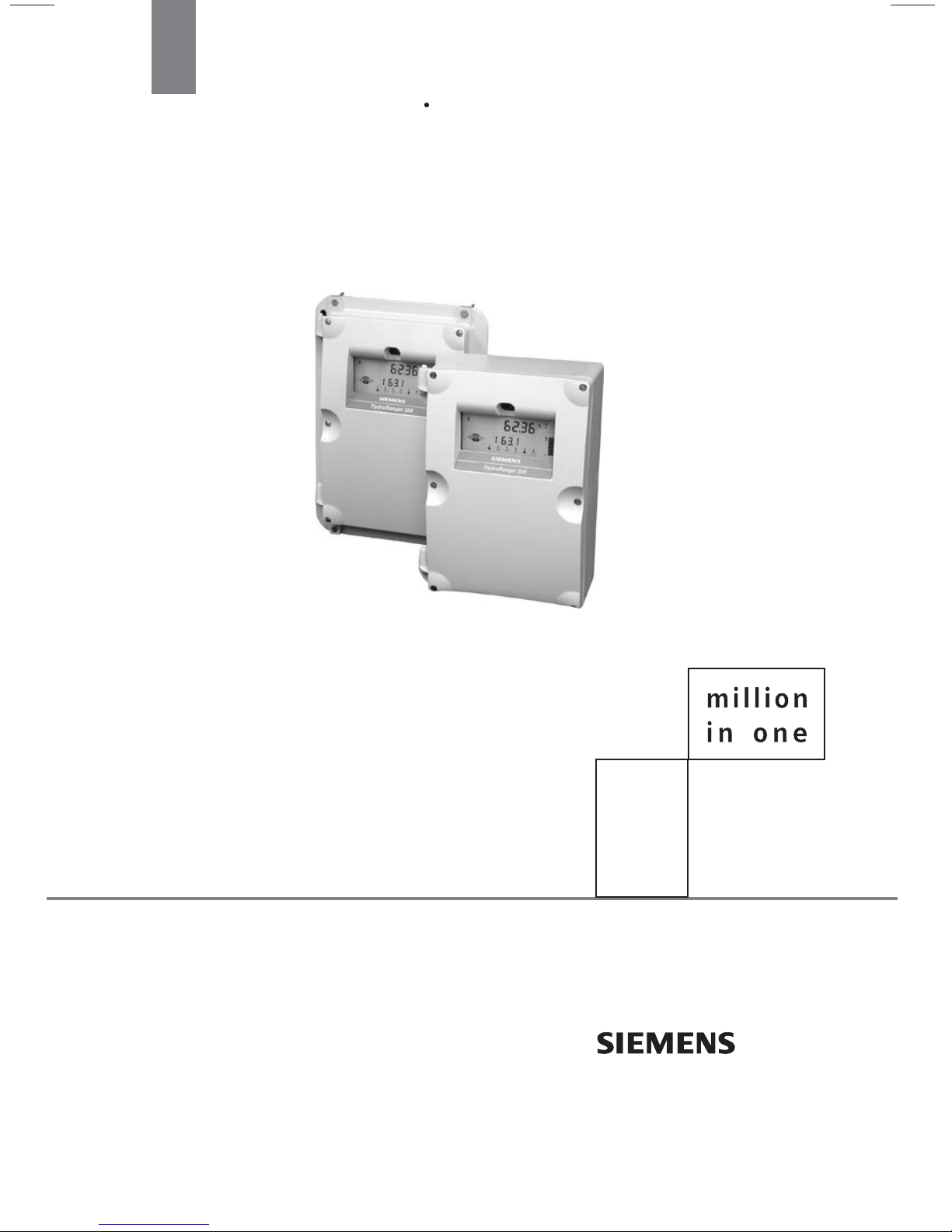

Siemens HydroRanger 200 Instruction Manual

Instruction Manual July 2009

hydroranger

200

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

• All new components are to be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: Cardboard shipping package provides limited humidity and moisture protection. This product

can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and

maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2009. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions

as designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic

versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent

editions. We welcome all suggestions for

improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens Milltronics Process Instruments Inc. Industry Sector

1954 Technology Drive, P.O. Box 4225 76181 Karlsruhe

Peterborough, Ontario, Canada, K9J 7B1 Deutschland

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

© Siemens Milltronics Process Instruments Inc. 2009

Table of Contents

Table of Contents

The HydroRanger 200 ................................................................................................................................1

HydroRanger 200 [1 or 3 relay model] ......................................................................................1

HydroRanger 200 [6 relay model] ..............................................................................................1

The Manual ...............................................................................................................................................1

Manual Symbols ............................................................................................................................2

Configuration Examples ...............................................................................................................2

Specifications ...............................................................................................................................................3

Installation ......................................................................................................................................................8

Mounting ...................................................................................................................................................8

Mounting Locations ......................................................................................................................8

Mounting Instructions ..................................................................................................................9

Wall Mount ........................................................................................................................... 9

Cable routed through a conduit:.................................................................................... 10

Panel Mount....................................................................................................................... 11

Mounting the Enclosure .................................................................................................. 12

HydroRanger 200 Board ............................................................................................................13

Installing the Battery ..................................................................................................................13

Installing SmartLinx Card ..........................................................................................................14

mmmmm

Wiring ..............................................................................................................................................................15

Terminal Board .......................................................................................................................................16

Cables .......................................................................................................................................................16

Transducers ............................................................................................................................................17

Relays .......................................................................................................................................................17

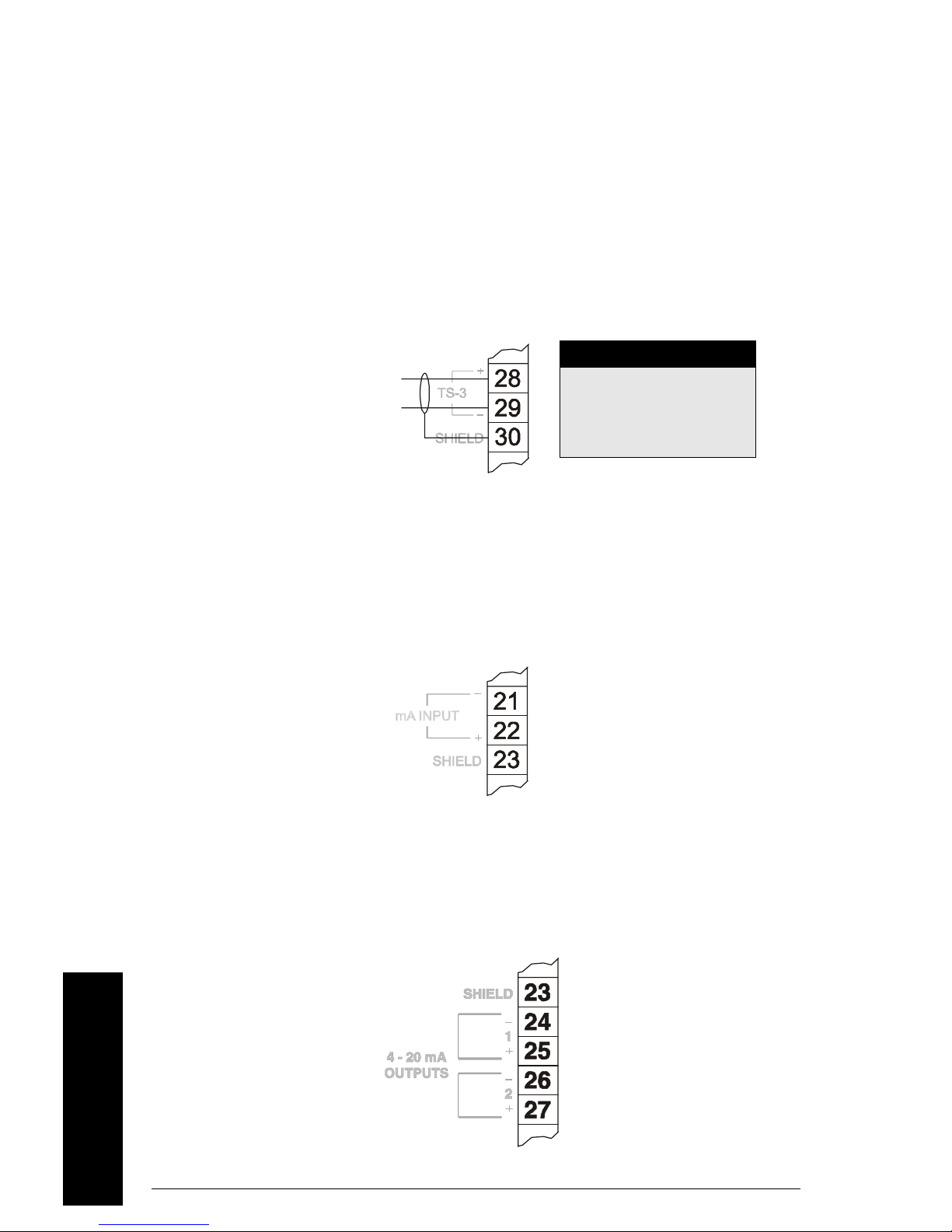

Temperature Sensor .............................................................................................................................18

mA Input [6 relay model] .....................................................................................................................18

mA Output ...............................................................................................................................................18

Level System Synchronization ...........................................................................................................19

Power .......................................................................................................................................................19

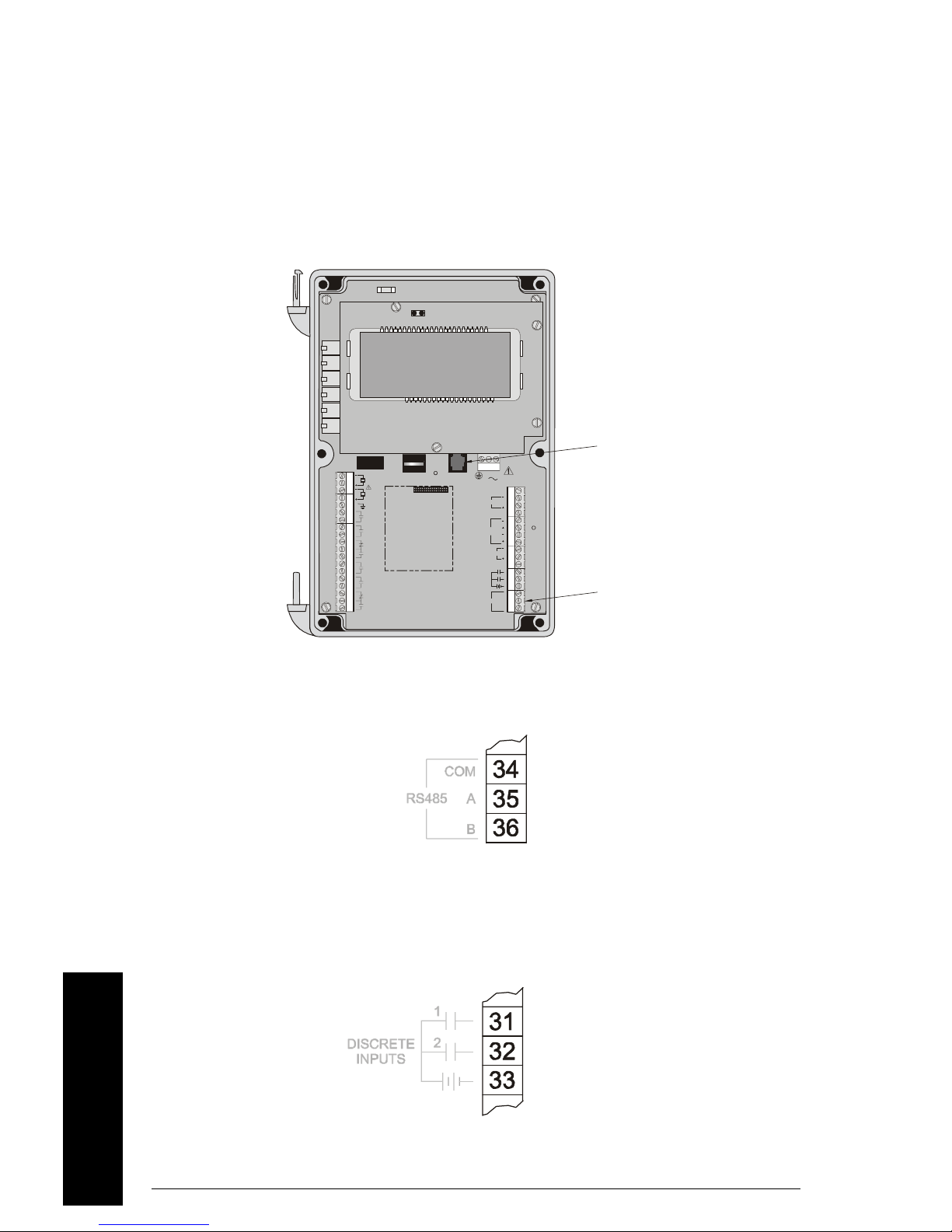

Digital Communications .......................................................................................................................20

RS-232 Serial Connection ..........................................................................................................20

RS-485 Serial Connection ..........................................................................................................20

Discrete Inputs................................................................................................................... 20

Operating the HydroRanger 200 ........................................................................................................21

RUN Mode ..............................................................................................................................................21

Readings in RUN Mode .......................................................................................................................22

Status Parameters ................................................................................................................................23

Controlling the Display .........................................................................................................................24

Adjusting the primary reading for four-digit LCD readout:...................................... 24

Auxiliary Reading ........................................................................................................................24

Multiple Readings [6 relay model] ..........................................................................................25

PROGRAM Mode ..................................................................................................................................26

Starting PROGRAM Mode ..................................................................................................................26

i

mmmmm

Hand Programmer .......................................................................................................................26

Programmer Keys ........................................................................................................................27

Dolphin Plus ............................................................................................................................................28

Dolphin Plus Toolbar Buttons ...................................................................................................29

SIMATIC Process Device Manager (PDM) .....................................................................................30

Device Description ......................................................................................................................30

Activating the HydroRanger 200 ........................................................................................................31

Changing Parameters .................................................................................................................31

Table o f Cont en ts

Security ....................................................................................................................................................32

Using Units or Percent (%) ..................................................................................................................32

Parameters Types ..................................................................................................................................32

Parameter Reset ....................................................................................................................................33

Display Readout .....................................................................................................................................33

Parameter Indexing ....................................................................................................................34

Primary and Secondary Indexes .......................................................................................................35

Primary Index..................................................................................................................... 35

Secondary Index................................................................................................................ 35

Starting Measurement ........................................................................................................................36

Single Point Models ....................................................................................................................36

Average or Differential [6 relay model]........................................................................ 37

Dual Point Models .......................................................................................................................37

Average or Differential [6 relay model]........................................................................ 37

Measurement Conditions ..........................................................................................................38

Response Rate................................................................................................................... 38

Dimensions [6 relay model] ............................................................................................ 38

Failsafe................................................................................................................................. 38

Relays ...............................................................................................................................................................39

General Introduction ...................................................................................................................39

Relay Function ............................................................................................................................39

Alarm.................................................................................................................................... 39

Pump..................................................................................................................................... 40

Miscellaneous.................................................................................................................... 40

Relay Status – Non Run Modes .................................................................................... 41

Relay States ..................................................................................................................................41

Relay Related Parameters ........................................................................................................41

Relay Wiring Test.............................................................................................................. 42

Relay Activation ...........................................................................................................................42

Relay Failsafe ...............................................................................................................................43

Preset Applications ...............................................................................................................................44

Backup Level Override ...........................................................................................................................45

Backup Level Override Parameters ..................................................................................................45

Discrete Inputs ...........................................................................................................................................46

Wiring the Discrete Inputs ..................................................................................................................46

Programming the Discrete Input Logic ............................................................................................46

mA I/O ..............................................................................................................................................................47

mA Input [6 relay model] .....................................................................................................................47

ii

mA Output ...............................................................................................................................................47

Volume [6 relay model] ...........................................................................................................................49

Readings ..................................................................................................................................................49

Tank Shape and Dimensions ..............................................................................................................49

Characterization Chart [6 relay model] ............................................................................................50

Example Chart ..............................................................................................................................50

HydroRanger 200 [6 relay model] ............................................................................................51

Alarms .............................................................................................................................................................52

Level ..........................................................................................................................................................52

Setting Simple Level Alarms .....................................................................................................53

Rate [6 relay model] ..............................................................................................................................53

In Bounds/ Out of Bounds Range [6 relay model] .........................................................................54

Cable Fault ..............................................................................................................................................54

Temperature [6 relay model] ...............................................................................................................54

Loss of Echo (LOE) .................................................................................................................................55

Pump Control ...............................................................................................................................................56

Setting a Pump Down Group ..............................................................................................................56

Setting a Pump Up (Reservoir) Group ..............................................................................................57

Other Pump Control Algorithms .........................................................................................................59

Set Relays to ALTERNATE DUTY BACKUP [6 relay model] ...............................................59

Set Relays to FIXED DUTY ASSIST ........................................................................................59

Set Relays to FIXED DUTY BACKUP [6 relay model] ..........................................................60

Set Relays to ALTERNATE DUTY SERVICE [6 relay model] ...............................................60

Set Relays to FIRST IN FIRST OUT (FIFO) ASSIST [6 relay] ..............................................61

Optional Pump Controls .......................................................................................................................61

Starting Pumps by Rate of Level Change [6 relay model] .................................................61

Rotating Pumps by Service Ratio [6 relay model] ...............................................................62

Totalizing Pumped Volume [6 relay model] ...........................................................................63

Setting Independent Failsafe Controls ...................................................................................63

Setting a Pump to Run On [6 relay model] ............................................................................64

Setting the Pump Start Delays [6 relay model] ....................................................................64

Reducing Wall Cling [6 relay model] .......................................................................................64

Grouping Pumps [6 relay model] .............................................................................................65

Setting a Flush Valve [6 relay model] .....................................................................................65

Relay Controlled by Communications ....................................................................................66

Tracking Pump Usage ..........................................................................................................................66

Table of Contents

mmmmm

Rake (Screen) Control [6 relay model] ...........................................................................................67

Setting a Rake Control .........................................................................................................................67

Setting the Common Parameters ............................................................................................68

Set Relay 1 (Operate Rake) .......................................................................................................68

Set Relays 2 to 4 (Level Alarms) ..............................................................................................68

External Totalizers and Flow Samplers [6 relay model] ......................................................69

Relay Contacts .......................................................................................................................................69

Totalizer ....................................................................................................................................................69

Flow Sampler ..........................................................................................................................................70

iii

mmmmm

Based on Volume and Time ......................................................................................................70

Open Channel Monitoring (OCM)

[6 relay model]

Table o f Cont en ts

Common Parameters ............................................................................................................................71

Setting Zero Head .......................................................................................................................72

Setting Totalized Volume .....................................................................................................................73

Applications Supported by HydroRanger 200 [6 relay model] ...................................................73

PMDs with Exponential Flow to Head Function ............................................................................77

Applicable Weir Profiles ............................................................................................................77

Non-Applicable Weir Profiles ..................................................................................................78

Parshall Flume ..............................................................................................................................78

Leopold Lagco Flume ..................................................................................................................79

Cut Throat Flume .........................................................................................................................80

Universal Calculation Support ...........................................................................................................81

Typical Flow Characterization ..................................................................................................81

Example Flumes ...........................................................................................................................82

Example Weirs .............................................................................................................................82

............................................................................................................................................71

BS-3680 / ISO 1438/1 Thin plate V notch weir ............................................................ 73

BS-3680 / ISO 4359 Rectangular Flume........................................................................ 74

Palmer Bowlus Flume ...................................................................................................... 75

H Flume................................................................................................................................ 76

Testing the Configuration ......................................................................................................................83

Simulation ...............................................................................................................................................83

Simulating a Single Measurement ...................................................................................................83

Simulating a Level Cycle ......................................................................................................................83

Checking Volume Characterization [6 relay model] ......................................................................84

Checking OCM Flow Characterization [6 relay model] ................................................................84

I/O Checkout ...........................................................................................................................................85

Application Test .....................................................................................................................................85

HydroRanger 200 Communications .................................................................................................87

HydroRanger 200 Communication Systems ...................................................................................87

Optional SmartLinx®Cards ................................................................................................................88

Communication Systems .....................................................................................................................88

Communication Ports ...........................................................................................................................88

Modbus ..........................................................................................................................................89

SmartLinx ................................................................................................................................................89

Dolphin Plus ............................................................................................................................................89

Communications Installation .............................................................................................................90

Wiring Guidelines ..................................................................................................................................90

Ports 1 and 2 .................................................................................................................................90

Ports 1 and 2: RS-232 RJ-11 Jack and RS-485 Locations ..................................................90

Port 1: RS-232 RJ-11 Jack ..........................................................................................................91

Port 2: RS-485 ...............................................................................................................................91

Configuring Communication Ports (Parameters) ...........................................................................92

iv

Modbus Register Map ............................................................................................................................95

Word Order (R40,062) ..........................................................................................................................96

Map ID (R40,063) ....................................................................................................................................96

Product ID (R40,064) ..............................................................................................................................97

Point Data (R41,010 – R41,031) ............................................................................................................97

Totalizer (R41,040 – R41,043) ................................................................................................................97

Input/Output (R41,070 – R41,143) .........................................................................................................98

Discrete Inputs (R41,070) ..........................................................................................................98

Relay Outputs (R41,080) ..............................................................................................................98

mA Input (R41,090) [6 relay model] ..........................................................................................98

mA Output (R41,110-41,111) ........................................................................................................98

Pump Control (R41,400 – R41,474) ............................................................................................98

Pump ON Setpoint (R41,420 – R41,425) ...................................................................................98

Pump OFF Setpoint (R41,430 – R41,435) .................................................................................99

Pumped Volume (R41,440 – R41,443) [6 relay model] ..........................................................99

Pump Hours (R41,450 – R41,461) .............................................................................................99

Pump Starts (R41,470 – R41,475) ..............................................................................................99

Parameter Access (R43,998 – R46,999) ............................................................................... 100

Parameter Indexing ................................................................................................................. 100

Indexing the Parameter Access Area....................................................................... 100

Reading Parameters .................................................................................................................101

Global Index Method (P782 = 0).................................................................................. 101

Parameter Specific Index Method (P782 = 1) ......................................................... 102

Writing Parameters .................................................................................................................. 102

Global Index Method (P782 = 0).................................................................................. 102

Parameter Specific Index Method (P782 = 1).......................................................... 102

Format Words (R46,000 to R46,999) ............................................................................................... 103

Global Index Method (P782 = 0) ............................................................................................ 103

Parameter-Specific Index Method (P782 = 1) .................................................................... 103

Format Registers ...................................................................................................................... 103

Table of Contents

mmmmm

Data Types .................................................................................................................................................. 105

Numeric Values .................................................................................................................................. 105

Bit Values .............................................................................................................................................. 105

Unsigned Double Precision Integer (UINT32) ............................................................................ 105

Split Values .......................................................................................................................................... 106

Text Messages .................................................................................................................................... 107

Relay Function Codes (P111 Only) ................................................................................................. 108

Error Handling .......................................................................................................................................... 109

Modbus Responses ........................................................................................................................... 109

Error Handling ..................................................................................................................................... 109

Communication Troubleshooting ...................................................................................................111

Generally ...............................................................................................................................................111

Specifically ............................................................................................................................................ 111

Communication Appendix A: Single Parameter Access (SPA) .....................................112

Mapping .................................................................................................................................................112

v

Reading Parameters ...........................................................................................................................112

Writing Parameters .............................................................................................................................113

Format Register ...................................................................................................................................113

Error Codes ...........................................................................................................................................114

mmmmm

Parameter Reference ............................................................................................................................115

HydroRanger 200 - 1, 3, or 6 relay models .....................................................................................115

Table o f Cont en ts

Helpful Hints .........................................................................................................................................115

Index types ............................................................................................................................................116

Quick Start (P001 to P007) .................................................................................................................117

For DPD and DPA Programming [6 relay model].................................................... 118

Volume (P050 to P055) [6 relay model] ...........................................................................................121

Display and Reading (P060 to P062) ..............................................................................................126

Backup Level Override .......................................................................................................................128

Failsafe (P070 to P072) ......................................................................................................................130

Relays (P100 to P119) .........................................................................................................................131

HydroRanger 200 [6 relay model] ............................................................................... 133

Pump Setpoint Modifiers (P121 and P122) [6 relay model] .......................................................138

Independent Relay Failsafe (P129) .................................................................................................139

Advanced Pump Control Modifiers (P130 to P137) [6 relay model] .........................................140

Flush Systems (P170 to P173) [6 relay model] ..............................................................................143

mA Output (P200 to P219) ..................................................................................................................145

Independent mA Setpoints (P210 and P211) .................................................................................148

mA Output Limits (P212 and P213) ...................................................................................................148

mA Output Trim (P214 to P215) .........................................................................................................149

mA Output Failsafe (P219) [6 relay model] ....................................................................................150

mA Input (P250 to P260) [6 relay model] ........................................................................................150

Discrete Input Functions (P270 to P275) .......................................................................................153

Standard Data Logging (P300 to P321) .........................................................................................154

Record Temperatures (P300 to P303) ............................................................................................154

Record Readings (P304 and P305) .................................................................................................156

Pump Records (P309 to P312) ...........................................................................................................156

Flow Records (P320 and P321) [6 relay model] ............................................................................157

LCD Totalizer (P322 and P323) [6 relay model] .............................................................................158

Profile Records (P330 to P337) ........................................................................................................159

Auto Record ON and OFF Setpoints (P334 to P337) ....................................................................162

Installation Records (P340 to P342) ...............................................................................................164

Open Channel Monitoring (P600 to P621) [6 relay model] ........................................................165

Example Exponents........................................................................................................ 167

Pumped Volume Totalizer (P622) [6 relay model] ........................................................................174

Totalizer (P630 to P645) [6 relay model] .........................................................................................175

Range Calibration (P650 to P654) ....................................................................................................178

Temperature Compensation (P660 to P664) ..................................................................................181

Rate (P700 to P708) ............................................................................................................................183

Measurement Verification (P710 to P713) ....................................................................................187

Transducer Scanning (P726 to P729) .............................................................................................190

Display (P730 to P739) .......................................................................................................................191

SmartLinx Reserved (P750 to P769) ...............................................................................................194

Communications (P770 to P782) .....................................................................................................194

SmartLinx Hardware Testing (P790 to P795) ................................................................................197

vi

Echo Processing (P800 to P807) ......................................................................................................199

Advanced Echo Processing (P815 to P825) ................................................................................. 203

Advanced TVT Adjustment (P830 to P835) .................................................................................. 207

Advanced Shot Adjustment (P840 to P852) ..................................................................................212

Test (P900 to P913) ..............................................................................................................................215

Measurement (P920 to P927) ...........................................................................................................218

Master Reset (P999) ......................................................................................................................... 221

Appendix A: Index Types .................................................................................................................... 223

Index types ........................................................................................................................................... 223

Appendix B: Technical Reference ................................................................................................ 224

Transmit Pulse ..................................................................................................................................... 224

Echo Processing ................................................................................................................................. 224

TVT (Time Varying Threshold) curves ........................................................................................... 225

Auto False-Echo Suppression ............................................................................................... 225

Distance Calculation ......................................................................................................................... 226

Sound Velocity .................................................................................................................................... 226

Scanning ............................................................................................................................................... 227

Volume Calculation [6 relay model] ............................................................................................... 227

Universal, Curved [6 relay model] ........................................................................................ 228

Flow Calculation [6 relay model] .................................................................................................... 228

Universal, Linear [6 relay model] .......................................................................................... 229

Universal, Curved [6 relay model] ........................................................................................ 229

Maximum Process Speed ................................................................................................................ 230

Table of Contents

mmmmm

Appendix C: Troubleshooting ........................................................................................................... 231

Common Problems Chart ................................................................................................................. 231

Noise Problems ................................................................................................................................... 232

Determine the Noise Source ................................................................................................. 232

Non-Transducer Noise Sources ........................................................................................... 233

Common Wiring Problems ..................................................................................................... 233

Reducing Electrical Noise ......................................................................................................233

Reducing Acoustical Noise .................................................................................................... 233

Measurement Difficulties ................................................................................................................. 234

Flashing LOE Display ............................................................................................................... 234

Adjust Transducer Aiming ........................................................................................... 234

Increase Failsafe Timer Value .................................................................................... 235

Install a Transducer with a Narrower Beam........................................................... 235

Use Dolphin Plus to Debug Echo................................................................................ 235

Fixed Reading ...................................................................................................................................... 235

Obstructions in the Sound Beam ......................................................................................... 235

Nozzle Mountings .................................................................................................................... 235

Set the HydroRanger 200 to Ignore the Bad Echo ........................................................... 236

Wrong Reading ................................................................................................................................... 236

Types of Wrong Readings ...................................................................................................... 236

Liquid Splashing ........................................................................................................................ 236

Adjust the Echo Algorithm ..................................................................................................... 236

Transducer Ringing ............................................................................................................................ 237

vii

mmmmm

Unit Repair and Excluded Liability ....................................................................................... 238

Appendix D: Pump Control Reference ........................................................................................ 239

Pump Control Options ....................................................................................................................... 239

Pump Groups ............................................................................................................................. 239

Pump by Rate [6 relay model] ................................................................................................ 239

Pump Control Algorithms ................................................................................................................. 239

Fixed Duty Assist (P111 = 50) ................................................................................................. 240

Table o f Cont en ts

Fixed Duty Backup (P111 = 51) [6 relay model] .................................................................. 240

Alternate Duty Assist (P111 = 52) ........................................................................................ 241

Alternate Duty Backup (P111 = 53) [6 relay model] .......................................................... 241

Service Ratio Duty Assist (P111 = 54) [6 relay model] ..................................................... 242

Service Ratio Duty Backup (P111 = 55) [6 relay model] ................................................... 243

First In First Out (FIFO) (P111 = 56) [6 relay model] ........................................................... 243

Pump by Rate (P121) [6 relay model] ................................................................................... 243

Other Pump Controls [6 relay model] ............................................................................................243

Appendix E: Updating Software ..................................................................................................... 245

Updating Software ............................................................................................................................. 245

Appendix F: Upgrading ........................................................................................................................ 246

Mounting a HydroRanger 200 (all models) ........................................................................ 246

Connecting the Transducer ................................................................................................... 246

Coaxial Transducer Extention..................................................................................... 246

Connecting a transducer with RG62 coaxial extension cable............................. 247

HydroRanger to HydroRanger 200 Parameters ................................................................ 248

Appendix G: Conduit Entry for Class 1, Div 2 Applications ............................................. 249

Appendix H: Software Revision History .................................................................................... 251

Programming Charts ............................................................................................................................. 255

viii

The HydroRanger 200

The HydroRanger 200 is available in two models, a 1 or 3 relay model, and a 6 relay model,

and is designed for a variety of applications:

• water and wastewater

• storage tanks, for measuring liquids, slurries, and solids

• hoppers, ore bunkers, flotation cells

HydroRanger 200 [1 or 3 relay model]

This model of the HydroRanger 200 is a single point level, one or three relay measurement

device. It is equipped with digital communications and offers the latest in echo

processing technology and diagnostic features.

HydroRanger 200 [6 relay model]

This model of the HydroRanger 200 is a single or dual-point, six relay device that offers

both level and volume measurement. It has Open Channel Monitoring capabilities, a

larger number of advanced pump control algorithms, and is equipped with digital

communications. It offers the latest in echo processing technology and diagnostic

features.

HydroRanger 200

mmmmm

The Manual

Notes:

• This product is intended for use in industrial areas. Operation of this equipment

in a residential area may cause interference to several frequency based

communications.

• Please follow the installation and operating procedures for a quick, trouble-free

installation and to ensure the maximum accuracy and reliability of your

HydroRanger 200.

The manual provides instruction for both models of the HydroRanger 200. For your

convenience, the manual uses HydroRanger 200 (1 or 3 relay model) features as its

standard content. Additional HydroRanger 200 features are clearly marked.

The manual is designed to help you get the most out of your HydroRanger, and it provides

information on the following:

• How to program the unit

• Example applications

• Principles of operation

• Parameter values

• Parameter uses

• Outline diagrams

• Wiring diagrams

• Installation requirements

•Modbus®1 register mapping

• Modem configuration

1.

Modbus is a registered trademark of Schneider Electric.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 1

If you have any questions, comments, or suggestions about the manual contents, please

email us at techpubs.smpi@siemens.com.

For the complete library of Siemens Milltronics manuals, go to

www.siemens.com/processautomation

.

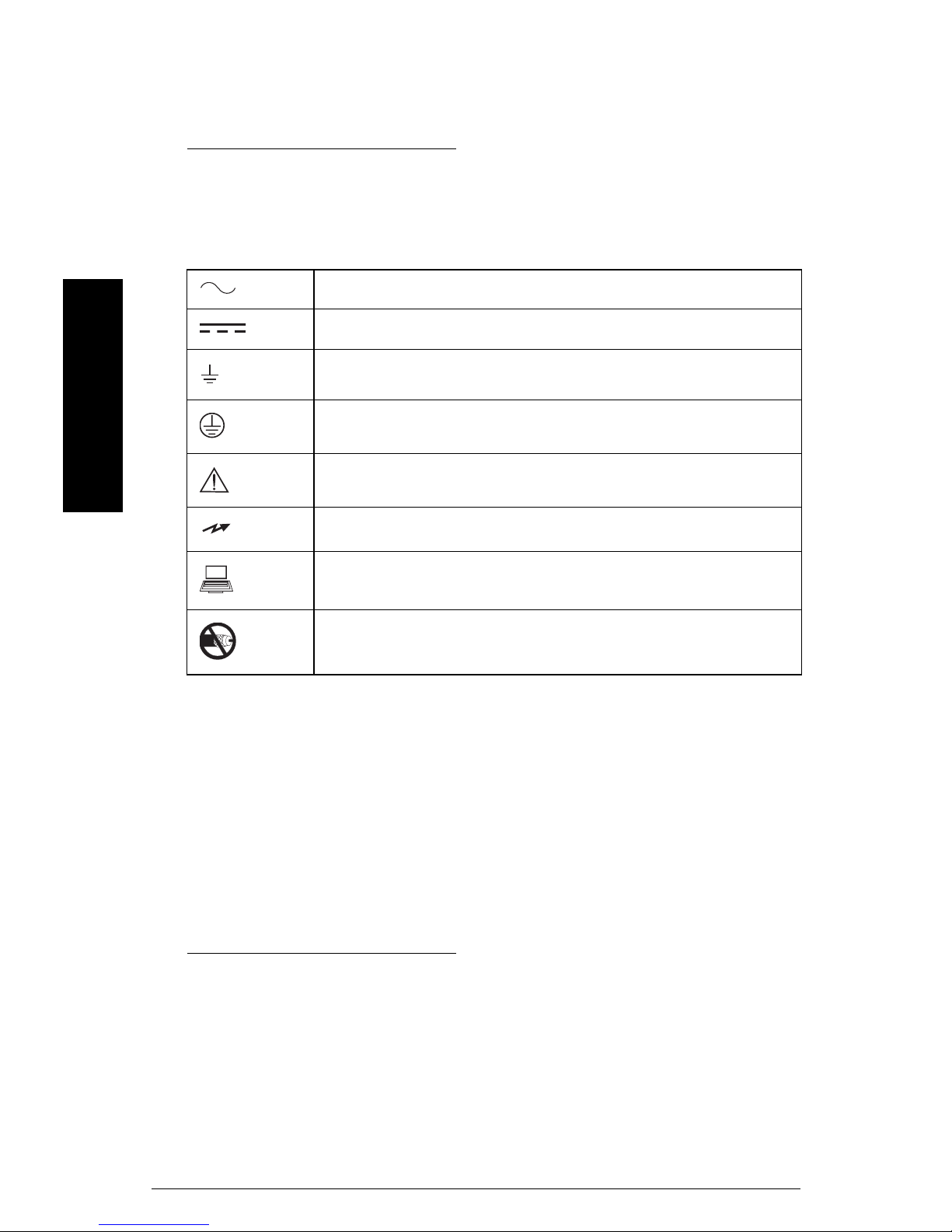

Manual Symbols

Please note their use carefully.

Alternating Current

Direct Current

Earth (ground) Terminal

mmmmm

Protective Conductor Terminal

HydroRanger 200

Caution (refer to instructions)

Infra-red communication port on front of instrument

RJ-11 communications port

No co-axial cable connections

Configuration Examples

The configuration examples used in this manual illustrate the versatility of the

HydroRanger 200. Because there is often a range of ways to approach an application,

other configurations may also apply.

In all examples, substitute your own application details. If the examples do not apply to

your application, check the applicable parameter reference for the available options.

Should you require more information, please contact your Siemens Milltronics

representative. For a complete list of Siemens Milltronics representatives, go to

www.siemens.com/processautomation

Page 2 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

.

Specifications

Power

AC version

• 100-230 V AC ± 15%, 50 / 60 Hz, 36 VA (17W)

• fuse: F3: 2 AG, Slow Blow, 0.375A, 250V

1

DC version

• 12-30 V DC, 20W

• fuse: F3: 2 AG, Slow Blow, 2A, 250V

1

Transmitter fuse

• F1: Belling Lee, L754, 4000A HRC, ceramic type, 100mA, 250V

Temperature Sensor fuse

• F2: Belling Lee, L754, 4000A HRC, ceramic type, 50mA, 250V

Mounting

Location

• indoor / outdoor

Specifications

mmmmm

Altitude

• 2000 m max.

Ambient temperature

• -20 to +50 °C (-5 to +122 °F)

Relative humidity

• Wall Mount: suitable for outdoors (Type 4X / Nema 4X, IP65 Enclosure)

• Panel Mount: suitable for outdoors (Type 3 / Nema 3, IP54 Enclosure)

Installation category

•II

Pollution degree

•4

1.

Power consumption is listed at maximum.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 3

Range

• 0.3 m (1 ft) to 15 m (50 ft), dependent on transducer

Accuracy

• 0.25% of maximum range or 6 mm (0.24”), whichever is greater

Resolution

• 0.1% of program range1 or 2 mm (0.08”), whichever is greater

Memory

• 1 MB static RAM with battery backup

• 512 kB flash EPROM

Programming

Primary

• handheld programmer

Secondary

• PC running SIMATIC PDM

• PC running Dolphin Plus software

mmmmm

Display

Specifications

• back lit LCD

Temperature Compensation

• Range: -50 to +150 °C (-58 to +302 °F)

Source

• integral transducer sensor

• TS-3 temperature sensor

• programmable fixed temperature

Temperature Error

Sensor

• 0.09 % of range

1.

Program range is defined as the empty distance from the face of the transducer

(P006) plus any range extension (P801).

Page 4 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

Fixed

• 0.17 % per °C deviation from programmed value

Outputs

Transducer drive

•315 V peak

mA Analog

HydroRanger 200 (all models):

Single or Dual point versions include two mA outputs

• 0-20 mA

• 4-20 mA

• 750 ohm maximum

• Resolution of 0.1%

•Isolated

Relays

1

•One:

•1 control

•Three:

•2 control

• 1 alarm control

•Six:

•4 control

• 2 alarm control

• All relays rated 5A at 250 V AC, non-inductive

Control Relays

• 1, 2 or 4 Form A, NO relays (numbers 1, 2, 4, 5)

Alarm Relay

• 0, 1 or 2 Form C, NO, or NC relay (numbers 3, 6)

Communication

• RS-232 running Modbus RTU and ASCII via RJ-11 connector

• RS-485 running Modbus RTU and ASCII via terminal blocks

Specifications

mmmmm

Optional

• SmartLinx® compatible

1.

All relays are certified only for use with equipment that fails in a state at or

under the rated maximums of the relays.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 5

Inputs

mA (analog) (1) [6 relay model]

• 0-20 or 4-20 mA, from alternate device, scalable

Discrete (2)

• 10-50 V DC switching level

• logical 0 = < 0.5 V DC

• logical 1 = 10 to 50 V DC

• 3 mA maximum draw

Enclosure

Wall Mount

• 240 mm (9.5") x 175 mm (6.9"). Width dimension includes hinges.

• Type 4X / NEMA 4X / IP 65

• Polycarbonate

1

Panel Mount

• 278 mm (10.93") x 198 mm (7.8") Width dimension includes flange.

• Type 3 / Nema 3 / IP54

• Polycarbonate

mmmmm

Specifications

Weight

• Wall mount: 1.37 kg (3.02 lb)

• Panel mount: 1.5 kg (3.3 lb)

Approvals

• See product nameplate

Compatible Transducers

• Echomax series and STH series

Transducer Frequency

•44 kHz

1.

For watertight applications, use only approved, suitable size hubs in the

enclosure’s conduit holes.

Page 6 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

Cable

• Do not use coaxial cable for transducer (see General Appendix F: Upgrading on

page 246 for more information)

• transducer and mA output signal to be 2 copper conductors, twisted with shield/drain

wire, 300 Vrms, 0.324 - 0.823 mm

adjacent conductors @ 1kHz = 62.3 pF/m (19 pF/ft). Nominal capacitance between

conductor and shield @ 1kHz = 108.3 pF/m (33 pF/ft) (Belden®

• 365 m maximum

Note: The HydroRanger 200 is to be used only in the manner outlined in this

instruction manual or protection provided by the equipment may be impaired.

2

(22 - 18 AWG), nominal capacitance between

1

8760 is acceptable)

Specifications

mmmmm

1.

Belden is a registered trademark of Belden Wire & Cable Company.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 7

Installation

Notes:

• Installation must only be performed by qualified personnel, and in accordance

with local governing regulations.

• This product is susceptible to electrostatic shock. Follow proper grounding

procedures.

All field wiring must have insulation suitable for at least 250 V.

Hazardous voltage present on transducer terminals during operation.

DC terminals shall be supplied from an SELV source in accordance with IEC

1010-1 Annex H.

• The non-metallic enclosure does not provide grounding between conduit

connections. Use grounding type bushings and jumpers.

Mounting

Mounting Locations

Recommended

• Ambient temperature is always within -20 to +50 °C (-5 to +122 °F)

• HydroRanger 200 display window is at shoulder level, unless most interaction is

through a SCADA system

• Easy access for hand programmer is provided

mmmmm

Installation

• Cable length requirements are minimal

• Mounting surface is free from vibration

• Leave is sufficient room to swing unit lid open and have clear access.

• A place for a laptop computer is provided for on-site Simatic PDM configuration

Avoid

• Exposure to direct sunlight. (Provide a sun shield to avoid direct sunlight.)

• Proximity to high voltage/current runs, contacts, SCR or variable frequency motor

speed controllers

Page 8 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

Mounting Instructions

The wall mount and panel mount units install differently. Please follow the specific

instructions for your unit.

Note: When routing cable through a conduit, please follow the Cable Routing

instructions on page 10 before mounting the HydroRanger 200.

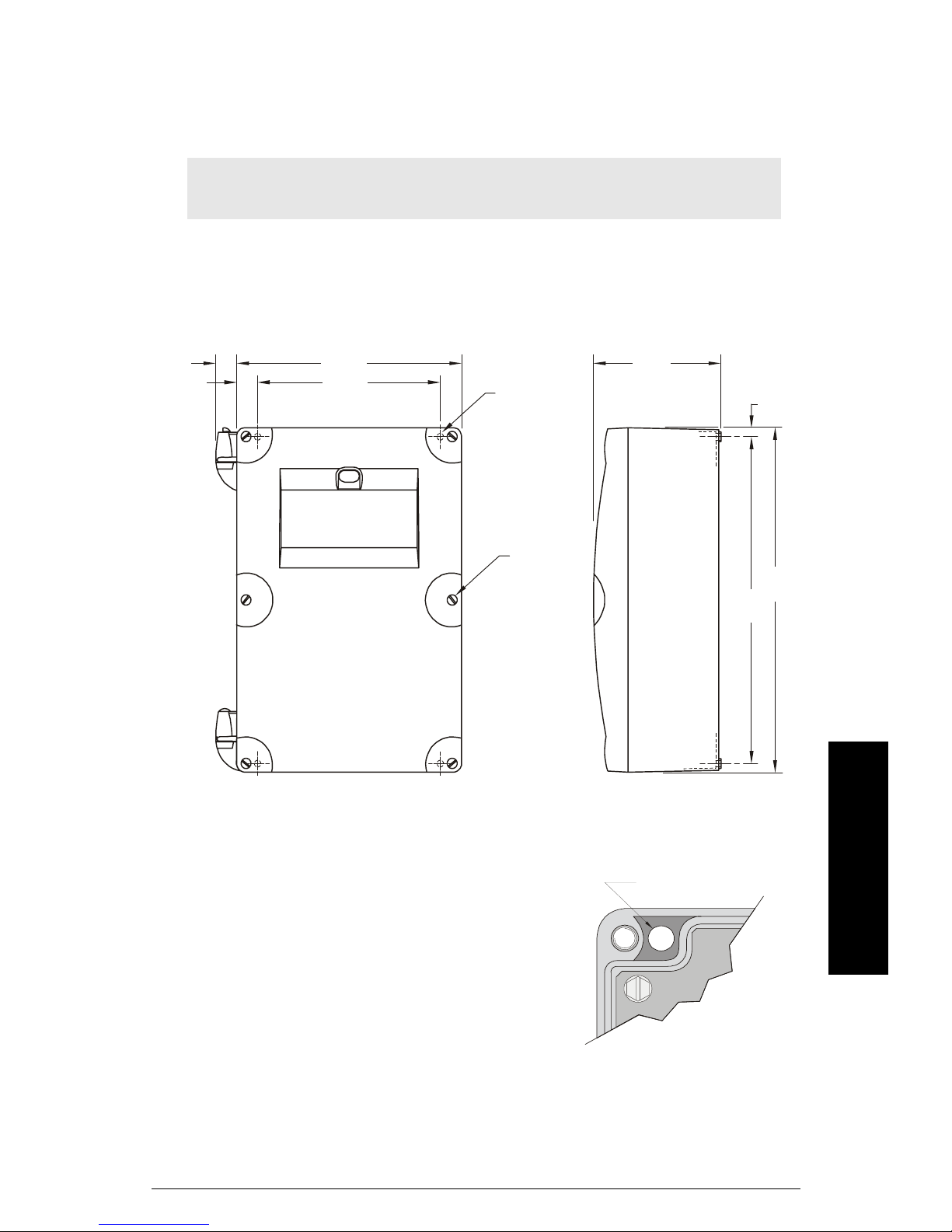

Wall Mount

Enclosure Dimensions

14.9 mm

(0.58")

15.2 mm

(0.6")

160.3 mm

(6.325")

130 mm

(5.125")

4.3 mm dia.

(0.17")

four mounting

holes

lid screws

(6)

91 mm

(3.58")

240 mm

227 mm

(8.93")

6.6 mm

(0.26")

(9.45")

Mounting the Enclosure

1. Remove the lid screws and open the lid to reveal the mounting screw holes.

2. Mark and drill four holes in the mounting

surface for the four screws (customer supplied).

3. Fasten with a long screwdriver.

Please note:

• Recommended mounting: directly to wall or to

electrical cabinet back panel

• Recommended mounting screws: #6

• If alternate mounting surface is used, it MUST

be able to support four times the weight of the

unit.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 9

Installation

mmmmm

mounting screw holes

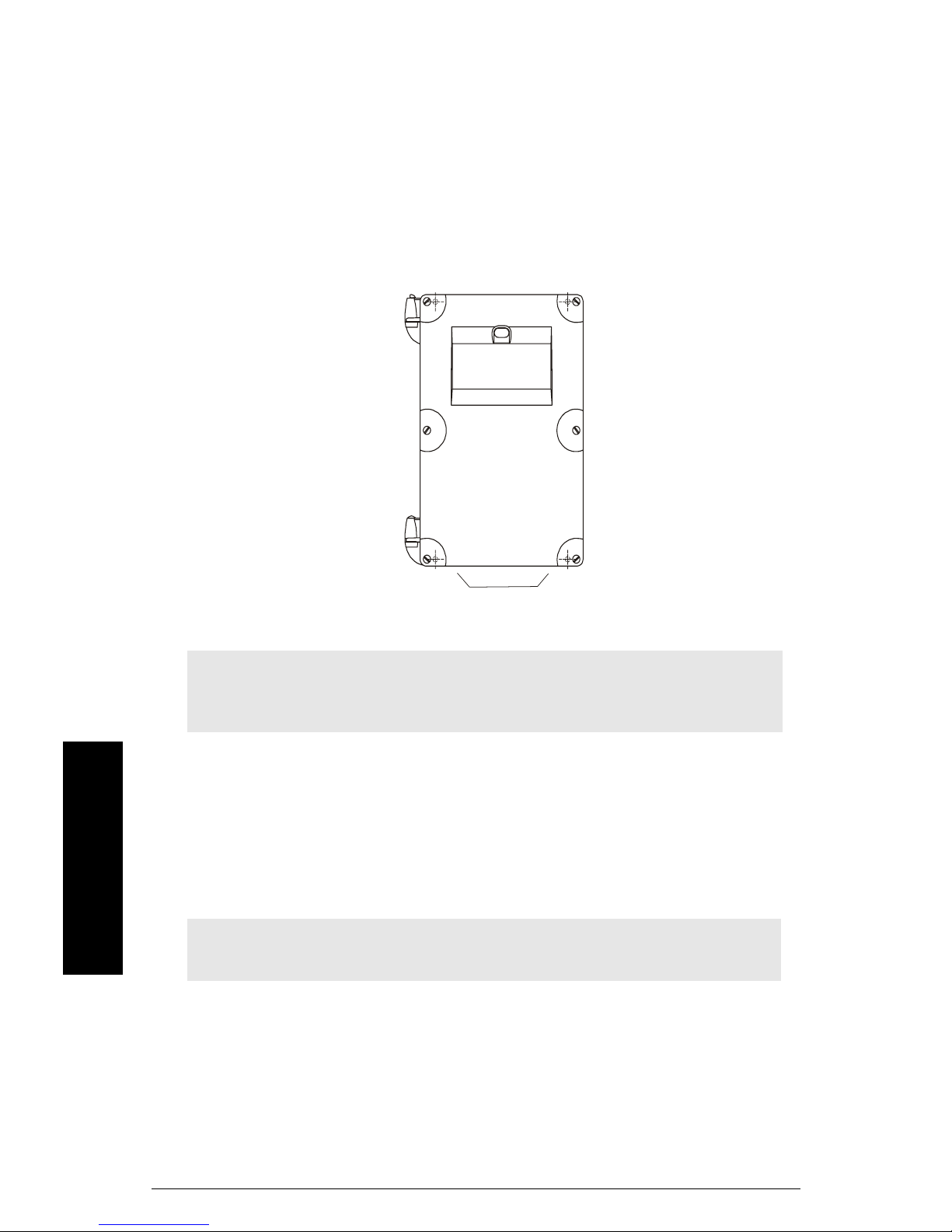

Cable routed through a conduit:

1. Remove the four mounting screws holding the motherboard to the enclosure.

2. Be careful not to damage the electronics with static electricity. Remove the

motherboard from the enclosure by pulling the board straight out.

3. Drill the required cable entry holes. Make sure conduit holes do not interfere with

the lower areas on the terminal block, circuit board, or SmartLinx card.

4. Attach the conduit to the enclosure using only approved suitable size hubs for

watertight application.

5. Reinstall the motherboard with the mounting screws.

suitable location for conduit entrances

.

Note: For conduit locations and assembly for hazardous mounting in Class 1 Div 2

applications, please see Drawing 23650314 in

1, Div 2 Applications

on page 249.

Appendix G: Conduit Entry for Class

Cable exposed and entering through the cable glands:

1. Unscrew the glands and attach them loosely to the enclosure.

2. Thread the cables through the glands. Ensure the power cable is kept separated

from the signal cables and then wire the cables to the terminal blocks.

mmmmm

3. Tighten the glands to form a good seal.

Installation

Note: Where more holes are required than are supplied in the enclosure, follow

the

Cable routed through a conduit

steps.

Page 10 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

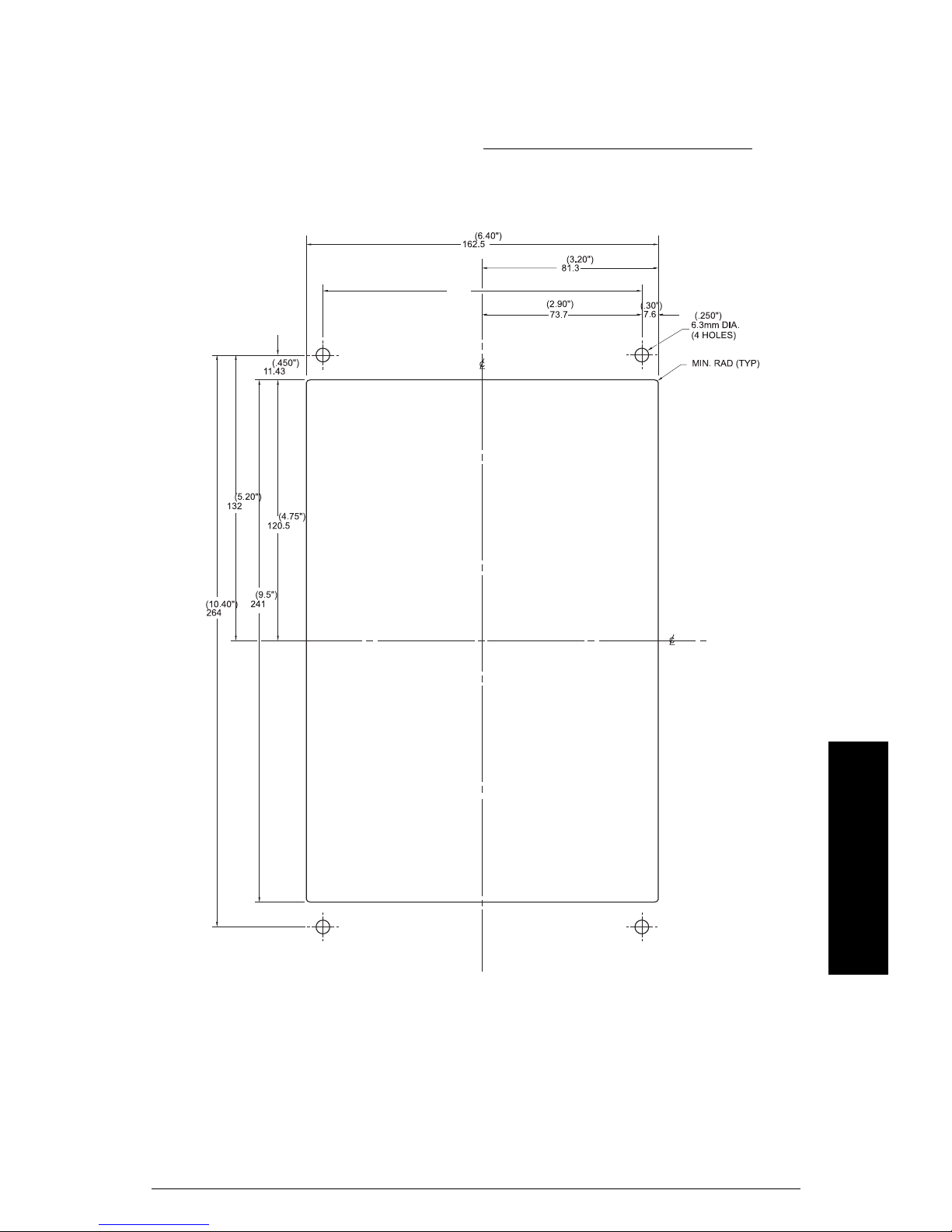

Panel Mount

Installing the panel mount unit requires making a cutout in the panel. The dimensions for

the cutout are provided in the illustration below. A full size cutout template is provided

with your unit or may be downloaded from www.siemens.com/processautomation

Cutout Dimensions

.

Cutout Instructions

1. Select a place for the unit and fasten the template onto the panel (use tape or

tacks).

2. Drill the four fastener holes.

3. Make the cutout using the appropriate tools.

4. Mount unit according to the instructions in this manual.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 11

Installation

mmmmm

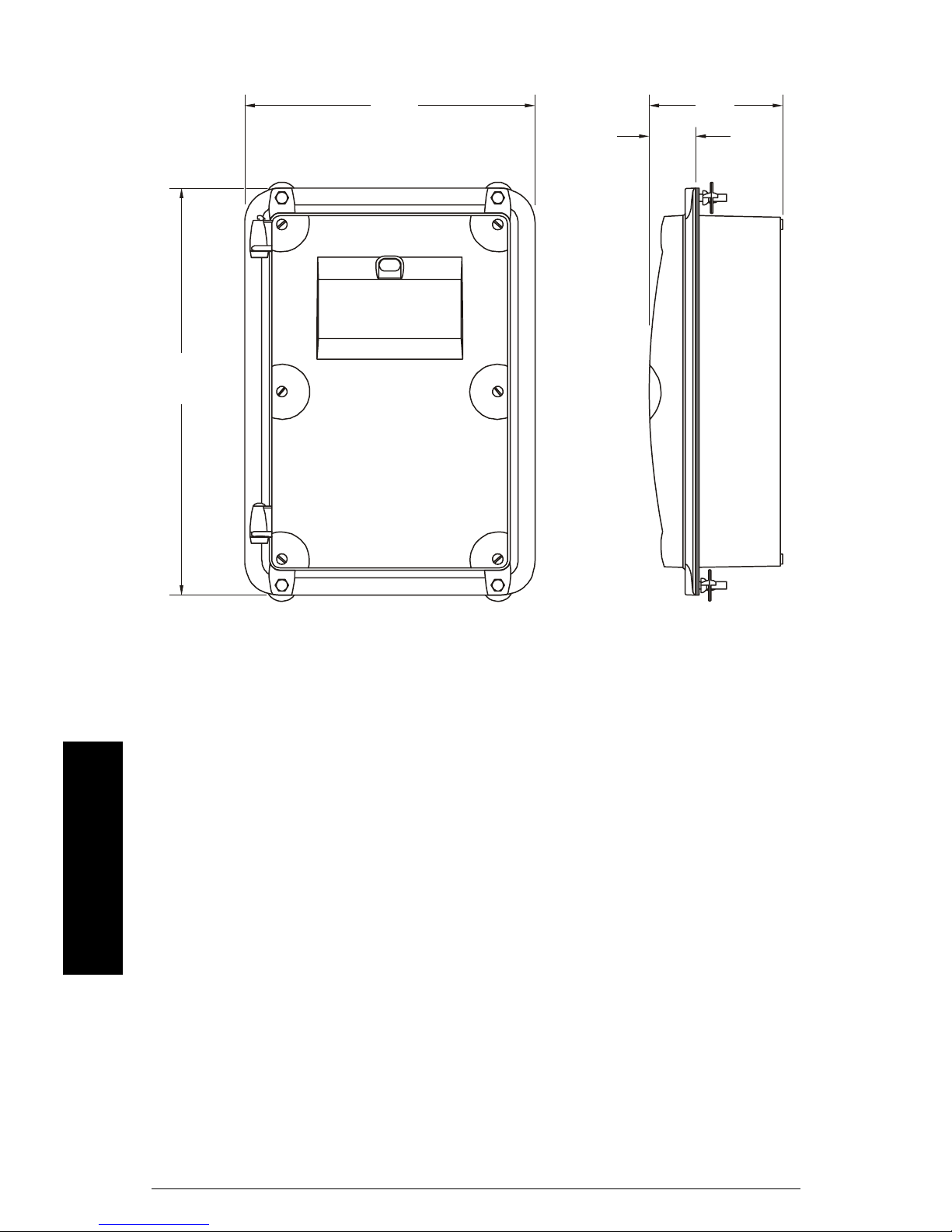

Panel Mount Dimensions

278 mm

(10.93")

198 mm

(7.80")

97 mm

(3.82")

36 mm

(1.40")

Mounting the Enclosure

Once cutout is complete and mounting holes are drilled, follow these steps:

1. Remove lid from unit by undoing the six lid screws and lifting it off its hinges.

2. Remove the four screws holding the motherboard to the enclosure.

3. Be careful not to damage the electronics with static electricity. Remove the

motherboard from the enclosure by pulling the board straight out.

4. Drill the required cable entry holes. Be sure to compensate for panel door

dimensions and make sure conduit holes do not interfere with the lower areas on

mmmmm

Installation

the terminal block, circuit board, or SmartLinx card.

5. Replace board and fasten the four screws.

6. Place the unit into the panel and insert hexagonal fasteners through bevel slots and

predrilled panel holes.

7. Fasten with wingnuts and hand tighten.

8. Add conduit or glands and wire as required, then replace the lid.

Helpful hint:

• Use tape to hold hexagonal heads in slots while attaching wingnuts.

Page 12 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

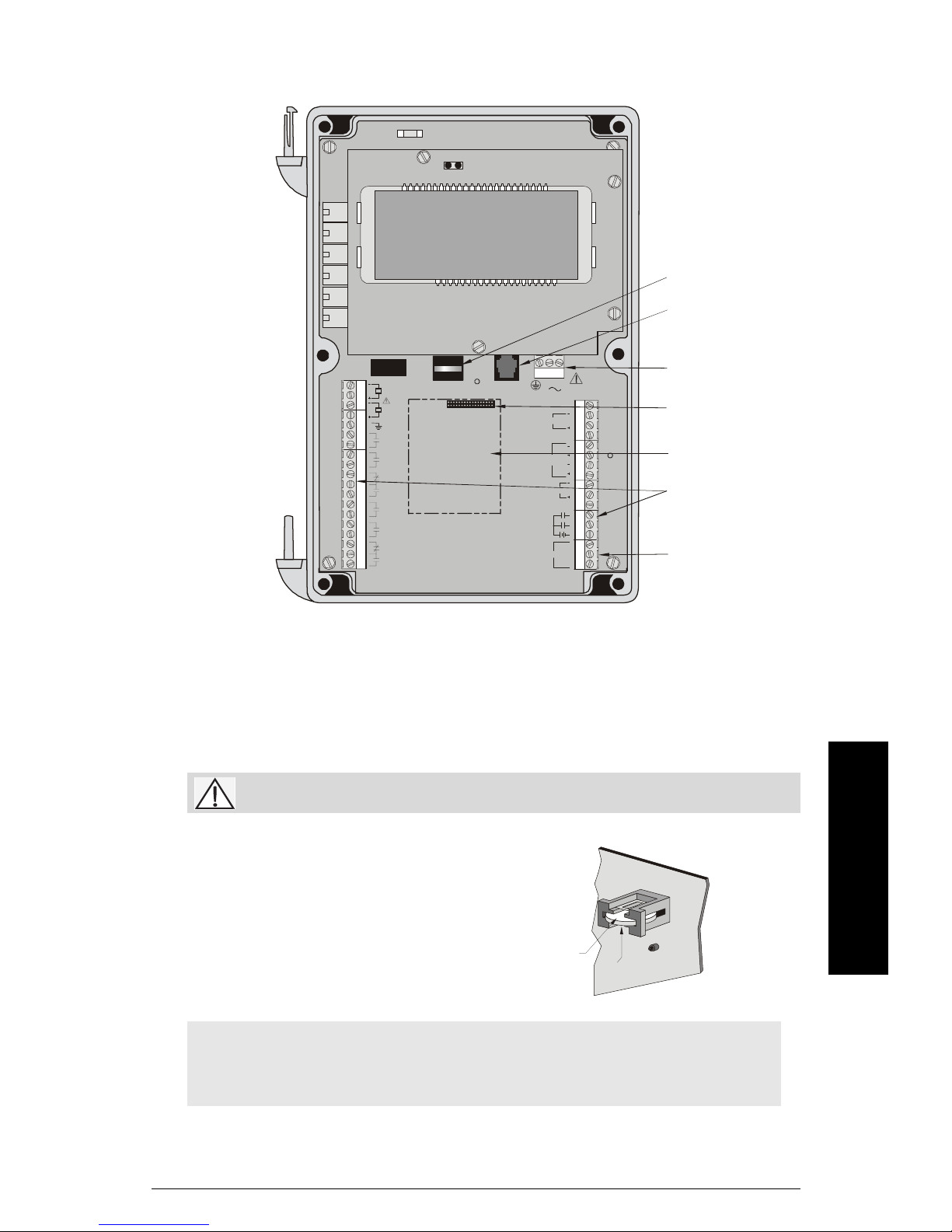

HydroRanger 200 Board

Battery

RS-232 RJ-11

Connector

DISCRETE

INPUTS

L2/N L1

mA INPUT

4 - 20 mA

OUTPUTS

RS485

SHIELD

TS-3

SHIELD

TB1

TB3

SYNC

1

2

Female Connector

for SmartLinx Card

SmartLinx Card

Te rm i n a l s

1

2

COM

A

B

RS-485

Connections

TB2

2

1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

RELAY 5

RELAY 6

Installing the Battery

The battery (Rayovac BR2032) has a ten-year life expectancy. Please note the life

expectancy may be reduced by ambient temperature. If the unit loses external and

battery power, a capacitor will power the RAM for about ten minutes.

Disconnect power before replacing the battery.

Power Supply

Installation

Installation Steps

1. Open the enclosure lid.

2. Slide the battery into the holder. Be sure to

align the + and – terminals correctly.

3. Close and secure enclosure lid.

Note: All parameter values are written to the EEPROM once every hour. The

battery is used to backup Standard Data Logging parameters (P300-P321)

between writes, in case of power failure.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 13

mmmmm

Battery

+

Installing SmartLinx Card

SmartLinx cards are generally pre-installed. If unit does not have a SmartLinx card, follow

these steps to install one.

1. Align card with the two mounting posts and then press-fit with the female

connector.

2. Use the screws supplied with the card to attach it to the mounting posts.

3. Wire in the SmartLinx card according to SmartLinx Manual.

mmmmm

Installation

Page 14 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

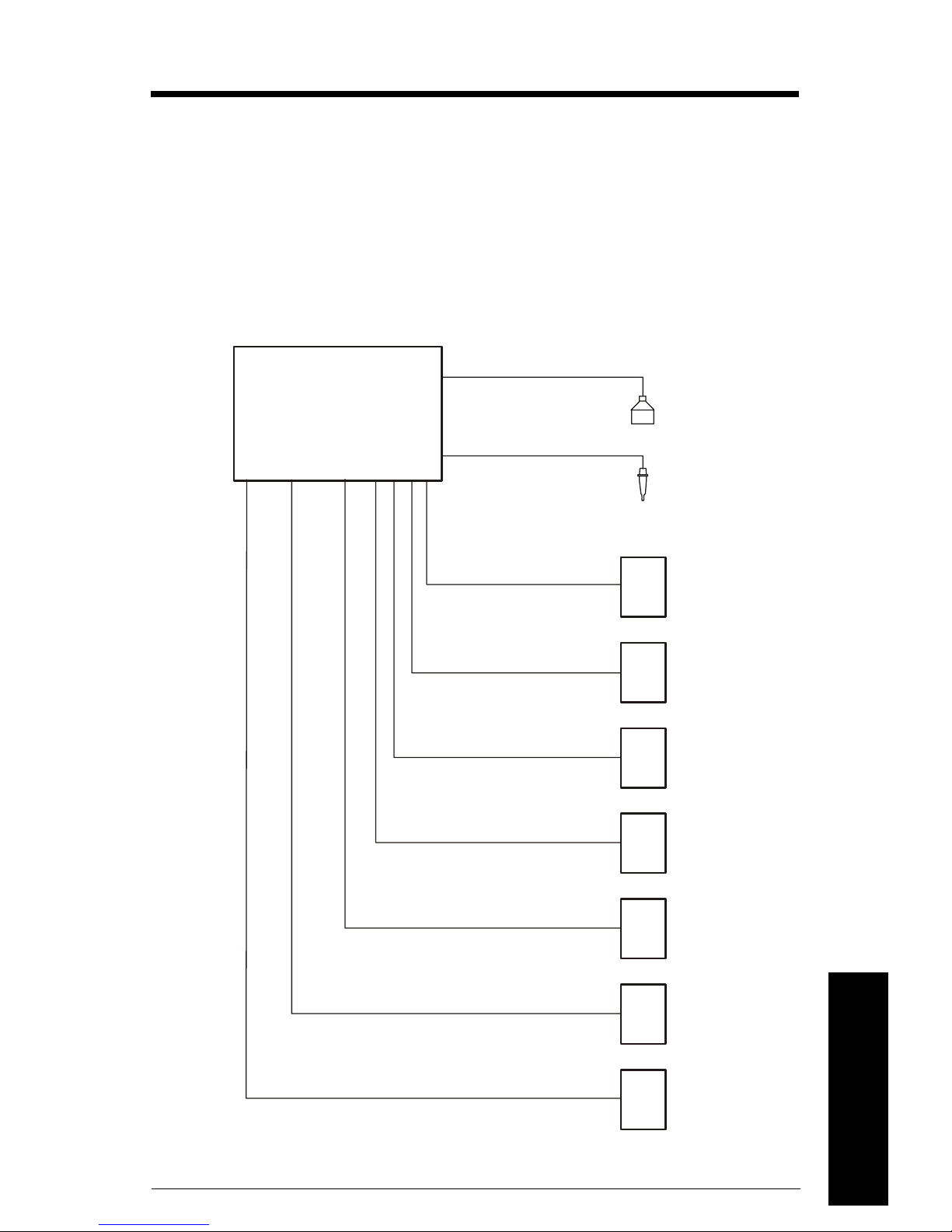

Wiring

Please note:

• Verify that all system components are installed in accordance with instructions.

• Connect all cable shields to the HydroRanger 200 Shield Terminals. Avoid differential

ground potentials by not connecting cable shields to ground (earth) anywhere.

• Keep exposed conductors on shielded cables as short as possible to reduce noise

on the line caused by stray transmissions and noise pickup.

HydroRanger 200

Siemens Milltronics

Transducer(s)

Siemens Milltronics

TS-3 Temperature

Sensor

Laptop running

Dolphin Plus

Customer Alarm,

Pump, or Control

Device

Customer Device,

digital output

Customer Device,

analog output

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 15

Customer Network or

Modem

SmartLinx Card

Display, PLC, Chart

recorder, or other

Control Device

Wiring

mmmmm

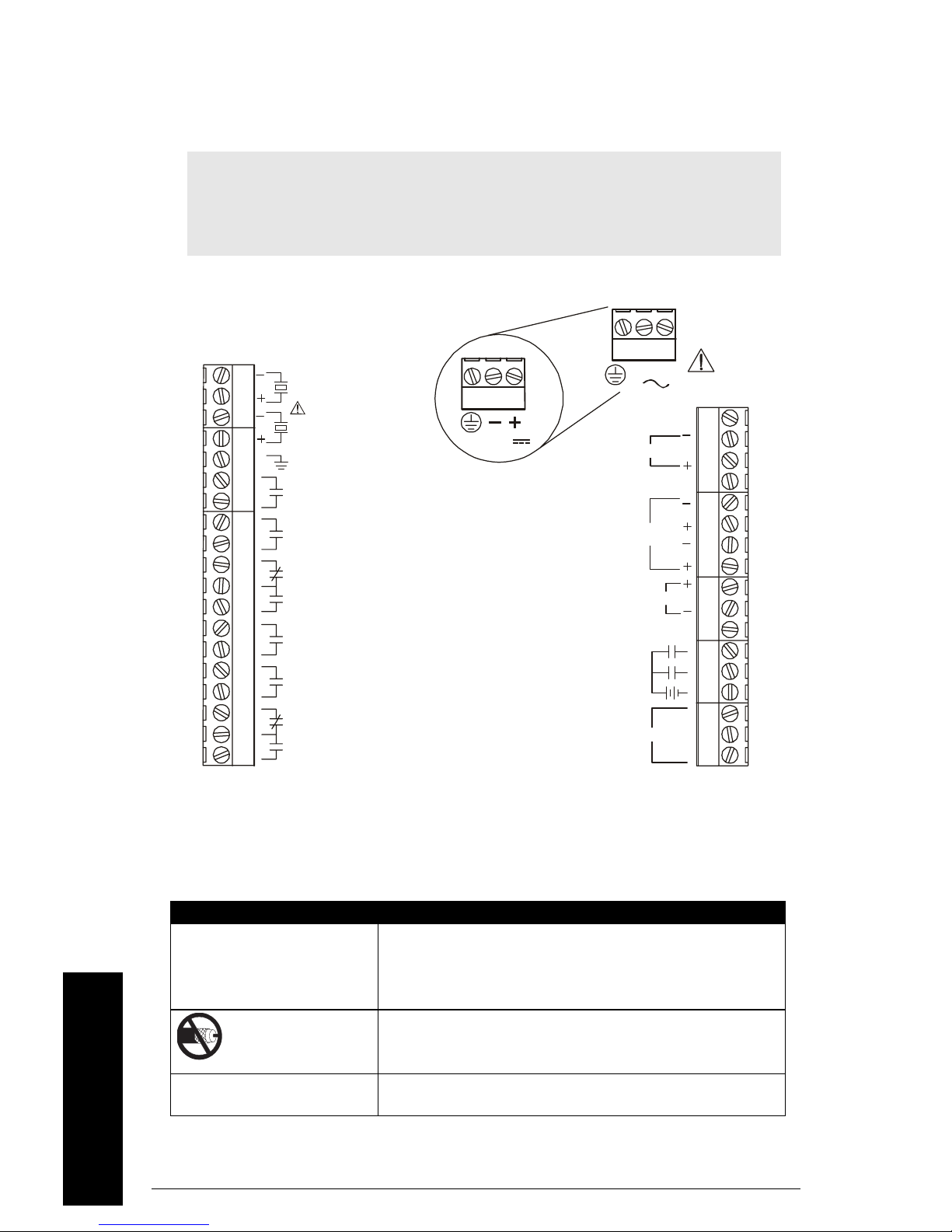

Terminal Board

The terminal board on the HydroRanger 200 allows all inputs and outputs to be connected

simultaneously.

Note: Recommended torque on terminal clamping screws.

• 0.56 - 0.79 Nm

• 5 - 7 in.lbs

Please do not overtighten the screws.

TB1

TB2

2

1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

RELAY 5

RELAY 6

12-30 V

DC Version

TB1

L2/N L1

mA INPUT

4 - 20 mA

OUTPUTS

DISCRETE

INPUTS

RS485

TB3

SYNC

SHIELD

1

2

TS-3

SHIELD

1

2

COM

A

B

Cables

The HydroRanger 200 transceiver requires a shielded two-wire connection to the

transducer.

Connection Cable Type

mA input and mA output

sync, Temperature sensor,

discrete input, dc input

Transducer

Relay output

mmmmm

Wiring

AC input

1.

Preferred shielding is braided screen.

Page 16 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

1

2 copper conductors, twisted, with shield

300V 0.324 - 0.0.823 mm

2

(22 - 18 AWG)

/drain wire,

Maximum length: 365 m

Do not use a coaxial transducer cable extension with the

HydroRanger 200. Electrical noise interference affects

performance.

Relay to be copper conductors per local requirements to

meet 250 V 5A contact rating.

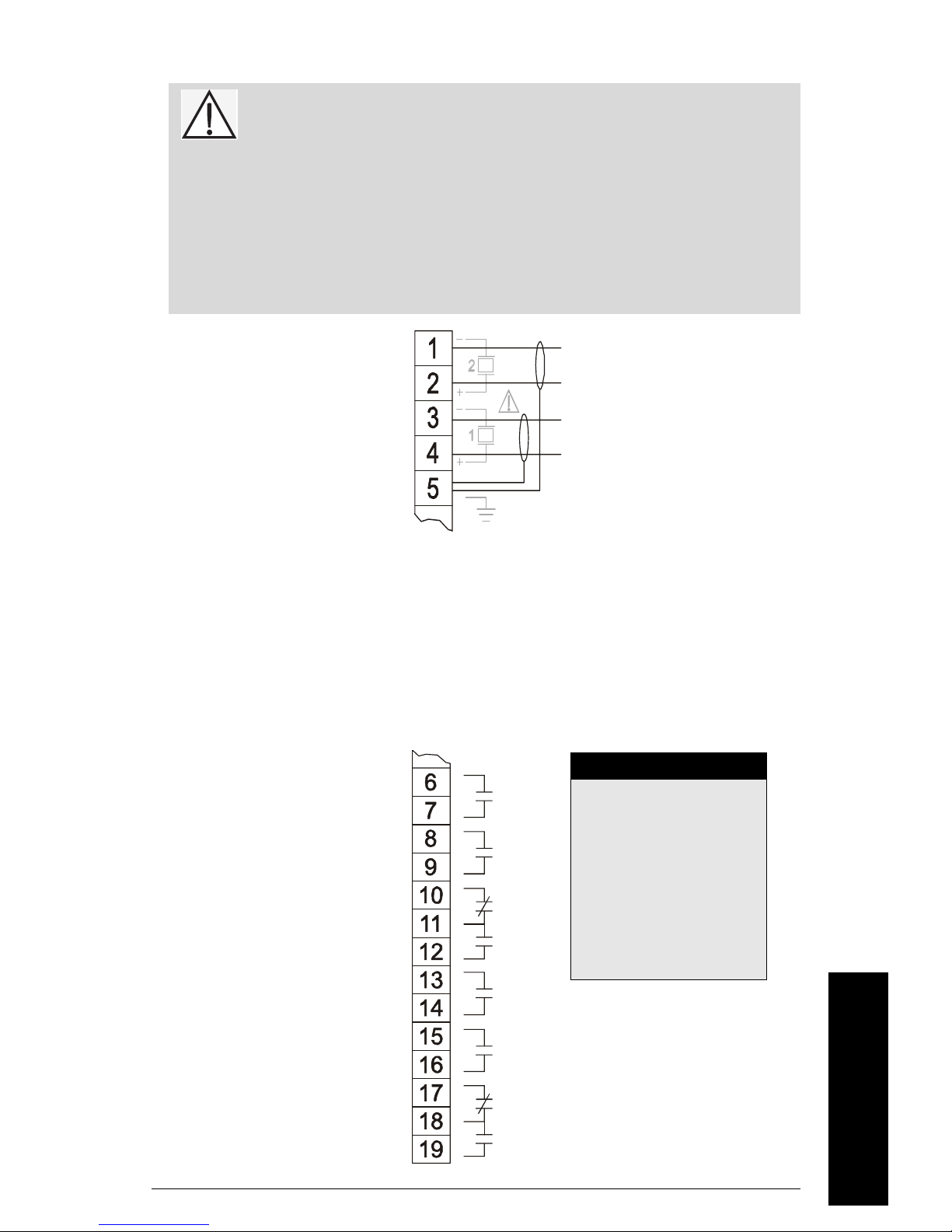

Transducers

Warning: Hazardous voltage present on transducer terminals during

operation.

Run the transducer cable in a grounded metal conduit, separate from other

wiring (except TS-3 temperature sensor wiring, if applicable).

Notes:

• Do not use coaxial cable because of electrical noise interference

• Do not connect the shield and white transducer wires together; wire to separate

terminals

• Disregard older transducer manuals that recommend these practices

white

TRANSDUCER TWO

black

white

TRANSDUCER ONE

black

A 0.1 µF (100V or greater) capacitor is included with the HydroRanger 200 for retrofitting

old HydroRanger installations. Please see

HydroRanger Installations)

on page 247.

HydroRanger 200 Installation (for retrofitting

Relays

Relay contacts are shown in the de-energized position. All relays are handled identically

and can be configured as positive or negative logic using P118.

Relay Ratings

• four Form A, NO

relays(1,2,4,5)

• two Form C, NO or

NC relays (3,6)

• 5A at 250Vac, noninductive

RELAY 1

RELAY 2

RELAY 3

Power Failure

Relays 1, 2, 4, and 5 are

normally open and will fail

in the normal state.

Relays 3 and 6 can be

wired either normally open

or normally closed, and

will fail in their deenergized states.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 17

RELAY 4

RELAY 5

RELAY 6

Wiring

mmmmm

Temperature Sensor

Accurate temperature readings are critical to accurate level measurements because the

speed of sound changes, depending on air temperature, and all Siemens Milltronics

Echomax and ST-H transducers have an internal temperature sensor.

If the following conditions apply, a separate TS-3 temperature sensor will ensure

optimum accuracy:

• the transducer is exposed to direct sunlight (or other radiant heat source)

• the transducer face and monitored surface temperature differs

• faster response to temperature changes is required

Note

TEMPERATURE SENSOR

Use a T-S3 Temperature

Sensor only. Leave

terminals open (unused) if

TS-3 is not deployed.

mA Input [6 relay model]

For more information, consult the Transducer (P004) and mA Input Parameters (P250,

P251, and P252) in the parameter reference section.

mA Output

For more information, consult the mA output parameters (P200 to P219) in the parameter

reference section.

mmmmm

Wiring

Page 18 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

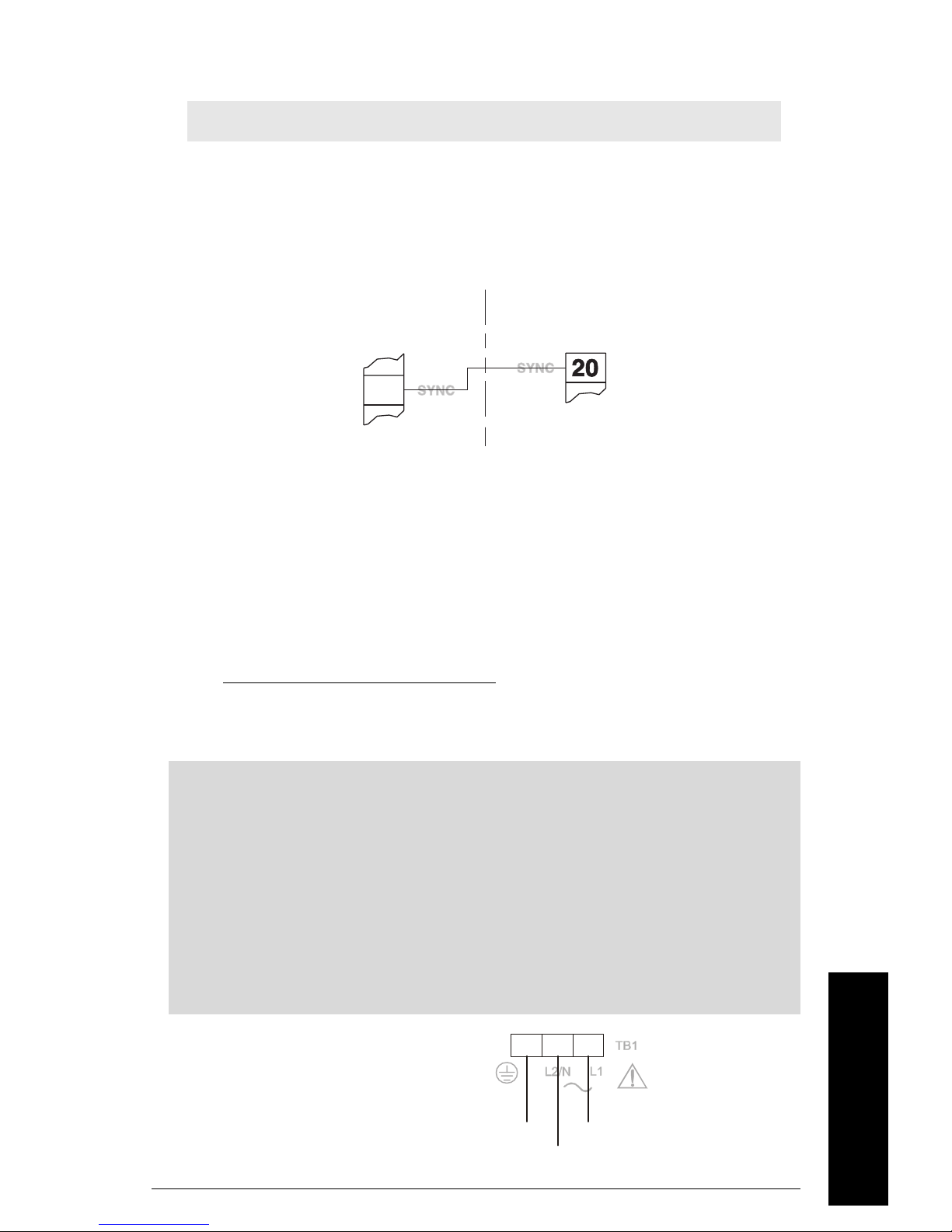

Level System Synchronization

Note: The HydroRanger 200 CANNOT be synchronized with the HydroRanger.

When using multiple ultrasonic level monitors, be sure to run the transducer cables in

separate grounded metal conduits.

When separate conduits are not possible, synchronize the level monitors so that no unit

transmits while another is waiting for echo reception.

Other Siemens

Milltronics Transceiver

HydroRanger 200

Synchronizing with another HydroRanger 200, or other Siemens Milltronics

instruments (DPL+, SPL, XPL+, LU01, LU02, LU10, LUC500, Hydro+,

EnviroRanger, MiniRanger):

• Mount the level monitors together in one cabinet

• Use a common power (mains) supply and ground (earth) for all units

• Interconnect the SYNC terminals of all level monitors

•Set parameter

P726 Level System Sync

on page 190.

• Contact Siemens Milltronics or your local distributor. Go to

www.siemens.com/processautomation.

Power

Important!

Before applying power to the HydroRanger 200 for the first time, ensure any

connected alarm/control equipment is disabled until satisfactory system operation

and performance is verified.

Notes for AC power connections

• The equipment must be protected by a 15 A fuse, or circuit breaker in the

building installation.

• A circuit breaker or switch in the building installation, marked as the disconnect

switch, must be in close proximity to the equipment and within easy reach of the

operator.

Note: Make sure unit is

connected to a

reliable ground.

7ML19985FC03 HydroRanger 200 – INSTRUCTION MANUAL Page 19

Ground

GND

Wiring

mmmmm

L1

L2/N

Digital Communications

Wiring the HydroRanger 200 for communications allows it to be integrated into a full

SCADA system or an industrial LAN.

The HydroRanger 200 can also be directly connected to a computer running Dolphin Plus.

RS-232 Serial Connection

TB2

2

1

RELAY 1

RELAY 2

RELAY 3

RELAY 4

RELAY 5

RELAY 6

RS-485 Serial Connection

DISCRETE

INPUTS

L2/N L1

mA INPUT

4 - 20 mA

OUTPUTS

TB1

TB3

SYNC

SHIELD

1

2

TS-3

SHIELD

1

2

COM

RS485

A

B

Connector

RS-485

Connection

(see below)

RS-232 RJ-11

Discrete Inputs

Discrete inputs have a positive and negative terminal. Requires an external power supply.

mmmmm

Wiring

Page 20 HydroRanger 200 – INSTRUCTION MANUAL 7ML19985FC03

Discrete Input (post.) 1

Discrete Input (pos.) 2

Common (neg.) for Discrete Input

Loading...

Loading...