NOTE: A special situation can occur when

two inputs are linked to each other and

one has an “OR” operation and the other

has an “AND” operation. This could lead to

a race condition, causing the SIPODs to

clatter as they try to satisfy both conditions.

In order to prevent this, the software

will automatically give both Inputs the

same Logic operation whenever it detects

the condition. In the case or an XOR or a

NAND, just the opposite is true, in that if

both inputs point to each other and have

XOR or both have NAND, this creates a

race condition, so the system removes

the Logic operation

Communication loss

Placing a value in register 781 indicates how

long (in minutes) the I/O board should wait

to determine if communication is lost. The

15th bit in register 781 specifies what to do

when communication is lost. If the 15th bit

is set, all SIPODs will be turned ON. If the

15th bit is not set, all SIPODs will be turned

OFF. The user enters the value in the

remaining 15 bits. The maximum value is

10000 minutes, the minimum value is 1

minute. If the value is FFFF, the I/O board

does not check for communication loss.

SIPOD Delay

The user can specify the time (in

milliseconds) for SIPODs to be ON for

the commands SIPOD_CLOSE and

SIPOD_OPEN. The default its 0. The

maximum is 65536.

1.1. Analog Gain Tables

Register Function Value

Analog Gain Output Table

0x2000 Lighting level 1 setting 0 - 4095

0x2001 Lighting level 2 setting 0 - 4095

0x2002 Lighting level 3 setting 0 - 4095

0x2003 Lighting level 4 setting 0 – 4095

0x2004 Lighting level 5 setting 0 – 4095

0x2005 Lighting level 6 setting 0 – 4095

0x2006 Lighting level 7 setting 0 – 4095

0x2007 Lighting level 8 setting 0 - 4095

0x2008 Lighting level 9 setting 0 – 4095

0x2009 Lighting level 10 setting 0 – 4095

Table 5.1

Analog Gain Input Table

0x200A Threshold level 1 setting 0 – 4095

0x200B Threshold level 2 setting 0 – 4095

0x200C Threshold level 3 setting 0 – 4095

0x200D Threshold level 4 setting 0 – 4095

0x200E Threshold level 5 setting 0 – 4095

0x200F Threshold level 6 setting 0 – 4095

0x2010 Threshold level 7 setting 0 – 4095

0x2011 Threshold level 8 setting 0 – 4095

0x2012 Threshold level 9 setting 0 – 4095

0x2013 Threshold level 10 setting 0 - 4095

Table 5.2

Analog Active PID Settings

0x2014 Desired Lighting level

analog channel 1 0 – 4095

0x2015 Desired Lighting level

analog channel 2 0 - 4095

Table 5.3

15

Page 18

Chapter 5

Communication Protocols

Analog Gain

If the analog feedback data from the lighting sensor falls between 0 and threshold

setting 1, Programmable Ramp sets the

analog output to level 1.

If the analog input data from the lighting

sensor falls between threshold setting 1

and threshold setting 2, Programmable

Ramp sets the analog output to level 2.

If the analog input data from the lighting

sensor falls between threshold setting 2

and threshold setting 3, Programmable

Ramp sets the analog output to level

3, etc.

Saved Parameters

Certain parameters of the I/O Board are

saved to flash memory, so they can be

recovered after the system is reset and/or

after the power is turned OFF and back ON.

These are the registers that are saved to

Flash memory:

Register Description

32-39 Analog configuration

106 (Number of flash writes)

107-110

116 (Analog Input 1 Hysteresis)

117 (Analog Input 1 Epsilon)

120 (Modbus device address)

121-123

256-380 (Output Group Definitions)

768-779 (Default Parameters)

1792-1825 (Input Types Table)

2048-2081

2816-2836 (POD Types Table)

3072-3103 (Input Timing Table)

3328-3369

3584-3617 (Input Logics Table)

8192-8213 (Analog Gain Tables)

Table 5.4

(Analog Output Correction

factors)

(RS-485 baud rate, parity,

and stop bits)

(Input-Output Mapping

Table)

(POD Override Timing

Table)

16

Page 19

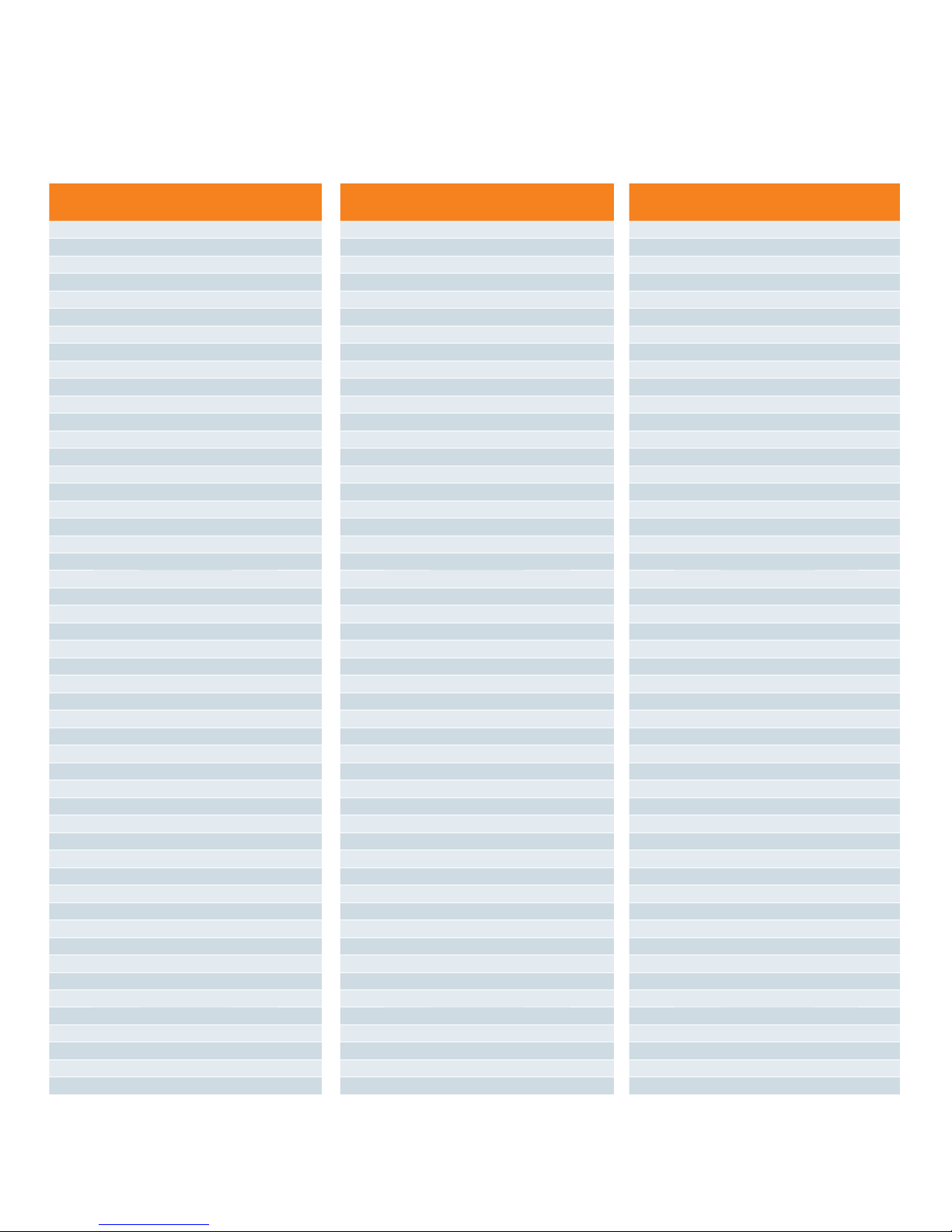

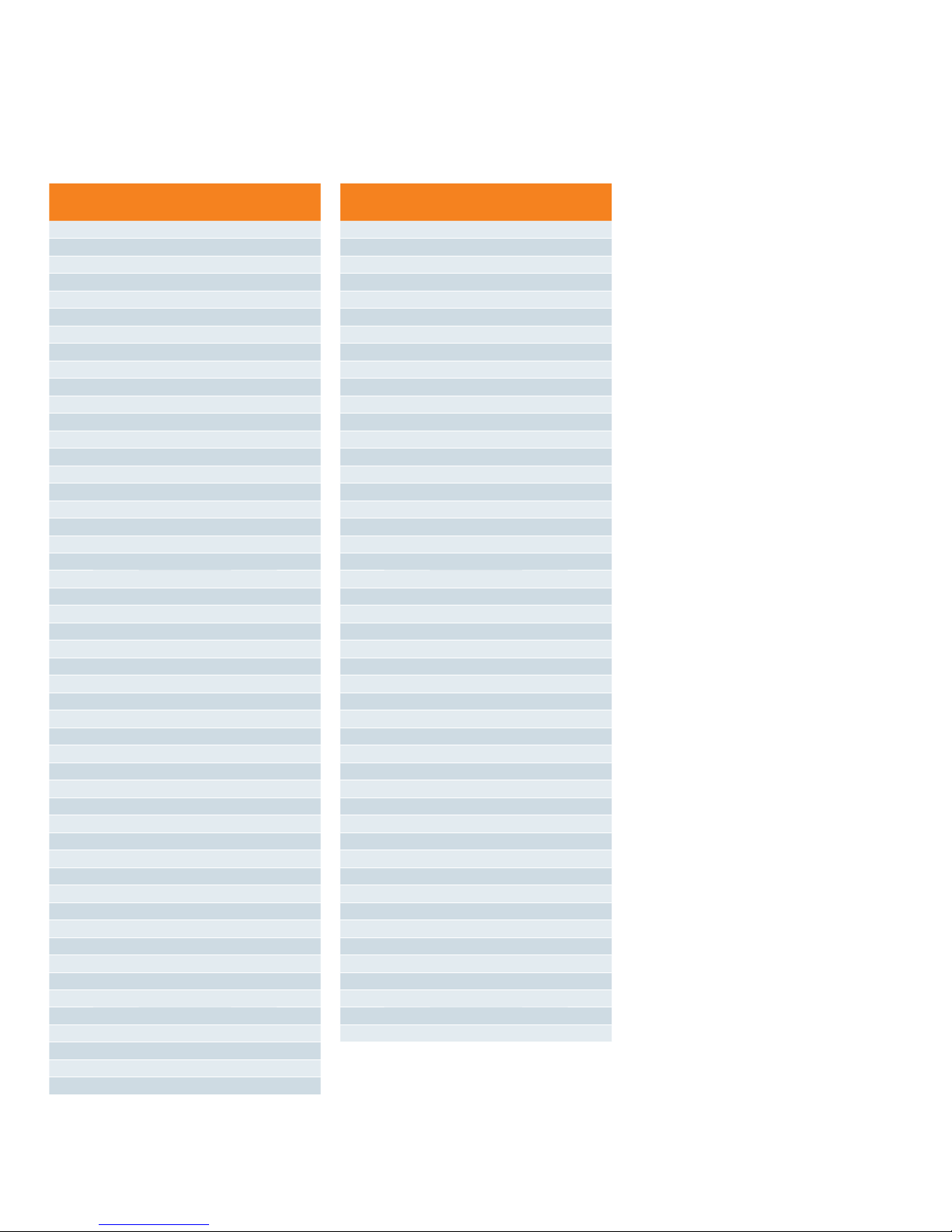

Appendix A

Modbus Address Table

Appendix B

Circuits (SIPODs) Modbus Address Table

Appendix C

Modbus Coils, Discrete Inputs, Input Registers and Holding Registers

Address Tables

Appendix D

Dimming Instructions

Appendix E

USB to RS485 Converter Driver Software Installations Instructions

Appendix F

Recommended input devices

Appendix G

Common Networking setups

17

Page 20

Appendix A

Modbus Address Tables

Modbus

Address

1 0 1

2 0 2

3 0 3

4 0 4

5 0 5

6 0 6

7 0 7

8 0 8

9 0 9

10 0 a

11 0 b

12 0 c

13 0 d

14 0 e

15 0 f

16 1 0

17 1 1

18 1 2

19 1 3

20 1 4

21 1 5

22 1 6

23 1 7

24 1 8

25 1 9

26 1 a

27 1 b

28 1 c

29 1 d

30 1 e

31 1 f

32 2 0

33 2 1

34 2 2

35 2 3

36 2 4

37 2 5

38 2 6

39 2 7

40 2 8

41 2 9

42 2 a

43 2 b

44 2 c

45 2 d

46 2 e

47 2 f

48 3 0

49 3 1

50 3 2

Dip Switch 1

(S4)

Dip Switch 2

(S5)

Modbus

Address

51 3 3

52 3 4

53 3 5

54 3 6

55 3 7

56 3 8

57 3 9

58 3 a

59 3 b

60 3 c

61 3 d

62 3 e

63 3 f

64 4 0

65 4 1

66 4 2

67 4 3

68 4 4

69 4 5

70 4 6

71 4 7

72 4 8

73 4 9

74 4 a

75 4 b

76 4 c

77 4 d

78 4 e

79 4 f

80 5 0

81 5 1

82 5 2

83 5 3

84 5 4

85 5 5

86 5 6

87 5 7

88 5 8

89 5 9

90 5 a

91 5 b

92 5 c

93 5 d

94 5 e

95 5 f

96 6 0

97 6 1

98 6 2

99 6 3

100 6 4

Dip Switch 1

(S4)

Dip Switch 2

(S5)

Modbus

Address

101 6 5

102 6 6

103 6 7

104 6 8

105 6 9

106 6 a

107 6 b

108 6 c

109 6 d

110 6 e

111 6 f

112 7 0

113 7 1

114 7 2

115 7 3

116 7 4

117 7 5

118 7 6

119 7 7

120 7 8

121 7 9

122 7 a

123 7 b

124 7 c

125 7 d

126 7 e

127 7 f

128 8 0

129 8 1

130 8 2

131 8 3

132 8 4

133 8 5

134 8 6

135 8 7

136 8 8

137 8 9

138 8 a

139 8 b

140 8 c

141 8 d

142 8 e

143 8 f

144 9 0

145 9 1

146 9 2

147 9 3

148 9 4

149 9 5

150 9 6

Dip Switch 1

(S4)

Dip Switch 2

(S5)

18

Page 21

Appendix A

Modbus Address Tables

Modbus

Address

151 9 7

152 9 8

153 9 9

154 9 a

155 9 b

156 9 c

157 9 d

158 9 e

159 9 f

160 a 0

161 a 1

162 a 2

163 a 3

164 a 4

165 a 5

166 a 6

167 a 7

168 a 8

169 a 9

170 a a

171 a b

172 a c

173 a d

174 a e

175 a f

176 b 0

177 b 1

178 b 2

179 b 3

180 b 4

181 b 5

182 b 6

183 b 7

184 b 8

185 b 9

186 b a

187 b b

188 b c

189 b d

190 b e

191 b f

192 c 0

193 c 1

194 c 2

195 c 3

196 c 4

197 c 5

198 c 6

199 c 7

200 c 8

Dip Switch 1

(S4)

Dip Switch 2

(S5)

Modbus

Address

201 c 9

202 c a

203 c b

204 c c

205 c d

206 c e

207 c f

208 d 0

209 d 1

210 d 2

211 d 3

212 d 4

213 d 5

214 d 6

215 d 7

216 d 8

217 d 9

218 d a

219 d b

220 d c

221 d d

222 d e

223 d f

224 e 0

225 e 1

226 e 2

227 e 3

228 e 4

229 e 5

230 e 6

231 e 7

232 e 8

233 e 9

234 e a

235 e b

236 e c

237 e d

238 e e

239 e f

240 f 0

241 f 1

242 f 2

243 f 3

244 f 4

245 f 5

246 f 6

247 f 7

Dip Switch 1

(S4)

Dip Switch 2

(S5)

19

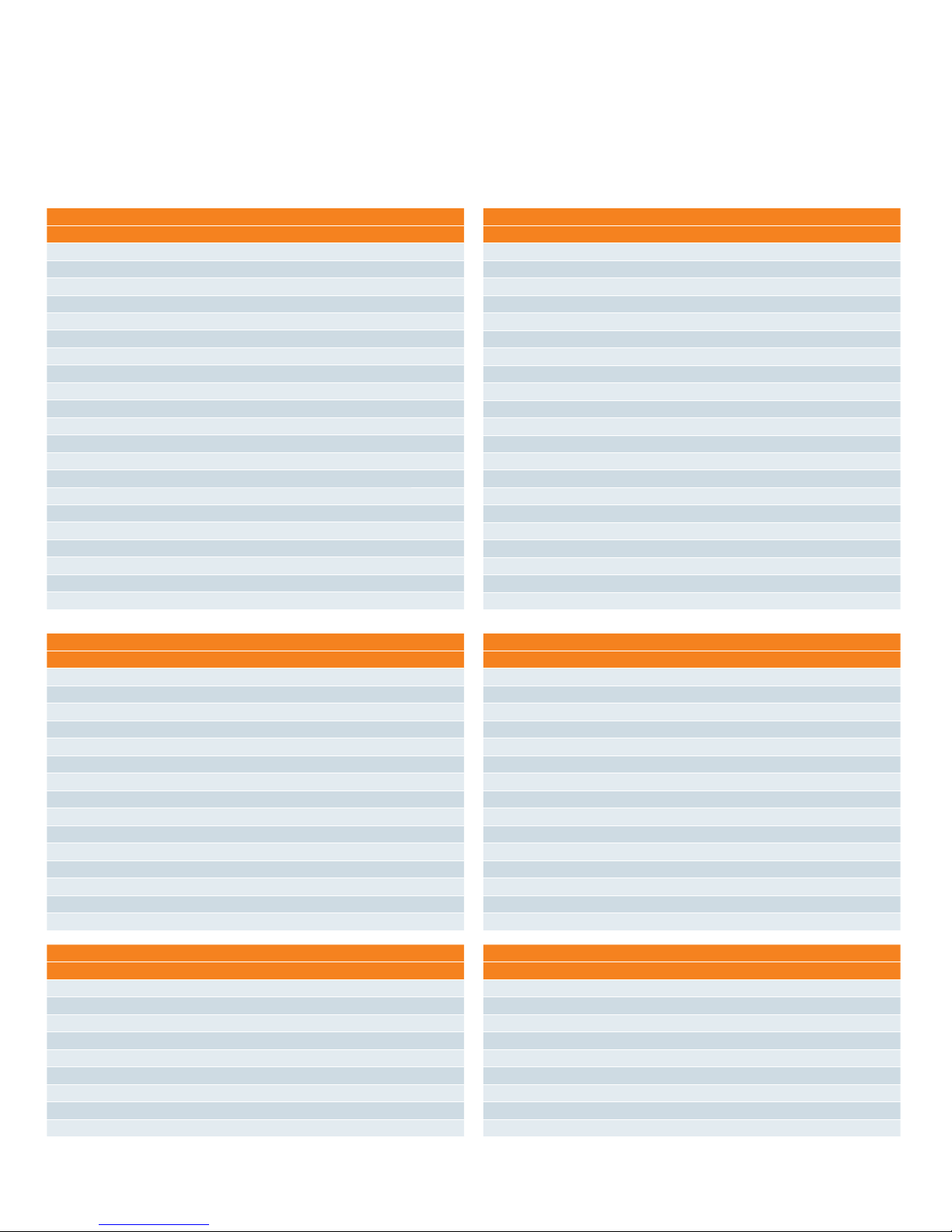

Page 22

Appendix B

Circuits (SIPODs) Modbus Address Table

1-3® Control Technology V2 – Circuit Numbering, Modbus Addressing

Top feed – 42 circuits – vertical numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1 02221

2 12322

3 22423

4 32524

5 42625

6 52726

7 62827

8 72928

9 83029

10 9 31 30

11 10 32 31

12 11 33 32

13 12 34 33

14 13 35 34

15 14 36 35

16 15 37 36

17 16 38 37

18 17 39 38

19 18 40 39

20 19 41 40

21 20 42 41

Top feed – 30 circuits – vertical numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Bottom feed – 42 circuits – vertical numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Bottom feed – 30 circuits – vertical numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Top feed – 18 circuits – vertical numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

2

3

4

5

6

7

8

9

20

0

1

2

3

4

5

6

7

8

16

17

18

19

20

21

22

23

24

21

22

23

24

25

26

27

28

29

Bottom feed – 18 circuits – vertical numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

2

3

4

5

6

7

8

9

29

28

27

26

25

24

23

22

21

10

11

12

13

14

15

16

17

18

8

7

6

5

4

3

2

1

0

Page 23

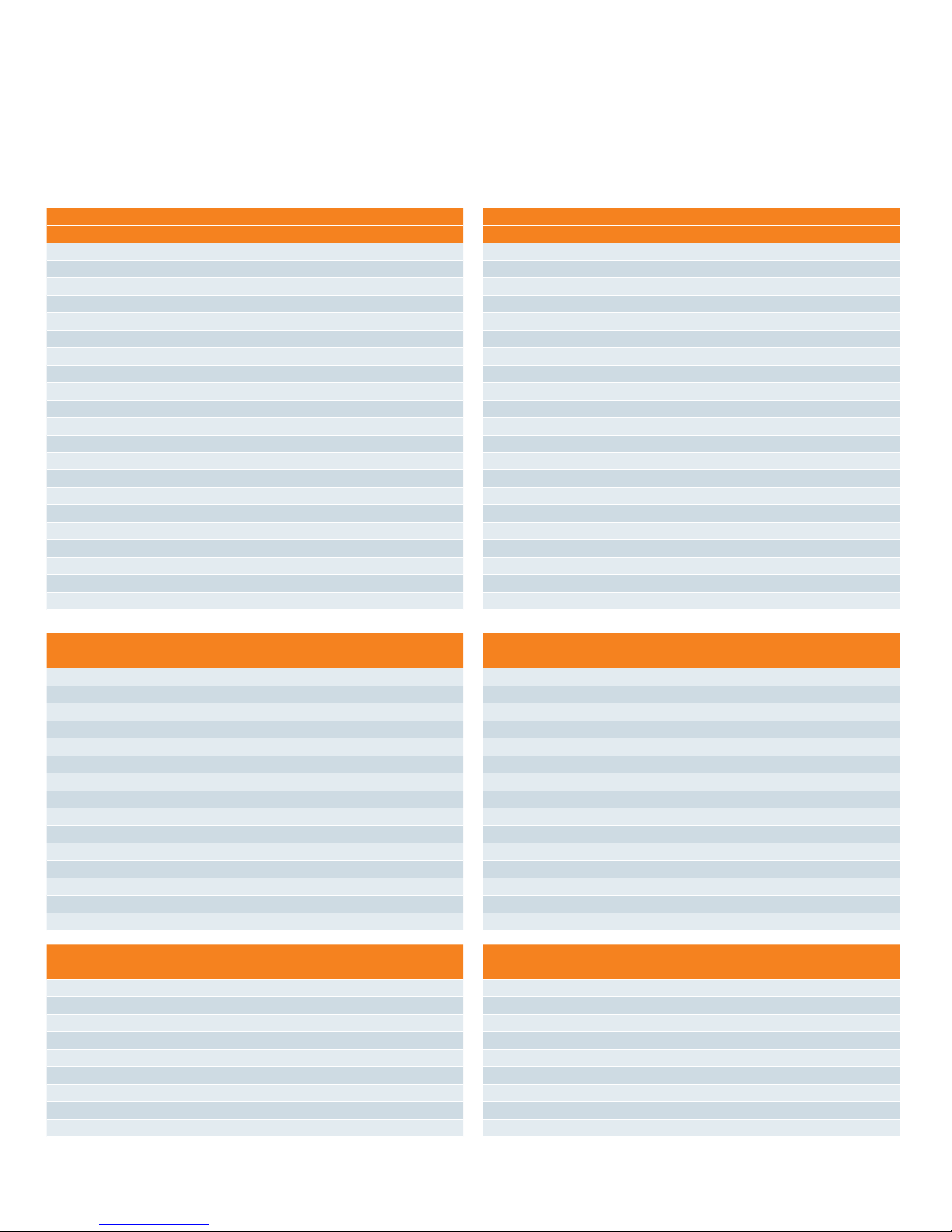

Appendix B

Circuits (SIPODs) Modbus Address Table

1-3® Control Technology V2 – Circuit Numbering, Modbus Addressing

Top feed – 42 circuits – horizontal numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

Top feed – 30 circuits – horizontal numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Bottom feed – 42 circuits – horizontal numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

Bottom feed – 30 circuits – horizontal numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

Top feed – 18 circuits – horizontal numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

3

5

7

9

11

13

15

17

0

1

2

3

4

5

6

7

8

2

4

6

8

10

12

14

16

18

21

22

23

24

25

26

27

28

29

Bottom feed – 18 circuits – horizontal numbering

Circuit No. Modbus Addr Circuit No. Modbus Addr

1

3

5

7

9

11

13

15

17

29

28

27

26

25

24

23

22

21

2

4

6

8

10

12

14

16

18

8

7

6

5

4

3

2

1

0

21

Page 24

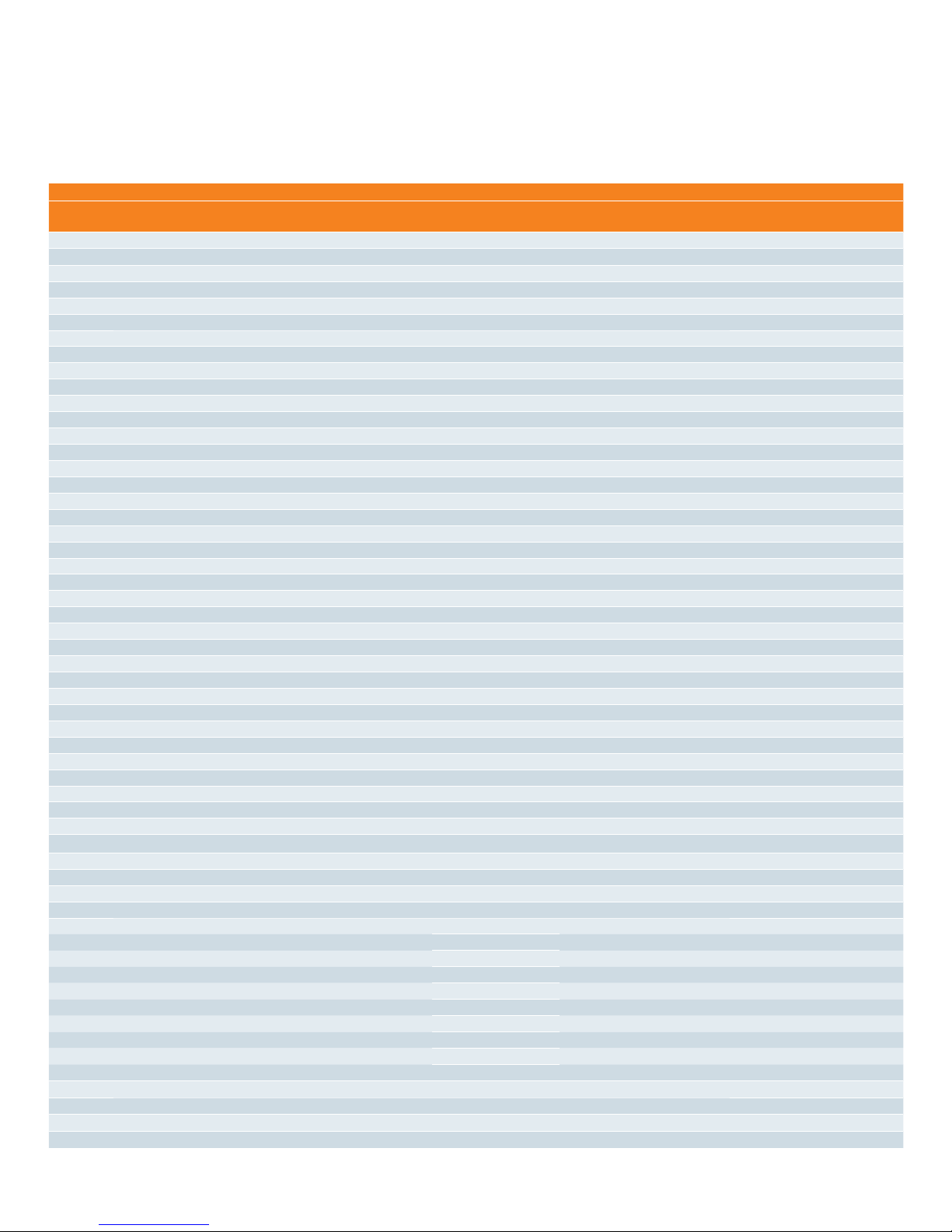

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Coils

Function Code

1 (Read Only) 0 00001 0 / 1 SIPOD 1 Open (0)/Close (1)

5 & 15 (Write Only) * 1 00002 0 / 1 SIPOD 2 Open (0)/Close (1)

Modbus

Base 0 address

2 00003 0 / 1 SIPOD 3 Open (0)/Close (1)

3 00004 0 / 1 SIPOD 4 Open (0)/Close (1)

4 00005 0 / 1 SIPOD 5 Open (0)/Close (1)

5 00006 0 / 1 SIPOD 6 Open (0)/Close (1)

6 00007 0 / 1 SIPOD 7 Open (0)/Close (1)

7 00008 0 / 1 SIPOD 8 Open (0)/Close (1)

8 00009 0 / 1 SIPOD 9 Open (0)/Close (1)

9 00010 0 / 1 SIPOD 10 Open (0)/Close (1)

10 00011 0 / 1 SIPOD 11 Open (0)/Close (1)

11 00012 0 / 1 SIPOD 12 Open (0)/Close (1)

12 00013 0 / 1 SIPOD 13 Open (0)/Close (1)

13 00014 0 / 1 SIPOD 14 Open (0)/Close (1)

14 00015 0 / 1 SIPOD 15 Open (0)/Close (1)

15 00016 0 / 1 SIPOD 16 Open (0)/Close (1)

16 00017 0 / 1 SIPOD 17 Open (0)/Close (1)

17 00018 0 / 1 SIPOD 18 Open (0)/Close (1)

18 00019 0 / 1 SIPOD 19 Open (0)/Close (1)

19 00020 0 / 1 SIPOD 20 Open (0)/Close (1)

20 00021 0 / 1 SIPOD 21 Open (0)/Close (1)

21 00022 0 / 1 SIPOD 22 Open (0)/Close (1)

22 00023 0 / 1 SIPOD 23 Open (0)/Close (1)

23 00024 0 / 1 SIPOD 24 Open (0)/Close (1)

24 00025 0 / 1 SIPOD 25 Open (0)/Close (1)

25 00026 0 / 1 SIPOD 26 Open (0)/Close (1)

26 00027 0 / 1 SIPOD 27 Open (0)/Close (1)

27 00028 0 / 1 SIPOD 28 Open (0)/Close (1)

28 00029 0 / 1 SIPOD 29 Open (0)/Close (1)

29 00030 0 / 1 SIPOD 30 Open (0)/Close (1)

30 00031 0 / 1 SIPOD 31 Open (0)/Close (1)

31 00032 0 / 1 SIPOD 32 Open (0)/Close (1)

32 00033 0 / 1 SIPOD 33 Open (0)/Close (1)

33 00034 0 / 1 SIPOD 34 Open (0)/Close (1)

34 00035 0 / 1 SIPOD 35 Open (0)/Close (1)

35 00036 0 / 1 SIPOD 36 Open (0)/Close (1)

36 00037 0 / 1 SIPOD 37 Open (0)/Close (1)

37 00038 0 / 1 SIPOD 38 Open (0)/Close (1)

38 00039 0 / 1 SIPOD 39 Open (0)/Close (1)

39 00040 0 / 1 SIPOD 40 Open (0)/Close (1)

40 00041 0 / 1 SIPOD 41 Open (0)/Close (1)

41 00042 0 / 1 SIPOD 42 Open (0)/Close (1)

42-63 ... Reserved

64 00065 0 / 1 Output Group (Zone) 1, Open (0) /Close (1)

65 00066 0 / 1 Output Group (Zone) 2, Open (0) /Close (1)

66 00067 0 / 1 Output Group (Zone) 3, Open (0) /Close (1)

67 00068 0 / 1 Output Group (Zone) 4, Open (0) /Close (1)

68 00069 0 / 1 Output Group (Zone) 5, Open (0) /Close (1)

69 00070 0 / 1 Output Group (Zone) 6, Open (0) /Close (1)

70 00071 0 / 1 Output Group (Zone) 7, Open (0) /Close (1)

71 00072 0 / 1 Output Group (Zone) 8, Open (0) /Close (1)

72 00073 0 / 1 Output Group (Zone) 9, Open (0) /Close (1)

73 00074 0 / 1 Output Group (Zone) 10, Open (0)/Close (1)

74 00075 0 / 1 Output Group (Zone) 11, Open (0)/Close (1)

75 00076 0 / 1 Output Group (Zone) 12, Open (0)/Close (1)

76 00077 0 / 1 Output Group (Zone) 13, Open (0)/Close (1)

Modbus

5 digit address

Value

(Read/Write*) Description

22

Page 25

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Coils

Function code

Modbus

base 0 address

77 00078 0 / 1 Output Group (Zone) 14, Open (0)/Close (1)

78 00079 0 / 1 Output Group (Zone) 15, Open (0)/Close (1)

79 00080 0 / 1 Output Group (Zone) 16, Open (0)/Close (1)

80 00081 0 / 1 Output Group (Zone) 17, Open (0)/Close (1)

81 00082 0 / 1 Output Group (Zone) 18, Open (0)/Close (1)

82 00083 0 / 1 Output Group (Zone) 19, Open (0)/Close (1)

83 00084 0 / 1 Output Group (Zone) 20, Open (0)/Close (1)

84 00085 0 / 1 Output Group (Zone) 21, Open (0)/Close (1)

85 00086 0 / 1 Output Group (Zone) 22, Open (0)/Close (1)

86 00087 0 / 1 Output Group (Zone) 23, Open (0)/Close (1)

87 00088 0 / 1 Output Group (Zone) 24, Open (0)/Close (1)

88 00089 0 / 1 Output Group (Zone) 25, Open (0)/Close (1)

89 00090 0 / 1 Output Group (Zone) 26, Open (0)/Close (1)

90 00091 0 / 1 Output Group (Zone) 27, Open (0)/Close (1)

91 00092 0 / 1 Output Group (Zone) 28, Open (0)/Close (1)

92 00093 0 / 1 Output Group (Zone) 29, Open (0)/Close (1)

93 00094 0 / 1 Output Group (Zone) 30, Open (0)/Close (1)

94 00095 0 / 1 Output Group (Zone) 31, Open (0)/Close (1)

95 00096 0 / 1 Output Group (Zone) 32, Open (0)/Close (1)

96 00097 0 / 1 Output Group (Zone) 33, Open (0)/Close (1)

97 00098 0 / 1 Output Group (Zone) 34, Open (0)/Close (1)

98 00099 0 / 1 Output Group (Zone) 35, Open (0)/Close (1)

99 00100 0 / 1 Output Group (Zone) 36, Open (0)/Close (1)

100 00101 0 / 1 Output Group (Zone) 37, Open (0)/Close (1)

101 00102 0 / 1 Output Group (Zone) 38, Open (0)/Close (1)

102 00103 0 / 1 Output Group (Zone) 39, Open (0)/Close (1)

103 00104 0 / 1 Output Group (Zone) 40, Open (0)/Close (1)

104 00105 0 / 1 Output Group (Zone) 41, Open (0)/Close (1)

105 00106 0 / 1 Output Group (Zone) 42, Open (0)/Close (1)

106 00107 0 / 1 Output Group (Zone) 43, Open (0)/Close (1)

107 00108 0 / 1 Output Group (Zone) 44, Open (0)/Close (1)

108 00109 0 / 1 Output Group (Zone) 45, Open (0)/Close (1)

109 00110 0 / 1 Output Group (Zone) 46, Open (0)/Close (1)

110 00111 0 / 1 Output Group (Zone) 47, Open (0)/Close (1)

111 00112 0 / 1 Output Group (Zone) 48, Open (0)/Close (1)

112 00113 0 / 1 Output Group (Zone) 49, Open (0)/Close (1)

113 00114 0 / 1 Output Group (Zone) 50, Open (0)/Close (1)

114 00115 0 / 1 Output Group (Zone) 51, Open (0)/Close (1)

115 00116 0 / 1 Output Group (Zone) 52, Open (0)/Close (1)

116 00117 0 / 1 Output Group (Zone) 53, Open (0)/Close (1)

117 00118 0 / 1 Output Group (Zone) 54, Open (0)/Close (1)

118 00119 0 / 1 Output Group (Zone) 55, Open (0)/Close (1)

119 00120 0 / 1 Output Group (Zone) 56, Open (0)/Close (1)

120 00121 0 / 1 Output Group (Zone) 57, Open (0)/Close (1)

121 00122 0 / 1 Output Group (Zone) 58, Open (0)/Close (1)

122 00123 0 / 1 Output Group (Zone) 59, Open (0)/Close (1)

123 00124 0 / 1 Output Group (Zone) 60, Open (0)/Close (1)

124 00125 0 / 1 Output Group (Zone) 61, Open (0)/Close (1)

125 00126 0 / 1 Output Group (Zone) 62, Open (0)/Close (1)

126 00127 0 / 1 Output Group (Zone) 63, Open (0)/Close (1)

Modbus

5 digit address

Value

(Read/Write*) Description

23

Page 26

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Discrete inputs

Function code

2 (Read Only) 0 10001 0 / 1 Digital Input 1 Off (0)/On (1)

Modbus

Base 0 address

1 10002 0 / 1 Digital Input 2 Off (0)/On (1)

2 10003 0 / 1 Digital Input 3 Off (0)/On (1)

3 10004 0 / 1 Digital Input 4 Off (0)/On (1)

4 10005 0 / 1 Digital Input 5 Off (0)/On (1)

5 10006 0 / 1 Digital Input 6 Off (0)/On (1)

6 10007 0 / 1 Digital Input 7 Off (0)/On (1)

7 10008 0 / 1 Digital Input 8 Off (0)/On (1)

8 10009 0 / 1 Digital Input 9 Off (0)/On (1)

9 10010 0 / 1 Digital Input 10 Off (0)/On (1)

10 10011 0 / 1 Digital Input 11 Off (0)/On (1)

11 10012 0 / 1 Digital Input 12 Off (0)/On (1)

12 10013 0 / 1 Digital Input 13 Off (0)/On (1)

13 10014 0 / 1 Digital Input 14 Off (0)/On (1)

14 10015 0 / 1 Digital Input 15 Off (0)/On (1)

15 10016 0 / 1 Digital Input 16 Off (0)/On (1)

16 10017 0 / 1 Digital Input 17 Off (0)/On (1)

17 10018 0 / 1 Digital Input 18 Off (0)/On (1)

18 10019 0 / 1 Digital Input 19 Off (0)/On (1)

19 10020 0 / 1 Digital Input 20 Off (0)/On (1)

20 10021 0 / 1 Digital Input 21 Off (0)/On (1)*

21 10022 0 / 1 Digital Input 22 Off (0)/On (1)*

22 10023 0 / 1 Digital Input 23 Off (0)/On (1)*

23 10024 0 / 1 Digital Input 24 Off (0)/On (1)*

24 10025 0 / 1 Digital Input 25 Off (0)/On (1)*

25 10026 0 / 1 Digital Input 26 Off (0)/On (1)*

26 10027 0 / 1 Digital Input 27 Off (0)/On (1)*

27 10028 0 / 1 Digital Input 28 Off (0)/On (1)*

28 10029 0 / 1 Digital Input 29 Off (0)/On (1)*

29 10030 0 / 1 Digital Input 30 Off (0)/On (1)*

30 10031 0 / 1 Digital Input 31 Off (0)/On (1)*

31 10032 0 / 1 Digital Input 32 Off (0)/On (1)*

32 10033 0 / 1 Analog Input 1 Off (0)/On (1)†

33 10034 0 / 1 Analog Input 2 Off (0)/On (1)†

34 - 63 ... Reserved

Modbus

5 digit address

Value

(Read/Only) Description

(*) Indicates only available in hardware version lower than 3 Ref: Holding Register 119).

(†) Indicates that the Analog Compare Register determines the status.

24

Page 27

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Input Registers

Function code

4 (Read Only) 0 30001 Bit-0 Digital Input 1 Off (0)/On (1) Bits read from Right to Left

Modbus

Base 0 address

1 30002 Bit-0 Digital Input 17 Off (0)/On (1)

2 30003 Bit-0 Analog Input 1 Off (0)/On (1) †

3 30004 Reserved

4 30005 Analog Input 1 Value

5 30006 Analog Input 2 Value

6 30007 Reserved

7 30008 Reserved

Modbus

5 digit address

Value

(Read/Only) Description

Bit-1 Digit

Bit-2 Digital Input 3 Off (0)/On (1)

Bit-3 Digital Input 4 Off (0)/On (1)

Bit-4 Digital Input 5 Off (0)/On (1)

Bit-5 Digital Input 6 Off (0)/On (1)

Bit-6 Digital Input 7 Off (0)/On (1)

Bit-7 Digital Input 8 Off (0)/On (1)

Bit-8 Digital Input 9 Off (0)/On (1)

Bit-9 Digital Input 10 Off (0)/On (1)

Bit-10 Digital Input 11 Off (0)/On (1)

Bit-11 Digital Input 12 Off (0)/On (1)

Bit-12 Digital Input 13 Off (0)/On (1)

Bit-13 Digital Input 14 Off (0)/On (1)

Bit-14 Digital Input 15 Off (0)/On (1)

Bit-15 Digital Input 16 Off (0)/On (1)

Bit-1 Digital Input 18 Off (0)/On (1)

Bit-2 Digital Input 19 Off (0)/On (1)

Bit-3 Digital Input 20 Off (0)/On (1)

Bit-4 Digital Input 21 Off (0)/On (1) *

Bit-5 Digital Input 22 Off (0)/On (1) *

Bit-6 Digital Input 23 Off (0)/On (1) *

Bit-7 Digital Input 24 Off (0)/On (1) *

Bit-8 Digital Input 25 Off (0)/On (1) *

Bit-9 Digital Input 26 Off (0)/On (1) *

Bit-10 Digital Input 27 Off (0)/On (1) *

Bit-11 Digital Input 28 Off (0)/On (1) *

Bit-12 Digital Input 29 Off (0)/On (1) *

Bit-13 Digital Input 30 Off (0)/On (1)*

Bit-14 Digital Input 31 Off (0)/On (1) *

Bit-15 Digital Input 32 Off (0)/On (1) *

Bit-1 Analog Input 2 Off (0)/On (1) †

Bits-2-15 Not Used

al Input 2 Off (0)/On (1)

Note

(*) Indicates only available in hardware version lower than 3 Ref: Holding Register 119).

(†) Indicates that the Analog Compare Register determines the status).

25

Page 28

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Holding Registers

Function

code

3 (Read Only) 0 40001 Bit-0 Mask for SIPOD 1 Open (0)/Close (1) Bits read from Right to Left

6 & 16 (Write Only)* Bit-1 Mask for SIPOD 2 Open (0)/Close (1)

Modbus base 0

address

1 40002 Bit-0 Mask for SIPOD 17 Open (0)/Close (1)

2 40003 Bit-0 Mask for SIPOD 33 Open (0)/Close (1)

3 40004 Reserved

4 40005 Bit-0 SIPOD 1 Open (0)/Close (1) Bits read from Right to Left

Modbus

5 digit address

Value

(Read/Write*) Description Note

Bit-2 Mask for SIPOD 3 Open (0)/Close (1)

Bit-3 Mask for SIPOD 4 Open (0)/Close (1)

Bit-4 Mask for SIPOD 5 Open (0)/Close (1)

Bit-5 Mask for SIPOD 6 Open (0)/Close (1)

Bit-6 Mask for SIPOD 7 Open (0)/Close (1)

Bit-7 Mask for SIPOD 8 Open (0)/Close (1)

Bit-8 Mask for SIPOD 9 Open (0)/Close (1)

Bit-9 Mask for SIPOD 10 Open (0)/Close (1)

Bit-10 Mask for SIPOD 11 Open (0)/Close (1)

Bit-11 Mask for SIPOD 12 Open (0)/Close (1)

Bit-12 Mask for SIPOD 13 Open (0)/Close (1)

Bit-13 Mask for SIPOD 14 Open (0)/Close (1)

Bit-14 Mask for SIPOD 15 Open (0)/Close (1)

Bit-15 Mask for SIPOD 16 Open (0)/Close (1)

Bit -1 Mask for SIPOD 18 Open (0)/Close (1)

Bit-2 Mask for SIPOD 19 Open (0)/Close (1)

Bit-3 Mask for SIPOD 20 Open (0)/Close (1)

Bit-4 Mask for SIPOD 21 Open (0)/Close (1)

Bit-5 Mask for SIPOD 22 Open (0)/Close (1)

Bit-6 Mask for SIPOD 23 Open (0)/Close (1)

Bit-7 Mask for SIPOD 24 Open (0)/Close (1)

Bit-8 Mask for SIPOD 25 Open (0)/Close (1)

Bit-9 Mask for SIPOD 26 Open (0)/Close (1)

Bit-10 Mask for SIPOD 27 Open (0)/Close (1)

Bit-11 Mask for SIPOD 28 Open (0)/Close (1)

Bit-12 Mask for SIPOD 29 Open (0)/Close (1)

Bit-13 Mask for SIPOD 30 Open (0)/Close (1)

Bit-14 Mask for SIPOD 31 Open (0)/Close (1)

Bit-15 Mask for SIPOD 32 Open (0)/Close (1)

Bit-1 Mask for SIPOD 34 Open (0)/Close (1)

Bit-2 Mask for SIPOD 35 Open (0)/Close (1)

Bit-3 Mask for SIPOD 36 Open (0)/Close (1)

Bit-4 Mask for SIPOD 37 Open (0)/Close (1)

Bit-5 Mask for SIPOD 38 Open (0)/Close (1)

Bit-6 Mask for SIPOD 39 Open (0)/Close (1)

Bit-7 Mask for SIPOD 40 Open (0)/Close (1)

Bit-8 Mask for SIPOD 41 Open (0)/Close (1)

Bit-9 Mask for SIPOD 42 Open (0)/Close (1)

Bit-10 Not Used

Bit-11 Not Used

Bit-12 Not Used

Bit-13 Not Used

Bit-14 Not Used

Bit-15 Not Used

Bit-1 SIPOD 2 Open (0)/Close (1) Read Only unless corresponding

mask bits are set to 1

Bit-2 SIPOD 3 Open (0)/Close (1)

Bit-3 SIPOD 4 Open (0)/Close (1)

26

Page 29

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Holding Registers

Function

code

Modbus Base 0

address

5 40006 Bit-0 SIPOD 17 Open (0)/Close (1)

6 4007 Bit-0 SIPOD 33 Open (0)/Close (1)

7 40008 Reserved

8 40009 Bit-0 SIPOD 1 Exists (1)/Not Exists (0) Bits read from Right to Left

Modbus

5 digit address

Value

(Read/Write*) Description Note

Bit-4 SIPOD 5 Open (0)/Close (1)

Bit -5 SIPOD 6 Open (0)/Close (1)

Bit-6 SIPOD 7 Open (0)/Close (1)

Bit-7 SIPOD 8 Open (0)/Close (1)

Bit-8 SIPOD 9 Open (0)/Close (1)

Bit-9 SIPOD 10 Open (0)/Close (1)

Bit-10 SIPOD 11 Open (0)/Close (1)

Bit-11 SIPOD 12 Open (0)/Close (1)

Bit-12 SIPOD 13 Open (0)/Close (1)

Bit-13 SIPOD 14 Open (0)/Close (1)

Bit-14 SIPOD 15 Open (0)/Close (1)

Bit-15 SIPOD 16 Open (0)/Close (1)

Bit-1 SIPOD 18 Open (0)/Close (1)

Bit-2 SIPOD 19 Open (0)/Close (1)

Bit-3 SIPOD 20 Open (0)/Close (1)

Bit-4 SIPOD 21 Open (0)/Close (1)

Bit -5 SIPOD 22 Open (0)/Close (1)

Bit-6 SIPOD 23 Open (0)/Close (1)

Bit-7 SIPOD 24 Open (0)/Close (1)

Bit-8 SIPOD 25 Open (0)/Close (1)

Bit-9 SIPOD 26 Open (0)/Close (1)

Bit-10 SIPOD 27 Open (0)/Close (1)

Bit-11 SIPOD 28 Open (0)/Close (1)

Bit-12 SIPOD 29 Open (0)/Close (1)

Bit-13 SIPOD 30 Open (0)/Close (1)

Bit-14 SIPOD 31 Open (0)/Close (1)

Bit-15 SIPOD 32 Open (0)/Close (1)

Bit-1 SIPOD 34 Open (0)/Close (1)

Bit-2 SIPOD 35 Open (0)/Close (1)

Bit-3 SIPOD 36 Open (0)/Close (1)

Bit-4 SIPOD 37 Open (0)/Close (1)

Bit -5 SIPOD 38 Open (0)/Close (1)

Bit-6 SIPOD 39 Open (0)/Close (1)

Bit-7 SIPOD 40 Open (0)/Close (1)

Bit-8 SIPOD 41 Open (0)/Close (1)

Bit-9 SIPOD 42 Open (0)/Close (1)

Bit-10 Not Used

Bit-11 Not Used

Bit-12 Not Used

Bit-13 Not Used

Bit-14 Not Used

Bit-15 Not Used

Bit-1 SIPOD 2 Exists (1)/Not Exists (0)

Bit-2 SIPOD 3 Exists (1)/Not Exists (0)

Bit-3 SIPOD 4 Exists (1)/Not Exists (0)

Bit-4 SIPOD 5 Exists (1)/Not Exists (0)

Bit -5 SIPOD 6 Exists (1)/Not Exists (0)

Bit-6

Bit-7

Bit-8

SIPOD 7 Exists (1)/Not Exists (0)

SIPOD 8 Exists (1)/Not Exists (0)

SIPOD 9 Exists (1)/Not Exists (0)

27

Page 30

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Holding Registers

Function

code

Modbus base 0

address

9 40010 Bit-0 SIPOD 17 Exists (1)/Not Exists (0)

10 40011 Bit-0 SIPOD 33 Exists (1)/Not Exists (0)

11 40012 Reserved

12 40013 Bit-0 SIPOD 1 Failure (1)/Non-Failure (0) Mode Bits read from Right to Left

Modbus

5 digit address

Value

(Read/Write*) Description Note

Bit-9

Bit-10

Bit-11

Bit-12 SIPOD 13 Exists (1)/Not Exists (0)

Bit-13 SIPOD 14 Exists (1)/Not Exists (0)

Bit-14 SIPOD 15 Exists (1)/Not Exists (0)

Bit-15 SIPOD 16 Exists (1)/Not Exists (0)

Bit-1 SIPOD 18 Exists (1)/Not Exists (0)

Bit-2 SIPOD 19 Exists (1)/Not Exists (0)

Bit-3 SIPOD 20 Exists (1)/Not Exists (0)

Bit-4 SIPOD 21 Exists (1)/Not Exists (0)

Bit -5 SIPOD 22 Exists (1)/Not Exists (0)

Bit-6 SIPOD 23 Exists (1)/Not Exists (0)

Bit-7 SIPOD 24 Exists (1)/Not Exists (0)

Bit-8 SIPOD 25 Exists (1)/Not Exists (0)

Bit-9 SIPOD 26 Exists (1)/Not Exists (0)

Bit-10 SIPOD 27 Exists (1)/Not Exists (0)

Bit-11 SIPOD 28 Exists (1)/Not Exists (0)

Bit-12 SIPOD 29 Exists (1)/Not Exists (0)

Bit-13 SIPOD 30 Exists (1)/Not Exists (0)

Bit-14 SIPOD 31 Exists (1)/Not Exists (0)

Bit-15 SIPOD 32 Exists (1)/Not Exists (0)

Bit-1 SIPOD 34 Exists (1)/Not Exists (0)

Bit-2 SIPOD 35 Exists (1)/Not Exists (0)

Bit-3 SIPOD 36 Exists (1)/Not Exists (0)

Bit-4 SIPOD 37 Exists (1)/Not Exists (0)

Bit -5 SIPOD 38 Exists (1)/Not Exists (0)

Bit-6 SIPOD 39 Exists (1)/Not Exists (0)

Bit-7 SIPOD 40 Exists (1)/Not Exists (0)

Bit-8 SIPOD 41 Exists (1)/Not Exists (0)

Bit-9 SIPOD 42 Exists (1)/Not Exists (0)

Bit-10 Not Used

Bit-11 Not Used

Bit-12 Not Used

Bit-13 Not Used

Bit-14 Not Used

Bit-15 Not Used

Bit-1 SIPOD 2 Failure (1)/Non-Failure (0) Mode

Bit-2 SIPOD 3 Failure (1)/Non-Failure (0) Mode

Bit-3 SIPOD 4 Failure (1)/Non-Failure (0) Mode

Bit-4 SIPOD 5 Failure (1)/Non-Failure (0) Mode

Bit -5 SIPOD 6 Failure (1)/Non-Failure (0) Mode

Bit-6 SIPOD 7 Failure (1)/Non-Failure (0) Mode

Bit-7 SIPOD 8 Failure (1)/Non-Failure (0) Mode

Bit-8 SIPOD 9 Failure (1)/Non-Failure (0) Mode

Bit-9 SIPOD 10 Failure (1)/Non-Failure (0) Mode

Bit-10 SIPOD 11 Failure (1)/Non-Failure (0) Mode

Bit-11 SIPOD 12 Failure (1)/Non-Failure (0) Mode

Bit-12 SIPOD 13 Failure (1)/Non-Failure (0) Mode

Bit-13 SIPOD 14 Failure (1)/Non-Failure (0) Mode

SIPOD 10 Exists (1)/Not Exists (0)

SIPOD 11 Exists (1)/Not Exists (0)

SIPOD 12 Exists (1)/Not Exists (0)

28

Page 31

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Holding Registers

Function

code

Modbus Base 0

address

13 40014 Bit-0 SIPOD 17 Failure (1)/Non-Failure (0) Mode

14 40015 Bit-0 SIPOD 33 Failure (1)/Non-Failure (0) Mode

15 40016 Reserved

16 40017 Bit-0 Mask for Digital Input 1 Off (0)/On (1) Bits read from Right to Left

17 40018 Bit-0 Mask for Digital Input 17 Off (0)/On (1)

Modbus

5 digit address

Value

(Read/Write*) Description Note

Bit-14 SIPOD 15 Failure (1)/Non-Failure (0) Mode

Bit-15 SIPOD 16 Failure (1)/Non-Failure (0) Mode

Bit-1 SIPOD 18 Failure (1)/Non-Failure (0) Mode

Bit-2 SIPOD 19 Failure (1)/Non-Failure (0) Mode

Bit-3 SIPOD 20 Failure (1)/Non-Failure (0) Mode

Bit-4 SIPOD 21 Failure (1)/Non-Failure (0) Mode

Bit -5 SIPOD 22 Failure (1)/Non-Failure (0) Mode

Bit-6 SIPOD 23 Failure (1)/Non-Failure (0) Mode

Bit-7 SIPOD 24 Failure (1)/Non-Failure (0) Mode

Bit-8 SIPOD 25 Failure (1)/Non-Failure (0) Mode

Bit-9 SIPOD 26 Failure (1)/Non-Failure (0) Mode

Bit-10 SIPOD 27 Failure (1)/Non-Failure (0) Mode

Bit-11 SIPOD 28 Failure (1)/Non-Failure (0) Mode

Bit-12 SIPOD 29 Failure (1)/Non-Failure (0) Mode

Bit-13 SIPOD 30 Failure (1)/Non-Failure (0) Mode

Bit-14 SIPOD 31 Failure (1)/Non-Failure (0) Mode

Bit-15 SIPOD 32 Failure (1)/Non-Failure (0) Mode

Bit-1 SIPOD 34 Failure (1)/Non-Failure (0) Mode

Bit-2 SIPOD 35 Failure (1)/Non-Failure (0) Mode

Bit-3 SIPOD 36 Failure (1)/Non-Failure (0) Mode

Bit-4 SIPOD 37 Failure (1)/Non-Failure (0) Mode

Bit -5 SIPOD 38 Failure (1)/Non-Failure (0) Mode

Bit-6 SIPOD 39 Failure (1)/Non-Failure (0) Mode

Bit-7 SIPOD 40 Failure (1)/Non-Failure (0) Mode

Bit-8 SIPOD 41 Failure (1)/Non-Failure (0) Mode

Bit-9 SIPOD 42 Failure (1)/Non-Failure (0) Mode

Bit-10 Not Used

Bit-11 Not Used

Bit-12 Not Used

Bit-13 Not Used

Bit-14 Not Used

Bit-15 Not Used

Bit-1 Mask for Digital Input 2 Off (0)/On (1)

Bit-2 Mask for Digital Input 3 Off (0)/On (1)

Bit-3 Mask for Digital Input 4 Off (0)/On (1)

Bit-4 Mask for Digital Input 5 Off (0)/On (1)

Bit -5 Mask for Digital Input 6 Off (0)/On (1)

Bit-6 Mask for Digital Input 7 Off (0)/On (1)

Bit-7 Mask for Digital Input 8 Off (0)/On (1)

Bit-8 Mask for Digital Input 9 Off (0)/On (1)

Bit-9 Mask for Digital Input 10 Off (0)/On (1)

Bit-10 Mask for Digital Input 11 Off (0)/On (1)

Bit-11 Mask for Digital Input 12 Off (0)/On (1)

Bit-12 Mask for Digital Input 13 Off (0)/On (1)

Bit-13 Mask for Digital Input 14 Off (0)/On (1)

Bit-14 Mask for Digital Input 15 Off (0)/On (1)

Bit-15 Mask for Digital Input 16 Off (0)/On (1)

Bit-1 Mask for Digital Input 18 Off (0)/On (1)

Bit - 2 Mask for Digital Input 19 Off (0)/On (1)

29

Page 32

Appendix C

Modbus Coils, Discrete Inputs, Input Registers & Holding Registers Address Tables

Holding Registers

Function

code

Modbus base 0

address

18 40019 Bit - 0 Control for Digital Input 1 Off (0)/On (1) Bits read from Right to Left

19 40020 Bit - 0 Control for Digital Input 17 Off (0)/On (1)

20 40021

21 40022

22 40023 Analog Output 1 Set (see “Analog In/Out” )

23 40024 Analog Output 2 Set (see “Analog In/Out” )

24 40025 Bit - 0

Modbus

5 digit address

Value

(Read/Write*) Description Note

Bit - 3 Mask for Digital Input 20 Off (0)/On (1)

Bit - 4 Mask for Digital Input 21* Off (0)/On (1)

Bit - 5 Mask for Digital Input 22* Off (0)/On (1)

Bit - 6 Mask for Digital Input 23* Off (0)/On (1)

Bit - 7 Mask for Digital Input 24* Off (0)/On (1)