Siemens SIMATIC ET 200SP, CPU 1515SP PC F, CPU 1515SP PC, HMI 128PT, HMI 2048PT User Manual

...

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC

ET 200SP Open Controller

CPU 1515SP PC (F)

Manual

05/2017

A5E32701806

-AC

Preface

Documentation guide

1

Safety notes

2

Product overview

3

Installing

4

Connection

5

Diagnostics, error and

system alarm

6

Commissioning

7

Functions

8

Maintenance

9

Technical data

10

Accessories/spare parts

A

Abbreviations

B

Troubleshooting

C

Siemens AG

Division Digital Fac

tory

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E32701806-AC

Ⓟ

04/2017 Subject to change

Copyright © Siemens AG 2014 - 2017.

All rights reserved

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

CPU 1515SP PC (F)

4 Manual, 05/2017, A5E32701806-AC

Preface

Purpose of the documentation

This manual supplements the system manual for the ET 200SP distributed I/O system.

Functions that generally relate to the system are described in this manual.

The information contained in this product manual and the system / function manuals enable

you put the CPU 1515SP PC (F) into operation.

Basic knowledge required

The system must be operated and used by qualified staff only.

The following knowledge is required:

● Installation guideline for SIMATIC ET 200SP

● Programming with STEP 7

● PC based automation with an S7-1500 software controller and with

WinCC Runtime Advanced

● Basic knowledge of PC technology

● Windows Embedded Standard 7 operating system

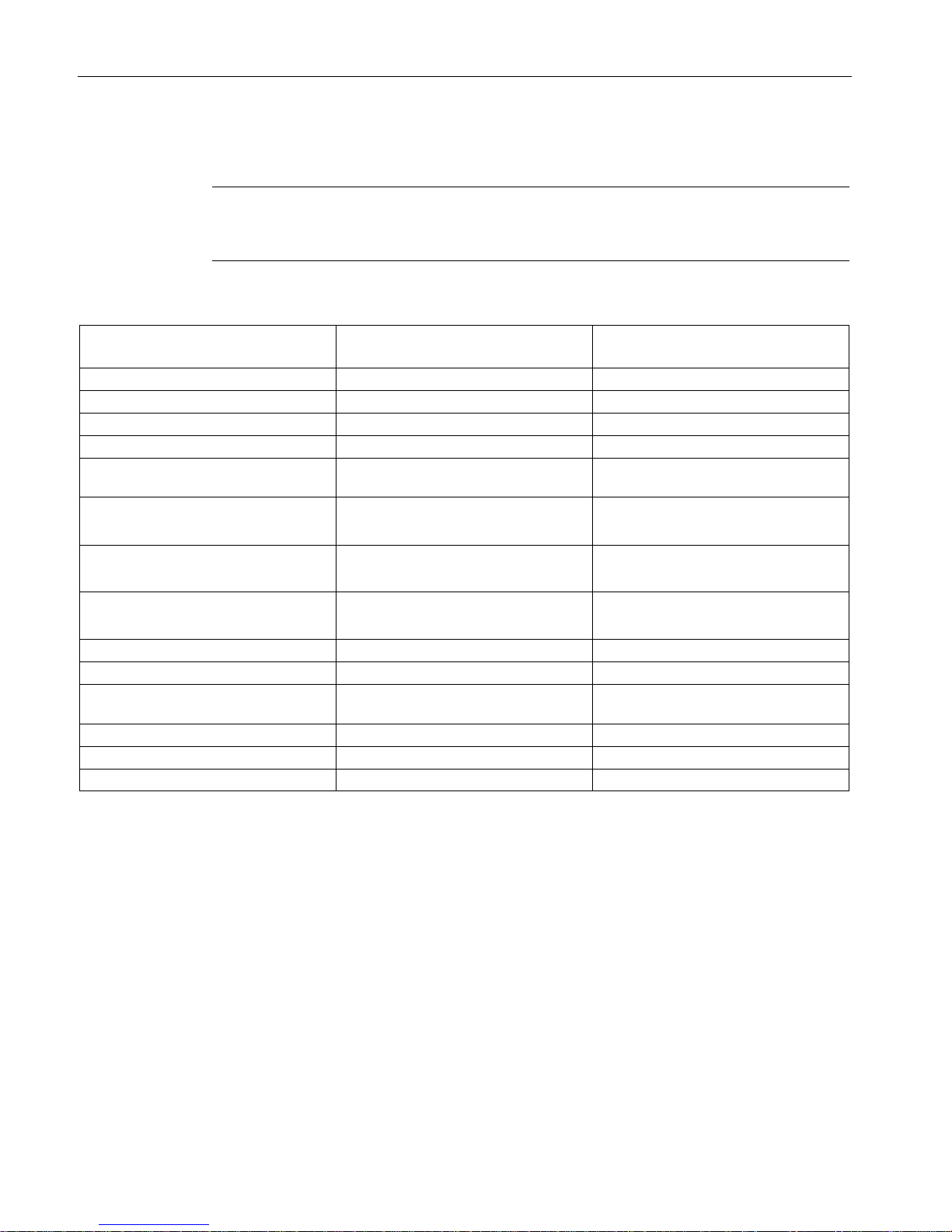

Scope of validity of the documentation

This documentation is valid for the following devices:

ET 200SP Open Controller

Article number

System version

WES7 E 32Bit 4GB RAM

System version

WES7 P 64Bit 4GB RAM

CPU 1515SP PC

6ES7677-2AA31-0EB0

6ES7677-2AA41-0FB0

CPU 1515SP PC + HMI 128PT

--

6ES7677-2AA41-0FK0

CPU 1515SP PC + HMI 512PT

--

6ES7677-2AA41-0FL0

CPU 1515SP PC + HMI 2048PT

--

6ES7677-2AA41-0FM0

CPU 1515SP PC F

6ES7677-2FA31-0EB0

6ES7677-2FA41-0FB0

CPU 1515SP PC F + HMI 128PT

--

6ES7677-2FA41-0FK0

CPU 1515SP PC F + HMI 512PT

--

6ES7677-2FA41-0FL0

CPU 1515SP PC F + HMI 2048PT

--

6ES7677-2FA41-0FM0

CPU 1515SP PC,

spare part, without CFast card, without soft-

ware

6ES7677-2AA40-0AA0

Preface

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

5

Conventions

Conventions STEP 7: In this documentation, "STEP 7" is used as a synonym for all versions

of the configuration and programming software "STEP 7 (TIA Portal)".

Please also observe notes marked as follows:

Note

A n

ote contains important information on the product described in the documentation, on the

handling of the product or on the section of the documentation to which particular attention

should be paid.

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

(http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

Preface

CPU 1515SP PC (F)

6 Manual, 05/2017, A5E32701806-AC

Siemens Industry Online Support

You can find current information on the following topics quickly and easily here:

●

Product support

All the information and extensive know-how on your product, technical specifications,

FAQs, certificates, downloads, and manuals.

●

Application examples

Tools and examples to solve your automation tasks – as well as function blocks,

performance information and videos.

●

Services

Information about Industry Services, Field Services, Technical Support, spare parts and

training offers.

●

Forums

For answers and solutions concerning automation technology.

●

mySupport

Your personal working area in Industry Online Support for messages, support queries,

and configurable documents.

This information is provided by the Siemens Industry Online Support in the Internet

(http://www.siemens.com/automation/service&support).

Industry Mall

The Industry Mall is the catalog and order system of Siemens AG for automation and drive

solutions on the basis of Totally Integrated Automation (TIA) and Totally Integrated Power

(TIP).

Catalogs for all the products in automation and drives are available on the Internet

(https://mall.industry.siemens.com).

Information about third-party software updates

This product contains third-party software. Siemens accepts liability with respect to

updates/patches for the third-party software only when these are distributed by Siemens in

the context of a Software Update Service contract or officially approved by Siemens.

Otherwise, updates/patches are installed at the user's own risk. You can find more

information about our software update service offer under

(http://w3.siemens.com/mcms/topics/en/simatic/licenses/software-update-

service/Pages/Default.aspx).

Notes on protecting administrator accounts

A user with administrator rights has extensive access and manipulation possibilities.

Therefore, make sure that the administrator account is adequately protected to prevent

unauthorized changes. To do this, set secure passwords and use a standard user account

for regular operation. Other measures, such as the use of security policies, should be

applied as required.

Preface

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

7

CPU 1515SP PC (F)

8 Manual, 05/2017, A5E32701806-AC

Table of contents

Preface ................................................................................................................................................... 4

1 Documentation guide ............................................................................................................................ 11

1.1 Documentation on CPU 1515SP PC (F) ................................................................................ 14

2 Safety notes .......................................................................................................................................... 15

2.1 Notes on use .......................................................................................................................... 17

3 Product overview .................................................................................................................................. 18

3.1 Fail-safe option....................................................................................................................... 18

3.2 Properties ............................................................................................................................... 19

3.3 Sample configuration ............................................................................................................. 21

3.4 Components ........................................................................................................................... 23

3.5 Configuration of the devices .................................................................................................. 24

3.6 Operator controls and display elements ................................................................................ 25

3.7 Scope of delivery.................................................................................................................... 28

3.7.1 Unpacking the device ............................................................................................................. 28

3.7.2 Scope of delivery - System version WES7 E 32Bit 4GB RAM .............................................. 30

3.7.3 Scope of delivery - System version WES7 P 64Bit 4GB RAM .............................................. 32

4 Installing ............................................................................................................................................... 34

4.1 Basics ..................................................................................................................................... 34

4.2 Hardware configuration .......................................................................................................... 37

4.3 Installing CPU 1515SP PC (F) ............................................................................................... 38

5 Connection ........................................................................................................................................... 40

5.1 Notes on connection .............................................................................................................. 40

5.2 Terminal and block diagram ................................................................................................... 41

5.3 Electrical configuration ........................................................................................................... 42

5.4 Connecting devices to networks ............................................................................................ 44

5.5 Securing cables...................................................................................................................... 44

6 Diagnostics, error and system alarm ..................................................................................................... 46

6.1 Status and error display ......................................................................................................... 46

Table of contents

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

9

7 Commissioning ..................................................................................................................................... 49

7.1 Notes on commissioning ......................................................................................................... 49

7.2 Initial commissioning ............................................................................................................... 50

7.3 Initial configuration of an Open Controller .............................................................................. 53

7.4 Installing license keys ............................................................................................................. 55

7.5 Windows Security Center ....................................................................................................... 57

7.6 Switching CPU 1515SP PC (F) on/off .................................................................................... 58

8 Functions .............................................................................................................................................. 59

8.1 Monitoring functions ................................................................................................................ 59

8.2 Retentive memory NVRAM ..................................................................................................... 60

8.3 BIOS description ..................................................................................................................... 61

8.3.1 Introduction ............................................................................................................................. 61

8.3.2 Starting BIOS setup ................................................................................................................ 62

8.3.3 BIOS setup menus .................................................................................................................. 63

8.3.3.1 Information menu .................................................................................................................... 65

8.3.3.2 Main menu .............................................................................................................................. 66

8.3.3.3 Advanced menu ...................................................................................................................... 67

8.3.3.4 Security menu ......................................................................................................................... 69

8.3.3.5 Power menu ............................................................................................................................ 70

8.3.3.6 Boot menu ............................................................................................................................... 71

8.3.3.7 Exit menu ................................................................................................................................ 73

8.3.4 BIOS setup default settings .................................................................................................... 74

8.3.5 BIOS update ........................................................................................................................... 75

8.4 Power options ......................................................................................................................... 76

8.5 Protective functions for data carriers ...................................................................................... 77

8.5.1 Enhanced Write Filter (EWF) .................................................................................................. 78

8.5.2 File-Based Write Filter (FBWF) ............................................................................................... 82

9 Maintenance ......................................................................................................................................... 84

9.1 Backing up and restoring data ................................................................................................ 84

9.2 Change partitioning ................................................................................................................. 85

9.2.1 Partitions in the delivery state ................................................................................................. 85

9.2.2 Change partitioning ................................................................................................................. 86

9.3 Restoring the delivery state .................................................................................................... 92

9.4 Restoring delivery state using USB stick ................................................................................ 95

9.5 Updating software ................................................................................................................... 97

9.6 Windows Embedded Standard 7 ............................................................................................ 98

9.7 Sending the device to customer service ................................................................................. 99

9.8 Removing and inserting the CFast card ............................................................................... 100

Table of contents

CPU 1515SP PC (F)

10 Manual, 05/2017, A5E32701806-AC

10 Technical data ..................................................................................................................................... 101

10.1 Standards and approvals ..................................................................................................... 101

10.2 Electromagnetic compatibility .............................................................................................. 105

10.3 Shipping and storage conditions .......................................................................................... 108

10.4 Mechanical and climatic ambient conditions ........................................................................ 108

10.5 Information on insulation, protection class, degree of protection and rated voltage ........... 110

10.6 Use of the ET 200SP in zone 2 potentially explosive atmospheres .................................... 111

10.7 Module data ......................................................................................................................... 112

10.7.1 CPU 1515SP PC, system version WES7 E 32Bit 4GB RAM .............................................. 112

10.7.2 CPU 1515SP PC F, system version WES7 E 32Bit 4GB RAM ........................................... 115

10.7.3 CPU 1515SP PC, system version WES7 E 32Bit 4GB RAM - spare part ........................... 118

10.7.4 CPU 1515SP PC, system version WES7 P 64Bit 4GB RAM .............................................. 121

10.7.5 CPU 1515SP PC F, system version WES7 P 64Bit 4GB RAM ........................................... 124

10.7.6 CPU 1515SP PC, system version WES7 E 64Bit 4GB RAM - spare part ........................... 127

10.7.7 CPU 1515SP PC (F) + HMI ................................................................................................. 130

10.7.8 S7-1500 Software Controller CPU 1505SP (F) ................................................................... 130

10.8 Dimension drawings ............................................................................................................. 131

10.8.1 CPU 1515SP PC (F) ............................................................................................................ 131

A Accessories/spare parts ....................................................................................................................... 133

B Abbreviations ....................................................................................................................................... 135

C Troubleshooting ................................................................................................................................... 137

Glossary .............................................................................................................................................. 138

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

11

1

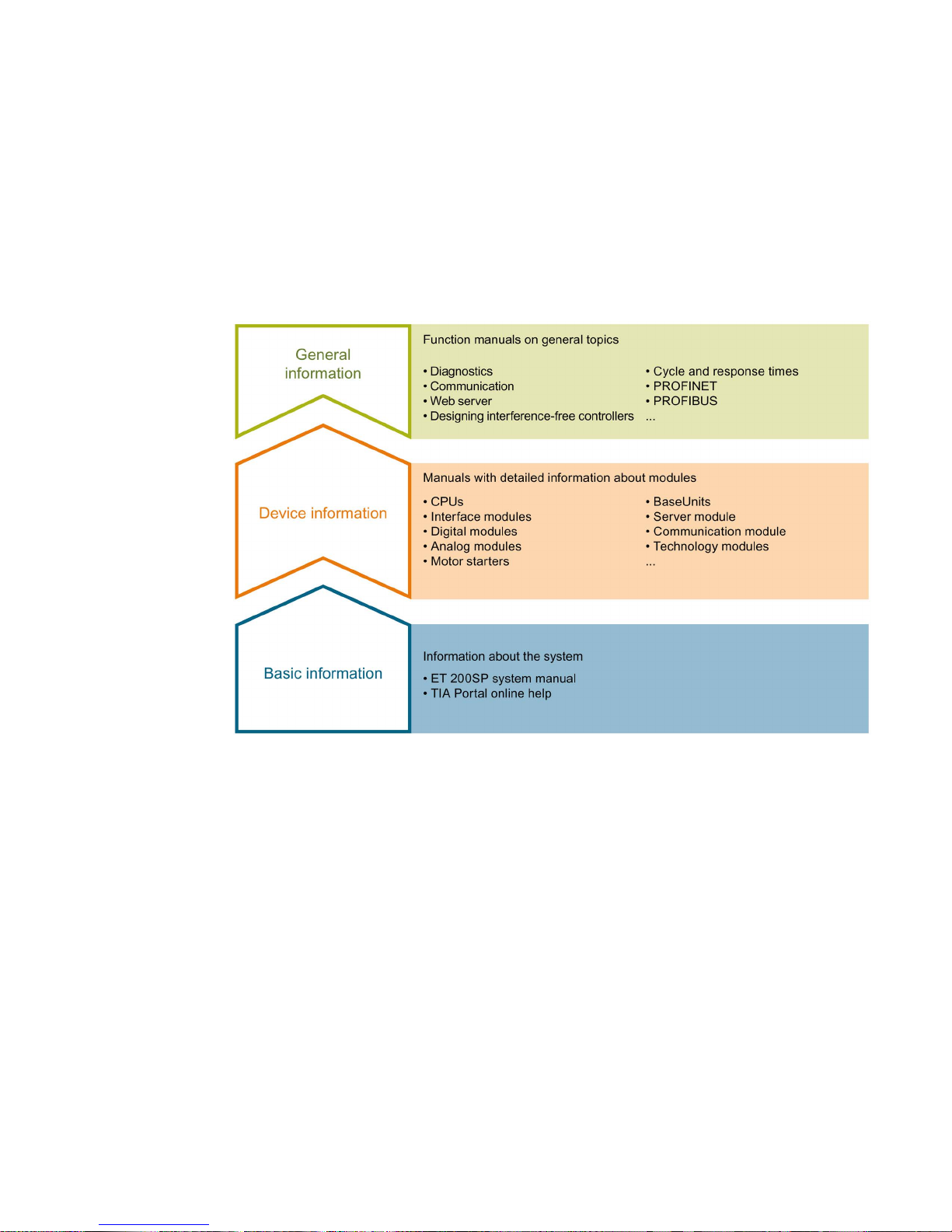

The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three

areas.

This arrangement enables you to access the specific content you require.

Basic information

The system manual describes in detail the configuration, installation, wiring and

commissioning of the SIMATIC ET 200SP. distributed I/O system. The STEP 7 online help

supports you in the configuration and programming.

Device information

Product manuals contain a compact description of the module-specific information, such as

properties, wiring diagrams, characteristics and technical specifications.

Documentation guide

1.1 Documentation on CPU 1515SP PC (F)

CPU 1515SP PC (F)

12 Manual, 05/2017, A5E32701806-AC

General information

The function manuals contain detailed descriptions on general topics regarding the SIMATIC

ET 200SP distributed I/O system, e.g. diagnostics, communication, Web server, motion

control and OPC UA.

You can download the documentation free of charge from the Internet

(http://w3.siemens.com/mcms/industrial-automation-systems-simatic/en/manual-

overview/tech-doc-et200/Pages/Default.aspx).

Changes and supplements to the manuals are documented in a Product Information.

You can download the product information free of charge from the Internet

(https://support.industry.siemens.com/cs/us/en/view/73021864).

Manual Collection ET 200SP

The Manual Collection contains the complete documentation on the SIMATIC ET 200SP

distributed I/O system gathered together in one file.

You can find the Manual Collection on the Internet

(http://support.automation.siemens.com/WW/view/en/84133942).

"mySupport"

With "mySupport", your personal workspace, you make the most of your Industry Online

Support.

In "mySupport" you can store filters, favorites and tags, request CAx data and put together

your personal library in the Documentation area. Furthermore, your data is automatically

filled into support requests and you always have an overview of your current requests.

You need to register once to use the full functionality of "mySupport".

You can find "mySupport" in the Internet (https://support.industry.siemens.com/My/ww/en).

"mySupport" - Documentation

In the Documentation area of "mySupport", you have the possibility to combine complete

manuals or parts of them to make your own manual.

You can export the manual in PDF format or in an editable format.

You can find "mySupport" - Documentation in the Internet

(http://support.industry.siemens.com/My/ww/en/documentation).

"mySupport" - CAx Data

In the CAx Data area of "mySupport", you can have access the latest product data for your

CAx or CAe system.

You configure your own download package with a few clicks.

Documentation guide

1.1 Documentation on CPU 1515SP PC (F)

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

13

In doing so you can select:

● Product images, 2D dimension drawings, 3D models, internal circuit diagrams, EPLAN

macro files

● Manuals, characteristics, operating manuals, certificates

● Product master data

You can find "mySupport" - CAx Data in the Internet

(http://support.industry.siemens.com/my/ww/en/CAxOnline).

Application examples

The application examples support you with various tools and examples for solving your

automation tasks. Solutions are shown in interplay with multiple components in the system separated from the focus in individual products.

You can find the application examples on the Internet

(https://support.industry.siemens.com/sc/ww/en/sc/2054).

TIA Selection Tool

With the TIA Selection Tool, you can select, configure and order devices for Totally

Integrated Automation (TIA).

This tool is the successor of the SIMATIC Selection Tool and combines the known

configurators for automation technology into one tool.

With the TIA Selection Tool, you can generate a complete order list from your product

selection or product configuration.

You can find the TIA Selection Tool on the Internet

(http://w3.siemens.com/mcms/topics/en/simatic/tia-selection-tool).

Documentation guide

1.1 Documentation on CPU 1515SP PC (F)

CPU 1515SP PC (F)

14 Manual, 05/2017, A5E32701806-AC

SIMATIC Automation Tool

You can use the SIMATIC Automation Tool to run commissioning and maintenance activities

simultaneously on various SIMATIC S7 stations as a bulk operation independently of the TIA

Portal.

The SIMATIC Automation Tool provides a multitude of functions:

● Scanning of a PROFINET/Ethernet network and identification of all connected CPUs

● Address assignment (IP, subnet, gateway) and station name (PROFINET device) to a

CPU

● Transfer of the data and the programming device/PC time converted to UTC time to the

module

● Program download to CPU

● Operating mode switchover RUN/STOP

● Localization of the CPU by means of LED flashing

● Reading out CPU error information

● Reading the CPU diagnostic buffer

● Reset to factory settings

● Updating the firmware of the CPU and connected modules

You can find the SIMATIC Automation Tool on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/98161300).

PRONETA

With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network

during commissioning. PRONETA features two core functions:

● The topology overview independently scans PROFINET and all connected components.

● The IO check is a fast test of the wiring and the module configuration of a system.

You can find SIEMENS PRONETA on the Internet

(https://support.industry.siemens.com/cs/ww/en/view/67460624).

1.1

Documentation on CPU 1515SP PC (F)

The following additional documentation is required for using the CPU 1515SP PC (F):

● Operating manual S7-1500 software controller

(http://support.automation.siemens.com/WW/view/en/109249299)

● System manual WinCC Advanced V14

(http://support.automation.siemens.com/WW/view/en/109742297)

● System manual ET 200SP distributed I/O system

(http://support.automation.siemens.com/WW/view/en/58649293)

● Manual Server module (http://support.automation.siemens.com/WW/view/en/63257531)

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

15

Safety notes

2

WARNING

Life-endangering voltage when control cabinet is open

If the device is installed in a control cabinet, areas or components can be under lifeendangering voltage when the control cabinet is open.

Contact with these areas or components may lead to death through electric shock.

Switch off the power before opening the control cabinet.

If the device is operated in a machine in accordance with the machinery directive, the

provisions of the guideline 2006/42/EC apply.

Safe operation of a plant

WARNING

Risk of fire

The device is classified for use in the area of Industrial Control Equipment as "Open Type"

according to UL508. If overheating occurs, burning material may leak and cause a fire.

For this reason, observe the following information:

• For approval and operation in accordance with UL508, the device must be installed in a

housing complying with UL508.

• Install the device in an enclosure that meets the requirements of sections 4.6 and 4.7.3

of the standards EN 60950-1:2006 and IEC/UL/EN/DIN-EN 60950-1.

If you have questions about the validity of installation in the planned environment, please

contact our service representatives.

N

OTICE

Protective measures

To ensure safe operation of a plant, you have to take suitable IT security measures, for

example, network segmentation.

Seal the cover with lead to protect the CFast card with the operating system of the

CPU 1515SP PC (F) against unauthorized access.

For more information on Industrial Security, refer to the Internet

(http://www.siemens.com/industrialsecurity).

Safety notes

CPU 1515SP PC (F)

16 Manual, 05/2017, A5E32701806-AC

Repairs

WARNING

Damage caused by opening the device

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or endanger the user.

Only authorized personnel are permitted to repair the device.

For additional information on repairs, see section Sending the device to customer service

(Page 99).

ESD guidelines

Modules containing electrostatic sensitive devices (ESDs) can be identified by the following

label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive to

ESD:

● Before working with modules with ESD, you need to ensure that you are free of

electrostatic charge (e.g. by touching a grounded object).

● All devices and tools must be free of static charge.

● Always pull the mains connector and disconnect the battery before installing or removing

modules which are sensitive to ESD.

● Handle modules fitted with ESDs only by their edges.

● Do not touch any connector pins or conductors on modules containing ESDs.

See also

Electromagnetic compatibility (Page 105)

Safety notes

2.1 Notes on use

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

17

2.1 Notes on use

WARNING

Hazards at an unprotected machine or plant

According to the results of a risk analysis, hazards can occur at an unprotected machine.

The hazards may lead to personal injury.

According to the risk analysis, the risk of injury to persons can be countered with the

following measures:

• Additional protective equipment at the machine or plant. In this case, the programming,

parameter assignment and wiring of the I/O used, in particular, must be performed in

accordance with the safety criteria (SIL, PL or Cat.) ascertained by means of an

appropriate risk analysis.

• Use of the device for its intended purpose, which can be established by performing a

functional test on the plant. This allows errors in programming, parameter assignment

and wiring to be detected.

• Documentation of the test results which can be entered, if required, into the relevant

safety certificates.

NOTICE

Ambient conditions

Ambient conditions for which the device is not suitable can lead to faults or damage the

device.

Note the following:

• Only operate the device in enclosed areas. If you do not comply with this instruction, the

warranty becomes void.

• Only operate the device in accordance with the ambient conditions given in the technical

specifications.

• Protect the device from dust, moisture and heat.

• Do not expose the device to direct sunlight or other strong sources of light.

• The device must not be used in places with more difficult operating conditions through

corrosive vapors or gases without taking additional protective measures, for example,

supply of clean air.

CPU 1515SP PC (F)

18 Manual, 05/2017, A5E32701806-AC

3

3.1

Fail-safe option

Areas of application

F-CPUs are mainly designed for personal and machine protection. In addition to the safety

program, you can also program standard applications. You can operate the F-CPUs in safety

mode or in standard mode.

Reference

Information on the use of F-CPUs in safety mode is available in the programming and

operating manual SIMATIC Safety - Configuring and Programming

(http://support.automation.siemens.com/WW/view/en/54110126).

You can find information on using the CPU 1505SP (F) software controller in the

corresponding product manual

(https://support.industry.siemens.com/cs/ww/en/view/109740725) and in the F product

information (https://support.industry.siemens.com/cs/ww/en/view/109478599).

Product overview

3.2 Properties

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

19

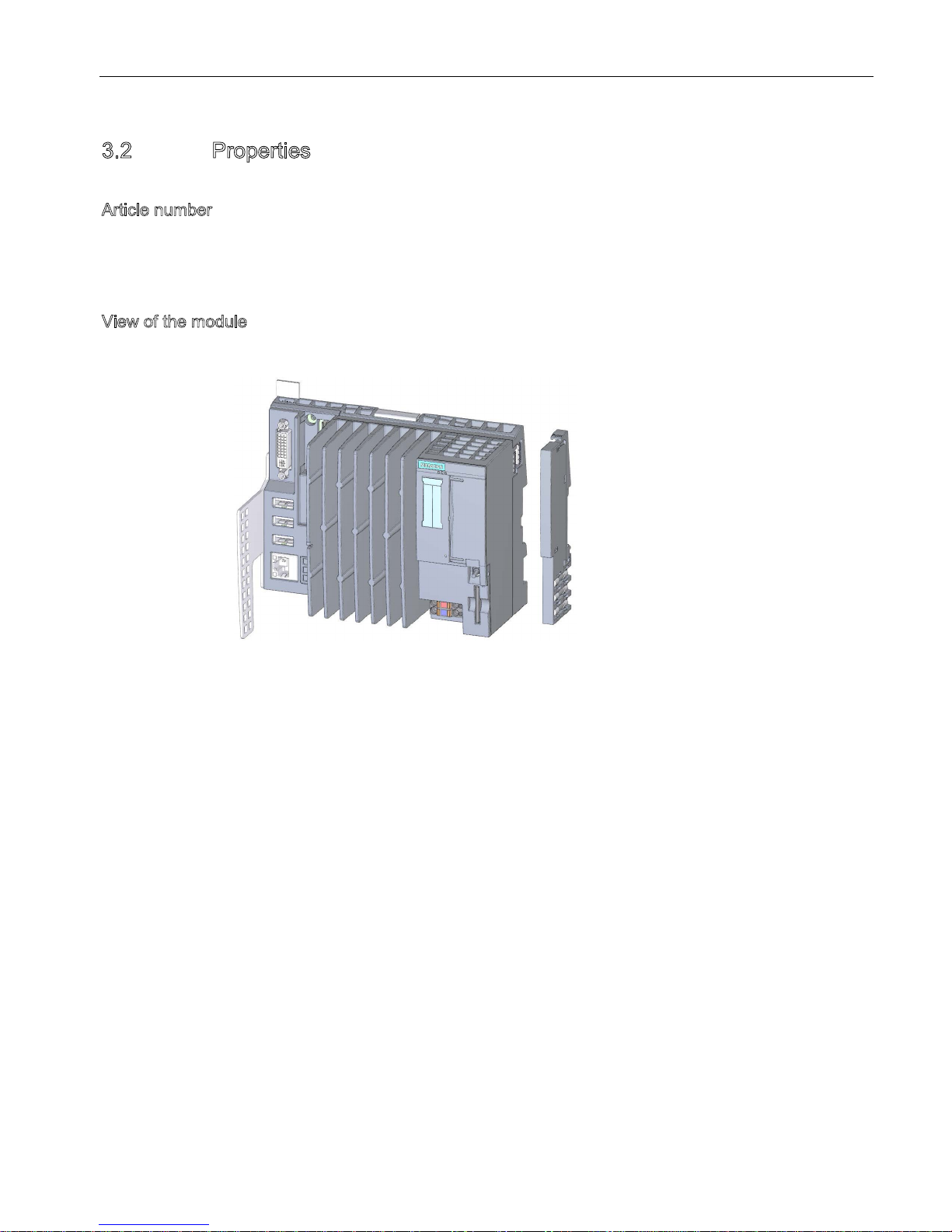

3.2 Properties

Article number

6ES7677-2xAxx-0xx0

The complete article number depends on the system version and the ordering option.

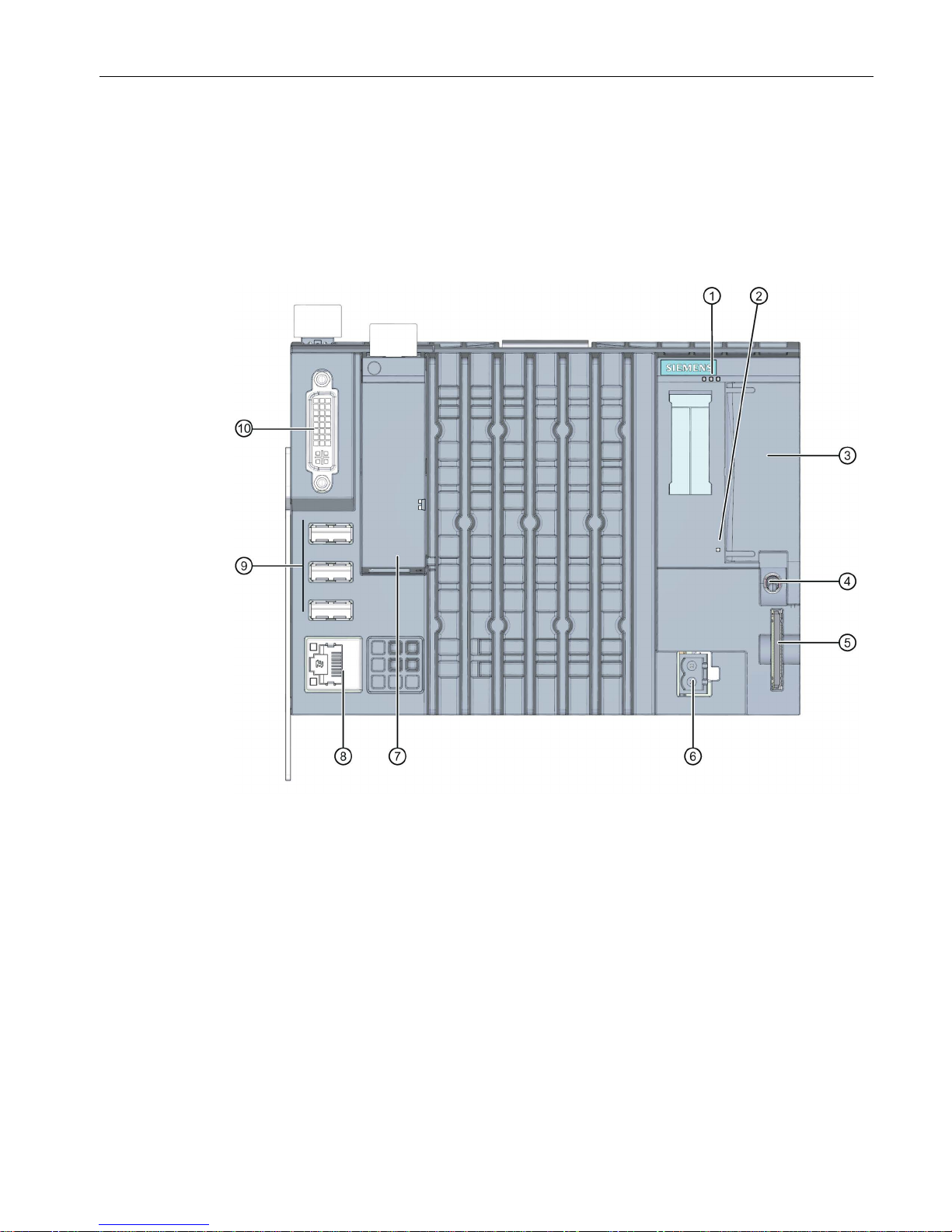

View of the module

The figure below shows the CPU 1515SP PC.

Figure 3-1 CPU 1515SP PC with supplied accessories

Product overview

3.2 Properties

CPU 1515SP PC (F)

20 Manual, 05/2017, A5E32701806-AC

Properties

CPU 1515SP PC (F) is a PC based automation device in the design of the ET 200SP. It is

used for control and visualization purposes. The supplied IPC DiagBase software provides

basic diagnostics functions and supports you in handling the BIOS.

CPU 1515SP PC (F) has the following technical properties:

● A removable CFast card with the following pre-installations is used as storage medium:

– Windows Embedded Standard 7 operating system

– S7-1500 Software Controller CPU 1505SP (F)

– Optionally with HMI: WinCC Runtime Advanced as of V14 SP1

● Interfaces

– An interface for the exchangeable ET 200SP BusAdapters for connection of

PROFINET IO (2 ports)

– An interface for connecting devices using Industrial Ethernet (Gigabit Ethernet)

– 3 interfaces for USB devices

– One DVI-I interface for a monitor

– A sealable slot for the CFast card

– A slot for an SD/MMC card as additional optional drive

● Supply voltage 1L+ 24 V DC (SELV/PELV). The connection plug is included in the scope

of delivery.

● CPU 1515SP PC (F) is designed for use in industrial environment:

– Compact design

– Fan-less operation

– High robustness

● The CPU 1515SP PC (F) is approved for the degree of protection IP20 and for the

installation in a control cabinet.

Product overview

3.3 Sample configuration

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

21

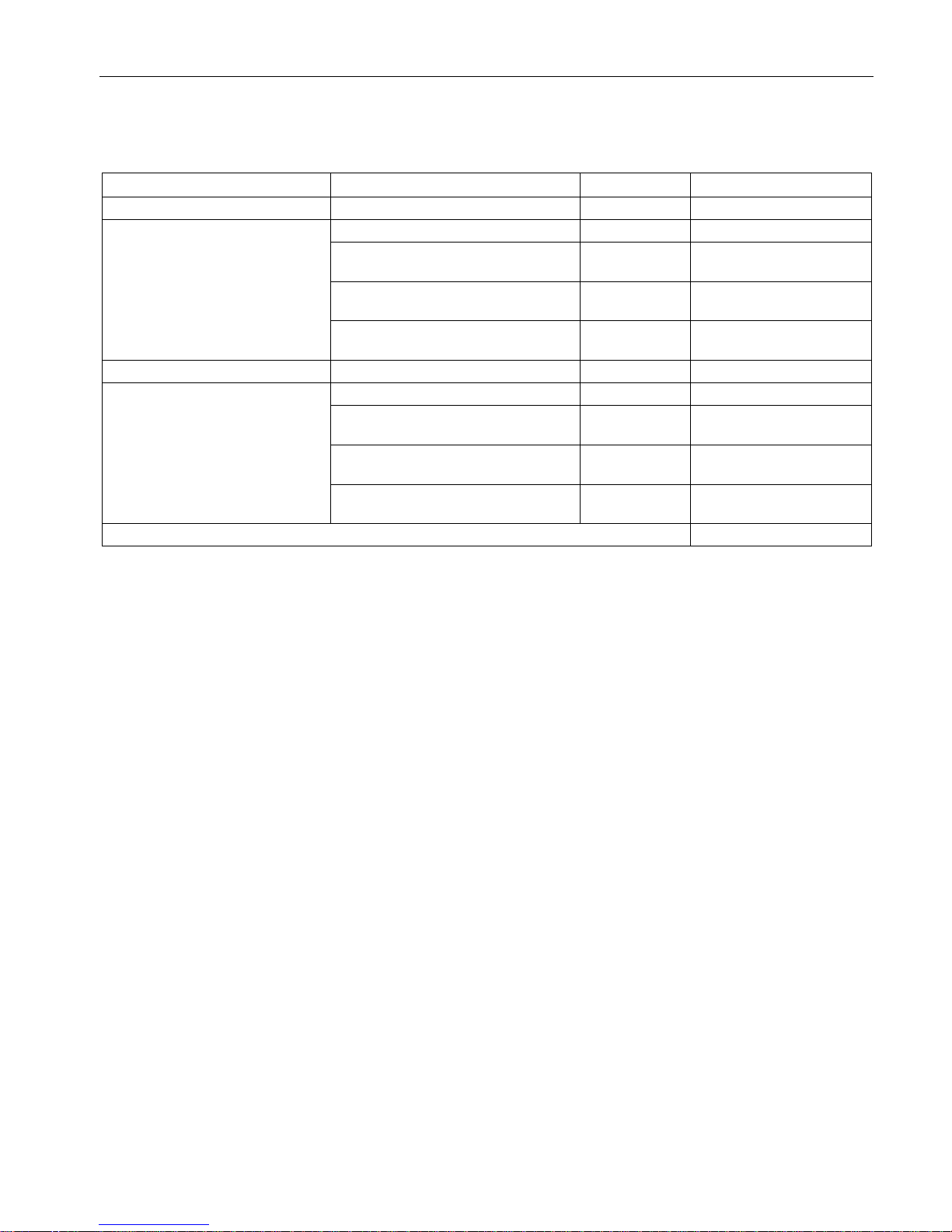

System versions and ordering options

System version

SIMATIC software

CFast card

Article number

WES7 E 32Bit

CPU 1505SP V2.1

30 GB

6ES7677-2AA31-0EB0

WES7 P 64Bit

(multitouch functionality)

CPU 1505SP V2.1 30 GB 6ES7677-2AA41-0FB0

CPU 1505SP V2.1 & WinCC Runtime

Adv. V14 SP1 128PT

30 GB 6ES7677-2AA41-0FK0

CPU 1505SP V2.1 & WinCC Runtime

Adv. V14 SP1 512PT

30 GB 6ES7677-2AA41-0FL0

CPU 1505SP V2.1 & WinCC Runtime

Adv. V14 SP1 2048PT

30 GB 6ES7677-2AA41-0FM0

WES7 E 32Bit

CPU 1505SP F V2.1

30 GB

6ES7677-2FA31-0EB0

WES7 P 64Bit

(multitouch functionality)

CPU 1505SP F V2.1

30 GB

6ES7677-2FA41-0FB0

CPU 1505SP F V2.1 & WinCC

Runtime Adv. V14 SP1 128PT

30 GB 6ES7677-2FA41-0FK0

CPU 1505SP F V2.1 & WinCC

Runtime Adv. V14 SP1 512PT

30 GB 6ES7677-2FA41-0FL0

CPU 1505SP F V2.1 & WinCC

Runtime Adv. V14 SP1 2048PT

30 GB 6ES7677-2FA41-0FM0

CPU 1515SP PC, spare part, without CFast card, without software

6ES7677-2AA40-0AA0

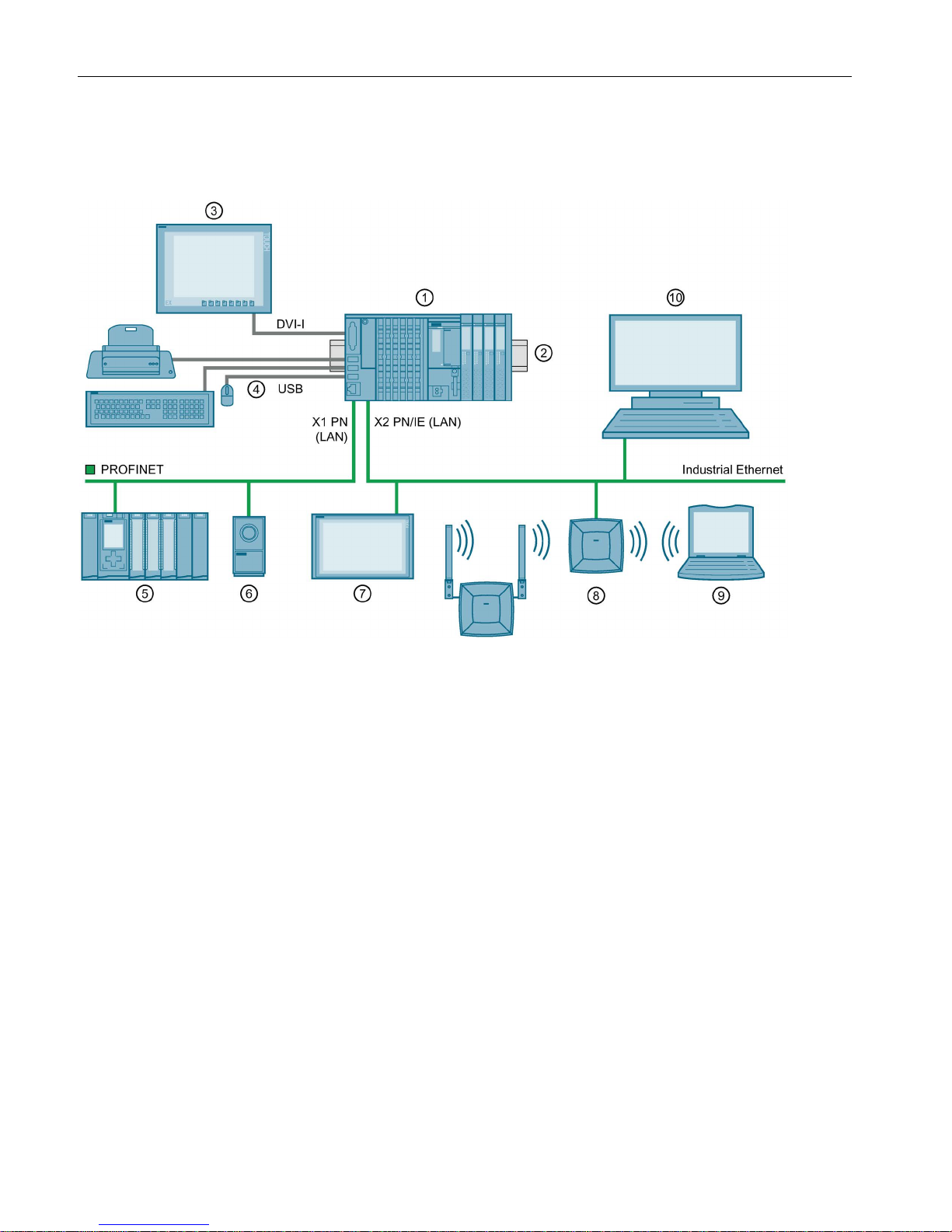

3.3

Sample configuration

Configuration

CPU 1515SP PC (F) is mounted on the mounting rail according to EN 60715. A modular

system is formed with ET 200SP modules in the central rack.

You can use the CPU 1515SP PC (F) as PROFINET IO controller. The PROFINET IO

devices are connected with the SIMATIC BusAdapter BA 2xRJ45 via the ports of the

interface X1 PN (LAN).

Devices can be connected via Industrial Ethernet using the integrated interface

X2 PN/IE (LAN).

The connection to PROFIBUS can be made using the DP master module.

Product overview

3.3 Sample configuration

CPU 1515SP PC (F)

22 Manual, 05/2017, A5E32701806-AC

Sample configuration

The figure below shows an example configuration with CPU 1515SP PC (F).

Figure 3-2 Example configuration with the CPU 1515SP PC (F)

①

CPU

1515SP PC (F), I/O module, server module

②

Mounting rail

③

Flat Panel

- Wide Screen Display

④

USB devices: Keyboard, mouse, printer ...

⑤

PROFINET IO device

⑥

Camera

⑦

Industrial Thin Client ITC

⑧

SCALANCE W786

⑨

Field programming device

⑩

P

C/Programming device

Product overview

3.4 Components

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

23

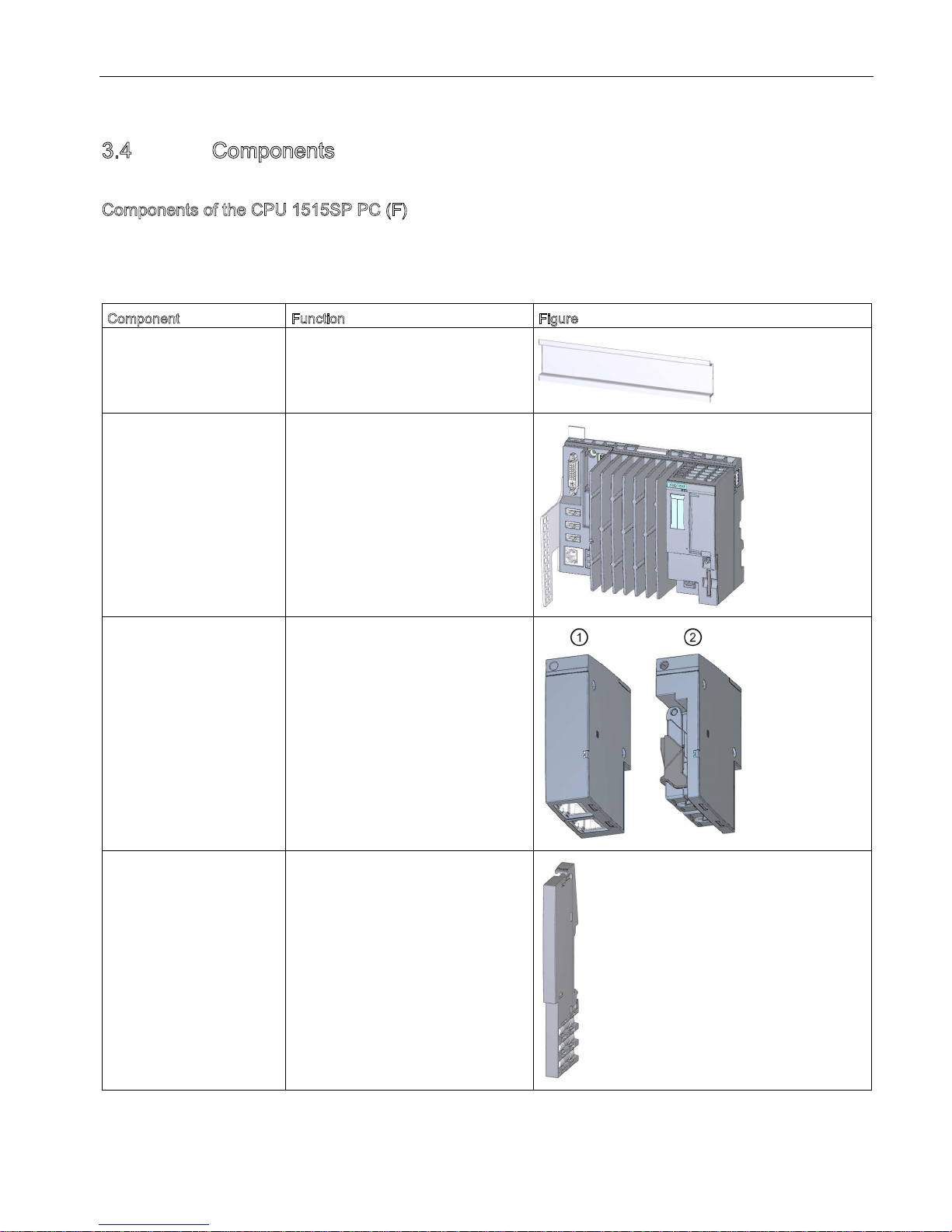

3.4 Components

Components of the CPU 1515SP PC (F)

The table below contains an overview of the components of the CPU 1515SP PC (F):

Table 3- 1 Components of the CPU 1515SP PC

Component

Function

Figure

Mounting rail in accordance

with EN 60715

The mounting rail is the module carrier for the CPU 1515SP PC (F).

CPU 1515SP PC (F) CPU with strain relief and white refer-

ence labels

BusAdapter The BusAdapter allows free selection

of the connection technology for

PROFINET IO. The following versions

are available for CPU 1515SP PC (F):

• For standard RJ45 plug

(BA 2×RJ45)

①

• For direct connection of the bus

cable (BA 2×FC) ②

Server module The server module completes the

configuration of the

CPU 1515SP PC (F) with I/O modules.

The server module is included in the

CPU's scope of delivery.

Product overview

3.5 Configuration of the devices

CPU 1515SP PC (F)

24 Manual, 05/2017, A5E32701806-AC

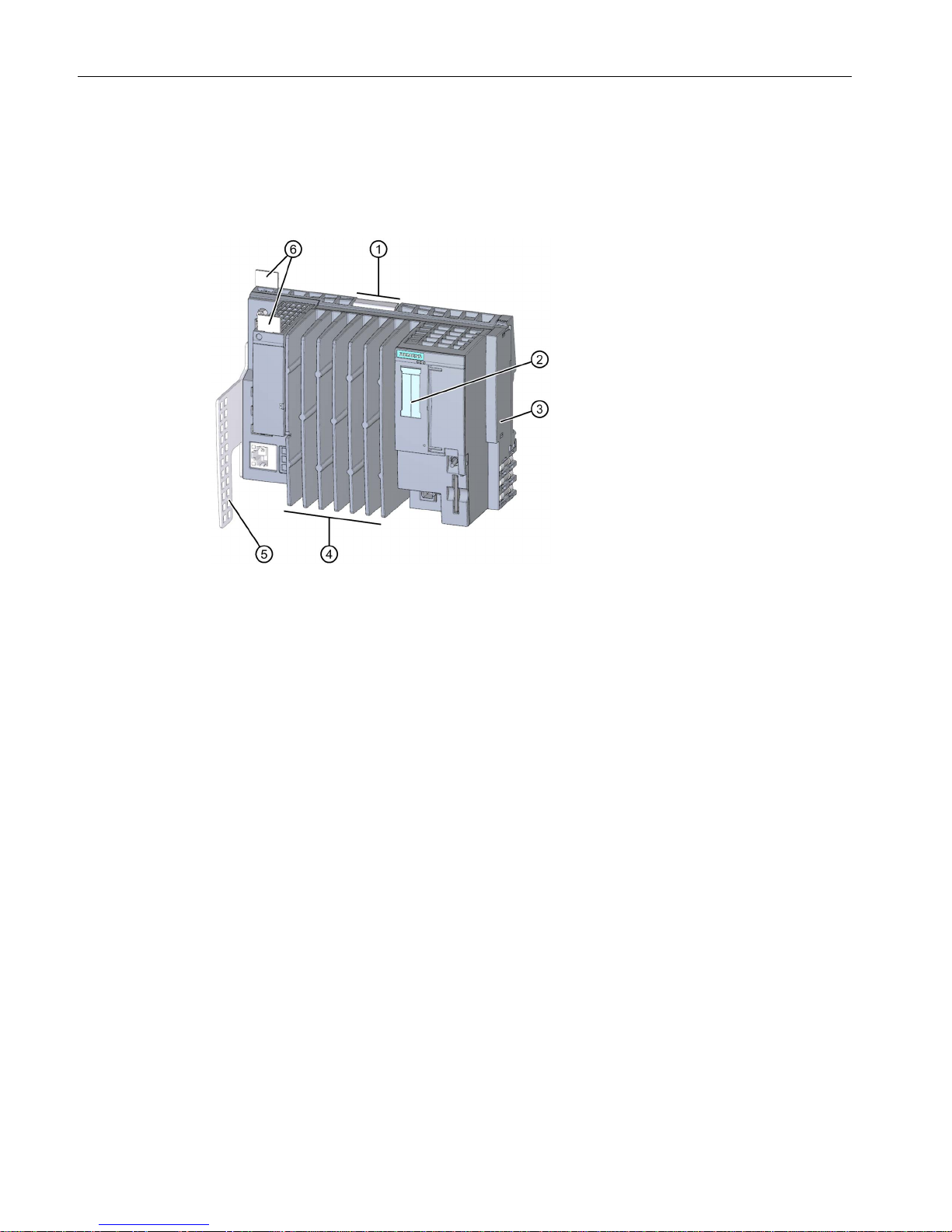

3.5

Configuration of the devices

Front view

Figure 3-3 Front view CPU 1515SP PC (F)

① Mounting rail release mechanism

② Labeling strips

③ Server module

④ Cooling fins

⑤ Strain relief

⑥ Reference labels

Product overview

3.6 Operator controls and display elements

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

25

3.6

Operator controls and display elements

Front view of the module

The figure below shows the operator control and connection elements of the

CPU 1515SP PC (F).

Figure 3-4 View of the CPU 1515SP PC (F)

①

LED displays for the current operating mode and diagnostic status of the CPU

②

Power LED

③

X50:

Slot for the CFast card (flash memory), sealable

④

Mode selector

⑤

X51:

Slot for an optional SD/MMC card

⑥

X80:

Connector for 24 V DC supply voltage

⑦

X1 PROFINET

(LAN):

Slot for BusAdapter for connection of PROFINET IO;

status display for PROFINET

⑧

X2 PN/IE (LAN):

GbE Ethernet connection with integrated display

⑨

X60, X61, X62:

3 USB connections

⑩

X70 DVI-I:

Connection for monitor

Product overview

3.6 Operator controls and display elements

CPU 1515SP PC (F)

26 Manual, 05/2017, A5E32701806-AC

Slot for CFast card

The operating system, Runtime software and project are installed on the supplied SIMATIC

CFast card. The CFast card is the only mass storage device of the CPU 1515SP PC (F).

Note

Unauthorized access

Seal the cover of the shaft with lead to protect the CFast card with the operating system of

the CPU

1515SP PC (F) against unauthorized access and manipulation.

Slot for SD/MMC card

You can use a SIMATIC SD or MMC card as additional storage drive. This drive can be used

to store data via Windows, for example a backup, but not the operating system, the Runtime

software or the project.

Permitted SD cards: SDHC up to 32 GB, SDXC up to 2 TB.

USB connections

Two USB high-current (500 mA) interfaces and one low-current (100 mA) interface can be

used at the same time.

MAC addresses

The MAC address consists of a 3-byte manufacturer ID and a 3-byte device ID (consecutive

number).

Each device is already assigned four MAC addresses in the factory. The front of the CPU

1515SP PC (F) is lasered with the MAC addresses 1 and 4. With the MAC addresses 2 and

3, the consecutive numbers are incremented. If, for example, the first MAC address is

08-00-06-6B-80-C0, the second MAC address is 08-00-06-6B-80-C1.

Table 3- 2 Assignment of the MAC addresses

Assignment

MAC address 1

X2 PN/IE (LAN)

• Visible in STEP 7 for accessible devices

• Lasered on the front of the CPU (start of the number range)

MAC address 2

X1 PROFINET (LAN)

• Visible in STEP 7 for accessible devices

MAC address 3

Port X1 P1 (required for LLDP, for example)

MAC address 4

Port X1 P2 R (required for LLDP, for example)

• Lasered on the front of the CPU (end of the number range)

Product overview

3.6 Operator controls and display elements

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

27

Connector for supply voltage

CPU 1515SP PC (F) has a 2-pole terminal for the power supply.

The connection plug for the supply voltage is plugged in when the CPU is shipped from the

factory.

Mode selector

Use the mode selector to set the CPU operating mode.

Table 3- 3 Mode selector positions

Position

Meaning

Description

RUN

Operating mode RUN1

The CPU is processing the user program.

STOP Operating mode STOP1 The CPU is not processing the user program.

The outputs are set to a "safe" state.

MRES Memory reset

For active S7-1500 software controller

2

only:

CPU memory reset

1

RUN and STOP indicate the

selected

operating state. The LED displays RUN and STOP display the

actual

operating

state of the CPU 1515SP PC (F).

2

See the S7-1500 software controller manual

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

28 Manual, 05/2017, A5E32701806-AC

3.7

Scope of delivery

3.7.1

Unpacking the device

When unpacking

When unpacking, make sure to check the following:

● Check packaging and contents for visible damage from transport.

● Check the delivery for completeness.

Please inform your Siemens contact partner should you determine damages from

transport or any irregularities.

● Keep the supplied documentation and licenses. They belong to the device and are the

proof that you have purchased the software preinstalled on the CFast card.

Documentation and licenses are required for initial commissioning and for any questions

that arise.

● Keep the original packaging in case the device needs to be transported again.

NOTICE

Damage to the device during transport and storage

If a device is transported or stored without packaging, it is unprotected from shocks,

vibrations, pressure and moisture. Damaged packaging indicates that environmental

conditions have already had a significant impact on the device.

The device might be damaged.

Do not dispose of the original packaging. Pack the device for transport and storage.

NOTICE

Damage to the device caused by condensation

If the device was exposed to low temperatures or extreme variations in temperature during

transport, this may cause moisture to build up on or in the device (condensation).

Moisture can cause short-circuits in the electrical circuits and damage the device.

Proceed as follows to avoid damage:

• Store the device in dry conditions.

• Make sure it adapts to room temperature before commissioning.

• Do not expose the device to direct heat radiation from a heater.

• If condensation has developed, wait for approximately 12 hours or until the device is

completely dry before you switch it on.

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

Manual, 05/2017, A5E32701806-AC

29

WARNING

Electric shock and fire hazard from damaged device

A damaged device can carry dangerous voltage and trigger a fire in the machine or plant. A

damaged device has unpredictable properties and states.

Death or severe injury could occur.

Make sure that the damaged device is not installed and commissioned accidentally. Label

the damaged device correspondingly and keep it locked up. Have the device repaired

without delay.

Identification data

The identification data can be used to clearly identify the device when a repair is necessary.

Make a note of the following data for your devices:

● The article number of the CPU 1515SP PC (F) is located on the order form.

● Depending on the scope of delivery, the "Certificate-of-License" is included in the license

verification for the S7-1500 software controller and for WinCC Runtime Advanced V14

SP1.

● The "Microsoft Windows Product Key" can be found on the "Certificate of Authenticity"

label.

● The first and the last MAC addresses are located on the device.

Product overview

3.7 Scope of delivery

CPU 1515SP PC (F)

30 Manual, 05/2017, A5E32701806-AC

3.7.2

Scope of delivery - System version WES7 E 32Bit 4GB RAM

Note

The designation CPU 1515SP PC

with the article number 6ES7677

-2AA40-0AA0

is always

on the device regardless of the order option.

The following components are included in the scope of delivery of the CPU 1515SP PC:

Order option

CPU 1515SP PC

CPU 1515SP PC

(spare part)

Article number

6ES7677-2AA31-0EB0

6ES7677-2AA40-0AA0

CPU

X

X

Strain relief with fixing screws

X

X

Server module

X

X

30 GB CFast card with the following

pre-installations:

• Windows Embedded Standard 7 E

operating system

X –

• S7-1500 Software Controller

CPU 1505SP

X –

• WinCC RT Advanced as of V14

SP1

– –

Restore DVD for image restore

X

–

"Documentation and Drivers" DVD

X

–

Windows-Certificate of Authenticity

(CoA)

X –

Certificate of License (COL)

X – USB stick with SIMATIC license keys

X

–

Product information

X

–

Loading...

Loading...