Installation instructions

Instructions for use

HG193510ME

HG195510ME

HG196510ME

HG197510ME

HG198210ME

HG198510ME

HG199210ME

HG199510ME

EN

...........

Installation instructions 1-22 | Instructions for use 23-90

Installation instructions

Safety precautions ___________________________________________ 3

Before installing _____________________________________________ 4

Appliance........................................................................................................ 4

Guideline for ventilation.................................................................................. 6

Installation __________________________________________________ 7

Fitting the adjustable feet ............................................................................... 7

Fitting the splash guard .................................................................................. 8

Electrical connection _________________________________________ 9

Gas connection _____________________________________________ 11

Converting the gas type ______________________________________ 15

Hotplate burners........................................................................................... 15

Oven burner ................................................................................................. 17

Grill burner.................................................................................................... 20

General nozzle table .................................................................................... 21

Positioning and levelling _____________________________________22

1

2

Safety precautions

This manual is valid for several models. Variations in

details for each cooker are possible.

The safe operation of this appliance can only be

guaranteed if it has been professionally assembled

and installed in accordance with these instructions.

The individual who assembled and installed the

appliance is liable for damage or faults resulting from

incorrect assembly or installation.

All installation and adjustment work, as well as the

conversion to a different type of gas must be

undertaken by an authorised expert and carried out in

accordance with the currently applicable rules and

regulations of the local gas and electricity supply

company.

Shut off the supply of electricity and gas before

carrying out any work.

Before installing the appliance, check that the local

conditions (type of gas and pressure) are compatible

with the appliance settings. The permissible

appliance settings can be found on the rating plate.

Electrical appliances must always be earthed.

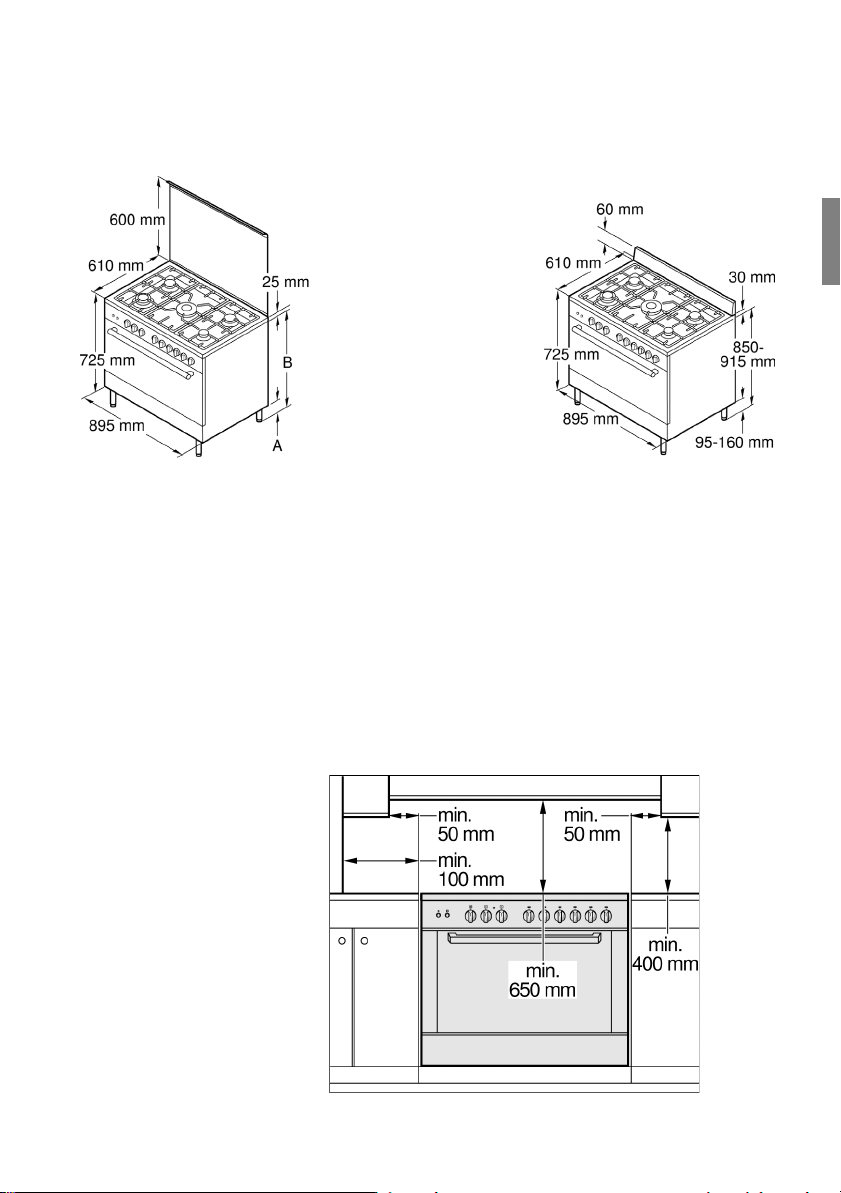

If an extractor hood is to be fitted, it must be fitted

according to the associated assembly instructions.

Ensure that the hood is fitted at least 650 mm clear of

the hob.

3

Before installing

Read the following information about the appliance

and the guidelines for ventilation.

Appliance

Unpacking Check the condition of the appliance after unpacking

it. Do not connect the appliance if it has been

damaged in transport.

Dispose of packaging in an environmentally-friendly

manner.

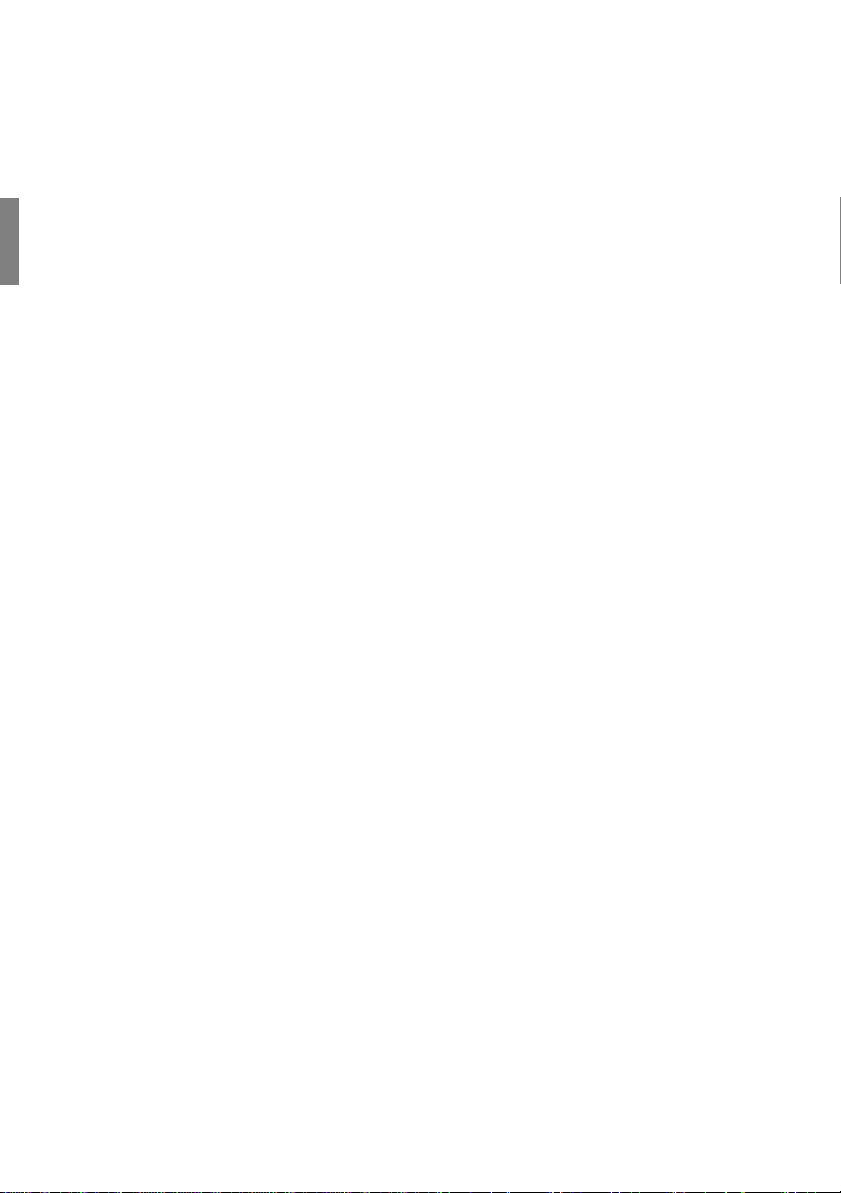

The appliance is bolted to the pallet with two bolts.

To release the appliance, proceed as follows:

• Undo the bolts on the rear of the appliance.

• Screw the bolts back into the appliance without

the connecting brackets.

Appliance class This appliance corresponds to the following

appliance classes:

Appliance class Description

Class 1

Non flush-fitted cooker

Class 2 - subclass 1

Cooker immediately adjacent to two

units, consisting of a single unit.

Can also be installed so that the

side walls are accessible.

4

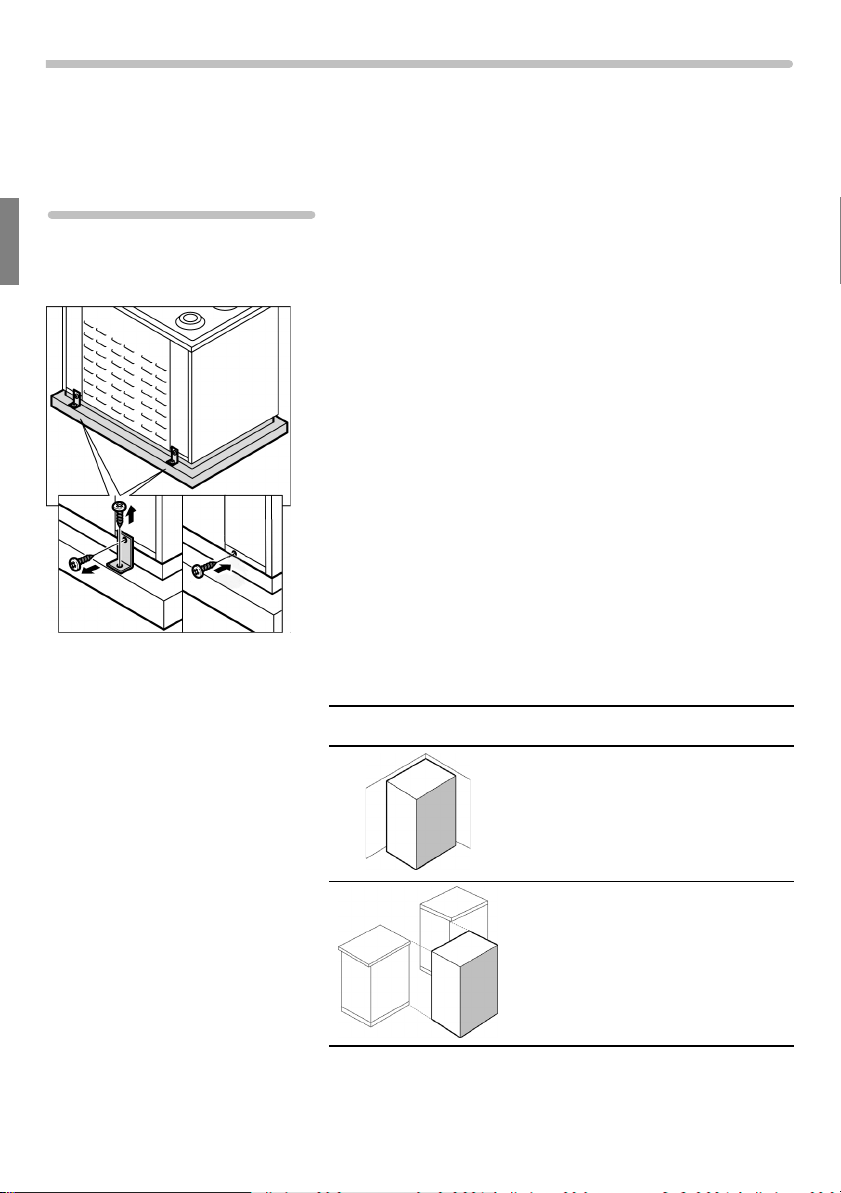

Appliance dimensions Note the specified dimensions.

HG193510ME, HG196510ME, HG197510ME,

HG198210ME, HG198510ME, HG199210ME,

HG199510ME

A = 95-160 mm

(HG193510ME, HG197510ME, HG198210ME,

HG199210ME: A= 90-145 mm)

B = 820-885 mm

(HG193510ME, HG197510ME, HG198210ME,

HG199210ME: B= 815-870 mm)

HG195510ME

Adjacent units Adjacent units must be made of non-combustible

material. The fronts of adjacent units must be

resistant to temperatures up to at least 90 °C. If the

appliance is fitted close to other units, the minimum

distances specified in the picture must be maintained.

5

Rating plate The technical data for the appliance can be found on

the rating plate on the inside of the storage

compartment flap.

Never remove the rating plate from the appliance.

The setting values are specified on a label on the

appliance packaging.

Use the table below to record the product number (E

no.),

production number (FD no.),

factory setting for type of gas and pressure and

if applicable, the type of gas and pressure

conversions.

E no. FD no.

After-sales service

Type of gas

Gas pressure

(factory setting)

Type of gas

Gas pressure

(conversion)

Guideline for ventilation

This appliance may only be set up in a sufficiently

ventilated room and according to the applicable

regulations and ventilation requirements.

Please note that the air volume required for

combustion must not be below 2 m

power (see kW total power on the rating plate).

6

3

/h per kW of

Installation

This appliance is always supplied with a set of

adjustable feet and, depending on the model, with a

splash guard.

The appliance may also be used without the splash

guard.

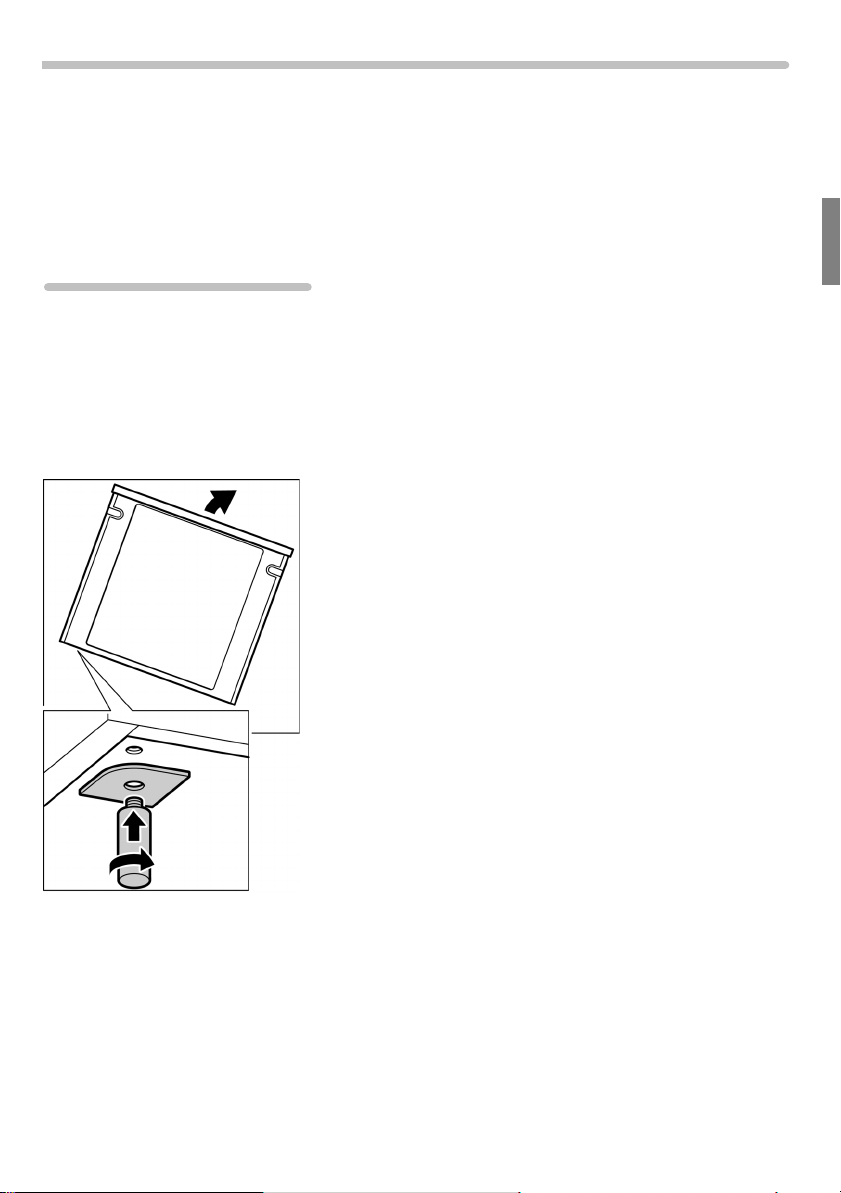

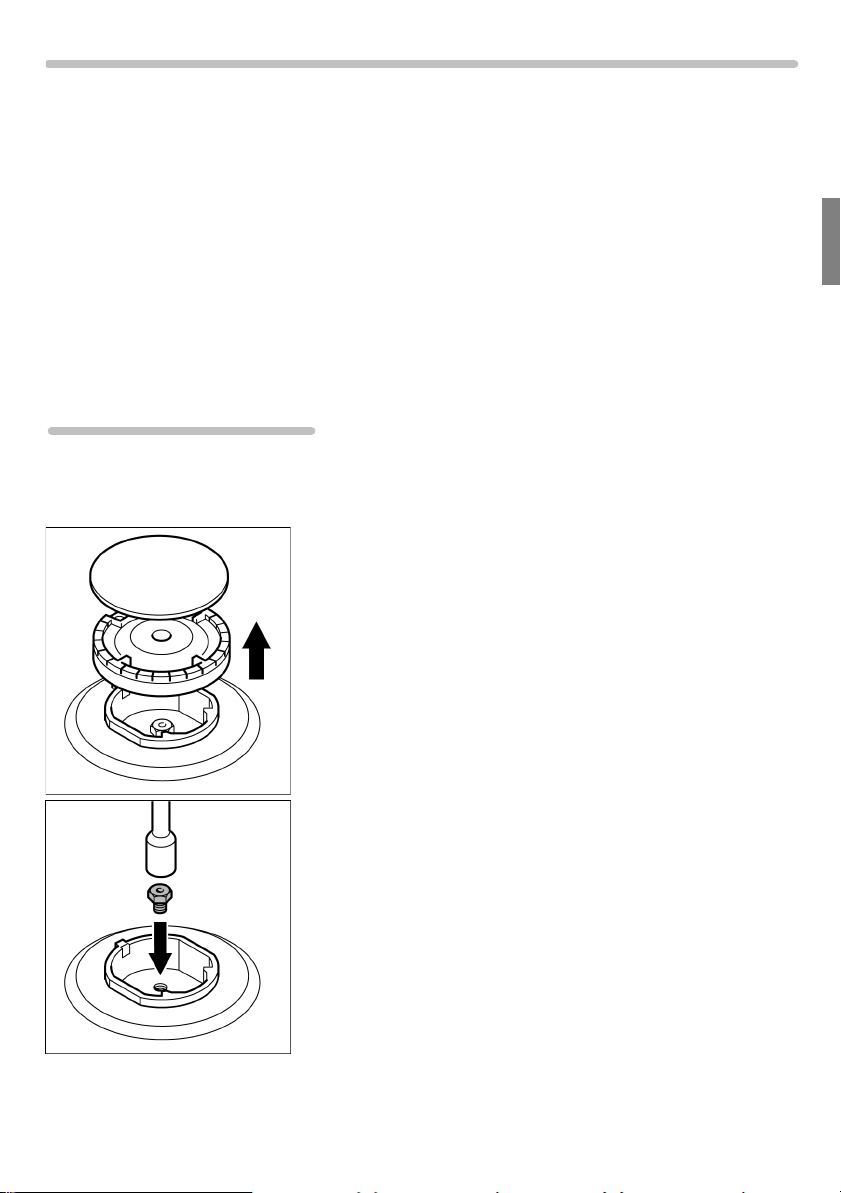

Fitting the adjustable feet

Beforehand:

• Remove all parts that are not permanently fixed,

especially the pan supports and burners.

• Remove the accessories from the oven.

Proceed as follows:

• Tilt the appliance by raising one side slightly from

the floor.

• With the plates in position, screw the adjustable

feet into the mounting holes on the underneath of

the appliance.

• Repeat the process on the other side.

You can make the final adjustments to the feet in

order to level the appliance once the gas and

electricity supply have been connected.

If it is necessary to pull the appliance, screw the

adjustable feet in fully. Make the final settings only

when the other installation tasks have been

completed.

7

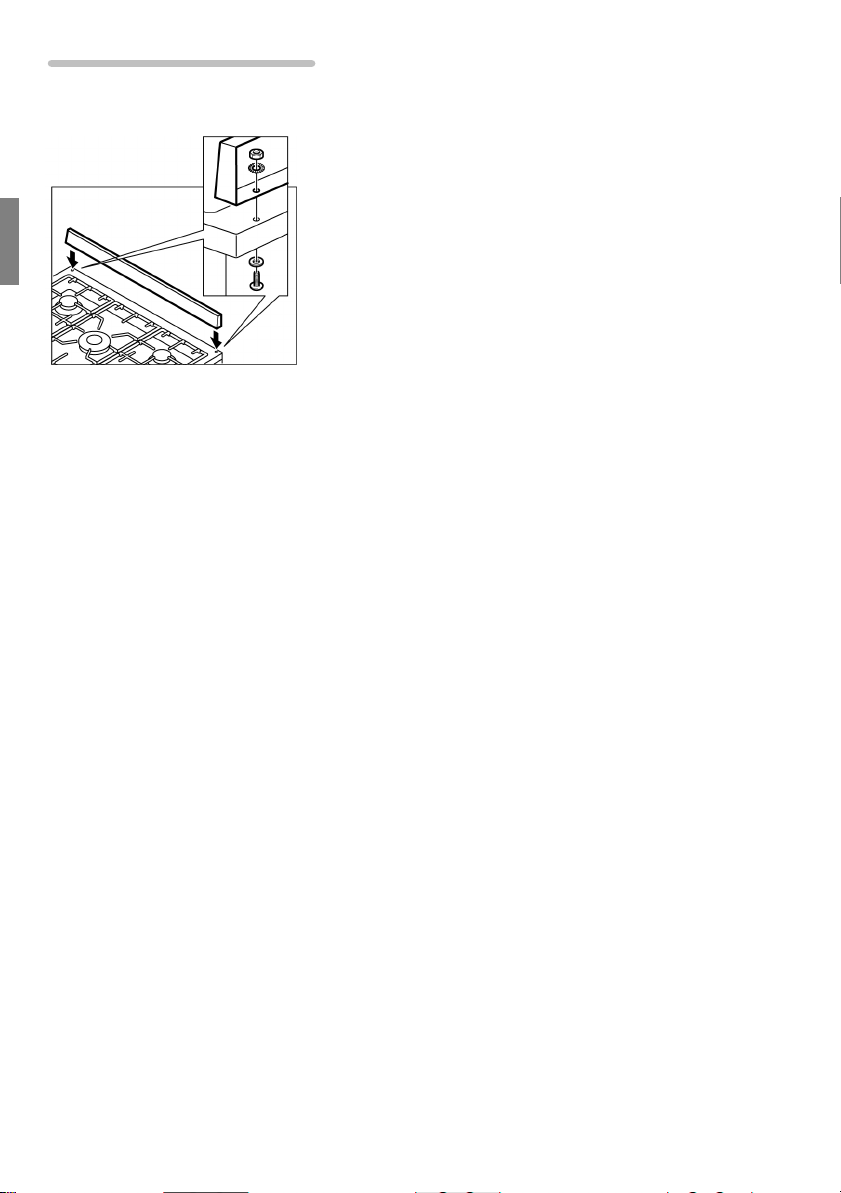

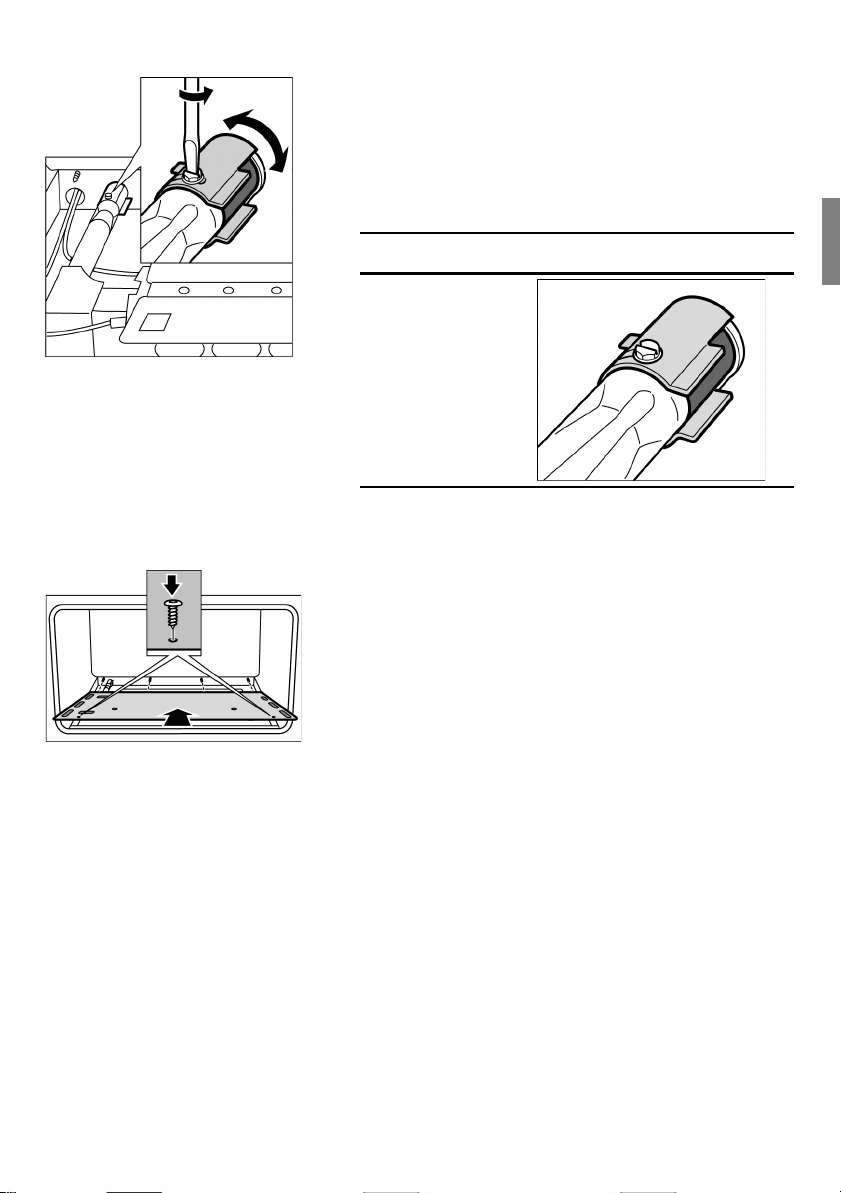

Fitting the splash guard

Depending on the model.

Proceed as follows:

• Remove the packaging and the protective film

• Screw the splash guard onto the rear of the

from the splash guard.

appliance using the 2 bolts, each with a washer,

retaining washer and nut.

8

Electrical connection

Only a licensed expert may connect the appliance.

The appliance must be installed according to the

most recent IEE regulations (Institute of Electrical

Engineers).

The appliance could become damaged if incorrectly

connected.

Make sure the voltage of the power supply

corresponds to the specified value on the rating plate.

The rating plate can be found on the inside of the

storage compartment flap.

Ensure that the power supply is properly earthed and

that the fuse and the wiring and piping system in the

building can withstand the load from the appliance.

It is recommended that you configure the circuit for

the appliance to 16 A.

When you route the mains cable, make sure that:

• the cable is not trapped or squashed.

• the cable does not come into contact with sharp

edges or cutting edges.

• the cable does not come into contact with parts

that can reach temperatures of more than 50 °C

above room temperature.

9

Connecting the mains

cable

Replacing the mains cable The mains cable is replaced via the terminal block.

Where the appliance is directly connected to the

power supply, an all-pole isolating switch with a

contact gap is required.

Complete disconnection in compliance with the

conditions specified in overvoltage category III must

be guaranteed.

The earth cable is excluded from this.

The mains cable must be of the following type:

• H05RRF

• 3 x 0.75 mm²

• 230 V~

Leave the mains cable slightly overlong so that you

can pull out the appliance for cleaning purposes.

Proceed as follows:

• Open the terminal box.

• Undo the screw on the terminal block that fixes

the cable in place.

• Loosen the screw contacts and replace the cable

with a new one of the same length.

The cable must comply with the stipulated specifications.

• Connect the yellow-green wire to the < terminal.

This wire must be at least 10 mm longer than the

other wires.

• Connect the blue neutral wire to terminal N.

• Connect the brown power wire to

terminal L.

10

Gas connection

The appliance must be connected in accordance with

the currently applicable regulations.

Before installing the appliance, check that the local

conditions (type of gas and pressure) are compatible

with the appliance settings. The permissible

appliance settings can be found on the rating plate.

Connection to the gas lines and seal fitting must be

carried out professionally according to the currently

applicable standards.

Gas connection on the

appliance

Default setting of the

burners

The gas connection (ISO 228-1, 1/2") is located at the

rear left of the appliance.

The following connections are provided with the

appliance:

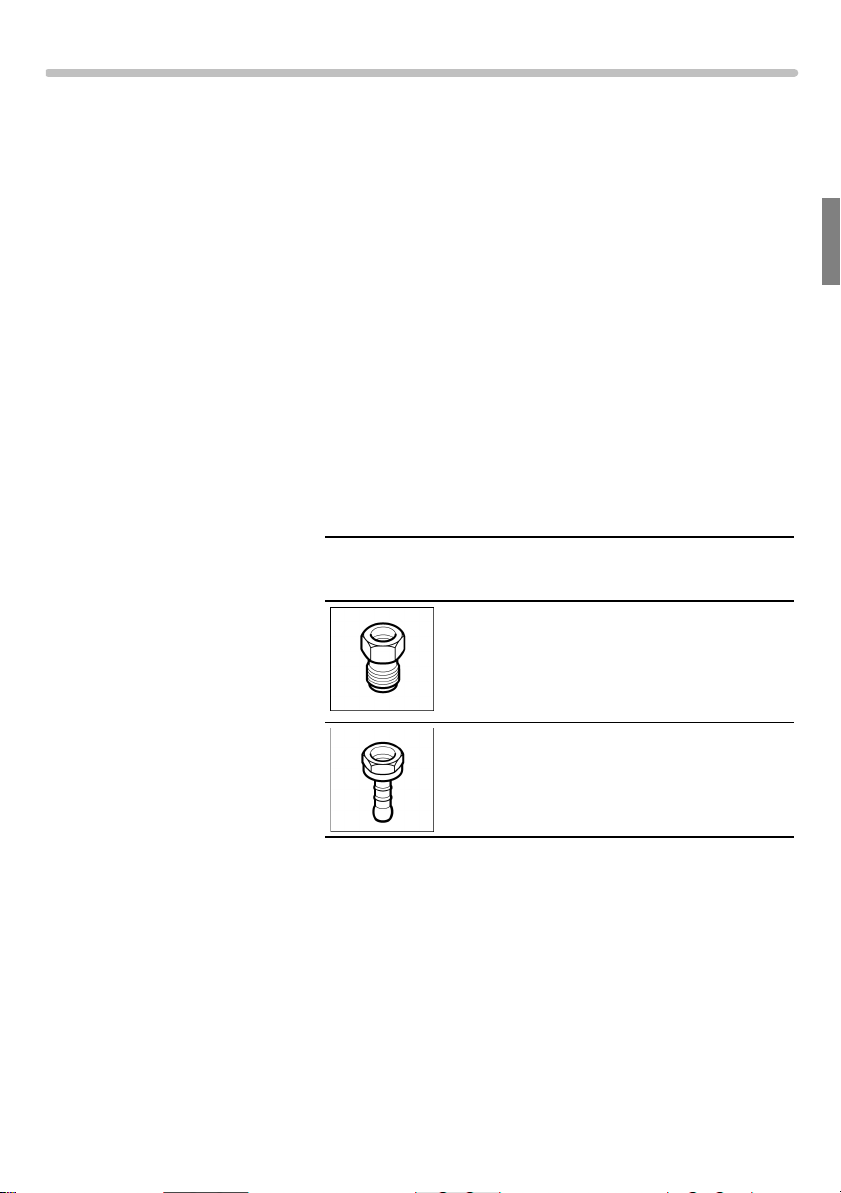

Connecting

pieces Description

Connecting piece ISO 228-1/ISO

7-1

(and seal)

LPG corrugated tube union

(and seal)

The burners are set up for G30 liquefied gas (29

mbar) on delivery.

A nozzle set for G20 natural gas (20 mbar) is supplied

with the appliance.

11

Country-specific

connection

Corrugated tube

union

(liquefied gas)

AE X X

AF X X

BD X X

BH X X

DZ X X

EG X X

GH X X

IR X X

JO X X

KW X X

LB X X

LY X X

MA X X

OM X X

PK X X

QA X X

SA X X

SD X X

SY X X

TN X X

YE X X

ISO 7-1

(natural gas)

12

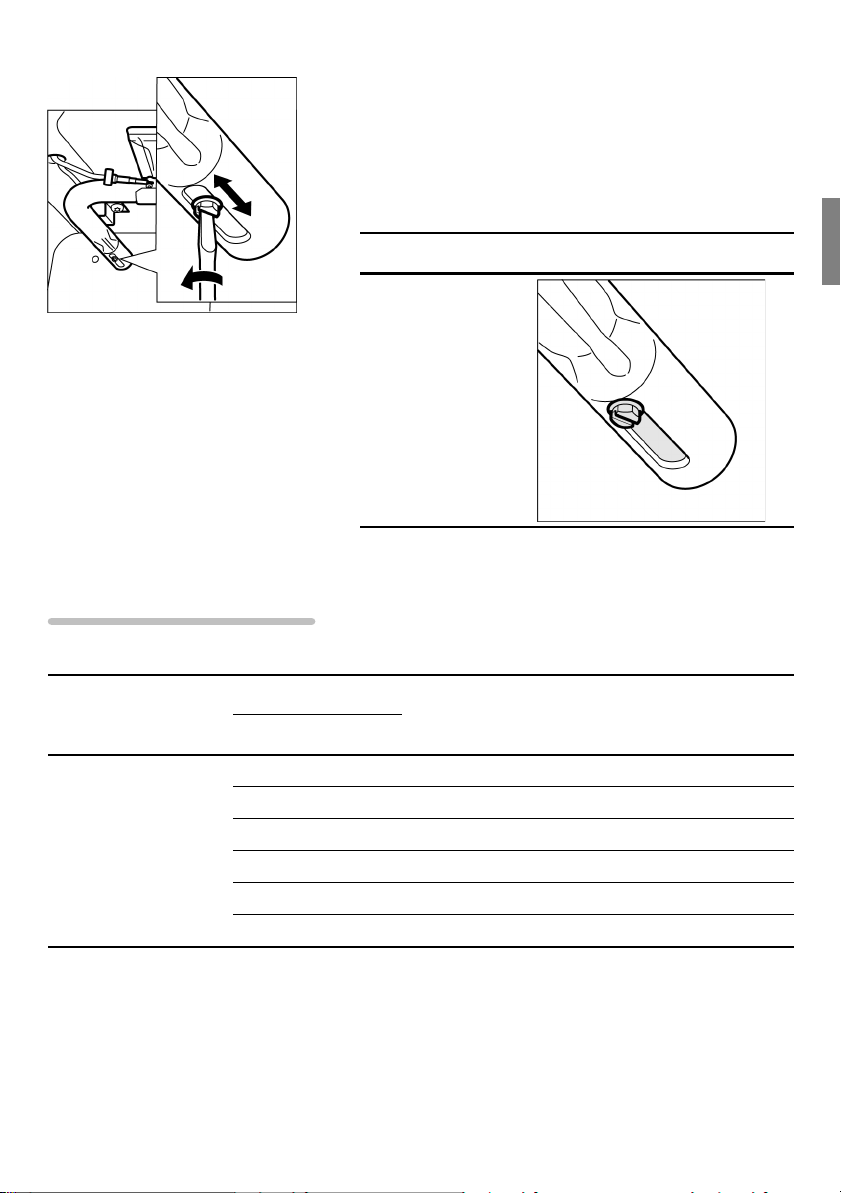

Connecting to liquefied gas If you connect the appliance to liquefied gas,

you must always install a suitable gas pressure

regulator.

Use the total gas consumption of the appliance stated

on the rating plate to select a suitable gas pressure

regulator.

Only use connecting lines or flexible hoses which

comply with the applicable regulations and which are

approved for this purpose.

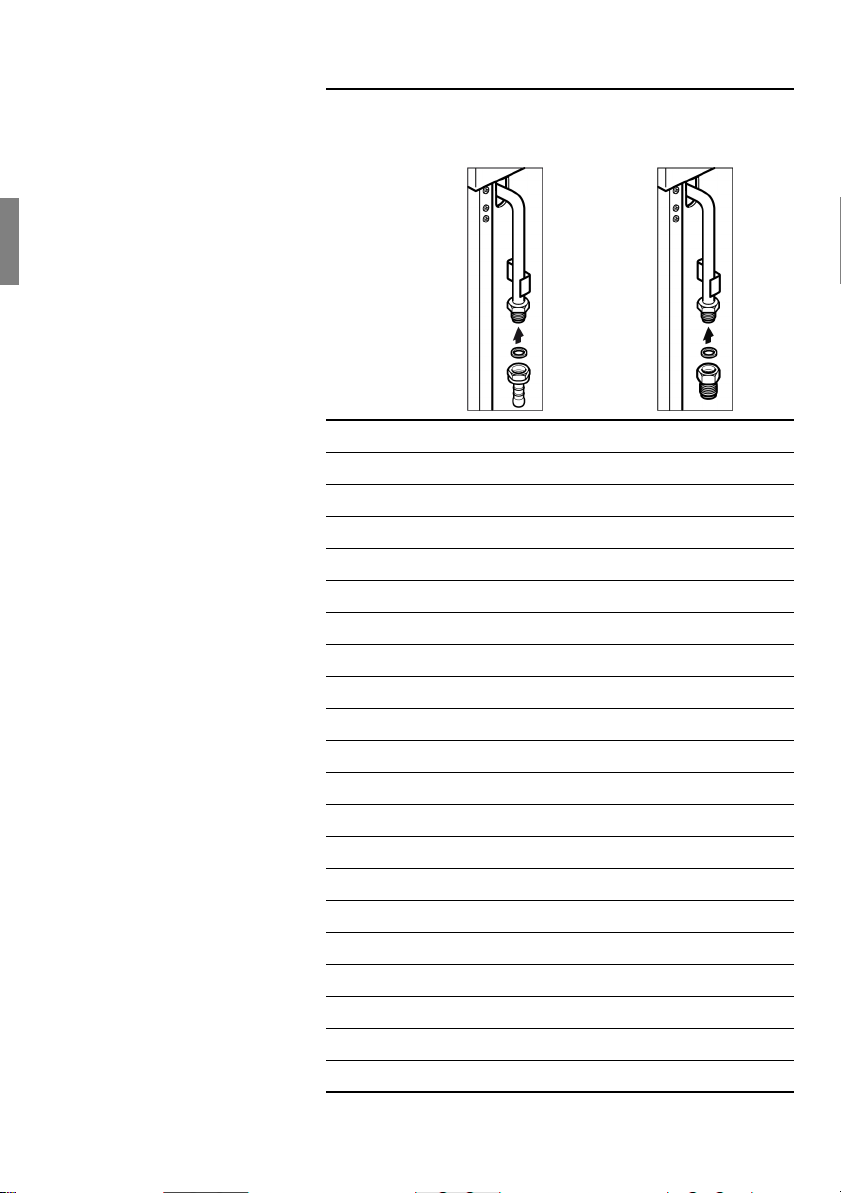

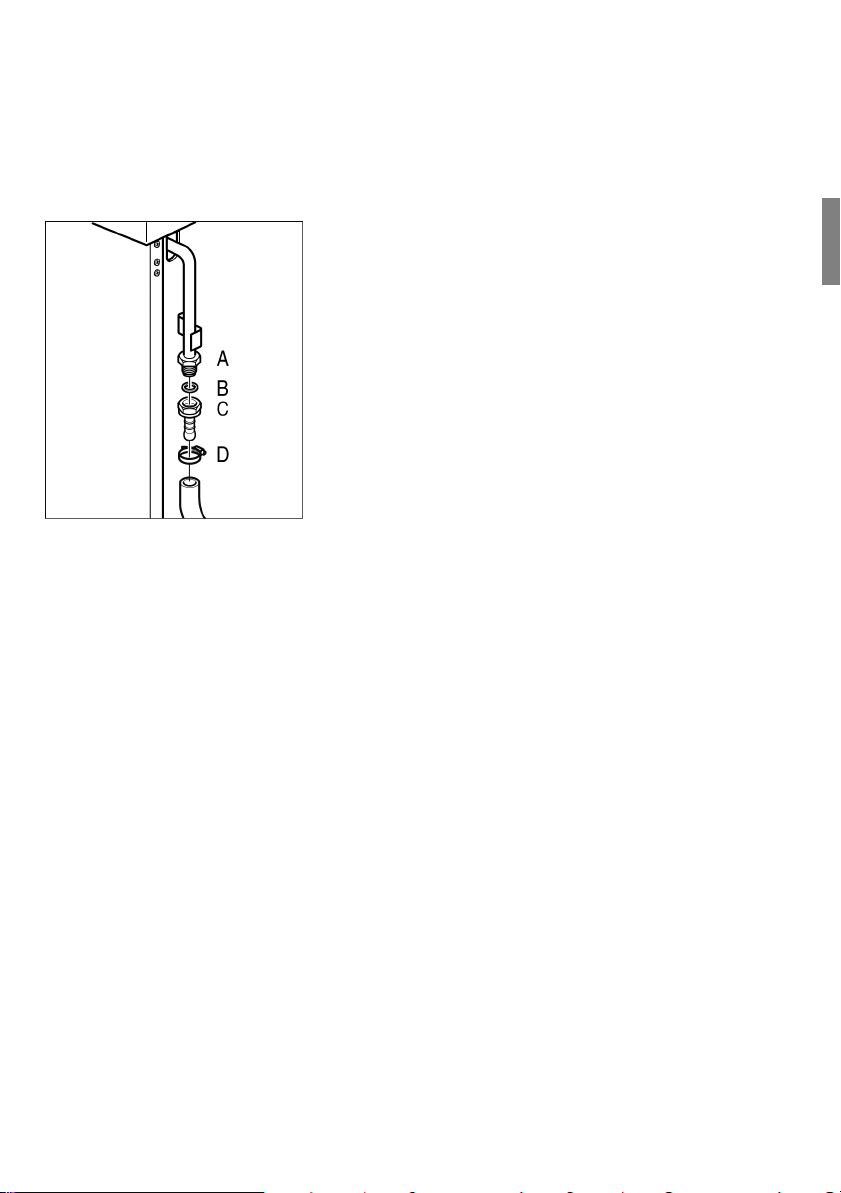

Proceed as follows:

• Screw the corrugated tube union (C) and the seal

(B) to the gas connection (A).

• Hold the corrugated tube union (C) in place with a

spanner and screw the connecting piece to a

flexible gas connecting hose (E).

E

• Tighten the clamp (D).

Only use approved sealing compound to seal the

thread.

13

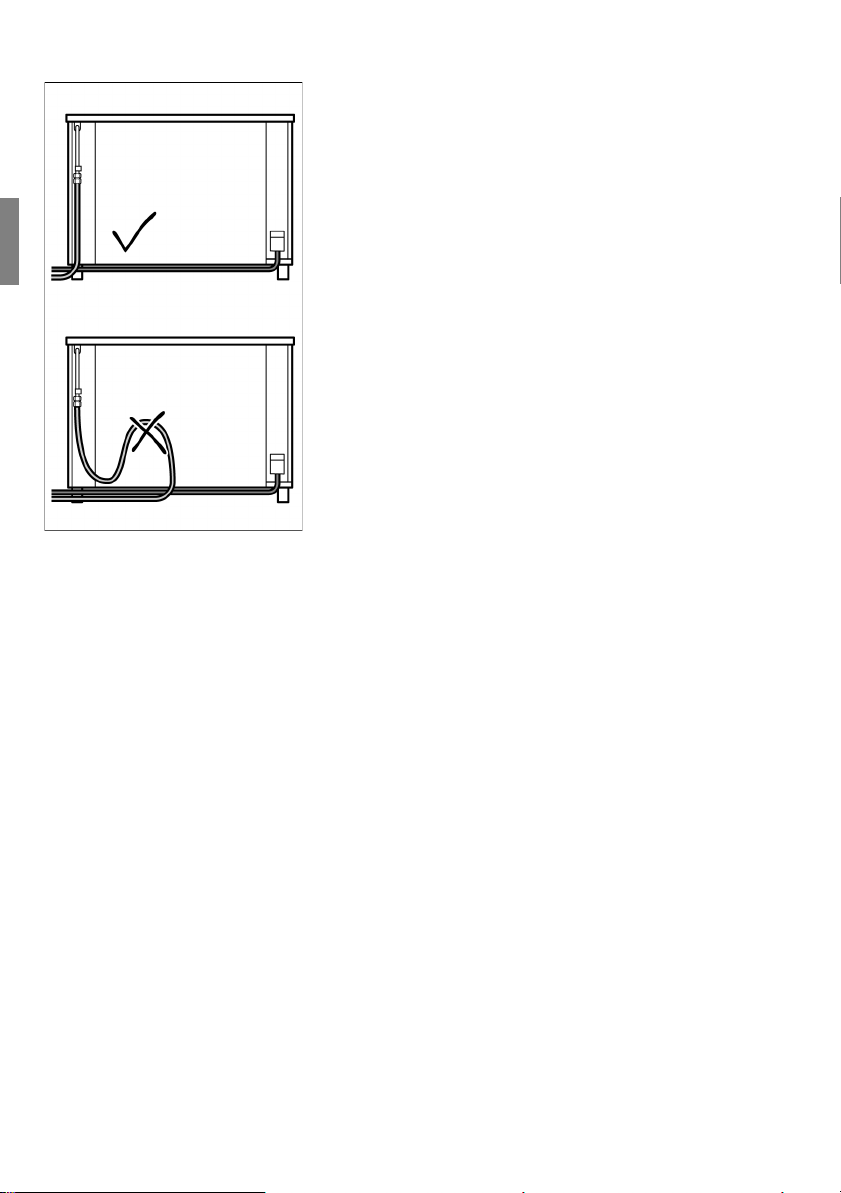

Flexible hose If you use flexible hoses, make sure that:

• the hoses do not become trapped or squashed.

• the hoses are not subject to twisting or pulling

forces.

• the hoses do not come into contact with sharp

edges or cutting edges.

• the hoses do not come into contact with parts that

could reach a temperature higher than 70 °C

above room temperature.

Ensure that the full length of the hoses are accessible

for inspection.

Safety valve The installation of a safety valve for opening and

closing the gas supply is a compulsory requirement.

Fit the safety valve between the gas connecting line

to the appropriate room and the hob. Ensure

unhindered access to this valve.

Checking for leaks After connecting the gas line, check the connections

for leaks using soapy water.

Initial use Switch the appliance on as described in the

instruction manual.

Light all the burners and check that the flames remain

stable at both the high and low settings.

14

Converting the gas type

If the appliance is not already set up for the existing

type of gas, the appliance must be converted.

The conversion to a different type of gas must be

carried out by an authorised expert in accordance

with the applicable regulations.

The type of gas and pressure that was preset at the

factory are indicated on the rating plate on the inside

of the storage compartment flap.

In order to convert to a different type of gas, the

nozzles must be replaced and the low flame and

primary air may have to be adjusted.

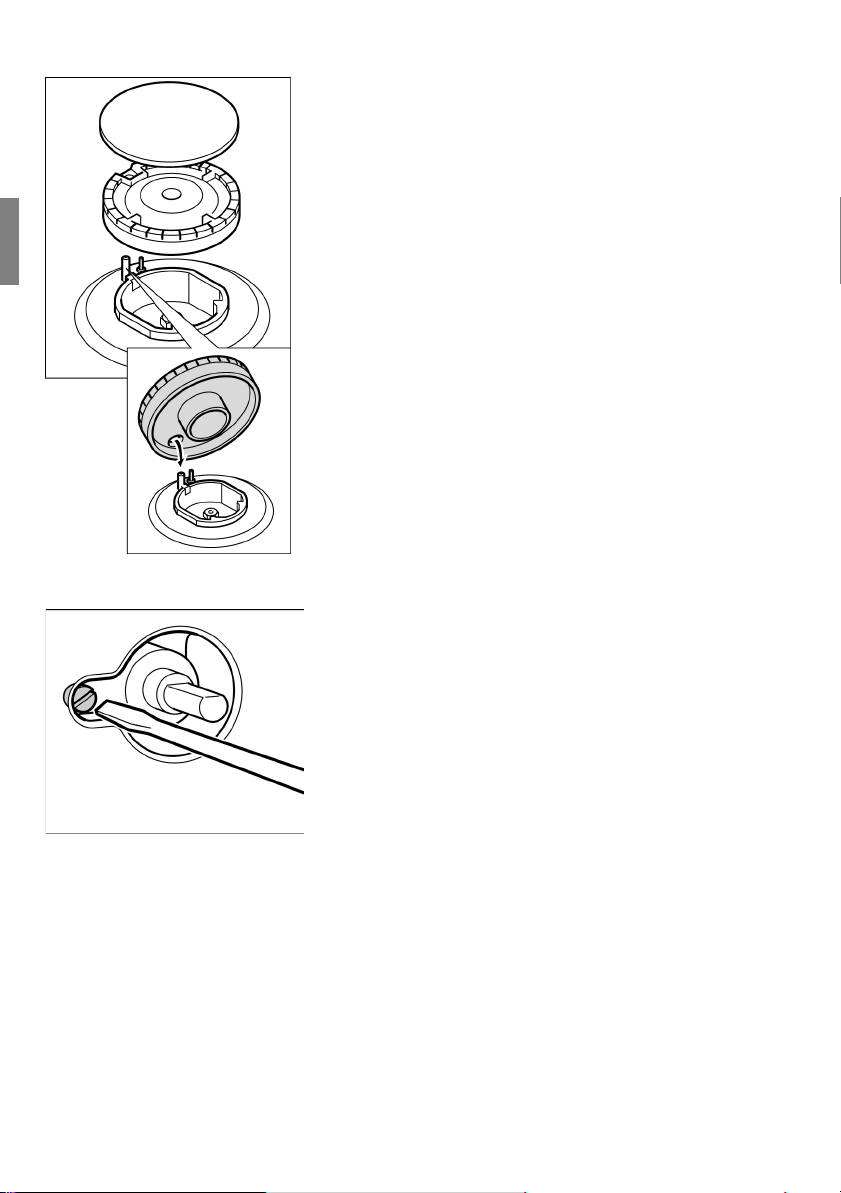

Hotplate burners

Replacing the nozzles

Proceed as follows:

A

B

• Remove the pan supports.

• Remove the burner lids (A) and burner cups (B)

from the burners (C).

C

• Remove the nozzle (D) and replace it with an

appropriate nozzle for the new type of gas (see

section “General nozzle table”).

D

• Replace the gas label with the new label that was

supplied with the nozzle set.

15

• Place each burner cup (B) on the burner (C).

A

B

C

Adjusting the low flame Proceed as follows:

• Position the relevant burner cap (A) exactly on

top of the cup.

• Refit the pan supports.

• Switch on the burner and turn the control knob

towards the small flame setting.

• Pull off the control knob.

• Adjust the inner setting screw through the gas tap

opening in the control panel until a stable flame is

burning correctly.

Loosen the setting screw to increase the gas flow

or tighten it to decrease the gas flow.

The setting is correct when the height of the small

flame is approx. 3 to 4 mm.

• Refit the control knob.

• Check that the flame does not go out when the

gas flow is quickly changed between maximum

and minimum and vice versa.

16

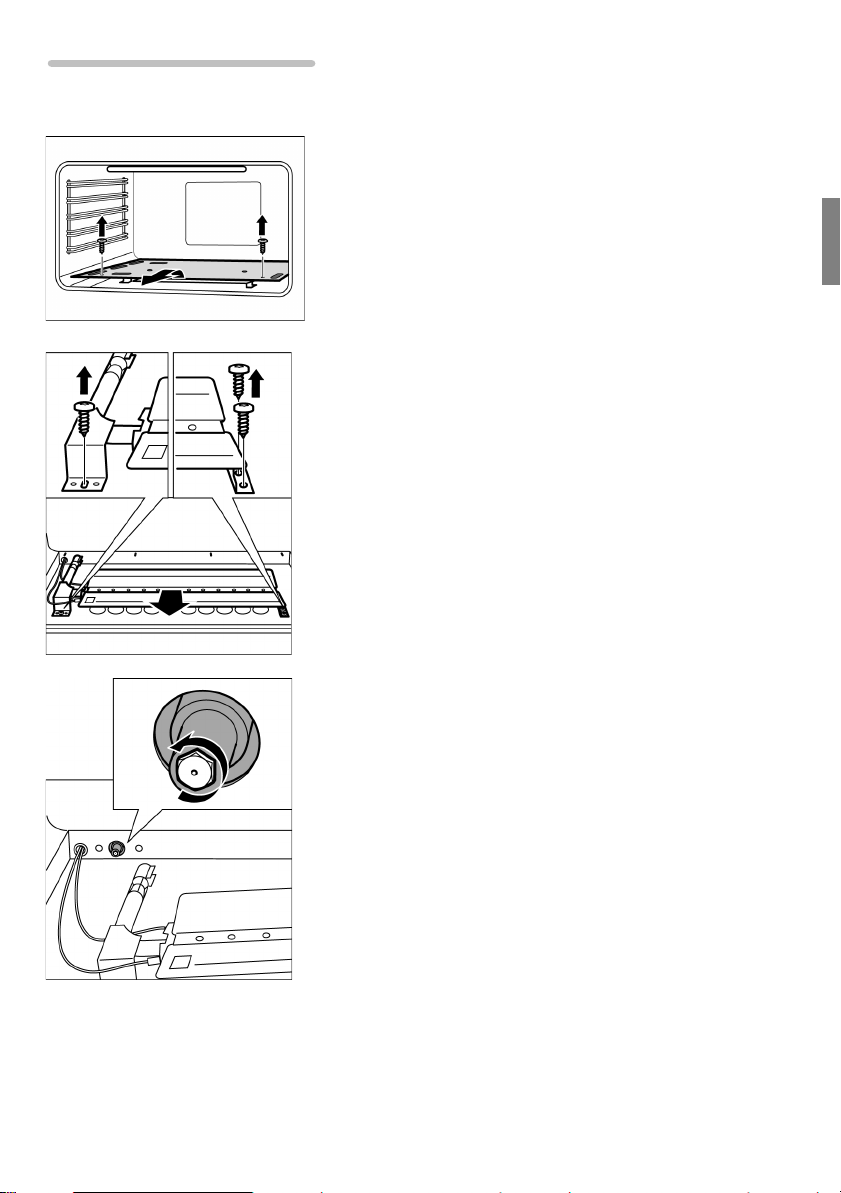

Oven burner

Replacing the nozzles Proceed as follows:

• Remove the removable floor of the oven by

undoing the 2 screws at the front and pulling the

floor out upwards and towards the front.

• Undo the 2 screws on the right and the screw on

the left of the oven burner and pull the burner

upwards and towards the front slightly.

• Unscrew the nozzle and replace it with a nozzle

which is suitable for the new type of gas (see

"General nozzle table" section).

• Replace the gas label with the new label that was

supplied with the nozzle set.

Reassembling the burner To reassemble the burner, proceed in the opposite

order.

17

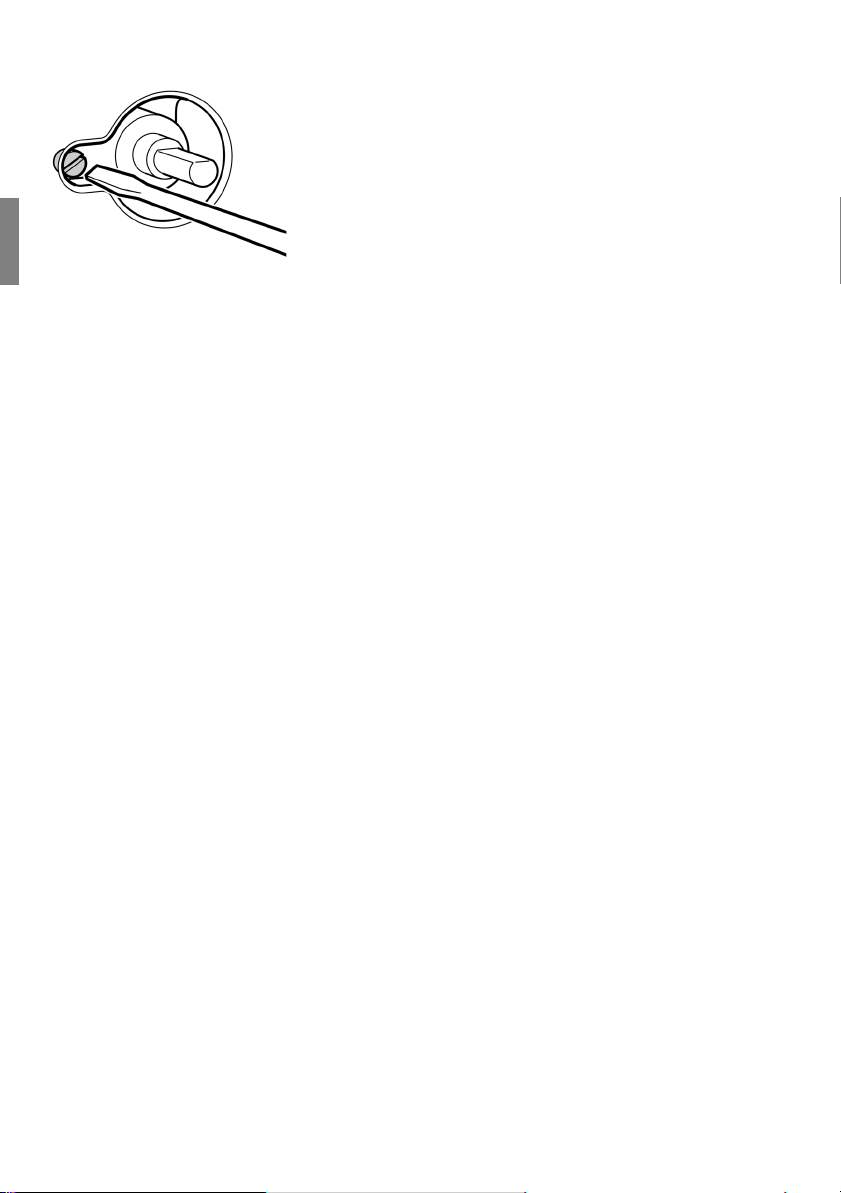

Adjusting the low flame Proceed as follows:

• Open the appliance door. Press the control knob

for the oven in and turn it anti-clockwise to the

maximum setting

The gas burner will light. Hold the control knob

depressed for around 15 seconds and then

release it.

• Close the appliance door. Remove the control

knob.

• Through the gas tap opening in the control panel,

loosen the internal setting screw slightly.

• Replace the control knob and heat the oven for

15 minutes.

• Then turn the control knob to the minimum setting

140

.

• Remove the control knob again.

• Now, through the gas tap opening in the control

panel, adjust the internal setting screw until a

stable flame is burning correctly.

Loosen the setting screw to increase the gas flow

or tighten it to decrease the gas flow. The setting

is correct when the height of the small flame is

around 3 to 4 mm.

In the case of a connection to liquefied gas,

tighten the setting screw.

• Refit the control knob.

• Make sure that the flame does not go out when

the gas flow is changed quickly from maximum to

minimum and vice versa, and when the

appliance door is opened and closed.

250.

18

Regulating the primary air The primary air is correctly set when the flame is

stable and blue/green.

Proceed as follows:

• Undo the screw.

• Turn the cover clockwise or anticlockwise. The

table below shows the correct setting for the

cover.

Type of gas Setting values

G30/29 mbar

• Tighten the screws again.

Reassembling the floor To reassemble the floor, proceed in the opposite

order and pay attention to the 4 screws in the back

wall of the cooking compartment when inserting the

removable floor.

19

Grill burner

Replacing the nozzles Proceed as follows:

• Undo the 2 screws on the left and the 2 screws

on the right of the grill burner and pull the burner

downwards and towards the front slightly.

• Unscrew the nozzle and replace it with a nozzle

which is suitable for the new type of gas (see

"General nozzle table" section).

• Replace the gas label with the new label that was

supplied with the nozzle set.

• To reassemble, follow the instructions in the

reverse order.

20

Regulating the primary air The primary air is correctly set when the flame is

stable and blue/green.

Proceed as follows:

• Undo the screw.

• Slide the inner cover forwards or backwards. The

table below shows the correct setting for the

cover.

Type of gas Setting values

G30/29 mbar

• Tighten the screws again.

General nozzle table

Type of gas mbar

Liquefied

gas

Butane

Propane

G30/G31

28-30/

37

Nozzle no.

85 42

65 31

50 27

96 60

100 55

66 65

Type of burner Output

High output burner

Standard output burner

Economy burner

Wok burner

Oven burner

Grill burner

3,600 262 g/h

Consumpti

(W)

3,000 219 g/h

1,750 128 g/h

1,000 73 g/h

4,300 313 g/h

2,000 146 g/h

on max.Nozzle Bypass

21

Positioning and levelling

Positioning the appliance When installing the appliance, make sure that there is

enough space in the final installation location to pull

the appliance forwards for cleaning and maintenance

work.

The ground underneath must be hard and stable.

The wall immediately behind the appliance must be

made from non-flammable material, e.g. tiles.

If you need to pull the appliance in order to position it,

make sure that the adjustable feet are screwed in

fully.

Levelling the appliance

Level the appliance once all other work has been

completed.

To do this, turn the adjustable feet.

22

Instructions for use

Important information________________________________________25

Safety precautions........................................................................................ 26

Property damage.......................................................................................... 28

Your new appliance:

HG197510ME, HG198210ME, HG198510ME, HG195510ME, HG199210ME,

HG199510ME _______________________________________________30

The control panel.......................................................................................... 31

The hob ........................................................................................................ 31

The oven ...................................................................................................... 33

The minute minder ....................................................................................... 36

The storage compartment ............................................................................ 36

Your new appliance:

HG196510ME _______________________________________________37

The control panel.......................................................................................... 37

The hob ........................................................................................................ 38

The oven ...................................................................................................... 40

The minute minder ....................................................................................... 43

The storage compartment ............................................................................ 43

Your new appliance:

HG193510ME _______________________________________________44

The control panel.......................................................................................... 44

The hob ........................................................................................................ 45

The oven ...................................................................................................... 47

The minute minder ....................................................................................... 50

The storage compartment ............................................................................ 50

Before using for the first time _________________________________ 51

Baking out the oven...................................................................................... 51

Cleaning the burner lids and cups................................................................ 53

Cleaning accessories ................................................................................... 53

How to operate your hob _____________________________________54

Operating gas burners.................................................................................. 54

Operating electric hotplates.......................................................................... 55

How to operate your oven:

HG196510ME, HG197510ME, HG198210ME, HG198510ME, HG195510ME,

HG199210ME, HG199510ME___________________________________ 56

Operating the oven gas burner..................................................................... 57

Operating the grill gas burner....................................................................... 58

Using the combination mode........................................................................ 59

Using the rotary spit ..................................................................................... 61

23

How to operate your oven:

HG193510ME _______________________________________________64

Operating the oven gas burner..................................................................... 65

Operating the grill gas burner....................................................................... 66

Using the rotary spit ..................................................................................... 67

Operating the minute minder __________________________________70

Cleaning and care ___________________________________________ 71

Catalytic cooking compartment panels......................................................... 71

Using the correct cleaning agent.................................................................. 72

Removing and fitting the appliance door ...................................................... 74

Removing and inserting the hook-in racks ................................................... 76

Faults and the after-sales service ______________________________ 78

Replacing the oven light bulb ....................................................................... 79

Aftersales service ......................................................................................... 80

Tips and tricks______________________________________________ 81

Tips for saving energy .................................................................................. 81

Tips on using the hob......................................................................... 81

Tips on using the oven ....................................................................... 82

Tips for using your appliance ....................................................................... 83

Boiling and frying................................................................................ 83

Baking ................................................................................................ 84

Roasting and grilling........................................................................... 86

24

Important information

Read the instructions for use carefully.

This will enable you to operate your appliance safely

and correctly.

This manual is valid for several models. Variations in

details for each cooker are possible.

Please keep the instruction manual, installation

instructions and the various accessories in a safe

place. Please pass on these manuals and

accessories to the new owner if you sell the

appliance.

Transport damage Check the appliance for damage after unpacking it.

Do not connect the appliance if it has been damaged

in transport.

Environmentally-friendly

disposal

Connections Have a licensed professional carry out the electric

Dispose of packaging in an environmentally-friendly

manner.

This appliance is labelled in accordance with

European Directive 2002/96/EC on Waste Electrical

¦

and Electronic Equipment WEEE.

and gas connection and the conversion to a different

type of gas.

Assembly instructions are supplied with the

appliance.

Any damage caused by the appliance being

incorrectly connected is not covered under the

guarantee. We assume no liability for damage and

faults caused by connection and setting errors.

25

Safety precautions

This appliance is intended for domestic use only.

This appliance must only be used for food

preparation.

Adults and children must not operate the appliance

without supervision if:

• they do not have the physical or mental ability;

• or they lack the knowledge and experience

required to operate the appliance safely and

correctly.

Never let children play with the appliance.

Hot surfaces Risk of burns.

Never touch the burners, the surfaces of the cooking

compartment, the heating elements or the oven

steam outlets when they are hot.

Children must be kept at a safe distance from the

appliance at all times.

Open the appliance door carefully. Hot steam may

escape.

If the burners are in operation for a prolonged period,

the areas between them can become hot.

Risk of fire.

Never leave flammable objects on the hob or in the

storage compartment, or keep them in the cooking

compartment.

Risk of short-circuit.

Never trap the mains cable of electrical appliances in

the appliance door when it is hot or pull the cable over

burners when they are hot. The cable insulation may

melt.

Overheated oil and fat Risk of fire.

Overheated oil or fat can ignite very quickly.

Never leave fat or oil to heat unattended. Should the

oil ignite, do not try to put it out by pouring water on it.

Cover the pan immediately with a lid or plate. Switch

off the gas burner. Allow the cookware to cool down

on the gas burner.

26

High-proof alcohol Be careful with food that is prepared using drinks with

a high alcohol content (e.g. cognac, rum).

Alcohol evaporates at high temperatures. In

unfavourable circumstances, the alcoholic vapours

could catch fire in the appliance.

Risk of burns.

Only use small quantities of drinks with a high alcohol

content and open the appliance door carefully.

Inadequate ventilation

when using gas burners

Repairs Risk of electrocution.

Never use the gas burners in unventilated rooms.

Cooking with gas burners releases extra heat and

moisture.

During prolonged cooking and baking times, switch

on the extractor hood or make sure that the area is

well ventilated.

Risk of fire.

Never switch on the extractor hood if the burners are

not covered by cookware.

Grease residue in the filter of the extractor hood may

ignite.

The intense heat may damage the extractor hood.

Incorrect repairs are dangerous.

Repairs may only be carried out by one of our

experienced after-sales engineers.

Risk of electrocution.

Never replace a damaged power cable yourself.

Power cables may only be replaced by one of our

experienced after-sales engineers.

Switch off the circuit breaker in the fuse box if the

appliance is faulty.

Shut off the gas supply.

Call the aftersales service.

27

Faults with the gas

installation/gas smell

Safety valve Close the safety valve on the gas supply line if the

If you can smell gas or identify faults with the gas

installation, you must

• shut off the gas supply and/or valve on the gas

cylinder immediately

• put out naked flames and cigarettes immediately

• switch off electrical appliances, even lamps

• open windows and ventilate the room well

• call the after-sales service or your gas supplier.

cooker will not be used for a prolonged period.

Property damage

Damage to the hob Only use the burners if cookware is placed on them.

Do not heat empty pots or pans. This will damage the

pan base.

Do not allow saucepans to boil dry, in particular

enamel and aluminium saucepans.

The pan base must be clean, dry and flat.

With electric hotplates, it is possible that not enough

heat is drawn off and the pans become red hot.

28

Please follow the manufacturer's instructions when

using special cookware. Aluminium foil and plastic

containers can melt and stick on hot burners.

Do not use a roasting dish which has to be heated

using two burners. This will cause heat to

accumulate. This could damage the appliance.

Please note that appliances with a hob cover may

only be used with the hob cover open.

Damage to the oven Never cook meals on the floor of the cooking

compartment. Do not leave the baking tray on the

cooking compartment floor. Do not cover it with

aluminium foil.

Do not place oven or cookware on the oven floor.

This will cause heat accumulation. The baking and

roasting times will no longer be correct and the

enamel will be damaged.

Never pour water directly into a hot oven. This will

damage the enamel.

When making very moist fruit flans, do not put too

much on the baking tray. Fruit juice dripping from the

baking tray leaves stains that cannot be removed.

Do not stand or sit on the open oven door.

Damage to the fronts of

adjacent units

Only leave the oven to cool down with the door

closed. The fronts of adjacent units may eventually

become damaged even if you only leave the oven

door open slightly.

If the oven door seal is very dirty, the appliance door

will no longer close properly during operation. The

fronts of adjacent units will become damaged over

time. Keep the seal clean.

29

Your new appliance

HG197510ME, HG198210ME, HG198510ME, HG195510ME,

HG199210ME, HG199510ME

Get to know your appliance. You will find information

about the control panel and hob, as well as the oven,

types of heating and accessories.

For the HG197510ME/HG198210ME/HG198510ME/

HG199210ME/HG199510ME model:

Hob cover

Steam outlet

Hob

Control panel

Oven

Storage

30

For the HG195510ME model:

Splash guard

Steam outlet

Hob

Control panel

Oven

Storage

The control panel

Control knob

Grill

Control knob

Oven

Control knobs

Gas burners

Function button

Rotary spit

Function button

Oven lighting

The hob

Steam outlet

Pan support

High output burner

(3.0 kW)

Control knob

Minute minder

Standard burner

(1.75 kW)

Economy burner

(1.0 kW)

Wok burner

(3.6 kW)

Gas burners

Gas burners Pot or pan diameter

Economy burner 8-16 cm

Standard output burner 12-20 cm

High output burner 20-23 cm

Wok burner 23-26 cm

31

Control knobs for gas

burners

Adjust the heat setting of the gas burners using the

control knobs.

The symbol above the control knob shows you to

which gas burner the control knob belongs.

Setting Meaning

>

Off

Gas supply open, the burner ignites.

J - Ÿ

Accessory

Accessory Description

Steam outlet Risk of burns.

Hot air from the oven escapes out of the steam outlet

on the hob.

Never touch the steam outlet.

Please note that, in the case of appliances with a hob

cover, the burners in the oven may also only be

switched on if the hob cover is open.

Burner power levels

Espresso attachment

Attachment for an espresso

pot, for attaching to the

economy burner.

32

The oven

Gas burners

Grill gas burner

(2.0 kW)

Oven gas burner

(4.3 kW)

Control knob for oven Use this control knob to set the heat output of the

oven gas burner.

Setting Meaning

0Off

140 - 250 Oven gas burner on, temperature

range in °C

0

There is a limit stop between settings 250 and

not turn the knob beyond this point.

. Do

Control knob for grill This control knob is used to adjust the heat setting of

the grill gas burner.

Setting Meaning

>

J - Ÿ

Burner power levels

There is a limit stop between settings

turn the knob beyond this point.

Off

Gas supply open, the burner ignites.

Ÿ

and > . Do not

33

Function button for oven

lighting

This function button is used to switch the oven

lighting on and off.

Setting Meaning

Off

On

Function button for rotary

spit

This function button is used to switch the rotary spit

on and off.

Setting Meaning

Off

On

34

Accessories The accessories can be inserted in the oven in 5

different shelf positions.

You can pull the accessories two-thirds of the way out

without them tipping. This allows meals to be

removed easily.

You can buy accessories from the after-sales service

or from specialist retailers.

Accessory Description

Baking and roasting shelf

For ovenware, cake tins,

roasts, grilling and frozen

meals.

Enamelled baking tray

For moist cakes, pastries,

frozen meals and large

roasts. Can also be

inserted underneath the

wire rack or rotary spit and

used as a drip tray to

collect fat.

Rotary spit

For roasts and large pieces

of poultry. Use only in

combination with the

enamelled baking tray.

35

The minute minder

The minute minder is a countdown

timer which emits an audible signal when

the cooking time has elapsed.

The minute minder runs independently of the oven.

Control knob for minute

minder

Use this control knob to set the cooking time.

Setting Meaning

>

1 - 59

The storage compartment

Open the storage compartment by folding down the

fascia panel.

This compartment can be used to store hob or oven

accessories.

Risk of fire.

Never leave combustible items in the storage

compartment.

Off

Cooking time in minutes

36

Your new appliance

HG196510ME

Get to know your appliance. You will find information

about the control panel and hob, as well as the oven,

types of heating and accessories.

Hob cover

Hob

Oven

The control panel

Control knob

Oven

Steam outlet

Control panel

Storage

Control knobs

Gas burners

Function button

Oven lighting

Function button

Rotary spit

Control knob

Minute minder

Control knobs

Electric hotplates

37

The hob

Steam outlet

Pan support

High output burner

Gas burners

Standard burner

(1.75 kW)

(3.0 kW)

Large hotplate

(1.5 kW)

Standard burner

(1.75 kW)

Economy burner

(1.0 kW)

Medium hotplate

(1.0 kW)

Gas burners Pot or pan diameter

Economy burner 8-16 cm

Standard output burner 12-20 cm

High output burner 20-23 cm

Control knobs for gas

burners

38

Adjust the heat setting of the gas burners using the

control knobs.

The symbol above the control knob shows you to

which gas burner the control knob belongs.

Setting Meaning

>

J - Ÿ

Burner power levels

Off

Gas supply open, the burner ignites.

Electric hotplates

Hotplate Diameter

Large hotplate 18.5 cm

Medium hotplate 15 cm

Control knobs for electric

hotplates

Accessory

Steam outlet Risk of burns.

The control knobs are used to adjust the heat setting

of the hotplates.

The symbol above the control knob shows you to

which gas burner the control knob belongs.

Setting Meaning

0Off

1 - 6 Burner power levels

Accessory Description

Hot air from the oven escapes out of the steam outlet

on the hob.

Never touch the steam outlet.

Espresso attachment

Attachment for an espresso

pot, for attaching to the

economy burner.

Please note that, in the case of appliances with a hob

cover, the burners in the oven may also only be

switched on if the hob cover is open.

39

The oven

Gas burners

Grill gas burner

(2.0 kW)

Oven gas burner

(4.3 kW)

Control knob for oven Use this control knob to set the heat output of the

oven gas burner.

Setting Meaning

0Off

140 - 250 Oven gas burner on, temperature

range in °C

There is a limit stop between settings 250 and

not turn the knob beyond this point.

Control knob for grill This control knob is used to adjust the heat setting of

the grill gas burner.

Setting Meaning

>

J - Ÿ

Burner power levels

There is a limit stop between settings

turn the knob beyond this point.

Off

Gas supply open, the burner ignites.

Ÿ

and > . Do not

0

. Do

40

Function button for oven

lighting

This function button is used to switch the oven

lighting on and off.

Setting Meaning

Off

On

Function button for rotary

spit

This function button is used to switch the rotary spit

on and off.

Setting Meaning

Off

On

41

Accessories The accessories can be inserted in the oven in 5

different shelf positions.

You can pull the accessories two-thirds of the way out

without them tipping. This allows meals to be

removed easily.

You can buy accessories from the after-sales service

or from specialist retailers.

Accessory Description

Baking and roasting shelf

For ovenware, cake tins,

roasts, grilling and frozen

meals.

Enamelled baking tray

For moist cakes, pastries,

frozen meals and large

roasts. Can also be

inserted underneath the

wire rack or rotary spit and

used as a drip tray to

collect fat.

Rotary spit

For roasts and large pieces

of poultry. Use only in

combination with the

enamelled baking tray.

42

The minute minder

The minute minder is a countdown

timer which emits an audible signal when

the cooking time has elapsed.

The minute minder runs independently of the oven.

Control knob for minute

minder

Use this control knob to set the cooking time.

Setting Meaning

>

1 - 59

The storage compartment

Open the storage compartment by folding down the

fascia panel.

This compartment can be used to store hob or oven

accessories.

Risk of fire.

Never leave combustible items in the storage

compartment.

Off

Cooking time in minutes

43

Your new appliance

HG193510ME

Get to know your appliance. You will find information

about the control panel and hob, as well as the oven,

types of heating and accessories.

Hob cover

Hob

Oven

The control panel

Function button

Rotary spit

Control knob

Oven

Function button

Oven lighting

Steam outlet

Control panel

Control knobs

Gas burners

Storage

44

Control knob

Minute minder

The hob

Steam outlet

Standard burner

(1.75 kW)

Pan support

High output burner

(3.0 kW)

Gas burners

Control knobs for gas

burners

Economy burner

(1.0 kW)

Wok burner

(3.6 kW)

Gas burners Pot or pan diameter

Economy burner 8-16 cm

Standard output burner 12-20 cm

High output burner 20-23 cm

Wok burner 23-26 cm

Adjust the heat setting of the gas burners using the

control knobs.

The symbol above the control knob shows you to

which gas burner the control knob belongs.

Setting Meaning

>

Off

Gas supply open, the burner ignites.

J - Ÿ

Burner power levels

45

Accessory

Accessory Description

Steam outlet Risk of burns.

Hot air from the oven escapes out of the steam outlet

on the hob.

Never touch the steam outlet.

Please note that, in the case of appliances with a hob

cover, the burners in the oven may also only be

switched on if the hob cover is open.

Espresso attachment

Attachment for an espresso

pot, for attaching to the

economy burner.

46

The oven

Gas burners

Grill gas burner

(2.0 kW)

Oven gas burner

(4.3 kW)

Control knob for oven Use this control knob to switch on the grill gas burner

and to set the heat output of the oven gas burner.

Setting Meaning

0Off

140 - 250 Oven gas burner on, temperature

range in °C

x

There is a limit stop between settings 250 and

not turn the knob beyond this point.

Grill gas burner on

x

. Do

47

Function button for oven

lighting

This function button is used to switch the oven

lighting on and off.

Setting Meaning

Off

On

Function button for rotary

spit

This function button is used to switch the rotary spit

on and off.

Setting Meaning

Off

On

48

Accessories The accessories can be inserted in the oven in 5

different shelf positions.

You can pull the accessories two-thirds of the way out

without them tipping. This allows meals to be

removed easily.

You can buy accessories from the after-sales service

or from specialist retailers.

Accessory Description

Baking and roasting shelf

For ovenware, cake tins,

roasts, grilling and frozen

meals.

Enamelled baking tray

For moist cakes, pastries,

frozen meals and large

roasts. Can also be

inserted underneath the

wire rack or rotary spit and

used as a drip tray to

collect fat.

Rotary spit

For roasts and large pieces

of poultry. Use only in

combination with the

enamelled baking tray.

49

The minute minder

The minute minder is a countdown

timer which emits an audible signal when

the cooking time has elapsed.

The minute minder runs independently of the oven.

Control knob for minute

minder

Use this control knob to set the cooking time.

Setting Meaning

>

1 - 59

The storage compartment

Open the storage compartment by folding down the

fascia panel.

This compartment can be used to store hob or oven

accessories.

Risk of fire.

Never leave combustible items in the storage

compartment.

Off

Cooking time in minutes

50

Before using for the first time

Please read the following instructions before using

your appliance for the first time.

Remove the appliance packaging and dispose of this

appropriately.

Baking out the oven

Cooking compartment

initial cleaning

Heating up the oven gas

burner

Remove the accessories from the cooking

compartment.

Completely remove any leftover packaging, e.g.

small pieces of polystyrene, from the cooking

compartment.

Some parts are covered with a protective film.

Remove this film.

1. Clean the outside of the appliance with a soft,

damp cloth.

2. If the hook-in racks have already been fitted,

unhook and remove them. For information on

removing the racks, see the section “Removing

and refitting hook-in racks.”

3. Clean the cooking compartment with warm soapy

water.

To remove the new cooker smell, heat up the oven

when it is empty and closed.

Please note that, in the case of appliances with a hob

cover, the burners in the oven may only be switched

on if the hob cover is open.

1. Open the hob cover and appliance door.

2. Press the control knob for the oven, turn it anti-

clockwise to position

knob pressed for a few seconds until the flame has

stabilised. Then close the appliance door.

250 °C

and hold the control

3. After 45 minutes, switch the oven off by turning the

control knob clockwise to position

0

.

51

Heating up the grill gas

burner

For the HG196510ME/HG197510ME/HG198210ME/

HG198510ME/HG195510ME/HG199210ME/

HG199510ME model:

1. Open the appliance door.

2. Press the control knob for the grill, turn it clockwise

to position

a few seconds until the flame has stabilised. Then

close the appliance door.

J

and hold the control knob pressed for

3. After 30 minutes, switch the grill off by turning the

control knob anti-clockwise to

position 0 .

For the HG193510ME model:

1. Open the appliance door.

2. Press the control knob for the oven in, turn it

clockwise to

in for a few seconds until the flame has stabilised.

Then close the appliance door.

x

and hold the control knob pressed

3. After 30 minutes, switch the grill off by turning the

control knob anti-clockwise until it reaches 0 .

Rinsing cooking

compartment after initial

cleaning

52

Clean the cooking compartment with hot soapy

water. Refit the hook-in racks.

Cleaning the burner lids and cups

Proceed as follows:

A

1. Clean the burner lids (A) and cups (B) with water

and washing-up liquid.

2. Dry the parts off well.

B

3. Place the burner cup in question (B)

on the burner (C).

4. Place the burner lid (A) exactly on top of

C

the burner cup (B).

Cleaning accessories

Before using the accessories, clean them thoroughly

using a cloth and warm soapy water.

53

How to operate your hob

Please note that, in the case of appliances with a hob

cover, the burners may only be switched on if the hob

cover is open.

Operating gas burners

Make sure that the burner lid always sits exactly on

top of the burner cup. The slots on the burner cup

must be open. All parts must be dry.

Switching on the gas

burner

Switching off the gas

burner

1. Press the control knob for the required burner and

turn it to position

The gas burner ignites.

Keep the control knob pressed for a few seconds

until the flame stabilises.

J

.

2. Adjust the burner to the desired flame setting.

Setting Meaning

Ÿ

J

The flame is not steady between position

>

and J . Therefore, always select a position

between

Turn the control knob for the required burner to

position

>

.

lowest flame setting

highest flame setting

J

and Ÿ .

54

If the flame goes out Switch off the control knob. Wait for one minute and

repeat steps 1 to 3.

If the flame goes out, gas will escape. Never leave

m

the gas burner unattended during operation. Ensure

that food does not boil over and that there are no

draughts when cooking.

If the gas burner does not

ignite

In the event of a power failure or damp ignition plugs,

light the gas burner with a gas lighter or a match.

Operating electric hotplates

For the HG196510ME model:

Make sure that the hotplates are dry before use.

Switching on the hotplate Turn the control knob for the required hotplate to the

desired power level.

Setting Meaning

1 lowest power setting

6 highest power setting

Switching off the hotplate Turn the control knob for the required hotplate

position 0

.

55

How to operate your oven

HG196510ME, HG197510ME, HG198210ME, HG198510ME,

HG195510ME, HG199210ME, HG199510ME

Please note that, in the case of appliances with a hob

cover, the burners in the oven may only be switched

on if the hob cover is open.

Switching on the oven

lighting

Switching off the oven

lighting

Operating modes

Operating mode Gas burners Use

ð

140 - 250 °C

Conventional heating

x J -

Ÿ

Grill

ð

140 - 250 °C and x J Combination

(conventional heating

plus grill)

Press down the function button for the oven lighting

until it locks into place.

The oven lighting switches on.

Press down the function button for the oven lighting

until it releases.

The oven lighting switches off.

Oven gas burner For cakes and pastries,

bakes, poultry, lean joints of

meat, e.g. beef, veal and

game.

Grill gas burner

Ÿ

Oven gas burner and

grill gas burner

For steaks, sausages, fish

and toast.

For cakes and pastries,

bakes and toast with

toppings, poultry and fish,

joints, sausages and

steaks.

56

Operating the oven gas burner

If you wish to heat your oven in the conventional way,

use the oven gas burner.

Switching on the oven gas

burner

1. Open the appliance door.

2. Press the control knob for the oven, turn it anti-

clockwise to position

knob pressed for a few seconds until the flame has

stabilised. Then carefully close the appliance

door.

250 °C

and hold the control

3. Set the required temperature using the control

knob. Do not turn the knob beyond 140.

Switching off the oven gas

burner

If the flame goes out Switch off the control knob. Wait one minute and

When the dish is ready, slightly depress the control

knob and turn it clockwise to position 0 .

switch the burner on again.

If the flame goes out, gas will escape. Never leave

m

the gas burner unattended during operation. Ensure

that there are no draughts.

57

Operating the grill gas burner

Please note that the appliance door must be closed

during grilling.

Switching on the grill gas

burner

1. Open the appliance door.

2. Press the control knob for the grill and turn it anti-

clockwise to position

The gas burner ignites.

Keep the control knob pressed for a few seconds

until the flame stabilises.

Do not turn the knob beyond this setting.

J .

3. Adjust the burner to the desired flame setting.

Setting Meaning

Ÿ

J

The flame is not steady between position

>

and J. Therefore, always select a position

between

lowest flame setting

highest flame setting

J

and Ÿ .

4. Carefully close the appliance door.

Switching off the grill gas

burner

If the flame goes out Switch off the control knob. Wait one minute and

When the dish is ready, turn the control knob

>

clockwise to position

switch the burner on again.

.

58

If the flame goes out, gas will escape. Never leave

m

the gas burner unattended during operation. Ensure

that there are no draughts.

Using the combination mode

Tips on using the

combination mode

Switching on combination

mode

Please note the following points when using the

combination mode:

• The temperature range marked on the control

knob for the oven only applies to conventional

heating. When the combination mode is used, the

temperature in the oven is higher than the

temperature which was set on the control knob.

• If you are operating the grill gas burner on the

lowest flame setting, you must also set the lowest

temperature for the oven gas burner.

1. Open the appliance door.

2. Switch on the grill gas burner by pressing the

control knob for the grill and turning it anticlockwise to position

The gas burner ignites.

Keep the control knob pressed for a few seconds

until the flame stabilises.

J

.

3. Carefully close the appliance door.

4. Open the appliance door after 10 minutes.

5. Press the control knob for the oven, turn it anti-

clockwise to position

knob pressed for a few seconds until the flame has

stabilised. Then carefully close the appliance

door.

250 °C

and hold the control

6. Using the control knob, set the desired

temperature and heat setting for both burners.

7. Allow the appliance to heat up for 15 minutes,

carefully open the appliance door and place the

dish inside.

59

Turning on the grill When using conventional heating, you can briefly turn

on the grill at the end of the cooking time for food and

baked goods which require more intense browning or

a crisped finish (e.g. crackling).

To turn on the grill, proceed as follows:

1. Carefully open the appliance door.

2. Turn on the grill gas burner and adjust to the

desired flame setting.

3. Carefully close the appliance door.

Switching off combination

mode

Turn off the grill and oven gas burners.

60

Using the rotary spit

The rotary spit can be used to cook joints such as

rolled joints and poultry with excellent results. The

meat is roasted thoroughly and evenly.

Use the rotary spit in conjunction with the grill or

combination mode.

Preparing joints Place the joint as centrally as possible on the rotary

spit and secure it at both ends with the retaining clips.

You can also truss the joint with string. With poultry,

bind the ends of the wings underneath the back and

the thighs against the body. This will prevent them

from becoming too dark.

Pierce the skin on the underside of the wings to allow

the fat to escape.

61

Inserting the rotary spit Insert the rotary spit as follows:

1. Hook the spit holder into the bracket on the ceiling

of the cooking compartment.

If you require to preheat the oven, hook in the

holder before preheating.

mRisk of burns

Never touch the hot surfaces of the cooking

compartment or the heating elements.

Children must be kept at a safe distance from the

appliance at all times.

Open the appliance door carefully. Hot steam may

escape.

2. If the oven has been preheated, only attach the

rotary spit if you are using an oven cloth or wearing

(thermal) oven gloves. To attach the spit, slide one

end into the recessed adapter in the left-hand side

panel of the cooking compartment.

3. Hook the other end into the holder.

4. Pour a little bit of water into the baking tray and

slide this into shelf position 1 to collect the run-off

fat.

Switching on the rotary spit Press the function button for rotary spit mode.

The button simply locks into place and operation

starts.

Switching off the rotary spit Press the function button for rotary spit mode.

The button releases and operation switches off.

62

Removing the rotary spit

Risk of burns.

m

Never touch the hot surfaces of the cooking

compartment or the heating elements.

Children must be kept at a safe distance from the

appliance at all times.

Open the appliance door carefully. Hot steam may

escape.

Risk of burns.

m

Never touch the rotary spit or other accessories

directly when they are hot.

Always wear oven gloves or heat-resistant gloves

when handling hot accessories.

Remove the rotary spit as follows:

1. Carefully open the appliance door. Carefully

remove the rotary spit from the holder.

2. Carefully withdraw the rotary spit from the

recessed adapter in the side panel and remove it

from the oven.

3. Take out the baking tray.

63

How to operate your oven

HG193510ME

Please note that, in the case of appliances with a hob

cover, the burners in the oven may only be switched

on if the hob cover is open.

Switching on the oven

lighting

Switching off the oven

lighting

Operating modes

Operating mode Gas burners Use

ð

140 - 250 °C

Conventional heating

x

Grill

Press down the function button for the oven lighting

until it locks into place.

The oven lighting switches on.

Press down the function button for the oven lighting

until it releases.

The oven lighting switches off.

Oven gas burner For cakes and pastries,

bakes, poultry, lean joints of

meat, e.g. beef, veal and

game.

Grill gas burner

For steaks, sausages, fish

and toast.

64

Operating the oven gas burner

If you wish to heat your oven in the conventional way,

use the oven gas burner.

Switching on the oven gas

burner

1. Open the appliance door.

2. Press the control knob for the oven, turn it anti-

clockwise to position

knob pressed for a few seconds until the flame has

stabilised. Then carefully close the appliance

door.

250 °C

and hold the control

3. Set the required temperature using the control

knob. Do not turn the knob beyond 140.

Switching off the oven gas

burner

If the flame goes out Switch off the control knob. Wait one minute and

When the dish is ready, slightly depress the control

knob and turn it clockwise to position 0 .

switch the burner on again.

If the flame goes out, gas will escape. Never leave

m

the gas burner unattended during operation. Ensure

that there are no draughts.

65

Operating the grill gas burner

Please note that the appliance door must be closed

during grilling.

Switching on the grill gas

burner

1. Open the appliance door.

2. Press the control knob for the oven in, turn it

clockwise to

in for a few seconds until the flame has stabilised.

Do not turn the knob beyond this setting.

x and hold the control knob pressed

3. Close the appliance door.

Switching off the burner When the meal is ready, turn the control knob anti-

clockwise until it reaches 0 .

If the flame goes out Turn the control knob to the off position. Wait one

minute and switch the burner on again.

If the flame goes out, gas will escape. Do not leave

m

the gas burners unattended while switched on.

Ensure that there are no draughts.

66

Using the rotary spit

The rotary spit can be used to cook joints such as

rolled joints and poultry with excellent results. The

meat is roasted thoroughly and evenly.

Use the rotary spit in conjunction with the grill.

Preparing joints Place the joint as centrally as possible on the rotary

spit and secure it at both ends with the retaining clips.

You can also truss the joint with string. With poultry,

bind the ends of the wings underneath the back and

the thighs against the body. This will prevent them

from becoming too dark.

Pierce the skin on the underside of the wings to allow

the fat to escape.

67

Inserting the rotary spit Insert the rotary spit as follows:

1. Hook the spit holder into the bracket on the ceiling

of the cooking compartment.

If you require to preheat the oven, hook in the

holder before preheating.

mRisk of burns

Never touch the hot surfaces of the cooking

compartment or the heating elements.

Children must be kept at a safe distance from the

appliance at all times.

Open the appliance door carefully. Hot steam may

escape.

2. If the oven has been preheated, only attach the

rotary spit if you are using an oven cloth or wearing

(thermal) oven gloves. To attach the spit, slide one

end into the recessed adapter in the left-hand side

panel of the cooking compartment.

3. Hook the other end into the holder.

4. Pour a little bit of water into the baking tray and

slide this into shelf position 1 to collect the run-off

fat.

Switching on the rotary spit Press the function button for rotary spit mode.

The button simply locks into place and operation

starts.

Switching off the rotary spit Press the function button for rotary spit mode.

The button releases and operation switches off.

68

Removing the rotary spit

Risk of burns.

m

Never touch the hot surfaces of the cooking

compartment or the heating elements.

Children must be kept at a safe distance from the

appliance at all times.

Open the appliance door carefully. Hot steam may

escape.

Risk of burns.

m

Never touch the rotary spit or other accessories

directly when they are hot.

Always wear oven gloves or heat-resistant gloves

when handling hot accessories.

Remove the rotary spit as follows:

1. Carefully open the appliance door. Carefully

remove the rotary spit from the holder.

2. Carefully withdraw the rotary spit from the

recessed adapter in the side panel and remove it

from the oven.

3. Take out the baking tray.

69

Operating the minute minder

The minute minder runs independently of the oven.

Setting a cooking time Turn the control knob once round clockwise, as far as

the limit stop, and then turn it anti-clockwise to set it

to the required time.

The cooking time has

elapsed

A signal sounds once the time has elapsed.

70

Cleaning and care

Never use high-pressure cleaners or steam jets. Risk

m

of short circuit.

Never use caustic or abrasive cleaning agents.

These could damage the surface. If such an agent

gets on the front of the appliance, wipe it off

immediately with water.

Do not clean any surfaces of the appliance while they

are hot.

Switching on the oven

lighting

To make it easier to clean the oven, you can switch

on the oven lighting.

To switch on the lighting, press the function button for

oven lighting until it locks into place.

Catalytic cooking compartment panels

For the HG195510ME, HG196510, HG199210ME or

HG199510ME model:

The catalytic cooking compartment panels are

coated with self-cleaning enamel.

The surfaces clean themselves while the oven is in

operation. Larger splashes will only be removed after

the oven has been used several times.

Self-cleaning surfaces The rear and side walls are protected with catalytic

panelling.

Never clean these surfaces with oven cleaner.

Slight discolouration of the enamel does not affect

automatic self-cleaning.

71

Using the correct cleaning agent

Do not use cleaning agents that contain abrasive

substances or acids, or cleaning aids such as steel

wool or stainless steel sponges. These could damage

the surfaces.

Appliance parts Cleaning agent and cleaning aid

Appliance door glass panel

Control panel and knobs

Seal

(on the cooking

compartment)

Hook-in racks

Cooking compartment

Enamelled surfaces

Gas burners

Burners

Gas burners

Oven and grill

Appliance exterior

Stainless steel surfaces

Glass cover

(in front of the oven lighting)

Pan support

• Use glass cleaner.

Risk of injury.

The lower edge of the door may have sharp edges.

Clean the door and glass panels with care.

• Do not use a glass scraper.

• Wipe with a damp, soft cloth.

• Use warm soapy water.

• Use warm soapy water.

• Use warm soapy water; Dry off with a soft cloth.

• Remove the burner cups and lids; use soapy water;

allow to dry well.

• Clean the ignition plugs and thermocouple with a

damp cloth or a small, soft brush; allow to dry well.

• When refitting: Place the burner cup onto the burner.

Position the burner lid exactly on the burner cup.

• The burner lids are coated with black enamel. Over

time they will change colour. This does not affect the

function.

• Never clean the gas burners in the cooking

compartment yourself.

• Use warm soapy water; Dry off with a soft cloth.

• Always remove flecks of limescale, grease, starch

and albumin (e.g. egg white) immediately.

• Special stainless steel cleaners are available from

the after-sales service or specialist shops.

• Use warm soapy water.

• Use warm soapy water.

• Do not clean the pan supports in the dishwasher.

72

Appliance parts Cleaning agent and cleaning aid

Accessory

• Soak in hot soapy water. Clean with a brush or

sponge.

73

Removing and fitting the appliance door

You can remove the appliance door for easier

cleaning.

The hinges of the appliance door are each secured

by a locking lever.

When the locking lever is folded in (A), the appliance

door is secured. It cannot be unhinged.

If the locking lever is open (B), only the hinge is

secured, and you can remove the appliance door.

Risk of injury.

Do not reach inside the hinge.

Removing the appliance

door

Proceed as follows:

1. Open the appliance door.

2. Lift up the locking levers on both sides.

3. Close the appliance door until you feel resistance

at an angle of around 15° (in relation to the closed

appliance door).

4. Grip the door on either side with both hands.

5. Close the appliance door a little further.

6. Lift the door upwards and at an angle to remove it.

Do not disassemble the door.

74

Fitting the appliance door Proceed as follows:

1. Hold the appliance door at an angle.

2. Insert both hinges, left and right, into the supports.

3. Position the door so that the hinge grooves

engage on both sides.

4. Open the appliance door.

5. Fold in the locking levers on both sides.

6. Close the appliance door.

75

Removing and inserting the hook-in racks

You can remove the hook-in racks in order to clean

them separately.

The hook-in racks are all fixed to the walls of the

cooking compartment at four points.

Removing the hook-in

racks

To remove the hook-in racks, proceed as follows:

1. Take hold of the bottom of the hook-in rack and

pull it slightly forward.

The lower hooks of the hook-in rack are released.

2. Take hold of the top of the hook-in rack and pull it

up and out of the drill holes.

76

Inserting the hook-in rack To reinsert the hook-in racks, proceed as follows:

1. Insert the upper hooks into the drill holes in the

side panel.

2. Pull the hook-in rack slightly downwards and insert

the lower hooks into the drill holes.

77

Faults and the after-sales service

Malfunctions often have simple explanations.

Please read the following notes before calling the

aftersales service.

Fault Possible cause Remedial action

The door panel steams up when

the oven is hot.

The flame (oven) does not burn

through all outlet openings.

The appliance does not work. Defective circuit

All dishes that are prepared in

the oven become burnt very

quickly.

The oven lighting has failed. Oven light is faulty Replace the oven light.

Normal occurrence;

caused by the

difference in

temperature.

Normal build-up of dirt The burner must be

breaker

Power cut Check whether the kitchen

Thermostat faulty Call the after-sales service.

Repairs may only be carried out by fully trained aftersales service engineers.

Not possible; this has no

effect on oven performance.

professionally cleaned.

Look in the fuse box and

check that the circuit breaker

for the appliance is in

working order.

light works, for example.

(see section "Replacing

oven light")

78

If your appliance is not repaired professionally, you

may be exposing yourself to substantial risks.

Replacing the oven light bulb

If the oven light bulb fails, it must be replaced.

Replacement heat-resistant bulbs can be obtained

from the after-sales service or from specialist

retailers. Please specify the E number and FD

number of your appliance. Do not use any other type

of bulb.

Proceed as follows:

1. Switch off the relevant circuit breaker in the fuse

box.

2. Open the appliance door.

3. Lay a tea towel in the cooking compartment if it is

cold to prevent damage.

4. Unscrew the glass cover from the bulb inside the

cooking compartment by turning it anti-clockwise.

5. Replace the bulb with one of the same type.

Voltage: 230 V

Power: 15 W

Thread: E14

Temperature resistance: 300°C

6. Screw on the glass cover again.

7. Remove the tea towel and switch the circuit

breaker back on.

Press the function button the oven lighting until it

locks into place

lighting is working properly.

in order to check whether the oven

79

Aftersales service

Our after-sales service is there for you if your

appliance needs to be repaired. You will find the

address and telephone number of your nearest aftersales service centre in the phone book. The aftersales service centres listed will also be happy to give

you the details of an after-sales service point near

you.

E number and FD number Please quote the E number (product number) and FD

number (production number) of the appliance when

contacting the after-sales service. These numbers

can be found on the identification plate which is

located on the inside of the storage compartment

flap. So you do not have to spend time looking for it if

there is a fault, you can enter the data for your

appliance here now.

E no.

After-sales service

FD no.

80

Tips and tricks

The following are tips and tricks to help you when

cooking food in your appliance.

Tips for saving energy

Here are a few tips for saving energy when using the

hob and oven.

Tips on using the hob

Suitable cookware

diameter

Cookware with lids Use cookware with a flat bottom.

Less water To reduce the cooking time for e.g. vegetables and

Make sure that the diameter of the cookware is

suitable for the diameter of whichever hotplate you

are using.

You can find an overview of suitable diameters in the

section entitled “Your new appliance - the hob”.

The flame of the gas burner must not be larger than

the diameter of the cookware.

If possible, use cookware with lids to save gas.

potatoes, use less water.

81

Tips on using the oven

Several cakes It is best to bake several cakes one after the other.

The oven is still warm. This reduces the baking time

for the second cake. You can also place two cake tins

next to each other.

Using residual heat Where longer cooking times are used, you can switch

the oven off 10 minutes before the end of the cooking

time and use the residual heat to finish cooking.

Closing the appliance door Always keep the appliance door closed when it is in

operation. If you need to open the appliance door,

close it again as soon as possible. Otherwise, the

temperature will drop and the oven will need to heat

itself up again.

82

Tips for using your appliance

The following tips relate to ovenware and cooking

and explain what to do if something goes wrong.

General tips Since a lower temperature allows more even

browning.

Clean the appliance and accessories after each use,

once they have cooled down.

Always place baking tins or ovenware in the centre of

the wire rack.

Always place cookware in the middle of the hotplate

on the hob.

Boiling and frying

Cookware For dishes which require a lot of liquid, use deep-

sided pots so that they do not boil over.

The pan base must be clean, dry and flat.

Application examples

Method

Heating

(depending on quantity)

Bringing to the boil

Simmering

(high or low, depending on

requirement)

Searing

Longer frying

* Depending on the model.

Power level

Gas Electro*

J

J

J - Ÿ

Ÿ

Ÿ

1-2

6

2

6

4

83

Baking

Baking tins Use light-coloured baking tins and trays wherever

possible.

Notes on tables Temperature and baking time depend on the amount

and composition of the ingredients.

Application examples More information can be found in the “Baking tips”

section which follows the baking tables.

Shelf

Type of baked item

Sponge cakes (2) 3 170 - 10 50

Filled sponge cake (2)

(Victoria sponge cake)

Bread 3 200 - 15 30

position

2 170 - 10 60

ðx

Preheating

time

Minutes

Cooking

time

Minutes

84

Baking tips

How to confirm whether your

sponge cake is cooked

through.

The cake collapses.

The cake has risen high in the

middle and less around the

edges.

The cake is too dark on the

top.

The cake is too dry.

The bread or cake looks good

but it is streaked with water

inside.

The pastries are not evenly

browned.

Approximately 10 minutes before the end of the

baking time stated in the recipe, pierce the highest

point of the cake with a wooden skewer. If no cake

mixture sticks to the wood, the cake is ready.

Next time, use less liquid or bake at a slightly lower

temperature. Note the stirring times indicated in the

recipe.

Do not grease the edges of the baking tin. After

baking, carefully loosen the cake using a knife.

Place the cake lower in the oven and bake at a lower

temperature for slightly longer.

Make tiny holes in the finished cake using a cocktail

stick. Then pour fruit juice or an alcoholic drink over

the cake. Next time, bake at a slightly higher

temperature for less time.

Next time, use less liquid and bake at a lower

temperature for slightly longer. For cakes with a moist