Page 1

Page 2

© 2008 Siemens Healthcare Diagnostics Inc. All rights reserved.

No part of this manual or the products it describes may be reproduced by any means in any form

without prior consent in writing from Siemens.

Hematek is a trademark of Siemens Healthcare Diagnostics.

Origin: United States

The information in this manual was correct at the time of printing. However, Siemens

continues to improve products and reserves the right to change specifications, equipment, and

maintenance procedures at any time without notice.

If the Hematek system is used in a manner not specified by Siemens, the protection

provided by the equipment may be impaired. See warning and hazard statements.

Page 3

Contents

Section 1: Introduction............................................................................................ 1-3

General Description and Intended Use...........................................................................................1-3

Theory of Operation .................................................................................................................1-4

Physical Characteristics....................................................................................................................1-5

Circular Bubble Level ...............................................................................................................1-5

Levelers ..................................................................................................................................1-5

Slide Transport System.....................................................................................................................1-6

Conveyor Spirals .....................................................................................................................1-6

Platen .....................................................................................................................................1-6

Slide Drying System .................................................................................................................1-7

Slide Drawer ...........................................................................................................................1-7

Waste Tank .............................................................................................................................1-7

Staining System.................................................................................................................................1-8

Volume Control Panel ..............................................................................................................1-8

Solution Pumps .......................................................................................................................1-8

Pump Tubing and Cannulas ......................................................................................................1-9

Sensing Switches ....................................................................................................................1-10

Electrical System ...............................................................................................................................1-11

Operating Lever .......................................................................................................................1-11

POWER Light ..........................................................................................................................1-12

LOW STAIN Light ....................................................................................................................1-12

Power Module .........................................................................................................................1-12

Line Cord Receptacle ...............................................................................................................1-12

Fuse Holder ............................................................................................................................1-13

ON / OFF Switch .....................................................................................................................1-13

Specifications .....................................................................................................................................1-13

Disposal of System Waste and Supplies ..................................................................................1-14

Section 2: Installation............................................................................................... 2-3

Overview .............................................................................................................................................2-3

Environmental Factors ......................................................................................................................2-3

Unpacking...........................................................................................................................................2-4

Instrument Setup ...............................................................................................................................2-4

Level the Instrument ................................................................................................................2-4

Plug the Line Cord into an Outlet ...............................................................................................2-5

Performance Check (Prior to Installing Tubing) ...........................................................................2-5

Install the Pump Tubing ............................................................................................................2-6

Install the Stain Pak .................................................................................................................2-9

Inspect Waste Tank and Slide Drawer .......................................................................................2-10

Familiarize Yourself with the Instrument .....................................................................................2-10

Check Pump Volumes ..............................................................................................................2-10

Section 3: Operating Instructions ........................................................................... 3-3

Contents

Page 4

General Guidelines for Optimal Staining ........................................................................................3-3

Operating Procedures.......................................................................................................................3-3

Start the Instrument .................................................................................................................3-3

Prime the Tubing .....................................................................................................................3-4

Load the Blood Smear Slides ....................................................................................................3-5

Stain the Smears .....................................................................................................................3-6

Clean the Tubing after Use .......................................................................................................3-7

Turn the Instrument Off at the End of the Day .............................................................................3-7

Stain Pak Replacement ....................................................................................................................3-7

Section 4: Specimens............................................................................................... 4-3

Overview .............................................................................................................................................4-3

Peripheral Blood Smears..................................................................................................................4-3

Bone Marrow Smears .......................................................................................................................4-5

Section 5: Maintenance............................................................................................. 5-3

General Cleaning...............................................................................................................................5-3

Daily Cleaning ....................................................................................................................................5-3

Cleaning the Platen ..................................................................................................................5-3

Cleaning the Stain Tubing and Cannula .....................................................................................5-4

Emptying the Waste Tank .........................................................................................................5-6

Weekly Cleaning................................................................................................................................5-6

Cleaning Drain Troughs and Rear Guide Rail .............................................................................5-6

Decontamination and Removal from Operation ............................................................................5-9

Section 6: Minor Replacements and Adjustments ................................................. 6-3

Fuse Replacement ............................................................................................................................6-3

Replacement of Light Assemblies ...................................................................................................6-4

Replacement of the Pump Tubing...................................................................................................6-7

Replacement of the Underplaten Tubing........................................................................................6-11

Pump Volume Adjustment................................................................................................................6-14

Check and Correct Instrument Operation Prior to Pump Volume Adjustment .................................6-15

Adjust the Stain, Buffer, and Rinse Volumes ..............................................................................6-15

Volume and Ratio Determination.....................................................................................................6-17

Sensing Switch Fingers Adjustment................................................................................................6-18

Section 7: Troubleshooting ..................................................................................... 7-3

Checklist for Quality of Stained Blood Smears..............................................................................7-3

Troubleshooting Chart.......................................................................................................................7-4

Section 8: Service, Supplies, and Replacement Parts .......................................... 8-3

Contents

Page 5

When to Call for Service...................................................................................................................8-3

For Service .........................................................................................................................................8-3

Siemens Authorized Representative ..........................................................................................8-3

Siemens Offices Worldwide .....................................................................................................8-4

Returning the Instrument for Repair, Exchange, Replacement, or Loaner................................8-7

Supplies and Replacement Parts ....................................................................................................8-8

Hematek Stain Pak – Modified Wright’s Stain .............................................................................8-8

Hematek Stain Pak – Modified Wright-Giemsa Stain ...................................................................8-8

Hematek Cannula Set ..............................................................................................................8-8

Hematek Pump Tube Set .........................................................................................................8-9

Hematek Underplaten Tubing ...................................................................................................8-9

Ordering Information for Supplies and Replacement Parts ...........................................................8-10

Appendix A: List of Symbols................................................................................... A-1

Symbols Used With This System ....................................................................................................A-1

Appendix B: Hematek Preservice Checklist........................................................... B-1

Contents

Page 6

Contents

Page 7

Section 1: Introduction............................................................................................ 1-3

General Description and Intended Use...........................................................................................1-3

Theory of Operation .................................................................................................................1-4

Physical Characteristics....................................................................................................................1-5

Circular Bubble Level ...............................................................................................................1-5

Levelers ..................................................................................................................................1-5

Slide Transport System.....................................................................................................................1-6

Conveyor Spirals .....................................................................................................................1-6

Platen .....................................................................................................................................1-6

Slide Drying System .................................................................................................................1-7

Slide Drawer ...........................................................................................................................1-7

Waste Tank .............................................................................................................................1-7

Staining System.................................................................................................................................1-8

Volume Control Panel ..............................................................................................................1-8

Solution Pumps .......................................................................................................................1-8

Pump Tubing and Cannulas ......................................................................................................1-9

Sensing Switches ....................................................................................................................1-10

Electrical System ...............................................................................................................................1-11

Operating Lever .......................................................................................................................1-11

POWER Light ..........................................................................................................................1-12

LOW STAIN Light ....................................................................................................................1-12

Power Module .........................................................................................................................1-12

Line Cord Receptacle ...............................................................................................................1-12

Fuse Holder ............................................................................................................................1-13

ON / OFF Switch .....................................................................................................................1-13

Specifications .....................................................................................................................................1-13

Disposal of System Waste and Supplies ..................................................................................1-14

Section 1: Introduction, Page 1—1

Page 8

Page 1—2, Section 1: Introduction

Page 9

Section 1: Introduction

General Description and Intended Use

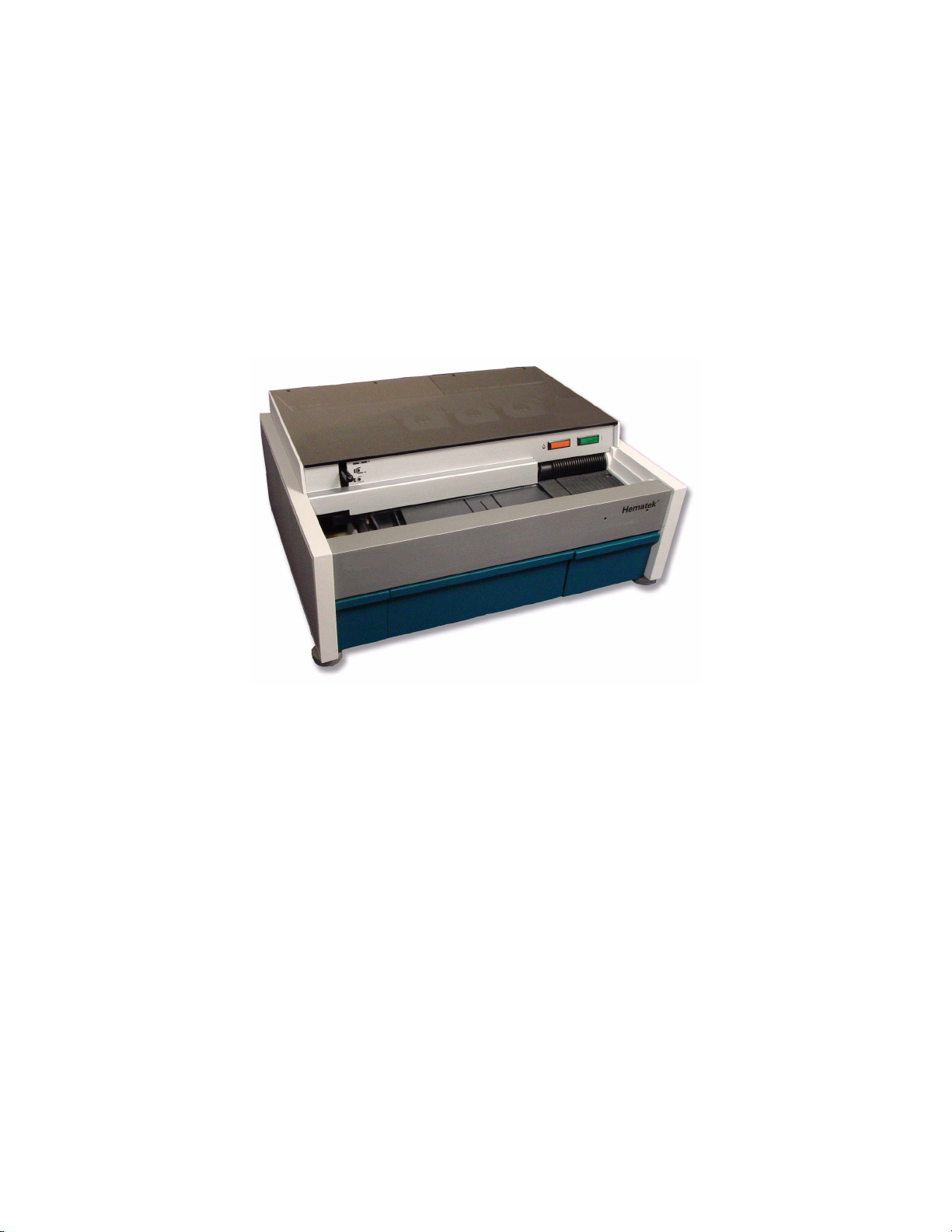

The Hematek

automated, bench-top instrument designed specifically for the staining of hematology

slides for in vitro diagnostic use. This self-contained precision instrument accepts,

conveys, fixes, stains, and delivers dry blood smear preparations that are spread on

standard thickness 25-mm x 75-mm or 1” x 3” glass slides. The slides are stained at the

rate of one slide per minute.

Two conveyor spirals move the slides along the platen. Three sensing switches are

triggered sequentially as the slide moves along the platen. Each switch activates its

respective solution pump, which meters and delivers the stain, buffer, or rinse into the

capillary space between the slide and platen. After staining and rinsing have been

accomplished, the slide is dried by a flow of air from a low velocity blower and it is then

deposited in a slide drawer.

Optimal results with the Hematek Slide Stainer are obtained by using one of the Hematek

Stain Paks. The Stain Pak consists of one bottle each of stain, buffer, and rinse solutions,

and is designed for easy installation and removal from the instrument.

NOTE:

Only Hematek Stain Paks should be used with the Hematek Slide Stainer. Use of other

stain packs or solutions may void the warranty.

®

Slide Stainer, shown in Figure 1-1. Hematek Slide Stainer is a fully

Section 1: Introduction, Page 1—3

Page 10

Theory of Operation

The Hematek Slide Stainer is designed to produce stained slides of consistent quality in a

continuous process. This is accomplished by having a fixed length of time in each of the

three phases of stain, buffer, and rinse, as well as a predetermined ratio of stain-to-buffer

volumes in the buffer phase.

A properly stained slide is the result of an interactive process involving the pump

volumes, the mixing process, and the stain-to-buffer ratio. A minimum ratio of 1:2 is

recommended; however, if the platen is filling properly, good mixing is occurring, and the

stained slides are acceptable under the microscope, the stain-to-buffer ratio should not be

adjusted.

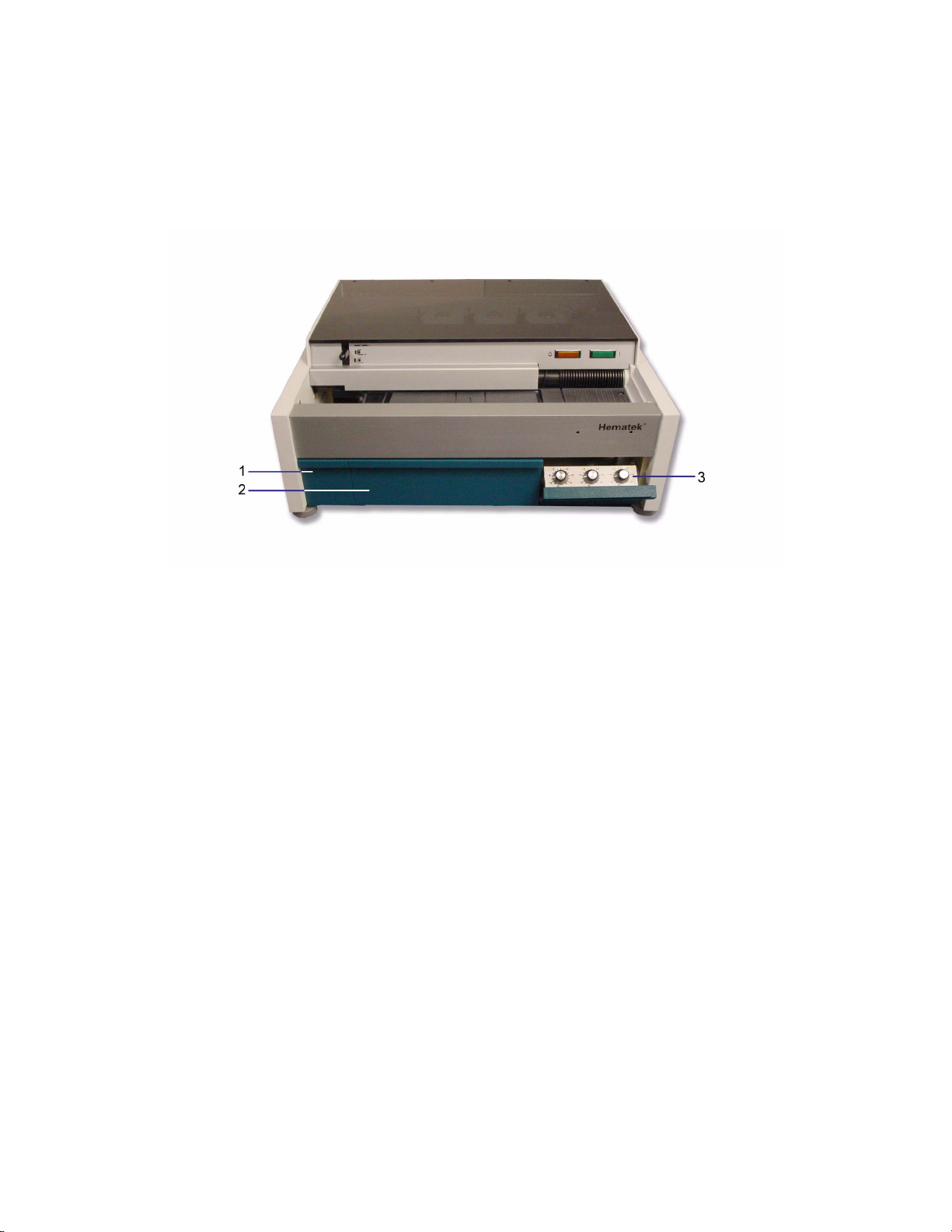

Figure 1-1. Hematek Slide Stainer

Page 1—4, Section 1: Introduction

Page 11

Physical Characteristics

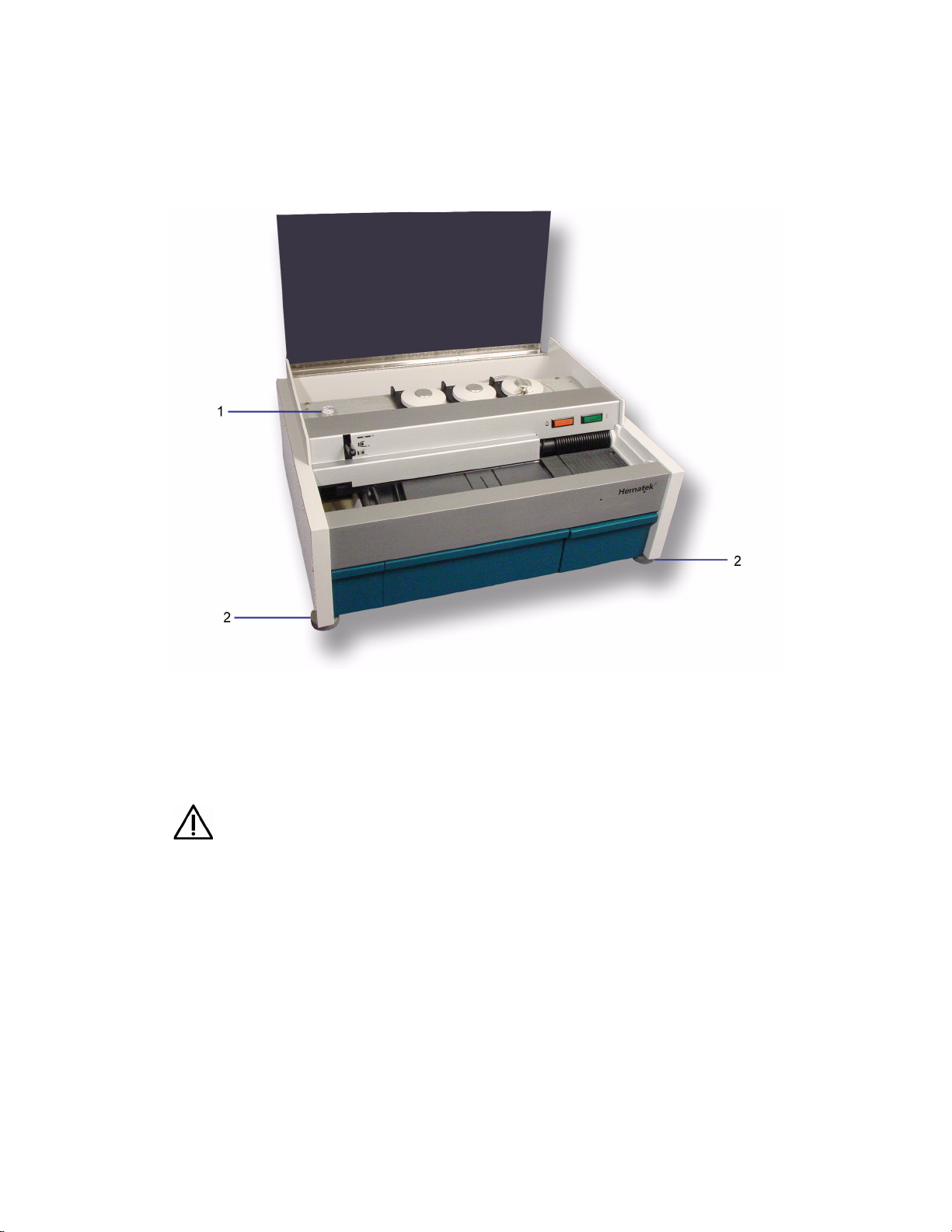

Figure 1-2. Circular Bubble Level and Leveling Feet, shows the physical characteristics of

the Hematek Slide Stainer, including the circular bubble level and the leveling feet.

Figure 1-2. Circular Bubble Level and Leveling Feet

1 Circular Bubble Level

2 Leveling Feet

Circular Bubble Level

CAUTION

Do not move the circular bubble level from its location directly behind the operating lever.

Proper leveling is essential for optimal mixing of the stain and buffer.

The circular bubble level is a water bubble gauge with an inscribed circle that can be

observed through the clear plastic lid of the instrument. The level is located on the

instrument panel to the left of the reagent pumps, directly behind the operating lever. It is

used to ensure the Slide Stainer is in a level position.

Levelers

The feet under the front corners of the instrument act as levelers and may be adjusted to

raise or lower the instrument to a level position. Observe the circular bubble level to verify

that the feet have been properly adjusted and the instrument is level.

Section 1: Introduction, Page 1—5

Page 12

Slide Transport System

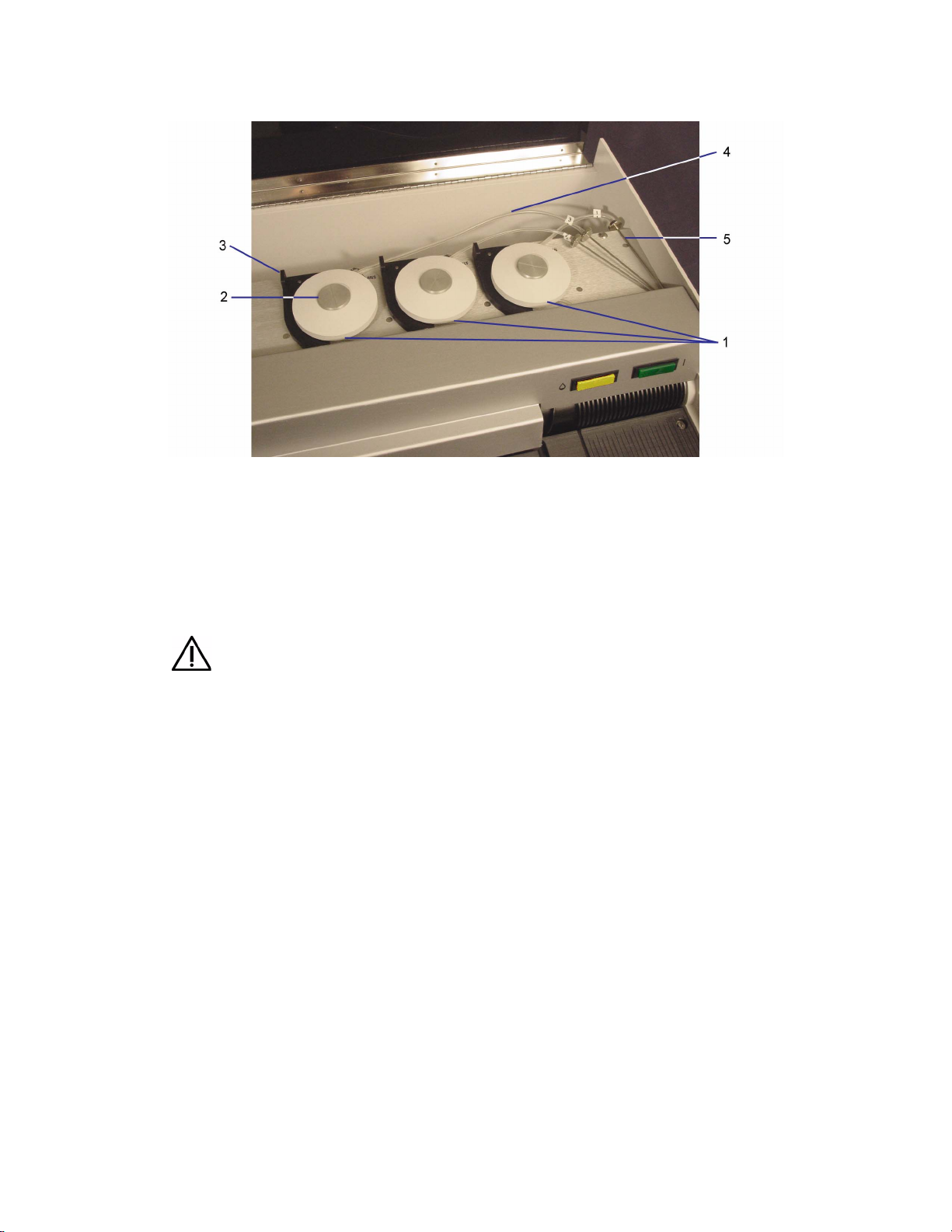

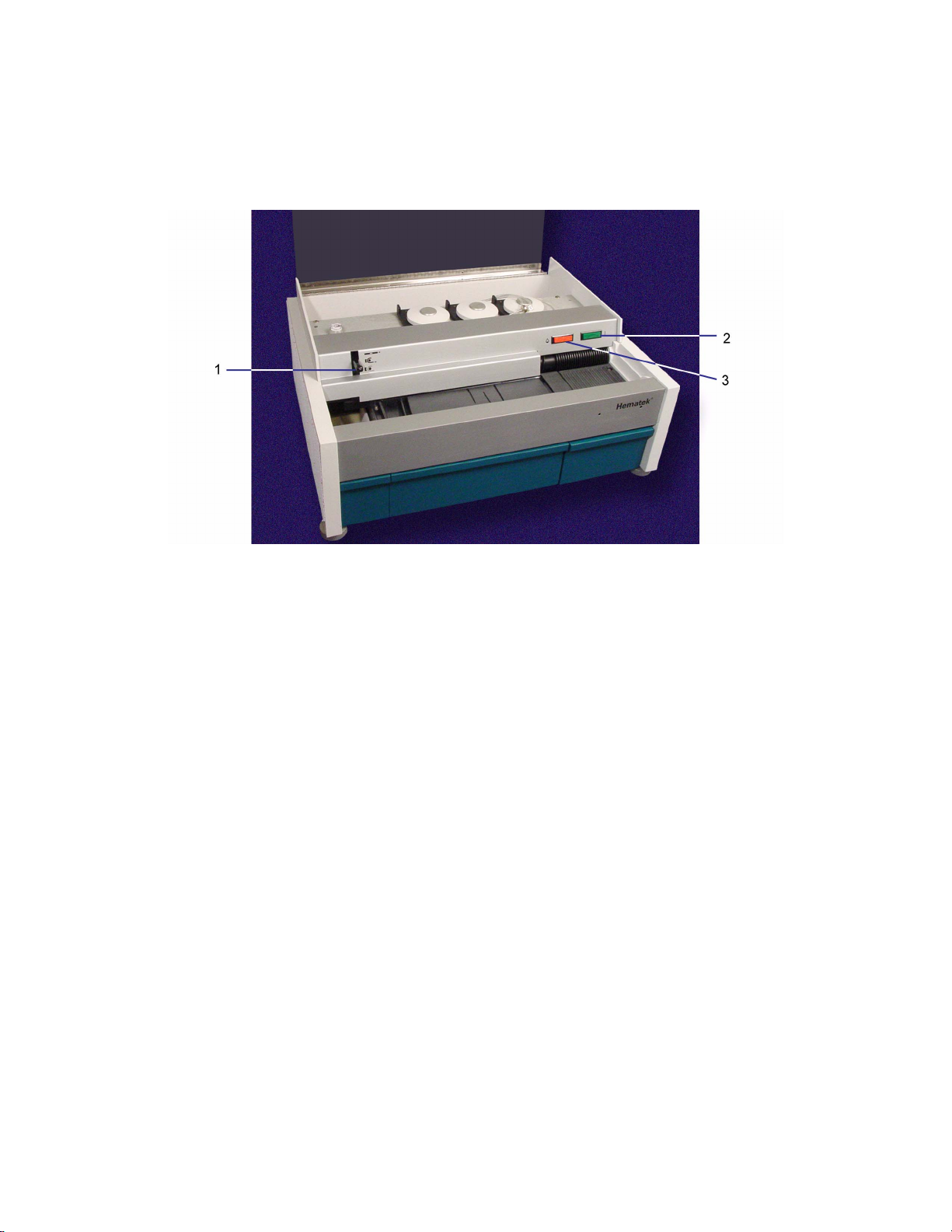

Figure 1-3. Slide Transport System and Figure 1-4. Slide Transport and Staining System

show the slide transport system, including the conveyor spirals, the platen, the platen

guide rails, and the slide drawer.

Figure 1-3. Slide Transport System

1 Conveyor Spirals

2 Platen

3 Platen Guide Rails

4 Slide Drawer

Conveyor Spirals

The conveyor spirals are two parallel spirals with opposing grooves. Slides to be stained

are fitted separately into the opposing grooves, which move the slides across the staining

surface. When loading slides onto the instrument, the side covered by the blood smear is

faced to the left of the operator, with the feathered edge to the back of the instrument.

Slides are moved by the conveyor spirals side by side, from right to left, first at the vertical

plane, then at the horizontal plane with the blood smear facing downward toward the

platen.

Page 1—6, Section 1: Introduction

Page 13

Platen

The platen spans the entire front of the instrument, between the conveyor spirals. The

outside ridges of the platen are elevated guide rails, which give support to the slides as

they are moved along the platen. It is a precision-machined component made from a highperformance plastic polymer material and is designed specifically for two main functions:

1. It maintains the exact volumes of the required solutions within a capillary space between the platen and the slide.

2. It provides a mixing system for the stain and buffer.

The platen also provides the necessary time interval after the rinsing step for proper drying

of the slides before they are deposited in the slide drawer. A trough around the perimeter

of the platen allows for drainage of used solutions into the waste tank below.

Slide Drying System

The dryer is a blower type fan that runs continuously when the instrument is in operation.

The airflow serves to cool the mechanical components inside the Slide Stainer, as well as

to dry the slides.

Slide Drawer

The slide drawer is located below the left end of the platen. It receives the slides as they

drop from the platen after being stained, rinsed, and dried. The drawer will hold 100

slides. See Figure 1-4. Slide Transport and Staining System .

Waste Tank

The waste tank is located underneath the platen and collects used and overflow staining

solutions. The waste tank should be emptied and rinsed once each day and whenever a

new Stain Pak is installed. Refer to Section 5: Maintenance for more information.

Section 1: Introduction, Page 1—7

Page 14

Staining System

Figure 1-4. Slide Transport and Staining System , Figure 1-5. Staining Systems, and Figure

1-6. Sensing Switches, illustrate the staining system, including the volume control panel,

pump assemblies, pump cap, pump arm, pump tubing, and cannula.

Figure 1-4. Slide Transport and Staining System

1 Slide Drawer

2 Waste Tank

3 Volume Control Panel

Volume Control Panel

The volume control panel tips out from the right front corner of the instrument and

contains three graduated adjustment knobs. The volume of reagent being delivered can be

adjusted by rotating the respective control dial clockwise to increase the volume or

counterclockwise to decrease the volume.

Solution Pumps

The instrument has three pump assemblies, one for each solution. Each assembly consists

of a pump motor, four rollers that are attached to the underside of a pump cap, and a pump

arm. All work together to maintain a constant metering speed to provide consistent

volumes of stain, buffer, and rinse, even though the line voltage may fluctuate. The

amount of solution pumped is electronically adjusted through the use of the volume

control knobs.

Page 1—8, Section 1: Introduction

Page 15

Figure 1-5. Staining Systems

1 Pump Assemblies

2 Pump Cap

3 Pump Arm

4 Pump Tubing

5 Cannula

Pump Tubing and Cannulas

CAUTION

Use only the Hematek Pump Tube Set with the Hematek Slide Stainer. Use of other tubing

may result in incorrect measurement and improper staining, buffering, and rinsing.

The pump tubing is provided as a set of three separate pieces of tubing. Notice that each

pump tube is identified with a number and symbol, which corresponds to the reagent

carried by the tubing:

1 for stain

•

2 for buffer

•

•

3 for rinse

Each tube has a clear plastic cuff that fits snugly up to the pump arm and holds the tube in

position without slippage. The tubing is a special type of rubber that is resistant to

leaching and brittleness. The special diameters and lengths of the tubing assure precise

measurement of solutions. Each pump tube is connected to a cannula that is inserted into

the appropriate bottle in the Stain Pak. Three cannulas are provided with the Hematek

Slide Stainer. With proper routine cleaning, the cannulas can be used for an extended

period of time.

Section 1: Introduction, Page 1—9

Page 16

Sensing Switches

The sensing switches are three finger-like devices located just above the back edge of the

platen. When contacted, the respective sensing switch is activated, which tells the

instrument that a slide is in position for the pump to run. After a specific time delay, the

pumping motor for the specific reagent is activated. The solution pumps are set so that

precise volumes of stain, buffer, and rinse are delivered to their respective areas on the

platen. Each reagent is delivered through its respective cannula and tubing network to the

platen orifice. The capillary space between the slide and the platen is then filled with the

measured volume of reagent.

Figure 1-6. Sensing Switches

1 Sensing Switches

Page 1—10, Section 1: Introduction

Page 17

Electrical System

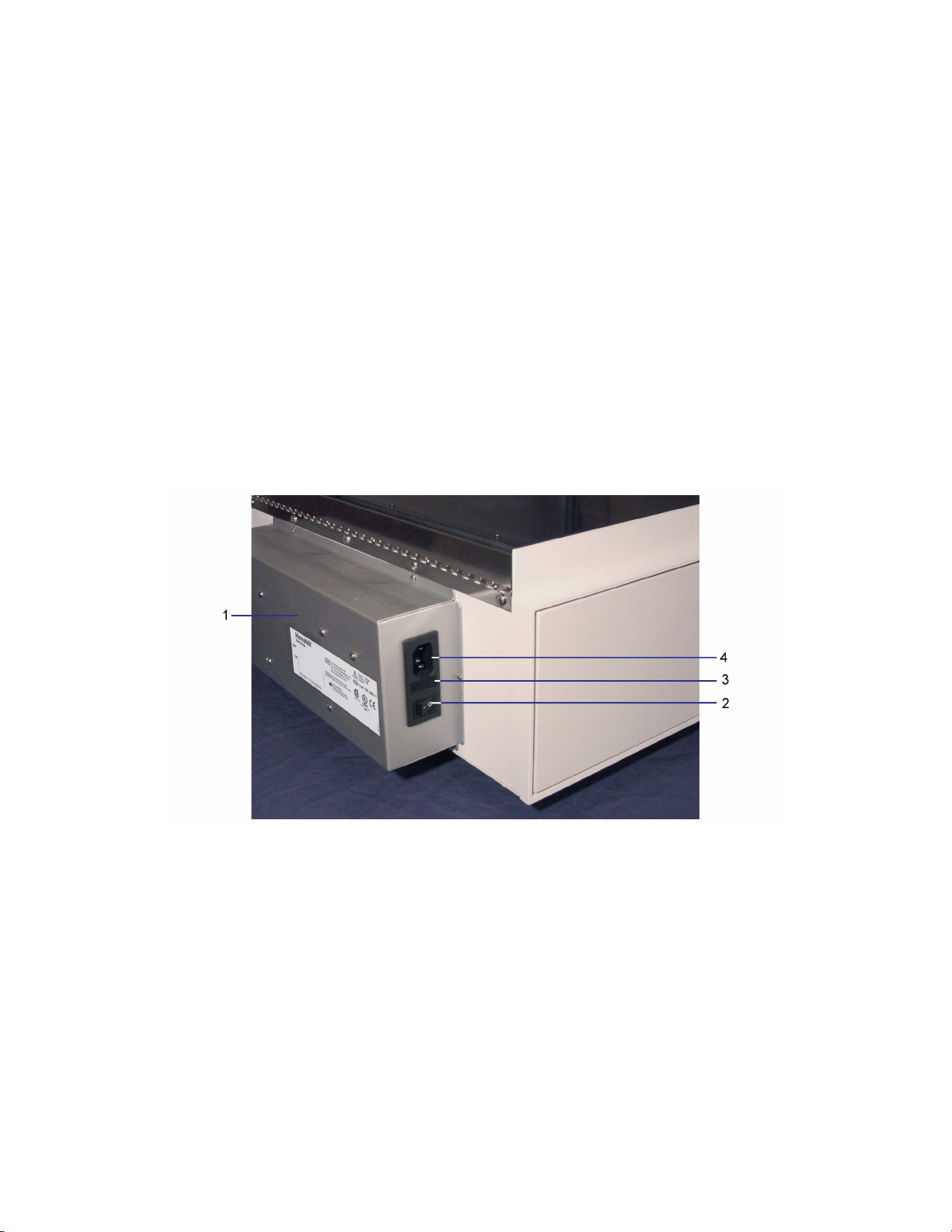

Figure 1-7. Electrical System and Figure 1-8. Electrical System–Rear of Instrument

illustrate the components of the electrical system.

Figure 1-7. Electrical System

1 Operating Lever

2 Power Light

3 Low Stain Light

Operating Lever

The operating lever is a multiple function, bar-shaped lever located at the front left side of

the instrument, near the top. The three positions of the lever are labeled and their related

functions are as follows:

UNLOCK releases the pressure of the reagent pump arms against the pump tubing.

•

LOCK locks the reagent pump arms into their proper position against the pump tubing.

•

•

PRIME provides an override control to allow the pumps to run continuously so the tubes

can be primed with solutions and cleared of air bubbles. The lever must be held

continuously in the

LOCK position.

PRIME position. When released, it returns automatically to the

Section 1: Introduction, Page 1—11

Page 18

POWER Light

The green POWER light is located at the right side of the instrument near the top. When

the instrument is turned on, the light illuminates.

LOW STAIN Light

The yellow LOW STAIN light is to the left of the POWER light. It is off under usual

operating conditions; however, when the Hematek Stain Pak contains sufficient reagents

to stain only about 20 slides, a weight-sensing device activates the circuit and illuminates

the light. The Stain Pak should be replaced at this time.

Power Module

The power module is located on the rear of the instrument; on one side of the module is

the panel that contains the line cord receptacle, fuse, and power switch. The power module

converts the line current coming into the instrument to 12 volts DC, which is the voltage

within the instrument.

Figure 1-8. Electrical System–Rear of Instrument

1 Power Module

2 ON / OFF Switch

3 Fuse Holder

4 Line Cord Receptacle

Line Cord Receptacle

The line cord connects into the line cord receptacle, which is located at the top of the panel

on the power module.

Page 1—12, Section 1: Introduction

Page 19

Fuse Holder

The fuse holder, in the center of the panel, holds the fuse that protects against serious

electrical overload. A spare fuse is also located in the fuse holder.

ON / OFF Switch

The ON / OFF Switch is located at the bottom of the panel and controls all power to the

instrument.

Specifications

Power Requirements 100 - 230 VAC + 10%, 50/60 Hz, 0.75

Amps

Fuse Rating 250 Volt, 1.0 Amps, 5mm x 20mm, Type T

Line Leakage Current <5 milliamperes

Testing protocol and allowable limits as

specified by the safety standards for

laboratory equipment outlined in UL 1262

and CSA 22.2 No. 151.

Dimensions Depth - 43.4 cm (17.1 in)

Width - 47.0 cm (18.5 in)

Height - 19.0 cm (7.5 in)

Weight 17.7 kg (39 lbs)

Throughput Stains 1 slide per minute

Section 1: Introduction, Page 1—13

Page 20

Disposal of System Waste and Supplies

Laws and regulations enacted to protect the environment and to encourage resource

conservation require the disposal of hazardous and biohazardous wastes in a specified

manner. Some of the wastes from the Hematek Slide Stainer can be classified as hazardous

or biohazardous wastes. It is essential that the laboratory take appropriate steps to

determine the laws and regulations applicable to their disposal and to effect compliance. If

it is necessary to sample instrument wastes and effluent in order to evaluate compliance

with applicable regulations, the laboratory should contact a local licensed biohazardous

waste disposal firm for assistance.

The principal wastes associated with the use of the Hematek Slide Stainer are pump and

underplaten tubing, effluents from the staining operation, and the container for stain,

buffer, and rinse.

Slides with human specimens, control materials, and all reagents, should also be handled

and disposed of in accordance with the prevailing regulations and guidelines of agencies

with jurisdiction over the laboratory. Refer to the product label and to Material Safety

Data Sheets for details concerning any special precautions related to the handling of

Hematek Stain Pak containers. Material Safety Data Sheets are available from Siemens.

BIOHAZARD

Wear personal protective equipment. Use universal precautions. Refer to Appendix A,

page A-1 for recommended precautions when working with biohazardous materials.

Page 1—14, Section 1: Introduction

Page 21

Section 2: Installation............................................................................................... 2-3

Overview .............................................................................................................................................2-3

Environmental Factors ......................................................................................................................2-3

Unpacking...........................................................................................................................................2-4

Instrument Setup ...............................................................................................................................2-4

Level the Instrument ................................................................................................................2-4

Plug the Line Cord into an Outlet ...............................................................................................2-5

Performance Check (Prior to Installing Tubing) ...........................................................................2-5

Install the Pump Tubing ............................................................................................................2-6

Install the Stain Pak .................................................................................................................2-9

Inspect Waste Tank and Slide Drawer .......................................................................................2-10

Familiarize Yourself with the Instrument .....................................................................................2-10

Check Pump Volumes ..............................................................................................................2-10

Section 2: Installation, Page 2—1

Page 22

Page 2—2, Section 2: Installation

Page 23

Section 2: Installation

Overview

This section provides detailed installation and setup instructions for the Hematek Slide

Stainer. The installation steps must be followed correctly to ensure proper installation,

operation, and service. Read this Operator’s Guide carefully before attempting to operate

the instrument. Follow all instructions carefully.

The Hematek Slide Stainer is a precision instrument and must be handled accordingly.

Rough handling or dropping of the instrument will disturb or damage internal

components. Always handle the instrument with care.

Environmental Factors

As with all sensitive electronic instruments, prolonged exposure to excessive humidity

and temperature should be avoided. Temperature should be held relatively constant to

obtain the highest degree of operating stability. The ambient temperature range for

operating the instrument is 18ºC to 30ºC (64ºF to 86ºF). The ambient operating humidity

range is 20% to 85% relative humidity.

Place the instrument in a well-ventilated area, avoiding exposure to corrosive vapors or

temperature extremes. Be sure it is near a power source that meets the electrical

requirements (voltage) specified on the rating label located on the rear of the instrument.

Avoid proximity to open windows, sinks, ovens, hot plates, open burners, radiators, and

dry ice baths. The instrument should not be used in an explosive atmosphere.

Section 2: Installation, Page 2—3

Page 24

Unpacking

Before opening the shipping carton, inspect it for visible signs of damage. Use the

following steps to unpack the instrument.

1. Carefully remove the Hematek instrument and supplies from the shipping carton.

The following items are provided with the instrument:

• Hematek pump tube set

• Hematek cannula set

• operating manual

• line cord

• warranty card - for use by US customers only

• FedEx PRP label - for use by US customers only

2. If the instrument shows any visible signs of damage, immediately file a complaint with the carrier.

3. Retain the shipping carton for further use. If the instrument ever needs to be shipped, the shipping carton will afford the best protection.

4. After the instrument has been unpacked, place it on a firm, level work surface in the designated work are by lifting the instrument by its frame.

Instrument Setup

Complete the following procedures to ensure proper installation and performance of your

Slide Stainer.

Level the Instrument

CAUTION

Do not move the circular bubble level from its location directly behind the operating lever.

Proper leveling is essential for optimal mixing of the stain and buffer.

1. Raise the hinged lid of the instrument and locate the circular bubble level.

The circular bubble level is located on the instrument panel to the left of the reagent

pumps, directly behind the operating lever.

Page 2—4, Section 2: Installation

Page 25

2. Adjust the two feet located under the front corners of the instrument to raise or lower the instrument to a level position.

Figure 2-1. Leveling the Instrument

3. Observe the circular bubble level to indicate when the feet have been properly adjusted and the instrument is level. The bubble in the level should be centered within the inscribed circle.

NOTE:

If necessary, make a final leveling check and adjustment by watching the flow of the waste

fluids during staining. Fluids should flow evenly to the drain hole at the left-front corner

of the waste trough.

Plug the Line Cord into an Outlet

CAUTION

Be sure the outlet supplies the proper voltage for your instrument. Refer to the rating label

located on the rear of the instrument to determine the proper voltage rating

Plug the appropriate end of the line cord into the instrument and the other end into an

appropriately grounded AC electrical outlet.

Performance Check (Prior to Installing Tubing)

1. Turn the instrument on by pressing the ON / OFF switch, located on the left side of the

power module at the rear of the instrument, to the

The green

revolves.

2. Inspect the slide dryer area for noticeable airflow.

3. Place five blank slides into the grooves on the right side of the conveyor spirals.

Section 2: Installation, Page 2—5

POWER light illuminates, the fan starts, and the conveyor spirals slowly

ON position.

Page 26

Be sure the slides are positioned in opposing slots, parallel to the inscribed lines on the

platen.

4. Allow the slides to automatically feed onto the platen.

5. As the slides move down the platen, make sure the leading edge of the slides contact and activate each of the three sensing switch fingers, located along the back wall of the platen above the platen trough.

As each switch is activated, the appropriate pump activates and you are able to

observe the pump cap rotating.

6. If the instrument functions properly in these steps, continue with the instrument setup procedures.

7. If a problem occurred, contact the your local technical support provider or distributor. Refer to Section 8: Service, Supplies, and Replacement Parts for more information.

Install the Pump Tubing

1. Remove the three cannulas and pump tube sets from their packaging.

Notice that each pump tube is identified with a number, which corresponds to the

reagent carried by the tubing:

• 1 for stain

• 2 for buffer

• 3 for rinse

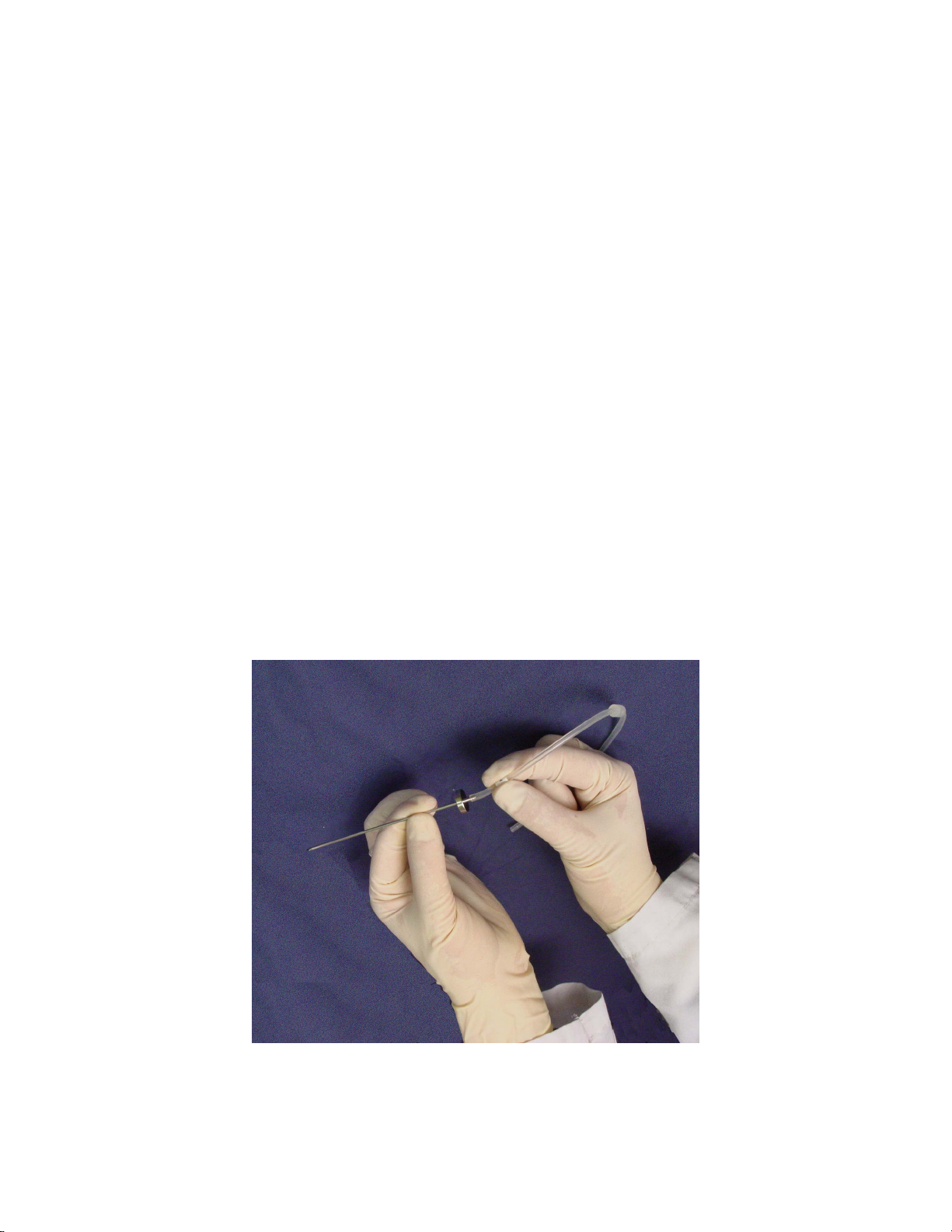

2. Attach the labeled end of each pump tube to a cannula.

Figure 2-2. Attaching Pump Tubing to Cannula

Page 2—6, Section 2: Installation

Page 27

3. Push the operating lever down to the UNLOCK position.

4. Extend each new tube to its respective pump (in numerical order from right to left) and thread the end of the tubing into the hole in the pump arm.

5. Push the thumb tab on the pump arm to the extreme left and push the tubing through until the plastic cuff is flush against the pump arm.

Figure 2-3. Threading Tubing through Pump Assembly

NOTE:

If you encounter difficulty in threading the tubing through the pump housing, lift the

operating lever to

PRIME for just a few seconds. This will cause the rollers inside the

pump housing to rotate slightly and relieve the interference. Then return the operating

lever to the

UNLOCK position.

6. Release the pump arm.

7. Repeat steps 4 and 5 for the other two pumps.

99E44889 Rev. D Section 2: Installation, Page 2—7

Page 28

8. Connect each tube to its proper recessed nipple, located on the backside of the circuit board housing.

9. Be sure that at least 7 mm (0.25 in.) of tubing is connected to the nipple for a secure connection.

Figure 2-4. Attaching Pump Tubing to Nipple

NOTE:

If it is difficult to connect the tube to its nipple, use forceps or hemostats to grasp and

attach the tubing.

CAUTION

Take care to not damage the tubing when using forceps or hemostats.

Page 2—8, Section 2: Installation

Page 29

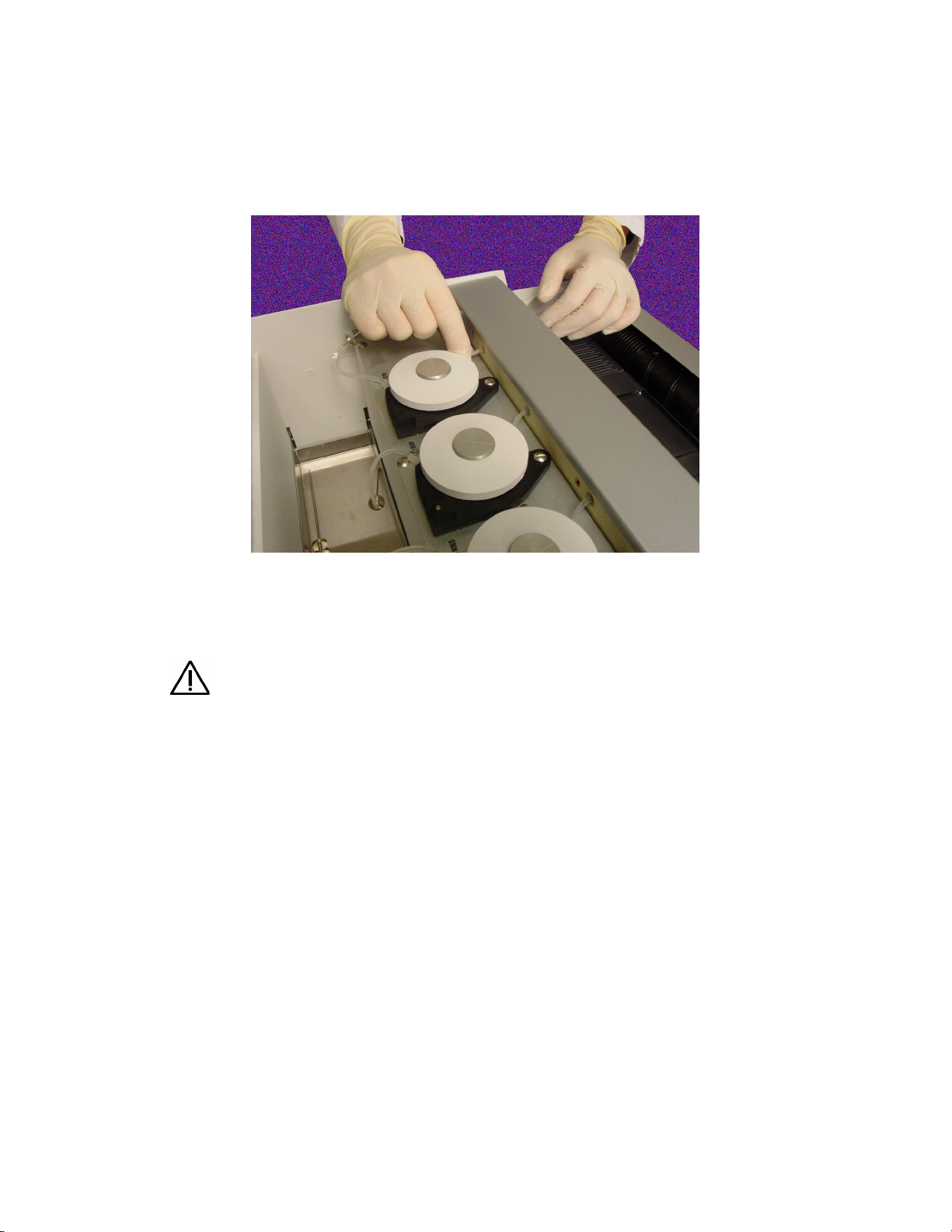

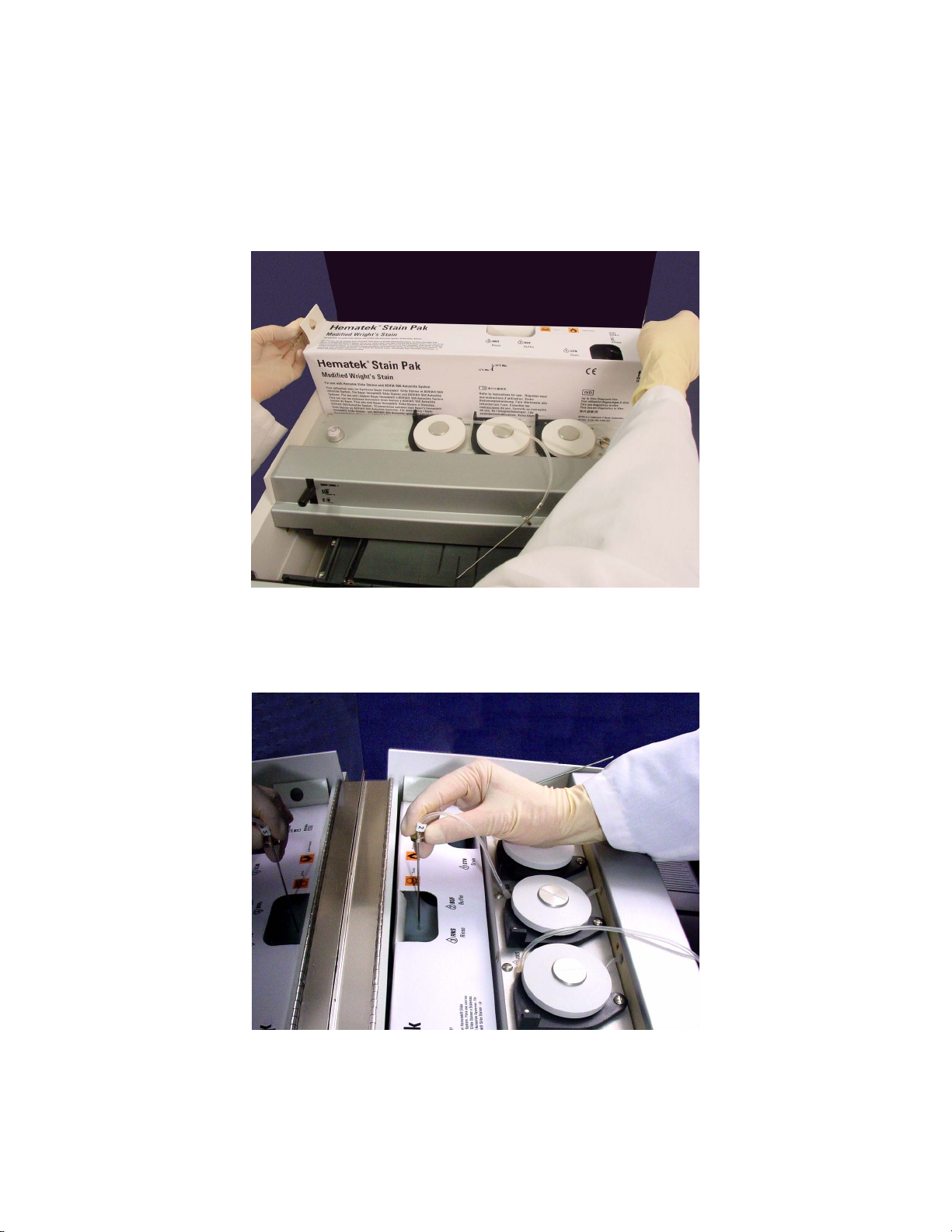

Install the Stain Pak

1. Remove the perforated tabs from the Hematek Stain Pak. Insert the carton, with the

STAIN bottle to the right, into the well at the rear of the instrument.

2. Make sure the carton is all the way down and resting on the tray at the bottom of the well. The carton should be level when properly installed.

Figure 2-5. Installing the Stain Pak

3. Insert the appropriate cannula into its respective bottle by puncturing the center of the indentation on the bottle.

Figure 2-6. Installing Cannula into Stain Pak Bottle

Section 2: Installation, Page 2—9

Page 30

4. Remove the cannula, turn it 1/4 turn, and insert it again into the same puncture.

The double puncture creates a slightly larger hole for venting.

NOTE:

If additional venting is desired, a second hole can be made in the top of the bottle, near the

indentation. A 20-gauge needle can be placed into the hole, if needed.

5. Push the cannula down until the guard at the top touches the plastic container.

6. Repeat steps 3 through 5 for each bottle.

Inspect Waste Tank and Slide Drawer

Inspect the waste tank and slide drawer for proper positioning below the platen. Each

should be pushed completely into its respective cavity in the front of the instrument so it is

flush with the control panel on the right front corner.

Familiarize Yourself with the Instrument

Before beginning normal instrument use, carefully review Section 3: Operating

Instructions, and Section 5: Maintenance, to become familiar with operating techniques

and instrument cleaning requirements.

Check Pump Volumes

Check the pump volumes and adjust them if necessary by following the procedures in

Pump Volume Adjustment on page 6-14 and Volume and Ratio Determination on page 6-

17. Do this before staining any patient slides for clinical evaluations.

Page 2—10, Section 2: Installation

Page 31

Section 3: Operating Instructions ........................................................................... 3-3

General Guidelines for Optimal Staining ........................................................................................3-3

Operating Procedures.......................................................................................................................3-3

Start the Instrument .................................................................................................................3-3

Prime the Tubing .....................................................................................................................3-4

Load the Blood Smear Slides ....................................................................................................3-5

Stain the Smears .....................................................................................................................3-6

Clean the Tubing after Use .......................................................................................................3-7

Turn the Instrument Off at the End of the Day .............................................................................3-7

Stain Pak Replacement ....................................................................................................................3-7

Section 3: Operating Instructions, Page 3—1

Page 32

Page 3—2, Section 3: Operating Instructions

Page 33

Section 3: Operating Instructions

Following initial installation (see Section 2: Installation), the Hematek Slide Stainer is

ready for routine operation. Carefully read this section before beginning any slide staining.

General Guidelines for Optimal Staining

• Use high quality slides. Do not use slides of variable thickness. Bevel-edged slides

should not be used, as they may break in the instrument.

• Make sure the blood smears are thoroughly dry before placing on the instrument for

staining.

• Clean the stain tubing with methanol after each run, especially if the Slide Stainer is not

to be used for one hour or more.

• Keep the staining grooves and guide rails clean, as instructed in Cleaning the Platen on

page 5-3. Use only methanol to clean.

• Change the pump tubing and underplaten tubing on a routine basis. Refer to

Replacement of the Pump Tubing on page 6-7 and Replacement of the Underplaten

Tubing on page 6-11 for recommended frequency.

• Check the alignment of the sensing switch fingers, as instructed in step 5 of Check and

Correct Instrument Operation Prior to Pump Volume Adjustment on page 6-15.

Operating Procedures

CAUTION

Use Hematek Stain Paks only. Other solutions may contain non-dissolved or particulate

materials.

Start the Instrument

1. Turn the instrument on by pressing the ON / OFF switch, located on the left side of the

power module at the rear of the instrument, to the

The green

will begin to slowly revolve.

NOTE:

When the Hematek Stain Pak contains sufficient reagents to stain only about 20 slides, the

yellow

Pak. Refer to Stain Pak Replacement on page 3-7.

LOW STAIN light will illuminate to indicate the need for replacement of the Stain

ON position.

POWER light will illuminate, the fan will start, and the conveyor spirals

Section 3: Operating Instructions, Page 3—3

Page 34

Prime the Tubing

1. Lift the stainer-operating lever to the PRIME position and hold in this position until the stain, buffer, and rinse reagents all flow evenly through their tubes to the platen without any air bubbles.

NOTE:

If the tubing is new and does not prime easily, it may be necessary to assist the priming

initially. Continue holding the operating lever in the

arm inwards (toward the pump) until the reagent fills the tubing, then release the pump

arm. It may also be helpful to pinch the tubing several times with the fingers, pinching in

the area between the cannula and the pump.

PRIME position and push the pump

Figure 3-1. Priming the Tubing

2. Release the lever, which will return automatically to the LOCK position.

CAUTION

Always wipe the platen from right to left. Damage to the position or shape of the sensing

switch fingers may result from not following recommended cleaning practices. Check the

position of the fingers after cleaning as described in step 5 of Check and Correct

Instrument Operation Prior to Pump Volume Adjustment on page 6-15.

3. After priming, wipe the platen with a soft disposable, lint-free absorbent cloth or tissue.

Page 3—4, Section 3: Operating Instructions

Page 35

Load the Blood Smear Slides

BIOHAZARD

Wear personal protective equipment. Use universal precautions. Refer to Appendix A,

page A-1 for recommended precautions when working with biohazardous materials.

1. Prime the platen.

The platen should be primed and wetted with reagents in order to ensure optimal

results on the specimen slides.

2. Mark blank or old blood smear slides as priming slides (for example, label them with

the name

You can reuse these priming slides

CAUTION

Slides must be inserted into the spiral grooves so they are parallel to the slide loading lines

inscribed on the platen. If slides are not placed correctly in the spiral grooves, breakage

can occur.

3. Load two to four priming slides and allow them to be transported across the platen ahead of the patient slides.

PRIME).

Figure 3-2. Priming the Platen

Section 3: Operating Instructions, Page 3—5

Page 36

4. Load the patient slides.

Place the properly prepared slides into the grooves of the conveyor spirals with the

blood smear side facing to the left of the operator and the feathered edge of the blood

smear toward the back of the instrument.

Figure 3-3. Loading the Blood Smear Slides

Stain the Smears

As the slides move along the platen, first vertically, then horizontally with the blood smear

side down, the instrument performs the following steps.

1. Three sensing switches are triggered sequentially.

Each switch senses the slide and passes the information to another switch, which

activates its respective solution pump as long as a slide is detected. The solution

pumps meter and deliver the stain, buffer, and then rinse into the capillary space

between the slide and platen.

NOTE:

If the reagents overflow, as opposed to filling the capillary space between the platen and

slide, or if you obtain improper staining results, the reagent pumps may need adjustment.

Refer to Pump Volume Adjustment on page 6-14 for more information.

2. After staining and rinsing have been accomplished, the slide is dried by a flow of air from a low velocity blower.

3. The slide is delivered into the slide drawer, ready for examination.

NOTE:

If the instrument is accidentally unplugged or there is a power failure during operation, it

may be necessary to remove the slides on the platen and reprocess them.

Page 3—6, Section 3: Operating Instructions

Page 37

Clean the Tubing after Use

If no slides are to be processed for an extended period (one hour or more), it is

recommended that the stain tubing be cleaned with methanol as described in Cleaning the

Stain Tubing and Cannula on page 5-4. Push the operating lever down to the

position to relieve the pressure against the pump tubing. You must re-prime the tubing and

the platen before processing any more slides.

Turn the Instrument Off at the End of the Day

CAUTION

Always clean the instrument after daily use. See Daily Cleaning on page 5-3. If using

frosted-end slides, it is especially important to clean the front guide rail on a regular and

frequent basis. This is because the stain may spread across the frosted portion of the slide

to the front rail. If allowed to accumulate, slide breakage may occur.

1. At the end of the day, clean the platen and stain tubing, and empty the waste tank.

UNLOCK

2. Push the operating lever to the

3. Turn the instrument off.

Stain Pak Replacement

If the LOW STAIN light illuminates when the instrument is first turned on or while slides

are being processed, a new Hematek Stain Pak is needed. Follow these steps to replace the

Stain Pak.

CAUTION

After replacement of the Stain Pak, the instrument must always be primed to remove any

air bubbles that may be present.

1. Remove the three cannulas from the used Stain Pak and lift the empty carton out of the well at the rear of the instrument.

2. Remove the perforated tabs from the new Stain Pak carton.

3. Insert the carton with the

instrument.

Make sure the carton is all the way down and resting on the tray at the bottom of the

well. The carton should be level when properly installed.

UNLOCK position.

STAIN bottle to the right into the well at the rear of the

4. Vent each bottle and insert the cannulas as described in Install the Stain Pak on page 2-9.

NOTE:

Check the cannulas with each new Stain Pak and replace them if they appear bent or

damaged.

5. Empty the waste tank into an appropriate receptacle and rinse it with water after each Stain Pak replacement. See Emptying the Waste Tank on page 5-6.

Section 3: Operating Instructions, Page 3—7

Page 38

Page 3—8, Section 3: Operating Instructions

Page 39

Section 4: Specimens............................................................................................... 4-3

Overview .............................................................................................................................................4-3

Peripheral Blood Smears..................................................................................................................4-3

Bone Marrow Smears .......................................................................................................................4-5

Section 4: Specimens, Page 4—1

Page 40

Page 4—2, Section 4: Specimens

Page 41

Section 4: Specimens

Overview

The Hematek Slide Stainer is designed specifically for the automatic staining of peripheral

blood smears that have been prepared on standard 25 mm x 75 mm or 1” x 3” glass slides.

Blood smears that are stained according to instructions will provide the examiner with

high quality differential staining characteristics for all cytologic blood components. See

Section 3: Operating Instructions for staining instructions.

Peripheral Blood Smears

BIOHAZARD

Wear personal protective equipment. Use universal precautions. Refer to Appendix A,

page A-1 for recommended precautions when working with biohazardous materials.

It is crucial to start with a properly prepared blood smear in order to obtain the best results

on the stained slide. The following suggestions are recommended:

• Use high quality slides that are new and thoroughly cleaned.

• Slides must be free of oil and grease.

• Do not touch the slide surfaces with the fingers or against the skin of the patient.

• Protect blank slides from moisture and high humidity, as well as contamination by

dust, flies, and other insects.

• Store the slides covered in a cool, dry place.

• Never use oxalated or heparinized blood for making blood smears.

• EDTA is the anticoagulant of choice.

• Protect blood smears from excessive heat (such as radiators and ovens), water

splatters, and high humidity.

Use the following procedure to prepare a blood smear.

1. Remove the cap from a tube of well-mixed anticoagulated whole blood. EDTA is the anticoagulant of choice.

NOTE:

Blood should be kept at room temperature prior to preparing the smear. Adaquate mixing

requires approximately 20 inversions prior to blood film preparation.

2. Place a drop of well-mixed blood near one end of a high quality slide. Hold a second

spreader slide at about a 45 degree angle and approach the drop of blood. Allow the

blood to spread almost to the width of of the slide edge. Then rapidly and smoothly

push the spreader slide to the opposite end of the slide, pulling the blood behind it.

NOTE:

The angle and speed at which the blood drop is spread determines the thickness or thiness,

and length of the blood film.

Section 4: Specimens, Page 4—3

Page 42

3. The ‘feather’ end of the blood film should be at least 1.57 cm (5/8 inch) from the opposite end of the slide to avoid extending beyond the platen surface and contact with the staining reagents.

Do not allow the smear to touch the edges of the slide as large cells tend to accumulate

there. This may mechanically effect the distribution of the cell types.

Since frosted-end glass slides limit the spreading area, extra care is needed when

preparing a blood film.

Figure 4-1. Making a Blood Smear

4. Allow the smear to dry thoroughly before staining. See Section 3: Operating Instructions for staining instructions.

After staining the slide, take the following precautions.

• Examine stained slides as soon as possible.

• Protect stained slides from direct sunlight and store them in a cool, dry place.

Page 4—4, Section 4: Specimens

Page 43

Bone Marrow Smears

BIOHAZARD

Wear personal protective equipment. Use universal precautions. Refer to Appendix A,

page A-1 for recommended precautions when working with biohazardous materials.

Many laboratories stain bone marrow smears with the same stain as is used for blood

smears. The procedure involves using the “squash” technique for smear preparation and

staining the slide once or twice on the Hematek Slide Stainer. The following procedure has

been verified as giving clinically useful staining results on bone marrow slides; however,

the stain quality is dependent upon the thickness and evenness of the bone marrow smear.

A thick smear is more likely to require a second pass through the instrument than a thinner

smear; an uneven smear will not stain uniformly.

1. Use bone marrow smears that have been prepared using the “squash” technique.

Be sure the smear is thoroughly dry before staining.

2. Place the slide onto the Hematek Slide Stainer and stain according to instructions in Section 3: Operating Instructions.

3. Remove the slide after it has been stained and examine it under high power (dry) for the

staining quality.

Do not use any oil on the slide for this examination.

4. If the slide is under-stained, place it on the slide stainer again and stain it a second time. In rare instances, a third staining may be necessary.

When using the Hematek Modified Wright Stain Pak (#4481), the bone marrow

smears must be stained twice; one pass through the instrument is generally insufficient

to produce distinct nuclear intensity. A third pass generally does not increase or

decrease the quality of the staining.

When using the Hematek Modified Wright-Giemsa Stain Pak (#4405), a single

staining is generally sufficient for most bone marrow smears. The smear may become

over stained, with the appearance of precipitate and nuclear artifacts, on slides stained

two or more times.

5. Thoroughly clean the platen after staining bone marrow slides to remove the greasy residue that can be left on the platen by the fat droplets in the marrow

Section 4: Specimens, Page 4—5

Page 44

Page 4—6, Section 4: Specimens

Page 45

Section 5: Maintenance............................................................................................. 5-3

General Cleaning...............................................................................................................................5-3

Daily Cleaning ....................................................................................................................................5-3

Cleaning the Platen ..................................................................................................................5-3

Cleaning the Stain Tubing and Cannula .....................................................................................5-4

Emptying the Waste Tank .........................................................................................................5-6

Weekly Cleaning................................................................................................................................5-6

Cleaning Drain Troughs and Rear Guide Rail .............................................................................5-6

Decontamination and Removal from Operation ............................................................................5-9

Section 5: Maintenance, Page 5—1

Page 46

Page 5—2, Section 5: Maintenance

Page 47

Section 5: Maintenance

The Hematek Slide Stainer is a precision instrument, designed to provide trouble-free

operation with a minimum of maintenance.

BIOHAZARD

Wear personal protective equipment. Use universal precautions. Refer to Appendix A,

page A-1 for recommended precautions when working with biohazardous materials.

General Cleaning

Keep the exterior surfaces of the instrument free of dust at all times. If needed, the exterior

may be cleaned using a damp cloth and mild detergent. A small amount of methanol may

be used to clean stain from the instrument.

Daily Cleaning

It is vitally important to clean the platen and tubing at least once each day in order to

maintain consistently high quality staining results. It is also important to empty the waste

tank at the end of each day.

Cleaning the Platen

After staining a large number of blood smears, precipitated stain solution tends to

accumulate in the mixing grooves of the platen. This precipitate must be removed at

regular intervals. Daily cleaning of the platen is imperative; after each run is optimal.

Cleaning is especially important if bone marrow slides have been stained because the fat

droplets can leave a greasy residue on the platen. Use the following procedure to clean the

platen:

1. Turn the instrument off.

2. Carefully flood the working area of the platen with methanol.

Avoid splashing the methanol.

CAUTION

Always wipe the platen from right to left. Damage to the position or shape of the sensing

switch fingers may result from not following recommended cleaning practices. Check the

position of the fingers after cleaning as described in step 5 of Check and Correct

Instrument Operation Prior to Pump Volume Adjustment on page 6-15.

Section 5: Maintenance, Page 5—3

Page 48

3. After priming, wipe the platen with a soft, disposable, lint-free absorbent cloth or tissue.

Wipe from right to left only.

Figure 5-1. Cleaning the Platen

CAUTION

If using frosted-end slides, it is especially important that the front guide rail be cleaned on

a regular and frequent basis. This is because the stain may spread across the frosted

portion of the slide to the front rail. If allowed to accumulate, slide breakage may occur.

4. Thoroughly clean the mixing grooves and the front guide rail.

Cleaning the Stain Tubing and Cannula

The tubing carrying the stain should be cleaned at least once daily (or after each run), as

described in the following procedure:

1. Remove the stain, buffer, and rinse cannulas from the Stain Pak bottles.

NOTE:

The buffer and rinse cannulas and tubing do not require cleaning. These cannulas are

removed so the buffer and rinse solutions are not wasted while the stain tubing is being

cleaned.

Page 5—4, Section 5: Maintenance

Page 49

2. Using the prime function, purge the stain from the tubing.

a. Place the stain cannula, with tubing attached, into a small container of methanol

and lift the operating lever to

Figure 5-2. Rinsing the Stain Tubing

PRIME.

b. Holding the lever in this position, continue to pump methanol through the stain

tubing until it is thoroughly rinsed and clear solution appears on the platen.

3. After the stain tubing has been cleaned, remove the cannula from the methanol and continue to prime until the tubing is emptied of all methanol

CAUTION

Always wipe the platen from right to left. Damage to the position or shape of the sensing

switch fingers may result from not following recommended cleaning practices. Check the

position of the fingers after cleaning as described in step 5 of Check and Correct

Instrument Operation Prior to Pump Volume Adjustment on page 6-15.

4. Carefully wipe the platen with a soft, disposable, lint-free absorbent cloth or tissue.

Wipe from right to left only.

Section 5: Maintenance, Page 5—5

Page 50

Emptying the Waste Tank

Empty the waste tank once each day, as well as after installing a new Stain Pak. To avoid

spilling the contents while emptying the waste tank, carefully pull the tank away from the

instrument, supporting the bottom of the tank to hold it level during removal. After

emptying into an appropriate receptacle, rinse the waste tank with water and reinstall it

into the instrument.

Figure 5-3. Removing the Waste Tank

Weekly Cleaning

Clean the drain troughs and the rear guide rail on a weekly basis.

Cleaning Drain Troughs and Rear Guide Rail

The back and front drain troughs of the stainer function as drains for excess stain, and

residues from the reagents that may accumulate and interfere with proper drainage. The

recommended procedure for proper cleaning is as follows:

1. Turn the instrument off and remove the line cord from the AC electrical outlet.

2. Raise the lid of the instrument.

Page 5—6, Section 5: Maintenance

Page 51

3. Loosen the two thumbscrews that are inserted through the notches in the back of the circuit board cover.

Figure 5-4. Location of Thumbscrews

4. Carefully raise the circuit board cover so the back trough is completely exposed and easily accessible.

Figure 5-5. Raising the Circuit Board Cover

5. Move the panel up and back, out of the way.

The circuit board cover is connected to the instrument by the two connectors of the

LOW STAIN and POWER lights. Rotate the panel carefully so the connectors are not

pulled loose.

Section 5: Maintenance, Page 5—7

Page 52

6. Flood both the front and back troughs with methanol to loosen any precipitated stain that may be present. Take care not to splash methanol onto the circuit board.

7. Using an applicator stick with a cotton swab attached, wipe from right to left along the length of the back and front troughs to remove the entire excess residue.

Figure 5-6. Cleaning the Back Trough

8. Clean other exposed areas that might be accidentally stained, including the rear guide rail, in the same careful manner.

NOTE:

Ensure that you do not scratch the platen.

9. Return the circuit board cover to its normal position, between the circuit board panel and the back edge of the screws, and tighten the two thumbscrews.

Be sure the panel is not resting on top of the screw heads before tightening.

Page 5—8, Section 5: Maintenance

Page 53

Decontamination and Removal from Operation

BIOHAZARD

Wear personal protective equipment. Use universal precautions. Refer to Appendix A,

page A-1 for recommended precautions when working with biohazardous materials.

Use this procedure to remove the Hematek system from operation for extended periods

and prior to packing and shipping the system to another location or to an off-site service

facility.

1. Remove and dispose of all slides in the appropriate receptacle.

2. Follow the first five steps of the Replacement of the Pump Tubing on page 6-7, procedure to empty and remove the pump tubing and discard it in an appropriate waste container.

3. Lift the used Hematek Stain Pak carton out of the well at the rear of the instrument.

4. Follow steps 3 through 8 of the Replacement of the Underplaten Tubing on page 6-11 to turn off the instrument and remove the underplaten tubing. Discard it in an appropriate waste container

5. Clean the platen with methanol, always wiping from right to left.

6. Empty the waste tank, fill with 10% solution of household bleach and water, empty the solution, and then rinse the tank with regular water.

7. Clean the exterior surfaces of the instrument with a damp cloth and mild detergent. A small amount of methanol may be used to clean stain from the instrument.

8. Screw the front feet all the way up.

The instrument is now ready for storage or for packing and shipping.

Section 5: Maintenance, Page 5—9

Page 54

Page 5—10, Section 5: Maintenance

Page 55

Section 6: Minor Replacements and Adjustments ................................................. 6-3

Fuse Replacement ............................................................................................................................6-3

Replacement of Light Assemblies ...................................................................................................6-4

Replacement of the Pump Tubing...................................................................................................6-7

Replacement of the Underplaten Tubing........................................................................................6-11

Pump Volume Adjustment................................................................................................................6-14

Check and Correct Instrument Operation Prior to Pump Volume Adjustment .................................6-15

Adjust the Stain, Buffer, and Rinse Volumes ..............................................................................6-15

Volume and Ratio Determination.....................................................................................................6-17

Sensing Switch Fingers Adjustment................................................................................................6-18

Minor Replacements and Adjustments, Page 6—1

Page 56

Page 6—2, Section 6: Minor Replacements and Adjustments

Page 57

Section 6: Minor Replacements and Adjustments

This section is provided as an aid for performing minor replacements and adjustments on

the Hematek Slide Stainer. Fully review and understand the procedures before attempting

them, and they must be performed with care. For any adjustments or replacements other

than those given in this section, or if any procedure appears to be too complex, refer to

Supplies and Replacement Parts on page 8-6, for instructions on service for your

instrument.

Fuse Replacement

Use the following procedure to replace the instrument line fuse for all voltage instruments.

The fuse is 1.0 amp, 5mm x 20mm, Type T (Part No. 40151108).

1. Turn the instrument off and remove the line cord from the AC electrical outlet.

2. Using a small, blade-type screwdriver, pry the fuse cover open.

.

Figure 6-1. Opening the Fuse Cover

Section 6: Minor Replacements and Adjustments, Page 6—3

Page 58

3. Pull the fuse holder out of the instrument.

4. Remove the fuse from the holder and discard it into an appropriate waste container.

Figure 6-2. Replacing the Fuse

CAUTION

Use only the specified fuse to avoid damage to the instrument.

5. Replace the defective fuse with an identical fuse, snapping it into place. Fuse specifications are in Section 1: Introduction, while ordering information is in Section 8: Service, Supplies, and Replacement Parts.

A spare fuse, located in the small, enclosed compartment in the fuse holder, is shipped

with the instrument. Push the fuse out of the compartment using a small screwdriver.

6. With the flat side up, return the fuse holder to its position in the instrument.

7. Firmly press the fuse cover until it snaps into place and is flush with the power module plate.

Replacement of Light Assemblies

Use the following procedure to replace the Power Light Assembly (PN 94000787) or Low

Stain Light Assembly (PN 94001073).

1. Turn the instrument off and remove the line cord from the AC electrical outlet.

2. Raise the lid of the instrument.

Page 6—4, Section 6: Minor Replacements and Adjustments

Page 59

3. Loosen the two thumbscrews that are inserted through the notches in the back of the circuit board cover.

Figure 6-3. Location of Thumbscrews

4. Lift the panel from the front wall, exposing the printed circuit board and the

connectors for the

LOW STAIN and POWER lights.

Figure 6-4. Raising the Circuit Board Cover

Section 6: Minor Replacements and Adjustments, Page 6—5

Page 60

5. Disconnect the wires from the circuit board for the light that is to be replaced.

Using a small, blade-type screwdriver, loosen the two small screws located on the top

of the connector (the screws will not come out completely), then pull on the connector

wires to remove them from the connector.

Figure 6-5. Removing the Connector Wires

6. Unsnap the burned-out light assembly from the circuit board cover by pinching together the two plastic retaining tabs on the light assembly.

If the tabs are too stiff, use a screwdriver to press against one side, then push that edge

partially through the opening. Repeat with the other side.

Figure 6-6. Unsnapping the Light Assembly

Page 6—6, Section 6: Minor Replacements and Adjustments

Page 61

7. Discard the burned-out light assembly into an appropriate waste container.

8. Insert the new light assembly into the circuit board cover, threading the wires through the opening from the front of the cover and pressing firmly on the light until it snaps into place.

9. Insert the connector wires into the holes on the connector on the printed circuit board.

Each wire can go into either hole.

10. Tighten the small screws to just past finger tight.

11. Return the circuit board cover to its normal position, between the circuit board panel and the back edge of the screws, and tighten the two thumbscrews.

Be sure the panel is not resting on top of the screw heads before tightening.

12. Replace the line cord into the AC electrical outlet and turn the instrument on to check the light operation.

Replacement of the Pump Tubing

If any one of the three pumps fails to deliver the proper amount of solution at the adjusted

volume setting, it is recommended that all pump tubes be replaced. Regular flushing of

the stain tubing with methanol prolongs the life of the tubing. All pump tubes should be

replaced after three Stain Paks have been used. If regular cleaning is not performed, or if

usage is very heavy, the tubing should be changed more frequently. Use the following

procedure to replace the pump tubes with new ones in the Hematek Pump Tube Set (PN

4482).

1. Remove the three cannulas from the Stain Pak.

2. Raise the operating lever to the

the tubes.

Figure 6-7. Priming the Tubing

PRIME position until the reagents are pumped out of

Section 6: Minor Replacements and Adjustments, Page 6—7

Page 62

3. Push the operating lever down to the UNLOCK position.

4. Disconnect each pump tube from its cannula and from the recessed nipple located in the wall in front of the pumps.

Figure 6-8. Removing Tubing from Cannula

Figure 6-9. Removing Tubing from Nipple

Page 6—8, Section 6: Minor Replacements and Adjustments

Page 63

5. Remove each tube from the pump assembly.

a. Push the thumb tab on the pump arm to the left as far as possible.

b. While holding the thumb tab in this position, pull the plastic cuff on the tube until

the tube is completely removed from the pump arm.

c. Discard the tube in an appropriate waste container.

Figure 6-10. Removing Tubing from Pump Assembly

6. Remove the new tubes from the Hematek Pump Tube Set.

Each tube is numerically coded to correspond with the numbers shown on the Stain

Pak.

Tube Code

stain tube

buffer tube

rinse tube

1

2

3

7. Attach the coded end of the new tube to its respective cannula.

a. Replace the cannula if it appears damaged or bent using the Hematek Cannula Set

(PN 4483).

b. If you are re-using any cannulas, make sure the cannula previously used for stain

is used only with the stain tubing.

Section 6: Minor Replacements and Adjustments, Page 6—9

Page 64

8. Insert tubing into the pump assembly.

a. Extend the new tube to its respective pump and thread the end into the hole in the

pump arm.

b. Push the thumb tab to the extreme left, as before, and push the tube through until

the plastic cuff is flush against the pump arm.

c. Release the pump arm.

NOTE:

If you encounter difficulty in threading the tubing through the pump housing, lift the

operating lever to

PRIME for just a few seconds. This will cause the rollers inside the

pump housing to rotate slightly and relieve the interference.

Figure 6-11. Inserting Tubing into Pump Assembly

9. Connect the tube to its proper recessed nipple.

NOTE:

If difficulty is encountered in connecting a tube to its nipple, use forceps or a hemostat to

grasp and attach the tube.

CAUTION

Take care to not damage the tubing when using forceps or hemostats.

10. Replace the cannulas into their respective reagent bottles.

Page 6—10, Section 6: Minor Replacements and Adjustments

Page 65

11. Prime the pumps until the solution in each tube is clear of all air bubbles.

NOTE:

New tubing is sometimes difficult to prime the first time and may need assistance. While

holding the operating lever in the

PRIME position, push the pump arm inwards (toward the

pump) until the reagent fills the tubing, then release the pump arm. It may also be helpful

for you to pinch the tubing several times with your fingers, pinching in the area between

the cannula and the pump arm.

12. Verify the pump timings and reset the volume controls if necessary. See Pump Volume Adjustment on page 6-14.

Replacement of the Underplaten Tubing

The underplaten tubing is the tubing between the spout under the platen and the nipple

behind the circuit board. The buffer and rinse tubing should be replaced after