Siemens HZM Installation Instructions Manual

HZM HZM

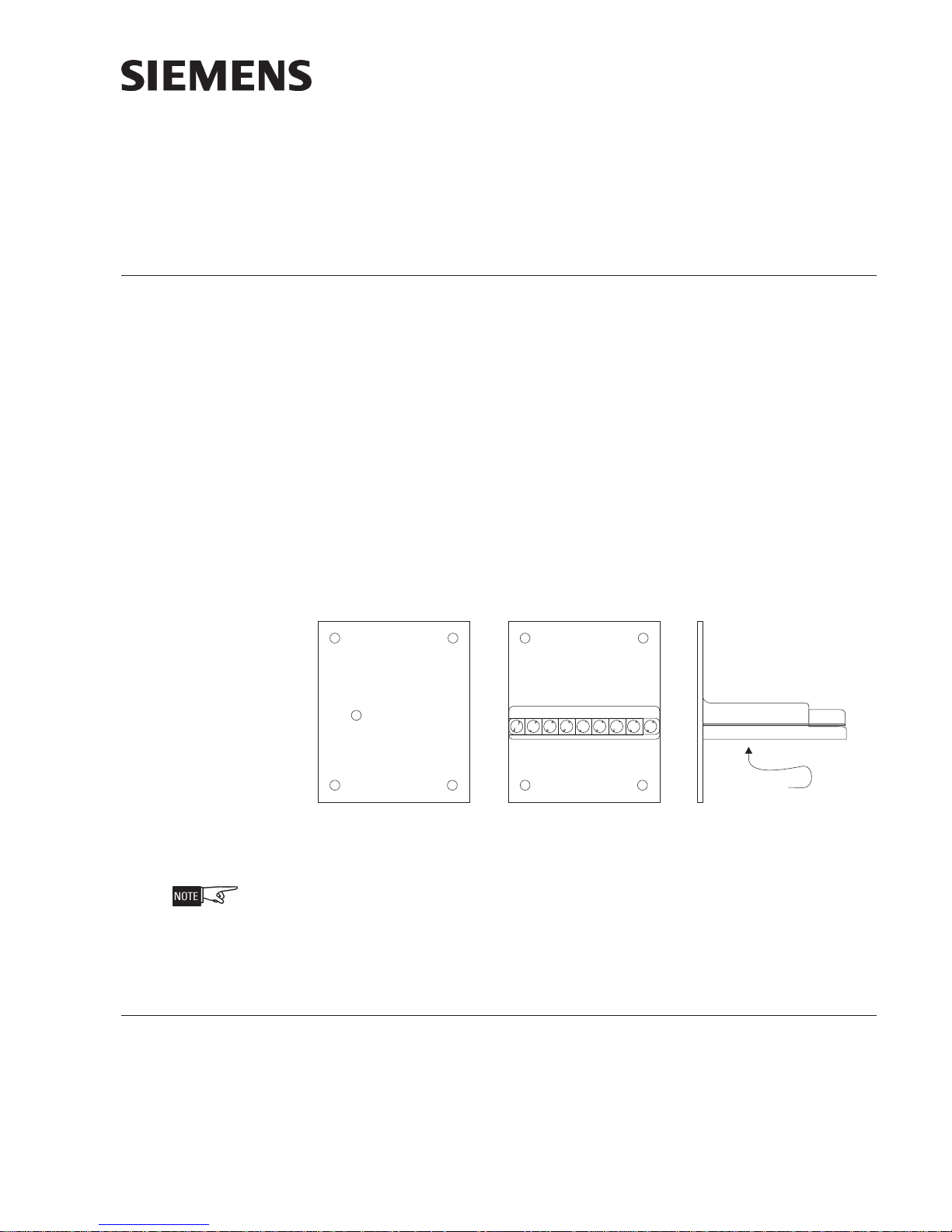

FRONT BACK SIDE

ALARM

1 2 3 456 7 8 9

PROGRAMMING

POINTS

Installation Instruct ions

Model HZM

Remote Conventional Zone Module

INTRODUCTION The Model HZM from Siemens Industry, Inc. is an intelligent device that connects a

single zone of conventional devices to a DLC (FireFinder-XLS System) or FS-DLC (FS250 System) device loop. The HZM can power up to fifteen compatible 2-wire, ionization or photoelectric smoke detectors or it can power one PB-1191 Beam Detector. It

can also monitor an unlimited number of shorting devices such as waterflow switches,

thermal detectors, manual stations, etc.

Each HZM can be assigned a custom message using either the Zeus Programming

Tool (FireFinder-XLS System) or the FS-CT2 (FS-250 System). Refer to the Zeus Quick

Start Manual, P/N 315-033875, or the FS-250 Programming Manual, P/N 315-049403,

as applicable. The alarm verification configuration is used only for non-shorting detectors.

The HZM supports Class A and Class B wiring. The module uses one address on the

device loop. It does not require any mechanical address programming. Use the DPU

Device Programming Unit to program and test the module.

Figure 1

HZM Module

The HZM is not listed for use in mass notification applications.

Controls And Indicators The HZM has a multicolor LED, visable through the cover plate, which indicates the

condition of the circuit. This multicolor LED displays red for alarm, yellow for trouble,

and green for normal operation (See Figure 1).

PRE-INSTALLATION Setting The Module Address

P/N 315-034850-8

1. Using the DPU Device Programming Unit, plug the programming cable into

the programming points on the HZM (See Figure 1).

2. Set the address for the HZM by following the instructions in the DPU

Manual, P/N 315-033260.

Building Building

Building

Building Building

Siemens Siemens

Siemens

Siemens Siemens

TT

ecec

hnologies Dihnologies Di

T

ec

hnologies Di

TT

ecec

hnologies Dihnologies Di

IndustryIndustry

Industry

IndustryIndustry

visionvision

vision

visionvision

,,

Inc. Inc.

,

Inc.

,,

Inc. Inc.

INSTALLATION

S

2

S

Remove all system power before installation, first battery then AC. (To power up,

connect the AC first, then the battery.)

Electrical Connections After you have set the HZM address, connect the field wiring.

connections

to the HZM: initiating devices, DLC or FS-DLC device loop, and 24 VDC

power. All terminals are power limited.

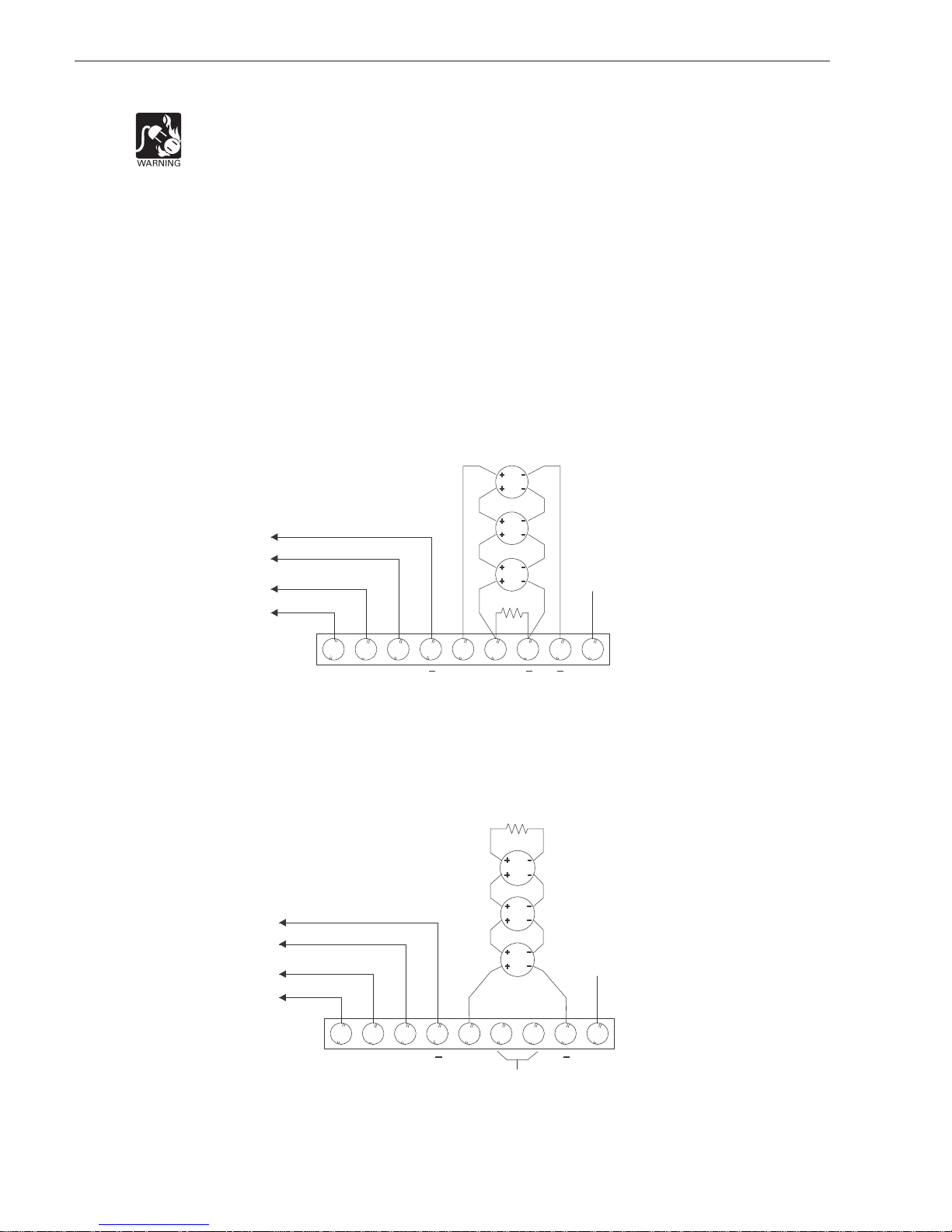

Initiating Devices (Figures 2, 3, and 4)

The HZM supports one zone of initiating devices in either Class A or Class B. The

initiating devices are connected to terminals 5–8 on the HZM terminal block. The

HZM is a polarity insensitive module and terminals 1 and 2 can be connected to

either line of the DLC or FS-DLC Device Loop. Figure 2 shows the Class A wiring.

Figure 3 shows the Class B wiring.

TYLE D/CLASS A

24VDC POWER

LINE 2

DEVICE LOOP

LINE 1

1

3

2

+++

5 6 7 8 9

4

* EOL DEVICE IS 4.7K, 1/4W (P/N 140-820188)

FOR CANADIAN APPLI CATIONS, USE MODEL †

EL-33 WITH 4.7K, 1/4W RESISTOR.

(DCLA)

EARTH

EOL * †

NOTES

1. Wire 18 AWG minimum, 12

2. Supervised, power limited to

3. Voltage 24VDC.

4. Positive and negative ground

Figure 2

HZM Initiating Devices Wiring Diagram

Class A/Style D (ULC DCLA) Installation

TYLE B/CLASS B

(DCLB)

EOL*

†

* EOL DEVICE IS 4.7K,

1/4W (P/N 140-820188)

FOR CANADIAN APPLICATIONS,†

USE MODEL EL-33 WITH

4.7K, 1/4W RESISTOR.

There are three basic

AWG maximum, 35 ohms Max.

NFPA 70 per NEC 760.

fault detected at <60K ohms

for terminals 5-8.

4VDC POWER

LINE 2

DEVICE LOOP

LINE 1

Figure 3

HZM Initiating Devices Wiring Diagram

Class B/Style B (ULC DCLB) Installation

Siemens Industry, Inc.

Building Technologies Division

EARTH

NOTES

1. Wire 18 AWG minimum, 12

1

2

3

5

4

6 7 8 9

++

NOT USED

AWG maximum, 35 ohms Max.

(both sides)

2. Supervised, power limited to

NFPA 70 per NEC 760.

3. Voltage 24VDC.

4. Positive and negative ground

fault detected at <60K ohms

for terminals 5, 8.

P/N 315-034850-82

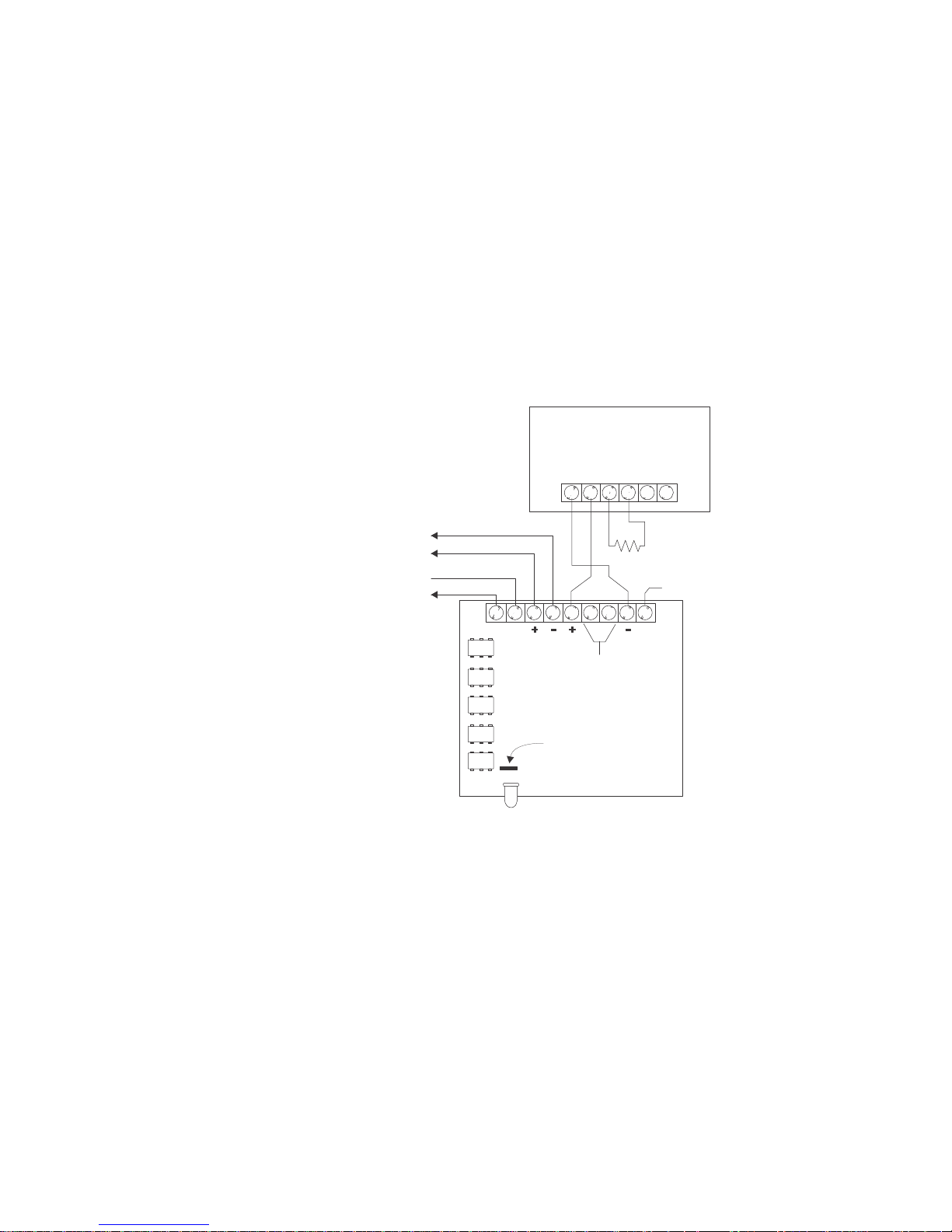

Figure 4 shows the wiring for the PB-1191 beam detector. When the PB-1191 is used,

R

D

the 2-position plug from jumper J1 must be removed.

Follow the steps listed below to remove the 2-position plug from J1:

a. Remove the screw from the center of the HZM plastic cover and place it to

one side.

b. Remove the circuit board and locate jumper J1.

c. Remove the 2-position plug from J1.

d. Reassemble the circuit board and plastic cover using the screw that was

removed in the first step.

e. Be sure to use the correct end of line device with the HZM in this configuration.

BEAM DETECTOR WIRING

CLASS B/STYLE B

(ULC DCLB)

O NOT CONNECT MORE THAN

ONE PB-1191 TO AN HZM

PB-1191

A B C D

E

F

3.6K, 1/4W

24VDC POWER

DLC DEVICE LOOP

LINE 2

LINE 1

1 2 3 4

5

6 7 8 9

NOT USED

EOL RESISTO

P/N 140-820185

EARTH

HZM

J1

NOTE:

Positive and negative ground fault detected at <60K ohms for terminals 5, 8.

Figure 4

HZM Wiring Diagram For PB-1191 Installation

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034850-83

Loading...

Loading...