Page 1

s

xTronic™Gas Convection Range

LP Conversion Kit

Cuisinière à gaz Nécessaire de conversion LP

Estufa de Gas Kit de Conversión a Gas LP

For use with models: HG2415UC, HG2416UC, HG2515UC,

HG2516UC, HD2515U, HD2516U, HD2515C, HD2416C

Please read instructions before using.

Important: Save these instructions.

Installer: Please leave these instructions with this unit for the owner.

Owner: Please retain these instructions for future reference.

Page 2

FR

Emplacement orifice

surface de cuisson LP

DOS CUISINIÈRE

ArG

ArD

AvG

AvD

DEVANT CUISINIÈRE

Arrière gauche (ArG) Brûleur - 101 (Rouge)

Avant gauche (AvG) Brûleur - 86 (Jaune)

Arrière droit (ArD) Brûleur - 70 (Vert)

Avant droit (AvD) Brûleur - 116 (Blanc)

EN

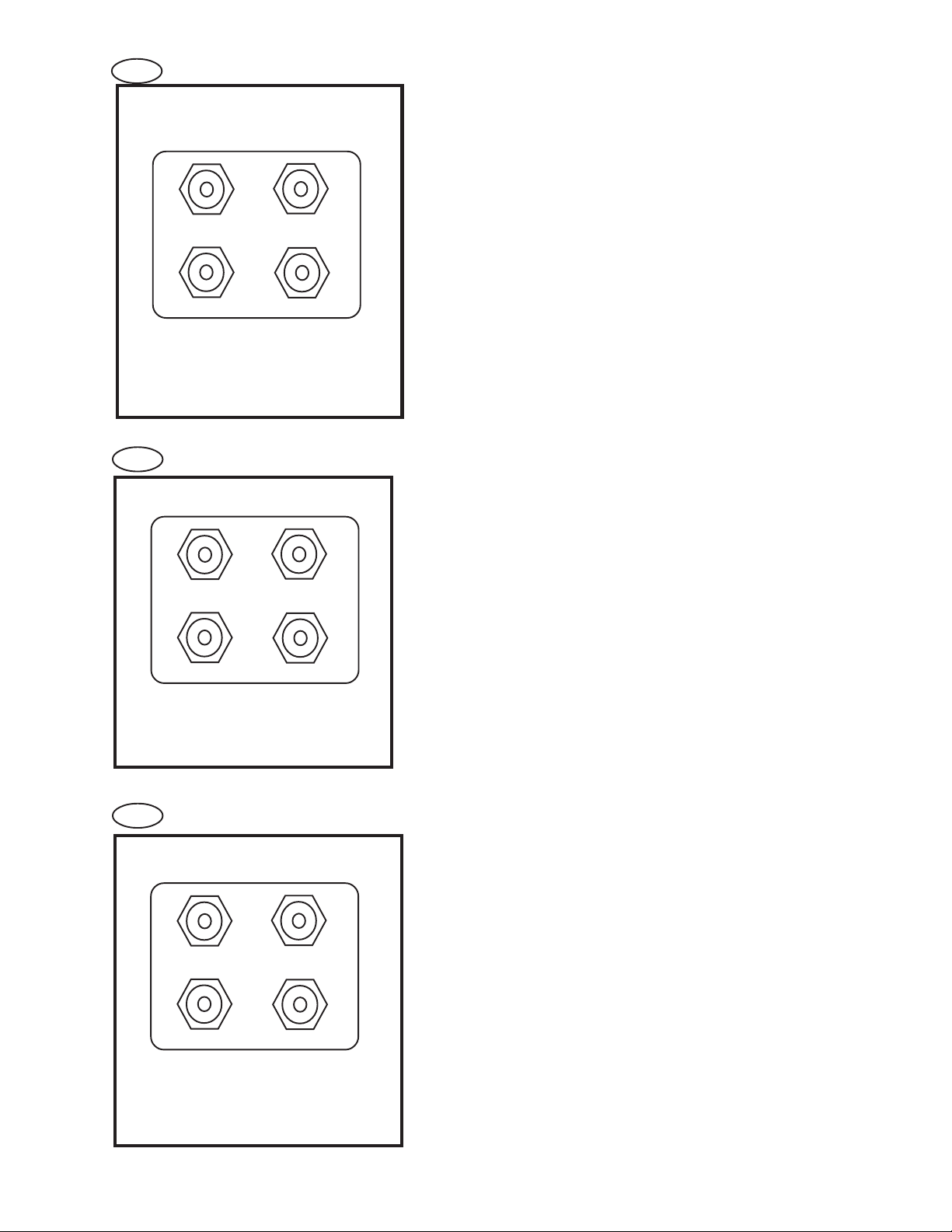

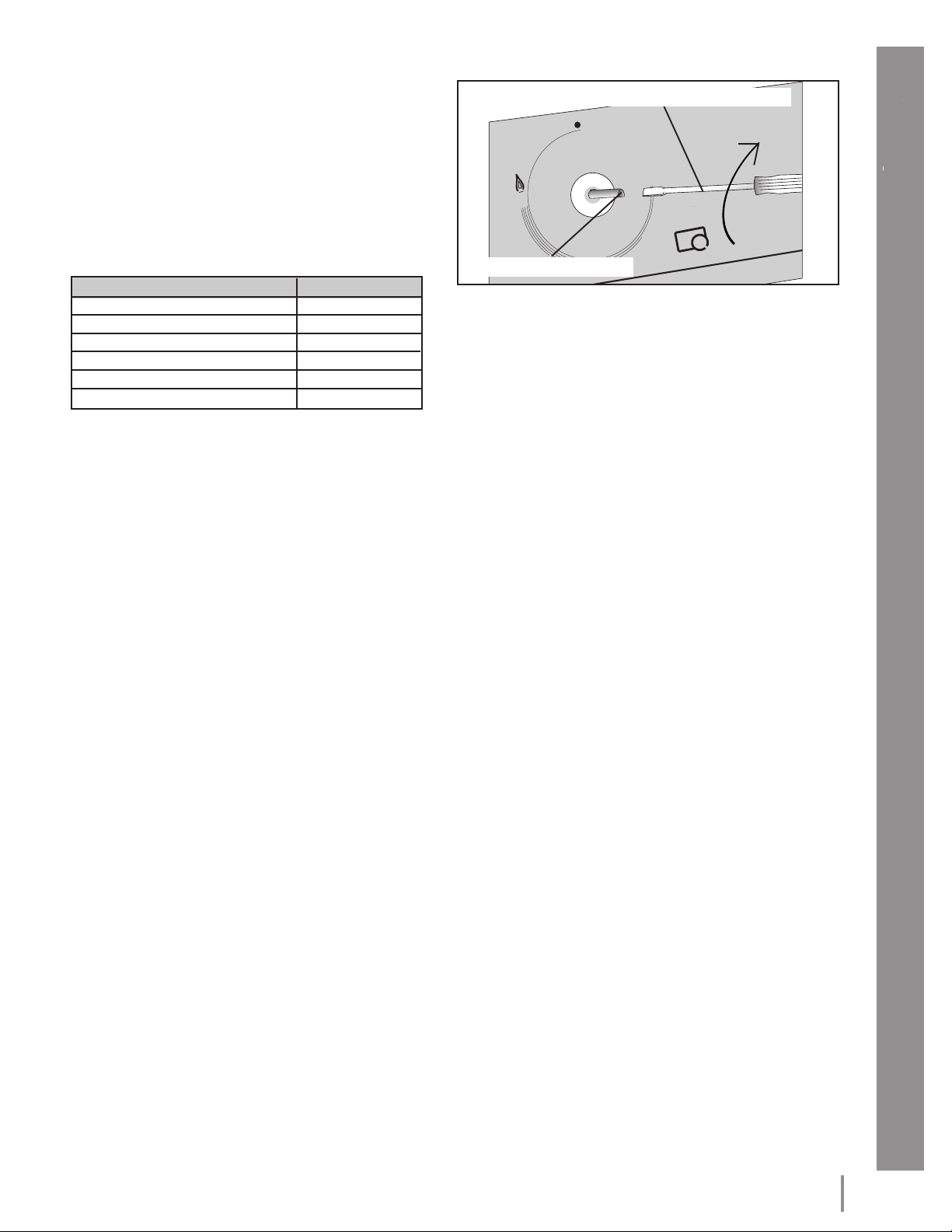

LP Cooktop Orifice Placement

BACK OF RANGE

LR

LF

FRONT OF RANGE

Left Rear (LR) Burner - 101 (Red)

Left Front (LF) Burner - 86 (Yellow)

Right Rear (RR) Burner - 70 (Green)

Right Front (RF) Burner -116 (White)

RR

RF

ES

Colocación de Orificios de Estufa LP

FONDO DE ESTUFA

TI

DI

FRENTE DE ESTUFA

Tras Izq. (TI) Quemador - 101 (Rojo)

Delant Izq. (DI) Quemador - 86 (Amarillo)

Tras Der. (TD) Quemador - 70 (Verde)

Delant Der. (DD) Quemador - 116 (Blanco)

TD

DD

Page 3

Important Safety Instructions

Please read Installation Instructions before beginning the conversion.

This kit is used to convert dual fuel ranges and gas ranges from natural gas operation to propane (LP) gas

operation. Only HD and HG model Siemens ranges can be converted using this kit*.

Please read all instructions before proceeding. Save the natural gas parts for possible conversion from LP back to

natural gas in the future.

Safety

WARNING

This conversion kit shall be installed by a qualified

service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements

of the authority having jurisdiction. If the information

in these instructions is not followed exactly, a fire,

explosion or production of carbon monoxide may result

causing property damage, personal injury or loss of life.

The qualified service agency is responsible for the

proper installation of this kit. The installation is not

proper and complete until the operation of the

converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

High Altitude Installation Note:

This range is CSA certified for safe operation up to an

altitude of 10,000 ft. without any modifications (except LP

conversion, when applicable).

For Massachusetts Installations:

1. Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified

or licensed by the state, province or region where

this appliance is being installed.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than

36 inches.

Kit Contents:

Conversion Kit Instructions

Conversion Sticker

4 LP Orifices (70, 86, 101, 116)

Tools Required:

7 mm Socket Driver w/ 3” extension

Torx (T20)-head screwdriver

Adjustable Wrench

Flathead Screwdriver (1/8” or smaller)

Phillips Head Screwdriver

CAUTION:

(1) When connecting the unit to the propane gas,

make certain the propane gas tank is equipped

with its own high pressure regulator. In addition,

a pressure regulator was supplied with the range.

This second regulator must be installed with the

range.

The maximum gas pressure to this appliance is

not to exceed 14.0 inches water column from the

propane gas tank regulator.

The following must be met when testing supply piping

system:

a) The appliance and its individual shut-off valve

must be disconnected from the gas supply piping

system at test pressures in excess of 1/2 psig (3.5

kPa).

b) The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.5 kPa).

Always Provide Adequate Gas Supply

Siemens Freestanding Dual Fuel and Gas Ranges are

shipped from the factory for use with natural gas. Use this

kit to convert the appliance for LP gas use if necessary.

Observe the following:

• Be sure the range is converted for use with the

appropriate gas before using it.

• Your range is designed to operate at a pressure of

10” of water column when used with LP gas.

• When checking for proper operation of the regulator,

the inlet pressure must be at least 1” greater than

the operating (manifold) pressure above. When

converting for LP gas use, the pressure supplied to

the regulator must be between 11” and 14” of water

column. See step 2 “Convert Pressure Regulator

from 5” to 10” W.C.”, next page.

• The pressure regulator located in the inlet of the

range manifold must remain in the supply line.

• Use a flexible metal appliance connector or rigid

pipe to connect the Range to the gas supply. The

connector should have an I.D. of 1/2” and be 5’ in

length (Exception: Maximum connector length in

Massachusetts installations is 3’). In Canada, the

connector must be single wall metal and not longer

than 6’.

Before You Begin

Cooktop/Oven

Test Conversion

*The model number is stamped on the plate behind the warming or storage drawer.

English •

1

Page 4

Conversion Instructions - Before you begin

1. CAUTION: Turn off Gas and Electricity

Before proceeding with the conversion; shut off the gas

supply to the appliance prior to disconnecting the

electrical power.

Shut off the outside propane tank gas valve to the range.

Remove range power cord from electrical outlet or turn

breaker off at breaker box, and turn all control knobs to

the “OFF” position.

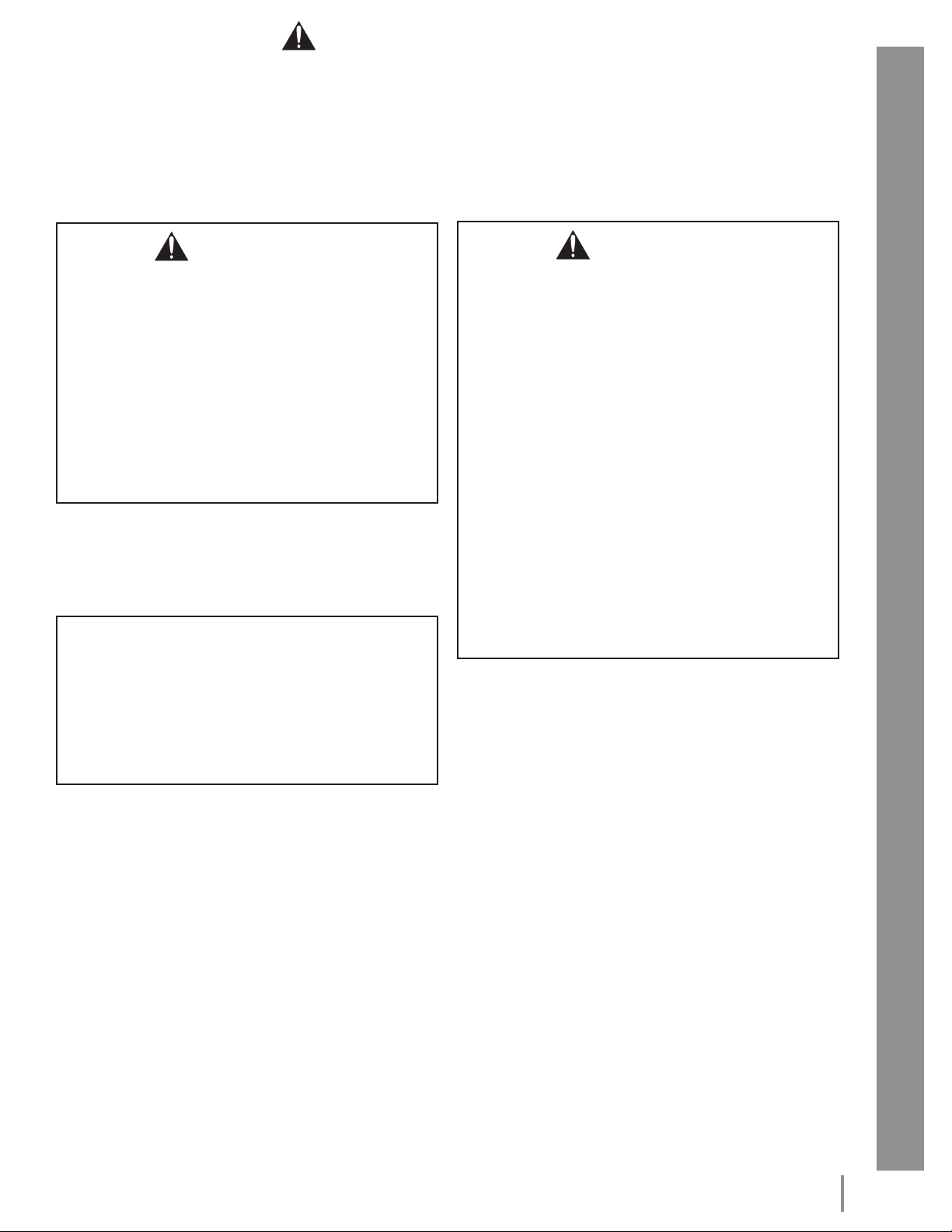

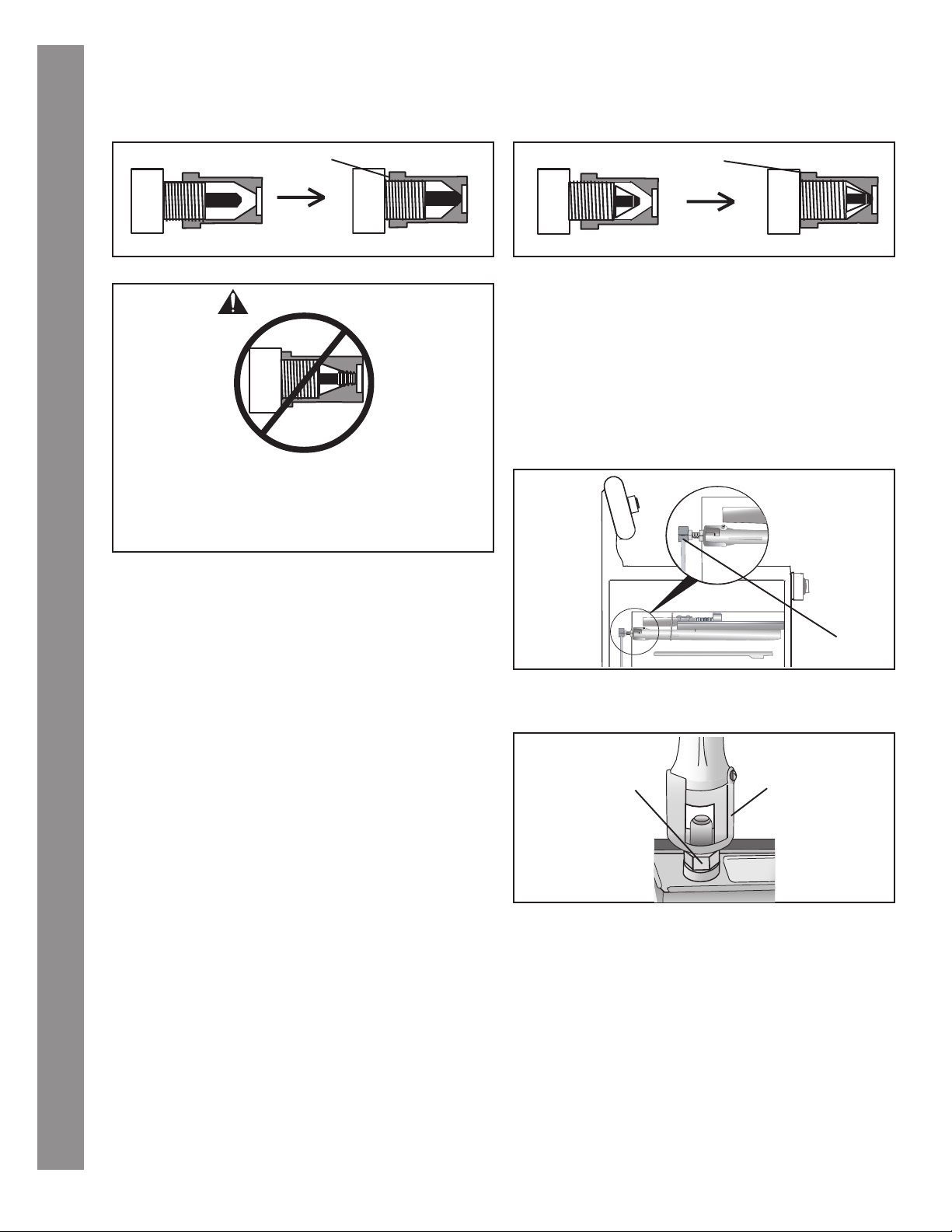

2. Convert Pressure Regulator from 5” W.C.

to 10” W.C.

1. Remove Warming Drawer; Pull drawer out until stop

is reached. Facing the range, push clip on left side

up and clip on right side down. Pull drawer the rest

of the way out.

2. Remove cover plate from interior back wall by

removing single screw on left side of panel. Use a

torx T-20 head screwdriver.

3. Remove the hexagon cap from the top of the

regulator with an adjustable wrench.

4. Pop out the plastic stem in the cap and turn it over

Before You Begin

pressing it firmly in place so that the letters “LP”

(rather than “NAT”) are seen upright in the stem .

5. Replace the cap and button assembly into the top of

the regulator sealing it firmly. Make certain spring is

still in place (See Fig. 1). DO NOT OVER TIGHTEN.

6. Fill out and affix the CONVERSION STICKER on the

back side of the cover plate so that it appears on

the back side of range next to the regulator.

Pin Position

for Propane

Pin Position

for Natural Gas

Hex

Cap

Pin

NA

T

NAT

LP

PRESSURE REGULATOR VIEW

Figure 1 - Convert Pressure Regulator

Grate

Burner Cap

Burner Base

Orifice

Hex

Cap

LP

Spring

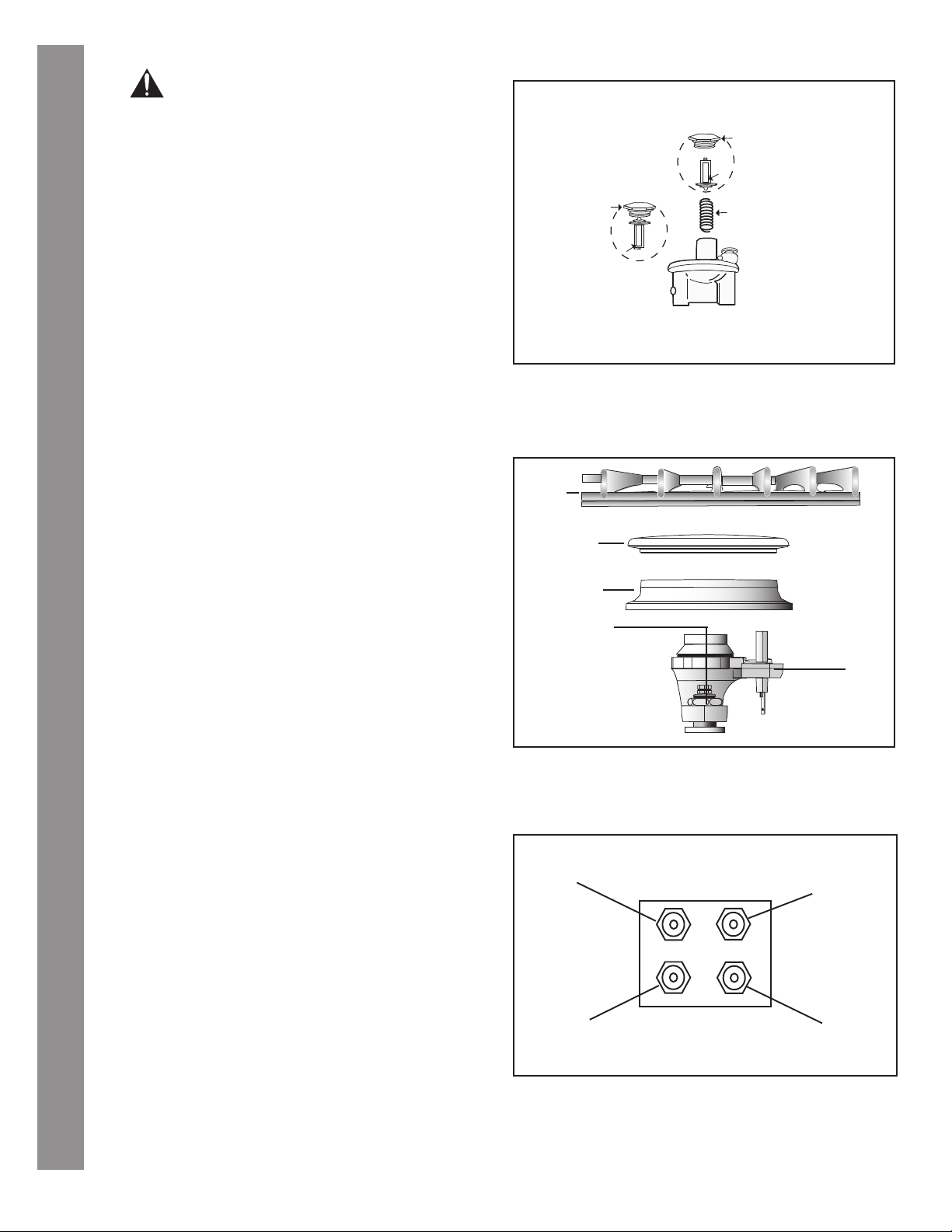

3. Replace Main Cooktop Orifices

Remove Grates, Burner Caps and Burner Bases. Unscrew

two (2) T20 screws inside each base and remove burner

bases (See Figure 2). Reinsert screws in jet holder to hold

tubing assembly in place.

Remove Natural Gas Cooktop Orifices. Insert the socket

driver with 3” minimum extension into the jet holders to

remove existing orifices. Place the old orifices in the

Cooktop/OvenTest Conversion Safety

space provided on page 6 in case future conversion back

to natural gas is necessary.

Assemble LP Cooktop Orifices. Place in cooktop exactly as

laid out on the inside of the front cover of this manual

(also shown in Figure 3). If the orifices become

separated from the cover, placement can be determined

by matching the number and/or color on the orifice with

the placement specifications displayed in Figure 3.

Place the new orifice into the socket then insert each

orifice into its respective threaded hole in the jet holder.

Tighten until the orifice stops turning. DO NOT OVER

TIGHTEN.

Remove screws to replace burner base, burner cap and

burner grate. Replace screws.

Note: Burner cap must be properly positioned on burner

base for burner to light.

Figure 2 - Remove Grate, Cap and Base

Left Rear Burner 11,000 BTU/h 101 (Red)

BACK OF RANGE

FRONT OF RANGE

Left Front Burner 7,500 BTU/h 86

(Yellow)

Figure 3 - LP Cooktop Orifice Placement

Ignitor

Right Rear Burner 5,000 BTU/h 70

(Green)

Right Front Burner 15,000 BTU/h 116

(White)

Page 5

Conversion Instructions - Cooktop

4. Convert Cooktop Valves for Propane Use

Adjust Bypass Jets on Valves

1. Verify that all knobs are in the “Off” position.

2. Remove knobs, springs and bezels by pulling straight

out on the bezel.

3. Insert 1/8” (or smaller) flat head screwdriver into

shaft and turn bypass screw clockwise until it stops

turning (bypass screw is inside shaft). See Figure 4.

DO NOT OVER TIGHTEN. Replace springs, bezels and

knobs.

Burner BTU/h - LP Gas

Cooktop - Left Rear

Cooktop - Right Rear

Cooktop - Left Front

Cooktop - Right Front

Oven - Broil (Gas Ranges Only)

Oven - Bake (Gas Ranges Only)

If your range is dual fuel your conversion is complete.

Replace the cover plate and warming drawer and

proceed to step 9 to test your conversion.

11,000

5,000

7,500

15,000

13,500

17,000

1/8” (or Smaller) Flathead Screwdriver

OFF

HI

Bypass Screw Inside Shaft

Figure 4 - Cooktop Valve

Safety

SIM

LO

Before You Begin

For gas range conversions, continue to step 5, next

page.

Cooktop/Oven

Test Conversion

English •

3

Page 6

Conversion Instructions - Oven (Gas Ranges Only)

5. Adjust Broil Burner Orifice 6. Adjust Bake Burner Orifice

Broil Orifice Conversion

Tightened, but not fully seated

Natural Gas Setting

LP Gas Setting

CAUTION!

DO NOT overtighten the broil burner orifice.

Overtightening may result in damage to the pin inside

Before You Begin

the orifice. This affects cooking performance. It could

cause inconsistent flames and unintentional release of

carbon monoxide.

Remove oven door (see section “Removing Oven Door”

in Use and Care manual).

Bake Orifice Conversion

Fully seated

Natural Gas Setting

Tighten Bake Orifice. The bake burner orifice is located

below the air shutter (See Figure 6). Reach it through the

access hole in the interior back panel of the warming

drawer cavity. Use a 1/2” wrench to turn orifice clockwise

until it stops (2 1/2 - 3 turns). Unlike the broil burner

orifice, the bake burner orifice should be tightened as

far as it will go in order to ensure that complete

conversion has occurred.

LP Gas Setting

Remove Broil Burner Assembly. The broil burner

assembly is attached to the top of the oven cavity with 7

screws. Remove screws and gently pull broil burner

assembly straight out being careful not to detach

electrical wires. Place broil burner against back wall of

oven cavity.

Adjust Broil Orifice. The orifice is located behind the

broil burner in the back oven wall (See Figure 5). Use a 1/

2” deep socket driver with 3” minimum extension to turn

Cooktop/OvenTest Conversion Safety

orifice clockwise until it stops (2- 2 1/2 turns). DO NOT

OVERTIGHTEN.

Replace Broil Assembly. Replace broil assembly being

careful to feed all wires through back wall of oven.

Reinsert all 7 screws.

Note: The air shutter on the broil burner fits over the

orifice when installed correctly.

Figure 5 - Broil Orifice: Oven Cavity Side View

Bake Orifice

Figure 6 - Bake Orifice and Air Shutter

Shutter

Broil Orifice

Page 7

Conversion Instructions - Test the Conversion

7. Test for Gas Leaks

Leak testing is to be conducted by the installer according

to the instructions given in this section.

Turn on supply line gas shut off valve. Apply a noncorrosive leak detection fluid to all joints and fittings in

the gas connection between the supply line shut-off valve

and the range. Include gas fittings and joints in the

range if connections may have been disturbed during

installation. Bubbles appearing around fittings and

connections indicate a leak.

If a leak appears, turn off supply line gas shut-off valve

and tighten connections. Retest for leaks by turning on

the supply line gas shut-off valve. When no bubbles

appear, test is complete. Wipe off all detection fluid

residue.

CAUTION

NEVER CHECK FOR LEAKS WITH A FLAME.

DO NOT CONTINUE TO THE NEXT STEP UNTIL

ALL LEAKS ARE ELIMINATED.

8. Test Electric Ignition

Test Cooktop Burner Ignition. Select a rangetop burner

knob. Push down and turn to the flame symbol. If the

ignitor/spark module is operating correctly, it will click.

Once the air has been purged from the supply lines, the

burner should light within four (4) seconds. After burner

lights, turn knob to the off position.

Test each rangetop burner in this fashion.

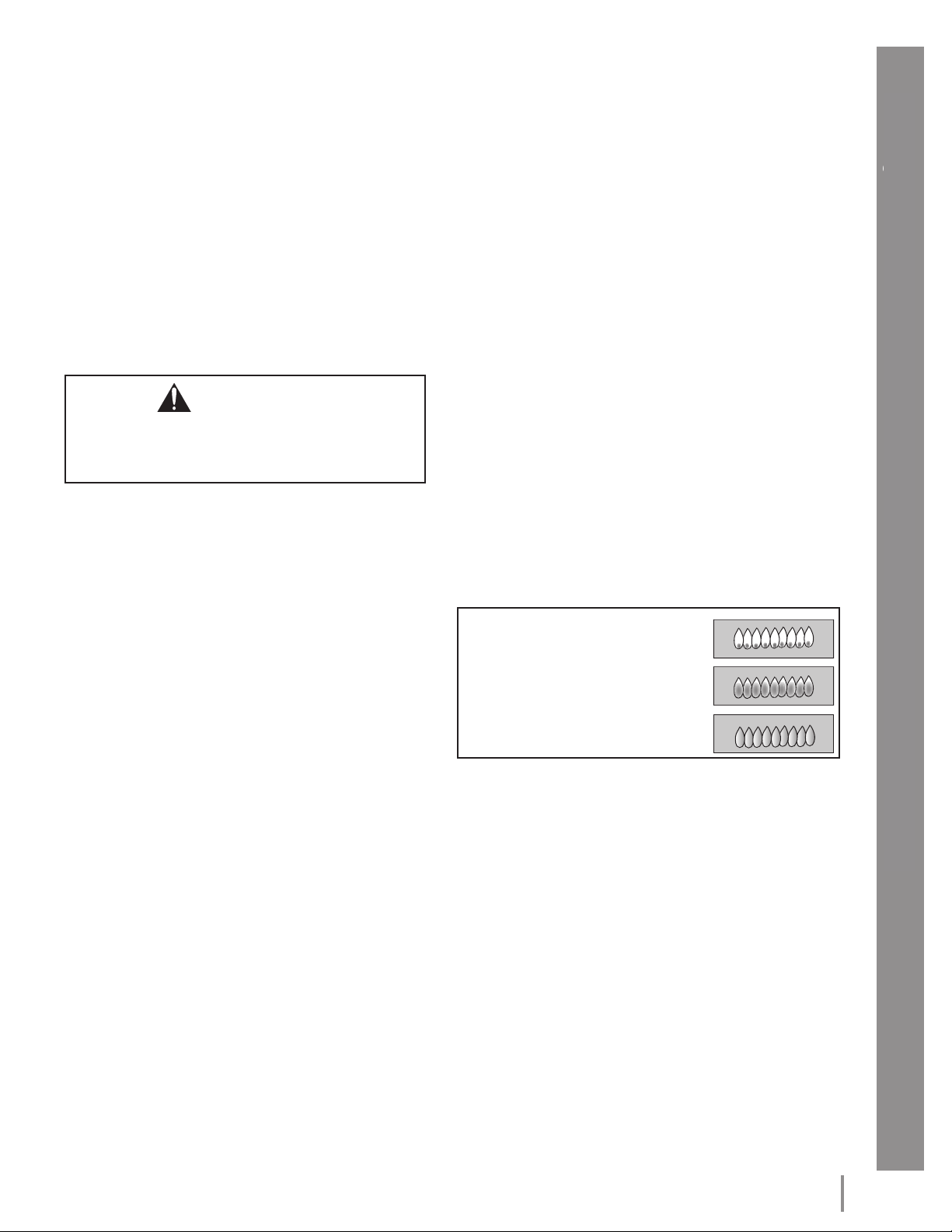

9. Test Flame

The combustion quality of the flame for each burner must

be visually inspected. If your range is a gas range, the

bake burner and broil burner flames must also be visually

inspected. The flame should be blue with yellow tips. It

should carry over, or surround, the entire burner and

should not lift or blow off the burner.

To inspect, turn the burner on. See Figure 7 for

appropriate flame characteristics. To view the bake

burner, the oven bottom cover must be removed; remove

two rear thumb screws, slide forward and out.

If the flame is completely or mostly yellow, the

corresponding air shutter and/or the orifice must be

adjusted. Verify that the orifice is all the way tightened.

If the flame is still yellow, adjust the air shutter. After

adjustment, retest.

Note: With LP use, some yellow tipping on outer cones is

normal.

All burners must also be inspected for carryover. The

flame should completely surround the burner. If the

cooktop burners do not carry over, the bypass jet must be

adjusted (See step 4, page 3). If the broil or bake burner

does not carry over, adjust the corresponding air shutter

(see steps 10 and 11, below and next page).

Yellow Flames:

Further adjustment is required.

Safety

Before You Begin

Cooktop/Oven

Test Broil Burner Ignition. Set cooking mode to Hi Broil.

The burner will ignite after 30-75 seconds.

Test Bake Burner Ignition. Set the oven to bake at 350°

F. After 30-75 seconds, the burner will ignite. The burner

will stay lit until the 350° F is reached and then shut off.

From this point forward, the burner will cycle on and off

to maintain the temperature.

Call Siemens Service 866-44SIEMENS (447-4363) if:

1. Any of the burners do not light.

2. The broil burner or bake burner does not stay lit.

3. The bake burner does not cycle.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

Figure 7 - Flame Characteristics

Test Conversion

English •

5

Page 8

Conversion Instructions - Test the Conversion

10. Adjust Broil Burner Air Shutter (if necessary)

Adjust Air Shutter. The air shutter is located on the back

end of the broil burner. Loosen screw and turn shutter.

Close the shutter if the flame is lifting or blowing or not

carrying over; Open the shutter if it is too yellow. (See

Figure 8). Tighten screw.

More Open:

•Less Yellow Flame

More Closed:

•Less Blue Flame

•More Carryover

•Less lifting or blowing

Figure 8 - Broil Burner Air Shutter

Before You Begin

11. Adjust Oven Burner Air Shutter (if

Shutter

Screw

necessary)

Adjust Air Shutter. The oven burner air shutter is

located to the left of the oven regulator. Reach it through

the access hole in the interior back panel of the warming

drawer. Loosen screw on shutter. Close the shutter if the

flame is lifting or blowing or not carrying over; Open the

shutter if it is too yellow. Tighten screw. (See Figure 9).

Reattach cover plate and replace warming drawer.

Save natural gas orifices for future conversion by placing

them in the appropriate space below.

Natural Gas

Cooktop Orifice Placement

Left Rear Burner - 12,500

BTU/ h 165

BACK OF RANGE

FRONT OF RANGE

Left Front Burner 9,100 BTU/h 139

Right Rear Burner 5,500 BTU/ h 109

Right Front Burner 15,000 BTU/h 180

Cooktop/OvenTest Conversion Safety

Shutter

More Open:

•Less Yellow Flame

Figure 9 - Oven Orifice and Air Shutter

More Closed:

•Less Blue Flame

•More Carryover

•Less lifting or

blowing

Page 9

Instructions importantes de sécurité

Lire les instructions d’installation avant d’effectuer la conversion.

Ce nécessaire est utilisé pour convertir les cuisinières à combustion jumelée et les cuisinières à gaz du gaz naturel

au gaz propane (LP). Seules les cuisinières Siemens, modèles HD et HG, peuvent être converties avec ce

nécessaire.*

Lire entièrement avant de procéder : conserver les pièces pour gaz naturel pour une conversion possible ultérieure

de LP au gaz naturel.

AVERTISSEMENT

Ce nécessaire de conversion doit être installé par une

agence de service qualifiée conformément aux

instructions du fabricant et à tous les codes et exigences

applicables ayant juridiction. Si ces instructions ne sont

pas suivies, il peut en résulter un incendie, une

explosion ou une production de monoxyde de carbone

causant des dommages à la propriété, des blessures ou

la mort. L’agence de service qualifiée est responsable

de l’installation appropriée de ce nécessaire.

L’installation n’est pas appropriée ni complétée tant que

le fonctionnement de l’appareil converti n’est pas

vérifié comme indiqué dans les instructions du

fabricant, fournies avec le nécessaire.

Remarque sur installation à haute altitude :

Cette cuisinière est approuvée CSA pour un

fonctionnement sûr à une altitude de 10 000 pi sans

modification (sauf conversion LP, si applicable).

(1) En branchant l’appareil sur le gaz propane, s’assurer

que le réservoir à gaz propane est doté de son

régulateur de haute pression. De plus, un régulateur

de pression est fourni avec la cuisinière. Ce second

régulateur doit être installé avec la cuisinière. La

pression de gaz maximale de cet appareil ne doit pas

dépasser 14,0 po, colonne d’eau, depuis le régulateur

du réservoir à gaz propane.

Ce qui suit est exigé au moment de tester le système de

canalisation :

a) L’appareil et sa soupape de sécurité doivent être

débranchés du système de canalisation

d’alimentation à des tests de pression excédant 1/2

2

lb/po

(3,5 kPa).

b) L’appareil doit être isolé du système de canalisation

d’alimentation en fermant sa soupape de sécurité

individuelle pendant le test de pression du système

de canalisation d’alimentation à des tests de

pression égaux ou inférieurs à 1/2 lb/po2 (3,5 kPa).

ATTENTION :

Sécurité

Avant de commencer

Surface de cuisson et four

Installation au Massachusetts :

1. L’installation doit être effectuée par un

entrepreneur qualifié ou avec licence, un plombier

ou un ajusteur.

de gaz qualifié ou avec licence par l’état, province

ou région où l’appareil est installé.

2. La soupape de sécurité doit être un robinet à gaz à

poignée en T.

3. Un connecteur de gaz flexible ne doit pas dépasser

36 po.

Nécessaire comprenant :

Instructions de conversion

Étiquette adhésive de conversion

Orifices (4) LP (70, 86, 101, 116)

Outils requis :

Tourne-écrou 7 mm avec rallonge 3 po

Tournevis à tête torx (T20)

Clé réglable

Tournevis à lame plate (1/8 po ou plus petit)

Tournevis à tête Phillips

*Le numéro de modèle est étampé sur la plaque derrière le tiroir ou le tiroir réchaud.

Toujours avoir une alimentation en gaz adéquate

Les cuisinières à gaz et combustion jumelée amovibles

Siemens sont expédiées de l’usine pour une utilisation au

gaz naturel. Utiliser ce nécessaire pour convertir

l’appareil au gaz LP, au besoin.

• S’assurer que la cuisinière est convertie pour

l’utilisation avec le gaz approprié avant d’utiliser.

• La cuisinière est conçue pour fonctionner à une

pression de 10 po, colonne d’eau, lorsqu’utilisée

avec le gaz LP.

• Au moment de vérifier le fonctionnement approprié

du régulateur, la pression d’entrée doit être à au

moins 1 po plus grande que la pression de

fonctionnement (distributeur) ci-dessus. En

convertissant au gaz LP, la pression fournie au

régulateur doit être entre 11 et 14 po, colonne

d’eau. Voir étape 2 «Conversion de pression au

régulateur de 5 à 10 po, C.E.», page suivante.

• Le régulateur de pression situé dans l’entrée du

distributeur de la cuisinière doit demeurer dans la

canalisation d’alimentation.

• Utiliser un connecteur en métal flexible pour électroménager ou un tuyau rigide pour brancher la

cuisinière sur l’alimentation en gaz. Le connecteur

doit avoir un D.I. (I.D.) de 1/2 po et avoir 5 po de

longueur (Exception : longueur maximale de

connecteur pour les installations au Massachusetts

est de 3 pi). Au Canada, le connecteur doit être en

métal à parois simples de pas plus de 6 po.

Français •

Test de conversion

1

Page 10

Instructions de conversion - avant de commencer

1. ATTENTION : fermer le gaz et

l’électricité

avant de procéder à la conversion. Fermer l’alimentation

en gaz avant de débrancher l’alimentation électrique.

Fermer la soupape de gaz du réservoir de propane

extérieur à la cuisinière. Retirer le cordon d’alimentation

Sécurité

de la cuisinière de la prise électrique ou mettre le coupecircuit hors circuit à la boîte de jonction. Régler tous les

boutons de contrôle à OFF.

2. Conversion du régulateur de pression de

5 à 10 po, C.E.

1. Retirer le tiroir-réchaud; le tirer jusqu’à ce qu’il

arrête. Pousser la pince, côté droit, vers le haut et

celle de gauche vers le bas. Tirer complètement le

tiroir.

2. Retirer la plaque de la paroi arrière intérieure en

enlevant la vis sur le côté du panneau.

3. Retirer le capuchon hexagonal au haut du régulateur

à l’aide d’une clé réglable.

4. Enlever la tige en plastique dans le capuchon et la

tourner en la pressant fermement en place afin que

Avant de commencerSurface de cuisson et four

les lettres LP puissent être vues à l’endroit plutôt

que NAT.

5. Remettre le capuchon et le bouton sur le dessus du

régulateur, le posant fermement.

6. Compléter et apposer l’ÉTIQUETTE DE CONVERSION

à l’arrière de la plaque afin qu’elle figure à l’arrière

de la cuisinière, près du régulateur.

Position tige

Capuchon

hexagonal

Position tige

pour gaz naturel

NA

T

Tige

NAT

pour propane

LP

LP

Tige

Ressort

Capuchon

hexagonal

VUE RÉGULATEUR DE PRESSION

Figure 1 - Conversion du régulateur de pression

Grille

Capuchon du

brûleur

Base du

brûleur

Orifice

3. Replacer les orifices principaux

Retirer grille, capuchon et base de brûleurs. Dévisser 2 vis

T20 à l’intérieur de chaque base et retirer les bases de

brûleur (figure 2). Réinsérer les vis dans le porte-jets pour

maintenir en place l’assemblage de tube.

Retirer les orifices de la surface de cuisson, gaz naturel.

Insérer le tourne-écrou avec rallonge 3 po dans le portejets pour retirer les orifices existants. Placer les anciens

orifices dans l’espace pérvu à la page 6 en cas de

conversion ultérieure au gaz naturel, au besoin.

Assembler les orifices de surface de cuisson. Placer dans

la surface de cuisson exactement comme indiqué sur le

verso de la couverture de ce guide (aussi à la figure 3). Si

les orifices se séparent du couvercle, L’emplacement peut

être déterminé en faisant correspondre le numéro et/ou

la couleur de l’orifice avec les données techniques

d’emplacement à la figure 3. Placer le nouvel orifice dans

la douille, puis insérer chaque orifice dans son trou fileté

respectif du porte-jet. Serrer jusqu’à ce que l’orifice

arrête. NE PAS TROP SERRER.

Enlever les vis pour replacer la base du brûleur, le

capuchon et la grille. Remplacer les vis.

Remarque : le capuchon du brûleur doit être positionné

adéquatement sur la base du brûleur afin que ce dernier

s’allume.

Test de conversion

Allumeur

Figure 2 - Retirer grille, capuchon et base

Brûleur arrière gauche 11 000 BTu/h 101

(Rouge)

Brûleur avant gauche 7 500 BTu/h 86

(Jaune)

Figure 3 -Emplacement des orifices de la surface de cuisson à gaz LP

ARRIÈRE DE LA CUISINIÈRE

AVANT DE LA CUISINIÈRE

Brûleur arrière droit -

5 000 BTu/h 70

(Vert)

Brûleur avant droit -

15 000 BTu/h 116

(Blanc)

Page 11

Instructions de conversion - Surface de cuisson

4. Conversion de soupapes de surface de

cuisson pour utilisation au propane

Réglage des jets déviateurs sur les soupapes.

1. Vérifier si les boutons sont en position OFF.

2. Enlever les boutons, ressorts et plaque indicatrice

en tirant droit sur la plaque indicatrice.

3. Insérer un tournevis à lame plate 1/8 po (ou plus

petit) dans l’arbre et tourner la vis de dérivation

dans le sens horaire jusqu’à ce qu’elle arrête (cette

vis est dans l’arbre). Voir figure 4. NE PAS TROP

SERRER. Remplacer ressorts, plaques et boutons.

Brûleur BTu/h - Gaz LP

Surface - arrière gauche

Surface - arrière droit

Surface - avant gauche

Surface - avant droit

Four - gril (cuisinière à gaz seul.)

Four - cuisson (cuisiniè. à gaz seul.)

Si la cuisinière est de type combustion jumelée, la

conversion est terminée. Replacer la plaque et le tiroirréchaud et passer à l’étape 9 pour tester la

conversion.

11 000

5 000

7 500

15 000

14 500

17 000

Sécurité

tournevis à lame plate 1/8 po (ou plus petit)

OFF

SIM

HI

Avant de commencer

LO

cette vis est dans l’arbre

Figure 4 - Soupape de surface de cuisson

Surface de cuisson et four

Pour conversion de cuisinière à gaz, passer à l’étape 5.

Test de conversion

Français •

3

Page 12

Instructions de conversion - four (cuisinière à gaz seulement)

5. Réglage orifice du brûleur de gril

Conversion d’orifice pour gril

Ne pas trop serrer

Sécurité

Réglages pour gaz LP

ATTENTION!

NE PAS trop serrer l’orifice du brûleur de gril. Sinon, cela

peut endommager la tige à l’intérieur de l’orifice. Ceci

modifie le rendement de cuisson. Cela peut causer une

flamme non constante et relâcher accidentellement du

Avant de commencerSurface de cuisson et four

monoxyde de carbone.

6. Réglage orifice brûleur four

Conversion d’orifice pour four

Bien ajusté

Réglages pour gaz naturelRéglages pour gaz naturel

Serrer l’orifice. L’orifice du brûleur four est situé en

dessous de l’obturateur d’air (figure 6). Y accéder par le

trou d’accès dans le panneau arrière intérieur de la cavité

du tiroir-réchaud. Utiliser une clé 1/2 po pour tourner

l’orifice dans le sens horaire jusqu’à ce qu’il s’arrête (2 à 2

1/2 fois). NE PAS TROP SERRER. Contrairement à l’orifice

de brûleur de gril, celui du brûleur de cuisson doit être

serrer le plus possible afin que la conversion complète soit

assurée.

Réglages pour gaz LP

Enlever la porte du four (voir «Retrait de la porte du

four» dans les instructions d’installation).

Retirer l’assemblage brûleur gril. Cet assemblage est

fixé au haut de la cavité du four à l’aide de 7 vis. Enlever

les vis et tirer droit délicatement sur l’assemblage en

faisant attention pour ne pas détacher les fils électriques.

Placer le brûleur gril contre la paroi arrière de la cavité du

four.

Réglage de l’orifice. L’orifice est situé derrière le brûleur

gril sur la paroi arrière (figure 5). Utiliser un tourne-écrou

de 1/2 po de profondeur avec rallonge 3 po pour tourner

l’orifice dans le sens horaire jusqu’à ce qu’il s’arrête (de 2

à 2 1/2 fois). NE PAS TROP SERRER.

Replacer l’assemblage gril. Replacer l’assemblage en

faisant attention pour alimenter les fils par la paroi

arrière du four. Remettre les 7 vis.

Remarque : l’obturateur d’air sur le brûleur gril s’ajuste

sur l’orifice lorsqu’installé adéquatement.

Orifice

Figure 5 - Cavité du four - vue latérale

Orifice Obturateur

Figure 6 - Orifice et obturateur d’air du four

Test de conversion

Page 13

Instructions de conversion- Test de conversion

7. Vérification des fuites de gaz

Le test de fuite doit être effectué par l’installateur

conformément aux instructions données dans cette

section.

Ouvrir la soupape d’arrêt de gaz de la canalisation

d’alimentation. Appliquer un liquide de détection de fuite

non corrosif sur tous les joints et raccords de la connexion

de gaz entre la soupape d’arrêt de la canalisation et la

cuinisière. Inclure les raccords et joints de gaz dans la

cuisinière si les connexions ont été dérangées pendant

l’installation. Les bulles indiquent qu’il y a une fuite.

S’il y a une fuite, fermer la soupape d’arrêt de gaz de

canalisation d’alimentation et serrer les connexions.

Vérifier de nouveau en ouvrant la soupape d’arrêt de gaz.

Lorsqu’il n’y a pas de bulles, le test est complet.

Essuyer les résidus de liquide de détection.

ATTENTION

NE JAMAIS VÉRIFIER LES FUITES AVEC UNE FLAMME.

NE PAS PASSER À L’ÉTAPE SUIVANTE TANT QUE LES

FUITES NE SONT PAS TOUTES ÉLIMINÉES.

8. Vérifier l’allumage électrique

Vérifier l’allumage du brûleur de surface de cuisson.

Choisir un bouton. Pousser et tourner au symbole de

flamme. Si le module allumeur/étincelle fonctionne

correctement, il fera un clic. Une fois l’air purgé des

canalisations d’alimentation, le brûleur devrait s’allumer

dans un délai de 4 secondes. Une fois le brûleur allumé,

touner le bouton en positon OFF.

Vérifier chaque brûleur de cette façon.

Vérifier l’allumage du brûleur gril. Régler le mode

cuisson à gril élevé. Le brûleur s’allume après 30 à 75

secondes.

Vérifier l’allumage du brûleur cuisson. Régler le four à

350 °F. Après 30 à 75 secondes, le brûleur devrait

s’allumer. Le brûleur demeure allumé jusqu’à ce que la

température de 350 °F soit atteinte, puis s’éteint. Par la

suite, le brûleur fait un cycle marche-arrêt pour maintenir

la température.

Appeler le service Siemens 866-44SIEMENS (447-

4363) si :

1. Un brûleur ne s’allume pas.

2. Le brûleur gril ou cuisson ne demeure pas allumé.

3. Le brûleur cuisson ne fait de cycle.

9. Vérification de flamme

La qualité de combustion de la flamme pour chaque

brûleur doit être visuellement vérifiée. Si l’appareil est

une cuisinière à gaz, les flammes des brûleurs gril et

cuisson doivent aussi être vérifiées visuellement. La

flamme doit être bleue avec un bout jaune et doit se

propager sur ou envelopper tout le brûleur et ne doit pas

être soulevée du brûleur.

Pour vérifier, mettre le brûleur en circuit. Voir figure 7

pour les caractéristiques de flamme appropriées. Pour

voir le brûleur de cuisson, le couvercle inférieur du four

doit être enlevé; enlever les deux vis arrières, faire glisser

devant et enlever.

Si la flamme est complètement ou presque toute jaune,

l’obturateur d’air correspondant et/ou l’orifice doit être

ajusté. S’assurer que l’orifice est bien serré. Si la flamme

est encore jaune, régler l’obturateur d’air. Après le

réglage, faire une remise.

Remarque : Avec le gaz LP, un bout jaune sur les cônes

extérieur est normal.

Tous les brûleurs doivent aussi être vérifiés pour un bon

étalement. La flamme doit envelopper complètement le

brûleur. Si les brûleurs ne sont pas bien étalés, le jet

déviateur doit être réglé (étape 4 à la page 3). Si le

brûleur gril ou cuisson n’est pas étalé, régler l’obturateur

d’air correspondant (étapes 10 et 11, ci-dessous et page

suivante).

Flamme jaune :

Réglage additionnel requis.

Pointe jaune sur cône extérieur :

Normal pour gaz LP.

Flamme bleue douce :

Normal gaz naturel .

Figure 7 - Caractéristiques de flamme

Sécurité

Avant de commencer

Surface de cuisson et four

Test de conversion

Français •

5

Page 14

Instructions de conversion - Test de conversion

10. Réglage de l’obturateur d’air du

brûleur gril (si nécessaire)

Réglage obturateur d’air. L’obturateur d’air est situé à

l’extrémité arrière du brûleur gril. Desserrer la vis et

tourner l’obturateur. Fermer l’obturateur si la flamme est

soulevée ou ne s’étale pas; ouvrir si elle est trop jaune.

Sécurité

(Voir figure 8). Serrer la vis.

Plus ouvert :

Obturateur

•Flamme moins

jaune

Plus fermé :

•Flamme moins bleue

•Plus étendue

•Moins soulevée, vacillante

Figure 8 - Obturateur d’air du brûleur gril

Vis

Avant de commencerSurface de cuisson et four

11. Régler obturateur d’air du brûleur four

(si nécessaire)

Réglage obturateur d’air. L’obturateur d’air du brûrleur

four est situé à la gauche du régulateur du four. Passer

par le trou d’accès dans le panneau arrière intérieur du

tiroir-réchaud. Desserrer la vis sur l’obturateur. Fermer

l’obturateur si la flamme est soulevée ou vacille ou ne

s’étale pas; ouvrir si elle est trop jaune. Serrer la vis. (Voir

figure 9).

Remettre la plaque et le tiroir-réchaud.

Conserver les orifices du gaz naturel à des fins de

conversions ultérieures en les plaçant dans l’espace

approprié ci-dessous.

Gaz naturel

Emplacement des orifices de la surface

Brûleur arrière gauche 12 500 BTu/h 165

ARRIÈRE DE LA CUISINIÈRE

DEVANT DE LA CUISINIÈRE

Brûleur avant gauche 9 100 BTu/h 139

Brûleur arrière droit -

5 500 BTu/h 109

Brûleur avant droit -

15 000 BTu/h 180

Obturateur

Plus fermé :

•Flamme moins bleue

•Plus étendue

Plus ouvert :

•Flamme moins

jaune

Figure 9 - Orifice et obturateur d’air du four

Test de conversion

•Moins soulevée,

vacillante

Page 15

Instrucciones Importantes de Seguridad

Favor de leer las instrucciones de instalación antes de iniciar la conversión.

Se usa este kit para convertir las estufas de doble combustible y las estufas de gas natural a una operación con gas

propano (LP). Sólo se pueden convertir los modelos de estufas Siemens HD y HG con este kit.*

Favor de leer todas las instrucciones antes de proceder. Guarde las partes para gas natural para una posible

conversión futura del gas LP a gas natural.

Seguridad

ADVERTENCIA

Una agencia calificada de servicio debe instalar este kit

de conversión de acuerdo con las instrucciones del

fabricante y los códigos y requerimientos aplicables de

la autoridad jurídica competente. El hecho de no

observar la información proporcionada en estas

instrucciones puede causar un fuego, explosión o la

producción de monóxido de carbono, resultando en

daños a la propiedad, heridas personales hasta la

muerte. La agencia calificada de servicio es

responsable de la instalación correcta de este kit. La

instalación no terminada y aprobada hasta que se

verifique la operación del aparato convertido de

acuerdo con las instrucciones del fabricante que se

incluyen con el kit.

Nota para instalaciones en gran altitud:

Esta estufa está certificada por CSA para una operación

segura hasta una altura de 10,000 pies (3,000 m) sin

ninguna modificación (excepto la conversión a gas LP, si

aplica).

Para instalaciones en Massachusetts:

1. Un contratista, fontanero o instalador de gas

calificado o autorizado por el estado, provincia o

región, donde se instala este aparato, debe

realizar la instalación.

2. La válvula de cierre debe ser una llave de gas,

tipo grifo en “T”.

3. El conectador flexible de gas no debe medir más

de 36 pulgadas (91.4 cm) de longitud.

Contenido del Kit:

Instrucciones del kit de conversión

Etiqueta de conversión

4 orificios LP (70, 86, 101, 116)

Herramientas que se necesitan:

Matraca de 7 mm con extensión de 3”

Desarmador de cabeza Torx (T20)

Llave ajustable

Desarmador de cabeza plana (1/8” o más pequeño)

Desarmador de cruz

CUIDADO:

(1) Al conectar la unidad al gas de propano, asegúrese

que el tanque de gas tenga su propio regulador de

alta presión. Además, se incluye un regulador de

presión con la estufa. Se debe instalar este

segundo regulador con la estufa. La máxima

presión de gas a este aparato no debe exceder

14.0 pulgadas de la columna de agua del regulador

en el tanque de gas de propano.

Se debe cumplir lo siguiente al probar la tubería del

suministro de gas:

a) Se debe desconectar el aparato y su válvula de

cierre individual del sistema de suministro de gas

a presiones de prueba arriba de 1/2 psig (3.5 kPa).

b) Se debe aislar el aparato del sistema de

suministro de gas cerrando su válvula individual

de cierre durante cualquier prueba de presión del

sistema de suministro de gas a presiones de

prueba iguales o inferiores que 1/2 psig (3.5 kPa).

Siempre proporcione un suministro

adecuado de gas

Las estufas autoestables Siemens de gas y de dos

combustibles vienen de fábrica para el uso con gas

natural. Use este kit para convertir el aparato para el uso

con gas LP si se necesita.

• Asegúrese de convertir la estufa para el uso con el

gas apropiado antes de usarla.

• Su estufa está diseñada para operar a una presión

de 10” de columna de agua cuando se usa con gas LP.

• Al checar la operación correcta del regulador, la

presión de entrada debe ser al menos 1” más grande

que la presión de operación de arriba (manifold).

Cuando se convierte para el uso con gas LP, la

presión aplicada al regulador debe estar entre 11” y

14” de la columna de agua. Vea el paso 2 “Convertir

la presión al regulador de 5” a 10” W.C.”, siguiente

página.

• El regulador de presión ubicado en la entrada del

manifold de la estufa debe permanenecer en la

línea de suministro.

• Use un conector metálico flexible o un tubo rígido

para conectar la estufa al suminstro de gas. El

conector debe tener un D.I. de 1/2” y una longitud

de 5’ (1.5 m) (Excepción: La máxima longitud del

conector en instalaciones en Massachussetts es de

3’. En Canadá, el conector debe ser metálico de una

sola pared y no más largo de 6’ (1.83 m).

Antes de COmenzar

Estufa/Horno

Probar la Conversión

*El número de modelo está estampado en la placa detrás del cajón calentador o del cajón de almacenamiento.

Español •

1

Page 16

Instrucciones de Conversión - Antes de comenzar

1. CUIDADO: Apague el gas y la luz

Antes de proceder con la conversión; cierre el suministro

de gas al aparato antes de desconectar la corriente.

Cierre la válvula de gas del tanque externo de propano.

Saque el cable de alimentación de la estufa o apague el

interruptor en la caja de interruptores y cambie todas las

perillas de control a la posición “OFF” (Apagado).

Seguridad

2. Convertir el Regulador de Presión de 5”

W.C. a 10” W.C.

1. Saque el cajón calentador; saque el cajón hasta

llegar al retén. Empuje el sujetador en el lado

derecho hacia arriba y en el lado izquierdo hacia

abajo. Saque el cajón completamente.

2. Quite la cubierta de la pared trasera interior

abriendo el tornillo sencillo en el lado izquierdo del

panel.

3. Saque la tapa hexagonal de la parte superior del

regulador con una llave ajustable.

4. Saque la espiga de plástico en la tapa y voltéela,

presionándola firmente en su lugar hasta poder ver

las letras “LP” en la espiga (en lugar de “NAT”).

5. Reemplace el conjunto de la tapa y botón en la

Antes de Comenzar

Estufa/Horno

Probar la Conversión

parte superior del regulador sellándolo bien.

Asegúrese que el resorte esté en su lugar (Vea la

Figura 1). NO APRIETE DEMASIADO.

6. Llene y pegue la ETIQUETA DE CONVERSIÓN en la

parte trasera de la placa de modo que aparezca en

el lado trasero de la estufa junto al regulador.

3. Reemplazar los orificios de la estufa

Quitar las rejillas, tapas y bases del quemador.

Desatornille dos (2) tornillos T20 dentro de cada base y

quite las bases de los quemadores (Vea la Figura 2).

Vuelva a insertar los tornillos en el portador del inyector

para mantener el conjunto de tubería en su lugar.

Quitar los orificios de la estufa para gas natural. Inserte la

matraca con una extensión mínima de 3” en los

portadores de inyector para quitar los orificios existentes.

Coloque los orificios viejos en el espacio proporcionado en

la página 6 en caso de una futura conversión de vuelta a

gas natural. Ensamblar los orificios de la estufa para gas

LP. Coloque la estufa exactamente como se muestra en la

contraportada de este manual (se muestra también en la

Figura 3). Cuando se separan los orificios de la cubierta,

se puede determinar la colocación emparejando el

número y/o color en el orificio con las especificaciones de

colocación indicadas en la Figura 3. Coloque el orificio

nuevo en el receptáculo y luego inserte cada orificio en su

respectivo agujero roscado en el portador. Apriete hasta

que el orificio deje de girar. NO APRIETE DEMASIADO.

Quite los tornillos para reemplazar la base, tapa y rejilla

de los quemadores. Reemplace los tornillos.

Nota: Se debe posicionar la tapa del quemador

correctamente sobre la base del quemador para que éste

se encienda.

posición de espiga

para propano

tapa hex

espiga

posición de espiga

para gas natural

tapa

hex

NAT

NA

T

espiga

LP

LP

resorte

VISTA DEL REGULADOR DE PRESIÓN

Figura 1 - Convertir el Regulador de Presión

Rejilla

Tapa del

quemador

Base del

quemador

Orificio

Figura 2 - Quitar la rejilla, tapa y base

Quemador trasero izq. 11,000 BTU/h 101

(Rojo)

Quemador delantero izq. 7,500 BTU/h 86

(Amarillo)

Figura 3 - Colocación de orificios de la estufa con gas LP

BACK OF RANGE

FRONT OF RANGE

Quemador trasero der. -

5,000 BTU/h 70

Quemador delantero der.

- 15,000 BTU/h 116

Ignitor

(Verde)

(Blanco)

Page 17

Instrucciones de Conversión - Estufa

4. Convertir las válvulas de la estufa para

el uso con gas de propano

Ajustar los inyectores en las válvulas.

1. Verifique que todas las perillas estén en la posición

“Off” (Apagado).

2. Quite las perillas, resortes y anillos biselados, jalando

directamente sobre el anillo biselado.

3. Inserte un destornillador plano de 1/8" (o más

pequeño) en el eje y gire el tornillo de paso en

sentido del reloj hasta que deje de girar (el tornillo

de paso está adentro del eje). Vea la Figura 4. NO

APRIETE DEMASIADO. Reemplace los resortes, los

anillos biselados y las perillas.

Quemador BTU/h - LP Gas

Estufa- Trasero Izquierdo

Estufa- Trasero Derecho

Estufa- Delantero Izquierdo

Estufa- Delantero Derecho

Horno- Asado (Estufas de gas)

Horno- Horn. (Estufas de gas)

Si su estufa es de doble combustible, su conversión ya

terminó. Reemplace la cubierta y el cajón calentador y

siga con el paso 9 para probar su conversión.

11,000

5,000

7,500

15,000

14,500

17,000

destornillador plano de 1/8" (o más pequeño)

OFF

SIM

HI

LO

el tornillo de paso está adentro del eje

Figura 4 - Válvula de la estufa

Seguridad

Antes de COmenzar

Para conversiones con estufas de gas, siga con el paso

5.

Estufa/Horno

Probar la Conversión

Español •

3

Page 18

Instrucciones de Conversión - Horno (Sólo estufas de gas)

6. Ajustar el orificio del quemador del horno5. Ajustar el orificio del quemador de asado

Conversión del orificio para asar

Apretado, pero no completamente sentado

Seguridad

Configuración

para Gas Natural

CUIDADO!

NO aplique demasiada fuerza cuando apriete el orificio

del quemador de asado. Si aplica demasiado torque

puede dañar el pin adentro del orificio. Esto afecta el

Antes de Comenzar

desempeño de la cocción. Podría causar llamas

inconsistentes y la liberación no intencional de

monóxido de carbono.

Configuración

para Gas LP

Conversión del orificio para hornear

Completamente sentado

Configuración

para Gas Natural

Apretar el orificio. El orificio del quemador del horno se

encuentra abajo del obturador de aire (Vea Figura 6). Lo

puede alcanzar a través del agujero de acceso en el panel

trasero de la cavidad del cajón calentador. Use una

matraca con dado de 1/2” para girar el orificio en sentido

del reloj hasta que se detenga (2- 2½ giros). NO APRIETE

DEMASIADO. A diferencia del orificio del quemador de

asado, se debe apretar al máximo el orificio del

quemador de horneado para asegurar la conversión

completa.

Configuración

para Gas LP

Quitar la puerta del horno (vea la sección “Quitar la

puerta del horno” en las instrucciones de instalación).

Quitar el conjunto del quemador de asado. El

conjunto del quemador de asado está fijado a la parte

superior de la cavidad del horno con 7 tornillos. Quite los

tornillos y jale el conjunto del quemador suavemente,

teniendo cuidado de no desconectar cables eléctricos.

Ponga el quemador de asado contra la pared trasera de

la cavidad del horno.

Estufa/Horno

Ajustar el orificio. El orificio se encuentra detrás del

quemador de asado en la pared trasera del horno (Vea la

Figura 5). Use una matraca con dado de 1/2” con una

extensión mínima de 3” para girar el orificio en sentido

del reloj hasta que se detenga (2- 2½ giros). NO APRIETE

DEMASIADO.

Reemplazar el conjunto del asador. Reemplace el

conjunto del asador teniendo cuidado de poner todos los

cables a través de la pared trasera del horno. Vuelva a

poner los 7 tornillos.

Nota: El obturador de aire en el quemador cabe encima

del orificio cuando se instala de modo correcto.

Orificio

Figura 5 - Cavidad del horno - vista lateral

Orificio Obturador

Figura 6 - Orificio del horno y obturador de aire

Probar la Conversión

Page 19

Instrucciones de Conversión - Probar la Conversión

7. Verificar fugas de gas

El instalador debe verificar si hay fugas de gas de acuerdo

a las instrucciones proporcionadas en esta sección.

Abra la válvula de cierre de la línea de suministro del gas.

Aplique un líquido no corrosivo de detección de fugas a

todas las uniones y conexiones entre la válvula de cierre

de la línea de suministro y la estufa. Incluya las

conexiones y uniones de gas en la estufa si éstas pudieron

haber sido manipuladas durante la instalación. Burbujas

que aparecen alrededor de conexiones indican una

fuga.

Cuando aparece una fuga, cierre la válvula de la línea de

suministro de gas y apriete las conexiones. Vuelva a

probar si hay fugas abriendo la válvula de cierre. Si no

aparecen burbujas, la prueba ha terminado. Limpie todos

los residuos del líquido de detección.

CUIDADO

NUNCA USE UNA LLAMA PARA VERIFICAR SI HAY

FUGAS. NO SIGA CON EL SIGUIENTE PASO HASTA

HABER ELIMINADO TODAS LAS FUGAS.

8. Probar la ignición eléctrica

Probar la ignición del quemador de estufa.

Seleccione una perilla de un quemador de la estufa.

Empújela y gírela hasta el símbolo de la llama. Si el

ignitor/módulo de chispas funciona bien, se escucha un

clic. Una vez que se haya purgado el aire de las líneas de

suministro, el quemador debe encenderse dentro de

cuatro (4) segundos. Después de encender el quemador,

gire la perilla a la posición de “Off”.

Verifique cada perilla de la estufa de este modo.

Probar la ignición del quemador de asado. Cambie el

modo de cocinar a Hi Broil (Asado Alto). El quemador se

va a encender después de 30-75 segundos.

Probar la ignición del quemador de horneado. Ajuste

el horno a una temperatura de 350°F. Después de 30-75

segundos se encederá el quemador. El quemador se

mantendrá encendido hasta alcanzar los 350°F y luego se

apaga. A partir de este punto, el quemador se prende y

apaga para mantener la temperatura.

Llame al servicio Siemens 866-44SIEMENS (447-

4363) cuando:

1. Algún quemador no se enciende.

2. El quemador de asado u horneado no se

mantiene encendido.

3. No se cicla el quemador de horneado.

9. Probar la llama

Se debe inspeccionar visualmente la calidad de

combustión de la llama. Si su estufa es de gas, se deben

verificar además las llamas de los quemadores de

horneado y asado. La llama debe ser azul con puntas

amarillas. Debe envolver todo el quemador y no levantar

o apagar el quemador.

Para inspeccionar, prenda el quemador. Vea la Figura 7

para las características apropiadas de las llamas. Para ver

el quemador del horno, se tiene que quitar la cubierta

inferior del horno; quite dos tornillos traseros de

mariposa, deslice hacia adelante y sáquelo.

Cuando la llama está totalmente o en su mayoría

amarilla, se debe ajustar el obturador de aire y/u orificio

correspondiente. Verifique que el orificio quede

totalmente apretado. Si la llama aún está amarilla, ajuste

el obturador de aire. Después del ajuste, vuelva a realizar

la prueba.

Nota: Con gas LP, puntas amarillas en los conos

exteriores es algo normal.

También se debe verificar el arrastre de los quemadores.

La llama debe envolver el quemador completamente.

Cuando los quemadores de la estufa no envuelven, se

debe ajustar el inyector de derivación (Vea el paso 4,

página 3). Cuando los quemadores del horno o asador no

envuelven, ajuste el obturador de aire correspondiente

(vea los pasos 10 y 11, a continuación y en la página

siguiente).

Llama amarilla:

Se requieren más ajustes.

Puntas amarillas en conos:

Normal para gas LP.

Llamas azules suaves:

Normal para gas natural.

Figura 7 - Características de las llamas

Seguridad

Antes de COmenzar

Estufa/Horno

Probar la Conversión

Español •

5

Page 20

Instrucciones de Conversión - Probar la Conversión

10. Ajustar el obturador de aire del

quemador de asado (si es necesario)

Ajustar el obturador de aire. El obturador de aire se

encuentra en el extremo trasero del quemador de asado.

Afloje el tornillo y gire el obturador. Cierre el obturador

cuando la llama no envuelve el quemador

completamente o cuando la llama se levanta o se apaga.

Seguridad

Abra el obturador si la llama es demasiado amarilla. (Vea

la Figura 8). Apriete el tornillo.

Más abierto:

•Menor llama

amarilla

Más cerrado:

•Menor llama azul

•Más arrastre

•Menos elevación y soplado

Figura 8 - Obturador de aire del quemador

Obturador

Tornillo

Antes de Comenzar

Guarde los orificios para gas natural en el espacio

apropiado abajo para una futura conversión.

Gas Natural

Colocación de Orificios de la Estufa

Quemador trasero izq. 12,500 BTU/ h 165

FONDO DE ESTUFA

FRENTE DE ESTUFA

Quemador delantero izq. 9,100 BTU/h 139

Quemador trasero der. -

5,500 BTU/ h 109

Quemador delantero der.

- 15,000 BTU/h 180

11. Ajustar el obturador de aire del

quemador del horno (si es necesario)

Ajustar el obturador de aire. El obturador de aire se

encuentra a la izquierda del regulador del horno. Lo

puede alcanzar a través del agujero de acceso en el panel

trasero interior del cajón calentador. Afloje el tornillo en

el obturador. Cierre el obturador cuando la llama no

envuelve el quemador completamente o cuando la llama

se levanta o se apaga; Abra el obturador si la llama es

demasiado amarilla. Apriete el tornillo. (Vea la Figura 9).

Vuelva a poner la cubierta y reemplace el cajón

Estufa/Horno

calentador.

Obturador

Más cerrado:

•Menor llama azul

Más abierto:

•Menor llama

amarilla

Figura 9 - Orificio del horno y obturador de aire

•Más arrastre

•Menos elevación o

soplado

Probar la Conversión

Page 21

Page 22

BSH reserves the right to change specifications or design without notice. Some models are certified for use in Canada. BSH is not

responsible for products which are transported from the United States for use in Canada. Check with your local Canadian distributor

or dealer. BSH Home Appliances, Corporation, 5551 McFadden Avenue, Huntington Beach, CA 92649.

For the most up to date critical installation dimensions by fax, use your fax handset and call 702/833-3600. Use code #8030.

S

5551 McFadden Avenue, Huntington Beach, CA 92649 • 866-44SIEMENS (447-4363)• www.siemens-home.com

9000008283 (10072 Rev B) No ECO • 06/05 • © BSH Home Appliances Corporation 2005 • Litho U.S.A.

Loading...

Loading...