Siemens HMS-2S, HMS-SA Installation Instructions Manual

Installation Instructions

Models HMS-2S / HMS-SA

Dual Stage Manual Pull Station (For Canadian Two-Stage Applications)

Single Stage Manual Pull Station with Auxiliary Contacts

INTRODUCTION The Model HMS-2S/-SA Manual Station from Siemens

Industry, Inc., is a field installed addressable device

containing advanced control panel communication

technology. This technology, which provides twodirection communication with the control panel,

produces an Intelligent Initiating Device.

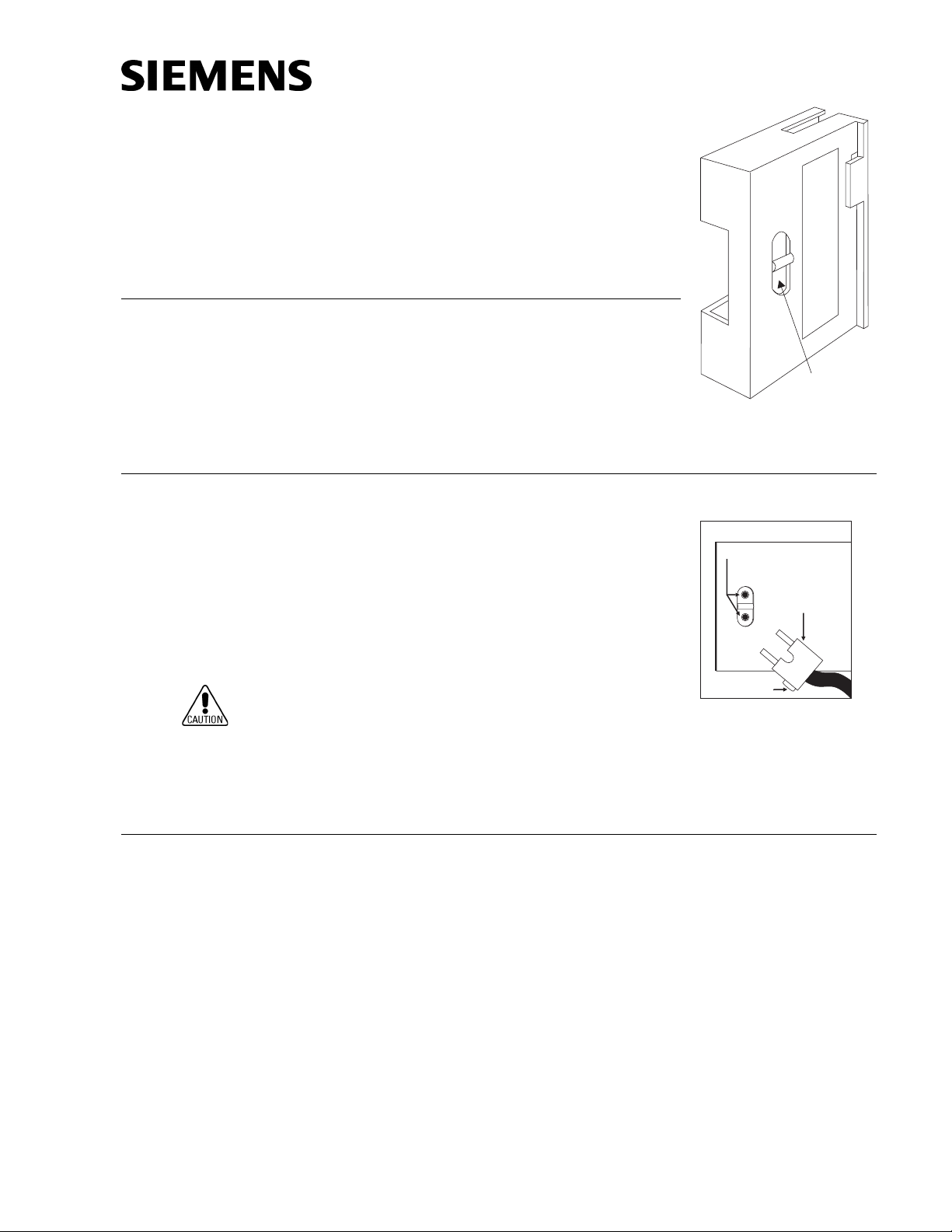

Figure 1

HMS Cover

PROGRAMMING Refer to Figure 1 to locate the opening on the HMS cover that allows access to the

INSTRUCTIONS

programming holes which are on the HMS printed

circuit board.

PROGRAMMING

To connect the HMS to the DPU Programmer/Tester,

POINTS

insert the plug from the DPU cable provided with the

Programmer/Tester into the opening on the HMS as

shown in Figure 2. Because HMS devices are polarity

insensitive, the programming plug can be inserted into

the programming holes in either direction.

To prevent potential damage to the DPU DO NOT

connect an HMS to the DPU until at least one wire is

removed from terminals 1 or 2 of the HMS.

LOCATING TAB

Figure 2

Connecting the DPU Plug

OPENING TO

PROGRAMMING

POINTS

PLUG FROM

DPU

Follow the instructions in the DPU Manual (P/N 315-033260) to program the HMS to

the desired address. Record the device address on the label located on the HMS

front panel. The HMS can now be installed and wired to the system.

OPERATION The HMS manual station operates with the FireFinder-XLS Control Panel via the DLC

Device Loop Card.

The HMS-2S/-SA manual station housing has a pull down lever that locks in position

after releasing a spring loaded switch. (See Figure 4.) To indicate the manual station is

activated, the pull down lever remains down and locked until the station is physically

reset. The HMS-2S/-SA manual station has a set of normally closed auxiliary contacts

which are available for releasing door holders and magnetic door locks.

The HMS-2S has a keyswitch which can activate a second address.

The unit is reset by opening the hinged housing cover with an Allen key and then

closing and locking the cover, or by returning the keyswitch to its original position.

Siemens Industry, Inc.

P/N 315-033430-6

Building Technologies Division

WIRING

NOTES:

1. Recommended wire sizes:

1

2

3

PIGTAIL LEADS

DLC LINE 1

DLC 2LINE

DLC 1LINE

DLC 2LINE

TO NEXT ADDRESSABLE DEVICE

FROM INITIATING CONTROL PANEL

OR PREVIOUS ADDRESSABLE DEVICE

EARTH GROUND

PROGRAMMABLE

N/C AUX CONTACT

24 VDC, 2A

(DOOR HOLDER OR

A MAGNETIC LOCK

RELEASE, ETC.)

ONLY CONNECT TO

POWER LIMITED SOURCE

2. Wire larger than 14 AWG can damage the connector.

3. When using shielded cable without metal raceway or with

4. When using shielded cable with metal raceway, the wiring shields

5. When using metal raceway without shielded cable, connect the

6. Metal raceway should be thoroughly grounded throughout the system.

7. Addressable Device Loop ratings:

18 AWG minimum, 14 AWG maximum

nonmetallic raceway, the shields should be terminated at the device

ground terminal. If the device box is already grounded by another

means, such as being mounted to a grounded structure, the wire

shields should be continuous and must be grounded solely at the point

of origin; for example, at the control panel.

shall be continuous and grounded solely at the point of origin. The

device ground terminal shall be connected to the grounded device box.

device ground terminal to the grounded device box.

Voltage: 31V max.

18V min. (pulsing)

Current maximum: 1mA

Figure 3

HMS-2S / HMS-SA Wiring Information

In supervisory: HMS-2S / HMS-SA draws 1mA.

8. The HMS-2S / HMS-SA is a polarity insensitive device. Line 1 and Line 2

can be either line of the loop.

The use of limited energy cable is not allowed.

INSTALLATION Distribute the manual station boxes throughout the protected area so that they

are unobstructed, readily accessible, and located in the normal exit path. Place the

manual station according to the regulations of the authorities having jurisdiction.

Surface Mounting Mount the backplate to a Model MC-5 Backbox as shown in Figure 4.

Flush Mounting Mount the backplate to a user supplied single gang switchbox as shown in Figure 4.

Do not overtighten the screws. Overtightening may distort the backplate.

BACKPLATE

SURFACE

MOUNTING

ENCLOSURE

Figure 4

Mounting The HMS

2¾ in.

KEYSWITCH

LOCKING

SCREW

HOUSING

MODEL

MC-5

NAMEPLATE

FLUSH

MOUNTING

ENCLOSURE

4 in.

5½ in.

HOUSING HINGED

TO BACKPLATE

BACKPLATE

3½ in.

3½ INCH DEEP

SWITCH BOX

(USER SUPPLIED)

3 in.

ELECTRICAL RATINGS

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

tnerruC.xaMAm1

Siemens Building Technologies, Ltd.

Fire Safety & Security Products

2 Kenview Boulevard

Brampton, Ontario L6T 5E4 Canada

pooLCLD-SF/CLD

P/N 315-033430-6

Loading...

Loading...