Page 1

SITRANS F

Communication Modules

Add-on modules

HART

Operating Instructions • 07/2010

Page 2

Page 3

HART add-on module

3

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Who should use this document? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Abbreviations and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Device Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Product interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Mechanical Installation MAG/MASS 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Mechanical installation MAG/MASS 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.3 General electrical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.4 HART electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.5 Current output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.5.1 MAG 5000 C/6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.5.2 MASS 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.6 Local display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.6.1 Menu item explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.6.2 Sensorprom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5. Device Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Dynamic Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 MAG 5000 C/6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 MASS 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Status Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

7.1 Device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2 Extended device status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.3 Additional device status (Command 48) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8. Universal Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9. Common-Practice Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10. Device-Specific Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11. Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11.1 Volume flow unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11.2 Volume unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.3 Mass flow unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.4 Mass unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.5 Temperature unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.6 Density unit codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12. Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12.1 Sampling rates MAG 5000 C/6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12.2 Sampling rates MASS 6000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13. Annex A - Capability Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14. Annex B - Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

15. Annex C - Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 4

4

HART add-on module

1.5 References

The Siemens HART interface for use with SITRANS F flow transmitters: MAG 5000 C, MAG 6000

and MASS 6000, revision 2, complies with HART protocol Revision 5.2. This document specifies

all the device specific features and documents HART Protocol implementation details (e.g. the

Engineering units supported). The functionality of this device is described sufficiently to allow its

proper application in a process and its complete support in HART capable Host Applications.

This specification is designed to compliment the operating manuals for MAG 5000 C, MAG 6000

and MASS 6000 flow transmitters by providing a complete, unambiguous description of this Field

Device from a HART communication perspective.

This operating manual does NOT cover MASS 6000 Ex d, MAG 6000 Industry and MAG 6000

Industry Ex d.

The specification is designed to be a technical reference for HART capable Host Application

Developers, System Integrators and knowledgeable End Users. It also provides functional

specifications (e.g., commands, enumerations and performance requirements) used during

Field Device development, maintenance and testing. This document assumes the reader is

familiar with HART Protocol requirements and terminology.

AOM Add-On-Module

USMII Concept with flexible plug & play fieldbus modules

SensorProm Storing unit for all settings

HCF HART communication foundation

FSK Frequency Shift Keying physical layer

CN Capacitance number; capacitance as a multiple of 5000 pF

pF Picofarad (10

-12

Farad); unit of electrical capacitance

PV Primary variable

SV Secondary variable

TV Tertiary variable

QV Quaternary variable

Literature 1 MAG 5000 C/MAG 6000 operating manual Order No FDK-521H0739

Literature 2 MASS 6000 operating manual Order No FDK-521H0991

1.1 Scope

1. Introduction / 2. Device Identification

1.2 Purpose

1.3 Who should use

this document?

1.4 Abbreviations and

Definitions

1. Introduction

This operating manual covers the specifications of the HART interface for MAG 5000 C, MAG 6000

and MASS 6000.

All HART interfaces are based on the same Firmware and Hardware. Below is a table showing

the relations between the flow transmitters and the HART interfaces.

HART interface

FDK:085U0226 FDK:085U0321 Integrated

MAG 5000 C X

MAG 6000 X

MASS 6000 X

MAG 6000 Industry* X

MAG 6000 Industry (Ex d)* X

MASS 6000 Ex d* X

* Not described in this operating manual

Devices with the following Firmware version and up are covered in this operating manual.

Firmware

HART module 2.00

MAG 5000 C 3.03

MAG 6000 3.03

MASS 6000 3.00

2. Device

Identification

Page 5

HART add-on module

5

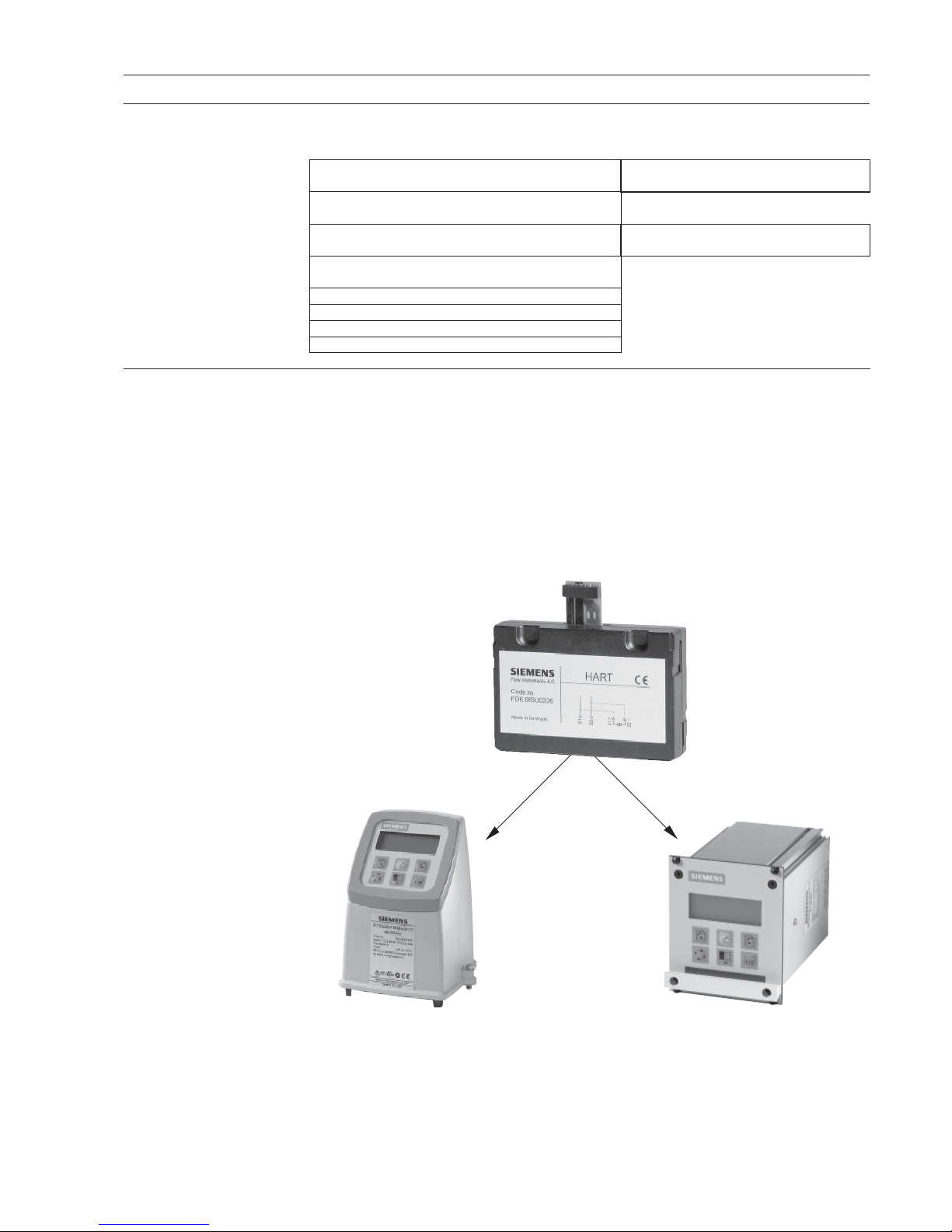

3. Product overview

MAG/MASS 6000

All interfaces apply to the following specifications:

Manufacturer Siemens

Name:

Manufacturer ID 42 (2A hex)

code:

HART Protocol 5.2

revision:

Number of Device MAG = 3

Variables: MASS = 4

Physical layers support: FSK

Physical Device Category: Current output

Loop powered: No

CN 10

Device Type 24 = MAG5/6000 + variants

Codes: 25 = MASS 6000

Device Revision:2

This operating manual describes the HART interface for the electromagnetic flowmeter

MAG 5000 C, MAG 6000 and the coriolis flowmeter MASS 6000.

The MAG/MASS 6000 series is based on the flexible USM II technology. This includes the AOM

(Add-On-Module) that provides digital communications capabilities for the USM II transmitters.

This approach gives far more flexibility, and greater long-term protection of your signal converter

investment, than is possible with factory standard, off-the shelf signal converter designs.

With this easy to use system, providing additional functionality to the already impressive lineup of standard features in your USM II transmitter is as easy as plugging in a small black box. You

have total control over

whether

to add anything at all,

what

it will be, and

when

to add it.

MAG/MASS 6000

The MAG 5000 C has a built-in HART interface, and cannot be mounted with new communication

modules.

3. Product overview

Page 6

6

HART add-on module

4. Product interfaces

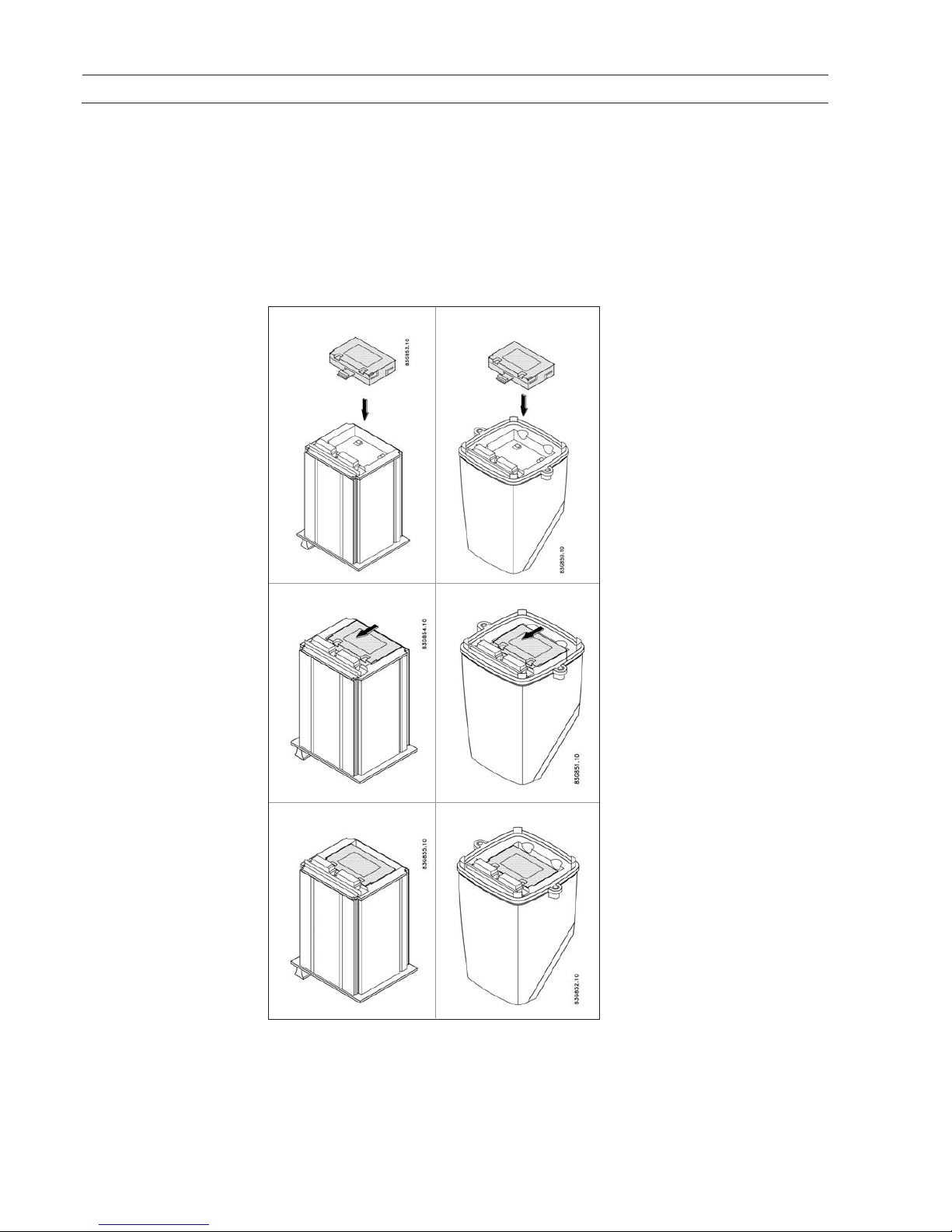

4.1 Mechanical

Installation

MAG 5000 C HART

The MAG 5000 C HART is delivered with a build-in HART interface. It is not possible to add

additional modules to the MAG 5000 C.

Before proceeding, please make sure that you have the right HART Add-on module. The

correct module for MAG 6000 and MASS 6000 is FDK:085U0226. The order number is

located on the label of the module.

The installation procedure for the HART module is as follows:

4.2 Mechanical

Installation

MAG/MASS 6000

4. Product interfaces

1. Unpack the add-on module and

insert it in the bottom of the signal

converter as shown.

19” rack mounted versions IP 67 compact versions

This completes the add-on module

installation, and the signal converter

may now be connected to the terminal

box. Communication with the display/

keypad and the electrical input/output

terminals is established automatically

when the power is applied.

2. Press the add-on module in the

direction shown, until it stops and

is firmly seated in position.

Page 7

HART add-on module

7

4.3 General electrical

information

4.4 HART electrical

connections

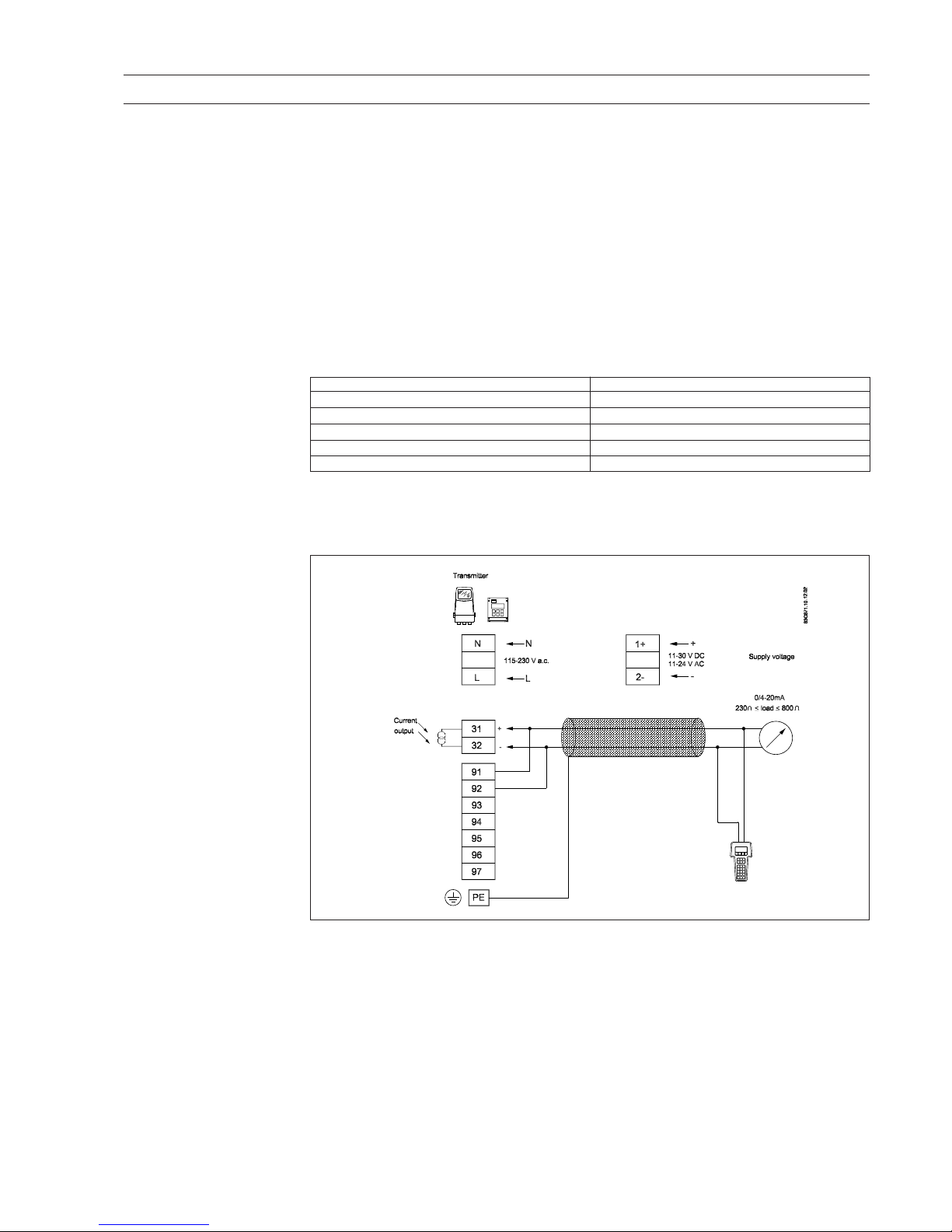

On the electrical termination boards for USM II transmitters, additional input/output terminals

have been reserved for add-on module functions. The numbering range of these terminals

is as follows, but how many are actually used depends on the type of add-on module.

Please refer to the relevant handbook for other electrical connection information.

Terminals reserved for add-on modules:

MAG 5000 C: . . . . . . .91 - 97

MAG 6000: . . . . . . . . .91 - 97

MASS 6000: . . . . . . . .91 - 100

Note

If the MASS 6000 is installed with extra outputs, i.e. have 3 current outputs, 2 digital outputs and

2 relay outputs, then it is not possible to install a HART interface. This is because the extra outputs

takes up all terminals.

The following table shows the connection layout for the USM II HART module:

In order to have the HART FSK signal combined with the Current output, two connections must

be made. Terminal 31 must be connected to 91 and terminal 32 must be connected to 92.

Electrical wirering can be seen in the drawing below.

4.5 Current output

A true HART signal consists of a Current output combined with a HART FSK signal. In order to

achieve this, connections must be made according to the chapter: HART electrical connections.

When a HART module is installed the Current output changes its behaviour in order to comply

with HART. This will be explained in the following chapters.

Terminal Description

91 HART FSK signal +

92 HART FSK signal 31 Current output +

32 Current output -

Shield/PE Shield

4.5.1 MAG 5000 C/6000 When the HART module is inserted, it automatically turns on the Current output with its factory

settings. The HART device with address „0“ is the only device that is allowed to control the Current

output loop.

Single point:

When only one device is connected to the network, the HART short address should be set to 0.

The Current output is fixed to Volume flow, which is the only process value in this device. Volume

flow is also mapped to the PV reading.

4. Product interfaces

Page 8

8

HART add-on module

Multidrop:

Multidrop mode is enabled by having the HART short address >0. If the HART short address is

different from 0, the Current output will be forced to 4 mA no matter what the Current output settings

are. This also means that errors can not be signalled.

4.5.2 MASS 6000 When the HART module is inserted, it automatically turns on the Current output with its factory

settings.

The HART device with address „0“ is the only device that is allowed to control the Current output

loop.

Single point:

When only one device is connected to the network, the HART short address should be set to 0.

The Current output is linked to the selected process value. From factory this is Massflow, which

also is mapped to the PV reading. Other selections can be made, this will however not influence

the PV, which is fixed to Massflow.

In single Pant mode the Current output will have the behaviour as described in the table below.

Parameter Selection Comment

Current output: Massflow The Current output is active. This selection is

recommended.

Volumeflow If one of these are selected, the Current output will

Density be linked to this Procees variable. PV will remain

Temperature Massflow!

Fraction A

Fraction B

Pct. Fraction A

OF F The Current output is deactivated. The Current

output is forced to 3 mA to indicate a Warning.

Current output mode: 0-20 mA Not possible.

0 mA can cause HART masters to stop

communicating or report errors. This is because

values below 4mA are used for alarms and validation

of the current loop.

4-20 mA Factory setting.

4-20 mA + Alarm Fatal errors = 1,3 mA

Pending errors = 2 mA

Warning errors = 3 mA

Multidrop:

Multidrop mode is enabled by having the HART short address >0. If the HART short address is

different from 0, the Current output will be forced to 4 mA no matter what the Current output settings

are. This also means that errors can not be signalled.

Parameter Selection Comment

Current output: ON The Current output is active. ON is selected

automatically during power up.

OF F The Current output is deactivated. The Current

output is forced to 3 mA to indicate a Warning.

Current output mode: 0-20 mA Not possible.

0 mA can cause HART masters to stop communi-

cating or report errors. This is because values

below 4 mA are used for alarms and validation of

the current loop.

4-20 mA Factory setting.

4-20 mA + Alarm Fatal errors = 1,3 mA

Pending errors = 2 mA

Warning errors = 3 mA

In single Pant mode the Current output will have the behaviour as described in the table below.

4. Product interfaces

Page 9

HART add-on module

9

When the HART module is inserted in the device, and the transmitter is powered up, a new menu

entry is available. The new menu hold all HART relevant information.

4.6 Local display

To change (or view) the HART settings from the keypad display.

1. Press [Top key] for two seconds. (NOTE: For “View” mode only, skip steps 2 & 3).

2. Type in password (1000) by pressing [Change key] two times, and then press

[Lock key] and wait for two seconds

3. The display now says “Basic settings”

4. Press [Forward key] until you reach the “HART module” menu item

5. Press [Lock key]

6. You can now cycle through all the HART settings by pressing [Forward key]

7. Press [Top key] for two seconds and you return to 1.

4. Product interfaces

Page 10

10

HART add-on module

4. Product interfaces / 5. Device Variables / 6. Dynamic Variables

The table below describes submenus under the main menu „HART module“.4.6.1 Menu item

explanation

This Field Device does not expose any Device Variables.

4.6.2 SENSORPROM

All of the transmitter HART settings are stored in the SENSORPROM. This means that if the HART

module is exchanged for another HART module, all of the relevant HART settings are kept.

The dynamic variables are fixed and can not be mapped to other than the specified PV, SV, TV

and QV.

6.1 MAG 5000 C/6000

Item Value Description

HART 0-15 Device address [Factory setting: 00]

short address

TAG name 8 characters Can be used to TAG the device.

TAG descriptor 16 characters Can be used to describe the TAG.

TAG date 3 bytes Can be used to date the installation.

HART x.xx Firmware version of the HART module.

SW version

6.2 MASS 6000

Meaning Units

PV Volume flow See Table: units

SV Totalizer 1 See Table: units

TV Totalizer 2 / Batch See Table: units

QV Not implemented

Meaning Units

PV Mass flow See Table: units

SV Density See Table: units

TV Temperature See Table: units

QV Volume flow See Table: units

5. Device Variables

6. Dynamic Variables

Page 11

HART add-on module

11

Bit Definition

7 Device Malfunction – The device detected a serious error or failure that compromises device

operations. This flag is set whenever an error of category „Fatal Error“ is pending in the

flowmeter. Detailed information can be found via HART command 48.

6 Configuration Changed – An operation was performed that changed the device’s configuration.

Any HART command, which writes information to the flowmeter, will set this flag. The flag can

be reset using command 38. The flag is handled separately for each HART master (primary/

secondary). Note: In the flowmeter, the flag is NOT stored during power cycles.

5 Cold Start – A power failure or Device Reset has occurred. This flag is only set in the first

response transmitted to a Hart Master after power failure. The flag is handled separately

for each HART master (primary/secondary).

4 More Status Available – More status information is available via Command 48, Read Additional

Status Information. This flag is set, whenever a transmitter specific error or warning is active

in the flowmeter.

3 Loop Current Fixed – The Loop Current is being held at a fixed value and is not responding to

process variations. This flag is always set, if the transmitter is in Multidrop mode – i.e. the

Hart address is not zero. This flag is also set in SingleDrop mode, if the flowmeters current

output is forced in Service Mode or via Hart Command #40.

2 Loop Current Saturated – The Loop Current has reached its upper (or lower) endpoint limit

and cannot increase (or decrease) any further. This flag is set whenever the flowmeters

overflow warning (error no. 30) is pending.

1 Non-Primary Variable Out of Limits – A Device Variable not mapped to the PV is beyond its

operating limits. This flag is always zero in the flowmeter (ie not used).

0 Primary Variable Out of Limits – The PV is beyound its operating limits. This flag is set

whenever the flowmeters overflow warning (error no. 30) is pending.

This chapter defines all status provided by the flowmeter including: the Device status byte; the

Extended Device Status byte; and status information returned in Command 48.

7. Status Information

7.1 Device status

7.2 Extended device

status

The extended device status bits are not supported by the flowmeter. Value is always zero.

7.3 Additional device

status (Command

48)

Command 48 returns 25 bytes of data. Bits not listed in the table below are set to zero. For detailed

USM II error number descriptions please look in the MAG/MASS manual, Literature 1 and 2.

Byte Bit Meaning Class

0 0 Set if any Warnings are active – See bytes18-21 below

1 Set if any Permanent errors are active – See bytes 14-17 below mode

2 Set if any Fatal errors are active – See bytes 1-5 below

1 0-7 USM Fatal Error 60, 61, 62, 63, 70, 71, 80, 81

(bit 0 corresponds to error 60, bit 7 to error 81) error

2 0-7 USM Fatal Error 82, 83, 84, 96, 97, 64, 65, 66

(bit 0 corresponds to error 82, bit 7 to error 66) error

3 0-7 USM Fatal Error 67, 68, 69, 72, 73, 74, 75, 76

(bit 0 corresponds to error 67, bit 7 to error 76) error

4 0-2 USM Fatal Error 77, 78, 79 (bit 0 corresponds to error 77, bit 2 to error 79) error

5 0-7 Reserved (=0)

6 0-7 Extended Device Status Not supported (=0) mode

7 0-7 Device Operating Mode Not supported (=0

)

mode

8-10 0-7 Analog Channel Saturated Not supported (=0) mode

11-13 0-7 Analog Channel Fixed Not supported (=0) mode

14 0-7 USM Permanent Error 40, 41, 42, 43, 44, 45, 46, 47

(bit 0 corresponds to error 40, bit 7 to error 47) error

15 0-7 USM Permanent Error 48, 49, 94, 95, 50, 51, 52, 53

(bit 0 corresponds to error 48, bit 7 to error 53) error

16 0-5 USM Permanent Error 54, 55, 56, 57, 58, 59

(bit 0 corresponds to error 54, bit 5 to error 59) error

17 0-7 Reserved (=0)

18 0-7 USM Warning 20, 21, 22, 23, 24, 30, 31, 90

(bit 0 corresponds to error 20, bit 7 to error 90) warning

19 0-7 USM Warning 91, 92, 93, 25, 26, 27, 28,2 9

(bit 0 corresponds to error 91, bit 7 to error 29) warning

20 0-7 USM Warning 32, 33, 34, 35, 36, 37, 38, 39

(bit 0 corresponds to error 32, bit 7 to error 39) warning

21-24 0-7 Reserved (=0)

7. Status Information

Page 12

12

HART add-on module

8. Universal Commands

8. Universal

Commands

Command Number Data in Command Data in Response

and Funktion

0 Read unique identifier None Byte 0 "254" (expansion)

Byte 1 Manufacturer ID

Byte 2 Mfr. device. Type

Byte 3 Number of preamble

Byte 4 Universal Command

revision

Byte 5 transmitter specific

command revision

Byte 6 software revision

Byte 7 hardware revision

Byte 8 device function flag

Byte -11 Device ID number

1 Read primary variable None Byte 0 PV unit code

Byte 1-4 Primary variable

2 Read Current & None Byte 0-3 current (mA)

% of range Byte 4-7 % of range

3 Read Current & None Byte 0-3 Current

four variables Byte 4 PV unit code

Byte 5-7 PV

Byte 9 SV unit code

Byte 10-13 SV

Byte 14 TV unit code etc.

Byte 15-18 TV

Byte 19 QV unit code etc.

Byte 20-23 QV

6 Write polling address Byte 0 =Short address As in command

11 Read unique id Byte 0-5 As Command 0

associated with tag TAG (8 characters)

12 Read message None Byte 0-23 Message

13 Read Tag, Descriptor & None Byte 0-5 Tag

Date Byte 6-17 descriptor

Byte 18-20 date

14 Read PV sensor number None Byte 0-2 sensor serial number

Byte 3 unit code for sensor limits

and min. span

Byte 4-7 upper sensor limit

Byte 8-11 lower sensor limit

Byte 12-15 minimum span

15 Read PV output None Byte 0 alarm select code

information Byte 1 transfer code

Byte 2 Upper and lower range

values unit code

Byte 3-6 Upper range value

Byte 7-10 Lower range value

Byte 11-14 Damping value (sec)

Byte 15 Write protect code = 1

Byte 16 Private-label distributor

code

16 Read final assembly None Byte 0-2 Final assembly number

number

17 Write Message Byte 0-23 As in command

Message

18 Write tag, descriptor Byte 0-5 As in command

and date TAG

Byte 6-17

Descriptor

Byte 18-20

Date

19 Write final assembly Byte 0-2 As in command

number Final assembly number

This device supports the following Universal Commands.

Page 13

HART add-on module

13

9. Common-Practice Commands

9. Common-Practice

Commands

This device supports the following Common-Practice Commands.

Command Number and Data in Command Data in reply

Function

33 Read transmitter variables Not implemented

34 Write damping value Byte 0-3 Byte 0-1 As in command

Damping value in sec.

35 Write range values Byte 0 range unit code As in command

Byte 1-4 upper range

Byte 5-8 lower range

36 Set upper range Not implemented

37 Set lower range Not implemented

38 Reset config. Flag None None

39 EEPROM control Byte 0 0= burn EEPROM As in command

1= restore from EEPROM

40 Enter/exit fixed Byte 0-3 Current (mA) Byte 0-3 Actual current (mA)

current mode Current = 0 ⇒ Exit fixed On exit (Data in command = 0),

Current mode the response is always 4 mA

41 Perform transmitter Not implemented

self-test

42 Perform master reset None None

(Set to default) (Busy for approx. 30 seconds

after reply)

43 Set PV zero None None

HART will respond, command

not implemented“ in the cases

that PV zero is not supported by

the application.

44 Write PV units Byte 0 PV units code As in command

45 Trim DAC Zero Not implemented

46 Trim DAC gain Not implemented

47 Write transfer function Not implemented

48 Read additional None See chapter 7, describing

transmitter status status information

49 Write PV sensor Not implemented

serial number

50-56 Not implemented

57-58 Read/Write unit tag Not implemented

59 Write number of Byte 0 Number of response As in command

preambles preamble bytes

60-107 Not implemented

108 Write burst mode Byte 0 Burst mode command As in command

command number number

1, 2 or 3 supported

109 Burst mode control Byte 0 0 = exit, 1 = enter As in command

110 Read all dynamic None Not implemented

variables

Page 14

14

HART add-on module 10. Device-Specific Commands

This device supports the following Device-Specific Commands. Except from command 170 and

171, these commands are reserved for software tools like PDM, AMS and HC275/375.

10. Device-Specific

Commands

Command Number and Data in Command Data in reply

Function

128 Read Integer8 Byte 0 CANAPP.ID Byte 0 Integer 8 value

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3-4 Index

129 Read Integer16 Byte 0 CANAPP.ID Byte 0-1 Integer 16 value

Byte 1 Attribute. ID

Byte 2 Attribute Qual

Byte 3-4 Index

130 Read Integer32 Byte 0 CANAPP.ID Byte 0-3 Integer 32 value

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3-4 Index

131 Read Unsigned8 Byte 0 CANAPP.ID Byte 0 Byte

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3-4 Index

132 Read Unsigned16 Byte 0 CANAPP.ID Byte 0-1 Two bytes

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3-4 Index

133 Read Unsigned32 Byte 0 CANAPP.ID Byte 0-3 Four bytes

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3-4 Index

134 Read Float32 Byte 0 CANAPP.ID Byte 0-3 Float

Byte 1 Attribute.ID

Byte 2 Attribute Qual Comment: When reading values

Byte 3 Unit code with no unit, the unit code must

Byte 4-5 Index be 251 (No unit)

135 Read Float64 Byte 0 CANAPP.ID Byte 0-7 Float 64

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3-4 Index

136 Read VisibleString Byte 0 CANAPP.ID Byte 0 Length of Message

Byte 1 Attribute.ID Byte 1-x User message

Byte 2 Attribute Qual <32 bytes

Byte 3-4 Index

137 Read OctetString Byte 0 CANAPP.ID Byte 0 Length of Message

Byte 1 Attribute.ID Byte 1-x User message

Byte 2 Attribute Qual <32 bytes

Byte 3-4 Index

138 Read OctetString Byte 0 CANAPP.ID Byte 0 Length of Message

w/parameters Byte 1 Attribute.ID Byte 1-x User message

Byte 2 Attribute Qual <32 bytes

Byte 3-4 Index

Byte 5 Length

Byte 6-n parameter 1 … and bytes

up to the limit given

by the length byte

140 Write Float32 Byte 0 CANAPP.ID Byte 0-3 Float

Byte 1 Attribute.ID Byte 4 Unit Code

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index

Byte 6-9 Float

Byte 10 Unit code

Page 15

HART add-on module

15

10. Device-Specific Commands

Command Number and Data in Command Data in reply

Function

141 Write Integer8 Byte 0 CANAPP.ID Byte 0 Integer value

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Byte 6 Integer8

142 Write Integer16 Byte 0 CANAPP.ID Byte 0-1 Integer value

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Byte 6-7 Integer16

143 Write Integer32 Byte 0 CANAPP.ID Byte 0-3 Integer value

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Byte 6-9 Integer32

144 Write Unsigned8 Byte 0 CANAPP.ID Byte 0 One byte

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Byte 6 Unsigned 8

145 Write Unsigned16 Byte 0 CANAPP.ID Byte 0-1 Two bytes

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Bytes 6-7 Unsign16

146 Write Unsigned32 Byte 0 CANAPP.ID Byte 0-3 Four bytes

Byte 1 Attribute.ID

Byte 2 Attribute Qual

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Byte 6-9 Unsign32

147 Write VisibleString Byte 0 CANAPP.ID Byte 0 Length of Message

Byte 1 Attribute.ID Byte 1-x User message

Byte 2 Attribute Qual <32 bytes

Byte 3 Reserved (0x00).

Byte 4-5 Index (2 bytes)

Byte 6-x VisibleString

148 Write OctetString Byte 0 CANAPP.ID Byte 0 Length of Message

Byte 1 Attribute.ID Byte 1-x User message

Byte 2 Attribute Qual <32 bytes

Byte 3 Reserved (0x00)

Byte 4-5 Index (2 bytes)

Byte 6-x OctetString

150 Request Set mode Byte 0 Bit0: SaveMode on(1)off(0) As in command

Bit1: ServiceMode on(1)

off(0) - Bit0 is least sign.

Bit of Byte 0

154 Req/rel UserLock Byte 0 Request = 1, Release = 0 As in command

160 Action Byte 0 CANAPP.ID As in command

Byte 1 Attribute.ID

Byte 2 Attribute Qualifier

170 Set Unit code Byte 0 Variable As in command

0=PV, 1=SV,

2=TV, 3=QV,

4= Totalizer 1

5= Totalizer 2

Byte 1 Unit code

Byte 2 Reserved (0x00)

Page 16

16

HART add-on module 10. Device-Specific Commands

Command Number and Data in Command Data in reply

Function

171 Read totalizer Byte 0 Totalizer no. Byte 0 Unit code

0 = Totalizer 1 Byte 1-4 Totalizer value

1 = Totalizer 2 Byte 5 Totalizer no.

172 Read status data Byte 0 log type Byte 0 As in command

0 = Error Pending Byte 1-18 9 logs consisting

1 = Status Log of two bytes,

Canapp_ID + Error

Number

173 Read status timestamp Byte 0 log type Byte 0-2 As in command

Byte 1 Canapp_ID Byte 3-12 days, hours and

Byte 2 ErrorNumber minutes

180 Write Currentoutput1 Byte 0 0 = Off As command

(MASS 6000 only) 1 = Massflow

2 = Fraction A

3 = Fraction B

4 = Volumeflow

5 = Sensor temperature

6 = Density

7 = Pct. Fraction A

181 Read Currentoutput1 None Byte 0 0 = Off

(MASS 6000 only) 1 = Massflow

2 = Fraction A

3 = Fraction B

4 = Volumeflow

5 = Sensor

temperature

6 = Density

7 = Pct. Fraction A

182 Write Digitaloutput1 Byte 0 0 = Off As command

1 = Pulse

2 = Frequency

3 = Error level

4 = Error number

5 = Direction/Limit

6 = Batch

183 Read Digitaloutput None Byte 0 0 = Off

1 = Pulse

2 = Frequency

3 = Error level

4 = Error number

5 = Direction/Limit

6 = Batch

184 Write Relayoutput1 MAG 5000 C/6000 As command

Byte 0 0 = Off

3 = Error level

4 = Error number

5 = Direction/Limit

6 = Batch

7 = Cleaning

MASS 6000

Byte 0 0 = Off

3 = Error level

4 = Error number

5 = Direction/Limit

Page 17

HART add-on module

17

Command Number and Data in Command Data in reply

Function

185 Read Relayoutput1 None MAG 5000 C/6000

Byte 0 0 = Off

3 = Error level

4 = Error number

5 = Direction/Limit

6 = Batch

7 = Cleaning

MASS 6000

Byte 0 0 = Off

3 = Error level

4 = Error number

5 = Direction/Limit

186 Write Digitalinput1 MAG 5000 C/6000 As command

Byte 0 0 = Off

1 = Start Batch

2 = Hold/continue Batch

3 = Stop Batch

4 = Zero Adjust

5 = Totalizer reset

6 = Force output

7 = Freeze output

8 = Q

max.

2 (night)

9 = Manual Cleaning

MASS 6000

Byte 0 0 = Off

1 = Start Batch

2 = Hold/continue Batch

3 = Stop Batch

4 = Zero Adjust

5 = Totalizer reset

6 = Force output

7 = Freeze output

187 Read Digitalinput1 None MAG 5000 C/6000

Byte 0 0 = Off

1 = Start Batch

2 = Hold/

continue Batch

3 = Stop Batch

4 = Zero Adjust

5 = Totalizer reset

6 = Force output

7 = Freeze output

8 = Q

max.

2 (night)

9 = Manual Cleaning

MASS 6000

Byte 0 0 = Off

1 = Start Batch

2 = Hold/

continue Batch

3 = Stop Batch

4 = Zero Adjust

5 = Totalizer reset

6 = Force output

7 = Freeze output

Comment: Index must always be 0,0

10. Device-Specific Commands

Page 18

18

HART add-on module

11.1 Volume flow

unit codes

Unit code Description Note

15 Cubic feet per minute

16 US gallons per minute

17 Liters per minute

18 UK gallons per minute

19 Cubic meters per hour

22 US gallons per second

23 Million US gallons per day

24 Liters per second

25 Million liters per day

26 Cubic feet per second

27 Cubic feet per day

28 Cubic meters per second

29 Cubic meters per day

30 UK gallons per hour

31 UK gallons per day

122 Normal liters per hour Same as l/h

130 Cubic feet per hour

131 Cubic meters per minute

136 US gallons per hour

137 UK gallons per second

138 Liters per hour

235 US gallons per day

240 Milli liters per second

241 Milli liters per minute

242 Milli liters per hour

243 Hector liters per second

244 Hecto liters per minute

245 Hecto liters per hour

247 BBL per second 31 USG

248 BBL per minute 31 USG

249 BBL per hour 31 USG

250 BBL per day 31 USG

251 No conversion

11. Tables

11. Tables

Page 19

HART add-on module

19

11.2 Volume unit codes

Unit code Description Note

40 Gallons

41 Liters

42 Imperial gallons

43 Cubic meters

46 Barrels 41 USG

110 Bushels

111 Cubic yards

112 Cubic feet

124 BBL liquid 31,5 USG

166 Normal cubic meters Same as Cubic meters

167 Normal liters Same as liters

168 Standard cubic feet Same as cubic feet

236 Hector liters

247 Bbl 31 USG

251 No Conversion

11.3 Mass flow

unit codes

11.4 Mass unit codes

Unit code Description Note

70 Grams per second

71 Grams per minute

72 Grams per hour

73 Kilograms per second

74 Kilograms per minute

75 Kilograms per hour

76 Kilograms per day

77 Metric tons per minute

78 Metric tons per hour

79 Metric tons per day

80 Pounds per second

81 Pounds per minute

82 Pounds per hour

83 Pounds per day

84 Short tons per minute

85 Short tons per hour

86 Short tons per day

87 Long tons per hour

88 Long tons per day

251 No Conversion

Unit code Description Note

60 Grams

61 Kilograms

62 Metric tons

63 Pounds

64 Short tons

65 Long tons

125 Ounce

251 No Conversion

11.5 Temperature unit

codes

Unit code Description Note

32 Degrees Celsius

33 Degrees Fahrenheit

35 Kelvin

251 No Conversion

Tables

Page 20

20

HART add-on module Tables / 12. Performance / 13. Annex A Capability Checklist

11.6 Density unit codes

Unit code Description Note

91 Grams per cubic centimetre

92 Kilograms per cubic meter

93 Pounds per gallon

94 Pounds per cubic foot

95 Grams per milliliter

96 Kilograms per liter

97 Grams per liter

98 Pounds per cubic inch

246 Tons per cubic meter

251 No Conversion

13. Annex A

Capability Checklist

Manufacturer Siemens

Model SITRANS F M Magflo MAG 5000 C

SITRANS F M Magflo MAG 6000

SITRANS F C Massflo MASS 6000

Device type Transmitter

HART protocol revision 5.2

Device descriptions PDM

Number of dynamic variables MAG: 3

MASS: 4

Mappable dynamic variables No

Number of Common-Practice commands 12

Number of Device-Specific commands 35

Bits of additional device status 76 bits informational (25 bytes in total)

Alternative operating modes No

Burst Mode Y es

Write protect No

12. Performance

12.1 Sampling rates

MAG 5000 C/6000

PV digital calculation (Volume flow) Equals the Excitation frequency

SV digital calculation (Totalizer 1) 2 per second

TV digital calculation (Totalizer 2 / Batch) 2 per second

Analog output update Equals the Excitation frequency

The excitation frequency is dependent on the sensor type and size. Large sensors have low

excitation frequencies and small sensors have high excitation frequencies (up to 30 Hz).

The excitation frequency can be viewed in the local keypad display under „Sensor characteristics“

menu.

12.2 Sampling rates

MASS 6000

PV digital calculation (Massflow) 2 per second

SV digital calculation (Density) 2 per second

TV digital calculation (Temperature) 2 per second

QV digital calculation (Volume flow) 2 per second

Analog output update 30 per second

Page 21

www.siemens.com/processautomation

Siemens A/S

Flow Instruments

Nordborgvej 81

DK-6430 Nordborg

Subject to change without prior notice

Order No.: A5E03089708

Lit. No.: A5E03089708-01

SFIDK.PS.023.F2.02

© Siemens AG 07.2010

For more information

www.siemens.com/flow

*A5E03089708*

Loading...

Loading...