Page 1

Installation Instruct ions

Model HCP

Intelligent Control Point

INTRODUCTION The Model HCP Intelligent Control Point from Siemens

Industry, Inc. provides remote, independent control of

any of the following:

1. A notification appliance circuit (NAC)

2. A telephone zone (XLS only)

3. A speaker zone (25V or 70.7V RMS) (XLS only,

FV2025/2050, FV922/924)

The HCP communicates through the DLC device loop

card of the FireFinder-XLS System, the FS-DLC device

loop card of the FS-250 System, the FC922/FV922,

FC2025/FV2025 periphery FCI2016 Board (250p)

detector circuits, and the FC2050/FV2050, FC924/FV924

FCI2017 periphery board (500p) detector circuits. Each HCP

uses one device address on the device loop.

PROGRAMMING

POINTS

E

ID

S

K

C

A

B

N

6

O

1

B

5

T

4

3

2

1

SIEMENS

MODEL: HCP

DEVICEADDRESS:

U

A

C

W

CT

NE

N

O

B

C

1

IS

B

D

T

N

O

INSTALLATIONINSTRUCTIONS

P/N315-034860

SIEMENSINDUSTRY, INC.

FLORHAMPARK, NJ, 07932

T

6

N

"2"

&

IO

"1"

T

INAL

RM

G

IN

M

AT TE

M

A

R

IRE

G

O

R

P

E

R

O

F

E

E

ID

S

K

C

A

B

N

O

1

2

B

2

3

4

5

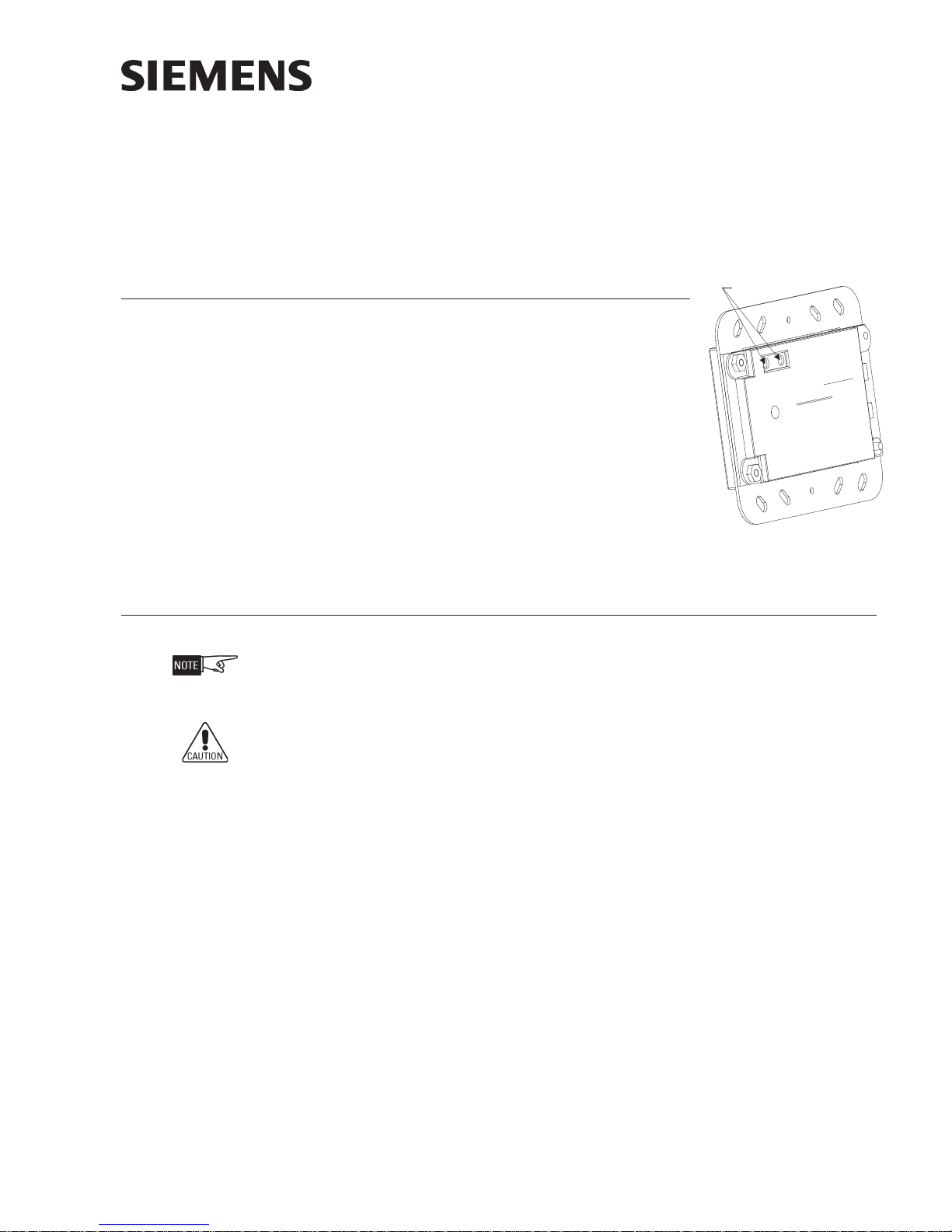

Figure 1

HCP Intelligent Control Point

PROGRAMMING Use the DPU Programmer/Tester to program and test the module.

The HCP may only be assigned addresses 1 to 60. It is recommended to program

the HCP devices first to ensure that enough addresses have been reserved for them.

Other devices may then be assigned to addresses in this range that were not

assigned to an HCP.

Disconnect wire at terminal 1 and 2 on TB1 before programming.

To set the HCP device address:

• Plug the programming cable of the DPU Programmer/Tester into the twopin programming points on the HCP. (See Figure 1 for location.)

• Set the device address for the HCP by following the instructions in the DPU

Programmer/Tester Manual, P/N 315-033260.

Each HCP can be assigned a custom message using either the Zeus Programming Tool

(XLS System), the FS-CT2 (FS-250 System), the FC2025/2050, FV2025/2050 FSX2002

Engineering Tool, or the FC922/924, FV922/924 FSX7212 Engineering Tool. Refer to

the Zeus Quick Start Manual, P/N 315-033875, or the FS-250 Programming Manual, P/

N 315-049403, as applicable.

P/N 315-034860-13

Building Building

Building

Building Building

SiemensSiemens

Siemens

SiemensSiemens

TT

ecec

hnologies Dihnologies Di

T

ec

hnologies Di

TT

ecec

hnologies Dihnologies Di

Industry Industry

Industry

Industry Industry

visionvision

vision

visionvision

,,

Inc. Inc.

,

Inc.

,,

Inc. Inc.

Page 2

COMPATIBILITY The following minimum revisions are required for proper operation of the HCP:

:METSYSSLX:METSYS052-SFMETSYS02SF

CLD0000.00.40CLD-SF05.1

IMP0000.00.40CAN81.20502/5202CFxx.xx.14

21-CSP0000.00.70

04-CAZ

SUEZ9100.00.40

0000.80.20

*0000.80.031

LENAP0.50502/5202VFxx.xx.06

OGISED

ORPSUREBREC

429/229CFxx.xx.14

429/229VFxx.xx.06

90.20.veR04-CAZ*

.0000.01.031/0000.01.20.veRro0000.80.031/0000.80.20.veRottreveR.PCHeht

WIRING

Remove all system power before installation, first battery then AC. (To power up,

connect the AC first, then the battery.)

Power down the 24 VDC power supply and the input source (ZAC, etc.) before

installing the HCP.

All wiring must comply with national and local codes. All wire must be 18 AWG

minimum, 12 AWG maximum.

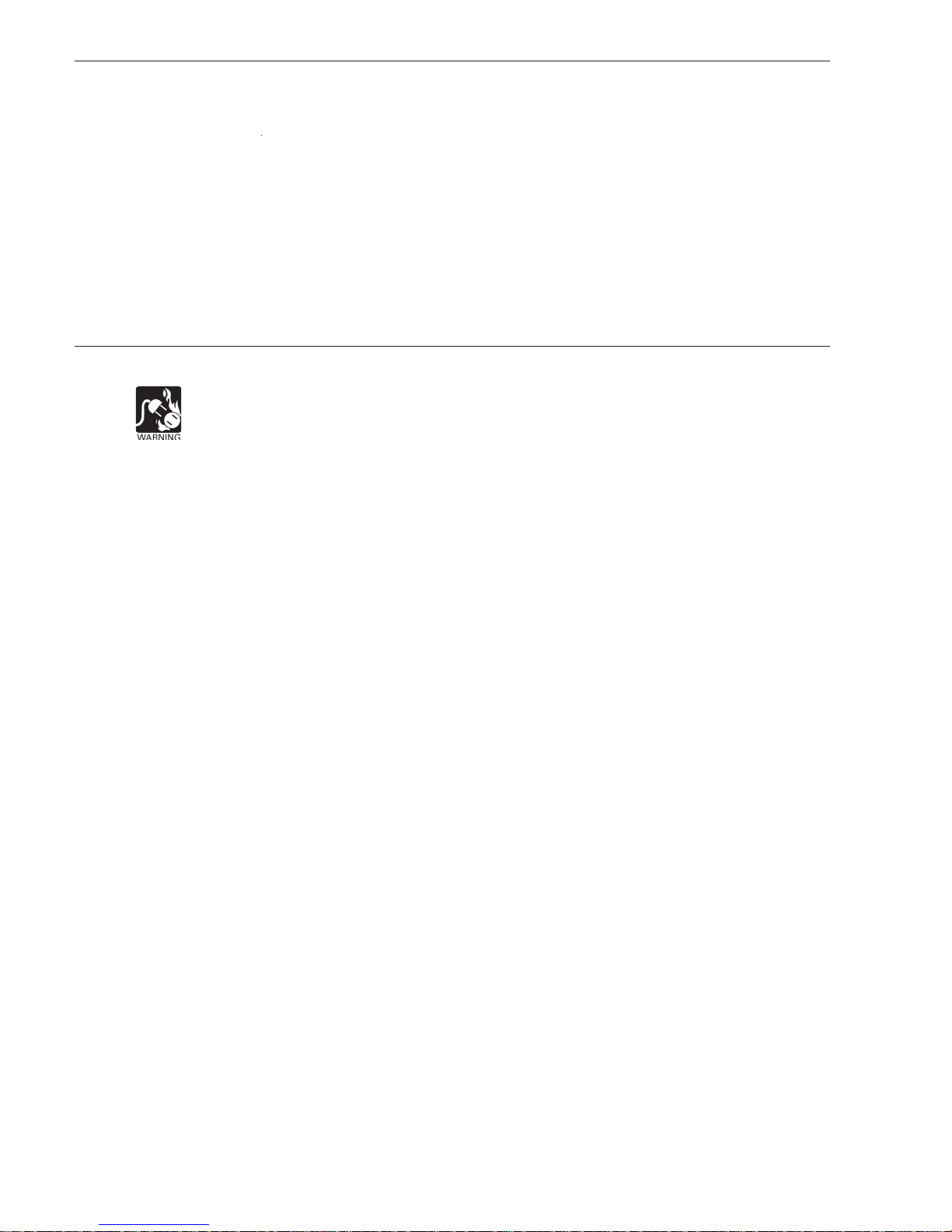

Device Loops The HCP communicates with the FireFinder-XLS/FS-250/Desigo FC2025/2050,

FV2025/2050/Cerberus PRO FC922/924, FV922/924 Systems through its addressable

device loops. These loops are connected to the DLC via terminal blocks on the CC-5

or CC-2 cardcage (XLS) or to the FS-DLC via TB3 on the FS-MB/FS-MB2 main board

(FS-250). They may be wired Class A (Style 6) or Class B (Style 4). Figure 2 shows

both wiring types and the connections to the DLC. See the DLC Installation Instructions, P/N 315-033090, for more information. Figure 3 shows both wiring types and

connections to the FS-DLC. See the FS-250 Installation, Operation and Maintenance

Manual, P/N 315-049353, for more information. Figure 4 shows both wiring types and

connections to the Periphery boards. See the Desigo FC2025/2050 FV2025/2050

Configuration Manual, Document ID A6V10315023, for more information. Figure 5

shows both wiring types and connections to the Periphery boards. See the Cerberus

PRO FC922/924 FV922/924 Configuration Manual, Document ID A6V10333423, for

more information.

htiwelbitapmocTONera0000.42.20.veRdna0000.12.20.veR,0000.90.031/0000.

HCP Power Supply For FireFinder-XLS Systems, compatible power supplies for the HCP are the PSC-12,

PSX-12, and PAD-4. Wiring should be connected to TB3 on the PSC-12 and PSX-12, or

the auxiliary power supply on the PAD-4.

For FS-250 Systems, the HCP is powered by the NAC circuits and PAD-4. Wiring

should be connected to the NAC circuits on the main board or the auxiliary power

supply on the PAD-4.

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-132

Page 3

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

12345678

910111213141516

CLASS A WIRING*

NO T-TAPPING ALLOWED

BOTH ZONES MUST BE WIRED AS CLASS A

12345678

910111213141516

CLASS B WIRING**

T-TAPPING ALLOWED

BOTH ZONES MUST BE WIRED AS CLASS B

*OPERATES IN FULL CONFORMANCE WITH STYLE 6 (ULC DCLA)

ZONE 1

DLC LOCATED IN

ONE SLOT OF CC-5 / CC-2

LINE 1

LINE 1

LINE 1 (RETURN)

LINE 1 (RETURN)

LINE 1 (OUT)

LINE 1 (OUT)

ZONE 2

LINE 2

LINE 2

LINE 2 (OUT)

LINE 2 (OUT)

LINE 2 (RETURN)

LINE 2 (RETURN)

NOT USED

NOT USED

NOT USED

NOT USED

**OPERATES IN FULL CONFORMANCE WITH STYLE 4 (ULC DCLB)

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

HCP

TB1

1

2

ZONE 1

ZONE 2

DLC LOCATED IN

ONE SLOT OF CC-5 / CC-2

CLASS

G

2

2

,

NOTES

1. Loop resistance 50 ohms

Max with 252 devices on

the loop. Refer to the DLC

Installation Instructions,

P/N 315-033090 if the

number of devices is less

than 252.

2. 12-18 AWG wire.

3. No EOL device required.

4. Supervised, power limited

per NEC 760.

5. All wiring must conform

to national and local

electrical codes.

Figure 2

FireFinder-XLS Device Loop

Connections

NOTES

1. Loop resistance 180 ohms

max with 252 devices on

loop.

2. 12-18 AWG wire.

3. No EOL device required.

4. Supervised, power limited

per NEC 760.

5. All wiring must conform

to national and local

electrical codes.

A WIRIN

TB1

X1401/X1402

X1801/X1802

4 3 2 1

1+ 1- 2+ 2-

HCP

TB1

HCP

CLASS B WIRING

1

2

TB1

1

2

HCP

1

2

TB1

1

2

HCP

X1401/X1402

X1801/X1802

4 3 2 1

1+ 1- 2+ 2-

TB1

1

HCP

TB1

1

HCP

Figure 3

FS20 Device Loop

Connections

Siemens Industry, Inc.

Building Technologies Division

Detector circui ts on periphery board

for FC922/FV922

FC2025/FV2025

P/N 315-034860-133

Page 4

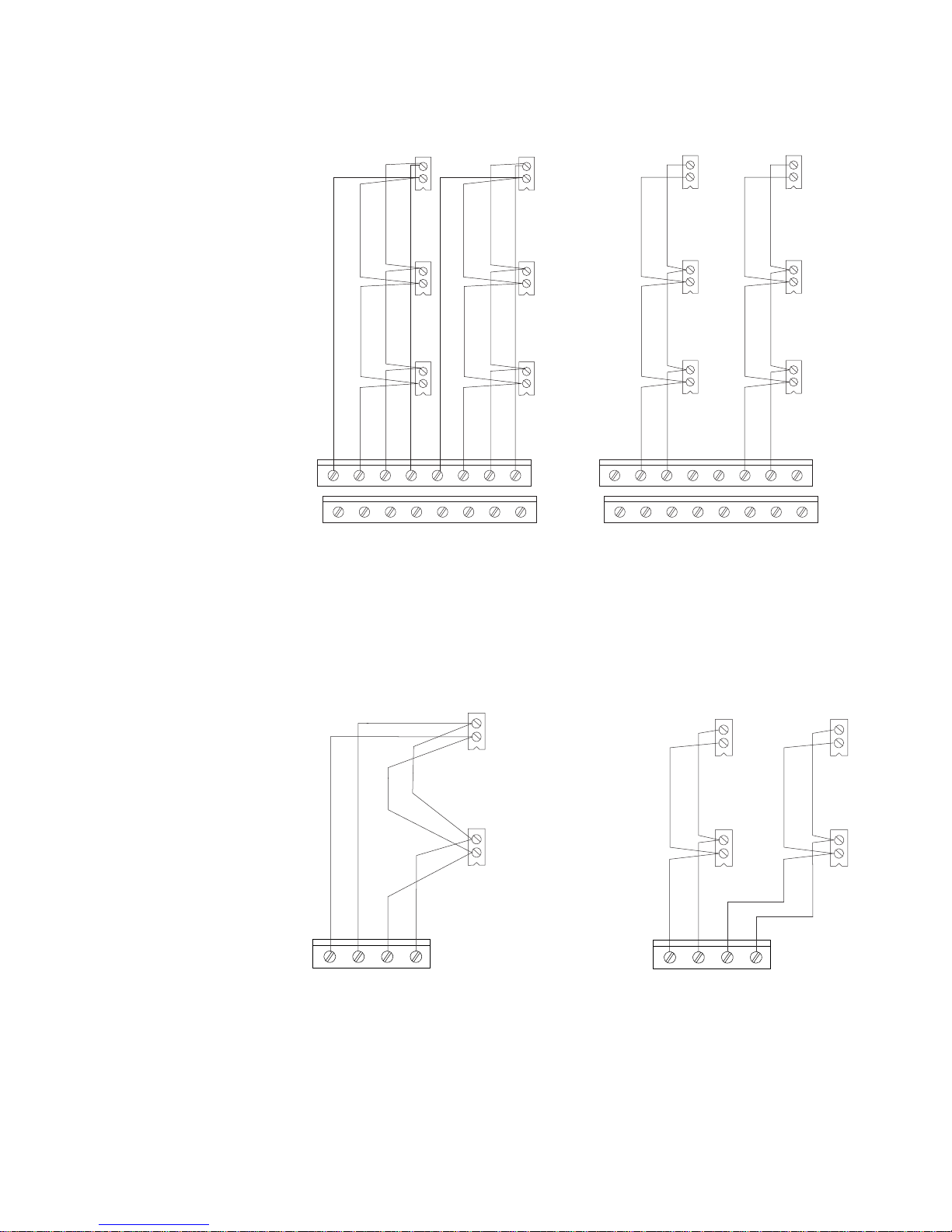

NOTES

1. Loop resistance 50 ohms

Max with 252 devices on

the loop. Refer to the FS250 Manual, P/N 315049353 if the number of

devices is less than 252.

2. 12-18 AWG wire.

3. No EOL device required.

4. Supervised, power limited

per NEC 760.

5. All wiring must conform

to national and local

electrical codes.

Figure 4

FS-250 Device

Loop Connections

FS-DLC Device

Loop Circuit

FS-DLC Device

Loop Circuit

CLASS A* INSTALLATION

*OPERATES IN FULL CONFORMANCE WITH STYLE 6

LINE 1 (OUT)

LINE 1 (RETURN)

LINE 2 (RETURN)

LINE 2 (OUT)

HCP

**OPERATES IN FULL CONFORMANCE WITH STYLE 4

LINE 1

NOT USED

NOT USED

LINE 2

HCP

NO T-TAPPING ALLOWED

TB1

2

1

CLASS B** INSTALLATION

TB1

2

1

HCP

T-TAPPING ALLOWED

HCP

(ULC DCLA)

ZONE

1

TB1

2

1

TB1

2

1

HCP

(ULC DCLB)

HCP

TB1

2

1

ZONE

1

TB1

2

1

DPU Loop Test When performing a loop test with the DPU be sure to apply power to the HCP.

Without power applied to the HCP a blinking “C” will appear on the DPU, indicating

that the HCP is in trouble.

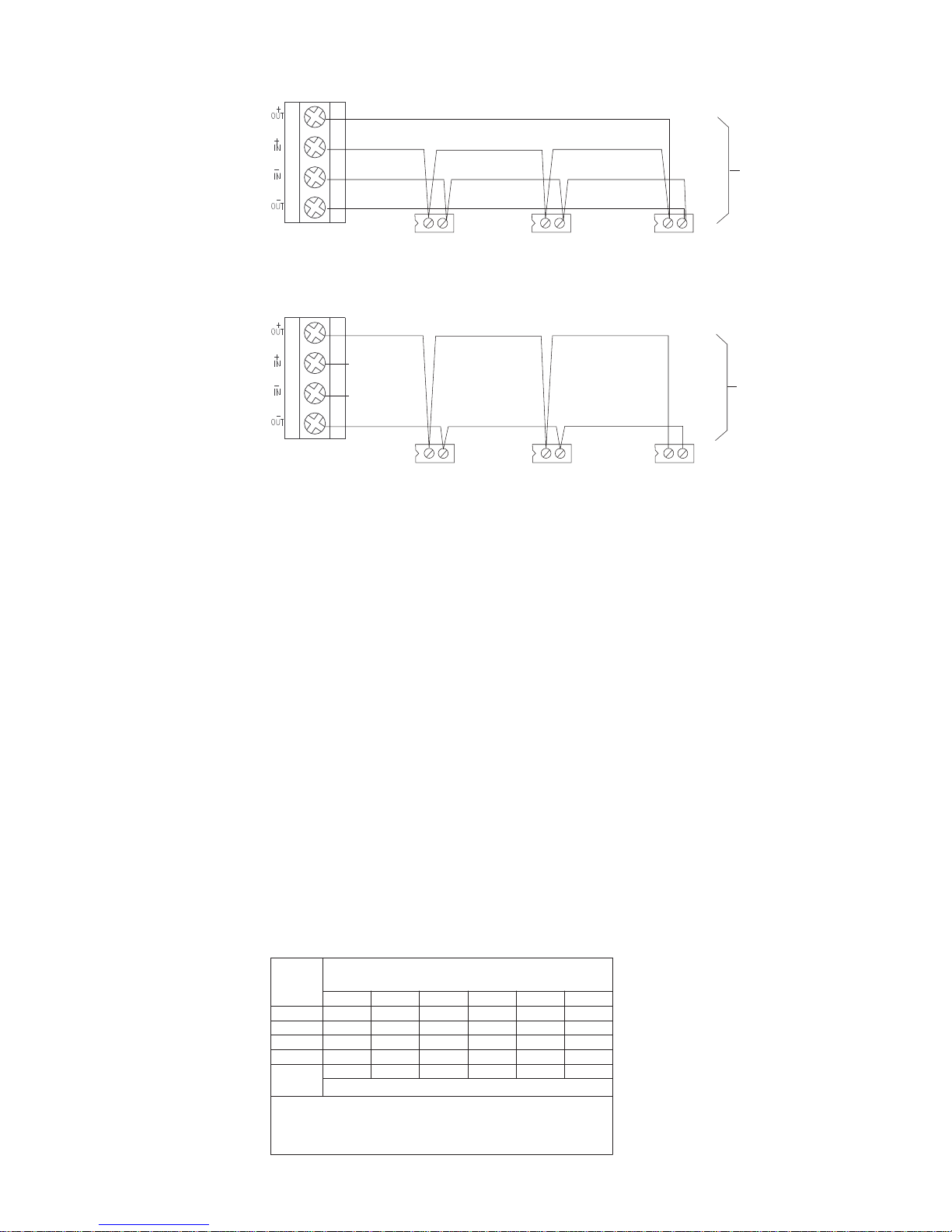

HCP As NAC Module This application uses the principle of polarity reversal to activate notification appli-

ances. Wiring is shown in Figure 4. Connect the HCP output zone wiring to the (+)

and (-) terminals of each notification appliance as shown in Figure 4. For a list of

compatible devices, refer to P/N 315-096363.

When used as a NAC module, the 24VDC provides power for the supervision circuitry

and to the notification appliances when they are activated. The power source must be

power limited. See the HCP Power Supply section (above) for compatible power sources.

The maximum output load that may be connected to an HCP is 1.5A at 24 VDC. If the 24

VDC is lost or the NAC line is broken or shorted while the HCP is in supervisory mode, a

trouble condition displays at the FireFinder-XLS, FS-250 System control panel, the Desigo

FC2025/2050, FV2025/2050 Operating Unit, and the Cerberus PRO FC922/924, FV922/

924 Operating Unit. For FS-250 Systems, the NAC circuit must be set to “always on” in

the panel or FS-CT2 configuration tool. See the Line Resistance table below for the

allowable line resistance for each HCP output circuit.

ECNATSISERENILTIUCRICTUPTUOPCHELBAWOLLAMUMIXAM

MUMIXAM

CD

RESIR

TNERRUC

)spmAni(

437.233.276.100.133.—

308.205.200.205.

268.276.233.200.276.100.1

139.238.276.205.233.200.2

5.69.229.238.257.276.205.2

SETON

:

mhO1.0mhO52.0mhO5.0mhO57.0mhO1smhO5.1

100.1—

rruclatotehtfI.2

.seriwhtobroferadeificepssecnatsiseR.1

ECNATSISERENILDNATNERRUCRESIRCDDEIFICEPSROF

)smhOni(ECNATSISERRESIRCD

RESIRNOPCHHCAEROFECNATSISERPOOLMUMIXAM

eratahtseilppusCDV42yrailixualacol,A4sdeecxetnemeriuqertne

.desuebyam,4-DAPsnemeiSsahcus,esugnilangisnoitcetorperifrofdetsilLU

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-134

Page 5

.

A

LL WIRING MUST COMPLY WITH NATIONAL AND LOCAL CODES.

D

DLC/FS-DLC

DEVICE LOOP

DC INPUT RATED

18.8-28.2VDC

SUPV: 30m A

ACTIVATE D: 1.5A MAX

C INPUT: 18.8-28.2VDC FILTERED FULL WAVE

XLS/FS-250: PAD-4* (TB16), FC2025/2050,

FCI2016/2017-U1 PERIPHERY BOARD AUX

POWER OR UL LISTED REGULATED 24 VDC

MODULE INPUT SUPPLY:

XLS: PSC-12 (TB3) or PSX-12 (TB3).

FS-250: FS-250 NAC Circuit.

FV2025/2050, FC922/924, FV922/924,

POWER SUPPLY (POWER LIMITED).

*REFER TO PAD-4 INSTALLATION INSTRUCTIONS, P/N 315-050217, FOR PROPER SETTING OF SWITCH 4. THE AUXILIARY POWER OUTPUT MUST BE CONFIGURED TO “ALWAYS ON”

LINE 2

PROGRAMMING

POINTS

EARTH

LINE 1

FROM

SUPERVISED STROBE ACTIVATION “SPECIAL APPLICATION”

18.8V-28.2V FILTERED FULL WAVE RECTIFIED

1 2 3 4 5 6

HCP HCP

6 5 4 3 2 1

SHIELD

HCP MODULE IS USED FOR

NAC SUPERVISION AND ACTIVATION

STYLE Y

SUPV: 1mA

ACTIVATED: 1.5A MAX

POLARITY SH OWN IN ACTIVE STATE

24K, W½, 5%

EOL RESISTOR

P/N 140-034677

24 VDC

NAC UNITS

SEE P/N 315-096363

PROGRAMMING

POINTS

EARTH

SHIELD

NAC SUPERVISION AND ACTIVATION

STYLE Z

24K, W, 5% ½

EOL RESISTOR

P/N 140-034677

1 2 3 4 5 6

6 5 4 3 2 1

HCP MODULE IS USED FOR

POSITIVE AND NEGATIVE

GROUND FA ULT

DETECTED AT

<500 OHMS FOR

TERMINALS 3-6 ON TB1.

The input power and NAC power inputs on TB2 (1-4)

must be connected to the same source.

Figure 5

HCP Used As An NAC Module

All HCPs connected to a given DLC/FS-DLC circuit

must reside within a single notification zone.

HCP As Telephone Zone When the HCP is used as a telephone zone module (FireFinder-XLS System only) as

shown in Figure 5, the 24 VDC provides power to the supervision and call-in detection

circuitry. If the 24 VDC is lost, a trouble condition displays on the PMI/PMI-2 of the

FireFinder-XLS.

The HCP provides a dial tone when a Fireman’s Master telephone (FMT) is taken off

hook or when a Portable FireFighter’s telephone (PFT) is jacked in.

Each HCP can support a maximum of 5 phones off hook. Throughout the system, no

more than 10 phones may be off hook at any one time.

The supervised telephone common talk riser starts at the TZC-8B module in the CAB

backbox. The common talk riser connects continuously to each HCP with a 10K end

of line device at the last HCP. Tie the shield of these riser wires together using

terminal 5 of TB2 and isolate them from the system circuits and the earth ground.

Individual phones may not be connected to a riser that is wired to HCPs. The TZC-8B

zone must be configured for Riser usage in Zeus.

Connect the supervised telephone zone wiring to the HCP with twisted pair cable.

Terminate at the last station with a 75K ohm end of line resistor. As with the common talk line described in the paragraph above, be sure that the shield is continuous

and isolated from both system circuits and earth ground and that the shields are

connected together using terminal 5 of TB-2.

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-135

Page 6

FROM DLC DEVICE

LOOP IN CC-5 / CC-2

POWER LIMITED

LINE 1

LINE 2

SUPERVISED, 24 OHMS MAX

UNSHIELDED, USE TWISTED PAIR

POSITIVE AND NEGATIVE GROUND FAULT

DETECTED AT <500 OHMS FOR

TERMINALS 3-6 ON TB1.

USE TWISTED PAIR

SUPERVISED

24 OHMS MAX

UNSHIELDED

POINTS

EARTH

SHIELD

1 2 3 4 5 6

SHIELD

TO

6 5 4 3 2 1

10K, 1/2W, +/-5%

EOL RESISTOR

+

WARDEN’S STATIONS

(FTS SERIES)

75K, ¼W, +/-5%

EOL RESISTOR

P/N 140-050797

AT LAST STATION

NOTES:

1. THE SHIELD ON THE COMMON TALK

LINE MUST BE CONTINUOUS AND

CONNECTED ONLY TO EARTH

GROUND AT CONTROL PANEL.

2. ALL WIRING MUST COMPLY WITH

NATIONAL AND LOCAL CODES.

3. 12-18 AWG OR AS REQUIRED

BY THE LOCAL AUTHORITY

HAVING JURISDICTION.

1 2 3 4 5 6

+

PROGRAMMING

POINTS

HCP HCP

SHIELD

TO

6 5 4 3 2 1

HCP DC SUPPLY

FROM PSC-12 (TB-3),

PSX-12 (TB-3),

OR PAD-4* (TB16)

ELECTRICAL:

INPUT DC SUPPLY: 18.8 - 28.2VDC,

30mA MAX

FILTERED FULL WAVE

*REFER TO PAD-4 INSTALLATION INSTRUCTIONS, P/N 315-050217, FOR PROPER SETTING OF SWITCH 4. THE AUXILIARY POWER OUTPUT MUST BE CONFIGURED TO “ALW AYS ON”.

EARTH

SHIELD

FROM PREVIOUS HCP OR TZC-8B

(100 OHMS MAXIMUM

LINE RESISTANCE)

COMMON TALK RISER

(POWER LIMITED)

SEE TZC-8B INSTALLA TI ON

INSTRUCTIONS, P/N 315-034110,

FOR RISER RATINGS

SHIELD

WHITE

WHITE

WHITE

WHITE

*

REMOVE 10K TERMINATING RESISTORS FROM THE FJ-303sALL

FJ-303

FJ-303

BLACK

BLACK

BLACK

BLACK

75K, ¼W, +/-5%

EOL RESISTOR

P/N 140-050797

AT LAST FJ-303

PROGRAMMING

Figure 6

HCP Used As A Telephone Zone

HCP As (70.7V/25V) Speaker Zone in an XLSV System

When the HCP is used as a speaker zone (FireFinder-XLS System only), the 24 VDC

provides power to the supervision circuitry. If the 24 volts is lost or there is an open

or shorted speaker output line, a trouble condition displays on the PMI/PMI-2 of the

FireFinder-XLS.

The 70.7V/25V RMS audio input to the HCP must be power limited, such as from the

ZAC-40. The ZAC-40 supervises the audio connection path to the HCP and provides

up to 40 watts of power. The ZAC-40 can be wired Style Y (Class B) only. Refer to the

ZAC-40 Installation Instructions, P/N 315-035400 for further information. In order to

function properly during degrade mode, the DLC to which the HCP is connected

must be located in the same enclosure as the DAC-NET and ZAC-40 that supply

audio to the HCP.

When the HCP is used as a speaker zone, the output speaker lines are only supervised when the zone is not active. The audio output must not be allowed to exceed

25 watts. The approximate decibel loss for the total speaker zone wire length for

various wire gauge sizes is shown in Figure 7 for the 70.7V option and in Figure 8 for

the 25V option. Connect the speaker output as Style Y (Class B) as shown in Figure 9.

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-136

Page 7

HCP As (70.7V/25V) Speaker Zone in a FV2025/FV2050 or FV922/FV924 System

100

0

-.5

-1.0

-1.5

-2.0

-2.5

200

300 400 500 600

TOTAL SPEAKER ZONE WIRE LENGTH (FEET)

dB LOSS

700 800 900 1000

SPEAKER LOAD: 25 WATTSAT 25V RMS

LOCATEDAT END OF RUN

DOES NOT INCLUDE ANY LOSS

IN RISER RUN

APPROXIMATE SPEAKER ZONE WIRE LOSS

IN DECIBELS FOR VARIOUS GAUGE WIRES VERSUS

TOTALSPEAKER ZONE WIRE LENGTH (FEET),

WHICH IS TWICE THE WIRE RUN LENGTH.

18 AWG

16 AWG

14 AWG

HCP USED FOR 25V RMS OPTION

The 70.7V/25V RMS audio input to the HCP must be power limited, such as from the

VCI2001-U1 Amplifier Card. The VCI2001-U1 supervises the audio connection path to

the HCP and provides up to 50 watts of power. The VCI2001-U1 can be wired Style Y

(Class B) or Style Z (Class A). Refer to the VCI2001-U1 Installation Instructions,

Document ID A6V10370410, for further information. In order to function properly

during degrade mode, the periphery FCI2016/2017-U1 to which the HCP is connected

must be located in the same enclosure as the FDNET and VCI2001-U1 that supply

audio to the HCP.

When the HCP is used as a speaker zone, the output speaker lines are only supervised when the zone is not active. The audio output must not be allowed to exceed

25 watts. The approximate decibel loss for the total speaker zone wire length for

various wire gauge sizes is shown in Figure 7 for the 70.7V option and in Figure 8 for

the 25V option. Connect the speaker output as Style Z (Class A) or Style Y (Class B) as

shown in Figures 10 and 11.

HCP USED FOR 70.7V RMS OPTION

SPEAKER LOAD: 25 WATTSAT 70.7V RMS

LOCATEDAT END OF RUN

DOES NOT INCLUDE ANY LOSS

IN RISER RUN

100

200

300 400 500 600

TOTAL SPEAKER ZONE WIRE LENGTH (FEET)

APPROXIMATE SPEAKER ZONE WIRE LOSS

IN DECIBELS FOR VARIOUS GAUGE WIRES VERSUS

TOTALSPEAKER ZONE WIRE LENGTH (FEET),

WHICH IS TWICE THE WIRE RUN LENGTH.

16 AW

G

18 AW

G

700 800 900 1000

-0.05

-0.10

dB LOSS

-0.15

-0.20

-0.25

0

Figure 7 Figure 8

Approximate Speaker Zone Wire Loss — 70.7V Option Approximate Speaker Zone Wire Loss — 25V Option

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-137

Page 8

AT <500 OHMS FOR

POSITIVE AND NEGATIVE

GROUND FAULT DETECTED

TERMINALS 3-6 ON TB1.

24K, W½, +/-5%

EOL RESISTOR

P/N 140-034677

68K, 1/4W, +/-5%

EOL RESISTOR

ON LAST HCP

SPEAKER ZONE

DEVICE

P/N 140-034728

STYLE Y

SUPV: 14 VDC, 1mA

ACTIVATED: 70.7 V/25V RMS, 25 WATTS MAX

SUPERVISED SPEAKER ZONE CONNECTIONS

CAPACITOR COUPLED

AT <500 OHMS FOR TERMINALS 3-6 ON TB1.

POSITIVE AND NEGATIVE GROUND FAULT DETECTED

123456

70.7V/25V RMS SPEAKERS

HCP

PROGRAMMING

POINTS

HCP

PROGRAMMING

POINTS

654321

EARTH

24K, W½, +/-5%

P/N 140-034677

EOL RESISTOR

EARTH

SHIELD

SHIELD

ALL WIRING MUST COMPLY WITH NATIONAL AND LOCAL CODES.

SHIELD

LINE 1

FROM DLC

DEVICE LOOP

STYLE Z

SUPV: 14 VDC, 1mA

SUPERVISED SPEAKER ZONE CONNECTIONS

LINE 2

IN CC-5 / CC-2

POWER LIMITED

ACTIVATED: 70.7 V/25V RMS, 25 WATTS MAX

AT <500 OHMS FOR TERMINALS 3-6 ON TB1.

POSITIVE AND NEGATIVE GROUND FAULT DETECTED

24K, W, +/-5%½

P/N 140-034677

EOL RESISTOR

123456 123456

HCP

PROGRAMMING

POINTS

SEE COMPATABILITY GUIDE

P/N 315-096363 FOR LIST OF

70.7V/25V RMS SPEAKER UNITS:

654321 654321

COMPATABLE SPEAKERS.

SHIELD

EARTH

SUPERVISED

RISER

SUPERVISED BY HCP MODULES

OR PAD-4* (TB16)

HCP DC SUPPLY FROM

PSC-12 (TB3), PSX-12 (Tb3),

EOL RESISTOR

68K, 1/4W, +/-5%

DC INPUT RATING

18.8-28.2VDC, 30mA

FILTERED FULL WAVE

P/N 140-034728

SWITCH 4. THE AUXILIARY POWER OUTPUT MUST BE CONFIGURED TO “ALWAYS ON”.

*REFER TO PAD-4 INSTALLATION INSTRUCTIONS, P/N 315-050217, FOR PROPER SETTING OF

ZAC-40 LOCATED IN ONE

SLOT OF CC-5/CC-2

NFPA STYLE Y

910111213141516

12345678

AUDIO RISER CONNECTIONS

SUPERVISORY: 14 VDC, 1mA

40 WATTS MAX

AUDIO OUTPUT: 70.7/25 VRMS,

POWER LIMITED

Figure 9

HCP Used On An XLSV As A 70.7V/25V Speaker Zone

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-138

Page 9

AT <500 OHMS FOR

POSITIVE AND NEGATIVE

GROUND FAULT DETECTED

TERMINALS 3-6 ON TB1.

24K, W½, +/-5%

EOL RESISTOR

P/N 140-034677

STYLE Y

SUPV: 14 VDC, 1mA

ACTIVATED: 70.7 V/25V RMS, 25 WATTS MAX

SUPERVISED SPEAKER ZONE CONNECTIONS

CAPACITOR COUPLED

AT <500 OHMS FOR TERMINALS 3-6 ON TB1.

POSITIVE AND NEGATIVE GROUND FAULT DETECTED

123456

70.7V/25V RMS SPEAKERS

HCP

PROGRAMMING

POINTS

HCP

PROGRAMMING

POINTS

654321

EARTH

24K, W½, +/-5%

P/N 140-034677

EOL RESISTOR

EARTH

SHIELD

SHIELD

NOTE: EARTH GROUND MUST

BE CONNECTED FOR PROPER

GROUND FAULT DETECTION

ALL WIRING MUST COMPLY WITH NATIONAL AND LOCAL CODES.

WIRING

IF CLASS A

LINE 4

LINE 3

FROM PERIPHERY

BOARD FCI2016/2017-U1

SHIELD

LINE 1

POWER LIMITED

DETECTOR CIRCUITS

STYLE Z

SUPV: 14 VDC, 1mA

ACTIVATED: 70.7 V/25V RMS, 25 WATTS MAX

SUPERVISED SPEAKER ZONE CONNECTIONS

LINE 2

AT <500 OHMS FOR TERMINALS 3-6 ON TB1.

POSITIVE AND NEGATIVE GROUND FAULT DETECTED

24K, W, +/-5%½

P/N 140-034677

EOL RESISTOR

123456 123456

HCP

PROGRAMMING

POINTS

SEE COMPATABILITY GUIDE

70.7V/25V RMS SPEAKER UNITS:

654321 654321

COMPATABLE SPEAKERS.

P/N 315-096363 FOR LIST OF

EARTH

SUPERVISED BULK

AUDIO RISER

SHIELD

SUPERVISED BY HCP MODULES

ON PERIBOARD

AUX POWER (X1001)

HCP DC SUPPLY FROM

68K, 1/4W, +/-5%

DC INPUT RATING

18.8-28.2VDC, 30mA

FILTERED FULL WAVE

FC2016/2017-U1,

OR PAD-4* (TB16)

1234

P/N 140-034728

EOL RESISTOR

SWITCH 4. THE AUXILIARY POWER OUTPUT MUST BE CONFIGURED TO “ALWAYS ON”. THIS

*REFER TO PAD-4 INSTALLATION INSTRUCTIONS, P/N 315-050217, FOR PROPER SETTING OF

VCI2001-U1 AMPLIFIER

LOCATED IN ONE AMPLIFIER

NFPA STYLE Y

50 WATTS MAX

SUPERVISORY: 14 VDC, 1mA

AUDIO RISER CONNECTIONS

AUDIO OUTPUT: 70.7/25 VRMS,

IS IN REFERENCE TO TERMINALS 2 AND 3 ON TB2.

SLOT OF VCA2002-U1

CARD CAGE

POWER LIMITED

Figure 10

HCP Used On An FV2025/2050 or FV922/924 As A 70.7V/25V Speaker Zone - Class A

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-139

Page 10

AT <500 OHMS FOR

POSITIVE AND NEGATIVE

GROUND FAULT DETECTED

TERMINALS 3-6 ON TB1.

24K, W½, +/-5%

EOL RESISTOR

P/N 140-034677

68K, 1/4W, +/-5%

EOL RESISTOR

ON LAST HCP

SPEAKER ZONE

DEVICE

P/N 140-034728

STYLE Y

SUPV: 14 VDC, 1mA

ACTIVATED: 70.7 V/25V RMS, 25 WATTS MAX

SUPERVISED SPEAKER ZONE CONNECTIONS

CAPACITOR COUPLED

AT <500 OHMS FOR TERMINALS 3-6 ON TB1.

POSITIVE AND NEGATIVE GROUND FAULT DETECTED

123456

70.7V/25V RMS SPEAKERS

HCP

PROGRAMMING

POINTS

HCP

PROGRAMMING

POINTS

654321

EARTH

24K, W½, +/-5%

P/N 140-034677

EOL RESISTOR

EARTH

SHIELD

SHIELD

NOTE: EARTH GROUND MUST

BE CONNECTED FOR PROPER

GROUND FAULT DETECTION

ALL WIRING MUST COMPLY WITH NATIONAL AND LOCAL CODES.

WIRING

IF CLASS A

LINE 4

LINE 3

FROM PERIPHERY

BOARD FCI2016/2017-U1

SHIELD

LINE 1

POWER LIMITED

DETECTOR CIRCUITS

STYLE Z

SUPV: 14 VDC, 1mA

SUPERVISED SPEAKER ZONE CONNECTIONS

LINE 2

ACTIVATED: 70.7 V/25V RMS, 25 WATTS MAX

AT <500 OHMS FOR TERMINALS 3-6 ON TB1.

POSITIVE AND NEGATIVE GROUND FAULT DETECTED

24K, W, +/-5%½

P/N 140-034677

EOL RESISTOR

123456 123456

HCP

PROGRAMMING

POINTS

SEE COMPATABILITY GUIDE

70.7V/25V RMS SPEAKER UNITS:

654321 654321

COMPATABLE SPEAKERS.

P/N 315-096363 FOR LIST OF

EARTH

SUPERVISED BULK

AUDIO RISER

SHIELD

SUPERVISED BY HCP MODULES

ON PERIBOARD

AUX POWER (X1001)

HCP DC SUPPLY FROM

68K, 1/4W, +/-5%

DC INPUT RATING

18.8-28.2VDC, 30mA

FILTERED FULL WAVE

FC2016/2017-U1,

OR PAD-4* (TB16)

1234

P/N 140-034728

EOL RESISTOR

SWITCH 4. THE AUXILIARY POWER OUTPUT MUST BE CONFIGURED TO “ALWAYS ON”. THIS

*REFER TO PAD-4 INSTALLATION INSTRUCTIONS, P/N 315-050217, FOR PROPER SETTING OF

VCI2001-U1 AMPLIFIER

LOCATED IN ONE AMPLIFIER

NFPA STYLE Y

50 WATTS MAX

SUPERVISORY: 14 VDC, 1mA

AUDIO RISER CONNECTIONS

AUDIO OUTPUT: 70.7/25 VRMS,

IS IN REFERENCE TO TERMINALS 2 AND 3 ON TB2.

SLOT OF VCA2002-U1

CARD CAGE

POWER LIMITED

Figure 11

HCP Used On An FV2025/2050 or FV922/924 As A 70.7V/25V Speaker Zone - Class B

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-1310

Page 11

Mounting

Be sure to program the HCP before mounting the unit to the switchbox. (Refer to

PROGRAMMING on page 1.)

The HCP should be installed in a UL listed electrical box. (See Figure 12.)

1. Use a standard 31/2-inch deep, double gang electrical switchbox or a 4-inch

square electrical box that is 2

1

extension or a 1

/4 -inch deep plaster ring extension.

1

/8 inches deep with either a 11/2-inch deep

2. Connect the field wiring.

3. Insert the HCP into the box and fasten the device plate to the box.

4. Cover the device front plate with the 5-inch switchplate (supplied) and

fasten with two plate screws.

DOUBLE GANG BOX

4-INCH SQUARE BOX

2 1/8-INCHES DEEP

3 1/2-INCHES DEEP

P

C

H

1 1/2-INCH DEEP EXTENSION

1 1/4-INCH DEEP PLASTER

RING EXTENSION

Figure 12

Mounting The HCP

ELECTRICAL RATINGS

OR

P

C

H

SWITCHPLATE

5-INCHES SQUARE

SWITCHPLATE

5-INCHES SQUARE

(SUPPLIED)

(SUPPLIED)

rewoPCDV42

egnaRegatloVCDV2.82-8.81

tnerruC.xaMAm03

pooLCLD-SF/CLD

tnerruC.xaMAm1

Siemens Industry, Inc.

Building Technologies Division

P/N 315-034860-1311

Page 12

Cyber security disclaimer

Siemens products and solutions provide security functions to ensure the secure operation of

building comfort, fire safety, security management and physical security systems. The security

functions on these products and solutions are important components of a comprehensive security

concept.

It is, however, necessary to implement and maintain a comprehensive, state-of-the-art security

concept that is customized to individual security needs. Such a security concept may result in

additional site-specific preventive action to ensure that the building comfort, fire safety, security

management or physical security system for your site are operated in a secure manner. These

measures may include, but are not limited to, separating networks, physically protecting system

components, user awareness programs, defense in depth, etc.

For additional information on building technology security and our offerings, contact your Siemens

sales or project department. We strongly recommend customers to follow our security advisories,

which provide information on the latest security threats, patches and other mitigation measures.

http://www.siemens.com/cert/en/cert-security-advisories.htm

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

Siemens Canada, Ltd.

1577 North Service Road East

Oakville, Ontario

L6H 0H6 Canada

P/N 315-034860-13

Document ID A6V10233196

Loading...

Loading...