Siemens GH180, 6SR41 Operating Instructions Manual

www.siemens.com/drives

This documentation pertains to Drives

manufactured in NMA Nuernberg, Germany

Operating Instructions

Installation Instructions

Medium-Voltage Drive

SINAMICS PERFECT HARMONY GH180

Type 6SR41

Edition 06/2017

30.06.2017 13:06

V15.00

Medium-Voltage Drive

SINAMICS PERFECT HARMONY

GH180

Type 6SR41

This documentation pertains to

manufactured in NMA Nuernberg, Germany

Introduction

1

Operating Instructions

Installation Instructions

Safety Notes

Description

Preparing for Use

Assembly

Electrical Connections

Commissioning

Operation

2

3

4

5

6

7

8

Maintenance

Disposal and Recycling

Service and Support

Technical Data

Quality

Abbreviations

9

10

A

B

C

D

Edition 06/2017

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If

products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E42249141A

Ⓟ 06/2017 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Table of contents

1 Introduction.................................................................................................................................................19

1.1 About these instructions.........................................................................................................19

1.2 Text format features...............................................................................................................20

1.3 Warning symbols on the device.............................................................................................21

1.4 Introduction............................................................................................................................22

2 Safety Notes...............................................................................................................................................23

2.1 General Safety Information....................................................................................................23

2.2 Safety Concept.......................................................................................................................24

2.3 Observing the Five Safety Rules............................................................................................25

2.4 Safety Information and Warnings...........................................................................................26

2.5 ESD-sensitive Components...................................................................................................28

2.6 Electromagnetic Fields in Electrical Power Engineering Installations ...................................30

2.7 Information for nominated persons in control of an electrical installation...............................31

2.7.1 Security information...............................................................................................................31

3 Description..................................................................................................................................................33

3.1 Cabinet Details.......................................................................................................................33

3.1.1 Supply Scope ........................................................................................................................33

3.1.2 Input / Output Section............................................................................................................33

3.1.3 Cell Section............................................................................................................................34

3.1.4 Control Section.......................................................................................................................34

3.1.4.1 Control Section.......................................................................................................................34

3.1.4.2 Control Door Cabinet Components........................................................................................36

3.1.5 Cooling Section......................................................................................................................41

3.1.6 Description of the option codes..............................................................................................44

3.1.6.1 Modbus Interface (software activation) (option G22).............................................................44

3.1.6.2 Modbus Interface (software activation) (option G32).............................................................44

3.1.6.3 DeviceNet profile 12 interface (option G23)...........................................................................44

3.1.6.4 DeviceNet profile 12 interface (option G43)...........................................................................44

3.1.6.5 Control Net Interface (option G26).........................................................................................44

3.1.6.6 Control Net Interface (option G46).........................................................................................44

3.1.6.7 Modbus Ethernet Interface (software activation) (option G28)...............................................44

3.1.6.8 Modbus Ethernet Interface (software activation) (option G38)...............................................45

3.1.6.9 PROFIBUS DP (option G91)..................................................................................................45

3.1.6.10 PROFIBUS DP (option G93)..................................................................................................45

3.1.6.11 Connection for control voltage provided by customer AC 220/230 V (option K68)................45

3.1.6.12 Control voltage AC 12 V internal (option K69).......................................................................45

3.1.6.13 Connection for control voltage provided by customer AC 120 V (option K79).......................45

3.1.6.14 Output reactor (option L09)....................................................................................................45

3.1.6.15 Bidirectional synchronized bypass operation (option L29).....................................................46

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 5

Table of contents

3.1.6.16 Cabinet illumination and service socket in trigger and control section (option L50)...............47

3.1.6.17 Cabinet anti-condensation heating, temperature-monitored (option L55)..............................48

3.1.6.18 2 x 2 thermistor protection relays for alarms and faults (option L81).....................................48

3.1.6.19 3 x 2 thermistor protection relays for alarms and faults (option L82).....................................48

3.1.6.20 2 Pt100 evaluation units with 3 inputs each (option L91).......................................................49

3.1.6.21 Pt100 evaluation unit with 6 inputs and 2 analog outputs (option L93)..................................49

3.1.6.22 Pt100 evaluation unit with 6 inputs for ex-proof motors and6 analog outputs(option L95)

...............................................................................................................................................49

3.1.6.23 Mechanical safety locking system - Castell (option M10)......................................................50

3.1.6.24 Gland plates (option M35)......................................................................................................50

3.1.6.25 Gland plates (option M36)......................................................................................................51

3.1.6.26 Gland plates (option M37)......................................................................................................51

3.1.6.27 IP42 degree of protection (option M42)..................................................................................51

3.1.6.28 Redundant fan (Option M61).................................................................................................51

3.1.6.29 Drive prepared for duct flange connection in front (M64).......................................................51

3.1.6.30 Harsh environment conditions (M67).....................................................................................52

3.1.6.31 Drive prepared for duct flange connection in rear (M68)........................................................52

3.1.6.32 Extended space for bottom cable entry (Option M69)............................................................53

3.1.6.33 Controlled outgoing circuit for auxiliary equipment 400 V 3 AC or 460/480 V 3 AC (option

N30).......................................................................................................................................53

3.1.6.34 Controlled outgoing circuit for auxiliary equipment 400 V 3 AC or 460/480 V 3 AC (option

N31).......................................................................................................................................54

3.1.6.35 Controlled outgoing circuit for auxiliary equipment 400 V 3 AC or 460/480 V 3 AC (option

N32).......................................................................................................................................55

3.1.6.36 Controlled outgoing circuit for auxiliary equipment 400 V 3 AC or 460/480 V 3 AC (option

N33).......................................................................................................................................56

3.1.6.37 Controlled outgoing circuit for auxiliary equipment 230 V 1 AC or 120 V 1 AC (option

N35).......................................................................................................................................56

3.1.6.38 Controlled outgoing circuit for auxiliary equipment 230 V 1 AC or 120 V 1 AC (option

N36).......................................................................................................................................57

3.1.6.39 Controlled outgoing circuit for auxiliary equipment 230 V 1 AC or 120 V 1 AC (option

N37).......................................................................................................................................58

3.1.6.40 Controlled outgoing circuit for auxiliary equipment 230 V 1 AC or 120 V 1 AC (option

N38).......................................................................................................................................58

3.1.6.41 Motor-side grounding switch (option N45).............................................................................59

3.1.6.42 Power supply for auxiliaries 24 V DC/2.5 A (option N75).......................................................59

3.1.6.43 Cell Bypass (option U11).......................................................................................................59

3.1.6.44 Individual redundant cell (option U12)....................................................................................59

3.1.6.45 Redundant cell rank (option U13)..........................................................................................60

3.1.6.46 Sinusodial filter (option Y15)..................................................................................................60

4 Preparing for Use.......................................................................................................................................61

4.1 Requirements for installation location....................................................................................61

4.2 Checking on delivery..............................................................................................................62

4.3 The purpose of shock and tilt indicators.................................................................................63

4.4 Monitoring the Transport........................................................................................................64

4.5 Transportation........................................................................................................................67

4.5.1 Transporting the cabinet units................................................................................................67

4.5.2 Transporting the cabinet units................................................................................................68

4.5.3 Transport Using a Crane........................................................................................................69

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

6 Operating Instructions Rev.201706301306

Table of contents

4.5.4 Transport Using a Fork Lift Truck...........................................................................................71

4.5.5 Definition of a packed and unpacked device..........................................................................72

4.5.6 Transport markings................................................................................................................72

4.5.7 Transport requirements..........................................................................................................72

4.5.8 Take the center of gravity into account..................................................................................73

4.5.9 Transport with a fork-lift truck.................................................................................................74

4.5.10 Transport with a crane...........................................................................................................74

4.5.11 Using lifting rods.....................................................................................................................75

4.5.11.1 Force absorption....................................................................................................................75

4.5.11.2 Using lifting rods.....................................................................................................................75

4.6 Receiving and Unpacking......................................................................................................77

4.6.1 Receiving...............................................................................................................................77

4.6.2 Unpacking..............................................................................................................................77

4.7 Off-Loading............................................................................................................................79

4.7.1 Off-Loading............................................................................................................................79

4.8 Transportation and Handling..................................................................................................80

4.8.1 Transporting the cabinet units................................................................................................80

4.8.2 Transporting the cabinet units................................................................................................81

4.8.3 Transport Using a Crane........................................................................................................82

4.8.4 Transport Using a Fork Lift Truck...........................................................................................84

5 Assembly....................................................................................................................................................87

5.1 Protective Earthing Bars Connection.....................................................................................87

5.2 Assembly instructions............................................................................................................88

5.2.1 Requirements for the installation location..............................................................................88

5.2.2 Required tools........................................................................................................................88

5.2.3 Required tools........................................................................................................................88

5.2.4 Combining two Transport Units: Output reactor (L09)and Sine-wave filter (Y15)..................89

5.2.5 Combining several Transport Units........................................................................................90

5.2.6 Unlocking the Power Section Doors manually.......................................................................91

5.2.7 Unlocking the Power Section Doors manually.......................................................................92

5.2.8 Connecting the Transport Units and Power Section Cables..................................................93

5.2.9 Connecting the Transport Units.............................................................................................95

5.2.10 Overview of connection points in the converter.....................................................................96

5.2.11 Connecting the power section cables (M69)..........................................................................97

5.2.12 Connecting the Power Section...............................................................................................98

5.2.13 Connecting the Power Section cables between Transformer Cabinet and Filter Cabinet

...............................................................................................................................................99

5.2.14 Installing the fans.................................................................................................................

100

5.2.15 Installing the Fans (IP42).....................................................................................................

101

5.2.16 Closing the Cabinet Units.....................................................................................................

103

5.2.17 Interface terminals (option L09 or Y15)................................................................................

103

5.2.18 Connecting the Interface Terminals.....................................................................................

104

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 7

Table of contents

6 Electrical Connections..............................................................................................................................

107

6.1 General Electrical ................................................................................................................

107

6.2 Installation External Wiring .................................................................................................

108

6.3 Torques................................................................................................................................

109

6.4 Grounding, Cabling, and Shielding Recommendations.......................................................

110

6.5 Electromagnetic compatibility...............................................................................................

113

6.6 Terminal Blocks....................................................................................................................

115

6.7 Cable Gland Plates Removal and Installation Guidelines....................................................

116

6.8 Closing the make-proof grounding switch............................................................................

117

6.9 E-Stops................................................................................................................................

119

6.10 Circuit Breaker (provided by the customer)..........................................................................

120

7 Commissioning.........................................................................................................................................

121

7.1 RCD Compatibility................................................................................................................

121

7.2 Cell Reforming.....................................................................................................................

122

7.3 Commissioning Process.......................................................................................................

123

8 Operation..................................................................................................................................................

125

8.1 Operating the Drive..............................................................................................................

125

8.2 Major Drive Faults and Alarms.............................................................................................

126

8.2.1 Faults / Alarms Types / Responses.....................................................................................

126

8.2.2 External Serial Communications Related Faults..................................................................

127

8.2.3 Input Transformer Temperature Related..............................................................................

127

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

8 Operating Instructions Rev.201706301306

Table of contents

8.2.4 Modulator Related Cell Faults..............................................................................................

128

8.2.5 Low Voltage Power Supply Related Faults..........................................................................

128

8.2.6 User Faults and Alarms........................................................................................................

128

8.2.7 User Defined Faults.............................................................................................................

129

8.2.8 Input Line Disturbance Faults and Alarms...........................................................................

129

8.2.9 Motor Output Related Faults and Alarms.............................................................................

130

8.2.10 Dedicated I/O For Input Protection.......................................................................................

132

8.2.11 Dedicated I/O For Input Protection (NXGpro)......................................................................

133

8.2.12 Input Over-Voltage Fault......................................................................................................

133

8.2.13 Speed Rollback....................................................................................................................

134

8.2.14 Disabling the Speed Rollup..................................................................................................

134

8.2.15 Synchronous Transfer Related Faults..................................................................................

135

8.2.16 Unexpected Output Conditions............................................................................................

135

8.2.17 Fault Reset...........................................................................................................................

137

8.3 General Troubleshooting Information...................................................................................

138

8.3.1 Handling General Cell and Power Circuitry Faults...............................................................

138

8.3.2 Cell Over Temperature Faults..............................................................................................

140

8.3.3 Status Indicator Summaries for MV Mechanical Bypass Boards.........................................

141

8.3.4 Overvoltage Faults...............................................................................................................

141

9 Maintenance.............................................................................................................................................

145

9.1 Safety instructions for maintenance.....................................................................................

145

9.2 Door Access.........................................................................................................................

148

9.2.1 Unlocking the doors.............................................................................................................

148

9.2.2 Electromagnetic Door Interlock System...............................................................................

148

9.2.3 Closing the make-proof grounding switch............................................................................

149

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 9

Table of contents

9.3 Preventive Maintenance.......................................................................................................

9.3.1 Inspection.............................................................................................................................

9.3.2 Preventive Maintenance Checklist.......................................................................................

9.3.3 Visual Inspections................................................................................................................

9.3.3.1 Equipment for visual inspections..........................................................................................

9.3.3.2 Checking the isolating clearances........................................................................................

9.3.3.3 Checking hoisting solenoids and security bolts....................................................................

9.3.3.4 Checking the plug connections............................................................................................

9.3.3.5 Checking the cable and screw terminals..............................................................................

9.3.3.6 Checking the filter mats........................................................................................................

151

151

151

152

152

152

153

153

153

153

9.4 Touch-Up Paint....................................................................................................................

154

9.5 Cleaning...............................................................................................................................

155

9.5.1 Contact for Cleaning Measures............................................................................................

155

9.5.2 Removing Dust Deposits......................................................................................................

155

9.6 Repair and Replace.............................................................................................................

156

9.6.1 Safety-relevant Checks........................................................................................................

156

9.6.2 Maintenance and Earthing Procedure..................................................................................

157

9.6.3 Part Replacement ...............................................................................................................

159

9.6.4 Replacing the Filter Mats.....................................................................................................

159

9.6.5 Replacing the Control Fuse..................................................................................................

161

9.6.6 Replacing the Door-Mounted Keypad and Operator Panel..................................................

162

9.6.7 Removing the Power Cell Procedure...................................................................................

162

9.6.8 Returning the Power Cell to Siemens..................................................................................

166

9.6.9 Replacing the Compact Flash Card (NXGpro).....................................................................

167

9.6.10 Installing Peferct Harmony Power Cells...............................................................................

168

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

10 Operating Instructions Rev.201706301306

Table of contents

9.6.11 Replacing Cell Input Power Fuses.......................................................................................

168

9.6.12 Replacing Cell Input Power Fuses Assembly......................................................................

169

9.6.13 Cell Input Power Fuse Replacement Procedure..................................................................

170

9.6.14 Printed Circuit Board Replacement Procedure (NXGpro)....................................................

170

10 Disposal and Recycling............................................................................................................................

173

10.1 Disposing of Device Components........................................................................................

173

10.2 Disposing of Packaging........................................................................................................

174

A Service and Support.................................................................................................................................

175

A.1 Siemens Industry Online Support (order documentation)....................................................

175

B Technical Data..........................................................................................................................................

177

B.1 Standards and regulations...................................................................................................

177

B.2 Storage, Transport and Operation Ambient Conditions.......................................................

178

B.3 Power Cell Specifications.....................................................................................................

180

B.3.1 Power Cell Specifications Table ..........................................................................................

180

B.4 System Specifications..........................................................................................................

182

B.4.1 9 Cell System Specifications................................................................................................

182

B.4.2 15 Cell System Specifications..............................................................................................

184

B.5 Output Filters Data...............................................................................................................

185

B.5.1 9 Cell Output Filter, Capacitance.........................................................................................

185

B.5.2 15 Cell Output Filter, Capacitance.......................................................................................

186

B.5.3 9 Cell Output Filter, Inductance............................................................................................

187

B.5.4 15 Cell Output Filter, Inductance..........................................................................................

188

B.6 Ingress Protection (IP) Ratings............................................................................................

189

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 11

Table of contents

C Quality......................................................................................................................................................

191

C.1 CE Marking and Directives for SINAMICS PERFECT HARMONY GH180 Products..........

191

C.1.1 CE Marking on Power Drive Systems (PDS).......................................................................

191

C.1.2 Directives that apply to the Power Drive System (PDS)......................................................

193

C.2 Motor Compatibility..............................................................................................................

195

C.3 IEEE 519 Conformance.......................................................................................................

197

D Abbreviations............................................................................................................................................

199

D.1 Abbreviations.......................................................................................................................

199

Glossary...................................................................................................................................................

205

Index.........................................................................................................................................................

217

Tables

Table 3-1 Outgoing circuit for auxiliary equipment (option N30).................................................................54

Table 3-2 T-X30 terminal strip for connecting auxiliary equipment.............................................................54

Table 3-3 Outgoing circuit for auxiliary equipment (option N31).................................................................54

Table 3-4 T-X30 terminal strip for connecting auxiliary equipment.............................................................55

Table 3-5 Outgoing circuit for auxiliary equipment (option N32).................................................................55

Table 3-6 T-X30 terminal strip for connecting auxiliary equipment.............................................................55

Table 3-7 Outgoing circuit for auxiliary equipment (option N33).................................................................56

Table 3-8 T-X30 terminal strip for connecting auxiliary equipment.............................................................56

Table 3-9 Outgoing circuit for auxiliary equipment (option N35).................................................................56

Table 3-10 T-X30 terminal strip for connecting auxiliary equipment.............................................................57

Table 3-11 Outgoing circuit for auxiliary equipment (option N33).................................................................57

Table 3-12 T-X30 terminal strip for connecting auxiliary equipment.............................................................57

Table 3-13 Outgoing circuit for auxiliary equipment (option N33).................................................................58

Table 3-14 T-X30 terminal strip for connecting auxiliary equipment.............................................................58

Table 3-15 Outgoing circuit for auxiliary equipment (option N33).................................................................58

Table 3-16 T-X30 terminal strip for connecting auxiliary equipment.............................................................59

Table 6-1 Tightening torque for screws.....................................................................................................

109

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

12 Operating Instructions Rev.201706301306

Table of contents

Table 6-2 Tightening torques for screw terminals for copper cables without cable lug 1)..........................

109

Table 6-3 Control Signal Cabling General Guidelines...............................................................................

112

Table 8-1 Fault / Alarm Types and Responses.........................................................................................

126

Table 8-2 External Serial Communication Related Faults.........................................................................

127

Table 8-3 Input Transformer Temperature Related Faults and Alarms Table...........................................

127

Table 8-4 Modulator Related Faults and Alarms ......................................................................................

128

Table 8-5 Low Voltage Power Supply Related Faults...............................................................................

128

Table 8-6 Input Line Disturbance Faults and Alarms ...............................................................................

129

Table 8-7 Motor Output Related Faults and Alarms..................................................................................

130

Table 8-8 Speed Rollup Control Flags......................................................................................................

135

Table 8-9 Synchronous Transfer Related Faults Table.............................................................................

135

Table 8-10 Operation Mode Displays -- Line 1............................................................................................

136

Table 8-11 Mode of Operation, Mode Displays -- Line 2 ...........................................................................

136

Table 8-12 MV Mechanical Bypass Board Status LEDs.............................................................................

141

Table B-1 Standards and conformity.........................................................................................................

177

Table B-2 General Ambient Conditions.....................................................................................................

178

Table B-3 Power Cell Frame Size 1 ..........................................................................................................

180

Table B-4 9-Cell System Parameters........................................................................................................

182

Table B-5 15-Cell System Parameters......................................................................................................

184

Table B-6 9-Cell Output Filter, Capacitance (40-260A).............................................................................

185

Table B-7 15-Cell Output Filter, Capacitance............................................................................................

186

Table B-8 9-Cell Output Filter, Inductance.................................................................................................

187

Table B-9 Fifteen Cell Output Filter, Inductance........................................................................................

188

Table D-1 Commonly Used Abbreviations.................................................................................................

199

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 13

Table of contents

Figures

Figure 2-1 ESD Protective Measures...........................................................................................................29

Figure 3-1 Multi-Language Keypad and Display Interface............................................................................37

Figure 3-2 Operator panel KTP700..............................................................................................................38

Figure 3-3 Cabinet anti-condensation heating..............................................................................................48

Figure 3-4 Principle of the mechanical safety locking system - Castell........................................................50

Figure 4-1 Transport Indicators....................................................................................................................64

Figure 4-2 Back view....................................................................................................................................70

Figure 4-3 Proper Fork Lift Handling and Dimensions..................................................................................72

Figure 4-4 Example Illustration of centers of gravity.....................................................................................73

Figure 4-5 Sticker.........................................................................................................................................76

Figure 4-6 Securing the lifting rods...............................................................................................................76

Figure 4-7 Back view....................................................................................................................................83

Figure 4-8 Proper Fork Lift Handling and Dimensions..................................................................................85

Figure 5-1 Installing the transport units........................................................................................................90

Figure 5-2 Combining power cell cabinet and transformer cabinet (back view)...........................................91

Figure 5-3 Orifice for opening the doors manually........................................................................................92

Figure 5-4 Orifice for opening the doors manually........................................................................................93

Figure 5-5 Connecting the transport units....................................................................................................95

Figure 5-6 Connection points in the converter..............................................................................................96

Figure 5-7 Lugs for power section cables.....................................................................................................97

Figure 5-8 Lugs in an additional cabinet (option L09 or Y15).......................................................................98

Figure 5-9 Schematic diagram for installing the fans (side view)...............................................................

101

Figure 5-10 Installing the fans......................................................................................................................

102

Figure 5-11 Example: Back view of power cell cabinet (without fans)..........................................................

103

Figure 5-12 Interface terminals in filter cabinet.............................................................................................

104

Figure 5-13 Connecting the interface terminals............................................................................................

105

Figure 6-1 Grounding of cable shields when multiple sections (or splices) are used.................................

111

Figure 6-2 Make-proof grounding switch....................................................................................................

118

Figure 8-1 Keypad Mode Display...............................................................................................................

135

Figure 8-2 Excessive Drive Loss Protection...............................................................................................

142

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

14 Operating Instructions Rev.201706301306

Table of contents

Figure 9-1 Make-proof grounding switch....................................................................................................

150

Figure 9-2 Output Cable to Motor...............................................................................................................

157

Figure 9-3 DC Bus View.............................................................................................................................

165

Figure 9-4 NXGpro Digital Control Rack - Compact Flash ........................................................................

167

Figure 9-5 Cut-Out View of Fuse Assembly...............................................................................................

169

Figure C-1 Power Drive System..................................................................................................................

192

Figure C-2 Overview of PDS containing the SINAMICS PERFECT HARMONY BDM and CDM...............

193

Figure C-3 Results: Harmonic Voltage Factor for 9 Cell Air-Cooled Principle............................................

195

Figure C-4 Results: 9-Cell - Harmonic Current Distortion (TDD < %) ........................................................

197

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 15

Table of contents

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

16 Operating Instructions Rev.201706301306

Introduction

1.1 About these instructions

These instructions describe the drive and explain how to handle it, from initial delivery to final

disposal of the equipment. Keep these instructions for later use.

Read these instructions before you handle the drive and follow the instructions. The

instructions contain information about the safe handling of the drive as well as its components

and modules. They provide information on assembling, installing, and maintaining the

equipment properly.

If you have suggestions for improving the document, please contact our Service Center.

1

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 17

Introduction

1.2 Text format features

1.2 Text format features

Text format features

The warning notice system is explained on the rear of the inside front. Always follow the safety

instructions and notices in these instructions.

In addition to the safety-related warning notices which you must read, you will find the text in

these instructions is formatted in the following way:

1. Handling instructions are always formatted as a numbered list. Always perform the steps

in the order given.

● Lists are formatted as bulleted lists.

– Lists on the second level are hyphenated.

Note

A Note is an important item of information about the product, handling of the product or the

relevant section of the document. Notes provide you with help or further suggestions/ideas.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

18 Operating Instructions Rev.201706301306

1.3 Warning symbols on the device

Please observe the warning symbols attached to the device. The warning symbols have the

following meaning:

Warning symbol Meaning

Warning: Voltage

Warning: Hot surface

General warning symbol: Observe the explanations about the hazard on the

device labels.

For transportation, observe the "transportation markings" on the device packaging.

Introduction

1.3 Warning symbols on the device

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 19

Introduction

1.4 Introduction

1.4 Introduction

About This Manual

This manual provides customer documentation for the SINAMICS PERFECT HARMONY

GH180 Variable Frequency Drive (VFD).

The content of this manual provides standard information as well as descriptions of all available

options for this product line. The contents also provides safety warning and notes, preparation

for use, assembly/installation, electrical, commissioning, operation, maintenance, spare parts,

and disposal information. The latter pages of this manual contain appendices for specific

technical documents, support services information, technical drawings, and other relevant data.

This manual is intended for use by trained personnel having unique job functions and

qualifications since there are areas on the VFD that are hazardous and therefore may cause

death or serious bodily harm to personnel and also cause serious damage to the Drive.

The manual is also intended for use by planners, project engineers, installation personnel,

programmers, commissioning personnel, operators, service and maintenance personnel.

This documentation contains the most important safety-related information for the SINAMICS

PERFECT HARMONY GH180 VFD. It is important supplementary information, but is not a

replacement for the operating instructions nor the other product documentation on your CD.

WARNING

Familiarity with the Product Documentation

Only the complete product documentation will allow you to assemble and install the

equipment, to put it into operation and to maintain it correctly and safely.

Incorrect work on the equipment can result in death, severe injury or material damage.

Always refer to the operating instructions when working on the equipment. You will find the

operating instructions and other equipment information about your product that you will need

on the CD supplied with the Drive.

Variable Frequency Drive Introduction

A variable frequency drive (VFD) system controls the rotational speed and torque of an

alternating current (AC) electric motor by adjusting the frequency and voltage of the electrical

power supplied to the motor. In an AC motor, frequency determines the motor speed.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

20 Operating Instructions Rev.201706301306

Safety Notes

2.1 General Safety Information

Proper Use

SINAMICS PERFECT HARMONY GH180 medium voltage drives must always be installed in

closed electrical operating areas. The drive is connected to the industrial network via a circuitbreaker.

The specific transport conditions must be observed when the equipment is transported. The

equipment shall be assembled/installed and the separate cabinet units connected properly by

cable and/or busbar in accordance with the assembly/installation instructions. The relevant

instructions regarding correct storage, EMC-compliant installation, cabling, shielding and

grounding and an adequate auxiliary power supply must be strictly observed. Fault-free

operation is also dependent on careful operation and maintenance.

The power sections are designed for variable-speed drives use with synchronous and

asynchronous motors. Operating modes, overload conditions, load cycles, and ambient

conditions different to those described in this document are allowed only by special

arrangement with the manufacturer.

Commissioning should only be carried out by trained service personnel in accordance with the

commissioning instructions.

2

See also

System components such as circuit-breaker, transformer, cables, cooling unit, motor, speed

sensors, etc., must be matched to VFD operation. System configuration may only be carried

out by an experienced system integrator.

Safety instructions for maintenance (Page 145)

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 21

Safety Notes

2.2 Safety Concept

2.2 Safety Concept

The medium-voltage variable frequency drive (VFD) and its components are subject to a

comprehensive safety concept which, when properly implemented, ensures safe installation,

operation, servicing, and maintenance.

The safety concept encompasses safety components and functions to protect the device and

operators.

The VFD is also equipped with monitoring functions to protect external components.

The VFD operates safely when the interlock and protection systems are functioning properly.

Nevertheless, there are areas on the medium-voltage drive that are hazardous for personnel

and that can cause material damage if the safety instructions described in this section and

throughout the product documentation are not strictly observed.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

22 Operating Instructions Rev.201706301306

2.3 Observing the Five Safety Rules

There are five safety rules that must always be observed to assure not only personal safety,

but to prevent material damage as well. Always obey safety-related labels located on the

product itself and always read and understand each safety precaution prior to operating or

working on the drive.

The five safety rules:

1. Disconnect the system.

2. Protect against reconnection.

3. Make sure that the equipment is de-energized.

4. Apply grounding means.

5. Cover or enclose adjacent components that are still live.

DANGER

Danger Due to High Voltages

High voltages cause death or serious injury if the safety instructions are not observed or if

the equipment is handled incorrectly.

Safety Notes

2.3 Observing the Five Safety Rules

Potentially fatal voltages occur when this equipment is in operation which can remain present

even after the VFD is switched off.

Ensure that only qualified and trained personnel carry out work on the equipment.

Follow the five safety rules during each stage of the work.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 23

Safety Notes

2.4 Safety Information and Warnings

2.4 Safety Information and Warnings

DANGER

Hazardous Voltage!

● Always follow the proper lock-out/tag-out procedures before beginning any maintenance

or troubleshooting work on the VFD.

● Always follow standard safety precautions and local codes during installation of external

wiring. The installation must follow wiring practices and insulation systems as specified in

IEC 61800-5-1.

● Hazardous voltages may still exist within the VFD cabinets even when the disconnect

switch is open (off) and the supply power is shut off.

● Only qualified individuals should install, operate, troubleshoot, and maintain this VFD. A

qualified individual is "a person, who is familiar with the construction and operation of the

equipment and the hazards involved."

● Always work with one hand, wear electrical safety gloves, wear insulated electrical hazard

rated safety shoes, and safety goggles. Also, always work with another person present.

● Always use extreme caution when handling or measuring components that are inside the

enclosure. Be careful to prevent meter leads from shorting together or from touching other

terminals.

● Use only instrumentation (e.g., meters, oscilloscopes, etc.) intended for high voltage

measurements (that is, isolation is provided inside the instrument, not provided by isolating

the chassis ground of the instrument).

● Never assume that switching off the input disconnector will remove all voltage from internal

components. Voltage is still present on the terminals of the input disconnector. Also, there

may be voltages present that are applied from other external sources.

● Never touch anything within the VFD cabinets until verifying that it is neither thermally hot

nor electrically alive.

● Never remove safety shields (marked with a HIGH VOLTAGE sign) or attempt to measure

points beneath the shields.

● Never operate the VFD with cabinet doors open. The only exception is the control cabinet

which contains extra low voltages (ELV).

● Never connect any grounded (i.e., non-isolated) meters or oscilloscopes to the system.

● Never connect or disconnect any meters, wiring, or printed circuit boards while the VFD

is energized.

● Never defeat the instrument’s grounding.

● When a system is configured with VFD bypass switchgear (e.g. contactors between line

and motor, and VFD and motor), these switches should be interlocked so that the line

voltage is never applied to the VFD output if the medium input voltage is removed from

the VFD.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

24 Operating Instructions Rev.201706301306

Safety Notes

2.4 Safety Information and Warnings

WARNING

Potential Arc Hazard

● Arcing can result in damage to property, serious injury and even death.

● The equipment has not been tested and rated for arc flash protection.

● Avoiding arc hazard risks is dependent upon proper installation and maintenance.

● Incorrectly applied equipment, incorrectly selected, connected or unconnected cables, or

the presence of foreign materials can cause arcing in the equipment.

● Follow all applicable precautionary rules and guidelines as used in working with medium

voltage equipment.

● The equipment may be used only:

– for the applications defined as suitable in the technical description.

– in combination with equipment and components supplied by other manufacturers which

have been approved and recommended by Siemens.

Additional safety precautions and warnings appear throughout this manual. These important

messages should be followed to reduce the risk of personal injury or equipment damage.

WARNING

Obey Rules to Avoid Risk of Death

● Always comply with local codes and requirements if disposal of failed components is

necessary.

● Always ensure the use of an even and flat truck bed to transport the VFD system. Before

unloading, be sure that the concrete pad is level for storage and permanent positioning.

● Always confirm proper tonnage ratings of cranes, cables, and hooks when lifting the VFD

system. Dropping the cabinet or lowering it too quickly could damage the unit.

● Never disconnect control power while medium voltage is energized. This could cause

severe system overheating and/or damage.

● Never store flammable material in, on, or near the drive enclosure. This includes

equipment drawings and manuals.

● Never use fork trucks to lift cabinets that are not equipped with lifting tubes. Be sure that

the fork truck tines fit the lifting tubes properly and are the appropriate length.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 25

Safety Notes

2.5 ESD-sensitive Components

2.5 ESD-sensitive Components

Guidelines for Handling Electrostatic Sensitive Devices (ESD)

NOTICE

ESD Sensitive Equipment

● Always be aware of electrostatic discharge (ESD) when working near or touching

components inside the VFD cabinet. The printed circuit boards contain components that

are sensitive to electrostatic discharge. Handling and servicing of components that are

sensitive to ESD should be done only by qualified personnel and only after reading and

understanding proper ESD techniques. The following ESD guidelines should be observed.

Following these rules can greatly reduce the possibility of ESD damage to printed circuit

board (PCB) components.

● Always transport static sensitive equipment in antistatic bags.

● Always use a soldering iron that has a grounded tip. Also, use either a metallic vacuumstyle plunger or copper braid when desoldering.

● Ensure that anyone handling the printed circuit boards is wearing a properly grounded

static strap. The wrist strap should be connected to ground through a 1 Megohm resistor.

Grounding kits are available commercially through most electronic wholesalers.

● Static charge build-up can be removed from a conductive object by touching the object

with a properly grounded piece of metal.

● When handling a PC board, always hold the card by its edges.

● Do not slide printed circuit boards (PCBs) across any surface (e.g., a table or work bench).

If possible, perform PCB maintenance at a workstation that has a conductive covering that

is grounded through a 1 Megohm resistor. If a conductive tabletop cover is unavailable, a

clean steel or aluminum tabletop is an excellent substitute.

● Avoid plastic Styrofoam™, vinyl and other non-conductive materials. They are excellent

static generators and do not give up their charge easily.

● When returning components to Siemens Industry, Inc. always use static-safe packing.

This limits any further component damage due to ESD.

Components that can be destroyed by electrostatic discharge (ESD)

NOTICE

Electrostatic discharge

Electronic components can be destroyed in the event of improper handling, transporting,

storage, and shipping.

Pack the electronic components in appropriate ESD packaging; e.g. ESD foam, ESD

packaging bags and ESD transport containers.

To protect your equipment against damage, follow the instructions given below.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

26 Operating Instructions Rev.201706301306

Safety Notes

2.5 ESD-sensitive Components

● Avoid physical contact with electronic components. If you need to perform absolutely

essential work on these components, then you must wear one of the following protective

gear:

– Grounded ESD wrist strap

– ESD shoes or ESD shoe grounding strips if there is also an ESD floor.

● Do not place electronic components close to data terminals, monitors or televisions.

Maintain a minimum clearance to the screen (> 10 cm).

● Electronic components should not be brought into contact with electrically insulating

materials such as plastic foil, plastic parts, insulating table supports or clothing made of

synthetic fibers.

● Place components in contact with ESD-suited materials e.g. ESD tables, ESD surfaces,

ESD packaging.

● Measure on the components only if one of the following conditions is met:

– The measuring device is grounded with a protective conductor, for example.

– The measuring head of a floating measuring device has been discharged directly before

the measurement.

The necessary ESD protective measures for the entire working range for electrostatically

sensitive devices are illustrated once again in the following drawings. Precise instructions for

ESD protective measures are specified in the standard DIN EN 61340-5-1.

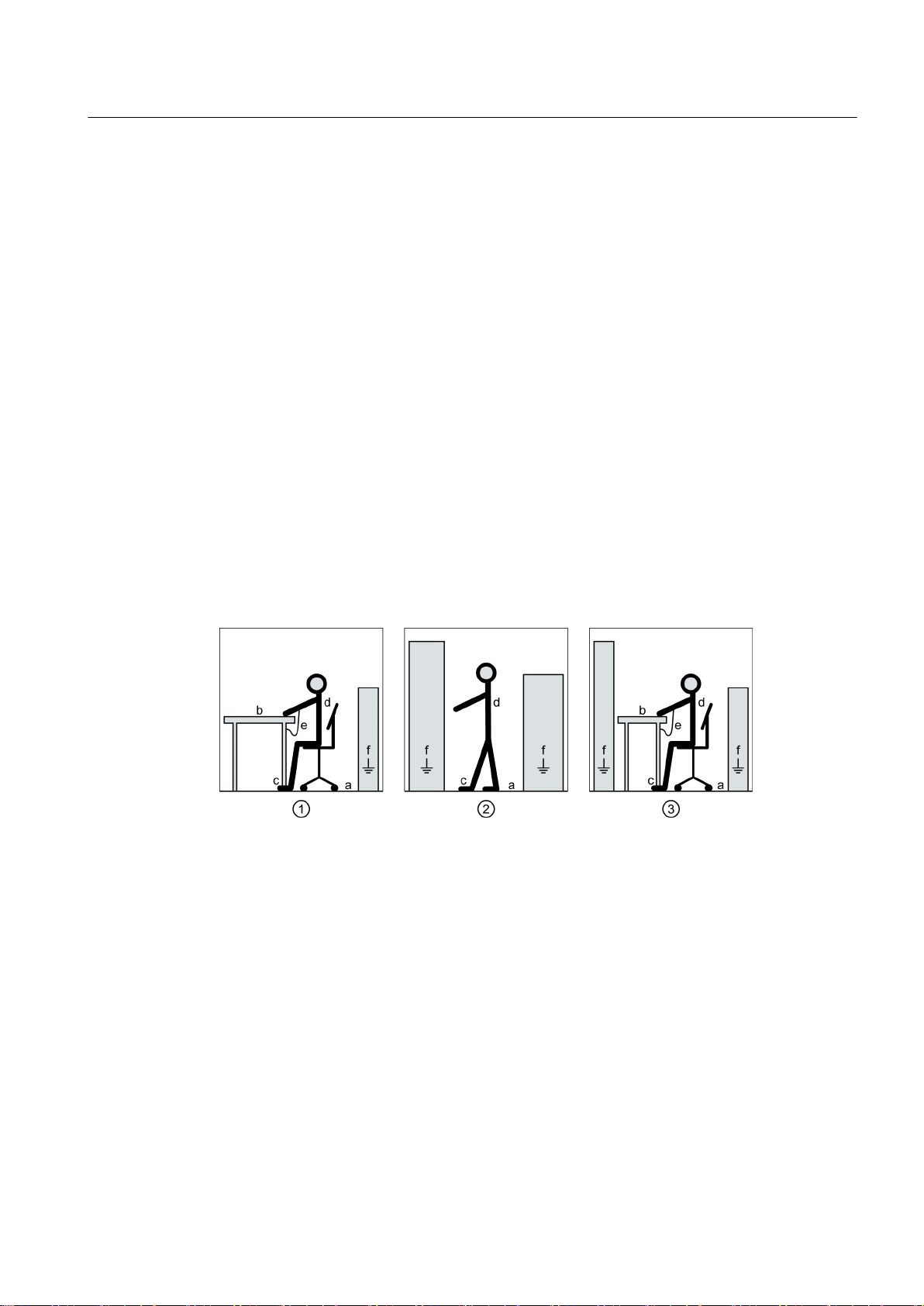

1 Sitting

2 Standing

3 Standing/sitting

a Conductive floor surface, only effective in conjunction with ESD shoes or ESD shoe grounding

strips

b ESD furniture

c ESD shoes or ESD shoe grounding strips are only effective in conjunction with conductive floor‐

ing

d ESD clothing

e ESD wristband

f Cabinet ground connection

Figure 2-1 ESD Protective Measures

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 27

Safety Notes

2.6 Electromagnetic Fields in Electrical Power Engineering Installations

2.6 Electromagnetic Fields in Electrical Power Engineering Installations

WARNING

Electromagnetic fields "electro smog" when operating electrical power engineering

installations

Electromagnetic fields are generated during operation of electrical power engineering

installations.

Electromagnetic fields can interfere with electronic devices, which could cause them to

malfunction. For example, the operation of heart pacemakers can be impaired, potentially

leading to damage to a person's health or even death. It is therefore forbidden for persons

with heart pacemakers to enter these areas.

The plant operator is responsible for taking appropriate measures (labels and hazard

warnings) to adequately protect operating personnel and others against any possible risk.

● Observe the relevant nationally applicable health and safety regulations. For example, in

Germany, "electromagnetic fields" are subject to regulations BGV B11 and BGR B11

stipulated by the German statutory industrial accident insurance institution.

● Display adequate hazard warning notices on the installation.

● Place barriers around hazardous areas.

● Take measures, e.g. using shields, to reduce electromagnetic fields at their source.

● Ensure personnel are wearing the appropriate protective gear.

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

28 Operating Instructions Rev.201706301306

2.7 Information for nominated persons in control of an electrical installation

2.7 Information for nominated persons in control of an electrical

installation

2.7.1 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines and

networks. Systems, machines and components should only be connected to the enterprise

network or the internet if and to the extent necessary and with appropriate security measures

(e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http://www.siemens.com/industrialsecurity

Safety Notes

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends to apply product updates as soon as available and to always

use the latest product versions. Use of product versions that are no longer supported, and

failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under:

http://www.siemens.com/industrialsecurity

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

Operating Instructions Rev.201706301306 29

Safety Notes

2.7 Information for nominated persons in control of an electrical installation

SINAMICS PERFECT HARMONY GH180 6SR41 manufactured in NMA Nuernberg, Germany

30 Operating Instructions Rev.201706301306

Loading...

Loading...